Page 1

78 00 10 78 00 00

Directions for Use

Laerdal Suction Unit

www.laerdal.com

Page 2

1 Cautions and Warnings

Read these Directions for Use carefully, and

become thoroughly familiar with the operation

and maintenance of the LSU before using it.

The LSU should only be used by persons trained

in the use of medical suction equipment.

The LSU is not suitable for use in the presence

of flammable liquids or gases;

there can be a danger of explosion or fire.

Do not use the LSU under environmental

conditions that are outside the ranges specified

under section 11.6.This can endanger safety and

adversely affect operation of the device.

Battery:

- To maintain satisfactory operation of the

battery, it is recommended to place the LSU

on continuous charge when not in use.

- The LSU must be placed on charge for a

minimum of 24 hours to reach full battery

capacity. The fast charging gives approximately

80% battery capacity after 3 hours (for a new

battery). Please note that repetitive 3 hour

charging is not recommended.

- If it is not possible to place the LSU on

continuous charge when not in use, make sure

the battery is charged for a minimum of

24 hours at least once a month.

- Do not store the battery when it is

discharged; always fully charge the batter y

before storage.

Do not immerse the LSU or allow it to stand in

water or other liquids.This might damage the

device, and cause electrical hazard.

Do not pump any cleaning solution or other liquids through the vacuum pump, i.e. through the

Vacuum Connector.This can damage the LSU.

Use only accessories supplied by Laerdal or one

of our authorised distributors to ensure that the

LSU operates satisfactorily.

Do not block the Exhaust Outlet during use. This

will lead to reduced flow and can also cause

damage to the LSU.

Do not use the Reusable version without a filter

or the Float Ball. Use only the disposable Abbott

liner with filter.

If overflow of liquid from the Canister into the

pump is suspected, the LSU must be returned for

service (see section 9). Overflow of suctioned

material can damage the device.

Disconnect the LSU from external power prior

to cleaning. Use a minimum of liquid to prevent

any electrical shock hazard.

2

Page 3

Contents

1 Cautions and Warnings . . . . . . . . . . . . . . . .2

2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Unpacking and prepare

the LSU for use . . . . . . . . . . . . . . . . . . . . . 4

2.2 Indications for Use . . . . . . . . . . . . . . . . . . 4

2.3 Contraindications . . . . . . . . . . . . . . . . . . . 4

2.4 Features and Benefits . . . . . . . . . . . . . . . . 4

2.5 Limited Warranty . . . . . . . . . . . . . . . . . . . 4

3 Description . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Quick Reference Guide . . . . . . . . . . . . . . 5

3.2 User Interface . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Canister Systems . . . . . . . . . . . . . . . . . . . . 8

3.4 Power Sources . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Automatic Power-save Function . . . . . . . . 9

4 Operation LSU

with Reusable Canister . . . . . . . . . . . . . . 10

4.1 Getting Started . . . . . . . . . . . . . . . . . . . . .10

4.2 Emptying the Canister . . . . . . . . . . . . . . .10

4.3 Assembly of the Reusable

Canister System . . . . . . . . . . . . . . . . . . . . .11

4.4 After Use . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Operation LSU

with Disposable Canister. . . . . . . . . . . . . 13

5.1 Getting Started . . . . . . . . . . . . . . . . . . . . 13

5.2 Replace the Disposable Canister . . . . . . 13

5.3 Assembly of the Disposable

Canister System . . . . . . . . . . . . . . . . . . . . 14

5.4 After Use . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Maintenance . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.2 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.3 Cleaning the Cabinet . . . . . . . . . . . . . . . .15

6.4 Decontamination of Reusable Par ts . . . .16

6.5 Charge the Batter y . . . . . . . . . . . . . . . . . 17

6.6 Check the Batter y Quality . . . . . . . . . . . 17

6.7 Replace the Batter y . . . . . . . . . . . . . . . . . 18

6.8 Fastening brackets . . . . . . . . . . . . . . . . . . 18

6.9 Release arm for Canister holder . . . . . . 18

7 Device Test . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 Run the test . . . . . . . . . . . . . . . . . . . . . . . 18

7.3 Evaluation of Device test Results . . . . . . 20

8 Accessories and Par ts . . . . . . . . . . . . . . . 21

9 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10 Trouble Shooting . . . . . . . . . . . . . . . . . . . 22

11 Specifications . . . . . . . . . . . . . . . . . . . . . . 23

11.1 Classification . . . . . . . . . . . . . . . . . . . . . . . 23

11.2 General tolerance . . . . . . . . . . . . . . . . . . 23

11.3 Physical Characteristics . . . . . . . . . . . . . . 23

11.4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . 23

11.5 Power Requirements . . . . . . . . . . . . . . . . 24

11.6 Environmental Conditions . . . . . . . . . . . 24

11.7 Material Chart . . . . . . . . . . . . . . . . . . . . . 24

11.8 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

11.9 EMC Specifications . . . . . . . . . . . . . . . . . 25

12 Addresses . . . . . . . . . . . . . . . . . . . . . . . . . 27

ENGLISH

3

Page 4

2 Introduction

2.1 Unpacking and prepare the LSU for use

- Remove the LSU from its packaging and

inspect all parts for damage. If there are any

signs of damage or if any parts are missing,

immediately notify Laerdal or one of our

authorised distributors.

- Insert the battery according to section 6.7.

- Place the LSU on charge for a minimum of

24 hours to make sure you have a fully

charged battery (see section 6.5).

- After being charged for 24 hours, perform the

Device Test according to section 7.

2.2 Indications for Use

The LSU is a portable, electrically powered,

medical suction equipment intended for field and

transport use. It is intended for intermittent

operation to remove secretions, blood or vomit

from a patient´s airway to allow ventilation.

Higher vacuum levels are generally selected for

oropharyngeal suctioning, and lower vacuum

levels are usually selected for tracheal suctioning

and the suctioning of children and infants.

2.3 Contraindications

None known.

2.4 Features and Benefits

- Splashproof, rugged and solid.

- Easy access to the tubing.

- Equipped with an internal battery that can

easily be replaced without using tools.

- Charging of battery can be done directly from

AC or DC mains - no external charger is

needed.

- Fast charge option of 3 hours, giving approx.

80% battery capacity.

- Operation possible from internal battery and

directly from AC or DC mains - no adapter is

needed.

- A large combined ON/OFF switch and

vacuum selector makes operation easy even

with heavy-duty gloves.

- A green LED bargraph makes it easy to

observe the actual vacuum level during

operation.

- Another green LED bargraph indicates approx.

remaining battery capacity.

2.5 Limited Warranty

The LSU comes with a five (5) year limited

warranty*. See the enclosed “Laerdal Global

Warranty” for terms and conditions.

The warranty is also available at

www.laerdal.com

* Excluding the canister and tubing systems.

4

Page 5

3 Description

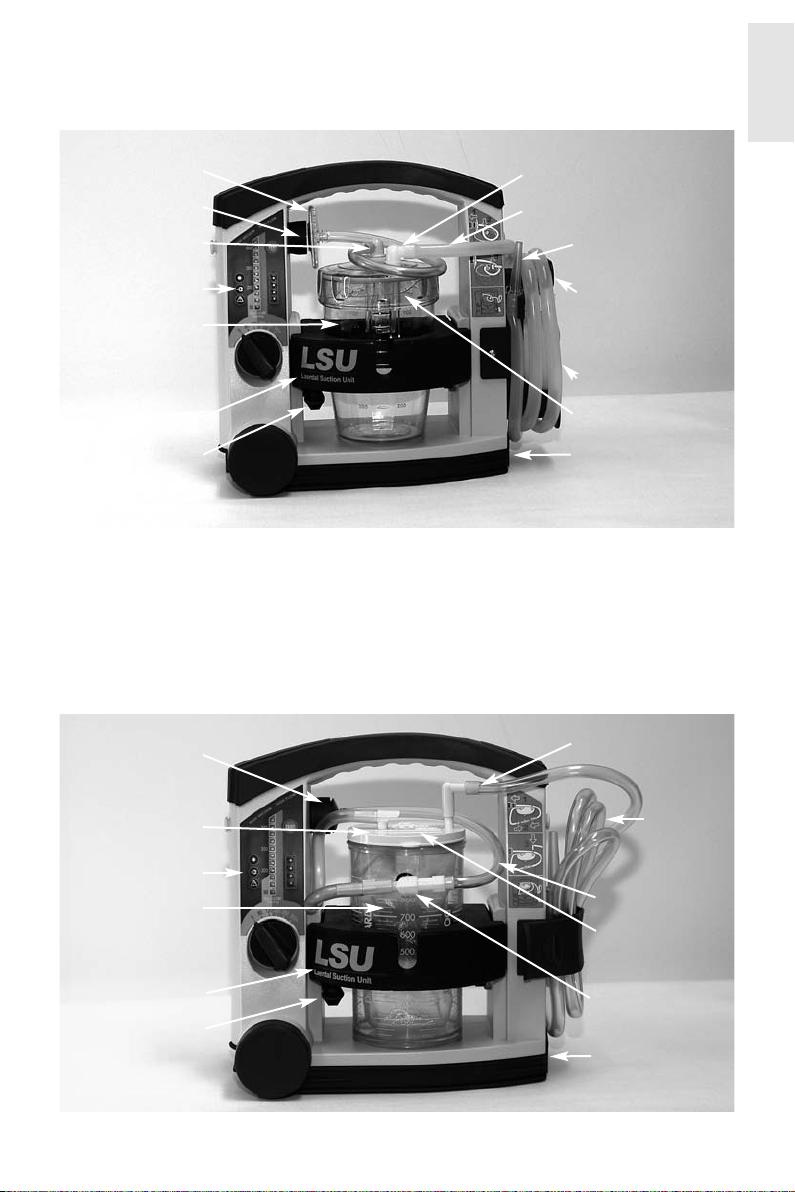

3.1 Quick Reference Guide

3.1.1 LSU w/Reusable Canister System

ENGLISH

Aerosol Filter

Vacuum Connector

VACUUM Inlet

User Interface

Canister

Canister Holder

Release Arm

3.1.2 LSU w/Disposable Canister System

Vacuum Connector

PATIENT Inlet

Patient Suction Tubing

Suction Catheter

Adapter

Holder for Water

Bottle/Patient

Suction Tubing.

Water Bottle

Canister Lid

with Float Ball

Battery Door

PATIENT Inlet

VACUUM Inlet

User Interface

Canister

Canister Holder

Release Arm

Patient

Suction

Tubing

Vacuum tubing

Abbott liner

with filter

T-bar

Battery Door

5

Page 6

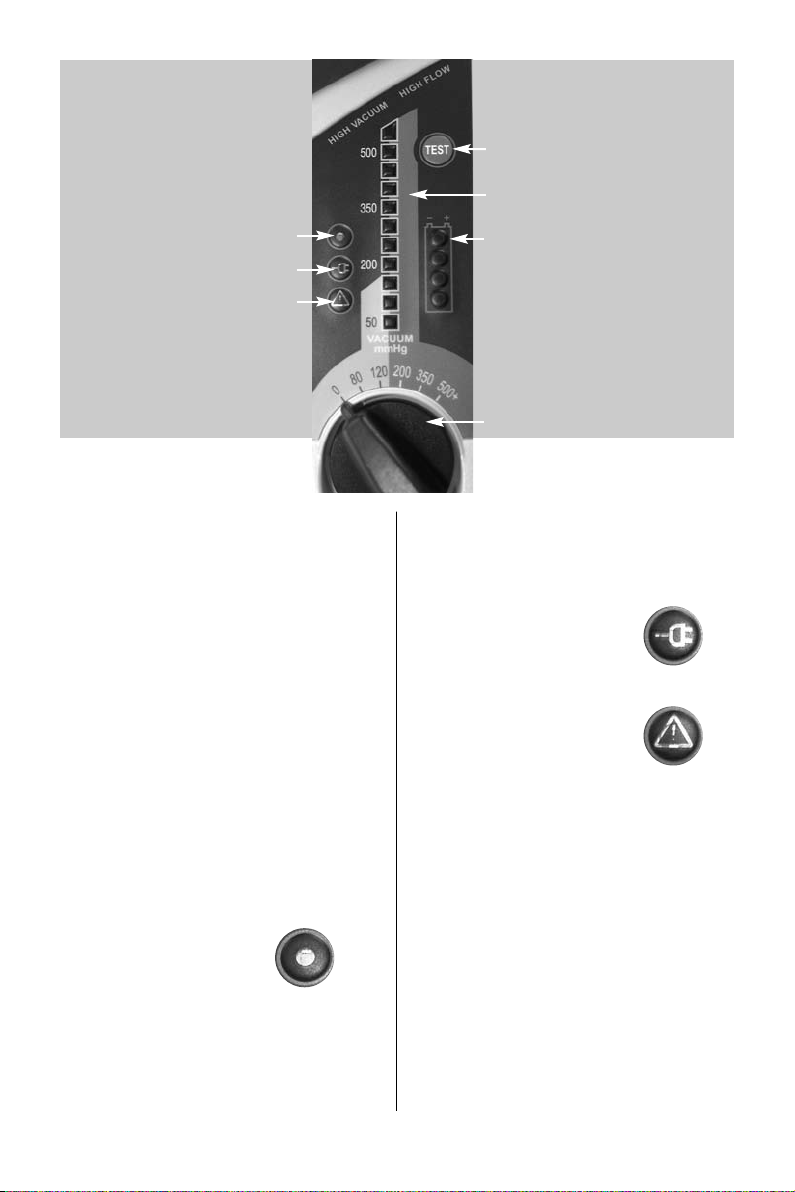

TEST-Button

Vacuum Indicator

Power ON Indicator

External Power Indicator

Failure Mode Indicator

3.2 User Interface

3.2.1 Operating Knob

The Operating Knob is a combined ON/OFF

switch and vacuum selector, located at the bottom of the User Interface.

The LSU is switched ON by turning the

Operating Knob to the required setting. Each setting indicates the maximum achievable vacuum

level for the selected position (80, 120, 200, 350,

500+ mmHg).The free air flow value changes

along with the increasing vacuum settings

(see section 11.4 for details).The LSU is switched

OFF by resetting the Operating Knob to "0".

Even if the Operating Knob is in “0” position,

voltage is present on some of the internal circuitry, when the LSU is connected to mains.To fully

remove power, pull out the Power Cord.

3.2.2 Indicators

3.2.2.1 Power ON Indicator

This green LED has 3 modes:

- It is lit continuously while the LSU is

switched ON.

- It flashes rapidly (approx. twice per second)

during the Device Test.

Battery Status Indicator

Operating Knob

- It flashes slowly (approx. once per second)

while the Automatic Power-save Function is

activated, if the Device Test is interrupted or

when the battery is discharged.

3.2.2.2 External Power Indicator

This green LED is continuously lit

while external AC or DC power is connected.

3.2.2.3 Failure Mode Indicator

The red LED is lit when a possible

malfunction of the LSU has been

detected. If lit, turn the LSU OFF, and then ON

again to check if the indication disappears.

Provided that the indication does not occur

again the LSU can be operated. If the Indicator

continues to lit after three OFF/ON cycles and

after replacing the battery with a fully charged

battery, discontinue use and return the LSU for

service. (See section 9).

6

Page 7

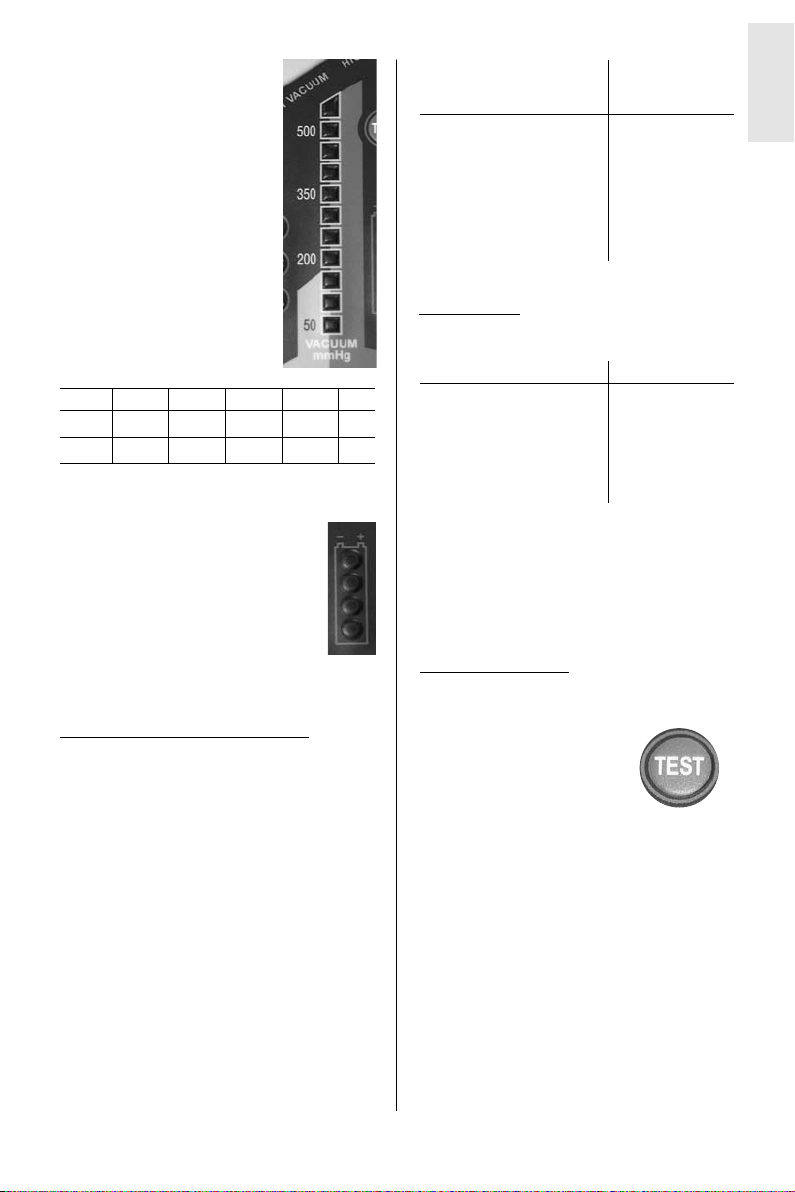

3.2.2.4 Vacuum Indicator

This green LED bargraph displays

the actual vacuum level during

operation of the LSU.

Each fully lit segment represents

50 mmHg. If a segment has a

weak light, this represents

25 mmHg (e.g 125 mmHg

means 2 fully lit and 1 weakly

lit segments).

mmHg 80 120 200 350 500

kPa 1116274767

mBar 107 160 267 467 667

CAPACITY for a

new battery stored in

room temperature OUTPUT

> 75 % 4 LEDs lit.

50 - 75% 3 LEDs lit.

25 - 50% 2 LEDs lit.

< 25% 1 LED lit.

Battery Low; (min. 2 minutes

of operation left based

on 500+ mmHg/free flow). 1 LED flashes.

During charging: indicates approx. achieved

battery capacity.

CAPACITY OUTPUT*

< 75% The LED's will be

lit sequentially.

75 - 80% 3 LED's lit and

4th flashing.

> 80% 4 LED's lit.

ENGLISH

3.2.2.5 Battery Status Indicator

This green LED bargraph has 3 functions:

- Indicates remaining battery capacity

during operation from internal batter y

- Indicates approx. achieved battery

capacity during charging

- Indicates which test is currently

in progress during device test

During operation from internal batter y:

- indicates approx. remaining battery capacity.

During operation from internal batter y and during charging the displayed values must only be

used as indications.

Several parameters can influence them e.g.

device settings, state of battery, temperature etc.

Note:

Immediately after turning the LSU ON and

immediately after switching from external power to

internal battery operation, all 4 LED's will flash for

5 seconds before the remaining battery capacity

is displayed.

*Note:

If no battery is installed, the battery status indicator

will be fully lit for approx. 5 sec. until it is turned off.

During the Device Test: indicates which step of

the test is currently in progress or which corre-

sponding test result is being displayed:

LED 1 (lower LED) lit = STEP 1,

LED 2 lit = STEP 2 etc.

3.2.3 TEST-Button

This button allows you to run a 4-step

user initiated Device Test program to identify

whether the LSU is operating satisfactorily or if it

needs service (see section 7).

7

Page 8

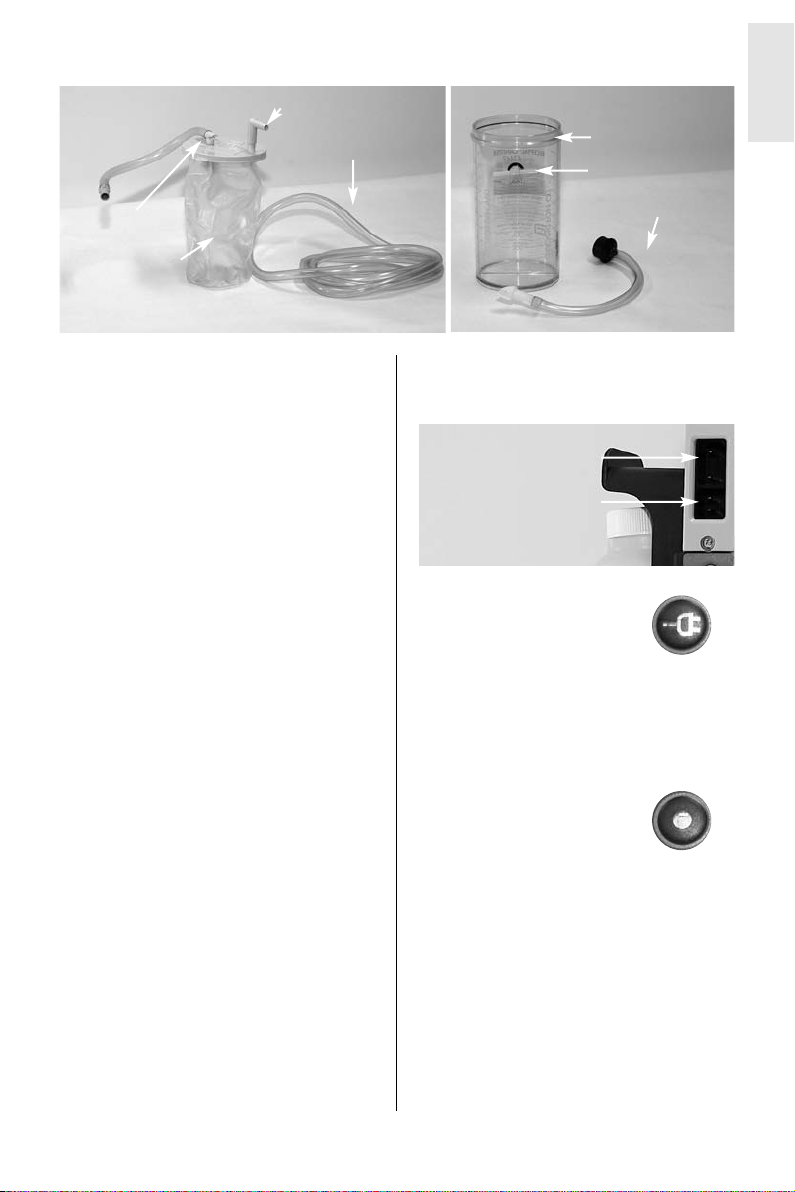

3.3 Canister Systems

The LSU can be delivered with a Reusable or a

Disposable Canister System as described below.

Both Canisters have a corresponding sized

Canister Holder.

3.3.1 LSU Reusable Canister System

Patient Suction Tubing

Angled Connector

Suction Catheter Adapter

Canister

Gasket

Vacuum seal

The LSU Reusable Canister System consists of:

- A 1000 ml transparent plastic Canister.

- A Canister Lid w/Float Ball that prevents

overflow if the Canister is full or the LSU

tips over.

- An Aerosol Filter with tubing that protects

the LSU by preventing aerosols from entering

the Pump Unit.*

The Canister Lid contains a Float Ball that shuts

off the vacuum if the canister is full or the LSU

tips over.To reset the valve, remove the Angled

Connector from the VACUUM Inlet.

The LSU Reusable Canister System must

not be used without the Aerosol Filter

or the Float Ball.

It is recommended always to have extra Aerosol

Filters with the LSU in case one has to be

discarded.

PATIENT Inlet

VACUUM Inlet.

Canister Lid w/Float Ball

Aerosol Filter

Decontamination must be performed in accordance with section 6.4.

For the Aerosol Filter the instructions below

must be followed:

- The Aerosol Filter is not designed for

decontamination.

- It is recommended that the Aerosol Filter be

replaced after each use or at least once every

shift. If the LSU is used on patients or in areas

where cross contamination is not an issue, the

Aerosol Filter should be replaced at least

once a month.

- If the Aerosol Filter becomes wet, it should

be replaced immediately or as soon as

possible after use.

*The Aersol Filter is not intended for microbiological or for particle filtration.

8

Page 9

3.3.2 Disposable Canister System

Disposable Parts

VACUUM Inlet

Disposable Liner

including lid with

filter, tube and

connectors

PATIENT Inlet

Patient Suction Tubing

Reusable Parts

ENGLISH

Reusable Canister

T-bar

Vacuum Connector

Tubing

The Disposable Canister System consists of:

- A 1000 ml reusable transparent plastic

Canister including a Canister Connector.

- A disposable liner including lid with filter, tube

and connectors.

The Abbott Receptal® Canister contains a

hydrophilic filter that shuts off the vacuum if the

canister is full or the LSU tips over.To restore the

vacuum, replace the inner liner.

Note:

Do not use an Abbott liner without a filter!

The disposable parts must be replaced after each

use.The Reusable Canister must be cleaned as

stated on the canister. The Vacuum Connector

Tubing is reusable and should be cleaned in

accordance with section 6.3.

A Filter Tubing is available for the Abbott Canister

System (see section 8).

3.4 Power Sources

The LSU is delivered with an AC Power Cord for

connection to AC mains and a DC Power Cord

for connection to DC mains.

The device can be operated from the internal

battery, and can be operated or charged from

one of the following external Power Sources:

- AC mains when used with the AC Power

Cord: 100-240 VAC (50/60/400 Hz).

- DC mains when used with the DC Power

Cord: 12-28 VDC .

A Wall Bracket to hold the LSU during operation

and (optional) charging is available separately

(see section 8).

AC Connector Socket

DC Connector Socket

External power connection will cause the

External Power Indicator to be lit.

Always check that it is lit when

connecting external power or

inserting the LSU into the Wall Bracket.

3.5 Automatic Power-save Function

The LSU has an Automatic Power-save Function

that switches the pump motor off.

While in this mode, the Power ON

Indicator will flash slowly

(approx. once per second).

This function will be activated when the

Operating Knob is set to 200, 350 or 500+

mmHg and the actual vacuum level has been

continuously higher than 120 mmHg for more

than 2 minutes.

To exit the Power-save Mode and revert to

normal operation, set the Operating Knob to

any other position and then go back to required

setting.

9

Page 10

4. Operating LSU with Reusable Canister

Note: Read all the Cautions and Warnings listed in

section 1 thoroughly before you use the LSU. The

parts are color coded to help re-assembly after

cleaning.

4.1 Getting Started

1. Check that no par ts are missing and that all

parts are clean.

2. If you decide to operate the LSU from

external power, connect to either external AC

or DC power as described in section 3.4.

If you decide to operate the LSU from internal

battery, check that the battery is installed.

3. Ensure that the Patient Suction Tubing is

securely connected to the PATIENT Inlet on

the Canister Lid; and the Aerosol filter is

securely fastened in the LSU and the lid.

5. Set the Operating Knob to the required

vacuum level.The LSU will automatically

be switched ON and start to operate.

The green Power ON Indicator is lit

continuously while the LSU is switched ON.

6. When suction is complete, set the Operating

Knob to "0"

Note:To prevent overflow, the LSU must be

transported in an upright position when the canister

contains suctioned material.

4.2 Emptying the Canister

Note:To prevent damage and keep the LSU in good

working order; empty the canister when 3/4 full.

Check the filter after each use.

If the filter is broken so liquid penetrates the

membrane, the pump will be contaminated, and

the LSU must be returned for service

(see section 9).

When liquid reaches the top of the Canister, the

LSU will stop suctioning.To continue suctioning,

empty canister and replace the filter.

Over flow of suctioned material can damage

the device.

4 Unwrap the Patient Suction Tubing.

Note:The LSU must be operated in the

upright position to prevent overflow of

suctioned material.

To remove the Canister, proceed as follows:

1. Disconnect the Filter Tubing from the blue

Vacuum Inlet (see section 3.3.1 regarding

handling instructions for the Aerosol Filter).

10

Page 11

2. To release the Canister Holder, press down

the Release Arm while sliding the Holder

towards you. Remove the Canister from the

Holder.

3. Release the Patient Suction Tubing

(if applicable).

4. Safely dispose of the contents of the Canister

according to local protocols.

5. Clean the LSU according to section 6.3 and its

reusable parts according to section 6.4.

4.3 Assembly of the Reusable Canister System

ENGLISH

3. Secure the Lid to the Canister by turning it

clockwise until it is securely fastened.

4. Connect the Suction Catheter Adapter to

the Patient Tube.

5. Connect the Angled Connector to the Patient

Tube.

1. Place the yellow Gasket in the Lid, make sure

that the gasket is placed flat in the Lid and

not twisted.

2. If the Float Ball has been removed, hold the

lid upside down and snap the ball into place

as shown.

Note: Never use the LSU without the Float Ball.

6. Mount the yellow Vacuum Seal in the centre

hole of the Lid and push it into place.

7. Connect the Aerosol Filter (blue ring) to

the blue Vacuum Inlet on the LSU.

(Color code: Blue on Blue)

11

Page 12

8. Inser t the Canister in the canister holder and

slide it into the LSU.

9. Connect the yellow Angled Connector to

the yellow Vacuum Seal

(Color code:Yellow on Yellow)

10. Connect the Angled Connector on the

Patient tubing to the PATIENT Inlet on the

canister Lid.

11. Perform the Device Test according to

section 7

4.3.1 Reusable

Canister System Quick reference

The assembly of the tubing is illustrated on the

right side of the LSU.

1. Connect the blue Aerosol filter to the blue

Vacuum Inlet.

2. Connect the yellow angled connector to the

yellow Vacuum Seal.

3. Connect the Patient Tubing to the Patient inlet.

4.4 After Use

- When suction is complete, set Operating

Knob to ”0” and inspect all parts for damage

or excessive wear. Replace parts if necessary.

- Clean the LSU according to section 6.3 and its

reusable parts according to section 6.4.

- Perform the Device Test according

to section 7.

- Place the LSU on charge (see section 6.5).

12. Wind the Patient Tubing on the Patient

Tubing Holder

13. Place the LSU on charge (see section 6.5)

Note: Connect tubing according to color code:

Blue on Blue & Yellow on Yellow.

12

Page 13

5. Operating LSU with Disposable Canister

5.1 Getting Started

Note: Read all the Cautions and Warnings listed in

section 1 thoroughly before you use the LSU.

1. Check that no parts are missing and that

all parts are clean.

2. If you decide to operate the LSU from

external power, connect to either external AC

or DC power as described in section 3.4.

If you decide to operate the LSU from internal

battery, check that battery is installed.

3. Ensure that the T-bar is securely tightened and

the yellow connector from the Abbott liner

goes to the yellow T-bar on the canister.

(Yellow on Yellow).

4. Connect the blue Vacuum Tubing connector to

the blue Vacuum Inlet on the LSU.

(Blue on Blue).

Connect the yellow connector to the yellow

T-bar (Yellow on Yellow).

5. Ensure that the Patient Suction Tubing is

securely connected to the PATIENT Inlet on

the Canister Lid.

8. When suctioning is complete, set the

Operating Knob to "0"

ENGLISH

Note:To prevent overflow the LSU should be

transported in an upright position when the canister

contains suctioned material.

5.2 Replace the Disposable Canister

Note: It is recommended to replace the Canister

when it is 3/4 full.

When liquid reaches the top of the Canister, the

LSU will not suction any more liquid. If over

flow of liquid from the Canister into the pump

is suspected, the LSU must be returned for service

(see section 9).

Over flow of suctioned material can damage the

device.

To remove the Canister, proceed as follows:

1. Disconnect the Vacuum Connector Tubing at

the yellow T-bar on the canister Connector.

6 Release the Strap holding the Patient Suction

Tubing.

Note:The LSU should be operated in the

upright position to prevent overflow of

suctioned material.

7. Set the Operating Knob to the required

vacuum level, and the LSU will automatically

be switched ON and start to operate.

The green Power ON Indicator is lit

continuously while the LSU is switched ON.

2. Release the Canister Holder, press down

the Release Arm while sliding the Holder

towards you.

3. Remove the Canister from the Holder.

4. Unwrap/release the Patient Suction Tubing

(if applicable).

13

Page 14

5. Safely dispose of the Abbott Liner according

to local protocols.

6. Clean the LSU according to section 6.3.

5.3 Assembly of the disposable canister system

1. Mount the Disposable Abbott Liner in

the Abbott Canister

2. Make sure that the yellow T-bar is securely

tightened. Connect the yellow connector

from the Abbott Liner to the yellow T-Bar on

the Abbott Canister.

(Color code:Yellow on Yellow).

4. Inser t the Canister in the in the Canister

Holder and slide it into the LSU.

5. Connect the yellow Connector on the Vacuum

tubing to the Yellow T-Bar on the Abbott

Canister (Color code:Yellow on Yellow).

6. Connect the white Angled Connector

to the Patient Tubing

7. Connect the white Angled Connector to the

white PATIENT INLET on the Abbott Liner

(Color code: White on White)

8. Perform the Device Test according to section 7

3. Connect the blue Vacuum Connector on the

Vacuum Tubing to the blue Vacuum Inlet on

the LSU.

(Color Code: Blue on Blue).

9. Strap the Patient Tubing to the side of the LSU.

10. Place the LSU on charge (see section 6.5)

Note:

Connect tubing to color code: Blue on Blue,

Yellow on Yellow & White on White.

14

Page 15

6. Maintenance

5.3.1 Disposable

Canister System Quick reference

The assembly of the tubing is illustrated on the

right side of the LSU.

1. Connect the blue Vacuum Connector on the

Vacuum Tubing to the blue Vacuum Inlet.

2. Connect the two yellow connectors to the

yellow T-bar on the Abbott canister.

3. Connect the white Patient Tubing to the

white Patient inlet.

5.4 After Use

- When suction is complete, set Operating

Knob to ”0” and inspect all parts for damage

or excessive wear. Replace parts if necessary.

- Clean the LSU according to section 6.3.

- Perform the Device Test according

to section 7.

- Place the LSU on charge (see section 6.5).

6.1 General

- Make sure the maintenance instructions

under section 4.4 and 5.4 are followed.

- If the device is not in frequent use

(i.e. less than once a month), the Device Test

(see section 7) should be performed both on

a monthly basis and after each use.

6.2 Battery

- To maintain satisfactor y operation of the

battery, it is recommended to place the LSU

on continuous charge when not in use.

- Replace the battery when it does not pass

the Battery Quality Check (see section 6.6

for details), or after 3 years.

- Do not store the LSU with an empty battery.

6.3 Clean the Cabinet

Warning: Disconnect the LSU from external power

prior to cleaning.

Use a minimum of liquid to prevent any electrical

shock hazard. Do not immerse the LSU or allow it

to stand in water or other liquids.This can damage

the device, and cause electrical shock resulting in

injury to persons.

- Use a cloth or sponge that is dampened with

a mild detergent (hand dishwashing liquid or

similar) to clean the external surfaces of the

LSU. Use a detergent that is compatible with

the materials listed under section 11.7, and

follow the detergent manufacturer´s

instructions.

- Use a cloth or sponge dampened with water

and wipe the surfaces again.

- Dry the surfaces using a clean cloth or

a paper towel.

ENGLISH

15

Page 16

6.4 Decontamination

of Laerdal Reusable Canister

6.4.1 Parts to be Decontaminated

After Each Use:

1. Canister Lid

2. Float Ball

3. Gasket.

4. Vacuum Seal

5. Angled Connector s

6. Canister

7. Patient Suction Tubing

8. Suction Catheter Adapter.

6.4.2 Preparation

- Remove and empty the Canister according

to section 4.2

- Disassemble the Canister into separate parts

as indicated in the picture above.

- The Float Ball on the reusable canister can

be snapped out of the lid.

6.4.3 Rinsing

- Rinse all parts under cold r unning water.

- Immerse in warm water (30-40°C).

6.4.4 Cleaning

- Immerse all par ts in hot water (60-70°C)

containing a mild detergent (see section 6.3).

- Thoroughly clean all surfaces, use a brush

where possible.

- Rinse in warm water and allow to dry.

- Inspect all parts to be visibly clean and dr y.

Note:

Thorough rinsing and cleaning are very important

steps prior to disinfection.

6.

1.

4.

2.

3.

5.

8.

7.

16

Page 17

6.4.5 Disinfection

To disinfect the par ts, the following methods are recommended:

ENGLISH

Method

Glutaraldehyde

Sodium Hypochlorite,

(not cleared

for use in the US)

Virkon

Steam autoclaving

Temperature/

Concentration

Room temperature/

Conc.: 2%

Room temperature/

Conc.: 0.5%

Room temperature/

Conc.: 1%

Autoclave at

max. 121° C

6.5 Charge the Battery

The internal rechargeable Lead-Acid battery can

be charged directly from external AC or DC

power as described in section 3.4. No external

charger is needed.To charge the battery, proceed

as follows:

1. Make sure the Operating Knob is set to "0".

Connect either external AC or DC power to

the LSU and charging will start automatically.

2. During charging the Battery Status Indicator

will indicate approx. achieved battery capacity

(see section 3.2.2.5 for details).

3. The LSU must be placed on charge for a

minimum of 24 hours to reach full battery

capacity. The fast charging gives approx.

80% capacity after 3 hours

(for a new battery).

Repetitive charging for only 3 hours is

not recommended.

Note:

- To maintain satisfactory operation of the battery,

it is recommended to place the LSU on

continuous charge immediately after use.

- It is recommended to always fully charge the

battery. Repetitive charging to a lower capacity

level will reduce battery life.

- If it is not possible to place the LSU on

continuous charge when not in use, make sure

the battery is charged for a minimum of

24 hours at least once a month.

Contact time

60 minutes

20 minutes

10 minutes

20 minutes

Post-treatment

Rinse all parts in clean,

warm water.Allow to dry.

Rinse all parts in clean,

warm water.Allow to dry.

Rinse all parts in clean,

warm water.Allow to dry.

Allow parts to cool.

- Do not store the batter y when it is discharged.

Always fully charge the battery before storage.

- The recommended ambient temperature for

charging is from 15°C to 25°C.

- The batter y will not be charged when the LSU

is in operation.

- If no batter y is installed, the battery status

indicator will be fully lit for approx. 5 sec. until

it is turned off.

6.5.1 External Battery Charge

The LSU battery can also be charged

in an optional External Battery Charger.

See section 8.

6.6 Check the Battery Quality

If poor battery quality is

suspected, charge the battery

for a minimum of 24 hours and

then perform the following test

without connection to external

LED 4____

LED 3____

LED 2____

LED 1____

power:

- Run the Device Test and then let the LSU

operate continuously at 500+ mmHg setting

and free air flow for 20 minutes.

- If the LSU stops before completing the

20 minutes, the battery should be discarded.

17

Page 18

6.7 Replace the Battery

Note:

Use only batteries recommended by Laerdal.

1. Open the Batter y Door.

2. To remove the battery, push and move it

slightly to the left and then release.

3. Withdraw the battery from the LSU.*

4. To insert a battery, push it fully in and then

to the right to lock it.

5. Close the Batter y Door.

6. After inser ting the batter y, place the LSU on

charge unless a fully charged battery

is inserted.

*When you discard the battery, dispose of safely in

accordance with local protocols for sealed lead acid

batteries.

Fastening

brackets

6.8 Fastening brackets

The fastening bracket is used to hold the LSU in

the optional wall bracket. Inspect the fastening

brackets for wear and tear regularly.

Replace if worn. See section 8.

7 Device test

The Device test is user initiated test program for

all models which can identify whether the LSU

operates satisfactorily or if the LSU needs

service.

The program runs 4 different tests:

1 It tests for occlusions in the Suction System

(including canister and tubing)

2 It tests the vacuum build-up efficacy of the

Pump System (How much vacuum is built up

within 3 seconds)

3 It tests the maximum achievable vacuum level

of the LSU (reaches this level within

10 seconds)

4 It tests if there are air leakages in the Pump

System (including canister and tubing)

7.1 Setup

Before the test can be performed

make sure that:

- The Patient Suction Tubing is unwound and

not blocked or bent

- The Suction Catheter Adapter is removed

from its holder (if applicable)

- The canister lid,T-bar, angled connector

and tubing are securely fastened.

7.2 Run the Test

6.9 Release arm for Canister holder

An extra release arm for the canister holder can

be attached. See section 8.

1 Press and hold the TEST-Button while setting

the Operating Knob to 500+ mmHg.

Note: Do not release the TEST-Button until min.

2 seconds after the Operating Knob has been set

to 500+ mmHg.The test will start immediately

18

Page 19

2 As soon as LED 2 from the bottom of the

Battery Status Indicator comes on (takes

approx. one second), fully block the Patient

Suction Tubing until all 4 LED’s have

illuminated and LED 1 lights up again.*

3 Keep the tubing blocked while LED 2 , 3

and 4 lights up.

* If the tubing is not occluded within 2 minutes, the

test will be interrupted and the Power ON Indicator

will start to flash slowly (approx. once per second).

To restart the test, set the Operating Knop to "0"

and start over again.

ENGLISH

4 Release the tubing when LED 1 comes

on again

5 Evaluate the test results (See section 7.3)

6 After evaluating the test results turn the

Operating Knob to "0" to exit the Device Test.

Note:

If you need to interrupt the test and revert to normal operation, turn the Operating Knob to another

position and then select the required setting.

Note:

To indicate that the LSU is in test mode, the Power

ON Indicator will flash rapidly (approx. twice per

second) until you exit the test program.

19

Page 20

7.3 Evaluation of Device Test Results

After the test is completed, the Vacuum Indicator will automatically display the first result (blockage).

To display the other results press the TEST-Button once for each test. If you continue pressing the button

after the 4th test result has been displayed, the earlier results will be repeated (Test 1,2,3,4,1,etc.).

To exit the test program, set the Operating Knob to another position.

Test no

Test 1

Test 2

Test 3

The program

has tested for

Blockage in the

Suction System

(including canister

and tubing

The vacuum

build-up efficacy

of the Pump

System (How

much vacuum is

built up within 3

seconds)

The maximum

achievable vacuum level of the

LSU (reaches this

level within 10

seconds)

Battery indicator:

LED #1 lit up

LED #2 lit up

LED #3 lit up

Test result indications

Test Passed

<100 mmHg

Fail

100 mmHg

Pass

Test Passed

Test Passed

>300 mmHg

Pass

300 mmHg

Fail

>500 mmHg

Pass

500 mmHg

Fail

Action if test failed

Check possible blockages

(e.g. twisted tubing, blocked filter,

blocked filter in the liner) and run

the Device.Test again.

Check Connectors, Tubes and

Canister Lid for leakage* or damage.

Check exhaust outlet for occlusion

and run the Device Test again

Check Connectors, Tubes and

Canister Lid for leakage* or damage.

Check exhaust outlet for occlusion

and run the Device Test again

Test 4

* If it is not obvious where the system is leaking; go step by step

through the connections. Start by disconnecting the Vacuum Tube at

the Canister and run the Device Test (blocking the tube). Reconnect

the tube and disconnecting the patient tube, run device test (block

the PATIENT inlet on the Canister). Continue with other connections

until the leakage is identified.

Air leakages in

the Pump System

(including canister

and tubing)

LED #4 lit up

Test Passed

20

>450 mmHg

Pass

450 mmHg

Check Connectors, Tubes and

Canister Lid for leakage* or damage

and run the Device Test again

Fail

Note: If the LSU does not pass one or more of the

steps in this test after suggested actions are taken,

the device might need to be returned for service

(see section 9).

Page 21

8.Accessories and Parts

Cat. No. Description

78 00 00 LSU w/Reusable Canister

78 00 10 LSU w/Abbott Receptal® Canister

Consumables

78 12 00 Aerosol Filter for LSU Reusable Canister

78 12 01 Vacuum Tube for LSU Abbott Canister

78 12 02 High Efficiency Filtration kit

for LSU Abbott Canister

77 04 61 Abbott Disposable Liner

Accessories

78 20 00 Carrying Bag (full covering)

78 20 10 Semirigid carrying bag

78 26 00 Wall Bracket w/DC-Power Cord

78 26 10 Wall Bracket w/AC-Power Cord US

78 26 20 Wall Bracket w/AC-Power Cord EU

78 26 30 Wall Bracket w/AC-Power Cord UK

78 26 40 Wall Bracket wo/ Power Cord

78 23 00 Shoulder Strap

78 24 00 Side Pouch

78 04 40 External Charger kit

Parts

78 03 00 Directions for Use

77 04 10 Suction Tubing 150 cm w/o tip

65 01 13 Suction Catheter adapter, pkg. 10

78 40 00 LSU Reusable Canister

78 04 30 LSU Reusable Canister Holder

78 10 06 Angled Connectors, pkg. 10

78 10 02 Float Ball, pkg. 10

78 40 07 Vacuum Seal

78 40 08 Gasket

79 35 00 Water Container

77 04 62 Abbott Receptal Canister

78 04 10 Abbott Canister Holder

78 04 14 T-bar for Abbott

Receptal Canister pkg. 5

78 04 33 Strap for Tubing

78 04 32 Release Arm

78 02 00 DC-Power Cord

78 02 10 AC-Power Cord US

78 02 20 AC-Power Cord EU

78 02 30 AC-Power Cord UK

78 04 00 LSU Battery

78 04 36 Fasten bracket left/right

78 04 35 Holder for water bottle

78 20 10

65 01 13

78 10 06

78 10 02

78 04 14

78 02 10

78 02 20

78 02 30

78 24 00

77 04 62

78 04 32

78 04 00

77 04 10

78 02 00

78 23 00

78 40 00

78 12 01

78 04 40

78 20 00

79 35 00

77 04 61

ENGLISH

78 04 35

78 12 00

78 40 07

78 40 08

78 04 12

78 12 02

78 04 36

78 26 10

78 26 20

78 26 30

78 26 40

78 04 33

78 04 10

78 04 30

Note: Parts or product configurations are subject to change without notice.

21

Page 22

9. Servicing

There are no user serviceable par ts inside the cabinet. Do not open cabinet.

Refer servicing to personnel qualified by Laerdal, or to Laerdal or one of its authorised distributors.

10.Trouble Shooting

FAULT

CONDITION

ACTION

The LSU does not operate

with the AC or DC Power

Cord connected.

The LSU cannot be operated

from the internal battery.

The LSU operates, but little

or no suction available.

External Power Indicator is

not lit when the Operating

Knob is set to "0".

External Power Indicator is lit.

Power ON Indicator is OFF.

Vacuum Seal blocked by float ball.

Canister full.

Poor vacuum connection between

Pump Unit and Canister.

Patient Suction Tubing twisted

or blocked.

T-bar on the Abbott canister

is leaking air into the tubes.

The Abbott liner is leaking

Check power cord connections

and the external AC- or

DC-power source.

The LSU must be returned

for service (see section 9).

Check that battery is installed.

Place the LSU on charge.

If still faulty after charging completed,

remove and replace the

battery (see section 6.7).

Unplug the Vacuum Seal

to release the vacuum

Remove and replace the

Canister (see section 4.2 or 5.2)

Install the Vacuum Connector

Tubing correctly.

Replace the filter or liner if the filter is

blocked Untwist the Patient Suction

Tubing and/or clear blockage

or replace the tubing.

Tighten the T-bar by screwing it in

or replace it.

Replace the Abbott liner

Battery Status Indicator is

not ON.

Vacuum Indicator indicates

more than 100 mmHg with

free air flow

The LSU does not charge with the

AC or DC power cord connected

Battery is not charged.

Tube(s) is kinked or twisted

The external Power indicator

is not lit.

22

Check power cord connections

and that battery is installed

Straighten / untwist the tube(s).

Check power cord connections

and the external AC- or DC-power

source.

The LSU must be returned

for service (see section 9).

Page 23

11. Specifications

11.1 Classification

Electrically powered medical suction equipment for field and transport use, according to

ISO10079-1:1999.

High vacuum/high flow.

Not suitable for use in the presence of flammable liquids or gases.

Internally powered/class ll equipment type BF, according to IEC 601-1:1988.

Protection class IP34D*, according to IEC 529:1989.

* - Protected against solid foreign objects of 2,5 mm Ø and greater

- Protected against splashing water

- Protected against access with a wire

11.2 General tolerance

Overall tolerance ±5%

11.3 Physical Characteristics

Size: 315 mm (12,4 in) x 330 mm (13 in) x 160 mm (6,3 in), (h x w x d)

Weight: 4kg (8,9 lbs) (including battery)

Canister Capacity: 1000 ml

Canister graduation

accuracy: ±5% of full scale

Patient Suction

Tubing (non-sterile): 8 mm (0.315 in.) inside diameter x 1.5 m (59 in.) length

11.4 Operation

Approx. free air flow at different settings:

80 mmHg 120 mmHg 200 mmHg 350 mm Hg 500+mmHg

12 sl/min. 16 sl/min. 20 sl/min. 23 sl/min. > 25 sl/min.

ENGLISH

sl = litre at standard atmospheric pressure and temperature.

Approx. battery operation

time (free air flow)

80 mmHg 120 mmHg 200 mmHg 350 mmHg 500+mmHg

3h 20 min 2h 20 min 1h 30 min 1h 45 min

at different settings (±10%):

Approx noise levels (free air flow)

at different settings:

80 mmHg 120 mmHg 200 mmHg 350 mmHg 500+mmHg

46 dBA 48 dBA 51 dBA 53 dBA 56 dBA

Vacuum - Max.: > 500 mmHg (67 kPa).

Vacuum - Range: 80 - 500+ mmHg (11 - 67 kPa).

Vacuum Indicator accuracy: ±5% of full scale.

23

Page 24

11.5 Power Requirements

Operating/charging AC:** 100-240 VAC +10%/15%, 50-60 Hz +/- 3 Hz (100-240 VAC),

400 Hz +/- 3 Hz (100-120 VAC)

Operating/charging DC:** 12-28 VDC +/-10%.

Battery: 12 VDC 2 Ah, Sealed Lead-Acid,

rechargeable.

Charging Time: 3 hours for approx. 80% batter y

capacity, 24 hours for fully charged.

Fuses:The LSU has no fuses to be replaced by

the user (see section 9).

** The external AC power source must be able to

deliver a current of min. 1A and the external

DC power source min. 6A, if not the LSU may switch

to battery operation.

11.6 Environmental Conditions

Operating/Charging Temperature:

0° C (32°F) to + 40° C (104° F).

Recommended Charging Temperature:

15°C (59°F) to + 25°C (77°F ).

Long term Storage Temperature:

0° C (32°F) to + 40° C (104° F).

Max. 24 hour Storage Temperature:

-30° C (-22°F) to + 70° C (158° F).

Humidity (Operating & Storage):

5 - 95% RH non-condensing

11.7 Material Chart

Cabinet front: Poly Cabonate/Acrylonitrile

Butadiene Styrene (PC/ABS)

Protector for front: Styrene Ethylene Betyl

Styrene (SEBS)

Cabinet back: PC/ABS

Cabinet base w/Protector: PC/ABS + SEBS

Battery door : SEBS

Connector retainer for battery:

Poly Oxy Methylene (POM)

Operating Knob: POM

Rotor for Operating Knob: PC/ABS

Manifold for vacuum: POM

Canister Holder: Polyethylene (PE)

Handle w/Protector: PC/ABS + SEBS

Manifold for exhaust: POM

Strap for patient suction tubing: SEBS

Canister Holder Release Arm: POM

User Interface: Polyester

Vacuum Connector: Silicone

Vacuum Connector Tubing Abbott : PVC + ABS

+ Polybutylene Terephthalate/PC (PBT/PC)

Abbott Canister: PC

Abbott Disposable Liner: ABS + PVC

Abbott Patient Suction Tubing:

Polyvinylchloride "flexible" (PVC)

Suction Catheter Adapter: PC

Suction Catheter Adapter Holder: PC

LSU Reusable Canister: PC - HT

Lid w/Floater Valve Cylinder,

LSU Reusable Canister: PC - HT

Gasket for Lid, LSU Reusable Canister: Silicone

Full covering Carrying Bag: PVC coated Polyester

Side Pouch: PVC coated Polyester

Shoulder Strap: POM + Polyester

Wallbracket: Aluminium + Steel + PA with fibers

Aerosol Filter, LSU Reusable Canister: PVC +

ABS Styrene-Butadiene Copolymer (SBC)

Float Ball, LSU Reusable Canister: PP

Vacuum Plug, LSU Reusable Canister: Silicone

24

Page 25

11.7.1 Dismantling/Disposal

!

When discarding the LSU, we recommend

it be dismantled and discarded according

to local protocol. Dismantle the LSU by

unscrewing the screws on the back side of the

LSU, remove the components and sort according

to the table in 11.7.

The cleaned LSU can also be delivered to your

local Laerdal Medical representative for

dismantling/disposal. Laerdal Medical AS will not

charge any fee for the dismantling; Sender is

reponsible for the cost of the shipment.

11.8 Symbols

(Direct Current).

(Alternating Current).

11.9 EMC Specifications

MEDICAL ELECTRICAL EQUIPMENT needs

special precautions regarding EMC and needs to

be installed and put into service according to the

EMC provided in this section.

Portable and mobile RF communication

equipment can affect MEDICAL ELECTRICAL

EQUIPMENT.

Warning:

MEDICAL ELECTRICAL EQUIPMENT should not be

used adjacent to or stacked with other equipment. If

adjacent or stacked use is necessary, the MEDICAL

ELECTRICAL EQUIPMENT should be obser ved to

verify normal operation in the configuration in which

it will be used.

ENGLISH

Class II Equipment, according to

IEC 601-1 (1988)

Type BF applied part, according to

601-1 (1988)

IP34D Protection class ref. IEC 529 (1989).

This product is in compliance with

the essential requirements

of MDD 93/42/EEC.

Do not reuse.

Date of production.

See Directions for Use.

Unique product type identification

C US

This product complies with the following ANSI/UL and CSA standards

CSA Standards:

CAN/CSA-C22.2 No: 0-M91 General Requirements – Canadian Electrical Code, part II

CAN/CSA-C22.2 No: 601.1-M90 Medical Electrical Equipment Par t I: General Requirements for Safety

CAN/CSA-C22.2 No: 601.1S1-94 Supplement No 1-94 to CAN/CSA-C22.2 No. 601.1-M90 – Medical Electrical

UL Standard No: 2601.1 Medical Electrical Equipment

Maximum cable length, AC Power cord:

1.5 meters

Maximum cable length, DC Power cord:

1.5 meters

Warning:

The use of accessories, transducers and cables other

than those specified, with exception of transducers

and cables sold by Laerdal as replacement parts for

internal components, may result in increased emission or decreased immunity of the LSU.

Equipment – Part 1: General Requirements for Safety US Standards:

25

Page 26

Guidance and manufacturer’s declaration – electromagnetic immunity

The Laerdal Suction Unit (LSU) is intended for use in the electromagnetic environment specified below. The customer or the user of the

LSU should assure that it is used in such an environment.

Immunity test

Electrostatic discharge

(ESD)

IEC 61000-4-2

Electrical fast

transient/burst.

IEC 61000-4-4

Surge IEC 61000-4-5

Voltage dips, shor t

interruptions and voltage

variations on power

supply input lines.

IEC 61000-4-11

IEC 60601-1-2 test

level

±6 kV contact

kV air

±8

±2 kV for power

supply lines

± 1 kV differential

mode

± 2kV common

mode

< 5% U

T

(> 95% dip in UT)

for 0,5 cycle

40% U

T

(60% dip in UT)

for 5 cycles

70% U

T

(30% dip in UT)

for 25 cycles

< 5% U

T

(> 95% dip in UT)

for 5 sec.

Compliance level

±6 kV contact

±8 kV air

±2 kV for power

supply lines

± 1 kV differential

mode

± 2kV common

mode

< 5% U

T

(> 95% dip in UT)

for 0,5 cycle

40% U

T

(60% dip in UT)

for 5 cycles

70% U

T

(30% dip in UT)

for 25 cycles

< 5% U

T

(> 95% dip in UT)

for 5 sec.

Electromagnetic environment - guidance

Floors should be wood, concrete or ceramic

tile. If floors are covered with synthetic material,

the relative humidity should be at least 30%.

Mains power quality should be that of a typical

commercial or hospital environment.

Mains power quality should be that of a typical

commercial or hospital environment.

Mains power quality should be that of a typical

commercial or hospital environment.

Power Frequency

(50Hz/60Hz) magnetic field.

IEC 61000-4-8

3A/m

3A/m

Also in compliance at Power Frequency of 400Hz

NOTE: UTis the AC mains voltage prior to application of the test level.

Guidance and manufacturer’s declaration – electromagnetic immunity

The Laerdal Suction Unit (LSU) is intended for use in the electromagnetic environment specified below. The customer or the user of the

LSU should assure that it is used in such an environment.

Emissions tests

RF emissions

CISPR 11

RF emissions

CISPR 11

Harmonic emissions

IEC 61000-3-2

Voltage fluctuations/flicker

emissions

IEC 61000-3-3

Compliance

Group 1

Class B

Class A

Complies

Electromagnetic environment - guidance

The LSU uses RF energy only for its internal function.Therefore,

its RF emissions are very low and are not likely to cause any

interference in nearby electronic equipment.

The LSU is suitable for use in all establishments, including domestic

establishments and those directly connected to the public lowvoltage power supply network that supplies buildings used for

domestic purposes.

26

Page 27

Guidance and manufacturer’s declaration – electromagnetic immunity

The Laerdal Suction Unit (LSU) is intended for use in the electromagnetic environment specified below. The customer or the user of the

LSU should assure that it is used in such an environment.

Immunity test

Conducted RF

IEC/EN 61000-4-6

Radiated RF

IEC/EN 61000-4-3

NOTE 1.At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2.These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from

structures, objects and people.

a. Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios,

amateur radio, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with accuracy.

To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be considered.

If the measured field strength in the location in which the LSU is used exceeds the applicable RF compliance level above, the LSU

should be observed to verify normal operation. If abnormal performance is observed, additional measures may be necessary,

such as reorienting or relocating the LSU.

b. Over the frequency range 150 kHz to 80 MHz, field strength should be less than 3 V/m.

IEC 60601-1-2 test

level

3 Vrms

150 kHz to 80

MHz

3 V/m

80 MHz to 2,5

GHz

Compliance level

3 Vrms

10 V/m

Electromagnetic environment - guidance

Portable and mobile RF communications equipment

should be used no closer to any part of the LSU,

including cables, than the recommended separation

distance calculated from the equation applicable to

frequency of the transmitter.

Recommended separation distance

d=1.2 •P

d=0.35•P 80 MHz to 800 MHz

d=0.7•P 800 MHz to 2,5 GHz

where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as determined by an electromagnetic site surveya, should be

less than the compliance level in each frequency

rangeb.

Interference may occur in the vicinity of equipment

marked with the following symbol:

ENGLISH

12 Addresses

Manufacturer:

Laerdal Medical AS

Stavanger, Norway

Distribution:

For World Wide distribution,

see Global Warranty or

www.laerdal.com

27

Page 28

© 2005 Laerdal Medical AS. All rights reser ved

8179 Rev B Printed in Norway

0434

Loading...

Loading...