Labconco Purifier Axiom 30441 Series, Purifier Axiom 30461 Series, Purifier Axiom 30468 Series, Purifier Axiom 30448 Series User Manual

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

To receive important product updates,

complete your product registration card

online at register.labconco.com

User’s Manual

Purifier

®

Biological Safety Cabinets

Models

30441 Series 30448 Series

30461 Series 30468 Series

Please read the User’s Manual before operating the equipment.

TYPE

C1

Original instructions

Original instructions

This page is intentionally blank.

Original instructions

Warranty

Labconco Corporation provides a warranty to the original buyer for the repair or replacement of parts and

reasonable labor as a result of normal and proper use of the equipment with compatible chemicals. Broken

glassware and maintenance items, such as filters, gaskets, light bulbs, finishes and lubrication are not

warranted. Excluded from warranty are products with improper installation, erratic electrical or utility supply,

unauthorized repair and products used with incompatible chemicals.

Purifier® Axiom® Biological Safety Cabinets carry a five-year warranty from date of installation or six years

from date of shipment from Labconco, whichever is sooner. Warranty is non-transferable and only applies to

the owner (organization) of record.

Buyer is exclusively responsible for the set-up, installation, verification, decontamination or calibration of

equipment. This limited warranty covers parts and labor, but not transportation and insurance charges. If the

failure is determined to be covered under this warranty, the dealer or Labconco Corporation will authorize

repair or replacement of all defective parts to restore the unit to operation. Repairs may be completed by 3rd

party service agents approved by Labconco Corporation. Labconco Corporation reserves the rights to limit this

warranty based on a service agent’s travel, working hours, the site’s entry restrictions and unobstructed access

to serviceable components of the product.

Under no circumstances shall Labconco Corporation be liable for indirect, consequential, or special damages

of any kind. This warranty is exclusive and in lieu of all other warranties whether oral, or implied.

Copyright © 2016 Labconco Corporation. The information contained in this manual and the accompanying

products are copyrighted and all rights reserved by Labconco Corporation. Labconco Corporation reserves

the right to make periodic design changes without obligation to notify any person or entity of such change.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight carrier.

Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery

carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar with

any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water,

land, or air and to comply with such regulations. Labconco Corporation is held harmless with respect to

user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-821-5525

or 1-816-333-8811, between the hours of 7:30 a.m. and 5:30 p.m., Central Standard Time.

Part #3848320 Rev. E

ECO K541

Original instructions

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION 1

CHAPTER 2: PREREQUISITES 2

Space Requirements 2

Clearance 2

Location Requirements 3

Exhaust Requirements 4

Electrical Requirements 6

Service Line Requirements 7

CHAPTER 3: GETTING STARTED 8

Unpacking the Biosafety Cabinet 9

Moving and Lifting the Biosafety Cabinet 9

Installing the Biosafety Cabinet on an Existing Work Surface 10

Installing the Biosafety Cabinet on a Labconco Base Stand 10

Telescoping Base Stands 10

Manual or Electric Hydraulic Lift Base Stands 10

SoLo™ Electric Hydraulic Lift Base Stands 11

Preparing the Biosafety Cabinet for Operation 11

Connecting the Biosafety Cabinet to Utility Service Lines 12

Optional Exhaust Connection Requirements 13

Exhaust Connection Configuration 14

Connecting the Axiom to an Exhaust System 14

Selecting the Configuration Menu 15

Disconnecting the Axiom from an Exhaust System 18

Selecting the Configuration Menu 19

Optional Vacu-PassTM Cord and Cable Portal Use 21

Drain Valve Installation 22

Initial Certification 23

CHAPTER 4: PERFORMANCE FEATURES AND SAFETY

PRECAUTIONS 24

HEPA Filters 25

ULPA Filters 25

Laminar Airflow 26

Directional Airflow 27

ChemZone™ Directly Exhausted Work Zone 28

Motor/Blowers 29

Original instructions

Cabinet Air Intakes (Grilles) 30

Ultraviolet (UV) Lamp 30

Safety Precautions 31

CHAPTER 5: USING THE CABINET 33

System Reset Switch 33

Blower Startup Sequence 33

Information Center 34

Alarm Screens 35

Operating the Sliding Sash 36

Starting the Biosafety Cabinet 36

The Axiom Touchpad 37

Navigating the Axiom Menu Screens 38

Navigating the MyLogicTM Menu Screens 39

Setting the Clock 39

Configuring the Axiom 40

Navigating the Settings Menu Screens 41

Display Options 41

Units of Measure 41

Startup Tone 42

Security Lock 42

RS-232 Output Rate 42

UV Settings 43

UV Lamp Hourmeter 43

Reset UV Lamp Hourmeter 43

Change UV Lamp Life 44

Service Menu Screens 44

Timer Operation 44

Interval Timer Operation 44

Stopwatch Timer Operation 45

If An Airflow Alert Activates 45

Resetting the Airflow Alert System 45

Working in the Biosafety Cabinet 45

CHAPTER 6: MAINTAINING THE CABINET 49

Routine Maintenance Schedule 49

Service Operations 50

Center Work Surface Removal 50

Wing Work Surfaces Removal 51

Front Grille Removal 52

Front Panel Removal & Installation 53

Changing the Fluorescent Lamps 54

Changing the Optional UV Lamp 54

Resetting a Circuit Breaker 54

Storage 55

Original instructions

CHAPTER 7: TROUBLESHOOTING 56

APPENDIX A: COMPONENTS 59

APPENDIX B: DIMENSIONS 61

APPENDIX C: SPECIFICATIONS 63

Electrical Data 63

Motor Specifications 63

Environmental Conditions 63

APPENDIX D: ACCESSORIES 64

APPENDIX E: QUICK CHART 65

CAUTION – See Manual. When this symbol is on the unit it

indicates a caution that is detailed in this manual.

ATTENTION - Voir manuel. Lorsque ce symbole est allumé

l'appareil, il indique une mise en garde qui est indiqué dans

ce manuel.

1

Original instructions

Chapter 1:

Introduction

Congratulations on the purchase of a Labconco® Purifier Axiom® Biosafety

Cabinet. The biosafety cabinet is designed to protect you, the product and the

laboratory environment from biohazardous aerosols. The Axiom is the result

of years of experience in manufacturing biohazard cabinetry, and users like

you suggested many of its features.

This biosafety cabinet offers many unique features to enhance safety,

performance and ergonomics. To take full advantage of them, please acquaint

yourself with this manual and keep it handy for future reference. If you are

unfamiliar with how biosafety cabinets operate, please review Chapter 4:

Performance Features and Safety Precautions before you begin working in

the cabinet. Even if you are an experienced biosafety cabinet user, please

review Chapter 5: Using the Cabinet; it describes the biosafety cabinet’s

features so that you can use it efficiently.

This manual and other technical information is available in PDF format

at our website: www.labconco.com.

If the unit is not operated as specified in this manual it may impair the

protection provided by the unit.

Si l'unité n'est pas utilisée comme spécifié dans ce manuel il peut

diminuer la protection fournie par l'unité.

Product Service 1-800-522-7658

2

Original instructions

Chapter 2:

Prerequisites

Before you install the Axiom, you need to prepare the site for installation.

Examine the location where you intend to install the cabinet. You must be

certain that the area is level and of solid construction. In addition, a dedicated

source of electrical power must be located near the installation site.

Carefully read this chapter to learn:

Location requirements.

Electrical power requirements.

Exhaust requirements.

Service utility requirements.

Space requirements.

Refer to Appendix C: Specifications, for complete biosafety cabinet electrical

and environmental conditions, specifications and requirements.

Space Requirements

The overall dimensions for the 4-foot Axiom are 64.2 inches (163 cm) high, 32.2

inches (82 cm) deep, and 54.2 inches (138 cm) wide. The overall dimensions for

the 6-foot Axiom are 64.2 inches (163 cm) high, 32.7 inches (83 cm) deep, and

78.2 inches (199 cm) wide.

Complete dimensions for the Axiom C1 biosafety cabinets are shown in

Appendix B: Dimensions.

Clearance

A minimum clearance of at least 4 inches (100 mm) is suggested on the top

and 6 inches (150mm) on both sides of the cabinet for service.

Product Service 1-800-522-7658

Chapter 2: Prerequisites

3

Original instructions

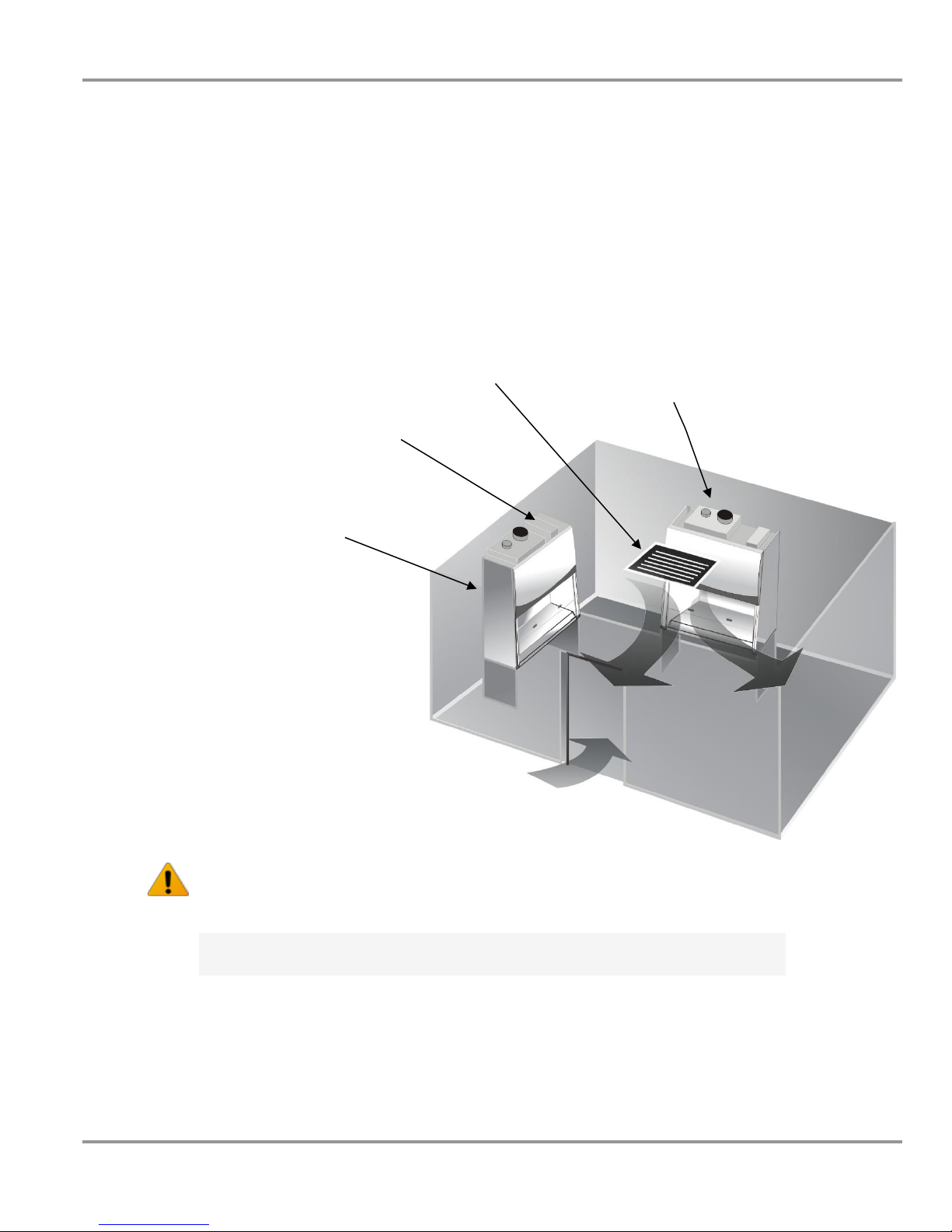

Figure 2-1a

Location Requirements

Note: The biosafety cabinet should be located away from traffic patterns,

doors, fans, ventilation registers, fume hoods and any other air-handling

devices that could disrupt its airflow patterns. All windows in the room

should remain closed. Figure 2-1a shows the preferred location for the

biosafety cabinet.

Air register blocked or redirected

to prevent cabinet disruption

Alternate location

Main Disconnect Device

(Power cord plug in back

of the electronics module).

Preferred location

Do not position the unit so that it is difficult to operate the main

disconnect device.

Ne placez pas l'appareil de sorte qu'il est difficile de faire fonctionner le

dispositif principal de déconnexion.

Product Service 1-800-522-7658

Chapter 2: Prerequisites

4

Original instructions

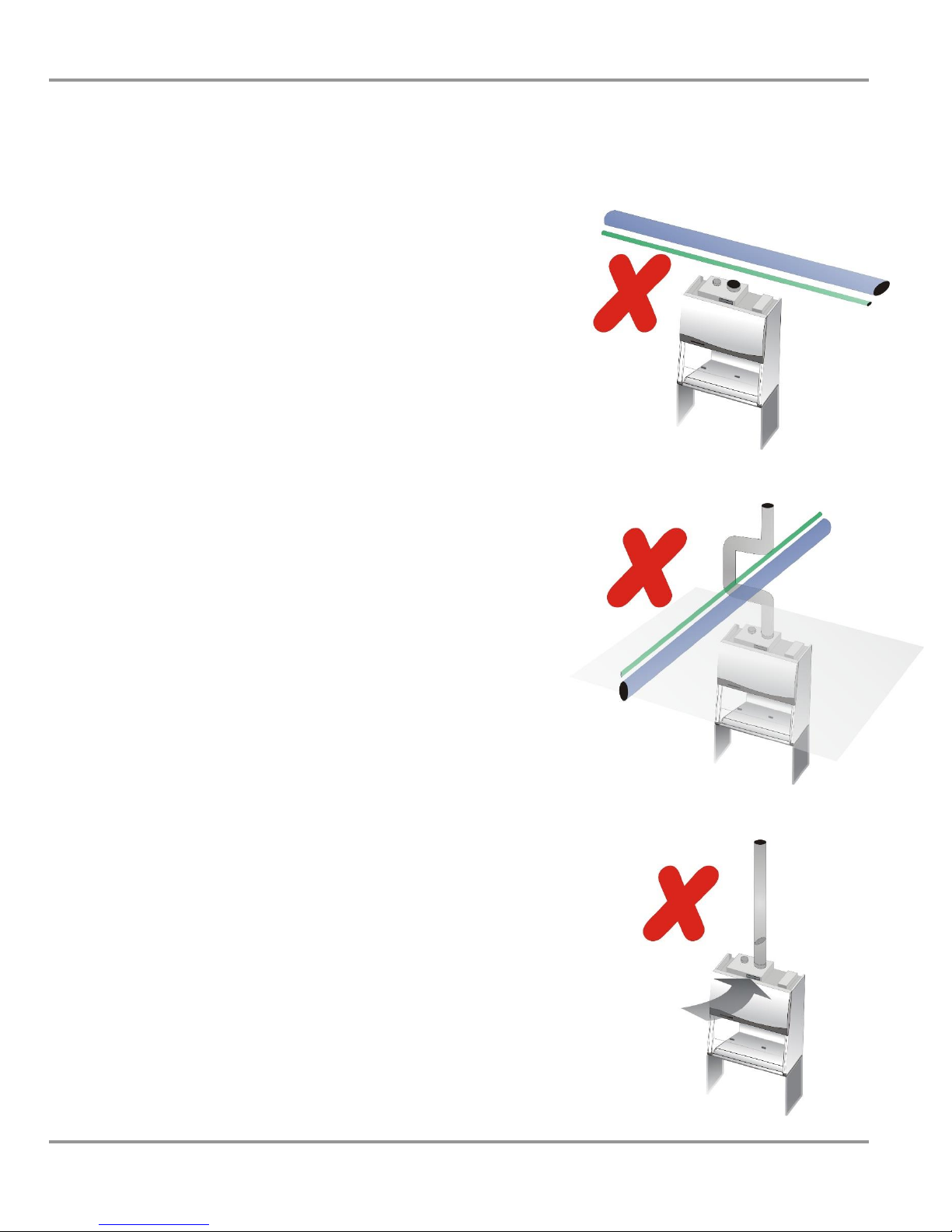

Figure 2-1b

Figure 2-1c

Figure 2-1d

If you intend to connect the biosafety cabinet to

an exhaust system:

NOTE: Only connect the cabinet to a suitable exhaust

system, one dedicated to the cabinet itself, or

dedicated to exhausting laboratory ventilation

equipment. DO NOT connect the unit to the building’s

HVAC system room exhaust.

Examine the location to ensure that it accommodates

the cabinet’s exhaust duct. The area directly above the

cabinet’s exhaust port should be clear of structural

elements, water and utility lines, or other fixed

obstructions. There should be enough clearance to

accommodate a 10-inch diameter duct.

Avoid cabinet locations that require an elbow

directly above the cabinet’s exhaust connection or

an excessive number of elbows in the exhaust

system. There should be a straight length 10 duct

diameters long between the cabinet and any elbow,

and between subsequent elbows.

The Inlet Relief Valve located on the top of the cabinet is

designed to draw a maximum of 100 CFM (2.83 m3/m).

Attempting to draw additional room air through the valve

(room air exhaust), can result in unstable cabinet operation.

Product Service 1-800-522-7658

Chapter 2: Prerequisites

5

Original instructions

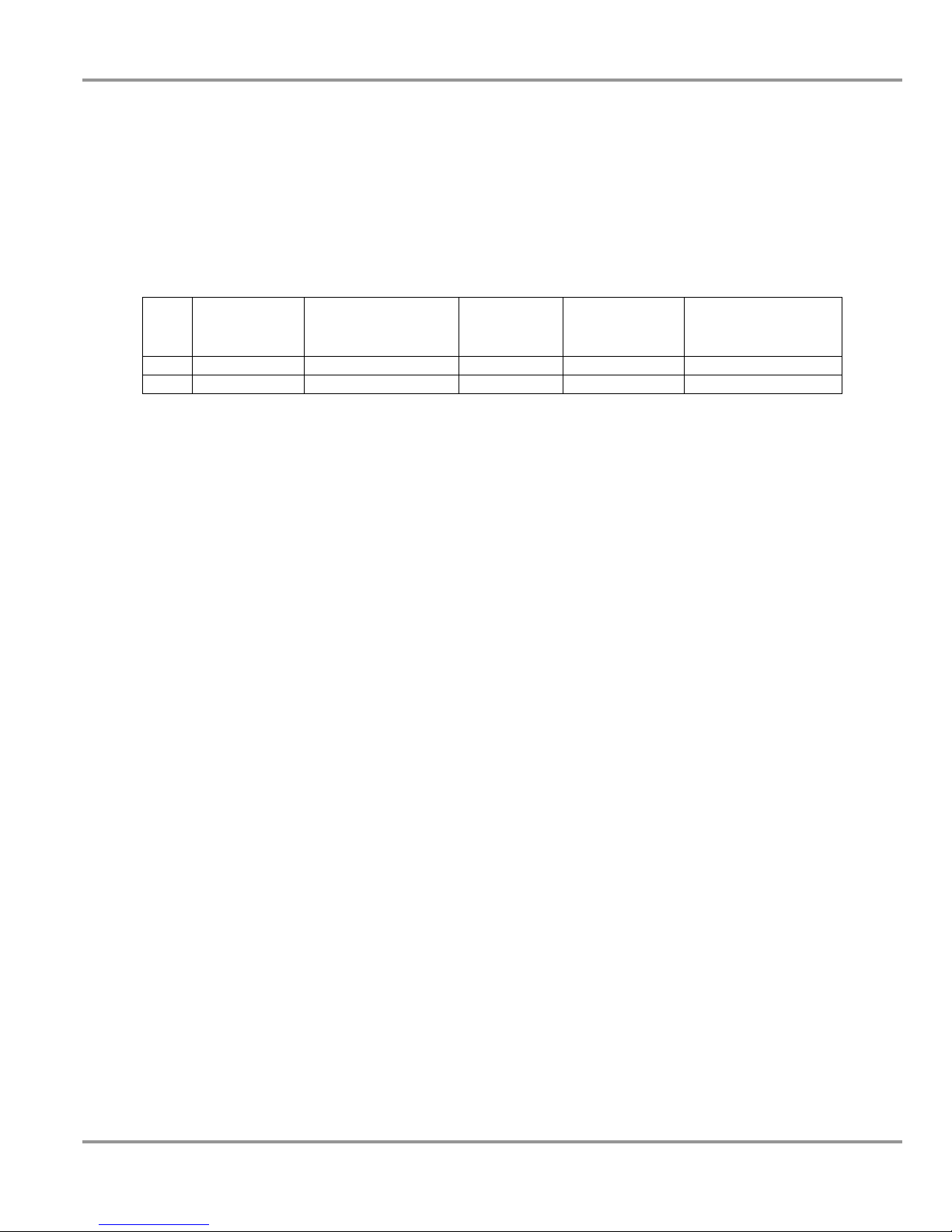

Axiom Type C1

Airflows

Airflow Volume

Concurrent

Balance Value

Recommended

Duct Vacuum1

ft3/min

m3/sec

ft3/min

m3/sec

WC

Pa

4-foot, 8" Sash

323

0.15

387

0.18

0.30

75

4-foot, 10" Sash

400

0.19

480

0.23

0.30

75

6-foot, 8" Sash

463

0.22

556

0.26

0.30

75

6-foot, 10" Sash

570

0.27

684

0.32

0.30

75

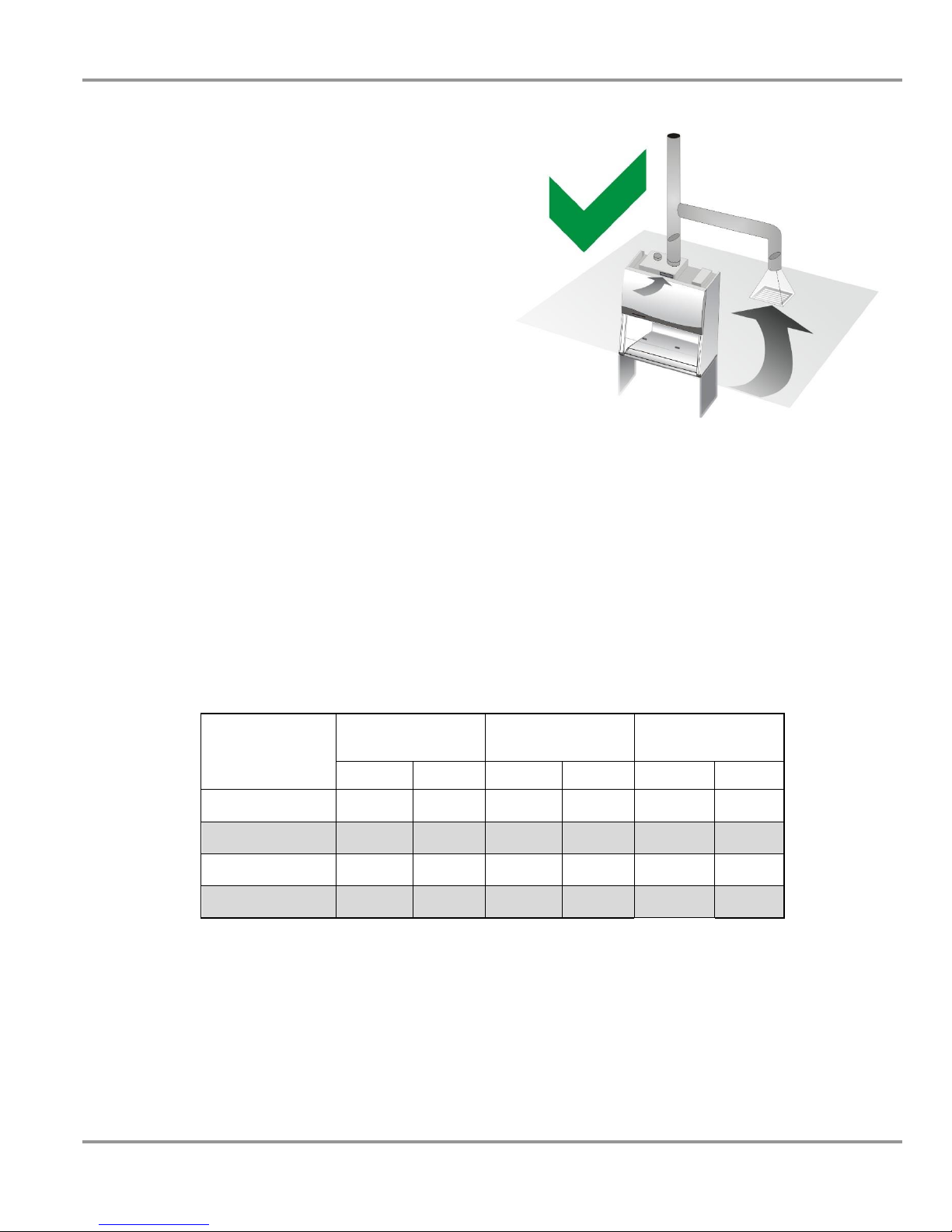

Figure 2-1e

Table 2-1

If additional room exhaust is needed

to be drawn through the exhaust

system, install an additional duct and

balancing damper downstream of the

cabinet’s damper. This will allow for

proper balancing of the system.

The exhaust system must be capable of moving the following volumes of

exhaust air at the negative pressures listed. The Airflow Volumes are the

values recorded via a direct measurement using a flow hood at the cabinet.

The Concurrent Balance Values are measured in the exhaust duct via

traverse methodology, and will always be higher due to differences in volume

measurement methodologies.

1 – Unlike Type B cabinets, the recommended vacuum will remain constant

throughout the life of the Exhaust HEPA filter. Duct vacuums below 0.2 WC

(25 Pa), or above 0.5 WC (125 PA) may result in erratic operation.

Product Service 1-800-522-7658

Chapter 2: Prerequisites

6

Original instructions

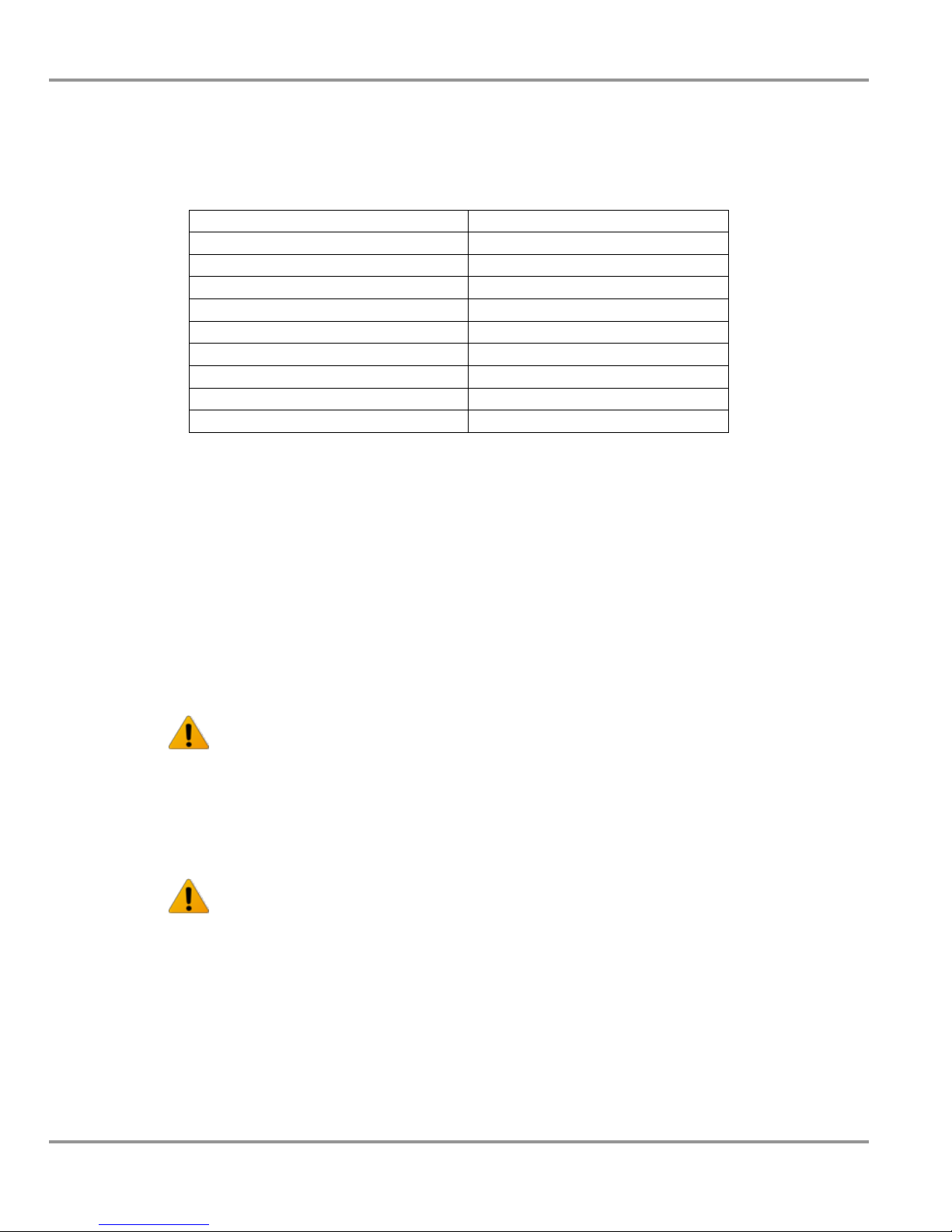

Model #

Requirements

30441xx0x, 30448xx0x

115 VAC, 60 Hz, 16 Amps

30441xx1x, 30448xx1x

100 VAC, 50/60 Hz, 16 Amps

30441xx-20, 30, 40, 50, 60, 70

230 VAC, 50/60 Hz, 8 Amps

30448xx-20, 30, 40, 50, 60, 70

230 VAC, 50/60 Hz, 8 Amps

30461xx0x, 30468xx0x

115 VAC, 60 Hz, 16 Amps

30461xx1x, 30468xx1x

100 VAC, 50/60 Hz, 16 Amps

30461xx-20, 30, 40, 50, 60, 70

230 VAC, 50/60 Hz, 8 Amps

30468xx-20, 30, 40, 50, 60, 70

230 VAC, 50/60 Hz, 8 Amps

Table 2-1

Electrical Requirements

The biosafety cabinet models have the following electrical requirements:

Note: A dedicated outlet with an appropriate circuit breaker should be

located as close as possible to the right rear side of the cabinet, at a

height even with, or higher than, the top of the bench or stand. Models

rated for 100 or 115 VAC will require a 20 Amp outlet. Consult your

local electrical codes for properly rated circuit breakers. For safe

operation the dedicated outlet must provide the protective earthing

ground connection to the cabinet.

Note: On 100 and 115 VAC models, both electrical outlets are protected by a

ground fault interrupter circuit (GFIC). Labconco does not recommend

plugging the biosafety cabinet into a GFIC outlet.

Electrical outlets in the cabinet are restricted to 5 amps

maximum current.

Prises électriques dans l'armoire sont limitées à 5 courant

maximum ampères.

Do not use any detachable power cord that is not adequately

rated for the unit.

Ne pas utliser un fil électrique amovible qui n’est pas du tension

nominale de l’appareil.

Product Service 1-800-522-7658

Chapter 2: Prerequisites

7

Original instructions

Service Line Requirements

All utility service lines should be ¼ inch O.D., brass, copper, or stainless

steel, and equipped with an easily accessible shut-off valve. The service

valves are rated for operation at 40 PSI (275 kPa). If the service line pressure

exceeds this, it must be equipped with a pressure regulator to reduce the line

pressure.

Note: The use of flammable gases or solvents should be avoided in the

biosafety cabinet. Open flame in the cabinet will disrupt the laminar airflow

in the cabinet and may damage the HEPA filters. Flammable gases or

solvents may reach explosive concentrations in the cabinet or ductwork. If

you feel that the procedure requires the use of an open flame or flammable

materials, contact the institution’s safety office.

The use of air or gases under high pressure should be avoided as they may

seriously disrupt the airflow patterns in the cabinet.

Product Service 1-800-522-7658

8

Original instructions

Chapter 3:

Getting Started

Now that the installation is properly prepared, you are ready to inspect,

install, and certify the Axiom biosafety cabinet. This chapter covers how to:

Unpack and move the biosafety cabinet.

Install the cabinet.

Connect the electrical supply source.

Connect the service lines.

Connect to an exhaust system (optional).

Arrange certification of the biosafety cabinet.

Tools required for installation the biosafety cabinet include two 1/2"

wrenches, a flat-blade screwdriver, a #2 Phillips screwdriver, and a

carpenter’s level.

Note: The biosafety cabinet models weigh between 630–900 lbs. (286-408

kg). The shipping pallet allows for lifting with a mechanical lift truck or

floor jack.

Product Service 1-800-522-7658

Chapter 3: Getting Started

9

Original instructions

Unpacking the Biosafety Cabinet

Carefully remove the outer carton and inspect the cabinet for damage that

may have occurred in transit. If the biosafety cabinet is damaged, notify the

delivery carrier immediately and retain the entire shipment intact for

inspection by the carrier.

Note: United States Interstate Commerce Commission rules require that

claims be filed with the delivery carrier within fifteen (15) days of delivery.

Do not return goods without the prior authorization of Labconco.

Unauthorized returns will not be accepted.

If the cabinet was damaged in transit, you must file a claim directly with the

freight carrier. Labconco Corporation and its dealers are not responsible for

shipping damages.

Do not discard the carton or packing material for the biosafety cabinet until

all of the components have been checked, installed and tested.

The cabinet is secured to the pallet in two places on each side. To access the

nuts and bolts, remove the side panels by removing and keeping the two

Phillips screws on both panels. Swing the front of each panel away from the

cabinet, and lift it straight up to remove the panel from the cabinet.

Note: The side panels must be removed to access the fasteners that secure the

biosafety cabinet to the pallet. DO NOT ATTEMPT TO LIFT THE

BIOSAFETY CABINET BY THE SIDE PANELS; DAMAGE WILL

OCCUR.

Moving and Lifting the Cabinet

Move the cabinet, attached to its pallet, by using a floor jack, or a furniture

dolly underneath the unit. DO NOT move the cabinet by tilting it onto a hand

truck. When lifting the cabinet DO NOT lift the cabinet in the middle front

area of the hull. Lifting here may bend or distort the bottom of the cabinet,

causing damage to the unit.

Product Service 1-800-522-7658

Chapter 3: Getting Started

10

Original instructions

Width

Base Stand w/Feet Model #

4'

3401004

6'

3401006

Width

Manual Lift Stand #

Electric (115V) Lift Stand #

Electric (230V) Lift Stand #

4'

3780201

3780101

3780104

6'

3780202

3780102

3780105

Table 3-1

Table 3-2

Installing the Biosafety Cabinet on an Existing

Work Surface

Note: The biosafety cabinet is very top heavy. Use caution when lifting or

moving it.

When installing the biosafety cabinet onto an existing work surface or benchtop,

ensure that the structure can safely support the combined weight of the cabinet

and any related equipment. The work surface should be at least as wide as the

cabinet and 31 inches (787 mm) deep to properly support the unit. A hole or

notch may be cut in the supporting surface in the right front corner to

accommodate the optional drain valve.

Installing the Cabinet on a Labconco Base Stand

Labconco offers accessory Base Stands in a variety of configurations to suit

your particular needs. Stands can be ordered with adjustable telescoping legs

or with a manually or electrically adjustable hydraulic lift.

Telescoping Base Stands

These stands are included with some Axiom models, or are available

separately. The base stands for each width cabinet are listed in Table 3-1

below. An optional caster wheel kit is available (part # 3730500).

Manual or Electric Hydraulic Lift Base Stands

These base stands offer infinitely adjustable height between 25.5 and 33.5

inches (648 to 851 mm), giving a cabinet work surface height of 28.0 to 36.0

inches. The height is adjusted either by a manual (hand crank) or electric

pump that drives the hydraulic legs of the stands. All of the hydraulic stands

are equipped with fixed feet, but can be converted to caster wheels with the

addition of Caster Kit #3784000. The base stands for each cabinet size is

listed in Table 3-2 below.

Note: When installing the cabinet on the hydraulic lift base stand, ensure that

the hydraulic lines and the electrical cord are clear of any obstructions before

installing the cabinet on the stand or operating the lift system.

Product Service 1-800-522-7658

Chapter 3: Getting Started

11

Original instructions

115V SoLo

Stand

230V SoLo

No. America Plug

230V SoLo

UK Plug

230V SoLo

Schuko Plug

230V SoLo China/

Australia Plug

4'

3780311

3780315

3780331

3780335

3780339

6'

3780313

3780317

3780333

3780337

3780341

SoLoTM Electric Hydraulic Lift Base Stands

These base stands permit the Axiom to be lowered enough to be transferred

through a standard doorway as low as 84 inches. Casters provide mobility

and lock in place. The SoLo Stands for each Purifier Axiom series model is

listed below.

Table 3-3

Preparing the Biosafety Cabinet for Operation

Installation instructions (Labconco P/N 1056801) are attached to the sash of

the biosafety cabinet. If these instructions are missing or unclear, contact

Product Service at 800-821-5525 or 816-333-8811. The following are located

in a box either underneath or secured to the work surface:

User’s Manual CD

Drain Valve Assembly and fasteners

Power Cord

Product Registration Card

Vacu-PassTM Accessories (optional)

If you did not receive one or more of the components listed for the cabinet, or

if any of the components are damaged, contact Labconco Corporation

immediately for further instructions.

Product Service 1-800-522-7658

Chapter 3: Getting Started

12

Original instructions

Figure 3-1

Connecting the Biosafety Cabinet to Utility

Service Lines

Note: Some models have a solenoid valve connected to the service valve on

the right side, rear position. The solenoid prevents gas from flowing to the

service valve when the unit blower is off. It is the only service valve position

that can be fitted with a solenoid valve. Connect the gas service to the

solenoid valve.

The service lines (if any) should be connected to the tube fitting(s) on the

outside of the liner wall as shown in Figure 3-1. To install the tubing, follow

these steps:

1. Ensure that the tubing is ¼ inch O.D., soft metal, and that the end has

been completely deburred.

2. Route the tubing from the rear of the cabinet, ensuring that it will line up

with the slot in the back of the side panel. The slot is located from 8 ¾ to

11 ¼ inches (222 to 288 mm) from the bottom of the cabinet.

Note: Make sure that the tube routing will not contact any electrical wires.

DO NOT loop service line tubing within the side panels of the cabinet.

3. Make sure that the nut on the tube fitting is loose, but do not remove it.

Look inside the fitting to make sure the tube ferrule is there.

4. Push the tube into the fitting until it is properly seated. The tube will go

approximately ¾ inch (19 mm) into the fitting.

5. Tighten the tube fitting nut hand tight and then, using a 7/16-inch wrench,

tighten it at least ¾ turn more.

6. Close the service valve in the biosafety cabinet and then slowly open the

shutoff valve on the service valve. Test all fittings for leakage. Tighten

the tube nut slightly if needed.

Tube fitting

Tube fitting nut

Product Service 1-800-522-7658

Chapter 3: Getting Started

13

Original instructions

Optional Exhaust Connection Requirements

Certain applications such as working with odorous products or volatile toxic

materials will require the connection of the biosafety cabinet to an exhaust

system.

Note: The Axiom exhaust connection includes an integral inlet relief valve,

which functions as a one-way, or check valve. During operation, the exhaust

system draws all of the cabinet’s exhaust air, plus a volume of room air

through the relief valve into the exhaust duct. The inlet relief valve functions

as a “shock absorber” allowing the cabinet to maintain optimal inflow during

changes in room air pressure.

Note: Because the Axiom cabinet has an integral exhaust fan, the vacuum

requirements of the exhaust system will be much lower than existing Type B

units. Please see the volume and vacuum requirements in Table 2-1, in If you

intend to connect the biosafety cabinet to an exhaust system: in Chapter 2:

Prerequisites

Note: If the research involves the use of toxic compounds or volatile

materials, contact the facility’s safety officer or Labconco to ensure that the

biosafety cabinet and its exhaust system are compatible with the materials

you will be working with.

Product Service 1-800-522-7658

Chapter 3: Getting Started

14

Original instructions

Figure 3-2

Exhaust Connection Configuration

Note: The Axiom is configured at the factory to operate unconnected to an

exhaust system. When operating in this mode, the cabinet ignores the inlet

relief valve position. If you intend to connect the cabinet to an exhaust

system, YOU MUST RECONFIGURE IT FOR THIS INSTALLATION.

Note: If the Axiom is connected to an exhaust system, and you choose to

disconnect it, to exhaust its HEPA-filtered air back into the laboratory, YOU

MUST RECONFIGURE IT FOR THIS INSTALLATION. These

instructions follow.

Connecting the Axiom to an Exhaust System

a) Mechanical configuration

1. Using an appropriate ladder or platform, remove the exhaust

cover panel(s) on the top right side of the exhaust cover, and

install them over the hole(s) on the left side. Hand tighten the

wing nuts to secure it, as shown in figure 3-2.

2. Connect the Axiom’s connection collar to the exhaust system,

ensuring the connection meets all appropriate codes and

regulations.

Exhaust cover installed over

exhaust outlet in left side of cover

top

Exhaust cover removed from the

right side of cover top

Product Service 1-800-522-7658

Chapter 3: Getting Started

15

Original instructions

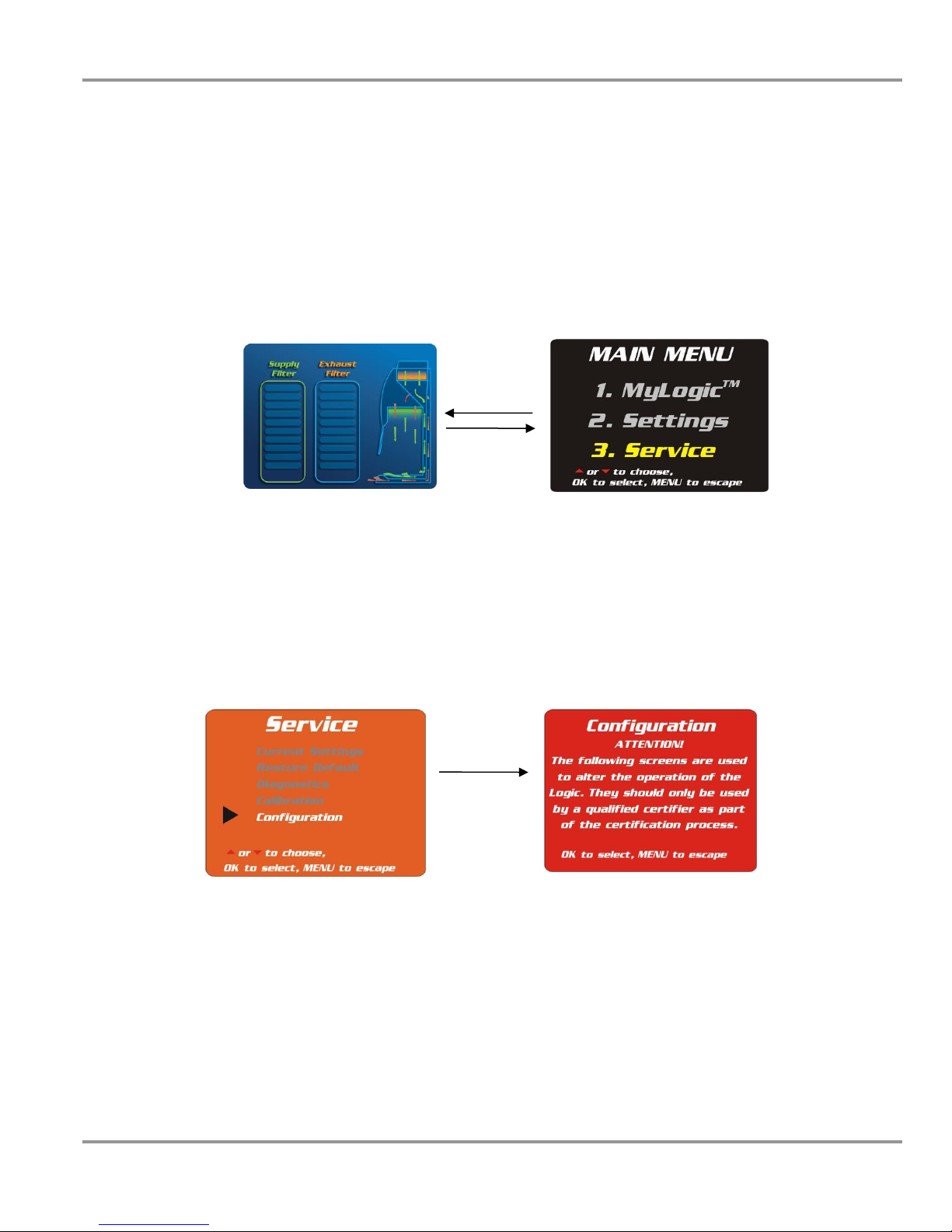

b) Electronic configuration

Keypad operations are shown as blue bold italic. Menu screen selections are

shown as green italics.

1. With the unit in operation, access the menu by pressing the Menu

button. The display panel will show the first level menu. Select

Service menu by pressing the ▲ or ▼ buttons until the Service is

highlighted. Press OK to accept that option, or press Menu to return

to the previous menu level.

Menu

Display Mode Menu Mode

Selecting the Configuration Menu

2. Using the ▲ and ▼ buttons on the touchpad, highlight the

Configuration option-it will be highlighted when selected. Press OK

and you will get an Attention screen, advising you the following

screens may alter the operation of the Axiom. Press OK to continue:

OK

Product Service 1-800-522-7658

Chapter 3: Getting Started

16

Original instructions

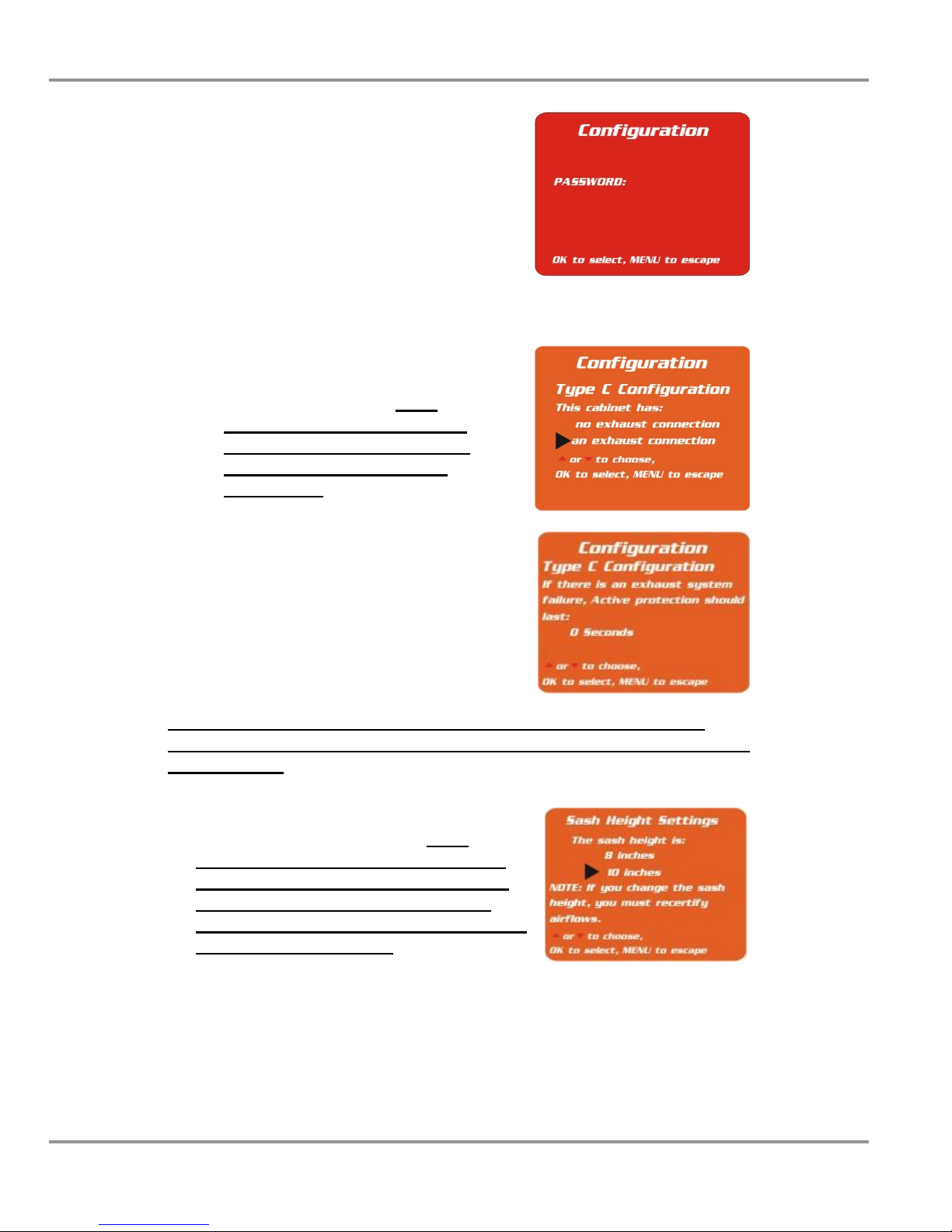

3. The screen will now prompt you for the

password; it is:

Light

UV Light

Timer

Timer

OK

Note: Any other key sequence will return you to the Attention screen.

4. The first screen allows you to select

whether the Axiom is connected to an

exhaust system or not. IT IS

CRITICAL THAT THE THIS

CABINET HAS AN EXHAUST

CONNECTION OPTION IS

SELECTED. Press OK to continue.

5. The second screen allows you to set

how long the blowers in the Axiom will

continue to operate in the event of an

exhaust system failure. The interval can

be programmed from 0-300 seconds.

Note: Consult with your facility’s safety officer or Labconco to help

establish how long the Axiom should continue to operate after an exhaust

system failure.

6. The third screen allows you to set the sash

height at either 8 or 10 inches. IT IS

CRITICAL THAT THE YOU LEAVE

THE SASH HEIGHT AS IT WAS SET

AT THE FACTORY, UNLESS YOU

WISH TO RECERTIFY THE CABINET

AT ITS NEW SETTING.

Product Service 1-800-522-7658

Loading...

Loading...