Page 1

RAPID DIGESTORS

Model 23012 Rapid Digestor-25 without digestion tubes

Model 23080 Rapid Digestor - 4 without digestion tubes

INSTRUCTION MANUAL

Product designs are subject to change without notice

© 1998 Labconco Corporation

Form 23058 REV H / ECO A652

Printed in U.S.A

Page 2

TABLE OF CONTENTS

Preface 4

General Description 5

Detailed Operational Function 5

Digestion Unit 5

Control Unit 6

Digestion Tubes, Flask Rack, and Retainer Plate 6

End Plates 7

Fume Removal System (Optional Equipment) 7

Specifications Digestor 25 - Place 8

Specifications Digestor 4 – Place 9

Installation 10

Unpacking 10

Operation & General Kjeldah Digestion Procedure 11

General Digestion for Feed, Grain 11

Routine Maintenance 13

Calibration 13

Troubleshooting 14

Service

Main Power Switch Replacement 15

Strip Heater Replacement 15

Indicator Lamp Replacement 15

Resistor Replacement 16

Ceramic Heater Replacement 16

Sensor Replacement 16

Parts and Service 17

References 18

Replacement Parts 19

Wiring Diagrams 21

Warranty 29

Shipping Claims 30

Contacting Labconco 31

Page 3

PREFACE

Thank you for displaying confidence in us by selecting a Labconco Rapid Digestor. Our

design engineers, assemblers and inspectors have utilized their skills and years of

experience to ensure that the new Labconco Rapid Digestors meets our high standards of

quality and performance.

IMPORTANT NOTICE

This manual should be read carefully by all the end users in order to become familiar

with the operation of the Rapid Digestors. Recommendations are made within the

manual to help you obtain maximum performance and life from your product.

We have included sections on initial set up, operation, maintenance and troubleshooting

to provide you with all the tools necessary to achieve maximum performance.

If you have questions or concerns, do not hesitate to call us at 1-800-821-5525 for

assistance.

WARNING: THE DISPOSAL OF SUBSTANCES USED IN CONNECTION

WITH THIS EQUIPMENT MAY BE GOVERNED BY VARIOUS FEDERAL,

STATE OR LOCAL REGULATIONS. ALL USERS OF THIS EQUIPMENT ARE

URGED TO BECOME FAMILIAR WITH ANY REGULATIONS THAT APPLY

IN THE USERS AREA CONCERNING THE DUMPING OF WASTE

MATERIALS IN OR UPON WATER, LAND OR AIR AND TO COMPLY WITH

SUCH REGULATIONS.

4

Page 4

INTRODUCTION

General Description

The Rapid Digestors are designed for wet digestions on material such as feeds, grains,

soils, plant tissues, water effluent, organic wastes, and food products. These digestions

are made prior to analysis for nitrogen, calcium, phosphorus, heavy metals, micronutrients, and other materials. The system consists of a control unit, a heating unit with

digestion tubes, and a flask rack for transporting tubes. The flask rack is equipped with

removable side panels providing increased heat transfer to the upper part of the digestion

tubes.

The heating unit consists of individual heaters constructed of ceramic materials providing

uniform and efficient heat transfer to the digestion tubes. The heaters are encased with an

efficient insulating material on four sides and the bottom to prevent heat loss, assuring

low energy consumption and safe casing temperatures. The close tolerance fit between

the inner ceramic tube and the digestion solution provides for shorter digestion times and

uniform digestion temperatures of the sample solution. The heating unit is enclosed in a

chemically etched aluminum casing, assuring easily cleaned surfaces with no paint to

flake off and providing a good appearance throughout the unit’s lifetime.

The control unit is of solid state design and regulates the temperature of the individual

heaters uniformly and accurately. The large temperature set point dial assures accurate

and repeatable temperature settings. The unique light display located on the heating unit

assures accurate temperature setting and allows for visual observation of the Digestor’s

operation.

The digestion tubes are thick-walled, rimmed, and made of borosilicate glass. Each tube

is manufactured to close tolerances to assure efficient and uniform digestions. Digestion

tubes are of the straight non-constricted type of approximately 250-ml capacity or with

construction and an accurate volumetric mark placed at 250-ml volume.

Detailed Operational Function

The Labconco Digestor consists of the digestion unit, the control unit, and accessories

(digestion tubes, flask rack, end plates, and retainer plate). The digestor can

simultaneously handle up to 25 samples, each weighing up to 5 g for solid materials or

approximately 25 ml for liquid samples.

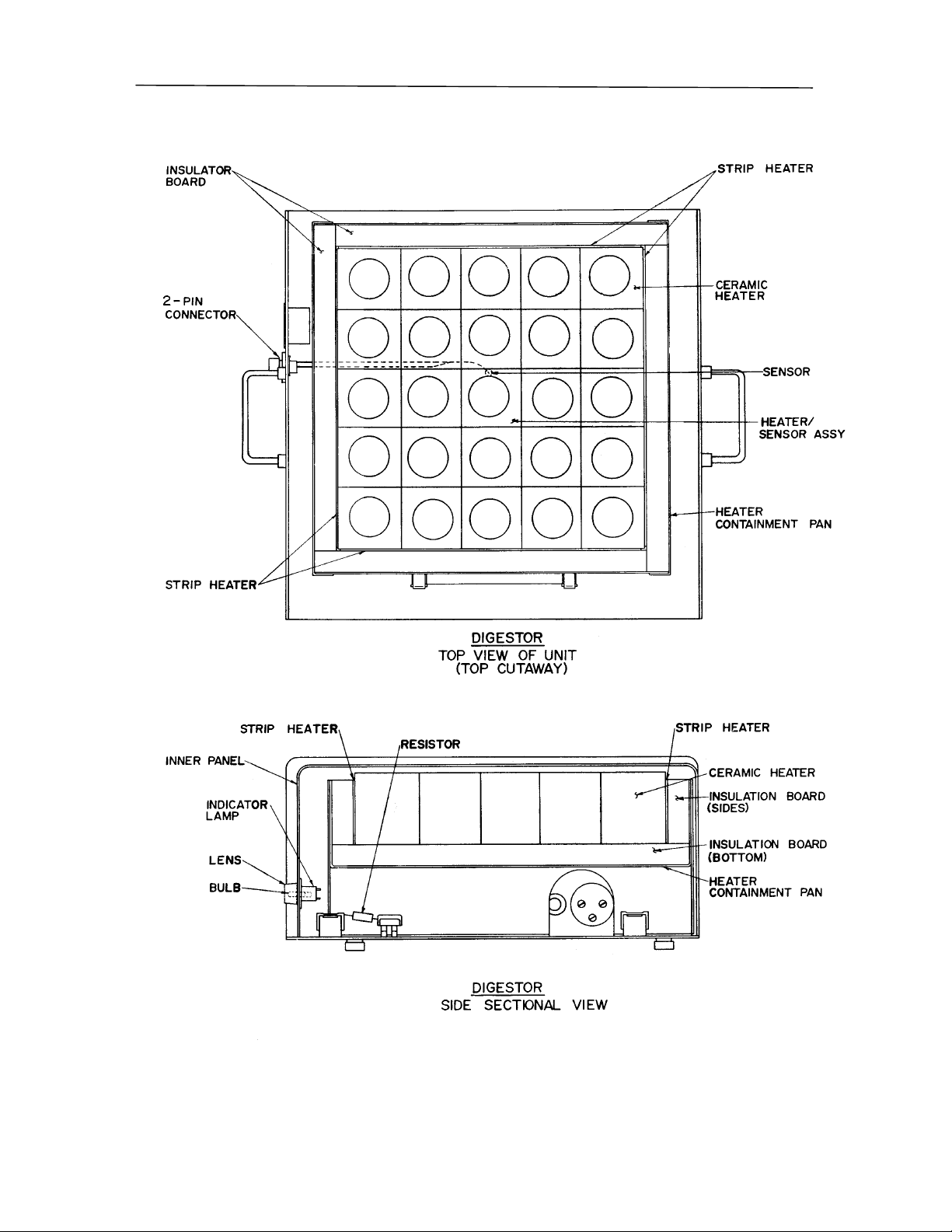

Digestion Unit

The digestion unit contains electrically heated ceramic cores retained in a pan insulated

from the aluminum casing to reduce heat loss and to prevent the metal casing from

becoming hot. The ceramic cores are precision molded to accommodate the digestion

tubes and provide maximum direct contact with the tubes.

The center heating element with the 25-Place, or the rear left with the 4-Place, contains a

RTD platinum sensor that is encased in ceramic to sense the temperature of the digestor

and signals the control unit providing uniform temperature control.

5

Page 5

INTRODUCTION

CAUTION: The top surface of the digestor is hot during operation and for a period of

time after shutdown. To avoid the possibility of burns, do not touch the surface with bare

hands.

The exposed surfaces of the unit are made of aluminum finished by a chemically etched

process to withstand corrosion. The light(s) located on the front of the digestor indicates

when the digestor has reached set-point temperature and any malfunction that could

occur, along with providing over and under temperature set-point indications. Flashing

of the light(s) indicates proper temperature control.

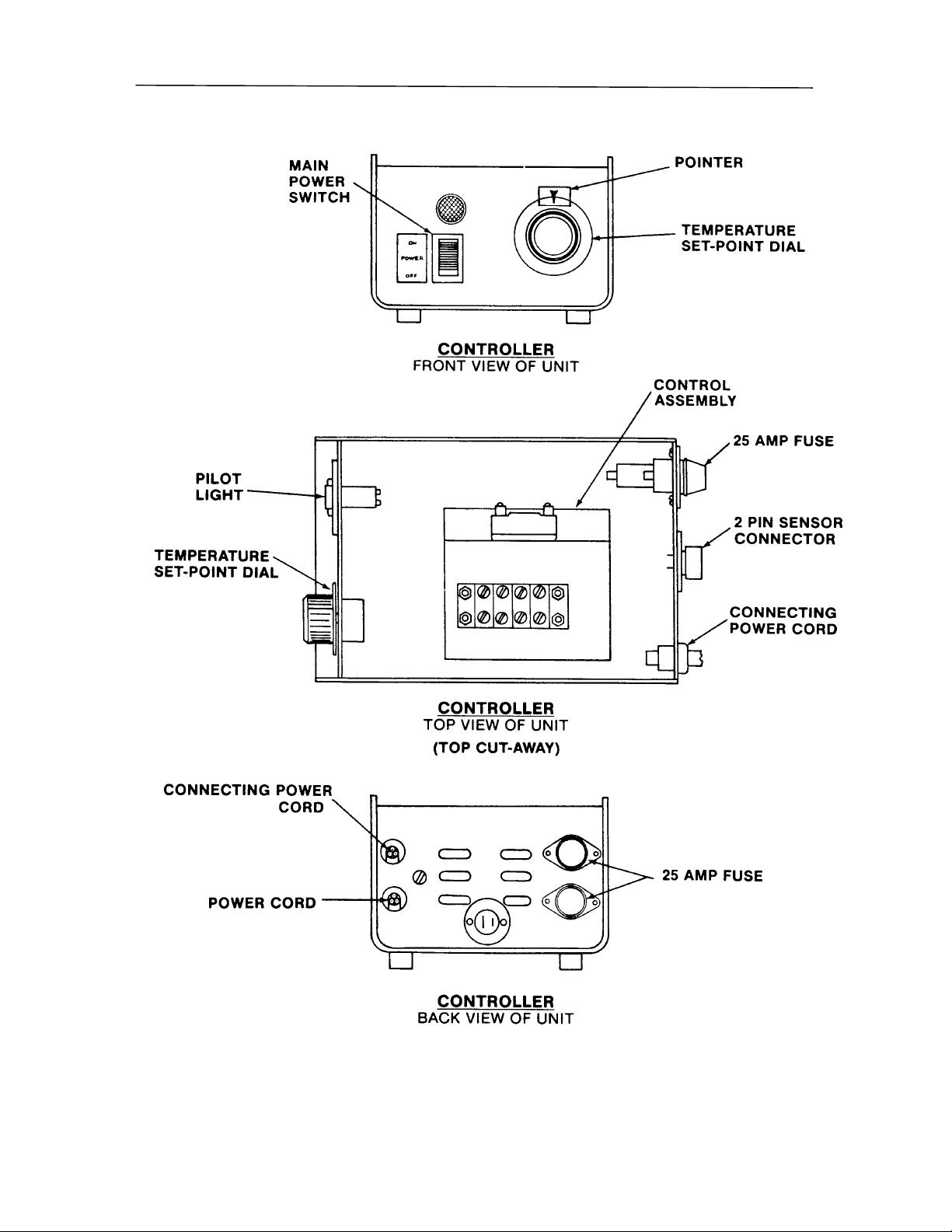

Control Unit

The solid state proportional controller regulates the temperature of the digestor unit. The

Rapid Digestor-25 control unit is factory set to accept 208/240 volts, 50/60 Hz requiring

20 amp fusing and the 4-Place set to accept 115 volts, 50/60 Hz requiring 15 amp fusing.

Temperatures from a few degrees above ambient to 450° C can be set on the set point

indicator dial. Each controller is factory calibrated for proper temperature setting before

leaving the factory and should not require re-calibration. A calibration resister is

provided for a calibration check of the set-point temperature if required. (Refer to

Maintenance Section of manual for procedure). A red indicator light on the front panel of

the control unit is illuminated when unit is energized. Flashing of the light(s) located on

the digestor unit indicates the set-point temperature, when it has been reached, the

temperature of the digestor is proportionately controlled by the controller.

Digestion Tubes, Flask Rack, and Retainer Plate

Digestor Model 23006 is supplied with one set of thick-walled, heavy rimmed, heat

resistant glass digestion tubes with volumetric calibration marks at 250-ml volume.

Digestor Model 23000 is supplied with tubes having the same features as with Model

23006 except without calibration markings. Models 23012 and 23080 are supplied without digestion tubes. The heavy rims allow the tubes to hang in the stand when the rack is

lifted. The flask rack is constructed of aluminum alloy and holds the tubes during digestion as well as during cooling, dilution, washing, drying, and weighing of samples.

Samples are weighed or volumetrically delivered into the tubes and the digestion mixture

added. The tubes in the rack are then lowered into the digestor unit. The samples are

digested at the proper temperature for a predetermined amount of time. Digestion

temperature and time is determined by the type of sample being digested. After

digestion is complete, the flask rack containing digested samples must be removed from

digestor, cooled and diluted with water. The digestion is now complete and ready for

appropriate determination. The retainer plate (Rapid Digestor 25-Place only) is attached

to the digestor flask rack to lock the tubes in place, allowing the tubes to be emptied,

washed, and dried as a unit, without removal from the rack. The retainer plate is not to

be used during digestion, cooling or dilution of the samples.

6

Page 6

INTRODUCTION

End Plates

The end plates are rectangular aluminum plates that attach to the open ends of the flask

rack during digestion. Closing the open ends of the rack promotes proper refluxing to

wash down the sides of the tubes for complete and efficient digestions. The end plates

are removed during cooling, dilution and washing.

Fume Removal System (Optional equipment)

An optional fume removal system is available to provide removal of the corrosive fumes

expelled during a digestion. The use of this system is highly recommended to prevent

damage to conventional fume removal hoods.

7

Page 7

SPECIFICATIONS

Specifications (Rapid Digestor, 25-Place)

1.

Electrical

Operating Voltage: 208-240V AC single phase

Current (Max.): 16 Amp at 230V AC

Fusing: 25 Amp fuses @208 or 240V AC

operation

Frequency: 50 or 60 Hz

2.

Physical

Weight: Digestion Unit: 78 lbs.

Control Unit: 10.8 lbs.

Tubes: 9.2 lbs./set of 25

Flask Rack: 3.6 lbs.

End Plates: 1.4 lbs.

Size Digestion Unit: 8" H x 19-1/4"W x 19" D

Control Unit: 5-1/8"H x 8" W x 12-1/8"D

Flask Rack: 6-1/2"H x 14-1/4"W x 14-1/4"D

Flask Rack w/ handles 6-1/2"H x 17-3/4"W x 14-1/4"D

End Plate: 6-1/2"H x 14-9/16"W x 1"D

Tubes: Volumetric 11-15/16"L x 1.65 OD

Straight 11-15/16"L x 1.65 OD

Sample Size: Up to 5 grams

3.

Features

Digestion Tubes (Types) 250 ml straight

250 ml constricted with volumetric mark

Capacity

(samples/digestion)

Temperature range Ambient to 450°C

Heat-up time to 410°C Approximately one hour

Temperature readout Set point dial with indication lamps

25

8

Page 8

SPECIFICATIONS

Specifications (Rapid Digestor 4-Place)

1.

Electrical

Operating voltage: 115V AC

Current (Max.): 6 Amp @ 115V AC

Fusing: 8 Amp @ 115V AC

Frequency: 50 or 60 Hz

2.

Physical

Weight (Shipping): 30 Lbs.

Size: Digestion Unit: 6-3/8"H x 9"W x 11-1/4"D

Control Unit 4-3/4"H x 6-3/4"W x 8-1/8"D

Sample size: Up to 5 grams

3.

Features

Digestion tube (types) 250 ml straight

250 ml constricted with volumetric mark

Capacity (samples/digestion) 4

Temperature range Ambient to 450°C

Heat-up time to 410°C Approximately 45 minutes

Temperature readout Set point dial with indication lamps

9

Page 9

INSTALLATION

Unpacking

Use caution when unpacking the digestor and accessories to avoid damage. Remove the

digestor unit from the carton first and carefully inspect all packing material to insure that

no accessories or small parts are discarded by accident. If damage from shipping has

occurred, the customer must file a claim with the carrier IMMEDIATELY! Do not return

any item to Labconco Corporation without written authorization from the factory. Your

local laboratory apparatus dealer can assist you and should be contacted if problems

occur.

Installation

• Locate the digestor unit under a suitable fume removal system to assure complete

removal of fumes and vapors given off during the digestion.

CAUTION: Acid fumes given off during digestion are very corrosive. Digestion

unit must be placed in venting system that is totally resistant to acid fumes or

damage will result to the removal system. It is highly recommended that

Labconco’s fume removal system, designed for acid removal from digestors, be

used in conjunction with a laboratory fume hood.

• Locate control unit outside hood away from any vapors or fumes. Damage to control

unit will result if subjected to corrosive vapors or fumes.

• Connect power cord from control unit to digestor unit. Remove calibration resistor

from 2-pin connector located on rear of control unit. Connect small diameter gray

sensor cord to the 2-prong receptacle provided.

• Connect main power cord from control unit to suitable electrical outlet. (208-240V

AC 3-wire installation fused at 25 amps for the 25-Place digestor or 115V AC for the

4-Place. Refer to electrical specifications pages 5 & 6).

• Adjust temperature set-point dial to approximately 300°C. Turn switch to ON

position. Red pilot light on controller panel will be illuminated along with the red

light(s) on the Digestor’s front panel.

• Allow approximately 40 minutes for unit to reach temperature setting. When unit

reaches temperature, the light(s) on the digestor unit will flash. When light(s) are on,

one half of the time the temperature indicated on the temperature dial has been

reached.

• Place digestion tubes in flask rack. System is now ready for operation.

10

Page 10

NORMAL OPERATION

Operation and General Kjeldah Digestion Procedure for Nitrate Free Samples 1 - 2

General Digestion for feed, grain, etc.

1. Turn main power switch located on front of controller to ON position. Set temper-

ature to 410°C using temperature set point dial on controller. Allow approximately

one hour for unit to reach pre-set temperature (digestor at pre-set temperature when

light(s) located on front of digestor is flashing).

2. Carefully insert the digestion tubes into the holes provided in the flask rack. The

flask rack can be used for convenient handling and transportation of the digestion

tubes.

3. Place weighed, well ground homogenous samples into digestion tubes and add 9g

K2SO4, 0.42 g Hg0, and 15 ml H2SO4.

4. After completing sample and reagent addition to the digestion tubes, carefully elevate

the rack by grasping the handles provided and place in position on the digestor unit.

As the rack is lifted, each tube will rest on its top rim. Carefully lower rack so that

each tube enters its respective hole and bottoms in the base of the unit.

5. If optional fume removal system has been purchased, place system on top of the

digestion tubes. Alignment is accomplished by a side to side, front to back motion.

Adjust water flow to aspirator to the point where all fumes are removed. (Refer to

instruction manual for Fume Removal System).

6. Place end plates on flask rack. These plates completely close the ends of the flask

rack and allow the temperature of the upper portion of the tube to elevate providing

for proper refluxing and condensation of the H2SO4 which washes the carbonized

material back into the digestion solution. (A certain amount of roaming will occur at

the beginning of the digestion. The refluxing of the acid washes any carbonized

material back into the digestion solution. If foaming is uncontrollable, reduce

digestion temperature and/or sample size).

7. Digest sample at 410° for 45 minutes for complete recovery of all types of nitrogen

containing samples. (Digestion time may be less for those samples not containing

refractory nitrogen. Refer to Labconco’s extracts).

Official Methods of Analysis of the Association of Official Analytical Chemists,

Thirteenth Edition, Washington, District of Columbia, 1980.

Methods utilizing copper as the catalyst and 20 minute digestions refer to reference

section of this manual and request appropriate Labconco extracts.

8. After digestion is complete, remove flask rack containing tubes from digestor and

place on heat resistant pad. Avoid having the hot tubes come into contact with a cool

or wet surface. (As a safety precaution, wear asbestos gloves and goggles when

removing the rack and tubes from the digestor).

11

Page 11

NORMAL OPERATION

9. Allow tubes to cool for 5-8 minutes. Dilute digest with approximately 100-ml water

when tubes are cool enough to handle. Dilution must be made before a cake is

formed from precipitated salts, but not before the digest is cool enough to contain the

exothermic reaction. (The cooling period is very important since, in the

determination procedure, caking of the salts will cause low recoveries of the nitrogen

contained in the cake.

10. After dilution of the digested sample, the nitrogen content can be determined by

Labconco’s Rapid Distillation Apparatus, normal Kjeldahl distillation, specific ion

electrode, steam distillation, or by manual or automated colorimetric determinations.

The general method presented for the digestion of total Kjeldahl nitrogen is a basic

method being used in many laboratories doing feeds and grain digestions.

12

Page 12

ROUTINE MAINTENANCE

Periodic cleaning of the surface is necessary to avoid stains from acid spills. This is best

accomplished with a detergent and water solution when the unit is cool. (Disconnect unit

from electrical source).

It is necessary to keep the cores of the ceramic heaters clear of any foreign material to

assure free insertion of the digestion tubes.

Calibration: The controller has been factory calibrated and should not require recalibration. In the event re-calibration is required the following procedure should be

followed:

1. Insert calibration resistor into the 2-pin sensor connector located on the rear of the

control unit.

2. Place ON-OFF switch, located on the controller, to the ON position.

3. Adjust set-point indicator dial to a position where the indicator lights, located on front

panel of digestor, are illuminated 50% of the time.

4. Loosen setscrews on set-point indicator dial and align calibration mark on dial with

pointer label. For calibration of Rapid Digestor 4-Place, align 220°C mark on dial

with pointer label. Retighten setscrews.

5. The digestor is now calibrated to give digestion temperature indicated on set-point

dial.

13

Page 13

TROUBLESHOOTING

Symptom Probable Cause Corrective Measure

Main pilot light does not

illuminate.

Main power fuse blown or

25 Amp fuse on control unit

ON-OFF switch defective Replace switch. Refer to

No heat applied to unit.

Main pilot light

illuminated

ON-OFF switch in off position Turn switch to ON position

Replace fuse or reset circuit

circuit breaker tripped

blown (8 Amp on Rapid

Digestor 4-Place)

Sensor defective Check continuity of sensor

breaker

Check continuity of fuse with

ohmmeter. Replace fuse if

blown. If fuse continues to

blow, locate cause.

Service Section for

replacement procedure.

by placing ohmmeter across

pins 1 & 2 of female sensor

receptacle. If resistance

measurements show sensor to

be open, replace sensor by

following Service Section on

Sensor Replacement.

Indicator lamp not

illuminated.

Defective resistor Check continuity of resistor

Defective ceramic heater Check continuity of each

Uneven heat applied to

unit (not applicable to

Rapid Digestor 4-Place

Bulb defective Check continuity of bulb

with ohmmeter and replace if

defective following Service

Section-Indicator Lamp

Replacement.

for the row of heaters behind

indicator lamp not

illuminated using ohmmeter.

heater contained in the row

behind indicator lamp that is

not illuminated. Replace

defective heater following

Ceramic Heater Replacement

section.

Strip heater defective Check continuity of each

strip heater and replace

defective heater following

Strip Heater Replacement

section.

14

Page 14

SERVICE

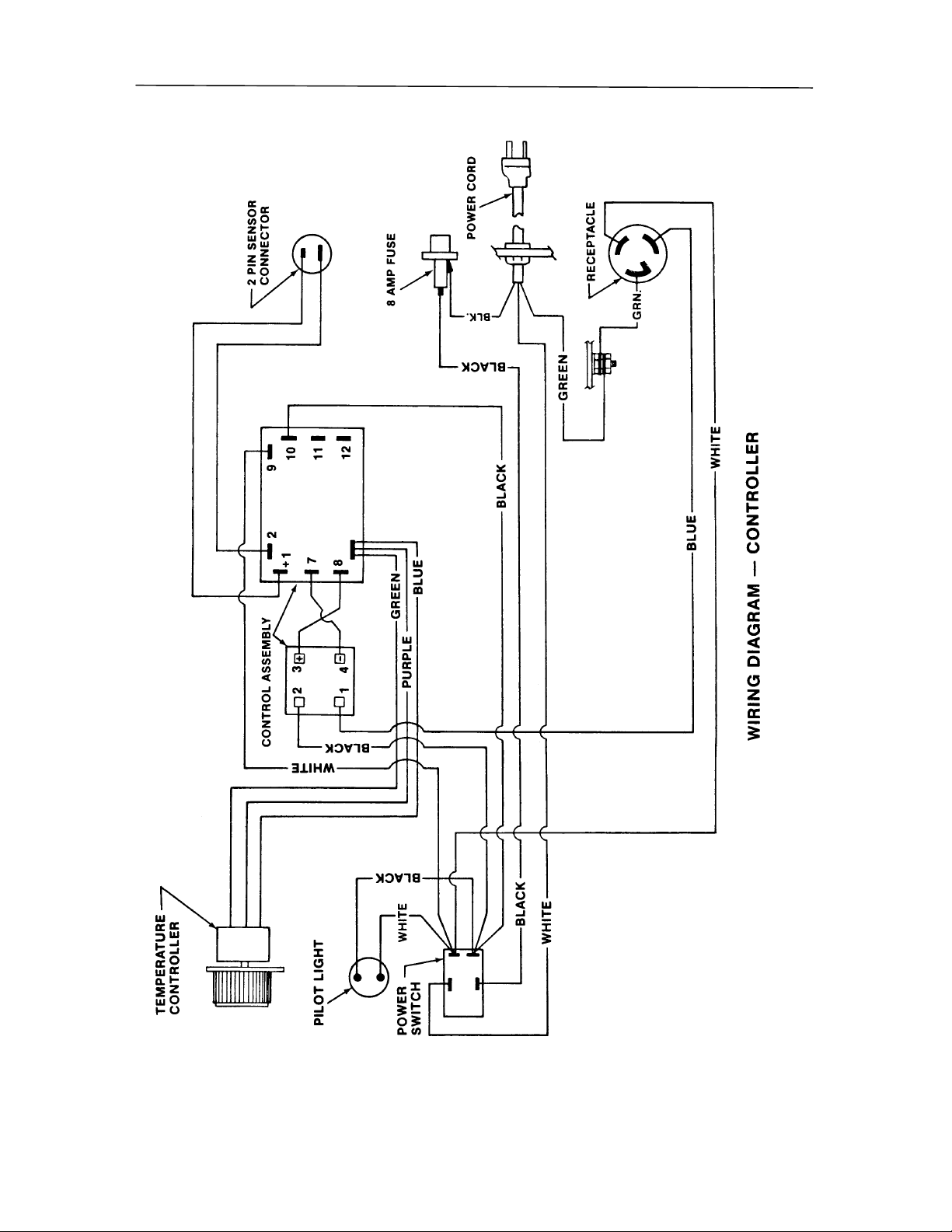

Refer to appropriate wiring diagrams or layout drawing for clarification.

Main Power Switch Replacement

• Disconnect main line cord from receptacle.

• Remove the #10-24 machine screws from sides of control unit and remove inner

panel exposing switch.

• Remove wires from old switch and replace switch.

• Rewire new switch referring to wiring diagram located on page 21 of manual. (Refer

to page 25 for Rapid Digestor 4-Place wiring diagram).

• Reassemble control unit.

• Reconnect main power supply.

Strip Heater Replacement (Not applicable to Rapid Digestor 4-Place).

• Disconnect main line cord from receptacle.

• Remove screws from sides of digestor and raise inner panel forward exposing

indicator lamp housings.

• Disconnect spade terminals to indicator lamp freeing the inner panel for complete

removal.

• Remove the six screws from bottom of digestor freeing heater containment pan.

• Tilt heater containment pan to expose wiring.

• Trace wiring to defective heater and disconnect heater wiring.

• Remove heater, replace and rewire.

• Reassemble in reverse order starting with number 3.

• Reconnect main power supply.

Indicator Lamp Replacement

• Disconnect main line cord from receptacle.

• Remove lens cap from defective bulb.

• Remove defective bulb from housing and replace.

• Reinstall lens cap.

15

Page 15

SERVICE

• Reconnect main power supply.

Resistor Replacement

• Follow steps 1-5 under “Strip Heater Replacement”.

• Remove defective resistor from buss bar and terminal strip.

• Install new resistor, retighten screws and reassemble in reverse order.

• Reconnect main power supply.

Ceramic Heater Replacement

• Follow steps 1-5 under “Strip Heater Replacement”.

• Remove defective heater from heater containment pan.

• Install new heater by threading wires through hole in the bottom of the insulator

board. Feed wires through hole and lower heater in place.

CAUTION: Do not bend wires or allow wires to fold up between bottom of heater

casing and insulator board. Heater life will be greatly reduced if heater is not

installed correctly.

• Reconnect heater wires and reassemble in reverse order.

• Reconnect main power supply.

Sensor Replacement

• Follow steps 1-5 under “Strip Heater Replacement”.

• Disconnect sensor leads attached to 2-pin connector located on left side of digestor.

(2-pin connector located on rear of Rapid Digestor 4-Place).

• Remove heater containing the sensor. (Refer to layout sketch on page 23 for 25Place or to page 27 for 4-Place). Heater-sensor assembly containing defective sensor

may be used as heater only by breaking sensor flush with bottom of heater.

• Install new heater sensor assembly by carefully threading wires through holes in the

bottom of the insulator board. Feed wires through holes and lower heater in place.

16

Page 16

SERVICE

CAUTION: Do not bend wires or allow wires to fold up between bottom of heater

casing and insulator board. Heater and sensor life will be greatly reduced if heater is

not installed correctly.

• Reconnect heater wires and solder sensor wires to the 2-pin connector.

• Reconnect main power supply.

• Recalibrate unit by following calibration procedure in Maintenance Section of this

manual.

Parts and Service

• If a problem should arise, please contact your local laboratory apparatus dealer

through whom you purchased the Labconco products. Please include Labconco

catalog and serial numbers on all phones or letter inquiries to obtain prompt action

on your particular unit. Consult nameplates to obtain this information. If contacting

Labconco directly, please furnish the name of the dealer from whom you purchased

the equipment.

WARNING: PERCHLORIC ACID IS A VERY RAPID OXIDIZER. IT

COMES TO A BOIL AT RELATIVELY LOW TEMPERATURES, WITH THE

LIQUID CONTENTS TOTALLY EVAPORATED IN A SHORT AMOUNT OF

TIME. THE RESIDUE WHICH REMAINS AFTER THE LIQUID IS DRAWN

OFF BECOMES ANHYDROUS AND VERY UNSTABLE.

FOR THIS REASON, LABCONCO WARNS AGAINST THE USE OF

PECHLORIC ACID WITH THIS EQUIPMENT AS A REACTION COULD

RESULT.

17

Page 17

REFERENCES

Official Methods of Analysis of the Association of Official Analytical Chemists,

Thirteenth Edition, Washington, D.C., 1980.

Hambleton, L.G. and Noel, R. J., Journal of the Association of Analytical Chemists, 58;

143-145, 1975.

Noel, R.J. , and Hambleton, L.G., Journal of the Association of Analytical Chemists, 59:

134-140, 1976.

Semi-Automated Method for Total Protein Nitrogen in Feeds - Applications Wall, L.L.,

Sr., Gehrke, C.W., and Smith, R.A., University of Missouri, Columbia, Experiment Station Chemical Laboratories, Columbia, Missouri.

“The Determination of Nitrogen Content from Predigested Samples with the Labconco

Rapid Distillation Apparatus”, Labconco Extracts 1:780, Labconco Corporation, Kansas

City, Missouri.

“Digestion Method for the Determination of Protein Nitrogen in Feeds, Grains, Cereals,

and Grasses Utilizing the Labconco 4-Place Rapid Digestor”, Labconco Extracts 2:880,

Labconco Corporation, Kansas City, Missouri.

“Digestion Method for the Determination of Protein Nitrogen in Feeds, Foods, Grains,

Cereals, and Grasses Utilizing the Labconco 25-Place Rapid Digestor”, Labconco

Extracts 3:880, Labconco Corporation, Kansas City, Missouri.

18

Page 18

REPLACEMENT PARTS

Rapid Digestor 25-Place

DIGESTOR - *1

Catalog No. Description

12761 Lens Cap, Red

12762 Indicator Lamp

23034 Heater Assembly with sensor cemented in place

13249 Resistor, 2 ohm 20 W

13459 Strip, Heater

23020 Assembly, Heater

23030-25 Tube Digestion, 250 ml volumetric (Pkg. of 25)

23040-25 Tube, Digestion with NO volumetric marking. (Pkg. of 25)

23051 Flask Rack

CONTROLLER - *2

Catalog No. Description

12707 Pilot Light, 230V

13240 Switch, DPST

23119 Control Assembly

23032 Calibration Resistor

*1. Refer to page 24 for digestor parts identification.

*2. Refer to page 23 for controller parts identification.

19

Page 19

REPLACEMENT PARTS

Rapid Digestor 4-Place

DIGESTOR - *1

Catalog No. Description

12767 Lens Cap, Red

12766 Indicator Lamp

13249 Resistor, 2 ohm 20 W

23084 Assembly, Heater

23030-05 Tube Digestion, 250 ml volumetric (Pkg. of 5)

23040-05 Tube, Digestion with NO volumetric marking. (Pkg. of 5)

23097 Flask Rack

CONTROLLER - *2

Catalog No. Description

12769 Pilot Light, 120V

13257 Switch, DPST

23124 Control Assembly

23032 Calibration Resistor

*1. Refer to page 28 for digestor parts identification.

*2. Refer to page 27 for controller parts identification.

20

Page 20

Wiring Diagram - Controller

WIRING DIAGRAM

21

Page 21

WIRING DIAGRAM

Wiring Diagram - Digestor

22

Page 22

WIRING DIAGRAM

23

Page 23

WIRING DIAGRAM

24

Page 24

WIRING DIAGRAM

25

Page 25

WIRING DIAGRAM

26

Page 26

WIRING DIAGRAM

27

Page 27

WIRING DIAGRAM

28

Page 28

WARRANTY

Labconco provides a warranty on all parts and factory workmanship. The warranty

includes areas of defective material and workmanship, provided such defect results from

normal and proper use of the equipment.

The warranty for all Labconco products will expire one year from date of installation or

two years from date of shipment from Labconco, whichever is sooner, except the

following:

• Purifier® Delta® Series Biological Safety Cabinets carry a three-year warranty

from date of installation or four years from date of shipment from Labconco,

whichever is sooner.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance

charges. In the event of a warranty claim, contact Labconco Corporation or the dealer

who sold you the product. If the cause is determined to be a manufacturing fault, the

dealer or Labconco Corporation will repair or replace all defective parts to restore the

unit to operation. Under no circumstances shall Labconco Corporation be liable for

indirect, consequential, or special damages of any kind. This statement may be altered by

a specific published amendment. No individual has authorization to alter the provisions

of this warranty policy or its amendments. Lamps and filters are not covered by this

warranty. Damage due to corrosion or accidental breakage is also not covered.

29

Page 29

SHIPPING CLAIMS

If a shipment is received in visibly damaged condition, be certain to make a notation on

the delivering carrier’s receipt and have their agent confirm the damage on your receipt.

Otherwise, the damage claim may be refused.

If concealed damage or pilferage is discovered, notify the carrier immediately and retain

the entire shipment intact for inspection. Interstate Commerce Commission rules require

that the claim be filed with the carrier within 15 days after delivery.

NOTE: Do not return goods. Goods returned without prior authorization will not be

accepted. Labconco Corporation and its dealers are not responsible for shipping damage.

Claims must be filed directly with the freight carrier by the recipient. If authorization has

been received to return this product, by accepting this approval, the user assumes all

responsibility and liability for biological and chemical decontamination and cleansing.

Labconco reserves the right to refuse delivery of any products, which do not appear to

have been properly cleaned and/or decontaminated prior to return.

30

Page 30

CONTACTING LABCONCO

If you have any questions that are not addressed in this manual, or if you need technical assistance,

please contact Labconco’s Sales Information at 800-821-5525 and Service Information at 800-5227658, or 816-333-8811 between the hours of 7:00 a.m. and 6:00 p.m. Central Standard Time.

Labconco’s mailing address is:

Labconco Corporation

8811 Prospect Avenue

Kansas City, Missouri 64132

Visit Labconco through the Internet at:

http://www.labconco.com

or

email:labconco@labconco.com

31

Loading...

Loading...