Lamar Technologies D-50 User Manual

OPERATING MANUAL

BETA D-50

BATTERY TESTER / ANALYZER

Lamar Technologies, 14900 40th Ave NE, Marysville WA 98271

Tel: (360) 651-8869 • Fax: (360) 651-6677

www.lamartech.com/powerpr od uct s

TABLE OF CONTENTS

1. SYSTEM OVERVIEW ... ......................................................................

.1

2. INSTALLATION ... .................................................................................. .4

3. QUICK OPERATING GUIDE ... ......................................................

4. DETAILED OPERATING INSTRUCTIONS ... ................................ …

5. CALIBRATION AND MAINTENANCE ... ..........................................

6. TROUBLE-SHOOTING ... ..............................................................

7. SPECIFICATIONS ... .........................................................................

APPENDIX A - BATTERY OVERVIEW ... ...........................................

WARRANTY ... ......................................................................................... ..

CERTIFICATION OF CALIBRATION .………………………………….

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V 2.2

…..6

.9

..18

…27

..29

....30

..32

...33

1. SYSTEM OVERVIEW

1. SYSTEM OVERVIEW

1.1 SYSTEM OVERVIEW

The Beta D-50 Tester/Analyzer is a self cont ained unit for d ischarge capacity test ing of

rechargeable batteries. It has been designed to accurately test and guarantee the

emergency capacity of sealed or vented lead-acid or nicke l-cadmiu m batteries.

Guaranteed emergency capacity is especially impor tant for air craft batteries.

The Beta D-50 enables testing of a battery's capacity by loading it w ith a const ant

current of max 50 amperes (usually set to 80-100% of the ba ttery's ca pacity rating)

during a fixed period of time (usually 60 minutes). The D-50 analy zes the discharge

characteristics and passes or fails the bat tery depend ing on the ba ttery’s ab ility to

maintain a specified minimum voltage (cu toff voltage) for th e duration of the test. The

unit has pass/fail indicators as well as displays for discharge current, cutoff voltage,

battery voltage, and test time.

The flexibility of test parameters of the Beta D-50 makes it usable for a wide variety of

batteries and voltages. The unit accurately tests lead-acid batteries of 12 or 24 volts, as

well as nickel-cadmium batteries up to 24 volts.

The use of solid state circuits in the Beta D-50 h as kept its weight to a mere 30 lbs. (14

kg). Consequently the unit is easy to move around to accommodate flexibility in the work

environment.

1.2 DISPLAYS AND CONTROLS

The Beta D-50 has been designed to have very sim ple and easy to un derstan d controls

and displays (see figure 1-1 and 1-2).

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V2.2

Page 1

1. SYSTEM OVERVIEW

ACCEPT LAMP

INDICATOR

Illuminates at end of

test when timer has

completed its preset

time

FAIL LA M P

INDICATOR

Illuminates when

voltage has

dropped to cutoff

before the timer

times out

CUTOFF

VOLTAGE

ADJUST

TRIMPOT

Adjusts cutoff

voltage

CUTOFF VOLTAGE

VIEW BUTTON

Pressed before or

during test to display

and adjust cutoff

voltage

Page 2

DIGITAL

VOLTMETER

Displays 1) battery

voltage during

discharge; or 2)

cutoff voltage

DIGITAL

DISCHARGE TIMER

Displays elapsed

discharge time. Can be

set with push buttons

CALIBRATION

START BUTTON

Pressed to start test

INSTRUCTION

PANEL

TEST PORTS

Provides output for %$ 77(5 <

voltmeter and ',6&+ $ 5 * (

ammeter calibration &$%/(

Figure 1-1. Front view of Beta D-50

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V2.2

DIGITAL

AMMETER

Displays

discharge

current.

AMPERE

ADJUST KNOB

Sets discharge

current

AC ON-OFF/

RESET SWITCH

Turns unit on or

off and resets all

indicators and

functions

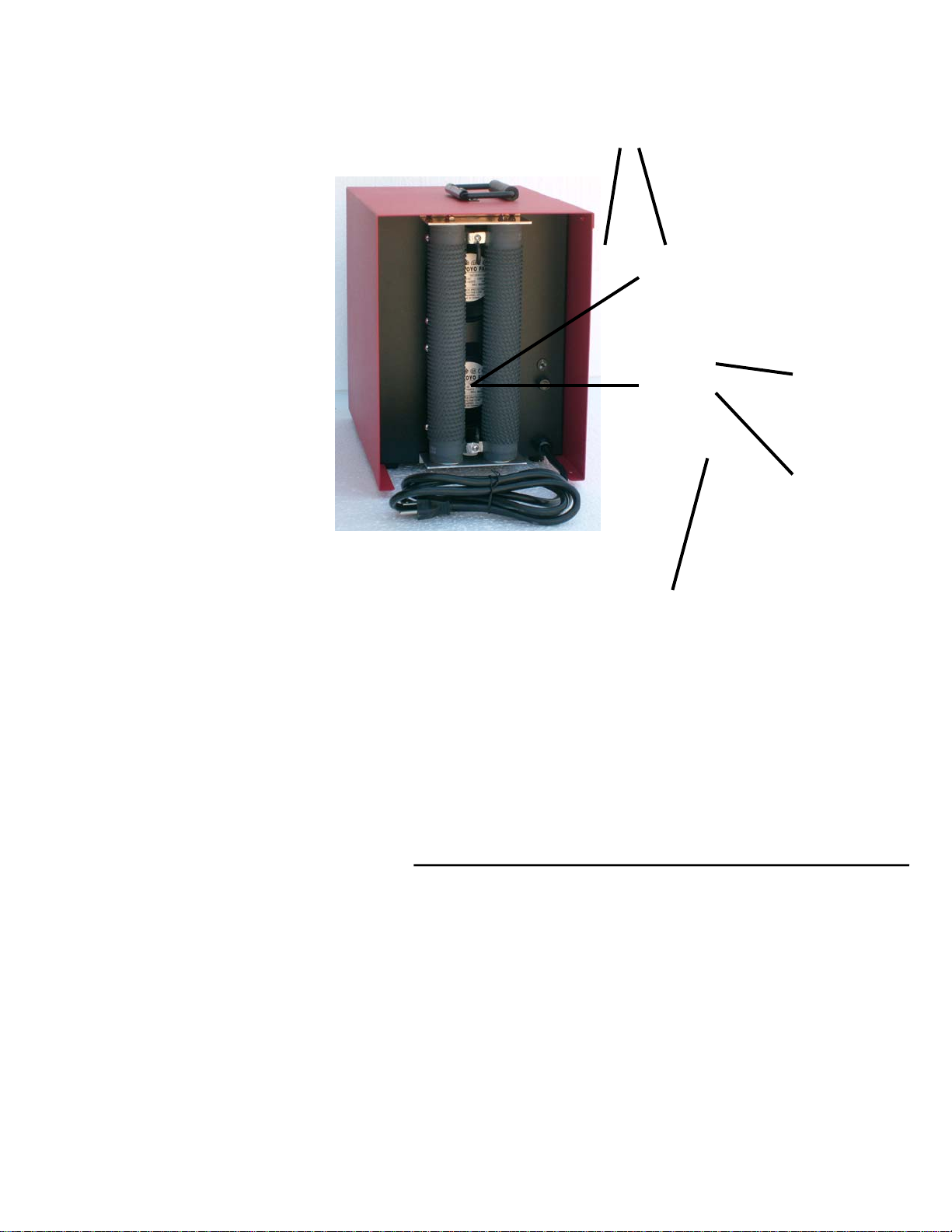

1. SYSTEM OVERVIEW

DISCHARGE

RESISTORS

AC VOLTAGE

SELECT DIAL

COOLING

FANS

Selects mains input

voltage (115 or 230

volts)

AC LINE FUSE

protects line and

equipment

AC MAINS

CABLE

Figure 1-2. Rear view of Beta D-50

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V2.2

Page 3

2. INSTALLATION

2. INSTALLATION

2.1 LINE VOLTAGE

The Beta D-50 can operate on either 115 or 230 Volts AC. The desired line voltage can

be selected on the rear of the unit.

CAUTION: Ensure that the unit is set for the appropriate line voltage before operation.

A. On the back of the unit locate the AC voltage select dia l.

B. Set dial for appropriately marked AC voltage (115 or 230 volts) using a screwd rive r.

C. For 230 VAC operation, the 115 VAC plug must be replaced w ith one for 230 V AC in

required configuration.

NOTE: If the plug has to be changed make sure to connect the green AC line wire to

ground.

Connect the unit to a wall outlet with at least a 10 ampere ca pacity. Shar ing of the line

with other equipment may result in erratic operat ion if other equipment draws hig h pulse

or surge currents.

NOTE: The Beta D-50 will maintain its operational integrity with line fluctuation less than

± 10%.

2.2 TERMINALS

Two important points about the DC battery cable and connector are:

A. If the aircraft battery quick disconnect connector is removed, the

ring terminals can be used to connect to a post terminal battery.

B. If the cable is extended or repaired during maintenance, the

sensing leads which run with the heavy DC cable mu st be

connected to the new terminal (see se ction 5.5).

Page 4

WARNING : Correct polarity must be observed.

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V2.2

2. INSTALLATION

2.3 SPACE REQUIREMENTS

The Beta D-50 system occupies 15" x 10 ¼" (381 mm x 260 mm) of table top space.

Place the unit on a sturdy workbench in a well-ventilated battery servicing area with the

battery adjacent to it.

The rear of the unit has air flow fr om h ot re sistors. Allow a t le ast 6" (150 mm) of

separation from the wall and adjacent equipment in or der to ma intain proper a ir flow.

WARNING: Due to the air flow from hot resistors on the

rear of the unit, use extreme caution on placement.

NOTE: In non air-conditioned rooms it is recommended

that circulating or extracting fans be used to aid in the

removal of heated air.

NOTE: Operation in dusty or otherwise dirty air

environments will severely reduce the cooling capacity of the

fans and can lead to premature failure.

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V2.2

Page 5

3. QUICK OPERATING GUIDE

3. QUICK OPERATING GUIDE

This section gives an overview of how to quickly get started capacity discharge testing a

battery using your Beta D-50. If there is uncertainty at any point on how to proceed, please

refer to the more detailed instructions in the section 4.

A.

Turn off the AC on-off/reset power switch.

B.

Repeatedly turn the Ampere Adjust knob fully

counter-clockwise to set discharge current to zero.

WARNING: Always turn the AC power switch off before

connecting or disconnecting a battery

NOTE: Once set, all settings are maintained and need not be

reset for duplicate testing

SWITCH OFF MAINS POWER

TURN DOWN DISCHARGE CURR

ENT

C.

CONNECT BATTERY

Connect the battery DC cable to the battery and ensure the

connector is plugged in completely.

SWITCH ON MAINS POWER

D.

Turn on the AC on-off/reset power switch. An audible alarm

sounds, and the Accept lamp illuminates. Meters read all

6's or 8's.

E.

SET TIMER

Set the timer by pushing buttons up or down to the

required discharge time (usually 60 minutes)

Page 6

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V2.2

3. QUICK OPERATING GUIDE

F. VIEW AND SET CUTOFF VOLTAGE

a. Press and hold the View Voltage Cutoff button. The set cutoff voltage

is shown on the voltm et e r d is p lay.

b. Use a 1/16 inch (2 mm) slot b lade pr ecisio n

type screw driver to adjust the cutoff voltage

to the desired level.

G.

PUSH START BUTTON

The audible alarm stops. The voltmeter displays the battery

voltage, the ammeter reads 0 and the timer starts. The red

LED on the timer illuminates. “OP” on the timer illuminates

and the red LED flashes.

H.

SET DISCHARGE CURRENT

Slowly turn the multi-turn Ampere Adju st knob clo ckwise t o

the desired discharge current. The ammeter displays the

current as it is being adjusted.

I. WAIT FOR THE DISCHARGE TEST TO

AUTOMATICALLY COMPLETE

During the test the battery voltage, discharge current, and

elapsed discharge time are displayed. The voltage wi ll

continuously decrease while the cur rent remain s constant. The

test completes when either the set discharge t ime or the low

cutoff voltage has been reached. An audible a larm sounds and

the displays freeze at their final values.

J. 1. IF TEST PASSED

The green Accept lamp illuminates. This ind icates the discharge

has continued through the duration of the set discharge t ime (the

red LED and “OP” on timer is off.) without the cutoff voltage bein g

reached. The battery is usually fit for serv ice, af ter co mplet e

recharge. See below under respective battery type.

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V2.2

Page 7

2. IF TEST FAILED

The Fail lamp illuminates if the discharge has

been discontinued because the cutoff voltage has been reached before

the completion of th e set discharge time. The red LED goes out. The

time is frozen at the elapsed time at which the test failed. The battery is

in need of reconditioning or must be rejected for

aircraft service. Refer to the battery manufacturer's maintenance

manual on how to proceed.

K.

SWITCH AC POWER OFF

Switch the AC on-off/reset switch off before r e m ov in g he ba t t er y .

NOTE: If in emergency it is required to stop the test, switch the un it to

off/reset. When the test is restarted the timer is rese t to ze ro. I t may be

necessary to recharge the battery before resuming the test.

Page 8

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V2.2

4. DETAILED OPERATING INSTRUCTIONS

4. DETAILED OPERATING INSTRUCTIONS

4.1 DISCHARGE CHARACTERISTICS

The lead-acid and the nickel-cadmium cells are gener ally assigne d nominal op en circu it

voltages of 2.10 volts and 1.35 volt s respective ly. Actu al open circu it voltage at 75°F/ 25°C

for a fully charged battery cell depends on stat e-of-charge and time afte r charge.

During discharge, the voltage of the cell or battery immediately begins to decrease

because of the effective internal resistance of the cell. This includes the resistance of

the terminal posts, active material, plate lugs and grids, separator s, and cont act

resistance between the surface of the active material and the electrolyte. The in ternal

resistance increases during discharge, being greater toward the end of discharge, when

the terminal voltage is lower.

As voltage gradually becomes lower during d ischarge, the point o f near exhaustion is

reached. At this point, the discharge volt age curve b egins to drop very sharp ly to a value

which is of no further practical use. Usua lly this happ ens at 18-20 volts for a 24 vo lt leadacid battery and 1 volt per cell for a nickel- cadmium b attery (see f igure 4-1).

Battery manufacturers specify a cutoff voltage which the battery must exceed during a

discharge test to have acceptable capacity. The cutoff voltage varies with the rate of

discharge (the discharge current/time combination used to draw the same capacity). For

example, the minimum cutoff voltages for a 30 ampere-hour, 24-volt naval aircraft leadacid storage battery are generally specified as is sho wn in table 4-1.

The specified final minimum cutoff voltage repre sents the va lue of voltag e at which the

rated ampere-hour capacity of the battery must have been de livered for the specif ied

discharge rate. Figure 4-1 is a typical discharge cur ve for a 40 a mpere-hour sealed

lead-acid (SLAB) aircraft storage battery discharged at a 1-h our rate of 40 amperes.

From figure 4-1, it is observed that at the end of 1 hour of disch arge time , the battery

voltage has reduced only to about 22 volt s. Becau se the m inimum required cu toff

voltage is 18 volts at the 1-hour discharge rate, the ba ttery exceeds the minimum

requirements. With increasing hours of use or age, the batt ery capacity decreases.

Therefore, battery manufacturers usually recommend testing for a capacity equal to

80% of the original ampere-hour rating.

Rate of Discharge Minimum

Discharge Current Cutoff Voltage

5 hours 6 amperes 21.0 volts

2 hours 15 amperes 19.2 volts

1 hour 30 amperes 18.0 volts

Table 4-1. Cutoff voltages at different discharge rates for a

30 ampere-hour, 24 volt lead-acid battery

BETA D-50 TESTER / ANALYZER - OPERATING MANUAL V2.2

Page 9

Loading...

Loading...