Page 1

PuriCare

™

Ve rtical Flow Stations

Models

3830000

3830020

User’s Manual

LABCONCO CORPORATION

8811 PROSPECT AVENUE

KANSAS CITY, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Labconco’s Mascot,

Labby the LABster

Register your product online at

www.labconco.com/productreg.html

or return the attached card and

receive FREE LabbyWear

™

!

Page 2

Copyright Information

Copyright © 2003 Labconco Corporation. All rights reserved.

Labconco Corporation

8811 Prospect Avenue

Kansas City, Missouri 64132

The information contained in this manual and the accompanying product are copyrighted and all rights are

reserved by Labconco Corporation. Labconco Corporation reserves the right to make periodic design

changes without obligation to notify any person or entity of such change.

PuriCare™ is a trademark of Labconco Corporation.

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas of

defective material and workmanship, provided such defect results from normal and proper use of the

equipment.

The warranty for all Labconco products will expire one year from date of installation or two years from

date of shipment from Labconco, whichever is sooner, except the following:

• Purifier® Delta® Series Biological Safety Cabinets and PuriCare™ Vertical Flow Stations carry a

three-year warranty from date of installation or four years from date of shipment from Labconco,

whichever is sooner.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the event of a

warranty claim, contact Labconco Corporation or the dealer who sold you the product. If the cause is

determined to be a manufacturing fault, the dealer or Labconco Corporation will repair or replace all

defective parts to restore the unit to operation. Under no circumstances shall Labconco Corporation be

liable for indirect, consequential, or special damages of any kind. This statement may be altered by a

specific published amendment. No individual has authorization to alter the provisions of this warranty

policy or its amendments. Lamps and filters are not covered by this warranty. Damage due to corrosion or

accidental breakage is also not covered.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar with

any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water,

land, or air and to comply with such regulations. Labconco Corporation is held harmless with respect to

user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical

assistance, contact Labconco’s Customer Service Department or Labconco’s Product

)

Visit Labconco’s web site at: http://www.labconco.com

Service Department at 1-800-821-5525 or 1-816-333-8811, between the hours of 7:00

a.m. and 6:00 p.m., Central Standard Time.

or email Labconco at: labconco@labconco.com.

Part #3794300, Rev A

ECO C722

Page 3

T

AABBLLEE

T

CHAPTER 1: INTRODUCTION 1

About This Manual 2

Typographical Conventions 3

CHAPTER 2: PREREQUISITES 5

Location Requirements 6

Exhaust Requirements 6

Electrical Requirements 7

Space Requirements 8

Overhead Clearance 8

CHAPTER 3: GETTING STARTED 9

Unpacking Your Vertical Flow Station 10

PuriCare Components 11

Preparing the Station for Operation 11

Exhaust System Requirements 12

Initial Certification 12

CHAPTER 4: THEORY OF OPERATION AND

HEPA Filters 14

Directional Airflow 15

Impellers and Motor/Blower 16

Speed Controls 16

Station Air Intakes (Grilles), Ductwork &

Air Balance Controls 17

Safety Precautions 17

CHAPTER 5: USING YOUR PURICARE 21

Operating the Sash 21

Working in Your PuriCare 23

CHAPTER 6: MAINTAINING YOUR PURICARE 26

Routine Maintenance Schedule 26

Service Operations 27

O

O

SAFETY PRECAUTIONS 13

FF

C

OONNTTEENNTTSS

C

Page 4

Downflow Velocities 30

Downflow Velocity Grid Patterns 30

Inflow Velocity Calculation – Primary Method 30

Inflow Velocity Calculation – Secondary Method 31

Speed Control Adjustments 32

Supply HEPA Filter Replacement 33

Exhaust HEPA Filter Replacement 35

Impeller and Motor/Blower Maintenance & Replacement 36

Diffuser Removal 38

Storage 39

CHAPTER 7: MODIFYING YOUR VERTICAL FLOW

STATION 40

Installing a Shelf 40

CHAPTER 8: TROUBLESHOOTING 42

APPENDIX A: VERTICAL FLOW STATION COMPONENTS 44

APPENDIX B: VERTICAL FLOW STATION DIMENSIONS 46

APPENDIX C: VERTICAL FLOW STATION

SPECIFICATIONS 47

Electrical Data 47

Impeller Specifications 47

Motor Specifications 48

APPENDIX D: PURICARE ACCESSORIES 51

Shelf Kit 51

APPENDIX E: QUICK CHART FOR THE PURICARE

VERTICAL FLOW STATIONS 52

APPENDIX F: REFERENCES 53

DECLARATION OF CONFORMITY 54

Page 5

C

HHAAPPTTEERR

C

I

NNTTRROODDUUCCTTIIOONN

I

Congratulations on your purchase of a Labconco

PuriCare Series Vertical Flow Station. Your PuriCare

product is designed to protect you, your product and

your laboratory environment from aerosols. It is the

result of Labconco’s years of experience manufacturing

laboratory equipment, and many of its features were

suggested to us by users like you.

The PuriCare offers many unique features to enhance

safety, performance and ergonomics. To take full

advantage of them, please acquaint yourself with this

manual and keep it handy for future reference. If you

are unfamiliar with how Vertical Flow Stations operate,

please review Chapter 4: Theory of Operation and

Safety Precautions before you begin working in the

station. Even if you are an experienced user, please

review Chapter 5: Using Your Vertical Flow Station; it

describes your PuriCare’s features so that you can use

the station efficiently.

1

1

Product Service 1-800-522-7658

1

Page 6

Chapter 1: Introduction

About This Manual

This manual is designed to help you learn how to

install, use, and maintain your Vertical Flow Station.

Instructions for installing optional equipment on your

station are also included.

Chapter 1: Introduction provides a brief overview of

the Vertical Flow Station, explains the organization of

the manual, and defines the typographical conventions

used in the manual.

Chapter 2: Prerequisites explains what you need to do

to prepare your site before you install your Vertical

Flow Station. Electrical and service requirements are

discussed.

Chapter 3: Getting Started contains the information

you need to properly unpack, inspect, install, and

certify your Vertical Flow Station.

Chapter 4: Theory Of Operation And Safety

Precautions explains how the PuriCare operates and the

appropriate precautions you should take when using the

station.

Chapter 5: Using Your PuriCare discusses the basic

operation of your station. Information on how to

prepare, use and shut down your PuriCare are included.

Chapter 6: Maintaining Your PuriCare explains how to

perform routine maintenance on your Vertical Flow

Station. Information on how to safely disinfect the

interior of your station and replace the lamps are

included.

Chapter 7: Modifying Your Vertical Flow Station

describes how to install the optional equipment on the

station.

Chapter 8: Troubleshooting contains a table of

problems you may encounter while using your Vertical

Flow Station including the probable causes of the

problems and suggested corrective actions.

2

Product Service 1-800-522-7658

Page 7

Appendix A: Vertical Flow Station Components

contains labeled diagrams of all of its components.

Appendix B: Vertical Flow Station Dimensions contains

comprehensive diagrams showing all of the dimensions

for the PuriCare model.

Appendix C: Vertical Flow Station Specifications

contains the electrical requirements for the Vertical

Flow Station. Wiring diagrams for both the 115V and

230V models are also included.

Appendix D: PuriCare Accessories lists the part

number and descriptions of all of the accessories

available for your Vertical Flow Station.

Appendix E: Quick Chart for the PuriCare Vertical

Flow Station provides useful operating specifications.

Appendix F: References lists the various resources

available that deal with biosafety.

Chapter 1: Introduction

Typographical Conventions

Recognizing the following typographical conventions

will help you understand and use this manual:

• Book, chapter, and section titles are shown in italic

type (e.g., Chapter 3: Getting Started).

• Steps required to perform a task are presented in a

numbered format.

• Comments located in the margins provide

suggestions, reminders, and references.

• Critical biosafety information is presented in

boldface type in paragraphs that are preceded by the

biosafety icon. Failure to comply with the

information following a biosafety icon may result in

illness or death.

Product Service 1-800-522-7658

3

Page 8

Chapter 1: Introduction

!

)

115V

230V

• Critical information is presented in boldface type in

paragraphs that are preceded by the exclamation

icon. Failure to comply with the information

following an exclamation icon may result in injury

to the user or permanent damage to your Vertical

Flow Station.

• Critical information is presented in boldface type in

paragraphs that are preceded by the wrench icon.

These operations should only be performed by a

trained certifier or contractor. Failure to comply

with the information following a wrench icon may

result in injury to the user or permanent damage to

your Vertical Flow Station.

• Important information is presented in capitalized

type in paragraphs that are preceded by the pointer

icon. It is imperative that the information contained

in these paragraphs be thoroughly read and

understood by the user.

• Information that is specific to a particular model of

Vertical Flow Station is preceded by a number icon.

The 115V icon indicates the text is specific to the

115 volt models. The 230V icon indicates the text

is specific to the 230 volt models.

4

Product Service 1-800-522-7658

Page 9

C

HHAAPPTTEERR

C

P

RREERREEQQUUIISSIITTEESS

P

Before you install your Vertical Flow Station, you need

to prepare your site for installation. Carefully examine

the location where you intend to install your station.

You must be certain that the area is level and of solid

construction. In addition, a dedicated source of

electrical power must be located near the installation

site.

Carefully read this chapter to learn:

• the location requirements for your installation

site.

• the electrical power requirements for your

installation site.

• the exhaust requirements for your installation

site.

• the space requirements for your installation site.

Refer to Appendix C: Vertical Flow Station

Specifications for complete station electrical and

environmental conditions, specifications and

requirements.

2

2

Product Service 1-800-522-7658

5

Page 10

Chapter 2: Prerequisites

Location Requirements

The PuriCare should be located away

!

from traffic patterns, doors, fans,

ventilation registers, fume hoods and

any other air-handling device that

could disrupt its airflow patterns. All

windows in the room should be closed.

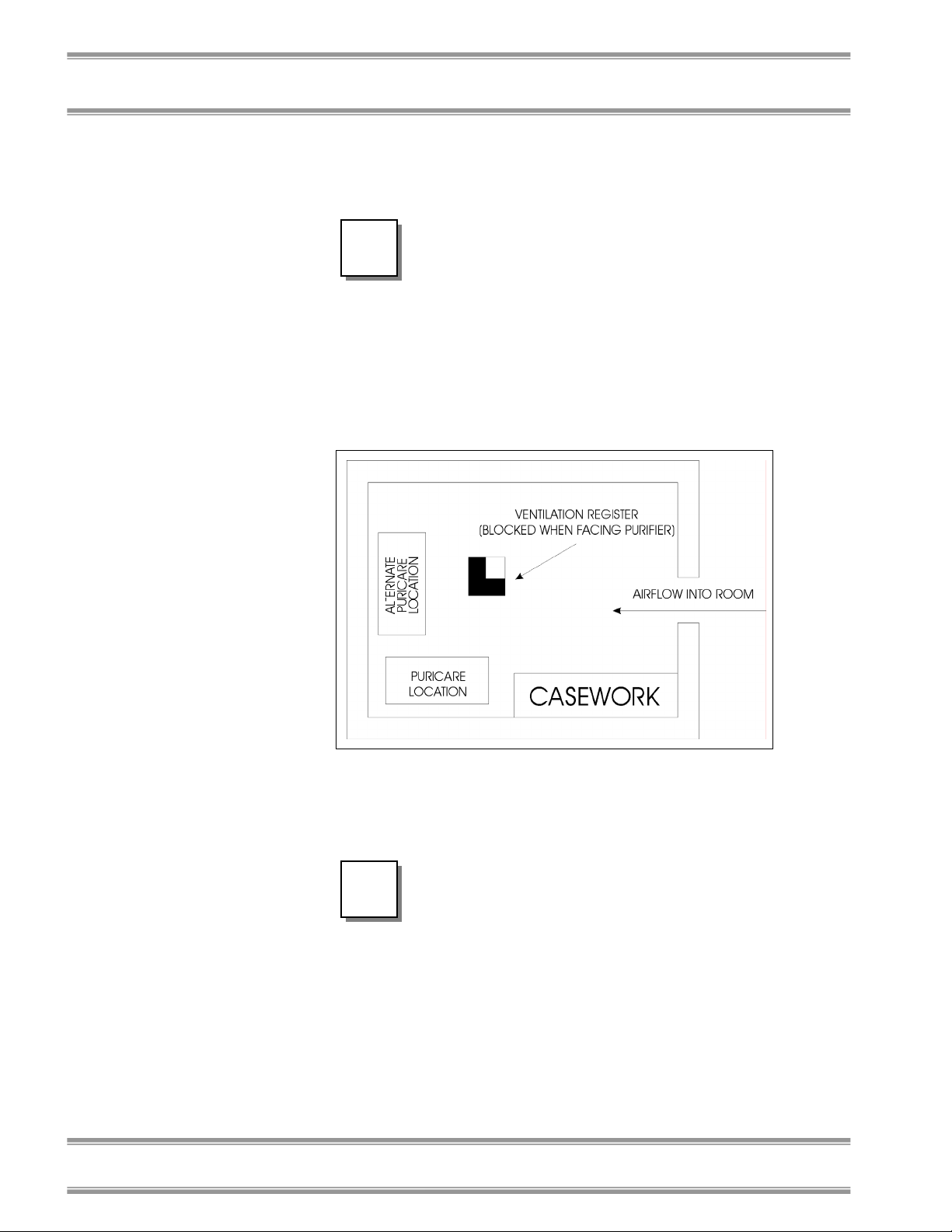

Figure 2-1 shows the optimum

location for the PuriCare.

Figure 2-1

6

Exhaust Requirements

THE VERTICAL FLOW STATION

DISCHARGES ITS FILTERED

)

EXHAUST AIR UNDERNEATH THE

UNIT. IT SHOULD BE PLACED AT

LEAST 12 INCHES AWAY FROM

ANY VERTICAL OBSTRUCTION TO

OPERATE PROPERLY.

Product Service 1-800-522-7658

Page 11

Electrical Requirements

The different PuriCare models have the following

electrical requirements:

Model # Requirements

38300- 00-09 115 VAC, 60 Hz, 12 Amps

38300- 20-29 230 VAC, 50 Hz, 6 Amps

All PuriCare Stations with model numbers ending in –

00 to –09 are designed for operation at 115 volts, 60Hz,

alternating current. PuriCare Stations with model

numbers ending in –20 to –29 are designed for

operation at 230 +/- 20 volts, 50 Hz alternating current.

A dedicated outlet with a circuit breaker rated at 20

Amps for 115 volt models and 10 Amps for 230 volt

models, should be located within 10 feet of the station.

Always follow the plug

manufacturer’s instructions for the

!

115V

proper assembly and testing of the

plug and power cord.

THE ELECTRICAL OUTLETS OF

THE 115 VOLT PURICARE IS

PROTECTED BY A GROUND FAULT

INTERRUPTER CIRCUIT (GFIC).

LABCONCO DOES NOT

RECOMMEND INSTALLING A GFIC

ON THE OUTLET THAT THE

PURICARE PLUGS INTO.

Table 2-1

Chapter 2: Prerequisites

Product Service 1-800-522-7658

7

Page 12

Chapter 2: Prerequisites

Space Requirements

The dimensions for the different models are shown in

Appendix B: Vertical Flow Station Dimensions.

Overhead Clearance

In order for the Vertical Flow Station to operate

properly, at least six inches (150 mm) clearance from

any overhead obstructions is required when the station

is in its final operating position.

8

Product Service 1-800-522-7658

Page 13

C

HHAAPPTTEERR

C

G

EETTTTIINNGG

G

Now that the site for your Vertical Flow Station is

properly prepared, you are ready to unpack, inspect,

install, and certify it. Read this chapter to learn how to:

• unpack and move your PuriCare.

• set up the station.

• connect the electrical supply source.

• arrange certification.

Depending upon which model you are installing, you

may need common tools in addition to a 3/4" wrench, a

flat-blade screwdriver, and a Phillips screwdriver.

The PuriCare models weigh

approximately 450 lbs. (205 kg). The

!

carton allows for lifting with a

mechanical lift truck or floor jack.

S

S

3

3

TTAARRTTEEDD

Product Service 1-800-522-7658

9

Page 14

Chapter 3: Getting Started

The United States

Interstate Commerce

Commission rules

require that claims be

filed with the delivery

carrier within fifteen (15)

days of delivery.

Unpacking Your Vertical

Flow Station

Carefully unpack your PuriCare and inspect it for

damage that may have occurred in transit. If your unit

is damaged, notify the delivery carrier immediately and

retain the entire shipment intact for inspection by the

carrier.

DO NOT RETURN GOODS

WITHOUT THE PRIOR

)

Do not discard the carton or packing material for your

PuriCare until you have checked all of the components

and installed and tested the unit.

!

AUTHORIZATION OF LABCONCO.

UNAUTHORIZED RETURNS WILL

NOT BE ACCEPTED.

IF YOUR STATION WAS DAMAGED

IN TRANSIT, YOU MUST FILE A

CLAIM DIRECTLY WITH THE

FREIGHT CARRIER. LABCONCO

CORPORATION AND ITS DEALERS

ARE NOT RESPONSIBLE FOR

SHIPPING DAMAGES.

Do not remove the PuriCare from its

shipping skid until it is ready to be

placed into its final location. Move the

unit by placing a flat, low dolly under

the shipping skid, or by using a floor

jack.

Do not move the station by tilting it

onto a hand truck.

10

Product Service 1-800-522-7658

Page 15

PuriCare Components

Labconco manufactures Vertical Flow Stations for use

with 115 volts or 230 volts.

Locate the station model you received in the following

group of tables. Verify that the components listed are

present and undamaged.

Catalog # PuriCare Description

3830000 Vertical Flow Station, 115 VAC, 60 Hz

3830020 Vertical Flow Station, 230 VAC, 50 Hz

Plus the Following:

Part # Component Description

3794300 User’s Manual

Power Cord

(4) Caster Wheels

(8) Washers

(4) Lock Washers

(4) Acorn Nuts

If you did not receive one or more of the components

listed for your PuriCare, or if any of the components are

damaged, contact Labconco Corporation immediately

for further instructions.

Chapter 3: Getting Started

Preparing the Station for

Operation

ASSEMBLY INSTRUCTIONS FOR

)

Product Service 1-800-522-7658

THE STATION (LABCONCO P/N

1058300) ARE ATTACHED TO THE

SASH OF THE PURICARE. IF THESE

INSTRUCTIONS ARE MISSING OR

UNCLEAR, CONTACT LABCONCO

AT 800-821-5525.

11

Page 16

Chapter 3: Getting Started

Exhaust System

Requirements

The Vertical Flow Station discharges its HEPA filtered

exhaust air beneath the unit.

Maintain at least 12 inches clearance

!

between the station and any vertical

obstruction on all sides of the unit.

Initial Certification

Prior to use, all PuriCare stations should be certified by

a qualified certifier. Under normal operating

conditions, the PuriCare stations should be recertified at

least annually or when serviced. The certifier should

perform the following tests:

• HEPA Filter Leak Tests

• Downflow Velocity Profile Test*

• Inflow Volume Test

• Airflow Smoke Patterns

*There is no tolerance on the downflow

profile values.

If you have any questions regarding certification

agencies or need assistance in locating one, contact

Labconco’s Product Service Department at 1-800-5227658 or 816-333-8811.

12

Product Service 1-800-522-7658

Page 17

C

HHAAPPTTEERR

C

T

HHEEOORRY

T

O

PPEERRAATTIIOONN

O

S

AAFFEETTYY

S

P

RREECCAAUUTTIIOONNSS

P

The Vertical Flow Station operates using the following

principles:

• Filtration and retention of particulates by High

Efficiency Particulate Air (HEPA) filters

Directional airflow

The major components in the Vertical Flow Station are:

• The HEPA filters

• The impellers and motor/blower to force air

through the unit

• A speed controls for the impellers and motor

• Station air intakes (grilles)

Y

O

O

4

4

F

F

A

A

NNDD

Product Service 1-800-522-7658

13

Page 18

Chapter 4: Theory Of Operation And Safety Precautions

HEPA Filters

HEPA filters are disposable, dry-type particulate filters.

The filter material or media is typically made of

borosilicate microfibers that are made into a thin sheet,

in a process similar to the production of paper. This

sheet is folded, or pleated to increase its surface area.

The pleats are held in place by aluminum diffusers or

by beads of glue that add rigidity to the media pack.

The media pack is then set into a suitable frame, and the

perimeter sealed to the filter frame, as shown in Figure

4-1.

The HEPA filter media is very fragile.

Do not touch or contact the media

!

!

surface. If you think the surface of a

HEPA filter is damaged, DO NOT

USE THE STATION. Have the

HEPA filter integrity tested by a

qualified certifier before using the

station.

HEPA Filters are only effective

against particulate material. Gases

will pass through the filter.

14

Product Service 1-800-522-7658

Page 19

Chapter 4: Theory Of Operation And Safety Precautions

Figure 4-1

Directional Airflow

Directional airflow plays a key role in the Vertical Flow

Station’s performance. Sterile, HEPA filtered air flows

downward throughout the work area, protecting the

animals inside from external and cross contamination.

All of this “supply” air and some room air is drawn into

the front of the station at the grille. This “curtain” of air

makes it difficult for aerosols to escape out of the work

area and into the outside environment.

Product Service 1-800-522-7658

15

Page 20

Chapter 4: Theory Of Operation And Safety Precautions

Figure 4-2

Impellers and Motor/Blower

The Vertical Flow Station uses two air handling

systems to direct air through it. In the top of the station

twin motorized impellers draw room air in through

prefilters and then force the air through the upper

(supply) HEPA filter. Below the worksurface there are

another set of prefilters, a heavy duty motor blower and

the exhaust HEPA filter.

Speed Controls

The speed controls should only be

!

adjusted by a qualified certifier.

16

Product Service 1-800-522-7658

Page 21

Chapter 4: Theory Of Operation And Safety Precautions

The speed controls are electronic circuits that allow the

certifier to set the speed of the motors by adjusting their

voltage. The PuriCare speed controls are rated for 10

Amps current each, far in excess of the motor's normal

current draw, to allow for greater reliability.

Station Air Intakes (Grilles),

Ductwork and Air Balance

Controls

The station’s containment and performance are affected

by the location, size, and pattern of the grilles at the

front and rear of the work area.

Never block or obstruct the grilles of

!

The internal ductwork of the PuriCare conveys the air

from the work area to the blower, and then from the

blower to the filters. The exhaust filter plenum of the

PuriCare is unique in the industry, utilizing perfect

manifold technology to deliver a more uniform airflow

to the exhaust HEPA filter, optimizing filter loading

and operational life.

the PuriCare.

Safety Precautions

The PuriCare Vertical Flow Station is

NOT a biosafety cabinet. Do not use

this device for the containment of

biohazardous, toxic, flammable, or

explosive materials. If you have

questions regarding the operation of

this device, contact Labconco at 800821-5525 or www.labconco.com.

Product Service 1-800-522-7658

17

Page 22

Chapter 4: Theory Of Operation And Safety Precautions

HEPA filters are only effective for the

!

!

entrapment of particulate matter.

Manipulations which generate gases

or vapors, i.e., toxic chemicals or

radionuclides, should not be

performed in this station.

The PuriCare Vertical Flow Station

should be certified by a qualified

certification technician before its

initial use. The station should be

recertified whenever it is relocated,

serviced or at least annually

thereafter.

Some components of the PuriCare

Vertical Flow Station should only be

serviced by a qualified certification

technician. Some internal components

of the PuriCare may become

contaminated with allergenic

materials during operation of the unit.

Only experienced personnel

competent in decontamination

procedures should decontaminate the

station before servicing contaminated

components. If you have any

questions regarding certification

agencies, or need assistance in locating

one, contact Labconco’s Product

Service Department at 800-522-7658

or 816-333-8811.

Ensure that the unit is connected to

electrical service in accordance with

local and national electrical codes.

Failure to do so may create a fire or

electrical hazard. Do not remove or

service any electrical components

without first disconnecting the

PuriCare from electrical service.

18

Product Service 1-800-522-7658

Page 23

)

Chapter 4: Theory Of Operation And Safety Precautions

Avoid the use of flammable gases or

solvents in the PuriCare. Care must

be taken to ensure against the

concentration of flammable or

explosive gases or vapors. An open

flame should NOT be used in the

PuriCare. Open flames may disrupt

the airflow patterns in the station,

burn the HEPA filter and/or damage

the filter’s adhesive. Gases under high

pressure should not be used in the

PuriCare station, as they may disrupt

the airflow patterns of the station.

The surface of the HEPA filters are

fragile and should not be touched.

Care must be taken to avoid

puncturing either HEPA filter during

installation or normal operation. If

you suspect that a HEPA filter has

been damaged, DO NOT use the

station; contact a local certification

agency or Labconco at 800-821-5525

or 816-333-8811 for recertification

information.

THE HEPA FILTERS IN THE

PURICARE STATION WILL

GRADUALLY ACCUMULATE

AIRBORNE PARTICULATE

MATTER FROM THE ROOM AND

FROM WORK PERFORMED IN THE

STATION. THE RATE OF

ACCUMULATION WILL DEPEND

UPON THE CLEANLINESS OF THE

ROOM AIR, THE AMOUNT OF TIME

THE STATION IS OPERATING AND

THE NATURE OF WORK BEING

DONE IN THE STATION.

Product Service 1-800-522-7658

19

Page 24

Chapter 4: Theory Of Operation And Safety Precautions

Proper operation of the station

depends largely upon the station’s

!

)

location and the operator’s work

habits. Consult the Installation and

Normal Operation sections of this

manual for further details.

WHEN SURFACE DISINFECTING

THE PURICARE STATION:

• AVOID SPLASHING THE

DISINFECTING SOLUTION ON SKIN

OR CLOTHING.

• ENSURE ADEQUATE

VENTILATION.

• CAREFULLY FOLLOW THE

MANUFACTURER’S SAFETY

INSTRUCTIONS WHEN HANDLING

DISINFECTANTS AND ALWAYS

DISPOSE OF DISINFECTING

SOLUTIONS IN ACCORDANCE

WITH LOCAL AND NATIONAL

LAWS.

DO NOT ALLOW DISINFECTANTS

WITH FREE CHLORINE TO

CONTACT THE STAINLESS STEEL

COMPONENTS OF THE PURICARE

FOR A LONG PERIOD OF TIME.

FREE CHLORINE WILL CORRODE

STAINLESS STEEL AFTER

EXTENDED CONTACT.

The electrical receptacle cover,

because of its construction, may be

difficult to surface decontaminate. In

the event of gross contamination, the

cover should be removed, sterilized

and/or decontaminated as required

and discarded. The receptacle cover

should then be replaced with the

repair part listed in Appendix A:

PuriCare Components.

20

Product Service 1-800-522-7658

Page 25

C

HHAAPPTTEERR

C

U

SSIINNG

U

P

UURRI

P

Operating the Sash

The sash of the Vertical Flow Station can be locked in

the full open position. To lock the sash open:

1. Grasp the bottom edge of the sash, and pivot it up

until the sash is fully opened.

2. Locate the sash locking bolt on the inside left side

of the sash, as shown in Figure 5-1.

3. Restrain the sash by aligning the bolt with the hole

in the left side wall of the station, and pressing the

bolt to the left until it engages the hole.

4. To release the sash, support the bottom edge while

pulling the bolt to the right. Allow the sash to pivot

down to its closed position, ensuring that the sash is

set in the closed position.

I

G

C

C

Y

Y

AARREE

5

5

OOUURR

Product Service 1-800-522-7658

21

Page 26

Chapter 5: Using Your PuriCare

Figure 5-1

22

The sash must be completely closed

!

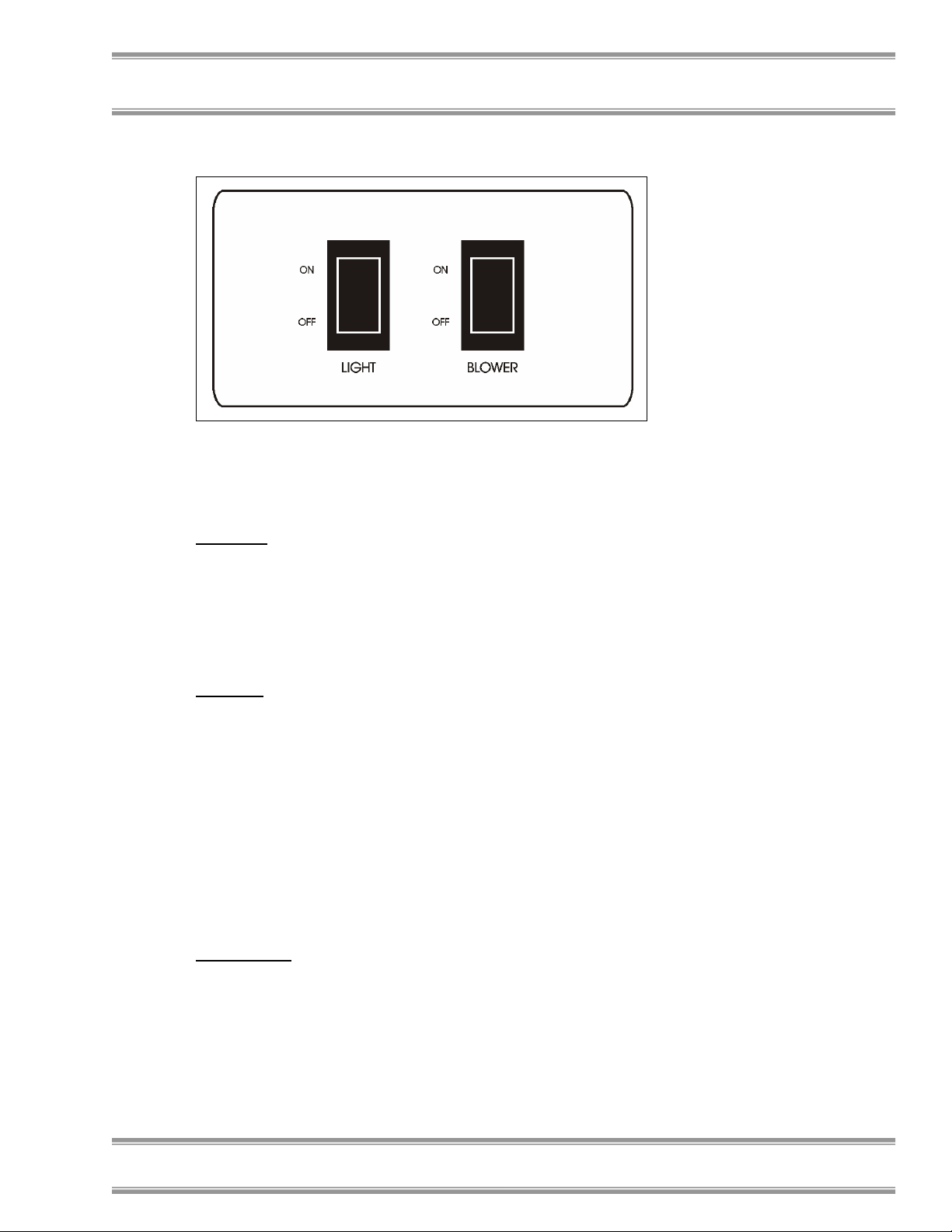

5. Turn the blower and light switches to the 'On'

position, as shown in Figure 5-2.

for the PuriCare to contain properly.

Product Service 1-800-522-7658

Page 27

Figure 5-2

Working In Your PuriCare

Planning

• Thoroughly understand procedures and

equipment required before beginning work.

• Arrange for minimal disruptions, such as room

traffic or entry into the room while the station is

in use.

Start-up

• Turn on fluorescent light and station blower.

• Check the return air grilles for obstructions, and

note the pressure gauge reading.

• Allow the station to operate unobstructed for 5

minutes.

• Wash hands and arms thoroughly with

germicidal soap.

• Wear a long sleeved lab coat with knit cuffs and

over-the- cuff rubber gloves. Use protective

eyewear. Wear a protective mask if appropriate.

Wipe-Down

• Pivot the sash to its full open position.

• Wipe down the interior surfaces of the station

with 70% ethanol, or a suitable disinfectant, and

allow to dry.

• Slowly close the sash.

Chapter 5: Using Your PuriCare

Product Service 1-800-522-7658

23

Page 28

Chapter 5: Using Your PuriCare

Loading Materials and Equipment

Work Techniques

Final Purging

Unloading Materials and Equipment

• Only load the materials required for the

procedure. Do not overload the station.

• Do not obstruct the grilles on the front, back or

sides of the work area.

• Large objects should not be placed close

together.

• Keep all materials at least 4 inches inside of the

sash, and perform all contaminated operations

as close to the center of the work area as

possible.

• Segregate all clean and contaminated materials

in the work area.

• Arrange materials to minimize the movement of

contaminated materials into clean areas.

• Keep all discarded contaminated material to one

zone work area.

• Avoid the use of an open flame.

• Use proper aseptic technique.

• Avoid using techniques or procedures that

disrupt the airflow patterns of the station.

• If there is a spill or splatter during use, all

objects in the station should be surface

decontaminated before removal. Thoroughly

disinfect the working area of the station WHILE

IT IS STILL IN OPERATION. This will

prevent the release of contaminants from the

station.

• Upon completion of work, the station should be

allowed to operate for two to three minutes

undisturbed, to purge airborne contaminants

from the work area.

• Objects in contact with contaminated material

should be surface decontaminated before

removal from the station.

• All open trays or containers should be covered

before being removed from the station.

24

Product Service 1-800-522-7658

Page 29

Wipe-Down

• Wipe down the interior surfaces of the station

with 70% ethanol, or a suitable disinfectant, and

allow to dry.

• Periodically lift the work surface and wipe

down the area beneath it.

• Inspect the prefilters located beneath the work

surface, beneath the work pan. Replace them if

necessary

• Dispose of rubber gloves appropriately, and

have lab coat laundered properly.

• Wash hands and arms thoroughly with

germicidal soap.

Shutdown

• Turn off the fluorescent light and station blower,

close the sashes.

Chapter 5: Using Your PuriCare

Product Service 1-800-522-7658

25

Page 30

C

HHAAPPTTEERR

C

M

P

Now that you have an understanding of how to work in

the Vertical Flow Station, we will review the suggested

maintenance schedule and the common service

operations necessary to maintain your PuriCare for

peak performance.

AAIINNTTAAIINNIINNG

M

C

P

!

UURRI

I

AARREE

C

Many of the service operations should

be performed only by trained and

experienced certification technicians

after the station has been properly

decontaminated. DO NOT attempt to

perform these operations if you are

not properly trained. The service

operations that require qualified

certifiers are preceded by the wrench

icon.

6

6

G

Y

Y

OOUURR

26

Routine Maintenance

Schedule

Weekly

Product Service 1-800-522-7658

• Using 70% ethanol, or a suitable disinfectant,

surface disinfect the inside of the station, and

the work surface.

Page 31

• Using an appropriate optical glass cleaner and

cloth, clean the sash.

• Operate the station blowers, noting the pressure

readings in an operational log.

• Lift the work surface and inspect the prefilters.

Monthly (or more often as required)

• Using a damp cloth, clean the exterior surfaces

of the station, particularly the front, back and

top of the unit, to remove any accumulated dust.

• Disinfect and lift the work surface. Surface

disinfect the lower plenum with a solution of

70% ethanol, or a suitable disinfectant. Check

the prefilters for retained materials.

• Replace the prefilters as needed.

• All weekly activities.

Annually

• Have the station recertified by a qualified

certification technician.

• All monthly activities.

Biannually

• Replace the fluorescent lamp.

Chapter 6: Maintaining Your PuriCare

Service Operations

Work Surface Removal:

1. Loosen and remove the three thumbscrews located

at the front of the work surface. Only loosen the

three thumbscrews on the back of the work surface.

2. Lift the front edge of the work surface up and pull it

out of the station work area.

Prefilter Removal and Cleaning:

The prefilters may be contaminated

!

Product Service 1-800-522-7658

with allergenic material. Take

appropriate precautions when

removing and handling the prefilters

to prevent exposure. The prefilters

are disposable and cannot be cleaned.

27

Page 32

Chapter 6: Maintaining Your PuriCare

Upper Prefilter Removal:

1. Loosen the nuts that secure the two upper prefilter

brackets as shown in Figure 6-1.

2. Swing the upper prefilter brackets until the

prefilters can be lifted out of the top of the units.

3. Replace the prefilter elements, ensuring the air flow

direction arrow on the prefilter frame points down.

Figure 6-1

28

Lower Prefilter Removal:

1. Remove the work surface as described earlier.

2. Loosen the nuts that secure the two lower prefilter

brackets as shown in Figure 6-2.

3. Swing the lower prefilter brackets until the

prefilters can be lifted out of the unit.

Product Service 1-800-522-7658

Page 33

Chapter 6: Maintaining Your PuriCare

4. Replace the prefilter elements, ensuring the air flow

direction arrow on the prefilter frame points down.

Figure 6-2

Changing the Fluorescent Lamp:

1. Unplug the station.

2. Swing up the sash.

3. Remove the fluorescent lamp by rotating it 90

degrees and pulling it straight down and out of its

sockets.

3. Install the new lamp by reversing the removal

procedure.

Resetting a Circuit Breaker:

To reset any of the circuit breakers located on the back

of the unit near the power cord outlet, depress the white

button until it sets.

Product Service 1-800-522-7658

29

Page 34

Chapter 6: Maintaining Your PuriCare

!

Downflow Velocities

The service operations listed in the

rest of this chapter should only be

performed by a qualified certifier.

The average downflow velocity for all Vertical Flow

Stations should be set at 50-55 FPM.

Downflow Velocity Grid

Patterns

The downflow velocity test grid for all Vertical Flow

Stations is as follows:

The perimeter of the down test grid is 6.00 inches from

the side walls and 6.00 from the rear of the work area.

The grid consists of three rows, 5.95 inches apart, from

the back to the front, with eight test points on each row,

spaced 5.21 inches apart. All points are read at the

bottom edge of the sash.

Inflow Volume Calculation -

30

Primary Method

The Inflow Volume can be measured directly, using a

Direct Inflow Measurement (DIM) meter, using the

following method:

1. Turn the station off and raise the sash.

2. Remove the work surface and the lower prefilters as

described earlier.

3. Using rigid cardboard, or fiberboard, cut two

patterns as shown in Figure 6-3.

4. Place the solid pattern over the prefilter hole

directly above the blower. Seal the pattern to the

prefilter shelf with duct tape if necessary.

Product Service 1-800-522-7658

Page 35

Chapter 6: Maintaining Your PuriCare

5. Place the pattern with the hole over the other

prefilter hole. Seal the pattern to the prefilter shelf

if necessary.

6. Place the DIM upside down over the hole in the

second pattern. Seal the DIM to the pattern with

duct tape if necessary.

7. Start the Station and let it run for at least two

minutes. Turn on the DIM and take at least 10

readings of the inflow volume. Average the

readings.

8. The average inflow volume, corrected for local

conditions, should be 650-670 CFM.

Figure 6-3

Inflow Volume Calculation Secondary Method

1. Turn the station off and raise the sashes.

2. Remove the work surface and the lower prefilters as

described earlier.

3. Using rigid cardboard or fiberboard, cut a 20 inch

square.

4. Use the square to cover the prefilter hole directly

above the blower.

5. At the other prefilter hole, mark a test grid at 4 ½

inch intervals around the perimeter of the hole,

establishing a 16 square grid in the hold.

Product Service 1-800-522-7658

31

Page 36

Chapter 6: Maintaining Your PuriCare

6. Using a thermal anemometer, measure the velocity

at the center of each of the squares.

7. Average the readings. Multiply the average

velocity by the correction factor 2.25 to obtain the

average inflow volume.

8. The average inflow volume, corrected for local

conditions, should be 650-670 CFM.

Speed Control Adjustments

!

1. Locate the two plugged speed control access holes

located on the lower front panel as shown in Figure

6-4.

2. Gently pry out the chrome plugs to gain access to

the speed control adjustment screws. The screw on

the bottom controls the lower Motor/Blower, the

one on the top controls the upper impellers.

3. Turn the screw(s) counterclockwise to increase the

speed, clockwise to decrease it.

!

4. After adjusting the appropriate speed control,

measure the downflow velocities or Inflow Volume

as needed.

The Vertical Flow Station blower

speeds should only be adjusted by a

qualified certification technician.

Adjustment of the impeller and/or

blower speeds will affect the

containment of the unit.

The Vertical Flow Station uses two

independent speed controls to control

the upper impellers (Supply Air) and

the lower Motor/Blower (Exhaust Air)

Turning the speed control adjustment

screw all the way counterclockwise

will shut the speed control circuit off

and the motor(s) will stop. If this

occurs, turn the screw clockwise until

the motor(s) start running again.

32

Product Service 1-800-522-7658

Page 37

Chapter 6: Maintaining Your PuriCare

Figure 6-4

Supply HEPA Filter

Replacement

The HEPA filters should only be

!

1. Unplug the station.

2. Remove the two upper prefilters as described earlier

in this chapter.

3. Remove the five screws that secure the upper rear

panel as shown in Figure 6-5.

4. Carefully swing the rear panel out.

serviced by a qualified certification

technician. Following replacement of a

HEPA filter, the station MUST be

recertified by a qualified certification

technician.

Product Service 1-800-522-7658

33

Page 38

Chapter 6: Maintaining Your PuriCare

5. Locate the four locking bolts that secure the upper

plenum. They are located in each corner of the

plenum, and they thread through the upper bracket

and down onto the top of the plenum. Loosen each

bolt at least ½ inch.

6. Locate the four plenum lift bolts that raise the upper

plenum. They are located in each corner of the

plenum, next to the locking bolts, and they thread

into the top of the plenum. Tighten each bolt until

there is approximately ¼ inch clearance between the

top of the HEPA filter and the bottom of the

plenum.

7. Slide the Supply HEPA filter straight out of the

station.

8. Ensure the replacement HEPA filter matches the

performance specifications of the original filter, in

particular the efficiency and the flow rate at a given

pressure drop.

9. Install the replacement HEPA filter by reversing the

disassembly steps.

10. Plug in the station and have it recertified before use.

Figure 6-5

34

Product Service 1-800-522-7658

Page 39

Chapter 6: Maintaining Your PuriCare

To Remove the Exhaust HEPA Filter:

The exhaust HEPA filter is awkward

!

to handle and heavy. Use appropriate

lifting techniques to remove and

handle it. Use two people to remove

the filter if possible.

Exhaust HEPA Filter

Replacement

1. Remove the lower rear panel by removing the #2

Phillips screws on the perimeter of the panel.

2. Remove the work surface and two lower prefilters

as described earlier in this chapter.

3. Locate the four locking bolts that secure the lower

plenum. They are located in each corner of the

plenum and they thread through the lower bracket

and down onto the top of the plenum, as shown in

Figure 6-6. Loosen each bolt at least ½ inch.

4. Locate the four plenum lift bolts that raise the lower

plenum. They are located in each corner of the

plenum, next to the locking bolts and they thread

into the top of the plenum. Tighten each bolt until

there is approximately ¼ inch clearance between the

top of the HEPA filter and the bottom of the

plenum.

5. Remove the two filter retainer brackets.

6. Slide the Exhaust HEPA filter straight out of the

station.

7. Ensure the replacement HEPA filter matches the

performance specifications of the original filter, in

particular the efficiency and the flow rate at a given

pressure drop.

8. Install the replacement HEPA filter by reversing the

disassembly steps.

9. Plug in the station and have it recertified before use.

Product Service 1-800-522-7658

35

Page 40

Chapter 6: Maintaining Your PuriCare

Figure 6-6

Impeller and Motor/Blower

Maintenance and

Replacement

)

To replace an Impeller:

1. Unplug the unit.

2. Remove the two upper prefilters as described earlier

in this chapter.

3. Remove the five screws that secure the upper rear

panel as shown in Figure 6-5.

4. Carefully swing the upper rear panel forward.

The motor/blower should be serviced

by a qualified certification technician.

The stations blower motor and

impeller bearings are sealed and

require no lubrication. DO NOT

attempt to lubricate them.

36

Product Service 1-800-522-7658

Page 41

Chapter 6: Maintaining Your PuriCare

5. Locate the four locking bolts that secure the upper

plenum. They are located in each corner of the

plenum, and they thread through the upper bracket

and down onto the top of the plenum. Loosen each

bolt as far as it will go.

6. Locate the four plenum lift bolts that raise the upper

plenum. They are located in corner of the plenum

next to the locking bolts, and they thread into the

top of the plenum. Tighten each bolt until the top of

the plenum contacts the lift brackets.

7. Slide the Supply HEPA filter straight out of the

station.

8. Disconnect the wiring for the impeller to be

replaced.

9. Remove the four ¼ inch bolts and nuts that secure

the impeller bracket to the plenum. Remove the

impeller/bracket assembly.

10. Remove the impeller from the bracket by removing

the four 5 mm screws that secure the impeller to the

bracket.

11. Install the new impeller by reversing the

disassembly steps.

To replace the Lower Motor/Blower:

1. Unplug the station.

2. Remove the lower rear panel.

3. Using a screwdriver, disconnect the motor ground

wire from the blower housing.

4. Disconnect the motor leads from the wiring harness

by pulling apart each of the 4 connectors.

5. Using a 1/2-inch wrench, remove the two upper and

one lower blower mounting bolts, as shown in

Figure 6-7.

The motor/blower assembly is heavy.

!

6. While supporting the blower assembly, pull the

assembly straight out the plenum.

7. To replace the motor/blower assembly, reverse the

above procedure. Before installing the lower rear

panel, ensure that the motors rotate in the correct

direction when turned on.

Handle with care.

Product Service 1-800-522-7658

37

Page 42

Chapter 6: Maintaining Your PuriCare

8. Plug in the station and have it recertified before use.

Figure 6-7

Diffuser Removal

Bending or distorting the diffuser may

!

Upper Diffuser Removal

1. Swing the sash up until it is in the locked position.

2. Locate and remove the four acorn nuts that secure

the upper diffuser brackets to the station. Support

the diffuser when removing the brackets and lower

the diffuser straight down.

Lower Diffuser Removal

1. Locate and remove the six screws that secure the

lower diffuser to the station, starting with the corner

screws. Support the diffuser when removing the

last two center screws and lower the diffuser

straight down.

affect the airflow in the station. Use

care when handling it.

38

Product Service 1-800-522-7658

Page 43

Chapter 6: Maintaining Your PuriCare

Storage

If the PuriCare is to be left unused for more than one

month, the unit should be prepared for storage.

The station should not be stored in

!

1. Lower the sashes completely and seal work area,

the bottom edge and the exhaust outlet with plastic

sheeting.

2. Unplug the unit.

3. Ensure that the station will not be moved or

disturbed while in storage.

areas of excess humidity or

temperature extremes. If the station

is moved during storage, it must be

recertified before use.

Product Service 1-800-522-7658

39

Page 44

C

HHAAPPTTEERR

C

M

V

S

Installing a Shelf

1. Ensure that the shelf kit you have is the proper one.

2. Remove the four plastic plugs on the appropriate

3. Lower the shelf brackets on the shelf and align them

4. Secure the shelf to the panel using the four screws

5. Identify which bracket has the trigger to release the

6. Place the dot on the lower panel, 1 ½ inches directly

OODDIIFFYYIINNGG

M

EERRTTIICCAAL

V

TTAATTIIOON

S

Kits for mounting on the operator’s left side are

#3794900. Kits for mounting the shelf on the

operator’s right side are #3794901.

side of the lower panel, as shown in figure 7-1.

with the holes in the panel.

included in the shelf kit.

shelf from its upright position. Remove the

adhesive backing of the white plastic dot included

in the shelf kit.

below the bottom of the bracket with the trigger.

This will prevent the trigger from scratching the

lower panel.

N

L

7

7

F

F

Y

OOUURR

Y

LLOOW

W

40

Product Service 1-800-522-7658

Page 45

Chapter 7: Modifying Your Open Access Station

Figure 7-1

Product Service 1-800-522-7658

41

Page 46

C

HHAAPPTTEERR

C

T

RROOUUBBLLEESSHHOOOOTTIINNGG

T

Refer to the following table if your Vertical Flow

Station fails to operate properly. If the suggested

corrective actions do not solve your problem, contact

Labconco for additional assistance.

PROBLEM CAUSE CORRECTIVE ACTION

Station blower and

lights won’t turn on

Circuit breakers

Blower(s) won’t

turn on but lights

work

Blower(s) motor is

Station blower turns

on but lights don’t

work

Lamp is defective Replace lamp.

Lamp wiring is

Defective lamp

Unit not plugged into

outlet

tripped

Blower(s) wiring is

disconnected

defective

Lamp(s) not installed

correctly

disconnected

ballast

8

8

Plug the PuriCare into appropriate

electrical service.

Reset circuit breakers.

Inspect blower(s) wiring.

Replace blower(s) motor.

Inspect lamp installation.

Inspect lamp wiring.

Replace lamp ballast.

42

Product Service 1-800-522-7658

Page 47

Chapter 8: Troubleshooting

PROBLEM CAUSE CORRECTIVE ACTION

Slight increase in

pressure reading

Prefilter loading Check the prefilters for obstruction(s).

Blockage or

Blockage of the

Contamination of

work in the station

Restriction of the

External factors are

Station is out of

HEPA filter loading The pressure reading will steadily

increase as the unit is used.

Clean if necessary.

Ensure that the plenum beneath the

restriction under the

work surface

exhaust outlet

Improper technique

or procedure for the

Vertical Flow Station

grille – blockage of

the exhaust outlet

disrupting the

station’s airflow

patterns or acting as a

source of

contamination

adjustment/HEPA

filter(s) are defective

work surface is unobstructed.

Ensure that the exhaust outlet is not

blocked or restricted.

See “Use of the Vertical Flow Station”

section in the manual.

Ensure that all return air slots, grilles

and the exhaust outlet are unobstructed.

See “Installation” section of this

manual.

Have station recertified.

Product Service 1-800-522-7658

43

Page 48

A

PPPPEENNDDIIXX

A

V

EERRTTIICCAALL

V

S

TTAATTIIOONN

S

C

OOMMPPOONNEENNTTSS

C

Illustration A-1 indicates the location of the following

service parts:

Vertical Flow Station Replacement Parts

Item Quantity Part No. Description

1 2 3717400 Impeller, 115 Volt

1A 2 3717500 Impeller, 230 Volt

2 1 3803100 Supply HEPA Filter

3 1 1211200 Motor, 115 VAC 4-foot

3A 1 1210502 Motor, 230 VAC 4-foot

4 1 3731101 Motor/Blower Assembly, 115 VAC 4-foot

4A 1 3751901 Motor/Blower Assembly, 230 VAC 4-foot

5 1 3739501 Exhaust HEPA Filter

6 4 3789300 Prefilter

7 2 9721900 Lamp, Fluorescent (not shown)

8 2 1287900 Receptacle Cover (not shown)

A

F

A

LLOOW

F

W

44

Product Service 1-800-522-7658

Page 49

Appendix A: Purifier Components

A-1

Product Service 1-800-522-7658

45

Page 50

A

PPPPEENNDDIIXX

A

V

EERRTTIICCAAL

V

S

TTAATTIIOON

S

N

B

F

L

F

D

D

B

LLOOW

W

IIMMEENNSSIIOONNSS

B-1

46

Product Service 1-800-522-7658

Page 51

A

PPPPEENNDDIIXX

A

V

EERRTTIICCAAL

V

S

TTAATTIIOONN

S

S

PPEECCIIFFIICCAATTIIOONNSS

S

Electrical Data

Station Model Electrical Requirements

3830000 to –09 115 VAC – 60 Hz, 1 Phase – 12 Amps

Station Model Electrical Requirements

3830020 to –29 230 VAC – 50/60 Hz, 1 Phase – 7 Amps

Impeller Specifications

Station Model Electrical Requirements

3830000 to –09 115 Volt – 60 Hz, 100 Watt, 2550 RPM

Station Model Electrical Requirements

3830020 to –29

L

C

F

C

F

LLOOW

W

Automatic Thermal Protection

230 Volt – 50/60 Hz, 100 Watt, 2550 RPM

Automatic Thermal Protection

Product Service 1-800-522-7658

47

Page 52

Appendix C: Vertical Flow Station Specifications

Motor Specifications

Station Model Electrical Requirements

3830000 to –09 115 VAC – 60 Hz, 3.8 Full Load Amps

Station Model Electrical Requirements

3830020 to –29 230 VAC – 50/60 Hz, 2.8 Full Load Amps

Environmental Conditions

• Indoor use only.

• Maximum altitude: 6562 feet (2000 meters).

• Ambient temperature range: 41° to 104°F (5° to

40°C).

• Maximum relative humidity: 80% for

temperatures up to 88°F (31°C), decreasing

linearly to 50% relative humidity at 104°F

(40°C).

• Main supply voltage fluctuations not to exceed

±10% of the nominal voltage.

• Transient overvoltages according to Installation

Categories II (Overvoltage Categories per IEC

1010). Temporary voltage spikes on the AC

input line that may be as high as 1500V for

115V models and 2500V for 230V models are

allowed.

• Used in an environment of Pollution degrees 2

(i.e., where normally only non-conductive

atmospheres are present). Occasionally,

however, a temporary conductivity caused by

condensation must be expected, in accordance

with IEC 664.

1/3 H.P. 1625 RPM Automatic Thermal

Protection

1/2 H.P. 1625 RPM Automatic Thermal

Protection

48

Product Service 1-800-522-7658

Page 53

Appendix C: Vertical Flow Station Specifications

C-1

Product Service 1-800-522-7658

49

Page 54

Appendix C: Vertical Flow Station Specifications

C-2

50

Product Service 1-800-522-7658

Page 55

A

PPPPEENNDDIIXX

A

P

UURRI

P

A

CCCCEESSSSOORRIIEESS

A

Shelf Kit

Shelf kits are available for either the left side (part

number 3794900) or the right side (part number

3794901). The shelves are suitable for mounting on

either side of the station. The shelves have a capacity

of 20 pounds, a trigger to release the shelf, and fold

down flat when not in use.

C

I

C

AARREE

D

D

Product Service 1-800-522-7658

51

Page 56

A

PPPPEENNDDIIXX

A

Q

UUIICCKK

Q

T

HHEE

T

V

EERRTTIICCAAL

V

S

TTAATTOONNSS

S

Supply Air Volume Displacement (CFM) 440

Exhaust Air Volume Displacement (CFM) 650-670

*For further details on the secondary inflow method,

consult the inflow velocity calculation – Secondary

Method section of Chapter 6: Maintaining Your

PuriCare.

Use the downflow velocity test grid as described in this

manual when checking the downflow air velocity.

P

Approximate Settings for new Filters

Number of Laskin Nozzles Needed 1

Number of Laskin Nozzles Needed 2

C

C

UURRI

P

Sash Height (inches) 14

Mag Gauge Reading 0.3-0.4 upper / 0.5-0.7 lower

Supply HEPA Filter Dims. (in.) 48x18x3

Exhaust HEPA Filter Dims (in.) 48x18x6

Fluorescent Light(s) 1 each F32T8/TL741

E

HHAARRTT

C

I

C

L

F

E

AARREE

F

LLOOW

F

F

W

OORR

Model 38300

Downflow (FPM) 50-55

52

Product Service 1-800-522-7658

Page 57

A

PPPPEENNDDIIXX

A

R

EEFFEERREENNCCEESS

R

Many excellent reference texts and booklets are

currently available. The following is a brief listing:

Biosafety in Microbiological and Biomedical

Laboratories. 4th Edition, May 1999. U.S. Department

of Health, Education, and Welfare, National Institutes

of Health, Division of Safety, Bethesda, MD 20892.

Laboratory Safety: Principles and Practices. 2nd

Edition 1995. American Society for Microbiology,

Washington, D.C.

The Foundations of Laboratory Safety. 1990. Stephen

R. Rayburn. Springer-Verlag, New York.

Websites of Interest:

www.absa.org

www.cdc.gov

www.labconco.com

F

F

Product Service 1-800-522-7658

53

Page 58

54

Product Service 1-800-522-7658

Loading...

Loading...