Page 1

Protector®

Multi-Hazard Glove Box

Models 5065000, 5065002

5065500, 5065502

INSTRUCTION MANUAL

Product designs are subject to change without notice

© 2002 Labconco Corporation

50937 Rev C, ECO 9999

Printed in U.S.A.

Page 2

TABLE OF CONTENTS

Introduction

Preface/Important Notices .................................................................4

Components Shipped .........................................................................5

General Description ...........................................................................6

Optional Filters ..................................................................................6

Charcoal Filters..................................................................................6

Additional Exhaust HEPA Filter Kit .................................................6

Performance .......................................................................................7

Environmental Conditions .................................................................7

Component Identification ..................................................................8

Installation....................................................................................................11

Location .............................................................................................11

Connection Exhaust ...........................................................................11

Glove Attachment ..............................................................................11

Glove Replacement............................................................................11

Safety Precautions........................................................................................12

Normal Operation........................................................................................13

Blower Operation...............................................................................13

Routine Maintenance...................................................................................14

Estimation of Filter Condition ...........................................................14

Filter Replacement.............................................................................14

Suggested Plan for Decontamination.................................................14

Gloves ................................................................................................15

Transfer Chamber Inner and Outer Door...........................................15

Fluorescent Lamp Replacement.........................................................16

Replacement Parts .......................................................................................17

Dimensional Data.........................................................................................24

Electrical Specifications ..............................................................................25

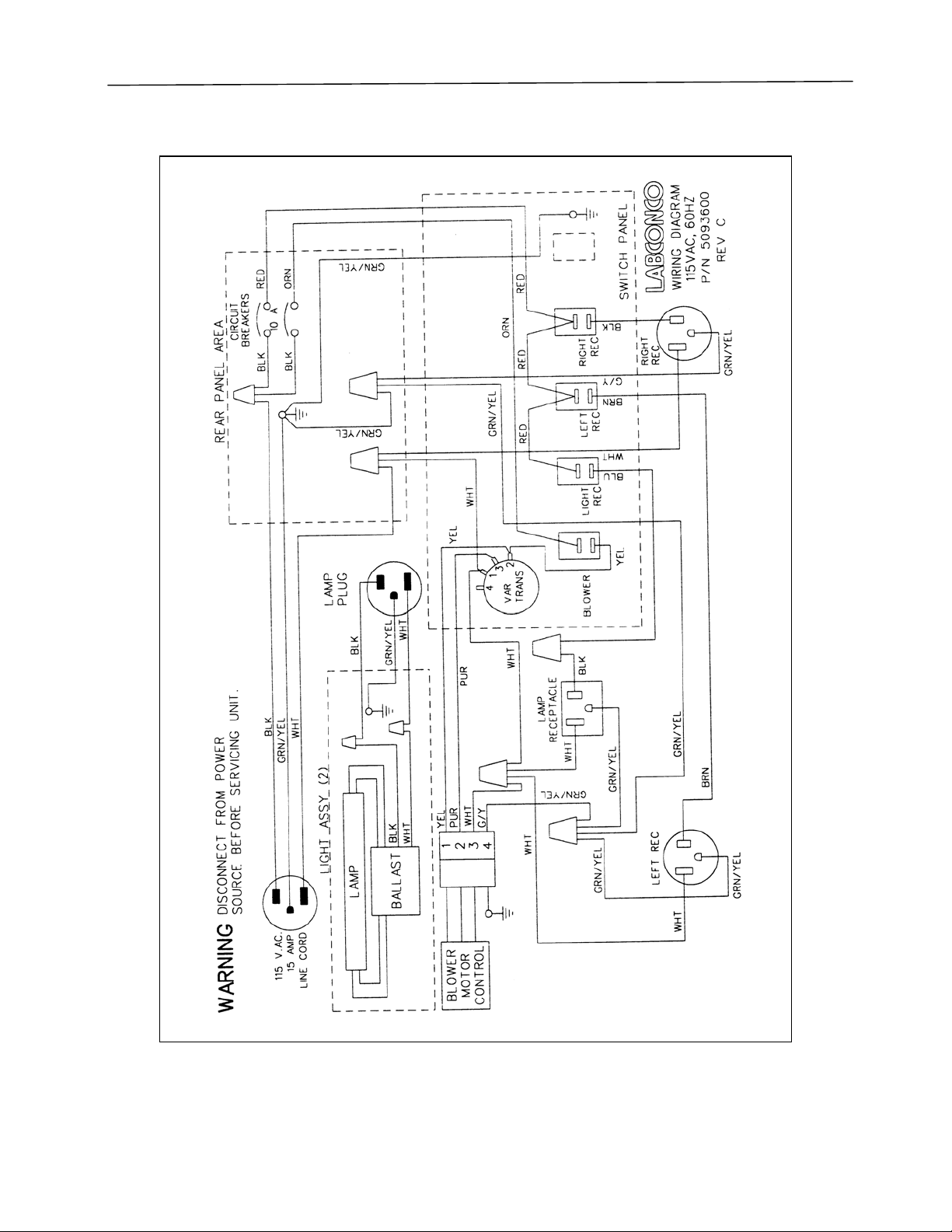

Wiring Diagrams..........................................................................................26

Accessories....................................................................................................28

Warranty ......................................................................................................29

Shipping Claims ...........................................................................................30

Contacting Labconco...................................................................................31

Declaration of Conformity ..........................................................................32

Page 3

PREFACE

Thank you for displaying confidence in us by selecting a Labconco Protector® MultiHazard Glove Box. Our design engineers, assemblers and inspectors have utilized their skills and

years of experience to ensure that the new Labconco Controlled Atmosphere Glove Box meets our

high standards of quality and performance.

IMPORTANT NOTICE

Labconco Protector® Glove Boxes are designed to contain chemical and some biohazardous materials. The Protector should not be considered a Class III Bio-Hazard Cabinet, nor

should they be considered for use with Biosafety Level 4 agents. While the Protector Glove Box

provides a physical barrier between the user and their work, it is the user’s responsibility to ensure

that all materials are appropriately decontaminated, inactivated, or rendered harmless before

removal from the unit. For further information regarding the handling of specific materials, please

contact your facilities safety officer.

All the end users should read this manual carefully in order to become familiar with the

operation of the glove box. Recommendations are made within the manual to help you obtain

maximum performance and life from your product.

We have included sections on initial set up, operation, maintenance and troubleshooting to

provide you with all the tools necessary to achieve maximum performance.

If you have questions or concerns, do not hesitate to call us at 1-800-821-5525 for

assistance.

4

Page 4

INTRODUCTION

Components Shipped

Carefully check the contents of the carton for damage that might have occurred in transit.

Do not discard the carton or packing material until all components have been checked against the

following component list and the equipment has been installed and tested.

As shipped, the carton should contain the following:

Part Number Description

5065000 Multi-Hazard Glove Box, Fiberglass

or

5065500 Multi-Hazard Glove Box, Stainless Steel

5005600 Glove Kit – Pair, Neoprene, size 9-3/4

(includes 2 - O-Rings)

5093700 Instruction Manual

5

Page 5

INTRODUCTION

General Description

The Multi-Hazard Glove Box is equipped with a blower, air damper and filter system that

provide versatility for many particular applications. The variable speed blower provides air

volumes between 10 and 50 CFM and negative glove box pressure up to 1.5 inches H2O

gauge. The air damper provides a means for operating the glove box at a more negative

pressure when the blower is running at low speed (low air volume). The filtering system

consists of one inlet HEPA and one exhaust HEPA filter (both rated at 99.99% efficient on

0.3 micron particulates). A “roughing” prefilter is also provided to capture room air

particles and extend the life of the inlet HEPA filter.

Optional Filters: (for installation between exhaust HEPA and blower).

Charcoal Filter: (Cat. No. 5065300) contains 4 lbs. of Barnebey and Sutcliffe type 787

impregnated, activated carbon for removal of gaseous radioisotopes.

Additional Exhaust HEPA Filter Kit (Cat. No. 5065200) same as filter shipped with unit,

plus an extended length tube for connection to blower.

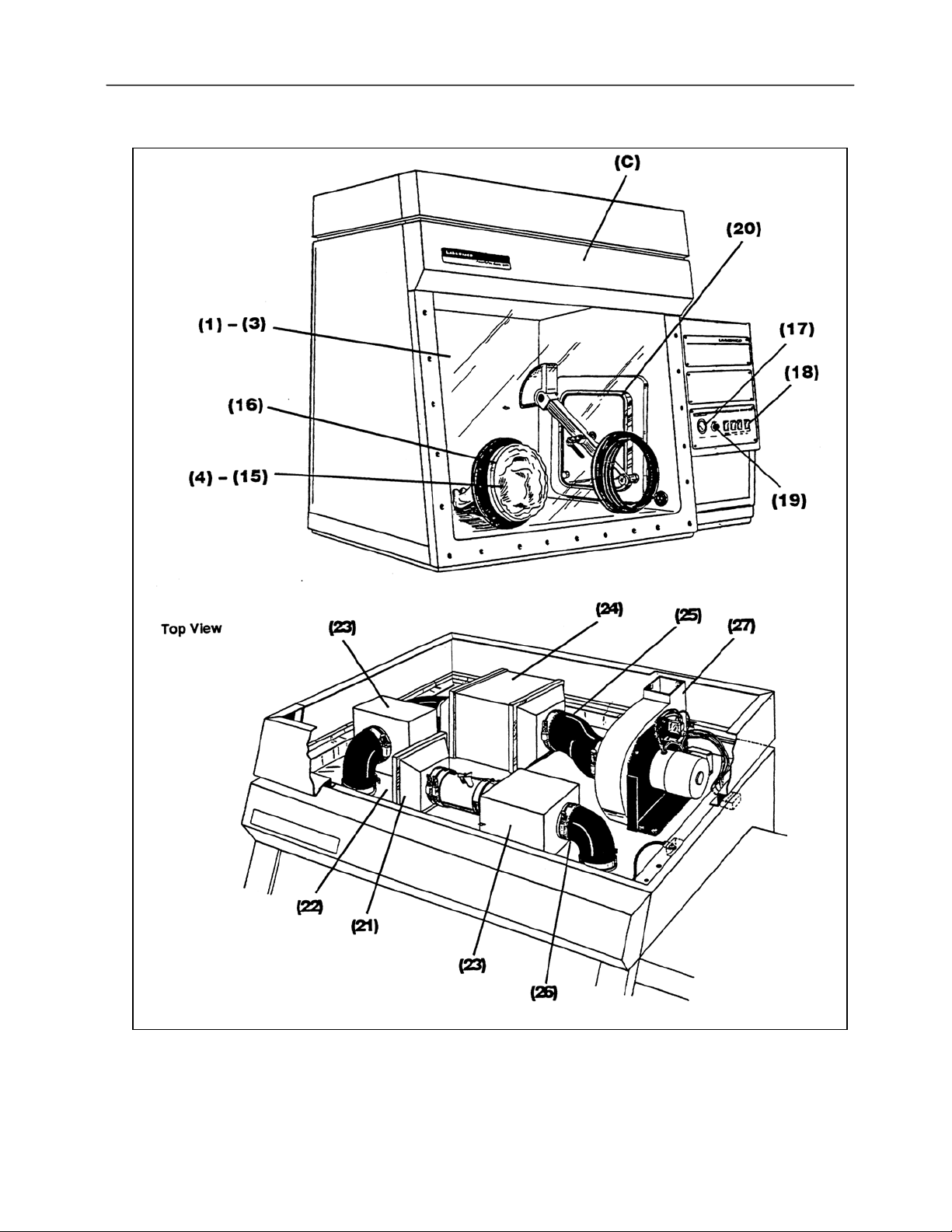

Figure 1

6

Page 6

INTRODUCTION

Performance

The Labconco Protector Multi-Hazard Glove Box has been carefully designed, constructed

and tested in order to provide an effective physical barrier between the laboratory and the glove

box interior. This barrier and the filtering system, provides a clean air enclosure for protection of

specimens and materials. It also provides protection to the technician from contaminated materials

and specimens.

Environmental Conditions

This equipment is designed to be safe under the following conditions:

• Indoor use

• Altitude up to 6562 Ft. (2000m)

• Temperature 41° to 104° (5° to 40°)

• Maximum relative humidity 80% for temperatures up to 88°F (31°C) decreasing linearly to

50% relative humidity at 104° (40°C)

• Main supply voltage fluctuations not to exceed ± 10% of the nominal voltage

• Transient over voltages according to Installation Categories II (Over voltage Categories per

IEC 1010)

• Pollution degrees 2 (Normally only non-conductive foreign matter, solid, liquid, or gaseous

(ionized gases), that may produce a reduction of dielectric strength or surface resistivity

occurs. Occasionally, however, a temporary conductivity caused by condensation must be

expected), in accordance with IEC 664

7

Page 7

INTRODUCTION

Component Identification

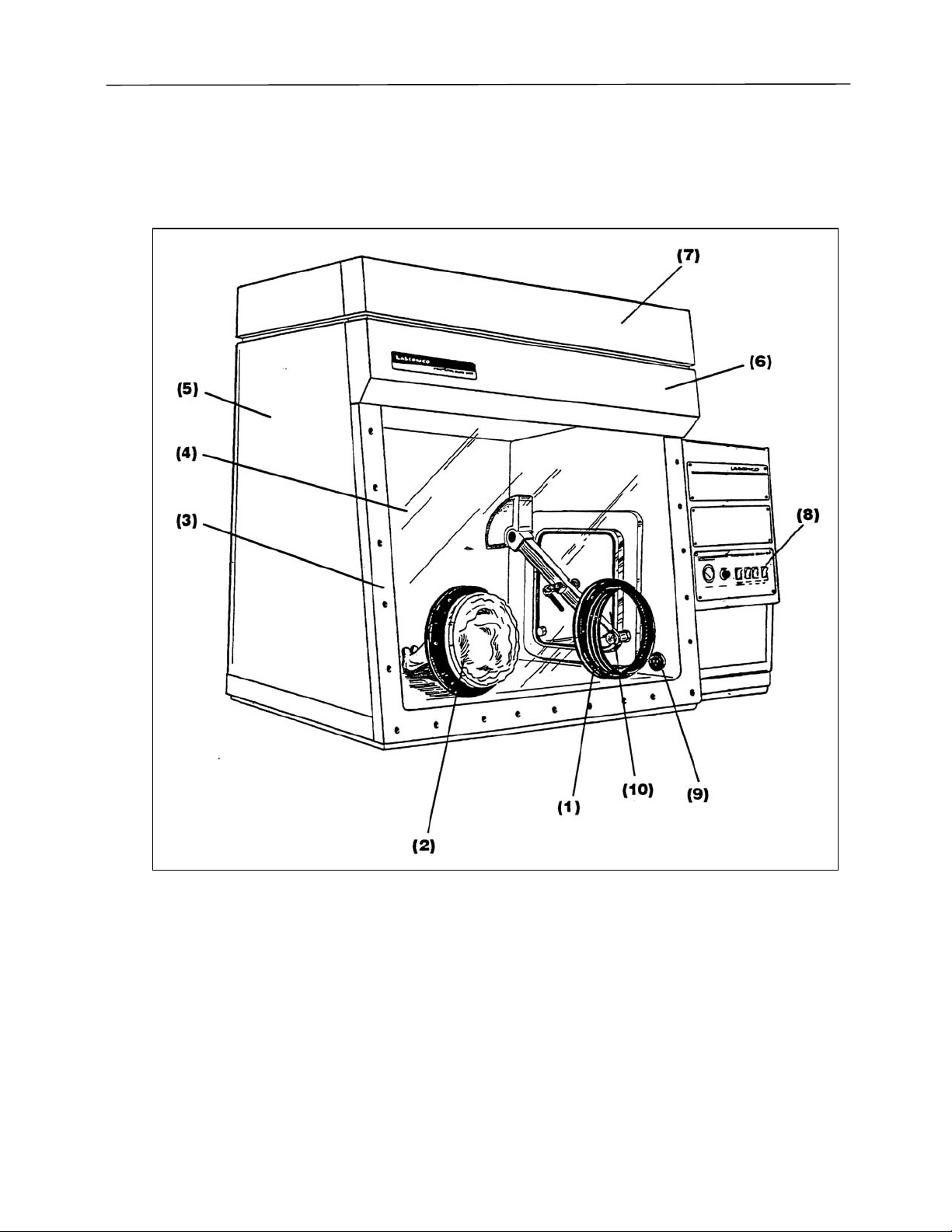

General components of the glove box are listed below and identified in Figure 2.

1. Glove Ports. Epoxy coated aluminum, 8" ID, spaced 17" apart, sealed to viewing window

with one-piece molded neoprene gasket. Supplied with dual O-ring grooves, neoprene

gloves, and retaining O-rings.

2. Neoprene Gloves. Supplied with the glove box, gloves are .015" thick neoprene, 30" long,

one pair, and size 9-3/4. (Note: For replacement gloves, see Replacement Parts on page

18.

3. Window Frame. 12-gauge epoxy coated steel, attached with 30 stainless steel, ¼-20

screws, removable for full access to the interior.

4. Viewing Window. 3/8" thick laminated safety glass, mounted at 10° angle and sealed with

one-piece molded neoprene gasket. Optional 3/8" thick polycarbonate with abrasion

resistant coating available. See page 18.

5. Left Side Panel. 20-gauge epoxy coated steel, easily removable for access to glove box

and left electrical outlet.

6. Fluorescent Lamp. 30 watts provides minimum of 60-foot candles illumination to interior

work surface. Supplied with electrical cord and plug, the lamp may be easily removed for

bulb replacement and for access to removable viewing window. For lamp replacement see

page 16.

7. Façade. 18-gauge, epoxy coated steel, conceals filter damper, and blower.

8. Control Panel. Contains gauge for glove box pressure and switches for fluorescent lamp,

interior receptacles, blower power, and blower speed control.

9. 115 Volt, 3-Wire Receptacles (Models 5065000 and 5065500). One right and one left

interior receptacle, 9 amps combined rating. Exterior switches provide separate control of

each receptacle.

230 Volt, 3-Wire Receptacles (Models 5065002 and 5065502). One right and one left

interior receptacle, 8 amps combined rating. Exterior switches provide separate control of

each receptacle.

10. Transfer Chamber Door. Counterweighted with quick operating latch.

8

Page 8

INTRODUCTION

Figure 2

9

Page 9

INTRODUCTION

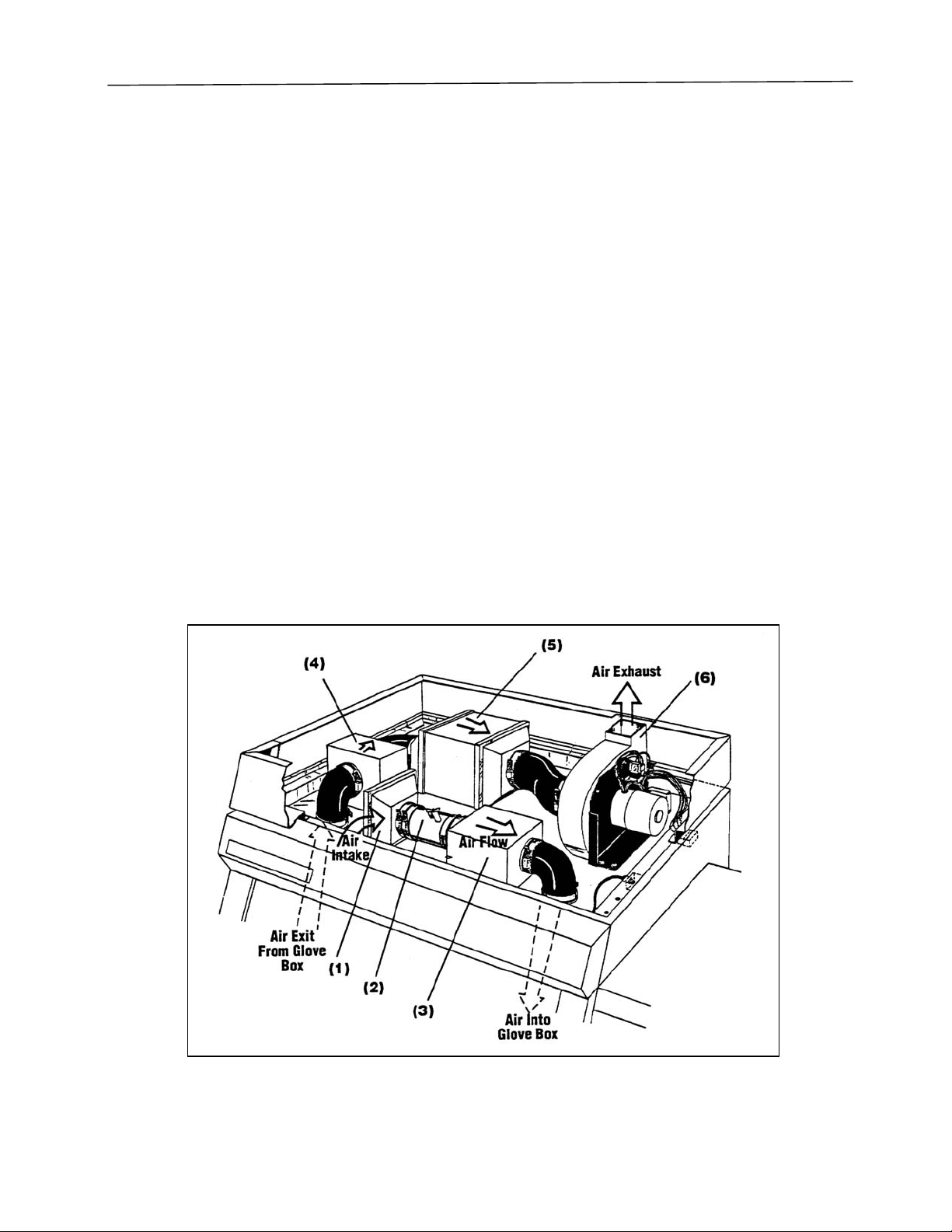

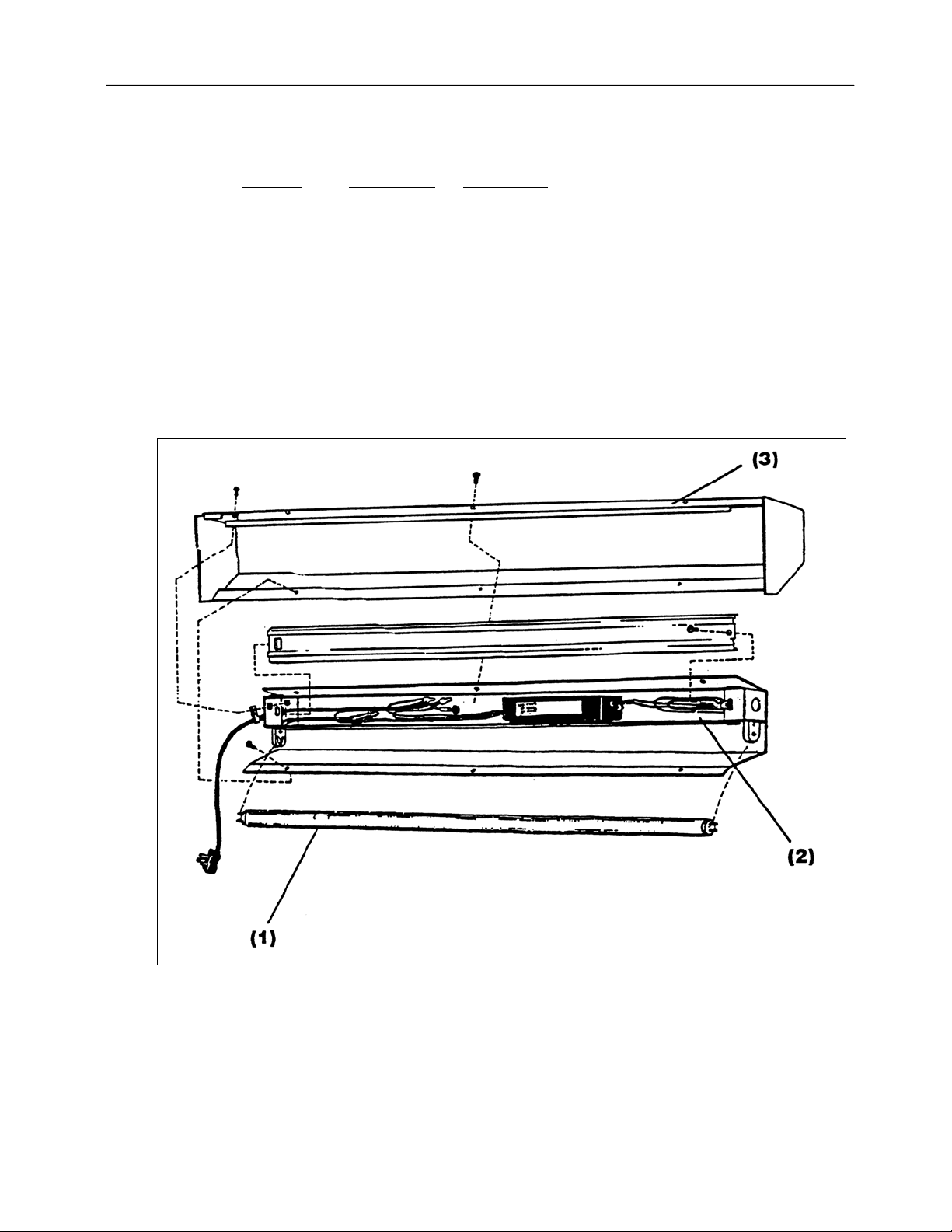

Airflow system components are listed below and are identified in Figure 3.

1. Inlet Pre-Filter. Polyester fiber mat filter captures larger room air particles to extend life

of inlet HEPA filter.

2. Air Damper. Adjust fully open (parallel with air flow) for maximum airflow volume.

Adjust toward closed position to increase glove box negative pressure differential (if

desired) when operating blower at low speed.

3. Inlet HEPA Filter. Rated 99.99% efficient on 0.3-micron particulates. NOTE: Inlet and

exhaust filters are identical. Airflow direction is indicated on the filter.

4. Exhaust HEPA Filter. Rated 99.99% efficient on 0.3-micron particulates.

5. NOTE: Unit is normally supplied with a removable tube at this location which can easily

be replaced with either of the two following optional filters:

Charcoal Filter (Cat. No. 5065300) contains 4 lbs. of Barnebey and Sutcliffe type 787

impregnated carbon (for removal of gaseous radioisotopes).

Additional Exhaust HEPA Filter Kit (Cat. No. 5065200)

6. Blower. Adjustable speed (control is located on front control panel) provides airflow

between 10 and 50 CFM. The discharge opening measures 3 inch square.

Figure 3

10

Page 10

INSTALLATION

Location

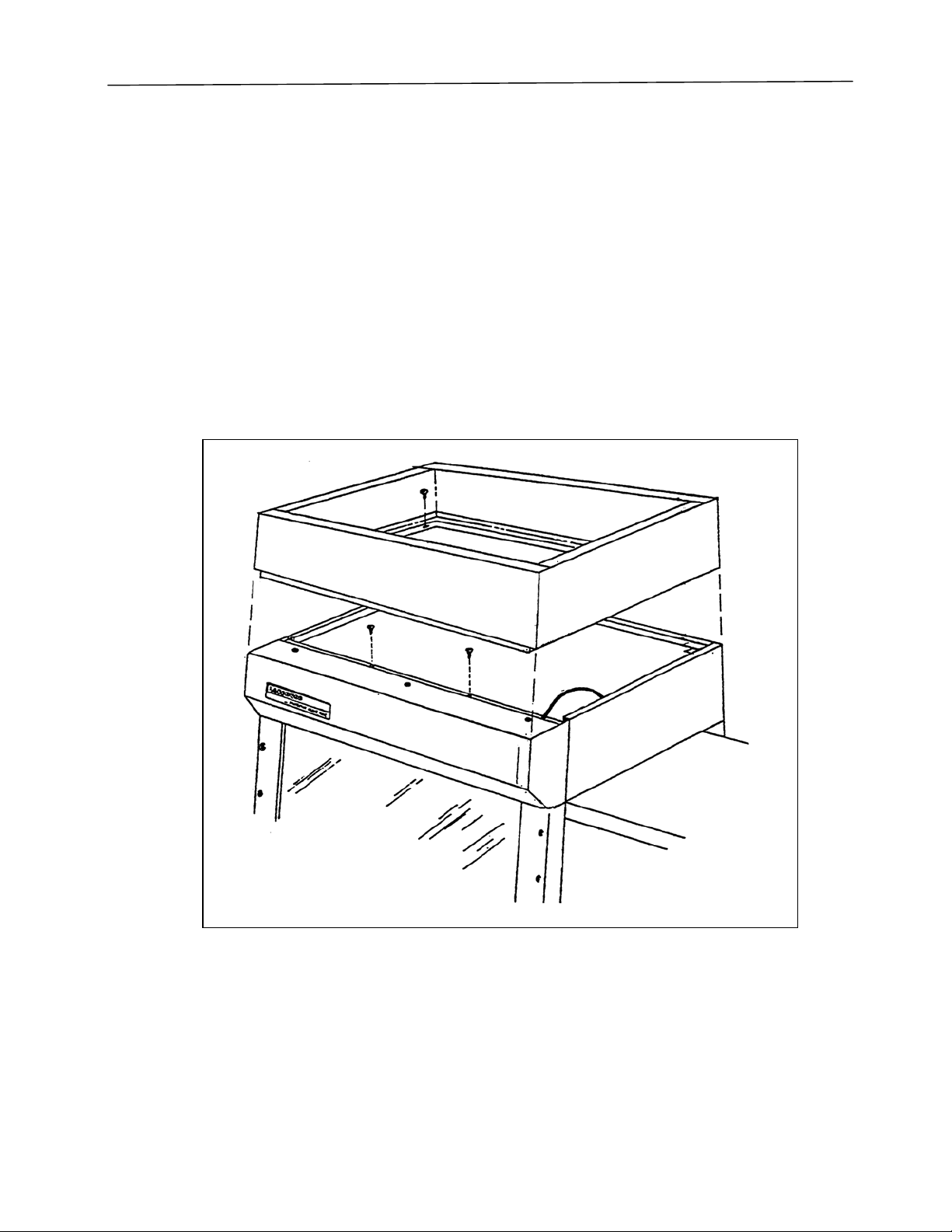

Glove box should be placed on a stable, level base stand near an appropriate electrical

receptacle. The base stand must be capable of supporting 500 lbs minimum, and the height should

provide a comfortable working position through glove ports (normally 35" to 37" height for

standing position).

Connections, Exhaust

NOTE: It is the user’s responsibility to determine if the exhaust should be vented to

outside the building. If it is ducted to the outside, duct restrictions should not exceed 0.5 inches

water gauge static pressure at 50 CFM.

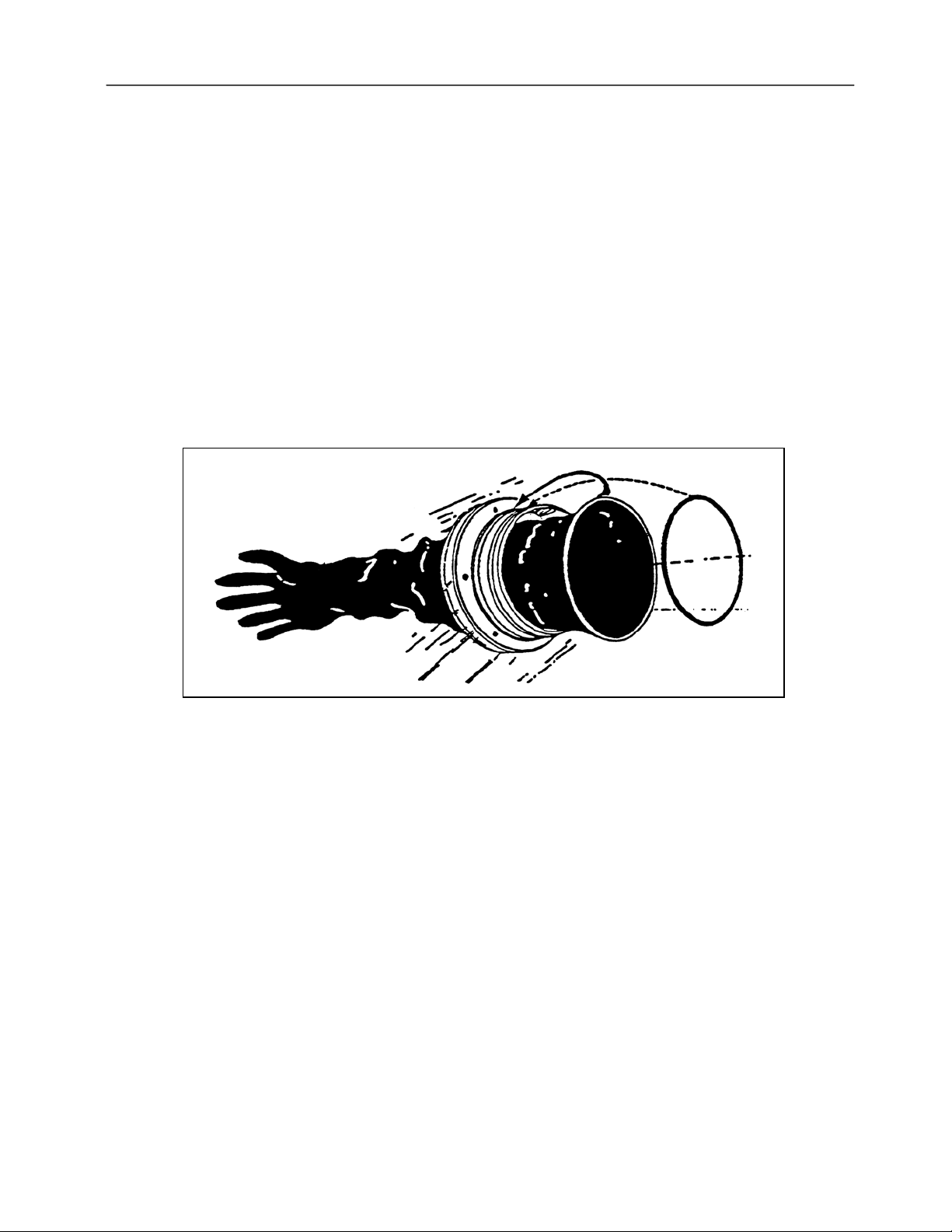

Glove Attachment

With glove thumbs up and right/left orientation, secure the gloves in place on the glove

ports by stretching the beaded glove cuff into the groove nearest the window. Install the 8"

diameter O-ring onto the outer groove over the glove surface.

Figure 4

Glove Replacement

If it becomes necessary to change gloves without disturbing the integrity of the glove box

environment, follow these steps:

1. Remove the O-ring from the old glove.

2. Roll the old glove cuff bead from the inner groove nearest the window to the outside

groove.

3. Insert the new glove through the old glove until the fingers of both are inside the glove box.

4. Stretch the new glove’s beaded cuff over the old glove cuff and into the groove nearest the

window.

5. To remove the old glove, grasp the new glove surface and manipulate the old glove bead

free from the outer groove.

6. With the other glove hand inside the box, pull the old glove into the glove box.

7. Install the O-ring over the new glove onto the outer groove.

11

Page 11

SAFETY PRECAUTIONS

• This product is neither designed nor intended to be an explosion-proof enclosure. It

is the responsibility of the user to determine the lower explosive limits and

flammability of the enclosed gases and other matter. The user is also responsible

for using proper precautions to prevent equipment damage or injury due to

explosion or combustion.

• It is the responsibility of the user to determine the suitability of this product for the

intended applications.

12

Page 12

NORMAL OPERATION

Start Up

NOTE: All internal wiring is protected by two manual reset circuit breakers located on the

rear panel.

• Confirm that the glove box electrical power cord is plugged into an appropriate

electrical power source.

• Switch on the fluorescent lamp and check to make sure bulb is working.

• Connect a test light to each interior receptacle and check for proper operation by

turning on the left and right outlet switches located on the control panel.

• Turn on the blower switch and check blower operation.

NOTE: This should be done with gloves installed so that glove box negative pressure will

be induced (observed by gauge on control panel). If the blower speed control is adjusted in

the low range, you will notice that the blower starts at a higher speed, then slows down.

• If unit is vented to the outside, confirm that ducting is sealed properly for positive

pressure operation.

Blower Operation

The blower is operated on and off by a switch located on the control panel. The speed of

the blower is regulated from 10% to 100% of maximum speed. Normal operation will be in the

30% to 50% area, depending on filter loading conditions and desired negative pressure within the

enclosure. It may be necessary, during continued operation to increase the blower speed to

compensate for possible restrictions to air flow caused by a dirty filter. The static pressure setting

should be within .25 to .5 H2O. Pressure settings higher than this may cause excessive air flow,

and are disruptive to operations within the enclosure.

13

Page 13

ROUTINE MAINTENANCE

Estimation of Filter Condition

The negative pressure inside the box will give a good indication of filter and system

condition. Set blower speed dial to the speed that gives the proper negative pressure conditions

inside the box. Record both the blower speed dial setting and the pressure reading on the gauge.

If box pressure begins to drop due to filter loading, increase the blower speed. To check filters,

reduce the blower speed dial setting to the setting recorded when the filters were clean. Read the

differential pressure gauge. When the gauge reading is one-half of the initial reading, replace

filters.

Filter Replacement

When filters become contaminated or after a predetermined length of time in use, the filter

should be replaced. Only experienced personnel, competent in the procedure of filter replacement

should perform this procedure.

Suggested Plan for Decontamination

Activities such as filter changing, service work, moving the cabinet, or gross spillage

generally require a gas decontamination procedure.

ONLY EXPERIENCED PERSONNEL COMPETENT IN THIS

PROCEDURE SHOULD BE USED.

LABCONCO strongly recommends reference to the Laboratory Safety Monograph (a

supplement to the NIH Guidelines for Recombinant DNA Research), published by the U.S.

Department of Health, Education and Welfare, January 1979.

Reference may also be made to the Formaldehyde Decontamination booklet available from

the U.S. Department of Health, Education and Welfare, Public Health Service, National Institute of

Health, National Cancer Institute.

For decontamination procedures with formaldehyde, refer to the following information.

1. NCI Safety Standards for Research Involving Chemical Carcinogens. Publication No.

(NIH) 76-900, 1975.

2. Carcinogen Safety Monographs, NCI Office of Research Safety.

3. “Potential Hazard of Tissue Culture Assays Arising from Carcinogenic Compounds

Incompletely Removed by Washing” E. B. Sansone, J. A. Poiley, R. J. Pienta and W. B.

Lebberz, III, Cancer Research 36.2455 – 1976.

4. “Recommended Decontamination Procedures for Aflatoxin”, L. Stoloff and W. Trager.

Journal of the Association of Official Agricultural Chemists, 48.681 – 1965.

14

Page 14

ROUTINE MAINTENANCE

Gloves

At least every three months (more often if subjected to heavy use), inspect the gloves for

signs of damage or wear. For replacement, refer to page 11.

Transfer Chamber Inner and Outer Door

Periodically check the closing tension of the door latches. Closing the latch handle should

require some firm force, indicating compression of the door seals. Seals, compression, and

latching force can be adjusted as follows:

1. Close and latch the door.

2. Using a 1/2" open-end wrench, turn the door adjustment screw (located between the door

and the latch bar) clockwise to increase seal compression and latching force. Turn screw

counterclockwise to decrease compression. Refer to figure 5.

Figure 5

15

Page 15

ROUTINE MAINTENANCE

Fluorescent Lamp Replacement

1. Turn the light switch off and unplug the lamp power cord from the receptacle located on

the outside top of the cabinet.

2. From the top of the lamp housing, remove the two Phillips screws attaching the lamp

assembly to the top edge of the window frame.

3. Remove the lamp assembly from the unit.

4. The lamp tube can then be easily removed and replaced. Replacement lamp part #12779

(fluorescent lamp) #F30T12/CW/RS may be purchased from most local lighting supply

stores.

5. Re-install the lamp assembly and attach with the two Phillips screws. Plug in the power

cord and switch on the lamp. Refer to figure 6.

Figure 6

16

Page 16

REPLACEMENT PARTS

Figure 7

17

Page 17

REPLACEMENT PARTS

Ref. No. Catalog No. Description

1 5066600 Glass Viewing Window

2 5066700 Polycarbonate Viewing Window (Optional)

3 5067200 Viewing Window Gasket (NOT SHOWN) – For Model 5065000

3A 5098400 Viewing Window Gasket (NOT SHOWN) – For Stainless Steel Model 5065500

4 5005500 Glove Kit 8-1/2 Size Neoprene

Gloves (1 Pr.) Two O-Rings

5 1640500 8-1/2 Size Neoprene Gloves (1 Pr.)

6 5005501 Kit: 8-1/2 size Butyl Gloves (1 Pr.) 2 O-Rings

7 1640501 8-1/2 Size Butyl Gloves (1 Pr.)

8 5005502 Kit: 8-1/2 Size Hypalon Gloves (1 Pr.) Two O-Rings

9 1640502 8-1/2 Size Hypalon Gloves (1 Pr.)

10 5005600 Kit: 9-3/4 Neoprene Gloves (1 Pr.) Two O-Rings

11 1640600 9-3/4 Size Neoprene Gloves (1 Pr.)

12 5005601 Kit: 9-3/4 Size Butyl Gloves (1 Pr. ) Two O-Rings

13 1640601 9-3/4 Size Butyl Gloves (1 Pr.)

14 5005602 Kit: 9-3/4 Size Hypalon Gloves (1 Pr.) Two O-Rings

15 1640602 9-3/4 Size Hypalon Gloves (1 Pr.)

16 1640000 O-Rings (1 Pr.) for Gloves

17 1952500 Pressure Differential Gauge

18 1329700 Switch, 115V

18A 1301500 Switch, 230V

19 5092600 Blower Speed Controller

20 5064200 Transfer Chamber Door Gasket (1 inner, 1 outer)

20A 5098300 Transfer Chamber Door Gasket, (1 inner, 1 outer) Stainless Steel

21 1928800 Housing Filter

22 1928900 Pre-Filter

23 5065100 Filter, HEPA

24 5065300 Charcoal Filter (Optional)

25 1490700 Tube, Offset

26 1490600 Elbow – 90°

27 5094600 Motor – Blower Assembly

5109700 Motor Assembly

1327900 Relay

5094400 Circuit Board Assembly

28 5104500 Transformer Assembly (NOT SHOWN) 230V models only

18

Page 18

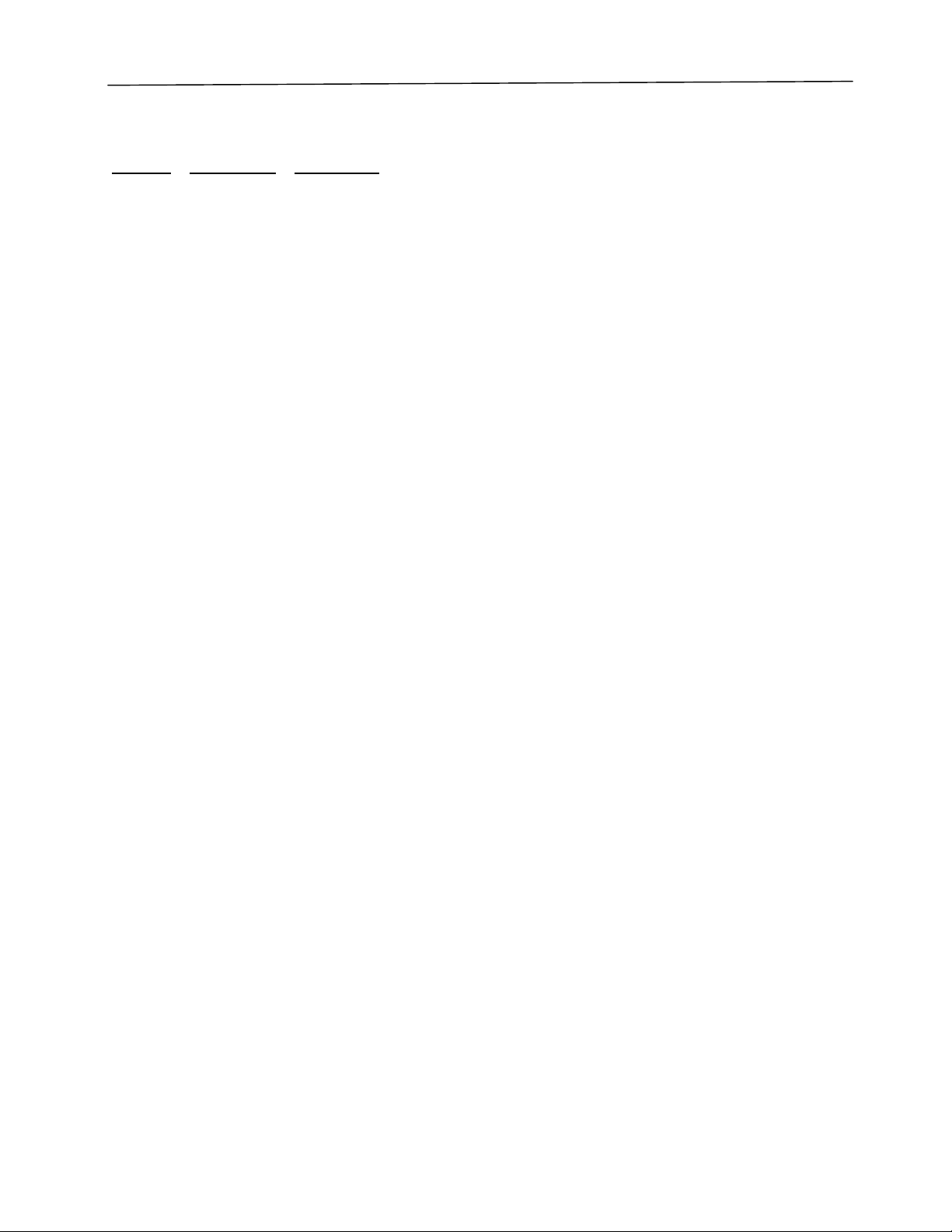

(A) Glove Port Components (Detailed on Page 19)

(B) Sealed Receptacle Components (Detailed on Page 20)

(C) Fluorescent Lamp Assembly (Detailed on Page 21)

(D) Inner Door Assembly (Detailed on Page 22)

(E) Outer Door Assembly (Detailed on Page 23)

A. Glove Ports

Ref. No. Catalog No. Description

REPLACEMENT PARTS

1 5074201 Glove Port

2 5074301 Glove Port Mounting Ring

3 5066800 Glove Port Gasket

4 1889310 Glove Port Mounting Screw

Figure 8

19

Page 19

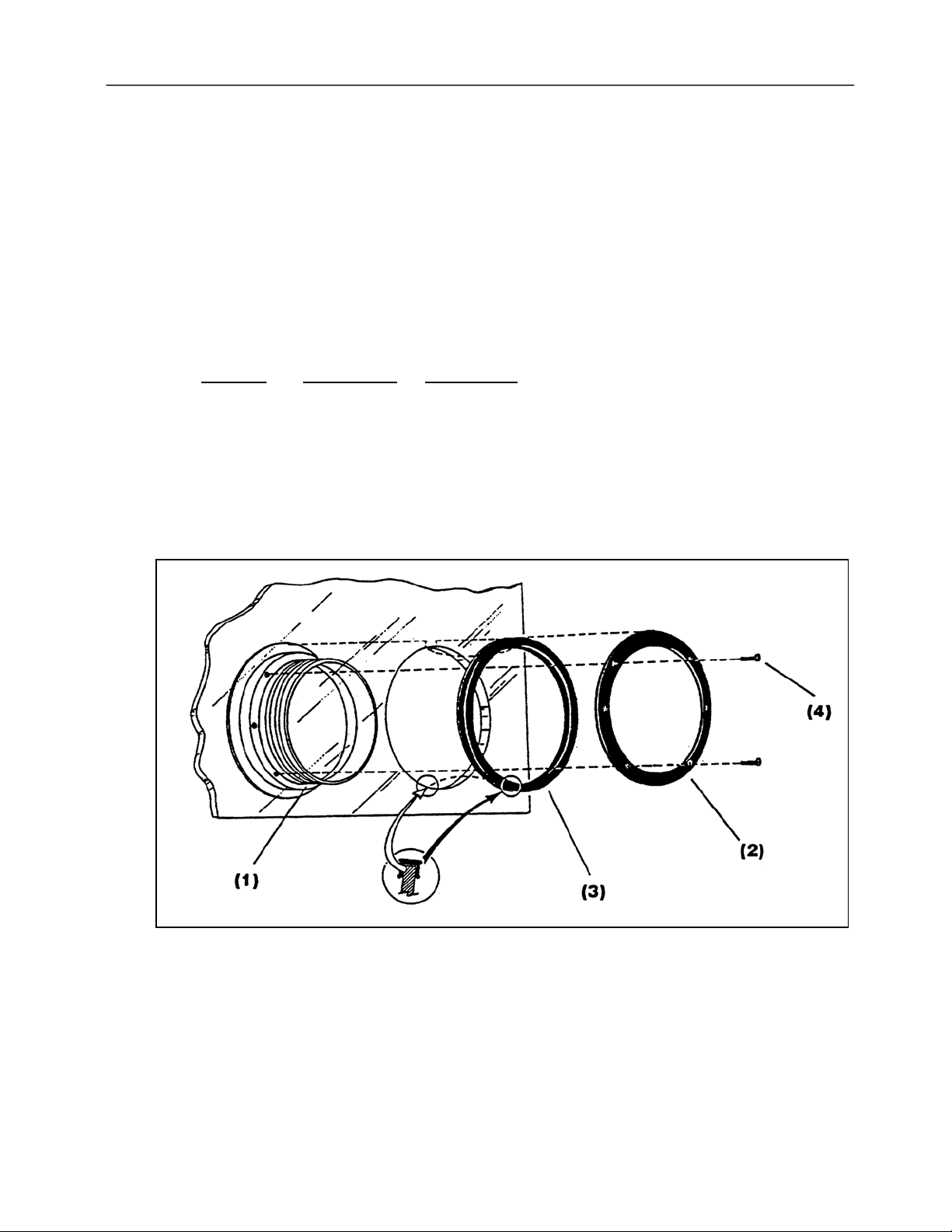

REPLACEMENT PARTS

B. Sealed Receptacle Assembly

Ref. No. Catalog No. Description

1 5075600 Sealed Receptacle, 115V

1A 5102100 Sealed Receptacle, 230V

2 1645702 Receptacle O-Ring

3 1349100 Cupped Washer

4 1349200 Locknut

Figure 9

20

Page 20

REPLACEMENT PARTS

C. Fluorescent Lamp Assembly (Complete with Bulb), No. 5072600

Ref. No. Catalog No. Description

1 1277900 Lamp Bulb #F30T12/CW/RS

(also available locally)

2 1279200 Lamp Fixture Assembly

3 5072901 Lamp Housing

Figure 11

21

Page 21

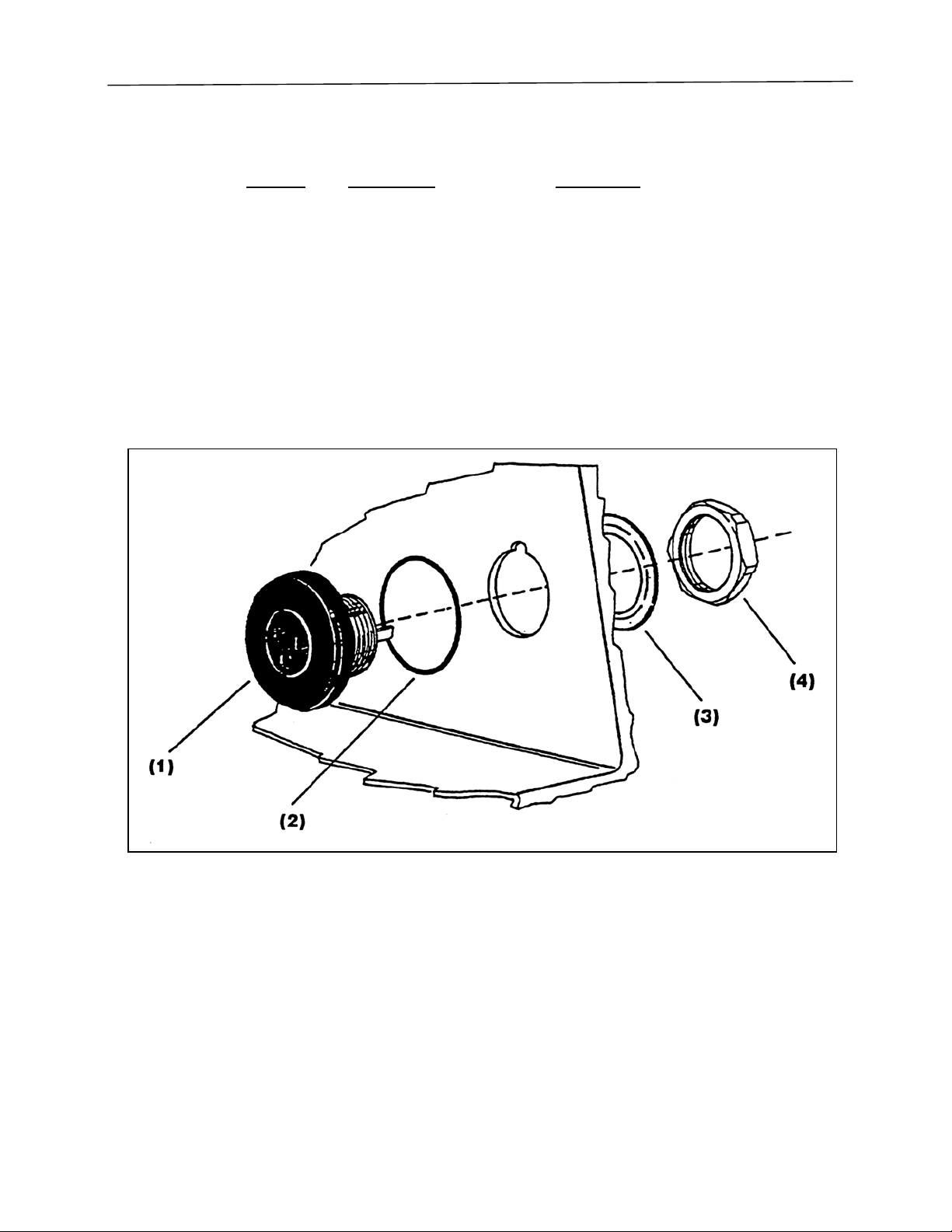

REPLACEMENT PARTS

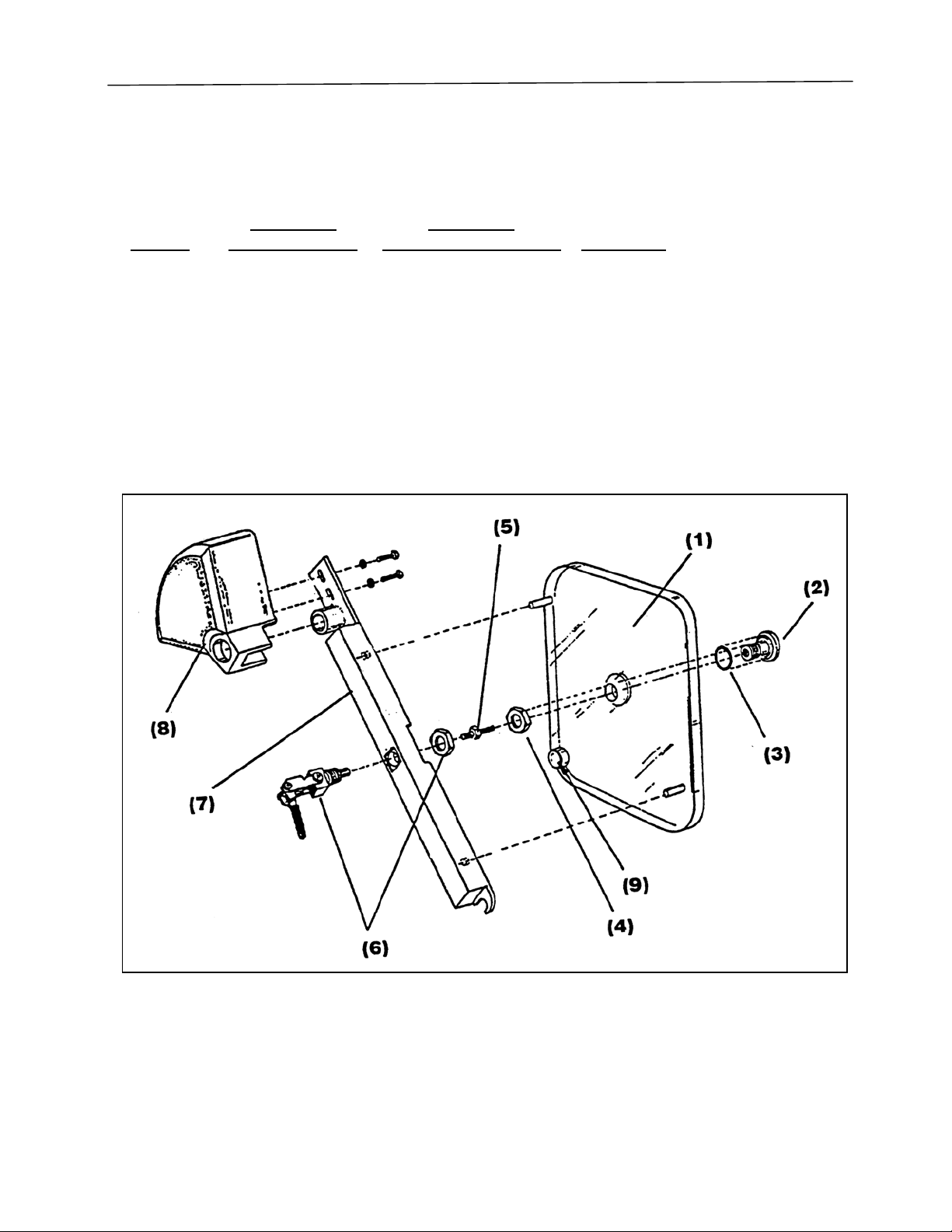

D. Inner Door Assembly, No. 5067700 (Used on 5065000)

No. 5098500 (Used on 5065500)

Catalog No.

Ref. No.

1 5102800 5097900 Inner Door Assembly

2 5064500 Door Fitting

3 1645701 Door O-Ring

4 1927000 Nut, Stainless Steel ¾-16

5 5064600 5064600 Door Adjusting Screw

6 5068600 5068600 Door Clamp

7 5085201 5085201 Inside Latch Bar Assembly

8 5074401 5074401 Inside Counterweight

9 5098100 Grab Knob

(Acrylic 5067700)

Catalog No.

(Stainless Steel 5098500)

Figure 11

Description

22

Page 22

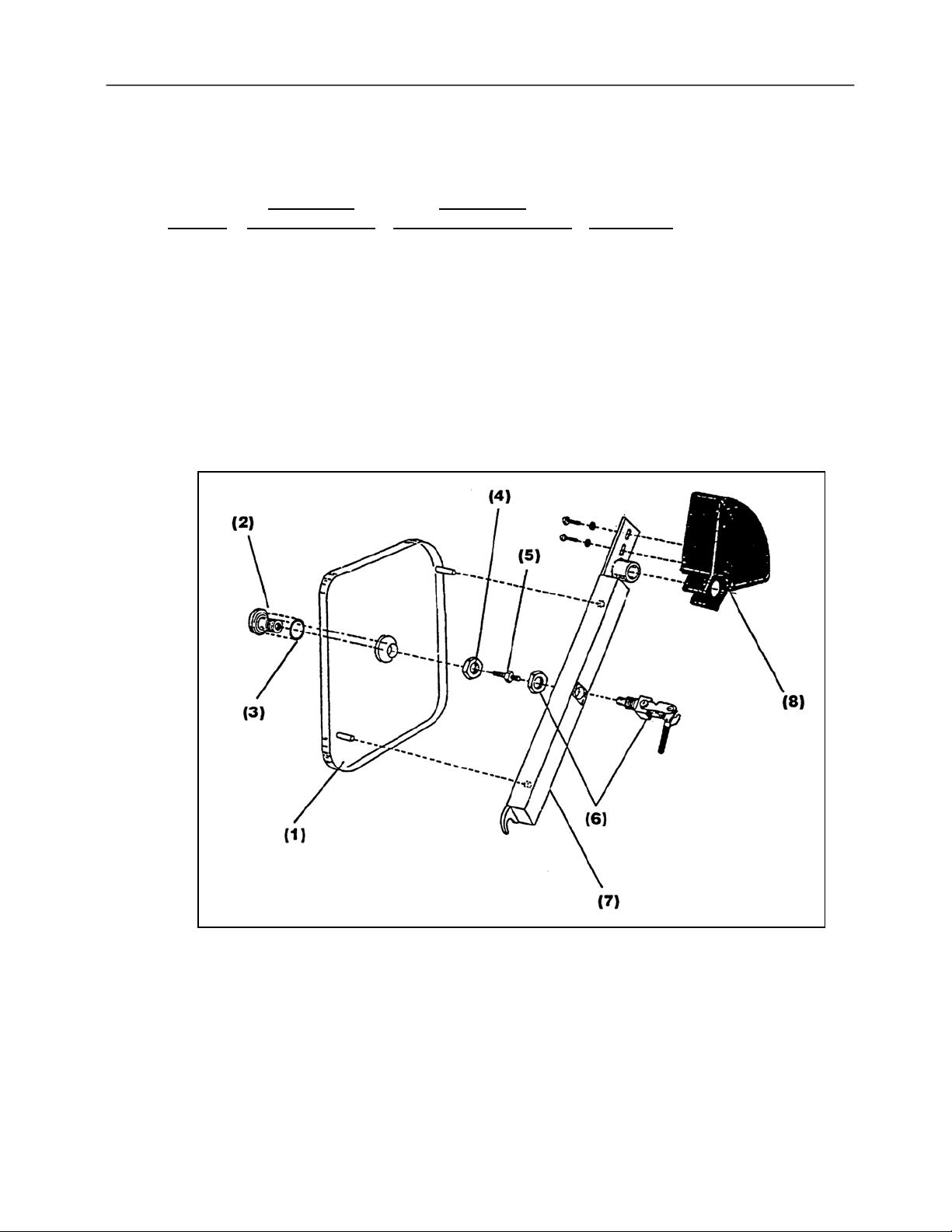

E. Outer Door Assembly, No. 5068400 (Used on 5065000)

No. 5098600 (Used on 5065500)

Catalog No.

Ref. No.

1 5102900 5097500 Outer Door Assembly

2 5064500 Door Fitting

3 1645701 Door O-Ring

4 1927000 Nut, Stainless Steel ¾-16

5 5064600 5064600 Door Adjusting Screw

6 5068600 5068600 Door Clamp

7 5085301 5085301 Outside Latch Bar Assembly

8 5074501 5074501 Outside Counterweight

(Acrylic 5068400)

Catalog No.

(Stainless Steel 5098600)

Figure 12

REPLACEMENT PARTS

Description

23

Page 23

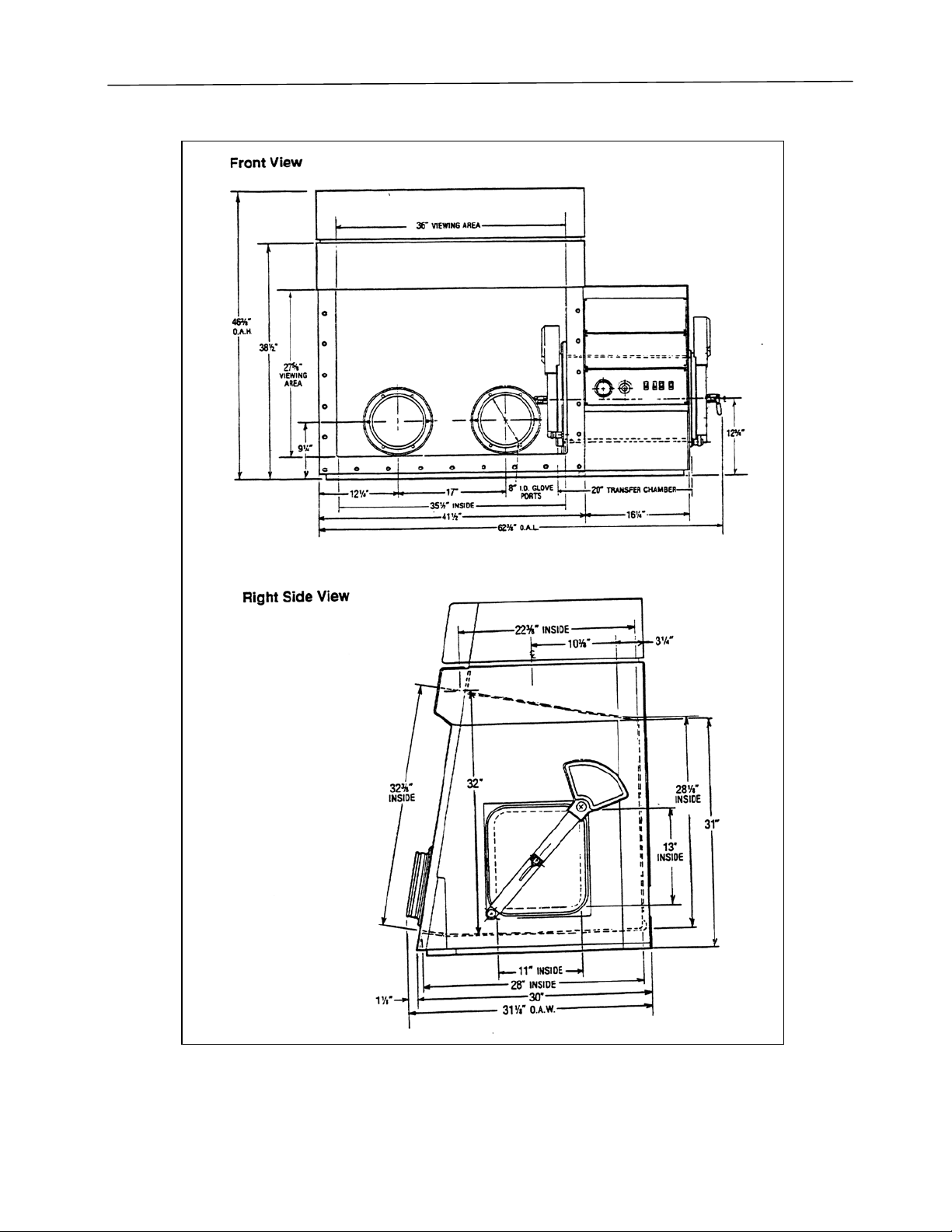

DIMENSIONAL DATA

24

Page 24

ELECTRICAL SPECIFICATIONS

Electrical Specifications for both the 5065000 and 5065500 models are as follows:

115 Volts, 60 Hz, 15 Amps

One 30-Watt Fluorescent Lamp

Two 115 Volt, combined 9 Amp electrical outlets (front, left and right interior of

cabinet)

One blower motor rated 1.8 FLA, 115V

Electrical Specifications for both the 5065002 and 5065502 models are as follows:

230 Volts, 50 Hz, 10 Amps

One 30-Watt Fluorescent Lamp

Two 230 Volt, combined 8 Amp electrical outlets (front, left and right interior of

cabinet)

One blower motor rated 1.8 FLA, 115V

One transformer 230/115V

25

Page 25

WIRING DIAGRAMS

Model 5065000 and 5065500 – 115 VAC, 60 Hz

26

Page 26

Models 5065002 and 5065502 – 230 VAC, 50 Hz

WIRING DIAGRAM

27

Page 27

ACCESSORIES

Accessory Part # Description

5061600

5062000

5062001

5060400

5060500

5065300

5065200

Interior Storage Shelves

Three stainless steel storage shelves are attached to epoxy coated stainless

steel upright supports. Shelves are adjustable height, measuring 6" D x 30" W

x 21-1/2" H. Components may be passed through the transfer chamber and

assembled within the glove box enclosure. Installation by customer.

Glove Box Mobile Base Stand

Welded steel construction, epoxy coated with black phenolic laminate top

surface. 1-1/8" thick x 30" D x 60" W, height adjustable from 30" - 37".

Lower shelf provides convenient storage space. Accessory includes 5" swivel

casters with locking brakes.

Glove Box Stand

Same as above except furnished with adjustable leveling feet instead of

casters.

Interior Glove Port Cover

12-gauge stainless steel with molded rubber self-centering gasket and spring

loaded latches with adjustable closure knob. Use for internal sealing of glove

port in event of worn or damaged gloves.

Exterior Glove Port Cover

12-gauge stainless steel with molded neoprene self-centering gasket.

Adjustable tension knob with latching bar attaches to port mounting ring

screw adaptor.

Charcoal Filter

Filter installs between exhaust HEPA filter and blower. Contains 4 lbs. of

Barnebey and Stucliffe type 787 activated carbon impregnated for removal of

gaseous radioisotopes.

Additional Exhaust HEPA Filter Kit

Filter installs between existing exhaust HEPA and blower. Rated 99.99%

efficient on 0.3 micron particulates.

28

Page 28

WARRANTY

We are committed to providing our customers with quality equipment and service after the sale.

Part of this objective involves keeping you informed of changes and new product additions. We,

therefore, request that you take a moment to fill out the product registration card so we many know

your location as well as some of the reasons that prompted you to purchase our product.

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas

of defective material and workmanship, provided such defect results from normal and proper use

of the equipment.

The warranty for all Labconco products will expire one year from date of installation or two years

from date of shipment from Labconco, whichever is sooner, except the following:

• Purifier® Delta® Series Biological Safety Cabinets carry a three-year warranty from date

of installation or four years from date of shipment from Labconco, whichever is sooner.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the

event of a warranty claim, contact Labconco Corporation or the dealer who sold you the product.

If the cause is determined to be a manufacturing fault, the dealer or Labconco Corporation will

repair or replace all defective parts to restore the unit to operation. Under no circumstances shall

Labconco Corporation be liable for indirect, consequential, or special damages of any kind. This

statement may be altered by a specific published amendment. No individual has authorization to

alter the provisions of this warranty policy or its amendments. Lamps and filters are not covered

by this warranty. Damage due to corrosion or accidental breakage is not covered.

WARNING: The disposal and/or emission of substances used in connection with this equipment

may be governed by various federal, state or local regulations. All users of this equipment are

urged to become familiar with any regulations that apply in the user’s area concerning the

dumping of waste materials in or upon water, land or air and to comply with such regulations.

29

Page 29

SHIPPING CLAIMS

If a shipment is received in visibly damaged condition, be certain to make a notation on the

delivering carrier’s receipt and have their agent confirm the damage on your receipt. Otherwise,

the damage claim may be refused.

If concealed damage or pilferage is discovered, notify the carrier immediately and retain the entire

shipment intact for inspection. Interstate Commerce Commission rules require that the claim be

filed with the carrier within 15 days after delivery.

NOTE: Do not return goods. Goods returned without prior authorization will not be accepted.

Labconco Corporation and its dealers are not responsible for shipping damage. Claims must be

filed directly with the freight carrier by the recipient. If authorization has been received to return

this product, by accepting this approval, the user assumes all responsibility and liability for

biological and chemical decontamination and cleansing. Labconco reserves the right to refuse

delivery of any products, which do not appear to have been properly cleaned and/or

decontaminated prior to return.

30

Page 30

CONTACTING LABCONCO

If you have any questions that are not addressed in this manual, or if you need technical assistance,

please contact Labconco’s Sales Information Department at 1-800-821-5525, and Service

Information at 1-800-522-7658 or 1-816-333-8811, between the hours of 7:00 a.m. and 6:00 p.m.

Central Standard Time.

Labconco’s mailing address is:

Labconco Corporation

8811 Prospect Avenue

Kansas City, Missouri 64132-2696

Fax # 816-363-0130

Visit Labconco through the Internet at:

http://www.labconco.com

or

email: labconco@labconco.com

31

Page 31

32

Loading...

Loading...