Page 1

CON 6/TDS 6

Meter Manual

The LaMotte 6 Series

Page 2

WARNING! This set contains chemicals

that may be harmful if misused. Read

cautions on individual containers

carefully. Not to be used by children

except under adult supervision

Page 3

CONTENTS

Introduction ..............................

Display & Keypad Functions ......................7

Display .................................. 7

Keypad ..................................

Preparation ...............................

Inserting & Removing Rubber Boot ................... 9

Inserting the Batteries .......................... 9

Battery Replacement ........................... 9

Conductivity Electrode Information .................. 10

Connecting the Probe to Meter ..................... 11

Turning the Meter On.......................... 12

Change Conductivity/TDS « Temperature Measurement Mode . . . 13

Calibration .............................. 14

Important Information on Meter Calibration .............14

Preparing the Meter for Calibration ................... 15

Selection of Automatic or Manual Calibration ............. 16

Automatic Calibration (Conductivity) ................. 17

Manual Calibration (Conductivity or TDS) .............. 18

Temperature Calibration ........................ 19

Measurement ............................. 20

With Automatic Temperature Compensation (ATC) .........20

Without ATC (Manual Temperature Compensation) ......... 20

Taking Measurements .......................... 21

Using Manual Ranging Function .................... 21

HOLD Function ............................. 22

Advanced Set-Up Functions .....................23

Advanced Set-up Overview ....................... 23

Select Cell Constant .......................... 25

Automatic Calibration (for CON 6) .................. 26

Setting the TDS Factor (for TDS 6) .................. 26

Temperature Coefficient ........................ 27

Normalization Temperature ....................... 27

Single-Point Calibration ........................ 28

Restore Factory Default Values ..................... 28

Probe Care and Maintenance ..................... 29

Trouble-Shooting Guide ....................... 30

5

8

9

3

Page 4

Error Messages............................. 31

Specifications ...........................32-33

Accessories .............................. 34

Conductivity Theory .........................35

Appendix 1: Calibration Tips..................... 36

Appendix 2: Calculating the TDS Conversion Factor ........37

Appendix 3: Calculation Temperature Coefficients .........37

Warranty ...............................38

Return of Items ............................39

4

Page 5

INTRODUCTION

Thank you for purchasing the CON 6 Conductivity Meter or TDS 6 Total

Dissolved Solids Meter. These economy microprocessor-based handheld meters

deliver up to ±0.5% full-scale accuracy. It has a large custom LCD (Liquid

Crystal Display) for clear and easy reading.

The CON 6 measures Conductivity (µS/mS) and Temperature (°C) while the

TDS 6 measures Total Dissolved Solids (TDS) and Temperature (°C). These

sturdy meters measure up to 5 different ranges with auto-ranging capabilities

that that will switch automatically to the appropriate measuring range.

The meters include a conductivity electrode (cell constant K = 1.0) with

built-in temperature sensor, a rubber boot, 4 alkaline “AAA” batteries, and an

instruction manual.

Read the manual thoroughly before operating the meter.

To order other accessories and buffer standard solutions, refer to the

Accessories Section for more information.

5

Page 6

mS

ON

OFF

HOLD

ENTER

CAL

MODE

CON 6

Conductivity/ Meter

C

°

6

Page 7

DISPLAY & KEYPAD FUNCTIONS

pptm

HO LO

%

m

S

µ

1

2

3

4

5

67

C°

Display

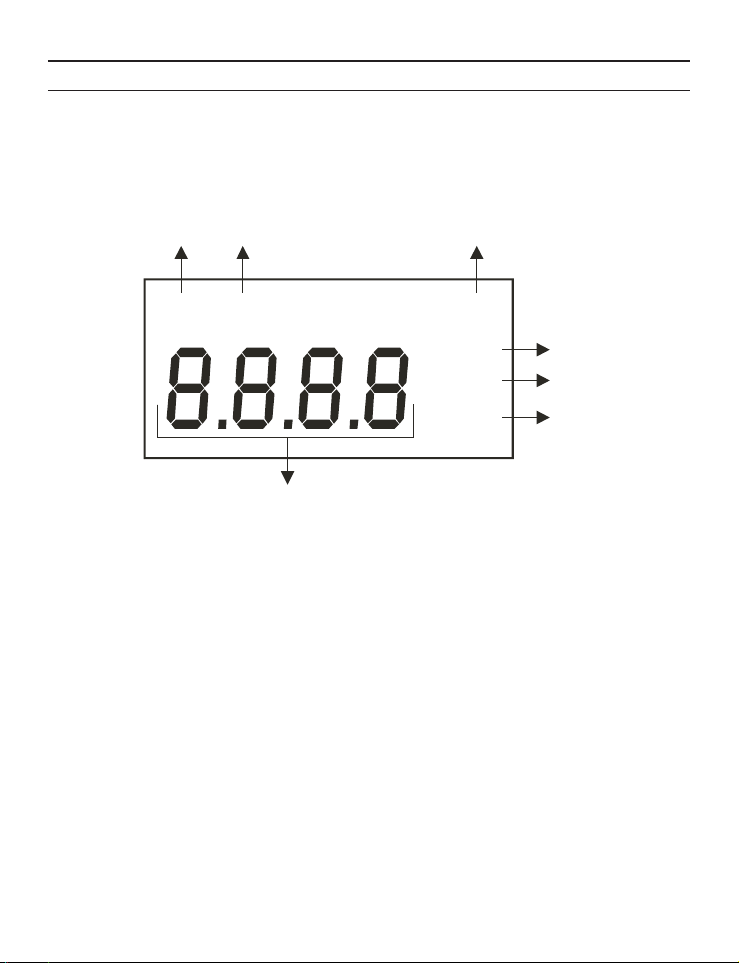

The meter has a large custom LCD that consists of 4-digit segments and

operation annunciators for uS/mS for the CON 6 meter, or ppm/ppt for the

TDS 6 meter, and °C (Temperature). Other annunciators include “HO”

(when the HOLD function is activated) and “LO” (low battery condition).

See Figure below.

LCD and Customized Annunciators for CON 6/TDS 6 meters

1. Primary display

2. Parts Per Million (ppm) or Parts Per Thousand (ppt)

indicator - TDS 6 meter only.

3. milli-Siemens/cm (mS) or micro-Siemens/cm (µS)

4. Temperature indicator

5. Percentage indicator for Temperature Coefficient.

6. Low battery indicator.

7. Hold (freezed) reading indicator.

indicator - CON 6 meter only.

7

Page 8

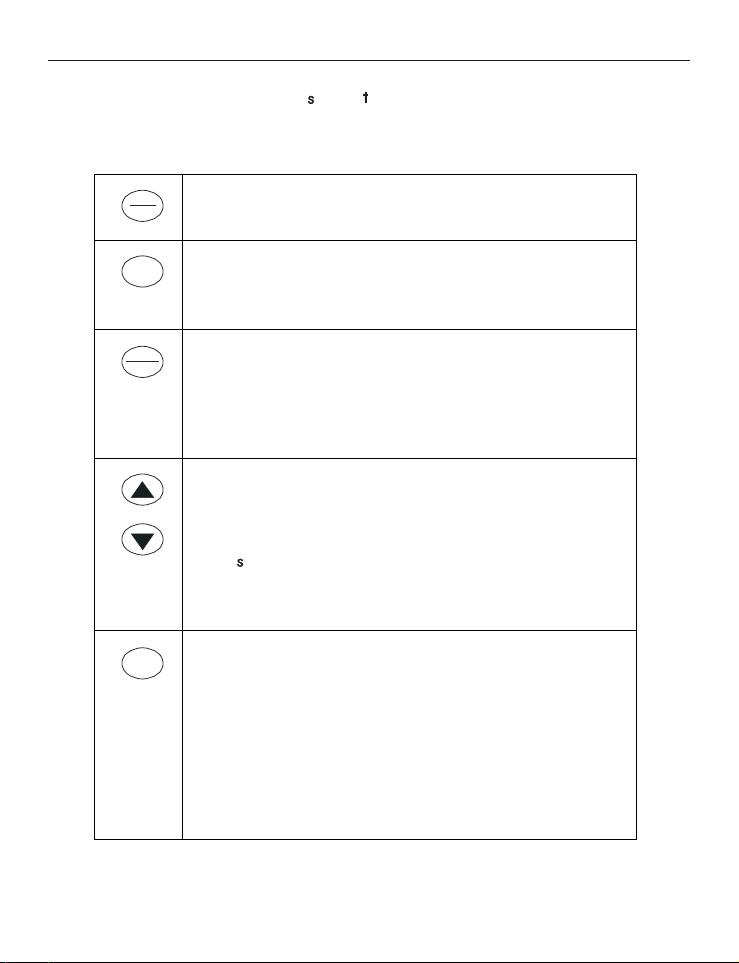

Keypad

ON

OFF

CAL

HOLD

ENTER

MODE

The CON 6 /TDS 6 meter has 6 buttons on the splash-proof keypad; ON/OFF,

HOLD/ENTER, CAL, MODE, and question buttons. Some buttons have

several functions depending on the mode of operation.

Powers on and shuts off the meter. Goes directly

into the measurement mode when the meter is

turned on.

Enters into the calibration mode for

Conductivity/TDS and Temperature.

To abort calibration or set-up mode without

confirming any set value.

HOLD: Freezes the measured reading. To activate,

press HOLD button while in measurement mode. To

release, press HOLD button again.

ENTER: Press to confirm values in the calibration

mode, and to confirm selections in the SET-UP

mode.

In Calibration Mode: Press to scroll through

calibration values.

In Set-up Mode: Press to scroll through the set-up

sub-group programs.

Press button during conductivity measurement

mode to activate manual ranging function. Each

button press will move to a higher conductivity

range.

Selects measurement mode for Conductivity/TDS

and Temperature.

Pressed together with ON/OFF button to go to the

SET-UP mode. This allows customization of meter

preferences such as selecting the electrode cell

constant, normalization temperature, temperature

coefficient factor, TDS factor (for TDS 6), automatic

calibration (CON 6 only) or manual calibration,

single-point or multi-point calibrations, and to reset

meter to factory default.

8

Page 9

PREPARATION

LO

S

µ

Inserting & Removing Rubber Boot

To insert the meter into the rubber boot, slide the top of the meter into the

rubber boot before pushing the bottom edges of

meter down to set it into position. Lift up the

stand at the back of meter for bench top

applications if necessary.

To remove the meter from the rubber boot, first

push the bottom edge of the meter out of the

boot. Ensure that the electrode or temperature

probe cables are not connected.

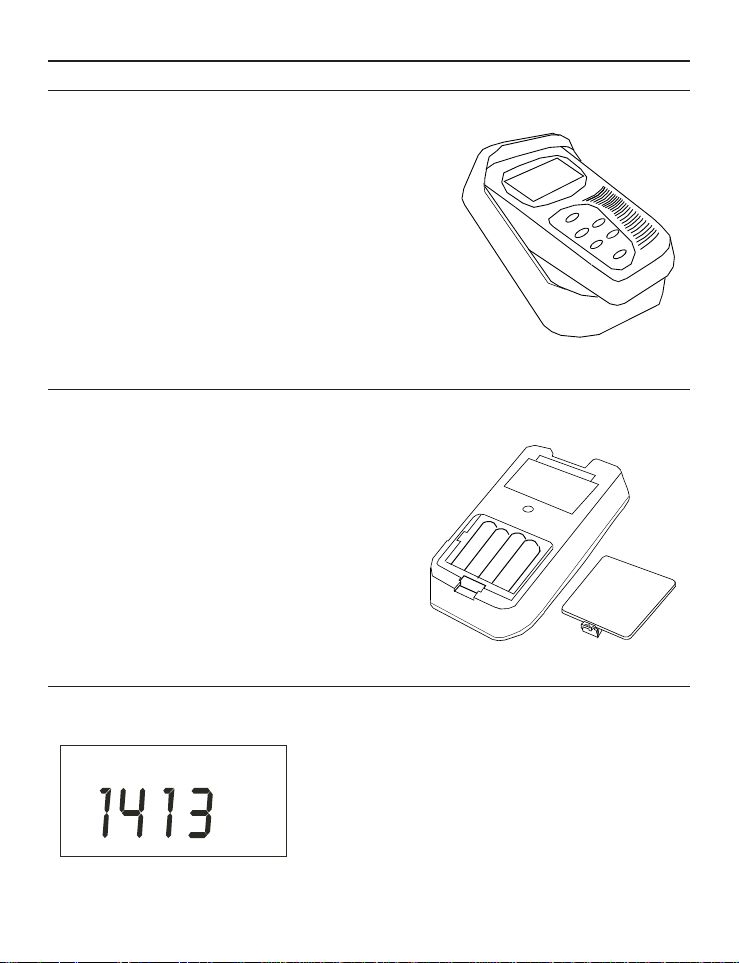

Inserting the Batteries

The battery compartment is found at the back of instrument as shown. To

open the battery compartment:

1. Remove the rubber boot. Open the

battery compartment. Push in the

direction of arrow and lift up the cover.

2. Insert four AAA batteries. Note the

polarity of battery before inserting into

position.

3. Replace the cover. Press down until it

clicks. Replace the rubber boot.

Battery Replacement

A “LO” annunciator in the LCD will indicate when the battery power is

running low. See Figure below. Replace the

batteries with the same type as recommended

by the manufacturer as soon as possible.

“LO” Battery Condition

Caution: Turn the meter off meter when changing the batteries.

9

Page 10

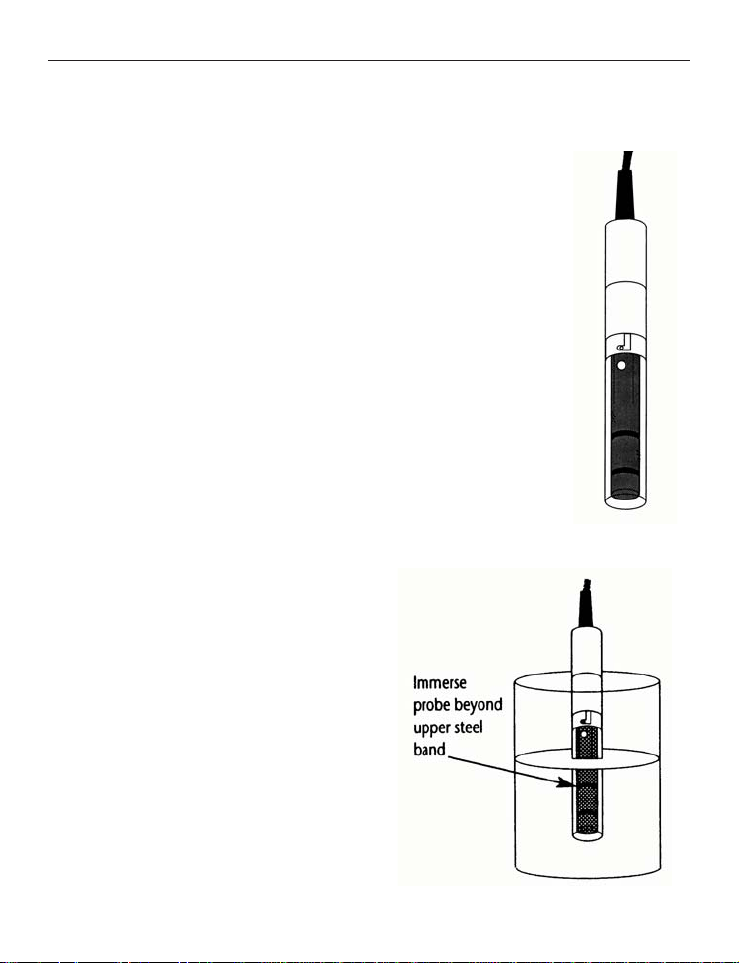

Conductivity Electrode Information

The CON 6/TDS 6 hand-held meter is supplied with a conductivity/TDS

electrode with a BNC connector. This conductivity/TDS electrode comes with

Stainless Steel rings, a cell constant of K = 1.0, and a built-in temperature

sensor for Automatic Temperature Compensation (ATC).

The specially designed Ultem-body housing has chemically

resistant properties. It provides fast temperature response and

reduces air entrapment, which makes it easy to obtain

accurate, stable readings.

The durable probe materials include:

1. Polyetherimide (Ultem) – protective probe guard

2. Polybutylterphalate (Valox) – sensor housing

3. Stainless Steel (SS 304) – 2 steel bands

Proper use of the probe is essential to ensure that the optimum

measurement is taken in the shortest amount of time.

The protective plastic probe guard is removable for simple

periodic maintenance but it must be kept intact during

measurement and calibration.

Always immerse the probe beyond upper steel band.

NOTE:

1. DO NOT remove the protective

probe guard during measurement

and calibration. It will affect the

results.

2. DO NOT submerge the probe

above the protective guard. The

cable can be submerged for brief

periods of time, but not

continuously.

See – “Probe Care and Maintenance”

for more information.

10

Page 11

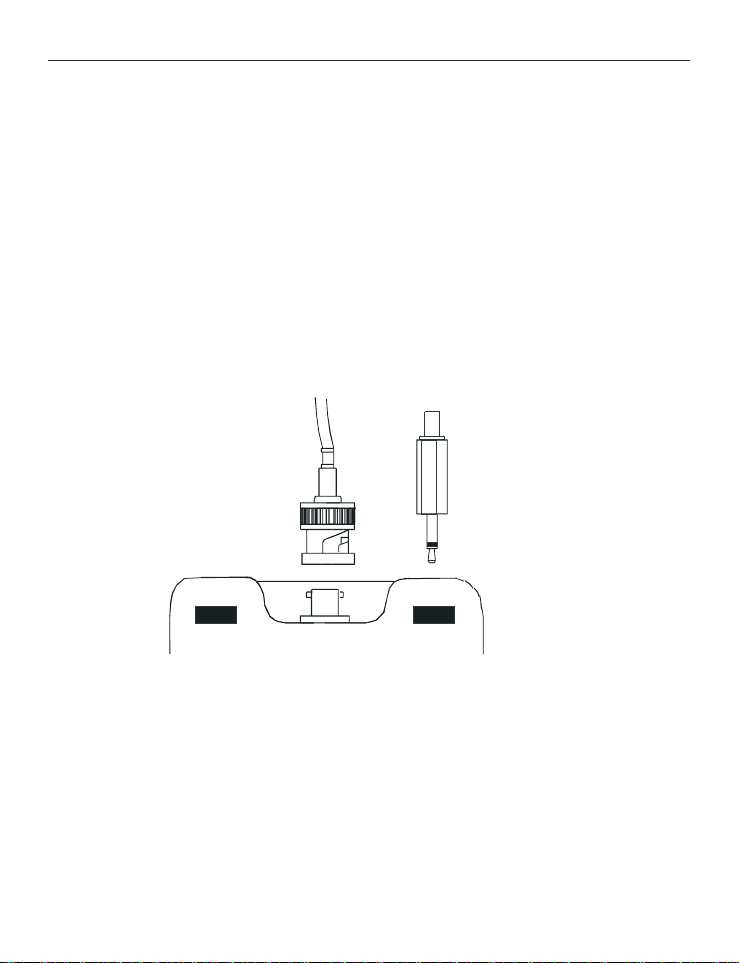

Connecting the Probe to the Meter

BNC connector for

conductivity probe

Phono jack for

Temperature probe

1. To connect the electrode to the meter, align the connector slots with the

posts of the meter socket and rotate the connector clockwise until it locks.

2. To remove, rotate the connector in a counter-clockwise direction until it

unlocks, and slide the connector off the socket.

3. Insert the mini phono jack on the temperature sensor into the socket on

the meter as shown below.

4. Unplug the phono jack when not in use or when measuring Conductivity

or TDS without any temperature compensation (see Manual Temperature

Compensation).

CAUTION: Do not pull on or force the probe cord or the probe wires might

disconnect.

NOTE: Keep connectors clean. Do not touch connectors with soiled hands.

Connection for Conductivity & Temperature Probes

11

Page 12

Turning the Meter On

Measurement Mode

m

S

µ

C°

%

pptmV

pH %MINMAXLOHO

FC°°

m

S

µS

µ

ON

OFF

Measurement Mode

C°

%

ON

OFF

ppm

pptmV

pH %MINMAXLOHO

FC°°

m

S

µ

pptm

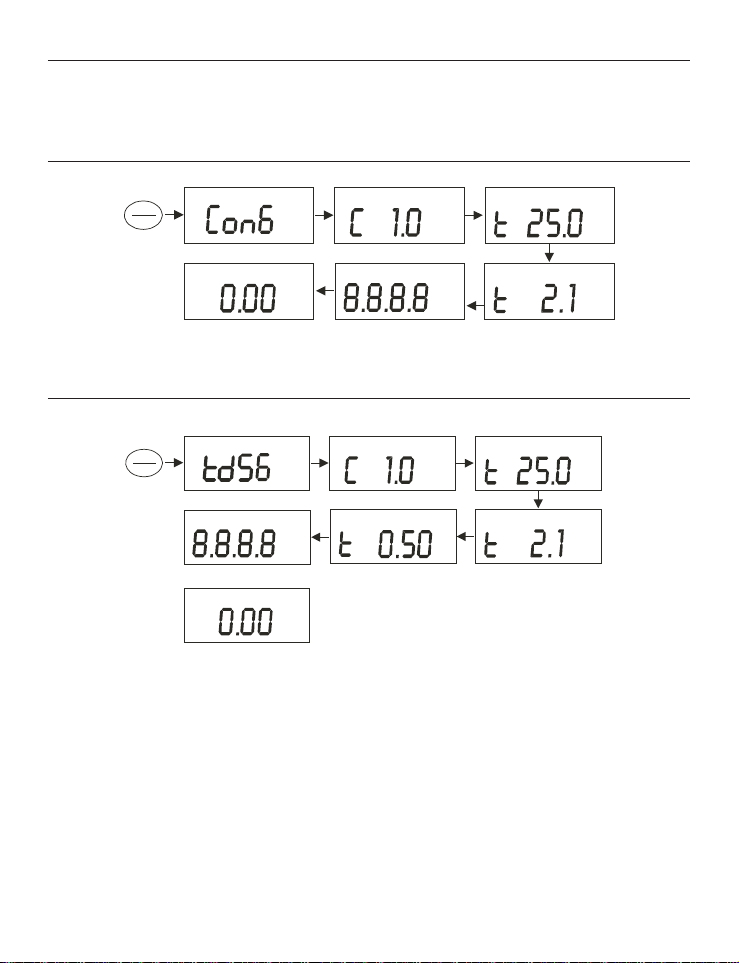

When the meter is turned on, it will go through a series of displays that show

the set-up parameters.

For CON 6

For TDS 6

Press ON/OFF button to turn on the meter.

1. First screen shows [Con 6] (or [tdS 6]) to identify the meter.

2. Second screen shows [C 1.0] which is the conductivity cell constant, k.

Cell constants of 0.1, 1.0 or 10.0 can be selected. Refer to Section on

Advance Set-up. Default value is k=1.0.

3. Third screen shows [t 25.0 °C] which is the Normalization Temperature.

Normalization Temperatures of 25 °C or 20 °C may be selected. Refer to

Section on Advance Set-up. Default value is 25 °C.

12

Page 13

4. Fourth screen shows [t 2.1%] which is the Temperature Coefficient. The

Annunciator

MODE

S

µ

C°

meter can be customized with different Temperature Coefficient values

from 0.0 to 3.0 %/°C in the Advance Set-up mode. Default value is 2.1

%/°C.

5. All LCD segments will light up for 2 seconds, and then advance into the

measurement mode.

6. The meter is ready to measure conductivity or TDS.

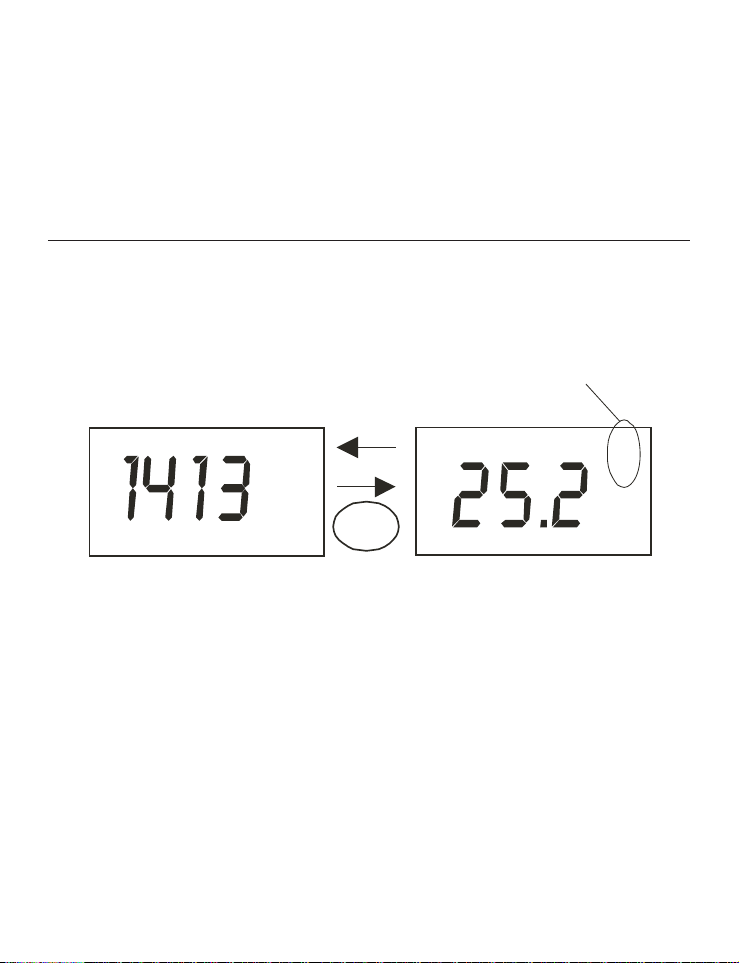

Change Conductivity/ TDS óTemperature Measurement Mode

To switch between the Conductivity/TDS measurement mode and

Temperature measurement mode, press the MODE button.

The customized annunciator will indicate the measurement parameter.

13

Page 14

CALIBRATION

Important Information on Meter Calibration

The meter has five measuring ranges. The meter can be calibrated at one po

int in each of the five measuring ranges. If measurements are being taken in

more than one range, each of the ranges were measurements are being made

must be calibrated.

The following table lists the corresponding conductivity and TDS ranges. Each

range should be calibrated with a solution that falls between the values in the

“recommended calibration solution range” column.

Conductivity

Range

Recommended

Calibration

Solution Range

TDS Range Recommended

Calibration

Solution Range

0.00 to 20.00 µS 6.00 to 17.00 µS 0.00 to 10.00 ppm 3.00 to 8.50 ppm

0.0 to 200.0 µS 60.0 to 170.0 µS 10.0 to 100.0 ppm 30.0 to 85.0 ppm

0 to 2000 µS 600 to 1700 µS 100 to 1000 ppm 300 to 850 ppm

0.00 to 20.00 mS 6.00 to 17.00 mS 1.00 to 10.00 ppt 3.00 to 8.50 ppt

0.0 to 200.0 mS 60.0 to 170.0 mS 10.0 to 200 ppt 30.0 to 170 ppt

When the meter is recalibrated, the old calibrations are replaced on a range by

range basis. For example, if the conductivity meter was previously calibrated at

1413 µS in the 0 to 2000 µS range and it is recalibrated at 1500 µS (also in the

0 to 2000 µS range), the meter will replace the old calibration data (1413 µS)

with the new calibration data (1500 µS ) for that range. The meter will retain

all calibration data in the other ranges.

To completely recalibrate the meter, or when a probe is replaced, it is best to

clear all calibration data. To erase all the old conductivity or TDS calibration

data completely, see – Restore Factory Default Values.

14

Page 15

Preparing the Meter for Calibration

Before starting calibration, be sure the meter is in the correct measurement

mode.

For best results, select a standard value close to the value of the sample that is

being measured. Alternatively use a calibration solution value that is

approximately 2/3 the full-scale value of the measurement range that is being

used. For example, in the 0 to 2000 µS conductivity range, use a 1413 µS

solution for calibration.

Calibrate all measurement ranges to ensure the highest accuracy throughout

the entire measurement range. Note that the CON 6/TDS 6 meter will not

accept calibration values less than 40 µS/cm (20 ppm). All new calibration

values will automatically override existing data.

If solutions with Conductivity lower than 100 µS/cm, or TDS lower than 50

ppm, are being measured the meter should be calibrated at least once a week

for optimum accuracy. If measurements are in the mid-ranges, and the probe is

washed with deionized water and stored dry, the meter can be calibrated once a

month. If measurements are taken at extreme temperatures, the meter should

be calibrated at least once a week.

Fresh conductivity standard solutions should be used during calibration. Do

not reuse standard solutions. They could be contaminated and affect the

calibration and accuracy of the measurements. Store solutions in a dry and cool

environment if possible.

Always rinse the probe with either deionized water or rinse solution before and

after each calibration/sample measurement to avoid cross-contamination. For

details refer to Probe Care and Maintenance.

NOTE: These meters are factory set to a temperature coefficient of 2.1% per

°C. For most applications this will provide good results.

To set the temperature coefficient to different value, see Temperature

Coefficient.

Also, see Appendix 3 - Calculating the Temperature Coefficient to determine

the appropriate temperature coefficient for any solution.

NOTE: The factory default value for normalization temperature is 25 °C. If a

value other than 25 °C is needed, see Normalization Temperature.

15

Page 16

Selection of Automatic or Manual Calibration

This meter is capable of performing either automatic (CON 6 only) or manual

calibration.

In the automatic calibration mode, the meter (CON 6 only) automatically

detects and verifies the appropriate known calibration standards solutions

being calibrated before accepting these particular calibration standards as one

of the calibration values in a specific measurement range. This automatic

calibration mode makes the manual calibration procedure unnecessary.

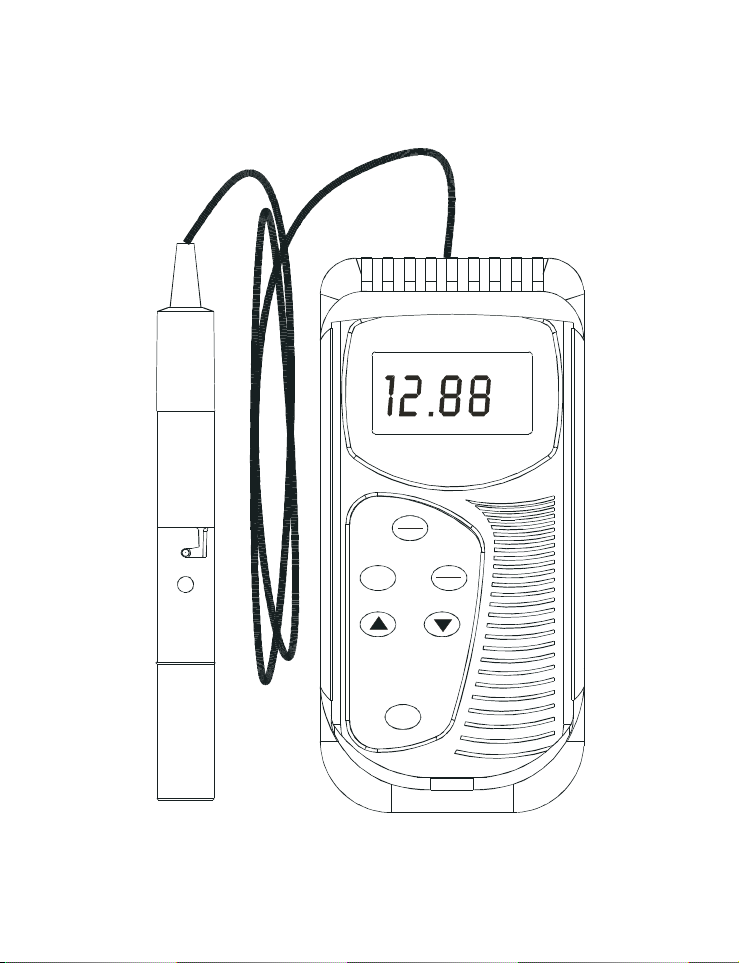

The calibration standards used for automatic calibration are:

Meter Normalization

Calibration Standards (Range)

Temperature

CON 6 25 °C

1. 84 µS (for 0 – 200 µS/cm)

2. 1413 µS (for 0 – 2000 µS/cm)

3. 12.88 mS (for 0.00 – 20.00 mS/cm)

4. 111.8 mS (for 0.0 – 200.0 mS/cm)

20 °C

1. 76 µS (for 0 – 200 µS/cm)

2. 1278 µS (for 0 – 2000 µS/cm)

3. 11.67 mS (for 0.00 – 20.00 mS/cm)

4. 102.1 mS (for 0.0 – 200.0 mS/cm)

Table 1: Conductivity Calibration Standards for Automatic calibration.

In the manual calibration, non-standard calibration values can be used for

calibration. The appropriate values can be manually input as the desired

calibration standards in each specific range. This is useful in situations with

customized calibration standards that are unique to an application.

To select Automatic or Manual Calibration settings, refer to Automatic

Calibration for more information.

16

Page 17

Automatic Calibration (Conductivity)

mS

mS

mS

mS

CAL

HOLD

ENTER

Measurement Mode

In the Automatic Calibration mode, the meter is capable of accepting a

single-point calibration or up to 4 points for multi-point calibration with the

maximum of 1 point per specific measurement range. For the automatic

calibration standard values refer to Table 1.

1. If necessary, press MODE button to select the

conductivity mode.

2. Rinse the probe thoroughly with deionized water or

a rinse solution, then rinse with a small amount of

calibration standard.

NOTE: For Automatic Calibration one of the

calibration standards listed in Table 1 must be used.

3. Dip the probe into the calibration standard.

Immerse the probe tip beyond the upper steel band .

Gently stir the sample with the probe to create a

homogeneous sample. Allow time for the reading to

stabilize.

4. Press CAL button to enter the conductivity

calibration mode. The [CA] indicator will appear for

1.5 seconds, and a value will appear flashing.

NOTE: To exit calibration without confirmation,

press CAL button again to go back to measurement

mode.

5. Wait for the value to stabilize and press ENTER

button. The calibration standard value will appear

for 3 seconds. If the calibration has been successfully

performed, [donE] will be displayed for about 3

seconds, and the meter will return to the

measurement mode.

6. To perform the next point calibration in the

multi-point calibration, repeat steps 1-5 until all

points have been calibrated.

IMPORTANT NOTES:

1. The meter allows a tolerance range of ±40% of the

calibration standard. An error message “Err 1” will be displayed for 3

seconds if an attempt is made to calibrate with a solution with a value

outside of the tolerance range.

For instance: For 1413 µS conductivity calibration standard, 40% tolerance

is from 848 µS to 1978 µS.

17

Page 18

2. If the temperature (t °C) of the conductivity calibration solution is below 0

mS

mS

mS

mS

CAL

HOLD

ENTER

Measurement Mode

°C or above 50 °C (0°C<t°C>50°C), an error message “Err 2” will be

displayed when performing the auto calibration, and meter will return to

measurement mode.

3. All new calibration data will over-ride existing stored calibration data for

each measuring range calibrated.

4. It is important to use fresh conductivity calibration standards.

5. Low conductivity standard solutions (less than 20 µS /cm) can become

contaminated as soon as they are exposed to the air. Exercise caution

during calibration in the first measurement range (0.00 to 20.0 µS /cm).

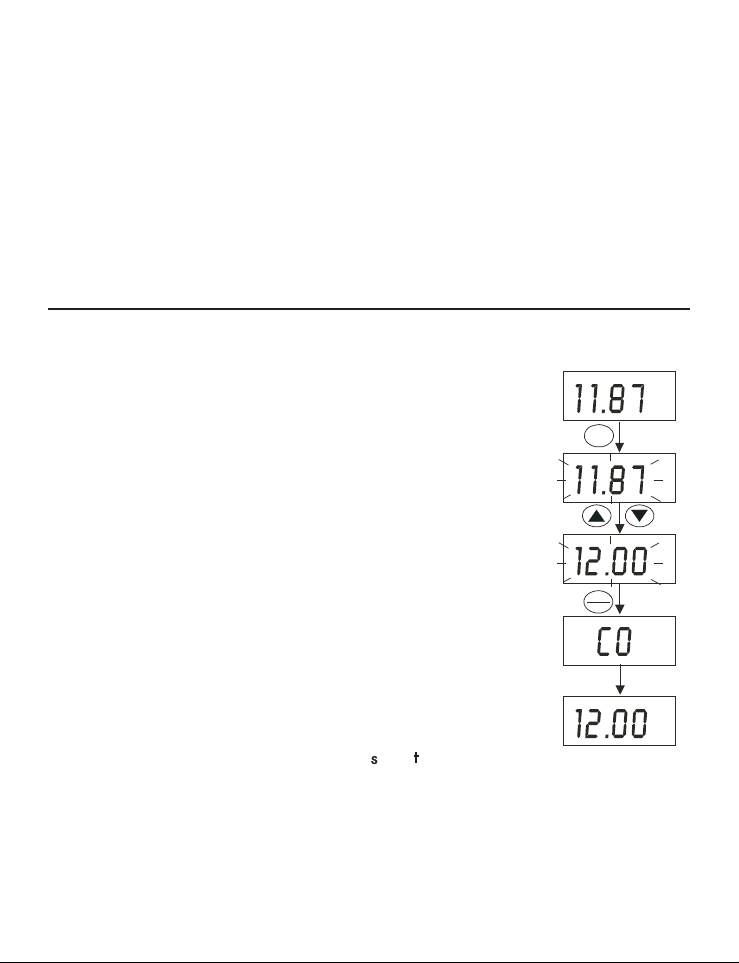

Manual Calibration (Conductivity or TDS)

In Manual Calibration mode (see page 23) the meter can be calibrated with

customized conductivity calibration standards that are

specific to a particular application. The following example

shows the calibration sequence of a 12.00 mS conductivity

calibration standard.

This procedure is for the CON 6 and TDS 6 meters.

1. If necessary, press the MODE button to select the

conductivity mode.

2. Rinse the probe thoroughly with deionized water or a

rinse solution, then rinse with a small amount of

calibration standard.

3. Dip the probe into the calibration standard. Immerse

the probe tip beyond the upper steel band. Gently stir

the sample with the probe to create a homogeneous

sample. Allow time for the reading to stabilize.

4. Press CAL button to enter conductivity calibration

mode. The [CA] indicator will appear for 1.5 seconds,

and a value will appear flashing.

NOTE: To exit calibration without confirmation, press

CAL button again to go back to measurement mode.

5. Wait for the value to stabilize. Press or button and

adjust the value to the calibration standard used.

6. Press the ENTER button. The [CO] indicator will appear for 1.5 seconds,

and the calibration has been successfully performed. The meter will return

to the measurement mode.

7. To perform the next point calibration in the multi-point calibration for the

next range, repeat steps 1-6 until all points have been calibrated.

18

Page 19

Temperature Calibration

The conductivity electrode has a built-in temperature sensor for ATC. The

temperature sensor is factory calibrated to the meter. Calibrate the sensor only

if it is suspected that temperature errors that may have occurred over a long

period of time or if the probe is a replacement probe.

1. Make sure that the phono jack (for temperature measurement) is properly

connected to the meter.

2. Turn on the meter and if necessary, press the MODE button to select the

temperature measurement mode.

3. Press CAL button to start temperature calibration process.

4. Dip the probe into a solution with known temperature (for example, a

temperature bath). Allow time for the temperature to stabilize.

5. After the value has stabilized, press question or button and adjust the

value to the solution temperature.

6. Press the ENTER button. The [CO] indicator will appear for 1.5 seconds,

and the reading will stop flashing. The temperature calibration has been

successfully performed. The meter will return to the measurement mode.

NOTE: To exit calibration without confirmation, press CAL button again to

go back to measurement mode.

NOTE: The temperature reading can be offset up to ±5 °C from the original

(default) reading.

19

Page 20

MEASUREMENT

C°

C°

C°

HOLD

ENTER

°C

CAL

The CON 6/TDS 6 meter is capable of taking measurements with automatic

temperature compensation or manual temperature compensation.

With Automatic Temperature Compensation (ATC)

For ATC, make sure the phono jack of the probe is securely connected to the

meter.

The conductivity/TDS reading displayed will be compensated for according to

the normalization temperature (20 °C or 25 °C) selected. See Normalization

Temperature.

Without ATC (Manual Temperature Compensation)

For manual temperature compensation, unplug the probe phono jack (not

BNC) from the meter.

To use manual temperature compensation, enter the temperature value of the

process into the meter. The meter will compensate the

result to this temperature. Any temperature between 0

and 50 °C (32 to 122 °F) can be selected. The default

value is 25 °C.

1. Make sure that the phono jack (for temperature

measurement) is disconnected from the meter.

2. Turn on the meter and if necessary, press the MODE

button to select the temperature measurement mode.

3. Press CAL button to start the temperature calibration

process.

4. “CA” will appear momentarily and the temperature

value will start flashing.

5. Check the temperature of the sample using an

accurate thermometer. Wait for the value to stabilize.

Press or button and adjust the value on the

display to match the value on the reference

thermometer.

6. Press the ENTER button. The [CO] indicator will

appear for 1.5 seconds, and the reading will stop

flashing. The temperature calibration has been

successfully performed. The meter will return to the

measurement mode.

20

Page 21

Taking Measurements

1. Rinse the probe with deionized or distilled water before use to remove any

impurities adhering to the probe body. Shake or air dry. To avoid

contamination or dilution of the sample, rinse the probe with a small

volume of the sample liquid.

2. Press ON to turn the meter on.

3. Dip the probe into the sample.

4. Allow time for the reading to stabilize. Note the reading on the display.

NOTE: When dipping the probe into the sample, take care to ensure that the

liquid level is above the upper steel band. Gently stir the sample with the

probe to create a homogenous sample.

Using Manual Ranging Function

By default the meter has auto-ranging ability and will automatically select the

range in which the readings appear.

However, a specific range may be selected. This is achieved by pressing

button successively for each measurement range. The five ranges are:

Conductivity

Range (CON 6)

TDS Range (TDS 6)

(if TDS factor is 0.5)

0 – 20.00 µS/cm 0 – 10.00 ppm

0 – 200.0 µS/cm 0 – 100.0 ppm

0 – 2000 µS/cm 0 – 1000 ppm

0 – 20.00 mS/cm 0 – 10.00 ppt

0 – 200.0 mS/cm 0 – 100 ppt

21

Page 22

NOTE:

S

µ

mSmS

Auto-ra nging Manual r anging: 0 - 2 0.00 uS/cm Manual r anging: 0 - 2 00.0 uS/cm

Manual r anging: 0 - 2 000 uS/cmManual r anging: 0 - 2 0.00 mS/cmManual r anging: 0 - 2 00.0 mS/cm

S

µ

S

µ

S

µ

S

µ

S

µ

HOLD

ENTER

HO

If the value of the solution being measured is higher than the range selected

[Or] will appear on the primary display. Press RANGE until the correct range

is selected.

The meter resets to the Auto-ranging function once it is turned off. The

manual ranging function must be reset each time the meter is turned on.

HOLD Function

The hold feature will freeze the display for a delayed

observation. HOLD can be used any time in

measurement mode.

1. To hold a measurement, press the HOLD button

while in measurement mode. [HO] will appear on the

display.

2. To release the held value, press the HOLD button

again. Continue to take measurements.

NOTE:

The meter will shut off automatically after 20 minutes of nonuse.

If the meter is shut off either automatically or manually, the HOLD value will

be lost.

22

Page 23

ADVANCED SET-UP FUNCTIONS

%

C°

Advanced Set-up Overview

The advanced set-up mode customizes the meter preferences and defaults. To

enter the advanced set-up mode:

1. Make sure that the meter is turned off.

2. Press ON and MODE buttons simultaneously, holding both buttons for 2

seconds. First release ON button first before releasing the MODE button.

3. [StUP] indicator will appear momentarily and [CELC] will appear next.

4. Overviews of the CON 6 and TDS 6 Set-up Menu are as follows.

Enter Set-Up Page.

Select Cell Constant. Choice of k =

0.1, 1.0, and 10.0.

Default value is 1.0.

Select Automatic Calibration. “Yes”

for auto calibration and “no” for

manual calibration.

Default value is “Yes”. (Available in

CON 6 meter only)

Adjust Temperature Coefficient

value from 0.0 to 3.0 %/°C.

Default value is 2.1 %/°C.

Select Normalization Temperature.

Choice of either 20 °C or 25 °C.

Default value is 25 °C.

Adjust TDS factor from 0.4 to 1.0.

Default value is 0.5. (Available in

TDS 6 meter only)

23

Page 24

Select Single Point Calibration.

%

C

°

Meter Off

Press ON/OFF and MODE buttons

simultaneously for 2 seconds, release

ON/OFF button first then release MODE

key button a second later.

A "StUP" indicator will appear for 1.5

seconds before showing the first menu

ON

OFF

MODE

Choice of “Yes” or “No”.

Default value is “Yes”.

User reset to factory defaults.

Choice of “Yes” or “No”.

Default value is “no”.

Overview of Advanced Set-Up

Overview of CON 6 Set-Up Menu

24

Page 25

Overview of TDS 6 Set-Up Menu

%

C°

Meter Off

Press ON/OFF and MODE buttons keys

simultaneously for 2 seconds, release

Release ON/OFF button first then release MODE button

a second later.

A "StUP" indicator will appear for 1.5

seconds before showing the first menu.

ON

OFF

MODE

HOLD

ENTER

Select Cell Constant

It is possible to select a cell constant of K = 1.0, 10, or 0.1.

Use a cell of K = 1.0 for midrange measurements

Use a cell ofK=10forhigh range measurements

(above 20 mS or 10 ppt).

Use a cell of K = 0.1 for low range measurements

(below 20 µS or 10 ppm).

The cell included with the meter has a cell constant

of K = 1.0.

1. Enter Advanced Set up.

2. Press or button until [CELC] appears on the

LCD. Press ENTER button.

3. Press or button to select either “1.0”, “0.1” or

“10.0”. Ensure the cell constant selected correspond

with the conductivity electrode that is being used

with the meter.

4. Press ENTER button to select. The meter will

return to the menu, [CELC].

5. Press or button to move to the next menu or

press CAL to exit to measurement mode.

25

Page 26

Automatic Calibration (for CON 6)

HOLD

ENTER

Press ENTER to confirm selection; or

Press CAL to escape without confirming selection

Press ENTER to confirm selection; or

Press CAL to escape without confirming selection

HOLD

ENTER

The automatic calibration allows the meter to be quickly

calibrated to any of the four widely used conductivity

calibration standards. For a list of calibration standards

refer to Table 1.

In the manual calibration mode, customized conductivity

calibration standard can be used to calibrate this meter.

1. Enter Advanced Set-up.

2. Press or button until [ACAL] appears on the

LCD. Press ENTER button.

3. Press or button to select either [Yes]or[no].

4. Press [ENTER] button to select. The meter will

return to the menu, [ACAL].

5. Press or button to move to the next menu or press CAL to exit to

measurement mode.

Setting the TDS Factor (for TDS 6)

The concentration of salts dissolved in solution increases the conductivity of

that solution. This relationship varies from salt to salt and is roughly linear

over a given range for a given salt. The TDS conversion factor is the number

used by the meter to convert from conductivity to TDS.

To calculate the TDS conversion factor refers to

Appendix 2 – Calculating TDS Conversion Factor.

TDS conversion factors for various types of salts can

also be found in chemical reference books.

The TDS conversion factor can be set between 0.4 and

1.0. The meter default is 0.5.

1. Enter Advanced Set-up.

2. Press or button until [tdS] appears on the LCD.

Press ENTER button.

3. Press or button to select a value between 0.4 to

1.0.

4. Press ENTER button to select. The meter will take

return to the menu, [tdS].

5 .Press or button to move to the next menu or press CAL to exit to the

measurement mode.

26

Page 27

Temperature Coefficient

Press ENTER to confirm selection; or

Press CAL to escape without confirming selection

%

%

%

HOLD

ENTER

Press ENTER to confirm selection; or

Press CAL to escape without confirming selection

C°

C°

C°

HOLD

ENTER

The temperature coefficient is the amount of change in

conductivity per degree of temperature; it is expressed in

percent per °C. Entering the exact temperature

coefficient of the solution being measured will accurately

compensate the temperature for almost any solution. The

temperature coefficient can be set between 0.0 and 3.0 %

per °C. The meter default is 2.1% per °C.

6. Enter Advanced Set-up.

7. Press or button until [t.Co %] appears on the

LCD. Press ENTER button.

8. Press or button to select a value between 0.0 and

3.0.

9. Press ENTER button to select. The meter will return

to the menu, [t.Co %].

Press or button to move to the next menu or press CAL to exit to the

measurement mode.

Normalization Temperature

The meter can be set to normalize the conductivity measurements to a

standard temperature of either 25 °C or 20 °C.

The default value is 25 °C.

1. Enter Advanced Set-up.

2. Press or button until [t.nr °C] appears on the

LCD. Press ENTER button.

3. Press or button to select either [25.0 °C]or[20.0

°C].

4. Press ENTER button to select. The meter will return

to the menu, [t.nr °C].

5. Press or button to move to the next menu or

press CAL to exit to the measurement mode.

27

Page 28

Single-Point Calibration

Press ENTER to confirm selection; or

Press CAL to escape without confirming selection

HOLD

ENTER

Press ENTER to confirm selection; or

Press CAL to escape without confirming selection

HOLD

ENTER

A single-point calibration refers to calibrating at one

conductivity value that will be used for all 5 conductivity

ranges.

By selecting [no] to single-point calibration, a calibration

for each conductivity range can be performed.

1. Enter Advanced Set-up.

2. Press or button until [S.P.CA] appears on the

LCD. Press ENTER button.

3. Press or button to select either [Yes]orno].

4. Press ENTER button to select. The meter will return

to the menu, [S.P.CA].

5. Press or button to move to the next menu or

press CAL to exit to the measurement mode.

Restore Factory Default Values

This function allows all parameters to be reset to the factory default settings.

This clears all calibration data and any other set-up

functions that may have been changed.

IMPORTANT: Once activated the meter settings and

calibration data will be erased. Always exercise caution.

Meter reset is not reversible.

1. Enter Advanced Set-up.

2. Press or button until [UrSt] appears on the LCD.

Press ENTER button.

3. Press or button to select either [Yes]or[no].

4. Press ENTER button to select.

5. The meter will return to the measurement mode after

the turn-on initialization.

28

Page 29

PROBE CARE AND MAINTENANCE

Keep the conductivity probe clean. Rinse the probe twice before using. Gently

swirl the probe in the solution while taking readings. Do not immerse the

probe in oily solutions.

For best accuracy, soak a dry probe for at least 5 to 10 minutes or longer before

calibration.

The conductivity probe included with the meter features a removable probe

guard to make cleaning easy.

To remove probe guard:

1. Grip the yellow probe guard and twist clockwise.

The locking notch will release.

2. Slide the probe guard off the end of the probe.

Clean the electrode thoroughly by stirring it in a mild

detergent bath or isopropyl alcohol. Wipe the probe

with a soft tissue paper. Rinse thoroughly in tap water

and then in deionized water. Recalibrate the meter after

cleaning the probe.

NOTE: Remember to re-attach the probe guard prior to

taking readings. Failure to do so could result in

erroneous readings.

Rinse the probe with deionized or tap water before

storing. Never scratch the bands with a hard substance.

Do not strike the probe against any hard surface.

29

Page 30

TROUBLESHOOTING GUIDE

Problem Cause Solution

Power on but

no display

a) Batteries not in

place

b) Batteries not in

correct polarity (+ and

– position)

a) Check that batteries

are in place and

making good contact.

b) Reinsert batteries

with correct polarity.

Unstable

readings

Slow

response

c) Weak batteries

a) Air bubbles in probe

c) Replace batteries.

a) Tap probe to remove

bubbles.

b) Dirty probe

b) Clean the probe and

c) Probe not deep

recalibrate.

enough in sample

c) Make sure sample

d) External noise

pickup or induction

entirely covers the

probe sensors.

caused by nearby

electric motor

d) Move or turn off

interfering motor.

e) Broken probe

e) Replace probe.

a) Dirty / Oily probe a) Clean probe. See

“Probe Care &

Maintenance”.

30

Page 31

ERROR MESSAGES

LCD Display Indicates Cause Solution

“LO”

indicator

appears.

Low battery

level

Need new

batteries or

battery

connection is

bad.

Err 1 Conductivity

calibration

error

Calibration

point is outside

the ±40%

window in the

auto-calibration.

Err 2 Temperature

calibration

error

Auto calibration

is performed

outside the

temperature

range (0 – 50

°C).

Err 3 Conductivity

calibration

error

Calibration

point is within

10% of the

measurement

range in the

manual

calibration

mode.

Clean battery

contacts.

Replace batteries

with fresh ones,

noting polarity.

Check the value

of the

conductivity

calibration

solution.

Turn to manual

calibration mode

and calibrate

again.

If message

persists, return

unit*.

Check the

temperature and

make sure that it

is within the

acceptable range.

If message

persists, return

unit*.

Check the value

of the

conductivity

calibration

solution.

If message

persists, return

unit*.

* See Sections on “Warranty” and “Return of Items”.

31

Page 32

If an error message appears, turning off the meter and

LO

S

µ

turning it on again may eliminate the error message.

Refer to diagram on right.

If error persists, or the meter shows incorrect values,

return the meter.

For a complete diagram of the display see page 3.

SPECIFICATIONS DESCRIPTIONS CON 6 TDS 6

Conductivity Range 0 to 20.00, 200.0,

X

2000 µS/cm;

0 to 20.00,

200.0 mS/cm

Resolution 0.01, 0.1, 1 µS/cm:

0.01, 0.1 ,S/cm

Accuracy ±1% F.S.

TDS Range 0 to 10.00, 10.0 to

100.0, 100 to 1000

ppm;

1.00 to 10.00, 10.00 to

100.0, Up to 200 ppt

depending on the

TDS factor setting.

Resolution 0.01, 0.1, 1 ppm;

XX

0.01, 0.1 ppt

Accuracy

Temperature Range -10.0 to 110.0 °C

±1% F.S. X X

XX

Resolution/Accuracy 0.1 °C / ± 0.5 for °C X

Cell Constant 0.1, 1.0, 10.0

XX

(selectable)

Temperature

Compensation

Automatic / Manual

(from 0 to 50 °C)

XX

X

X

X

X

32

Page 33

SPECIFICATIONS DESCRIPTIONS CON 6 TDS 6

Temperature

0.0 to 3.0% / °C

X

Coefficient

Normalization

Temperature

20.0 °C and 25.0 °C

(selectable)

XX

Conductivity to TDS

0.4 to 1.0

Conversion factor

Number of

calibration points

5: Maximum 1 per

range

Auto- &

Manual-ranging

HOLD Function

Auto Power Off 20 minutes after last

button operation

Inputs BNC for conductivity

and phono jack for

temperature

Display Single Custom LCD

Power Requirements 4 ‘AAA’ Batteries

Battery Life > 100 hours

Dimension / Weight

Meter: 14x7x3.5cm;

200 g

X

XX

XX

XX

XX

X

X

XX

XX

XX

XX

33

Page 34

ACCESSORIES

Replacement Meter and Meter accessories

Item Code

CON 6, portable conductivity meter

complete with conductivity probe of

k=1.0 and case

TDS 6, portable TDS meter complete

with conductivity probe of k=1.0 and

case

Electrode, stainless steel 3 ring,

Ultem body with ATC, BNC plug

(for CON 6), cell constant = 1.0,

x110 mm, 1m cable length

Protective Rubber Boot 5-0040

Calibration Solutions

5-0039-01

5-0037-01

5-0106

84mS, 25 mL

1413mS, 100 mL

6312-G

6354-J

12.88 mS, 25 mL 6317-G

34

Page 35

CONDUCTIVITY THEORY

Conductivity is defined as the ability of a solution to conduct an electrical

current, or the reciprocal of the solution’s ability to resist the current. The

current is conducted by electrically charged particles called ions, which are

present in almost all solutions. Different solutions have different kinds and

amounts of ions. Distilled water has very few ions, and therefore a low

conductivity, while seawater has a large number of ions, and a high

conductivity.

Although a conductivity reading provides an overall measurement of the ionic

strength of a solution, it is not possible to distinguish the specific amounts of

individual ions. For this reason, conductivity is often used to measure the total

dissolved solids (TDS) of a solution. TDS is defined as the amount of solids

that will pass through a 45 micron filter. Rather than filtering a solution, the

TDS can be estimated by multiplying the conductivity measurement by a

predetermined factor. This factor, which is determined gravimetrically, will fall

between 0.55 and 0.9. A commonly used factor is 0.7.

Conductivity is measured using a probe which has two parallel plates separated

by a fixed distance. When a voltage from the meter is applied across the

electrodes, the ions in the solution conduct a current that flows between the

two electrodes. The greater the concentration of ions in the solution, the

larger the current generated and the higher the conductivity. Likewise, the

smaller the concentration of ions, the lower the conductivity. The meter

converts the current measured to a conductivity reading. Conductivity values

are related to the conductance of a solution by the physical dimensions - area

and length — or the cell constant of the measuring electrode. The physical

distance between the plates is also critical, as it effects the strength of the

electric field between the plates. By using cells with defined plate areas and

separation distances, it is possible to standardize conductance measurements.

The relationship between conductance and specific conductivity is:

Specific Conductivity S.C. = (Conductance) (cell constant, k)

= siemens x cm/cm

= siemens/cm

2

where C is the conductance (siemens)

k is the cell constant, length/area or cm/cm

2

Conductivity is measured in microsiemens per centimeter (mS/cm). In waters

of higher conductivity, mS/cm may be multiplied by 1000, giving results as

millisiemens per centimeter (mS/cm). Total dissolved solids are measured in

parts per million (ppm). Therefore:

µS/cm X 0.7 = ppm TDS

35

Page 36

Conductivity measurements are very dependent on temperature. The ability of

the ions to move through the solution, and conduct the current, is related to

the temperature of the solution. As the temperature of the solution rises, the

ions move more quickly through the solution, increasing the conductivity. As

the temperature decreases the ions move more slowly and the conductivity

decreases. Since the conductivity of the same solution can change by as much

as 2 percent per °C, accurate temperature measurements must be made

simultaneously to with the conductivity reading. The CON 6/TDS 6 has a

temperature sensor within the probe that will measure the temperature of the

solution.

To make conductivity readings taken at different times and places comparable,

measurements are often converted to what the conductivity of the solution

would be at 20°Cor25°C. The CON 6/TDS 6 automatically applies this

conversion before displaying a reading.

Because it is a quick, reliable, and inexpensive way of monitoring the ionic

content of a solution, conductivity measurements are widely used in many

areas of water testing from environmental monitoring to municipal water

supplies to many industrial applications.

APPENDIX 1: CALIBRATION TIPS

Only one calibration point is needed to measure solutions throughout the

entire range of the meter. If a range was not calibrated, the meter will

automatically detect the closest range calibrated and use that calibration

information. However, only the ranges that were calibrated will have

maximum accuracy.

If the solutions being measured are near to or greater than 20 mS (10 ppt), or

near to or lower than 100 µS (50 ppm), the meter should be calibrated at least

once a week to get the specified ±1% F.S. accuracy.

If the solutions being measured are in the mid-ranges and the probe was

washed in deionized water and stored dry, the meter should be calibrated at

least once a month.

Wet the probe for 10 minutes before calibrating or taking readings to saturate

the probe surface and minimize drift. If measurements are made at extreme

temperatures, the meter should be calibrated at least once a week.

Use only the conductivity/TDS probe specified for the CON 6/TDS 6 meters.

This probe has a built-in temperature sensor. If a probe without a temperature

sensor is used, the temperature of the solutions must be measured and manually

entered into the meter. (see Manual Temperature Compensation section 5.2)

36

Page 37

APPENDIX 2: CALCULATING The TDS CONVERSION FACTOR

The meter can be calibrated using TDS calibration standard solutions. The

TDS value of the solution at a standard temperature, such as 25 °C, is required.

To determine the conductivity-to-TDS conversion factor use the following

formula:

Factor = Actual TDS ÷ Actual Conductivity @ 25 °C

Definitions:

•Actual TDS: Value from the solution bottle label or as calculated when

prepared with high purity water and precisely weighed salts.

•Actual Conductivity: Value measured using a properly calibrated

Conductivity/Temperature meter.

Both the Actual TDS value and the Actual Conductivity values must be in the

same magnitude of units. For example, if the TDS value is in ppm the

conductivity value must be in µS; if the TDS value is in ppt the conductivity

value must be in mS.

The calculated factor can be checked by multiplying the conductivity reading

by the factor. The result should be the TDS value.

APPENDIX 3: CALCULATING TEMPERATURE COEFFICIENTS

To determine the temperature coefficient of the sample solution:

Where:

tc = Temperature coefficient 25 = 25 °C

C

= Conductivity at Temp 1 CT2= Conductivity at Temp 2

T1

T

= Temp 1 T2= Temp 2

1

NOTE: A controlled temperature water bath is ideal for this procedure.

1. Immerse the probe in the solution and adjust the temperature coefficient to

0% (that is, no compensation) by following instructions as described in

Temperature Coefficient.

37

Page 38

2. Wait for 5 minutes. Note T1and CT1(conductivity at T1).

3. Condition the sample solution and probe to a temperature (T

about 5 °C to 10 °C different from T

C

.

T2

, and note the conductivity reading

1

NOTE: Record the results for future reference. Ideally T

bracket the measurement temperature, and should not differ by more than

) that is

2

and T2should

1

5 °C.

4. Calculate the temperature coefficient of the solution according to the

formula shown above.

5. Enter the calculated temperature coefficient into the meter. Refer to

Temperature Coefficient.

The calculated temperature coefficient will not be applied to all the meter

readings.

WARRANTY

This Instrument is guaranteed to be free from defects in material and

workmanship for a period of three (3) years from the original purchase date.

The probe is guaranteed to be free from defects in material and workmanship

for a period of six (6) months from the original purchase date. In the event

that a defect is found during the warranty time frame, LaMotte Company

agrees that it will be repaired or replaced without charge except for the

transportation costs. This guarantee does not cover batteries.

This product can not be returned without a return authorization number from

LaMotte Company. For warranty support or a Return Authorization Number,

contact LaMotte Company at 1-800-344-3100 or tech@lamotte.com.

Limitations

This guarantee is void under the following circumstances:

• Damage due to operator negligence, misuse, accident or improper

application.

• Damage or alterations from attempted repairs by an unauthorized

(non-LaMotte) service.

• Damage due to improper power source, AC adapter or battery.

• Damage caused by acts of God or natural disaster.

• Damage occurred while in transit with a shipping carrier.

LaMotte Company will service and repair out-of-warranty products at a

nominal charge..

38

Page 39

Packaging and Delivery

Experienced personnel at LaMotte Company assure adequate protection

against normal hazards encountered during shipping. After the product leaves

the manufacturer, the transporter assures all responsibility for its safe delivery.

Damage claims must be filed immediately with the transporter to receive

compensation for damaged good

RETURN OF ITEMS

Should it be necessary to return the meter for repair or servicing, pack the

meter carefully in a suitable container with adequate packing material. A

return authorization number must be obtained from LaMotte Company by

calling 1-800-344-3100, faxing 1-410-778-6394, or emailing

tech@lamotte.com. Often a problem can be resolved over the phone or by

email. If a return of the meter is necessary, attach a letter with the return

authorization number, meter serial number, a brief description of problem and

contact information including phone & FAX numbers to the shipping carton.

This information will enable the service department to make the required

repairs more efficiently.

39

Page 40

LaMOTTE COMPANY

Helping People Solve Analytical Challenges®

PO Box 329 • Chestertown • Maryland • 21620 • USA

800-344-3100 • 410-778-3100 • Fax 410-778-6394

Visit us on the web at www.lamotte.com

626094-26/28 - 09/08

Loading...

Loading...