Page 1

User’s Manual

PuriCare

Stations

Models

3840000

™

Bedding Disposal

3840020

To receive important product updates,

complete your product registration card

online at register.labconco.com

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Please read the User’s Manual before operating the equipment.

Page 2

Copyright © 2003, 2007 Labconco Corporation. All rights reserved.

The information contained in this manual and the accompanying products are copyrighted and all rights

reserved by Labconco Corporation. Labconco Corporation reserves the right to make periodic design

changes without obligation to notify any person or entity of such change.

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas

of defective material and workmanship, provided such defect results from normal and proper use of

the equipment.

The warranty for all Labconco products will expire one year from date of installation or two years

from date of shipment from Labconco, whichever is sooner, except the following;

• Purifier® Delta® Series Biological Safety Cabinets and PuriCare® Lab Animal Research

Stations carry a three-year warranty from date of installation or four years from date of

shipment from Labconco, whichever is sooner.

• SteamScrubber® & FlaskScrubber® Glassware Washers carry a two-year warranty from

date of installation or three years from date of shipment from Labconco, whichever is

sooner.

• Blood Drawing Chairs carry a ten year warranty.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the

event of a warranty claim, contact Labconco Corporation or the dealer who sold you the product. If

the cause is determined to be a manufacturing fault, the dealer or Labconco Corporation will repair

or replace all defective parts to restore the unit to operation. Under no circumstances shall

Labconco Corporation be liable for indirect, consequential, or special damages of any kind. This

statement may be altered by a specific published amendment. No individual has authorization to

alter the provisions of this warranty policy or its amendments. Lamps and filters are not covered by

this warranty. Damage due to corrosion or accidental breakage is not covered.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight carrier.

Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery

carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar with

any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water,

land, or air and to comply with such regulations. Labconco Corporation is held harmless with respect to

user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-821-5525

or 1-816-333-8811, between the hours of 7:00 a.m. and 6:00 p.m., Central Standard Time.

Part #3785900, Rev. G

ECO E225

Page 3

T

AABBLLEE

T

CHAPTER 1: INTRODUCTION 1

About This Manual 2

Typographical Conventions 3

Your Next Step 4

CHAPTER 2: PREREQUISITES 5

Location Requirements 6

Electrical Requirements 6

Space Requirements 7

Overhead Clearance 7

Your Next Step 7

CHAPTER 3: GETTING STARTED 9

Unpacking Your Bedding Disposal Station 10

PuriCare Components 11

Removing the Shipping Skid 11

Measuring the Inflow Velocity 13

Initial Certification 13

Your Next Step 13

CHAPTER 4: THEORY OF OPERATION AND

Prefilter 16

HEPA Filter 16

The Activated Carbon/Alumina Postfilter 17

Directional Airflow 18

Impellers 19

Speed Control 19

Airfoil, Baffle & Ductwork 19

Safety Precautions 20

Your Next Step 22

O

O

SAFETY PRECAUTIONS 15

FF

C

C

OONNTTEENNTTSS

Page 4

CHAPTER 5: USING YOUR PURICARE 23

Starting the Station 23

Reading the Filter System Indicator 23

Working in Your PuriCare 24

Your Next Step 25

CHAPTER 6: MAINTAINING YOUR PURICARE 27

Routine Maintenance Schedule 28

Service Operations 28

Speed Control Adjustment 31

Filter Indicator System Adjustment 32

HEPA Filter Replacement 33

HEPA Filter Leak Test Procedure 35

Inflow Velocity Test Procedure 37

Airflow Smoke Patterns 38

Motorized Impeller Replacement 38

Storage 39

CHAPTER 7: TROUBLESHOOTING 41

APPENDIX A: BEDDING DISPOSAL STATION

COMPONENTS 43

APPENDIX B: BEDDING DISPOSAL STATION

DIMENSIONS 45

APPENDIX C: BEDDING DISPOSAL STATION

SPECIFICATIONS 47

Electrical Data 47

Impeller Specifications 47

APPENDIX D: QUICK CHART FOR THE PURICARE

BEDDING DISPOSAL STATION 51

APPENDIX E: REFERENCES 53

DECLARATION OF CONFORMITY 55

Page 5

C

HHAAPPTTEERR

C

I

NNTTRROODDUUCCTTIIOONN

I

Congratulations on your purchase of a Labconco

PuriCare Bedding Disposal Station. Your PuriCare

product is designed to protect you and your laboratory

environment from aerosols. It is the result of

Labconco’s years of experience manufacturing

laboratory equipment, and many of its features were

suggested to us by users like you.

The PuriCare offers many unique features to enhance

safety, performance and ergonomics. To take full

advantage of them, please acquaint yourself with this

manual and keep it handy for future reference. If you

are unfamiliar with how bedding disposal stations

operate, please review Chapter 4: Theory of Operation

and Safety Precautions before you begin working in the

station. Even if you are an experienced user, please

review Chapter 5: Using Your Bedding Disposal

Station; it describes your PuriCare’s features so that

you can use the station efficiently.

1

1

Product Service 1-800-522-7658

1

Page 6

Chapter 1: Introduction

About This Manual

This manual is designed to help you learn how to

install, use, and maintain your bedding disposal station.

Chapter 1: Introduction provides a brief overview of

the bedding disposal station, explains the organization

of the manual, and defines the typographical

conventions used in the manual.

Chapter 2: Prerequisites explains what you need to do

to prepare your site before you install your disposal

station. Electrical and service requirements are

discussed.

Chapter 3: Getting Started contains the information

you need to properly unpack, inspect, install, and

certify your disposal station.

Chapter 4: Theory Of Operation And Safety

Precautions explains how the PuriCare operates and the

appropriate precautions you should take when using the

station.

Chapter 5: Using Your PuriCare discusses the basic

operation of your station. Information on how to

prepare, use and shut down your PuriCare are included.

Chapter 6: Maintaining Your PuriCare explains how to

perform routine maintenance on your disposal station.

Information on how to safely disinfect the interior of

your station and replace the lamps are included.

Chapter 7: Troubleshooting contains a table of

problems you may encounter while using your disposal

station including the probable causes of the problems

and suggested corrective actions.

Appendix A: Bedding Disposal Station Components

contains labeled diagrams of all of its components.

2

Product Service 1-800-522-7658

Page 7

Appendix B: Bedding Disposal Station Dimensions

contains comprehensive diagrams showing all of the

dimensions for the PuriCare model.

Appendix C: Bedding Disposal Station Specifications

contains the electrical requirements for the Bedding

Disposal Station. Wiring diagrams for both the 115V

and 230V models are also included.

Appendix D: Quick Chart for the PuriCare Bedding

Disposal Station provides useful operating

specifications.

Appendix E: References lists the various resources

available that deal with biosafety.

Chapter 1: Introduction

Typographical Conventions

Recognizing the following typographical conventions

will help you understand and use this manual:

• Book, chapter, and section titles are shown in italic

type (e.g., Chapter 3: Getting Started).

• Steps required to perform a task are presented in a

numbered format.

• Comments located in the margins provide

suggestions, reminders, and references.

• Critical biosafety information is presented in

boldface type in paragraphs that are preceded by the

biosafety icon. Failure to comply with the

information following a biosafety icon may result in

illness or death.

• Critical information is presented in boldface type in

paragraphs that are preceded by the exclamation

icon. Failure to comply with the information

following an exclamation icon may result in injury

to the user or permanent damage to your bedding

disposal station.

!

Product Service 1-800-522-7658

3

Page 8

Chapter 1: Introduction

)

• Critical information is presented in boldface type in

paragraphs that are preceded by the wrench icon.

These operations should only be performed by a

trained certifier or contractor. Failure to comply

with the information following a wrench icon may

result in injury to the user or permanent damage to

your bedding disposal station.

• Important information is presented in capitalized

type in paragraphs that are preceded by the pointer

icon. It is imperative that the information contained

in these paragraphs be thoroughly read and

understood by the user.

Your Next Step

If your PuriCare needs to be installed, proceed to

Chapter 2: Prerequisites to ensure your installation site

meets all of the requirements. Then, go to Chapter 3:

Getting Started for instructions on how to install your

bedding disposal station and make all of the necessary

connections.

If you would like to review how the bedding disposal

station operates, go to Chapter 4: Theory Of Operation

And Safety Precautions.

For information on the operational characteristics of

your bedding disposal station, go to Chapter 5: Using

Your PuriCare.

If your bedding disposal station is installed and you

need to perform routine maintenance on the station,

proceed to Chapter 6: Maintaining Your PuriCare.

Refer to Chapter 7: Troubleshooting if you are

experiencing problems with your PuriCare.

4

Product Service 1-800-522-7658

Page 9

C

HHAAPPTTEERR

C

P

RREERREEQQUUIISSIITTEESS

P

Before you install your Bedding Disposal Station, you

need to prepare your site for installation. Carefully

examine the location where you intend to install your

station. You must be certain that the area is level and

of solid construction. In addition, a dedicated source of

electrical power must be located near the installation

site.

Carefully read this chapter to learn:

• the location requirements for your installation

site.

• the electrical power requirements for your

installation site.

• the space requirements for your installation site.

Refer to Appendix C: Bedding Disposal Station

Specifications for complete station electrical and

environmental conditions, specifications and

requirements.

2

2

Product Service 1-800-522-7658

5

Page 10

Chapter 2: Prerequisites

Location Requirements

The PuriCare should be located away

!

from traffic patterns, doors, fans,

ventilation registers, fume hoods and

any other air-handling device that

could disrupt its airflow patterns. All

windows in the room should be closed.

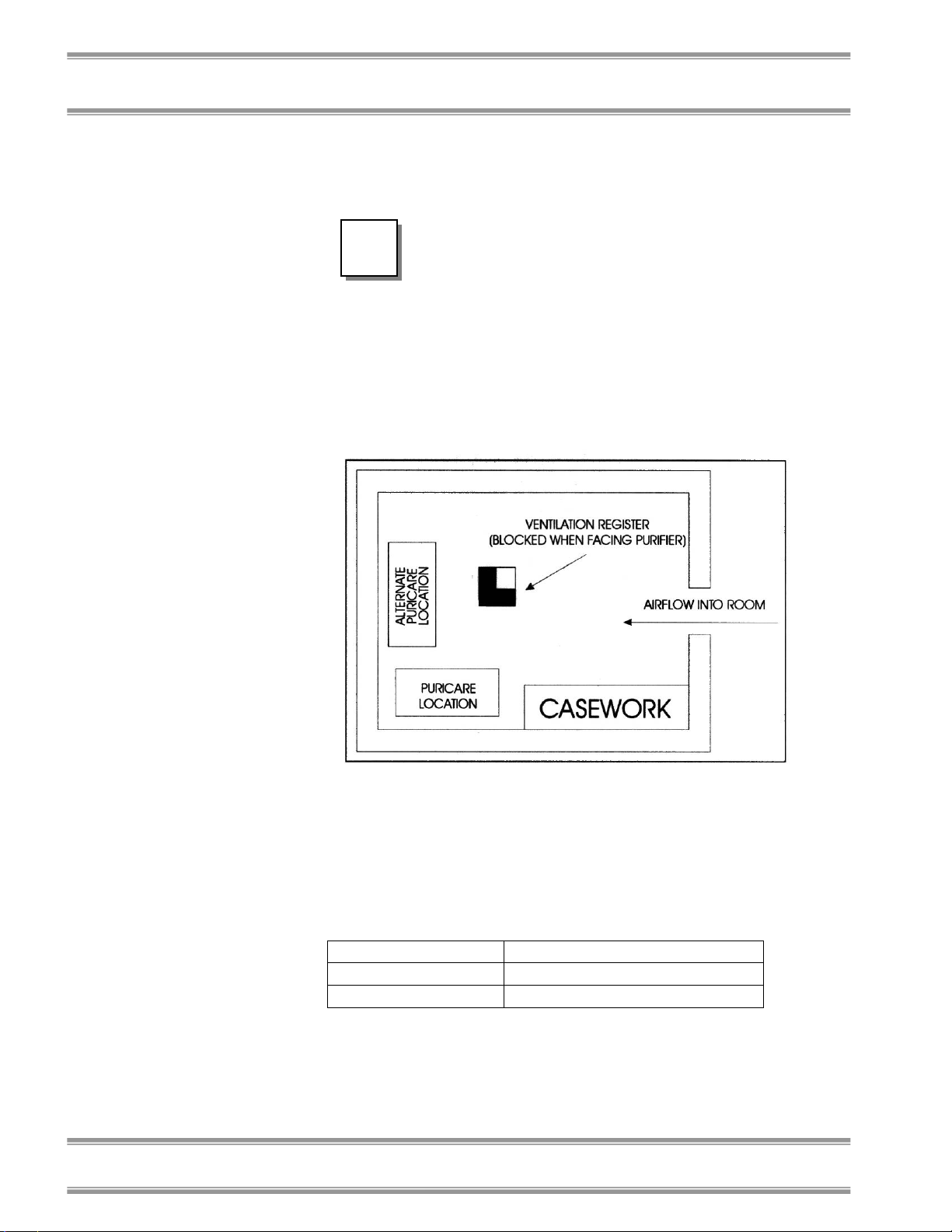

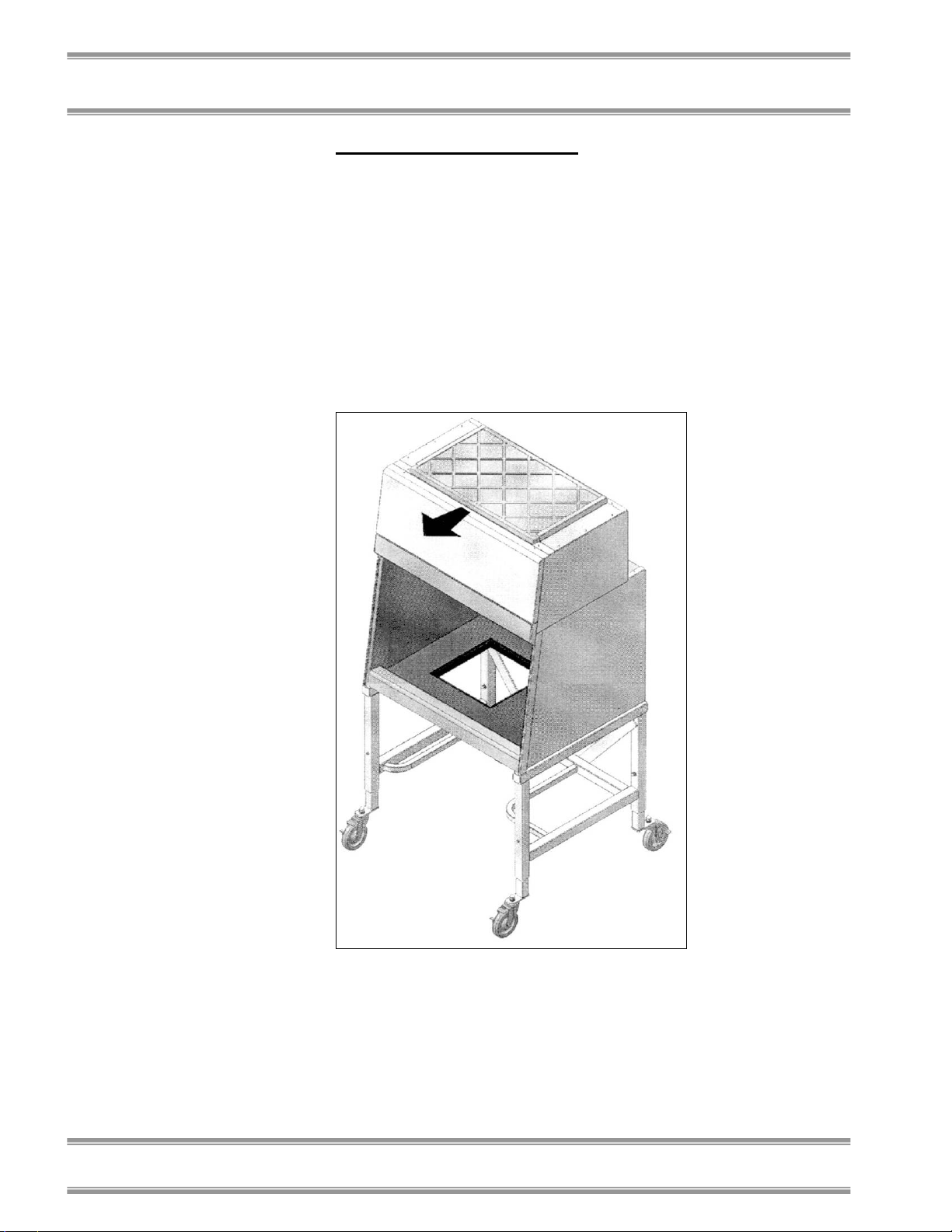

Figure 2-1 shows the optimum

location for the PuriCare.

Figure 2-1

6

Electrical Requirements

The different PuriCare models have the following

electrical requirements:

Model # Requirements

38400- 00-09 115 VAC, 60 Hz, 5 Amps

38400- 20-29 230 VAC, 50 Hz, 3 Amps

Product Service 1-800-522-7658

Table 2-1

Page 11

All PuriCare Stations with model numbers ending in –

00 to –09 are designed for operation at 115 volts, 60Hz,

alternating current. PuriCare Stations with model

numbers ending in –20 to –29 are designed for

operation at 230 +/- 20 volts, 50 Hz alternating current.

A dedicated outlet with a circuit breaker rated at 10

amps should be located as close as possible to the right

rear side of the station.

Always follow the plug

manufacturer’s instructions for the

!

proper assembly and testing of the

plug and power cord.

Space Requirements

The dimensions for the different models are shown in

Appendix B: Bedding Disposal Station Dimensions.

Chapter 2: Prerequisites

Overhead Clearance

In order for the bedding disposal station to operate

properly, there must be at least six inches (150 mm)

clearance from any overhead obstructions when the

station is in its final operating position.

Your Next Step

After you have determined that the location you have

selected accommodates the installation and operational

requirements of your station, you are ready to begin

installation. Proceed to Chapter 3: Getting Started.

Product Service 1-800-522-7658

7

Page 12

Chapter 2: Prerequisites

8

Product Service 1-800-522-7658

Page 13

C

HHAAPPTTEERR

C

G

EETTTTIINNGG

G

Now that the site for your bedding disposal station is

properly prepared, you are ready to unpack, inspect,

install, and certify it. Read this chapter to learn how to:

• unpack and move your PuriCare.

• set up the station.

• connect the electrical supply source.

• arrange certification.

Depending upon which model you are installing, you

may need common plumbing and electrical installation

tools in addition to a 3/4" wrench, a flat-blade

screwdriver, and a Phillips screwdriver.

The Bedding Disposal Station weighs

!

approximately 400 lbs. (182 kg). The

carton allows for lifting with a

mechanical lift truck or floor jack. If

you must lift the PuriCare manually,

use at least four (4) persons and follow

safe-lifting guidelines.

S

S

3

3

TTAARRTTEEDD

Product Service 1-800-522-7658

9

Page 14

Chapter 3: Getting Started

The United States

Interstate Commerce

Commission rules

require that claims be

filed with the delivery

carrier within fifteen (15)

days of delivery.

Unpacking Your Bedding

Disposal Station

Carefully unpack your PuriCare and inspect it for

damage that may have occurred in transit. If your unit

is damaged, notify the delivery carrier immediately and

retain the entire shipment intact for inspection by the

carrier.

DO NOT RETURN GOODS

WITHOUT THE PRIOR

)

Do not discard the carton or packing material for your

PuriCare until you have checked all of the components

and installed and tested the unit.

!

)

AUTHORIZATION OF LABCONCO.

UNAUTHORIZED RETURNS WILL

NOT BE ACCEPTED.

IF YOUR STATION WAS DAMAGED

IN TRANSIT, YOU MUST FILE A

CLAIM DIRECTLY WITH THE

FREIGHT CARRIER. LABCONCO

CORPORATION AND ITS DEALERS

ARE NOT RESPONSIBLE FOR

SHIPPING DAMAGES.

Do not remove the PuriCare from its

shipping skid until it is ready to be

placed into its final location. Move the

unit by placing a flat, low dolly under

the shipping skid, or by using a floor

jack.

DO NOT MOVE THE STATION BY

TILTING IT ONTO A HAND TRUCK.

10

Product Service 1-800-522-7658

Page 15

PuriCare Components

Labconco manufactures bedding stations for operation

on 115V or 230V.

Locate the station model you received in the following

group of tables. Verify that the components listed are

present and undamaged.

Catalog # PuriCare Description

3840000 Bedding Disposal Station, 115 VAC

3840020 Bedding Disposal Station, 230 VAC

Plus the Following:

Part # Component Description

3785900 User’s Manual

Power Cord

(4) Caster Wheels

(4) Flat Washers

(4) Lock Washers

(4) Hex Nuts

If you did not receive one or more of the components

listed for your PuriCare, or if any of the components are

damaged, contact Labconco Corporation immediately

for further instructions.

Chapter 3: Getting Started

Preparing the Station for

Operation

ASSEMBLY INSTRUCTIONS FOR

)

Product Service 1-800-522-7658

THE STATION (LABCONCO P/N

1058500) ARE ATTACHED TO THE

FRONT PANEL OF THE PURICARE.

IF THESE INSTRUCTIONS ARE

MISSING OR UNCLEAR, CONTACT

LABCONCO AT 800-821-5525.

11

Page 16

Chapter 3: Getting Started

Before Turning on the Unit:

1. Remove the postfilter from its holder on top of the

station by pulling it forward, as shown in Figure

3-3.

2. Remove the clear plastic wrapping off of the filter.

3. Reinstall the postfilter, orienting it as shown by the

flow arrows on the filter frame. Push the filter back

into position until it stops.

Figure 3-3

12

Product Service 1-800-522-7658

Page 17

Measuring the Inflow

Velocity

Inflow values and measurement

procedures for the PuriCare are

described fully in Chapter 6:

Maintaining Your PuriCare.

Initial Certification

Prior to use, all PuriCare stations should be certified by

a qualified certifier. Under normal operating

conditions, the PuriCare stations should be recertified at

least annually and when serviced. The certifier should

perform the following tests:

• HEPA Filter Leak Test

• Inflow Velocity Test

• Airflow Smoke Patterns

If you have any questions regarding certification

agencies or need assistance in locating one, contact

Labconco’s Product Service Department at 1-800-5227658 or 816-333-8811.

Chapter 3: Getting Started

Your Next Step

After your PuriCare has been installed and certified,

you are ready to proceed to Chapter 4: Theory Of

Operation And Safety Precautions.

Product Service 1-800-522-7658

13

Page 18

Chapter 3: Getting Started

14

Product Service 1-800-522-7658

Page 19

C

HHAAPPTTEERR

C

T

HHEEOORRY

T

O

PPEERRAATTIIOONN

O

S

AAFFEETTYY

S

P

RREECCAAUUTTIIOONNSS

P

The Bedding Disposal Station operates using the

following principles:

• Filtration and retention of particulates by High

Efficiency Particulate Air (HEPA) filter

• Directional airflow

The major components in the Bedding Disposal Station

are:

• The prefilter

• The HEPA filter

• The activated carbon/alumina postfilter

• The impellers to force air through the unit

• A speed control for the motor

• Station air intakes (baffles) and ductwork

Y

O

O

4

4

F

F

A

A

NNDD

Product Service 1-800-522-7658

15

Page 20

Chapter 4: Theory Of Operation And Safety Precautions

Prefilter

The prefilter is located just below the HEPA filter. Its

purpose is to lengthen the operating life of the HEPA

filter by removing large particles before they can block

it.

REGULARLY SCHEDULED

INSPECTION AND REPLACEMENT

)

OF THE PREFILTER IS KEY TO

MAINTAINING PROPER

OPERATION OF THE ENCLOSURE.

HEPA Filter

HEPA filters are disposable, dry-type particulate filters.

The filter material or media is typically made of

borosilicate microfibers that are made into a thin sheet,

in a process similar to the production of paper. This

sheet is folded, or pleated to increase its surface area.

The pleats are held in place by aluminum diffusers or

by beads of glue that add rigidity to the media pack.

The media pack is then set into a suitable frame, and the

perimeter sealed to the filter frame, as shown in Figure

4-1.

The HEPA filter media is very fragile.

!

Do not touch or contact the media

surface. If you think the surface of a

HEPA filter is damaged, DO NOT

USE THE STATION. Have the

HEPA filter integrity tested by a

qualified certifier before using the

station.

HEPA Filters are only effective

against particulate material. Gases

will pass through the filter.

16

Product Service 1-800-522-7658

Page 21

Chapter 4: Theory Of Operation And Safety Precautions

Figure 4-1

The Activated

Carbon/Alumina Postfilter

The postfilter in your Bedding Disposal Station is

unique. Inside of its polyester media are granular

activated carbon for the adsorption of odors, plus

activated alumina impregnated with potassium

permanganate, for additional removal of odors and light

gases.

Product Service 1-800-522-7658

17

Page 22

Chapter 4: Theory Of Operation And Safety Precautions

Directional Airflow

Directional airflow also plays a key role in the Bedding

Disposal Station’s performance. Air is drawn into the

front of the station and odors. This “curtain” of air

makes it difficult for aerosols and odors to escape out of

the work area and into the outside environment. This

airflow is often calculated and referred to as the

Average Inflow Velocity. This is shown graphically in

Figure 4-2.

Figure 4-2

18

Product Service 1-800-522-7658

Page 23

Chapter 4: Theory Of Operation And Safety Precautions

Impellers

The impellers pull air into the front of the station,

through the pre- and HEPA filters, and then discharge it

through the postfilter.

Speed Control

The speed control should only be

!

The speed control is an electronic circuit that allows the

certifier to set the impellers’ speed by adjusting its

voltage. The PuriCare speed control is rated for 10

Amps current, far in excess of the impellers’ normal

current draw, to allow for greater reliability.

adjusted by a qualified certifier.

Airfoil, Baffle and Ductwork

The station’s containment and performance are affected

by the location, size, and pattern of the airfoils at the

front, and the baffle at the rear of the work area.

Never block or obstruct the airfoils or

!

The internal ductwork of the PuriCare conveys the air

from the work area to the pre- and HEPA filters, then to

the blower, and then to the postfilter.

baffle of the PuriCare.

Product Service 1-800-522-7658

19

Page 24

Chapter 4: Theory Of Operation And Safety Precautions

Safety Precautions

The PuriCare Bedding Disposal

Station is NOT a biosafety cabinet.

Do not use this device for the

containment of biohazardous, toxic,

flammable, or explosive materials. If

you have questions regarding the

operation of this device, contact

Labconco at 800-821-5525 or

www.labconco.com.

!

The PuriCare Bedding Disposal

Station should be certified by a

qualified certification technician

before its initial use. The station

should be recertified whenever it is

relocated, serviced or at least annually

thereafter.

Some components of the PuriCare

Bedding Disposal Station should only

be serviced by a qualified certification

technician. Some internal components

of the PuriCare may become

contaminated during operation of the

unit. Only experienced personnel

competent in the decontamination

procedure should decontaminate the

station before servicing contaminated

components. If you have any

questions regarding certification

agencies, or need assistance in locating

one, contact Labconco’s Product

Service Department at 800-522-7658

or 816-333-8811.

Ensure that the unit is connected to

electrical service in accordance with

local and national electrical codes.

Failure to do so may create a fire or

electrical hazard. Do not remove or

service any electrical components

20

Product Service 1-800-522-7658

Page 25

!

)

Chapter 4: Theory Of Operation And Safety Precautions

without first disconnecting the

PuriCare from electrical service.

Avoid the use of flammable gases or

solvents in the PuriCare. Care must

be taken to ensure against the

concentration of flammable or

explosive gases or vapors. An open

flame should NOT be used in the

PuriCare. Open flames may disrupt

the airflow patterns in the station or

damage the filters’ adhesive. Gases

under high pressure should not be

used in the PuriCare station, as they

may disrupt the airflow patterns of

the station.

The surface of the HEPA filters are

fragile and should not be touched.

Care must be taken to avoid

puncturing the HEPA filter during

installation or normal operation. If

you suspect that a HEPA filter has

been damaged, DO NOT use the

station; contact a local certification

agency or Labconco at 800-522-7658

or 816-333-8811 for recertification

information.

THE HEPA FILTER IN THE

PURICARE STATION WILL

GRADUALLY ACCUMULATE

AIRBORNE PARTICULATE

MATTER FROM THE ROOM AND

FROM WORK PERFORMED IN THE

STATION. THE RATE OF

ACCUMULATION WILL DEPEND

UPON THE CLEANLINESS OF THE

ROOM AIR, THE AMOUNT OF TIME

THE STATION IS OPERATING AND

THE NATURE OF WORK BEING

DONE IN THE STATION.

Product Service 1-800-522-7658

21

Page 26

Chapter 4: Theory Of Operation And Safety Precautions

Proper operation of the station

depends largely upon its location and

!

)

the operator’s work habits. Consult

the Installation and Normal Operation

sections of this manual for further

details.

WHEN SURFACE DISINFECTING

THE PURICARE STATION:

• AVOID SPLASHING THE

DISINFECTING SOLUTION ON

SKIN OR CLOTHING.

• ENSURE ADEQUATE

VENTILATION.

• CAREFULLY FOLLOW THE

MANUFACTURER’S SAFETY

INSTRUCTIONS WHEN

HANDLING DISINFECTANTS

AND ALWAYS DISPOSE OF

DISINFECTING SOLUTIONS IN

ACCORDANCE WITH LOCAL

AND NATIONAL LAWS.

DO NOT ALLOW DISINFECTANTS

WITH FREE CHLORINE TO

CONTACT THE STAINLESS STEEL

COMPONENTS OF THE PURICARE

FOR A LONG PERIOD OF TIME.

FREE CHLORINE WILL CORRODE

STAINLESS STEEL AFTER

EXTENDED CONTACT.

22

Your Next Step

After you understand the theory of operation and safety

precautions, you are ready to proceed to Chapter 5:

Using Your PuriCare.

Product Service 1-800-522-7658

Page 27

C

HHAAPPTTEERR

C

U

SSIINNG

U

P

UURRI

P

Starting the Station

To start the PuriCare, turn the blower switch to the

“ON” position, as shown in Figure 5-1.

Reading the Filter System

Indicator

The two light system located on the control panel as

shown in Figure 5-1 indicates the total system pressure.

During operation, a green “NORMAL” indicator light

stays on. When the pre- or HEPA filters become

excessively loaded, the “NORMAL” light turns off and

the “SERVICE” light turns on, indicating the unit

should be serviced. If the “SERVICE” light stays on

after replacing the prefilter, a qualified certifier can

then determine if the HEPA filter needs to be replaced.

I

G

C

C

Y

Y

AARREE

5

5

OOUURR

Product Service 1-800-522-7658

23

Page 28

Chapter 5: Using Your PuriCare

Working In Your PuriCare

Planning

Start-up

Wipe-Down

Figure 5-1

• Thoroughly understand procedures and

equipment required before beginning work.

• Arrange for minimal disruptions, such as room

traffic or entry into the room while the station is

in use.

• Turn on fluorescent light and station blower.

• Check the airfoil and baffle for obstructions, and

note the indicator lights.

• Allow the station to operate unobstructed for 5

minutes.

• Wash hands and arms thoroughly with

germicidal soap.

• Wear a long sleeved lab coat with knit cuffs and

over-the-cuff rubber gloves. Use protective

eyewear. Wear a protective mask.

• Wipe down the interior surfaces of the station

with 70% ethanol, or a suitable cleaner, and

allow to dry.

24

Product Service 1-800-522-7658

Page 29

Bedding Disposal Operations

• Do not obstruct the front airfoils or rear baffle.

• Large objects should not be placed close

together.

• Keep all materials at least 4 inches inside of the

airfoil, and perform all operations as far to the

rear of the work area as possible.

• Avoid the use of an open flame.

• Avoid using techniques or procedures that

disrupt the airflow patterns of the station.

Final Purging

• Upon completion of work, the station should be

allowed to operate for two to three minutes

undisturbed, to purge airborne contaminants

from the work area.

Wipe-Down

• Wipe down the interior surfaces of the station

with 70% ethanol, or a suitable cleaner, and

allow to dry.

• Inspect and clean the prefilter located under the

HEPA filter.

• Dispose of rubber gloves appropriately, and

have lab coat laundered properly.

• Wash hands and arms thoroughly with

germicidal soap.

Shutdown

• Turn off the fluorescent light and station blower.

Chapter 5: Using Your PuriCare

Your Next Step

After you understand how to operate and work in the

Bedding Disposal Station, you are ready to proceed to

Chapter 6: Maintaining Your PuriCare.

Product Service 1-800-522-7658

25

Page 30

Chapter 5: Using Your PuriCare

26

Product Service 1-800-522-7658

Page 31

C

HHAAPPTTEERR

C

M

P

Now that you have an understanding of how to work in

the Bedding Disposal Station, we will review the

suggested maintenance schedule and the common

service operations necessary to maintain your PuriCare

for peak performance.

AAIINNTTAAIINNIINNG

M

C

P

UURRI

I

C

AARREE

Many of the service operations should

!

be performed only by trained and

experienced certification technicians

after the station has been properly

decontaminated. DO NOT attempt to

perform these operations if you are

not properly trained. The service

operations that require qualified

certifiers are preceded by the wrench

icon.

6

6

G

Y

Y

OOUURR

Product Service 1-800-522-7658

27

Page 32

Chapter 6: Maintaining Your PuriCare

Routine Maintenance

Schedule

After Each Work Session

• Inspect the prefilter and replace if needed.

Weekly

• Using 70% ethanol, or a suitable disinfectant,

surface disinfect the inside of the station, and

the work surface.

• Operate the station blower, noting the indicator

lights.

Monthly (or more often as required)

• Using a damp cloth, clean the exterior surfaces

of the station, particularly the front and top of

the unit, to remove any accumulated dust.

• Replace the prefilter if needed.

• All weekly activities.

Annually

• Have the station recertified by a qualified

certification technician.

• All monthly activities.

Biannually

• Replace the fluorescent lamp.

28

Service Operations

Prefilter Removal:

The prefilter may be contaminated

!

with allergenic material. Take

appropriate precautions when

removing and handling the prefilters

to prevent exposure.

Product Service 1-800-522-7658

Page 33

Chapter 6: Maintaining Your PuriCare

Prefilter replacement:

1. Turn the station off.

2. Loosen the four thumbscrews that secure the

prefilter access panel to the top of the work area, as

shown in Figure 6-1. Let the access panel swing

down.

3. Pull the prefilter straight out and down.

4. Install a new prefilter, orienting the prefilter airflow

directional arrows up towards the HEPA filter.

Figure 6-1

Postfilter replacement:

1. Remove the postfilter from its holder on top of the

station by pulling it forward, as shown in Figure

6-2.

2. Discard the old postfilter.

3. Remove the clear plastic wrapping off of the new

postfilter.

Product Service 1-800-522-7658

29

Page 34

Chapter 6: Maintaining Your PuriCare

4. Install the postfilter, orienting it as shown by the

flow arrows on the filter frame. Push the filter back

into position until it stops.

Figure 6-2

30

Dress Panel Removal:

1. Locate the front dress panel, just above the control

panel. Remove the two screws located on the top of

the panel. Remove the panel by pulling it slightly

upward and out, as shown in Figure 6-3.

Product Service 1-800-522-7658

Page 35

Chapter 6: Maintaining Your PuriCare

Fluorescent Lamp Removal:

1. Remove the front dress panel as described above.

2. Locate the control panel on the front of the cabinet,

which has the filter indicator lights and switches.

Remove the screws located on each lower end of

the panel. Swing the panel upward for access to the

fluorescent lamp, as shown in Figure 6-3.

3. Remove the fluorescent lamp by rotating the lamp

and pulling it straight out of its sockets.

4. Install the new lamp by reversing the removal

procedure.

Figure 6-3

Speed Control Adjustment

The speed control should only be adjusted by a

qualified certifier.

1. Remove the front dress panel as described

above.

2. Adjust the speed control as required by turning

the screw counterclockwise to increase blower

speed, or clockwise, to decrease the blower

speed, as shown in Figure 6-4.

Product Service 1-800-522-7658

31

Page 36

Chapter 6: Maintaining Your PuriCare

3. Replace the front dress panel and reestablish the

inflow air velocity.

Figure 6-4

Filter Indicator System

Adjustment

The Filter Indicator System was

!

To adjust system, do the following:

1. Ensure that the prefilter is new and the station is

operating within its airflow tolerance.

2. Remove the two screws that secure the front

dress panel, as shown in Figure 6-3, and remove

the panel.

3. Locate the adjustment screw access plug, on the

left side of the enclosure frame, above the

HEPA filter. Remove the plug. Replace the

dress panel.

4. Using cardboard, or a similar material, block off

approximately ½ of the postfilter. This will

simulate an increased load on the system.

adjusted at the factory and should not

require recalibration until the HEPA

filter is replaced.

32

Product Service 1-800-522-7658

Page 37

5. If the ‘NORMAL’ light is on, remove the dress

panel, and using the appropriate hex wrench,

turn the adjustment switch slowly clockwise as

shown in Figure 6-5. Reinstall the dress panel.

Repeat this procedure until the ‘SERVICE’ light

turns on when the dress panel is replaced.

6. If the ‘SERVICE’ light is on, remove the dress

panel, and using the appropriate hex wrench,

turn the adjustment switch slowly

counterclockwise as shown in Figure 6-5.

Reinstall the dress panel. Repeat this procedure

until the ‘NORMAL’ light turns on when the

dress panel is replaced.

7. To confirm correct operation, turn the unit off,

uncover the postfilter and restart the station.

The ‘NORMAL’ light will be on. When the

postfilter is slowly covered over, the

‘SERVICE’ light will illuminate.

Figure 6-5

Chapter 6: Maintaining Your PuriCare

HEPA Filter Replacement

The HEPA filter should be serviced

!

1. Unplug the cabinet.

2. Remove the front dress panel as described in

Customer Service Operations section of this

manual.

Product Service 1-800-522-7658

only by a qualified certifier. After the

HEPA filter is replaced, the unit

MUST be certified.

33

Page 38

Chapter 6: Maintaining Your PuriCare

3. Remove the two access hole plugs on the top of

the unit.

4. Using the 9/16” deep socket, loosen the filter

clamp nuts located in the access holes. Refer to

Figure 6-6 for further details.

5. With the clamp bolts loosened, the supply filterclamping frame should be clear of filter.

Carefully pull the filter straight out of the unit

and discard properly.

6. With the filter removed, inspect the clamping

frame and the frame of the cabinet for damage.

7. Cover the surface of the new HEPA filter gasket

with a light coating of silicone grease, if desired.

8. Install the new HEPA filter by pushing it

straight into the cabinet, ensuring that it is

correctly oriented and the filter fits properly in

the cabinet.

!

9. Tighten the clamp nuts uniformly until the filter

gasket is properly compressed against the

cabinet frame. Inspect the seal thoroughly

before proceeding.

10. Reinstall the front dress panel and the access

hole plugs on the top of the unit.

11. Plug the cabinet in and have it recertified before

use.

The filter clamp nuts should only be

tightened enough to ensure a proper

seal at maximum tightness, the height

of the filter spring should equal 1"

(25mm). NEVER tighten the clamp

nut beyond this setting. See Figure

6-6.

34

Product Service 1-800-522-7658

Page 39

Chapter 6: Maintaining Your PuriCare

Figure 6-6

HEPA Filter Leak Test

Procedure

To ensure dirty room air does not affect the HEPA

Filter Leak Test and that the control panel and sash

gaskets are sealing, take the following steps:

1. Turn on the enclosure and set the average inflow

velocity as indicated in inflow velocity test

procedure. Remove the postfilter

2. Tape closed all openings full length across top,

front and sides of the front dress panel as shown

in Figure 6-7.

3. Turn the photometer on and calibrate it per the

manufacturer’s instructions. The upstream

concentration of DOP will be approximately

24 ug/l. Use these values to establish the

upstream value of 100%.

Product Service 1-800-522-7658

35

Page 40

Chapter 6: Maintaining Your PuriCare

4. Place photometer pickup over the exhaust

discharge and sample the concentration. The

concentration must not exceed 0.005%.

5. If the unit fails, check the gasket between the

control panel and the upper cabinet flange.

Also, check gasket attached to underside of the

upper cabinet for contact with the upper edge of

the sash when it is in the closed position.

6. Use a Laskin nozzle-type generator. DO NOT

use more than one nozzle. Operate the

generator at 10 PSIG. The calculations listed

above are based on the use of Di-octyl-Pthalate

as an aerosol challenge. You may need to

correct the valves listed if you use an alternate

fluid.

7. Place the generator discharge near the work

access opening of the enclosure.

8. Start the generator. Ensure that only one nozzle

is operating at 10 PSIG.

9. To establish the downstream concentration of

aerosol, place the photometer pick up over the

exhaust discharge, and sample the concentration

at several locations.

10. The average concentration at each of the points

must not exceed 0.005% of the upstream

concentration.

Figure 6-7

36

Product Service 1-800-522-7658

Page 41

Chapter 6: Maintaining Your PuriCare

Inflow Velocity Test Procedure

Inflow velocity can be determined by use of a thermal

anemometer at the face of the work access opening by

taking the following steps:

1. If the meter has an adjustable time constant, set

it at 10 to 15 seconds.

2. Take three rows of readings at 8, 12 and 16

inches from the top of the opening at positions

that are 6 and then 12 inches in from both

sidewalls. This will yield a grid of 12 sampling

points. See Figure 6-8 for probe placement.

3. Add the 12 readings together and divide by

twelve to obtain the average inflow velocity.

4. The factory inflow velocity setting should equal

or exceed 65 FPM. The blower speed can be

adjusted by turning the speed control located

behind the front dress panel.

Figure 6-8

Product Service 1-800-522-7658

37

Page 42

Chapter 6: Maintaining Your PuriCare

Airflow Smoke Patterns

Non-thermal smoke should be released from one side of

the enclosure to the other, along a line in the middle of

the work area, two inches above the work surface. The

smoke should flow directly into the rear baffle. Smoke

released near the front end of the enclosure, or at the

top of the enclosure may exhibit vortexing and a reflux

along the sidewalls or top of the enclosure. This

turbulence is normal and does not negatively impact

containment of aerosols above the disposal hole.

Motorized Impeller

Replacement

The motorized impeller should be replaced by a

qualified certifier. The motorized impeller is a nonserviceable component and must be replaced as a unit.

When the motorized impeller is replaced, its capacitor

should be replaced with a new one. Following

replacement of the motorized impeller, the cabinet

MUST be recertified by a qualified certifier.

1. Unplug the enclosure. Remove the post filter.

Remove the top panel by removing all of the

fasteners on the top as described in the

Customer Service Operations section of this

manual.

2. Disconnect the motor ground wire from the

frame. Disconnect the wires connecting the

motorized impeller to the wiring harness.

3. Using a small wrench, remove the four lock nuts

that secure the motor brace to the blower shelf.

Remove the brace and motorized impeller as an

assembly. Placing the assembly on a flat

surface, remove the four screws that secure the

motorized impeller to the brace. Disconnect the

two wires from the motor to its capacitor,

located on the side of the brace. Remove the

motorized impeller from the brace.

38

Product Service 1-800-522-7658

Page 43

Chapter 6: Maintaining Your PuriCare

4. Replace the capacitor with a new one of equal

voltage and capacity.

5. Reassemble the unit by reversing the

disassembly steps. Recertify the enclosure.

Storage

If the Bedding Disposal Station is to be left unused for

more than one month, the unit should be prepared for

storage.

1. Surface disinfect or contaminate the cabinet as

required.

2. Unplug the unit.

3. Cover and seal the work area access opening

and the exhaust outlet with plastic sheeting.

4. Ensure that the cabinet will not be moved or

disturbed while in storage.

The cabinet should not be stored in excessive humidity

or temperature extremes. If the cabinet is moved during

storage it must be recertified before use.

Product Service 1-800-522-7658

39

Page 44

Chapter 6: Maintaining Your PuriCare

40

Product Service 1-800-522-7658

Page 45

C

HHAAPPTTEERR

C

T

RROOUUBBLLEESSHHOOOOTTIINNGG

T

Refer to the following table if your Bedding Disposal

Station fails to operate properly. If the suggested

corrective actions do not solve your problem, contact

Labconco for additional assistance.

PROBLEM CAUSE CORRECTIVE ACTION

Station impellers

and lights won’t

turn on

Circuit breakers

Motorized impellers

won’t turn on but

lights work

Impeller switch is

Motorized impeller is

Capacitor is defective Replace capacitor

Cabinet impeller

turns on but lights

don’t work

Lamp wiring is

7

7

Unit not plugged into

outlet

tripped

Impeller wiring is

disconnected

defective

defective

Lamp not installed

correctly

disconnected

Plug the PuriCare into appropriate

electrical service.

Reset circuit breakers.

Inspect impeller wiring

Replace impeller switch

Replace motorized impeller

Inspect lamp installation.

Inspect lamp wiring

Product Service 1-800-522-7658

41

Page 46

Chapter 7: Troubleshooting

PROBLEM CAUSE CORRECTIVE ACTION

Cabinet impeller

turns on but lights

don’t work (cont.)

Lamp switch is

Defective lamp

Service light is on

Prefilter loading Replace prefilter

HEPA filter loading The light will turn on when the filter is

Lamp is defective Inspect lamp wiring.

Replace lamp switch

defective

Replace lamp ballast

ballast

Blockage of the

exhaust grille

Check the exhaust grille on top of the

unit to ensure they are not blocked or

restricted

loaded

42

Product Service 1-800-522-7658

Page 47

A

PPPPEENNDDIIXX

A

B

EEDDDDIINNGG

B

S

TTAATTIIOONN

S

C

OOMMPPOONNEENNTTSS

C

Illustration A-1 indicates the location of the following

service parts:

Bedding Disposal Station Replacement Parts

Item Quantity Part No. Description

1 1 1327204 Circuit Breaker, 5 Amp

2 2 1327200 Circuit Breaker, 3 Amp

3 2 3717400 Impeller, 115 VAC

3A 2 3717500 Impeller, 230 VAC

4 1 3704400 Speed Control Assembly, 115 VAC

4A 1 3704401 Speed Control Assembly, 230 VAC

5 1 3707901 HEPA Filter

6 1 3801000 Waste Container

7 1 3801500 Dolly

8 1 1230900 Lamp, 17 watt Fluorescent (F17T8) (not shown)

9 2 1302300 Switch – 2 Position (not shown)

10 1 1306500 Capacitor, 115 VAC (not shown)

10A 1 1304600 Capacitor, 230 VAC (not shown)

11 1 3803200 Prefilter (not shown)

12 1 3796201 Postfilter (not shown)

D

D

A

A

IISSPPOOSSAALL

Product Service 1-800-522-7658

43

Page 48

Appendix A: PuriCare Components

A-1

44

Product Service 1-800-522-7658

Page 49

A

PPPPEENNDDIIXX

A

B

EEDDDDIINNGG

B

S

TTAATTIIOON

S

N

B

B

D

D

D

D

IISSPPOOSSAALL

IIMMEENNSSIIOONNSS

B-1

Product Service 1-800-522-7658

45

Page 50

Appendix B: Bedding Disposal Station Dimensions

46

Product Service 1-800-522-7658

Page 51

A

PPPPEENNDDIIXX

A

B

EEDDDDIINNGG

B

S

TTAATTIIOONN

S

S

PPEECCIIFFIICCAATTIIOONNSS

S

Electrical Data

Station Model Electrical Requirements

3840000 to –09 115 VAC – 60 Hz, 1 Phase – 5 Amps

Station Model Electrical Requirements

3840020 to –29 230 VAC – 50/60 Hz, 1 Phase – 3 Amps

Impeller Specifications (2 each)

Station Model Electrical Requirements

3840000 to –09

Station Model Electrical Requirements

3840020 to –29 230 VAC – 50/60 Hz, 100 Watts, 2550 RPM,

D

D

C

C

IISSPPOOSSAALL

115 VAC – 60 Hz, 100 Watts, 2550 RPM,

Automatic Thermal Protection

Automatic Thermal Protection

Product Service 1-800-522-7658

47

Page 52

Appendix C: Bedding Disposal Station Specifications

Environmental Conditions

• Indoor use only.

• Maximum altitude: 6562 feet (2000 meters).

• Ambient temperature range: 41° to 104°F (5° to

40°C).

• Maximum relative humidity: 80% for

temperatures up to 88°F (31°C), decreasing

linearly to 50% relative humidity at 104°F

(40°C).

• Main supply voltage fluctuations not to exceed

±10% of the nominal voltage.

• Transient overvoltages according to Installation

Categories II (Overvoltage Categories per IEC

1010). Temporary voltage spikes on the AC

input line that may be as high as 1500V for

115V models and 2500V for 230V models are

allowed.

• Used in an environment of Pollution degrees 2

(i.e., where normally only non-conductive

atmospheres are present). Occasionally,

however, a temporary conductivity caused by

condensation must be expected, in accordance

with IEC 664.

48

Product Service 1-800-522-7658

Page 53

Appendix C: Bedding Disposal Station Specifications

C-1

Product Service 1-800-522-7658

49

Page 54

Appendix C: Bedding Disposal Station Specifications

50

Product Service 1-800-522-7658

Page 55

A

PPPPEENNDDIIXX

A

Q

UUIICCKK

Q

T

HHEE

T

B

EEDDDDIINNGG

B

S

TTAATTOONNSS

S

Total Air Volume Displacement (CFM) 262-314

Number of Laskin Nozzles Needed 1

P

C

C

UURRI

P

Opening Height (inches) 23

Inflow (FPM) 65 or greater

Work Area (ft2) 5.23

HEPA Filter Dims. (in.) 30x18x3

Fluorescent Light(s) F17T8

D

HHAARRTT

C

I

C

D

D

D

AARREE

IISSPPOOSSAALL

Model 38400

F

F

OORR

Product Service 1-800-522-7658

51

Page 56

Appendix D: Quick Chart for the PuriCare Bedding Disposal Station

52

Product Service 1-800-522-7658

Page 57

A

PPPPEENNDDIIXX

A

R

EEFFEERREENNCCEESS

R

Many excellent reference texts and booklets are

currently available. The following is a brief listing:

Primary Containment for Biohazards: Selection,

Installation and Use of Biological Safety Stations.

September 1995. U.S. Department of Health and

Human Services, Public Health Service, Centers for

Disease Control and Prevention and National Institutes

of Health.

Biosafety in Microbiological and Biomedical

Laboratories. 4th Edition, May 1999. U.S. Department

of Health, Education, and Welfare, National Institutes

of Health, Division of Safety, Bethesda, MD 20892.

Biosafety in the Laboratory. 1989. National Research

Council, National Academy Press, Washington, D.C.

Laboratory Safety: Principles and Practices. 2nd

Edition 1995. American Society for Microbiology,

Washington, D.C.

The Foundations of Laboratory Safety. 1990. Stephen

R. Rayburn. Springer-Verlag, New York.

Websites of Interest:

www.absa.org

www.cdc.gov

www.labconco.com

E

E

Product Service 1-800-522-7658

53

Page 58

Appendix E: References

54

Product Service 1-800-522-7658

Page 59

DECLARATION OF CONFORMITY

Application Council Directive(s): 73/23/EEC, 89/336/EEC

Standard(s) to which conformity is declared: EN61010, EN55022, EN50082-1

Manufacturer’s Name: Labconco Corporation

Manufacturer’s Address: 8811 Prospect Avenue

Kansas City, MO 64132 USA

Importer’s Name: See Shipping/Customs Documents*

Importer’s Address: See Shipping/Customs Documents for your equipment

Type of Equipment: Laboratory Equipment

Model No: PuriCare Bedding Disposal Station

3840020 3-foot wide

Serial No.: Various – See Individual Declaration

Year of Manufacture: 2003 and subsequent

I, the undersigned, hereby declare that the equipment specified above conforms to the

above Directive(s) and Standard(s).

See individual Declaration of Conformity which

will be signed by the importer for your country.

Place: _______________________________________

(Signature)

Date: _______________________________________

(Full Name)

_______________________________________

(Position)

*An individual version of this declaration is included with your shipping/customs

documentation.

Labconco P/N 36960-36, REV. -

Product Service 1-800-522-7658

55

Loading...

Loading...