Laguna MLA Revo User Manual

REVO 20-36 & 24-36 Lathe Manual

Model MLA REVO 20-0180

Model MLA REVO 24-0180

LAGUNA TOOLS

17101 Murphy Ave.

Irvine, California 92614

Ph: 800.234.1976

www.lagunatools.com

Part No. MLA REVO 20-0180

Part No. MLA REVO 24-0180

© 2013 Laguna Tools, Inc. All rights reserved.

2

Dear Woodworker:

Thank you for your purchase and welcome to the Laguna Tools group

of discriminating woodworkers. I understand that you have a choice

of where to purchase your machines and appreciate the confidence

you have in our products.

Every machine sold by Laguna Tools has been carefully designed and

well thought through from a woodworker’s perspective. I cut on our

bandsaws, lathes, table saws and combination machines. Through

my hands-on experience, I work hard to make our machines better.

I strive to give you machines that inspire you to create works of art.

Machines that are a joy to run and work on. Machines that

encourage your performance.

Twenty years ago Laguna Tools was founded to introduce European

woodworking machines to the North American woodworker. Today,

we offer high-performance machines with innovative solutions that

meet the needs of woodworkers and their ever-evolving craft.

I started Laguna Tools as a woodworker, I still am.

Thank you again for becoming a Laguna Tools customer.

Torben Helshoj

President and Founder - Laguna Tools

Imagination, Innovation and Invention at work.

4

Safety Rules

As with all machinery there are certain hazards involved with the operation

and use. Using it with caution will considerably lessen the possibility of

personal injury. However, if normal safety precautions are overlooked or

ignored, personal injury to the operator may result. If you have any

questions relative to the installation and operation, do not use the

equipment until you have contacted your supplying distributor.

Read carefully before operating the machine.

1. Keep the working area clean and be sure adequate lighting is

available.

2. Do not wear loose clothing, gloves, bracelets, necklaces or

ornaments. Wear face, eye, respiratory and body protection devices

as indicated for the operation or environment.

3. Be sure that the power is disconnected from the machine before

tools are serviced or an attachment is to be fitted or removed.

4. Never leave the machine with the power on.

5. Do not use dull, gummy or cracked cutting tools.

6. Be sure that the keys and adjusting wrenches have been removed

and all the nuts and bolts are secured.

5

Limited Warranty

New woodworking machines sold by Laguna Tools carry a one-year warranty

from the date of shipping. Laguna Tools guarantees all new machines sold to be

free of manufacturers’ defective workmanship, parts and materials. We will

repair or replace without charge, any parts determined by Laguna Tools, Inc. to

be a manufacturer’s defect. We require the defective item/part returned to

Laguna Tools. In the event the item/part is determined to be damaged due to

lack of maintenance, cleaning or misuse/abuse the customer will be responsible

for the cost to replace the item/part, plus all related shipping charges. This limited

warranty does not apply to natural disasters, acts of terrorism, normal wear and

tear, product failure due to lack of maintenance or cleaning, damage caused by

accident, neglect, lack of or inadequate dust collection, misuse/abuse or damage

caused where repair or alterations have been made or attempted by others.

Laguna Tools, Inc. is not responsible for additional tools or modifications sold or

performed (other than from/by Laguna Tools, Inc.) on any Laguna Tools, Inc.

woodworking machine. Warranty may be voided upon the addition of such noted

tools and/or modifications, determined on a case-by-case basis.

Normal user alignment, adjustment, tuning and machine settings are not covered

by this warranty. It is the responsibility of the user to understand basic

woodworking machinery settings and procedures and to properly maintain the

equipment in accordance with the standards provided by the manufacturer.

Parts, under warranty, are shipped at Laguna Tools, Inc’s cost either by common

carrier, UPS Ground service or similar method. Technical support to install

replacement parts is primarily provided by phone, fax or email. The labor

required to install replacement parts is the responsibility of the user.

Laguna Tools is not responsible for damage or loss caused by Freight Company

or other circumstances not in our control.

Only new machines sold to the original owner are covered by this warranty. For

warranty repair information, call 1-800-332-4094.

Copyright 2010 Laguna Tools, Inc.

** Warning – no portion of these materials may be reproduced without written

approval from Laguna Tools, Inc.

INTRODUCTION TO THE LATHE

Turbo lathes are designed and built to satisfy the most imaginative fantasies of

woodworkers. With outstanding new features, energetic performances and so many userfriendly considerations, Turbo lathes simply turn turning jobs an unprecedented

experience.

Featuring

High grade cast iron structure for headstock, beds and stands to secure maximum

stability

All beds are precisely ground to mirror like surface for smooth operations

Driven by advanced Servo DC brushless motor with variable speeds 50-3500 RPM

Digital wide angle speed readout with blue backlight

Extraordinarily high torque at low speeds for easy working on large workpiece

Oversized alloy spindle supported by three precision bearings

Easy belt changing without taking off spindle

Sliding headstock for easy outboard turning

Unique “Swing-away” Extension Bed System (SEB) for easy tailstock storage

(standard for T-60, optional for T-50)

Heavy duty banjo with easy maneuver and secure locking

Cast steel chrome trimmed tool rest

End mounts for extension bed for longer center distance

Side mounts of extension bed for back turning

Lower end mounts of extension bed for outboard turning set up

Extension bed mounts on both ends of bed

Built-in spindle lock and index

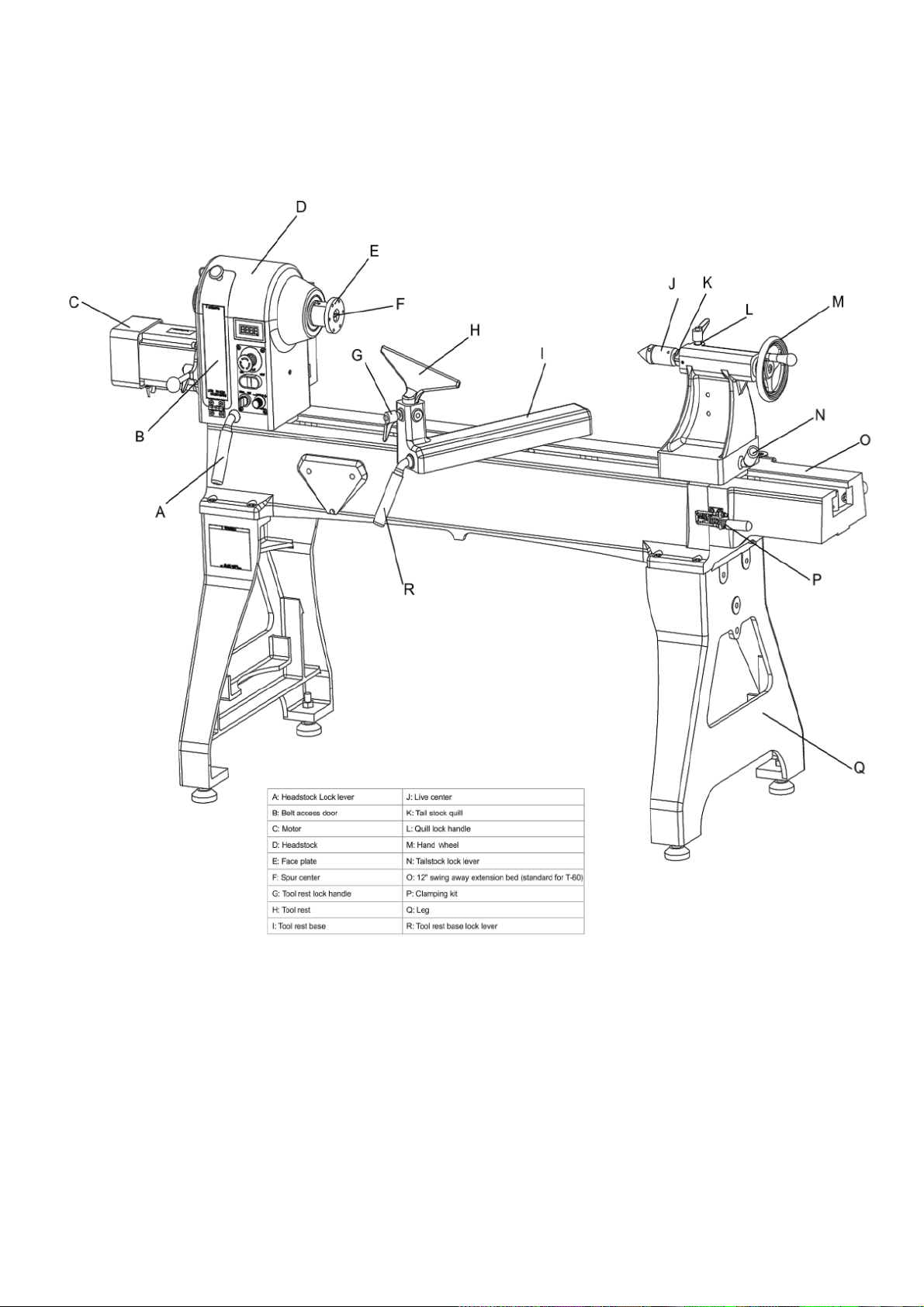

Identifications

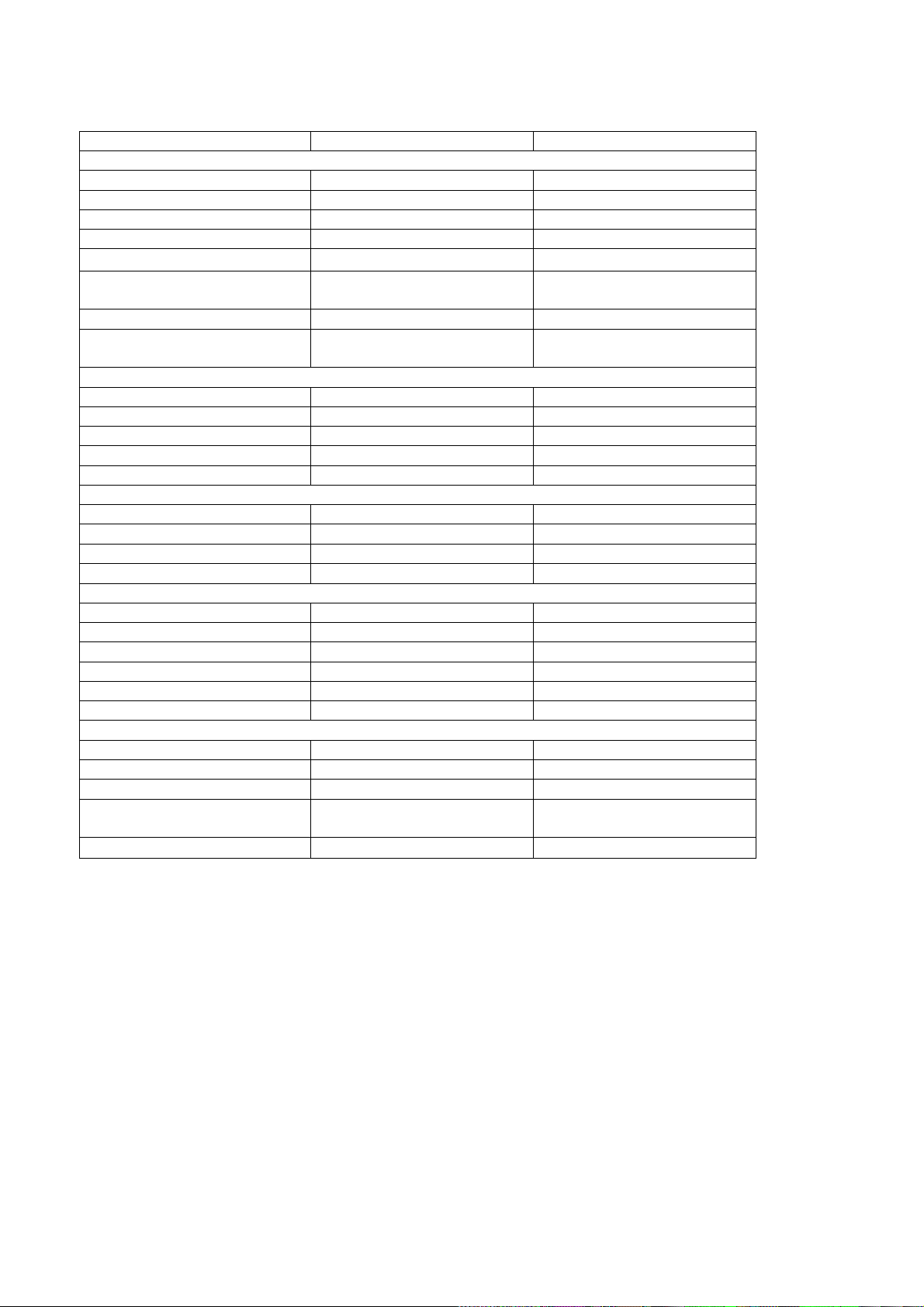

Specifications

Models

T-50

T-60

Operation Information

Swing Over Bed

20”

24”

Dist. Between Centers

36”

48”

Swing Over Tool Rest Base

16”

20”

Spindle Speeds: H

200-3500rpm (Variable)

200-3500rpm (Variable)

L

50-820rpm (Variable)

50-820rpm (Variable)

Floor to Spindle Center

Height

44”

44”

Headstock Travel

Full Length

Full Length

Max. Outboard Turning

Swing

32”

34”

Spindle

Spindle Taper

MT#2

MT#2

Spindle Size

1-1/4 x 8(RH) TPI

1-1/4 x 8(RH) TPI

Spindle Bore

5/8”

5/8”

Spindle Index#

48

48

Spindle Bearing

2x6209 Front, 1x6208 Rear

2x6209 Front, 1x6208 Rear

Tailstock

Tailstock Taper

MT#2

MT#2

Hole through Tailstock

3/8”

3/8”

Tailstock Quill Travel

4-1/2”

4-1/2”

Swing away

Optional

Standard

Accessories

Tool Rest Width

14”

14”

Face Plate

3”

3”

Swing away Bed Length

12”

12”

Spur Center

MT#2

MT#2

Live Center

MT#2

MT#2

Extension Bed

20”

20”

Electrical and Motor information

Motor Type

DC Brushless

DC Brushless

Motor Power

2HP

3HP

Speed

0-3500rpm

0-3500rpm

Switch

On/Off w/contactor, Variable

Speed Dial

On/Off w/contactor, Variable

Speed Dial

Power requirement

230V/single phase

230V/single phase

Standard accessories:

Spur Center

Live Center

Face Plate

Knockout Rod

Tool Kits

Optional accessories:

12” Extension bed with swing away system (standard for T60)

20” Extension bed

2nd lathe bed

Tool rest riser bushing for outboard turning

Chisel storage pan

Spindle shield

Comparator kits

Mobility kits

POWER SUPPLY

Warning: For your own safty and protection of property, consult an electrician if you are

unsure about wiring practices or electrical codes in your area.

Caution: If the plug does not fit the available receptacle, or the machine must be

reconnected for use on a different type of circuit, or use an extension cord with this

machine, the reconnection must be made by a qualified electrician and comply with all

local codes and ordinances.

Nominal Voltage-----------220V/240V

Cycle--------------------------50/60Hz

Phase-------------------------Single-Phase

Power Supply Circuit----- 15Amps (T-50), 20Amps (T-60)

ASSEMBLY & SETUP

Location of the lathe

A level concrete floor is the best location for the lathe. The lathe should be located in a dry

area. Keep electrical box and motor away from direct sun shine. Plenty of space around

the lathe is good for operations and maintenances.

Unpacking

Report any damage to your shipping agent or dealer immediately as soon as check for

shipping damage.

Check the shipping crate with the following parts list to make sure all parts are intact. If

there is any missing parts please report to your dealer. Read this manual thoroughly for

assembly, maintenance, operation and safety instructions.

Contents of the Shipping Crate(Fig.1)

A, Lathe bed with Headstock,

Tailstock, Tool Rest Base (Banjo),

Tool Rest

B, Leg Assemblies x 2

C, Knockout rod x 1

D, Face plate wrench x 1

E: Spindle lock rod x 1

F: Live center pin x 1

G: Live center x 1

H: Spur center x 1

I: 12mm alan wrench x 1

J, 3mm alan wrench

K,12mm bolt x 6

L, 12mm spring washer x 6

M, 12mm flat washer x 2

N, Tool storage bracket x 1

O, Foot x 4

P, Operation Manual

Fig. 1

Loading...

Loading...