LAB-LINE 460, 460JPN, 460RH, 460-1, 460-1CE User manual

...

OPERATION MANUAL

AUTOMATIC CO2 INCUBATORS

MODEL NO. WATER-JACKETED AUTOMATIC CO2:

Models With Thermal Conductivity Sensor:

460, 460JPN, 460RH*, 460-1, 460-1CE, 462, 462-1,

462-1CE, 464, 464RH, 464-1, 464-1CE

Models With Infrared Sensor:

465, 465RH*, 465-1, 467, 467-1, 469, 469-1,

8/01

MANUAL NO. 057-588-00

REV. O

LAB-LINE

AIR-JACKETED AUTOMATIC CO

Models With Thermal Conductivity Sensor:

490, 490RH*, 490-1, 490-1CE, 492, 492-1, 492-1CE,

494, 494-1, 494-1CE

Models With Infrared Sensor:

495, 495JPN, 495RH*, 495-1, 497, 497-1, 499, 499-1

Models With Thermal Conductivity Sensor And Large Chamber Capacity:

391, 391-1, 391-2**, 391-3**

*With Relative Humidity Display

**With 3-Pen Strip Chart Recorder

DESIGNERS AND MANUFACTURERS

A SUBSIDIARY of Barnstead|Thermolyne

1999 North 15th Ave.

PHONE: (563) 556-2241 or (800) 522-5463; FAX: (563) 589-0516

, Melrose Park, IL 60160-1491 USA

2:

TABLE OF CONTENTS

2

SECTION TITLE

1 Introduction

2 Description

3 Specifications

4 Features

5 Installation

6 Operation

7 Maintenance

8 Replacement Parts

Warranty

3

BE ADVISED:

IT IS MOST IMPORTANT THAT THE USER FOLLOW INSTALLATION

INSTRUCTIONS EXACTLY AS WRITTEN. FAILURE TO DO SO IS LIKELY TO

LEAD TO IMPROPER OPERATION, ERRONEOUS CALIBRATIONS AND

POSSIBLE DAMAGE TO THE EQUIPMENT. UNDER NO CIRCUMSTANCES

SHOULD THE USER ATTEMPT OPERATION WITHOUT THIS INFORMATION.

THE FOLLOWING EQUIPMENT IS TO BE SUPPLIED BY THE USER:

• Dry CO2 gas (research grade or better).

• A dual-stage regulator for the CO2 tank.

• ¼" (6.35mm) ID Flexible tubing (appropriate length from tank to

Incubator), and connected per local codes.

• Distilled or deionized water (if humidification is desired).

• Fyrite or similar chemical-based CO2 analyzer.

BE ADVISED: INSTALLATION AND PRE-OPERATION PROCEDURE WI LL

TAKE AT LEAST 24 HOURS TO COMPLETE. DO NOT ATTEMPT TO RUSH

THE PROCESS WITH SHORT CUTS TO THE PROCEDURES DESCRIBED IN

THIS MANUAL.

4

CERTIFICATION OF DECONTAMINATION:

We cannot accept for service or credit a product that has been exposed

to or contaminated with chemically or biologically toxic or infectious substances

or subjected to radioactivity without first being certified as free from said

contamination.

Please have your Medical and/or Safety Officer sign this form certifying

that proper decontamination procedures have been followed to render the

product safe and free from hazards.

Any product forwarded to us, not accompanied by this form and a proper

Return Goods Authorization Number, will be returned to the sender. To obtain a

Return Goods Authorization Number, contact the Customer Relations

Department at (800) 522-5463.

We hereby certify that the LAB-LINE INSTRUMENTS, INC. product:

Model No. and Serial No. ,

that is being forwarded has been properly decontaminated and is free from all toxic

hazards, infectious agents, radioactivity and/or other hazards.

Company/Institution Name:

Street Address:

City: State Zip

Name (please print): Title

Signature:

Phone:

DECONTAMINATION PROCEDURE (Be Specific):

Nature of Hazard That Required Decontamination:

5

SECTION 1

6

INTRODUCTION

THANK YOU

for selecting Lab-Line Instruments for your equipment needs. For maximum value and

ease of start-up,

PLEASE PROCEED AS FOLLOWS:

• Inspect the carton and contents for shipping damage. Notify the carrier immediately

if damage is found.

• Use the Accessory Checklist when unpacking to verify that the complete unit has

been received. Do not discard packing materials until all is accounted for.

• Read this Operation Manual thoroughly before deciding upon an appropriate

location for the unit: you will want to consider, where applicable, the availability of

power, water, hook-ups, drains and other unit requirements, as well as user

convenience.

• Insist that every operator of this unit becomes familiar with the Operation Section of

this manual.

• Be sure to fill out the Warranty Registration Card and mail it in to Lab-Line

Instruments within seven (7) days after receiving the unit.

IF

after reading this manual you should have any difficulties with the installation or

operation instructions, please call:

Lab-Line Customer Relations Department

(563) 556-2241 or (800) 522-5463

ALL RIGHT RESERVED

The information contained in this manual is the exclusive property of Lab-Line Instruments, Inc., and has been provided solely to enable the users of the equipment described herein to operate and maintain such equipment. Any

other use of this information, or the reproduction or transmission of all or any portion of this manual without prior

written consent of the manufacturer is expressly prohibited. © 2001, Lab-Line Instruments, Inc.

SECTION 2

7

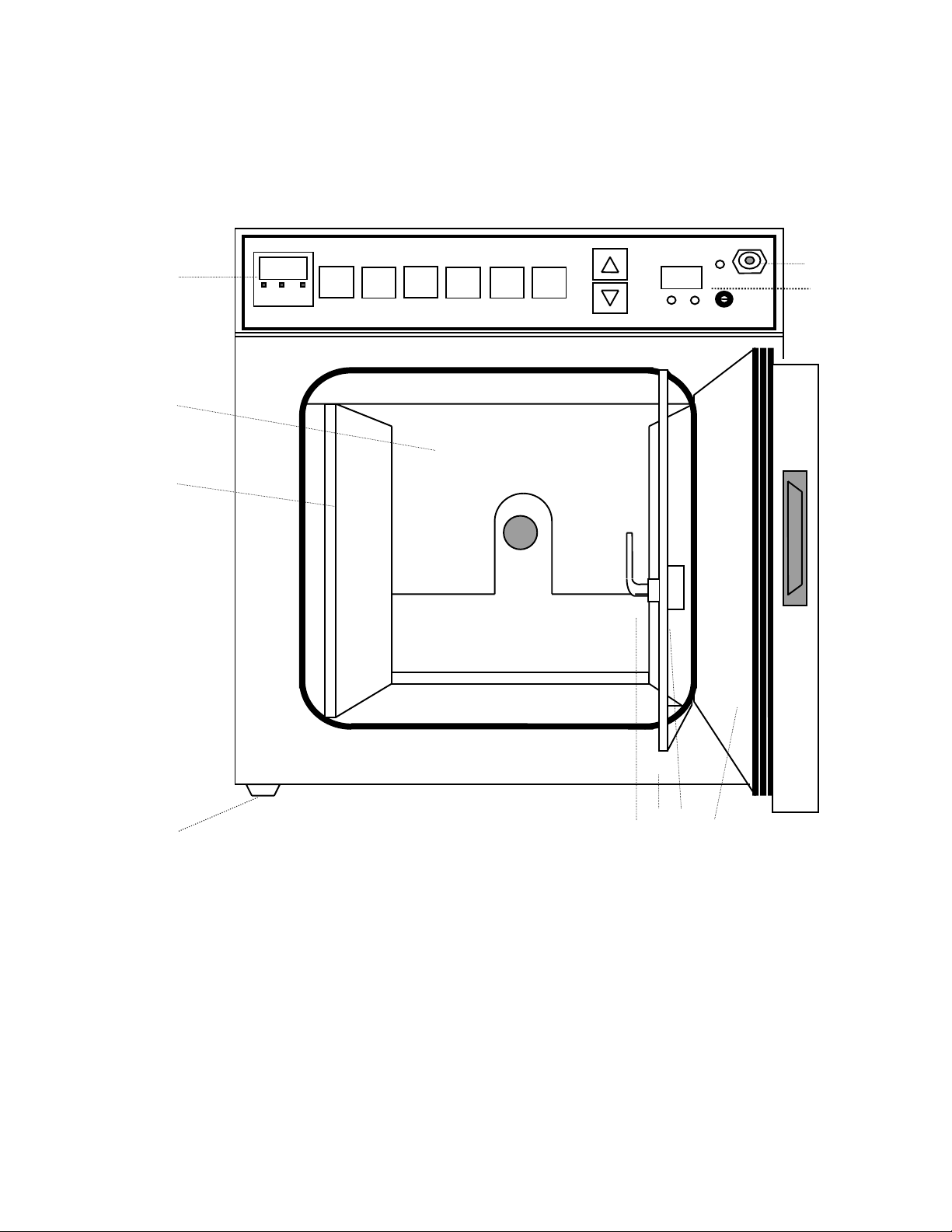

BASIC COMPONENTS, AN INITIAL OVERVIEW:

FRONT VIEW:

1

2

3

DESCRIPTION

9

10

4 567 8

1. CONTROL PANEL

2. REAR WALL COVER

3. SIDE PANEL

4. FEET, LEVELING

5. INNER GLASS DOOR

LATCH

DESCRIPTION: (Con’t)

6. INNER GLASS DOOR

7. INNER GLASS DOOR, KNOB

8. OUTER STEEL DOOR/GASKET

9. SAMPLE PORT

10. RH DISPLAY; MODELS 460RH, 490RH,

465RH, 495RH ONLY

8

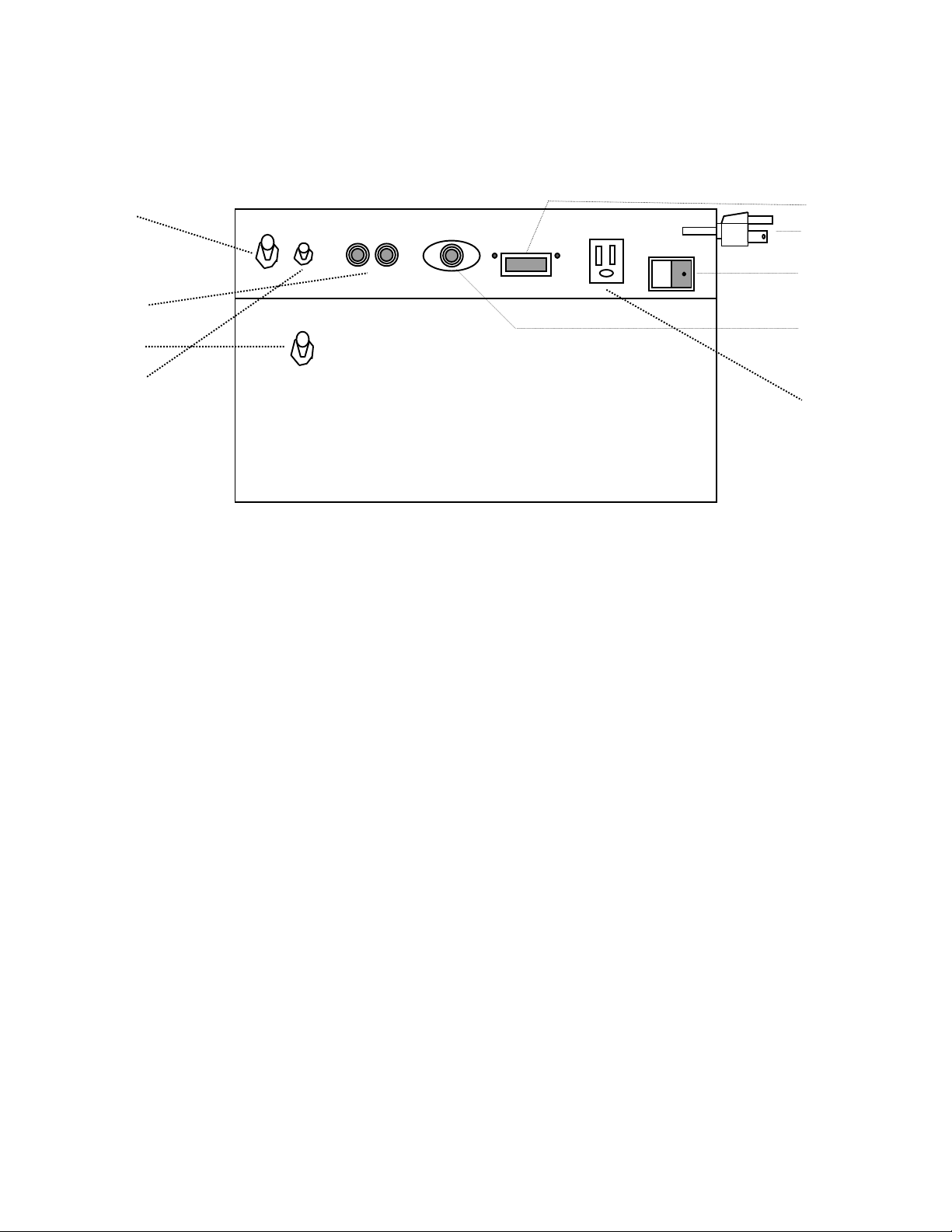

BASIC COMPONENTS, AN INITIAL OVERVIEW:

REAR VIEW

1 5

2

3

4

1. GAS INLET PORT

2. CIRCUIT BREAKERS

3. WATER OVERFLOW OUTLET (460/465 SERIES ONLY)

4. TOGGLE SWITCH FOR RH DISPLAY (460RH, 465RH, 490RH, 495RH)

5. RS232 DATA PINS CONNECTOR

6. CORDSET

7. POWER SWITCH

8. OPTIONAL ALARM RELAY OUTPUT

9. OUTLET (120 VAC UNITS ONLY)

(CON’T)

6

7

8

9

DESCRIPTION: (Con’t)

INFRARED CONTROL OF CO2

9

This sensor is impervious to relative humidity and is less susceptible to drift

and re-calibration. By measuring the absorption of infrared light within a CO2

atmosphere, the highest level of sensitivity is provided.

THERMAL-CONDUCTIVITY CONTROL OF CO2:

This sensor measures CO2 within an atmosphere by the heat of

conduction method and provides precise and reliable control.

SYSTEMS AND FEATURES:

All required operating commands are immediately accessible in a

functional format on the front of the unit and permit rapid start-up, close

monitoring and efficient control of incubation protocols.

Temperature is measured by platinum RTD (resistance temperature

detector) producing excellent control within ±0.1ºC. It is combined with the

exclusive SmartGas® algorithm method for controlling CO2 within ±0.1%. The

result is a chamber that produces excellent environmental conditions for the most

sensitive of incubations.

Air passes downward over the heated area and is then directed upward in a

gentle, uniform flow from the chamber floor. This upward draft inhibits the

contamination of cultures. If the temperature exceeds the set point by more than

the set point setting, power to the heaters is discontinued.

Audible and visual alarms alert the user of any deviation in the chamber of

temperature (±1.0°C or better) or carbon dioxide (±1.0°%). In addition, other

signals alert the user of such conditions as power failure, door ajar and low water

on water jacketed models.

To conserve gas, the CO2 solenoid valve shuts off automatically any time

the insulated, incubator door is opened. The fan motor shuts off during door

openings as well.

Required operating commands are immediately accessible in a functional

format on the front of the unit and permit rapid start-up, close monitoring and

efficient control of the incubation protocols.

To prevent unauthorized access to or alteration of command entries, a

password feature may be accessed.

Side-by-side and stacked units are available.

The crevice-free stainless steel interior is designed for easy maintenance

and prolongs useful life.

DOUBLE-DOOR CONSTRUCTION WITH INNER DOOR DEFOGGER:

A tempered glass inner door allows observation of chamber contents

without disturbing the chamber environment. Inside the steel outer door is a

heater that can defog the glass door when necessary. Each door seals to a

one-piece silicone gasket for a leak-tight environment.

SECTION 3

10

SPECIFICATIONS

ELECTRICAL REQUIREMENTS, MODEL VOLTS HZ AMPS WATTS

WATER-JACKETED MODELS:

460 120 50/60 6.3 750

460JPN* 100 50/60 7.5 750

460-1* 230/240 50/60 3.1 750

462* 120 50/60 12.5 1500

462-1* 230/240 50/60 6.3 1500

464* 120 50/60 12.5 1500

464-1* 230/240 50/60 6.3 1500

465** 120 50/60 6.3 750

465-1** 230/240 50/60 3.1 750

467** 120 50/60 12.5 1500

467-1** 230/240 50/60 6.3 1500

469** 120 50/60 12.5 1500

469-1** 230/240 50/60 6.3 1500

ELECTRICAL REQUIREMENTS,

MODEL VOLTS HZ AMPS WATTS

AIR-JACKETED MODELS:

391 120 50/60 11.3 1350

391-1 230/240 50/60 5.6 1350

391-2*** 120 50/60 11.3 1350

391-3*** 230/240 50/60 5.6 1350

490* 120 50/60 7.1 850

490-1* 230/240 50/60 3.5 850

492* 120 50/60 14.2 1700

492-1* 230/240 50/60 7.1 1700

494* 120 50/60 14.2 1700

494-1* 230/240 50/60 7.1 1700

495** 120 50/60 7.1 850

495JPN**100 50/60 8.5 850

495-1** 230/240 50/60 3.5 850

497** 120 50/60 14.2 1700

497-1** 230/240 50/60 7.1 1700

499** 120 50/60 14.2 1700

499-1** 230/240 50/60 7.1 1700

NOTE: UNITS WITH A CE SUFFIX, REFER TO COVER PAGE, ARE CE CERTIFIED AND HAVE THE SAME

NOTE:MODELS WITH RH DISPLAYS HAVE SAME SPECIFICATIONS AS 120VAC UNITS WITHOUT RH DISPLAY.

NOTE: MODELS 492, 492-1, 497, 497-1, 462, 462-1, 467 AND 467-1ARE SIDE-BY-SIDE UNITS.

NOTE: MODELS 494, 494-1, 499, 499-1, 464, 464-1, 469 AND 469-1 ARE STACKED UNITS.

* MODELS WITH THERMAL CONDUCTIVITY CO2 SENSOR.

** MODELS WITH INFRARED CO2 SENSOR.

***MODELS WITH 3-PEN STRIP CHART RECORDER. A SEPARATE RECORDER MANUAL IS PROVIDED WITH

SPECIFICATIONS AS UNITS WITH A –1 SUFFIX.

THESE UNITS.

SPECIFICATIONS: (Con’t)

11

TEMPERATURE RANGE:

WITH IR SENSOR (465/495 SERIES): Ambient +5ºC to 55ºC

WITH TC SENSOR: Ambient +5ºC to 60ºC

CONTROL: ±0.1ºC

TEMPERATURE UNIFORMITY: ±0.25ºC

ALGORITHM: TEMPERATURE: PID

CO2: SmartGas®

CARBON DIOXIDE TENSION: Range: 0% to 20%

Control: ±0.1%

CAPACITY PER CHAMBER:

460/490 SERIES: 6.2 cu. ft. (176 l)

391 SERIES: 10.4 cu. ft. (295 l)

SHELVES: 5

CHAMBER DIMENSIONS:

460/490 SERIES, SINGLE UNIT: Interior: 22" W x 22" D x 22" H (56 x 56 x 56 cm)

Exterior: 24-5/8" W x 25" D x 33" H (63 x 64 x 84 cm)

391 SERIES: Interior: 30" W x 20" D x 30" H (76 x 51 x 76 cm)

Exterior: 32½" W x 25½" D x 45" H (83 x 65 x 114 cm)

SHIPPING WEIGHT:

460/465 SERIES: 230 lb (104 kg)

490/495 SERIES: 245 lb (111 kg)

462/464, 467/469 SERIES: 460 lb (209 kg)

492/497, 494/499 SERIES: 490 lb (222 (kg)

391 SERIES: 340 lb (154 kg)

UNIT’S ENVIRONMENTAL OPERATING CONDITIONS:

POLLUTION DEGREE: 2

INSTALLATION CATEGORY: II

ALTITUDE: 2000 Meters MSL (Mean Sea Level)

HUMIDITY: 80% maximum, non-condensing

ELECTRICAL SUPPLY: 120VAC or 240VAC

VOLTAGE TOLERANCE: ±10% of normal rated line

TEMPERATURE: 15ºC to 40ºC

PRODUCT USAGE: This product is intended for use indoors only

SECTION 4

12

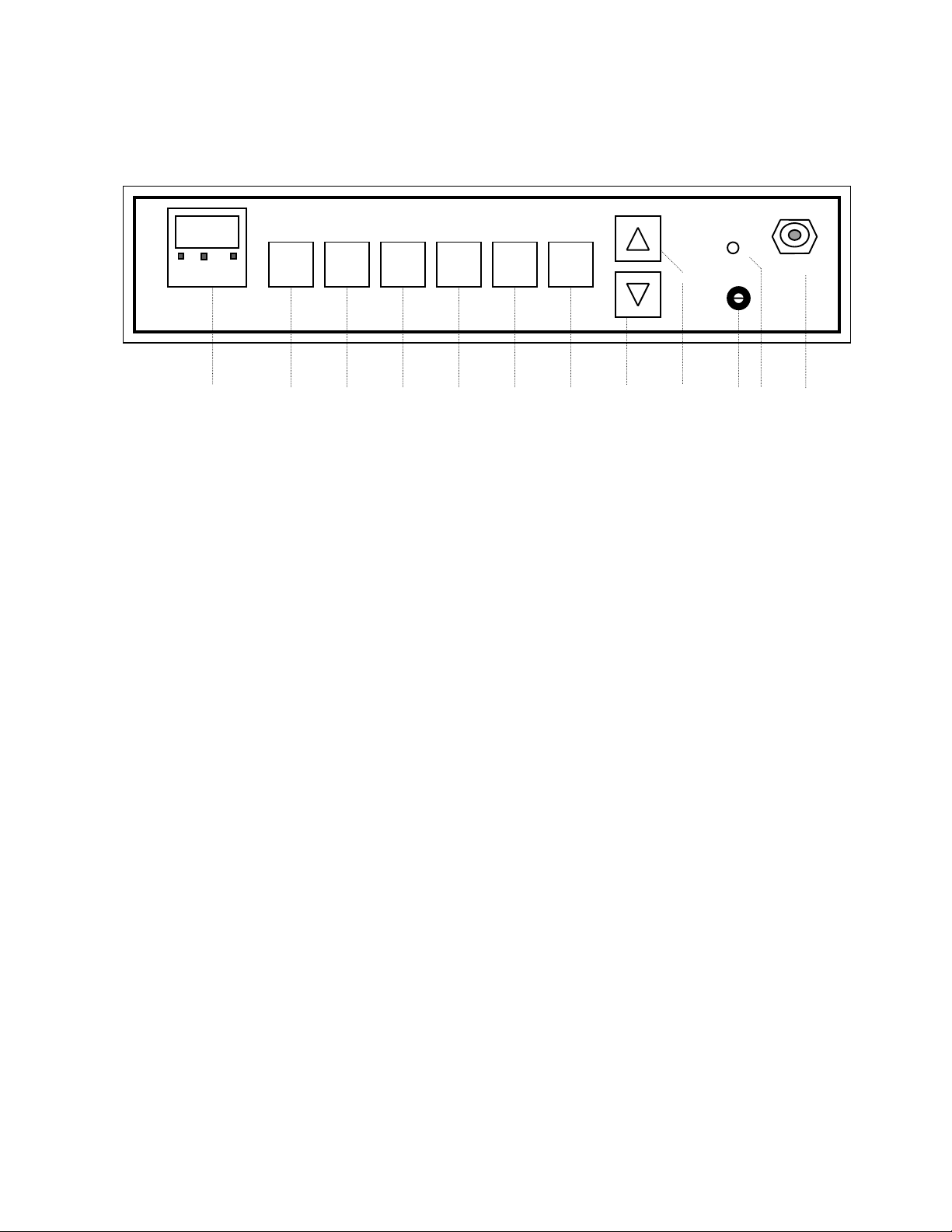

The control panel for all models has a series of command keys which

enables the user to enter set point values for temperature, carbon dioxide, door

heat and to calibrate the unit as required. LED readouts provide the user with

current status information regarding the foregoing parameters.

CONTROL PANEL:

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

1 23456789101112

FEATURES

SET CAL CO2 TEMP DOOR SCAN

1. LED READOUT: The LED displays current CO2 tension and temperature

in the Incubator and, in the set mode, displays the set point values

for these two parameters as well as door heat setting. It also enables the

user to enter values necessary to calibrate temperature and CO2.

Indicating lights and legends serve to identify which parameter is being

displayed.

2. SET COMMAND KEY: The SET key is the beginning point for and

initiates subsequent actions of the other keys on the control panel.

3. CAL COMMAND KEY: The CAL key permits calibration of temperature

and CO

used to change the readout to correspond with the readings obtained from

known standards of temperature or CO2 measurement. Both temperature

and CO

2 when in this command mode. The Up and Down arrow keys are

2 calibration use the zero point shift method.

FEATURES: (Con’t)

13

CONTROL PANEL: (Con’t)

SET CAL CO2 TEMP DOOR SCAN

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

1 23456789101112

4. CO2 COMMAND KEY: Pressing the SET key and then the CO2 key

allows the user with the Up and Down keys to enter the desired carbon

dioxide level in the Incubator.

• High and low limit alarm set points are factory set at ±1% above and

below the user-established set point. In the event CO2 exceeds the

indicated limits, an audible alarm will sound and indicating light

above the key will flash.

• Pressing any key will silence the alarm for a period of one hour. The

user should immediately investigate the reason for the alarm and

take steps to correct the problem. Note that the indicating light

continues to flash. If a problem is not solved the alarm resumes.

• By pressing the CAL (#3) and CO

calibrate CO2. The Up and Down arrow keys will change the readout

to correspond with the readings obtained from known standards of

CO2 measurement.

FEATURES: (Con’t)

2 (#4) keys sequentially users can

14

CONTROL PANEL: (Con’t)

SET CAL CO2 TEMP DOOR SCAN

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

1 23456789101112

5. TEMP COMMAND KEY: Pressing the SET key and then the TEMP

command key allows the user with the Up and Down arrow keys to

establish the desired set point temperature in the Incubator.

• High and low limit alarm set points are factory-set at ±1ºC. If the

temperature deviates from these limits, an audible, continuous alarm

will sound and the temperature lamp will flash.

• While pressing any key will silence the alarm for a one-hour period,

the user should immediately investigate the reason for the alarm and

take steps to correct the problem. Note that indicating light continues

to flash. If problem is no t corrected, the alarm will resume after one

hour has passed.

• By pressing the CAL (#3) and TEMP (#5) keys sequentially users

can calibrate temperature. The Up and Down arrow keys will change

the readout to correspond with the readings obtained from known

standards of temperature measurement.

NOTE: DECREASES IN TEMPERATURE AND CO2 DUE TO NORMAL DOOR OPENINGS ARE

TOLERATED WITHOUT INITIATI NG THE ALARMS.

FEATURES: (Con’t)

15

CONTROL PANEL: (Con’t)

SET CAL CO2 TEMP DOOR SCAN

ºC %CO2 HEAT HOLD HI LIMIT SAMPLE

1 23456789101112

6. DOOR HEAT COMMAND KEY:

• When the SET key is pressed followed by the DOOR-HEAT key, the

level of heat can be entered with the Up and Down keys as a

percentage value being applied to the inner glass door.

• A flashing DOOR-HEAT indicator light above the key indicates that

heat is being applied to the inner glass door.

• A good starting point for the door heat control is 35%; if fogging still

occurs, increase in 10% increments until fogging disappears.

7. SCAN/HOLD COMMAND KEY: Permits holding the value of a single

parameter for continued viewing or scans alternately between the values

of the two parameters on a 2-second interval.

8. DOWN-ARROW KEY: This key decreases numerical value of the

parameter which has been accessed.

9. UP-ARROW KEY: This key increases the numerical value of the

parameter that has been accessed.

NOTE: A 5 SECOND DELAY AFTER ANY FINAL ENTRY RESULTS IN AUTOMATIC ENTRY

OF THAT CHANGE.

FEATURES: (Con’t)

16

Loading...

Loading...