Page 1

Vega 900 Handbook

�

Part Number 17155

NOMINAL INPUT VOLTAGE RANGE 165 - 240VAC

MAX. INPUT VOLTAGE RANGE 150 - 264VAC

INPUT FREQUENCY 47- 63Hz

MAXIMUM INPUT CURRENT 9 A AC

INRUSH CURRENT <40 AMPS

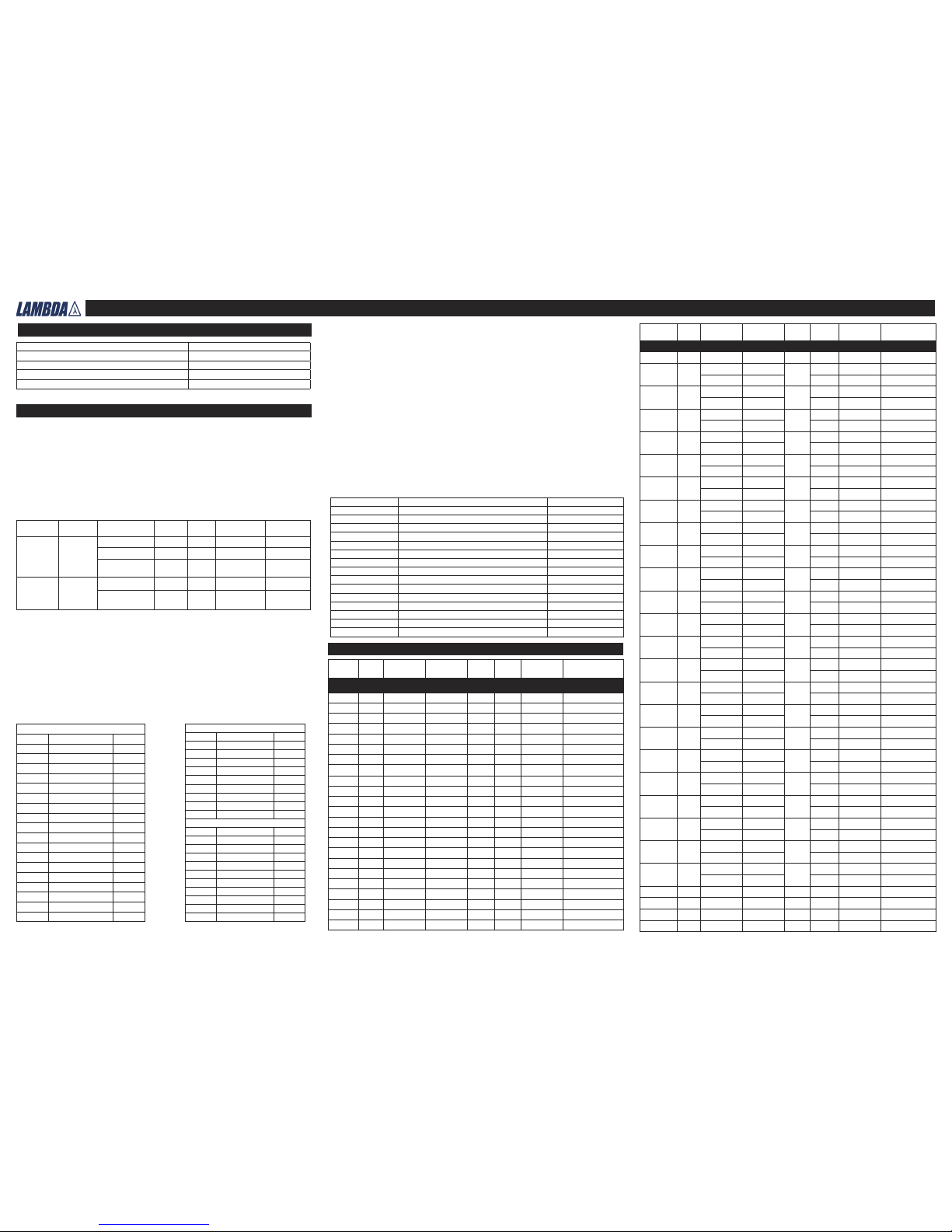

Adjustment and Derating.

The Vega 900 series is designed to provide a max output power of 900W at nominal output voltages. The following procedure must be used to ensure the PSU is operated within its ratings

a Calculate user power for each module (volts x amps).

b Add all the individual module powers together. The total power must not exceed the value

given.

c Calculate secondary transformer turns x amps for each module. See the outputs table

for transformer secondary turns.

d Add all the module turns x amps together and this must not exceed the ampere turns.

e If necessary reduce the loading until the conditions are met, ie. power and ampere-turns

maxima.

Input Parameters

Output Parameters

Test requirements include: PSU to be fitted in its end-use equipment and operated under the

most adverse conditions permitted in the end-use equipment handbook/specification and which

will result in the highest temperatures in the PSU. To determine the most adverse conditions

consideration should be given to the end use equipment maximum operating ambient, the PSU

loading and input voltage, ventilation, end use equipment orientation, the position of doors & covers, etc. Temperatures should be monitored using type K fine wire thermocouples (secured with

cyanoacrylate adhesive, or similar) placed on the hottest part of the component (out of any direct

airflow) and the equipment should be run until all temperatures have stabilised.

Customer Air Cooling (option C):

The following method must be used for determining the safe operation of PSUs when C option

(Customer Air) is fitted, ie fan not fitted to PSU.

For PSUs cooled by customer supplied airflow the components listed in the following table must

not exceed the temperatures given. Additionally ratings specified for units with an internal fan

must still be complied with, eg mains input voltage range, maximum output power, ampere turns,

module voltage / current ratings and maximum ambient temperature. To determine the component

temperatures the heating tests must be conducted in accordance with the requirements of

IEC/EN/CSA60950-1:2001 Clause 4.5. Consideration should also be give to the requirements of

other safety standards.

Note 1:The PSU main transformer has three regions for module secondaries seperated by two

primary windings. Starting nearest slot 1, region A, primary winding, region B, primary winding,

region C. The total ampere turns (AT) in any two adjacent regions is limited to that in the table

above column, “ Max AT in adjacent regions (note 1)”.See mains transformer regions table

below for modules allowed in each region. The table uses module widths with a twin output

module being single width.

n/a=not applicable

Main transformer regions table:

* Ruggedised fan (Papst 622HH, not for use in PSU’s fitted with IEC inlet).

Modules Note Output Range Current Slots Turns

Max. Current

Limit

Settings for hazard-

ous energy

Standard Modules

L1 4.2-5.5V 35A 1 1 43.8A >5.4V

H1L/1L

1.8-3.8V 12A

1

1 15A -

1.8-3.8V 8A 1 12A -

H1L/1H

1.8V-3.8V 12A

1

1 15A -

3.9-5.5V 8A 1 12A -

H1H/1L

3.9-5.5V 12A

1

1 15A -

1.8-3.8V 8A 1 12A -

H1H/1H

3.9-5.5V 12A

1

1 15A -

3.9-5.5V 8A 1 12A -

H1L/2

1.8-3.8V 12A

1

1 15A -

5.6-9V 6A 2 9A -

H1H/2

3.9-5.5V 12A

1

1 15A

5.6-9V 6A 2 9A -

H1L/3

1.8-3.8V 12A

1

1 15A -

9.1-16.2V 6A 3 9A -

H1H/3

3.9-5.5V 12A

1

1 15A -

9.1-16.2V 6A 3 7.5A -

H1L/4

1.8-3.8V 12A

1

1 15A -

16.3-25V 4.5A 4 6A -

H1H/4

3.9-5.5V 12A

1

1 15A -

16.3-25V 4.5A 4 6A -

H2/1L

5.6-9V 10A

1

2 15A -

1.8-3.8V 8A 1 12A -

H2/1H

5.6-9V 10A

1

2 15A -

3.9-5.5V 8A 1 12A -

H2/2

5.6-9V 10A

1

2 15A -

5.6-9V 6A 2 9A

H2/3

5.6-9V 10A

1

2 15A -

9.1-16.2 6A 3 7.5A -

H2/4

5.6-9V 10A

1

2 15A -

16.3-25V 4.5A 4 6A -

H3/1L

9.1-16.2V 10A

1

3 15A >16V

1.8-3.8V 8A 1 12A -

H3/1H

9.1-16.2V 10A

1

3 15A >16V

3.9-5.5V 8A 1 12A -

H3/2

9.1-16.2V 10A

1

3 15A >16V

5.6-9V 6A 2 9A -

H3-3

9.1-16.2V 10A

1

3 15A >16V

9.1-16.2V 6A 3 7.5A -

H3/4

9.1-16.2V 10A

1

3 15A >16V

16.3-25V 4.5A 4 6A -

H5/1L

16.2-28V 5A

1

5 7.5A >32V

1.8-3.8V 8A 1 12A -

H5/1H

16.2-28V 5A

1

5 7.5A >32V

3.9-5.5V 8A 1 12A -

H5/2

16.2-28V 5A

1

5 7.5A >32V

5.6-9V 6A 2 9A -

X1 6,7 0-10V 90A 1 - -

X2 6,7 0-20V 64.5A 1 - - -

X4 6,7 0-40V 32.4A 1 - ---

X8 6,7 0-80V 16.2A 1 - - -

Modules Note Output Range Current Slots Turns

Max. Current

Limit

Settings for hazard-

ous energy

Standard Modules

B1L 1.8-3.8V 20A 1 1 25A B1H 3.9-5.5V 20A 1 1 25A

B2 5.0-9V 25A 1 2 31.3A >7.6V

B3 9.1-16.2V 12A 1 3 15A >16V

B5 21.6-31V 6A 1 5 7.5A >32V

C1 1.8-4.1V 35A 1 1 43.8A >5.4V

C1Y 1 1.8-4.1V 40A 1 1 50A -

C3 9.1-16.2V 18A 1 3 22.5A >10.6V

C4 16.3-21.5V 14A 1 4 17.5A >13.7V

C5 21.6-31V 10A 1 5 12.5A >19.2V

D1L 2 1.8-3.8V 50A 1.5 1 62.5A >3.8V

D1H 2 3.9-5.5V 50A 1.5 1 62.5A >3.8V

D2 2 3.8-8V 45A 1.5 2 56.25A >4.2V

D3 2 8-16.5V 24A 1.5 3 30A >8V

D4 2 14-21.5V 18A 1.5 4 22.5A >10.6V

D5 2 21-28V 15A 1.5 5 18.75A >12.8V

E1 1.8-3.8V 60A 2 1 75A >3.2V

E2 3 3.8-8V 60A 2 2 75A >3.2V

E3L 8-13.9V 40A 2 3 50A >4.8V

E3H 14-15V 36A 2 3 45A >5.3V

E4 14-19.9V 30A 2 4 37.5A >6.4V

E5L 20-24V 27A 5 33.8A >7.1V

E5H 24-28V 25A 2 5 31.3A >7.6V

Slot 1 Slot 5.5

Region A Region B Region C

Single Dual Dual

Blank Dual Dual

Single Dual, Single Single

Single Dual Single

Single Dual -

- Dual -

Single Single, Single, Single Single

Single Single,Single Single

Single Single -

- Single -

1.5 Dual 1.5

Single Dual 1.5

- Dual 1.5

Single 1.5,Single Single

Single 1.5 -

Single 1.5 Single

1.5 1.5,Single Single

1.5 1.5 1.5

Slot 1 Slot 5.5

Region A Region B Region C

Single 1.5 1.5

- 1.5 1.5

- 1.5 -

- Single,Single Dual

- 1,5, Single Single

- Dual, Single Single

1.5 1.5 Single Single, Single Dual

1.5 1.5 Dual

Combined Modules

Single Dual Dual

- Dual Dual

1.5 Dual 1.5

Single Dual 1.5

- Dual 1.5

Single 1.5,1.5 Single

Single 1.5,1.5 -

- 1.5,1.5 -

1.5 1.5, Dual -

1.5 1.5, Single Single

1.5 1.5 1.5

Cooling

Option

Max

Ambient

Dual Width

Modules Fitted

Max

Power

Max AT

(total)

Max AT adjacent

regions (note 1)

Max Current

Rating

F,D

(Standard or

Ruggedised

Fan Foward

Airflow

50

No 900 220 180 100%

Yes 900 220 180 100%

No 650 220 n/a 100%

Q

(Quiet Fan

Foward

Aairflow

50

No 750 180 n/a 100%

Yes 750 180 140 100%

Modules

CIRCUIT REF. DESCRIPTION MAX. TEMP (°C)

- Power transformer primary, secondary and core 130

T1, TX101, TX201 Module current transformer windings 127

XQ1 E & F Primary option transformers 90

XTR1 EV & FV Primary option transformers 90

TX1 xEW & xFW Primary option transformers 130

L1, L2, XT601 Choke winding 110

T2 Choke winding 117

L4 Choke winding 120

Various All other choke & transformer windings 110

RLY1 Relay 100

C15 X capacitor 100

Various All other X capacitors 105

C2, C3, C4 Electrolytic Capacitor 67

Various All other 10mm dia Electrolytic Capacitor 80

Various All other 12.5mm dia Electrolytic Capacitor 85

Page 2

Vega 900 Handbook

�

Part Number 17155

Modules Note Output Range Current Slots Turns

Max. Current

Limit

Settings for hazard-

ous energy

Standard Modules

H5/3

16.2-28V 5A

1

5 7.5A >32V

9.1-15.5 6A 3 7.5A -

H5/4

16.2-28V 5A

1

5 7.5A >32V

16.3-24V 4.5A 4 6A -

Seriesed Modules

BB4 32.6-40V 10A 2 8 12.5A >19.2V

CC3 18.2-30V 18A 2 6 22.5A >10.6

CC5 48.1-60V 10A 2 10 12.5A

>19.2V

DD4 28-36V 18A 3 8 22.5A >10.6V

DD5 42-56V 15A 3 10 18.75A >12.8V

EE2 7.6-15V 55A 4 4 75A >3.2V

EE4 28-38V 30A 4 8 37.5 >6.4

EE5L 40-48V 18A 4 10 33.8 >7.1

EE5H 48-56V 18A 4 10 31.3 >7.6

HH5/3 25.3-38V 5A 1 8 7.5A >32V

HH5/4 32.5-46V 4.5A 1 9 6A >40V

C5B4 43-48V 10A 2 9 12.5A >19.2V

Paralleled Modules

Z2(D1L+D1L) 1.8-3.4V 95A 3 1+1 125A >1.9V

Z3(E1+E1) 1.8-3.4V 114A 4 1+1 150A >1.6V

Z4(D1H+D1H) 3.9-5.1V 95A 3 1+1 125A >1.9V

Z6(E2+D1H) 3.9-5.1V 104.5A 3.5 2+1 137.5A >1.7V

Z7(D3+D3) 8-15V 45.6A 3 3+3 60A >4V

Z18(L1+L1) 4.2-5.1V 66.5A 2 1+1 87.5A >2.7V

Z19 (E5H+D5) 24-28V 36 3.5 5+5 40.05A >5.9

Wide Range Modules

W5 5 0.25-32V 8.5A 1 5 9.5A 18>25.2V

1 C1Y module is only permitted in slot.

2 For PSUs with three D modules fitted or two D modules and an E module in slots

4/5 then D1L & D1H in slots 2/3 is limited to 42A and in slots 4/5 is limited to 47A.

D2 in slots 2/3 is limited to 40A.

3 E2 module fitted in slots 4/5 is limited to 55A.

4 SELV and Outputs connected in Series

Outputs are SELV except as described below

- Non-earthed outputs that have secondaries with 2 or more turns are non-SELV as

a single fault in the secondary may make them exceed the SELV limit between

output and earth.

- Non-earthed ouputs that are connected in series are non-SELV unless all the

seriesed outputs use 1 turn secondaries and there are no more than 3 outputs

connected in series.

- Outputs connected in series are non-SELV if the total output voltage + 20% of the

max, rated output voltage of the output with the highest rated voltage exceeds

60dc (the 20% addition allows for a single fault in any one individual channel)

- The total voltage of a seriesed output must not exceed 160V

- If any ouput or seriesed output is non-SELV then all the outputs in the PSU must

be considered non-SELV

Note

- Non-SELV outputs must be gaurded or a deflector fitted during installation to

avoid a service

engineer making inadvertent contact with the output terminals, or dropping a tool

onto them.

- All outputs operational spacings to earth, and due consideration must be given to

this in the end product design.

5 W5 is followed by V or R indicating Voltage or Resistance programming, both

followed by #

6 Actual voltage and current output of an X module is dependent, and limited by, the

ratings of the modules from which it is fed. The ratings given above for the X module

are additional rating limitations imposed by the X module itself.

7 The maximum power output of psu’s fitted with X modules is reduced from 900W by the

following power:

Power=0.55 x (Total X1 current) + 0.7 x (Total X2 + X4 current) + 0.9 x (Total X8 cur-

Module Limitations- Notes:

Safety approvals

UL60950-1 and CSA22.2 No.60950-1 - UL Recognised. C-UL for Canada.

IEC/EN60950-1 - BSI Kitemark and CE mark.

CE marking when applied to any Vega product, indicates compliance with the Low Voltage Directive

(73/23EEC) as modified by the CE Marking Directive

(93/68/EEC) in that it complies with EN60950-1.

IEC/EN61010-1 and IEC/EN60601-1. CB Report .and BSI Kitemark

UL60601-1 and UL61010-1-UL Recognised, C-UL for Canada.

8. Adjusting output voltage beyond the stated range may cause overvoltage protection

(OVP) to operate, whereby all outputs will turn off. To reset OVP, turn back output

voltage adjustment and remove the mains supply for 30 seconds and then will switch

back on.

Approval Limitations: Use in North America (AC units only)

When this product is used on 180VAC-250VAC mains with no neutral, connect the two live wires

to L(live) and N (neutral) terminals on the input connector. In this instance double pole fusing is

required.

High Voltage Warning

Dangerous voltages present within the power supply. Do not remove covers.

External Hot Surfaces

Section 6 of the Health and Safety at Work Act requires that manufacturers have an obligation to

protect service engineers as well as users. In order to comply with this, a label must be fitted to

these products which is clearly visible to service personnel accessing the overall equipment, and

which legibly warns that surfaces of these products may be hot and must not be touched when the

products are in operation.

Safety Earthing Screw

On products with an enclosure, special safety earthing screws are used which connect the cover to

the chassis. They must not be removed.

Safety Class of Protection

These products are designed for the following parameters : Material Group IIIb, Pollution Degree 2,

Overvoltage Category II, Class 1 (earthed), Indoor use as part of an overall equipment such that

the product is accessible to service engineers only.

Energy Hazards

Certain modules are capable of providing hazardous energy (240VA) according to output voltage

setting. Final equipment manufacturers must provide protection to service personnel against

inadvertent contact with these module output terminals. If set such that hazardous energy can

occur then the module terminals or connections must not be user accessible.

Servicing

These products are not customer serviceable. Repairs may only be carried out by Lambda UK or

their authorised agents. These products are not authorised for use as critical components in nuclear

control systems, life support systems or equipment for use in hazardous environments without the

express written approval of the Managing Director of Coutant Lambda Ltd.

Important safety instructions

The Vega family of component power supplies is designed for use within other equipment or

enclosures which restrict access to authorised competent personnel only. For safe installation and

operation of this product, carefully follow the instructions listed below.

i) The unit covers/chassis are designed to protect only skilled personnel from hazards and must

not be made user accessible.

ii) These products are Class 1 and must therefore be reliably earthed and professionally installed

in accordance with the prevailing electrical wiring regulations and the safety standards covered

herein.

iii) These products are IPX0, and therefore chemicals/solvents, cleaning agents and other liquids

must not be used.

iv) If the earth terminal of the Vega PSU is connected to the main incoming earth conductor of

the end equipment, the installer must cover the Vega earth symbol with a label bearing the earth

symbol of IEC60417-5019.

General installation instructions

Emissions : EN55022 Conducted RFI-Class A or B (depending on product - Consult Technical

Sales). Radiated RFI - Class A

EN61000-3-2 / A14 - Pass - Class A and D. EN61000-3-3 / A1 - Pass

Immunity: EN61000-4-2 - Level 4 Criteria B EN61000-4-3 - Level 3 Criteria B

EN61000-4-4 - Level 4 Criteria B EN61000-4-5 - Level 4 Criteria B, (Installation Class 4, Criteria B)

EN61000-4-6 - Level 3 Criteria B EN61000-4-11 - Pass

EMC performance

Dielectric Strength testing is carried out as follows

Primary mains circuit to earth - 2.25 - 2.35kVDC

Primary mains circuits to transformer core - 4.25 - 4.35kVDC*

Primary mains circuits to secondary -4.25 - 4.35kVDC*

Outputs to each other and to earth are isolated to 200VDC.

*This test is not possible with modules fitted to the unit as damage to RFI capacitors will occur)

Environmental parameters

Operation

Temperature 0 to 500C (derating 2.5%0C above 500C to 650C - Not covered by approvals).

Humidity 5 to 95% RH non-condensing. Air Pressure 78kPa to 106kPa.

Altitude -200m to 3000m.

Storage and Transportation

Temperature -250C to +850C. Humidity 5% to 95% RH non-condensing.

Air Pressure 54kPa to 106kPa. Altitude -200m to 5000m.

Vibration and shock

10-200Hz @ 1.5G sinewave, 20G for 15 minutes in 3 axes random vibration / 3000 bumps, 10G

(16mS) half sinewave.

Cooling

Provided that the fan air intake and air outlet slots are not impeded, these units may be mounted

in any of 4 orientations: Horizontal, on either side, or vertical with airflow upwards. For correct

airflow, allow 50mm clearance around the side and ends of the product.

Level of insulation

Input markings and symbols

Terminal Block

Fast-ons

N L

L

N

alternating current (a.c.)

direct current (d.c.)

danger, shock hazard

caution, refer to supplementary documents.

Earth

L

Live

N

Neutral

Custom Model

Model: NS-THE/V9FSSF B/S 28E5HS (K90036)

Input: 90-264Vac, 47-63Hz

Maximum output: 28V, 25A, maximum output power: 700W

Page 3

Vega 900 Handbook

�

Part Number 17155

Primary Options

Specified Option Pin 5 Logic 0 Pin 6 Logic 1

Inhibit Outputs OFF Outputs OFF

Enable Outputs ON Outputs ON

Secondary Options

Module Good

Inhibit Anode

Mating input faston connectors

Brand Colour Wire size (awg) Part number Current rating

Amp Red 22 - 18 2-520407-2 15A

Amp Blue 16 - 14 3-520408-2 15A

Input Connections

Input tabs - 6.3mm x 0.8mm, tin plated brass, rated 15A. Internal fuse (F1) 16A/250V fast acting

HBC fuse 6.3x32mm

Input Screw Terminals: 6-32 screws with 8.25mm spacing between screw head centres. Screw

head diameter is 6.6mm.

Input IEC 320: Rated 10A/250Vac (15A/132Vac)

Connection details

Inhibit

Remote Sense +VE

Inhibit/Enable Anode

Remove Sense -VE

Inhibit/Enable

Share

Com-

Share

Module Good Collector

Remote Sense +VE

Analogue programming

(Voltage or resistive with respect to comman)

Module Good Emitter

Single output wide range programmable module

Inhibit/Enable Anode

Inhibit/Enable Cathode

0-32K resistance

Ω

0-5V external voltage prog.pin

Prog signal return

Inhibit/Enable Anode

Inhibit/Enable Cathode

0-5V current prog. pin

Prog. signal return

Prog. signal return

Transistor ON (saturated) when

module is GOOD.

Module is GOOD when output

voltage is between (88-96%) and

(104-112%) of its set voltage.

Max Vce 70V

Vsat <0.4V at

1mA current

Module good Collector

Module good Emmitter

Single output module digital option

TWIN Output Module ”R” Option

TWIN Output Module ”N” Option

Inhibit Anode

Remote Sense -VE

Inhibit Cathode

Remote Sense -VE

Inhibit Anode

Inhibit Cathode

Module Good Collector

Remote Sense +VE

Module Good

Module Good Collector

Remote Sense +VE

Module Good

CH1

CH2

Remote Sense +VE

Remote Sense +VE

Remote Sense -VE

Remote Sense -VE

C H 1

C H 2

Internally is a 390

resistor is series with

diode of an optocoupler. Drive

≥2mA to inhibit module (max

13mA).

INH A

INH C

390

VF=1.1V

Ω

Ω

Remote Sense Option

SINGLE Output Module ”N” Option

Remote Sense -VE

Inhibit Cathode

Module Good Collector

Share

Share

Inhibit Anode

Module Good Collector

Module Good Emitter

Internally is the output of an opto-isolated transistor.

Transistor “on”=AC + Temp O.K. Vce max = 30V Ic max =

5mA, 5mS warning of thermal shutdown or loss of AC.

Logic 0 = 0-0.8V. Logic 1 = 2.0 - 5.0V with respect to 0V (Pin 3)

AC + Temp Fail, E

AC + Temp OK

AC + Temp Fail, C

AC + Temp Fall, C

AC + Temp Fall, E

0V

Aux Voltage

INH/ENA Logic 0 (TTL Logic Levels)

INH/ENA Logic 1(TTL Logic Levels)

Pin 1

Pin 6

Maximum Torque Settings for Output Screw Terminals

M3 - 0.75Nm M4 - 1.5Nm M5 - 2.0Nm

Output Connections

Output Connector Ratings: Single slot, single output modules (B, C, L modules): Two 6.35mm

fast-ons per output each rated at 18A or M4 screw terminals rated at 35A. Single slot, twin output

modules (H modules); One 6.35mm fast-on per output rated at 18A or M3 screw terminals rated at

15A. Dual slot, single output modules (D, E modules): Two 9.5mm fast-ons per output each rated

at 32A, or M5 screw terminals rated at 90A

Special instructions for applications covered by IEC/EN/UL/CSA61010-1.

Whilst all individual module single outputs are classed as SELV outputs in accordance with IEC/EN/

UL/CSAEN60950-1 (<60Vdc or 42.4V peak) serried combinations of these modules may exceed

these values and become hazardous output voltages. For IEC/EN/UL/CSA61010-1 the equivalent

limits are 70Vdc, 33Vrms or 46.7V peak.

Under single fault conditions these limits are increased for IEC/EN/UL.CSA61010-1 and UL3101-1

to 140Vdc, 55Vrms or 78V peak. Provided these levels are not exceeded, the outputs are not

considered hazardous for IEC/EN/UL/CSA61010-1

DO NOT USE MOUNTING SCREWS WHICH PENETRATE THE UNIT BY MORE THAN 4.5 MM.

Weight 2 Kg dependent upon configuration.

Mechanical parameters

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Applicable to products with L, R and T filter options only.

i) These products are designed for continuous operation within an overall enclosure, and must

be mounted such that access to the mains terminals isrestricted. See Clause 16, IEC/EN/UL/

CSA60601-1,

ii) These products are NOT suitable for use in the presence of flammable anaesthetic mixtures

with air or with oxygen or with nitrous oxide.

iii) These products are classed as ordinary equipment according to IEC/EN/UL/CSA60601-1 and

are NOT protected against the ingress of water.

iv) Connect only apparatus complying with IEC/EN/UL/CSA60601-1, to the signal ports.

v) Except for permanently installed equipment as defined in Clause 57.6 of IEC/EN/UL/

CSA60601-1, the overall equipment in which these products are installed must have double pole

fusing on the input mains supply or DC supply as appropriate. The products themselves have

single pole fusing in the live line or positive DC line as appropriate.

vi) Reference should be made to local regulations concerning the disposal of these products at

the end of their useful life.

Special instructions for medical applications (IEC/EN/UL/CSA60601-1)

Input Filter Options

Option Max. Leakage at 264VAC,63Hz RFI EN55022 Class

Standard 1.5mA max B/A

M 650uA max A

L 290uA max A

R 175uA max Above A

T 60uA max Above A

Note: When primary options EW or FW are fitted the above values increase 100uA

Page 4

Vega 900 Handbook

�

Part Number 17155

Right Angle Screw Terminal Input

IEC 320 (Switched) Input

Quick Connect (Faston) Input

Customer fixing

s

Customer Air and Fixing detail

Customer fixings are M4

Customer fixings are M4

Customer fixings are M4

CEL Part No. 17155 Issue 09,May 2006

Coutant Lambda Limited,

Kingsley Avenue,

Ilfracombe,

Devon, EX34 8ES.

Telephone - Sales and Service (01271) 856666.

Head Office and Works (01271) 856600.

Facsimile (01271) 864894.

WEBSITE: www.lambda-gb.com

Customer fixings are M4

Loading...

Loading...