Page 1

User’s Manual

Protector®Storage Cabinets –

Standard, Acid, Solvent

and Vacuum Pump

Models

9900000 9901000 9902000 9903000 9904000

9900100 9901100 9902100 9903100 9904100

9900200 9901200 9902200 9903200 9904200

9900300 9901300 9902300 9903300 9904300

9900400 9901400 9902400 9903400 9904400

9900500 9901500 9904500

9900600 9901600

9900700

9900800

9905000 9906000 9907000

9905100 9906100 9907100

9905200 9906200

9905300 9906300

To receive important product updates,

complete your product registration card

online at register.labconco.com

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Please read the User’s Manual before operating the equipment.

Page 2

Copyright © 1999, 2007 Labconco Corporation. All rights reserved.

The information contained in this manual and the accompanying products are copyrighted and all rights

reserved by Labconco Corporation. Labconco Corporation reserves the right to make periodic design

changes without obligation to notify any person or entity of such change.

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas of

defective material and workmanship, provided such defect results from normal and proper use of the

equipment.

The warranty for all Labconco products will expire one year from date of installation or two years

from date of shipment from Labconco, whichever is sooner, except the following;

• Purifier® Delta® Series Biological Safety Cabinets and PuriCare® Lab Animal Research

Stations carry a three-year warranty from date of installation or four years from date of

shipment from Labconco, whichever is sooner.

• SteamScrubber® & FlaskScrubber® Glassware Washers carry a two-year warranty from date

of installation or three years from date of shipment from Labconco, whichever is sooner.

• Blood Drawing Chairs carry a ten year warranty.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the

event of a warranty claim, contact Labconco Corporation or the dealer who sold you the product. If

the cause is determined to be a manufacturing fault, the dealer or Labconco Corporation will repair or

replace all defective parts to restore the unit to operation. Under no circumstances shall Labconco

Corporation be liable for indirect, consequential, or special damages of any kind. This statement may

be altered by a specific published amendment. No individual has authorization to alter the provisions

of this warranty policy or its amendments. Lamps and filters are not covered by this warranty.

Damage due to corrosion or accidental breakage is not covered.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight carrier.

Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery

carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar with

any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water,

land, or air and to comply with such regulations. Labconco Corporation is held harmless with respect to

user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-821-5525

or 1-816-333-8811, between the hours of 7:00 a.m. and 6:00 p.m., Central Standard Time.

Part #9918500, Rev. E

ECO E394

Page 3

T

AABBLLEE

T

CHAPTER 1: INTRODUCTION 1

About This Manual 3

Typographical Conventions 4

CHAPTER 2: PREREQUISITES 5

CHAPTER 3: GETTING STARTED 6

Unpacking Your Cabinet 7

Storage Cabinet Components 7

Setting Up Your Cabinet 9

Component Identification 10

Standard Base Storage Cabinets 10

Acid Storage Cabinets 12

Solvent Storage Cabinets 14

Vacuum Pump Storage Cabinets 16

Installation 18

Cabinet Leveling – All Cabinets 18

Vent Installation 19

Acid Storage Cabinet 19

Solvent Storage Cabinet 20

Filler Panel – All Cabinets 21

SpillStopper Work Surface 22

Electrical Ground Connection – Solvent Storage Cabinet 24

Acid Storage Cabinet Shelf Liner 25

Adjustable Shelf – Solvent Storage Cabinet 25

Junction Box Connection – Vacuum Pump Cabinet 25

Environmental Conditions 26

CHAPTER 4: USING YOUR STORAGE CABINETS 27

Normal Operation 27

CHAPTER 5: MAINTAINING YOUR STORAGE CABINETS 29

APPENDIX A: CABINET DIMENSIONS 30

O

O

FF

C

OONNTTEENNTTSS

C

Page 4

APPENDIX B: CABINET REPLACEMENT PARTS 35

APPENDIX C: CABINET ACCESSORIES 36

APPENDIX D: QUICK REFERENCE STORAGE CABINETS 39

DECLARATION OF CONFORMITY 40

Page 5

C

HHAAPPTTEERR

C

I

NNTTRROODDUUCCTTIIOONN

I

Congratulations on your purchase of a Protector®

Storage Cabinet. Labconco manufacturers four types of

Storage Cabinets – Acid, Solvent, Standard Base, and

Vacuum Pump.

Protector® Acid Storage Cabinets have been

engineered to efficiently store and ventilate corrosive

materials and include an interior plastic liner to protect

the metal from corrosion.

Protector® Solvent Storage Cabinets are designed to

efficiently store flammable materials and includes a 11/2" double wall construction for fire protection.

Protector® Standard Base Storage Cabinets are utilized

for general storage and are not recommended for

corrosive or flammable materials.

Protector® Vacuum Pump Storage Cabinets are utilized

for vacuum pump storage.

All cabinets’ feature 18 gauge steel construction with

epoxy coated paint, to give you both a durable and

chemically resistant finish that ensures many years of

quality service.

The Labconco Protector® Storage Cabinets has been

engineered in accordance with NFPA 30, OSHA 191062, and all pertinent SEFA regulations. The cabinets

1

1

Product Service 1-800-522-7658, International 816-333-8811

1

1

Page 6

Chapter 1: Introduction

are available in several configurations to meet your

various requirements.

All Protector® Storage Cabinets are designed with

provisions for venting to the exterior of your laboratory.

Vent connections are located on the back wall of the

cabinet and can be used at the discretion of the

customer.

The vent connection on the Solvent Storage Cabinet is

supplied with a closure plug on both sides, and is

diametrically opposed on the back wall of the cabinet

for optimum airflow throughout its interior.

The vent connection on the Acid Cabinet and Standard

Base Cabinet is located on the back wall of the cabinet

and does not include a closure plug.

2

Product Service 1-800-522-7658, International 816-333-8811

Page 7

About This Manual

This manual will help you learn how to install, use, and

maintain your Storage Cabinet. Instructions for

performing routine maintenance and for minor

modifications to your Storage Cabinet are included.

Chapter 1: Introduction provides a brief overview of

the Storage Cabinets, explains the organization of the

manual, and defines the typographical conventions used

in the manual.

Chapter 2: Prerequisites explains what you need to do

to prepare your site before you install the Storage

Cabinet.

Chapter 3: Getting Started contains the information

you need to properly unpack, inspect, and install the

Storage Cabinet.

Chapter 4: Using Your Storage Cabinet discusses the

normal operation of the Storage Cabinet.

Chapter 5: Maintaining Your Storage Cabinet explains

how to perform routine maintenance on the Storage

Cabinet.

Appendix A: Storage Cabinet Dimensions contains

comprehensive diagrams showing the dimensions for

the Storage Cabinets.

Appendix B: Storage Cabinet Replacement Parts

contains a list of service parts for the Storage Cabinets.

Appendix C: Storage Cabinet Accessories lists the part

numbers and descriptions of the accessories available

for the Storage Cabinet.

Appendix D: Storage Cabinet Quick Reference lists

sizes and part numbers for Solvent, Acid, Standard

Base, and Vacuum Pump Cabinets.

Chapter 1: Introduction

Product Service 1-800-522-7658, International 816-333-8811

3

Page 8

Chapter 1: Introduction

!

)

A

B

S

V

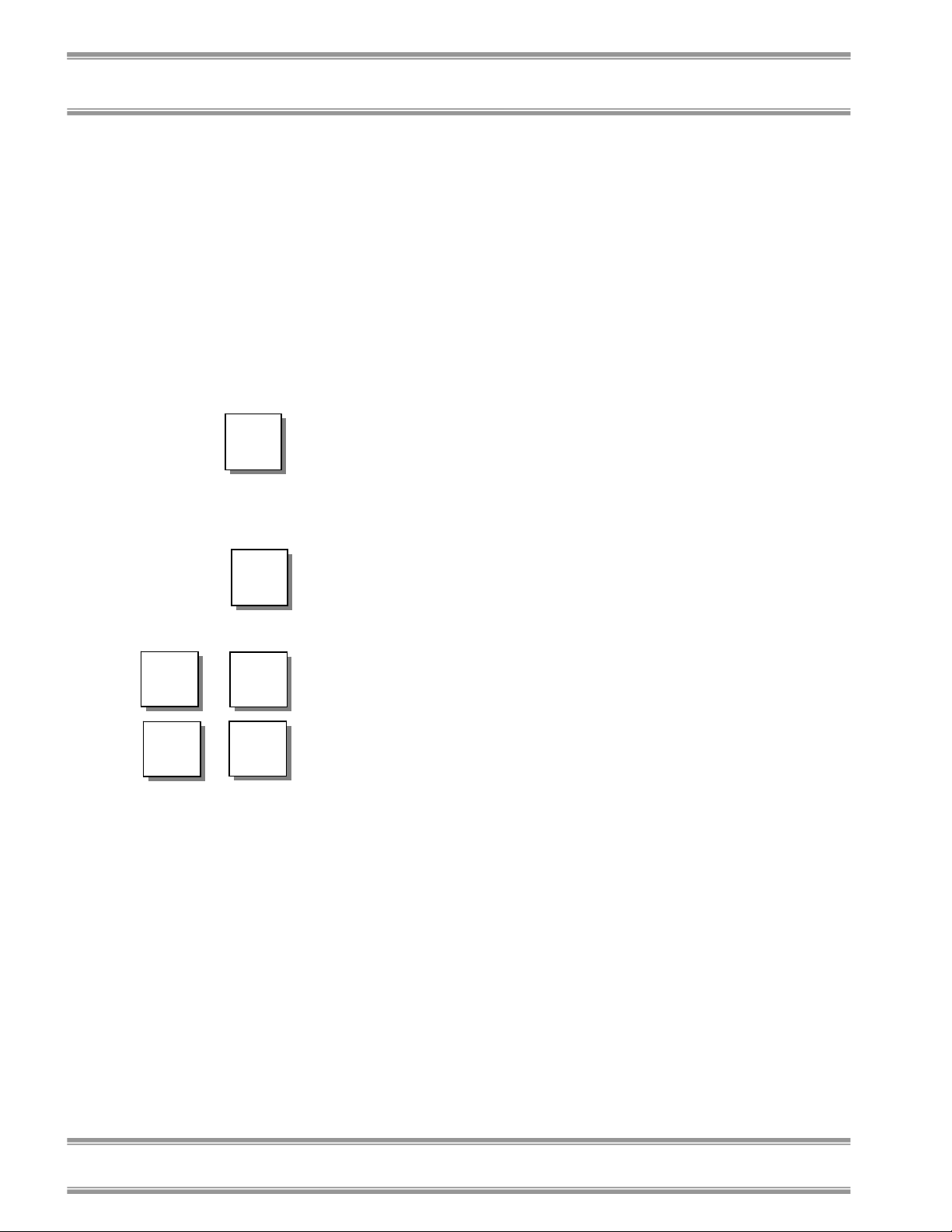

Typographical Conventions

Recognizing the following typographical conventions

will help you understand and use this manual:

• Book, chapter, and section titles are shown in italic

type (e.g., Chapter 3: Getting Started).

• Steps required to perform a task are presented in a

numbered format.

• Comments located in the margins provide

suggestions, reminders, and references.

• Critical information is presented in boldface type in

paragraphs that are preceded by the exclamation

icon. Failure to comply with the information

following an exclamation icon may result in injury

to the user or permanent damage to the Storage

Cabinet.

• Important information is presented in capitalized

type in paragraphs that are preceded by the pointer

icon. It is imperative that the information contained

in these paragraphs be thoroughly read and

understood by the user.

• Information that is specific to a particular model of

Storage Cabinet. The A icon indicates text specific

to the Acid Storage Cabinet, the S icon indicates

text specific to the Solvent Storage Cabinet, the B

icon indicates text specific to the Standard Base

Storage Cabinet, and the V icon indicates text

specific to the Vacuum Pump Storage Cabinet.

4

Product Service 1-800-522-7658, International 816-333-8811

Page 9

C

HHAAPPTTEERR

C

P

RREERREEQQUUIISSIITTEESS

P

Before you install your Storage Cabinet, you need to

prepare your site for installation. Carefully examine the

location where you intend to install the Storage

Cabinet. You must be certain that the area is level and

of solid construction. In addition, your Storage Cabinet

should be adjacent to a vent connection to allow for

venting to the exterior of the building, if so desired.

Otherwise, it is typical to vent the Storage Cabinet

through the work surface and fume hood, which is

supported by the Storage Cabinet.

2

2

Space Requirements

Refer to Appendix A: Storage Cabinet Dimensions for

complete Storage Cabinet dimensional specifications.

Product Service 1-800-522-7658, International 816-333-8811

5

5

Page 10

C

HHAAPPTTEERR

C

G

EETTTTIINNGG

G

Now that the site for your Storage Cabinet is properly

prepared, you are ready to unpack, inspect, and install,

the Storage Cabinet. Read this chapter to learn how to:

• Unpack and move the Storage Cabinet.

• Set up the Storage Cabinet – Acid, Solvent,

Standard Base, and Vacuum Pump.

• Properly level the Storage Cabinet.

• Properly install the accessory work surface.

• Attach the filler panel for additional

aesthetics.

• Properly vent the Storage Cabinet.

• Properly ground the Solvent Cabinet.

• Connect the electrical supply source to the

Vacuum Pump Cabinet.

Depending upon which model of Storage Cabinet you

are installing, you will need common hand tools,

including a Phillips head screwdriver, a flat blade

screwdriver, a ¾" open end wrench, and pliers to

complete the instructions in this chapter.

S

S

3

3

TTAARRTTEEDD

6

Product Service 1-800-522-7658, International 816-333-8811

Page 11

Unpacking Your Storage

Cabinets

Carefully unpack the Storage Cabinet and inspect it for

damage that may have occurred in transit. If your

Storage Cabinet is damaged, notify the delivery carrier

immediately and retain the entire shipment intact for

inspection by the carrier.

DO NOT RETURN ANY STORAGE

CABINET WITHOUT THE PRIOR

)

)

Do not discard the carton or packing material for your

Storage Cabinet until you have checked all of the

components, installed, and tested the Storage Cabinet.

AUTHORIZATION OF

LABCONCO. UNAUTHORIZED

RETURNS WILL NOT BE

ACCEPTED.

IF YOUR STORAGE CABINET

WAS DAMAGED IN TRANSIT,

YOU MUST FILE A CLAIM

DIRECTLY WITH THE FREIGHT

CARRIER. LABCONCO

CORPORATION AND ITS

DEALERS ARE NOT

RESPONSIBLE FOR SHIPPING

DAMAGE.

Chapter 3: Getting Started

Storage Cabinet

Components

As previously mentioned Labconco manufactures four

types of Storage Cabinets, Acid, Solvent, Standard

Base, and Vacuum Pump.

The different Storage Cabinet models require different

assembly components. Locate the model of Storage

Cabinet you received in the following tables. Verify

that the components listed are present and undamaged.

Product Service 1-800-522-7658, International 816-333-8811

7

Page 12

Chapter 3: Getting Started

Model Number Description

9900000 48" Standard Base Cabinet

9900100 36" Standard Base Cabinet

9900200 30" Standard Base Cabinet

9900300 24" Standard Base Cabinet – Right Hinged

9900400 18" Standard Base Cabinet – Right Hinged

9900500 12" Standard Base Cabinet – Right Hinged

9900600 24" Standard Base Cabinet – Left Hinged

9900700 18" Standard Base Cabinet – Left Hinged

9900800 12" Standard Base Cabinet – Left Hinged

9904000 24" ADA Standard Base Cabinet – Right Hinged

9904100 18" ADA Standard Base Cabinet – Right Hinged

9904200 12" ADA Standard Base Cabinet – Right Hinged

9904300 24" ADA Standard Base Cabinet – Left Hinged

9904400 18" ADA Standard Base Cabinet – Left Hinged

9904500 12" ADA Standard Base Cabinet – Left Hinged

9901000 48" Acid Cabinet

9901100 36" Acid Cabinet

9901200 30" Acid Cabinet

9901300 24" Acid Cabinet – Right Hinged

9901400 18" Acid Cabinet – Right Hinged

9901500 24" Acid Cabinet – Left Hinged

9901600 18" Acid Cabinet – Left Hinged

9905000 24" ADA Acid Cabinet – Right Hinged

9905100 18" ADA Acid Cabinet – Right Hinged

9905200 24" ADA Acid Cabinet – Left Hinged

9905300 18” ADA Acid Cabinet – Left Hinged

9902000 48" Manual Closing/Self Latching Solvent Cabinet

9902100 36" Manual Closing/Self Latching Solvent Cabinet

9902200 30" Manual Closing/Self Latching Solvent Cabinet

9902300 24" Manual Closing/Self Latching Solvent Cabinet – Right Hinged

9902400 24" Manual Closing/Self Latching Solvent Cabinet – Left Hinged

9903000 48" Self Closing/Automatic Latching Solvent Cabinet

9903100 36" Self Closing/Automatic Latching Solvent Cabinet

9903200 30" Self Closing/Automatic Latching Solvent Cabinet

9903300 24" Self Closing/Automatic Latching Solvent Cabinet – Right Hinged

9903400 24" Self Closing/Automatic Latching Solvent Cabinet – Left Hinged

9906000 24" Manual Closing/Self Latching ADA Solvent Cabinet – Right

Hinged

9906100 24" Manual Closing/Self Latching ADA Solvent Cabinet – Left Hinged

9906200 24" ADA Self Closing Automatic Latching Solvent Cabinet – Right

Hinged

9906300 24" ADA Self Closing/Automatic Latching Solvent Cabinet – Left

Hinged

9907000 18" Vacuum Pump Cabinet – Right Hinged

9907100 18" Vacuum Pump Cabinet – Left Hinged

8

Product Service 1-800-522-7658, International 816-333-8811

Page 13

Plus the Following:

Part # Component Description

9920301 Panel, Filler Standard (for 30” Interior Depth

Protector® XL Fume Hood)

or

9920304

9920400 Angle, Filler Panel (for 30” Interior Depth

Protector® XL Fume Hood)

or

9920401

1928300 Leveling Feet (4)

Different filler panel depths are available; refer to

Appendix C: Storage Cabinet Accessories for filler

panel selection.

If you do not receive one or more of the components

listed for your Storage Cabinet, or if any of the

components are damaged, contact Labconco

Corporation immediately for further instructions.

Panel, Filler ADA (for 30” Interior Depth

Protector® XL Fume Hood)

Angle, Filler Panel ADA (for 30” Interior

Depth Protector® XL Fume Hood)

Chapter 3: Getting Started

Setting Up Your Storage

Cabinet

After you verify the Storage Cabinet components listed

on the following pages, move your Storage Cabinet to

the location where you want to install it. Then, follow

the steps for installation.

Product Service 1-800-522-7658, International 816-333-8811

9

Page 14

Chapter 3: Getting Started

B

Component Identification

Protector Standard Base Storage Cabinets

Models 9900000, 9900100, 9900200, 9900300,

9900400, 9900500, 9900600, 9900700, 9900800,

9904000, 9904100, 9904200, 9904300, 9904400,

9904500

1. Cabinet. - Features 18 gauge steel exterior

sidewalls. The cabinet shell is epoxy coated to

provide a durable chemical resistant surface.

2. Door Assembly - Cabinet features one or two

manual closing, non-locking doors. The doors are

18 gauge epoxy coated steel and feature a strike and

latch assembly to hold them in position once closed.

3. Vent Connection - Cabinet features two vent

connections on the back wall of the cabinet. The

vent openings have been left open, and venting is at

the discretion of the customer. Instructions for

venting can be found on page 22. For Base Vent

Kit accessory see page 43.

4. Optional – Accessory Shelf – Features 16-gauge

steel shelf to provide additional storage. Shelf

support kit allows height adjustment.

5. Leveling Feet - Four individual leveling feet

provide adjustability to level the cabinet per the

requirements of your laboratory floor.

10

Product Service 1-800-522-7658, International 816-333-8811

Page 15

Protector Standard Base Storage Cabinet

Chapter 3: Getting Started

Product Service 1-800-522-7658, International 816-333-8811

11

Page 16

Chapter 3: Getting Started

A

Protector Acid Storage Cabinets

Models 9901000, 9901100, 9901200, 9901300,

9901400, 9901500, 9901600, 9905000, 9905100,

9905200, 9905300

1. Cabinet. Features 18 gauge steel exterior sidewalls.

The cabinet shell is epoxy coated to provide a

durable chemical resistant surface.

2. Door Assembly. Depending on the width, the

cabinet features one or two manual closing, nonlocking doors. The doors are 18 gauge epoxy

coated steel and feature a strike and latch assembly

to hold them in position once closed. The backs of

the doors are lined with polyethylene to provide

additional corrosion protection.

3. Vent Connection. Cabinet features two vent

connections located on the back wall of the cabinet.

These vents are open. Using a Vent Kit, the cabinet

may be vented to the fume hood or directly outside.

Instructions for venting can be found on page 22.

For Acid Vent Kit accessory see page 43.

4. Optional – Accessory Shelf. Features 16 gauge

steel shelf with polyethylene molded tray to hold

spills and provides a chemical resistant surface. The

shelf support kit allows height adjustment.

5. Leveling Feet. Four individual leveling feet provide

adjustability to level the cabinet per the

requirements of your laboratory floor.

6. Acid Shelf Liners. Vacuum formed polyethylene

liner trays fit down into both the adjustable shelf

and the bottom floor of the cabinet. These liner

trays give additional chemical resistance to the

cabinet interior and are removable for easy

cleaning. The liners are watertight in construction

and will contain any minor spills and/or drips from

containers stored in the cabinet.

7. Interior Liner. Interior sides and back are fully

lined with polyethylene plastic to provide excellent

corrosion resistance.

12

Product Service 1-800-522-7658, International 816-333-8811

Page 17

Protector Acid Storage Cabinet

Chapter 3: Getting Started

Product Service 1-800-522-7658, International 816-333-8811

13

Page 18

Chapter 3: Getting Started

S

Protector Solvent Storage Cabinets

Models 9902000, 9902100, 9902200, 9902300,

9902400, 9903000, 9903100, 9903200, 9903300,

9903400, 9906000, 9906100, 9906200, 9906300

1. Factory Mutual Approval on Models; 9902000,

9902100, 9902300, 9903000, 9903100, 9903200

2. Double Wall Construction. Cabinet features 18

gauge epoxy coated steel exterior and interior liner

walls with a 1-1/2" air space located between them.

3. Locking Door Assembly. Cabinet features one or

two manual closing/self latching doors. NOTE:

Some models feature one or two selfclosing/automatic latching doors.

4. Shelf. 16 gauge steel shelf features fully welded

corners to hold spills and epoxy coated to provide a

chemical resistant surface. The shelf supports

inside the cabinet allows for height adjustment.

5. Vent Connection. Two vent connections are

located on the back wall of the cabinet and are

diametrically opposed. Each vent connection

includes a threaded coupling, two flame arrestors,

and closure plugs. Instructions for venting can be

found on page 23.

6. Leveling Feet Four individual leveling feet provide

adjustability to level the cabinet per the

requirements of your laboratory floor.

7. Optional Self-Closing Doors. Some models

include a self-closing door mechanism to close

doors automatically in case of fire.

8. Sequential Kit. Allows doors with self-

closing/automatic latching to be sequenced so the

left door closes before the right.

9927400 - 30" models

9927401 - 48" models only

14

Product Service 1-800-522-7658, International 816-333-8811

Page 19

Protector Solvent Storage Cabinet

Chapter 3: Getting Started

Product Service 1-800-522-7658, International 816-333-8811

15

Page 20

Chapter 3: Getting Started

V

Protector Vacuum Pump Storage Cabinets

Models 9907000, 9907100

1. Cabinet – Features 18 gauge steel exterior

sidewalls. The cabinet shell has been epoxy coated

to provide a durable chemical resistant surface.

2. Door Assembly – Cabinet features one manual

closing, non-locking door. The door is of 18 gauge

epoxy coated steel and features a strike and latch

assembly to hold it in position once closed.

3. Vent Connection. Cabinet features two vent

connections on the back wall of the cabinet. These

vent openings have been left open and venting is

left to the discretion of the customer.

4. Electrical Connection – Cabinet features 115V, 60

Hz electrical outlet to provide power for the vacuum

pump.

5. Leveling Feet – Four individual leveling feet

provide adjustability to level the cabinet per the

requirements of your laboratory floor.

16

Product Service 1-800-522-7658, International 816-333-8811

Page 21

Protector Vacuum Pump Storage Cabinet

Chapter 3: Getting Started

Product Service 1-800-522-7658, International 816-333-8811

17

Page 22

Chapter 3: Getting Started

Installation

A

B

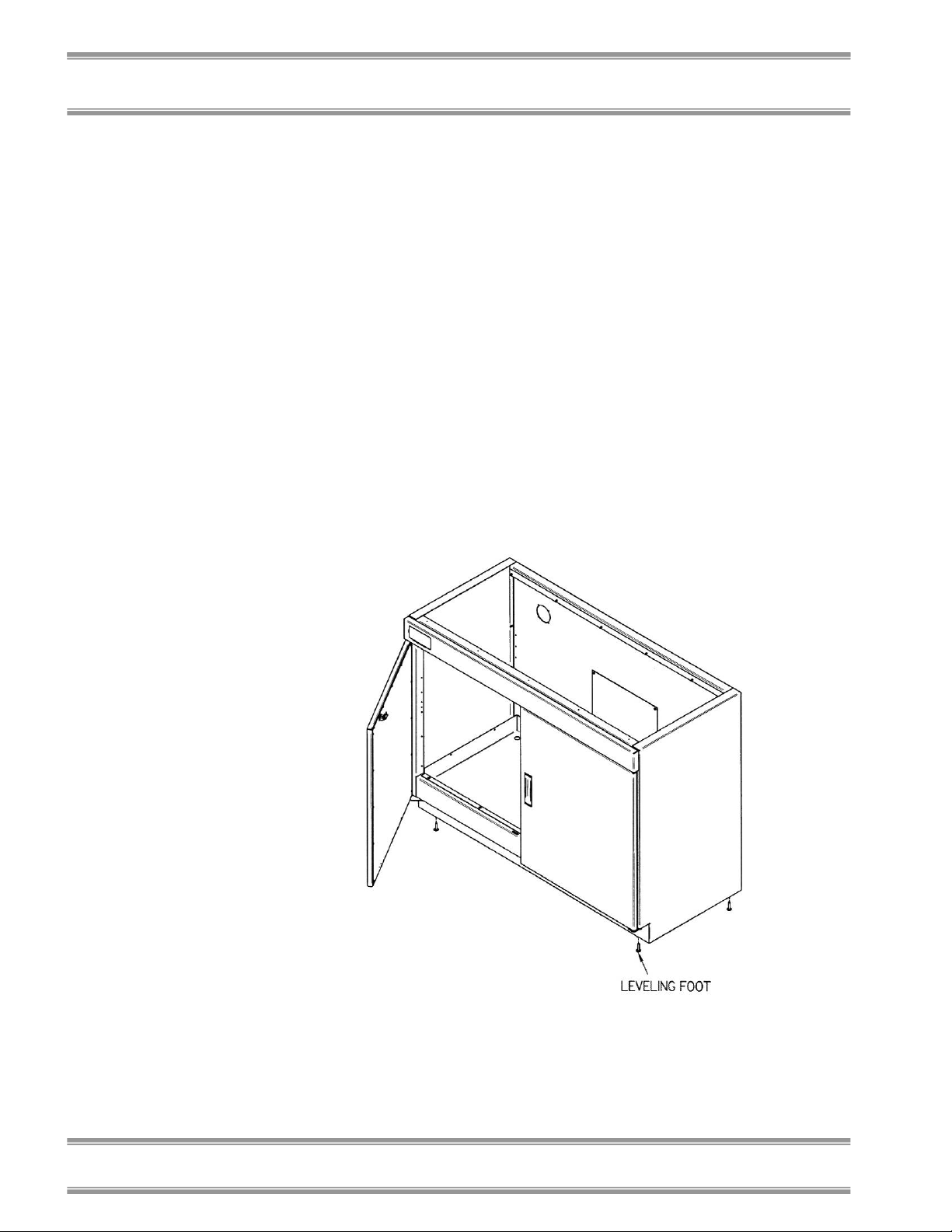

Cabinet Leveling – All Models

Each cabinet is supplied with four independent leveling

feet. These leveling feet have been packaged separately

and must be installed on the bottom of the cabinet

before installation. Each leveling foot is independently

adjustable by turning it by means of a crescent wrench

underneath the cabinet. All of the leveling feet, with

exception to the Solvent Storage Cabinet, can be

adjusted with a flat blade screw driver from inside the

cabinet through the access holes in the lower metal pan.

18

Product Service 1-800-522-7658, International 816-333-8811

Page 23

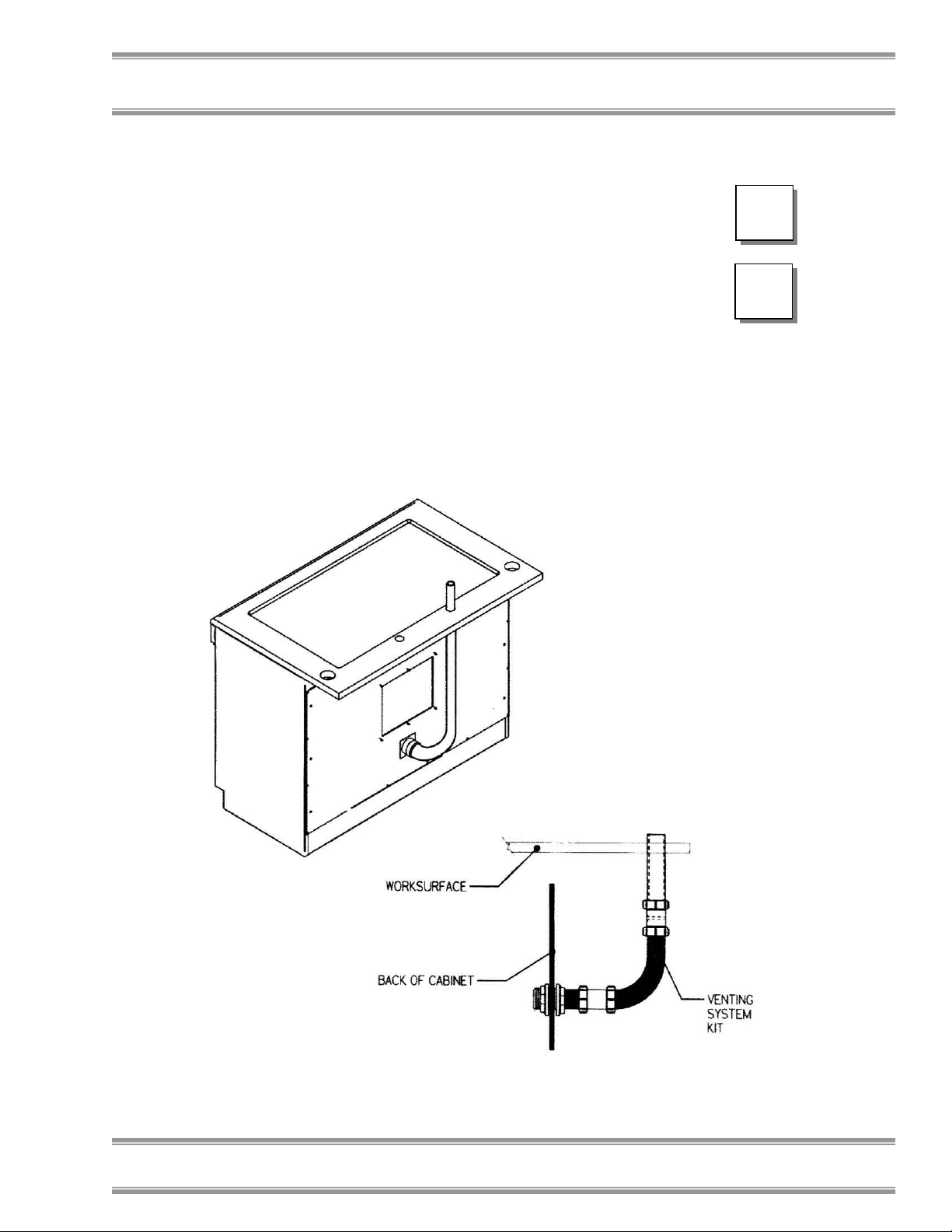

Vent Installation – Acid and Standard

Base Cabinet

Chapter 3: Getting Started

To ventilate the Acid Storage Cabinet and the Standard

Base Storage Cabinet properly, first decide which of the

two vent connections in the back of the cabinet that you

intend to use. The lower vent connection should be

used for heavier than air vapors and the upper vent

connection should be used for lighter than air vapors to

obtain the best results within the cabinet structure.

Vent Kit, P/N 35911, allows the Acid Storage Cabinet

or Standard Base Cabinet to be vented directly into a

Protector® Laboratory Hood. Run the vent line

through the work surface into the fume hood or connect

through separate duct system to the outside. The vent is

sized for 2" diameter nominal plastic pipe.

A

B

Product Service 1-800-522-7658, International 816-333-8811

19

Page 24

Chapter 3: Getting Started

S

Vent Installation – Solvent Storage

Cabinet

To ventilate the cabinet properly remove both the

exterior and interior barrel plugs from the vent

connection that you are venting.

The lower vent connection should be used for heavier

than air vapors and the higher vent connection on the

back wall should be used for lighter than air vapors to

obtain the best fume removal within the cabinet.

The cabinet vent connections are designed to accept 2"

diameter threaded metal pipe material, which can be

purchased locally. Once the connection on the back of

the cabinet has been completed, remove both the

internal and external plugs from the remaining vent

connection to allow for proper airflow from the cabinet.

CAUTION

!

used with your vent connections

should it become necessary to isolate

the cabinet from the vent connection

as ducted.

: Retain the barrel plugs

20

Product Service 1-800-522-7658, International 816-333-8811

Page 25

Filler Panel – All Cabinets

One 8.0" filler panel and filler panel angle has been

supplied with your cabinet to close off the plumbing

access. Attach the filler panel angle directly to the back

wall of the cabinet structure using the four #8 sheet

metal screws that hold the back panel in position. Next,

attach the filler panel to this angle by the three #8 sheet

metal screws provided.

Different filler panel depths are available; refer to

Appendix C: Storage Cabinet Accessories for filler

panel selection.

Chapter 3: Getting Started

S

V

Product Service 1-800-522-7658, International 816-333-8811

21

Page 26

Chapter 3: Getting Started

SpillStopper™ Work Surface

A S

B

V

Once your cabinet has been properly leveled, vented

(optional), and filler panel installed, place the epoxy

work surface directly on top of the cabinet. It is not

necessary to attach the work surface to the cabinet. It is

held in place both by its own weight and the weight of

the fume hood and other equipment on top of it. Align

the work surface on top of the cabinet before making

plumbing or electrical connections through the work

surface itself. Normally, the work surface is aligned

flush with the top front of the cabinet and overhangs the

back of the cabinet.

WARNING: Never use screws and/or

!

bolts to fasten the epoxy molded work

surface directly to the cabinet as this

can damage the work surface.

22

Product Service 1-800-522-7658, International 816-333-8811

Page 27

SpillStopper™ Work Surface Installation Detail

Chapter 3: Getting Started

Dimensions Shown in Inches

Hood Depth

“B”

33.19" 24" 8" 30"

39.19" 30" 14" 36"

45.19" 36" 20" 42"

Hood Internal

Depth

“D”

Filler Panel

Depth

“E”

Work Surface

Depth

Product Service 1-800-522-7658, International 816-333-8811

23

Page 28

Chapter 3: Getting Started

S

Electrical Ground Connection – Solvent

Storage Cabinet

Use the grounding screw located in the lower right hand

corner on the back panel of your solvent storage cabinet

to properly ground the cabinet structure. Remove the

grounding screw and attach a grounding wire directly to

the back of the cabinet at this point. Make sure you

have a tight bond when you retighten the grounding

screw.

24

Product Service 1-800-522-7658, International 816-333-8811

Page 29

Shelf Liner – Acid Storage Cabinet

Polyethylene liner trays have been included in your

Acid Storage Cabinet for added chemical resistance.

Place a shelf liner in the cabinet floor. The watertight

tray collects spills and drips from bottles and containers

stored within the cabinet.

Chapter 3: Getting Started

A

Adjustable Shelf – Solvent Storage

Cabinet

Remove the four shelf brackets included with the

cabinet’s leveling feet and place one bracket in each of

the shelf positions located on the interior walls of the

cabinet. Make sure that the shelf brackets are located at

the same height to assure that the shelf will be level

when placed in its working position. To install, simply

squeeze the shelf bracket with pliers and place in the

shelf positions of your cabinet.

Junction Box Connection – Vacuum

Pump Storage Cabinet

Connect power to the electrical junction box, provided

for the vacuum pump, through the back panel to the

receptacle.

S

V

Product Service 1-800-522-7658, International 816-333-8811

25

Page 30

Chapter 3: Getting Started

Environmental Conditions

This equipment is designed to be safe under the

following conditions:

• Indoor use

• Altitude up to 6562 Ft. (2000m)

• Temperature 41° to 104° F (5° to 40°C)

• Maximum relative humidity 80% for

temperatures up to 88°F (31°C) decreasing

linearly to 50% relative humidity at 104°F

(40°C)

• Main supply voltage fluctuations not to

exceed ± 10% of the nominal voltage

• Transient overvoltages according to

Installation Categories II (Overvoltage

Categories per IEC 1010)

• Pollution degrees 2, in accordance with IEC

664, normally only non-conductive foreign

matter, solid, liquid, or gaseous (ionized

gases), that may produce a reduction of

dielectric strength or surface resistivity

occurs. Occasionally, however, a temporary

conductivity caused by condensation must

be expected

26

Product Service 1-800-522-7658, International 816-333-8811

Page 31

C

HHAAPPTTEERR

C

U

SSIINNG

U

S

TTOORRAAGGEE

S

After the Storage Cabinet has been installed as detailed

in Chapter 3: Getting Started, you are ready to begin

using it. Read this chapter to learn how to:

• Properly store and vent chemicals.

• Operate it in a safe manner.

Normal Operation

Although the Storage Cabinet is engineered to maintain

the optimum in operator safety, caution should always

be used while working with it. Good general

housekeeping procedures with the following specific

recommendations should allow you to operate your

cabinet safely for years to come.

• Properly vent your storage cabinet to the

outside atmosphere.

G

Y

Y

4

4

OOUURR

C

AABBIINNEETT

C

• It is not recommended to store solvents and

acids in the same storage cabinet. For best

results, use two separate storage cabinets to

safeguard or protect these materials.

Product Service 1-800-522-7658, International 816-333-8811

27

Page 32

Chapter 4: Using Your Storage Cabinet

• Do not block open the door assembly on the

S

• Do not store flammable material in excess of

• Do not block either vent connection as it

• Always clean up spills immediately to

solvent storage cabinet. This is an unsafe

practice should a fire occur.

the individual Solvent Storage Cabinet

rating. Ratings are located on the nameplate

of each Solvent Storage Cabinet.

will alter the airflow pattern in the cabinet

and could interfere with ventilation of the

cabinet.

prolong the life of your Storage Cabinet.

28

Product Service 1-800-522-7658, International 816-333-8811

Page 33

C

HHAAPPTTEERR

C

M

S

Under normal conditions, the Storage Cabinet requires

little maintenance. The following maintenance

schedule is recommended:

As Needed:

Remove liquid containers from cabinet and clean up

spills.

AAIINNTTAAIINNIINNG

M

TTOORRAAGGEE

S

5

5

C

Y

G

Y

AABBIINNEETTSS

C

OOUURR

Product Service 1-800-522-7658, International 816-333-8811

29

Page 34

A

PPPPEENNDDIIX

A

S

TTOORRAAGGEE

S

D

IIMMEENNSSIIOONNSS

D

The following drawings provide dimensions for the

Standard Base Cabinet, Acid Storage Cabinet, Solvent

Storage Cabinet, and the Vacuum Pump Cabinet.

X

A

A

C

C

AABBIINNEET

T

30

Product Service 1-800-522-7658, International 816-333-8811

Page 35

Protector Standard Base Cabinet

Appendix A: Dimensions

Product Service 1-800-522-7658, International 816-333-8811

31

Page 36

Appendix A: Dimensions

Protector Acid Storage Cabinet

32

Product Service 1-800-522-7658, International 816-333-8811

Page 37

Protector Solvent Storage Cabinet

Appendix A: Dimensions

Product Service 1-800-522-7658, International 816-333-8811

33

Page 38

Appendix A: Dimensions

Protector Vacuum Pump Cabinet

34

Product Service 1-800-522-7658, International 816-333-8811

Page 39

A

PPPPEENNDDIIX

A

S

TTOORRAAGGE

S

R

EEPPLLAACCEEMMEENNT

R

P

AARRTTS

P

The following pages list components that are typical

replacement parts. If other parts are required, contact

Product Service.

Part # Description Cabinet Type

1928300 Leveling Feet All

1663600 Door Bumpers All

1928400 Handle, Acid All but Solvent

3598300 Lock Handle, Solvent Solvent Only

1934500 Rotary Catch, Door Latch All but Solvent

1930600 Shelf Support Clip, Solvent Solvent Only

9921200 48" Adjusting Solvent Shelf Solvent Only

9921201 36" Adjusting Solvent Shelf Solvent Only

9921202 30" Adjusting Solvent Shelf Solvent Only

9921203 24" Adjusting Solvent Shelf Solvent Only

1934100 Bushing, Brass – Door Hinge Support All

9917100 Lower Hinge Assembly, Right All

9717101 Lower Hinge Assembly, Left All

9920700 Upper Hinge Pin All

9922100 48" Lower Acid Polyethylene Tray Acid Only

9922101 36" Lower Acid Polyethylene Tray Acid Only

9922102 30" Lower Acid Polyethylene Tray Acid Only

9922103 24" Lower Acid Polyethylene Tray Acid Only

9922104 18" Lower Acid Polyethylene Tray Acid Only

S

E

X

C

B

B

C

AABBIINNEET

T

T

Product Service 1-800-522-7658, International 816-333-8811

35

Page 40

A

A

B

A

PPPPEENNDDIIXX

A

S

TTOORRAAGGEE

S

A

CCCCEESSSSOORRIIEESS

A

The following accessories are available for the Storage

Cabinets.

Vent Kit - Part No. 3591100

Includes one plastic vent tube assembly complete with

2" diameter threaded connector locknut, flexible tubing

and vent extension. Vent kit is used for venting Acid

Storage Cabinets through Spillstopper worksurface and

into the fume hood. Shipping weight 5 lbs. (2.3 kg).

Shelf Kits for Acid Storage Cabinets -

These kits provide additional shelf, polyethylene

tray, and mounting hardware.

48" 9919000

36" 9919001

30" 9919002

24" 9919003

18" 9919004

C

C

C

C

AABBIINNEETT

36

B

Product Service 1-800-522-7658, International 816-333-8811

Shelf Kits for Standard Base Cabinets –

These kits provide additional shelf, and mounting

hardware.

48" 9919100

36" 9919101

30" 9919102

24" 9919103

18" 9919104

12" 9919105

Page 41

Appendix C: Accessories

Work Surfaces

9727500 4' Work Surface Only, 30" Depth

9727501 5' Work Surface Only, 30" Depth

9727502 6' Work Surface Only, 30" Depth

9727503 8' Work Surface Only, 30" Depth

9727504 10' Work Surface Only, 30" Depth – Two Piece

9727505 12' Work Surface Only, 30" Depth – Two Piece

9727506 16' Work Surface Only, 30" Depth – Three Piece

9727507 4' Work Surface Only, 36" Depth

9727508 5' Work Surface Only, 36" Depth

9727509 6' Work Surface Only, 36" Depth

9727510 8' Work Surface Only, 36" Depth

9727511 10' Work Surface Only, 36" Depth – Two Piece

9727512 12' Work Surface Only, 36" Depth – Two Piece

9727513 16' Work Surface Only, 36" Depth – Three Piece

9727514 4' Work Surface Only, 42" Depth

9727515 5' Work Surface Only, 42" Depth

9727516 6' Work Surface Only, 42" Depth

9727517 8' Work Surface Only, 42” Depth

9727518 10' Work Surface Only, 42" Depth – Two Piece

9727519 12' Work Surface Only, 42" Depth – Three Piece

9727520 16' Work Surface Only, 42" Depth – Three Piece

9732000 4' HOPEC Work Surface

9732001 5' HOPEC Work Surface

9732002 6' HOPEC Work Surface

9732003 8' HOPEC Work Surface

9732004 4' HOPEC Work Surface with (1) cupsink cutout

9732005 5' HOPEC Work Surface with (1) cupsink cutout

9732006 6' HOPEC Work Surface with (1) cupsink cutout

9732007 8' HOPEC Work Surface with (1) cupsink cutout

Other Work Surfaces with cutout options are available. Contact Labconco

Corporation for ordering.

Self-Closing Kit for Solvent Storage Cabinets

9914700 Self-Closing/Automatic Latching Solvent Left Hinged Door

Kit

9914701 Self-Closing/Automatic Latching Solvent Right Hinged

Door Kit

9914702 Self-Closing/Automatic Latching Solvent Double Door Kit

- 30" and 36" units

9914703 Self-Closing/Automatic Latching Solvent Double Door Kit

- 48" unit

Product Service 1-800-522-7658, International 816-333-8811

37

Page 42

Appendix C: Accessories

Filler Panel Kits

9920300 Panel, Filler 24" for Interior depth Protector XL Fume Hood

9920301 Panel, Filler 30" for Interior depth Protector XL Fume Hood

9920302 Panel, Filler 36" for Interior depth Protector XL Fume Hood

9920303 Panel, Filler ADA 24" for Interior depth Protector XL Fume

Hood

9920304 Panel, Filler ADA 30" for Interior depth Protector XL Fume

Hood

9920305 Panel, Filler ADA 36" for Interior depth Protector XL Fume

Hood

9920306 Panel, Filler Protector Fume Hood

9920307 Panel, Filler ADA Protector Fume Hood

*Individual kits contain one filler panel, filler panel angle, and

mounting screws.

38

Product Service 1-800-522-7658, International 816-333-8811

Page 43

APPENDIX D

QUICK REFERENCE

STORAGE CABINETS

Size/Description Dual Doors Right Hinge Left Hinge Dual Doors Right Hinge Left Hinge

48" 9902000* - - 9901000 - 36" 9902100* - - 9901100 - 30" 9902200* - - 9901200 - 24" - 9902300 9902400 - 9901300 9901500

18" - - - - 9901400 9901600

12" - - - - - 48" w/Self Closing /Automatic

Latching Doors

36" w/Self Closing /Automatic

Latching Doors

30" w/Self Closing /Automatic

Latching Doors

24" w/Self Closing /Automatic

Latching Doors

24" ADA - 9906000 9906100 - 9905000 9905200

24" ADA w/Self Closing Doors - 9906200 9906300 - - 18" ADA - - - - 9905100 9905300

12" ADA - - - - - -

Size/Description Dual Doors Right Hinge Left Hinge Dual Doors Right Hinge Left Hinge

48" 9900000 - - - - 36" 9900100 - - - - 30" 9900200 - - - - 24" - 9900300 9900600 - - 18" - 9900400 9900700 - 9907000 9907100

12" - 9900500 9900800 - - 48" w/Self Closing Doors - - - - - 36" w/Self Closing Doors - - - - - 30" w/Self Closing Doors - - - - - 24" w/Self Closing Doors - - - - - 24" ADA - 9904000 9904300 - - 24" ADA w/Self Closing Doors - - - - - 18" ADA - 9904100 9904400 - - 12" ADA - 9904200 9904500 - - -

9903000* - - - - -

9903100* - - - - -

9903200* - - - - -

- 9903300 9903400 - - -

*Factory Mutual Listed

SOLVENT ACID

STANDARD BASE VACUUM PUMP

Product Service 1-800-522-7658, International 816-333-8811

39

39

Page 44

Declaration of Conformity

DECLARATION OF CONFORMITY

Application Council Directive(s): 73/23/EEC, 89/336/EEC, 2002/95/EC (ROHS),

2002/96/EC (WEEE)

Standard(s) to which conformity is declared: EN61010-1, EN61326-1

Manufacturer’s Name: Labconco Corporation

Manufacturer’s Address: 8811 Prospect Avenue

Kansas City, MO 64132 USA

Importer’s Name: See Shipping/Customs Documents

Importer’s Address: See Shipping/Customs Documents for your equipment

Type of Equipment: Laboratory Equipment - Storage Cabinets

Model No.:

9904000 thru 9904500 ADA Standard Base Cabinet

9901000 thru 9901600 Acid Storage Cabinet

9905000 thru 9905300 ADA Acid Storage Cabinet

9902000 thru 9902400 Solvent Storage Cabinet

9903000 thru 9903400 Self Closing Solvent Storage Cabinet

9906000 thru 9906100 ADA Solvent Storage Cabinet

9906200 thru 9906300 ADA Self Closing Solvent Storage Cabinet

9907000 thru 9907100 Vacuum Pump Cabinet

Serial No.: Various – See Individual Declaration

Year of Manufacture: 1999 and Subsequent

I, the undersigned, hereby declare that the equipment specified above conforms to the

above Directive(s) and Standard(s).

See individual Declaration of Conformity which

will be signed by the importer for your country.

Place: _______________________________________

(Signature)

Date: _______________________________________

(Full Name)

_______________________________________

(Position)

Labconco P/N 36960-19, Rev. B, ECO E394

9900000 thru 9900800 Standard Base Cabinet

40

Product Service 1-800-522-7658, International 816-333-8811

Loading...

Loading...