Page 1

User’s Manual

Purifier®XT Clean Benches

Models

32000 Series

To receive important product updates,

complete your product registration card

online at register.labconco.com

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Please read the User’s Manual before operating the equipment.

Page 2

Copyright © 2013 Labconco Corporation. All rights reserved.

The information contained in this manual and the accompanying products are copyrighted and all rights

reserved by Labconco Corporation. Labconco Corporation reserves the right to make periodic design

changes without obligation to notify any person or entity of such change.

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas of

defective material and workmanship, provided such defect results from normal and proper use of the

equipment.

The warranty for all Labconco products will expire one year from date of installation or two years

from date of shipment from Labconco, whichever is sooner, except the following;

• Purifier® Logic® Biological Safety Cabinets and PuriCare® Lab Animal Research Stations

carry a three-year warranty from date of installation or four years from date of shipment from

Labconco, whichever is sooner.

• SteamScrubber® & FlaskScrubber® Glassware Washers carry a two-year warranty from date

of installation or three years from date of shipment from Labconco, whichever is sooner.

• Blood Drawing Chairs carry a ten year warranty.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the

event of a warranty claim, contact Labconco Corporation or the dealer who sold you the product. If

the cause is determined to be a manufacturing fault, the dealer or Labconco Corporation will repair or

replace all defective parts to restore the unit to operation. Under no circumstances shall Labconco

Corporation be liable for indirect, consequential, or special damages of any kind. This statement may

be altered by a specific published amendment. No individual has authorization to alter the provisions

of this warranty policy or its amendments. Lamps and filters are not covered by this warranty.

Damage due to corrosion or accidental breakage is not covered.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight carrier.

Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery

carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar with

any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water,

land, or air and to comply with such regulations. Labconco Corporation is held harmless with respect to

user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-821-5525

or 1-816-333-8811, between the hours of 7:00 a.m. and 6:00 p.m., Central Standard Time.

Part #3207700, Rev. A

ECO H572

Page 3

T

AABBLLEE

T

CHAPTER 1: INTRODUCTION 1

About This Manual 1

Typographical Conventions 3

CHAPTER 2: PREREQUISITES 4

Location Requirements 5

Electrical Requirements 6

Service Line Requirements 6

Space Requirements 7

CHAPTER 3: GETTING STARTED 8

Unpacking Your Clean Bench 9

Clean Bench Components 9

Removing the Shipping Skid 10

Securing the Purifier XT Clean Bench 13

Initial Certification 14

Moving XT Clean Bench through Tight Doorway 16

CHAPTER 4: THEORY OF OPERATION AND

HEPA Filters 19

Laminar Airflow 21

Motor/Blower 21

Speed Control 22

Safety Precautions 22

CHAPTER 5: USING YOUR XT CLEAN BENCH 25

Starting the Clean Bench 25

Use of the Clean Bench 26

O

O

SAFETY PRECAUTIONS 19

FF

C

C

OONNTTEENNTTSS

Page 4

CHAPTER 6: MAINTAINING YOUR MEDIA

PREP CLEAN BENCH 28

Routine Maintenance Schedule 29

Service Operations 30

Resetting the Circuit Breaker 30

Changing the Prefilter 30

Speed Control Adjustment 31

Diffuser Removal 32

HEPA Filter Replacement 32

Motor/Blower Service 33

Motor/Blower Replacement 34

Storage 35

CHAPTER 7: TROUBLESHOOTING 36

APPENDIX A: XT CLEAN BENCH COMPONENTS 37

APPENDIX B: DIMENSIONS 39

APPENDIX C: XT CLEAN BENCH SPECIFICATIONS 40

Electrical Data 40

Motor Specifications 40

Environmental Conditions 41

Wiring Diagrams 42

APPENDIX D: XT CLEAN BENCH ACCESSORIES 43

Ergonomic Chair with Armrests 43

Adjustable Footrest 43

APPENDIX E: QUICK CHART FOR THE CLEAN BENCH 44

DECLARATION OF CONFORMITY 45

Page 5

C

HHAAPPTTEERR

C

I

NNTTRROODDUUCCTTIIOONN

I

Congratulations on your purchase of a Labconco Purifier® XT Clean Bench.

Your XT Clean Bench is designed to protect your product from particulate matter

contamination.

The XT Clean Bench offers many features to enhance safety, performance and

ergonomics. To take full advantage of them, please acquaint yourself with this

manual and keep it handy for future reference. If you are unfamiliar with how

clean benches operate, please review Chapter 4: Theory of Operation and Safety

Precautions before you begin working in the bench. Even if you are an

experienced clean bench user, please review Chapter 5: Using Your XT Clean

Bench; it describes your XT Clean Bench’s features so that you can use it

efficiently.

1

1

About This Manual

This manual is designed to help you learn how to install, use, and maintain your

XT Clean Bench. Instructions for installing optional equipment on your bench

are also included.

Chapter 1: Introduction provides a brief overview of the XT Clean Bench,

explains the organization of the manual, and defines the typographical

conventions used in the manual.

Chapter 2: Prerequisites explains what you need to do to prepare your site before

you install your XT Clean Bench. Electrical and service requirements are

discussed.

Product Service 1-800-522-7658

1

Page 6

Chapter 1: Introduction

Chapter 3: Getting Started contains the information you need to properly unpack,

inspect, install, and certify your XT Clean Bench.

Chapter 4: Theory Of Operation And Safety Precautions explains how a clean

bench operates and the appropriate precautions you should take when using the

bench.

Chapter 5: Using Your XT Clean Bench discusses the basic operation of your

bench. Information on how to prepare, use and shut down your XT Clean Bench

is included.

Chapter 6: Maintaining Your XT Clean Bench explains how to perform routine

maintenance on your XT Clean Bench. Information on how to safely disinfect the

interior of your bench is included.

Chapter 7: Troubleshooting contains a table of problems you may encounter

while using your clean bench including the probable causes of the problems and

suggested corrective actions.

Appendix A: XT Clean Bench Components contains labeled diagrams of all of the

components of the XT Clean Bench.

Appendix B: Dimensions contains comprehensive diagrams showing all of the

dimensions for the XT Clean Bench.

Appendix C: XT Clean Bench Specifications contains the electrical requirements

for the XT Clean Bench. Wiring diagrams for both the 115V and 230V units are

also included.

Appendix D: XT Clean Bench Accessories lists the part number and descriptions

of all of the accessories available for your clean bench.

Appendix E: Quick Chart for the Clean Bench provides useful operating

specifications.

2

Product Service 1-800-522-7658

Page 7

!

)

Chapter 1: Introduction

Typographical Conventions

Recognizing the following typographical conventions will help you understand

and use this manual:

• Book, chapter, and section titles are shown in italic type (e.g., Chapter 3:

Getting Started).

• Steps required to perform a task are presented in a numbered format.

• Comments located in the margins provide suggestions, reminders, and

references.

• Critical biosafety information is presented in boldface type in paragraphs that

are preceded by the biosafety icon. Failure to comply with the information

following a biosafety icon may result in illness or death.

• Critical information is presented in boldface type in paragraphs that are

preceded by the exclamation icon. Failure to comply with the information

following an exclamation icon may result in injury to the user or permanent

damage to your XT Clean Bench.

• Critical information is presented in boldface type in paragraphs that are

preceded by the wrench icon. These operations should only be performed by

a trained certifier or contractor. Failure to comply with the information

following a wrench icon may result in injury to the user or permanent damage

to your XT Clean Bench.

• Important information is presented in capitalized type in paragraphs that are

preceded by the pointer icon. It is imperative that the information contained

in these paragraphs be thoroughly read and understood by the user.

Product Service 1-800-522-7658

3

Page 8

C

HHAAPPTTEERR

C

P

RREERREEQQUUIISSIITTEESS

P

Before you install your XT Clean Bench, you need to prepare your site for

installation. Carefully examine the location where you intend to install your

bench. You must be certain that the area is level and of solid construction, and a

wall is nearby to secure the back of the XT Clean. In addition, a dedicated source

of electrical power must be located near the installation site.

Carefully read this chapter to learn:

• the location requirements for your installation site.

• the electrical power requirements for your installation site.

• the service line requirements for your installation site.

• the space requirements for your installation site.

Refer to Appendix C: XT Clean Bench Specifications for complete XT Clean

Bench electrical and environmental conditions, specifications and requirements.

2

2

4

Product Service 1-800-522-7658

Page 9

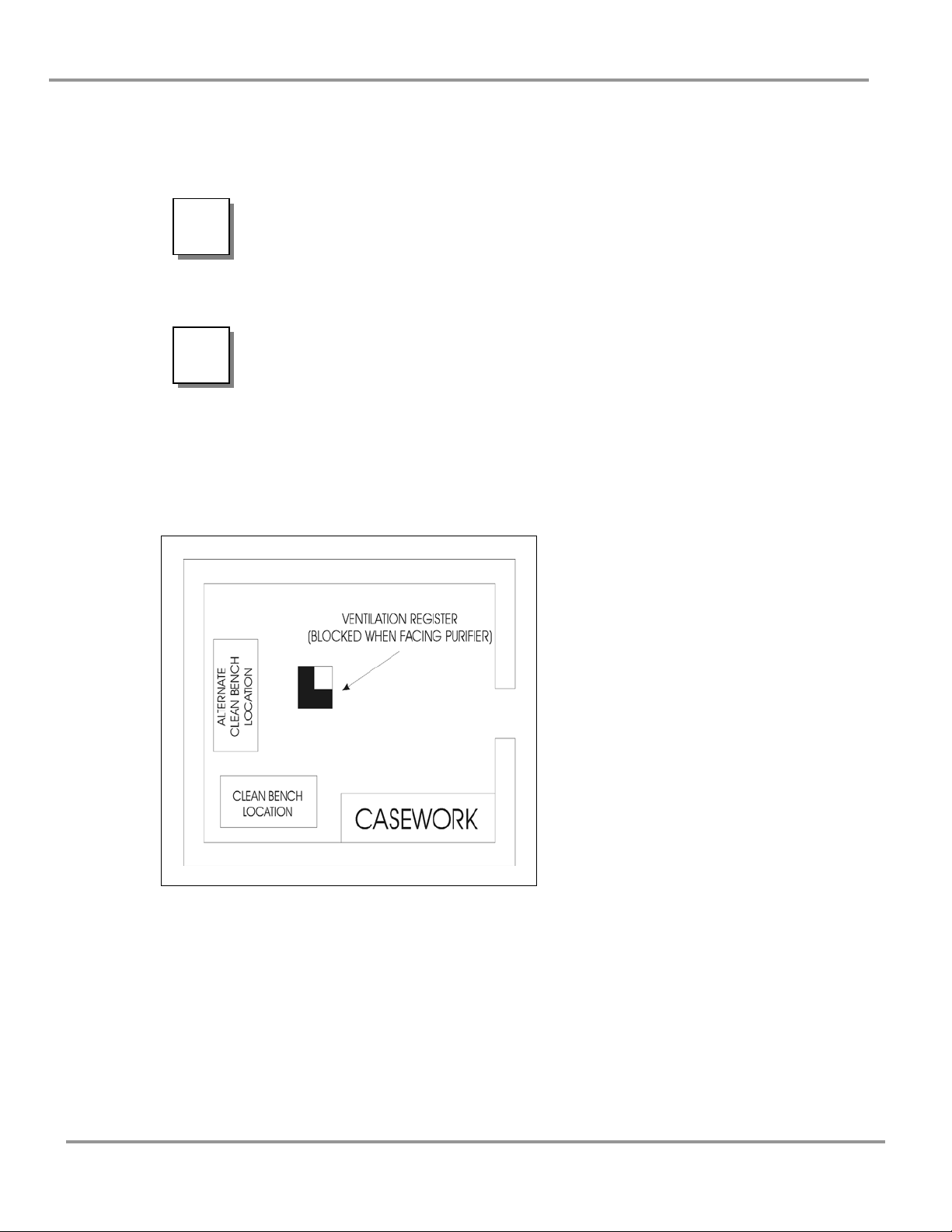

Location Requirements

The Purifier XT Clean Bench should be located away from traffic

!

!

patterns, doors, fans, ventilation registers, fume hoods and any

other air-handling device that could disrupt its airflow patterns.

All windows in the room should be closed. Figure 2-1 shows the

optimum location for the bench.

L’hotte à flux laminaire Purifier doit etre située à l’écart de la

circulation, des portes, des ventilateurs, des registres de ventilation,

des sorbonnes et n’importe quel dispositif de traitement d’air qui

peut interrompre le circuit du courant d’air. Toutes les fênetres de

la chambre doit etre fermée. La figure 2-1 montre l’emplacement

optimal pour l’hotte.

Figure 2-1

Chapter 2: Prerequisites

Product Service 1-800-522-7658

5

Page 10

Chapter 2: Prerequisites

Electrical Requirements

The different Purifier XT Clean Bench models have the following electrical

requirements:

All Purifier XT Clean Benches with model numbers ending in -00 are designed

for operation at 115 volts, 60 Hz, alternating current. XT Clean Benches with

model numbers ending in -01 through -04 are designed for operation at 230 volts,

50/60 Hz alternating current. A dedicated outlet with a circuit breaker rated at 20

amps should be located as close as possible to the right, rear side of the bench in

its final location. If your electrical outlet is distant from this location, contact

Labconco’s Product Service Department for information on longer cords.

32000 -01, -02, -03, -04 230 VAC, 50/60 Hz, 6 Amps

!

!

Model # Requirements

32000 -00 115 VAC, 60 Hz, 10 Amps

Do not use any detachable power cord that is not adequately

rated for the unit.

Ne pas utliser un fil électrique amovible qui n’est pas du tension

nominale de l’appareil.

Table 2-1

Service Line Requirements

All service lines to the XT Clean Bench should be quarter inch outside diameter,

metal, and equipped with an easily accessible shut-off valve should disconnection

be required. If the service line pressure exceeds 40 PSI, it must be equipped with

a pressure regulator to reduce the line pressure.

The use of flammable gases or solvents should be avoided in

!

6

the clean bench. Open flames in the cabinet will disrupt the

laminar airflow in the bench. If you feel that your procedure

requires the use of an open flame or flammable materials,

contact the appropriate safety official.

Product Service 1-800-522-7658

Page 11

The use of air or gases under high pressure should be

considered carefully as they may seriously disrupt the airflow

patterns in the bench.

L’utilisation de gaz inflammables ou de solvants dans l’hotte doit

!

être évitée. Les flammes nues interromprent le circuit du courant

d’air laminaire dans l’hotte. Si vous estimez que votre procedure

exige l’utilisation d’une flamme nue ou des matériaux

inflammables, Prenez contact avec un officiel de sécurité

competent.

Prenez en considération l’uilisation d’air ou de gaz sous haute

pression car il peut interrompre gravement le circuit du courant

d’air dans l’hotte.

Space Requirements

Chapter 2: Prerequisites

The dimensions for the different models are shown in Appendix B: XT Clean

Bench Dimensions.

The XT Clean Bench is designed to house tall media preparation machines or

other large equipment, and therefore is taller in height. The XT Clean Bench

must be properly secured to a wall using the bracket and lashing strap provided to

tie the back of the bench to an adjacent wall. Instructions for attaching the

bracket and lashing strap to the bench and adjacent wall are located in Chapter 3:

Getting Started.

Product Service 1-800-522-7658

7

Page 12

C

HHAAPPTTEERR

C

G

EETTTTIINNGG

G

Now that the site for your XT Clean Bench is properly prepared, you are ready to

unpack, inspect, install, and certify your unit. Read this chapter to learn how to:

• unpack and move your bench.

• set up the bench.

• connect the electrical supply source.

• connect the service lines.

• arrange certification of your XT Clean Bench.

Depending upon which model you are installing, you may need common

plumbing and electrical installation tools in addition to two 1/2" wrenches, a

7/16" wrench, a flat-blade screwdriver, a Phillips screwdriver, and a carpenter

level to complete the instructions in the chapter.

The Purifier XT Clean Bench models weigh between 400 – 600

lbs. (182-272 kg). The carton skid allows for lifting with a

!

!

mechanical lift truck or floor jack.

Les modèles de hotte à flux laminaire Purifier XT Clean Bench

pèsent entre 400 à 600 lbs (182-272 kg). Le carton permet le

levage avec un chariot élévateur á fourche.

S

S

3

3

TTAARRTTEEDD

8

Product Service 1-800-522-7658

Page 13

The United

States Interstate

Commerce

Commission

rules require

that claims be

filed with the

delivery carrier

within fifteen

(15) days of

delivery.

Chapter 3: Getting Started

Unpacking Your Clean Bench

Carefully unpack your Purifier XT Clean Bench and inspect it for damage that

may have occurred in transit. If your unit is damaged, notify the delivery carrier

immediately and retain the entire shipment intact for inspection by the carrier.

DO NOT RETURN GOODS WITHOUT THE PRIOR

AUTHORIZATION OF YOUR DEALER AND LABCONCO.

)

Do not discard the carton or packing material for your clean bench until you have

checked all of the components and installed and tested the unit.

Do not remove the clean bench from its shipping skid until it is ready to be placed

into its final location. Move the unit by placing a flat, low dolly under the

shipping skid, or by using a floor jack.

!

!

UNAUTHORIZED RETURNS WILL NOT BE ACCEPTED.

IF YOUR BENCH WAS DAMAGED IN TRANSIT, YOU MUST

FILE A CLAIM DIRECTLY WITH THE FREIGHT CARRIER.

LABCONCO CORPORATION AND ITS DEALERS ARE NOT

RESPONSIBLE FOR SHIPPING DAMAGES.

Do not move the bench by tilting it onto a hand truck.

Ne pas déplacer l’hotte au moyen de incliner sur un diable.

Clean Bench Components

Labconco manufactures XT Clean Benches for operation on 115V or 230V. Each

of these benches is available in 3-foot models with work surface depths of 29”.

Locate the cabinet model you received in the following group of tables. Verify

that the components listed are present and undamaged.

Catalog # Description

3200000 Purifier XT Clean Bench, 115 VAC

3200001 to -04 Purifier XT Clean Bench, 230 VAC

Plus the Following:

Product Service 1-800-522-7658

9

Page 14

Chapter 3: Getting Started

Part # Component Description

3208000 Purifier Clean Bench Owner’s Manual CD

3952900 Strap, Lashing

3894400 Bracket, Tie-Down

1337100 Power Cord, 115V

Or (one of the following)

1338000 Power Cord, 230V United States

1332600 Power Cord, 230V United Kingdom

1336100 Power Cord, 230V Schuko

1332700 Power Cord, 230V China/Australia

If you did not receive one or more of the components listed for your clean bench,

or if any of the components are damaged, contact the Labconco Product Service

Department immediately for further instructions @ 1-800-821-5525.

Removing the Shipping Skid

LEAVE THE CLEAN BENCH ATTACHED TO ITS SHIPPING

)

After you verify the XT Clean Bench components, move your XT Clean Bench to

the location where you want to install it. Then, follow the steps listed below to

remove the shipping skid from your unit.

To remove the shipping skid:

1. Remove the plastic wrapping and packaging material from the bench.

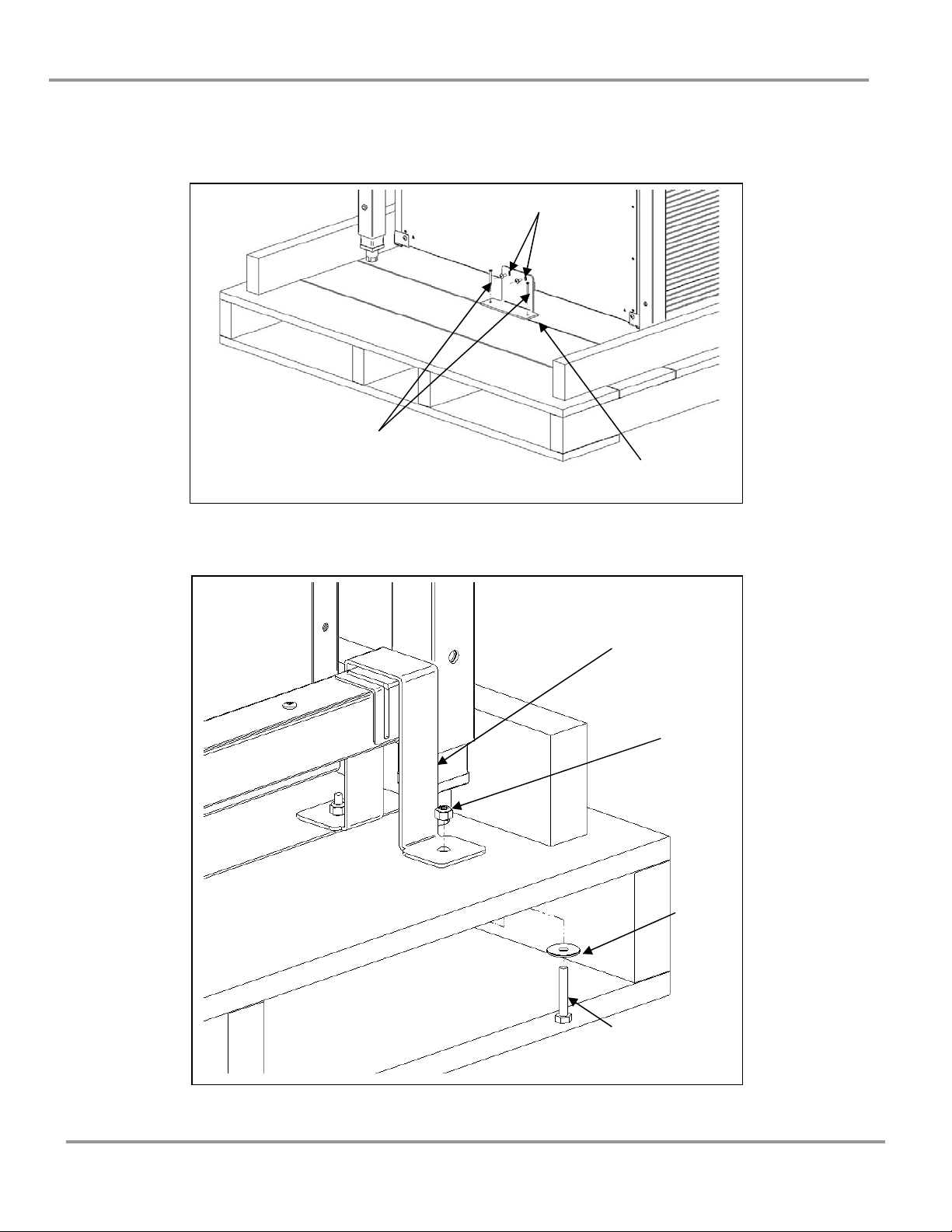

2. Remove and discard the three brackets holding the unit to the skid, as shown

in Figures 3-1a and 3-1b.

3. Lift clean bench off of shipping skid using a mechanical lift, forklift, or two

pallet jacks with boards slid underneath the clean bench spanning the two

pallet jacks.

4. Set the four legs to desired working height by removing the four bolts,

extending each leg and replacing each bolt and washers, secure acorn nut

firmly. The integrated stand has three working height options. The lowest

hole will set the worksurface height at 29.2”, and each higher hole raises that

height by 1.5”. To raise clean bench off of its legs, use mechanical lift, fork

lift, or pallet jack with boards as shown in Figure 3-2.

5. Once in final location, adjust leveling feet to ensure clean bench is level.

SKID UNTIL IT IS AS CLOSE TO ITS FINAL LOCATION AS

POSSIBLE. MOVE THE UNIT BY USING A SUITABLE

FLOOR JACK, OR BY PLACING A FURNITURE DOLLY

UNDERNEATH THE SKID. DO NOT MOVE THE BENCH BY

TILTING IT ONTO A HAND TRUCK.

10

Product Service 1-800-522-7658

Page 15

Figure 3-1a

Chapter 3: Getting Started

Cabinet screws (2)

Figure 3-1b

Wood screws (2)

Shipping

Bracket

Shipping

Bracket

(1 ea side)

Nut

(2 ea

side)

Product Service 1-800-522-7658

Washer

(2 ea

side)

Bolt

(2 ea side)

11

Page 16

Chapter 3: Getting Started

Figure 3-2

Bolt, Washers &

Acorn Nut (ea leg)

Support

Boards

Pallet Jack

12

Product Service 1-800-522-7658

Page 17

Chapter 3: Getting Started

Securing the Purifier XT Clean Bench

BEFORE USING THE CLEAN BENCH, IT MUST BE

PROPERLY SECURED TO A WALL OR STRUCTURAL

)

Obtain the following items from the box located on the Purifier XT Clean Bench

worksurface:

(1) Wall-Mount Bracket p/n 3894400

(2) Lashing Strap p/n 3952900

Follow the steps below to secure the clean bench to a wall or other significant

vertical structural building element.

To secure the clean bench:

1. Using proper screws, secure the Wall-Mount Bracket to the wall behind the

final position of the clean bench. Center bracket behind clean bench final

position, with the bracket approximately 68” (1700mm) off the floor. See

Figure 3-3 below.

2. Run the Lashing Strap through the slot in the Wall-Mount Bracket, then

through one of the slots on the back of the clean bench. Run the Lashing

Strap through the other slot on the back of the clean bench. Run the Lashing

Strap through the ratchet mechanism on the strap. See Figure 3-4 below.

3. Push the clean bench against the wall and cinch the Lashing Strap down.

Strap does not have to be tight, but slack should be minimal.

Figure 3-3

BEAM TO AVOID TIPPING OVER.

Wall

Secure

through both

holes to wall

Product Service 1-800-522-7658

Wall-Mount

Bracket

13

Page 18

Chapter 3: Getting Started

Figure 3-4

Back of

clean bench

Slot for

Lashing

Strap

Initial Certification

Prior to use, all Purifier XT Clean Benches should be certified by a qualified

certifier. Under normal operating conditions, the Purifier XT Clean Bench should

be recertified at least annually and when moved or serviced. The certifier should

perform the following tests, as recommended in Institute of Environmental

Sciences and Technology, IEST RP-CC0002.2:

• Airflow Velocity Test

• HEPA Filter Leak Test

• Introduction Leak Test/Backstreaming (when appropriate)

• Airborne Particle Count (when appropriate)

• Lighting Intensity Test (when appropriate)

• Noise Level Test (when appropriate)

• Vibration Test (when appropriate)

In addition, the following tests should also be performed at the user’s discretion:

• Electrical Leakage and Ground Circuit Resistance Test

• Measurement of Line Voltage and Current

• Smoke Test to determine airflow patterns

THE XT CLEAN BENCH USES A SELF-ADJUSTING ECM

MOTOR TO MAINTAIN AIRFLOW ACROSS THE WORK

)

AREA. THE SPEED CONTROL

14

Product Service 1-800-522-7658

Page 19

Chapter 3: Getting Started

ADJUSTMENT ESTABLISHES THE DESIRED FACE

VELOCITY (FPM), AND AS THE HEPA FILTERS LOAD, THE

MOTOR WILL SPEED UP TO MAINTAIN THE DESIRED

FACE VELOCITY. HAVE THE FACE VELOCITY CHECKED

AT LEAST ANNUALLY AS INDICATED IN CHAPTER 6:

MAINTAINING YOUR XT CLEAN BENCH. REPLACE HEPA

FILTERS WHEN FACE VELOCITY DROPS BELOW DESIRED

RANGE.

If you have any questions regarding certification agencies or need assistance in

locating one, contact Labconco’s Product Service Department at 1-800-821-5525.

Product Service 1-800-522-7658

15

Page 20

Chapter 3: Getting Started

Moving XT Clean Bench through Tight

Doorway

MAKE SURE THERE IS NO ALTERNATE DOORWAY OF

GREATER WIDTH. DISASSEMBLY OF UNIT INVOLVES

)

To remove the Side Windows:

1. Obtain a T20 Torx Head Driver Bit and electrical screwdriver or drill.

2. Unscrew all screws around both the right and left window frames as seen in

Figure 3-5a below. NOTE!!! Do NOT remove Screws next to a small cut-out

as seen in Figure 3-5b. Remove both side window assemblies.

SIGNIFICANT TIME AND LIFTING OF HEAVY

COMPONENTS.

Figure 3-5a

Side

Windows

Torx Screws

16

Product Service 1-800-522-7658

Page 21

Chapter 3: Getting Started

!

Figure 3-5b

Cut-outs

Leave the

screws by

cut-outs

The Top Window assembly is heavy. Lift & handle with care.

L’ensemble première fenêtre est lourd. Soulever et manipuler

avec precaution.

Product Service 1-800-522-7658

17

Page 22

Chapter 3: Getting Started

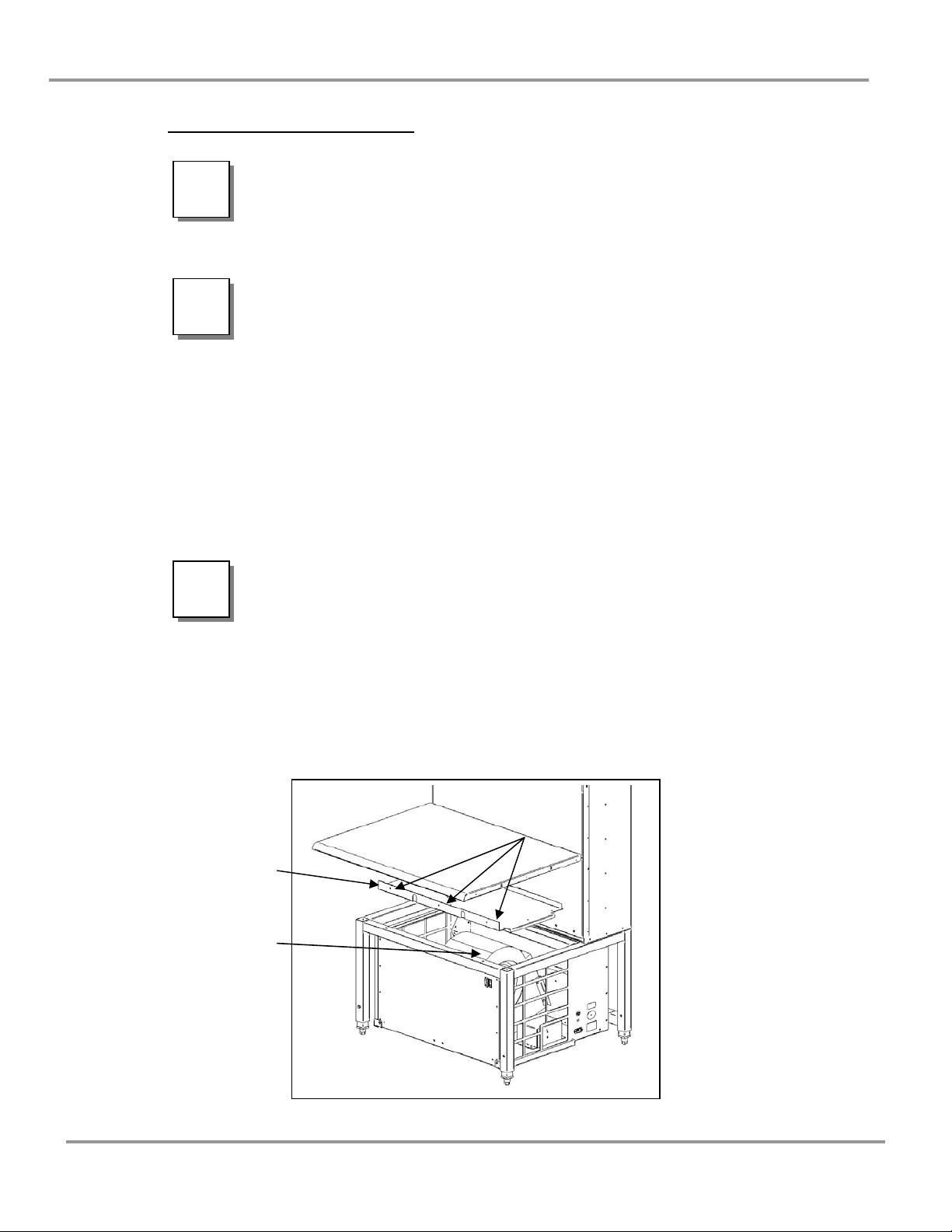

3. Remove the Torx Head Screws on top side and top back of unit to remove

Top Window as seen in Figure 3-5c.

4. Remove the two Bolts and Washers underneath Worksurface as shown in

Figure 3-5c.

5. Pull up on front edge of Worksurface, and then pull Worksurface out.

6. Reinstall components in reverse to reassemble the XT Clean Bench.

Figure 3-5c

Top

Window

Worksurface

Worksurface

Bolts & Washers

18

Product Service 1-800-522-7658

Page 23

C

HHAAPPTTEERR

C

T

HHEEOORRY

T

S

AAFFEETTYY

S

All clean benches operate using the following principles:

• Filtration and retention of particulates by High Efficiency Particulate Air

(HEPA) filter(s)

• Laminar airflow

The major components in a clean bench are:

• The HEPA filter

• The motor/blower to force air through the unit

• A speed control for the motor

HEPA Filters

Y

O

O

P

P

4

4

F

O

F

O

PPEERRAATTIIOONN

RREECCAAUUTTIIOONNSS

A

A

NNDD

HEPA filters are disposable, dry-type particulate filters. The filter material or media

is typically made of borosilicate microfibers that are made into a thin sheet, in a

process similar to the production of paper. This sheet is folded, or pleated to increase

its surface area. The pleats are held in place by aluminum diffusers or by beads of

glue that add rigidity to the media pack. The media pack is then set into a suitable

frame, and the perimeter sealed to the filter frame, as shown in Figure 4-1.

The HEPA filter media is very fragile. Do not touch or contact

!

Product Service 1-800-522-7658

the media surface. If you think the surface of a HEPA filter is

damaged, DO NOT USE THE BENCH. Have the HEPA filter

integrity tested by a qualified certifier before using the cabinet.

19

Page 24

Chapter 4: Theory of Operation and Safety Precautions

HEPA Filters are only effective against particulate material.

Gases will pass through the filter.

Le matériel du filtre HEPA est très fragile. Ne pas toucher ou

!

être en contact avec la surface du matériel. Si vous pensez que la

surface d’un filter HEPA est endommagé, NE PAS UTILISER

L’HOTTE. Faire tester l’intégrité du filter HEPA par un

certificateur qualifié avant d’utiliser l’hotte.

Filtres HPA ne sont efficaces que contre les matières

particulaires. Le gaz passe à travers du filtre.

Figure 4-1

Continuous

Sheet of Flat

Filter Medium

Glue Beads

Note - The HEPA Filters in the Purifier XT Clean Bench

are separatorless filters that utilize a series of glue beads to

hold the filter medium in place.

Filter

Frame

Adhesive bond

between Filter

Pack and Integral

Frame

20

Product Service 1-800-522-7658

Page 25

Chapter 4: Theory of Operation and Safety Precautions

Laminar Airflow

Laminar airflow is defined as the movement of a body of air in a single direction,

with a uniform velocity. In practice, the horizontal laminar flow of sterile air in

the clean bench flushes out any aerosol generated in the work area of the bench.

This sterile airflow maintains the sterility of sterile items inside the clean bench.

In order to be true laminar flow, a number of individual velocity test points (The

Velocity Profile) must be +/- 20 % of the average of all the test points. This is

shown graphically in Figure 4-2.

Figure 4-2

Motor/Blower

The motor/blower assembly pulls air through the prefilters on the bottom sides of

the bench, and flows through the HEPA filter, which then flows horizontally

through the work area.

Product Service 1-800-522-7658

21

Page 26

Chapter 4: Theory of Operation and Safety Precautions

Speed Control

The speed control should only be adjusted by a qualified

!

!

The speed control is an electronic circuit that allows the certifier to set the air face

velocity (fpm) by adjusting its voltage.

)

!

!

certifier.

Le contrôle de la vitesse doit être réglée uniquement par un

certificateur qualifié.

THE XT CLEAN BENCH USES A SELF-ADJUSTING ECM

MOTOR TO MAINTAIN AIRFLOW ACROSS THE WORK

AREA. THE SPEED CONTROL

ADJUSTMENT ESTABLISHES THE DESIRED FACE

VELOCITY (FPM), AND AS THE HEPA FILTERS LOAD, THE

MOTOR WILL SPEED UP TO MAINTAIN THE DESIRED

FACE VELOCITY. HAVE THE FACE VELOCITY CHECKED

AT LEAST ANNUALLY AS INDICATED IN CHAPTER 6:

MAINTAINING YOUR XT CLEAN BENCH. REPLACE HEPA

FILTERS WHEN FACE VELOCITY DROPS BELOW DESIRED

RANGE.

Never block or obstruct the air intake at the bottom sides of

the clean bench.

Ne jamais bloquer l’entrée d’air au dessus de l’hotte.

Safety Precautions

Because air from the work area is dispersed directly into the

laboratory, the Purifier XT Clean Bench should never be used

in conjunction with biohazardous material, toxins, or

radionuclides. The operator and qualified safety officer(s)

must carefully assess the risk associated with any operation

performed in a Clean Bench.

Étant donné que l’air de la zone de travail est dispersée

directement dans le laboratoire, l’hotte à flux laminaire Purifier

22

XT ne doit jamais être utilisé conjointment avec des matières

Product Service 1-800-522-7658

Page 27

!

!

Chapter 4: Theory of Operation and Safety Precautions

infectieuses, des toxins ou des radionucléides. L’opérateur et

l’oficiel de sécurité competent doivent soigneusement évaluer le

risque associé à tous les opérations effectuées dans un hotte à

flux laminaire.

The Purifier XT Clean Bench should be certified by a qualified

certification technician before its initial use. The clean bench

should be recertified whenever it is relocated, serviced, or at

least annually thereafter.

Some components of the Purifier XT Clean Bench should only

be serviced by a qualified certification technician. Ensure that

the unit is connected to electrical service in accordance with

local and national electrical codes. Failure to do so may create

a fire or electrical hazard. Do not remove or service any

electrical components without first disconnecting the clean

bench from electrical service.

Le Purifier Clean Bench doit être certifié par un technician de

certification qualifié avant la première utilization. L’hotte doit

être certifié à nouveau chaque fois qu’il est déplacé, reparé ou au

moins une fois par an par la suite.

Certains composants de la Purifier Clean Bench ne doit être

réparé que par un technician de certification qualifié. Assurezvous que l’appareil est connecté à un service électrique qui est en

conformité avec les règlements de sécurité locaux et nationaux.

Non-respect des règlements peut causer un incendie ou autre

danger électrique. Ne pas enlever ou réparer des compasants

électriques sans débrancher l’hotte du service électrique.

Avoid the use of flammable gases or solvents in the clean

bench. An open flame should NOT be used in the clean bench.

Open flames may disrupt the airflow patterns in the Clean

Bench. Gases under high pressure should not be used in the

Purifier Clean Bench, as they may disrupt the airflow patterns.

The surface of the HEPA filter is fragile and should not be

touched. Care must be taken to avoid puncturing the HEPA

filter during installation or normal operation. If you suspect

that the HEPA filter has been damaged, DO NOT use the clean

bench; contact a local certification agency or Labconco at 800821-5525 for recertification information.

Évitez l’utilisation de gaz inflammables ou de solvants pour

nettoyer l’hotte. Une flamme nue ne doit PAS être utilisé dans

l’hotte. Flammes nues peuvent interrompre le circuit du courant

Product Service 1-800-522-7658

23

Page 28

Chapter 4: Theory of Operation and Safety Precautions

d’air dams l’hotte. Gaz sous haute pression ne doit pas être

utilisé dans l’hotte, car il peut interrompre le ciruit du courant

d’air dans l’hotte.

La surface du filtre HEPA est fragile et ne doit pas être touchée.

Faites attention de ne pas percer le filtre HEPA lors de

l’installtion ou le fonctionnement normal. Si vous pensez que le

filtre HEPA a été endommagé. NE PAS utiliser l’hotte, prenez

contact avec une agence de certification locale ou avec Labconco

à 800-821-5525 pour de plus amples informations sur la

recertification.

THE HEPA FILTER IN THE PURIFIER XT CLEAN BENCH

WILL GRADUALLY ACCUMULATE AIRBORNE

)

)

PARTICULATE MATTER FROM THE ROOM. THE RATE OF

ACCUMULATION WILL DEPEND UPON THE

CLEANLINESS OF THE ROOM AIR, THE AMOUNT OF TIME

THE CLEAN BENCH IS OPERATING AND THE NATURE OF

WORK BEING DONE IN THE CLEAN BENCH. IN TYPICAL

INSTALLATIONS AND USAGE, THE HEPA FILTERS WILL

LAST TWO TO FIVE YEARS BEFORE REQUIRING

REPLACEMENT.

PROPER OPERATION OF THE CLEAN BENCH DEPENDS

LARGELY UPON THE CLEAN BENCH’S LOCATION AND

THE OPERATOR’S WORK HABITS. CONSULT THE

Installation AND Normal Operation SECTIONS OF THIS

MANUAL FOR FURTHER DETAILS.

WIPE THE INTERIOR SURFACES OF THE CLEAN BENCH

WITH STAINLESS STEEL CLEANER OR 70% ETHANOL.

DO NOT USE ABRASIVE CLEANERS, BLEACH OR

SOLVENTS, AS THEY MAY DAMAGE THE WORK

SURFACE.

WHEN SURFACE DISINFECTING THE PURIFIER:

• AVOID SPLASHING THE DISINFECTING SOLUTION ON

SKIN OR CLOTHING.

• ENSURE ADEQUATE VENTILATION.

• CAREFULLY FOLLOW THE MANUFACTURER’S SAFETY

INSTRUCTIONS WHEN HANDLING DISINFECTANTS AND

ALWAYS DISPOSE OF DISINFECTING SOLUTIONS IN

ACCORDANCE WITH LOCAL AND NATIONAL LAWS.

24

Product Service 1-800-522-7658

Page 29

C

HHAAPPTTEERR

C

U

SSIINNG

U

B

EENNCCHH

B

Starting the Clean Bench

Before starting the Clean Bench, plug the power cord in and make sure the Circuit

Breaker is depressed. To turn on the Clean Bench, push the blower switch to the

“ON” position, as shown in Figure 5-1.

Figure 5-1

G

Y

Y

OOUURR

5

5

X

T

X

T

C

C

LLEEAANN

On/Off

Switch

Product Service 1-800-522-7658

Circuit Breaker

Power Cord Plug-in

25

Page 30

Chapter 5: Using Your XT Clean Bench

Use of the Clean Bench

Planning

Start-Up

Loading Materials and Equipment

Work Techniques

Final Purging

• Thoroughly understand procedures and equipment before beginning work.

• Arrange for minimal disruptions, such as room traffic or entry into the

room, while the clean bench is in use.

• Turn on clean bench blower.

• Check the prefilter for obstructions.

• Wipe down the interior surfaces of the clean bench with stainless steel

cleaner or 70% ethanol. DO NOT use abrasive cleaners, bleach or

solvents, as they may damage the work surface of the clean bench.

• Allow the clean bench to operate undisturbed for 5 to 15 minutes before

loading materials.

• Wear long sleeved lab coat with knit cuffs and over-the-cuff rubber

gloves. Use protective eyewear.

• Only load the materials required for the procedure. Do not overload the

clean bench.

• Do not obstruct the air diffuser.

• Large objects should not be placed close together.

• After loading the clean bench, wait 2 to 3 minutes to purge airborne

contaminants from the work area.

• Keep all materials at least 4 inches inside of the clean bench and perform

all contaminated operations as far to the front of the work area as possible.

• Perform sterile operations as far to the rear of the work area as possible.

• Segregate all clean and contaminated materials in the work area.

• Arrange materials to minimize the movement of contaminated materials

into clean areas.

• Keep all discarded contaminated material to the front of the clean bench.

• Avoid moving materials or the operator’s hands and arms in and out of the

work area during use.

• Avoid the use of an open flame.

• Use proper aseptic technique. – “Sterile Air First”

• Avoid using techniques or procedures that disrupt the airflow patterns of

the clean bench.

• Upon completion of work, the clean bench should be allowed to operate

for 2 to 3 minutes undisturbed, to purge airborne contaminants from the

work area.

26

Product Service 1-800-522-7658

Page 31

Chapter 5: Using Your XT Clean Bench

Wipe-Down

• Wipe down the interior surfaces of the clean bench with stainless steel

cleaner or 70% ethanol and allow to dry.

Shutdown

• Turn off the clean bench blower.

Product Service 1-800-522-7658

27

Page 32

C

HHAAPPTTEERR

C

M

C

Now that you have an understanding of how to work in the XT Clean Bench, we

will review the suggested maintenance schedule and the common service

operations necessary to maintain your clean bench for peak performance.

AAIINNTTAAIINNIINNG

M

LLEEAANN

C

Many of the service operations should be performed only by

!

!

trained and experienced certification technicians. DO NOT

attempt to perform these operations if you are not properly

trained. The service operations that require qualified certifiers

are preceded by the wrench icon.

La plupart des operations d’entretien doivent être effectués

uniquement par des techniciens de certification qualifiés et

expérimentés. NE PAS tenter effectuer ces operations si vous

n’êtes pas bien formés. Les operations de service qui exigent des

certificateurs qualifies sont précédés par l’icône de la clé.

6

6

B

EENNCCHH

B

G

Y

Y

OOUURR

X

X

T

T

28

Product Service 1-800-522-7658

Page 33

Chapter 6: Maintaining Your XT Clean Bench

Routine Maintenance Schedule

Under normal operation, your Purifier XT Clean Bench will require little routine

maintenance. The following schedule is recommended:

Weekly

• Wipe down the interior surfaces of the clean bench with stainless steel

cleaner or 70% ethanol and allow to dry.

• Using a damp cloth, clean the exterior surfaces of the clean bench,

particularly the front and top of the clean bench to remove any

accumulated dust.

Monthly (or more often as required)

• Check all service valves, if so equipped, for proper operation.

• Check the prefilters and replace if necessary. The prefilters should be

replaced at least quarterly.

• All weekly activities.

Quarterly

• Replace the prefilter. See Appendix A: XT Clean Bench Components for

• All monthly activities.

Annually

• Have the clean bench recertified by a qualified certification technician.

• All quarterly activities.

ordering information.

Product Service 1-800-522-7658

29

Page 34

Chapter 6: Maintaining Your XT Clean Bench

Service Operations

Resetting the Circuit Breaker:

1. The circuit breaker is located next to the power cord on the lower right panel

of the bench as shown in Figure 6-1. If the circuit breaker trips, it can be reset

by pressing the white button in.

Pre-Filter

Retainer

Changing the Prefilter:

The prefilter should be replaced at least quarterly, or more often as conditions

require. See Appendix A: XT Clean Bench Components for replacement prefilter

ordering information.

1. Make sure the clean bench is off.

2. Using a Phillips screwdriver, remove the prefilter retainer(s) located on the

front edge of the prefilters, as shown on Figure 6-1.

3. Remove both prefilters by sliding them straight forward.

4. Install new prefilters by reversing the above steps.

Do NOT contact blower wheel while still in motion.

!

NE PAS être en contact avec la roué du ventilateur tant qu’il est

en marche.

Figure 6-1

Circuit Breaker

30

Product Service 1-800-522-7658

Page 35

Chapter 6: Maintaining Your XT Clean Bench

Speed Control Adjustment:

!

1. Remove the right side prefilter only, as described on previous page.

2. Locate the speed control. It is in the electrical box mounted on the floor of the

blower housing. The speed control rheostat is just behind the small hole in the

electrical box.

3. Using a small jewelers straight blade screwdriver turn the speed control screw

clockwise to decrease the blower speed, or counter-clockwise to increase the

blower speed as shown in Figure 6-2.

4. After completing the speed control adjustment, establish the average air

velocity, using a calibrated thermal anemometer with an accuracy of ± 3%.

Establishing a boundary of 6 inches from the sides, top and bottom, measure

the velocities in 6-inch increments, 6 inches in front of the diffuser. This

methodology is more fully defined in the IEST recommended practice #IESTRP-CC0002.2

5. The average velocity should be 65 ± 10 FPM, with all measured values falling

within ± 20% of the average.

6. Reinstall the prefilters.

Product Service 1-800-522-7658

Adjusting the speed control will have an effect on the air

velocities and the effectiveness of the clean bench. Only a

qualified certification technician, as part of the recertification

process, should adjust the speed control.

Do NOT contact blower wheel while still in motion.

NE PAS être en contact avec la roué du ventilateur tant qu’il est

en marche.

Figure 6-2

Electrical

Box

Speed

Control

Adjustment

31

Page 36

Chapter 6: Maintaining Your XT Clean Bench

Diffuser Removal:

1. Locate and remove the diffuser screws, shown in Figure 6-3. Pull the diffuser

straight out.

HEPA Filter Replacement:

1. Unplug the clean bench.

2. Remove the diffuser as described above.

3. Loosen and remove the filter clamps and filter center strap as shown in Figure

6-4.

)

4. Gently pull out the Secondary HEPA filter gasket on the top and both sides of

the HEPA filter as shown in Figure 6-4. Save the gasket for reinstallation.

The HEPA filters should only be serviced by a qualified

certification technician. Following replacement of the HEPA

filters, a qualified certification technician MUST recertify the

clean bench.

THE TOP, BOTTOM AND SIDE FILTER CLAMPS ARE

DIFFERENT ASSEMBLIES.

Figure 6-3

32

Product Service 1-800-522-7658

Page 37

Chapter 6: Maintaining Your XT Clean Bench

Filter

Gasket (both

sides and top

of HEPAs)

5. Remove the filter by pulling it straight out of the clean bench.

6. Install the new filter(s) by placing the filter(s) back into the clean bench.

7. Reinstall the secondary HEPA filter gasket, ensuring that the seal is in place

8. Reinstall the Filter Center Strap. Thread screws into holes, but do not tighten.

9. Reinstall the HEPA filter clamps. Tighten the clamp bolt until the filter

10. Tighten the Filter Center Strap screws. Plug the clean bench back in.

11. Test the filter for leakage as described in IEST recommended practice #IEST-

12. Reinstall the diffuser.

13. Establish the average velocity of the filter. It should be 65 ± 10 FPM, with all

Motor/Blower Service:

)

Figure 6-4

Filter Clamps

(3 ea top, 3 ea

bottom, & 1

ea sides)

Filter Center

Strap

Make sure that the HEPA filter(s) is centered side-to-side in the clean bench.

completely around the sides and top of the filter frame(s).

gasket is compressed approximately 50% or 1/8 of an inch.

RP-CC0002.2.

values falling within ± 20% of the average.

THE MOTOR BEARINGS ARE PERMANENTLY

LUBRICATED AND SEALED. NO FURTHER LUBRICATION

IS NEEDED.

Product Service 1-800-522-7658

33

Page 38

Chapter 6: Maintaining Your XT Clean Bench

Motor/Blower Replacement:

A QUALIFIED CERTIFICATION TECHNICIAN SHOULD

SERVICE THE MOTOR/BLOWER. FOLLOWING

)

!

1. Unplug the clean bench.

2. Remove the prefilters, as described earlier.

3. Remove the side windows, and worksurface, as described in Chapter 3,

Section: Moving XT Clean Bench through Tight Doorway

4. Remove (3) Torx Head Screws to remove Blower Compartment Panel, as

shown in Figure 6-5. NOTE!!! Two other screws will be left in place.

5. Disconnect the two wiring harnesses from the head of the motor.

6. Remove two bolts on the blower housing flange (left side).

!

7. Pull Motor Blower Assembly at an angle to remove right side flange from

inside plenum compartment.

8. Remove Motor Blower Assembly from Blower Compartment.

9. To replace the motor/blower, reverse the above steps.

10. Recertify the unit before use.

REPLACEMENT OF A MOTOR/BLOWER, A QUALIFIED

CERTIFICATION TECHNICIAN MUST RECERTIFY THE

CLEAN BENCH.

Do NOT contact blower wheel while still in motion.

NE PAS être en contact avec la roué du ventilateur tant qu’il est

en marche.

The motor/blower assembly is heavy. Lift & handle with care.

L’ensemble moteur/ventilateur est lourd. Soulever et manipuler

avec precaution.

Blower

Compartment

Panel

Blower Motor

Assembly

34

(3) Torx Head

Screws from here

Product Service 1-800-522-7658

Figure 6-5

Page 39

Chapter 6: Maintaining Your XT Clean Bench

Storage

IF THE XT CLEAN BENCH IS TO BE LEFT UNUSED FOR

MORE THAN ONE MONTH THE UNIT SHOULD BE

)

1. Unplug the clean bench.

2. Cover and seal the prefilters and the work area opening with plastic sheeting.

!

!

PREPARED FOR STORAGE.

The clean bench should not be stored in areas of excess

humidity or temperature extremes. If the clean bench is

moved during storage, it should be recertified before use.

L’hotte ne doit pas être entreposés dans des zones de l’excès

d’humidité ou de températures extrêmes. Si l’hotte est déplacée

pendant le stockage, il doit être certifié de nouveu avant

l’utilisation.

Product Service 1-800-522-7658

35

Page 40

C

HHAAPPTTEERR

C

7

7

T

RROOUUBBLLEESSHHOOOOTTIINNGG

T

Refer to the following table if your Purifier XT Clean Bench fails to operate

properly. If the suggested corrective actions do not solve your problem, contact

Labconco Product Service for additional assistance.

PROBLEM CAUSE CORRECTIVE ACTION

Blower and lights

won’t turn on

Motor won’t run

Contamination of

work in the clean

bench

Contamination of

work in the clean

bench (cont.)

Excessive vibration

Unit not plugged into

outlet

Circuit breakers tripped Reset circuit breakers.

Speed control out of

adjustment

Defective speed control Replace speed control.

Improper technique or

procedure for the clean

bench

External factors are

disrupting the clean

bench airflow patterns

or acting as a source of

contamination

Clean bench is out of

adjustment/HEPA

filter(s) are defective

Motor/blower out of

adjustment

Application requires

equipment isolation

Plug the clean bench into appropriate

electrical service.

Have speed control adjusted by a

qualified certifier.

See “Use of the XT Clean Bench”

section of this manual.

See “Installation” section of this

manual.

Have clean bench recertified.

Repair/Replace Motor/Blower Assy.

Accessory vibration table.

36

Product Service 1-800-522-7658

Page 41

A

PPPPEENNDDIIXX

A

X

T

X

T

C

C

Illustration A-1 indicates the location of the following service parts:

Purifier XT Clean Bench Replacement Parts

Item Quantity Part No. Description

1 2 3838402 HEPA Filter

2 2 3768900 Pre-Filter

3 1 3832206 Motor/Blower Assembly

4 2 1934601 Pass-Thru Iris Port

C

LLEEAANN

C

OOMMPPOONNEENNTTSS

A

A

B

B

EENNCCHH

Product Service 1-800-522-7658

37

Page 42

Appendix A: Clean Bench Components

1

A-1

2

4

3

38

Product Service 1-800-522-7658

Page 43

A

PPPPEENNDDIIXX

A

D

IIMMEENNSSIIOONNSS

D

Worksurface Height D 29.2, 30.7, 32.2

Width A 38.6

Depth B 41.6

Shipping Height C 85.1

Working Height 91.6-94.6

Interior Width E 37.5

Interior Depth F 28.6

Interior Height G 60.7

B

B

Inches

B-1

Product Service 1-800-522-7658

39

Page 44

A

PPPPEENNDDIIXX

A

X

T

C

X

S

S

Electrical Data

Bench Model Electrical Requirements

3200000 115 VAC – 60 Hz, 1 Phase – 10 Amps

Bench Model Electrical Requirements

3200001 to -04 230 VAC – 50/60 Hz, 1 Phase – 6 Amps

T

PPEECCIIFFIICCAATTIIOONNSS

LLEEAANN

C

C

C

B

B

EENNCCHH

Motor Specifications

Bench Model Electrical Requirements

3200000 to -04 115 VAC / 230 VAC – 50/60 Hz, 6.0 Full Load

Amps

3/4 H.P. ECM Motor

40

Product Service 1-800-522-7658

Page 45

Appendix C: XT Clean Bench Specifications

Environmental Conditions

• Indoor use only.

• Maximum altitude: 6562 feet (2000 meters).

• Ambient temperature range: 41° to 104°F (5° to 40°C).

• Maximum relative humidity: 80% for temperatures up to 88°F (31°C),

decreasing linearly to 50% relative humidity at 104°F (40°C).

• Main supply voltage fluctuations not to exceed ±10% of the nominal

voltage.

• Transient overvoltages according to Installation Categories II

(Overvoltage Categories per IEC 1010). Temporary voltage spikes on the

AC input line that may be as high as 1500V for 115V models and 2500V

for 230V models are allowed.

• Used in an environment of Pollution degrees 2 (i.e., where normally only

non-conductive atmospheres are present). Occasionally, however, a

temporary conductivity caused by condensation must be expected, in

accordance with IEC 664.

Product Service 1-800-522-7658

41

Page 46

Appendix C: XT Clean Bench Specifications

C-1

C-2

42

Product Service 1-800-522-7658

Page 47

A

PPPPEENNDDIIXX

A

X

T

X

T

A

A

Ergonomic Chair with Armrests (# 3744000)

Chair has 6-way articulating seat and back control for personalized adjustment.

Pneumatic mechanism adjusts seat height from 18.25" to 25.75". Five-leg black

reinforced composite base rests on 2" ball bearing casters. Aluminum support ring.

Removable arm rests. Black vinyl upholstery. Shipping weight 35 lbs. (15.9 kg).

Adjustable Footrest (# 3746000)

Elevates feet and permits angle repositioning while in use. 18.5" w x 11.5" d x 8" h.

Shipping weight 6 lbs. (2.7 kg).

C

LLEEAANN

C

CCCCEESSSSOORRIIEESS

D

D

B

B

EENNCCHH

Product Service 1-800-522-7658

43

Page 48

A

PPPPEENNDDIIXX

A

Q

UUIICCKK

Q

X

X

T

T

C

C

Grid Distance from Sidewalls (inches) 6

E

E

C

HHAARRTT

C

LLEEAANN

Avg. Velocity Reading Grid (inches) 6 x 6

Grid Distance from Diffuser (inches) 6

Exhaust Volume Range (CFM) 950-1000

Number of Laskin Nozzles needed 2

B

B

HEPA Filter Dims. (in.) 60 x 18 x 3

Average Velocity (FPM) 65 ±10

F

OORR

F

EENNCCHHEESS

Width (feet) 3’

Work Area (ft2) 15.0

Motor HP 3/4

P

P

UURRIIFFIIEERR

44

Product Service 1-800-522-7658

Page 49

Product Service 1-800-522-7658

45

Loading...

Loading...