Page 1

Centrifuge User Manual

C0336

C0336R

Copyright 2017

Page 2

This manual was prepared with special care.

LABNET INTERNATIONAL may change the manual at any time and without notice because

of improvements, typographical errors, inaccuracies of current information or improvements

to facilities.

Page 3

Content

page

1 Application ..........................................................................................1

2 Technical specification

3 Installation

3.1 Content of the package ...................................................................... 2

3.2 Location ......................................................................................2

3.3 Current protection ............................................................................3

..........................................................................................2

..........................................................................1

4 Safety notes ........................................................................................3

4.1 Operating personnel .......................................................................... 3

4.2 Warranty ......................................................................................3

4.3 Loading the rotor .............................................................................4

4.4 Safety hints ...................................................................................4

4.5 Maintenance conditions ......................................................................5

4.6 Safety precautions ............................................................................ 5

4.7 Residual risk ..................................................................................6

5 Operating ............................................................................................6

5.1 Centrifuge description ........................................................................6

5.2 Centrifuge overview ..........................................................................6

5.3 Construction ..................................................................................6

5.4 Rotor and accessories installation ........................................................... 7

5.5 Control device ................................................................................7

5.6 Setting parameters ...........................................................................7

5.7 Safety features................................................................................8

5.8 Increase in temperature (C0336 only) ....................................................... 8

6 Centrifuging ........................................................................................8

6.1 Control panel .................................................................................8

6.2 Display ........................................................................................9

6.3 Centrifuging notes .......................................................................... 10

6.4 Setting up RPM, RCF, TIME, temperature .................................................11

6.5 User programs .............................................................................. 12

6.6 Programs with user characteristics ....................................................... 15

6.7 Choosing rotors ............................................................................ 15

6.8 SHORT mode ............................................................................... 16

6.9 Terminating centrifugation .................................................................. 16

7 Temperature control ............................................................................ 16

7.1 Initial cooling during centrifuging –FAST COOL .......................................... 17

7.2 Initial cooling– THERMAL CHAMBER ..................................................... 17

7.3 Cooling in “START DELAY – OF TEMPERATURE” mode ............................... 17

7.4 Cooling in „SHORT” mode ................................................................. 17

7.5 Cooling notes ............................................................................... 17

8 Parameters of centrifugation ................................................................. 18

8.1 Accelerating/decelerating – changing characteristics .................................... 18

8.2 Radius ....................................................................................... 18

8.3 Sample density ............................................................................. 18

8.4 Temperature offset ......................................................................... 19

8.5 Thermal chamber ........................................................................... 19

8.6 Automatic lid opening ...................................................................... 20

Page 4

8.7 Start delay - of time ......................................................................... 20

8.8 Start delay – of temperature ............................................................... 20

8.9 Errors ........................................................................................ 21

8.10 Temporarily disabled functions ............................................................. 22

8.11 Unbalance .................................................................................. 22

8.12 Screen saver ................................................................................ 23

8.13 Visual alarm ................................................................................. 23

8.14 Types of main screen ....................................................................... 23

8.14.1 Switching the basic display to simplified screen .......................................... 23

8.14.2 Switching the simplified screen to basic display .......................................... 23

8.15 Rotating time ................................................................................ 24

8.16 Sounds ...................................................................................... 24

8.17 Time/date ................................................................................... 24

8.18 Language choosing ........................................................................ 25

8.19 Other ........................................................................................ 25

8.20 Password protection ........................................................................ 26

8.21 Total work time ............................................................................. 27

8.22 Diagnostics ................................................................................. 27

8.23 Factory settings ............................................................................ 27

8.24 Rotor runtime .............................................................................. 27

8.25 Cycles history .............................................................................. 27

8.26 Manufacturer’s details ..................................................................... 27

9 Maintenance ...................................................................................... 28

9.1 Cleaning of the centrifuge .................................................................. 28

9.2 Maintenance of centrifuge elements ....................................................... 28

9.3 Sterilization ................................................................................. 29

9.3.1 Autoclaving ................................................................................. 29

9.4 Chemical resistance ........................................................................ 30

10 Troubleshooting ................................................................................. 31

10.1 Emergency cover release .................................................................. 32

Appendix A

Equipment Disposal - European Regulations ................................................ 32

Symbols and Conventions

Limited Warranty

NOMOGRAM

.................................................................................... 33

......................................................................................... 34

........................................................................ 32

Page 5

1 Application

Centrifuges are used for separation samples taken from people’s, animal’s and plant’s components of different densities, under the influence of the centrifugal force, to provide information about their biological state (C0336 – ventilated,

C0336R– with cooling).

Its construction ensures easy operation, safe work and wide range of applications at laboratories engaged in routine

medical analyses, biochemical research works etc.

This centrifuge is not biotight and therefore during centrifugation of preparations requiring biotightness one has to

use closed and sealed containers and rotors. In the centrifuge, it is prohibited to centrifuge caustic, inflammable and

explosive preparations.

2 Technical specification

manufacturer LABNET INTERNATIONAL

type C0336 C0336R

mains voltage (L1+N+PE) 230V 120V 230V 120V

10% ±5% 10% ±5%

mains frequency 50/60Hz

connected load (max.) 250W 600W

overcurrent protection T 4A T 10A

cooling medium - R507 (CFC/HCFC free)

capacity (max.) 500 ml

speed – RPM 90 * 18000 rpm (step 1 rpm)

force – RCF 24270 x g (step 1 x g)

kinetic energy (max.) 8800 Nm

running time 00:00:01 ÷ 99:59:59 – [hours, min., sec] (step 1s)

time counting since start button is pressed / since preselected speed is reached

short-time operation mode – SHORT yes

continuous operation mode – HOLD yes

user programs 100

adjustable temperature - -20 ÷ 40*C* (step 1°C)

initial cooling (Fast Cool) no yes

guaranteed temperature with max.

rotor speed

cooling/heating without centrifuging no/no yes/no

cooling/heating with centrifuging no/no yes/no

acceleration (ACEL) 10 linear curves

deceleration (DECEL) 10 linear curves

programmable non-linear curves:

acceleration 10

deceleration 10

USB communication yes

Electromagnetic compatibility according to EN 61326-2-6:2006

ambient conditions PN-EN 61010-1 p.1.4.1

set-up site indoors only

ambient temperature 2° ÷ 40*C

humidity (maximum relative humidity) < 80%

excess-voltage category II EN 61010-1

pollution degree 2 EN 61010-1

safety area 300 mm

- ≤4*C

50Hz 60Hz

60Hz

Centrifuge user manual | 1

Page 6

Degree of protection:

(according to PN-IEC 34-5)

dimensions: height (H) 320 mm

width (W) 365 mm

depth (D) 495 mm 660 mm

with open cover (Hoc) 665 mm

noise level 56 dB

weight 230V 28 kg 47 kg

weight 120V 29,5 kg 50,7 kg

* time and possibility of obtaining a set temperature is dependent on multiple factors, including: rotor type, established

RPM, ambient temperature; accuracy: - ±1*C appropriate for place of temperature sensor.

Menu languages: POLISH, ENGLISH, GERMAN, SPANISH, ITALIAN, PORTUGUESE, RUSSIAN, SWEDISH, FRENCH

(without national characters).

IP 21 IP 20

3 Installation

Open the package. Remove the box containing the accessories. Take out centrifuge from the container. Keep the box

and packing materials in case of service shipping.

3.1 Content of the package

name qty (pcs.)

centrifuge C0336 1

complete clamp 1

spanner for the rotor 1

emergency opening of the cover

power cord 230V / 120V 1

Fuse WTA T 4A 250V / WTA T10A 250V 2

petroleum jelly 20ml 1

USB A-A cable 1

user manual 1

3.2 Location

• The device is heavy, so lifting and carrying the centrifuge can lead to back injuries. Risk of injury

• Lifting and transporting of the centrifuge should be done with a sufficient number of helpers. Use

• The device should be lifted by the underside in the vicinity of the its feet and placed directly on

while lifting and carrying heavy loads.

a transport aid for transporting the centrifuge.

a suitable lab table.

2 | Centrifuge user manual

Page 7

• Ensure safe location.

• The centrifuge shall not be located near source of heat and shall not be subjected to direct sunlight.

• Centrifuge should be flat-leveled. Effect of leveling shall be ensured by stable and flat-leveled table

top for the centrifuge.

• Centrifuge should be set horizontally on a rigid base.

• It is necessary to ensure a ventilation zone of the minimum 30cm round the centrifuge from every

direction. Do not veil ventilation holes!

• Table for centrifuge should possess safety zone of the minimum 30cm round the centrifuge from

every direction (safety needs in case of malfunction according to EN 61010-020.

• Table for centrifuge should be free of contaminants before locating of centrifuge.

• Passed parameters of the centrifuge are referring to the above named temperatures (see 2. Technical

specification).

• At the change of the place from cold to warm one, condensation of water will occur inside the centrifuge. It is important then that sufficient time be provided for drying the centrifuge prior to starting

the centrifuge again (min. 4 hours).

• Do not position the centrifuge so that it is difficult to operate the power switch

• Supply voltage given on the rating plate has to be consistent with local supply voltage. LABNET

INTERNATIONAL laboratory centrifuges are 1st safety class devices and they are provided with the

three-core cable with the plug resistant to dynamic loadings. Mains socket shall be provided with

the safety pin.

• It is recommended to install emergency cut-out that shall be located far from the centrifuge, near the

exit or beyond the room.

•

Before switching on, check whether the centrifuge is connected to power supply correctly. It is

obligatory to use only power cord recommended by manufacturer.

• Before using check whether the device is correctly installed.

3.3 Current protection

The centrifuge is equipped with thermal current protection. Fuse is situated in the plug-in socket unit

at back wall of the centrifuge.

4 Safety notes

4.1 Operating personnel

• Laboratory centrifuge can be operated by laboratory personnel after getting acquainted with user

manual.

• User manual shall be always held near the centrifuge.

• The centrifuge cannot be misused.

• If the centrifuge is used in a manner not specified by the manufacturer, the protection provided by

the device may be impaired.

4.2 Warranty

• Warranty period amounts to minimum 24 months (unless otherwise specified in the purchase documents).

• The service life of the centrifuge specified by the manufacturer amounts to 10 years.

• Manufacturer reserves the right to make technical changes in manufactured products.

• Maximum period of storage of not used centrifuge amounts to 1 year. After this period, a service

authorized by manufacturer should carry out technical inspection of the centrifuge.

Centrifuge user manual | 3

Page 8

4.3 Loading the rotor

• Laboratory centrifuge can be operated by laboratory personnel after getting acquainted with user

manual.

• User manual shall be always held near the centrifuge.

• The centrifuge cannot be misused.

• It is necessary to insert test tubes symmetrically on the opposite sides.

FILLING TUBES

• Fill test tubes outside the centrifuge.

• Please pay special attention to the quality and proper thickness of the glass test tubes walls. Those

shall be test tubes for centrifuges.

• Fill test tubes outside the centrifuge.

4.4 Safety hints

ROTORS MAINTENANCE

• Lubricate the swing-out rotor journal pins.

• Use only accessories in good condition.

• Protect equipment against corrosion using accurate preventive maintenance.

HS ACCESSORIES MAINTENANCE

• HS accessories maintenance.

• Make sure that rubber O-rings are lightly coated with silicone grease.

HAZARDOUS MATERIALS

• Accessories are not biotight. For centrifuging infectious materials, it is necessary to use hermetically

closed tubes meeting demands of biotightness, in order to prevent germs migration into the centrifuge

and beyond it.

• It is not allowed to subject to centrifugation toxic materials with damaged leak proof seals of the

rotor or test-tube. Proper disinfection procedures have to be carried out when dangerous substances

contaminated the centrifuge or its accessories.

CORRECT

CORRECT

WRONG

WRONG

4 | Centrifuge user manual

Page 9

EXPLOSIVE AND COMBUSTIBLE MATERIALS

• It is not allowed to centrifuge explosive and inflammable materials.

• It is not allowed to centrifuge substances prone to reacting in result of supplying high energy during

centrifugation. The centrifuge cannot be operated in explosion-endangered areas

• It is not allowed to centrifuge materials capable of generating inflammable or explosive mixtures

when subjected to air.

4.5 Maintenance conditions

START-UP

• Prior to switching the centrifuge on, one shall read carefully all sections of this instruction in order to

ensure smooth operation and avoid damages of this device or its accessories.

• In order to protect the centrifuge against unbalance, fill in the test tubes up to the same weight.

TRANSPORTATION

• Centrifuge must not be transported with the rotor mounted on the shaft.

GENERAL HINTS

• One must use original rotors, test-tubes and spare parts only.

• In case of faulty operation of the centrifuge one shall ask for assistance of service of LABNET

INTERNATIONAL company or its authorized representatives.

• It is not allowed to switch the centrifuge on if it is not installed properly or rotor is not fitted correctly.

CENTRIFUGES SUBSTANCES

• It isn’t allowed to exceed load limit set by the manufacturer. Rotors are intended for fluids of average

homogeneous density equal to 1,2 g/cm3 or smaller when centrifugation is carried out at maximum

speed. When fluids of higher density shall be used, then it is necessary to change density of centrifuges

sample in PARAM/DENSITY field.

4.6 Safety precautions

For safety reasons, inspections of the centrifuge carried out by the authorized service at least once a year after the

period of warranty. The reason for more frequent inspections could be corrosion inducing environment. Examinations should end with issuing report of validation that checks on the technical state of the laboratory centrifuge. It

is being recommended to establish document where every repairs and reviews are being registered. Both these

documents should be stored in the place of use of the centrifuge.

INSPECTION PROCEDURES CARRIED OUT BY THE OPERATOR

Operator has to pay special attention to the fact that the centrifuge parts of key importance due to

safety reasons are not damaged. This remark is specifically important as for:

• Centrifuge accessories and especially structural changes, corrosion, preliminary cracks, abrasion

of metal parts.

• Screw joints.

• Inspection of the rotor assembly.

• Inspection of bioseals of the buckets if such are used.

• Control of execution of the guarantee yearly technical inspection of the centrifuge

Only the manufacturer-specified holders, included in the equipment list, as well as centrifuge capillaries, which diameter, length and durability are suitable, should be used for spinning in this centrifuge.

The use of equipment made by other manufacturers should be consulted with the manufacturer of

the centrifuge.

• It is not allowed to lift or shift the centrifuge during operation, and rest on it.

• It is not allowed to stay in the safety zone within 30 cm distance around the centrifuge neither leave

within this zone some things, e.g. glass vessels.

• It is not allowed to put any objects on the centrifuge.

COVER OPENING

• It isn’t allowed to open the cover manually in emergency procedure when rotor is still turning.

Centrifuge user manual | 5

Page 10

ROTORS

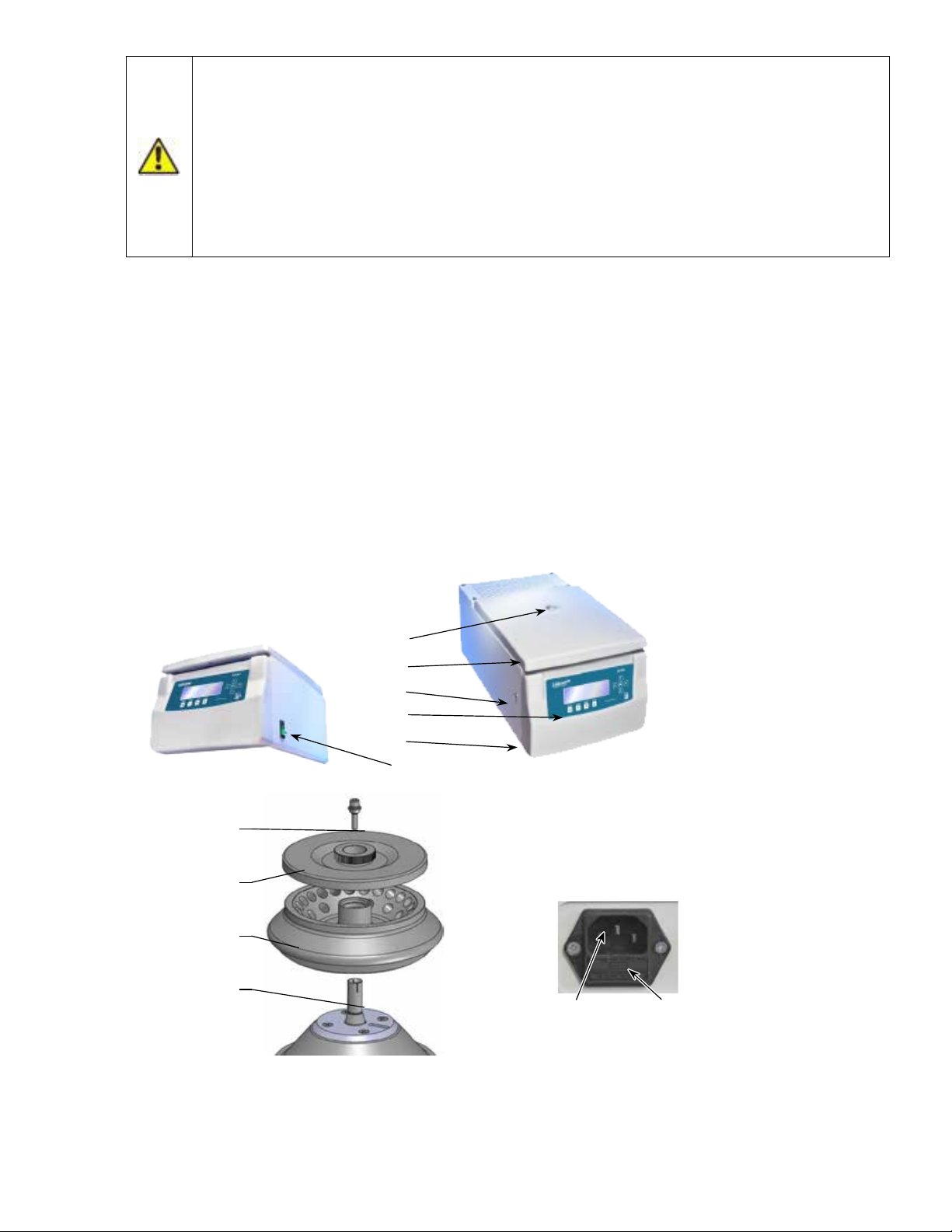

Fig.3. Assembly of angle rotor

4. Complete clamp

• It is not allowed to use the rotors and round carriers with signs of corrosion or other mechanical

defects.

• It is not allowed to centrifuge highly corrosive substances which may cause material impairment and

lower mechanical properties of rotor and round carriers.

• It isn’t allowed to use rotors and accessories not admitted by the manufacturer. Let to use commercial

glass and plastic test tubes, which are destined to centrifuging in this laboratory centrifuge. One

should absolutely not use poor quality elements. Cracking of glass vessels and test tubes could

result in dangerous vibration of the centrifuge.

• It is not allowed to carry out centrifugation with the rotor caps taken off or not driven tight.

4.7 Residual risk

The centrifuge is built according to the state-of-the-art and the recognized safety regulations.

Nevertheless, still remain some level of residual risk due to improper operation and malfunctions. It is possible to

decrease residual risk by strictly applying user manual conditions and correcting malfunction which could threaten

safety, immediately.

5 Operating

5.1 Centrifuge description

New generation of LABNET INTERNATIONAL laboratory centrifuges is provided with state-of-the-art microprocessor control systems, very durable and quiet asynchronous brushless motors and accessories consistent with

requirements of the present-day user.

5.2 Centrifuge overview

Fig.2. Right side of centrifuge

1. Motor axle

2. Rotor

3. Rotor lid

Fig.1. General view

6

5

4

3

2

1

4

3

2

1

Fig.4. Mains socket back

of the centrifuge

1

1. Main socket

2. Fuse socket

1. Power switch

2. USB

3. Control panel

4. Point of emergency lid opening

5. Lid

6. Inspection glass

2

5.3 Construction

6 | Centrifuge user manual

The centrifuge has rigid self-supporting structure. Housing was made of sheet aluminum, back made of steel

sheet. Front and cover was made of ABS type plastic. Cover is fixed on steel axles of hinges and from the front it

Page 11

is locked with two electromagnetic locks blocking possible opening during centrifugation. Rotation chamber casing

was made of thick steel sheet. The rotation chamber bowl is made of stainless steel sheet. Rotors and containers

are from aluminum, lids from polycarbonate and reductive inserts from the polypropylene.

5.4 Rotor and accessories installation

• Connect the centrifuge to the mains (master switch on the back side of the centrifuge).

• Turn on the centrifuge (button on the side of the centrifuge).

• Open the cover of the centrifuge by pressing the COVER key (see section Centrifuging/Control Panel). Prior

to putting the rotor in, one has to check if the rotating chamber is free of impurities, e.g., such as dust, glass

splinters, residues of fluids that must be taken away.

• One shall fit the rotor on the motor shaft driving it home on the cone.

• Screw-in the bolt for fixing the rotor (clockwise) and screw it tightly home with the supplied spanner for the rotor.

• Swing-out rotors have to be provided with the buckets in all seats. One should remember that every buckets

swings individually. Bucket suspension studs should be lubricated periodically with petroleum jelly.

• In case of rotors designed with the cover they must not be used without it. Rotor covers must be closed exactly.

Rotor covers ensure smaller drags of the rotors, proper setting of the test-tubes and airtight sealing.

• One should use only buckets intended for selected types of the rotor.

• Fill test tubes outside the centrifuge.

• In case of centrifuging in an angle rotor, test tubes (buckets) have to be filled properly in order to prevent from

pouring fluids during centrifuging.

liquid

Tubes must be filled so that the material does not escape from

the reservoir during centrifugation.

centrifugal force

One shall fill tubes according to formula:

Max liquid level < Tube height – Internal tube diameter/2

Internal tube diameter

Tube height

Max liquid level

Observe the manufacturer’s restrictions about the filling of the test tube.

It is recommended to equalize vessels loads as much as possible in order to ensure minimal vibrations

during operation.

• In order to prolong lifetime of the rotor and gaskets rotors shall be lubricated with the maintenance oil, while

gaskets and threaded parts shall be lubricated with the petroleum jelly.

• For replacement of the rotor one shall unscrew clamping and then grab the rotor with both hands at opposite

sides, taking it away from drive shaft by pulling it up.

5.5 Control device

The microprocessor control unit of the centrifuge ensures broad possibilities of providing, realization and reading

of work parameters.

5.6 Setting parameters

Data setting and read-out system forms hermetically closed keyboard with distinctly accessible operation points.

Easily readable displays signaling individual performed operations facilitate operator’s programming and recording

of parameters and condition of the centrifuge.

The centrifuge is provided with the USB interface that enables connection of the centrifuge to external PC unit

with the printer and recording the centrifugation parameters.

Centrifuge user manual | 7

Page 12

5.7 Safety features

Cover lock

The centrifuge can be started only with properly closed cover. While, the cover can be opened only after stopping the rotor. In case of emergency opening of the cover during operation, the centrifuge will be immediately

switched-off and the rotor will brake till complete stopping.

Unbalance detecting

When loads of opposite buckets or carriers in rotors are unbalanced, the drive will be switched-off during acceleration or operation of the centrifuge – and the error message will be displayed.

Rotor verification and checking compatibility with loaded program

Directly after starting centrifuging, a unit verifies the type of the rotor applied and in the case of its incompatibility

with the type indicated in the application or absence of the rotor, the spinning process shall be stopped with

simultaneous displaying the error message. The conformity of the type of the rotor is signaled with a single audible

signal. In case auto identification (see 9.8 Other) option is checked, proper rotor will be automatically chosen,

without user engagement.

Rest state inspection

Opening of the centrifuge’s cover is possible only with the rotor in the state of rest. When the rotor is being

stopped, the STOP diode is on and goes off when it is stopped. (Excepting emergency cover opening) – see p.

TROUBLESHOOTING.

Checking of excessive temperature

If temperature in rotation chamber exceeds 50°C (C0336) / 65°C (C0336R) caused by, for example, malfunction

of cooling system, drive will be switched off and error message will be displayed. The reboot is only possible after

chilling device.

5.8 Increase in temperature (C0336 only)

In uncooled centrifuges, the temperature in the rotor chamber, rotor and sample can increase to above 40°C,

based on the run time, g-force (RCF)/speed and ambient temperature.

6 Centrifuging

Power switching ON/OFF is carried out with master switch situated on the side wall of the centrifuge. All settings

on the centrifuge are done by means of the control panel.

6.1 Control panel

The control panel placed on the front casing serves the purpose of controlling centrifuge operation.

8 | Centrifuge user manual

Page 13

Control panel

► ►

►

FAST COOL start fast cooling mode

SHORT

1

short-time centrifuging

START start centrifugation run

2

STOP

end centrifugation run

COVER cover opening

▲

▼

◄

►

BACK

RPM/RCF

UP navigation in menu / increasing values

DOWN navigation in menu / decreasing values

LEFT navigation in menu

RIGHT navigation in menu

exit the current menu / cancelling

switching between rpm display mode and rcf display mode

SET SET changing parameters / confirming changes

1

the centrifuge is working as long as the key is pressed

2

first-time pressing press – will make stopping centrifuging with acceleration characteristics set in the current

program (confirm message with pressing STOP or BACK key), second-time pressing – will make the centrifuging

as fast as possible (quickest characteristic). During setting of the parameters, it serves for exiting zones on the

primary screen without introducing changes.

6.2 Display

The display is located in the centre of the control panel. The main screen variants are presented below.

MAIN SCREEN

C0336

C0336R

SPEED rotor speed assigned/measured

RCF centrifugal force assigned/measured

TIME centrifuging time assigned/measured

TEMP temperature assigned/measured

PROG –– program no.

11199 / ––––– rotor no.

PARAM parameters of the centrifuge

MENU configuration menu

changing values

user acc/dec curves

(ACC/DEC 10-19)

density > 1,2 g/cm3

counting time down (decreasing) counting time up (increasing)

Cooling to the desired temperature

Centrifuge user manual | 9

Page 14

centrifuging

rotor stopped / closed cover rotor stopped / opened lid

stopping rotor fastest decelerating

identifying rotor

thermal chamber

temperature delay

time delay

drop-down list

temporarily disabled

locked

time counting (blinking)

(with automatic cover opening)

centrifuging

disabled option active option

6.3 Centrifuging notes

• Connect the centrifuge to the mains (master switch on left side of the centrifuge).

• Open the cover of the centrifuge by pressing the COVER key. Prior to putting the rotor in, one has to check if

the rotating chamber is free of impurities, e.g. such as dust, glass splinters, residues of fluids that must be taken

away.

• One shall fit the rotor on the motor shaft driving it home on the cone.

Fitting the rotor too shallow will result in lack of identification of the rotor after start of the centrifuge,

displaying the error message and stopping the centrifuge.

• Screw-in the bolt for fixing the rotor (clockwise) and screw it tightly home with the supplied spanner for the rotor.

• Swing-out rotors have to be provided with the buckets in all seats. One should remember that every buckets

swings individually. Bucket suspension studs should be lubricated periodically with petroleum jelly.

• In case of rotors designed with the cover they must not be used without it. Rotor covers must be closed exactly.

Rotor covers ensure smaller drags of the rotors, proper setting of the test-tubes and airtight sealing.

• One should use only buckets intended for selected types of the rotor.

• Fill test tubes outside the centrifuge.

• Put on or screw the caps on vessels and rotors (if applicable).

• In case of centrifuging in an angle rotor, test tubes (buckets) have to be filled properly in order to avoid overflows.

Centrifuge will tolerate small weight differences occurring during loading of rotors. However, it is

recommended to equalize vessels loads as much as possible in order to ensure minimal vibrations

during operation. When the centrifuge is started with large imbalance, the unbalance control system

will switch-off the drive system and error signal will be transmitted. On the monitoring panel, error

message will be displayed.

• In order to prolong lifetime of the gaskets and threaded parts shall be lubricated with the petroleum jelly

• For replacement of the rotor one shall unscrew clamping and then grab the rotor with both hands at opposite

sides, taking it away from drive shaft by pulling it up.

10 | Centrifuge user manual

Page 15

6.4 Setting up RPM, RCF, TIME, temperature

On the main screen, it is possible to set:

rotating speed - RPM SPEED

relative centrifugal force RCF

centrifuging time TIME

centrifuging temperature TEMP (R only)

Exemplary change of SPEED setting:

• Press SET (to enter edit mode).

• With ▲▼◄► keys mark SPEED fold (blinking).

• Press SET.

• Choose demanded order of magnitude

by pressing ◄►, e.g.: 926 (9 - blinking).

• Set demanded value by pressing ▲▼.

• Repeat above two steps for other orders of magnitude.

• Confirm set value by pressing SET.

• Leave edit mode by pressing BACK.

Exemplary change of RCF setting:

Exemplary change of TIME setting:

• Press SET (to enter edit mode).

• With ▲▼◄► keys mark RCF fold (blinking).

• Press SET.

• Choose demanded order of magnitude

by pressing ◄►, e.g.: 926 (9 - blinking).

• Set demanded value by pressing ▲▼.

• Repeat above two steps for other orders of magnitude.

• Confirm set value by pressing SET.

• Leave edit mode by pressing BACK.

• Press SET (to enter edit mode).

• With ▲▼◄► keys mark TIME fold (blinking).

• Press SET.

• Choose demanded order of magnitude

by pressing ◄►, e.g.: 13:18:00 (1 - blinking).

• Set demanded value by pressing ▲▼.

• Repeat above two steps for other orders of magnitude.

• Confirm set value by pressing SET.

• Leave edit mode by pressing BACK.

Centrifuge user manual | 11

Page 16

Exemplary change of TEMP setting:

• Press SET (to enter edit mode).

• With ▲▼◄► keys mark TEMP fold (blinking).

• Press SET.

• Set demanded value by pressing ▲▼.

• Confirm set value by pressing SET.

• Leave edit mode by pressing BACK.

Changing parameters during run

There is a possibility to change parameters: SPEED, RCF,

TIME, TEMP during centrifuging. Such modifications give in

currently running program. Modification during run is represented by PROG –– symbol.

Detailed description of setting values (e.g. TIME).

• Press SET (to enter edit mode).

• With ▲▼◄► keys mark TIME fold (blinking).

• Press SET.

0 0 : 0 2 : 11

[hh : mm : ss]

e.g.:

• centrifuging time – 2 minutes 11 seconds

• Choose “hours”, “minutes” or “seconds” by pressing ◄►, e.g.:

• Set demanded value by pressing ▲▼.

• Repeat above two steps to set demanded time.

• Confirm set value by pressing SET.

• Leave edit mode by pressing BACK.

00:07:00 (00 - blinking).

HOLD mode

6.5 User programs

set value

current value (most significant digits)

continuous operation mode

• To run centrifuging in HOLD mode set 00:00:00 time.

• To end centrifuging in HOLD mode press STOP.

After switching centrifuge on, program that was used in previous

session is being loaded.

Modification during run is represented by PROG – – symbol.

Choosing program:

12 | Centrifuge user manual

Page 17

• Press SET.

• With ▲▼◄► keys mark PROG – – zone (blinking).

• Press SET.

The program list is displayed.

• With ▲▼ keys choose demanded

program number. (marked by

).

• Confirm by pressing SET - the selection frame is displayed

• With ▲▼ keys choose one of four possibilities: LOAD,

SAVE, DELETE, NEW:

– currently loaded program.

• LOAD – load program,

• SAVE – save settings as a program

(confirm by selecting YES and pressing SET)

• DELETE – delete program (confirm by selecting YES)

NEW – load default parameters:

• TEMPERATURE: +20°C,

• SPEED: 2000 RPM,

• TIME: 2 min.

User acceleration/deceleration

characteristics

CURVES – create acceleration or deceleration

characteristics

• With ▲▼ keys choose saved program for

which you intend to create the acceleration or deceleration

characteristics (marked with symbol

).

• Press SET - the selection frame is displayed.

• With ▲▼ keys choose ACCELERATION to create accelera-

tion characteristics or DECELERATION

to create deceleration characteristics

• Confirm selection by pressing SET.

Acceleration characteristic PROG / CURVES / ACCELERATION

After choosing PROG → CURVES → ACCELERATION the window of the characteristics wizard

will be displayed:

Current acceleration characteristic connected with the loaded program will be displayed

on the screen.

Centrifuge user manual | 13

Page 18

NO. section no. (max. 4)

TIME total acceleration time

SPEED final RPM

ACC:12 characteristic’s no. (10-19)

In the first moment, the EXIT field is marked (the message is blinking). Pressing the SET key will cause returning

to the PROG → CURVES fold, without making changes in the acceleration characteristics.

„1” SECTION

After setting the time the device will proceed to setting the speed of the given section of characteristics (the set

value TIME + SPEED blinks). With UP and DOWN keys one should set the speed value and press the SET key.

The set speed value is limited by the maximum speed of the rotor connected with the edited program.

After the end of programming the speed, the graphical displaying of the section (of all sections) will occur

TIME+SPEED of the user’s acceleration characteristics.

After programming the section 1, there is a possibility to program the next section, number 2:

„2” SECTION

Programming of new section possible (the whole line 2 is blinking).

Programming as in the case of section 1. It is possible also to

abandon the programming: with UP/DOWN keys choose the OK

option (it will blink) and save (press the SET) only the acceleration characteristics of 1 section with TIME/SPEED parameters

described in the line 1.

The minimal speed of the next section of acceleration characteristics is equal to the speed of the already

programmed previous section.

„3” SECTION

Programming of new section possible (the whole line 3 is blinking).

Programming as in the case of section 1. It is possible also to

abandon the programming: with UP/DOWN keys choose the EXIT

option (it will blink) and save (press the SET) only the acceleration characteristics of 2 section with TIME/SPEED parameters

described in the line 1 and 2.

„4” SECTION

Programming of new section possible (the whole line 4 is blinking). Programming as in the case of section 1. It is possible also

to abandon the programming: with ▲▼ keys choose the OK

option (it will blink) and save (press the SET) only the acceleration characteristics of 3 section with TIME/SPEED parameters

described in the line 1, 2 and 3.

Repeated attempt to program already programmed sections of the acceleration characteristics will cause beginning

of programming of the whole acceleration characteristics once again (with settings of the program loaded to edition.

Deceleration characteristic PROG / CURVES / DECELERATION

After choosing CONFIG → CURVES → DECELERATION the window of the characteristics wizard will be displayed:

Default deceleration characteristics connected with the loaded program will be displayed on the screen.

Creating of deceleration characteristics takes place a little differently than acceleration characteristics

NO. section no. (max. 4)

TIME total acceleration time

SPEED final RPM

DEC:10 characteristic’s no. (10-19)

In the first moment, the EXIT field is marked (the message is blinking). Pressing the SET key will cause returning

to the PROG → CURVES, without making changes in the deceleration characteristics.

14 | Centrifuge user manual

„1” SECTION

Page 19

To edit the deceleration characteristics, one should mark the section of characteristics with ▲▼ key (the whole

TIME+SPEED line will begin to blink; at this stage, it is only one section, with the number 1) and then press the

SET key. The device will proceed to setting the characteristics’ section time (only the set TIME value is blinking).

With ▲▼ keys, one should set the required time value and press the SET key.

In order to compete the creation of the deceleration curve it is necessary for the speed of the last of

programmed sections of the curve to be equal = 0. Otherwise the curves wizard will not enable the end

of programming (it will be impossible to select the OK option).

After programming the section 1, there is a possibility to program the next section, number 2:

„2” SECTION

New section programming possible (the whole line 2 is blinking).

Programming as in the case of the section 1. To stop creating the

deceleration curve at the stage of two sections, it is necessary to

set the speed in section 2 to 0 and press the SET key.

The maximum speed of the next section of deceleration characteristic is equal to the speed programmed

already of the previous section.

„3” SECTION

New section programming possible (the whole line 3 is blinking).

Programming as in the case of the section 1. To stop creating the

deceleration curve at the stage of three sections, it is necessary

to set the speed in section 3 to 0 and press the SET key.

„4” SECTION

New section programming possible (the whole line 4 is blinking).

Programming as in the case of the section 1. If speed of the last

section=0, it is possible to save the created characteristics by

choosing the OK option with ▲▼ keys and pressing the SET key.

Repeated attempt to program already programmed sections of the acceleration characteristics will cause

beginning of programming of the whole deceleration characteristics once again (with settings of the

program loaded to edition).

6.6 Programs with user characteristics

Loading a modified program in the CURVES fold is signaled by the icon on the main screen:

Icon signals that program with user acceleration/deceleration

characteristics are loaded.

It is not possible to change parameters (speed, rotor no. and others) during run, when program with user characteristic is loaded. Changing these parameters is possible in PARAM/ ACCELERATION, PARAM/DECELERATION.

6.7 Choosing rotors

Loading a modified program in the CURVES fold is signaled by the icon on the main screen:

• Press SET.

• With ▲▼◄► keys mark 11199 / ––––– zone.

• Press SET.

• With ▲▼ keys mark choose demanded rotor.

• Confirm by pressing SET.

Centrifuge user manual | 15

Page 20

6.8 SHORT mode

SHORT mode

• In SHORT mode the centrifuge is working as long as the ►► (SHORT) key is pressed or when set

time is over.

• Centrifuging ends when the SHORT key is released.

6.9 Terminating centrifugation

STOPPING CENTRIFUGATION CYCLE

• When preselected time is reached, centrifugation will end automatically

• Pressing STOP for the first time will stop centrifuging with the characteristic set in loaded program.

Confirm message by pressing STOP or SET.

x1

• Pressing STOP second time will stop centrifuging with the fastest characteristic.

x2

7 Temperature control

C0336R only

Centrifuge is equipped with ecological refrigerating system with temperature control. During centrifugation, there may

appear differences in temperature on the display and temperature of the samples in the rotor. It depends on thermal

conductivity of the rotor, and samples and centrifugation time.

Exemplary change of TEMP setting:

• Press SET (to enter edit mode).

• With ▲▼◄► keys mark TEMP fold (blinking).

• Press SET.

• Set demanded value by pressing ▲▼.

• Confirm set value by pressing SET.

• Leave edit mode by pressing BACK.

• Cooling is indicated by a symbol (blinking).

16 | Centrifuge user manual

Page 21

7.1 Initial cooling during centrifuging –FAST COOL

• The parameters allowable to change at FAST COOL mode:

• temperature (lower than current temperature shown by centrifuge)

• In order to centrifuge reduced temperature samples (e.g., storage in the external refrigerator)

centrifuge chamber, rotor and centrifuge container must be pre-cooling to the predetermined

temperature. It causes minimalization of temperature differences.

• Initial cooling may be activated by FAST COOL key (lid must be closed – rotor is spinning at FAST

COOL mode)

• When FAST COOL mode is active, cooling system automatically set proper parameters to obtain

demanded temperature the fastest way.

FAST COOL mode is marked by symbol blinking in the right

upper side of display.

It is possible to exit FAST COOL mode at any time by pressing

STOP key. Interruption of the function is signaled by a message.

7.2 Initial cooling– THERMAL CHAMBER

PARAM → THERMAL CHAMBER

• There is possible to run centrifuge in THERMAL CHAMBER mode - cooling for R (rotor is at standstill).

0 RPM

• How to enable THERMAL CHAMBER is described in Parameters of centrifugation chapter.

7.3 Cooling in “START DELAY – OF TEMPERATURE” mode

PARAM → START DELAY – OF TEMPERATURE

• Centrifuging process will start, when preselected temperature is reached.

•

2500 RPM

How to enable run START DELAY – OF TEMPERATURE

centrifugation chapter.

function is described in Parameters of

7.4 Cooling in „SHORT” mode

SHORT mode

• Cooling features are available in SHORT mode.

• How to enable run centrifugation in SHORT mode

is described in Centrifugation/SHORT mode.

7.5 Cooling notes

Centrifuges with cooling (C0336R) is equipped with an efficient cooling system. It allows obtaining selected

temperatures in the chamber even at maximum spin speed or fast obtaining desired temperatures (e.g. 4ºC and

36ºC). Note that time and possibility of obtaining a set temperature is dependent on multiple factors, including:

the power of the cooling system, the shape of the rotor, the rotor speed, ambient temperature, etc. The accuracy

of the temperature stability of ± 1ºC is determined by the installation place of the temperature sensor.

Centrifuge user manual | 17

Page 22

8 Parameters of centrifugation

ACCELERATION chosen acc. characteristic (0-the fastest, 9-the slowest)

DECELERATION chosen dec. characteristic (0-the fastest, 9-the slowest)

RADIUS [mm] current rotor radius [mm]

DENSITY (g/cm3) sample density [g/cm3]

TEMP. OFFSET (OC) value of temperature correction

TH.CH. DELAY (min) delay between set thermal chamber mode and start it

THERMAL CHAMBER cooling of the chamber without centrifuging

AUT. LID OPEN opening cover after centrifuging automatically

START DELAY starting delayed (after pressing START)

• Press SET.

• With ▲▼◄► keys select PARAM.

• Press SET.

8.1 Accelerating/decelerating – changing characteristics

• ACCELERATION – 10 linear accelerating characteristics

assigned to every rotor (0 ÷ 9),

• DECELERATION – 10 linear decelerating characteristics

assigned to every rotor (0 ÷ 9).

8.2 Radius

• RADIUS [mm] - control of the radius of the rotor within the

range from R

min

to R

rotor, see ––––– / ––––– (LIST OF ROTORS fold).

• To change the rotor radius select RADIUS [mm] with ▲▼ keys.

[MM].

• Press SET.

• Set demanded value by pressing ▲▼.

When radius is changed is activated,

the screen.

Reducing of the rotor radius (and the resulting change of displayed

RCF value) applies until switching off the power supply of the

centrifuge or setting the R

the program does not change this setting!).

8.3 Sample density

• DENSITY (g/cm3) – default density is set to 1,2 g/cm3

To change the density (possible values 1,2÷9,9 g/cm

• Via ▲▼ keys select DENSITY (g/cm

• Press SET.

• Set demanded value by pressing ▲▼.

. Avalaible values depends on chosen

max

symbol is visible on

maximum radius once again (loading

max

3

):

3

)

18 | Centrifuge user manual

Page 23

8.4 Temperature offset

When density is changed, symbol is visible on the screen.

Increasing density of the sample above 1,2 g/cm3 (and limiting of

the maximum speed of centrifuging resulting from it) applies until

switching off power supply of the centrifuge or setting the device

back to 1,2 g/cm3.

• With▲▼keys select TEMP. OFFSET.

• Press SET.

• Use the ▲ ▼ keys to select the difference between the

temperature that the cooling system will aim for, and set

temperature. Confirm selection by pressing SET.

Attention!

The use of the offset cannot extend the temperature range

achieved by the centrifuge.

Function description

At a set temperature of 20ºC and the set offset value equal to

-5ºC, cooling system will actually strive to reach 15ºC. With

a setpoint temperature of 20ºC and a set offset value of 5ºC the

system will actually try to reach 25ºC.

The temperature displayed on the main screen is corrected for

offset value.

Offset can be selected range from -20ºC to 20ºC.

Activation of the function is signaled on the main screen with

or

depending on the offset value sign.

8.5 Thermal chamber

C0336R only

without centrifuging THERMAL CHAMBER

• With ▲▼◄► keys select THERMAL CHAMBER.

• Press SET (to turn on/off).

• With ▲▼ keys select temperature value.

Set demanded value by pressing ▲▼.

• When THERMAL CHAMBER function is activated,

symbol is visible on the screen.

• Changing temperature from the main screen is not possible.

• Opening cover terminates THERMAL CHAMBER function

(closing cover back turns it on).

• If THERMAL CHAMBER is turned on (in PARAM fold) and centrifugation completes,

THERMAL CHAMBER will activate itself.

• THEMRAL CHAMBER can be only activated when any other program is not running.

Centrifuge user manual | 19

Page 24

8.6 Automatic lid opening

Automatic lid opening OPEN LID AFTER RUN

• When centrifuge process is finished, cover will be opened

automatically.

• When centrifuging is terminated by pressing STOP, opening

cover is possible by pressing COVER.

• symbol means that OPEN LID AFTER RUN is active.

8.7 Start delay - of time

Start centrifuging since preselected delay is reached.

START DELAY / OF TIME function cannot be run when START DELAY / OF TEMP. is activated.

STARY DELAY / OF TIME

• With ▲▼ keys select START DELAY. Press SET.

• Start delay can be set from 0 : 0 0 : 0 1 to 9 : 5 9 : 5 9.

• With ▲▼ keys select OF TIME. Press SET.

• Press ▼, then ► select time zone (e.g. 0 : 0 0 : 4 2).

• With ▲▼ keys set demanded value.

Confirm by pressing SET.

• When START DELAY function is activated, symbol is visible

on the screen.

8.8 Start delay – of temperature

C0336R only

Start centrifuging since preselected temperature is reached.

START DELAY / OF TEMP

• With ▲▼ keys select START DELAY. Press SET.

• With ▲▼ keys select OF TEMP. Press SET.

• With ◄► keys select temperature zone.

• With ▲▼ keys set demanded value.

When the function is active, the speed can be reduced to the optimum values for the FAST COOL function,

when the set speed is lower than the optimum value, the rotor rotates at the set speed

START DELAY / OF TEMP. function cannot be run when START DELAY / OF TIME is activated.

20 | Centrifuge user manual

• When START DELAY – OF TEMPERATURE is turned on,

symbol is visible on the screen.

Page 25

8.9 Errors

End of centrifuging – manual mode

End of centrifuging – normal mode

Additional messages

Centrifuging may be stopped at the any moment via the STOP

key. The information message:

CYCLE CANCELLED will be displayed.

Stopping centrifuging in accordance the set time causes

generating multiton audible signals (after stopping the rotor)

and displaying the message

FINISH OF CENTRIFUGING

In case of power shortage while centrifuging, after repeated switching it on, the following error screen will be displayed:

SUPPLY DECAY WHILE CENTRIFUGING

After operating for 2000 hours, after every switching on the centrifuge the error screen is being displayed with information about

the necessity to carry out servicing activities.

After pressing the SET key, the device proceeds to the main

screen and the device may operate.

Identified number of the installed rotor is not compatible with the

number of rotor remembered in program

Rotor is braking (only when centrifuge was switched off during

rotor running).

After pressing SET or STOP, the device returns to the main screen.

Screen messages that may occur during operation.

MESSAGE EXPLANATION

“SPEED OF ROTOR”

“IDENTIFICATION <> 90 RPM”

“IMBALANCE FAST STOP!”

“PLEASE REMOVE CAUSE”

“THEN RESTART”

“NO ROTOR OR IDENTIFICATION”

“SENSOR DAMAGED!”

“INCORRECT ROTOR NUMBER!” ROTOR’S ID NOT CORRECT

“WRONG DIRECTION OF ROTATION”

“OR UNKNOWN ROTOR!”

“PLEASE CLOSE THE LID”

“HAND!”

“ROTOR STOPPING!”

“Please wait...”

“CYCLE’S ABORTED!”

“CYCLE’S FINISHED” CENTRIFUGING ENDED {WITHOUT ERRORS}

SPEED OF ROTOR IDENTIFICATION <> 90 RPM

ERROR OF ROTOR IDENTIFICATION {LIMIT OF 6

WRONG DIRECTION OF ROTATION / UNKNOWN

INITIALIZING AFTER MAINS FAILURE

CENTRIFUGING ENDED BECAUSE

UNBALANCE DETECTED

SEC. IS OVER}

ROTOR

CLOSING THE LID MANUALLY

WITH ROTATING ROTOR

OF PRESSING STOP

Centrifuge user manual | 21

Page 26

Emergency messages

In case of emergency messages (centrifuge is not working properly) contact the manufacturer’s authorized

service center.

MESSAGE

“OVERHEATING MOTOR!”

“INVERTER ERROR!”

"INVERTER SERIAL BUS ERROR!"

"TEMPERATURE SENSOR ERROR"

"PRESSURE CONTROL FAILURE!"

"OPENING COVER in RUN!"

"SPEED METER ERROR"

"I2C BUS ERROR"

"OVERHEATING CENTRIFUGE!"

"ROTOR OVERSPEED !"

"COVER LOCK MALFUNCTION!"

“WORKING 2000 HOURS:”

“CALL SERVICE FOR”

8.10 Temporarily disabled functions

Functions written below can be temporarily disabled.

THERMAL

CHAMBER

SPEED RCF TIME TEMP PROG –– ––––– / ––––– PARAM MENU

● ● ● ○ ● ● ● ●

During run SPEED RCF TIME TEMP PROG –– ––––– / ––––– PARAM MENU

PROG 99 ○ ○ ○ ○ ○ ○ ○ ●

ACC/DEC

10-19

Standstill SPEED RCF TIME TEMP PROG –– ––––– / ––––– PARAM MENU

PROG 99 ○ ○ ○ ○ ● ○ ○ ●

ACC/DEC

10-19

● available ○ disabled

○ ○ ● ● ○ ○ ● ●

○ ○ ● ● ● ○ ● ●

8.11 Unbalance

The centrifuge is provided with the rotor unbalance sensor and when it will be activated, centrifugation process

will be stopped through fast braking and at the same time an error message will be displayed. Cancellation of

this error is possible only through pressing BACK key after stopping of the rotor.

One must check if rotor was correctly loaded, close the cover and once more start the program. In order to protect

the rotor against beating in opposite areas of the rotor, it has to be provided with identically filled buckets, carriers,

test-tubes etc. for getting the best balance possible (see section 4.3).

Then close the cover and restart the program.

Unbalance causes noise and vibrations during operation, and adversely affects power transmission

system (motor, shock absorbers). The better balance, the smoother will be the centrifuge operation

and therefore longer life of usage of the driveline. Moreover, the ideal separation level is then obtained,

as already separated constituents would not be moved up by vibration.

Emergency stop

In any moment of centrifuging it is possible interrupt the process and fast stop the rotor. Single-time pressing

of the STOP key will make centrifuging stop with acceleration characteristics set in the program (after pressing

the SET or STOP key, the device returns to the main screen). Pressing and holding it up to 1s will make the

centrifuging quick stop.

22 | Centrifuge user manual

Page 27

8.12 Screen saver

Setting time of screen saver CONFIG / SCREEN

• Press SET.

• With ▲▼◄► keys select SCREENSAVER.

• Press SET.

• With ▲▼ keys select demanded value from 1 to 60 minutes.

• Mark selection by pressing SET.

• Leave the menu by pressing BACK.

8.13 Visual alarm

Visual alarm CONFIG / SCREEN MODE

• Via ▲▼ keys choose VISUAL ALARM

• Mark it by pressing SET.

VISUAL ALARM cause blinking screen after ending of centrifuging

or after error occurring.

8.14 Types of main screen

Default setting is BASIC DISPLAY.

To switch to SIMPLIFIED SCREEN, follow the rules in section 9.3.1.

Types of main screen

BASIC DISPLAY SIMPLIFIED SCREEN

8.14.1 Switching the basic display to simplified screen

• Press SET (to enter edit mode).

• Via▲▼◄► keys select MENU (blinking).

• Press SET.

• Via◄► keys select CONFIGURATION tab.

• Press SET.

• Via◄► keys select SCREEN tab.

• Press SET.

• Via◄► keys select BASIC DISPLAY tab.

• Press SET.

• Leave menu Via BACK key.

8.14.2 Switching the simplified screen to basic display

Press the BACK button for 1 sec. to return to the basic display

(a short menu is displayed on the screen), then:

Centrifuge user manual | 23

Page 28

8.15 Rotating time

• Via ▲▼ keys select MENU (blinking).

• Press SET.

• Via◄► keys select CONFIGURATION tab.

• Press SET.

• Via◄► keys select SCREEN tab.

• Press SET.

• Via◄► keys select SIMPLIFIED SCREEN tab.

• Press SET.

• Leave menu Via BACK key.

MENU/CONFIGURATION/ RUNTIME

• Via ▲▼ choose demanded option.

• Mark it by pressing SET.

Counting since:

Presenting mode:

COUNTING SINCE ROTOR IS IDENTIFIED

COUNTING FROM ASSIGNED SPEED

COUNTING DOWN

COUNTING UP

8.16 Sounds

Switching ON/OFF short audible signals

accompanying every pressing of any key.

Warning signals are always switched on.

MENU/CONFIGURATION/ BUZZER

• With ▲▼ keys select demanded option.

• Mark selection by pressing SET.

8.17 Time/date

Setting up time and date MENU/CONFIGURATION/ DATE/TIME

• Via keys ◄► mark DATE/TIME field (blinking).

• Press SET.

• Via◄► keys choose demanded value.

• Via ▲▼ keys change chosen value.

• Confirm by pressing SET.

• Repeat above steps for other values.

• Press BACK.

Set date and time are still active even after restart of centrifuge.

24 | Centrifuge user manual

Page 29

8.18 Language choosing

Changing menu language MENU/CONFIGURATION/ LANGUAGE

• Via▲▼ keys choose demanded menu language

• Mark it by pressing SET.

8.19 Other

Information about the running time of the

centrifuge

MENU/CONFIGURATION/ OTHER

After operating for 2000 hours, after every switching on the

centrifuge the error screen is being displayed with information

about the necessity to carry out servicing activities.

Warning message can be disabled. In order to it follow the

instructions below:

• Via ▲▼ keys choose

• WARNING: WORKING 2000 HOURS.

• Press SET (

The CYCLE WARNING MESSAGE is turned off by default.

Rotor automatic identification MENU/CONFIGURATION/ OTHER

Thanks to the automatic rotor identification, the centrifuge automatically identifies the rotor in the chamber. Rotor identification

is indicated by the message.

When the function is deactivated, it is necessary to manually select

the desired rotor as described in “6.7 Choosing rotors”.

The AUTOMATIC IDENTIF. is turned on by default.

To enable the function:

• Via ▲▼ keys choose

AUTOMATIC IDENTIF.

• Press SET (

Choice of temperature unit MENU/CONFIGURATION/ OTHER

The TEMPERATURE in °C is turned on by default.

To change the temperature unit:

• Via ▲▼ keys select unit

• Confirm by pressing SET.

change to ).

change to ).

TEMPERATURE IN °C TEMPERATURE IN °F

Centrifuge user manual | 25

Page 30

8.20 Password protection

Setting up password MENU / PASSWORD

To prevent from an unauthorized use, a PASSWORD can be set.

Note: No PASSWORD is set by default.

The PASSWORD can be set as follows when the rotor is at a standstill.

• Press the ▲▼ keys until “PASSWORD”: blinks.

• Press SET.

• Press ►

• With ◄► keys set the valid 1000s place of the PASSWORD.

e.g.,: 1xxx. With ▲▼ keys set correct value.

• Repeat above steps for all places.

• Press SET.

• As a confirmation repeat instructions described above.

When the PASSWORD is set, the Key sign is displayed in the CODE zone. It is also displayed in the main menu

(lower right corner of the screen).

From then on, access to the MENU is possible after entering the password.

In case of incorrect password, it will show message: ACCESS DENIED!

To delete the PASSWORD, “0000” must be set. If the PASSWORD is forgotten, the emergency code “7654”

should be used to clear password and remove all locks.

Setting up locks

• With ▲▼ keys choose a lock.

• Mark a lock by pressing SET.

• Repeat above steps for desired locks.

• Leave menu with BACK key.

Disabled* description

SAVE PROGRAM

DELETE PROGRAM

CHANGE PARAMETERS

LOAD PROGRAM

START KEY

* Executing disabled procedures is only possible after entering the correct

SAVE button • no programs can be saved

• no programs can be deleted

DELETE button

fields:

SPEED

RCF

TIME

TEMP

PROG––

––––– / –––––

PARAM

PROG

LOAD button • no programs can be called up

START key • centrifugation cannot be started

• saving programs on position where

one was already stored is disabled

• parameters cannot be modified

26 | Centrifuge user manual

Page 31

8.21 Total work time

Total working time of centrifuge CONFIGURATION / CYCLES

In the CYCLES menu the following statistics are displayed:

• total working (centrifugation) time

• working cycles counter

8.22 Diagnostics

Information about errors arisen in working of

the centrifuge (service field).

Intended for service purposes!

CONFIGURATION / DIAGNOSTICS

In any moment, it is possible to delete the contents of the field.

• Via ▲▼ keys choose demanded error.

• Press SET.

• Confirm by pressing YES or refuse by pressing NO.

8.23 Factory settings

Restoring factory settings. MENU/ FACTORY SETTINGS

All settings of user programs will be deleted.

• Via ◄► keys choose YES or NO.

• Confirm by pressing SET.

8.24 Rotor runtime

Information about the time of centrifuging

and of the quantity of the working cycles of

each rotor. The table also contains icons

warning of the duty of execution of validation.

8.25 Cycles history

Information concerning parameters

of last 10 centrifuging cycles.

8.26 Manufacturer’s details

Information about the type of the centrifuge,

firmware version, and contact details.

CONFIGURATION / ROTOR CYCLE

• The list can be scrolled using ▲▼ keys.

• To exit press SET key.

Symbols:

– more than 100 cycles left

– less than 100 cycles left

– worn rotor

CONFIGURATION / 10-CYCLES

• Number of cycle can be changed by ◄► keys.

• The list can be scrolled using ▲▼ keys.

• To exit press SET/BACK key.

CONFIGURATION / CONTACT US

• The list can be scrolled using ▲▼ keys.

• To exit press BACK key.

Centrifuge user manual | 27

Page 32

9 Maintenance

9.1 Cleaning of the centrifuge

Attention!

• Pull the mains plug before cleaning.

• Before any cleaning or decontamination process other than that is recommended by the manufacturer,

the user has to ask the manufacturer if the planned process does not damage the device.

• For cleaning, water with soap or other water soluble mild detergent shall be used.

• One should avoid corrosive and aggressive substances. It is prohibited to use alkaline solutions,

inflammable solvents or agents containing abrasive particles.

• Do not lubricate the centrifuge motor shaft.

• The unused centrifuge should have cover opened.

Once a week

• Using wiping cloth, remove condensate or residues of the products from the rotor chamber.

Once a month

• Check the rotor clamping thread. In case of damage, replaced it.

• Check the centrifuging chamber whether it is damaged. In case of damage it cannot be longer put

into operation. Notify Service Center.

9.2 Maintenance of centrifuge elements

• The rotor pins shall be always lubricated with petroleum jelly.

• In this way, the uniform deflection of the buckets and quiet centrifuge operation is ensured.

Cleaning of the accessories

• In order to ensure safe operation, one shall carry out in regular way periodical maintenance of the

accessories.

• Rotors, buckets and round carriers have to withstand high stresses originating from the centrifugal

force. Chemical reactions as well as corrosion (combination of variable pressure and chemical

reactions) can cause destruction of metals. Hard to observe surface cracks increase gradually

and weaken material without visible symptoms.

Wipe rotor’s pins clean and dry with a paper towel after approx. 400 uses, cleaning or/and autoclaving and then lubricate socket with the petroleum jelly.

• In case of observation of surface damage, crevice or other change, as well as the corrosion,

the given part (rotor, bucket, etc.) shall be immediately replaced.

• Clamping rotor, containers and reducer inserts must be cleaned regularly to prevent corrosion.

• Cleaning of the accessories shall be carried out outside of the centrifuge once every week or still

better after each use. For cleaning them one should use neutral agent of pH value 6÷8.

It is forbidden to use alkaline agent of pH > 8. Then, those parts shall be dried using soft fabric

or in the chamber drier at ca. 50°C.

• Angle rotor should be placed on a fabric with holes facing down, for effective drying.

• Do not use bleach on plastic parts of the rotor.

• In this way, the useful service life of the device is substantially increased and susceptibility to corrosion is diminished. Accurate maintenance increases the service life as well and protects against

premature rotor failures.

Do not use bleach on plastic parts of the rotor.

According to laboratory standards, minimize the immersion time in each solution.

• Especially prone to the corrosion are parts made of aluminum.

• Corrosion and damages resulting from insufficient maintenance could not be subject of claims

lodged against the manufacturer.

• The unused rotor should have the lid removed.

HS accessories maintenance.

• Check the general condition of seals.

• Make sure that rubber O-rings are lightly coated with silicone grease. Use high vacuum grease.

• The rotor pins shall be always lubricated with petroleum jelly.

28 | Centrifuge user manual

Page 33

9.3 Sterilization

Plastics - legend to abbreviations

PS polystyrene ECTFE ethylene/chlorotrifluoroethylene

SAN styrene-acrylonitrile ETFE ethylene/tetrafluoroethylene

PMMA polymethyl methacrylate PTFE polytetrafluoroethylene

PC polycarbonate FEP tetrafluoroethylene/perfluoropropylene

PVC polyvinyl chloride PFA tetrafluoroethylene/perfluoroalkylvinylether

POM acetal Polyoxymethylenel FKM fluorocarbon rubber

PE-LD low density polyethylene EPDM ethylene propylene diene

PE-HD high density polyethylene NR natural rubber

PP polypropylene SI silicon rubber

PMP polymethylpentene

One can use all standard disinfectants. Centrifuges and devices are made of different materials, one should

consider their variety.

O

radiation β

radiation γ 25 kGy

C

2H4

(ethylene oxide)

PS ● ○ ●

SAN ○ ● ●

PMMA ● ○ ●

PC ● ● ●

PVC ○ ● ●

POM ● ● ●

PE-LD ● ● ●

PE-HD ● ● ●

PP ● ● ●

PMP ● ● ●

ECTFE, ETFE ○ ● ●

PTFE ○ ● ●

FEP, PFA ○ ● ●

FKM ○ ● ●

EPDM ○ ● ●

NR ○ ● ●

SI ○ ● ●

● may be used ○ cannot be used

In the centrifuge, disinfectants and cleaning agents generally used in medical care should be used (e.g. Aerodesina-2000, Lysoformin 3000, Melseptol, Melsept SF, Sanepidex, Cutasept F).

formalin,

ethanol

9.3.1 Autoclaving

• Rotors, buckets and round carriers can be sterilized in autoclave with temperature 121°C during 20 min (215

kPa), unless otherwise specified in the OPTIONAL ACCESSORY.

• During sterilization (autoclaved) by means of steam one should to consider temperature resistance of individual

materials.

• Deformation of the accessories (carriers or lids made of plastic) may occur during autoclaving.

• Do not autoclave disposable materials (e.g. tubes, cyto-container).

• The life of the accessory depends on the frequency of autoclaving and use.

• Autoclaving reduce lifespan of plastic and mechanical components. PC tubes can become useless.

• Pressure in closed containers can cause plastic deformation or explosion.

• Prior to autoclaving the rotors and accessories, thoroughly wash and rinse with distilled water.

• Never exceed the permissible autoclaving temperature and time.

• If you want to keep the hermetic seals, replace the sealing rings after each autoclave.

Centrifuge user manual | 29

Page 34

Chemical resistance of plastics

PS ○ PMP ●

SAN ○

PMMA ○ PTFE ●

PC ● FEP, PFA ●

PVC ○

POM ● EPDM ●

PE-LD ○ NR ○

PE-HD ○ SI ●

PP ●

○ may be used ● cannot be used

1)

Except PVC hoses which are resistant to the steam sterilization in the temperature 121 °C.

9.4 Chemical resistance

Chemical resistance of plastics

autoclaving

121 °C, 20 min

1)

autoclaving

121 °C, 20 min

ECTFE,

ETFE

FKM ●

●

ahs

haloid

hydrocarbons

aldehydes

cyclic alcohols

esters

ether

ketones

strong or

concentrated

acids

weak or

oxidizing

diluted acids

cyclic

substances

hydrocarbons

PS ○ ● ○ ○ ○ ○/● ○/● ○ ○ ○ ○ ●

SAN ○ ● ○ ○ ○ ○ ○/● ○ ○ ○ ○ ●

PMMA ○/● ● ○ ○ ○ ○ ○/● ○ ○/● ○ ○ ○

PC ○/● ● ○ ○ ○ ○ ○/● ○ ○/● ○ ○ ○

PVC ○ ● ○ ○ ○ ● ● ○ ● ○ ○ ●

POM ○/● ● ○ ● ● ○ ○ ○ ● ● ● ●

PE-LD ● ● ● ○/● ● ● ○ ● ● ● ●

PE-HD ● ● ○/● ○/● ○/● ● ● ○ ● ○/● ○/● ●

PP ● ● ○/● ○/● ○/● ● ● ○ ● ○/● ○/● ●

PMP ○/● ● ○/● ○/● ● ● ○ ○/● ○ ○ ●

ECTFE

ETFE

● ● ● ● ○ ● ● ● ● ● ● ●

PTFE

FEP

● ● ● ● ● ● ● ● ● ● ● ●

PFA

FKM ● ○ ○ ○ ○ ○ ● ○/● ○/● ○/● ○/● ○/●

EPDM ● ● ○/● ○ ○/● ● ● ○/● ○ ○ ○ ●

NR ○/● ● ○/● ○ ○ ○ ○/● ○ ○ ○ ○ ●

SI ○/● ● ○/● ○ ○ ○ ○/● ○ ○ ○ ○ ○/●

alkalis

● very good

○/●

good to

○ limited

30 | Centrifuge user manual

limited

Permanent action of the substance does not cause damage through 30 days.

The material is able to be resistant through years

Continuous action of the substance causes insignificant and partly reversible

damage through the period of 7-30 days (e.g. puffing up, softening, reduced

mechanical durability, discoloring).

The material should not have the continuous contact with the substance.

The immediate occurrence of damage is possible (e.g. the loss of mechanical

durability, deformation, discoloring, bursting, and dissolving).

Page 35

Rubber inserts shall be exactly cleaned or possibly replaced. Centrifuges and accessories are made of different

materials.

Do not use bleach on plastic parts of the rotor.

DANGER!

Accessories are not biotight. For centrifuging infectious materials it is necessary to use hermetically

closed tubes meeting demands of biotightness, in order to prevent germs migration into the centrifuge

and beyond it.

User is responsible for proper disinfections of the centrifuge, if some dangerous material was spilled

inside or outside of the centrifuge. During the above mentioned works one must wear safety gloves.

10 Troubleshooting

Majority of faults could be removed by switching the centrifuge OFF and then ON. After switching the centrifuge ON,

there shall be displayed parameters of the recently implemented program and sound signals comprising four successive tones shall be generated. In case of short-duration power failure the centrifuge terminates the cycle and displays

PROGRAM ERROR code.

problem question remedy

Centrifuge does not start

Motor error is displayed Call service.

Centrifuge does not start

(indications are proof for cycle in

progress and motor does not start)

Centrifuge does not accelerate

(unbalance error)

(motor error)

It is not possible to open the cover

Mains failure during run

Temperature sensor error

Error of the exceeding the temperature (50°C) in the chamber

Is supply cable plugged into mains? Plugs supply cable correctly.

Is master switch ON? Switch ON power supply.

symbol displayed?

Is

Is symbol displayed?

symbol blinking?

Is

Unequal rotor load. Centrifuge load shall be balanced.

Inclined centrifuge. Centrifuge shall be leveled.

Faulty drive (mechanical damage). Call service.

Was centrifuge displaced during

operation.

After stopping error rotor message is

displayed

Centrifuge does not recognize the

rotor and does not stop.

symbol on the display is blinking,

after pressing COVER key single

tone is audible

The sensor is connected correctly,

and the error is still applying.

The message will be displayed on

the display about the decay of tension.

The overheating message will be

displayed.

The overheating message will be

displayed

Wait till rotor stops

and the

Close cover.

symbol must switch off.

Centrifugation cycle in progress,

press STOP key or wait till cycle

ends.

Switch ON the centrifuge again after

opening and closing the cover.

Check if rotor number in started program is consistent with the number of

the rotor installed in the centrifuge.

Check rotor status (if there are

coding magnets inserted)

Rotor is still rotating. Wait for stopping of the rotor and displaying of the

symbol goes off.

symbol.

Call service.

Wait for stopping of the rotor, clear

the error by pressing the SET key.

Switch the centrifuge OFF, then ON.

Call service.

Call service.

Centrifuge user manual | 31

Page 36

10.1 Emergency cover release

EMERGENCY COVER RELEASE

In case of e.g. mains failure it is possible to open cover manually. At first, one must be sure that rotor

is not in the move (use inspection glass). On the left-hand side of the casing there is a lock. Insert