laguna PowerJet 100, PowerJet 200, PowerJet 800, PowerJet 350 Installation And Maintenance Manual

Installation and

Maintenance Guide

READ THOROUGHLY BEFORE ATTEMPTING INSTALLATION AND

KEEP FOR FUTURE REFERENCE

Einbau- und

Wartungsanleitung

SORGFÄLTIG VOR BEGINN DER INSTALLATION DURCHLESEN UND FÜR SPÄTERE

VERWENDUNG AUFBEWAHREN

Notice d’installation et

d’entretien

LIRE SOIGNEUSEMENT AVANT D’ENTREPRENDRE L’INSTALLATION DE L’APPAREIL.

CONSERVER CETTE NOTICE POUR RÉFÉRENCES ULTÉRIEURES.

Instalación y guía de

mantenimiento

LEA ATENTAMENTE ESTE FOLLETO ANTES DE INTENTAR LA INSTALACIÓN Y

GUARDAR ESTAS INSTRUCCIONES COMO REFERENCIA EN UN FUTURO

Guida all’installazione

e Manutenzione

LEGGERE ATTENTAMENTE E CONSERVARE QUESTE

ISTRUZIONI PER OGNI FUTURO RIFERIMENTO

800

200

350

100

60Hz

50Hz

Jolie Products Inc

1

Examples of different installations

Exemples d’installations

Beispiele für verschiedene Installationen

Ejemplo de direntes instalaciones

Esempi di diverse installazioni ................................................................................................2

Part Numbers

Numéro des pièces

Teile-Nummer

Numéro de piezas

Codici ricambi...........................................................................................................................2

English Instructions..................................................................................................................3

Instructions en français............................................................................................................4

Gebrauchsanleitung deutsch ..................................................................................................5

Instrucciones español...............................................................................................................6

Istruzioni in italiano.................................................................................................................7

Winterizing the Pump

Préparation de la pompe pour l’hiver

So machen Sie Ihre Pumpe winterfest

Acondicionamiento para el invierno de la bomba

Preparazione della pompa per l’inverno................................................................................8

Warranty Card

Fiche de garantie

Garantie-Registrierungskarte ............................................................................................9-10

Jolie Products Inc

Examples of different installations

Exemples d’installations

Beispiele für verschiedene Installationen

Ejemplo de direntes instalaciones

Esempi di diverse installazioni

Laguna Powerflo Underwater Filter

Filtre submersible Laguna Powerflo

Laguna Powerflo Unterwasser-Filter

Filtro Sumergible Laguna Powerflo

Filtro Interno Laguna Powerflo

FOUNTAIN AND ORNAMENT

(200/800)

FONTAINE ET ORNEMENT

(200/800)

SPRINGBRUNNEN UND

ORNAMENT

(NUR 200/800)

FUENTE Y ADORNOS

(200/800)

DECORAZIONE PER

FONTANA

(SOLO POWERJET 200/800)

FOUNTAIN AND WATERFALL

(200/800)

FONTAINE ET CASCADE

(200/800)

SPRINGBRUNNEN UND

WASSERFALL

(NUR 200/800)

FUENTE Y CASCADAS

(200/800)

FONTANA E CASCADA

(SOLO POWERJET 200/800)

ORNAMENT

(ALL MODELS)

ORNEMENT

(TOUS LES MODÈLES)

ORNAMENT

(ALLE MODELLE)

ADORNOS

(TODOS LOS MODELOS)

DECORAZIONE

(TUTTI I MODELLI)

FOUNTAIN ONLY

(ALL MODELS)

FONTAINE SEULEMENT

(TOUS LES MODÈLES)

NUR SPRINGBRUNNEN

(ALLE MODELLE)

FUENTE

(TODOS LOS MODELOS)

FONTANA

(TUTTI I MODELLI)

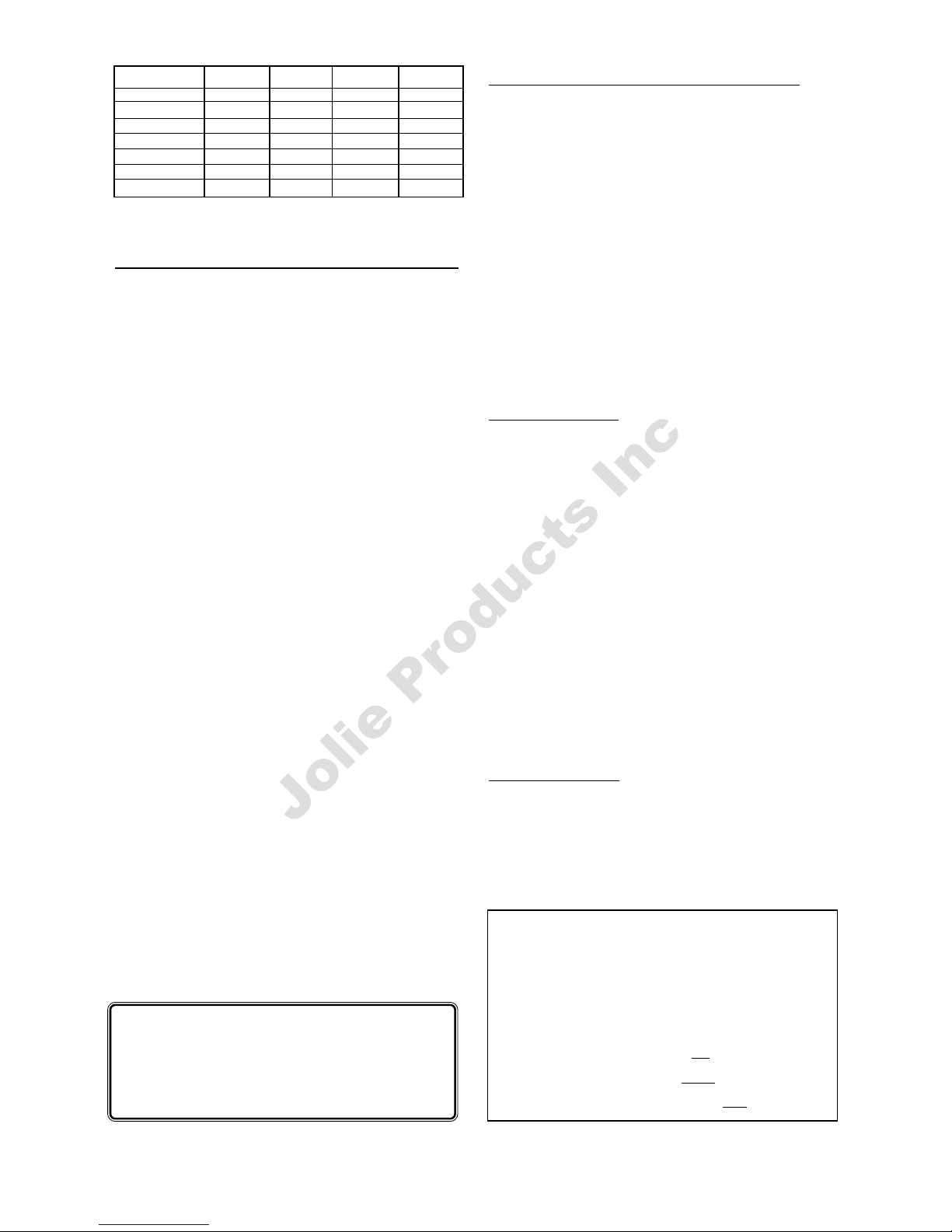

PART NUMBERS / NUMÉRO DES PIÈCES / TEIL-NUMMER / NÚMERO DE PIEZAS / CONDICI RICAMBI

200/800

1

8

3

4

5

9

11

10

7

2

6

2

12

To remove Ceramic Shaft unit, use

tool provided.

Pour enlever le bloc de l’arbre de

céramique, utiliser l’outil fourni.

Zum Entfernen der Keramikachsen-Einheit

beigef

ü

gtes Werkzeug benutzen.

Para desmontar el conjunto de v

á

stago de

cerámica, colocar un pequeño destornillador de cabeza plana debajo

de uno de los rebordes amarillos, y

levantarlo suavemente.

Usare l’apposito attrezzo per rimuovere

l’albero ceramico.

100/350

1

8

4

5

6

7

Ensure that the pump is elevated to help prevent blockage of the strainer

S’assurer que la pompe est surélevée pour aider à empêcher l’obstruction du préfiltre

Stellen Sie sicher, daß die Pumpe erhöht steht um eine Verstopfung des Vorfilters zu vermeiden

Àsegúrese de que la bomba está elevada para impedir que se bloquee el prefiltro

Per evitare l’intasamento del filtro, posizionare la pompa su una superficie elevata

in modo che l’aspirazione rimanga libera dalla sporcizia che si deposita sul fondo del laghetto

60Hz

1 PT710 PT712

2 PT756 PT758

3 PT450 PT452

4 PT732 PT734

5 PT470 PT472

6 PT744 PT746

7 PT724 PT726

8 PT600 PT605

9 PT610 PT610

10 PT660 PT660

11 PT650 PT650

12 PT603

50Hz

1 PT710 PT712

2 PT756 PT758

3 PT450 PT452

4 PT732 PT734

5 PT470 PT472

6 PT744 PT746

7 PT724 PT726

8 PT600 PT605

9 PT610 PT610

10 PT660 PT660

11 PT650 PT650

12 PT603

100 200

(PT-320) (PT-322)

350 800

(PT-320) (PT-322)

Jolie Products Inc

FOUNTAIN AND WATERFALL PUMPS FOR PONDS.

For freshwater and submersible use only.

Read thoroughly prior to installation and operation.

WARNING: SAFETY & ELECTRICAL CONNECTIONS

IMPORTANT SAFEGUARDS

1.

DANGER

- To avoid possible electric shock, special care should be

taken since water is employed in the use of pond equipment. To guard

against injury, basic safety precautions should be observed.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

on the use and

maintenance of this appliance. Disregarding this advice may result in damage

to the pump or personal injury.

2. For each of the following situations, do not attempt repairs yourself; return

the pump to an authorised service facility for service or discard the pump.

A. If the pump falls in the water DON’T reach for it! Unplug it from the

electrical supply BEFORE retreiving it. Carefully examine the integrity

of the pump; if the motor body is cracked or damaged, DISCARD. If

electrical components in the pump get wet unplug it immediately.

B. Do not operate any pump which malfunctions, has a damaged cord or

plug, or if it has been dropped or damaged in any way. The power cord

of this pump cannot be replaced; if the cord is damaged discard the

pump. Never cut the cord.

C. If the appliance shows any sign of current leakage or if RCD (GFCI -

Ground Fault Current Interruptor) switches off, disconnect the power

supply cord from mains and remove pump from water.

3. Children must be closely supervised at all times near water.

4.

IMPORTANT

: Always disconnect the pump when not in use, before

adding or removing parts and before cleaning. Never yank the cord and

never lift the pump by the cable.

5. To avoid injury, do not touch moving parts or hot parts.

6. THIS IS A POND PUMP. Do not use the pump for any other purpose than

that which is intended (ie. do not use in swimming pools, bathrooms, etc.).

The use of attachments not recommended or sold by the manufacturer may

cause unsafe conditions.

* Do not use this pump in swimming pools or other situations where people

are immersed.

* This pump is suitable for use in water temperatures up to 35

°C (95°F).

* Do not use this pump with inflammable or drinkable liquids.

7. Do not install or store this pump where it will be exposed to freezing

conditions or when there is the possibility of below zero temperatures.

Remove and store the pump in a sheltered place. Shelter pump also from

direct sunlight. The materials have high stability to sunlight but direct rays

may over heat the motor and speed up insulator ageing.

8.

WARNING

- Risk of electric shock! This pump is supplied with a grounding conductor an groundig-type attachment plug. To reduce risk of electric

shock, be certain that is connected only to a properly grounded, grounding

type receptacle. Do not remove cord and strain relief. Do not connect conduit

to the pump. To reduce risk of electric shock, use only on portable self-contained fountains no larger than 5 feet in any dimensions (for U.S.A. only).

Check the installation and earth connections before switching on the pump.

9. It is best not to use extension cords. If an extension cord is required,

ensure connection is water tight and dust proof. The cord must have three

leads (Live - Neutral - Earth). Carefully check that the leads are properly

connected. If in doubt consult a qualified electrician.

10. Do not allow pump to run dry. Pump must be immersed in water completely.

11. IMPORTANT: Supply through a Residual Current Device (RCD or GFCI-

Ground Fault Current Interrupter) with rated residual operating current not

exceeding 30mA.

12. Read and observe all the important notices in this leaflet.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Only the faithful observation of these installation, electrical and

maintenance guidelines will ensure the safe and efficient use of this pump.

PUMP INSTALLATION INSTRUCTIONS

Warning: Always unplug or disconnect all appliances in the pond from the

electrical supply before installing, repairing, maintaining or handling

the equipment in the water.

Caution: To prevent constant clogging of the strainer, install the pump on an

elevated surface so that the pump intake is clear of waste, debris and mud at

the bottom of the pond.

Install the pump on an elevated, secure, flat and level surface. The pump base

can be removed and secured to a raised fixed base. A brick, for example, would

provide a firm platform and may help elevate the pump from the pond bed.

Pump Strainer

The pump strainer is not a pond filter. The purpose of the pump strainer is to

prevent debris from entering the impeller.

Caution: Never operate the pump without the strainer material installed in the

pump strainer housing. Failure to use the strainer material will cause the pump

to clog with waste and debris, severely restricting the pump’s output as well as

the fountain heads.

If the pump strainer supplied with the pump is not adequate for your requirements, a Laguna PowerFlo Underwater Filter (PT-500, PT-505 or PT-1750) should

be fitted. (See page 2.)

To clean the pump strainer housing & strainer material, remove them from the

pump and rinse in clean water.

Important:

- Always use the largest diameter hose possible

- Avoid sharp bends in the hose, gentle curves are preferred

MAINTENANCE

FOUNTAIN JETS

Remove jet head from Riser Pipe. 2-Step, 3-Step and Waterbell Jets can be

disassembled. Rinse parts in clean water and reassemble.

IMPELLER

CAUTION: The pump motor includes a high quality ceramic shaft that provides

long-lasting, reliable performance when properly maintained. However, extreme

care should be taken when handling the shaft during maintenance. Avoid

dropping or pressing too hard on it to avoid breakage or hairline fractures,

which may cause the shaft to snap while in operation.

To clean the impeller and impeller housing:

1. Remove strainer housing and strainer.

2. Remove impeller cover

3. Remove impeller.

4. Clean all components in clean water. DO NOT USE DETERGENTS OR OTHER

CHEMICAL CLEANERS.

5. Reassemble impeller assembly and replace strainer assembly.

PUMP CARE

To avoid shortening the life of your Powerjet Pond Pump, please follow this

procedure. Maintenance is simple to carry out and essential.

Once a week - Remove and clean strainer (depending on pool conditions).

Once a month - Remove and clean impeller assembly checking for build up of

limescale which can seriously affect the pump performance. Impeller well

should also be checked.

To keep your Powerjet pond pump in good working order always replace

any worn parts.

If you experience any difficulty, contact your local supplier or Customer

Services: See back cover.

TROUBLE SHOOTING

LOW FLOW FROM PUMP

Check strainer is clean.

Check hose for blockages.

POOR FOUNTAIN DISPLAY

Clean fountain jet.

NO FLOW FROM PUMP

Check power supply is on.

Check fuse (UK market only) and wiring.

Disconnect the pump, remove impeller assembly and clean,

and then reconnect the pump.

POWERJET PUMP 100

200 350 800

Voltage (V) 120 120 230-240 230-240

Frequency (Hz) 60 60 50 50

Wattage (W) 6.5 11 5 12

Maximum depth (m) 2 2 2 2

Max flow rate (LPH/GPH) 380/100 810/214 380/100 810/214

Max head (cm/ft) 80/2.6 130/4.26 80/2.6 130/4.26

Degree of protection IPX8 IPX8 IPX8 IPX8

ADDITIONAL INSTRUCTIONS FOR U.K. ONLY

This product is designed to be permanently wired to the mains supply in a

dry weatherproof enclosure through a double pole switched fused spur

which complies to BS3676, fitted with a 3 Amp fuse. The installation must

conform to the regulations of the Local Electricity Authority which could

include the use of plastic or metal conduit to protect the cable.

A 30 mA Residual Current Device ‘RCD’ must be fitted to the mains supply.

WARNING - THIS APPLIANCE MUST BE EARTHED.

IMPORTANT

- The wires in this mains lead are coloured in accordance with

the following code:

BROWN - LIVE BLUE - NEUTRAL GREEN/YELLOW - EARTH

The Brown lead should be connected to the Live

terminal, which may be

marked with an ‘L’ or coloured brown or red.

The Blue lead should be connected to the Neutral

terminal, which may be

marked with an ‘N’ or coloured blue or black.

The Green/Yellow lead should be connected to the Ear

th terminal, which

may be marked with an ‘E’ or coloured green or yellow.

WARRANTY

The Powerjet Pond Pumps are guaranteed against defects in material or

workmanship for a period of 3 years from date of purchase, under normal usage.

Powerjet Pond Pumps will be repaired or replaced at manufacturer’s discretion, free

of charge. This warranty does not apply to any Powerjet Pond Pump which has

been subjected to misuse, negligence, tampering or accidental damage to impeller

or impeller shaft. No liability is assumed with respect to loss or damage to livestock

or personal property irrespective of the cause thereof. This warranty does not affect

your statutory rights. Failure caused by misuse is not covered by this warranty.

3

Jolie Products Inc

Loading...

Loading...