Page 1

Owner’s Manual

Straight Line Rip Saw

MRS5000-0280

lagunatools.com | lagunacleanair.com | supermaxtools.com

Page 2

Features

• Precision fence locks securely and

accurate parallelism to the

• Double anti-kick fingers for

maximum safety.

• Ruggedly constructed frame,

massive table

• Precision built saw head assembly

assures absolute straign line rip

saw operation.

• Easy quick change for speeds feed.

• Precision built V-way track assures

absolute straight line up saw

operations.

• Automatic lubrication to V-way track

facilitate chains smooth running.

Arbor motor 7.5 HP / 10 HP / 15 HP

Saw blade diameter

Saw arbor diameter

Working thickness 100 mm

Hold down rollers 5

Distance between saw & column 460 mm

Spindle rotation (50Hz) 3600 R.P.M

Spindle rotation (60Hz) 4500 R.P.M

Feeding motor 1 HP / 2 HP

Feeding speed (50Hz) 11~45 m/ min (15 / 20 / 25 / 30 m/min)

Feeding speed (60Hz) 13~31 m/ min (15 / 20 / 25 / 30 m/min)

Table area 900 x 1450 mm

Net weight 900 kgs

Gross weight 1150 kgs

Packing size 1550 x 1130 x 1700 mm

Page 3

General safety rules

1. Know your machine. Read this operation manual carefully. Learn t

machine application and limition, as well as the specic potential hazards

peculiar to it.

2. Keep guards in place and in working order.

3. The machine must be properly grounded to prevent electric shock.

4. Keep chil

. Don’t use in dangerous environment. Don’t use the machine in damp or

5

wet locations, or exposit to rain. Keep work area well lighted.

6. Keep children and visitors away.

7. Wear proper apparel. No loose clothing, gloves, neckties, rings, bracelets,

or other jewelry to get caught in moving parks. Non slip wear is

recommended. Wear protective hair covering to contain long hair.

8. Use safety glasses.

9. Holds work securely.

10. Don’t overreach. Keep proper footing and balance at all times.

dren area clean. Cluttered areas invite accidents.

he

11. Disconnect machine before servicing and when changing accessories,

such as saw blade etc.

12. Avoid accidental staring. Make sure switch is in “OFF” position before

plugging in power wires.

13

Never leave the machine running unattended, turn o power. Never

leave machine until it complete stop.

14. Never have any part if your body in line with the path of the blade.

15. Disconnect the machine from the power source performing

replacement,adjustment, service, and maintenance.

16. Keep saw blade sharp atall times.

3

Page 4

SAFETY RULES

READ CAREFULLY BEFORE OPERATING THE MACHINE

1. Learn the machines applications and limitations, as well as the specific

potential hazards particular to this machine. Follow available safety

instructions and safety rules carefully.

2. Keep working area clean and be sure adequate lighting is available.

3. Do not wear loose clothing, gloves, bracelets, necklaces, or ornaments.

Wear face, eye, ear, respiratory and body protection devices, as indicated

for the operation or environment.

4. Keep hands well away from saw bade and all moving parts. Do not clear

chips and sawdust away with hands. Use a brush.

5. Make sure the blade is moving at operation speed before cutting. Do not

push the saw blade to hard. The saw will perform better and be safer

working at the rate for which it was designed.

6. Whenever possible use a dust collector with shaving hood to minimize

health hazards.

7. Never leave the machine with the power on.

8. Keep children away. Make sure that visitors are kept at a safe distance

from the work area.

9. Use recommended speed saw blade and accessories, and work piece

material.

10. Never stand on tool. Serious injury could occur if the tool is tipped or if the

sanding tool is unintentional

11. Be sure saw blades are securely locked in the machine.

12. Use suitable support if stock does not have a flat surface.

13. Do not force the machine. It will do the job better and be safer at a rate for

which it was designed.

14. Keep guards in place and in work

maintenance or cleaning make sure it is properly attached before using the

tool again.

15. Be sure that key and adjusting wrenches have been removed before

turning power on.

16. Use only accessories designed for the machine.

17. Make sure tool is properly grounded. If tool is e

plug, if should be pl

remove the third prong.

18. Always disconnect tool before servicing and when changi

sure as saw blades.

19. Make sure that switch is in “OFF” position before plugging in cord.

20. Hold material firmly agai

21. Use ONLY recommended accessorie

recommended by may result in a risk of injury.

22. Do not use this Rip Saw for other than its intended use. If used for other

purposes, disclaims any real or implied warranty and hol

for any injury, which may result from that use.

ugged into a three-prong electrical receptacle. Never

ly contacted.

ing order. If a guard must be removed for

quipped with three-pong

ng accessories

nst the table.

s. Use of accessories NOT

ds itself harmless

4

Page 5

Single Straight Line Rip Saw

Single straight-line rip saws are carefully tested and inspected before

shipment and if properly used will give perfect results. However, a reasonable

amount of care and attention is necessary to ensure perfect performance and

accurate work. It is imperative that you take a few moments to familiarize

yourself with these instructions, as they will no doubt save you a lot of time and

trouble.

Unpack and Clean-up

To ensure maximum perfoom your single straight-line rip saw, rmance fr

clean it properly; and install it accurately before use. As soon as you

receive the rip saw, we recommend you follow these procedures:

I. Finish removing the contents of the shipping wooden case and compare

with the contents list on page 8.

II. Report damage, if any to your local distributor.

III. Clean all rust protected surfaces with a mild solvent or kerosene. Do not

use lacquer thinner; paint thinner or gasoline. These will damage painted

surfaces.

IV. To prevent rust, apply a light coating of paste wax to surface.

Installation

1. The machine must be lifted or moved with a forklift, verify that the capacity

of the forklift is sucient in order to lift the machine.

2. Machine must be evenly balanced on both sides in order for the wooden

case to be steady and leveled on the lift.

3. The forks of the lifter must protrude over the machine bottom for steady

distribution of the entire machine weight.(Figure A)

4. The machine must be installed on a solid foundation and can be bolted if

desired.

5. Work area must be well lighted and spacious in order to allow operator to

move around the machine and handle the materials that need to be cut,

without any obstacles.

6. Four (4) steel pads are furnished with the machine; these pads are to be

placed under the leveling screws at the four corners under the machine

base. (Figure B)

7. Make leveling adjustments after the machine has been properly installed on

the work area.

5

Page 6

A

Figure A Figure B

ttention!

If in doubt contact a qualified

electrician before connected the

machine to the power outlet.

Electrical requirements

The motor of the machinery has

been designed for a specific voltage

frequency. Check the voltage of you

power outlet before connecting to the

power source; make sure the power

outlet corresponds with the voltage

specified on your motor plate, a

voltage with a greater power source

can cause serious injuries to the work

operator and damage the machine.

If in doubt contact a qualified

electrician before connecting the

machine to the power outlet.

Machine must be properly

grounded at all times in order to avoid

electric shock to the work operator.

The use of an extension cord is

not recommended, if required verify

that the extension cord can carry out

the full amount of power required for

the motor.

If the extension cord is damaged,

cut, or worn out; replace immediately

before proceeding with further

operations.

Warning!

A voltage with a greater power source

can cause serious injuries to the work

operator and damage the machine

Conner wires

3 Phase, 50/60HZ.

Voltage is specified by

customers.

1.POWER

SUPPLY

2.CURRENT

3.SETUP

CABLE

RATED

4.CIRCUIT

BREAKER

The setup environment is

effective for EMI, but should

be separate from other

machines or facility.

Keep the voltage variation in

10%.

SAW WHEEL DRIVE

MOTOR: 7.5 / 10 / 15HP

The rated current is 11A /

14.5A / 21.3A (575V/600V)

19.2A / 25.1A / 37.1A (220V)

Cross section…

5.5mm (575V/600V)

8mm (220V)

According to the current to

select its suitable breaker.

6

Page 7

Wiring Diagram

ELECTRICAL CONTROL PANEL

7

Page 8

A

Single straight-line rip saws are precision built and need no further

adjustments once received. However the machine may need a few adjustments

when the machine has been in operation for a long period of time. Follow these

procedures for any necessary adjustments:

1. Re-tighten any bolts or screws that may seem loose, and verify that they

are properly tightened.

2. Always verify the deviating oscillation of the saw arbor and the moving gap

of the arbor direction with a disc indicator once a month. Note: no noise

level must be heard when saw arbor is rotating, this situation can influence

the quality and life of the manufactured product.

3. Belt may become loose or slide off track; this may damage your machine.

Always verify that the belt is at a suitable tightness for any operation being

performed.

Verifications before operations

1.

ll safety guards must be locked in place.

2. Correctly set and verify the width of cut.

3. Verify the running direction of the saw blade.

4. Remove any adjustment tools that are left behind on the machine.

5. Verify that the dust collection system is running properly.

Operating procedures

The following procedures should be performed to verify that the machine is

running in perfect condition:

1. Start the saw blade; let it run for about 10 seconds and then start the

caterpillar. Verify if the machine is running in the proper direction, the

proper running direction must be counter-clockwise, in the case that the

rotation is clockwise switch two power wires among the three installed on

the machine. This procedure will direct the rotation in the proper direction,

allow the saw arbor to rotate 2-3 times to verify that the direction is correct.

2. Verify the automatic lubrication feeding system of the caterpillar; observe

the oil output of the lubricating oil from the lubricator. Allow the main shaft

and caterpillar to run for a few minutes to observe that the heating situation

is normal.

3. Perform a trial cut at a low speed; inspect the thickness of the Woodstock. If

necessary, make further adjustments for thickness of cut.

4. Once machine is running in perfect condition, work operations can now

proceed.

8

Page 9

Feed Speed

Adj

Adj

We recommend that a slow feed selection be selected when performing

operations. When sawing is in process; observe that the motor load has not

been overloaded. If over loading occurs; reduce the feed speed or change the

saw blade to allow the saw arbor to function normally.

usting Feed Speed

1. Loosen the four screws on the side

plate and remove.

2. Loosen nut (1) and remove the belt.

3. Place the belt at the desired speed.

4. Put back the motor bracket.

5. Re-tighten nut (1) and adjust belt at

the proper tension.

6. Re-tighten screws on the side plate.

usting V-belt tension

Your machine will require

adjustments after a long period of

operations; the v-belt may have

loosened gradually. Adjust your v-belt

with the following procedures:

1. Disconnect the machine from the

power source before making any

adjustments.

2. Open the rear door panel of the

machine.

3. Loosen nut (1) then turn the v-belt

tension adjustment screw (2) in

order to adjust the tension.

4. Reverse the above procedures after

the v-belt tension has been properly

adjusted.

Figure 8

9

Page 10

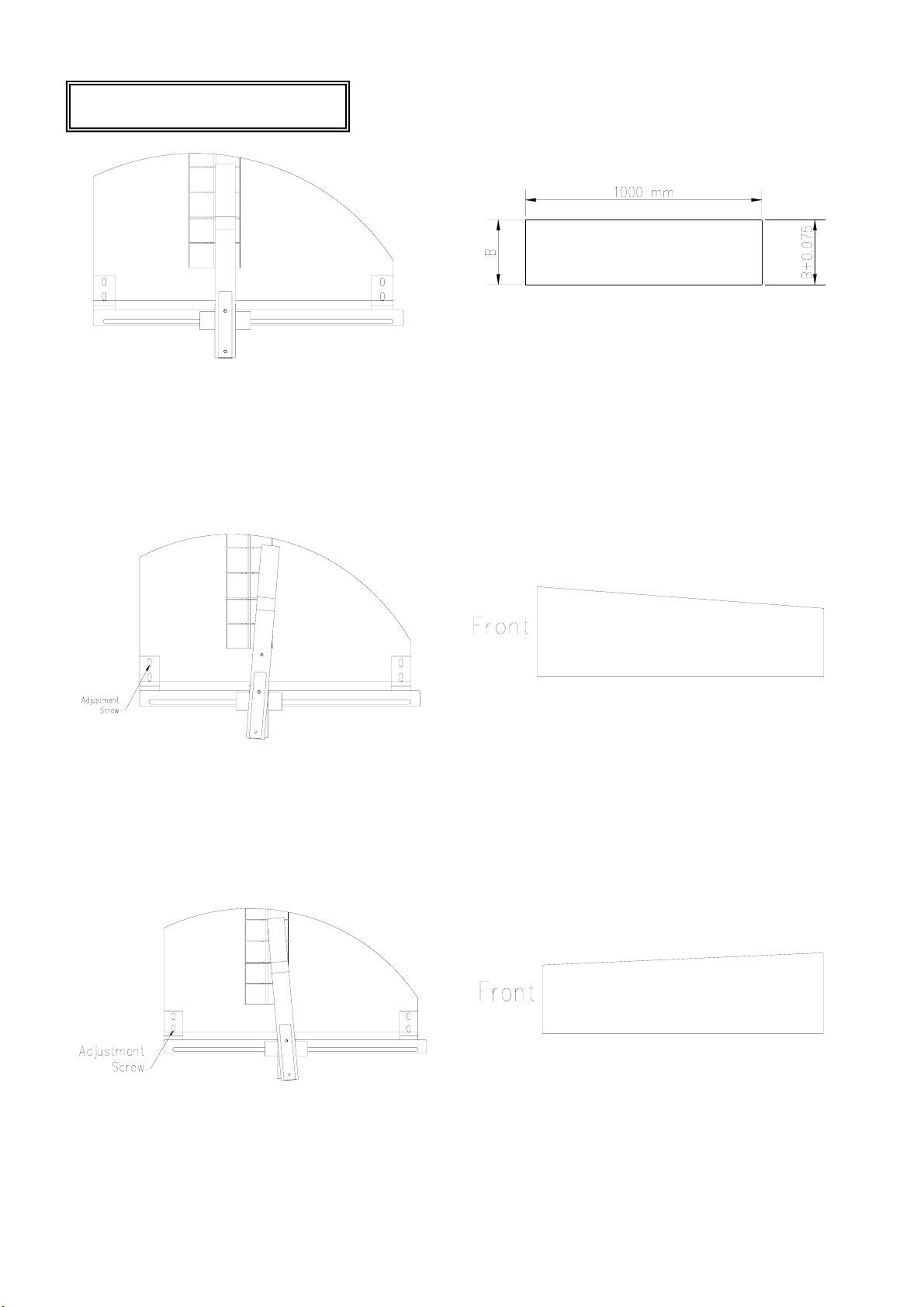

Cutting alignment

Correct alignment:

Cutting line must be parallel to fence.

Cut Result

If the cutting line is parallel, the width

difference after cut between the front

and rear end is ±0.075 mm tolerance

is acceptable.

Cut Result

Improper alignment:

Fence is not parallel; it moves to the right side.

Cut Result

Improper alignment:

Fence is not parallel; it moves to the left side.

10

Page 11

Replacin

g

1. Disconnect the machine from the power source;

verify that the machine has come to a full stop.

2. Loosen the saw arbor lock lever (1), open the cover

of the pressure mechanism; raise the saw arbor by

turning hand wheel (2) until the teeth are 5-10mm

higher than the caterpillar.

3. Insert the saw arbor wrench into the spindle shaft (3);

rotate the saw blade clamp screw with the T-wrench

(4).

4. Remove the saw blade flange and screw; these

procedures will allow the loading or unloading of the

saw blade.

5. Clean the inner sides of machine, the saw blade and

the washer; before replacing with a new saw blade.

6. Reverse the above procedure after blade has been

properly installed.

7. Remove T-wrench and saw arbor wrench.

8. The saw blade teeth should be 0.5-1.5mm lower than

the caterpillar.

9. Always keep the saw blade sharp in order to reduce

the cutting load and ensure the service life of the

machine.

saw blade

Figure 1

SHAPES AND FEEDINGS OF WOOD

1. The proper method for feeding curved wood is

illustrated in Fig.2 when curved wood is fed with its

curve upwards refer to Fig.3 the pressure rollers on

both sides of the saw will block and the marginal part

of wood will most commonly pop out.

2. If curved wood needs to be cut along the curve; it

must be placed with its curve upwards as illustrated

in Fig.4 if positioned otherwise to be fed; the pressure

rollers will not function smoothly and precision of the

object will not result in satisfactory work. Fig.5

illustrates an improper method of feeding.

3. If the outer covering of wood is to be processed,

(Fig.6) it must be fed into the machine with the

covering facing up. Unsatisfactory results will be

achieved if the outer covering is under pressure from

the rollers. (Fig.7)

Figure 2

Figure 3

Figure 4 Figure 5 Figure 6 Figure 7

11

Page 12

Machine and lubrication

Lubricator should be verifed daily before starting work operations; this will

ensure normal functions at all times. A lubrication failure may cause serious

damage to the machine, if the lubricator is damaged; stop machine operations

immediately in order to prevent damage to the caterpillar.

The lubricator of this machine has been designed with a safety device in

order to ensure a longer service life. When the oil is under the minimum

requirement amount it will shut o the machine immediately, ll up the lubricator

in order to re-start your machine

♦ Interior of oil box must be kept clean at all times.

♦ The track of caterpillar’s chain, must be lubricated at all times this is an

important factor for ensuring the accuracy of the machine.

Never over-ll the oil tank, never use recycled oil.

♦

Oil must be relled after 100 hours of operations, and changed after 200

♦

hours of operation. Insucient oil may cause serious noise and fast

wear of gears; excessive oil into the gear reducer may cause oil

leakage.

♦

Rell the oil in the gear reducer until the level reaches over half of its

full capacity.

♦ Properly clean and dust your machine each time work operations are

completed.

Contents list

♦ 1-pc Tool Box

♦ 1-pc Oil Pot

♦ 1-pc T-Wrench #19

♦ 1-set Open-Ended Wrench

♦ 1-set Hex Wrench Set

♦ 4-pc Screw M16 x 80

♦ 4-pc Nut M16

♦ 4-pc Steel Pad

♦ 1-pc Open Wrench #45

Page 13

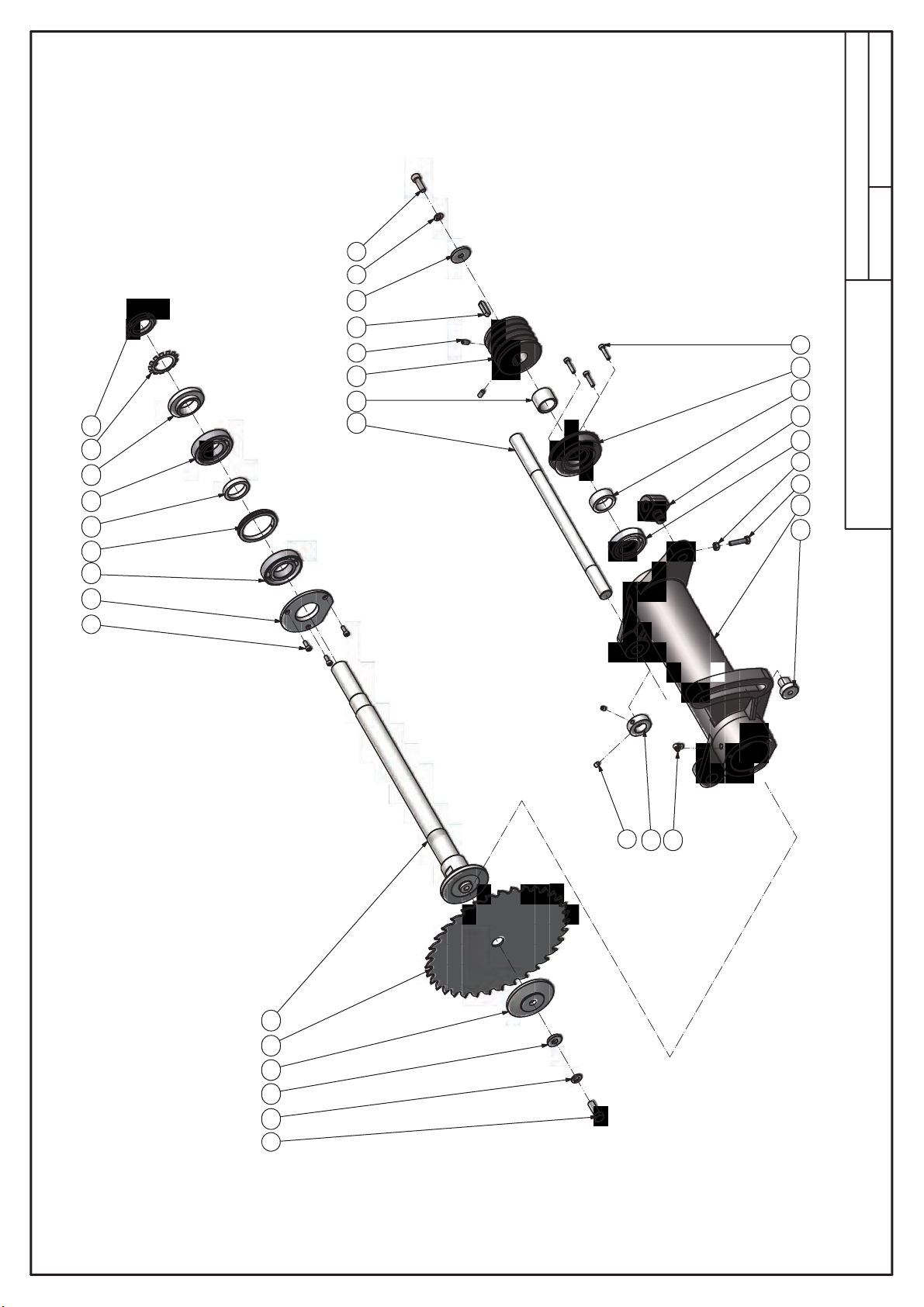

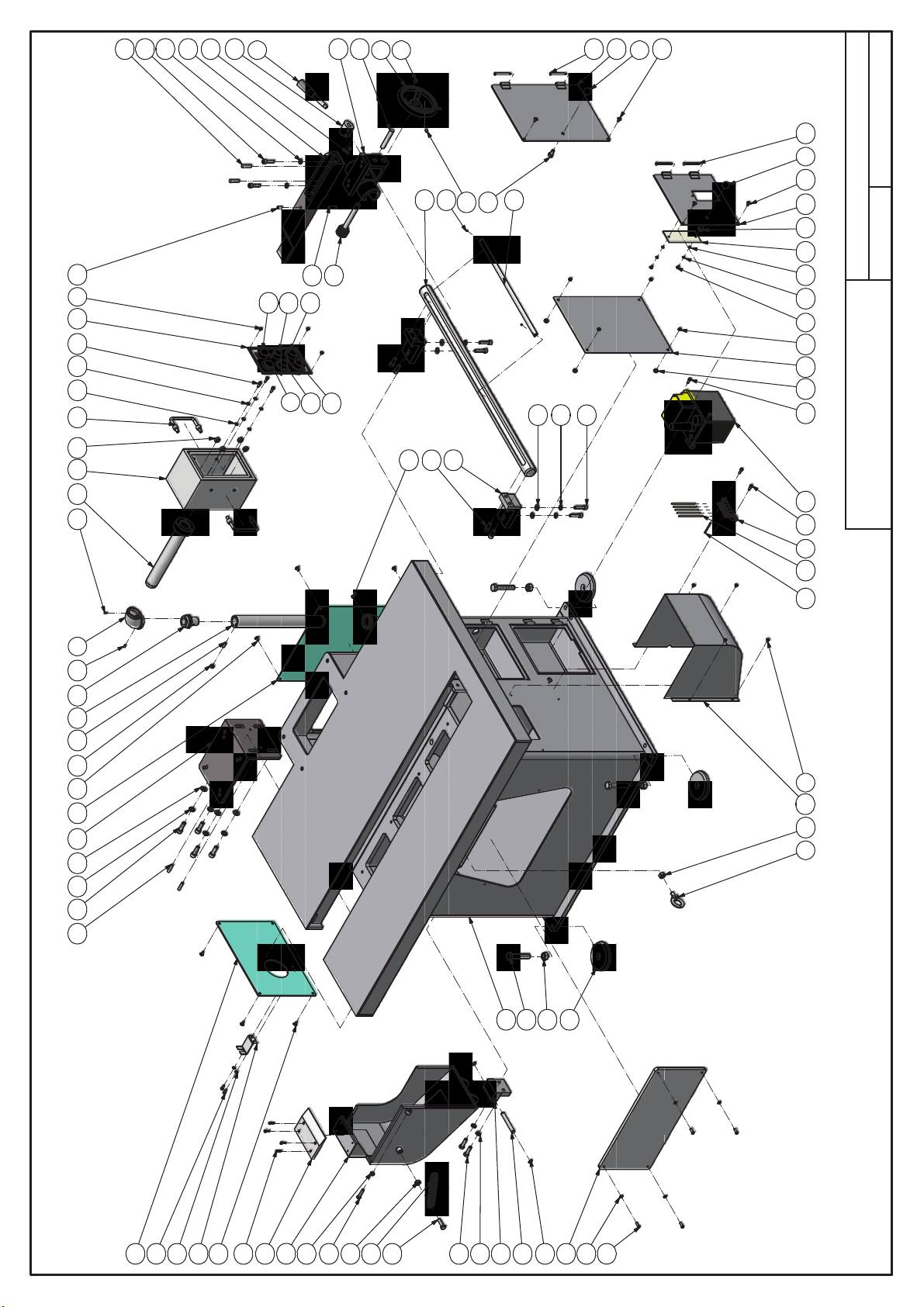

192311

5

Arbor Spindle Assembly

14

19 15

2 17 13 31 32 13

2221

24

20 18 3

29

8 12

7

26 16

30

6 10 28 27 33

4

34

25

Page 14

1

1

1

1recpS3103-SR12

1

1

1

1

1gniR

1

1

1

1

QUANTITY

Arbor Spindle Assembly

DESCRIPTION

PARTS LIST

Shaft

Set Collar

Special Nut

Flat Washer

Pulley, Spindle

Special Washer

Press Plate

Special Nut

Main Spindle

Saw Blade, 12"-48T-4W

Grease Nipples, 1/8"-90

23 RS-3015

22 RS-3014

24 RS-3016

25 RS-3018

27 RS-3020

NO. PART NO.

103-01M ,wercS paC5011201041

361-6M ,wercS paC3501201042

303-6M ,wercS paC7501201043

26 RS-3019

261-8M ,wercS teS250270104

1

2

29 RS-3041

28 RS-3021

1

1

1

32 RS-3059 Ring133 413012108

31 RS-3058

30 RS-3051

1

1

34 410030003

1

1

2

1

1

1

1

1

1tnorF ,reppotS

PARTS LIST

Ball Bearing, 6207-2NK

Set Screw, M8-10

Hex Head Bolt, M12-35

Hex Head Bolt, M8-35

Lock Washer, 12mm

Lock Washer, 10mm

Parallel Key, 10-8-36

Ext Tooth Washer, AW08

Spanner Lock Nut, AN08

Ball Bearing, 7208

Spindle Shaft Box

Cover, Spindle

401160003

12 403017137

13 403020001

401120003

15

14

RS-3003

16

RS-3008 Cover, Front

17

20 RS-3012 Stopper, Rear

18 RS-3009

19 RS-3011

401230022

5

NO. PART NO. DESCRIPTION QUANTITY

4 401072049

7 401010022

6 401010053

8 401101005 Hex Nut, M8

9 401150005

10 401150006

11

Page 15

2

3

13

392640

9

37

41

36

12

40

35

38

9

16

33

19

17

11

43

45

144847

44

Infeed Body Assembly

13

50

42 6

5

21

49146

14

17 10

2

7

15

18

34

28

25

14

4

31 13 13

8

29

23

24

20

27

22

9

163032

Page 16

2

1

1

1

2

1revoC6503-SR24

2

1taeS

1

1

36

1

1

1

1

Infeed Body Assembly

PARTS LIST

Special Ring

Bushing

Special Ring

Special Pin

Spacer

RS-3048

Anti-Kickback Finger

Block

Block

Shaft

RS-7012-4

RS-7013-JET-GR

RS-7015-JET

Adjustable Hand Levers, M12-30

Bracket

Shaft

NO. PART NO. DESCRIPTION QUANTITY

38 RS-3044

1

39 RS-3045

1

40 RS-3046

1

41

4

36 RS-3042 Cover

37 RS-3043

1

2

44

45

43 RS-7011-GR3

4

4

46 RS-7014-JET-GR

252-8M ,wercS paC97022010401

4

7

49 RS-7038-GR

47

48 RS-7016-JET

50 402040005

152-5 ,niP gnirpS20000210452

4

5

661-8M ,wercS teS25017010431

26-6M ,wercS teS33017010421

4

6

5

3

4

1

1

1

223-5 ,niP gnirpS30000210462

1

1

1

1

1

1

1

1

QUANTITY

DESCRIPTION

PARTS LIST

Lock Washer, 8mm

Lock Washer, 6mm

Gear Lever Handles, 1162-M10-125

Wandwheel, D200-20

Set Screw, 3/8-16-3/8

Wandwheel, D200-25

Phillips Head Screw, M5-12

Lifting Eye Bolt, M12

Lock Washer, 12mm

Washer, 12*24

Special Taper Pin, 10-45

Washer, 8*17

Parallel Key, 7-7-18

Eat Tooth Washer, AW04

Spanner Lock Nut, AN04

Thrust Bearing, 51104

Bevel Gear, 30T

Bevel Gear, 14T

Locking Stopper

Shaft

Lead Screw

Lock Seat

Lead Screw

401150006

15

16 401150003

401150004

17

18 401140022

19 401140013

20 401230004

21 401220002

22 403060001

23 401120001

24 401160001

27 RH-2020

RH-2024

28

29 RS-1001 Cover, Gear Box130 RS-1002 Gear Box131

RS-1005

32 RS-1006

33 RS-1008

34 RS-3001-2

35 RS-3040

402010002

1

NO. PART NO.

2 401072133

3 402050002

402050004

4

401271004

5

6 401042004

401021132 Cap Screw, M12-55

7

8 401021030 Cap Screw, M5-16

401022082 Cap Screw, M8-40

9 401022057 Cap Screw, M6-30

11

401071035 Set Screw, M6-10

14

Page 17

371078

34 46

77

48

12

58

43

59

77

16

20

39

27

62

83

25

57

12 76

45

Roll & Frame Assembly

34

10 47

75

25

14

10

84

56

10

48

36

1

15

17

4

54

74

46

13

34

67

44

50

34

47

52

84

56

44

25

15

17

40

19

23

66

38 72 60 71 3213033

2

29 32

8

24

7 28 73 7 28 31 22 61 26 18

64

8

65

29

41

11

42

48

49

52

10

55

36

41

42

55

36

36

1

53

4

1

36

4

54

74

13

36

55

10

51

44

49

53

4

56

84

1

36

36

55

51

50

70 63

5

3582

10

56

84

79356 8180

47

34

67

46

9

68

69

34

44

Page 18

2

3

3

2thgiR ,mrA1102-SR

3

2

2

4

4

2

2

29

1

1

1

1

1

1

1

1

1

1

2

1

1

1revoC7305-SR37

1

2

1

1

1

1

2

1

2

1

2

4

Roll & Frame Assembly

PARTS LIST

Bearing Cover, Right

Bearing Cover, Left

Shaft

Arm, Left

Shaft

Bearing Cover, Left

Bearing Cover, Right

Roller, Left

Shaft

Roller, Right

Anti-Kickback Finger

Shaft

Shaft

Slide Plate

Lock Bar

Chip Funnel

Lock Bar

Back Safety Guard

Knob Screw, M10-20

Knob

Hinge (Big)

Roller

Shaft

Hinge (Small)

Needle

Roller Seat

Roller

Block

Bracket

Bracket, 100mm

Shaft

Wobble Arm

Side Guard

Adjustable Hand Lever, M12-45

Grease Nipples, M6

PART NO. DESCRIPTION QUANTITY

RS-5034

71

69 RS-2096-GR

70 RS-2097-GR

318M ,tuN xeH50010110452

6

36M ,tuN xeH40010110442

RS-6021-JET

RS-6025-JET

RS-7003-JET

RS-8052 Bushing

74

75

77

72 RS-5036

2

4

2

5

78 RS-7037-8

76 RS-6026-GR

2

2

2

81 RS-8054

79

80 RS-8053

82 RS-8055 Bushing283 402040004

84 410030001

2taeS gnirpS2002-SR

1mm55 ,gnirpS eriW

8

6

4

1

1

1

2mm551 ,gnirpS eriW3002-SR24

1

4

1

NO.

RS-2016

RS-2017

RS-2008

47

48 RS-2009

46 RS-2007

4

2

1

RS-2012

49 RS-2010

50

51

261-6M ,wercS daeH nottuB230230104

4

2

RS-2015

52 RS-2013

53 RS-2014

54

302-6M ,wercS paC5502201048

202-8M ,wercS paC8702201049

4

55

17

RS-2022_1

56

57

58 RS-2023-GR

59 RS-2025

202-8M ,wercS teS450270104

4

16-6M ,wercS teS

4

62 RS-2031

60 RS-2029

4

63 RS-2034-GR

61 RS-2030

303-8M ,wercS teS65027010461

4

6

66 RS-2083-1

64 RS-2039

65 RS-2040

67 RS-2094-JET

68 RS-2095-GR

2

2

2

201M ,tuN xeH60010110432

2

QUANTITY

PARTS LIST

Hex Head Bolt, M12-40

Hex Head Bolt, M10-35

Washer, 6.5*25

Phillips Head Screw, M6-12

Phillips Head Screw, M4-30

Phillips Head Screw, M5-12

Button Head Screw, M6-25

Hex Head Bolt, M10-80

Hex Head Bolt, M8-20

Hex Nut, M4

Lock Washer, 12mm

Lock Washer, 5mm

Lock Washer, 10mm

Lock Washer, 8mm

Lock Washer, 6mm

Washer, 8*17

Washer, 6*13

Washer, 4*9

Ball Bearing, 6302-2NSE

Spring Pins, 6-28

Ball Bearing, 6204-2NSE

Ball Bearing, 696-ZZ

Limit Switch TZ7311

Bracket

Roller

401072057 Set Screw, M8-35

10 401071035 Set Screw, M6-10

401071033

12 401071049 Set Screw, M8-10

11

6.5-25-2.0

1

NO. PART NO. DESCRIPTION

401042010

4

2 401042002

3 401042004

401021028 Cap Screw, M5-12

5

6 401032034

7

13 401071052 Set Screw, M8-16

401072055 Set Screw, M8-25

17

15

14

20 401010054

18 401010038

19 401010043

22 401101002

21 401010019

27 401150006

28 401150002

26 401150005

30 401150004

29 401150003

33 401140004

32 401140010

31 401140001

36 403015162

34 403015134

37 401200019

35 403070001

RS-2001-GR2 Roller Seat

38 416040001

39 RS-1007

41

40

RS-2006-GR

RS-2004 Wire Spring, 135mm

43 RS-2003-JO

45

44

Page 19

13

34

41

63

3

65

21

61

4

5

64

60

82

21

45

24

2

46

56

10

46

2

10

55

Table & Stand Assembly

19

9

44

18

40 36

79

29

74

1 20 76

20

77 75

83

50

62

80

80

8

81

81

59

20

12

37

34

14

39 73 2418

39

32 9

33 54

78

18

6

47 48

10 33 23

52 53

35 38

42 15

31

49

26

58

9

66

30

7

17

71

36

57

10

70

27

28

16

33

67

51

25

25

34

68

72

69

43

11

40

Variable Speed + safe protecting cover

Page 20

1

5

4

QUANTITY

DESCRIPTION

PARTS LIST

Shaft, Hinge

Oil Tube, 4x2.5-270

Oil Tube, 4x2.5-700

1

4

1raeG

1

1

Plank, Electrical Box

Bracket

1

1revoCD_2-1004-SR

1

1

2

Stand

Bracket

1

1ecneF

1xoB raeG3RG-9104-SR16

Special Screw

Column Gear

1

1

1

Shaft

1

Setting Block

Cover Plate

1

1

Shaft

Backet

1revoC2305-SR07

1

1

1

1

1

1

1

Switch Box

Bracket

Acrylic Piece

Arm, Control Box

2

1

Arm, Control Box

Lubricator, SMA-602-5FB

"U" Collapsidle Handle, A-42-A-3/8"

25-3# ,teviR20008210428

2NO ,nottuB21001061418

2FFO ,nottuB31001061408

1

Table & Stand Assembly

Electric Power Button

Variable Speed + safe protecting cover

410050005

46 KT02

47

NO. PART NO.

QUANTITY

DESCRIPTION

PARTS LIST

48 410050010

1

1

2

Elbow, 1-1/4PT

Gear Lever Handles, 7108-M12-138

Ball Knobs 1110-25-M10

RS-2100 Tension Spring, 150

50 RS-1033-GR

49 RH-1015 Cast Iron Feet

51

1

1

1

Contactor, Lubrication DB-7

Set Screw, 3/8-16-3/8

Wandwheel, D150

52 RS-3047

1

Lifting Eye Bolt, M12

RS-4001-2_C

53 RS-4001-2_A Cover154

1

10

Phillips Head Screw, M5-8

55

12

Phillips Head Screw, M6-12

RS-4001-2_F Cover

56 RS-4001-2_E Cover157

4

4

Button Head Screw, M6-20

RS-7030-JET

RS-7031-JET-GR Rotation Seat

RS-7032-JET

75

1

76

461M ,tuN xeH

RS-7033-JO

77

4

78 417010001

79 402020004

8

4

68M ,tuN xeH50010110433

Lock Washer, 10mm

Lock Washer, 12mm

83 416010014

253-7 ,sniP repaT10002210424

204-01 ,sniP repaT200022104

5

Lock Washer, 6mm

4

4

4

7

Washer, 5*10

Washer, 10*21

Washer, 12*24

Washer, 6*13

1

1

2

Scale, 480mm

Panel

Retaining Rings For Shaft, S12

RS-5035

58 RS-4001-JO

59 RS-4016

4

253-01M ,wercS paC60112010431

62 RS-4025

60 RS-4017

4

63 RS-4028-GR1

7

221-6M ,wercS paC150220104

461-5M ,wercS paC03022010461

66 RS-5009 Cover

64 RS-4031-GR

65 RS-4032-GR

4

161-01M ,wercS teS56017010491

301-6M ,wercS teS53027010402

69 RS-5019

67 RS-5017

68 RS-5018

2

1

2

Hex Head Both, M10-20

Set Screw, M8-16

72 RS-6008 Cover

71

3

4

Hex Head Both, M16-80

74

73 RS-6013

1

4

101M ,tuN xeH600101104

Hex Head Both, M8-35

K-036

43 401252007

K-026

45

44

402050001

5

6 417020001

401271004

7

401032033

8 416010011 Emergercy Stop

9 401042008

11

10 401042101

12 401021104 Cap Screw, M10-25

401072133

1 410020002

3 402010009

2 402060001

NO. PART NO.

4

401021107 Cap Screw, M10-40

14

401021128 Cap Screw, M12-35

15

18 401021053 Cap Screw, M6-16

17

22 401072052

21 401072049 Set Screw, M8-10

401010038 Hex Head Both, M10-35

24 401010035

23 401072054 Set Screw, M8-20

27 401010022

28

25

26 401010070

29 401101013 Hex Nut, M10 x 1.25

32 401101004 Hex Nut, M6

31 401101012

30 401101007 Hex Nut, M12

34 401150005

35 401150006

36 401150003

37 401140005

38 401140014

39 401140023

40 401140003

41

Page 21

4

3

13

37

30

59

20

57

5

58

55

74

54

20

40

23

2

50

41

10

2 41

10

49

23

Table & Stand Assembly

18

75

67 19 1 19 68 66 7125 36 32 17 39 9

69

45

56

72

72

8

73

73

19

53

12

33

14

30

35 65

35

17

42 43 6 17 70 29 48 28 9

9

60

26

7

38 15 31 34 46 47 10 29 22

27

24

52

44

16

63

32

10

51

16

9

62

61

11

64

36

Variable Speed + standard protecting cover

Page 22

1

1

1revoC

QUANTITY

DESCRIPTION

PARTS LIST

Bracket

Plank, Electrical Box

1

1revoC

1revoCD_2-1004-SR94

1

2

1

Bracket

Stand

1

1ecneF

1xoB raeG3RG-9104-SR

Column Gear

1

Special Screw

Shaft

1revoC1305-SR16

1

1

Setting Block

1

1

Bracket

Bracket

1

1revoC

1

Switch Box

Acrylic Piece

1

1

1taeS noitatoRRG-TEJ-1307-SR76

Arm, Control Box

2

1

Arm, Control Box

Lubricator, SMA-602-5FB

"U" Collapsidle Handle, A-42-A-3/8"

25-3# ,teviR200082104

2NO ,nottuB21001061437

2FFO ,nottuB31001061427

1

Table & Stand Assembly

Electric Power Button

Variable Speed + standard protecting cover

RS-4001-2_A

46 RS-3047

47

NO. PART NO.

QUANTITY

DESCRIPTION

PARTS LIST

48 RS-4001-2_C

1

1

2

Elbow, 1-1/4PT

Gear Lever Handles, 7108-M12-138

Ball Knobs 1110-25-M10

RS-4001-2_F Cover

50 RS-4001-2_E

51

1

1

1

Contactor, Lubrication DB-7

Set Screw, 3/8-16-3/8

Wandwheel, D150

RS-4017

53 RS-4016

54

52 RS-4001-JE

1

1

13

Lifting Eye Bolt, M12

Phillips Head Screw, M5-8

55

12

Phillips Head Screw, M6-12

RS-4028-GR1

56 RS-4025

57

58 RS-4031-GR

59 RS-4032-GR

60 RS-5009 Cover

4

4

Button Head Screw, M6-20

4

4

253-01M ,wercS paC60112010431

421-6M ,wercS paC25012010461

RS-6008

64

301-6M ,wercS teS53027010491

66 RS-7030-JET

65 RS-6013

4

68 RS-7032-JET

2

261-8M ,wercS teS25027010412

1

Set Screw, M8-20

Hex Head Both, M10-20

62 RS-5033

63 RS-5035

7

1

402020004

69 RS-7033-JO

70 417010001

71

1

452.1 x 01M ,tuN xeH31010110452

4

Hex Head Both, M16-80

416010014

74

75

204-01 ,sniP repaT20002210473

5

5

4

6

46M ,tuN xeH400101104

Lock Washer, 12mm

Lock Washer, 10mm

4

4

4

Lock Washer, 6mm

Washer, 12*24

Washer, 10*21

Washer, 5*10

253-7 ,sniP repaT10002210483

7

Washer, 6*13

4

1

1

Shaft, Hinge

Scale, 480mm

Panel

4

1

5

1raeGRG-3301-SR

Oil Tube, 4x2.5-270

Oil Tube, 4x2.5-700

42 410050005

43 410050010

RH-1015 Cast Iron Feet

45

44

402050001

5

6 417020001

401271004

7

401032033

8 416010011 Emergercy Stop

9 401042008

11

10 401042101

12 401021104 Cap Screw, M10-25

401072133

1 410020002

3 402010009

2 402060001

NO. PART NO.

4

401021107 Cap Screw, M10-40

14

401021128 Cap Screw, M12-35

15

18 401071065 Set Screw, M10-16

17

20 401072049 Set Screw, M8-10

22 401072054

23 401010035

24 401010070

27 401101012 Hex Nut, M16428

26 401101007 Hex Nut, M12

29 401101005 Hex Nut, M8

30 401150005

31 401150006

32 401150003

33 401140005

34 401140014

35 401140023

36 401140003

401021053 Cap Screw, M6-16

KT02

39 K-026

41

40 K-036

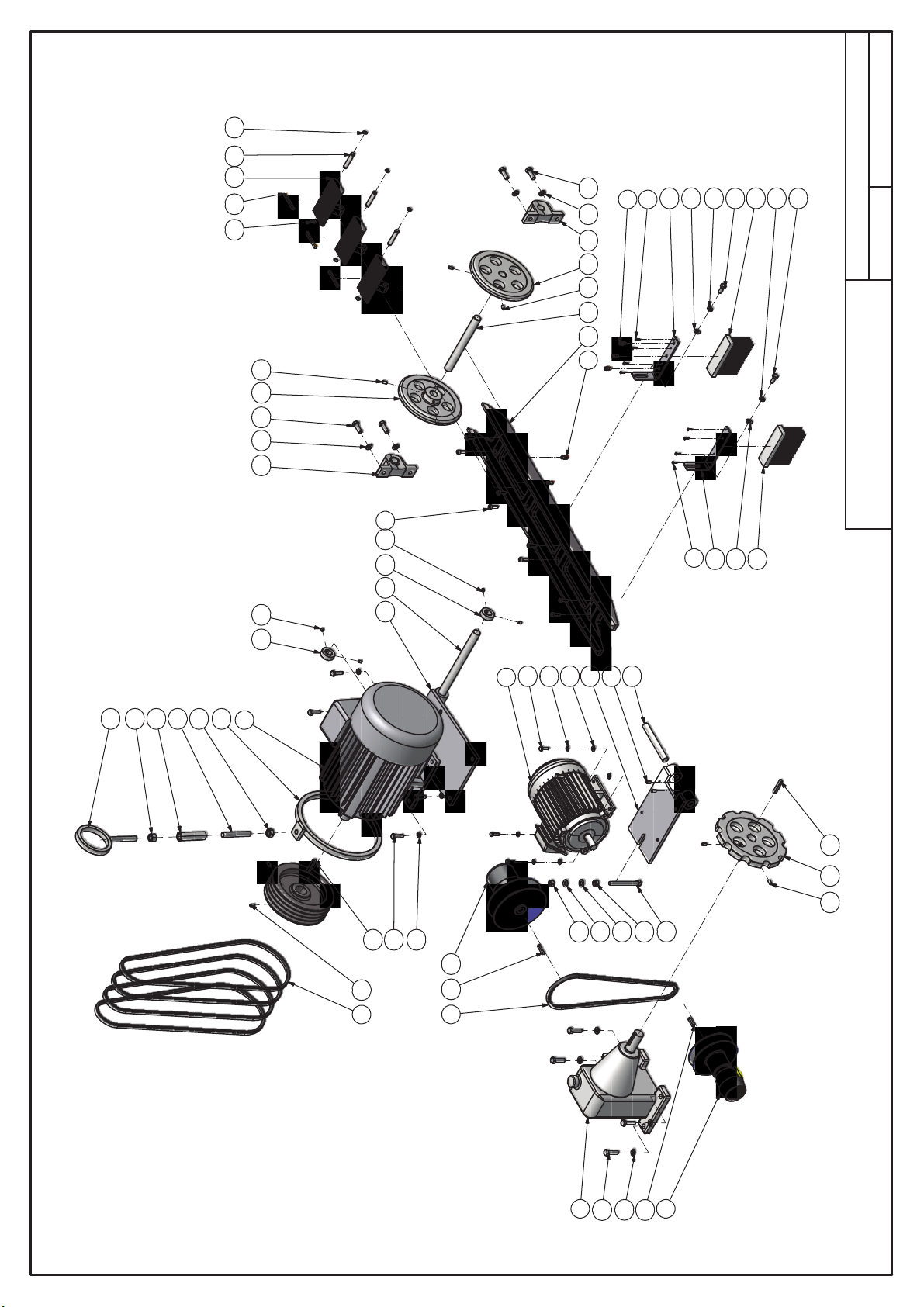

Page 23

29

44

43

45

29

11152152

51

9

32 10

38

10

32

41

15

52 21

51

11

47

42

1

7

1

50

23

20

12

46

12

20

Motor & Drive Unit Assembly

7

49

23

46

4

36

30

33

35

2

19

34

20

26

13

31

11

5

27

3

25

40

17

22

18

39

11

11 48 26

24

18

24

14

8

16

6

21

28

(10+2)HP / (15+2)HP + Variable Speed

Page 24

1

1

1

1

PARTS LIST

Special Bolt, M16-110

Pulley

Shaft

Shaft

1

1

1

38

38

Rail Body

Caterpillar Block

Shaft

1

1

2

38

Brush

Bakelite

1ecarB

Shaft

Sprocket 10T

2

2

1ecarB

Motor & Drive Unit Assembly

Ball Bearing Assembly, UCP205

Idle Wheel

RS-3053 Motor Seat, 10HP

36 RS-3026

37 RS-3028

NO. PART NO. DESCRIPTION QUANTITY

QUANTITY

DESCRIPTION

PARTS LIST

38 RS-3032-JET

1

5

1

Motor, 10HP/15HP

Handy Couplings, 1/8"-4mm

Cog Tooth Belt, 1220VB30-22

41

39 RS-3036

40 RS-3052 Motor Seat, 2HP

4

1

1

V-Bell, A-55

Reducer Pulley, AH2-24

RS-4007

42 RS-4005

43 RS-4006-C

44

852-8M ,wercS paC9702201049

8

1

Phillips Head Sheet Metal Screw, #8-3/4"

Reducer Worm Gear, B-80-1/50

RS-5013

RS-4030-A

46 RS-5007

47

45

48 RS-5022

0161-8M ,wercS teS250270104

2

4

Hex Head Bolt, M10-25

Hex Head Bolt, M10-35

51 RS-5030

50 RS-5029

49 RS-5028

1

Hex Head Bolt, M12-110

52 403100001

6

161M ,tuN xeH21010110491

4

Hex Head Bolt, M12-35

221M ,tuN xeH70010110481

4

4

Hex Head Bolt, M12-40

Hex Head Bolt, M8-25

8

4

2

2

4

Lock Washer, 10mm

Lock Washer, 8mm

Washer, 10*21

Washer, 12*24

Lock Washer, 12mm

Washer, 8*17

1

2

1

Parallel Key, 10-8-56

Parallel Key, 8-7-32

Parallel Key, 7-7-40

1

1

76

Reducer Pulley, PH2-22

Retaining Rings For Shaft, S12

Hex Nut, M16-Left

1

2

Set Collar

1

1

Adjusting Ring

Spec Eye-Bolt

Special Nut, M16-LH/RH

PART NO.

401010053

12 401010036

13 401010039

401011008

14

410010008

1

NO.

90L4P Motor, 2HP

2 132M4P

4

3 405020003

405010002

5

6 405120203

401060001

7

8 406060125

10 401072051 Set Screw, M8-10411

15

16 401010054

401010020

17

20 401150005

21 401150006

22 401150004

23 401140005

24 401140014

25 401140004

26 401230027

27 401230015

401230005

28

29 401252007

30 M 16 - LEFT

31 405120207

32 RS-3018

34 RS-3023

33 RS-3022

35 RS-3024

(10+2)HP / (15+2)HP + Variable Speed

Page 25

OIL

LEVEL

CONTROL

16

R1

OIL

LEVEL

CONTROL

M2

6

SB4

4

12

2

B

S

SB3

M1

5

SB5

T1

7

10

S1

8

D1

PU

2M1M

18

2

L

O

HL2

11

9

S1 D1

T1

OL1

15

R1

17

HL1

PUMP

MAIN

MAIN

FEED

FEEDING

LIGHT

LIGHT

7 2 7

POWER

1

Q

S

3-1

1

B

S

3

U

A

F

3

1

R1

T1

2

HL0

LIGHT

6

11

5

16 12

4

3-1

3

2

Poewr supply: 220V 60HZ 【380V 50HZ】

R1,T1=LASER

*

R1

220V

TC

120VA

220V

【380V】

0.5mm²

R1 T1

T1

0V

0V

1.25mm²

M2

OL2

1.25mm²

W2V2U2

M

3~

M2

PE

ROTOM DEEFROTOM NIAM

1.5KW 2HP

2W2U

V2

U2

8 945 6

1 2 3

7

W2

8 9

V2

5 6

1 2 3

4

7

【220V60HZ】【380V50HZ】

5.5mm²

【3.5mm²】

M1 D1 S1

OL1

5.5mm²

【3.5mm²】

W1V1 1Y1U X1Z1

M

3~

M1

W1

V1

U1

11.25KW 15HP

Y1

Y1X1Z1

U1 V1 W1

Z1 X1

PE

R

S

T

PE

Limit of Equipment

Page 26

2072 Alton Parkway Irvine, CA 92606 U.S.A.

For Customer Service: +1 (949) 474-1200 or email customerservice@lagunatools.com

Laguna Tools is not responsible for errors or omissions. Specifications subject to change. Machines may be shown with optional accessories.

© 2018, Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo® are the registered trademarks of Laguna Tools, Inc. All rights reserved.

825 Bistline Drive, West Columbia, SC 29172 U.S.A

Loading...

Loading...