Dear Craftsman:

Thank you for your purchase and welcome to the Laguna Tools group of

discriminating craftsman. I understand that you have a choice of where to

purchase your machines and appreciate the confidence you have in our

products.

Every machine sold by Laguna Tools has been carefully designed and well

thought through from a woodworker’s perspective. I cut on our bandsaws,

lathes, table saws, combination machines, and CNC routers and Plasma

machines. Through my hands-on experience, I work hard to make our machines

better. I strive to give you machines that inspire you to create works of art;

machines that are a joy to run and work on; machines that encourage your

performance.

Today, we offer high-performance machines with innovative solutions that meet

the needs of Craftsman and their ever-evolving craft.

I started Laguna Tools as a woodworker and craftsman; I still am and more.

Thank you again for becoming a Laguna Tools customer.

Torben Helshoj

President and Founder -Laguna Tools

Imagination, Innovation and Invention at Work.

2

Table of contents.

Page number

Safety Rules 4

Warranty 9

Noise emission 10

Specification sheet 10

Receiving your machine 11

Introduction to your machine 11

Parts of the machine 11

What you will receive with the machine 16

Where to locate your machine 17

Unpacking your machine 18

Assembly and setup 19

Maintenance 30

Troubleshooting 33

Electrical drawing 35

Exploded view drawings 36

3

Safety Rules.

"WARNING": For Your Own Safety Read Instruction Manual before Operating Lathe

(a) Wear eye protection.

(b) Do not wear gloves, a necktie, or loose clothing.

(c) Tighten all locks before operating.

(d) Rotate work piece by hand before applying power.

(e) Rough out work piece before installing on faceplate.

(f) Do not mount split work piece or one containing a knot.

(g) Use lowest speed when starting new work piece.

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS AND WRENCHES. Form habi

and adjusting wrenches are removed from tool before turning it on.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. DON'T USE IN A DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet

locations, or expose them to rain. Keep work area well lighted.

5. KEEP CHILDREN AWAY. All visitors should be kept at a safe distance from

the work area.

6. MAKE YOUR WORKSHOP KID PROOF with padlocks, master switc

or by removing starter keys.

7. DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was

designed.

8. USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not

designed.

9. USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a d

power and overheating. Tabe A shows the correct size to use depending on cord length

and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the chord.

10. WEAR PROPER APPAREL Do not wear loose clothing, gloves, neckties, rings, bracelets,

or other jewelry which may get caught in moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair.

t of checking to see that keys

hes,

rop in line voltage resulting in loss of

Règles de sécurité

"AVERTISSEMENT" : Pour votre sécurité, lire le manuel d'instru on a en vement avant d' liser le tour à bois.

(a) Portez des lune

(b) Ne pas porter de gants, de cravate, ou de vêtements amples.

(c) Serrer tous les verrous avant d'opérer la machine.

(d) Tourner la pièce à la main avant d'appliquer le courant.

(e) Débiter grossièrement la pièce avant de l'installer sur le plateau de montage.

(f) Ne pas monter une pièce fendue ou comportant un nœud.

(g) U

liser la vitesse la plus lente au démarrage d'une nouvelle pièce.

1. CONSERVEZ TOUS LES DISPOSITIFS DE PROTECTION EN PLACE et en bon état de fonc

2. ENLEVEZ LES CLÉS ET OUTILS. Prenez l'habitude de vérifier si les clés et autres ou

machine avant de la démarrer.

3. CONSERVEZ LA SURFACE DE TRAVAIL PROPRE ET LIBRE D'ENTRAVES. Les endroits encombrés augmentent le risque

d'accident.

4. NE PAS UTILISER DANS LES ENVIRONNEMENTS DANGEREUX. N'

humides, détrempés, ou sous la pluie. Conservez l'espace de travail bien éclairé.

5. TENEZ LES ENFANTS À L'ÉCART. Tous les vis

6. RENDEZ L'ATELIER À L'ÉPREUVE DES ENFANTS avec des verrous, des interrupteurs principaux ou en enlevant les clés

de démarrage sur les

7. NE FORCEZ PAS L'OUTIL. L'ou

lequel il a été conçu.

8. UTILISEZ L'OUTIL APPROPRIÉ. Ne forcez pas un ou

conçu.

été

9. UTILISEZ UNE RALLONGE ÉLECTRIQUE APPROPRIÉE. Assurez-vous que votre rallonge électrique est en bon état et

que le calibre du filage soit adéquat pour transporter le courant que la machine a besoin. Une rallonge de trop

faible calibre induira une perte d'intensité du voltage, ce qui provoquera une surchauffe et une perte de puissance.

Le tableau A indique le bon calibre à u

du moteur. En cas de doute, u

fort calibre.

es de protec

ls ne sont pas trop près de la

lisez pas d'ou ls électriques dans les endroits

iteurs doivent être tenus à une distance sécuritaire de l'aire de travail.

l effectuera un meilleur travail et de façon sécuritaire s'il est u lisé au rythme pour

l ou un accessoire pour effectuer un travail pour lequel il n'a pas

liser en fonc on de la longueur de la rallonge et de la demande en intensité

lisez la rallonge de calibre plus fort. Plus le numéro est pe

onnement.

t, plus la rallonge est de

eration is

11. ALWAYS USE SAFETY GLASSES. Also use a face or dust mask if cutting o

dusty. Everyday eyeglasses only have impact resistant lenses, they are NOT safety

glasses.

12. SECURE WORK. Use clamps or a vise to hold the work when practical.

It's safer than using your hand and it frees both hands to operate the tool.

13. DON'T OVERREACH. Keep proper footing and balance at all times.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating

15.

DISCONNECT TOOLS before servicing and when changing accessories, such as blades,

bits, cutters, and the like.

16. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure power switch is in the

and changing accessories.

p

OFF position before plugging the machine in.

17. USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons.

18. NEVER STAND ON TOOL Seriou

tool is unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and

perform its intended function - check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that may affect its operation.

A guard or

20. DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation of

the blade or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave tool

other part that is damaged should be properly repaired or replaced.

s injury could occur if the tool is tipped or if the cutting

until it comes to a complete stop.

10. PORTEZ DES VÊTEMENTS APPROPRIÉS. Ne portez pas de vêtements amples, des gants, des colliers, des bracelets,

ou tout autre bijou ou accessoire qui pourrait être entraîné par des pièces mobiles. Des souliers à semelle

dérapante sont également recommandés. achez les cheveux longs et portez un bonnet pour contenir la

an

chevelure trop abondante.

11. PORTEZ DES LUNETTES DE PROTECTION. Portez également u

dégage de la poussière. Veuillez prendre note que les lune

impacts et qu'elles ne sont pas homologuées à

12. IMMOBILISEZ VOTRE TRAVAIL.

C'est plus sécuritaire que d'u

confortablement.

13. NE VOUS ÉTIREZ PAS AU

14. ENTRETENEZ LES OUTILS AVEC SOIN. Gardez les

performances. Suivez les ins

15. DÉBRANCHEZ LES OUTILS avant d'en effectuer l'entr

couteaux.

16. RÉDUISEZ LES RISQUES DE DÉMARRAGE NON INTENTIONNEL. Assurez-vous que l'interrupteur est

fermée avant le branchement d'un ou

17. UTILISEZ LES ACCESSOIRES RECOMMANDÉS. Consultez le manuel d'instru

recommandés. L'u

18. NE VOUS TENEZ JAMAIS DEBOUT SUR UNE MACHINE. Des blessures graves pourraient survenir si la machine

bascule ou si les

19. VÉRIFIEZ LES PIÈCES ENDOMMAGÉES. Avant de poursuivre l'u lisa on d'un l, tout disposi f de prot ou

toute pièce endommagée devra être inspecté pour déterminer si elle peut fonc

l'u

lisa on qui en est prévue. Vérifiez l'alignement des pièces mobiles à savoir s'il y a blocage, un bris, ou toute

autre co

20. SENS D'ALIMENTATION. Alimentez la pièce vers l

seulement.

21. NE LAISSEZ JAMAIS UN OUTIL FONCTIONNER DANS SURVEILLANCE – ÉTEIGNEZ L'OUTIL. Ne laissez pas l'ou

surveillance jusqu'à ce qu'il s'arrête complètement.

lisa on d'accessoires inappropriés pose des risques de blessures aux lisateurs.

ls coupants sont touchés accidentellement.

on qui nuirait à son lisa on. Une pièce ou un protecteur endommagé doit être réparé ou remplacé.

lisez des serres ou un étau pour immobiliser votre travail lorsque c'est possible.

liser votre main, et ça permet de libérer vos deux mains pour opérer l

-DESSUS DE LA MACHINE. Demeurez solidement en équilibre sur vos pieds en tout temps.

du fabricant pour la lubrifica on et l'entr en des accessoires.

l.

a lame ou le couteau dans le sens contraire de sa rota

n masque contre la poussière si le travail exécuté

es de prescrip ordinaire ne résistent pas aux

re de lune es de sécurité.

ls de coupe tranchants et propres pour en rer les meilleures

en ou lors du changement d'accessoires tels que lames ou

en posi

pour connaître les accessoires

onner correctement et selon

on

l sans

on

4

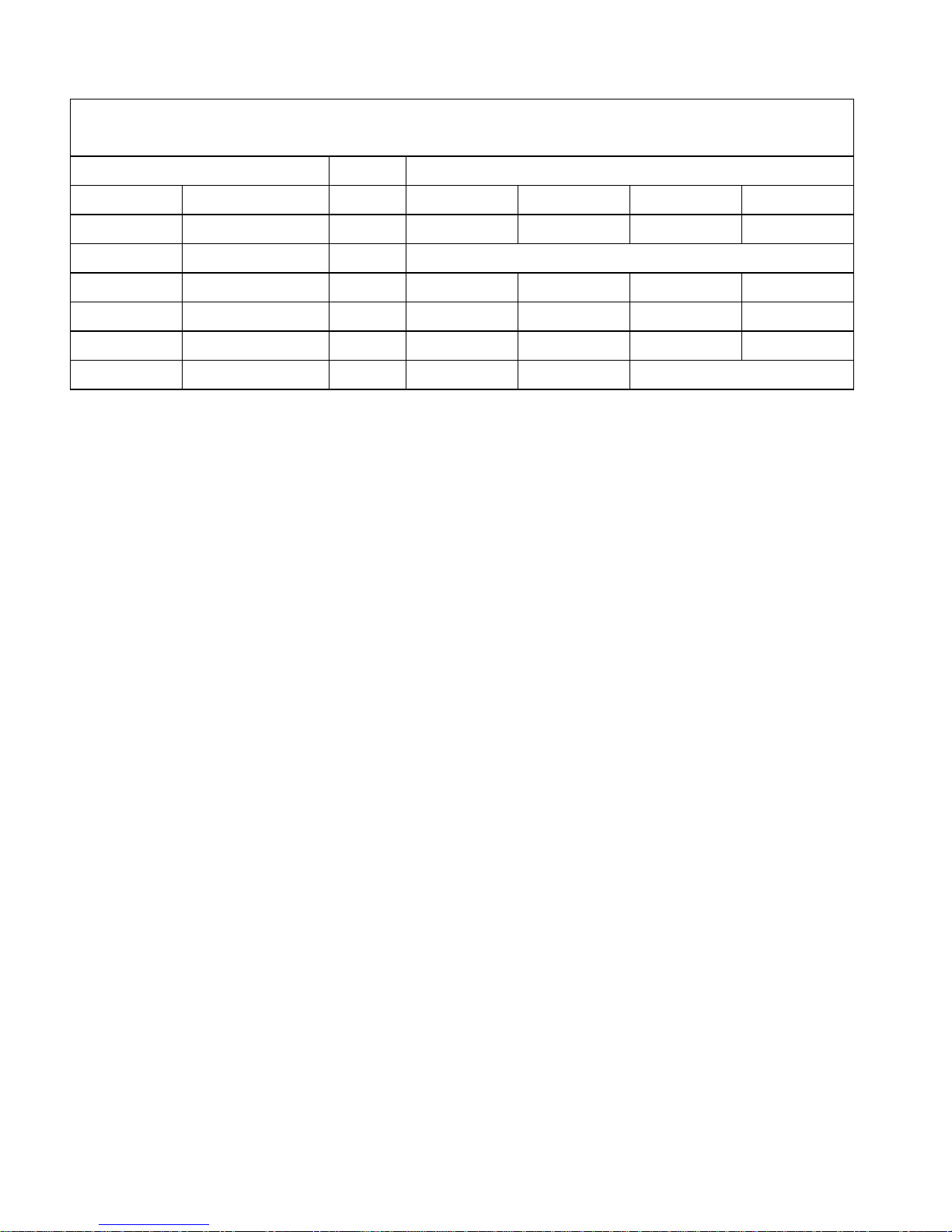

Table A

Ampere Rating Volts Total length of cord in feet

120 25 50 100 150

240 50 100 200 300

More Than Not More Than Minimum gage for cord

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

GROUNDING INSTRUCTIONS

1. All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor

with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding

conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3 pole receptacles that accept the tool's

plug.

Repair or replace damaged or worn cord immediately.

2. Grounded, cord-connected tools intended for use on a supply circuit having a nominal rating less than 150 volts:

This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Sketch A in Fig. 1.

The tool has a grounding plug that looks like the plug illustrated in Sketch A in Fig. 1. A temporary adapter,

which looks like the adapter illustrated in Sketch B and C, may be used to connect this plug to a 2 pole receptacle

as shown in Sketch B if a properly grounded outlet is not available. The temporary adapter should be used only

until a properly grounded outlet can be installed by a qualified electrician. This adapter is not permitted in

Canada. The green-colored rigid ear, lug, and the like, extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box.

3. Grounded, cord-connected tools intended for use on a supply circuit having a nominal rating between 150 – 250

volts, inclusive:

This tool is intended for use on a circuit that has an outlet that looks like the one illustrated in Sketch D. The tool

has a grounding plug that looks like the plug illustrated in Sketch D. Make sure the tool is connected to an outlet

having the same configuration as the plug. No adapter is available or should be used with this tool. If the tool

must be reconnected for use on a different type of electric circuit, the reconnection should be made by qualified

service personnel; and after reconnection, the tool should comply with all local codes and ordinances.

Fig. 1

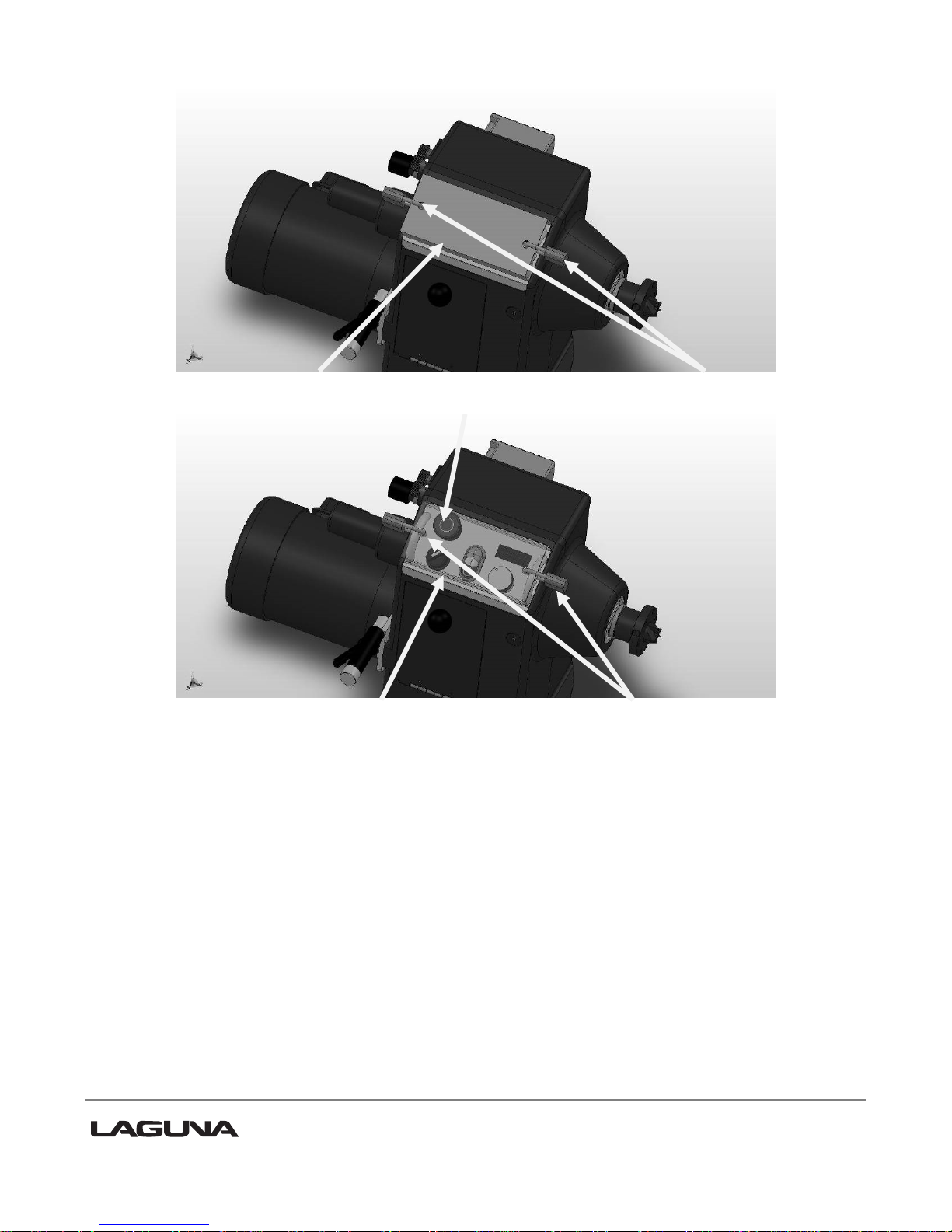

Locking the lathe

It is strongly recommended that the lathe is never be left unattended in the unlocked

condition.

To lock the machine it is recommended that a cover (not supplied) is made to lock the control

panel. We have supplied two concepts for locking the panel (see below). The cover can be

made from wood or plastic.

First, push down the emergency stop. Then lock the cover together by putting padlocks [not

included] on the two handles on the control panel. To safeguard your machine from

unauthorized operation and accidental starting by young children, the use of padlocks is

strongly recommended.

7

Wooden safety cover Padlocks

Emergency stop switch

Plastic safety cover Padlocks

8

Limited Warranty.

New woodworking machines sold by Laguna Tools carry a one-year warranty from the date of

shipping. Laguna Tools guarantees all new machines sold to be free of manufacturer's

defective workmanship, parts, and materials.

We will repair or replace, without charge, any parts determined by Laguna Tools, Inc. to be a

manufacturer's defect. We require the defective item/part to be returned to Laguna Tools. In

the event the item/part is determined to be

damaged due to lack of maintenance, cleaning or misuse/abuse, the customer

will be responsible for the cost to replace the item/part, plus all related shipping charges.

This limited warranty does not apply to natural disasters, acts of

terrorism, normal wear and tear, product failure due to lack of maintenance or cleaning,

damage caused by accident, neglect, lack of or inadequate dust

collection, misuse/abuse or damage caused when repair or alterations have

been made or attempted by others.

Laguna Tools, Inc. is not responsible for additional tools or modifications sold or performed

(other than from/by Laguna Tools, Inc.) on any Laguna Tools, Inc. woodworking machine.

Warranty may be voided upon the addition of such noted tools and/or modifications,

determined on a case-by-case basis.

Normal user alignment, adjustment, tuning and machine settings are not

covered by this warranty. It is the responsibility of the user to understand

basic woodworking machinery settings and procedures and to properly maintain the

equipment in accordance with the standards provided by the manufacturer.

Parts, under warranty, are shipped at Laguna Tools, Inc's cost either by

common carrier, FedEx Ground service or a similar method.

Technical support to install replacement parts is primarily provided by phone, fax, or e-mail.

The labor required to install replacement parts is the responsibility of the user.

Laguna Tools is not responsible for damage or loss caused by a freight company or other

circumstances not in our control.

Only new machines sold to the original owner are covered by this warranty.

For warranty repair information, call 1-800-332-4094.

9

Noise Emission.

Notes concerning noise emission:

Given that there exists a relationship between noise level and exposure times, it is not

possible to precisely determine the need for supplementary precautions. The factors

affecting the true level of exposure to operators are clearly the amount of time exposed and

the characteristics of the working environment, such as other sources of dust and noise, etc.,

for example, adjacent machines - in other words, the level of ambient noise. It is possible that

exposure level limits will vary from country to country.

Specification sheet.

Motor Induction,1725RPM, 2 HP 220V Induction,1725RPM, 1.5 HP

110V

Voltage 220v 60hz single phase input, 3

phase output

Recommended

15 amp 15 amp

110v 60hz single phase input 3

phase output

breaker size

Swing over bed 18" (457mm) 18" (457mm)

Swing over banjo 13.5" (343mm) 13.5" (343mm)

Outboard swing

32" (813mm) 32" (813mm)

max

Distance between

36" (914mm) 36" (914mm)

centers

Floor to spindle

41.5"(1054mm) 41.5"(1054mm)

center

Floor to bed height 32.5" with pads (826mm) 32.5" with pads (826mm)

Floor space W60" D26" H47"(1524mm,

660mm, 1194mm)

W60" D26" H47"(1524mm,

660mm, 1194mm)

Tool rest 12" (305mm) 12" (305mm)

Speed range high 135 - 3500 RPM 135 - 3500 RPM

Speed range low 50 - 1300 RPM 50 - 1300 RPM

VFD DeltaS1 variable frequency

drive

Drive belt Poly-groove drive belt with

easy access

DeltaS1 variable frequency

drive

Poly-groove drive belt with

easy access

Spindle 1.25" x 8 tpi right hand thread 1.25" x 8 tpi right hand thread

Spindle taper MT 2 MT 2

Spindle lock Spring loaded Spring loaded

Spindle index 14 / 36 / 48 positions with lock 14 / 36 / 48 positions with lock

10

Headstock &

0.375" dia (9.5mm dia) 0.375" dia (9.5mm dia)

tailstock bore

Tail stock travel 4.5" (114mm) 4.5" (114mm)

Tail stock removal Self- ejecting Self- ejecting

Tailstock tapers MT 2 MT 2

Face plate 3" diameter (76mm) 3" diameter (76mm)

Bed material Steel Steel

Weight (Net / ship) 427/452 lbs (194kg / 206 kg) 425/450 lbs(193/205 kg)

Receiving your machine.

Note. It is probable that your machine will be delivered by a third party. Before you unpack

your new machine you will need to first inspect the packing, invoice and shipping documents

supplied by the driver.

Insure that there is no visible damage to the packing or the machine. You need to do this prior

to the driver leaving. All damage must be noted on the delivery documents and signed by you

and the delivery driver. You must then contact the seller (Laguna Tools) as soon as practical.

If damage is found after delivery, contact the seller as soon as is practical.

Note. It is probable that you will find sawdust within your machine. This is because the

machine has been tested prior to shipment from the factory and or Laguna Tools.

Laguna Tools endeavours to test machines prior to shipping to customers as movement can

take place during transportation. It must be noted that additional machine movement can take

place between Laguna Tools and the end user and some adjustments may have to be

undertaken by the customer. These adjustments are covered in the various sections of this

manual.

Introduction to lathes.

This machine is designed to give you years of safe service. Read this owner's manual in its

entirety before assembly or use.

Parts of the lathe.

The lathe consists of a number of major parts, which are discussed in this manual. Take the

time to read this section and become familiar with the machine.

11

Identification.

There is a plate at the back of the machine

listing all the manufacturing data, including

the serial number, model, etc.

Lathe Bed.

The bed is a machined heavy steel welded construction.

Underside of lathe bed

12

Lathe legs.

The Legs are cast iron, and their heavy construction gives the machine a low center of gravity

and ensures that it is very stable. The legs are supplied with adjustable feet to allow the

machine to be leveled.

Legs with adjustable feet assembled

Head stock.

The head stock is cast iron and houses the variable speed control and motor. The

Spindle can be locked in 14 / 36 and 48 positions.

Headstock removed from the bed

Headstock attached to bed

13

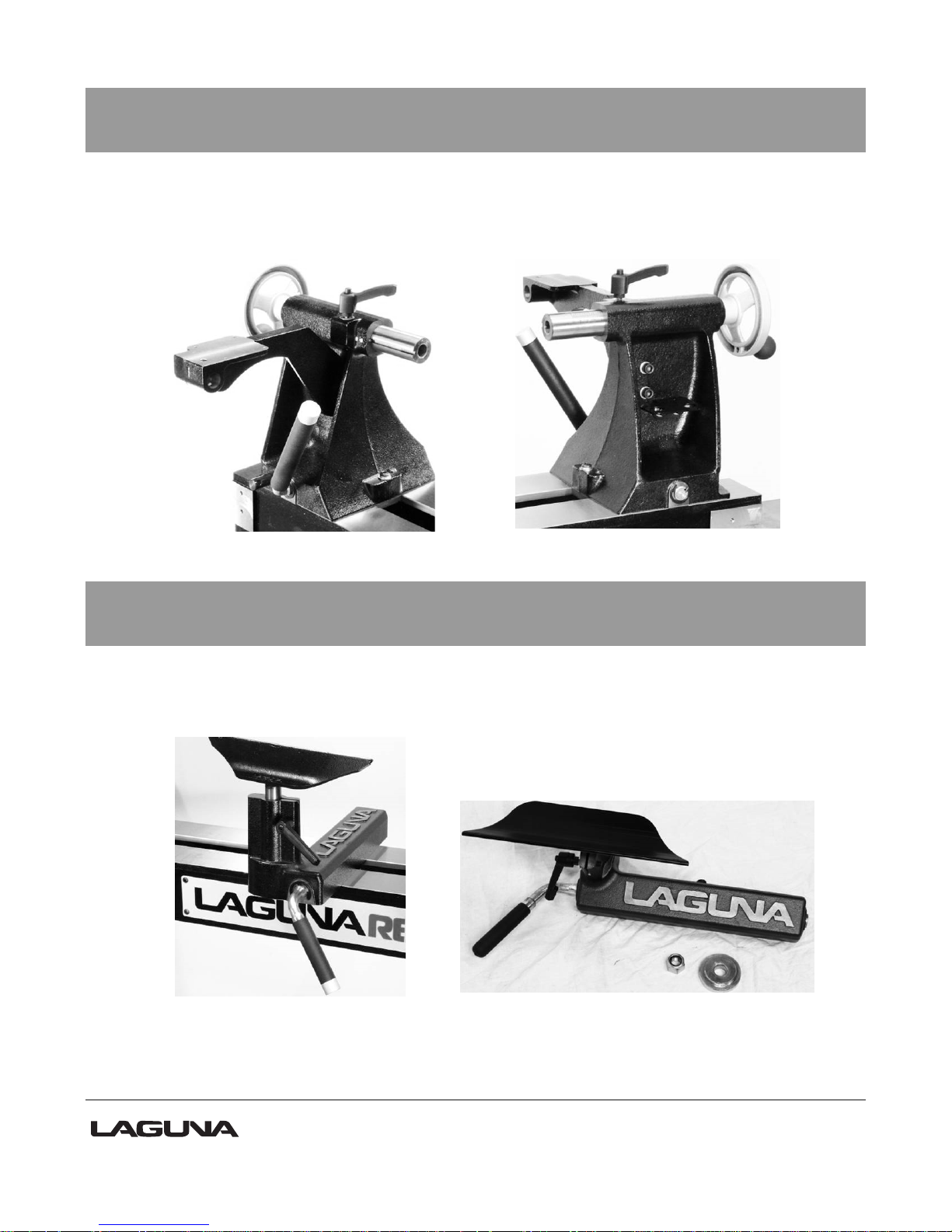

Tail stock.

The tail stock is of cast iron construction, and the spindle has a travel of 4 1/2 in. It can

accommodate centers and other tools which have a number 2 Morse Taper. The tail stock can

be moved to any position on the lathe bed and locked to suit the job at hand.

Tailstock viewed from the back

Tailstock viewed from the front

Tool rest.

The tool rest can be moved to any position on the lathe bed and locked to suit the job at hand.

The tool rest has a tall profile to allow the bowl turner to turn steep angles. The leading edge

is made from 6mm hardened steel.

Tool rest assembled to the bed

Tool rest

14

Electrical system.

220V: The electrical control system (VFD) is housed at the back of the head stock, The VFD

converts single phase 220v to three phase. There is a speed readout at the front of the lathe

with controls to fine adjust the RPM of the spindle. . A power cord with 220V plug is provided.

110V: The electrical control system (VFD) is housed at the back of the head stock, The VFD

converts single phase 110v to three phase. There is a speed readout at the front of the lathe

with controls to fine adjust the RPM of the spindle. A power cord with 110V plug is provided.

VFD with cover open

Power cord

Tool storage.

A tool storage bracket which can be mounted on

either leg.

Tool storage bracket

15

What you will receive with the lathe.

Head stock Tool rest Tail stock Drive &live center storage

Tool storage Leg Bed Banjo Adjustable feet Leg

16

Face plate Tool rack Rotating center Adjustable feet Tail stock bracket

Removal tool Drive center Knock out rod Head stock bracket

Tail stock knob Tool rest comes fitted to banjo

Where to locate your machine.

Before you remove your machine from the packaging, select the area where you will use your

machine. There are no hard and fast rules for its location, but below are a few guidelines:

1. There should be sufficient area at the front of the machine to allow you to work on it

comfortably.

2. There should be sufficient area at the back of the machine to allow access for adjustments

and maintenance to be conducted.

3. Adequate lighting. The better the lighting the more accurately and safely you will be able to

work.

4. Solid floor. You should select a solid flat floor, preferably one made of concrete or

something similar.

5. Locate it close to a power source and dust collection.

6. Allow an area for the storage of blanks, finished products and tools.

17

Unpacking your machine.

To unpack your machine you will need tin snips, a knife, and a wrench.

1. Using the tin snips, cut the banding that is securing the packing box (If fitted). WARNING:

EXTREME CAUTION MUST BE USED, BECAUSE THE BANDING WILL SPRING AND

COULD CAUSE INJURY.

Lathe in packaging

Leg Parts of the lathe

Second leg

Top packaging removed

2. Open the box and remove the parts sent with the lathe including the first leg.

Note. The legs are heavy and caution must be exercised. They are cast iron and if dropped

they will break.

3. Remove the top packaging and remove the second leg.

4. Remove the lathe bed. It is recommended that it be lifted with a hoist or forklift using a

"sling". as it is very heavy.

18

Note. The machine is heavy. Ensure that you have enough people to do the job safely.

Note. If you have any doubt about the described procedure, seek professional assistance.

Do not attempt any procedure that you feel is unsafe, or that you do not have the physical

capability of achieving.

5. Lower the bed of the lathe onto 2 stacks of wood. This will allow access to the underside of

the bed.

Assembly and setup.

The machine comes mostly assembled. You will have to assemble the legs, headstock,

tailstock, tool storage and the tool rest to the bed of the machine.

Note. It is recommended that the head stock, tool rest and tailstock be removed from the bed

of the lathe to ease assembly (Covered later in the manual).

Assembling the legs to the bed of the lathe.

There is a stop at both ends of the bed. The stop is a safety feature that makes

it impossible for the headstock or tailstock to slide off the end of the bed.

Remove the stops and loosen the clamps on both the head stock, tool rest and tailstock.

Slide them off the bed. This will greatly reduce the weight of the bed and allow easier

assembly.

Note : The headstock and tailstock are very heavy and extreme caution must be exercised

when removing them from the bed of the lathe. Take care not to cause damage during

removal.

19

Stop

Tailstock clamp handle

Bed with headstock and tailstock

removed

Leg fixing screws Bed Leg

Lay the bed on 2" X 4" timbers in the upside down position.

Lift the legs to the vertical position and lower them onto the

bed. Secure with the fixing screws provided.

Note. At least two people will be needed to perform the

assembly, one to hold the leg in position and one to fit the fixing

screws.

Note. If you have any doubt about the described procedure,

Leveling foot

seek professional assistance. Do not attempt any procedure

that you feel is unsafe, or that you do not have the physical capability of achieving.

Fit the 4 leveling feet to the lathe legs with the lock nut on the underside of the leg.

Once both legs have been fitted turn the assembly up to the correct position.

20

Assemble the head stock, tool rest and tailstock back onto the bed of the lathe and fit the

stops.

Note. If you have any doubt about the described procedure, seek professional assistance.

Do not attempt any procedure that you feel is unsafe, or that you do not have the physical

capability of achieving.

Assembled lathe

21

If you decide to fit the tool rest after fitting the tail stock, follow the below procedure.

Fit the tool rest onto the bed of the lathe ensuring that the washer recess fits into the slot in

the bed.

Fit the banjo onto the bed with the bolt through the washer and assemble the nut onto the

thread.

Adjust the nut so that the clamp handle locks the banjo with approximately 30 degree of

movement.

Tool rest unassembled

Washer

Tool rest clamp handle

Washer assembled in position

Banjo clamp handle

22

Fitting the stock knob.

Screw the tail stock knob onto the tail stock

handle.

Tail stock knob

Tail stock handle

Connecting the electrical supply.

Ensure that the electrical supply corresponds with that of

the machine (Single phase 220V or 110V).

It is recommended that you use a 15-amp main breaker.

Note. A qualified electrician must carry out the

installation.

Electrical cable

Cleaning the machine.

Remove the rust protection grease with WD 40 or a similar solvent.

It is important that you remove all the grease and re-lubricate with a Teflon-based lubricant.

(Teflon has a lower tendency to attract sawdust and cause clogging).

23

Fitting the rotating center.

Ensure that the bore of the tail stock is clean. The rotating

Rotating center

center has a number 2 Morse Taper that fits into the tail

stock.

Push the center into the tail stock bore firmly, and ensure

that it is securely located. To remove the center, rotate the

adjusting handle until it is as far back as possible and this

will eject the center.

Fitting the drive center into the head stock.

To remove the face plate from the head stock spindle, insert the

removal tool into the hole in the face plate large diameter. Lock the

spindle with the lathe spindle lock and unlock the face plate by rotating

it. Take care not to drop the faceplate onto the bed of the lathe.

Note. The face plate has a left-hand thread.

Adjusting handle

Spindle lock Face plate hole

Removal tool

Lathe spindle lock

24

Drive center removal shaft

Headstock drive center

Ensure that the bore of the head stock is clean. The drive center has a number No. 2 Morse

Taper that fits into the head stock

Push the center into the head stock bore firmly, and ensure that it is securely located.

To remove the center, push the removal shaft into the back of the head

stock, and give it a sharp knock. This will remove the drive center.

Note. Never leave the removal shaft in the head stock with the machine running.

Fitting the face plate.

Reverse the removal procedure, described earlier.

Lathe controls.

Emergency stop button

The emergency stop button will lock in the OFF position when fully depressed.

To reset it, twist clockwise and it will pop out.

Forward / reverse switch.

The forward / reverse switch selects the direction of the rotation of the spindle.

The forward / reverse switch must only be used once the spindle has come to a

complete stop.

Start / Stop buttons.

The start / stop buttons start the motor and the rotation of the spindle.

Speed display.

The speed display shows the RPM of the spindle.

Variable speed adjustment knob.

The Variable speed adjustment knob adjusts the spindle speed.

25

Emergency stop button Start / stop buttons Speed display

Forward / reverse switch Variable speed adjustment knob

Head stock clamp lever.

The head stock clamp lever allows the head stock to be released and moved to any position

on the lathe bed. It is located at the back of the head stock.

Head stock clamp lever

26

Variable speed adjustment knob.

Increase speed Decrease speed

The Variable speed adjustment knob adjusts the spindle speed. Turns clockwise to increase

the speed, turns counter-clockwise to decrease the speed

High / low speed.

The lathe has two sets of pulleys for high (135 - 3500 RPM ) and low

(50 - 1300 RPM) speed ranges.

Adjust between the speed ranges as follows.

1. Disconnect the electric supply to the lathe.

2. Open the pulley cover.

3. Loosen the motor lock handle and lift the motor to the highest

position with the motor adjustment handle, then lock the motor lock

handle.

4. Move the drive belt to the required set of pulleys.

Speed range

5. Loosen the motor lock handle and with the motor adjustment handle tension the drive belt,

then lock the motor lock handle.

The belt should be tensioned so that there is approximately 1/8 to 1/4 " deflection when the

belt is pressed with moderate thump pressure.

27

Pulley cover

Pulleys and drive belt

Motor lock handle Motor adjustment handle

Indexing the spindle.

The spindle has 3 sets of indexing holes 14 / 36 / 48. The selection plunger is located at the

end of the head stock. To move between the 3 sets of holes, loosen the clamp knobs and

slide the indexing plunger assembly to align with the selected hole set. Clamp in position with

the clamp knobs. Try the plunger in a few different holes to check that it inserts and removes

smoothly.

The indexing plunger is spring loaded and this is used only to temporarily align the plunger in

the selected hole.

To fix the plunger in a selected hole, it must be attached to the housing by screwing into the

clamped position.

There is a hole selection indicator that allows you to view which hole in a selected hole set

has been selected.

28

Indexing holes

Clamping knobs

Hole selection indicator

Hole selection Indexing plunger

Indexing plunger engaged

Indexing plunger disengaged

29

Maintenance.

General.

Keep your machine clean. At the end of each day, clean the machine. Wood contains

moisture, and if sawdust or wood chips are not removed they will cause rust.

In general, we recommend that you only use a Teflon-based lubricant on the lathe.

Regular oil attracts dust and dirt. Teflon lubricant tends to dry and has less of a tendency

to accumulate dirt and saw dust.

Periodically check that all nuts and bolts are tight.

Drive belt.

The drive belt should last for many years (depending on the usage) but needs to be inspected

regularly for cracks, cuts and general wear. If damage is found, replace the belt.

Bearings.

All bearings are sealed for life and do not require any maintenance. If a bearing becomes

faulty, replace it.

Rust.

The lathe is made from steel and cast iron. All none-painted surfaces will rust if not protected.

It is recommended that they be protected by applying wax or a Teflon- based lubricant to

them.

Center point alignment and slide

clearance adjustment.

The center point alignment and slide

clearance are adjusted at the factory and no

adjustment should be required.

Should movement or wear have taken place,

the following adjustment procedure should

be conducted.

Note. The slide clearance of the headstock

and the tailstock must be checked and

adjusted should it be needed prior to

adjusting the center point alignment.

Center points aligned

Slide adjustment.

Loosen the clamp handle on the tailstock and check for side movement.

If it is excessive, Insert an Allen key into the adjusting screw and tighten.

Note. By rotating the adjustment screw, it moves into the adjusting slot which opens and

removes the excessive clearance between the tailstock and the bed.

Note . Only make very small adjustments and then recheck the clearance. After adjustment

30

the tailstock should be slid along the bed to check for any area that it binds in the bed slot.

The same procedure as above should be conducted on the head stock should it be required.

Note. It is very unlikely that the headstock will require adjustment as it is not moved as often

as the tailstock, so has less tendency's for ware.

Adjustment slot

Adjustment slot

View under the tailstock

View under headstock

Clamp screw Adjusting screw

31

Center point alignment.

The tailstock has two clamp screws that are accessible from the top of the tailstock.

The clamp screws hold the slide plate to the tailstock casting. There is clearance in the holes

that allows the tailstock to be moved in relation to the slide plate. The headstock also has two

clamp screws, but one is accessible from under the

headstock.

By loosening the clamp screws the headstock and

tailstock can be moved and the center points aligned.

Note. It is recommended that the head stock be adjusted

and not the tail stock. If the tail stock is not adjusted

parallel to the bed slide, the center point will not be in

alignment when the spindle is extended or retracted.

1. Loosen the clamp screw that is accessible from the top

on the head stock.

2. Tap the side of the headstock with a rubber mallet

close to the base in the direction requiring adjustment

and retighten the clamp screw.

3. Recheck the center point alignment and repeat if

required.

Headstock clamp screw

Note. Never hit any part of the lathe that is cast iron with

a metal hammer or similar as it will break the casting.

32

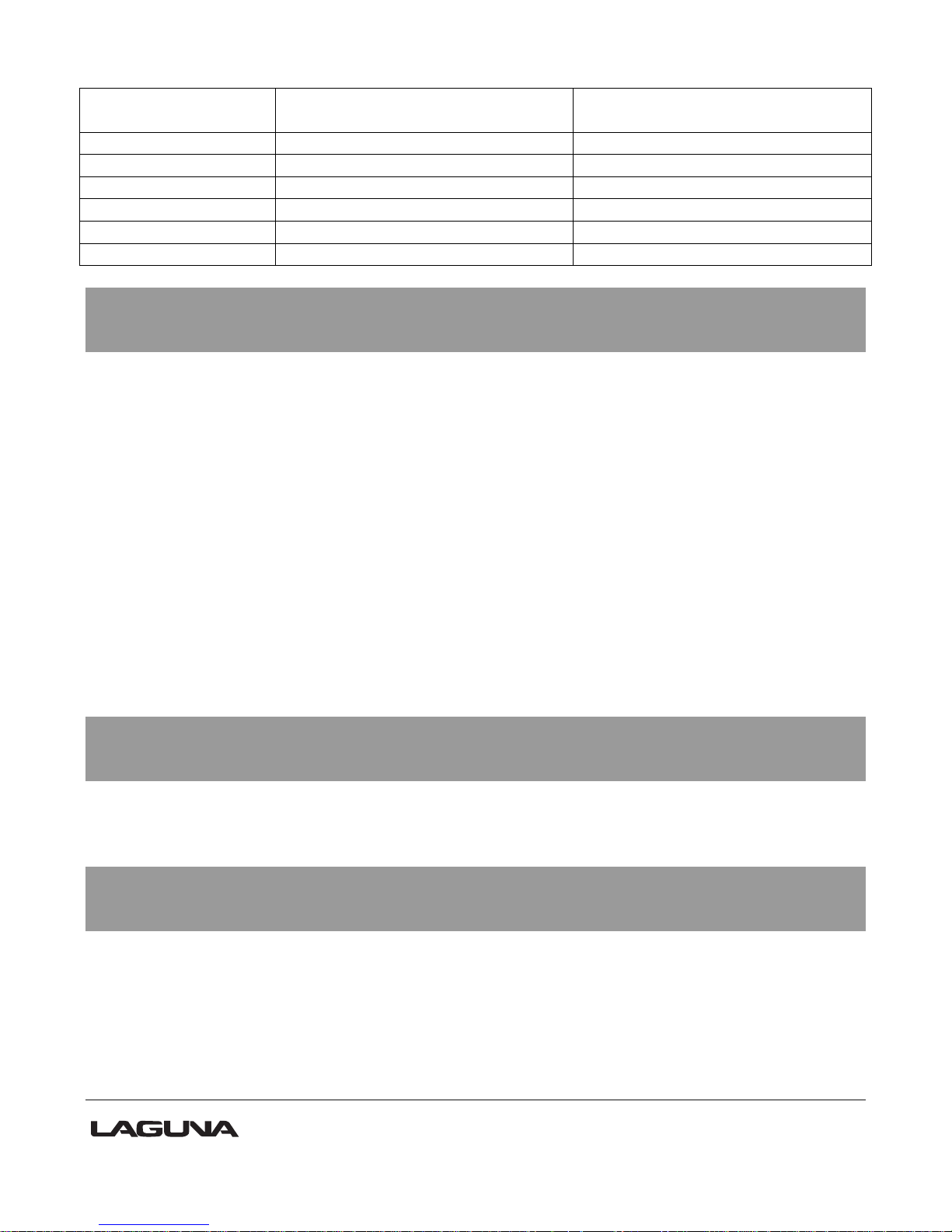

Troubleshooting.

Lathe will not start.

1. Check that the start switch is in the correct position.

2. Check that the electrical power cord is plugged into the power outlet.

3. Check that the electrical supply is on (reset the breaker).

4. With the power disconnected from the machine, check that the wiring to the plug is correct.

Check that the rubber insulation is stripped enough and is not causing a bad connection.

Check that all the screws are tight.

5. Emergency stop button engaged. Reset emergency stop button. Twist and it will pop out.

The machine will not stop.

This is a very rare occurrence as the machine is designed to be fail-safe. If it should occur

and you cannot fix the fault, seek professional assistance. The machine must be

disconnected from the power and never run until the fault has been rectified.

1. The stop switch is faulty. Replace the stop switch.

Motor tries to start but will not turn.

1. With the power disconnected from the machine, try to turn the spindle by hand.

If the spindle will not turn, check the reason for jamming.

2. Capacitor faulty. Replace the capacitor.

3. Motor faulty. Replace the motor.

4. Power line overloaded. Correct overloaded condition.

5. Low voltage. Correct low voltage condition.

Motor overheats.

The motor is designed to run hot, but should it overheat it has an internal thermal overload

protector that will shut it down until the motor has cooled, and then it will reset automatically.

If the motor overheats, wait until it has cooled and restart. If the motor shuts down consistently

check for the reason. Typical reasons are dull cutting tools, the motor cooling fan being

clogged or faulty, the motor cooling fins are clogged, overfeeding the job, and excessive

ambient temperature.

Squeaking noise.

1. Check that the motor cooling fan is not contacting the fan cover.

2. Check the bearings.

3. Check the drive belt is tensioned correctly.

Spindle slows down during a cut.

1. Dull cutting tools. Replace the tool or have it re-sharpened.

2. Feeding the wood too fast. Slow down the feed rate.

3. Oil or dirt on the drive belt. Clean or replace the drive belt.

4. Drive belt loose. Re-tension drive belt.

33

Machine vibrates.

1. Machine not level on the floor. Re-level the machine ensuring that it has no movement.

2. Damaged drive belt. Replace the belt.

3. Job is not balanced. Change to slower speed and/ or balance the job.

4. Damaged pulley. Replace the pulley.

5. Worn spindle bearing. Replace the bearing.

34

Electrical drawing.

35

Exploded view drawings and parts list.

36

37

REVO 18│36 LATHE

Index

Part Number

Item Description

Specification

Qty

1

PLAREVO1836-101

Bed

1 2 PLAREVO1836-102

Spindle Pulley

1 3 PLAREVO1836-103

Spring

1 4 PLAREVO1836-104

Spindle Lock Plunger

1 5 PLAREVO1836-105

Locking Collar

1 6 PLAREVO1836-106

Bearing Nut

1 7 PLAREVO1836-107

Door

1 8 PLAREVO1836-108

Tailstock

1 9 PLAREVO1836-109

Motor Pulley

1

10

PLAREVO1836-110

Motor Plate

1

11

PLAREVO1836-111

Headstock Locking Handle

1

12

PLAREVO1836-112

Headstock

1

13

PLAREVO1836-113

3" Faceplate

1

14

PLAREVO1836-114

Clamp Bolt

3

15

PLAREVO1836-115

Sleeve

2

16

PLAREVO1836-116

Rubber Sleeve

2

17

PLAREVO1836-117

Knob

1

18

PLAREVO1836-118

Headstock Adjusting Plate

1

19

PLAREVO1836-119

Clamp

2

20

PLAREVO1836-120

Lock Handle

1

21

PLAREVO1836-121

Control Panel

1

22

PLAREVO1836-122

Handwheel

1

23

PLAREVO1836-123

Motor 2HP

1

PLAREVO1836-110-150123

Motor 1.5HP

1

24

PLAREVO1836-124

Spur Center

1

25

PLAREVO1836-125

Spindle

1

26

PLAREVO1836-126

Index Stud

1

27

PLAREVO1836-127

Index Shaft

1

28

PLAREVO1836-128

Index Bracket

1

29

PLAREVO1836-129

Spring

1

30

PLAREVO1836-130

Spring

1

31

PLAREVO1836-131

Index Plate

1

32

PLAREVO1836-132

Disc, Spindle Lock

1

33

PLAREVO1836-133

Index Bolt

1

34

PLAREVO1836-134

Index Knob

1

38

35

PLAREVO1836-135

Tool Rest Support Base

1

36

PLAREVO1836-136

Cord Holder

1

37

PLAREVO1836-137

Tool Rest Locking Handle

1

38

PLAREVO1836-138

12" Tool Rest

1

39

PLAREVO1836-139

Leg

2

40

PLAREVO1836-140

Lock Handle

1

41

PLAREVO1836-141

Handwheel

1

42

PLAREVO1836-142

Quill

1

43

PLAREVO1836-143

Tailstock Locking Handle

1

44

PLAREVO1836-144

Live Center Assembly

1

45

PLAREVO1836-145

Tailstock Adjusting Plate

1

46

PLAREVO1836-146

Lead Screw

1

47

PLAREVO1836-147

Stop Bolt

3

48

PLAREVO1836-148

Key

1

49

PLAREVO1836-149

Quill Lock Sleeve

1

50

PLAREVO1836-150

Tool Caddy

1

51

PLAREVO1836-151

Knockout Rod

1

52

PLAREVO1836-152

Braking Resistor Cord

1

53

PLAREVO1836-153

Lock Handle

1

54

PLAREVO1836-154

Control Box

1

55

PLAREVO1836-155

Control Cord

1

56

PLAREVO1836-156

Tailstock Tool Caddy

1

57

PLAREVO1836-157

Hex Cap Screw

M6x6

4

58

PLAREVO1836-158

Door Hinge

1

59

PLAREVO1836-159

Speed Knob

1

60

PLAREVO1836-160

Rubber Sleeve

2

61

PLAREVO1836-161

Rubber Bushing

1

62

PLAREVO1836-162

Bottom Cover

1

63

PLAREVO1836-163

Inverter 220V

1

PLAREVO1836-110-150163

Inverter 110V

1

64

PLAREVO1836-164

Braking Resistor

1

65

PLAREVO1836-165

Screw

M4x12

1

66

PLAREVO1836-166

Digital Readout

1

67

PLAREVO1836-167

Digital Readout Sensor

1

68

PLAREVO1836-168

Screw

M3x20

2

69

PLAREVO1836-169

Control Pot Assembly

1

70

PLAREVO1836-170

ON/ OFF Switch

1

39

71

PLAREVO1836-171

Emergency Stop

1

72

PLAREVO1836-172

Spacer

2

73

PLAREVO1836-173

Fwd/Rev Switch

1

74

PLAREVO1836-174

Relay 220V

1

PLAREVO1836-110-150174

Relay 110V

1

75

PLAREVO1836-175

Ball Bearing

6205LLU

1

76

PLAREVO1836-176

Ball Bearing

6207LLU

1

77

PLAREVO1836-177

Pillar

2

78

PLAREVO1836-178

Index Label

1

79

PLAREVO1836-179

Index Indicator

1

80

PLAREVO1836-180

Power Cord 220V

1

PLAREVO1836-110-150180

Power Cord 110V

1

81

PLAREVO1836-181

Knob

1

82

PLAREVO1836-182

Leveling Foot

4

83

PLAREVO1836-183

Bushing

1

84

PLAREVO1836-184

Wave Washer

6205

1

85

PLAREVO1836-185

Key

6x6x30

2

86

PLAREVO1836-186

Key

8x7x25

1

87

PLAREVO1836-187

Key

8x7x60

1

88

PLAREVO1836-188

E-Ring

E19

2

89

PLAREVO1836-189

E-Ring

E15

4

90

PLAREVO1836-190

E-Ring

E5 1 91

PLAREVO1836-191

C-Ring

R22

1

92

PLAREVO1836-192

Socket Head Cap Screw

1/4-20UNCx1"

1

93

PLAREVO1836-193

Hex Cap Screw

3/8-16UNCx1/2"

1

94

PLAREVO1836-194

Socket Head Button Screw

M8x20

2

95

PLAREVO1836-195

Socket Head Cap Screw

3/8-16UNCx1"

1

96

PLAREVO1836-196

Knob

1

97

PLAREVO1836-197

Socket Head Cap Screw

5/16-18UNCx1"

8

98

PLAREVO1836-198

Set Screw

5/16-18UNCx3/8

2

99

PLAREVO1836-199

Set Screw

M8x6

4

100

PLAREVO1836-1100

Set Screw

M4x4

2

101

PLAREVO1836-1101

Set Screw

1/4-20UNCx1/4

3

102

PLAREVO1836-1102

Key

5x5x50

1

103

PLAREVO1836-1103

Screw

M4x15

2

104

PLAREVO1836-1104

Screw

M3x8

8

105

PLAREVO1836-1105

Phillips Flat Head Screw

M3x8

2

40

106

PLAREVO1836-1106

Phillips Flat Head Screw

M6x16

4

107

PLAREVO1836-1107

Screw

M3x4

2

108

PLAREVO1836-1108

Motor Cord

1

109

PLAREVO1836-1109

Flat Washer

D3xD8x1t

2

110

PLAREVO1836-1110

Nylon Insert Lock Nut

M18x2.5

3

111

PLAREVO1836-1111

Hex Nut

3/8-16UNC

4

112

PLAREVO1836-1112

Flat Washer

D10xD23x2t

7

113

PLAREVO1836-1113

Flat Washer

D8xD18x2t

14

114

PLAREVO1836-1114

Lock Washer

5/16"

12

115

PLAREVO1836-1115

Lock Washer

3/8"

5

116

PLAREVO1836-1116

Phillips Flat Head Screw

3/8-16UNCx3/4"

4

117

PLAREVO1836-1117

Strain Relief

7N-2

3

118

PLAREVO1836-1118

Strain Relief

SB2F-1

1

119

PLAREVO1836-1119

Set Screw

1/4-20UNCx3/8

1

120

PLAREVO1836-1120

Socket Head Button Screw

M8x25

1

121

PLAREVO1836-1121

Socket Head Button Screw

M8x45

1

122

PLAREVO1836-1122

Socket Head Cap Screw

5/16-18UNCx1/2"

3

123

PLAREVO1836-1123

Poly-V Belt

PJ8-190

1

124

PLAREVO1836-1124

Set Screw

3/1624UNCx3/16

2

125

PLAREVO1836-1125

Set Screw

5/16-18UNCx1/4

1

126

PLAREVO1836-1126

Socket Head Button Screw

3/8-16UNCx5/8"

2

127

PLAREVO1836-1127

Screw

M3x12

2

128

PLAREVO1836-1128

Spacer

2

129

PLAREVO1836-1129

Handle

2

130

PLAREVO1836-1130

Sensor Bracket

1

131

PLAREVO1836-1131

Phillips Flat Head Screw

M3x4

4

132

PLAREVO1836-1132

Knob

1

133

PLAREVO1836-1133

Screw

M3x4

1

134

PLAREVO1836-1134

Screw

M3x10mm

3

135

PLAREVO1836-1135

Clamp

1

136

PLAREVO1836-1136

Handle, Faceplate

1

137

PLAREVO1836-1137

Logo Plate

1

138

PLAREVO1836-1138

Strain Relief

6N-4

4

139

PLAREVO1836-1139

Bracket

1

140

PLAREVO1836-1140

Thimble

1

141

PLAREVO1836-1141

Socket Flat Head Screw

M3x8

1

142

PLAREVO1836-1142

Cord Holder

1

41

143

PLAREVO1836-1143

O-Ring

P29

1

144

PLAREVO1836-1144

Speed Label

1

145

PLAREVO1836-1145

Cap

4

146

PLAREVO1836-1146

Socket Head Button Screw

1/4-20UNCx3/8"

8

147

PLAREVO1836-1147

Headstock Bracket

1

148

PLAREVO1836-1148

Socket Head Cap Screw

3/8-16UNCx11/4"

2

149

PLAREVO1836-1149

Tailstock Bracket

1

150

PLAREVO1836-1150

Socket Head Cap Screw

3/8-16UNCx3/4"

2

151

PLAREVO1836-1151

Magnet

1

152

PLAREVO1836-1152

Screw

M4x6

2

153

PLAREVO1836-1153

Hex Nut

M4x0.7

1

154

PLAREVO1836-1154

Braking Resistor Cover

1

42

Optional Headstock Guard

Index

1 PLAREVO1836-201 Plunger 1

2 PLAREVO1836-202 Retaining Collar 2

3 PLAREVO1836-203 Guard 1

4 PLAREVO1836-204 Set Screw 1/4-20UNCx1/4" 2

Part Number

Item Description Specification

Qty

43

44

Optional 20" Bed Extension with Riser Block and Tool Rest Extension

Index

1 PLAREVO1836-301 20" Bed Extension 1

2 PLAREVO1836-147 Stop Bolt 2

3 PLAREVO1836-195 Socket Head Cap Screw 3/8-16UNCx1" 3

4 PLAREVO1836-304 Riser Block 1

5 PLAREVO1836-305 Riser Block Locking Handle 1

6 PLAREVO1836-306 Riser Block Adjusting Plate 1

7 PLAREVO1836-119 Clamp 1

8 PLAREVO1836-114 Clamp Bolt 1

9 PLAREVO1836-115 Sleeve 1

10 PLAREVO1836-116 Rubber Sleeve 1

11 PLAREVO1836-1145 Cap 1

12 MPAREVO1836-189 E-Ring E15 4

13 PLAREVO1836-185 Key 6x6x30 1

14 PLAREVO1836-194 Socket Head Button Screw M8x20 1

15 PLAREVO1836-315 Socket Head Button Screw M8x50 1

16 PLAREVO1836-199 Set Screw M8x6 2

17 PLAREVO1836-1110 Nylon Insert Lock Nut M18x2.5 1

18 PLAREVO1836-1114 Lock Washer 5/16" 2

19 PLAREVO1836-319 Tool rest Extension 1

20 PLAREVO1836-320 Socket Head Button Screw 3/8-16UNCx1-1/4" 1

21 PLAREVO1836-1115 Lock Washer 3/8" 1

Part Number

Item Description Specification

Qty

45

Optional 12" Swing-Away Extension

Index

Part Number

Item Description Specification

1 PLAREVO1836-401 12" Bed Extension 1

2 PLAREVO1836-402 Draw Latch Assembly 1

3 PLAREVO1836-403 Hinge 1

4 PLAREVO1836-404 Pin 2

5 PLAREVO1836-147 Stop Bolt 1

6 PLAREVO1836-406 Socket Head Cap Screw M6x12 4

7 PLAREVO1836-407 Phillips Flat Head Screw M5x12 5

8 PLAREVO1836-320 Socket Head Button Screw 3/8-16UNCx1-1/4" 2

9 PLAREVO1836-409 Set Screw 3/16-24UNCx3/8" 4

Qty

46

Optional Comparator

Index

1 PLAREVO1836-501 Center 2

2 PLAREVO1836-502 Lock Handle 2

Part Number

Item Description Specification

Qty

47

Optional Industrial Flood Light

Index

1 PLAREVO1836-601 Work Light 1

2 PLAREVO1836-602 Screw M4x15 4

Part Number

Item Description Specification

Qty

48

49

Optional Inverter for Vacuum

Index

1 PLAREVO1836-801 Connecting Shaft 1

2 PLAREVO1836-802 Vacuum Adaptor Body 1

3 PLAREVO1836-803 Cover 1

4 PLAREVO1836-804 Vacuum System Box 1

5 PLAREVO1836-805 Plate 1

6 PLAREVO1836-806 Vacuum Generator Bracket 1

7 PLAREVO1836-807 Vacuum System Bracket 1

8 PLAREVO1836-808 O-Ring P14 1

9 PLAREVO1836-809 Vacuum Generator 1

10 PLAREVO1836-810 Silencer 1

11 PLAREVO1836-811 L-Type Fitting 1

12 PLAREVO1836-812 Air Flow Regulator 1

13 PLAREVO1836-813 Quick Release Fitting 1

14 PLAREVO1836-814 Pressure Vacuum Gauge 1

15 PLAREVO1836-815 Gauge Fitting 1

16 PLAREVO1836-816 Vacuum Switch 1

17 PLAREVO1836-817 H-Type Fitting 1

18 PLAREVO1836-818 Flat Type Silencer 1

19 PLAREVO1836-819 T-Type Fitting 1

20 PLAREVO1836-820 Straight Fitting-Female 1

21 PLAREVO1836-821 Ball Bearing 6003ZZ 1

22 PLAREVO1836-822 Screw M4x30 2

23 PLAREVO1836-823 Air Hose 1

24 PLAREVO1836-824 Screw M2.5x5 3

25 PLAREVO1836-825 Set Screw M5x5 2

26 PLAREVO1836-826 Hex Nut M12 1

27 PLAREVO1836-827 Socket Head Cap Screw 5/16-18UNCx1/2" 4

28 PLAREVO1836-1113 Flat Washer D8xD18x2t 4

29 PLAREVO1836-829 Screw M4x10 6

30 PLAREVO1836-830 Flat Washer D1/2"xD26x2.5t 1

31 PLAREVO1836-831 Quick Fitting- Inlet 1

Part Number

Item Description Specification

Qty

50

Optional Deluxe Wheel System

Index

Part Number

Item Description Specification

Qty

1 PLAREVO1836-901 Support Bracket-Right 2

2 PLAREVO1836-1115 Lock Washer 3/8" 24

3 PLAREVO1836-195 Socket Head Cap Screw 3/8-16UNCx1" 24

4 PLAREVO1836-904 Support Bracket-Left 2

5 PLAREVO1836-905 Nylon Insert Lock Nut M8x1.25 6

6 PLAREVO1836-906 Support Bracket 2

7 PLAREVO1836-907 Socket Head Cap Screw M8X45mm 2

8 PLAREVO1836-1146 Socket Head Button Screw 1/4-20UNCx3/8" 8

9 PLAREVO1836-909 Spacer 4

10 PLAREVO1836-910 Cylinder 2

11 PLAREVO1836-911 Nylon Insert Lock Nut M10x1.5 4

12 PLAREVO1836-912 Support Bracket 2

13 PLAREVO1836-913 Bushing 2

14 PLAREVO1836-914 Socket Head Cap Screw M10x35mm 4

15 PLAREVO1836-915 Connecting rod 2

16 PLAREVO1836-916 Bushing 2

17 PLAREVO1836-917 Foot Brake 2

18 PLAREVO1836-918 Socket Head Cap Screw M8X30mm 2

19 PLAREVO1836-919 Bushing 2

20 PLAREVO1836-920 Socket Head Cap Screw M8X50mm 2

21 PLAREVO1836-199 Set Screw M8x6 8

22 PLAREVO1836-922 Spacer 4

23 PLAREVO1836-923 Rod 2

24 PLAREVO1836-924 Nut 1/2"-12UNC 4

25 PLAREVO1836-925 Flat Washer 1/2" 4

26 PLAREVO1836-926 Caster 4

27 PLAREVO1836-927 Support Bracket 2

52

Optional 3" Riser Blocks

Index

Part Number

Item Description Specification

1 PLAREVO1836-701 3" Riser Blocks 2

2 PLAREVO1836-702 Socket Head Cap Screw 3/8-16UNCx3-1/2" 4

3 PLAREVO1836-1115 Lock Washer 3/8" 8

4 PLAREVO1836-1146 Socket Head Button Screw 1/4-20UNCx3/8" 4

5 PLAREVO1836-705 Support Bracket 2

6 PLAREVO1836-706 Support Bracket 2

7 PLAREVO1836-707 Socket Head Cap Screw 3/8-16UNCx3/4" 8

Qty

53

2072 Alton Parkway. Irvine, CA 92606

Ph: 800.234.1976 | www.lagunatools.com

Laguna Tools is not responsible for errors or omissions.

Specifications subject to change. Machines may be shown with optional accessories.

© 2017, Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo® are the

registered trademarks of Laguna Tools, Inc. All rights reserved.

Loading...

Loading...