Page 1

User Manual

C2500-R

C2500-R-230V

Lit M00502 July 2012 v2

Page 2

Page 3

Table of Content

1. Safety Precautions.............................................................. 1

1.1. Operation Safety Precautions..................................... 1

2. General Description............................................................ 3

2.1. Features .................................................................... 3

3. Getting Started .................................................................... 3

3.1. Unpacking.................................................................. 3

3.2. Initial Operation.......................................................... 4

3.3. Opening and Closing the Lid ...................................... 5

3.4. Loading the Rotor ...................................................... 5

3.5. Starting and Stopping a Run....................................... 6

3.6. Emergency Lid Release ............................................. 7

4. Overview.............................................................................. 8

5. Operation............................................................................10

5.1. Setting the Time (TIME) ............................................10

5.2. Setting the Speed (RPM)...........................................10

5.3. Setting the Centrifugal Force (RCF) ..........................11

5.4. Setting the Temperature (TEMP) ............................... 11

5.5. Cooling ..................................................................... 11

5.6. Quick-Spin Operation................................................13

5.7. Changing the Settings During a Run .........................13

6. Service and Maintenance...................................................13

6.1. Centrifuge Service ....................................................13

6.2. Cleaning the Centrifuge.............................................14

6.3. Cleaning the Rotor....................................................14

6.4. Disinfection...............................................................14

6.5. Replacing the Rotor ..................................................14

6.6. Replacing fuses ........................................................15

7. Troubleshooting.................................................................15

Appendix A: Technical Specifications ........................................17

Appendix B: Warranty..................................................................18

Page 4

1. Safety Precautions

Before using the Prism R refrigerated microcentrifuge for the first

time, please read this entire operating manual carefully. To guarantee

problem free, safe operation, it is essential to observe the following

points:

1.1. Operation Safety Precautions

1. When using infectious, radioactive, toxic and other solutions

which may pose health risks, please observe the appropriate

safety precautions.

2. Do not use this machine in a potentially explosive environment

or with potentially explosive chemicals.

3. Install the machine in location free of excessive dust.

4. Avoid placing the machine in direct sunlight.

5. Choose a flat, stable surface capable of withstanding the

weight of the machine.

6. Install the machine in the room temperature 15~30°C, relative

humidity 20~80%.

7. Don’t block the air vents.

8. Make sure the power source conforms to the required

p

ower supply specifications.

9. To avoid electric shock, make sure the machine is plugged

into a grounded electric outlet.

10. Do not allow water or any foreign objects to enter the various

openings of the machine.

11. Switch off the power switch before cleaning or performing any

service on the machine, such as replacing the fuses.

12. The rotor and the rotor lid must always be installed

securely on the motor shaft.

13. Always load the rotor symmetrically. Each tube shoul

counterbalanced by another tube of the same type and

weight.

d be

Prism R Refrigerated Microcentrifuge

1

Page 5

14. To guarantee sufficient ventilation, ensure that the

centrifuge has at least 30 cm of free space on all sides,

including the rear.

15. Repair should be carried out by Labnet International'

authorized service personnel only.

16. Use original spare parts and accessories only.

Warning Label: Please be aware of the danger of electric shock

or other dangers.

2

Page 6

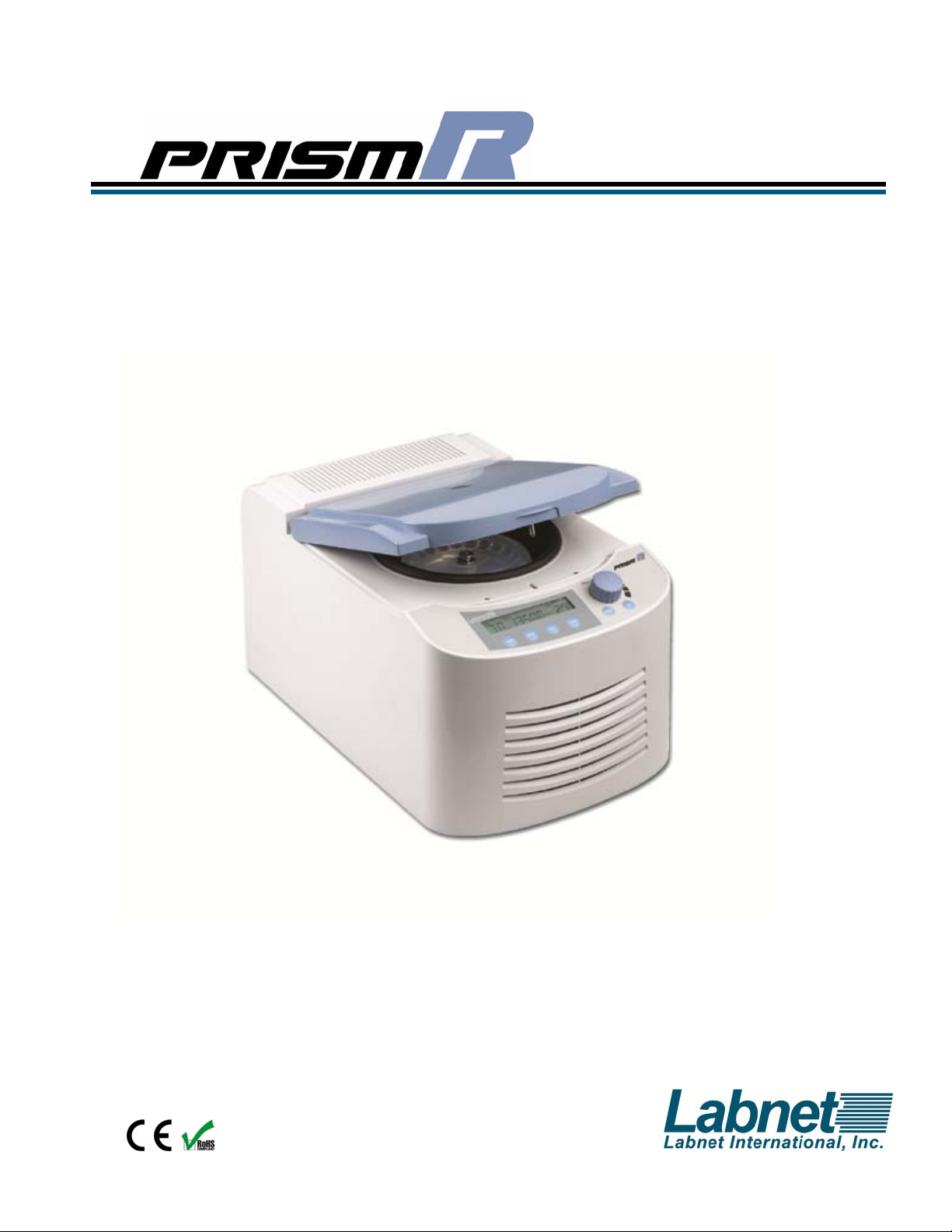

2. General Description

The Prism R refrigerated microcentrifuges is a compact, bench-top

centrifuge which is suitable for both research and clinical laboratories.

The motor is brushless and requires no routine maintenance. It is

supplied with a 24 x 1.5/2.0 ml rotor for micro samples. The maximum

speed of Prism R is 13,500 rpm (17,135 rcf). The temperature range

is from –10°C to 40°C.

2.1. Features

Brushless motor drive, control speed up to 13,500rpm/1

Powerful refrigeration system, maintain 4°C at max. speed

Includes unique easy access rotor (24 x 1.5ml)

Exceptionally quiet and compact

Optional StripSpin adapter available for 0.2ml tubes and strips

Compact, ergonomic design

User-friendly operation interface.

Quick button for instant run without setting

Low noise level

Complies with CE, RoHS

7,135xg

3. Getting Started

3.1. Unpacking

The centrifuge is delivered in an external carton and an internal

carton with protective PE foam cushions. Remove the centrifuge from

each carton. All packaging should be retained until it has been

established that the centrifuge is working properly.

Prism R™ Refrigerated Microcentrifuge

3

Page 7

2ml

Open the Prism R refrigerated microcentrifuge package and confirm

that all items are included:

Prism R unit with a 24 x 1.5/

rotor and a rotor lid

Electric fuses (7A &3.15A) Warranty card

Rotor wrench Power cord

Operation manual

If there are any items missing, damaged, or not according to your

order, please contact your distributor or sales representative

immediately.

Note: Please use 7A fuse in power source 100~120/50~60Hz

countries, while 3.15A fuse is for power source 200~230V/50~60Hz

countries.

3.2. Initial Operation

Place the machine on a stable, flat table. Please keep the machine at

least 30 cm from the surrounding area or objects.

Mains power and frequency “MUST”

be compatible with the

information given on the product label on the rear of the centrifuge.

Connect the power cord to the power socket of the centrifuge, then to

the power source. Switch the Power On/Off switch to turn on the

centrifuge. After the LCD display is on and the buzzer beeps twice,

the centrifuge is ready to operate.

4

Page 8

3.3. Opening and Closing the Lid

The lid can be opened only when the centrifuge is powered on. Press

button to open the lid.

The lid will be locked automatically when the user presses down the

front edge of the lid.

Note: Do not slam the lid!

3

.4. Loading the Rotor

For safety reasons, the rotor must be loaded with centrifuge tubes

symmetrically. The difference in the weight between the tubes should

not exceed 0.1 gram.

The centrifuge tubes should be loaded in pairs opposite each other

and each should contain roughly the equal weight of sample. One or

two additional loaded tubes may need to be added to achieve this.

Please refer Figure 1 to see an example of a properly loaded rotor.

Attention: To reduce air friction and noise, the rot

be attached to the rotor during centrifugation. Make sure that the

rotor lid snaps securely into place, by pressing down on center

catch.

Prism R™ Refrigerated Microcentrifuge

or lid should

5

Page 9

screw

Securing

Figure 1. Loading the rotor

3.5. Starting and Stopping a Run

Please refer Chapter 5 Operation to set up your preferred settings of

time, speed and temperature.

To start a run, press down the

When the pre-set time expires, the centrifuge will stop automatically.

To stop the centrifuge prior to the expiration of set time, press the

(START/STOP) knob again.

When the time is set as “continuous”( - - ), the centrifuge will run

continuously. To stop the continuous run, press the

(START/STOP) knob.

By pressing and holding the

(START/STOP) knob.

button, the centrifuge will continue a

6

Page 10

short-run of set speed. The short-run will stop if the button is

released.

Note:

1. For safety reasons, the (START/STOP) knob will be

inactivated when the lid is open. A symbol “ ” will be

flashing until the lid is closed.

3.6. Emergency Lid Release

When the lid can’t be opened by pressing the

open the lid manually. First, turn off the power of the centrifuge.

Second, use a flat-head screw driver or other tool to remove the

Emergency Lid Release Plug ( Please refer Figure 2 ) on the

right-hand side of the machine. Third, pull the wire (attached to the

plug) while gently pushing downward on the lid. The lid willnow

release.

button, users can

Prism R™ Refrigerated Microcentrifuge

7

Page 11

& fuse

box

Lid lock hole

4. Overview

This section presents an overview of the Prism R microcentrifuge’s

various components and control panel (see Figure 2) as well as the

symbols and indicators on the LCD display (see Figure 3).

Air vents

Power On/Off switch

Emergency lid

release plug

Figure 2. Prism R refrigerated microcentrifuge overview

START/STOP

knob

Figure 3. LCD display panel

8

Page 12

Value

Start/Stop a run by pressing

Rotate to Increase/decrease the

speed

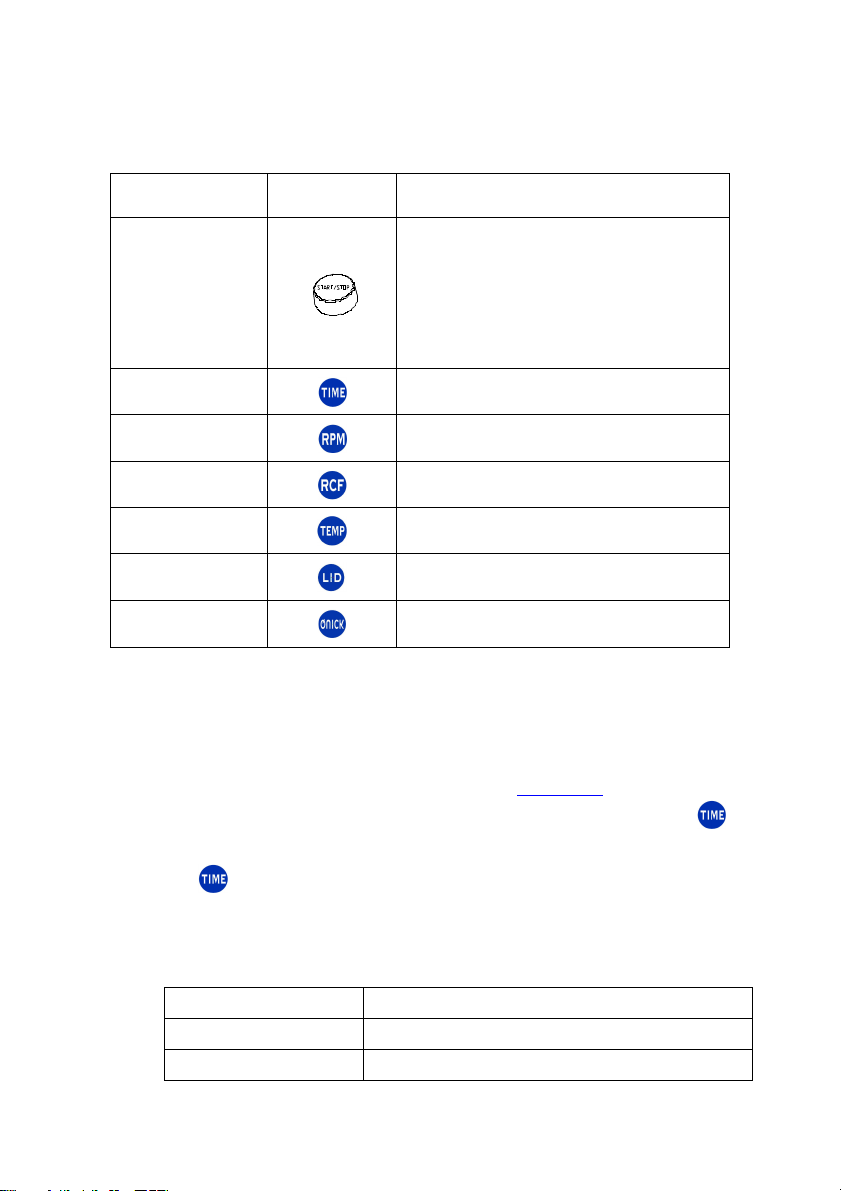

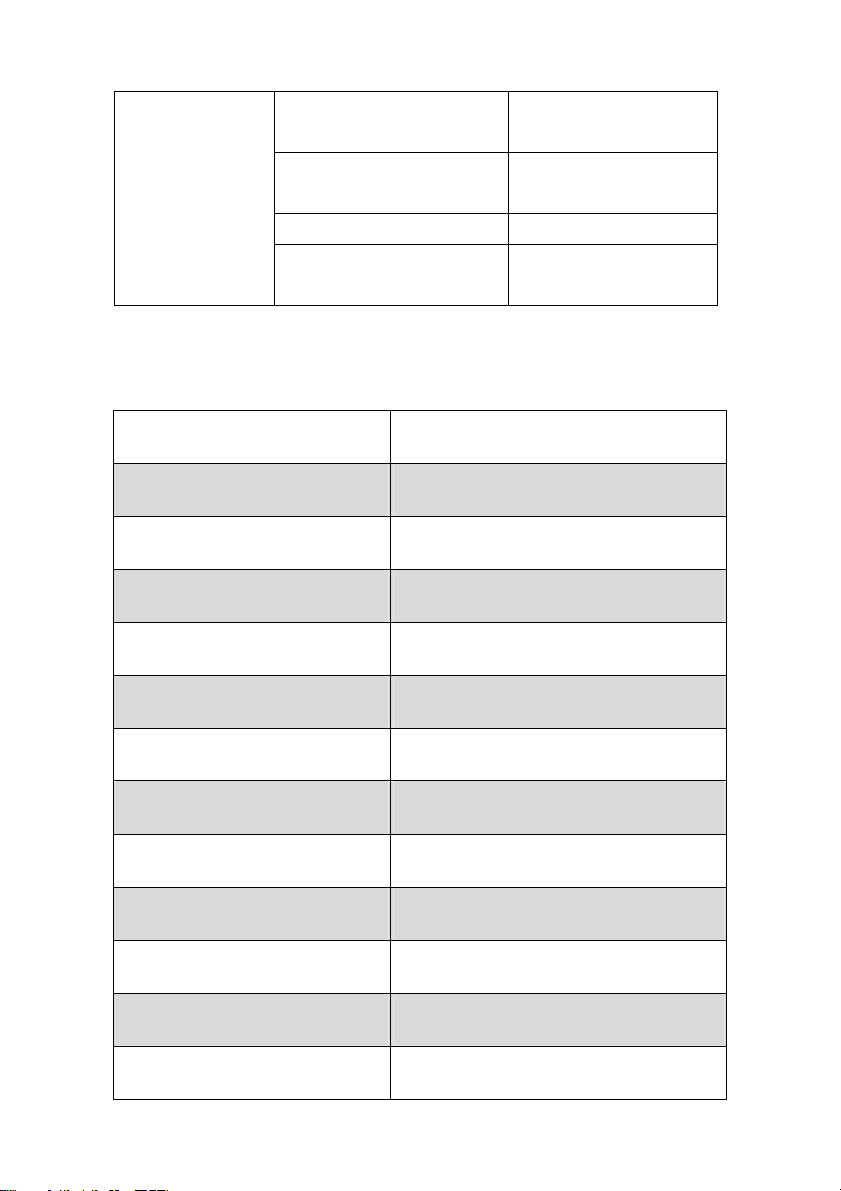

Keypad Function

Button Symbol Function Description

START/STOP

and

Adjustment

Knob

TIME button

RPM button

RCF button

TEMP button

LID button

QUICK button

down

values of time, temperature,

or g force

To adjust run time setting

To adjust speed setting

To adjust RCF setting

To adjust temperature setting

Open the lid

Quick-Spin centrifugation

Audible Signals

The audible signals are beneficial when you are familiarizing yourself

with the operating procedure of the Prism R refrigerated

microcentrifuge. They can also be disabled if desired by pressing

button six times. The audible signal function can be resumed by

pressing button six times again.

Definition of the audible sounds are shown in the table below.

Audible Sound Operation

2 beeps Power on machine

3 beeps End of a run

Prism R™ Refrigerated Microcentrifuge

9

Page 13

5. Operation

Users can pre-set the time, temperature and speed (RPM/RCF)

before a run.

Attention: Never attempt to operate the centrifuge with rotors or

adapters that show signs of corrosion or mechanical damage.

Never centrifuge strongly corrosive materials that may damage

the rotors, accessories or bowl of the unit.

5

.1. Setting the Time (TIME)

Operating time can be selected from 0.5 min to 99 min or

“continuous”. Press button to change the time setting. The 2

digits of TIME on the display will flash. Turn the (START/STOP)

knob to increase or decrease the value. Press

confirm the selection or press (START/STOP) knob to store and

run the selection. The flashing of time value will stop and the time

value will be stored automatically if no button is pressed after 6

seconds of the adjustment.

button again to

Operating time can be set as “continuous” by turning the

(START/STOP) knob clockwise or counter-clockwise to make the

2 digits of TIME to display “- -“. When the time is set as “Continuous”,

the centrifuge will continue to run without a stop. Press

(START/STOP) knob to end the continuous operation.

5.2. Setting the Speed (RPM)

The speed (RPM) can be selected from 500 to 13,500 rpm. Press

button to change the speed setting. The 5 digits of speed (RPM) on

10

Page 14

the display will flash. Turn the (START/STOP) knob to increase or

decrease the value. Press button again to confirm the selection

or press (START/STOP) knob to store and run the selection. The

flashing of RPM value will stop and the RPM value will be stored

automatically if no button is pressed after 6 seconds of the

adjustment.

5.3. Setting the Centrifugal Force (RCF)

The speed can be selected from 20 to 17,200 x g, too. Press

button to change the RCF setting. The 5 digits of RCF on the display

will flash. Turn the (START/STOP) knob to increase or decrease

the value. Press button again to confirm the selection or press

(START/STOP) knob to store and run the selection. The flashing

of RCF value will stop and the RCF value will be stored automatically

if no button is pressed after 6 seconds of the adjustment.

5.4. Setting the Temperature (TEMP)

The temperature can be selected from -10 to 40°C. Press

to change the temperature setting. The 2 digits of temperature on the

display will flash. Turn the (START/STOP) knob to increase or

decrease the value. Press button again to confirm the selection

or press

flashing of TEMP value will stop and the value will be stored

automatically if no button is pressed after 6 seconds of the

adjustment.

(START/STOP) knob to store and run the selection. The

button

5.5. Cooling

The temperature can be set from -10 °C and + 40 °C. The set

Prism R™ Refrigerated Microcentrifuge

11

Page 15

temperature can also be changed during the run.

Pre-Cooling

Pre-Cooling starts a temperature-control run at 6,000RPM.

It allows the rotor to be cooled down to the new, pre-set

temperature quickly. Cooling down from room

temperature to 4 °C takes approximately 8 min. (max. 16

minutes.) To activate Pre-Cooling function, press and hold

button, then press (START/STOP) key. Both

“RPM” and “TEMP” icons will flash during Pre-Cooling. The

Pre-Cooling can be stopped by pressing the

(START/STOP) key. The Pre-Cooling will function only

when the set temperature is lower than the ambient

temperature.

Standby Cooling

When the centrifuge is powered on, the refrigeration

system will cool down the chamber to the pre-set

temperature before or after the run if the chamber

temperature is above the pre-set temperature.

Note:

1. To extend the life cycle of the compressor, always remember

to inactivate the Standby Cooling (by increasing the set

temperature above room temperature) or power off the

centrifuge when it is not in use.

2. When the lid is open, the Standby Cooling will stop after 3

minutes.

12

Page 16

5.6. Quick-Spin Operation

The centrifuge can be operated for a short run by pressing and

holding the button. The centrifuge will continue to run as long as

the button is depressed and the time, in seconds, will count up

on the time display. The Quick-Spin speed and temperature is based

on the last run settings remaining in the memory. The icon “RPM” will

flash during Quick-Spin operation.

5.7. Changing the Settings During a Run

Users can change the settings while the rotor is running. Through a

one-time pressing of any function buttons (

the current value will switch into the pre-set value mode.

The to-be-changed value flashes, and can then be changed. Once

the display switches into the current value mode after completion of

the entered values, the new values are activated.

, , , ) ,

The new values are stored and executed by pressing the function

button again or by waiting 6 seconds.

6. Service and Maintenance

Always unplug the power plug before service and maintenance.

6.1. Centrifuge Service

The brushless motor in the Prism R requires no routine maintenance.

Any required service should be performed by authorized, qualified

Prism R™ Refrigerated Microcentrifuge

13

Page 17

personnel only. Repairs performed by unauthorized personnel may

void the warranty.

6.2. Cleaning the Centrifuge

Always keep the centrifuge housing, rotor chamber, rotor and rotor

accessories clean. All parts should be wiped down periodically with a

soft cloth. For more thorough cleaning, use a neutral cleaning agent

(pH between 6 and 8) applied with a soft cloth. Excessive amounts of

liquid should be avoided. Liquid should not come into contact with the

motor. After cleaning, ensure that all parts are dried thoroughly by

hand or in a warm air cabinet ( Maximum temperature: 50°C).

6.3. Cleaning the Rotor

The rotor should be cleaned after each use. When spinning samples

containing phenol or phenol chloroform, the rotor should be cleaned

immediately after use

6.4. Disinfection

Should a spill of infectious materials occur within the rotor or chamber,

the unit should be disinfected. This should be performed by qualified

personnel with proper protective equipment.

6.5. Replacing the Rotor

The Prism R

To remove the rotor, remove the rotor securing screw from the motor

shaft by turning the screw, using the rotor wrench on two holes of the

securing screw (Please refer Figure 1). Lift the rotor directly upward in

a straight vertical motion.

comes complete with a standard 24-place rotor installed.

14

Page 18

To replace rotor, first make sure the motor shaft and rotor mounting

hole are clean. Place the rotor on the motor shaft. Reinstall the rotor

securing screw on the motor shaft by turning it clockwise. Hold the

rotor with one hand and tighten the rotor securing screw, using the

rotor wrench.

6.6. Replacing fuses

Check fuse when it is recommended in the Technical Specifications

of this manual. The fuse holder is located in the power inlet on the

right-hand side of the unit. Disconnect the power cord from the power

inlet. Open the fuse holder drawer by inserting a small screwdriver

under the tab and prying it open. Remove the innermost (operative)

fuse from its retaining tabs and replace the fuse if necessary. A spare

fuse is located in the outer most chamber of the fuse drawer. Replace

only with a fuse of the exact same value as the original.

7. Troubleshooting

To ensure the product’s quality and performance, the Prism R

refrigerated microcentrifuge is 100% inspected by the manufacturer.

Error messages will appear on the display if the Prism R

microcentrifuge fails to perform the attempted action properly. In the

case of Error (Err) messages or faults, please refer to the solutions in

the following table to clear the error messages or faults.

If the following solutions are not able to resolve the problem, please

contact Labnet International Inc.’ Service Department to arrange for

Prism R™ Refrigerated Microcentrifuge

refrigerated

15

Page 19

Check power

authorized service.

Symptom Possible Cause Solution

Press

Close the lid “ ” Error

(START/STOP)

knob when Lid is open.

Defective lid lock

Call for service

sensor

“ ” Error

(rotor

imbalance)

Tubes are not inserted

symmetrically in rotor

holes

Sample liquid in tubes

not properly balanced

Load tubes

symmetrically

Make sure that the

same volume of

liquid is in each tube

Defective or improperly

Call for service

adjusted balance

sensor

Rotor is stuck when a

Call for service

run starts

Lid not closed correctly Close lid correctly Centrifuge

cannot be

started,

No speed or time has

been selected

Set speed and/or

time

although power

is on

Centrifuge will

not start

No power supply

source

Check the power

cord connection

Check the power

cord quality

Blown fuse Check the fuse and

replace if necessary

16

Page 20

Lid Lock will

not release

Defective lid lock Open manually and

have unit serviced

No power from PC

board

Lid lock jammed Call for service

Centrifuge is not

receiving power

Call for service

See “Centrifuge will

not start”

Appendix A: Technical Specifications

Model C2500-R

Max. Speed 13,500 rpm

Max. RCF 17,135 g

Acceleration Time < 17 seconds

Deceleration Time < 18 seconds

Temperature Range –10°C to 40°C

Max. Rotor Capacity 24 x 2.0/1.5ml tubes

Rotor Lid Easy snap-on type

Time Range 0.5 to 99 min. or “continuous”

Admissible Sample Density 1.2Kg/ml

Noise at Max. Speed 56 dB

Operating Temperature 5°C to 30°C

Operating Humidity (RH) 20~80%

Prism R™ Refrigerated Microcentrifuge

17

Page 21

100V/50~60 Hz, 6.0A

Power Supply

Dimensions (W x L x H) 280 x 430 x 248 mm

Weight (with Rotor) 22 Kgw

Certification Complies with CE, Class B

Note:

1. Specifications are subject to change without prior notice

110V/ 50~60 Hz, 5.5A

230V/ 50~60 Hz, 2.8A

(EN60101-1-2, EN 55011)

Complies RoHS

Appendix B: Warranty

Prism R

two years against defects in materials and workmanship. This period

begins from the date of purchase, and within this period all defective

parts will be replaced at no charge by Labnet International Inc. The

warranty does not cover defects caused by excessive wear and tear

or damage due to shipping, accident, abuse, misuse, problems with

electrical power, or usage not in accordance with product instructions,

or if other than original spare parts supplied by the manufacturer have

been used. Each Prism R

documented by the manufacturer before shipping. Labnet

International Inc.’ Quality Control System guarantees that the

performance of the Prism R

purchased is within its specifications.

refrigerated microcentrifuges are covered by a warranty for

refrigerated microcentrifuge is tested and

refrigerated microcentrifuge you have

18

Page 22

Manufacturer: Labnet International, Inc,., 31 Mayfield Ave., Edison, NJ 08837 USA

Labnet International declares that the devices described below are in conformity

with the EC directives listed. In the event of unauthorized modification of any of the

devices listed below, this declaration becomes invalid.

Device Name: Prism R Refrigerated Microcentrifuge

Device Models Numbers: C2500-R

C2500-R-230V

Relevant EC Directives: Low Voltage Directive 2006/95/EC

EMC Directive 2004/108/EC

RoHS 20

WEEE 2002/96/EC

Harmonized Standards: EN 61010-1:2010

EN 61010-2-020:2006

EN 61326-1:2006

EN 55011:2007

IEC 61000-3-3:1995+A1:2001 + A2:2005

IEC 61000-4-2:1995 + A1: 1998 + A2:2000

IEC 61000-4-3:2006

IEC 61000-4-4:2004

IEC 61000-4-5:2005

IEC 61000-4-8:1993 + A1:2000

IEC 61000-4-11:2004

Date: July 1, 2012

______________________________

Peter Will

Product Line Manager

Declaration of Conformity

Number: CE 00502

02/95/EC

11

Page 23

LIMITED WARRANTY

Labnet International, Inc. warrants that this product will be free from defects in material and workmanship for a period of

two (2) years from date of purchase. This warranty is valid only if the product is used for its intended purpose and within

the guidelines specified in the supplied instruction manual.

Should this product require service, contact Labnet International, Inc.’s Service department at 732-417-0700 to receive a

return authorization number and shipping instructions. Products received without proper authorization will be returned.

All items returned for service should be sent postage prepaid in the original packaging or other suitable carton, padded to

avoid damage. Labnet International, Inc. will not be responsible for damage incurred by improper packaging. Labnet

International, Inc. may elect for onsite service for larger equipment.

This warranty does not cover damage caused by accident, neglect, misuse, improper service, natural forces or other

causes not arising from defects in original material or workmanship. This warranty does not cover motor brushes, fuses,

light bulbs, batteries or damage to paint or finish. Claims for transit damage should be filed with the transportation carrier.

ALL WARRANTIES INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE LIMITED IN DURATION OF 24 MONTHS FROM THE ORIGINAL DATE OF PURCHASE.

LABNET INTERNATIONAL, INC.’S SOLE OBLIGATION UNDER THIS WARRANTY IS LIMITED TO THE REPAIR OR

REPLACEMENT, AT LABNET INTERNATIONAL, INC. DISCRETION, OF A DEFECTIVE PRODUCT. LABNET

INTERNATIONAL, INC. IS NOT LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGE, C OMMERCIAL LOSS OR

ANY OTHER DAMAGES RESULTING FROM THE USE OF THIS PRODUCT.

Some states do not allow limitation on the length of implied warranties or the exclusion or limitation of incidental or

consequential damages. This warranty gives you specific legal rights. You may have other rights which vary from state to

state.

No individual may accept for, or on behalf of Labnet International, Inc., any other obligation of liability, or extend the period

of this warranty.

Mail Warranty Registration to : or Register online at

Labnet International, Inc. www.labnetinternational.com

31 Mayfield Ave.

Edison, NJ 08837

To validate the warranty, complete and return this card within 10 days.

Model ____________________________________________________________________________

Serial No. ______________________________ Date Tested________________________________

Date Rec’d _____________________________ PO#______________________________________

Name/Title ________________________________________________________________________

Phone ___________________________________________________________________________

Institution _________________________________________________________________________

Address __________________________________________________________________________

City ______________ State _____ Zip/Postal Code ____________ Country __________________

Purchased from (distributor) __________________________________________________________

How would you rate the quality of this product? Excellent Good Fair Poor

What feature(s) on this product made you purchase it? ____________________________________

What feature(s) would you change to improve the performance of this product? __________________

cut along the dotted line

31 Mayfield Avenue. Edison.NJ.08837

(p) 732.417.0700 (f) 732.417.1750)

Page 24

Loading...

Loading...