Page 1

LABCONCO CORPORATION 8811 Prospect Ave, Kansas City, MO 64132

(816) 333-8811, Fax (816) 363-0130, (800) 821-5525

Pressure Controller Operating Instructions

General Description

These operating instructions are designed for the operation of the Pressure Controller used with

Labconco’s Precise Glove Boxes. The Pressure Controller performs three automatic modes on

the glove box. First, it cycles the purging/filling process in the main glove box chamber and

transfer chamber up to 199 cycles. Second, it regulates vacuum/pressure between -5 and +5

inches of water gauge in the main glove box chamber through the glove box pressure control

program mode. Third, it regulates vacuum in the transfer chamber between 0 and -29 inches of

mercury during the purging/filling process.

Models covered in these operating instructions:

5238600, Glove Box Pressure Controller, 100/115 volt, 50/60Hz

5238601, Glove Box Pressure Controller, 230 volt, 50/60Hz

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 1 of 20

Page 2

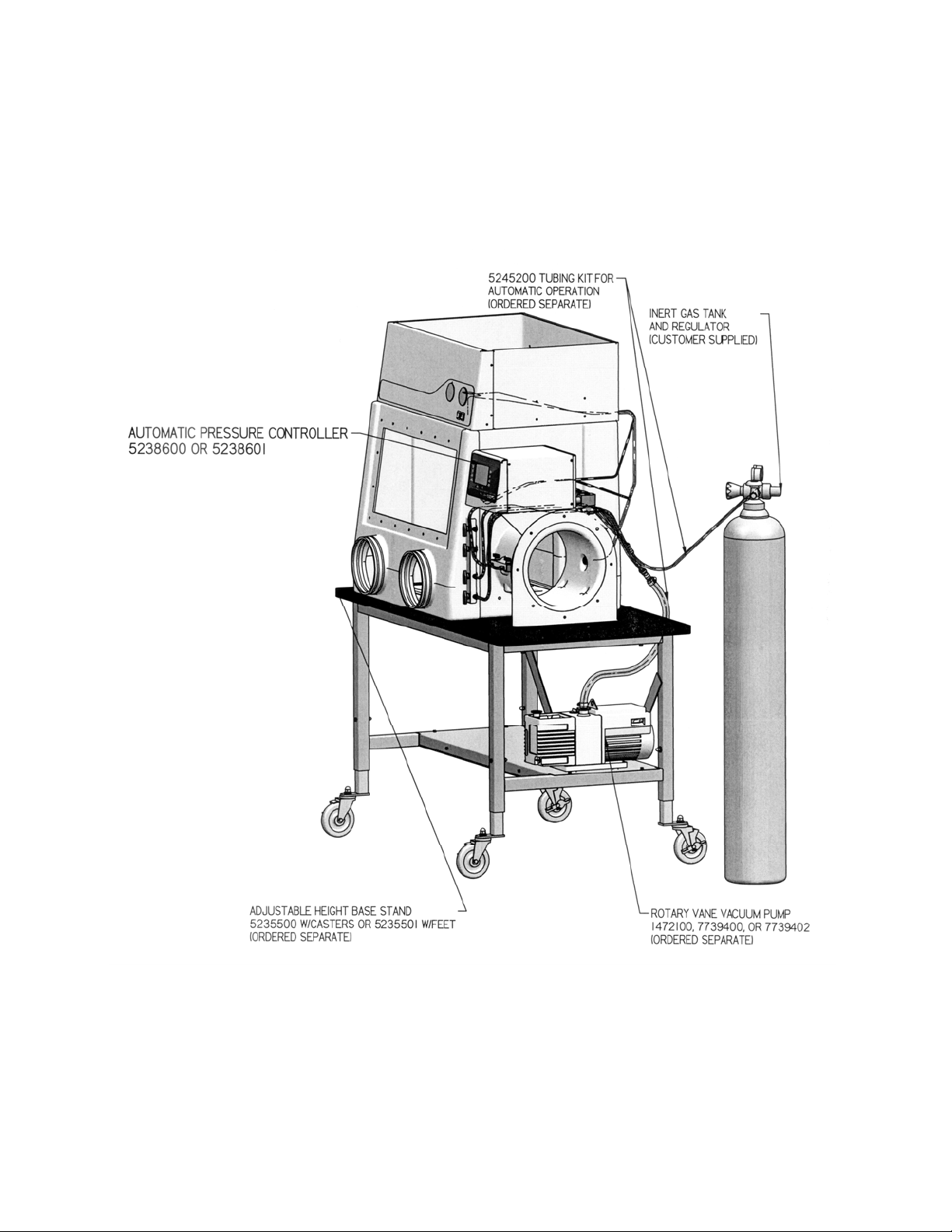

Setup

Connect the Glove Box Controller using the Labconco connections/tubing kit #5245200 (ordered

separately). Follow the separate mechanical installation instructions included with the Pressure

Controller and also listed on pages 14 through 19 of these operating instructions. When

completed, the installed system should look like the diagram below.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 2 of 20

Page 3

Front Panel Description

The front panel includes a large display screen and touchpad keys that are adjacent to the LCD

display. The operation of these keys will be defined by text on the display screen (LCD). Each

key may perform a different operation depending on the control mode selected.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 3 of 20

Page 4

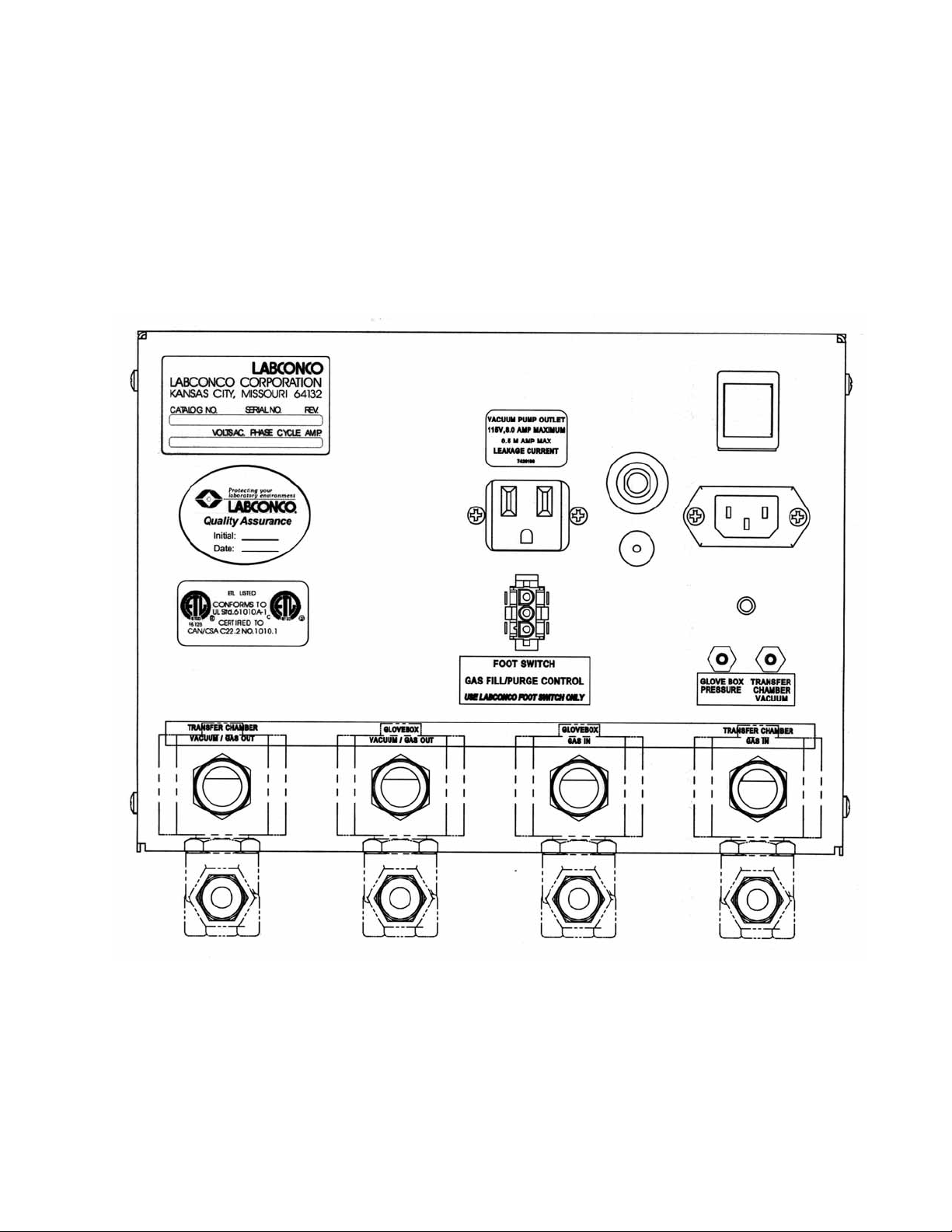

Rear Panel Description

The rear panel includes the power inlet and circuit breakers, power on/off switch, the outlet

receptacle for plugging in a vacuum pump (the receptacle varies for 115 volt and 230 volt

models), and electrical connection for the glove box pressure control footswitch. The 4 electric

solenoid valves that provide control of the glove box Main Chamber gas in/gas out, and Transfer

Chamber gas in/gas out are also located on the rear panel. See the separate mechanical

installation instructions for plumbing connections to these valves. For your convenience, the

separate mechanical and plumbing installation instructions are also located at the back of these

operating instructions on pages 14 through 19.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 4 of 20

Page 5

Main Modes of Operation

The Labconco Glove Box Pressure Controller display has four main screens that provide access

to the 4 modes of operation listed below. The operation modes are covered in the next sections of

this document.

1.) Glove Box Pressure Control Mode

2.) Glove Box Purge and Fill Mode

3.) Transfer Chamber Purge and Fill Mode

4.) Setup Mode

Press the Mode key at the upper-left hand corner of the display screen to switch between each of

these four operation modes. Please be aware that if one of the glove box modes is

running/started, other glove box operation modes cannot be used. For example, if the Glove Box

Pressure Control mode has started (using the start key), the menu page for the Glove Box

Purge/Fill mode cannot be used – this prevents operational control conflicts from occurring at the

same time.

Mode Key

Mute/Alarm

Increase

Lower Limit

Decrease

Lower Limit

Manual

Purge

Start/Stop

Setup

Increase

Upper Limit

Decrease

Upper Limit

Manual

Fill

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 5 of 20

Page 6

Glove Box Pressure Control – Operation Mode 1

The Pressure Control mode will allow the user to set a high pressure limit up to +5 inches water

column and a low pressure limit to -5 inches water column [+/- 12.6 mBar or +/- 1245 Pacals].

Set these high and low pressure limits with the keys adjacent to the “up” and “down” arrows on

the display. Once these limits are set, and the START key is pressed, the Pressure Controller will

automatically control the gas inlet valve, gas outlet valve, and the power to the outlet receptacle

for a vacuum pump. Pressure in the Glove Box Main Chamber will be displayed inside the glove

box icon on the display screen.

Mode Key

Mute/Alarm

Lower Limit

Decrease

Lower Limit

Increase

Manual control keys for “PURGE” and “FILL” (located along the bottom of the display) will

allow the corresponding valves to be controlled by the user to increase or decrease the pressure

inside the glove box. Note: These manual keys will not operate the valves when the pressure

is outside the limits of +/- 5 inches of water [+/- 12.6 mBar]. A three-position footswitch is

included with the Automatic Pressure Controller. The footswitch provides manual foot control of

the gas inlet and vacuum outlet valves. The pressure inside the glove box will be displayed inside

the glove box icon on the display screen.

An audio alarm will actuate if the pressure exceeds the maximum limits of +/- 5 inches of water.

An “alarm reset” key (identified by the musical icon) is provided to mute this alarm. The alarm

will reset automatically when the pressure returns within +/- 5 inches [+/- 12.6 mBar].

Manual

Purge

Start/Stop

Setup

Increase

Upper Limit

Decrease

Upper Limit

Manual

Fill

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 6 of 20

Page 7

Glove Box Purge/Fill – Operation Mode 2

The Glove Box Purge/Fill mode uses the same solenoid valves on the glove box that are used in

the Pressure Control Mode. The Pressure Control mode will be temporarily suspended while a

“Purge/Fill” command is being executed.

Mode Key

Mute/Alarm

Increase

Lower Limit

Decrease

Lower Limit

Note that this display screen looks similar to the Pressure Control mode described previously.

However, the “SETUP” key has changed to a “Cycles” key. Up to 199 cycles can be set for

automatic “Purge/Fill” of the glove box main chamber by holding the “Cycles” key. To decrease

the number cycles, press the “Cycles” key to 199 cycles and go around again until a lower cycle

quantity appears. Use this display screen to also set the low pressure level for purging and the

high pressure level for filling by adjusting the upper and lower limit keys. The Labconco

Pressure Controller allows the glove box Main Chamber pressure levels to be set to +/- 5 inches

of water column [+/- 12.6 mBar]. Once the pressure limits and number of cycles have been

selected, press the key adjacent to “Start,” and the automated purge and fill process will begin

and continue for the number of cycles selected. Each cycle number will be displayed during the

process. To cancel the automated purge and fill process, press the key adjacent to “Stop” and the

process will be stopped.

Note that when the “Glove Box Purge/Fill” mode is in operation, there are no keys available to

allow for system setup as the “Cycles” key replaced the “SETUP” key. Use the “Mode” key in

the upper left hand corner adjacent to the icon to return to the “Glove Box Pressure Control”

screen to use the “Select” mode.

Manual

Purge

Start/Stop

Cycles

Increase

Upper Limit

Decrease

Upper Limit

Manual

Fill

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 7 of 20

Page 8

Transfer Chamber Purge and Fill – Operation Mode 3

The Transfer Chamber Purge/Fill mode controls the pressure exchange inside the transfer

chamber. Pressure in the transfer chamber will be displayed inside the transfer chamber icon on

the display screen. This operation mode controls the gas inlet and gas outlet solenoid valves

connected to the transfer chamber.

Mode Key

Mute/Alarm

Increase

Lower Limit

Lower Limit

Decrease

The user may select up to 199 “Purge/Fill” cycles by adjusting the cycles increase and decrease

arrow keys. The user can select the level of pressure inside the transfer chamber during each purge

between 0 and -29.5 inches of Mercury/Hg [0 -999 mBars] by adjusting the lower limit keys. Once

the lower pressure limit and number of cycles have been selected, press the key adjacent to “Start,”

and the automated purge and fill process will begin and continue for the number of cycles selected.

Each cycle will be displayed during the process. To cancel the automated purge and fill process,

press the key adjacent to “Stop” and the process will be stopped.

Manual

Purge

Start/Stop

Setup

Increase

Cycles

Decrease

Cycles

Manual

Fill

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 8 of 20

Page 9

Setup Menu – Operation Mode 4

Pressing the key opposite the word “Setup,” allows access to the setup operation mode. In the

setup mode, the user may select their preferred units of pressure that are displayed, restore

settings back to the default state, or calibrate the pressure sensors. The keys adjacent to the up

and down arrows on the lower right of the display are used to select one of the three options.

After toggling up or down, push the NEXT key to select the option.

Select

Key Up

Select

Key Down

Back to

Previous

Screen

Next

Screen

Option 1

Units of Measure: If this option is selected, the key adjacent to “Next” is used to select pressure

units of inches of water/inches of mercury or mBar.

Helpful conversions are as follows:

1 mBar = .39 inches of water column

1 mbar = .0292 inches of mercury

1 inch of water = 2.52 mBar = .0737 inches of mercury

1 inch of mercury = 34.25 mBar

All pressures are measured with respect to atmosphere pressure.

Option 2

Restore Defaults: The restore defaults option restores all control settings to the initial

programmed settings which are listed in the back of these operating instructions.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 9 of 20

Page 10

Option 3

Calibration: The pressure sensors inside the controller can be calibrated using atmospheric

pressure (single point calibration) or atmospheric pressure and a specific pressure level (two

point calibration). Two point calibration provides increased accuracy; however, Labconco

recommends that only the single point calibration be used because it does not require a calibrated

pressure measurement standard. When “Calibration” is selected, the display screen below

appears. The keys adjacent to the up and down arrows on the lower right of the display are used

to select one of the options. After toggling up or down, push the NEXT key to select the option.

Select

Key Up

Select

Key Down

Back to

Previous

Screen

Next

Screen

Note: If option 2 or 3 above is selected, an accurate, traceable pressure measuring device must

be connected to the Labconco pressure sensors. Consult Labconco for further instructions for this

type of calibration.

Option 1 above is normally selected. Both doors must be open so atmospheric pressure is

available to both the glove box main chamber and transfer chamber. Select the NEXT key to

advance the screen to sensor offset for Option 1. The display screen changes are shown on the

next page for Option 1.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 10 of 20

Page 11

Back to

Previous

Screen

Yes, All

Doors

Open

To calibrate the pressure sensors for both chambers, the doors must be open so that atmospheric

pressure is present at both sensors. This is the “zero point” for both sensors. Both pressure

gauges on the glove box will also read “zero.”

With both doors open, press the key adjacent to “Yes.” Once this is done, the following display

screen on the next page appears:

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 11 of 20

Page 12

Main Glove

Box Chamber

Select Key

This display screen confirms that the doors are open and the sensors are ready for auto-zeroing.

First, select the Main Glove Box Chamber key (Box) and wait for complete calibration to zero

pressure. Next, select the Transfer Chamber key (CH) and wait for complete calibration to zero

pressure. Once the key adjacent to “Save” is pressed, the new sensor offset valves for both

chambers are stored, and this pressure becomes the zero point for both chambers. Select the

back key two times when calibration is complete to return to the three main modes of operation.

Pressure Control Foot Switch (Labconco #5243600)

Back to

Previous

Screen

Transfer

Chamber

Select Key

Save

Zero

Point

The three position (increase gas/fill, off, purge/decrease gas) foot switch should be plugged into

the back panel of the Labconco Pressure Controller. The Foot Switch has the same effect as

pressing the Purge and Fill keys on the display panel. The action of the Foot Switch depends on

what mode of operation is shown on the display. If the transfer chamber screen is shown on the

display, the Foot Switch will control the Transfer Chamber gas in and gas out valves. If the

display shows the Glove Box Pressure Control or the Glove Box Purge/Fill, the Foot Switch will

control the Glove Box Main Chamber gas in and gas out valves. The foot switch will not work

when the pressure/vacuum inside has exceeded the user preset limits shown on the display.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 12 of 20

Page 13

Labconco Glove Box Controller Specifications

Glove Box

Operating Range Default Settings

Pressure Control

Pressure Control Limits -5 inches of water column to

+5 inches of water column;

+/- 5 inches of water column;

[+/- 12.6 mBar].

[+/- 12.6 mBar]

Manual Control Available Purge (Gas out);

Fill (Gas in)

Audio Alarm level Whenever pressure

outside limits

Glove Box Purge/Fill

Purge/Fill Pressure Limit +/- 5 inches of water column;

Manual Control Available Purge (Gas out);

+/- 5 inches of water column;

[+/- 12.6 mBar].

[+/- 12.6 mBar].

Fill (Gas in)

Number of Purge/Fill

0 to 199 1

Cycles

Audio Alarm level Whenever pressure

outside limits

Transfer Chamber

Purge/Fill

Purge Pressure Limit -29.5 inches of Mercury/Hg

[-999 mBars]

Fill Pressure Limit 0 inches of Mercury/Hg

[0 mBars](atmosphere)

Number of Purge/Fill

0 to 199 1

-29.5 inches of Mercury/Hg

[-999 mBars]

0 inches of Mercury/Hg

[0 mBars](atmosphere)

Cycles

Audio Alarm level -29.5 inches of Mercury/Hg

[-999 mBars]

Whenever pressure/vacuum

outside limits

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 13 of 20

Page 14

Mechanical and Plumbing Installation Instructions

NOTE: The Pressure Controller is configured to mount on the Glove Box. If your use

is better served in the benchtop configuration, a benchtop mounting bracket (#5239100)

can be ordered separately.

Glove Box Mounting:

Installation

1. Remove the two acorn nuts and lock washers as shown in Detail A insert. Place the

Pressure Controller assembly over the studs as shown and secure with the previously

removed nuts and washers.

2. See the plumbing installation section for the Glove Box mounting.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 14 of 20

Page 15

Benchtop Mounting:

Installation (Detail B)

1. Disconnect the power source from the Pressure Controller.

2. Remove the Glove Box mounting bracket and attach the Benchtop mounting bracket.

3. Remove the eight screws that attach the Pressure Controller Cover to the Pressure

Controller. Lift the cover straight up and set aside.

4. Remove the six nuts securing the Pressure Controller to the Glove Box bracket.

5. Next, place the Pressure Controller on top of the Benchtop Mounting Bracket, attach

with the six nuts previously removed securing the Pressure Controller to the Benchtop

Mounting Bracket.

6. See plumbing installation section for benchtop mounting.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 15 of 20

Page 16

Plumbing:

Always install the polyvinyl tubing to the solenoid valves on the pressure

controller before placing at the benchtop location. Refer to Detail C for valve

inlet and outlet order.

Glove Box Installation

1. The Pressure Controller has been pre-plumbed for installation in the Glove Box

configuration.

2. Route the tubing to the Glove Box and Transfer Chamber as shown in Detail C. Note:

Tube routing maybe dependent upon your application. Always insure that the

tubing is routed to the correct solenoid valve on the Pressure Controller as

stated on the back of the unit.

3. See Detail D for proper tube installation to the valves on the Glove Box and Transfer

Chamber.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 16 of 20

Page 17

Benchtop Installation: With the Pressure Controller temporary located at the benchtop location

proceed as follows.

1. Measure the distance between the solenoid valves of the Pressure Controller and the

valves on the glove box. Cut the 3/16 ID tubing (the larger of the tubing in your kit)

to the measured lengths.

2. The solenoid valves are embossed with IN or OUT port on the body of the valve, to

indicate the direction of flow. Install the cut lengths of the tubing to the correct port

of the solenoid valve as shown in Detail C.

3. Secure the tubes to the underside of the mounting bracket using the “C” clips

provided and place at the approximate locations shown in Detail C.

4. Route the tubing to the Glove Box and Transfer Chamber as shown in Detail C. Note:

Tube routing maybe dependent upon your application. Always insure that the

tubing is routed to the correct solenoid valve on the Pressure Controller as

stated on the back of the unit.

5. See Detail D for proper tube installation to the valves on the Glove Box and Transfer

Chamber.

Sensor Integration:

The Pressure Controller must be integrated to the glove box. This connection

allows your Pressure Controller to monitor the condition of the glove box

chamber and transfer chamber.

TUBE INSERT

TUBE FERRULE

BACK FERRULE

NUT

TUBING

Installation

1. Your kit comes with extra length of polyvinyl tubing so you can integrate the

Pressure Controller with the glove box. This integration requires you to splice into the

existing tubing of your Glove Box, install a bulkhead fitting and new tubing.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 17 of 20

Page 18

2. Bulkhead Fitting

a. Locate the brass mini bulkhead fitting in your kit and install the fitting at the

opening provided on the back wall of the glove box wrapper (see Detail E).

3. Glove Box Pressure

a. Locate the line that comes from the pressure gauge (see Detail E ) to the

fitting installed at the top of your glove box. This gauge is labeled on the front

panel and is the one on your right when looking at the back of the front panel

(see Detail E). This line is also a contaminated line on existing glove boxes

and the appropriate precautions should be taken.

b. Make a cut in the line about halfway between the gauge and the fitting. Join

the cut lengths together with the brass tee that came with you kit.

c. Measure and cut a length of the 3/32 ID polyvinyl tubing (the smaller of the

tubing) and connect the spliced tee to the mini bulkhead fitting on the back of

the Glove Box wrapper.

d. Again, measure and cut a length of the same tubing and connect it between the

mini bulkhead fitting on the glove box wrapper and the port labeled “Glove

Box Pressure” on the back of the Pressure Controller (see Detail E).

4. Transfer Chamber Vacuum

a. Locate the existing line that comes from the back of your glove box wrapper

to the transfer chamber fitting (see Detail E).

b. Make a cut in the line at a point near or within 12 inches of the transfer

chamber fitting and join the line together with a brass tee that came with your

kit.

c. Measure and cut a length of the 3/32 ID polyvinyl tubing (the smaller of the

tubing) and connect the spliced tee to the port labeled “Transfer Chamber

Vacuum” on the back of he Pressure Controller (see Detail E).

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 18 of 20

Page 19

Parts List:

Part No. Description

1 5239800 Pressure Controller 115V

1 5239801 Pressure Controller 230V

2 5239100 Benchtop bracket (ordered separately)

3 5237000 Glove Box bracket

4 1539500 3/16 ID Polyvinyl Tubing

5 1409900 Tube Inserts

6 1407400 Brass Tee

7 1554304 3/32 ID Polyvinyl Tubing

8 1337100 Power Cord – 115V

8 1338000 Power Cord – 230V

9 1449400 Mini Bulkhead Fitting

10 1937700 “C” Clips

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 19 of 20

Page 20

Copyright © 2007 Labconco Corporation. Al l right s reser ved .

The information contained in this manual and the accompanying products are copyrighted and all rights reserved by

Labconco Corporation. Labconco Corporation reserves the right to make periodic design changes without

obligation to notify any person or entity of such change.

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas of

defective material and workmanship, provided such defect results from normal and proper use of the

equipment.

The warranty for all Labconco products will expire one year from date of installation or two years from

date of shipment from Labconco, whichever is sooner, except the following;

• Purifier® Delta® Series Biological Safety Cabinets and PuriCare® Lab Animal Research

Stations carry a three-year warranty from date of installation or four years from date of shipment

from Labconco, whichever is sooner.

• SteamScrubber® & FlaskScrubber® Glassware Washers carry a two-year warranty from date of

installation or three years from date of shipment from Labconco, whichever is sooner.

• Blood Drawing Chairs carry a ten year warranty.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mi shan dl ed.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the event of

a warranty claim, contact Labconco Corporation or the dealer who sold you the product. If the cause is

determined to be a manufacturing fault, the dealer or Labconco Corporation will repair or replace all

defective parts to restore the unit to operation. Under no circumstances shall Labconco Corporation be

liable for indirect, consequential, or special damages of any kind. This statement may be altered by a

specific published amendment. No individual has authorization to alter the provisions of this warranty

policy or its amendments. Lamps and filters are not covered by this warranty. Damage due to corrosion or

accidental breakage is not covered.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be accepted. If

your shipment was damaged in transit, you must file a claim directly with the freight carrier. Labconco Corporation

and its dealers are not responsible for shipping dam ages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery carrier

within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by various

federal, state, or local regulations. All users of this equipment are required to become familiar with any regulations

that apply in the user’s area concerning the dumping of waste materials in or upon water, land, or air and to comply

with such regulations. Labconco Corporation is held harmless with respect to user’s compliance with such

regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact Labconco’s

Customer Service Department or Labconco’s Product Service Department at 1-800-821-5525 or 1-816-333-8811,

between the hours of 7:00 a.m. and 6:00 p.m., Central Standard Time.

Labconco Operating Instructions 5242600, Rev. B 4/27/07, ECO E275 20 of 20

Loading...

Loading...