Page 1

Rapid Distillation Apparatus

MODEL 65000

INSTRUCTION MANUAL

Product designs are subject to change without notice

© 1988, 2013 Labconco Corporation

6504000 REV. N / ECO H435

Printed in U.S.A.

Page 2

Page 3

TABLE OF CONTENTS

Introduction

General Description 1

Performance 1

Component Identification 2

Installation

Installation Factors 4

Assembly 4

Start-Up and Initial Check-Out 5

Normal Operation 7

Samples Digested Utilizing Micro-Digestor

Start-Up and Operation 7

Shutdown 7

Samples Digested Utilizing Rapid Digestor

Start-Up and Operation 9

Principle 9

Apparatus 9

Reagents 9

Determination 10

Calculations 11

Routine Maintenance Schedule

Console 12

Glass Still 12

Stopcock 13

Replacement Parts 14

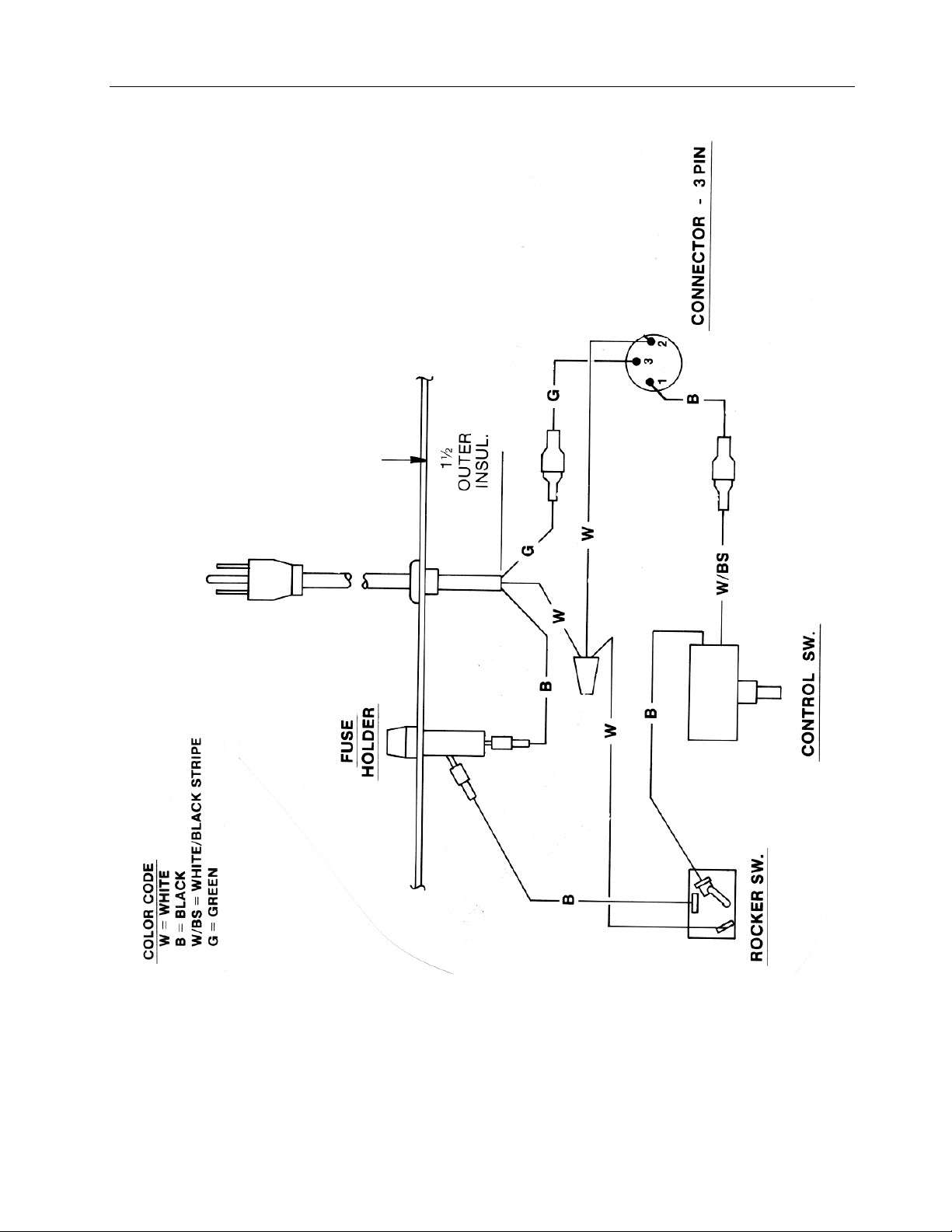

Wiring Diagram 16

References 17

Warranty 18

Shipping Claims 19

Contacting Labconco 20

Page 4

Page 5

INTRODUCTION

General Description

The Labconco Rapid Distillation Apparatus is designed expressly for rapid, semi-automatic

steam distillation from sulfuric acid digest prepared from nitrogen-bearing materials such as feeds,

grains, soils, plant tissue, water effluent, organic waste food products, etc. Sample digestions are

accomplished utilizing either Labconco’s Micro Distillation Apparatus or Rapid Digestor units.

The distillation apparatus can be used for micro or macro levels of nitrogen determination.

Figure 1

Performance

Your Labconco Rapid Distillation Apparatus has been designed to accept digested samples

up to 4 ml (max.) equivalent of concentrated acid, and is capable of giving reproducible results in

ranges as low as 10 micrograms (gamma) #1% nitrogen. Ideal nitrogen of 0.15 mgs makes this

apparatus an excellent companion for the Labconco Micro and Rapid Digestors

The distillation apparatus many also be utilized for other steam distillations that DO NOT

exceed the volume limitations of the units mixing chamber (approx. 50 to 55 ml).

1

Page 6

INTRODUCTION

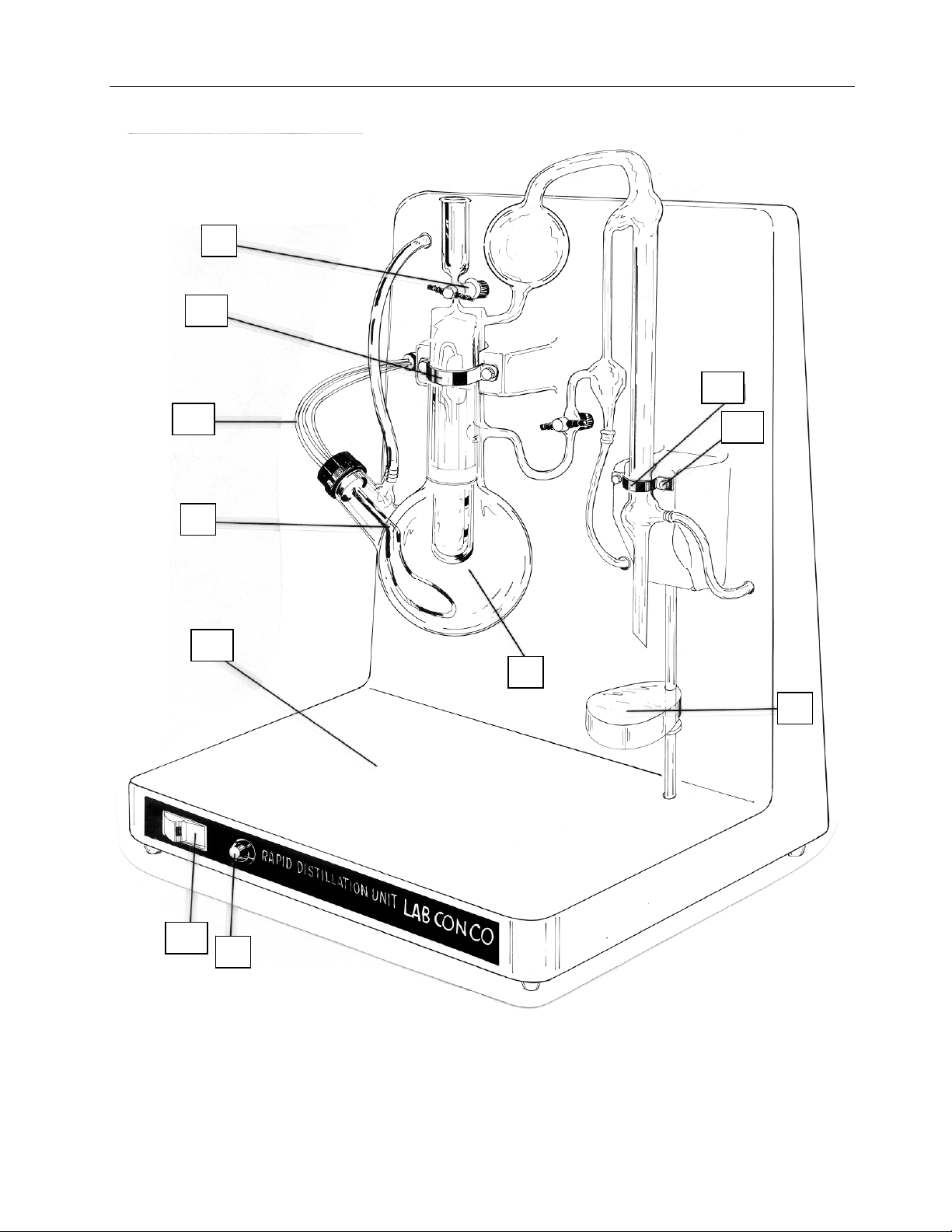

Component Identification

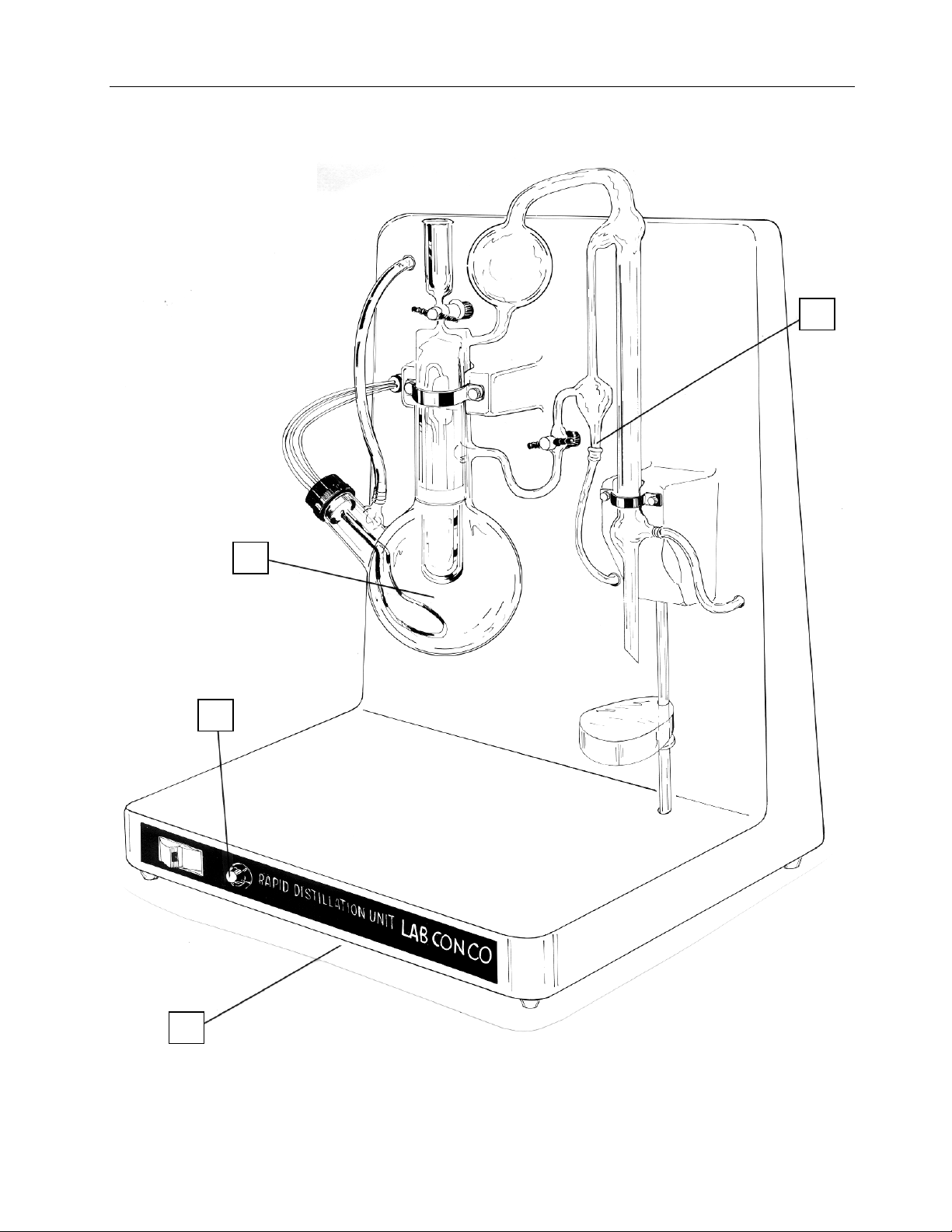

(1) Console. A one piece assembly molded out of linear polyethylene to provide both chemical

resistance and light weight capabilities for the distillation apparatus.

(2) Still. One piece still fabricated from borosilicate glass and featuring chemically inert PTFE

stopcocks. Because the still does not incorporate rubber or plastic tubing connections, the

possibilities of leakage have been greatly reduced.

(3) Variable Heat Control. The electric immersion heater provides fast, efficient heat. Steam

generation starts very rapidly from a cold start. Electrical input to the heater is controlled

by a built-in variable heat control switch, which allows complete control of the steam.

(4) *Flow Control Valve. The unit is supplied with a fine metering valve that is installed

between a water source and the water inlet tube connector to the steam reservoir. Adjust

valve to keep water level in the steam reservoir approximately 2/3 full during distillation.

(5) Aspirator. The unit has a built-in glass aspirator to purge spent samples after

determination. The water used for cooling of this condenser is also used for aspirating. A

twist of the stopcock draws the sample and rinse water down the drain.

*Not shown

2

Page 7

Component Identification

INTRODUCTION

5

3

2

1

Figure 2

3

Page 8

INSTALLATION

Your Rapid Distillation Apparatus has been shipped to you in one carton. In unpacking,

remove the packing material carefully, checking all material for two separately packed parts. The

carton will contain a heater element assembly and clmaps wrapped in protective paper, and the

one-piece glass still packed between foam pads inside of a cardboard carton.

Inspect this material thoroughly prior to installation and report any damage that may have

occurred in transit.

Figure 3

Installation Factors

Assembly

(1) Remove the condenser clamp screws and clamp from the console.

(2) Lay the console unit on its back and position the glass still assembly on the console, lining

up the glass trap and condenser sections, as shown in Figure 2.

(3) Replace both the large and small clamps, insert and tighten down the clamp screws until

the glassware is firmly attached to the console.

NOTE: Check clearance on the condenser tip with the movable flask support shelf.

Adjust the entire glassware unit, by slightly loosening the clamp screws, so that enough

room is provided to insert the receiver flask. Retighten clamp screws to secure this

position.

(4) Place still in a location having a convenient 115 volt, AC outlet, and accessibility to

distilled water, tap water and drain facilities.

4

Page 9

INSTALLATION

(5) Obtain several lengths of Tygon tubing (5/16" bore x 1/16" wall). Tubing IS NOT

furnished with the unit and may be obtained from local laboratory supply dealers. Tubing

will be used for connecting water lines (refer to steps 6, 11 and 12).

(6) Measure distance from tube connector on steam reservoir through the tubing access port in

console (upper left corner) to a water outlet. Cut tubing and connect to tube connector on

still and water source. If the flow control valve is to be used, install between water source

and tube connector located on top of steam reservoir. The valve is provided with a hose

barb fitting on one end and a female 1/8" NPT connector on the other. Install with ridged

tubing from water source to 1/8" NPT. Connect 5/16" Tygon tubing to the hose barb

fitting. A tee may be installed to allow use of the same water source for the condenser

cooling and steam reservoir..

(7) Remove protective wrapper from formed metal heater element and seal stopper assembly.

NOTE: Water tubing clamps are usually placed on heater “lead wires” to prevent loss in

shipping. Two clamps are provided – remove them from the heater leads and use when

making tubing connections at the tap water inlet and tap water source connection points.

(8) Insert heater assembly in steam reservoir (see labeled diagram in Figure 2).

NOTE: A very tight seal between rubber stopper and neck of the flask must be obtained.

(9) Insert line cord in 115 Volt AC receptacle. Turn off with console “On-Off” switch to

prevent possible heater burn-out.

(10) Connect heater lead wire plug to female receptacle provided on the console.

(11) Connect Tygon tubing to the outlet of the condenser water aspirator. Run tubing through

access port on console to drain area.

(12) Connect Tygon tubing to condenser inlet. Run tubing through access port provided to the

tap water source. Clamp tubing securely at water source and condenser inlet points.

Start-up and Initial Check-out

If all of the assembly steps, as listed previously have been followed, your Rapid Distillation

Apparatus will now be ready for its initial start-up.

The start-up process should begin as follows:

(1) Make sure the illuminated “On-Off” switch is in the off position.

CAUTION: Do not energize heater unit unless heater element is properly immersed in

water.

5

Page 10

INSTALLATION

(2) Fill steam reservoir flask 2/3 full with ammonia free distilled water. Adjust flow control

valve to give approximately 7 ml/minute flow. Proper adjustment of valve will replace the

water lost from the distillation. If the flow control valve is to be used for low level

nitrogen determinations, it may be necessary to install a deionization cartridge (available

from your laboratory supply dealer) between the flow control valve and water source.

Usually a blank determination on reagents and water is sufficient for most low level

nitrogen determinations.

(3) Check sample addition funnel stopcock. Mare sure it is CLOSED!

(4) Close aspirator stopcock located between condenser and steam reservoir.

(5) Turn on tap water source and fill condenser.

(6) Place a small graduated cylinder on receiving holder at output of condenser to measure

distillation rate.

(7) Turn heater control dial to “9.” Press On/Off switch to “On.”

(8) The water in the steam reservoir will begin boiling in about 5-6 minutes. The heater

control setting should be turned down until a distilling rat of 5 ml/min. is obtained. The

flow control valve is adjusted to replace water lost during distillation.

(9) Measure temperature of distillate and adjust cooling water input at tap water source to

maintain distillate temperature of 25°C or lower.

(10) For low level nitrogen determinations, allow steam distillation to continue until distillate is

nitrogen free. Removal of nitrogen entrained in steam reservoir water may require 30

minutes at initial start-up, or if the apparatus has been out of use for sufficient time to allow

nitrogen containing fumes to be reabsorbed in steam reservoir liquid. Add approximately

15 ml of ammonia free distilled water to the mixing chamber through the sample-addition

funnel. Close sample stopcock after test liquid drains through! Open the aspirator

stopcock and siphon off all liquid in the mixing chamber to check out aspirator operation.

Water flow to condenser can be adjusted to increase or decrease “siphon” rate. When

mixing chamber is cleared of the test liquid, close the aspirator stopcock.

(11) The unit is now ready for samples. Refer to the following appropriate method for the

determination of nitrogen content from predigested samples.

6

Page 11

NORMAL OPERATION

Samples Digested Utilizing Micro-Digestor –

Start-up and Operation

The Labconco Rapid Distillation Apparatus is designed to conform with standard Micro

Kjeldahl distillation techniques. The preparation of digested samples, chemical treatment of the

sample prior to distillation and titration techniques following the distillation are adequately

described in A.O.A.C. Methods of Analysis and other technical references, and should be referred

to in ALL cases.

(1) Turn on cooling water and adjust to normal rate.

(2) Turn on heater – check reservoir level and adjust to 2/3 full if required. Set heat control at

“9” on the dial. Allow steam reservoir water to come to “boiling” and turn down heat

control to proper setting. Adjust flow control valve to replace water lost during distillation.

(3) Allow still to reach thermal equilibrium – check for 4-5ml/min. distilling rate, with small

graduate (refer to Step 8 of Start-up and Check Out).

(4) Open aspirator stopcock joining still chamber and water aspirator aspirate inner chamber –

close the stopcock.

(5) Place a receiver flask, containing a volume of receiving solution on shelf at outlet of

condenser.

(6) Check stopcock on sample addition funnel to see that it is closed. Place entire diluted

digest sample in addition funnel.

(7) Open “addition” funnel stopcock to transfer digest sample to the mixing chamber. Close

stopcock.

(8) Rinse digestion flask with several small amounts of ammonia-free distilled water (total

volume of rinses not to exceed 8 to 10 ml). Adding each small rinse to the inner chamber

through the addition funnel separately and closing stopcock after each addition.

(9) Rinse addition funnel with 3 to 4 ml ammonia-free distilled water, leaving some water as a

liquid seal.

(10) Raise receiver flask shelf, positioning it so that the condensate outlet is slightly below the

receiving liquid surface level.

(11) Add strong alkali solution (calculated to produce excess base in mixing chamber when

completely added) to addition funnel. Open funnel SLOWLY and allow alkali to slowly

flow into the mixing chamber. Stop flow if “neutralizing action” becomes too vigorous or

siphon back of receiving solution. Continue intermittent feeding of alkali to mixing

7

Page 12

NORMAL OPERATION

chamber until all of the solution is added. Leave column of caustic in the funnel stem to

act as a liquid seal.

NOTE:

re-calculate required alkali solution strengths so that inner chamber contents will have a

normality of 4 to 8. A small amount of caustic should be left in the addition funnel to act

as a liquid seal during each distillation. If foaming is a problem during distillation, add 1

or 2 drops of anti-foam reagent.

(12) Allow distillation to proceed long enough to complete the quantitative recovery of

ammonia free from the sample. Average time of distilling is 3 to 5 minutes.

(13) Lower receiver flask shelf and allow distillation to continue approximately one minute.

(14) Place receiver flask aside. It is now ready for titration.

(15) Place an extra flask on receiver shelf, open aspirator tube stopcock, to “drain out” the

mixing chamber. Open sample addition stopcock, letting liquid seal pass into the mixing

chamber. Close addition stopcock. Drain out by means of the aspirating action. Follow

with several good washes of ammonia-free distilled water, adding each wash through the

addition funnel, closing the addition stopcock and aspirating the washing solution to the

drain.

NOTE:

(16) The unit is ready to handle the next sample

NOTE: If long delays are encountered between sample runs, aspirate mixing chamber just

prior to sample digest introduction.

Shutdown

(1) Turn off heater with main switch.

(2) Remove receiver flask.

(3) Wash out mixing chamber thoroughly, leaving it about ½ full (10-12 ml – refer to Step 15

of Start-up and Operation).

(4) Turn off cooling water source to condenser and flow control valve.

If reaction is uncontrollable, REDUCE all future acid digest sample volumes and

Close aspirator stopcock before addition of each wash.

8

Page 13

NORMAL OPERATION

Samples Digested Utilizing Rapid Digestor –

Start-up and Operation

Same as information under Samples Digested Utilizing Micro-Digester.

Principle

(1) After sample digestion, utilizing the Labconco Rapid Digestor-4, Rapid Digestor-25, or

equivalent digestion apparatus, a portion of the sample is transferred to the Rapid

Distillation Apparatus. Ammonia is steam distilled into standard acid and back titrated

with standard alkali. Complete recovery of nitrogen is accomplished in 3 – 5 minutes

distillation time.

Apparatus

(1) Labconco Rapid Distillation Apparatus Model 65000. Available from Labconco

Corporation, 8811 Prospect Avenue, Kansas City, MO 64132.

(2) Erlenmeyer Flasks. 125 ml Erlenmeyer flasks for standard acid receiving solution.

(3) Pipets. 20 ml volumetric pipets for sample transfer.

(4) Burets. 15 ml buret for standard acid and standard alkali. Separate burets should be used

for the addition of the acid and alkali.

Reagents

(1) Sodium hydroxide/potassium sulfide. Dissolve 45g solid NaOH in water. While still

warm, dissolve 10g of K2S in the NaOH solution, cool and dilute to 1 liter.

(2) Methyl red indicator. Dissolve 1g methyl red in 200 ml ethyl alcohol.

(3) Sodium hydroxide standard solution. 0.01N, prepare as in AOAC Official Methods of

Analysis, Thirteenth Edition, p. 877.

(4) Sulfuric acid standard solution. 0.05N, prepare as in AOAC Official Methods of Analysis

Thirteenth Edition, p. 877.

Standardize each standard solution with primary standard and check one against the other.

Refer to AOAC Official Methods of Analysis

before use by blank determination with 1g sugar.

, Thirteenth Edition, Chapter 50. Test all reagents

,

9

Page 14

NORMAL OPERATION

Determination

(1) Samples are digested utilizing the Labconco Rapid Digestor 5 place of the 25 place units

equipped with 250 ml volumetric digestion tubes (refer to digestion methods available

upon request from Labconco). After digestion, remove rack of tubes from digestor and

allow to cool for 8 – 10 minutes (cooling time depends upon air flow around tubes). Direct

rapid spray of water (kitchen sink dish rinsing sprayer works well) to bottom of each tube

to dissolve acid digest completely. If precipitate forms, dissolve by manual mixing or by

placing tubes in ultrasonic bath. Low recovery of nitrogen will result if precipitate is not

completely dissolved. Let sample cool, dilute to the mark and mix thoroughly by inversion

20 times. Using a 25 ml buret, prepare the sulfuric acid receiving solution by adding the

calculated amount of 0.05N sulfuric acid standard solution to a 125 ml Erlenmeyer flask.

Add 5 – 7 drops of indicator (see calculating section for amount of standard solution to

add). Dilute volume with water to approximately 70 – 75 ml.

Pipet ml aliquot of sample solution to sample addition funnel on the Rapid Distillation

Apparatus. Distillation rate must be between 4 – 5 ml minute. Adjust water flow control

valve to keep water level in the steam reservoir approximately 2/3 full. Introduce sample

into sample chamber. Rinse funnel with 3 – 4 ml portions of water. Raise 125 ml

Erlenmeyer flask, containing the receiving solution, into position under the condensate

outlet tube of the still. Correct position is where the top of the outlet tube is completely

submerged below the receiving solution liquid level. Add 10 ml + 1 ml of sodium

hydroxide/potassium sulfide to the addition funnel. Slowly add alkali to the sample

chamber. (It is very important to add the caustic slowly, while visually monitoring the

standard acid solution to see that the solution does not siphon back through the condenser

and into the steam reservoir.) Leave column of caustic in the funnel stem to act as a liquid

seal. Distill for 3 – 5 minutes, lower receiving flask and allow distillation to continue for

approximately one minute. Titrate excess standard acid with 0.01N sodium hydroxide

standard solution. Correct for blank determination on reagents.

10

Page 15

CALCULATIONS

11

Page 16

ROUTINE MAINTENANCE

Console

The console is constructed of plastic and resists staining. To preserve its general

appearance, acid and alkali “spills” should be removed as soon as possible by washing and

sponging with a damp cloth.

Glass Still (Replacement)

(1) Disconnect line cord from 115 volt AC outlet disconnect heater plug connections.

(2) Remove heater assembly and stopper.

(3) Disconnect ALL tubing connections on glass still.

(4) Remove clamp screws (4).

(5) Remove clamps (2).

(6) Lift still assembly from console and lay carefully aside.

(7) Remount new glass still assembly and reconnect all parts and tubing, by reversing above

steps.

12

Page 17

ROUTINE MAINTENANCE

Stopcock

The Labconco Rapid Distillation Apparatus is equipped with (2) PTFE stopcocks. The

PTFE stopcocks do not

to wash away any solid particles that might accumulate during long service. If solid particle s

become lodged between the plug and glass barrel, or project from the glass surfaces, they can score

the PTFE plug around its bore and result in a “leaky” plug.

When alkalies or other liquids corrosive to glass are used in PTFE-glass stopcock valve

assemblies, rinse all valve components thoroughly with water after each use. Roughness of the

glass barrel due to liquid concentrate formed on evaporation may score the plug. Additional

information is provided with this unit and may be referred to for service.

require lubricants. The plug and glass barrel may be cleaned with Acetone

Stopcock

Figure 4

13

Page 18

REPLACEMENT PARTS

3

12

13

10

9

14

11

1

8

18

4

Figure 5

14

Page 19

REPLACEMENT PARTS

ITEM

1 65001 Glass micro still assembly with PTFE stopcocks

2 13525 PTFE plug replacements for PTFE stopcock

*3 13237 Heat controller

4 18765 Knob, for heat controller

*5 19175 Fastener, nylon round head, canoe type

*6 13432 Fuse holder

*7 13410 Fuse only – 115 Volt AC AGC-3

8 65008 Receiver flask platform assembly

9 65042 Heater assembly, complete with stopper and male

10 12823 Plugs, heater lead jack, only

11 65021 Housing assembly, complete (less all glassware and

12 65056 Saddle clamp, large

13 65058 Saddle clamp, small

14 19030-08 Screws, for large and small clamps

*15 13174 Transformer (230 V to 115 V, 50/60 Hz, 300 Watt)

*16 19093-26 Nut

*17 65045 Flow control valve

18 13270 Switch-lighted rocker

*Items not shown

PART

NUMBER

DESCRICPTION

plug; 115 VAC, 280 Watts

heater)

15

Page 20

WIRING DIAGRAM

Figure 6

16

Page 21

REFERENCES

Many excellent reference texts and booklets are currently available. The following is a

brief listing:

Official Methods of Analysis of the Association of Official Analytical Chemists

Edition, Washington, District of Columbia, 1980.

Hambleton, L.G. and Noel, R.J., Journal of the Association of Analytical Chemists

1975.

“Digestion Method for the Determination of Protein Nitrogen in Feeds, Foods, Grains, Cereals,

and Grasses Utilizing the Labconco 4-Place Rapid Digestor (R/D-4),” Labconco Extracts 2:880,

Labconco Corporation, Kansas City, MO.

“Digestion Method for the Determination of Protein Nitrogen in Feeds, Foods, Grains, Cereals,

and Grasses Utilizing the Labconco 25-Place Rapid Digestor (R/D-25),” Labconco Extracts 3:880,

Labconco Corporation, Kansas City, MO.

, Thirteenth

, 58:143-145,

17

Page 22

WARRANTY

We are committed to providing our customers with quality equipment and service after the

sale. Part of this objective involves keeping you informed of changes and new product additions.

We therefore request that you take a moment to fill out the product registration card so we may

know your location as well as some of the reasons that prompted you to purchase our products

Labconco Corporation warrants products of its manufacture for one year, from

receipt of the equipment by they purchaser, against defects in materials and workmanship.

This limited warranty covers parts and labor but not transportation and insurance charges.

In the event of a warranty claim, contact the dealer who sold you the product. If the cause is

determined to be a manufacturing fault, the dealer or Labconco Corporation will repair or replace

all defective parts to restore the unit to operation. Under no circumstance shall Labconco

Corporation be liable for indirect, consequential or special damages of any kind. This

statement of warranty may be altered by a specific published amendment. No individual has

authorization to alter the provisions of the warranty policy or its amendments. Lamps and

expendable items such as filters are not covered by this warranty. Damage due to corrosion or

accidental breakage is also not covered.

WARNING: The disposal and/or emission of substances used in connection with this

equipment may be governed by various federal, state or local regulations. All users of this

equipment are urged to become familiar with any regulations that apply in the user’s area

concerning the dumping of waste materials in or upon water, land or air and to comply with such

regulations.

18

Page 23

SHIPPING CLAIMS

If shipment is received in visibly damaged condition, be certain to make a notation on the

delivering carrier’s receipt and have his agent confirm the damage on your receipt. Otherwise, the

damage claim may be refused.

If concealed damage or pilferage is discovered, notify the carrier immediately and retain

the entire shipment intact for inspection. Interstate Commerce Commission rules require that the

claim be filed with the carrier within 15 days after delivery.

NOTE

accepted. Labconco Corporation and its dealers are not responsible for shipping damage. Claims

must be filed directly with the freight carrier by the recipient. If authorization has been received to

return this product, by accepting this approval, the user assumes all responsibility and liability for

biological and chemical decontamination and cleansing. Labconco reserves the right to refuse

delivery of any products, which do not appear to have been properly cleaned and/or

decontaminated prior to return.

: Do not return goods. Goods returned without prior authorization will not be

19

Page 24

CONTACTING LABCONCO

If you have any questions that are not addressed in this manual, or if you need technical

assistance, please contact Labconco’s Customer Service Department at either (800) 821-5525 of

(816) 333-8811, between the hours of 8:00 a.m. and 5:00 p.m., Central Standard Time.

Labconco’s mailing address is:

Labconco Corporation

8811 Prospect Avenue

Kansas City, Missouri 64132-2696

Fax # 816-363-0130

Visit Labconco through the Internet at:

http://www.labconco.com

or

email: labconco@labconco.com

20

Loading...

Loading...