Page 1

1

Original instructions

Type C1 Biosafety Cabinet Models

30441 30448

30461 30468

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Axiom Technical Manual and Specifications

Page 2

2

Labconco Training Programs:

In order to assist technicians gain a better understanding of our products,

Labconco Corporation offers Training Seminars at our Kansas City Facility on

a regular basis. For further details about these training programs, contact

Labconco's Product Service Department at 800-821-5525, or (816) 333-8811

from 7:30 a.m. to 5:30 p.m. C.S.T.

Additional Copies:

Additional copies of this document can be downloaded from Labconco’s

website at www.labconco.com. Electronic copies are available to members of

the service community free of charge. Please request electronic copies by

contacting our Product Service Department.

Labconco Purifier Axiom Technical Manual and Specifications

Printed in the U.S.A.

©2014 by Labconco Corporation, Kansas City, MO.

All Rights reserved. No part of this document may be translated or

reproduced in any form without written permission from Labconco

Corporation, 8811 Prospect, Kansas City, Missouri, 64132, U.S.A.

While the advice and information offered in this document are believed to be

true and accurate at the date of going to press, neither the author, nor

Labconco Corporation can accept any legal responsibly for any errors or

omissions that may be made.

P/N 3849911

Rev. G, ECO J633

Product Service 1-800-522-7658

Page 3

3

Table of Contents

Introduction 7

Contacting Labconco 7

Section One – Background Information

QuickStarts 8

What’s the password for the Axiom? 9

How do I calibrate blower speed, filter life & airflow sensor? 10-11

How do I see the current settings? 12

How do I change the configuration? 13-14

How do I run a diagnostic on the:

Sash position switches? 15

Keypad, relays and contact? 16

Inlet Relief Valve? 17

Airflow Sensor? 18

How do I set up automatic operation of the blower & lights? 19

Axiom Filter Life Gauge Operation and Resetting for Local Conditions 20

QuickCharts

Axiom Type C1 Purifiers 21-23

Identifying Axiom Models 24

Serial Number Tags 25

Model Numbering System 26

Axiom Data Plate 27

Final Inspection and Test Report 28

Theory of Operation

Background 29

Airflow Patterns and Features 29

Chem-ZoneTM Directly Exhausted Work Zone 30

Inlet Relief Valve 31

Exhaust System 31

Exhaust System Alarm 32

Airflow Patterns of Axiom 33

ECM Motor 34-35

Electronics 35-36

Section Two – Installation Requirements

Prerequisites 37

Space Requirements 37

Clearance 37

Location Requirements 38

If You Intend to Connect the Axiom to an Exhaust System 39-41

Electrical Requirements 42

Service Line Requirements 43

Product Service 1-800-522-7658

Page 4

4

Section Three – Installation 45

Unpacking the Biosafety Cabinet 46

Preparing the Biosafety Cabinet for operation 46

Moving and Lifting the Cabinet 47

Installing the Biosafety Cabinet on an Existing Work Surface 47

Installing the Cabinet on a Labconco Base Stand 48

Telescoping Base Stands 48

Manual or Electric Lift Base Stands 48

SoLo Electric Hydraulic Lift Base Stands 48

Optional Exhaust System Connection Requirements 49

Configuring for an Exhaust System Connection 50-53

Disconnecting the Axiom from an Exhaust System to Operate in

Recirculation 54-56

Connecting the Biosafety Cabinet to Utility Service Lines 57

Optional Vacu-Pass Cord and Cable Portal 58

Drain Valve Installation (optional) 59

Section Four – Initial Operation of the Axiom

System Reset Switch 61

Information Center 62

Alarm Screens 63

Operating the Sliding Sash 64

Starting the Biosafety Cabinet 64

The Axiom Touchpad 65

Navigating the Axiom Menu Screens 66

Navigating the MyLogic Menu Screens 67-69

Setting the Clock 67

Configuring the Axiom 68-69

Navigating the Settings Menu Screens 69-71

Display Options

Units of Measure 69

Startup Tone 70

Security Lock 70

RS-232 Output 70

UV Settings

UV Lamp Hour meter 71

Reset UV Lamp Hour Meter 71

Change UV Lamp Life 71

Timer Operation

Interval Timer Operation 72

Stopwatch Timer Operation 72

If An Airflow Alert Activates 72

Resetting the Airflow Alert System 72

Product Service 1-800-522-7658

Page 5

5

Section Five – Certification Procedures for the Axiom

Accessing the Certifier’s Menu 73

Adjusting the Inflow, Downflow and Filter Life Gauges 73-74

Axiom Filter Life Gauge Operation and Resetting for Local Conditions 75

HEPA Filter Leak Test Information

Supply HEPA Filter Leak Test 76

If the Axiom is contaminated 77

Supply HEPA Filter Leak Test Specifications 77

If the Axiom is uncontaminated 77-79

Exhaust HEPA Filter Leak Test 80-81

Exhaust HEPA Filter Leak Test Specifications 80

Downflow Velocities 81-82

Downflow Test Specifications 81

Inflow Velocity Calculation

Primary Inflow Method 83

Secondary Inflow Method 84-87

Concurrent Balance Values 88

Work Area Air Cleanliness Test (optional) 89

Fluorescent Light Level (optional) 90

Noise Level (optional) 90

Vibration (optional) 91

UV intensity (optional) 91

Ground Fault Circuit Interrupter 92

Section Six – Axiom Service Operations

Recommended Tools for Service 93

External Dress Components

Front Dress Panel Removal and Installation 94

Side Panel Removal 95

Side Panel Installation 95

Corner Post Lower Trim 95-96

Sash Operation/Adjustment 97

Sash Position Switches

Sash Closure Position Switch 98

Sash Restricted Opening Switch 98

8” and 10” Sash Operating Position Switches 99

Sash Cable Retainer 100

HEPA Filter Replacement 100-03

Supply Motor/Blower Replacement 103-05

Exhaust Motor/Blower Replacement 105-06

Center Work Surface Removal 107

Wing Work Surfaces Removal 107-08

Grille Removal 109

Diffuser Removal 110-11

Preparing the Logic for Gaseous Sterilization 112

Section Seven –Electrical System Service Operations

Fluorescent Lamp

Lamp Identification 113

Changing the Fluorescent Lamp 113

Lamp Socket Replacement 114

Optional Ultraviolet Lamp

Product Service 1-800-522-7658

Page 6

6

Lamp Identification 114

UV Lamp Specifications 114

Changing the UV Lamp 115

Lamp Socket Replacement 115

Electronics Module Access 116

Electronic Module Component Identification 116

Circuit Breaker

Resetting a circuit breaker 117

Circuit breaker specifications 117-18

Testing a circuit breaker 118

Replacing a circuit breaker 118

Power Supply Board Service Operations

Fuse Testing & Replacement 119

Display Board Service Operations 120

Touchpad Connections 120

Diagnostic Operations 121

Motor Service Operations

Motor Testing 121-23

Motor Output Signal Testing 124

Wiring Diagrams 125-26

Section Eight – Purifier Axiom Accessories

Air Flow Sensor Kit 127-30

Service Fixture Kit 131-32

U.V. Lamp Kit 133-35

I.V. Bar Kit 136

Vacu-Pass Cord & Cable Portal 137

RS-232 Connection Kits 138-40

Using the RS-232 Receptacle 141

Connection for Computer Interface 141

Optional Axiom RS-232 Data Output 142-43

Axiom Relay Contact Outputs 144-48

Section Nine - Miscellaneous

Troubleshooting 149-52

Purifier Logic Replacement Parts 153

Dimensions 154-55

Product Service 1-800-522-7658

Page 7

7

INTRODUCTION

This text is designed for you, the Biohazard Cabinet Certifier. Based on

your suggestions, comments, and ideas, Labconco has compiled this

information for you to use in the certification or servicing of our

Purifier Axiom Biosafety Cabinets.

When you use this document in your office or in the field, we would

appreciate your input so that we can make further improvements to

future editions.

As always, we at Labconco want to assist you in having a better

understanding of our products and their operation; if you have any

questions, or need additional information, please contact us.

Thanks again for all your support in the past, and in the future.

Labconco

CONTACTING LABCONCO

Labconco’s Address is:

LABCONCO Corporation

8811 Prospect

Kansas City, MO 64132

Our hours of operation are from 07:30 - 17:30 CST, Monday through Friday,

except national holidays

We can be reached at the following numbers:

(800) 821-5525

(816) 333-8811

Our Fax numbers are:

(816) 444-5343

(816) 363-0130

Should you require Technical Assistance, Service Parts, or have general

questions regarding the Purifiers, please direct them to our Product Service

Department, so that your call can be properly routed and answered.

Product Service 1-800-522-7658

Page 8

8

SECTION ONE –

Background Information

Quickstart

The Axiom is a significant step forward in Biosafety Cabinet technology. While many

internal components are the same or similar to our Logic+-platform products, its

operation and certification are different. The

show you how to answer the questions asked in each case. Keystrokes are shown in

bold blue italics

, while screen selections are shown in

Quickstarts

that follow will help you

green italics

.

Product Service 1-800-522-7658

Page 9

9

Quickstart

What’s the password for the Axiom?

Like the Logic, the Axiom models password protects the user from entering the

Calibration

the airflow sensor readings. New to the Axiom is a

Configuration

connection status, whether its sash height is 8” or 10” and airflow sensor optionsthere is more on this in the Quickstart “How do I change the BSC configuration?”

The password for all protected screens is:

1. Light

2. UV Light

3. Timer

4. Timer

5. OK/Mute

menu to prevent them from adjusting the blower speed, filter gauge or

Service

; entering this option allows you to configure the Axiom’s exhaust

menu selection entitled

Product Service 1-800-522-7658

Page 10

10

Quickstart

MAIN MENU

1. MyLogic

TM

2. Settings

3. Service

or to choose,

OK to select, MENU to escape

or to choose,

OK to select, MENU to r eturn

Current Settings

Restore Default

Diagnostics

Configuration

Calibration

Service

ATTENTION!

The following screens are used

to alter the operation of the

Logic. They should only be used

by a qualified certifier as part

of the certification process.

Calibration

OK to proceed, MENU to return

PASSWORD:

Calibration

The ECM setting is: 80

The current RPM is: 1050

The average RPM is: 1020

Calibration

Supply Fan Speed

or to change motor speed,

OK to select, MENU to escape

How do I recalibrate the

blower speed

filter life gauge

airflow sensor reading

of the Axiom?

1. Press the

2. Press the ▼ button until the

turn yellow).

3. Press

4. Press the ▼ button until the

will turn white).

5. Press

6. You will see a

alter the BSC’s settings.

7. Press

8. When requested for the password press

Timer, Timer

9. If the password is properly entered, the first certification screen

will display the supply blower motor’s PWM setting. Press the ▲

or ▼ button to increase or decrease the blower speed as

needed. When the speed is set properly, press the

button to lock the new blower speed setting, and continue to the

filter life screen.

Menu

OK/Mute

OK/Mute

warning screen

OK/Mute

then

button.

Services

option is highlighted (it will

to enter the Services menu screen.

Calibration

option is highlighted (it

to start the calibration procedure.

alerting you that you are about to

to input the password.

Light, UV light

OK/Mute

.

OK/Mute

,

Product Service 1-800-522-7658

Page 11

11

Quickstart

The Inflow displayed

value is: 102 FPM

Calibration

Inflow Display

or to change display value,

UV Light to reset to 105 FPM,

OK to select, MENU to finish

Calibration

Supply Filter Gauge

or to change filter gauge,

OK to select, MENU to escape

Reset Filter Gauge to 100%

Leave Gauge unchanged

Set Gauge to new setting

The ECM setting is: 80

The current RPM is: 1050

The average RPM is: 1020

Calibration

Exhaust Fan Speed

or to change motor speed,

OK to select, MENU to escape

Calibration

Exhaust Filter Gauge

or to change filter gauge,

OK to select, MENU to escape

Reset Filter Gauge to 100%

Leave Gauge unchanged

Set Gauge to new setting

How do I recalibrate the

blower speed

filter life gauge

airflow sensor reading

of the Axiom? - Continued

10. If this is an initial certification or a recertification after supply

HEPA filter replacement, select

this is an annual recertification, select

If you want to set the filter gauge at a preset value, select

Gauge to new setting

. Then press

11. The next certification screen will display the exhaust blower

motor’s PWM setting. Press the ▲ or ▼ button to increase or

decrease the blower speed as needed. When the speed is set

properly, press the

OK/Mute

speed setting, and continue to the filter life screen.

12. If this is an initial certification or a recertification after exhaust

HEPA filter replacement, select

this is an annual recertification, select

If you want to set the filter gauge at a preset value, select

Gauge to new setting

. Then press

13. If the unit is has no airflow sensor, after the filter gauge option

is selected and you press

down, and then restart with the new settings. If the Unit has an

airflow sensor, you will then be asked to calibrate the inflow

sensor to match the value you obtained when you measured the

inflow. After the inflow is calibrated, and you press

the Axiom will power down, and then restart with the new

settings.

Reset Filter Gauge to 100%

Leave Gauge unchanged

OK/Mute

.

button to lock the new blower

Reset Filter Gauge to 100%

Leave Gauge unchanged

OK/Mute

OK/Mute

, the Axiom will power

.

OK/Mute

. If

.

Set

. If

.

Set

,

Product Service 1-800-522-7658

Page 12

12

Quickstart

MAIN MENU

1. MyLogic

TM

2. Settings

3. Service

or to choose,

OK to select, MENU to escape

or to choose,

OK to select, MENU to return

Current Settings

Restore Default

Diagnostics

Calibration

Configuration

Service

Current Settings

Supply System

or to change, OK to return

The ECM setting is: 65

The current RPM is: 0

The average RPM is: 0

The new filter RPM is: 1450

C1, with afs, with UV

10484 -

Current Settings

Exhaust System

or to change, OK to return

The ECM setting is: 65

The current RPM is: 0

The average RPM is: 0

The new filter RPM is: 1450

C1, with afs, with UV

10484 -

How do I see the Current Settings of the Axiom?

1. Press the

2. Press the ▼ button until the

turn yellow). Press

screen.

3. Press the ▼ button until the

highlighted (it will turn white). Press

configuration.

4. The first screen shows the current settings of the supply blower

system.

5. By pressing the ▲ or ▼ button, you can see the current

settings of the exhaust blower system. If you are recertifying the

unit, you may want to record the data on this screen. The

firmware revision is shown in the bottom right corner as a -, or

as a letter.

Menu

button.

OK/Mute

Services

option is highlighted (it will

to enter the Services menu

Current Settings

OK/Mute

option is

to see the

Product Service 1-800-522-7658

Page 13

13

Quickstart

MAIN MENU

1. MyLogic

TM

2. Settings

3. Service

or to choose,

OK to select, MENU to escape

or to choose,

OK to select, MENU to return

Current Settings

Restore Default

Diagnostics

Calibration

Configuration

Service

Configuration

PASSWORD:

ATTENTION!

The following screens are used

to alter the operation of the

Logic. They should only be used

by a qualified certifier as part

of the certification process.

Configuration

OK to proceed, MENU to return

How do I change the Configuration of the Axiom?

1. Press the

2. Press the ▼ button until the

turn yellow).

3. Press

4. Press the ▼ button until the

(it will turn white).

5. Press

6. You will see a

alter the BSC’s settings.

7. Press

8. When requested for the password press

Timer, Timer

Menu

OK/Mute

OK/Mute

warning screen

OK/Mute

then

button.

Services

to enter the Services menu screen.

Configuration

to alter the configuration.

alerting you that you are about to

to input the password.

OK/Mute

.

option is highlighted (it will

option is highlighted

Light, UV light

,

Product Service 1-800-522-7658

Page 14

14

This cabinet is not configured

for a UV light

If you want to install a UV

light, contact Labconco Product

Service at 800-821-5525

Attention

MENU to return

Configuration

Type C Configuration

This cabinet has:

an

or to choose,

OK t o select , MENU to escape

no exhaust connect ion

exhaust connection

Configuration

Type C Configuration

If there is an exhaust system

failure, Active protection should

last:

or to choose,

OK t o select , MENU to escape

0 Seconds

The sash height is:

or to choose,

OK to select, MENU to escape

8 inches

10 inches

NOTE: If you change the sash

height, you must recertify

airflows.

Sash Height Settings

This Logic has:

or to choose,

OK to select, MENU to escape

a UV light

NO UV light

UV Settings

Quickstart

How do I change the Configuration of the Axiom? – continued

9. The first screen allows you to decide if the cabinet is connected to

an exhaust system or not. When the unit is configured for no

exhaust connection, the Axiom will ignore the inlet relief valve

sensor’s status. Selecting connected to an exhaust system

activates the sensor; if the valve is open, the unit operates

normally, if closed, an exhaust alarm is activated. Use the ▲or▼

buttons to select the exhaust configuration, and then press

OK/Mute.

10. If the unit is configured to be connected to an exhaust system,

then the next screen allows you to program the amount of time

interval of Active Protection. Active Protection will allow the Axiom

blowers to continue to operate after the detection of an exhaust

system failure. This will maintain a safe inflow to allow the user a

programmed time interval to secure any hazardous materials in

the cabinet before the BSC shuts off.

11. This screen configures the sash height. After your selection is

chosen, and you press OK/Mute.

12. This screen configures the unit for a UV light or not. After your

selection is chosen, and you press OK/Mute, the unit will shut off

and then reset in the new configuration.

13. If the unit is configured to NOT have a UV light, and the user

presses the UV Light button, they will get this message.

Product Service 1-800-522-7658

Page 15

15

Quickstart

MAIN MENU

1. MyLogic

TM

2. Settings

3. Service

or to choose,

OK to select, MENU to escape

or to choose,

OK to select, MENU to return

Current Settings

Restore Default

Calibration

Configuration

Diagnostics

Service

Diagnostics

Test the alarm by closing the

inlet valve.

Note the alarm status below:

Open

OK to return

How do I run a diagnostic on the sash position switches?

1. Press the

2. Press the ▼ button until the

turn yellow).

3. Press

4. Press the ▼ button until the

will turn white).

5. Press

6. Press the ▼ button until the Diagnostic

highlighted (it will turn white). Press

7. Lower the sash, and note the status line – it should properly

report the sash as open too high, open, nearly closed or closed

when the sash is in the corresponding position.* Press

OK/Mute

Menu

button.

OK/Mute

OK/Mute

to enter the Services menu screen.

to enter the Diagnostic submenu.

to exit the diagnostic.

Services

option is highlighted (it will

Diagnostic

OK/Mute

option is highlighted (it

Sash sensors

.

option is

Product Service 1-800-522-7658

Page 16

16

Quickstart

MAIN MENU

1. MyLogic

TM

2. Settings

3. Service

or to choose,

OK to select, MENU to escape

or to choose,

OK to select, MENU to return

Current Settings

Restore Default

Calibration

Configuration

Diagnostics

Service

How do I run a diagnostic on the keypad, relays and contacts?

1. Press the

2. Press the ▼ button until the

turn yellow).

3. Press

4. Press the ▼ button until the

will turn white).

5. Press

6. Press the ▼ button until the Diagnostic

(it will turn white). Press

7. Press any button on the keypad (except

display.

Menu

OK/Mute

OK/Mute

button.

Services

option is highlighted (it will

to enter the Services menu screen.

Diagnostic

option is highlighted (it

to enter the Diagnostic submenu.

Keypad-Relays

OK/Mute

.

Menu

option is highlighted

), and note the

Product Service 1-800-522-7658

Page 17

17

MAIN MENU

1. MyLogic

TM

2. Settings

3. Service

or to choose,

OK to select, MENU to escape

or to choose,

OK to select, MENU to return

Current Settings

Restore Default

Calibration

Configuration

Diagnostics

Service

Diagnostics

or t o choose,

OK to select, MENU to escape

Sash sensors

Keypad - Relays

Inlet Relief Valve

Airflow Sensor

Diagnostics

Test the alarm by closing the

inlet valve.

Note the alarm status below:

Open

OK to return

Quickstart

How do I run a diagnostic on the Inlet Relief Valve?

1. Press the

2. Press the ▼ button until the

turn yellow).

3. Press

4. Press the ▼ button until the

will turn white).

5. Press

6. Press the ▼ button until the Diagnostic

is highlighted (it will turn white). Press

7. The display shows the status of the Inlet Relief Valve. During

normal operation, it will be open, and during an exhaust alarm,

it will be closed. NOTE: The inlet relief valve function is

OPPOSITE OF THE MAGNETIC SWITCH FUNCTION! – WHEN

THE INLET VALVE IS OPEN, THE MAGNETIC SWITCH IS

CLOSED.

Menu

OK/Mute

OK/Mute

button.

Services

option is highlighted (it will

to enter the Services menu screen.

Diagnostic

option is highlighted (it

to enter the Diagnostic submenu.

Inlet Relief Valve

OK/Mute

.

Product Service 1-800-522-7658

option

Page 18

18

MAIN MENU

1. MyLogic

TM

2. Settings

3. Service

or to choose,

OK to select, MENU to escape

or to choose,

OK to select, MENU to return

Current Settings

Restore Default

Calibration

Configuration

Diagnostics

Service

Quickstart

How do I run a diagnostic on the Airflow Sensor?

1. Press the

2. Press the ▼ button until the

turn yellow).

3. Press

4. Press the ▼ button until the

will turn white).

5. Press

6. Press the ▼ button until the Diagnostic

highlighted (it will turn white). Press

7. The display shows the status of the airflow sensor. Its current

output, alarm setting and zero point in Millivolts, along with the

corrected Inflow velocity currently being displayed.

Quickstart

Menu

OK/Mute

OK/Mute

button.

Services

option is highlighted (it will

to enter the Services menu screen.

Diagnostic

option is highlighted (it

to enter the Diagnostic submenu.

Airflow Sensor

OK/Mute

.

Product Service 1-800-522-7658

option is

Page 19

19

How do I set up automatic operation of the blower and lights?

1. Press the

2. Press the ▼ button until the

turn blue).

3. Press

Menu

OK/Mute

button.

MyLogic

to enter the MyLogic menu screen.

option is highlighted it will

4. Press the ▼ button until the option

option is highlighted (it will turn white).

5. Press the ▼ button to select either Smart-Start or manual

operation of the cabinet blower. (In Smart-Start, the cabinet

blower will automatically start every time the sash is opened.

6. Press the ▼ button to select either Smart-Start or manual

operation of the fluorescent lights.

7. Press the ▼ button to select either Night-Smart or manual

operation of the cabinet blower. (In Night-Smart, the cabinet

blower will automatically operate at idle every time the sash is

closed.

8. Press the ▼ button to select either Night-Smart or manual

operation of the UV Light.*

9. Press the ▼ button to select the time interval the UV light will

operate for until it automatically shuts off.*

* - These screens will only appear if the unit is configured for a UV light.

configure my Logic for use

Axiom Filter Life Gauge Operation and Resetting

for Local Conditions

Product Service 1-800-522-7658

Page 20

20

The filter life gauge calculates the remaining filter life by measuring and comparing

the current motor speed to the initial speed noted at the factory during assembly,

and the calculated maximum motor speed, using the formula:

100-(100x (current speed-original speed) ) = % filter life left

max. speed-original speed

So

anything

Blocking the grille.

Raising the air temperature.

Lowering the barometric pressure.

will increase the motor’s speed, causing the Filter Life Gauge to decrease. Electronic

dampening of the gauge will limit the change in readings to approximately

1%/minute.

Axiom Biosafety Cabinets being installed at altitudes or operating at temperatures

significantly different from those at the time of manufacture (900 +/- 500 ft above

sea level, 75o +/- 5o F)

conditions. Failure to do so will result in the users noticing a steady drop in Percent

(%) Filter Life remaining as the unit operates. Below are the instructions on how to

correct the Filter Life Gauge for local conditions.

that changes the motor’s current speed, like:

must

have their filter life gauge recalibrated for local

1. Ensure to correct all measurement equipment for local conditions

(temperature, absolute pressure). Anemometers may not have this

ability and might have to be done manually; whereas, a

ShortRidgeTM instrument has a setting to correct for local conditions.

2. As the elevation or the ambient temperature rises, the motor power

factor will have to be reduced to compensate. For an initial

certification, the motor speed should be reduced until it equals the

Axiom’s “Initial Motor Speed” as reported on the unit’s test sheet,

plus approximately 10-15 RPM per each additional 1000 feet of

elevation.

3. The Axiom MUST be recertified using instruments corrected for local

conditions.

4. When the unit is recertified, and operating properly, the certifier

MUST RESET THE FILTER LIFE GAUGE, INDICATING A NEW FILTER

HAS BEEN INSTALLED.

5. Only by performing Step #4 AFTER THE UNIT IS READJUSTED AND

RECERTIFIED FOR ITS LOCAL CONDITION, will the filter life gauge

register 100% (+/- 2%) during operation. As the Filters then load,

the filter life gauge will then begin to drop as appropriate.

Product Service 1-800-522-7658

Page 21

21

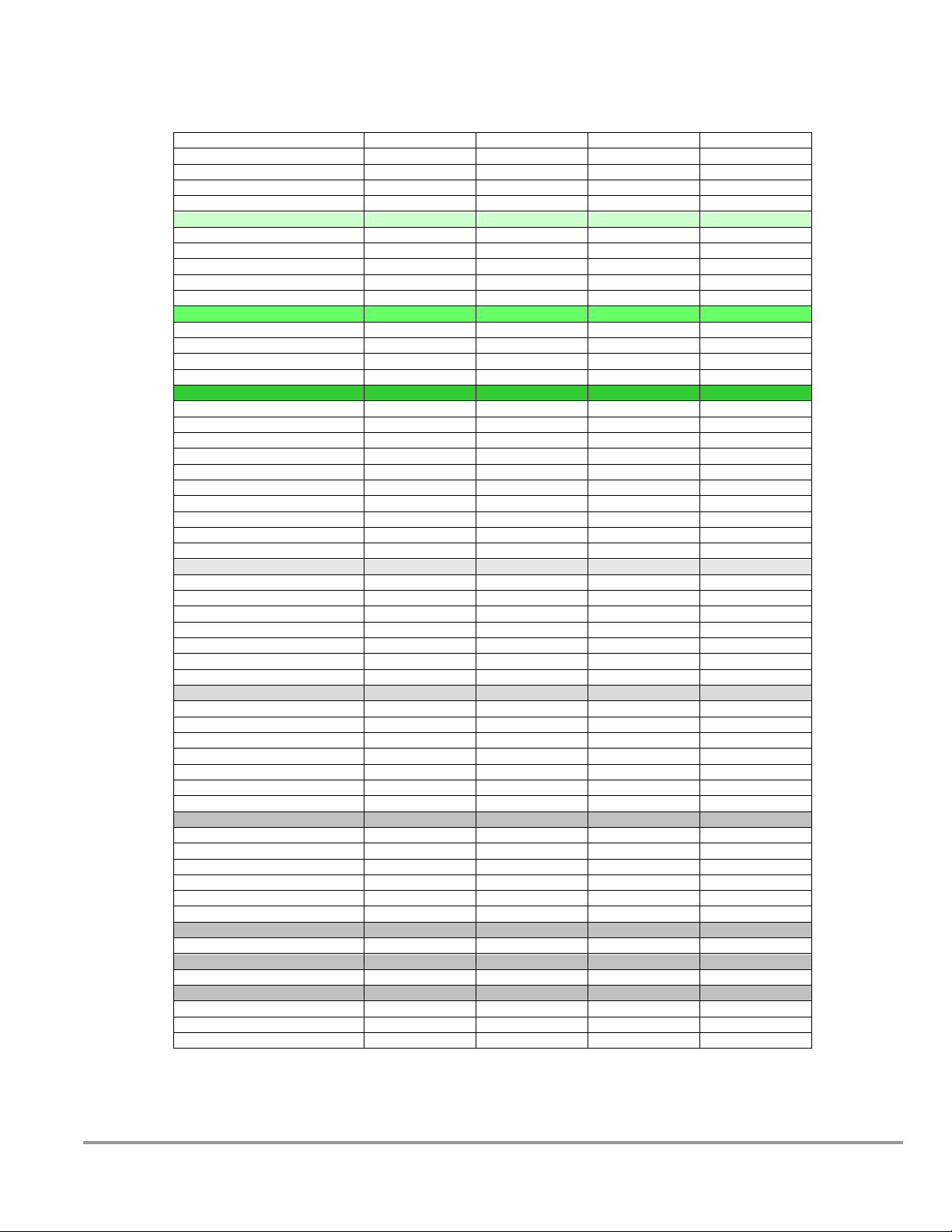

QuickChart – Axiom Type C1 BSCs – Imperial Units

Model

30441

30448

30461

30468

Type

C1

C1

C1

C1

Cabinet Size (in feet)

4 4 6

6

Sash Opening (inches)

10 8 10

8

Starting Serial #

1503_

1503_

1503_

1503_

Downflow Data

Nominal Avg. Downflow (FPM)

65+/-5

65+/-5

55+/-5

55+/-5

grid # of points (rows x columns)

24 (3x8)

24 (3x8)

36(3x12)

36(3x12)

Grid distance from back & sides

6.0

6.0

6.0

6.0

Distance between rows

5.55

5.75

5.55

5.75

Distance between columns

5.21

5.21

5.50

5.50

Inflow Data

Nominal Average Inflow (FPM)

105+/-5

105+/-5

105+/-5

105+/-5

Sash Open Area (Sq. Ft)

3.37

2.69

5.03

4.03

Nominal Avg. Exhaust Vol. (CFM)

354

283

529

423

Avg. Exhaust Vol. Range (CFM)

337-371

269-296

503-553

403-443

Secondary Inflow Data

Sash Opening Template

1

4+

4+

6+

6+

Sensor distance (inches)2

3.25

3.25 4 4

# of Test points

8 8 12

12

Test point location

* * *

*

Nominal Avg. Inflow Vel. (FPM)

354

283

289

231

Avg. Inflow Vel. Range (FPM)

312-344

249-274

252-277

202-222

Correction Factor (CF)

1.08

1.08 2 2

Avg. Inflow Volume (CFM)

337-371

269-296

503-553

403-443

Sash Open Area (Sq. Ft)

3.37

2.69

5.03

4.03

Inflow Velocity Range (FPM)

100-110

100-110

100-110

100-110

Supply HEPA Data

Air Displacement (CFM)

530

530

660

660

Laskin Nozzles needed

1 1 1

1

Theoretical aerosol conc. (ug/l)3

25

25

20

20

Width x Depth x Height (in.)4

48x18x3.06

48x18x3.06

72x18x3.06

72x18x3.06

Performance (CFM)

445

445

665

665

Performance (Pressure in. H2O)

<.45”

<.45”

<.42”

<.42”

Labconco P/N

3838401

3838401

3838403

3838403

Exhaust HEPA Data

Air Displacement (CFM)

354

283

529

423

Laskin Nozzles needed

1 1 1

1

Theoretical aerosol conc. (ug/l)3

38

48

26

32

Width x Depth x Height (in.)

4

26x18x5.88

26x18x5.88

48x18x5.88

48x18x5.88

Performance (CFM)

354

354

529

52

Performance (Pressure in. H2O)

<0.3

<0.3

<0.3

<0.3

Labconco P/N

3838501

3838501

3838503

3838503

Exhaust Volume Data

DIM Exhaust Volume (CFM)5

400

323

570

463

Traverse Exhaust Volume (CFM)6

480

387

684

556

Differential Pressure (in. H20)7

0.3

0.3

0.3

0.3

IRV Inflow Range (CFM)8

20-100

20-100

20-100

20-100

Nominal IRV Slot Velocity (FPM)

240-260

240-260

240-260

240-260

Nominal IRV Slot Volume (CFM)

50

50

50

50

Supply Motor/Blower Data

Motor HP

1/3

1/3

1/3

1/3

Exhaust Motor/Blower Data

Motor HP

1/3

1/3

1/3

1/3

Fluorescent Lamp Data

Fluorescent Lamps (2 each)

F32T8 TL741

F32T8 TL741

F40T8 SP41

F40T8 SP41

Fluor. Lamp Labconco Part #

9721900

9721900

9721903

9721903

Fluor. Ballast Labconco Part #

3838100

3838100

3838100

3838100

Product Service 1-800-522-7658

Page 22

22

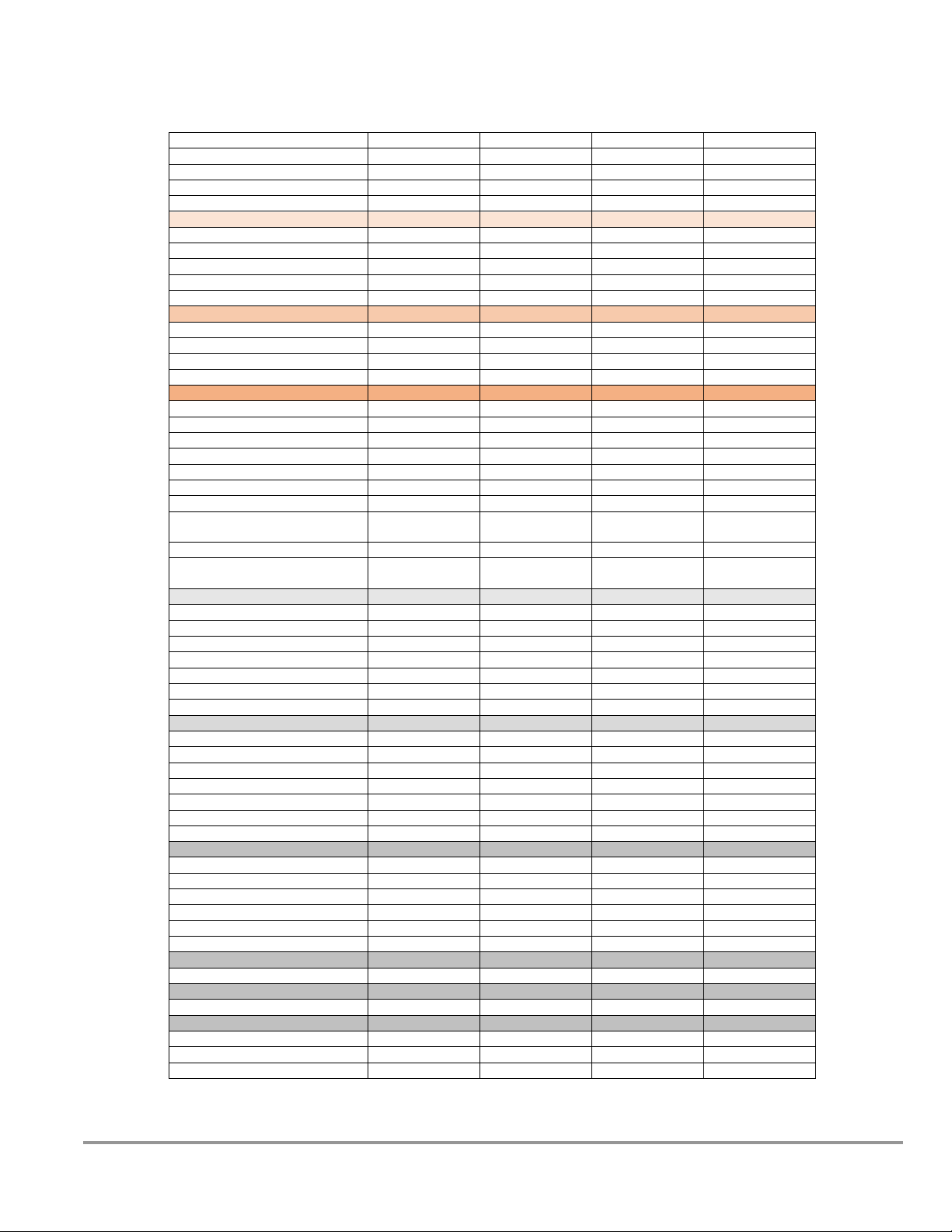

QuickChart – Axiom Type C1 BSCs – Metric Units

Model

30441

30448

30461

30468

Type

C1

C1

C1

C1

Cabinet Size (in m)

1.22

1.22

1.83

1.83

Sash Opening (mm)

254

203

254

203

Starting Serial #

1503_

1503_

1503_

1503_

Downflow Data

Nominal Avg. Downflow (FPM)

65+/-5

65+/-5

55+/-5

55+/-5

grid # of points (rows x columns)

24 (3x8)

24 (3x8)

36(3x12)

36(3x12)

Grid distance from back & sides (mm)

152

152

152

152

Distance between rows (mm)

141

146

141

146

Distance between columns (mm)

132

132

140

140

Inflow Data

Nominal Average Inflow (m/s)

.533+/-.03

.533+/-.03

.533+/-.03

.533+/-.03

Sash Open Area (Sq. m)

.313

.250

5.03

4.03

Nominal Avg. Exhaust Vol. (m3/s)

354

283

.468

.374

Avg. Exhaust Vol. Range (m3/s)

337-371

269-296

503-553

403-443

Secondary Inflow Data

Sash Opening Template

1

4+

4+

6+

6+

Sensor distance (mm)2

83

83

102

102

# of Test points

8 8 12

12

Test point location

* * *

*

Nominal Avg. Inflow Vel. (m/s)

1.80

1.44

1.47

1.17

Avg. Inflow Vel. Range (m/s)

1.71-1.88

1.37-1.50

1.40-1.53

1.12-1.23

Correction Factor (CF)

.0929

.0929

.1700

.1700

Average Inflow Volume Range

(AIV) (Avg. velocity x CF)

.159-.175

.127-.140

.238-.261

.190-.209

Sash Open Area (Sq. m)

.313

.250

.468

.374

Inflow Velocity Range

(AIV / Sash open area)

.533+/-.03

.533+/-.03

.533+/-.03

.533+/-.03

Supply HEPA Data

Air Displacement (m3/s)

.250

.250

.311

.311

Laskin Nozzles needed

1 1 1

1

Theoretical aerosol conc. (ug/l)3

25

25

20

20

Width x Depth x Height (in.)4

48x18x3.06

48x18x3.06

72x18x3.06

72x18x3.06

Performance (CFM)

445

445

665

665

Performance (Pressure in. H2O)

<.45”

<.45”

<.42”

<.42”

Labconco P/N

3838401

3838401

3838403

3838403

Exhaust HEPA Data

Air Displacement (m3/s)

.167

.134

.250

.200

Laskin Nozzles needed

1 1 1

1

Theoretical aerosol conc. (ug/l)3

38

48

26

32

Width x Depth x Height (in.)

4

26x18x5.88

26x18x5.88

48x18x5.88

48x18x5.88

Performance (CFM)

283

283

423

423

Performance (Pressure in. H2O)

<0.3

<0.3

<0.3

<0.3

Labconco P/N

3838501

3838501

3838503

3838503

Exhaust Volume Data

DIM Exhaust Volume (m3/s)5

.189

.152

.269

.219

Traverse Exhaust Volume (m,3/s)6

.227

.183

.323

.262

Differential Pressure (Pascal)7

75

75

75

75

IRV Inflow Range (m/s)

.010-.047

.010-.047

.010-.047

.010-.047

Nominal IRV Slot Velocity (m/s)

1.22-1.32

1.22-1.32

1.22-1.32

1.22-1.32

Nominal IRV Slot Volume (m3/s)

.235

.235

.235

.235

Supply Motor/Blower Data

Motor HP

1/3

1/3

1/3

1/3

Exhaust Motor/Blower Data

Motor HP

1/3

1/3

1/3

1/3

Fluorescent Lamp Data

Fluorescent Lamps (2 each)

F32T8 TL741

F32T8 TL741

F40T8 SP41

F40T8 SP41

Fluor. Lamp Labconco Part #

9721900

9721900

9721903

9721903

Fluor. Ballast Labconco Part #

3838100

3838100

3838100

3838100

Product Service 1-800-522-7658

Page 23

23

QuickChart – Axiom/Cell Axiom Type C1 BSCs footnotes

Axiom Model Identification

The primary serial tag is on the lower right edge of the front dress panel.

The secondary serial tag is located on the front of the electronics module on the top

right side of the cabinet.

The first two digits of the serial number are the year of production; the next two are

the month. The next 5 digits are the sequence of production, and the letter following

the serial number is the revision level of the cabinet.

Downflow Test Specifications

All models are classified as uniform downflow.

All tests performed as described in ANSI/NSF Standard 49:2012.

UV Lamp, IV bar and all other accessories must be removed before measuring

downflow.

Inflow Test Specifications

All tests performed as described in ANSI/NSF Standard 49:2012.

Secondary Inflow Test Specifications

Must use Labconco holder P/N 3836405 to perform this test properly.

1. Use the appropriate template included in Certifier Kit# 3858403.

2. Measured from the bottom edge of the probe holder to the center of the thermal

anemometer sensor element.

* - Locate the single row of holes at the front of the grille. Mark the 6th hole from the

side wall and subsequent test points every 9 holes until the number of test points

marked equals the width of the cabinet in feet (3-foot cabinet, mark the first 3 points).

Repeat for the opposite side.

HEPA Filter Leak Test Specifications

3. Based on mineral oil.

4. Without gasket

Aerosol generator should be placed in the left rear corner of the work area, pointing

toward the rear grille.

For uncontaminated units, the upstream concentration can be sampled from the

tube located under the work surface.

Metric calculation of concentration is:

# of Laskin nozzles @ 138K Pascal x 6.372/Volume of air in m3/sec. = Conc.

In ug/l

Exhaust Data

5. Total Exhaust Volume; The sum of the inflow and air drawn into the Inlet Relief

6. Measured as per ASHRAE methodology for measuring air volume in round ducts.

7. Measured at the exhaust transition sampling point, relative to atmosphere.

8. IRV = Inlet Relief Valve.

UV lamp Specifications

For all models, the UV lamp number is G30T8. The Labconco part number is

For all 115/230 VAC models, the ballast assembly is Labconco part number 3829901.

For all 100 VAC models, the ballast assembly is Labconco part number 3830600. The

Valve.

1271300.

The ballast is Robertson part number PSM2GPH18MVW.

ballast is Robertson part number RSO1GPH30100.

Product Service 1-800-522-7658

Page 24

24

IDENTIFYING AXIOM MODELS

The Axiom platform Biosafety Cabinet can be identified readily by several

external features, as shown in Figure 1-1:

Model number Stars with 304xxxxxx

Serial number beginning with 1503xxxxx.

Exhaust System Cover.

Segmented Work Surfaces.

Figure 1-1

Exhaust System Cover

Axiom Logo

Segmented Work

Surfaces

Product Service 1-800-522-7658

Page 25

25

SERIAL NUMBER TAGS

The model/serial number tag is located on the bottom right edge of the

dress panel. A second tag is located on the front of the electronics module

on the top of the unit. This tag includes the unit’s operating voltage and

amperage. The model and serial numbers of each unit are also recorded on

the unit test report attached beneath the front dress panel. These items are

shown graphically in the figures 1-3 to 1-5 below:

Figure 1-3

Primary Serial Tag

Figure 1-4

Secondary Serial Tag

Figure 1-5

Final Inspection and Test Report Form

Obviously, you can get confirmation of the Biosafety Cabinet's model by

contacting Labconco's Product Service Department, and providing us with

the serial number. From this number, we can tell the date of production and

its model.

Product Service 1-800-522-7658

Page 26

26

AXIOM MODEL NUMBERING SYSTEM

Axiom units’ model numbers define the configuration of the cabinet. The first

five digits define the unit's configuration, while the last four are assigned

based on the unit's options and electrical configuration. Thus, a model

number of:

30448xxxx

Labconco Product Group

3=Laminar Flow Products

Indicates the Product Family

0= Logic

1= PuriCare

2-4= Cell Logic

Indicates the Cabinet Type

1= Type A1

2= Type A2

3= Type B2

4= Type C1

Indicates the Cabinet width

3= 3-foot Wide

4= 4-foot Wide

5= 5-foot Wide

6= 6-foot Wide

Indicates the sash height

1= 10” sash opening

2= 12” sash opening

8= 8” sash opening

9= 9” sash opening

Product Service 1-800-522-7658

Page 27

27

Axiom Data Plate

The Axiom Data Plate contains much of the information required to certify

the unit. Information on the plate includes nominal inflow and downflow

velocity settings, a description of how to establish the downflow grid and the

secondary inflow methodology are also included on the data plate, as shown

below. The plate is located in the upper left corner of the dress panel.

Figure 1-6

Product Service 1-800-522-7658

Page 28

28

Final Inspection and Test Report Form

A copy of the Final Inspection Test Report is attached to the blower plenum

cover, beneath the front dress panel. The report contains initial setup

information on inflow and downflow velocities, and the initial blower torque

setting. A copy of the report is shown in Figure 1-7, below

Figure 1-7

Model/Serial

Numbers

HEPA Filter

Information

Test Results

Downflow Test

Results

Product Service 1-800-522-7658

Page 29

29

Theory of Operation

Background

The Axiom Type C1 BSC was the result of a customer request for a Type B

(directly exhausted) cabinet that could operate at a constant exhaust system

vacuum of only 0.25 inches of H2O. Realizing that this was impossible for

existing Type B technologies, Labconco developed a new type of BSC; The

proposed Type C1.

Figure 1-8

Airflow Patterns and Features

The overall airflow pattern in the Type C1 is similar to a Type B1, with three

important differences:

1. In the C1, the directly exhausted portion of downflow air is

taken from the center of the work area (The Chem-ZoneTM).

2. An inlet relief valve, unique to the Axiom, stabilizes the inflow

as exhaust system airflows fluctuates, and closes during an

exhaust system failure, signaling the Axiom to initiate a timed

“Active Protection” of the user and their work.

3. A constant volume exhaust blower upstream of the Exhaust

HEPA maintains constant inflow, and allows the unit’s blowers

to continue to operate during an exhaust system failure

(Active Protection), maintaining safe inflows and downflows

while the user secures any hazardous materials in the work

area.

Product Service 1-800-522-7658

Page 30

30

Figure 1-8a

Chem-ZoneTM Directly Exhausted Work Zone

Unique to the Axiom is the Chem-Zone, a directly exhausted work zone. The

central portion of the work surface is surrounded by grilles on the sides,

front and back. Air entering these grilles is drawn to the Exhaust HEPA filter,

and when the cabinet is connected to an exhaust system, out of the

laboratory. This feature prevents the recirculation of volatile chemicals as

seen in Type A cabinets, while exhausting much less air than Type B2

models. This is illustrated in Figure 1-8a.

Product Service 1-800-522-7658

Page 31

31

Inlet Relief Valve

Also unique to the Axiom is the Inlet Relief Valve, The intake valve is angled

such that the incoming make-up (room) air must keep the valve open to

maintain normal operation; a loss of exhaust volume will allow gravity and

air pressure to close the inlet valve and open the magnetic switch, resulting

in an exhaust alarm.

Figure 1-8b

Intake Valve

Alarm Switch

Exhaust System

Key to the Axiom is its exhaust flexibility. When properly configured, the

HEPA-filtered exhaust can be recirculated back into the laboratory.

When configured for, and connected to an external exhaust system, the

airflow patterns are similar to the definition of a Type B1, however, the

integral exhaust blower and Inlet Relief Valve changes the operating

characteristics of the Axiom.

The CAP (Constant Airflow Profile)-programmed exhaust fan motor draws a

constant volume of air through the exhaust ductwork and exhaust HEPA

filter, and ‘presents’ the air to the exhaust system. This means the inflow

volume will remain constant as the exhaust system fluctuates, or as the

exhaust HEPA filter loads.

This arrangement lowers the vacuum required to operate the unit to a

constant 0.3 inches H2O; far lower than traditional Type B BSCs.

The inlet relief valve is pulled opened when the exhaust system draws more

air than the Axiom exhausts. If the exhaust system fails, gravity and positive

air pressure cause the Inlet Relief Valve to close, activating the sensor to

signal an exhaust alarm.

Product Service 1-800-522-7658

Page 32

32

Exhaust System Alarm

The Axiom is unique in its response to an exhaust alarm. Instead of shutting

off the BSC’s blowers, the Axiom starts its “Activate Protection Protocol” – a

certifier-programmed interval of up to 5 minutes. During this interval, the

Axiom’s exhaust blower speeds up to compensate for the loss of the remote

exhaust fan to provide constant inflow. The supply blower maintains

downflow. This offers the user time to secure any hazardous material in the

BSC. At the end of the Active Protection cycle, the supply blower shuts off,

followed by the exhaust fan 10 seconds later, to ensure containment until

the unit shuts off completely.

Figure 1-8c

10” Exhaust System

Connection

Inlet Relief Valve

Exhaust Fan System

Product Service 1-800-522-7658

Page 33

33

Inlet Relief Valve Open

Inlet Relief Valve Closed

Airflow Patterns of the Axiom in Recirculating and

Figure 1-8d

Exhausted Modes.

Product Service 1-800-522-7658

Page 34

34

ECM Motor

The modern Class II Biosafety Cabinet was developed in the early 1960’s as

a result of the increased availability of High Efficiency Particulate Air (HEPA)

filter technology. The motor of choice at the time to drive the cabinet’s

blower was the Permanent Split Capacitor (PSC) type. At the time, the PSC

motor offered manufacturers an inexpensive power source whose speed

could be electronically controlled to allow for airflow adjustment as the HEPA

filter(s) loaded.

The PSC motor is known as an induction type, for stationary windings

(stator) surround a rotating part (rotor) composed of iron or steel. As

current passes through the stator windings, it induces a magnetic field in the

rotor, causing it to rotate towards the shifting field in the stator. Because a

magnetic field must be induced in the rotor, the PSC motor is asynchronous,

with the rotor constantly lagging behind the fields being created in the

stator. As a result of this asynchronous operation, the PSC motor is

inefficient, and generates high amounts of waste heat. Attempting to control

the blower speed by reducing its voltage only increases the inefficiency of

the PSC motor.

DC motors are more efficient than their AC counterparts. In a typical DC

motor, the stator in an AC motor is replaced with permanent magnets. The

rotor then has a series of windings around it. When current is applied to the

motor, a magnetic field is created in some of the windings of the rotor,

causing it to rotate toward the magnetic field created by the permanent

magnets. Brushes in contact with a commutator allow the current, and thus

the magnetic field in the rotor to progressively shift from winding to winding,

forcing the rotor to keep rotating.

The greatest drawback of brushed DC motors is the brushes-they wear

themselves and the commutator down, eventually causing motor failure.

With the development of greater microprocessor power in the 1970s and

80s, the stage was set for an even more efficient type of DC motor – the

Electronically Commutated Motor (ECM).

Figure 1-9

In the ECM, the magnets and windings switch position –

the permanent magnet is on the rotor, and the series of

windings are placed around the rotor. The

microprocessor precisely controls the creation of

magnetic fields in the stator, so that the rotor is always

synchronous with the magnetic fields being created in

the stator. As a result, the ECM will always run more

efficiently and cooler than a comparable PSC motor.

Because of the simple, robust construction of the ECM, it

offers far greater reliability and operational service life

than the PSC motor.

Product Service 1-800-522-7658

Page 35

35

Controlling the motor’s operation with a microprocessor adds numerous

advantages. Motor speed can be efficiently controlled across a speed range

that would damage or destroy a PSC motor. Given enough microprocessor

memory and power, the manufacturer can program in any number of userselected programs controlling motor speed, power and even direction of

rotation. The ultimate expression of the power of the ECM was the

development of the constant volume algorithm, by General Electric, and

used in the Axiom BSC. By testing a prototype model to a variety of airflows

and filter pressures, the motor/blower can be “characterized” for that size

cabinet. This characterization allows for the creation of a model-specific

motor-blower curve. By programming the curve values into the motor during

assembly, the motor will deliver the correct volume of air as the HEPA filters

load.

Electronics

The Axiom utilizes two microprocessors. The first is part of the ECM motor,

attached to end of the motor housing, as shown in Figure 1-10. This

processor controls motor operation, and communication with the display

board. The second is located on the control board, located on the right side

wall, as shown in Figure 1-11. It controls the display and its interface to the

touchpad.

Figure 1-10

The ECM Microprocessor board is encapsulated in

epoxy to prevent moisture and dirt contamination of

the microelectronics.

Figure 1-11

The control board assembly

(located on the right side wall)

Product Service 1-800-522-7658

Page 36

36

The Axiom has three circuit boards. The ECM microprocessor and power

supply board, located in the end of the ECM, the control board on the right

side wall, shown in Figure 1-11, and the power supply board assembly,

located in the electronics module, as shown in Figure 1-12.

Figure 1-12

UV Relay

Light Relay

Outlet Relay

RS-232 Board

Location

The Axiom also has an optional contact/RS232 board. This must be installed

if the user wants to signal external building monitors or controllers, or wants

the Axiom to output operating information to a data logger. The optional

board is located in the electronics module.

Product Service 1-800-522-7658

Page 37

37

Section Two –

Installation Requirements

This section offers an overview of site requirements and how to prepare the

unit for operation.

Prerequisites

Before you install the Axiom, you need to prepare the site for installation.

Examine the location where you intend to install the cabinet. You must be

certain that the area is level and of solid construction. In addition, a

dedicated source of electrical power must be located near the installation

site.

Carefully read this chapter to learn:

Location requirements.

Electrical power requirements.

Exhaust requirements.

Service utility requirements.

Space requirements.

Refer to Section Nine: Miscellaneous, for complete biosafety cabinet

electrical and environmental conditions, specifications and requirements.

Space Requirements

The overall dimensions for the 4-foot Axiom are 64.2 inches (163 cm) high, 32

inches (81 cm) deep, and 54.2 inches (138 cm) wide. The overall dimensions

for the 6-foot Axiom are 64.2 inches (163 cm) high, 32.6 inches (83 cm) deep,

and 78.2 inches (199 cm) wide.

Complete dimensions for the Axiom biosafety cabinets are shown in

Nine: Miscellaneous

.

Section

Clearance

A minimum clearance of at least 4 inches (100 mm) is suggested on the top

and 6 inches (150mm) on both sides of the cabinet for service.

Product Service 1-800-522-7658

Page 38

38

Location Requirements

Figure 2-1

Note: The biosafety cabinet should be located away from traffic patterns,

doors, fans, ventilation registers, fume hoods and any other air-handling

devices that could disrupt its airflow patterns. All windows in the room

should remain closed. Figure 2-1 shows the preferred location for the

biosafety cabinet.

Preferred location

Air register blocked or redirected

to prevent cabinet disruption

Alternate location

Main Disconnect Device

(Power cord plug in back

of the electronics module).

Do not position the unit so that it is difficult to operate the main

disconnect device.

Ne placez pas l'appareil de sorte qu'il est difficile de faire

fonctionner le dispositif principal de déconnexion.

Product Service 1-800-522-7658

Page 39

39

If You Intend to Connect the Axiom to an Exhaust System:

Figure 2-1a

Figure 2-1b

NOTE: THE EXHAUST BLOWER CANNOT RUN AT ITS NOMINAL FLOW RATE

WITH THE SASH COMPLETELY CLOSED. IF YOU CHOOSE TO CLOSE THE

SASH COMPLETELY TO USE THE UV LIGHT FOR SURFACE DISINFECTION,

THEN THE EXHAUST BLOWER MUST BE SHUT OFF, OR ITS FLOW RATE

REDUCED 90% OR MORE FOR PROPER OPERATION. THE AXIOM HAS AN

OPTIONAL EN/CONTACT CIRCUIT BOARD THAT HAS DRY CONTACTS THAT

CAN BE CONFIGURED TO SIGNAL THE EXHAUST BLOWER TO TURN ON

WHEN THE AXIOM’s BLOWER IS ON. FOR FURTHER INFORMATION,

CONTACT LABCONCO’S PRODUCT SERVICE DEPARTMENT. AS AN

ALTERNATIVE, A REMOTE ELECTRICAL SWITCH FOR THE EXHAUST

BLOWER CAN BE INSTALLED NEAR THE AXIOM.

NOTE: Only connect the cabinet to a suitable exhaust system, one dedicated

to the cabinet itself, or dedicated to exhausting laboratory ventilation

equipment. DO NOT connect the unit to the

building’s HVAC system room exhaust.

Examine the location to ensure that it accommodates

the cabinet’s exhaust duct. The area directly above

the cabinet’s exhaust port should be clear of structural

elements, water and utility lines, or other fixed

obstructions. There should be enough clearance to

accommodate a 10-inch diameter duct.

Avoid cabinet locations that require an elbow directly above the cabinet’s

exhaust connection or an excessive number of elbows in the exhaust system.

There should be a straight length 10 duct

diameters long between the cabinet and any

elbow, and between subsequent elbows.

Product Service 1-800-522-7658

Page 40

40

Figure 2-1c

Figure 2-1d

The Inlet Relief Valve located on the top of the cabinet is

designed to draw a maximum of 100 CFM (2.83 m3/m).

Attempting to draw additional room air through the valve

(room air exhaust), can result in unstable cabinet

operation.

If additional room exhaust is needed to be

drawn through the exhaust system, install an

additional duct and balancing damper

downstream of the cabinet’s damper. This will

allow for proper balancing of the system.

Product Service 1-800-522-7658

Page 41

41

The exhaust system must be capable of moving the following volumes of

Axiom Type C1

Airflows

Airflow Volume

Concurrent

Balance Value

Recommended

Duct Vacuum1

ft3/min

m3/sec

ft3/min

m3/sec

WC

Pa

4-foot, 8" Sash

323

0.15

387

0.18

0.30

75

4-foot, 10" Sash

400

0.19

480

0.23

0.30

75

6-foot, 8" Sash

463

0.22

556

0.26

0.30

75

6-foot, 10" Sash

570

0.27

684

0.32

0.30

75

Table 2-1

exhaust air at the negative pressures listed. The Airflow Volumes are the

values recorded via a direct measurement using a flow hood at the cabinet.

The Concurrent Balance Values are measured in the exhaust duct via

traverse methodology, and will always be higher due to differences in volume

measurement methodologies.

1 – Unlike Type B cabinets, the recommended vacuum will remain constant

throughout the life of the Exhaust HEPA filter. Duct vacuums below 0.3 WC

(37 Pa), or above 0.5 WC (125 PA) may result in erratic operation.

Product Service 1-800-522-7658

Page 42

42

Electrical Requirements

Model #

Requirements

30441xx0x, 30448xx0x

115 VAC, 60 Hz, 16 Amps

30441xx1x, 30448xx1x

100 VAC, 50/60 Hz, 16 Amps

30441xx-20, 30, 40, 50, 60, 70

230 VAC, 50/60 Hz, 8 Amps

30448xx-20, 30, 40, 50, 60, 70

230 VAC, 50/60 Hz, 8 Amps

30461xx0x, 30468xx0x

115 VAC, 60 Hz, 16 Amps

30461xx1x, 30468xx1x

100 VAC, 50/60 Hz, 16 Amps

30461xx-20, 30, 40, 50, 60, 70

230 VAC, 50/60 Hz, 8 Amps

30468xx-20, 30, 40, 50, 60, 70

230 VAC, 50/60 Hz, 8 Amps

Table 2-1

The biosafety cabinet models have the following electrical requirements:

Note: A dedicated outlet with an appropriate circuit breaker should

be located as close as possible to the right rear side of the cabinet,

at a height even with, or higher than, the top of the bench or stand.

Consult your local electrical codes for properly rated circuit

breakers. For safe operation the dedicated outlet must provide the

protective earthing ground connection to the cabinet.

Note: On 100 and 115 VAC models, both electrical outlets are protected by

a ground fault interrupter circuit (GFIC). Labconco does not recommend

plugging the biosafety cabinet into a GFIC outlet.

Electrical outlets in the cabinet are restricted to 5 amps maximum

current.

Prises électriques dans l'armoire sont limitées à 5 courant maximum

ampères.

The biosafety cabinet models have the following electrical requirements:

Do not use any detachable power cord that is not adequately rated

for the unit.

Ne pas utliser un fil électrique amovible qui n’est pas du tension

nominale de l’appareil.

Product Service 1-800-522-7658

Page 43

43

Service Line Requirements

All utility service lines should be ¼ inch O.D., brass, copper, or stainless

steel, and equipped with an easily accessible shut-off valve. If the service

line pressure exceeds 40 PSI, it must be equipped with a pressure regulator

to reduce the line pressure.

Note: The use of flammable gases or solvents should be avoided in the

biosafety cabinet. Open flame in the cabinet will disrupt the laminar airflow

in the cabinet and may damage the HEPA filters. Flammable gases or

solvents may reach explosive concentrations in the cabinet or ductwork. If

you feel that the procedure requires the use of an open flame or flammable

materials, contact the institution’s safety office.

The use of air or gases under high pressure should be avoided as they may

seriously disrupt the airflow patterns in the cabinet.

Product Service 1-800-522-7658

Page 44

44

THIS PAGE INTENTIONALLY BLANK

Product Service 1-800-522-7658

Page 45

45

Section Three –

Installation

Now that the installation is properly prepared, you are ready to inspect, install, and

certify the Axiom biosafety cabinet. This chapter covers how to:

Unpack and move the biosafety cabinet.

Install the cabinet.

Connect the electrical supply source.

Connect the service lines.

Connect to an exhaust system (optional for Type As).

Tools required for installation the biosafety cabinet include two 1/2" wrenches, a flatblade screwdriver, a #2 Phillips screwdriver, and a carpenter’s level.

Note: The biosafety cabinet models weigh between 400–700 lbs. (182-318 kg). The

shipping pallet allows for lifting with a mechanical lift truck or floor jack. If you must lift

the product manually, use at least six (6) persons and follow safe-lifting guidelines.

Product Service 1-800-522-7658

Page 46

46

Unpacking the Biosafety Cabinet

Carefully remove the outer carton and inspect the cabinet for damage that may have

occurred in transit. If the biosafety cabinet is damaged, notify the delivery carrier

immediately and retain the entire shipment intact for inspection by the carrier.

Note: United States Interstate Commerce Commission rules require that claims be filed

with the delivery carrier within fifteen (15) days of delivery.

Do not return goods without the prior authorization of Labconco. Unauthorized returns

will not be accepted.

If the cabinet was damaged in transit, you must file a claim directly with the freight

carrier. Labconco Corporation and its dealers are not responsible for shipping damages.

Do not discard the carton or packing material for the biosafety cabinet until all of the

components have been checked, installed and tested.

The cabinet is secured to the pallet in two places on each side. To access the nuts and

bolts, remove the side panels by removing and keeping the two Phillips screws on both

panels. Swing the front of each panel away from the cabinet, and lift it straight up to

remove the panel from the cabinet.

Note: The side panels must be removed to access the fasteners that secure the

biosafety cabinet to the pallet. DO NOT ATTEMPT TO LIFT THE BIOSAFETY

CABINET BY THE SIDE PANELS; DAMAGE WILL OCCUR.

Preparing the Biosafety Cabinet for Operation

Installation instructions (Labconco P/N 1056801) are attached to the sash of the

biosafety cabinet. If these instructions are missing or unclear, contact Product Service at

800-821-5525 or 816-333-8811. The following are located in a box either taped to the

top of or underneath the work surface:

User’s Manual CD

Drain Valve Assembly and fasteners

Power Cord

Product Registration Card

Vacu-PassTM Accessories (optional)

If you did not receive one or more of the components listed for the cabinet, or if any of

the components are damaged, contact Labconco Corporation immediately for further

instructions.

Moving and Lifting the Cabinet

Move the cabinet, attached to its pallet, by using a floor jack, or a furniture dolly underneath the

unit. DO NOT move the cabinet by tilting it onto a hand truck.

Product Service 1-800-522-7658

Page 47

47

When lifting the cabinet DO NOT lift the cabinet in the middle front area of the hull. Lifting here

may bend or distort the bottom of the cabinet, causing damage to the unit.

Installing the Biosafety Cabinet on an Existing Work Surface

Note: The biosafety cabinet is very top heavy. Use caution when lifting or moving it.

When installing the biosafety cabinet onto an existing work surface or benchtop, ensure

that the structure can safely support the combined weight of the cabinet and any related

equipment. The work surface should be at least as wide as the cabinet and 31 inches (787

mm) deep to properly support the unit.

A hole or notch may be cut in the supporting surface in the right front corner to

accommodate the optional drain valve.

Product Service 1-800-522-7658

Page 48

48

Installing the Cabinet on a Labconco Base Stand

Width

Base Stand w/Feet Model #

4'

3401004

6'

3401006

Width

Manual Lift Stand #

Electric (115V) Lift Stand

#

Electric (230V) Lift Stand

#

4'

3780201

3780101

3780104

6'

3780202

3780102

3780105

115V SoLo Stand

#

230V SoLo

No. America

Plug #

230V SoLo

UK Plug #

230V SoLo

Schuko Plug

#

230V SoLo

China/Australia

Plug #

4'

3780311

3780315

3780331

3780335

3780339

6'

3780313

3780317

3780333

3780337

3780341

Table 3-1

Table 3-2

Table 3-3

Labconco offers accessory Base Stands in a variety of configurations to suit your

particular needs. Stands can be ordered with adjustable telescoping legs or with a

manually or electrically adjustable hydraulic lift.

Telescoping Base Stands

These stands are included with some Axiom models, or are available separately. The

base stands for each width cabinet are listed in Table 3-1 below. An optional caster

wheel kit is available (part # 3730500).

Manual or Electric Hydraulic Lift Base Stands

These base stands offer infinitely adjustable height between 25.5 and 33.5 inches (648

to 851 mm), giving a cabinet work surface height of 28.0 to 36.0 inches. The height is

adjusted either by a manual (hand crank) or electric pump that drives hydraulic rams in

the legs of the stands. All of the hydraulic stands are equipped with fixed feet, but can

be converted to caster wheels with the addition of Caster Kit #3784000. The base

stands for each cabinet size is listed in Table 3-2 below.

Note: When installing the cabinet on the hydraulic lift base stand, ensure that the

hydraulic lines and the electrical cord are clear of any obstructions before installing the

cabinet on the stand or operating the lift system.

SoLoTM Electric Hydraulic Lift Base Stands

These base stands permit the Axiom to be lowered enough to be transferred through a

standard doorway as low as 78 inches. Casters provide mobility and lock in place. The

SoLo Stands for each Purifier Axiom series model is listed below.

Product Service 1-800-522-7658

Page 49

49

Optional Exhaust Connection Requirements

Certain applications such as working with odorous products or volatile toxic materials

will require the connection of the biosafety cabinet to an exhaust system.

Note: The Type C1 exhaust connection includes an integral inlet relief valve, which

functions as a one-way, or check valve. During operation, the exhaust system draws all

of the cabinet’s exhaust air, plus a volume of room air through the relief valve into the

exhaust duct. The inlet relief valve functions as a “shock absorber” allowing the cabinet

to maintain optimal inflow during changes in room air pressure.

Note: Because the Type C1 cabinet has an integral exhaust fan, the vacuum

requirements of the exhaust system will be much lower than existing Type B units.

Please see the volume and vacuum requirements in Table 2-1, in

connect the biosafety cabinet to an exhaust system:

Note: If the research involves the use of toxic compounds or volatile materials, contact

the facility’s safety officer or Labconco to ensure that the biosafety cabinet and its

exhaust system are compatible with the materials you will be working with.

in

Chapter 2: Prerequisites

If you intend to

Product Service 1-800-522-7658

Page 50

50

Configuring for an Exhaust System Connection

Figure 3-1

Note: The Type C1 is configured at the factory to operate in recirculating mode (NOT

connected

inlet relief valve position. If you intend to connect the Type C1 to an exhaust

system, YOU MUST RECONFIGURE IT FOR THIS INSTALLATION.

Note: If the Type C1 is connected to an exhaust system, and you choose to disconnect

it from the exhaust system, to exhaust its HEPA-filtered air back into the laboratory,

YOU MUST RECONFIGURE IT FOR THIS INSTALLATION. These instructions

follow.

to an exhaust system). When operating in this mode, the cabinet ignores the

a) Mechanical configuration

1. Unplug the Axiom. Using an appropriate ladder or platform, remove the

exhaust cover panel on the top right side of the exhaust cover, and install it

over the hole on the left side. Hand tighten the wing nuts to secure it, as

shown in figure 3-1.

2. Connect the Axiom’s connection collar to the exhaust system, ensuring the

connection meets all appropriate codes and regulations.

Exhaust Cover Panel

Product Service 1-800-522-7658

Page 51

51

b) Electronic configuration

Keypad operations are shown as

green italics

1. With the unit in operation, access the menu by pressing the

Display Mode Menu Mode

Selecting the Configuration Menu

2. Using the ▲ and ▼ buttons on the touchpad, highlight the

.

display panel will show the first level menu. Select

▲ or ▼ buttons until the

or press

it will be highlighted when selected. Press OK and you will get an Attention

screen, advising you the following screens may alter the operation of the Axiom.

Press OK to continue:

Menu

to return to the previous menu level.

blue bold italic

Service

Menu

. Menu screen selections are shown as

Menu

Service

is highlighted. Press OK to accept that option,

menu by pressing the

Configuration

button. The

option-

OK

Product Service 1-800-522-7658

Page 52

52

3. The screen will now prompt you for the password;

it is:

Light

UV Light

Timer

Timer

OK

Note: Any other key sequence will return you to the

Attention screen.

4. The first screen allows you to select whether the

Axiom is connected to an exhaust system or not.

IT IS CRITICAL THAT THE

HAS AN EXHAUST CONNECTION

SELECTED. Press OK to continue.

5. The second screen allows you to set how long the

blowers in the Axiom will continue to operate in the

event of an exhaust system failure. The interval

can be programmed from 0-300 seconds.

THIS CABINET

OPTION IS

Note: Consult with your facility’s safety officer or Labconco to help establish how long

the Axiom should continue to operate after an exhaust system failure.

6. The third screen allows you to set the sash height at

either 8 or 10 inches. IT IS CRITICAL THAT THE

YOU LEAVE THE SASH HEIGHT AS IT WAS SET

AT THE FACTORY, UNLESS YOU WISH TO

RECERTIFY THE CABINET AT ITS NEW

SETTING.

Product Service 1-800-522-7658

Page 53

53

7. The fourth screen allows you to select

whether the Axiom has a UV light or not. IT

IS CRITICAL THAT THE YOU LEAVE THE

UV LIGHT CONFIGURATION AS IT WAS

SET AT THE FACTORY. Press OK to return

to the first Configuration screen.

The unit is now properly configured for operation connected to an exhaust system. In

this mode, the unit will display an exhaust alarm if the inlet relief valve closes during

operation.

NOTE: If you ever want to disconnect the Axiom from the exhaust system, and use it in

a recirculating mode, you must reconfigure it as such.

Product Service 1-800-522-7658

Page 54

54

Disconnecting the Axiom from an Exhaust System Connection to Operate in

Figure 3-1a

Reciculation

a) Mechanical configuration

1. Unplug the Axiom. Using an appropriate ladder or platform, remove the

exhaust cover panel on the top left side of the exhaust cover, and install it

on the studs on the right side. Hand tighten the wing nuts to secure it, as

shown in figure 3-1a.

2. Disconnect the Axiom’s connection collar from the exhaust system, and cap

the building’s exhaust connection in a way that meets all appropriate codes

and regulations. Leave the Axiom’s exhaust collar open to allow for

unrestricted airflow out of the unit.

Exhaust Cover Panel

Product Service 1-800-522-7658

Page 55

55

b) Electronic configuration

Keypad operations are shown as

green italics

1. With the unit in operation, access the menu by pressing the

Menu Mode

Selecting the Configuration Menu

2. Using the ▲ and ▼ buttons on the touchpad, highlight the

.

display panel will show the first level menu. Select

▲ or ▼ buttons until the

or press

Display Mode

it will be highlighted when selected. Press OK and you will get an Attention

screen, advising you the following screens may alter the operation of the Axiom.

Press OK to continue:

Menu

to return to the previous menu level.

blue bold italic

Service

is highlighted. Press OK to accept that option,

Menu

. Menu screen selections are shown as

Service

Menu

button. The

menu by pressing the

Configuration

option-

OK

Product Service 1-800-522-7658

Page 56

56

3. The screen will now prompt you for the password;

it is:

Light

UV Light

Timer

Timer

OK

Note: Any other key sequence will return you to the Attention screen.

4. The first screen allows you to select whether the

Axiom is connected to an exhaust system or not. IT

IS CRITICAL THAT THE

NO EXHAUST CONNECTION

SELECTED. Press OK to continue.

.

THIS CABINET HAS

OPTION IS

5. The second screen allows you to set the sash height

at either 8 or 10 inches. IT IS CRITICAL THAT

THE YOU LEAVE THE SASH HEIGHT AS IT WAS