laguna TS SERIES, TSS SERIES, MTSS000020 User Manual

TS / TSS Tablesaw

Manual

LAGUNA TOOLS

2072 Alton Parkway

Irvine, California 92606

Ph: 800.234.1976

www.lagunatools.com

© 2017, Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo® are the registered trademarks of Laguna Tools, Inc. All rights reserved.

Model Number: MTSS000020

3

Table of contents

Safety Rules

Warranty

Noise emission

Specification sheet

Receiving your machine

Unpacking your machine

Introduction to your machine

Assembly and set up

Where to locate your machine

Operating your machine

Maintenance

Troubleshooting

Accessories

Electrical drawing

Spare parts

Exploded view drawings and parts lists

4

Safety Rules

As with all machinery there are certain hazards involved with the operation

and use. Using it with caution will considerably lessen the possibility of

personal injury. However, if normal safety precautions are overlooked or

ignored, personal injury to the operator may result. If you have any

questions relative to the installation and operation, do not use the equipment

until you have contacted your supplying distributor.

Read carefully before operating the machine.

1. Keep the working area clean and be sure adequate lighting is

available.

2. Do not wear loose clothing, gloves, bracelets, necklaces or

ornaments. Wear face, eye, respiratory and body protection devices as

indicated for the operation or environment.

3. Be sure that the power is disconnected from the machine before tools

are serviced or an attachment is to be fitted or removed.

4. Never leave the machine with the power on.

5. Do not use dull, gummy or cracked cutting tools.

6. Be sure that the keys and adjusting wrenches have been removed and

all the nuts and bolts are secured.

Limited Warranty

New machines and accessories sold by Laguna Tools carry a one-year warranty

effective from the date of shipping. Machines sold through dealers must be registered

with Laguna Tools within 30 days of purchase to be covered by this warranty. Laguna

Tools guarantees all new machines and accessories sold to be free of manufacturers’

defective workmanship, parts and materials. We will repair or replace, without charge,

any parts determined by Laguna Tools, Inc. to be a manufacturer’s defect. We require

that the defective item/part be returned to Laguna Tools with the complaint. Any

machines returned to Laguna Tools must be returned with packaging in the same

manner in which it was received. If a part or blade is being returned it must have

adequate packaging to ensure no damage is received during shipping. In the event the

item/part is determined to be damaged due to lack of maintenance, cleaning or

misuse/abuse, the customer will be responsible for the cost to replace the item/part,

plus all related shipping charges. This limited warranty does not apply to natural

disasters, acts of terrorism, normal wear and tear, product failure due to lack of

maintenance or cleaning, damage caused by accident, neglect, lack of or inadequate

dust collection, misuse/abuse or damage caused where repair or alterations have been

made or attempted by others.

Laguna Tools, Inc. is not responsible for additional tools or modifications sold or

performed (other than from/by Laguna Tools, Inc.) on any Laguna Tools, Inc.

machine. Warranty maybe voided upon the addition of such described tools and/or

modifications, determined on a case-by-case basis.

Software purchased through Laguna Tools Inc. is not covered under this warranty

and all technical support must be managed through the software provider. Software is

non-refundable.

Normal user alignment, adjustment, tuning and machine settings are not covered by

this warranty. It is the responsibility of the user to understand basic machinery

operation, settings and procedures and to properly maintain the equipment in

accordance with the standards provided by the manufacturer.

Parts, under warranty, are shipped at Laguna Tools, Inc.’s cost either by common

carrier, FEDEX ground service or a similar method. Technical support to install

replacement parts is primarily provided by phone, fax, e-mail or Laguna Tools

Customer Support Website. The labor required to install replacement parts is the

responsibility of the user.

Laguna Tools is not responsible for damage or loss caused by a freight company or

other circumstances not in our control. All claims for loss or damaged goods must be

notified to Laguna Tools within twenty-four hours of delivery. Please contact our

Customer Service Department for more information.

Only new machines sold to the original owner are covered by this warranty.

For warranty repair information, call 1-800-332-4094.

6

Noise emission

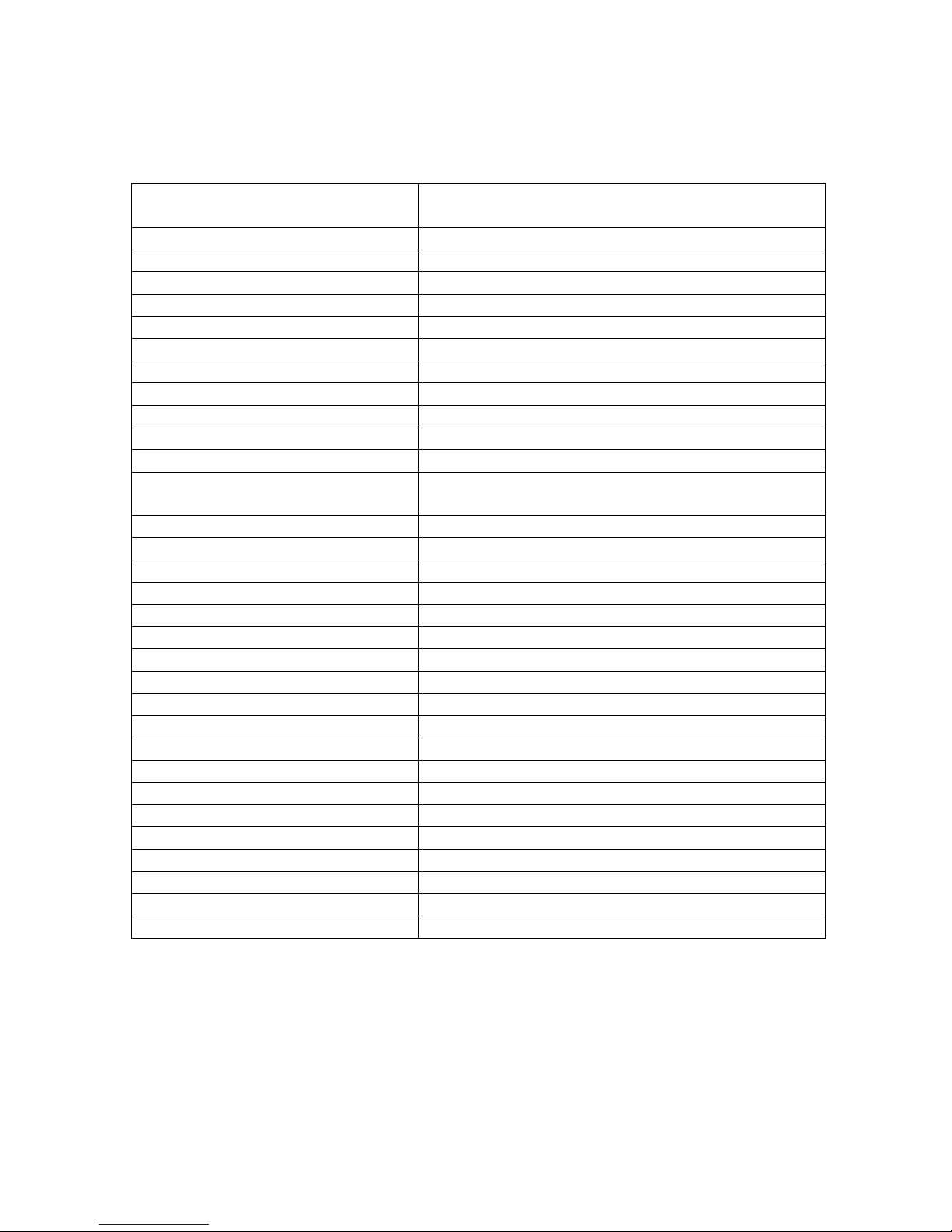

Specification

Blade

12”max x 5/8” bore

Max cut height 12” blade

3 ¾” [2 ½” at 45 deg]

Max cut height 10” blade

2 ¾” [2” at 45 deg]

Dado capacity

13/16”

Main motor

3,5 hp single phase 220 volts 3450 rpm

Breaker

20 amp

Electrical cable [not supplied]

Up to 20’ 10-3 20’ to 50’ 8-3

Scoring motor [Optional]

1,2 hp single phase 220 volts 3450 rpm

Scoring blade [Optional]

120mm x 5/8” bore

Cast iron [ground] table size

31 ½” x 21 ½”

Miter slot

¾” x 3/8”

Extension table pressed steel with ribs and legs

31 ½” x 35”

Sliding table out rigger table [Optional]

Yes

Cutting width on rip fence

50”

Slider length

4’ 2”

Slider travel

5’ 11”

Weight TS

630 lb

Weight TSS

730 lb

Machine footprint

4’ 10” x 3’ x 2’ 10”H

Machine footprint

4’ 10” x 7’ x 2’ 10”H

Dust port

4”

Large throat plate with leveling screws

Yes

Blade guard

Yes

Notes concerning noise emission

Given that there exists a relationship between noise level and exposure times, it is not

precise enough to determine the need for supplementary precautions. The factors

affecting the true level of exposure to operators are clearly the amount of time exposed,

the characteristics of working environment other sources of dust and noise etc. For

example, adjacent machines in other words the level of ambient noise. It is possible that

exposure level limits will vary from country to country.

7

Standard equipment supplied

with TS

Spare blank throat plate insert

Rip fence

Extension table with legs

Blade guard

Tool kit

Options for TS

Miter gauge

Spare blank throat plate insert

Sliding table

Mobility kit

Scoring unit

Standard equipment supplied

with TSS

Spare blank throat plate insert

Extension table with legs

Blade guard

Tool kit

Sliding table

Miter fence with flip stop and clamp

Miter fence 90-degree flip stop.

Options for TSS

Miter gauge

Spare blank throat plate insert

Mobility kit

Scoring unit

Sliding table out rigger table

Flip stop

Clamp

Straight line rip plate

24” fence

24” fence with telescopic extension

5 hp single phase [Leason]

Miter fence 90-degree flip stop.

8

TSS floor plan

TS floor plan

9

Receiving your machine.

Note. It is probable that a third party will deliver your machine.

Before you unpack your new saw you will need to first inspect the packing, invoice and

shipping documents supplied by the driver. Insure that there is no visible damage to the

packing or the machine. You need to do this prior to the driver leaving. All damage must

be noted on the delivery documents and signed by you and the delivery driver. You must

then contact the seller [Laguna Tools] as soon as practical. If damage if found after

delivery, contact the seller as soon as practical.

Introduction to Table saws

This Table saw is designed to give you years of safe service. Read this owners manual in

its entirety before assembly or use.

Parts of the Table saw.

The table saw does not have many parts. The major parts are discussed in this manual. If

you are not familiar with the table saw take the time to read this section and become

familiar with the machine.

Identification.

There is a plate at the back of the machine listing all the manufacturing data including the

serial number, model, etc.

10

Cabinet

The cabinet has a large footprint and is a welded construction manufactured from heavy

gauge steel plate [4mm [0.16”] thick]. The cabinet houses all the parts of the machine and

the heavy construction ensures that the saw is stable. This weight also helps to absorb any

vibration that is produced during cutting.

Table

The table is manufactured from cast iron [cast iron is a live material and will move over

time] and is provided with a leveling system to ensure that your table remains flat during

the life of the machine. This system allows you to stress the table and take out any

warpage that occurs over time. The table is attached to the cabinet and located with dowel

pins that are removable should adjustment be needed between the miter slot and the saw

blade. On the TS the table is split so that should you require you can fit a sliding table at

a later date.

Trunnion

The trunnion assembly is attached and doweled to the cabinet. It is a heavy cast iron

construction. It houses the motor, saw spindle, riving knife, tilt mechanism, and vertical

movement adjustment. This is the heart for your saw.

The advantage of attaching the trunnion to the case rather than the table is that its weight

is supported by the cabinet and will not twist or distort the table.

Electrical system

The electrical system consists of an electrical motor, start switch, stop switch and

contactor. No cable or plug is supplied as the length of the cable and the type of plug will

be dependant on your installation.

Rip fence.

The rip fence is a “T” square design that gives superior rigidity and is adjustable for

parallel to the blade.

Dust collection.

Dust collection port is located at the back of the machine and is 4” diameter. It connects

to the bottom of the trunnion assembly and collects the sawdust as it leaves the blade.

You will need a dust collection system with a minimum of 1000 cubic feet per minuite.

Throat plate.

On the TS the throat plate is solid cast iron with an insert that can be slid in or out for

easy change between inserts. It is adjustable for level to the table.

The TSS has a fixed throat plate that has inserts that clip in and out. It is also adjustable

for level to the table.

11

Sliding table.

The sliding table is manufactured from heavy aluminum extrusion. The table is supported

by ball bearings that roll on polished round steel rods. The clearance between the ball

bearings and the polished round steel guide rods is adjustable. The advantage of the

bearing system is that there is only point contact between the balls and the rods, which

virtually eliminate the problem of dirt, building up and the sliding table will remain

accurate for many years. When wear takes place the polished round steel rods can be

rotated and present a new surface to the ball bearing.

Miter gauge [Optional].

The miter gauge has a cast iron body with an aluminum fence. The miter gauge is

adjustable for angle and has dowel holes every 15 degrees for quick accurate setting. The

fence is movable in relation to the body so that you can adjust it to suite the job.

Miter fence TSS.

The miter fence is manufactured from cast iron and heavy-duty gauge aluminum

extrusion. It is supplied with a flip stop and a job clamp. It can be set at any angle and has

an adjustable 90-degree flip stop that is fitted to the side of the sliding table.

Mobility kit [Optional]

The mobility kit is easy to fit and the machine is located directly on the floor when the

mobility kit is not in use.

Scoring unit [optional]

The scoring unit can be purchased with the saw or fitted as an option later. The scoring

unit has a separate motor and is adjustable vertically and horizontally. All machines are

supplied with locating / fixing holes and faces machined to accept a scoring unit.

The machine should never be started with both motors engaged. The main motor

must be started and when at full steed then the scoring motor started. If both motors are

started at the same time excessive load is put on to the contactor and it will burn out.

12

Where to locate your machine.

Before you remove your machine from the pallet select the area where you will use your

machine. There are no hard and fast rules for its location but below are a few guidelines.

1/ There should be an area at the front and back of the machine suitable for the length of

wood that you will be cutting.

2/ Adequate lighting. The better the lighting the more accurate and safely you will be able

to work

3/ Solid floor. You should select a solid flat floor, preferably concrete or something

similar.

4/ Close to power source and dust collection.

5/ Allow an area for the storage of blanks and cut jobs.

Unpacking your machine.

To unpack your machine you will need tin snips, knife and a wrench.

1/ Using the tin snips, cut the banding that is securing the packing box [If fitted].

WARNING: EXTREME CAUTION MUST BE USED BECAUSE THE BANDING

WILL SPRING AND COULD CAUSE INJURY.

2/ Dismantle the box or remove the row of screws around the base of the box and lift the

box off the pallet. You will need two people to lift the box off the pallet.

3/Using the knife cut the plastic wrap. The extension table, fence and accessories that

were ordered are in the box.

4/ Remove the base mounting bolts that secure the machine to the base of the box.

5/ It is recommended that the machine be removed from the pallet by lifting it with a

hoist or forklift. Remove the pallet and lower to the floor. [To lift with a hoist, four lifting

hooks are provided that fit into the holes at the bottom of the body.]

The machine can be lifted using a forklift truck, sliding it onto the forks or by using a

"SLING" with a lifting capability of 2000 Kg [4400lb]

If no lifting device is available you can fit the mobility kit [if ordered] build a temporary

ramp and roll the machine off the pallet.

Note The machine is heavy; ensure that you have sufficient people.

Note: If you have any doubt about the described procedure seek professional assistance.

Do not attempt any procedure that you feel is unsafe or that you do not have the physical

capability of achieving.

13

Fitting the optional mobility kit [If ordered]

Slide the axel through the lower inside holes on the side of the machine and fit the spacer

[large washer] onto the axel.

Fit the wheel assembly, nut and washer on to the axel.

To activate the moblity kit, insert the handle into the tube and rotate so that the machine

is lifted. When in the up position insert the sliding pin.Repeate on the other side of the

machine.

Fit the cast iron bracket to the front of the machine with the bolts provided into the

tapped holes. Move the machine by inserting the transport bar and lifting.

14

Assembly and set up

Lifting hooks and tools

Optional mobility kit

Fence system

Optional straight line rip bracket

Extension table and spare throat plate

Miter fence

What you will receive with the machine.

15

Cleaning the machine.

Leveling bolt

Switch box shown with optional scoring

switch

Vertical control handle

Angle control handle

Remove the rust protection grease with WD 40 or similar solvent

It is important that you remove all the grease and re lubricate with a Teflon bases

lubricant as Teflon has less tendency to attract sawdust and cause clogging. You should

also wax the table, as this also protects the cast iron from rust.

Leveling the machine.

The machine is provided with 4 leveling bolts. Move your machine to its final position,

and using a sprit level on the table, adjust the leveling bolts so that the table is level in

both directions. Ensure that the machine does not rock.

The start / stop switches are located on the side of the machine next to the blade vertical

control handle. The knob in the center of the control handle, is a lock that locks the blade

in the vertical position selected.

The handle on the front of the machine, controls the angle of the saw blade. The angle

read out is on the side of the machine by the vertical control knob. When moving the

blade to an angle, the yellow-hinged dust plate MUST be closed. Damage may occur if

the yellow hinge plate is not closed.

16

Switch cover shown open

To start your machine, release the red stop button by moving the button to the right. The

Riving knife adjustment

Riving knife adjustment

Locking rod

Fitting blade Arbor spacer

door will be released and the green button will be accessible. Press the green button, and

the machine will start. To stop the machine, press the red button.

The machine should never be started with both motors engaged. The main motor

must be started, and when at full steed, then the scoring motor started. If both motors are

started at the same time, excessive load is put on to the contactor, and it will burn out.

To adjust the riving knife for different diameters of saw blade, loosen the clamp screw,

and slide the knife up or down or laterally to suite the blade selected. Once adjustment is

completed, ensure that the screw is re tightened.

To adjust the riving knife parallel and inline with the blade, four adjusting screws are

provided.

17

To fit a blade, disconnect the saw from the power. Move the arbor to the maximum up

Dust cover clips

Locking rod

Loosen

Guard in up position

Guard in down position

position. Rotate the saw arbor so that the hole in the arbor lines up with the hole in the

saw table. Insert the locking rod, and loosen the arbor nut. Remove the large clamping

disc, and fit the blade. When refitting the clamping disc, ensure that the key lines up with

the key way. The nut must be tightened, and the locking rod removed before starting the

machine.

Note. The arbor has a left hand thread.

Note. The arbor is shown with the spacer removed. The spacer is only removed when you

fit a dado cutter. It is left on the arbor when fitting a saw blade.

To release the yellow dust cover, release the clips at both ends. Never move the saw

arbor with the dust cover loose, as it could become damaged.

Fit the saw blade guard, and fit a dust hose if required. The size of dust hose should be 1

½”.

18

Leveling screws

TS throat plate Insert

Straight edge

TSS throat plate

The throat plate is made from cast iron, and has a phenolic insert. A spare insert is

provided that you can machine to suite your requirements [Dado, Zero clearance, etc].

There are two types of throat plate, TSS and TS. To adjust the TS throat plate, adjust the

leveling screws so that the throat plate is level with the table. To remove the insert slid

out as shown.

To adjust the TSS throat plate, place a rule [straight edge] across the table so that it

extends across the throat plate. Each clamp screw is provided with jacking screws, and by

19

loosening the clamp screw, and adjusting the jacking screws, the plate can be adjusted for

Retaining clip

Insert TSS throat plate

Dust port

level to the table, and for parallel to the table. Ensure that the clamping screws are tight

before you use the saw.

On the TSS, releasing the clips and sliding the insert towards the blade will remove the

insert. Note. The blade will have to be in the down position. To fit a new insert, slide into

the throat plate and you will hear a click as the catches engage.

The machine has a dust port at the back of the machine close to the ground. It takes a 4 “

diameter hose, and needs to be connected to a dust collector with a capacity of 1000

cubic feet per minute minimum [The stronger the dust collector the better].

20

Dado cuter

Fitting the dado cutter

Dado cutter

Extension table legs

Extension table

Extension table fixing bolt

To fit the dado cutter, disconnect the machine from the power and remove the arbor nut,

clamping disc, and spacer.

Fit the dado and lock in position with the clamp washer and arbor nut. Ensure that the

lock rod is removed before you start the machine. A blank throat plate is supplied that

you can machine to suit the dado that you are using. Optional additional throat plate

inserts are available.

Fitting the extension table

Fit the legs to the table prior to fitting the table to the saw.

Attach the table to the main table with the fixing bolts provided. DO NOT FULLY

TIGHTEN THE BOLTS.

21

Straight edge

Extension table Jack screw

Using a straight edge, adjust the legs so that with the straight edge flat on the main table

Fence tube Side angle

Tube fixing bolts

View from underside of tube and

angle

the part of the extension table that is directly above the legs is level with the table.

Above the table fixing bolts are leveling screws. Adjust the leveling screws so the table is

level with the main table, and fully tighten the fixing bolts.

Note. The table is attached to the side angles, and after you have completed all the

adjustments, you will have to drill through the holes in the angles, and attach the table to

the angles, with the screws and nuts provided. Do not drill the holes at this point in time.

Note. Do not level the table or attach the angles until the machine is in the final position.

Fit the angle iron rails to the side of the main table. Make sure that the angle with the

fence holes is on the side of the machine with the on / off switch. Use the countersunk

screws to attach the angle to the main table.

The angle on the other side of the machine is attached with hex bolts.

Fit the fence tube to the angle with the hex bolts and washers from the under side of the

angle. It is recommended that this be assembled with two people, as the tube has a

tendency to slide off the angle during assembly.

The angles will have to be adjusted vertically and this is covered latter.

22

Switch box open

Ground

Electrical connection

Note the machine is not supplied with an electrical plug or cable, as the type of plug and

cable, will be dependant on the installation. A qualified electrician must carry out the

electrical installation.

Fitting the electrical cable. The electrical cable is fitted as shown. The recomented cable

size 10.3 gauge for runs of up to 20’. For longer runs up to 50’use cable 8-3 gauge.

Recommended breaker size is 20 amps.

On the machine you will see a wire that is yellow and green, this is the ground wire, the

other colored wires are power. It does not matter what color combination you use. Green

and yellow is ground; all other wiring is power (there is no neutral). On single phase the

wiring can be interchanged as you wish; it would not affect the rotation of the motor. The

direction of rotation of machines with a single: phase supply is predetermined during

production.

Before starting the machine

1/ Read and understand the instruction manual before operating the saw.

2/ If you are still not thoroughly familiar with the operation of the saw get advice from a

qualified person.

3/ Make sure the machine is properly grounded and that the wiring codes are followed.

4/ Do not operate the machine while under the influence of drugs, alcohol, and medicine

or if tired.

5/ Always wear eye protection, safety glasses or a safety shield, and hearing protection.

6 /Wear dust mask; long term exposure to the fine dust created by the saw is not healthy.

7/ Remove your tie, rings, watch, and all jewelry. Roll up your sleeves, and never ware

loose clothing. You do not want anything to get caught in the saw.

8/ Make sure that the guards are in place and use them at all times. The guards protect

you from coming in contact with the blade.

9/ Make sure that the saw blade teeth point in the correct direction.

10/ Stop the machine before removing the scrap piece from the table.

11/ Always keep your hands and fingers away from the blade.

12/ Make sure that you use the proper size and type of blade.

23

13/ Hold the work piece firmly against the table. Do not attempt to saw stock that does

Stop switch

Optional Scoring switch

not have a flat surface facing down.

14/ Use a push stick at the end of a cut. This is the most dangerous time, because the cut

is complete and the blade is exposed. Push sticks are commercially available.

15/ Hold the wood firmly, and feed it into the blade at a moderate speed.

16/ Turn off the machine if you have to back the material out of an uncompleted or

jammed cut.

Machine test

Now is the time to test the machine.

Note. Never start the main saw motor and the scoring motor at the same time. It will

damage the magnetic contactor. Always start the main motor and when running at full

speed then start the scoring motor.

1/ Check that the machine is clear of all tools, and other loose objects.

2/ Check that all the adjusting and locking handles are tight.

3/ Check that there is no blade fitted, it is far safer to test the machine with out a blade

fitted.

4/ Start the machine by pressing the green start switch.

5/. Saw arbor is now turning.

6/. Now is the time to check that the safety switch is functioning correctly before you fit a

blade.

7/ With the machine running [no blade fitted] operate the red stop switch by pressing

towards the machine. The motor should have the power removed and slow down.

8/ If the safety switch fails to operate correctly do not use the machine until the fault has

been corrected.

Before you cut any wood read the safety rules at the front of this manual

24

To fit the measurement tape.

Marking the fence tube

Assembling the measurement tape

Fine adjusting slots

1/ Clean the steel tube with solvent to remove all traces of grease and dirt.

2/ With a blade fitted, and the power disconnected from the machine, fit the fence to the

tube and push it up against the blade so that it is just touching.

3/ Mark a point on the tube with a pencil or pen at the curser line.

4/ Remove the fence. Line the end of the tape up with the pencil mark and peel off the

backing in short sections, sticking the measurement tape to the tube.

Fine adjustment of the hair line can be done in a number of ways but the most effective

way is to lock the fence [1”] and to cut a piece of wood. Measure the wood and adjust the

hairline read out.

Note. Do not over tighten the read out as you may crack the plastic.It is possible to adjust

the read out closer to the tape by inserting washers between the two parts of the readout.

Make sure that the plastic is not in contact with the tape at any point along its travel.

Loading...

Loading...