laguna 16HD, 16HD classic, Resaw Master, LT18, LT32 User Manual

...

LAGUNA BANDSAWS

16HD-37 MANUAL

LAGUNA TOOLS

2072 Alton Parkway

Irvine, California 92606

Ph: 800.234.1976

www.lagunatools.com

© 2017, Laguna Tools, Inc. LAGUNA® and the LAGUNA Logo® are the registered trademarks of Laguna Tools, Inc. All rights reserved.

3

Chapter 1.Safety rules and warranty Pg. 4-5

Chapter 2.Getting to know your bandsaw Pg. 6-13

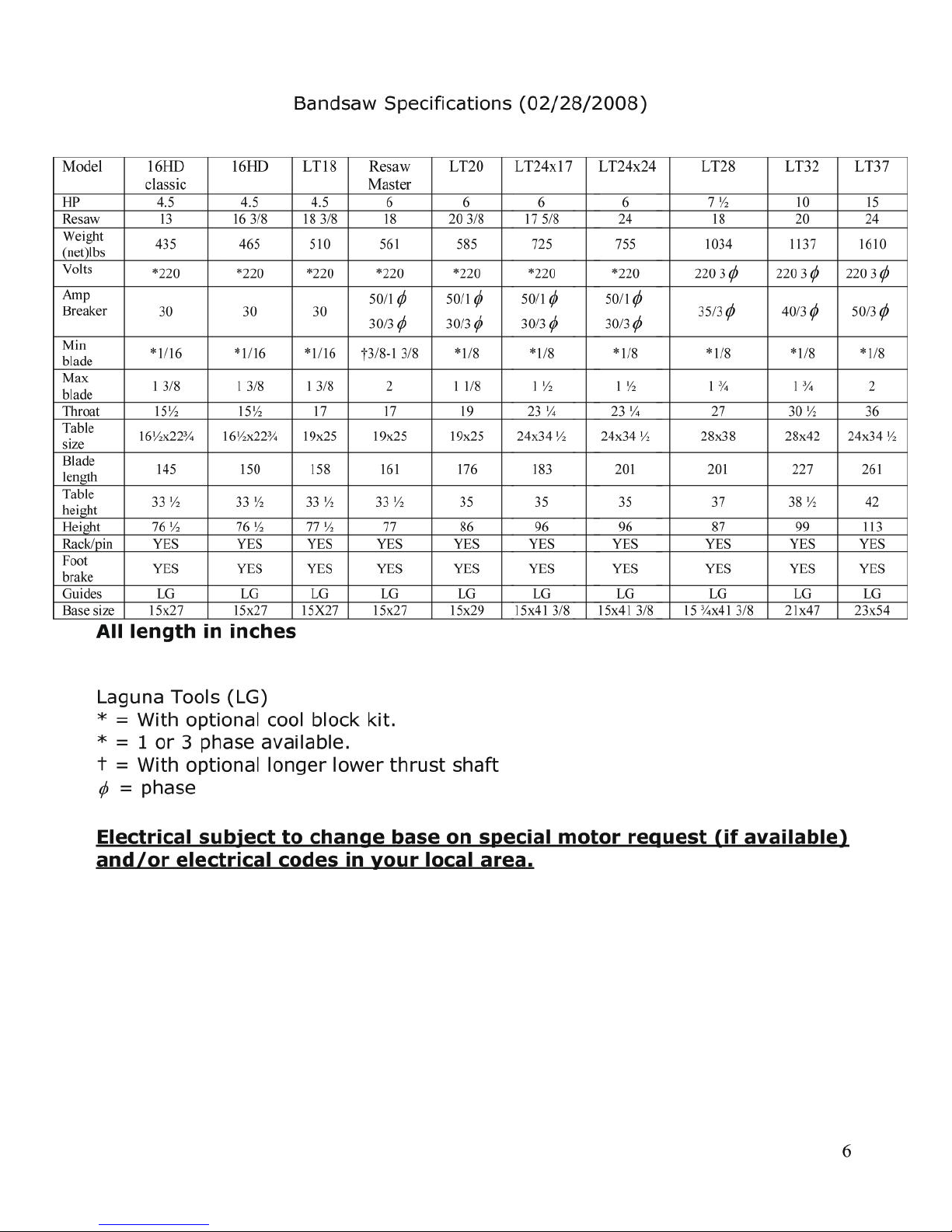

Specification Pg. 6

Noise emission Pg. 7

Receiving your machine Pg. 7

Introduction to bandsaws Pg. 8

What you will receive with your machine Pg. 9

Parts of the bandsaw Pg. 10-13

Where to locate your bandsaw Pg. 13

Chapter 3. Assembling your bandsaw Pg. 14-36

Unpacking your machine Pg. 14-15

Assembling your bandsaw Pg. 16-22

Adjusting the bandsaw Pg. 23-36

Chapter 4. Using your bandsaw Pg. 37-40

Chapter 5. Blades Pg. 41-39

Introduction Pg. 41

Blade terms Pg. 41-36

Blade selection Pg. 36-48

Chapter 6. Maintenance and troubleshooting Pg. 49-56

Chapter 7. Accessories Pg. 57

Chapter 8. Electrical drawings Pg. 58-62

Chapter 9. Spare parts and exploded view drawings Pg. 63-64

4

Read First!!!

Safety Rules

As with all machinery there are certain hazards involved with the operation and

use. Using each one with caution will considerably lessen the possibility of

personal injury. However, if normal safety precautions are overlooked or

ignored, personal injury to the operator may result. If you have any questions

relative to the installation and operation, do not use the equipment until you

have familiarized yourself with the machine.

Read carefully before operating the band saw

1. Keep the working area clean and be sure adequate lighting is available.

2. Do not wear loose clothing, gloves, bracelets, necklaces or ornaments.

Wear face, eye, respiratory and body protection devices as indicated for

the opera tion or environment.

3. Be sure that the power is disconnected from the machine before making

adjustments or fitting and removing an attachment.

4. Never leave the machine with the power on.

5. Do not use dull, gummy or cracked blades.

6. Be sure that the keys and adjusting wrenches have been removed and all

the nuts and bolts are secured.

Limited Warranty

New machines and accessories sold by Laguna Tools carry a one-year warranty

effective from the date of shipping. Machines sold through dealers must be registered

with Laguna Tools within 30 days of purchase to be covered by this warranty. Laguna

Tools guarantees all new machines and accessories sold to be free of manufacturers’

defective workmanship, parts and materials. We will repair or replace, without charge,

any parts determined by Laguna Tools, Inc. to be a manufacturer’s defect. We require

that the defective item/part be returned to Laguna Tools with the complaint. Any

machines returned to Laguna Tools must be returned with packaging in the same

manner in which it was received. If a part or blade is being returned it must have

adequate packaging to ensure no damage is received during shipping. In the event the

item/part is determined to be damaged due to lack of maintenance, cleaning or

misuse/abuse, the customer will be responsible for the cost to replace the item/part,

plus all related shipping charges. This limited warranty does not apply to natural

disasters, acts of terrorism, normal wear and tear, product failure due to lack of

maintenance or cleaning, damage caused by accident, neglect, lack of or inadequate

dust collection, misuse/abuse or damage caused where repair or alterations have been

made or attempted by others.

Laguna Tools, Inc. is not responsible for additional tools or modifications sold or

performed (other than from/by Laguna Tools, Inc.) on any Laguna Tools, Inc.

machine. Warranty maybe voided upon the addition of such described tools and/or

modifications, determined on a case-by-case basis.

Software purchased through Laguna Tools Inc. is not covered under this warranty

and all technical support must be managed through the software provider. Software is

non-refundable.

Normal user alignment, adjustment, tuning and machine settings are not covered by

this warranty. It is the responsibility of the user to understand basic machinery

operation, settings and procedures and to properly maintain the equipment in

accordance with the standards provided by the manufacturer.

Parts, under warranty, are shipped at Laguna Tools, Inc.’s cost either by common

carrier, FEDEX ground service or a similar method. Technical support to install

replacement parts is primarily provided by phone, fax, e-mail or Laguna Tools

Customer Support Website. The labor required to install replacement parts is the

responsibility of the user.

Laguna Tools is not responsible for damage or loss caused by a freight company or

other circumstances not in our control. All claims for loss or damaged goods must be

notified to Laguna Tools within twenty-four hours of delivery. Please contact our

Customer Service Department for more information.

Only new machines sold to the original owner are covered by this warranty.

For warranty repair information, call 1-800-332-4094.

7

Measuring system

Standard ISO 7960 - annex J ( NFE 64-209 )

Measurements tolerance

< 4 dB

Working, without

aspiration

L Aeq

LW (A)

Lpc

84,7 dB (A)

97,1 dBw (A)

5,1 mW (A) < 130 dB (A)

Noise emission

Notes concerning noise emission: Given that there exists a relationship between

noise level and exposure times, it is not precise enough to determine the need

for supplementary precautions. The factors affecting the true level of exposure

to operators are clearly the amount of time exposed, the characteristics of the

working environment, other sources of dust and noise, etc.: for example,

adjacent machines, in other words the level of ambient noise. It is possible that

exposure level limits will vary from country to country.

Measuring system Standard ISO 7960 - annex J ( NFE 64-209 )

Receiving your machine

Note: It is probable that your machine will be delivered by a third party. Before

you unpack your new bandsaw you will need to first inspect the packing,

invoice and shipping documents supplied by the driver. Insure that there is no

visible damage to the packing or the machine. You need to do this prior to the

driver leaving. All damage must be noted on the delivery documents and signed

by you and the delivery driver. You must then contact the seller [Laguna Tools]

as soon as practical. If damage is found after delivery, contact the seller as

soon as practical.

8

Introduction to bandsaws

This bandsaw is designed to give you years of safe service. Read this owner’s

manual in its entirety before assembly or use.

The bandsaw is generally defined as a saw blade in the form of an endless steel

band that rotates around two or more wheels. This blade is a continuous metal

band with teeth on one side. As the wheels rotate, so does the band, which

creates the continuous sawing action. Because the direction of the blade is

always downward toward the table, there is little danger [except for special

cuts] that the wood will be thrown back at the operator, which is called a

kickback. There is always danger of kickback when a circular saw is being used.

For safety reasons many woodworkers prefer the bandsaw especially when

cutting small pieces. The unique feature of the bandsaw is that the work piece

can be rotated around the blade creating a curve. It is the tool most often used

when curves have to be cut in wood. Because the bandsaw blade is fairly thin,

it can cut thick stock with a minimum of horsepower. For this reason the

bandsaw is often used when valuable pieces of wood are made into a thin piece

of veneer.

9

Tool Kit

Fence, table insert, and door guard

Table

What you will receive with the bandsaw.

10

Parts of the bandsaw

The bandsaw does not have many parts. The major parts are discussed in this

manual. If you are not familiar with the bandsaw, take the time to read this

section and become familiar with the machine.

Flywheel

The blade is suspended over two wheels that are covered with rubber called a

tire. The tire cushions the blade and protects the teeth from coming in contact

with the metal of the flywheel. The lower wheel is the drive wheel and is

attached to the motor with a rubber drive belt. The lower flywheel powers the

blade and pulls the blade down through the work piece. The top wheel has two

functions. One function is to balance or track the blade on the wheels, and the

second one is to tension the blade. Both functions are adjustable.

11

Body

The body of the bandsaw is a "U"-shaped frame, which houses all the parts of

the machine. This is the heart of the bandsaw and has to be very rigid as it

takes the strain of the blade being tensioned.

Table

The table supports the workpiece and can tilt to produce cuts at various angles.

It has a groove to the right-hand side of the blade which is used to guide the

miter gauge. In the center there is a plastic table insert which the blade passes

through. Should the blade wander off center, this table insert will protect the

blade from damage as it is soft and will not damage the blade. The table also

supports the adjustable fence, which is used for parallel cuts. There is an

aligning pin, which joins both sides of the table and stops the table from

warping [attached by a wire]. The pin must always be fitted in the table and

only removed when removing or fitting a blade.

Blade guides

There are two sets of blade guides, one above and one below the table. The

function of the guides is to give the blade stability and ensure that the blade

movement left / right, forward / back is kept to a minimum. The guides above

the table are fitted to a shaft that has vertical adjustment. The upper guides

are adjustable so that the guides are held just above the job being cut. This

gives the blade the maximum amount of stability and also keeps the amount of

blade that is exposed to a minimum. If you are using blades narrower than ¼",

you will need to purchase a cool block guide system.

Guards

When running, the blade can be very dangerous and the amount of blade that

is exposed must be kept to a minimum. The machine is supplied with a number

of guards all of which MUST be installed and used while the machine is running.

There is a guard that is attached to the lower door and is adjustable vertically

once the door is closed. There is a hinged guard on the guide vertical

adjustment shaft. The guard is only opened to install or remove the blade.

There is a clear plastic guard on the upper blade guide. This guard must be

adjusted just above the wood being cut.

Drive

The drive [power] is supplied to the machine by an electric motor located at the

back of the machine. It powers the lower flywheel through a rubber drive belt

and is controlled by switches that are mounted on the frame vertical post at the

front of the machine. It is also controlled by switches on the upper door and the

12

foot brake.

Electrical connection

This is achieved by connecting the electrical supply to a terminal box located at

the back of the machine. Never connect directly to the electrical motor, and all

electrical connections must be conducted by a qualified electrician. For detailed

instructions see the assembly section of the manual.

Brake

The machine is supplied with a foot brake. It is located close to the ground on

the righthand side of the machine. It has two functions. First, to remove the

power to the motor, which is achieved with a switch that is mounted on the

body of the machine. The second function is to slow the lower flywheel and this

is achieved by applying a brake pad to the flywheel. The more pressure that is

applied, the faster the flywheel slows.

Dust collection

The bandsaw produces a lot of sawdust, so extraction is very important. This is

achieved by connecting a dust extraction hose to the back of the machine with

a minimum capacity of 1,000 CFM.

Identification

There is a plate at the back of the machine listing all the manufacturing data

including the serial number, model, blade length etc.

Tension scale

Tension scales are designed to indicate the compression of a spring. As a rule,

the greater the spring compression, the greater the tension on the blade. The

tension scale does not register until the blade is relatively taut and is located on

the inside of the body vertical post. The tension scale is a general reference and

not a rule.

Tilt and tension mechanism

The upper wheel is attached to the tilt and tension mechanism. This mechanism

adjusts the wheel so that the bandsaw blade can be adjusted for tracking. This

is achieved by a screwed handle at the back of the machine that pushes on the

mechanism and adjusts the axis of the wheel so that it runs true with the lower

wheel. The second function is to tension the blade, which is achieved by

adjusting the upper flywheel vertically. A handle is located below the wheel

13

and, when rotated, will move the wheel up or down. The mechanism has a

spring, which helps to keep the tension constant as the blade expands and

contracts with the heat generated by the cutting action. The lower flywheel is

also adjustable for tracking and has 4 bolts at the back of the machine that

adjust the wheel shaft. The lower wheel is factory set and should not need

adjustment.

Fence

The fence is located to the left of the blade and is used to assist in parallel cuts.

It is adjustable for the drift of the blade and also the thickness of the cut.

Where to locate your bandsaw

Before you remove your bandsaw from the pallet, select the area where you

will use your machine. There are no hard and fast rules for its location but

below are a few guidelines.

1. There should be an area at the front and back of the machine suitable for

the length of wood that you will be cutting. If you intend to use your saw

for scrollwork, this may not be important but should be considered at this

stage.

2. Adequate lighting. The better the lighting, the more accurate and safely

you will be able to work

3. Solid floor. You should select a solid flat floor, preferably concrete or

something similar.

4. Close to power source and dust collection.

14

Unpacking your machine

To unpack your machine, you will need tin snips, knife and a wrench.

1. Using the tin snips, cut the banding that is securing the machine to the

pallet.

WARNING: EXTREAM CAUTION MUST BE USED BECAUSE THE

BANDING WILL SPRING AND COULD CAUSE INJURY.

2. Lift the box off and discard.

3. Using the knife, cut the plastic wrap from the top. The table, motor, fence

and accessories that were ordered could be attached to the side of the

machine and extreme caution must be taken that the parts do not fall and

cause injury or damage. Remove them in order from the top and set

aside.

4. Place the motor on the pallet behind the machine. Ensure that there is no

tension on the motor wiring. It is

recommended that the motor be assembled to

the bandsaw prior to removing the bandsaw

from the pallet [see mounting motor]. If you

decide to remove the bandsaw prior to

assembling the motor to the bandsaw, ensure

that there is no tension on the motor wiring at

any stage of the operation.

5. Remove the base mounting bolts that secure

the machine to the pallet [shown removed].

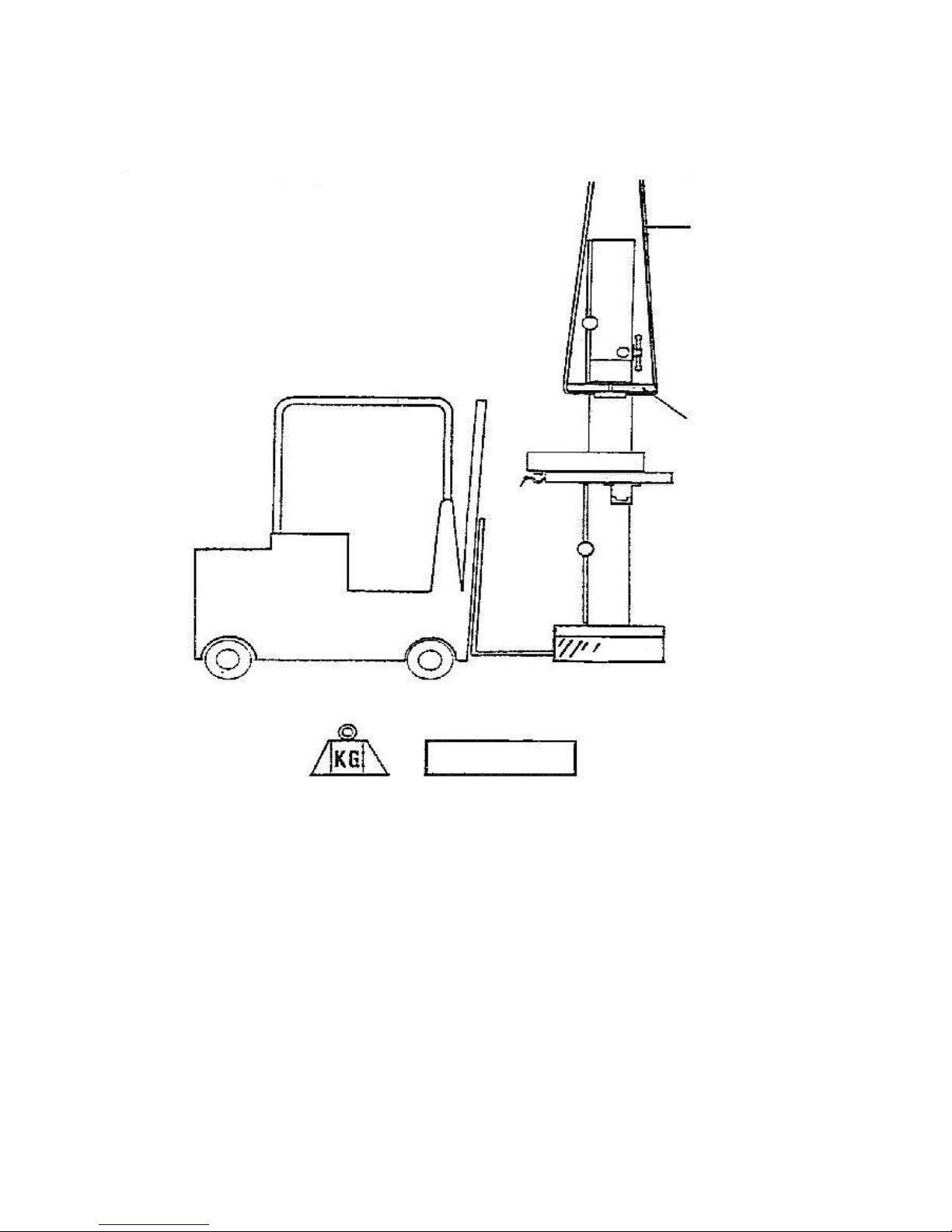

6. It is recommended that the machine be

removed from the pallet by lifting it with a

hoist or forklift. There is an eyebolt at the top

of the machine, and this should NEVER be

used to lift the machine. It is used to secure

the machine horizontally during ship ping only and is not designed to take

the load of the machine.

Place a sling through the bandsaw as shown below behind the tension-adjusting

wheel and lift vertically.

Remove the pallet and lower to the floor.

The machine can be lifted using a forklift truck, sliding it onto the forks or by

using a forklift “SLING”, as shown with a lifting capability of 2,000 Kg (440lb).

15

If no lifting device is available, the machine can be removed from the pallet as

follows: Note: The machine is heavy, and if you have any doubt about the

described procedure, seek professional assistance. Do not attempt any

procedure that you feel is unsafe or that you do not have the physical capability

of achieving. With two or more people, move the machine so that the base of

the bandsaw is over the edge of the pallet. Tilt the bandsaw away from the

pallet so that the base of the machine touches the floor, slide the pallet from

under the machine and then move the bandsaw to the vertical position so that

it is completely resting on the floor

16

Belt tensioning bolt

Mounting the motor

Two people are required to assemble the motor to the bandsaw; build up

wooden blocks to the right height to rest the motor on. One person holds the

motor in position, and the other will fit the drive belt

and the bolts.

1. Remove the two mounting nuts on the rear of

the machine. Make sure that there are washers

between the bolts and the inside face of the

machine.

2. Hold the bolts to prevent them pushing through.

3. Using a block to

support the motor,

guide the motor onto

the mounting bolts.

Insure that the drive

belt is on both the

motor pulley and the

fly wheel pulley. The

drive belt can be fitted

later if you prefer, but

it is preferable to

assemble it at this

stage. If you decide to

fit the drive belt after

fitting the motor, you

will have to adjust the

motor to its lowest position and once fitted the

motor back up to the tensioned position.

4. Once the belt is mounted on both the

pulley "V" grooves, apply tension by

adjusting the tensioning bolt, using the

supplied 17 mm wrench. The correct

tension is 3/16" deflection when using

your thumb on one side of the belt. If the

tension is too tight, you will experience

motor strain: if it is too loose you will

experience belt slippage and lack of

power. After a few hours of operation it

is necessary to check that the tension is

correct, as the belts will bed into the "V"

grooves. As a guide, the belt should have

the same tension/deflection as the fan or

alternator belt on your car.

17

Mobility kit

If you have purchased a mobility kit, now is the ideal time to fit it as the table

has not been fitted to the machine and the bandsaw is lighter, but the mobility

kit can be fitted later if you require it.

Mobility kit assembly procedure

1. Rest the bandsaw on a 2" X 4" wood or something similar.

2. Fit the shaft through the base of the bandsaw.

3. Fit the wheels, washers and split pins as shown on both sides of the base.

4. Fit the front bracket as shown. Note the number of holes in the bracket

may vary depending on the bracket supplied.

Note: The mobility kit may be supplied with 2 spacers that are used to

adapt it for other machines. Discard the spacers.

Note: Leveling bolts and a flat head counter sunk screw are provided

with the machine. If you are fitting a mobility kit you will not need the

bolts/screw. Discard them.

18

Installing the Table

The bandsaw is supplied

with a zero stop that is

adjustable and comes

factory set

Insert

Two people are required to mount the table

to the machine.

1. Remove the lock-down bolt, handle and

the pin from the trunnion.

2. Position the table on the

trunnion, taking care not to

damage any of the table or

trunnion surfaces.

3. While one person supports the

table, the other person feeds the bolts and the lock down through the

trunnion slots.

4. The table can be tilted to a maximum of 45 degrees away from the

column. To angle the table, remove the table insert to allow the blade to

pass through the hole. Loosen the lock-down handle, using the supplied

wrench. Crank the trunnion gear so that the table moves to the required

angle and lock in position. To return the table to the zero position,

reverse the procedure.

Table insert

The machine is supplied with a removable table

insert. The holes of the insert improve the dust

collection near the blade. Adjusting screws at the

bottom of the table allows the insert to be

adjusted vertically so that the level between the

table and the insert are level. It is recommended

that the insert be replaced when the slot becomes

19

too wide; this will ensure that the job is supported efficiently and safely. When

the insert is replaced, you will have to sand the sides so that the insert fits

correctly in the table hole. You will also have to cut the blade slot to suit your

machine.

20

Fence

The bandsaw is supplied with a cast iron or aluminum fence depending on the

machine that you purchased. Assemble the fence to the cast-iron bracket with

the bolts and steel block provided. Adjustment and squaring of the fence will be

covered later in the manual. Slide the bracket onto the round steel bar

[attached to the table]. The fence is used to the left of the blade, so ensure

that it is on the correct side of the table before locking in position with the

ratchet handle provided. Note: The aluminum fence can be fitted so that it can

be used in high or low position [also covered later in the manual].

Dust collection

The bandsaw must be connected to a dust collection system or machine. As a

general rule the stronger the extraction, the better; but 1,000 cubic feet a

minute is the minimum that should be used. The diameter of the dust collection

port on the bandsaw is 4". Most US standard hoses are 4" in diameter. You can

purchase a step-down adaptor from Laguna Tools or from your local hardware

store in the plumbing or heating department if you

use a smaller hose.

21

Bottom blade guard

It is very important to have the blade covered for

safety. A guard is provided at the top of the lower

door. This guard must be moved vertically and

clamped in position before operating the bandsaw. To

open the door, the guard will have to be lowered.

Should the blade break, this guard protects the

operator from the blade

escaping under the table. To

assemble the guard remove

the thumbscrew that you will

find stored on the inside of

the door.

Align the guard on the bolt and install

the thumbscrew on the outside of the door.

Foot brake

A foot brake is attached to an arm inside the machine

with two bolts. As it is moved down, a switch removes

power to the motor. Continued downward movement

contacts a brake pad that slows the lower flywheel.

Should the blade break the foot brake only slows the lower flywheel and the

upper flywheel may still be rotating, so care must be exercised when opening

the doors. To assemble the foot brake, remove the bolts from the arm inside

the bandsaw. Push the foot brake through the slot on the side of the bandsaw

and assemble to the arm with the two screws.

Leveling the bandsaw

After you have located your bandsaw in its final

position, you will have to level it [only applicable if you

have not fitted a mobility kit]

1. Place a spirit level on the table. You will have to

level the saw in both directions [parallel with the

saw blade and at 90 degrees to the saw blade].

2. The base of the machine is provided with four

threaded leveling holes and bolts. You can also bolt

the machine to the floor [bolts not provided]

3. If you decide to bolt the machine to the floor, you will have to level it with

shims [shims not provided]. Do not over tighten the machine to the floor, as

it could cause the machine to vibrate.

4. When leveling the machine that is not bolted to the floor, insert the

leveling bolts into the 4 corner holes. Make sure that you use the headless

screw in the hole at the front on the lower door. If you use a bolt with a

22

head, the door will not be able to be opened.

5. Adjust the bolts so that the machine is level in both planes and does not

rock.

23

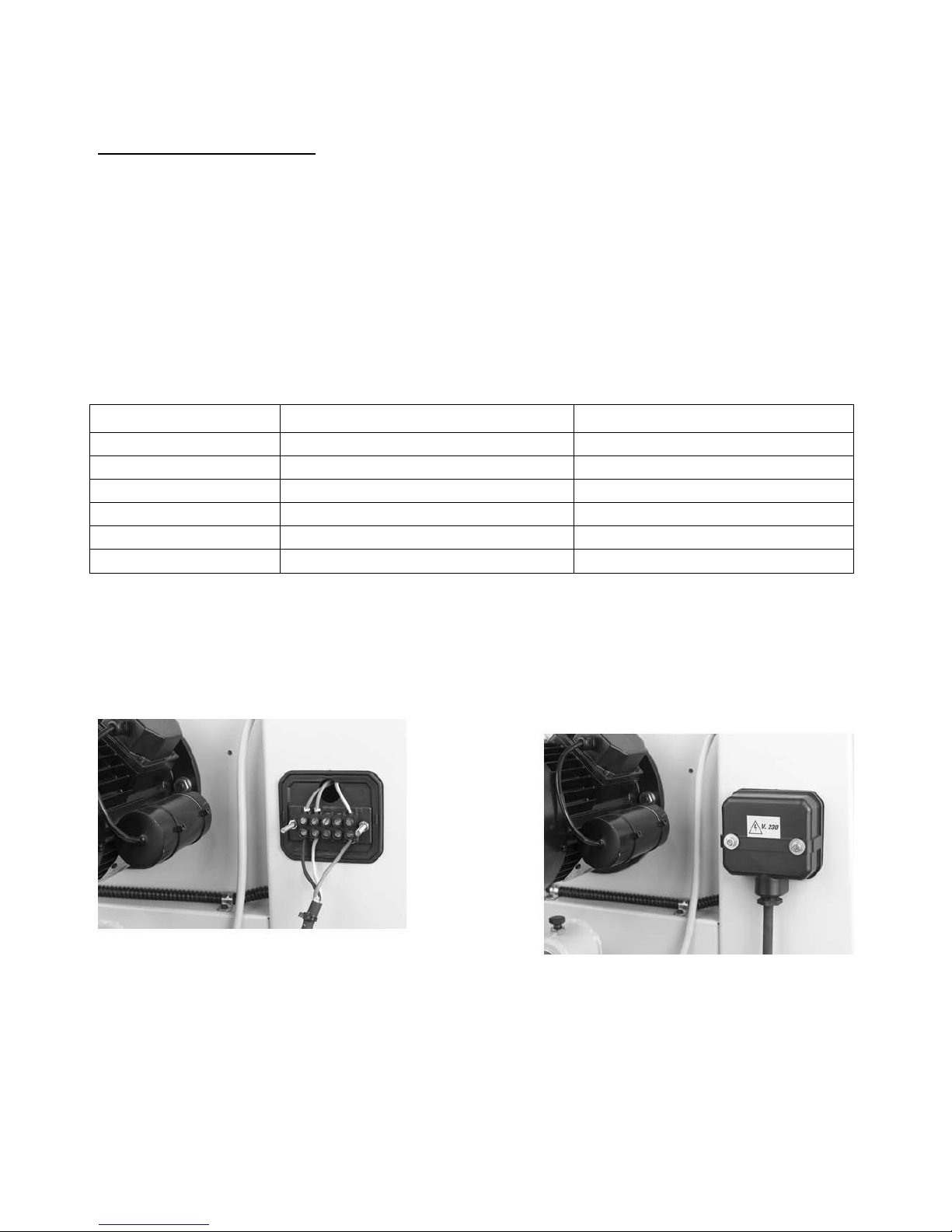

Phase

Distance

Wiring suggested

1 phase

0-10 ft

12/3

1 phase

10-15 ft

10/3

1 phase

15+ ft

8/3

3 phase

0-10 ft

12/4

3 phase

10-15ft

10/4

3 phase

15+ ft

8/4

Electrical connection

Note the machine is not supplied with an electrical cord or plug, as the

size of the cable and the type of plug will be dependent on the

installation.

A qualified electrician must carry out the electrical installation. The main

connection should be made using the terminal box shown. Ensure that the

main supply corresponds with that of the machine, single phase or threephases. Use wiring suitable for the power of the motor, which is 230 volts, and

the cable is required.

All machines require the minimum of a 30-amp circuit breaker regardless of

the phase.

Connect the electrical wires to the terminals opposite the wires going to the

machine. On a single-phase machine you will find 3 wires. On a 3-phase

machine you will find 4. On the machine you will see a wire that is yellow and

green, which is the ground wire; the other colored wires are power. In either 1phase or 3-phase it does not matter what color combination you use. Green is

ground; all other wiring is power (there is no neutral). On single-phase the

wiring can be interchanged as you wish; it would not affect the rotation of the

24

motor. The direction of rotation of machines with a single phase supply is

predetermined during production. On a 3-phase machine the lower wheel must

rotate in a clockwise rotation. If it rotates in a counterclockwise direction you

need to swap locations of 2 of the power leads, and it will rotate in the correct

direction.

25

Before starting the machine

1. Read and understand the instruction manual before operating the saw.

2. If you are still not thoroughly familiar with the operation of the

bandsaw, get advice from a qualified person.

3. Make sure the machine is properly grounded and that the wiring codes

are followed.

4. Do not operate the bandsaw while under the influence of drugs,

alcohol, medicine or if tired.

5. Always wear eye protection, safety glasses or a safety shield, and

hearing protection.

6. Wear dust mask; long-term exposure to the fine dust created by the

band saw is not healthy.

7. Remove your tie, rings, watch and all jewelry. Roll up your sleeves;

you do not want anything to get caught in the saw.

8. Make sure that the guards are in place and use them at all times. The

guards protect you from coming in contact with the blade.

9. Make sure that the saw blade teeth point downward towards the table.

10. Adjust the upper blade guard so that it is just clearing the material

being cut.

11. Make sure that the blade has been properly tensioned and tracked.

12. Stop the machine before removing the scrap piece from the table.

13. Always keep your hands and fingers away from the blade.

14. Make sure that you use the proper size and type of blade.

15. Hold the work piece firmly against the table. Do not attempt to saw

stock that does not have a flat surface facing down, unless a suitable

support is used.

16. Use a push stick at the end of a cut. This is the most dangerous time

because the cut is complete and the blade is exposed. Push sticks are

commercially available.

17. Hold the wood firmly and feed it into the blade at a moderate speed.

18. Turn off the machine if you have to back the material out of an

uncompleted or jammed cut.

26

Stop switch in the

on/out position

(should see yellow

ring)

Stop switch in

the off/in

position

Yellow ring showing

No yellow ring

showing

Machine test

Now is the time to test the machine.

1. Close the doors. If you try to start the

machine with the doors open, the machine

will not start, as the safety switch is not

engaged.

2. Check that the foot break is in the fully up

position. The machine will not start if the foot

break is not fully up, as the safety switch will

not be engaged.

3. Check that the red safety switch is in the fully

out position.

4. Check that the machine is clear of all tools

and other loose objects.

5. Check that all the adjusting and locking

handles are tight.

6. Check that there is no blade fitted; it is far

safer to test the machine without a blade

fitted.

7. Start the bandsaw by turning the start switch

fully to the right, and once started release

the switch.

8. The lower flywheel is now turning.

9. Now is the time to check that all the safety

switches are functioning correctly before you

fit a blade. Never complete the following tests

with a blade fitted as it could cause injury.

10. With the machine running [no blade fitted],

operate the foot break. The motor should

have the power removed and the lower wheel

slowed down.

11. With the machine running [no blade fitted],

operate the red stop switch by pressing

towards the machine. The motor should have

the power removed and slowed down.

12. With the machine running [no blade fitted],

open the doors very slowly until the top door

switch functions. The motor should have the

power removed and slowed down. Close the door and wait for the

flywheels to completely stop before you fully open the doors.

13. If any of the safety switches fail to operate correctly, do not use the

machine until the fault has been corrected.

27

Adjusting the bandsaw

Fitting a blade to the bandsaw

A lot of people do not like to change the blades and go to great lengths to avoid

doing it. To use the bandsaw to its greatest advantage, you will have to use the

appropriate blade and track it quickly. This is a habit that can be easily

developed. If you use a step-by-step method of tracking, the procedure should

only take a minute or two. Be careful when using blades, especially wide ones.

Always use gloves and safety glasses.

Installing the blade

Disconnect the power to the bandsaw.

Adjust the side guide and back guide out as far as they will go [both upper and

lower guides]. This will ensure that they do not interfere with the blade while

you are fitting, tracking and tensioning the blade.

1. Uncoil the blade. Remember to use gloves

and safety glasses. The blade may have dirt

or oil on it so by using a clean rag, clean the

blade and pull rearwards so that the cloth

does not hook on the teeth.

2. Inspect the teeth and the general condition of

the blade. If the teeth are pointing in the

wrong direction when you hold the blade up

to the machine, you will have to turn it inside

out. To do this, hold the blade with both

hands and rotate. Remove the table pin.

3. With the hinged guard on the guide support

shaft open and the table insert removed, hold

the blade with both hands with the teeth

towards you. Slide it through the table slot and place it on the wheels.

Hang the blade on the top wheel and then line it up with the lower

wheel. If the top wheel needs to be lowered, rotate the tension handle

wheel.

4. Apply tension to the blade by

adjusting the tension hand wheel.

Do not fully tension the blade at

this stage.

28

5. Start rotating the wheels by hand in the normal direction. As you do

Tracking knob

Check

deflection

here

Tension

gauge

Locking handle

this, watch the blade to

determine where the blade wants

to track. If the blade is tracking

too far forward or backward,

make small adjustments with the

tracking adjustment knob located

at the back of the bandsaw while

still rotating the wheel. Once the

blade is tracking in the correct

position, fully tension the blade

and re-track.

Note: The blade must be fully tensioned for final tracking.

Note: Never track the blade with the saw running.

6. Lock the tracking adjustment handle.

7. Tensioning the blade The blade

tension indicator [mounted on the

vertical post of the bandsaw]; is used

as a general guide, and the following

tensioning procedure is recommended.

Looking at the top wheel, place your

finger at the 9 o'clock position. Move

your finger down 6" and using

moderate pressure with your thumb,

press on the flat of the blade. You

should get 3/16" to ¼" of deflection.

8. Note: If you are not using the bandsaw for extended periods of time

[overnight], remove the tension on the blade. This will increase the life

of your blade and the machine. If tension is left on the machine, flat

spots or grooves can be formed in the rubber of the wheels which will

detract from the performance of the machine and in extreme cases

cause vibration when the machine is run.

9. Close the guard on the upper guide support post. Close the doors

move the door blade guard up and lock in position. Replace the table

insert, and check that the blade moves freely through the table insert.

Replace the table pin. Check that all wrenches and loose parts are

29

removed from the machine.

10. Plug the machine into the power, turn the machine on for a second

and switch off. Watch how the blade runs. If the blade tracks well,

then run the machine at full power.

30

Pin

Removing the blade from the band saw

1. Disconnect the power to the

bandsaw.

2. Remove the pin that aligns the

two table halves.

3. Open the upper-hinged blade

guard.

4. Remove the table insert.

5. Remove the tension on the upper

flywheel.

6. Open the doors and remove the

blade from the wheels [use gloves and eye protection], and gently

slide the blade through the table slot.

Tracking position of the blade on the wheels

Tracking large blades. There has been a lot of discussion on the position that

the blade should be on the wheels. One group of people recommends that with

large blades you should track the blade so that the teeth hang just over the

front edge of the rubber. The second group recommends that all blades

regardless of their size should run in the center of the wheel. The advantage of

running the large blades with the teeth not contacting the rubber of the wheel

is that they cannot damage the tire. The disadvantage is that the wheel is

crowned and the blade is not tensioned in the center of the band, which gives

the blade a tendency to wobble or flutter. The advantage of running large

blades on the center of the wheels is that they are tensioned in the center of

the band and have fewer tendencies to wobble and flutter. The disadvantage is

that blades with a large set on the teeth have a tendency to damage the rubber

of the tire. This does not have a great effect on the performance of the

bandsaw as all blades are running on the center section of the tire which is not

affected. We recommend that you balance all blades on the center of the

wheels for optimum performance and a smoother cut.

Adjusting the blade guides

Introduction

Welcome to a new era in bandsawing. You have purchased a bandsaw with a

revolutionary blade guide system [patent pending] that is designed to give you

years of safe, high quality bandsawing. Most blade guides are designed to

support the blade on the sides and either above or below the side guides the

back of the blade. This can allow the blade to twist as pressure from the wood

Loading...

Loading...