LaMotte SMARTLink3 User Manual

1910-MN 2.13.12

CONTENTS |

|

GENERAL INFORMATION |

|

Packaging & Delivery ...................................................................................... |

3 |

General Precautions ...................................................................................... |

3 |

Safety Precautions ......................................................................................... |

3 |

Limits of Liability ............................................................................................. |

4 |

Warranty ......................................................................................................... |

4 |

Register Your Meter......................................................................................... |

4 |

Specifications ................................................................................................ |

5 |

Statistical and Technical Definitions ............................................................... |

6 |

Contents and Accessories ............................................................................. |

7 |

EPA Compliance ............................................................................................ |

8 |

CE Compliance .............................................................................................. |

8 |

IP 67 Certification ............................................................................................ |

8 |

CHEMICAL TESTING |

|

Water Sampling for Chemical Analysis .......................................................... |

9 |

Filtration ....................................................................................................... |

10 |

An Introduction to Colorimetric Analysis ..................................................... |

11 |

Reagent Blank ............................................................................................. |

12 |

Colorimeter Tubes & Chamber ................................................................... |

12 |

Meter Care.................................................................................................... |

12 |

Selecting an Appropriate Wavelength ........................................................ |

12 |

Calibration .................................................................................................... |

13 |

Calibration Curves ....................................................................................... |

13 |

Standard Additions ...................................................................................... |

16 |

Sample Dilution & Volumetric Measurements ............................................ |

17 |

Interferences ................................................................................................ |

18 |

Stray Light Interference ............................................................................... |

18 |

OPERATION OF THE SMART 3 COLORIMETER |

|

Overview ...................................................................................................... |

20 |

Components ................................................................................................ |

20 |

GENERAL OPERATING PROCEDURES |

|

The Keypad ................................................................................................. |

21 |

Sample Holders............................................................................................ |

21 |

The Display & the Menus ............................................................................ |

22 |

Looping Menus............................................................................................. |

24 |

TESTING |

|

Testing Menu ............................................................................................... |

25 |

Test Sequences ........................................................................................... |

26 |

General Testing Procedures ........................................................................ |

26 |

Testing With LaMotte Pre-Programmed Tests ............................................. |

27 |

Calibrating LaMotte Pre-Progammed Tests ................................................. |

29 |

Measuring in the Absorbance Mode............................................................ |

34 |

EDITING MENU |

|

Editing a Sequence ..................................................................................... |

36 |

Adding a Test ............................................................................................... |

38 |

Deleting a Test ............................................................................................... |

40 |

Edit User Tests ............................................................................................. |

42 |

Naming the Test ........................................................................................... |

44 |

Selecting the Vial and Wavelength ............................................................. |

47 |

Entering a Two Point Calibration ................................................................. |

48 |

Entering a Multiple Point Calibration............................................................. |

52 |

Selecting the Numerical Format of the Result ............................................. |

55 |

Selecting Units of Concentration ................................................................. |

56 |

Setting the Clock .......................................................................................... |

57 |

Logging Data................................................................................................ |

58 |

Factory Setup ............................................................................................... |

59 |

Setting the Power Save Function................................................................. |

59 |

Setting the Backlight Time ............................................................................ |

61 |

Selecting a Language ................................................................................... |

62 |

COMPUTER CONNECTION |

|

PC Link .......................................................................................................... |

64 |

Output .......................................................................................................... |

64 |

Computer Connection.................................................................................. |

64 |

SMARTLink 3 ................................................................................................. |

64 |

BATTERY |

|

Battery/AC Operation .................................................................................... |

65 |

Battery Replacement..................................................................................... |

65 |

MAINTENANCE |

|

Cleaning ...................................................................................................... |

66 |

Repairs.......................................................................................................... |

66 |

Meter Disposal.............................................................................................. |

66 |

TROUBLESHOOTING |

|

Error Messages ............................................................................................ |

67 |

Troubleshooting Guide................................................................................. |

67 |

SMART3 COLORIMETER TEST PROCEDURES

APPENDIX

GENERAL INFORMATION

PACKAGING & DELIVERY

Experienced packaging personnel at LaMotte Company assure adequate protection against normal hazards encountered in transportation of shipments. After the product leaves the manufacturer, all responsibility for its safe delivery is assured by the transportation company. Damage claims must be filed immediately with the transportation company to receive compensation for damaged goods.

Should it be necessary to return the instrument for repair or servicing, pack instrument carefully in a suitable container with adequate packing material. A return authorization number must be obtained from LaMotte Company by

calling 1-800-344-3100 or emailing tech@lamotte.com. Attach a letter with the authorization number to the shipping carton which describes the kind of trouble experienced. This valuable information will enable the service department to make the required repairs more efficiently.

GENERAL PRECAUTIONS

Before attempting to set up or operate this instrument it is important to read the instruction manual. Failure to do so could result in personal injury or damage to the equipment.

The SMART3 Colorimeter should not be stored or used in a wet or corrosive environment. Care should be taken to prevent water or reagent chemicals from wet colorimeter tubes from entering the colorimeter chamber.

NEVER PUT WET TUBES IN COLORIMETER.

SAFETY PRECAUTIONS

Read the labels on all LaMotte reagent containers prior to use. Some containers include precautionary notices and first aid information. Certain reagents are considered hazardous substances and are designated with a * in the instruction manual. Material Safety Data Sheets (MSDS) can be found at www.lamotte. com. Read the MSDS before using these reagents. Additional emergency information for all LaMotte reagents is available 24 hours a day from the Poison Control Center listed in the front of the phone book or by contacting the 24 hour emergency line for ChemTel 1-800-255-3924 (USA, Canada, Puerto Rico); locations outside the North American Continent 813-248-0585 (call collect). Be prepared to supply the name and four-digit LaMotte code number found on the container label or at the top of the MSDS or in the contents list of the procedure. LaMotte reagents are registered with a computerized poison control information system available to all local poison control centers.

Keep equipment and reagent chemicals out of the reach of young children.

SMART3 Colorimeter 11.10 |

3 |

LIMITS OF LIABILITY

Under no circumstances shall LaMotte Company be liable for loss of life, property, profits, or other damages incurred through the use or misuse of its products.

WARRANTY

LaMotte Company warrants this instrument to be free of defects in parts and workmanship for 2 years from the date of shipment. If it should become necessary to return the instrument for service during or beyond the warranty period, contact our Technical Service Department at 1-800-344-3100 or tech@lamotte.com for a return authorization number or visit www.lamotte. com for troubleshooting help. The sender is responsible for shipping charges, freight, insurance and proper packaging to prevent damage in transit. This warranty does not apply to defects resulting from action of the user such

as misuse, improper wiring, operation outside of specification, improper maintenance or repair, or unauthorized modification. LaMotte Company specifically disclaims any implied warranties or merchantability or fitness for a specific purpose and will not be liable for any direct, indirect, incidental or consequential damages. LaMotte Company’s total liability is limited to repair

or replacement of the product. The warranty set forth above is inclusive and no other warranty, whether written or oral, is expressed or implied.

REGISTER YOUR METER

To register your meter with the LaMotte Service Department, go to www.lamotte.com and choose SUPPORT on the top navigation bar.

4 |

SMART3 Colorimeter 02.12 |

SPECIFICATIONS

INSTRUMENT TYPE: Colorimeter

Readout |

160 x 100 backlit LCD, 20 x 6 line graphical display |

Wavelengths |

428 nm, 525 nm, 568 nm, 635 nm |

Wavelength Accuracy |

±2% FS |

Readable Resolution |

Determined by reagent system |

Wavelength Bandwidth |

10 nm typical |

Photometric Range |

–2 to +2 AU |

Photometric Precision |

± 0.001 AU at 1.0 AU |

Photometric Accuracy |

±0.005 AU at 1.0 AU |

Sample Chamber |

Accepts 25 mm diameter flat-bottomed test tubes, 10 |

|

mm square cuvettes, 16 mm COD test tubes |

Light Sources |

4 LEDs |

Detectors |

4 silicon photodiodes |

Modes |

Pre-programmed tests, absorbance, %T |

Pre-Programmed Tests |

YES, with automatic wavelength selection |

User Defined Tests |

Up to 25 user tests can be input |

Languages |

English, Spanish, French, Portuguese, Italian, |

|

Chinese, Japanese |

USB Port |

Mini B |

Power Requirements |

USB wall adapter, USB computer connection or |

|

lithium ion rechargeable battery |

Battery |

Charge Life: Approximately 380 tests with backlight |

|

on to 1000 tests with backlight off. (Signal averaging |

|

disabled). |

|

Battery Life: Approximately 500 charges. |

Electrical Rating |

Provided on nameplate label |

Data Logger |

500 test results stored for download to a PC |

Waterproof |

IP67 with USB port plug in place |

Dimensions (LxWxH) |

3.5 x 7.5 x 2.5 inches, 8.84 x 19.05 x 6.35 cm |

|

|

Weight |

13 oz, 362 g (meter only) |

SMART3 Colorimeter 02.12 |

5 |

STATISTICAL & TECHNICAL DEFINITIONS RELATED TO

PRODUCT SPECIFICATIONS

Method Detection Limit (MDL): “The method detection limit (MDL) is defined as the minimum concentration of a substance that can be measured and reported with 99% confidence that the analyte concentration is greater than zero and is determined from analysis of a sample in a given matrix containing the analyte.”1 Note that, “As Dr. William Horwitz once stated, ‘In almost all cases when dealing with a limit of detection or limit of determination, the primary purpose of determining that limit is to stay away from it.’”2

Accuracy: Accuracy is the nearness of a measurement to the accepted or true value.3 The accuracy can be expressed as a range, about the true value, in which a measurement occurs (i.e. ±0.5 ppm). It can also be expressed as the % recovery of a known amount of analyte in a determination of the analyte (i.e. 103.5 %).

Resolution: Resolution is the smallest discernible difference between any two measurements that can be made.4 For meters this is usually how many decimal places are displayed. (i.e. 0.01). Note that the resolution many change with concentration or range. In some cases the resolution may be less than the

smallest interval, if it is possible to make a reading that falls between calibration marks. A word of caution, that resolution has very little relationship to accuracy or precision. The resolution will always be less than the accuracy or precision but it is not a statistical measure of how well a method of analysis works. The resolution can be very, very good and the accuracy and precision can be very bad! This is not a useful measure of the performance of a test method.

Repeatability: Repeatability is the within-run precision.5 A run is a single data set, from set up to clean up. Generally, one run occurs on one day. However, for meter calibrations, a single calibration is considered a single run or data set, even though it may take 2 or 3 days.

Reproducibility: Reproducibility is the between-run precision.6

Detection Limit (DL): The detection limit (DL) for the 2020we/wi

is defined as the minimum value or concentration that can be determined by the meter, which is greater than zero, independent of matrix, glassware, and other sample handling sources of error. It is the detection limit for the optical system of the meter.

1CFR 40, part 136, appendix B

2Statistics in Analytical Chemistry: Part 7 – A Review, D. Coleman and L Vanatta, American Laboratory, Sept 2003, P. 31.

3Skoog, D.A., West, D. M., Fundamental of Analytical Chemistry, 2nd ed., Holt Rinehart and Winston, Inc, 1969, p. 26.

4Statistics in Analytical Chemistry: Part 7 – A Review, D. Coleman and L Vanatta, American Laboratory, Sept 2003, P. 34.

6 |

SMART3 Colorimeter 11.10 |

5Jeffery G. H., Basset J., Mendham J., Denney R. C., Vogel’s Textbook of Quantitative Chemical Analysis, 5th ed., Longman Scientific & Technical, 1989, p.

6Jeffery G. H., Basset J., Mendham J., Denney R. C., Vogel’s Textbook of Quantitative Chemical Analysis, 5th ed., Longman Scientific & Technical, 1989, p.

CONTENTS AND ACCESSORIES

CONTENTS

SMART3 Colorimeter Test Tubes, with Caps COD/UDV Adapter USB Wall Adapter USB Cable

SMART3 Colorimeter Quick Start Guide SMART3 Colorimeter Manual

ACCESSORIES

Test Tubes, with Caps |

Code 0290-6 |

Replacement Chamber |

Code 3-0038 |

USB Cable |

Code 1720 |

USB Wall Adapter |

Code 1721 |

COD/UDV Adapter |

Code 1724 |

Car Charger |

Code 5-0132 |

SMARTLink3 Program (CD) |

Code 1901-CD |

Small Field Carrying Case |

Code 1910-GCS150 |

(37.5 27.5 x 13.75 cm) |

|

Large Field Carrying Case |

Code 1910-GCS440 |

(45 x 32.5 x 20 cm) |

|

SMART3 Colorimeter 02.12 |

7 |

EPA COMPLIANCE

The SMART3 Colorimeter is an EPA-Accepted instrument. EPA-Accepted means that the instrument meets the requirements for instrumentation as found in test procedures that are approved for the National Primary Drinking Water Regulations (NPDWR) or National Pollutant Discharge Elimination System (NPDES) compliance monitoring programs. EPA-Accepted instruments may be used with approved test procedures without additional approval.

CE COMPLIANCE

The SMART3 Colorimeter has earned the European CE Mark of Compliance for electromagnetic compatibility and safety. The Declaration of Conformity for the SMART3 colorimeter is available at www.lamotte.com.

IP67 CERTIFICATION

The SMART3 meets IP67 standards for protection against dust and immersion only when the USB port plug is in place. Documentation is available at www. lamotte.com.

8 |

SMART3 Colorimeter 11.10 |

CHEMICAL TESTING

WATER SAMPLING FOR CHEMICAL ANALYSIS

Taking Representative Samples

The underlying factor to be considered for any type of water sampling is whether or not the sample is truly representative of the source. To properly collect a representative sample:

•Sample as frequently as possible.

•Collect a large sample or at least enough to conduct whatever tests are necessary.

•Make a composite sample for the same sampling area.

•Handle the sample in such a way as to prevent deterioration or contamination before the analysis is performed.

•Perform analysis for dissolved gases such as dissolved oxygen, carbon dioxide, and hydrogen sulfide immediately at the site of sampling. Samples for testing these factors, as well as samples for pH, cannot be stored for later examination.

•Make a list of conditions or observations which may affect the sample. Other considerations for taking representative samples are dependent upon the source of the sample. Taking samples from surface waters involves different considerations than taking samples from impounded and sub-surface waters.

Sampling of Open Water Systems

Surface waters, such as those found in streams and rivers, are usually well mixed. The sample should be taken downstream from any tributary, industrial or sewage pollution source. For comparison purposes samples may be taken upstream and at the source of the pollution before mixing.

In ponds, lakes, and reservoirs with restricted flow, it is necessary to collect a number of samples in a cross section of the body of water, and where possible composite samples should be made to ensure representative samples.

To collect samples from surface waters, select a suitable plastic container with a tight fitting screw cap. Rinse the container several times with the sample

to be tested, then immerse the container below the surface until it is filled to overflowing and replace the cap. If the sample is not to be tested immediately, pour a small part of the sample out and reseal. This will allow for any expansion. Any condition which might affect the sample should be listed.

Sub-surface sampling is required to obtain a vertical profile of streams, lakes, ponds, and reservoirs at specific depths. This type of sampling requires more sophisticated sampling equipment.

For dissolved oxygen studies, or for tests requiring small sample sizes, a Water

SMART3 Colorimeter 11.10 |

9 |

Sampler (LaMotte Code 1060) will serve as a subsurface or in-depth sampler. This weighted device is lowered to the sampling depth and allowed to rest at this depth for a few minutes. The water percolates into the sample chamber displacing the air which bubbles to the surface. When the bubbles cease to rise, the device has flushed itself approximately five times and it may be raised to the surface for examination. The inner chamber of the sampling device is lifted out and portions of the water sample are carefully dispensed for subsequent chemical analysis.

A Snap-Plunger Water Sampler (LaMotte Code 1077) is another “in-depth” sampling device which is designed to collect large samples which can be used for a multitude of tests. Basically, this collection apparatus is a hollow cylinder with a spring loaded plunger attached to each end. The device is cocked above the surface of the water and lowered to the desired depth. A weighted messenger is sent down the calibrated line to trip the closing mechanism

and the plungers seal the sample from mixing with intermediate layers as it is brought to the surface. A special drain outlet is provided to draw off samples for chemical analysis.

Sampling of Closed System

To obtain representative samples from confined water systems, such as pipe lines, tanks, vats, filters, water softeners, evaporators and condensers,

different considerations are required because of chemical changes which occur between the inlet and outlet water. One must have a basic understanding of the type of chemical changes which occur for the type of equipment used. Also, consideration should be given to the rate of passage and retaining time for the process water.

Temperature changes play an important part in deciding exactly what test should be performed. Process water should be allowed to come to room temperature, 20–25°C, before conducting any tests.

When drawing off samples from an outlet pipe such as a tap, allow sample to run for several minutes, rinsing the container several times before taking the final sample. Avoid splashing and introduction of any contaminating material.

FILTRATION

When testing natural waters that contain significant turbidity due to suspended solids and algae, filtration is an option. Reagent systems, whether EPA, Standard Methods, LaMotte or any others, will generally only determine dissolved constituents. Both EPA and Standard Methods suggest filtration through a 0.45 micron filter membrane, to remove turbidity, for the determination of dissolved constituents.** To test for total constituents, organically bound and suspended or colloidal materials, a rigorous high temperature acid digestion is necessary.

**LaMotte offers a filtering apparatus: syringe assembly (Code 1050) and membrane filters, 0.45 micron, (Code 1103).

10 |

SMART3 Colorimeter 11.10 |

AN INTRODUCTION TO COLORIMETRIC ANALYSIS

Most test substances in water are colorless and undetectable to the human eye. To test for their presence we must find a way to “see” them. The SMART3 Colorimeter can be used to measure any test substance that is itself colored or can be reacted to produce a color. In fact a simple definition of colorimetry is “the measurement of color” and a colorimetric method is “any technique used to evaluate an unknown color in reference to known colors”. In a colorimetric chemical test the intensity of the color from the reaction must be proportional to the concentration of the substance being tested. Some reactions have limitations or variances inherent to them that may give misleading results. Many such interferences are discussed with each particular test instruction. In the most basic colorimetric method the reacted test sample is visually compared to a known color standard. However, accurate and reproducible results are limited by the eyesight of the analyst, inconsistencies in the light sources, and the fading of color standards.

To avoid these sources of error, a colorimeter can be used to photoelectrically measure the amount of colored light absorbed by a colored sample in reference to a colorless sample (blank).

White light is made up of many different colors or wavelengths of light. A colored sample typically absorbs only one color or one band of wavelengths from the white light. Only a small difference would be measured between white light before it passes through a colored sample versus after it passes through a colored sample. The reason for this is that the one color absorbed by the sample is only a small portion of the total amount of light passing through the sample. However, if we could select only that one color or band of wavelengths of light to which the test sample is most sensitive, we would see a large difference between the light before it passes through the sample and after it passes through the sample.

The SMART3 Colorimeter passes one of four colored light beams through one of four optical filters which transmits only one particular color or band of wavelengths of light to the photodectector where it is measured. The

difference in the amount of colored light transmitted by a colored sample is a measurement of the amount of colored light absorbed by the sample. In most colorimetric tests the amount of colored light absorbed is directly proportional to the concentration of the test factor producing the color and the path length through the sample. However, for some tests the amount of colored light absorbed is inversely proportional to the concentration.

The choice of the correct wavelength for testing is important. It is interesting to note that the wavelength that gives the most sensitivity (lower detection limit) for a test factor is the complementary color of the test sample. For example the Nitrate-Nitrogen test produces a pink color proportional to the nitrate-nitrogen concentration in the sample (the greater the nitrate-nitrogen concentration, the darker the pink color). A wavelength in the green region should be selected to analyze this sample since a pinkish-red solution absorbs mostly green light.

SMART3 Colorimeter 11.10 |

11 |

REAGENT BLANK

Some tests will provide greater accuracy if a reagent blank is determined to compensate for any color or turbidity resulting from the reagents themselves. A reagent blank is performed by running the test procedure on demineralized or deionized water. Use sample water to SCAN BLANK. Insert the reacted reagent blank in the colorimeter chamber and select SCAN SAMPLE. Note result of reagent blank. Perform the tests on the sample water as described. Subtract results of reagent blank from all subsequent test results. NOTE: Some tests require a reagent blank to be used to SCAN BLANK.

COLORIMETER TUBES AND CHAMBER

Colorimeter tubes and colorimeter chambers which have been scratched through excessive use should be discarded and replaced with new ones. Dirty tubes should be cleaned on both the inside and outside. Fingerprints on the exterior of the tubes can cause excessive light scattering and result in errors. Handle the tubes carefully, making sure the bottom half of the tube is not handled.

LaMotte Company makes every effort to provide high quality colorimeter tubes. However, wall thicknesses and diameter of tubes may still vary slightly. This may lead to slight variations in results (e.g. if a tube is turned while in the sample chamber, the reading will likely change slightly). To eliminate this error put the tubes into the sample chamber with the same orientation every time.

The tubes that are included with the colorimeter have an index mark to facilitate this. If possible, use the same tube to SCAN BLANK and SCAN SAMPLE.

METER CARE

The optical system of the SMART3 must be kept clean and dry for optimal performance. Dry the colorimeter tubes before placing them in the chamber to avoid introducing moisture. For best results store the instrument in a area that is dry and free from aggressive chemical vapors.

SELECTING AN APPROPRIATE WAVELENGTH

The most appropriate wavelength to use when creating a calibration curve is usually the one which gives the greatest change from the lowest reacted

standard concentration to the highest reacted standard concentration. However, the absorbance of the highest reacted standard concentration should never

be greater than 2.0 absorbance units. Scan the lowest and highest reacted standards at different wavelengths using the absorbance mode to find the wavelength which gives the greatest change in absorbance without exceeding 2.0 absorbance units. Use this wavelength to create a calibration curve.

12 |

SMART3 Colorimeter 02.12 |

Below is a list of suggested wavelengths for the color of the reacted samples. Use these as a starting point.

Sample Color |

Wavelength Range |

Yellow |

428 |

|

|

Pink |

525 |

|

|

Red |

568 |

|

|

Green and Blue |

635 |

CALIBRATION

As with all pre-calibrated meters, it is highly recommended, even if not required by regulations, that the user periodically verify the performance of the meter by running standards with a predetermined concentration. Results outside of specification are an indication that the meter needs to be adjusted. This can be done following the user calibration described on page 28. If the user calibration fails to properly adjust the meter then the meter should be returned to LaMotte Company for recalibration. (See page 65).

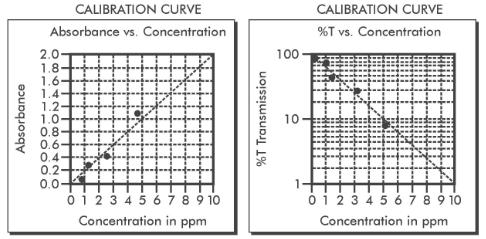

CALIBRATION CURVES

The SMART3 Colorimeter contains tests for the LaMotte reagent systems. The first step in using a non-LaMotte reagent system with your SMART3 Colorimeter is to create a calibration curve for the reagent system. To create a calibration curve, prepare standard solutions of the test factor and use the reagent system to test the standard solutions with the SMART3 Colorimeter. Select a wavelength for the test as described above.

Plot the results (in ABS or %Transmittance) versus concentration to create a calibration curve. The calibration curve may then be used to identify the concentration of an unknown sample by testing the unknown, reading

Absorbance or %T, and finding the corresponding concentration from the curve. The linear range of the reagent system can be determined and this information can be used to input a User Test into the SMART3 Colorimeter (see Edit User Tests, page 41).

PROCEDURE

Prepare 5 or 6 standard solutions of the factor being tested. The concentration of these standards should be evenly distributed throughout the range of the reagent system, and should include a 0 ppm standard (distilled water). For instance, the solutions could measure 0, 10%, 30%, 50%, 70%, and 90% of the system’s maximum range.

1.Turn on the SMART3 Colorimeter. Select the appropriate wavelength from the absorbance mode. Be sure to select the appropriate wavelength for the color produced by the reagent system.

2.Use the unreacted 0 ppm standard to standardize the colorimeter by using it

SMART3 Colorimeter 11.10 |

13 |

to scan blank.

3.Following the individual reagent system instructions, react each standard solution beginning with 0 ppm. Continue with standards in increasing concentration. Record the reading and the standard solution concentration on a chart. Readings can be recorded as percent transmittance (%T) or absorbance (A).

4.Plot results on graph paper or computer using any available plotting program. If results are as %T versus concentration, semilog graph paper must be used. Plot the standard solution concentrations on the horizontal, linear axis, and the %T on the vertical, logarithmic axis. If results are as absorbance versus standard solution concentration, simple linear graph paper can be used. Plot the standard solution concentration on the horizontal axis, and the absorbance on the vertical axis.

5.After plotting the results, draw a line, or curve, of best fit through the plotted points. The best fit may not connect the points. There should be approximately an equal number of points above the curve as below the curve. Some reagent systems will produce a straight line, while others produce a curve. Many computer spreadsheet programs can produce the curve of best fit by regression analysis of the standard solution data.

NOTE: Only reagent systems which produce a straight line can be used for a User Test.

A sample of each type of graph appears below:

14 |

SMART3 Colorimeter 11.10 |

PREPARING DILUTE STANDARD SOLUTIONS

Standard solutions should be prepared to create a calibration curve. Standard solutions can be prepared by diluting a known concentrated standard by specified amounts. A chart or computer spreadsheet can be created to determine the proper dilutions. Use volumetric flasks and volumetric pipets for all dilutions.

1.In Column A – Record the maximum concentration of test as determined by the range and path length.

2.In Column B – Record the percent of the maximum concentration the standard solution will be.

3.In Column C – Calculate the final concentration of the diluted standard solutions by multiplying the maximum concentration (In Column A) by the % of maximum concentration divided by 100. (C = A x B/100).

4.In Column D – Record the final volume of the diluted sample (i.e. volume of volumetric flask).

5.In Column E – Record the concentration of the original standard.

6.In Column F – Calculate the milliliters of original standard required (F = (C x

D/E)).

A sample chart appears below:

A |

B |

C = |

D |

E |

F = |

|

|

|

A x B/ |

|

|

C x D/ |

E |

|

|

100 |

|

|

|

|

Maximum |

% of Maximum |

Final |

Volume of |

Concentration |

mL of |

|

concentration |

concentration |

concentration |

Standard |

of Original |

Original |

|

of test |

|

of Diluted |

|

Standard |

Standard |

|

|

|

Standard |

|

|

Required |

|

10.0 ppm |

90 |

9.0 ppm |

100 mL |

1000 ppm |

0.90 mL |

|

10.0 ppm |

70 |

7.0 ppm |

100 mL |

1000 ppm |

0.70 mL |

|

10.0 ppm |

50 |

5.0 ppm |

100 mL |

1000 ppm |

0.50 mL |

|

10.0 ppm |

30 |

3.0 ppm |

100 mL |

1000 ppm |

0.30 mL |

|

10.0 ppm |

10 |

1.0 ppm |

100 mL |

1000 ppm |

0.10 mL |

|

10.0 ppm |

0 |

0 ppm |

100 mL |

1000 ppm |

0 mL |

|

SMART3 Colorimeter 11.10 |

15 |

STANDARD ADDITIONS

A common method to check the accuracy and precision of a test is by standard additions. In this method a sample is tested to determine the concentration

of the test substance. A second sample is then “spiked” by the addition of a known quantity of the test substance. The second sample is then tested. The determined concentration of the spiked sample should equal the concentration of the first plus the amount added with the spike. The procedure can be repeated with larger and larger “spikes.” If the determined concentrations do not equal the concentration of the sample plus that added with the “spike”, then an interference may exist.

For example, a 10.0 mL water sample was determined to contain 0.3 ppm iron. To a second 10.0 mL sample, 0.1 mL of 50 ppm iron standard was added. The concentration of iron due to the “spike” was (0.10 mL x 50 ppm)/10.0 mL = 0.50 ppm. The concentration of iron determined in the spiked sample should be 0.3 + 0.5 = 0.8 ppm iron. (Note: any error due to the increased volume from the “spike” is negligible).

LaMotte offers a line of calibration standards which can be used to generate calibration curves and perform standard additions.

16 |

SMART3 Colorimeter 11.10 |

SAMPLE DILUTION TECHNIQUES & VOLUMETRIC MEASUREMENTS

If a test result using the SMART3 Colorimeter gives an over range message then the the sample must be diluted. The test should be repeated on the diluted sample to obtain a reading which is in the concentration range for the test. (Note: This is not true for colorimetric determination of pH.)

Example:

Measure 5 mL of the water sample into a graduated cylinder. Add demineralized water until the cylinder is filled to the 10 mL line. The sample has been diluted by one-half, and the dilution factor is therefore 2. Perform the test procedure, then multiply the resulting concentration by 2 to obtain the test result.

The following table gives quick reference guidelines on dilutions of various proportions. All dilutions are based on a 10 mL volume, so several dilutions will require small volumes of the water sample. Graduated pipets should be used for all dilutions.

|

Deionized Water to |

|

Size of Sample |

Bring Volume to 10 mL |

Multiplication Factor |

10 mL |

0 mL |

1 |

5 mL |

5 mL |

2 |

2.5 mL |

7.5 mL |

4 |

1 mL |

9 mL |

10 |

0.5 mL |

9.5 mL |

20 |

If the above glassware is not available, dilutions can be made with the colorimeter tube. Fill the tube to the 10 mL line with the sample then transfer it to another container. Add 10 mL volumes of demineralized water to the container and mix. Transfer back 10 mL of the diluted sample to the tube and follow the test procedure. Continue diluting and testing until a reading, which is in the concentration range for the test, is obtained. Be sure to multiply the concentration found by the dilution factor (the number of total 10 mL volumes used).

Example:

10 mL of sample is diluted with three 10 mL volumes of demineralized water; the dilution factor is four.

SMART3 Colorimeter 11.10 |

17 |

INTERFERENCES

LaMotte reagent systems are designed to minimize most common interferences. Each individual test instruction discusses interferences unique to that test. Be aware of possible interferences in the water being tested.

The reagent systems also contain buffers to adjust the water sample to the ideal pH for the reaction. It is possible that the buffer capacity of the water sample may exceed the buffer capacity of the reagent system and the ideal pH will not be obtained. If this is suspected, measure the pH of a reacted distilled water reagent blank using a pH meter. This is the ideal pH for the test. Measure the pH of a reacted water sample using the pH meter. If the pH is significantly different from the ideal value, the pH of the sample should be adjusted before testing.

Interferences due to high concentration of the substance being tested, can be overcome by sample dilution (see page 16)

STRAY LIGHT INTERFERENCE

When scanning samples in 16 mm tubes, such as COD, the sample chamber lid can not be closed. The COD adapter minimizes stray light. To further reduce stray light interference, do not scan sample in direct sunlight.

18 |

SMART3 Colorimeter 11.10 |

OPERATION OF THE

SMART3 COLORIMETER

OVERVIEW

The SMART3 is a portable, microprocessor controlled, direct reading colorimeter. It has a graphical liquid crystal display and 6 button keypad. These allow the user to select options from the menu driven software, to directly read test results or to review stored results of previous tests in the data logger. The menus can be displayed in seven different languages.

The test library consists of over 80 LaMotte tests and 25 “User Tests”. The LaMotte tests are precalibrated for LaMotte reagent systems.The colorimeter displays the result of these tests directly in units of concentration. The 25 “User Tests” may be used to enter additional calibrations. All of these tests may be arranged in any of 3 sequences. These sequences can be modified a limitless number of times to meet changing testing needs.

The optics feature 4 different colored LEDs. Each LED has a corresponding silicon photoiode with an integrated interference filter. The interference filters select a narrow band of light from the corresponding LED for the colorimetric measurements. The microporcessor automatically selects the correct LED/ photodiode combination for the test.

A USB wall adapter, USB computer connection or lithium battery powers the SMART3.

A USB port on the back of the meter allows an interface of the meter with a Windows-based computer for real-time data acquisition and data storage using a PC. The SMART3 may be interfaced with any Windows-based computer by using the LaMotte SMARTLink3 Program.

SMART3 Colorimeter 11.10 |

19 |

COMPONENTS

Figure 1 shows a diagram of the SMART3 Colorimeter and its components.

20 |

SMART3 Colorimeter 11.10 |

GENERAL OPERATING PROCEDURES

The operation of the SMART3 Colorimeter is controlled by a microprocessor. The microprocessor is programmed with menu driven software. A menu is a list of choices. This allows a selection of various tasks for the colorimeter to perform, such as, scan blank, scan sample, and edit test sequences. The

keypad is used to make menu selections which are viewed in the display. There are three selections accessible from the Main Menu: Testing Menu, Editing Menu and Run PC Link.

THE KEYPAD

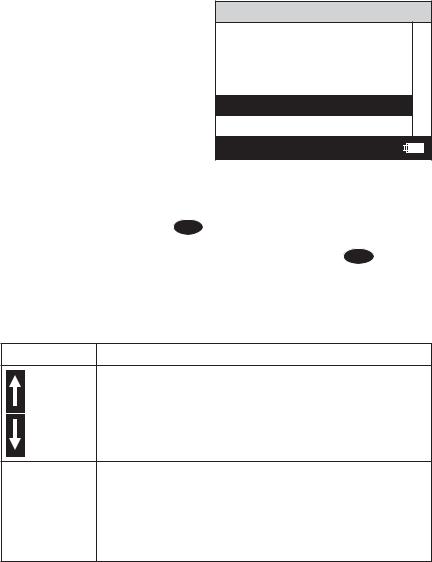

The keypad has 6 buttons which are used to perform specific tasks.

This button will scroll up through a list of menu selections.

ENTER |

The button is used to select choices in a menu viewed in |

|

the display. |

||

|

This button controls the backlight on the display.

|

This button will scroll down through a list of menu |

|

selections. |

EXIT |

This button exits to the previous menu. |

|

|

|

This button turns the meter on or off. |

ENTER

EXIT

SAMPLE HOLDERS

The sample chamber is designed for 25 mm round tubes. An adapter to hold 16 mm COD tubes and 1 cm square UDV cuvettes is included.

Position the COD/UDV Adapter (Code 1724) so that the notches in the adapter fit around the posts on the chamber. Turn the adapter counterclockwise until the arrows are at the top and bottom of the chamber and the adapter is locked into place. Turn the adapter clockwise to unlock the adapter and remove it from the chamber.

SMART3 Colorimeter 11.10 |

21 |

THE DISPLAY & THE MENUS

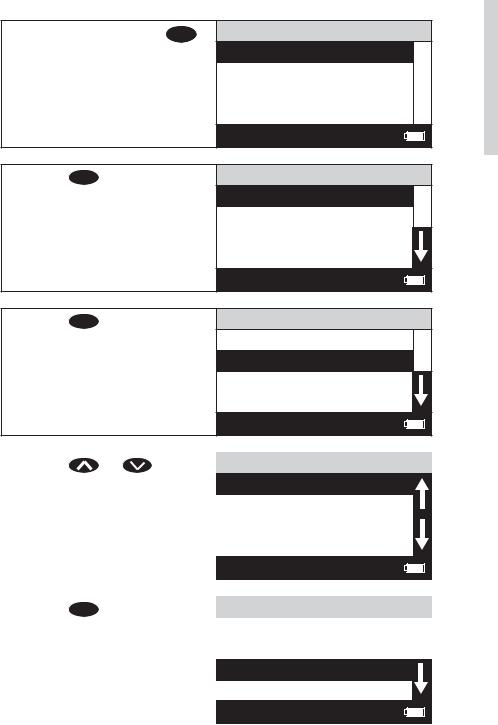

The display allows menu selections to be viewed and selected. These selections instruct the SMART3 to perform specific tasks. The menus are viewed in the display using two general formats that are followed from one menu to the next. Each menu is a list of choices or selections.

The display has a header line at the top and a footer line at the bottom. The header displays the title of the current menu. The footer line displays the time and the date, the data logger status and the battery status. The menu selection window is in the middle of the display between the header and the footer.

The menu selection window displays information in two general formats. In the first format only menu selections are displayed. Up to 4 lines of menu selections may be displayed. If more selections are available they can be viewed by pressing the arrow buttons to scroll the other menu selections into the menu selection window. Think of the menu selections as a vertical list in

the display that moves up or down each time an arrow button is pressed. Some menus in the SMART3 are looping menus. The top and bottom menu choices are connected in a loop. Scrolling down past the bottom of the menu will lead to the top of the menu. Scrolling up past the top of the menu will lead to the bottom of the menu.

Header

Main Window Selection

Footer

Menu Title

First Choice

Second Choice

Third Choice

Another

12:00:00 001/500

And Another

And So On

A black bar will indicate the menu choice. As the menu is scrolled through, the black bar will highlight different menu choices. Pressing the ENTER button will select the menu choice that is indicated by the black bar.

In the second format the menu choice window takes advantage of the graphical capabilities of the display. Large format graphic information, such as test results or error messages or the LaMotte logo is displayed. The top two lines of the display are used to display information in a large, easy to read format. The menus work in the same way as previously described but two lines of the menu are visible at the bottom of the display.

22 |

SMART3 Colorimeter 11.10 |

Header Message or Result Window

Main Window Selection

Footer

Menu Title

Result or Message

Another And Another

12:00:00 001/500

And So On

Last Choice

As described previously, the EXIT button allows an exit or escape from the current menu and a return to the previous menu. This allows a rapid exit from an inner menu to the main menu by repeatedly pushing the EXIT button. Pushing  at any time will turn the SMART3 off.

at any time will turn the SMART3 off.

The display may show the following messages:

Battery Status

Battery Status

More choices are available and can be viewed by scrolling up and/or down through the display.

Header |

Identifies the current menu and information on units |

|

and reagent systems if applicable. |

Footer |

In the data logging mode the number of the data point |

|

is displayed and the total number of data points in the |

|

memory will be shown. The footer also shows current |

|

time and battery status |

SMART3 Colorimeter 11.10 |

23 |

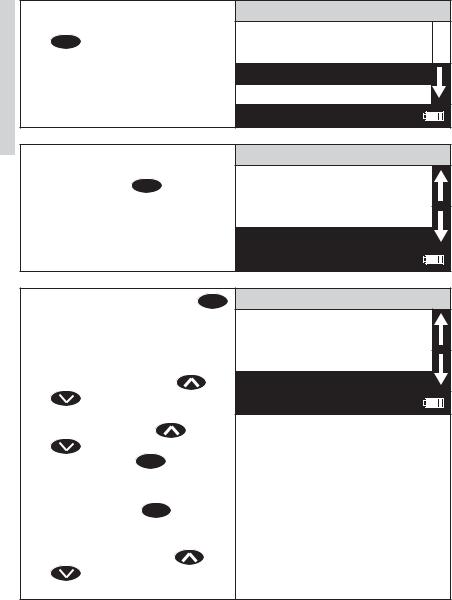

LOOPING MENUS

Long menus, such as All Tests, incorporate a looping feature which allows the user to quickly reach the last choice in the menu from the first choice. In a looping menu the last choices in the menu are above the first choice and

scrolling upward moves through the menu in reverse order. Scrolling downward moves through the menu from first choice to last but the menu starts over following the last choice. So all menu choices can be reached by scrolling in either direction. The diagrams below demonstrate a looping menu.

AND SO ON |

|

AND SO ON |

|

AND SO ON |

|||||||||||

: |

: |

: |

|

|

|

: |

: |

: |

|

: |

: |

: |

|

||

: |

: |

: |

|

|

|

: |

: |

: |

|

: |

: |

: |

|

||

THIRD TO LAST |

|

LAST CHOICE |

|

LAST CHOICE |

|||||||||||

SECOND TO LAST |

|

AND SO ON |

|

AND SO ON |

|||||||||||

LAST CHOICE |

: |

: |

: |

|

: |

: |

: |

|

|||||||

TESTING MENU |

|

TESTING MENU |

|

TESTING MENU |

|||||||||||

FIRST CHOICE |

|

: |

: |

: |

|

|

: |

: |

: |

|

|||||

SECOND CHOICE |

|

THIRD TO LAST |

|

THIRD TO LAST |

|||||||||||

THIRD CHOICE |

|

SECOND TO LAST |

|

SECOND TO LAST |

|||||||||||

ANOTHER |

|

|

|

|

LAST CHOICE |

|

LAST CHOICE |

||||||||

12:00:00 |

001/500 |

|

|

|

12:00:00 |

001/500 |

|

12:00:00 |

001/500 |

||||||

|

|

|

|

||||||||||||

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|||||||||

AND ANOTHER |

|

FIRST CHOICE |

|

FIRST CHOICE |

|||||||||||

AND SO ON |

|

SECOND CHOICE |

|

SECOND CHOICE |

|||||||||||

: |

: |

: |

|

|

|

|

THIRD CHOICE |

|

THIRD CHOICE |

||||||

: |

: |

: |

|

|

|

|

ANOTHER |

|

|

ANOTHER |

|

||||

LAST CHOICE |

|

AND ANOTHER |

|

AND ANOTHER |

|||||||||||

24 |

SMART3 Colorimeter 11.10 |

TESTING

TESTING MENU

The Testing Menu is used to run all LaMotte pre-programmed tests, User Tests and Absorbance tests at one of four wavelengths. Testing from any of three sequences can also be done.

1. Press and briefly hold |

|

|

Main Menu |

|||||||

|

||||||||||

|

||||||||||

|

to turn the meter on. The |

Testing Menu |

|

|

|

|

||||

|

LaMotte logo screen will |

Editing Menu |

|

|

|

|

||||

|

appear for about 3 seconds |

|

|

|

|

|||||

|

Run PC Link |

|

|

|

|

|||||

|

and the Main Menu will |

|

|

|

|

|||||

|

|

|

|

|

|

|||||

|

appear. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12:00:00 |

001/500 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|||||

2. |

Press ENTER |

to select Testing |

Testing Menu |

|||||||

|

Menu. |

|

|

|

|

All Tests Menu |

|

|

|

|

|

|

|

|

|

|

Sequence 1 |

|

|

|

|

|

|

|

|

|

|

Sequence 2 |

|

|

|

|

|

|

|

|

|

|

Sequence 3 |

|

|

|

|

|

|

|

|

|

|

12:00:00 |

001/500 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

|

|

||||||

3. |

Press |

or |

to scroll |

Testing Menu |

||||||

|

to desired option. All Tests |

All Tests Menu |

|

|

|

|

||||

|

contains all of the available |

Sequence 1 |

|

|

|

|

||||

|

pre-programmed tests. The |

|

|

|

|

|||||

|

Sequence 2 |

|

|

|

|

|||||

|

three sequences have user |

|

|

|

|

|||||

|

Sequence 3 |

|

|

|

|

|||||

|

selected tests. Absorbance |

|

|

|

|

|||||

|

has %T/ABS tests. |

|

|

|

12:00:00 |

001/500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|||||||

|

|

|

|

|||||||

4. |

Press ENTER |

to select the |

All Tests |

|||||||

|

option. |

|

|

|

|

001 Alkalinity UDV |

|

|||

|

|

|

|

|

|

002 Aluminum |

|

|

|

|

|

|

|

|

|

|

003 Ammonia-N LRF |

||||

|

|

|

|

|

|

004 Ammonia-N LRS |

||||

|

|

|

|

|

|

12:00:00 |

001/500 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Testing

SMART3 Colorimeter 11.10 |

25 |

Testing

TEST SEQUENCES

Sequence 1, Sequence 2, And Sequence 3 are alterable sequences. They may be edited using the Editing Menu. Any of the LaMotte pre-programmed tests or User Tests may be placed in these sequences in whatever testing order that is preferred. Some examples of typical sequences are given below.

|

Sequence 1 |

|

|

Sequence 2 |

|

|

Sequence 3 |

||||||||

015 Chlorine F UDV |

|

|

|

002 Aluminum |

|

|

003 Ammonia-N LRF |

|

|||||||

079 Phosphate HR |

|

|

|

035 Cyanuric Acid |

|

|

032 Cu UDV |

|

|||||||

009 |

Benzotriazole |

|

|

|

053 Iron Phenanthro |

|

|

064 |

Nitrate-N LR |

|

|||||

076 pH UDV |

|

|

|

055 |

Manganese LR |

|

|

067 |

Nitrite-N LR |

|

|||||

12:00:00 |

001/500 |

|

|

|

12:00:00 |

001/500 |

|

12:00:00 |

001/500 |

|

|||||

|

|

|

|

|

|||||||||||

|

|

|

|

|

|||||||||||

061 Molybdenum HR |

|

064 Nitrate-N LR |

|

074 pH PR |

|||||||||||

086 |

Silica HR |

067 |

Nitrite-N LR |

078 |

Phosphate LR |

||||||||||

045 |

Hydrazine |

077 |

Phenol |

085 |

Silica LR |

||||||||||

032 Cu UDV |

|

078 Phosphate LR |

|

|

|

|

|

||||||||

051 |

Iron Bipyridyl |

090 |

Sulfide LR |

|

|

|

|

|

|||||||

These alterable sequences allow a series of tests to be setup that are run frequently. The order of the individual tests in the sequence is determined by the

user. After running a test, press ENTER to select the next test in the sequence. Continue this pattern until the entire sequence has been completed.

All Tests is a fixed sequence containing the LaMotte pre-programmed tests, User Tests, and Absorbance tests.

Modification of the alterable sequences is accomplished through the Editing Menu. This menu is explained in greater detail in Editing Menu (p. 35).

Pressing EXIT while in a sequence menu will escape back to the Testing Menu. Pressing  the at any time will turn the colorimeter off.

the at any time will turn the colorimeter off.

GENERAL TESTING PROCEDURES

The following are some step by step examples of how to run tests from the Testing Menu. These test procedures are designed to be used with LaMotte SMART Reagent Systems.

LaMotte Company continuously updates the list of pre-programmed tests as the calibrations become available. Pre-programmed calibrations can be added to the SMART3 Colorimeter in the field. A Windows-based computer running a Windows Operating System is required.

Call LaMotte Technical Services at 1-800-344-3100 (410-778-3100 outside the USA) or email at tech@lamotte.com for a current list of available calibrations and downloading instructions.

26 |

SMART3 Colorimeter 11.10 |

TESTING WITH LaMOTTE PRE-PROGRAMMED TESTS

1. Press and briefly hold  to turn the meter on. The LaMotte logo screen will appear for about 3 seconds and the Main Menu will appear.

to turn the meter on. The LaMotte logo screen will appear for about 3 seconds and the Main Menu will appear.

Main Menu

Testing Menu

Editing Menu

Run PC Link

12:00:00 001/500

2.Press ENTER to select Testing Menu.

Testing Menu

All Test Menu

Sequence 1

Sequence 2

Sequence 3

12:00:00 001/500

Testing

3.Press ENTER to select All Tests Menu.

All Tests

001 Alkalinity UDV

002 Aluminum

003 Ammonia-N LRF

004 Ammonia-N LRS

12:00:00 001/500

|

4. |

Press |

or |

to scroll |

|

All Tests |

|

|||

|

|

to the desired test. |

|

001 Alkalinity UDV |

|

|

|

|||

|

|

|

|

|

002 Aluminum |

|

|

|

||

|

|

|

|

|

003 Ammonia-N LRF |

|

|

|

||

|

|

|

|

|

004 Ammonia-N LRS |

|

|

|

||

|

|

|

|

|

12:00:00 |

001/500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

5. |

Press ENTER |

to select the test. |

|

002 Aluminum |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Scan Bank |

|

||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Scan Sample |

|

|

|

||

|

|

|

|

|

12:00:00 |

001/500 |

|

|

|

27 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||||

|

SMART3 Colorimeter 11.10 |

|

|

|

|

|

||||

Testing

6.Insert the blank into the chamber. Close the lid.Press ENTER to scan the blank. The

screen wil display Blank Done for about 1 second and then return to the Test Menu.

002 Aluminum

Scan Blank

Scan Sample

12:00:00 001/500

7.Insert the reacted sample into the chamber. Close the lid. Press ENTER to scan the sample. The screen will

display READING for about 1 second. The result will appear on the screen.

002Aluminum

1.00ppm

Scan Blank

Scan Sample

12:00:00 001/500

8.To repeat the test, press ENTER to scan the sample again. The last blank scaned is used by the colorimeter for repeated scans. A different blank can

be used by pressing |

or |

to scroll to Scan Blank |

|

and then scanning another |

|

blank. Scroll with |

or |

and make another selection with ENTER . The %T or Absorbance of the last test can be viewed by choosing

%T/Abs. Press EXIT |

to |

escape to previous menus. |

|

NOTE: The menus loop in |

|

this screen so either |

or |

will lead to the menu selection needed.

002Aluminum

1.00ppm

Scan Bank

Scan Sample

12:00:00 001/500

28 |

SMART3 Colorimeter 11.10 |

Loading...

Loading...