Labconco Paramount 69632 Series, Paramount 69633 Series, Paramount 69634 Series, Paramount 69635 Series, Paramount 69636 Series User Manual

User’s Manual

Paramount®Ductless Enclosures

Models

69632 Series, 2' Widths

69633 Series, 3' Widths

69634 Series, 4' Widths

69635 Series, 5' Widths

69636 Series, 6' Widths

To receive important product updates,

complete your product registration card

online at register.labconco.com

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Please read the User’s Manual before operating the equipment.

Copyright © 2008, 2009, 2010 Labconco Corporation. All rights reserved.

The information contained in this manual and the accompanying products are copyrighted and all rights

reserved by Labconco Corporation. Labconco Corporation reserves the right to make periodic design

changes without obligation to notify any person or entity of such change.

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas

of defective material and workmanship, provided such defect results from normal and proper use of

the equipment.

The warranty for all Labconco products will expire one year from date of installation or two years

from date of shipment from Labconco, whichever is sooner, except the following;

• Purifier® Logic® Biological Safety Cabinets and PuriCare® Lab Animal Research

Stations carry a three-year warranty from date of installation or four years from date of

shipment from Labconco, whichever is sooner.

• SteamScrubber® & FlaskScrubber® Glassware Washers carry a two-year warranty from

date of installation or three years from date of shipment from Labconco, whichever is

sooner.

• Blood Drawing Chairs carry a ten year warranty.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the

event of a warranty claim, contact Labconco Corporation or the dealer who sold you the product. If

the cause is determined to be a manufacturing fault, the dealer or Labconco Corporation will repair

or replace all defective parts to restore the unit to operation. Under no circumstances shall

Labconco Corporation be liable for indirect, consequential, or special damages of any kind. This

statement may be altered by a specific published amendment. No individual has authorization to

alter the provisions of this warranty policy or its amendments. Lamps and filters are not covered by

this warranty. Damage due to corrosion or accidental breakage is not covered.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight

carrier. Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery

carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar

with any regulations that apply in the user’s area concerning the dumping of waste materials in or upon

water, land, or air and to comply with such regulations. Labconco Corporation is held harmless with

respect to user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-8215525 or 1-816-333-8811, between the hours of 7:00 a.m. and 6:00 p.m., Central Standard Time.

Part #6968600, Rev. D

ECO G099

T

AABBLLEE

T

CHAPTER 1: INTRODUCTION 1

CHAPTER 2: PREREQUISITES 3

Support and Stability Requirements 3

Location and Air Current Requirements 4

Exhaust and Blower Requirements 4

Electrical Requirements 6

Space Requirements 6

CHAPTER 3: GETTING STARTED 7

Unpacking the Enclosure 8

Set Up the Ductless Enclosure on a Supporting Structure and

Work Surface 8

Install Carbon Filters and/or HEPA Filters 11

Connect the Electrical Supply 12

Set Filter Life and Filter Check Timers 12

Initial Safety-First™ Vapor Sensor Warm Up Period 13

Reset or Change the Airflow Face Velocity (If Necessary) 13

Validate the Enclosure 14

Seal the Enclosure to the Work Surface 14

Connecting to the Exhaust System (If Applicable) 14

CHAPTER 4: PERFORMANCE FEATURES AND SAFETY

High Performance Containment 17

Safety-First™ Vapor Sensor 18

Smart-Flow™ Airflow Monitor 19

Quiet, Energy-Efficient ECM Impeller 19

Audible/Visual Alarms 19

Large Control Panel LCD Display 19

Ergonomic Sloped Front 20

Convenient Filter Replacement 20

Durable Construction 20

Fluorescent Light with Electronic Ballast 20

Utility Iris Ports 20

O

O

PRECAUTIONS 15

FF

C

C

OONNTTEENNTTSS

Maximum Visibility 21

Simple Electrical Connection 21

Safety Precautions 21

Misapplications that Could Result in a Hazardous Situation 24

CHAPTER 5: USING THE DUCTLESS ENCLOSURE 25

Information Center 25

Status Area 26

Operating the Pivoting Sash 26

Starting the Ductless Enclosure 26

The Paramount Touchpad 27

All Program Screens 28

Calibration Program Screens 31

Diagnostic Program Screens 32

User Selectable Features 33

Clock Timer Operation 33

Interval Timer Operation 33

Elapsed Timer Operation 33

Light Lamp Timer and Blower Timer 34

Blower Operation 34

Enclosure Set Up 34

Units of Measure 34

Security Lock 34

Filter Setup Display Options 35

Restoring Software Default Settings 35

Calibration 35

Diagnostic Test Operation 35

If a Check Airflow Activates 36

Resetting the Airflow Alert System 36

Working in the Paramount Ductless Enclosure 36

CHAPTER 6: MAINTAINING THE DUCTLESS ENCLOSURE 38

Routine Maintenance Schedule 38

Determination of When to Replace Carbon Filters 39

Determination of When to Replace HEPA Filters 41

Install Carbon Filters and/or HEPA Filters 42

Set Filter Life and Filter Check Timers 42

HEPA Filter Leak Test 42

Change the Airflow Face Velocity (If Necessary) 44

Initial Certification 44

Re-Certification 44

Fluorescent Light Replacement 45

Motorized Impeller Replacement 47

Main Control Board Replacement 48

Organic Sensor Board Replacement 49

CHAPTER 7: ACCESSORIZING THE DUCTLESS

ENCLOSURE 50

Filters 50

Work Surfaces 51

Work Surface with Deck Mounted Valves, Gooseneck,

and Cupsink 52

Base Stands, Accessory Shelves, Seismic Supports and

Hydraulic Lift Base Stands 53

Storage Cabinets 54

Exhaust Transitions 55

Remote Blowers 56

Exhaust Dampers 57

Utility Shelf Kits and Holders 57

Syringe Pump Kit and Detector Tubes 57

Sash Closures 58

CHAPTER 8: TROUBLESHOOTING 59

APPENDIX A: REPLACEMENT PARTS 62

APPENDIX B: PARAMOUNT DIMENSIONS 65

APPENDIX C: SPECIFICATIONS 66

APPENDIX D: QUICK CHART 67

APPENDIX E: ESTIMATED FILTER LIFE CALCULATION 68

APPENDIX F: FILTRATION EFFICIENCY TEST RESULTS 70

Acetone 71

Ethyl Alcohol 72

Isopropyl Alcohol 73

Toluene 74

Hydrochloric Acid 75

DECLARATION OF CONFORMITY 76

CChhaapptteerr 11::

IInnttrroodduuccttiioonn

Congratulations on the purchase of a Labconco Paramount

Enclosure, commonly called a ductless fume hood. Unlike traditional fume

hoods, the Paramount Ductless Enclosure is considered green as it conserves

energy because it requires no ducting. The Paramount Ductless Enclosure

is a self-contained work station that protects the operator from specified

vapors and/or particulates released in the work area, through the use of

carbon filters and/or HEPA filters. Typical organic solvents, formaldehyde,

acid gases, ammonia, amines, particulates, and powders are contained inside

the enclosure to protect the operator and then filtered. Purified air is drawn

from the filters and returned to the room. Vapors are adsorbed on activated

carbon filters or impregnated carbon filters and particulates/powders are

filtered by the HEPA filter.

Each Paramount Ductless Enclosure includes the Safety-First™ Vapor

Sensor that detects filter saturation and alerts the operator to replace the

filters. The early warning provided by the Safety-First Vapor Sensor

provides the user ample time (5-10% remaining filter life) to complete work

in process before changing the filters. The Safety-First Vapor Sensor

includes a primary and secondary sensor for redundant monitoring and the

sensor detects typical organic solvents, smoke particulates, ammonia gases,

formaldehyde gases, and hydrogen sulfide gases. The Paramount Ductless

Enclosure is the result of Labconco’s years of experience in the design and

manufacture of fume hoods and ductless hoods.

The Paramount Ductless Enclosure offers many unique features to enhance

safety, performance, and ergonomics. Safety is illustrated with the SafetyFirst Vapor Sensor. Performance and Safety are illustrated with validated

containment and patented aerodynamic features (U.S. Patent No. 6,461,233).

Ergonomics is illustrated with the patented inclined design (U.S. Patent No.

D538,941). To take full advantage of all features, please acquaint yourself

with this manual and keep it handy for future reference. If you are unfamiliar

with how ductless enclosures operate, please review Chapter 4: Performance

Features and Safety Precautions, before you begin working.

®

Ductless

Product Service 1-800-522-7658

1

Chapter 1: Introduction

Even if you are an experienced ductless enclosure user, please review

Chapter 5: Using the Ductless Enclosure; it describes the Paramount

Ductless Enclosure features so that you can use it efficiently and effortlessly.

The Paramount Ductless Enclosure ships without any filters. Chapter 3:

Getting Started and Chapter 6: Maintaining the Ductless Enclosure, must

be followed to properly select and install filters.

This manual and other technical information is available in PDF format

at our website: www.labconco.com.

2

Product Service 1-800-522-7658

CChhaapptteerr 22::

PPrreerreeqquuiissiitteess

Before you install the Paramount Ductless Enclosure, you need to prepare

your site for installation. A dedicated source of electrical power should be

located near the installation site to power the ductless enclosure and other

apparatus. Additionally, the enclosure should be strategically placed in the

lab to provide efficient workflow.

Carefully read this chapter to learn the requirements for your installation site:

• The support and stability requirements.

• The location and air current requirements.

• The exhaust and blower requirements.

• The electrical power requirements.

• Space requirements.

Refer to Appendix B: Dimensions for complete enclosure dimensions.

Refer to Appendix C: Specifications for complete enclosure electrical and

environmental conditions, specifications and requirements.

Support and Stability Requirements

At a minimum, the supporting structure usually consists of a base cabinet or

stand and a chemically resistant work surface. Please consider the following:

• Work surfaces should be of a thick rigid material that remains stable.

• A bench that is rigidly mounted to the floor or fixed to the wall may

be appropriate.

• Tubular stands or mobile benches with locking casters may be

appropriate.

Product Service 1-800-522-7658

3

Chapter 2: Prerequisites

Location and Air Current Requirements

The Paramount Ductless Enclosures have been designed to contain hazards

by negating typical cross drafts and turbulence within the opening. However,

it is recommended that the enclosure be placed in an area to avoid:

• High traffic areas where walking might cause an air disturbance or be a

nuisance.

• Overhead or wall HVAC diffusers, fans, radiators or other lab equipment

producing air currents.

• Near doorways or windows that may be opened.

Exhaust and Blower Requirements

The Paramount Ductless Enclosure uses a green, 95% energy efficient,

electronically-commutated motorized (ECM) impeller to draw room air past

the operator and through the enclosure (see Appendix D for power usage by

model). This contaminated air is passed through filters and exhausted out the

top of the enclosure. The filtered exhaust air is normally recirculated into the

laboratory or may be exhausted outside with the addition of the Canopy

Exhaust Connection and remote blower listed in Chapter 7. Contact

Labconco for blower sizing assistance for exhausting to the outside.

Electrical connections are covered in Chapter 2 for this configuration.

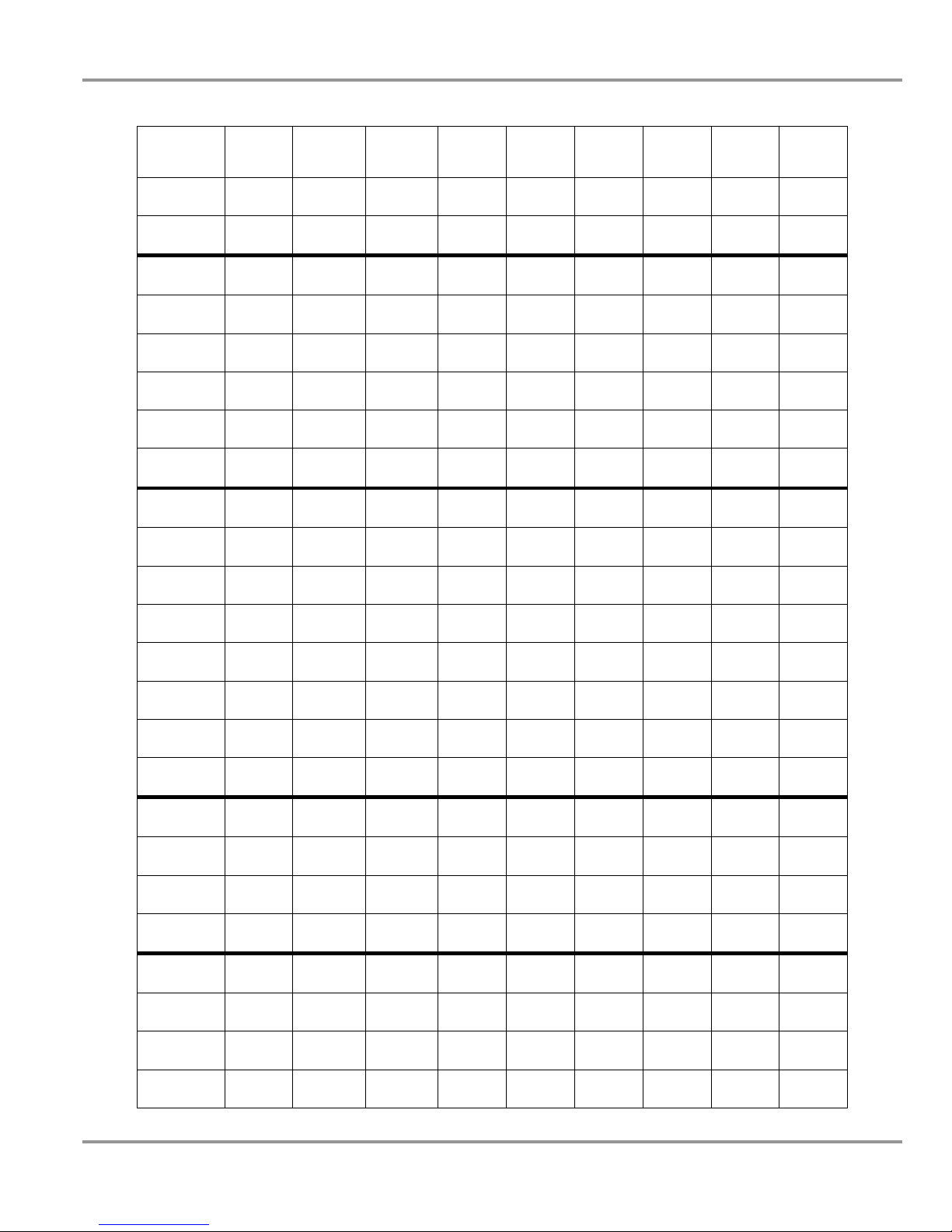

Data for the enclosure’s exhaust volume, noise pressure and face velocity are

listed on the next page in chart form for each Paramount Ductless Enclosure

model at face velocities of 60, 80, and 100 fpm. All models are shipped to

operate at 75-80 fpm, but can be reset by the Safety Officer or certification

technician through a password protected menu.

Important Note: If the enclosure is connected directly to a house exhaust system,

an adjustable damper (or valve) must be installed to control the airflow properly.

This is equally important when a house exhaust system is controlling multiple

ductless enclosures. See Chapter 7 for information on accessories.

4

Product Service 1-800-522-7658

Chapter 2: Prerequisites

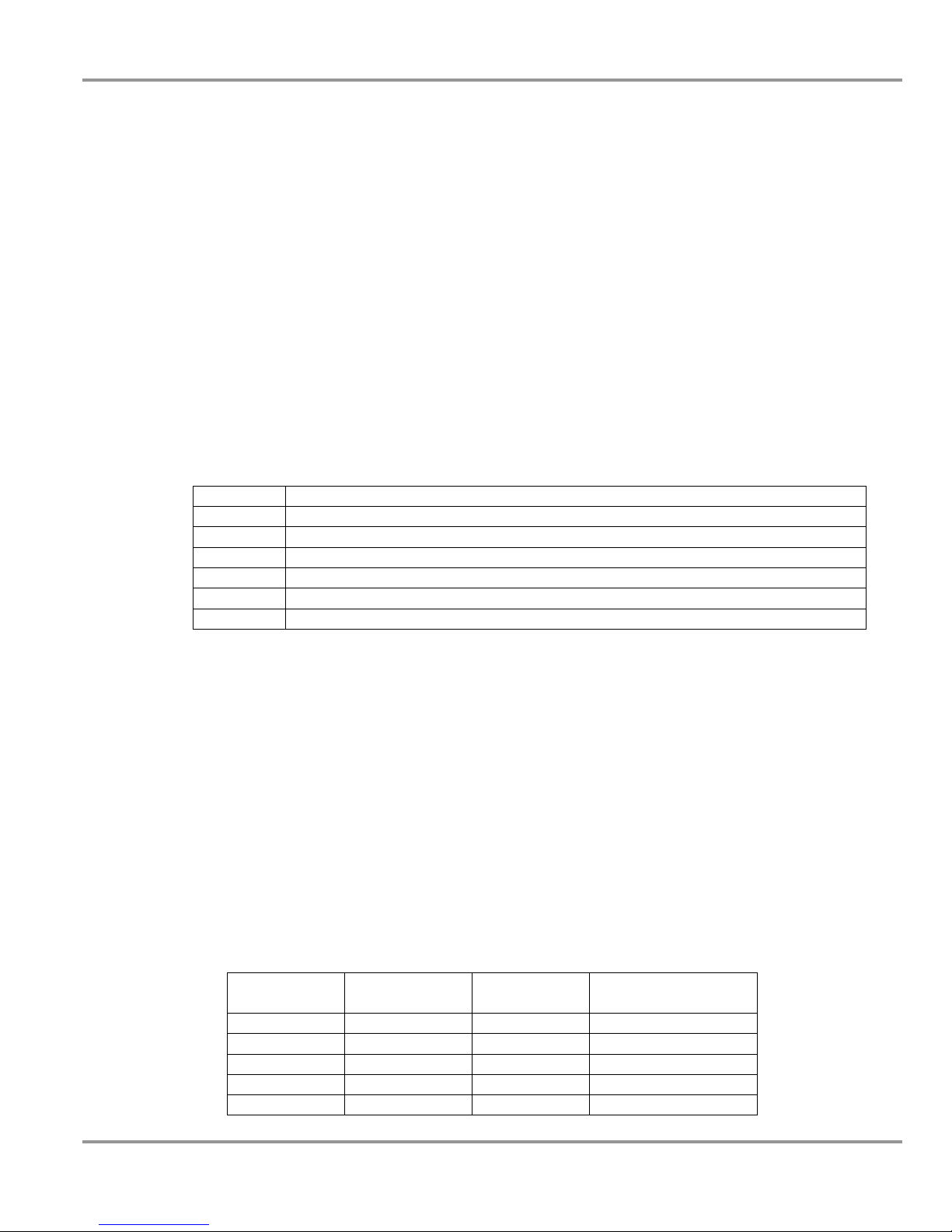

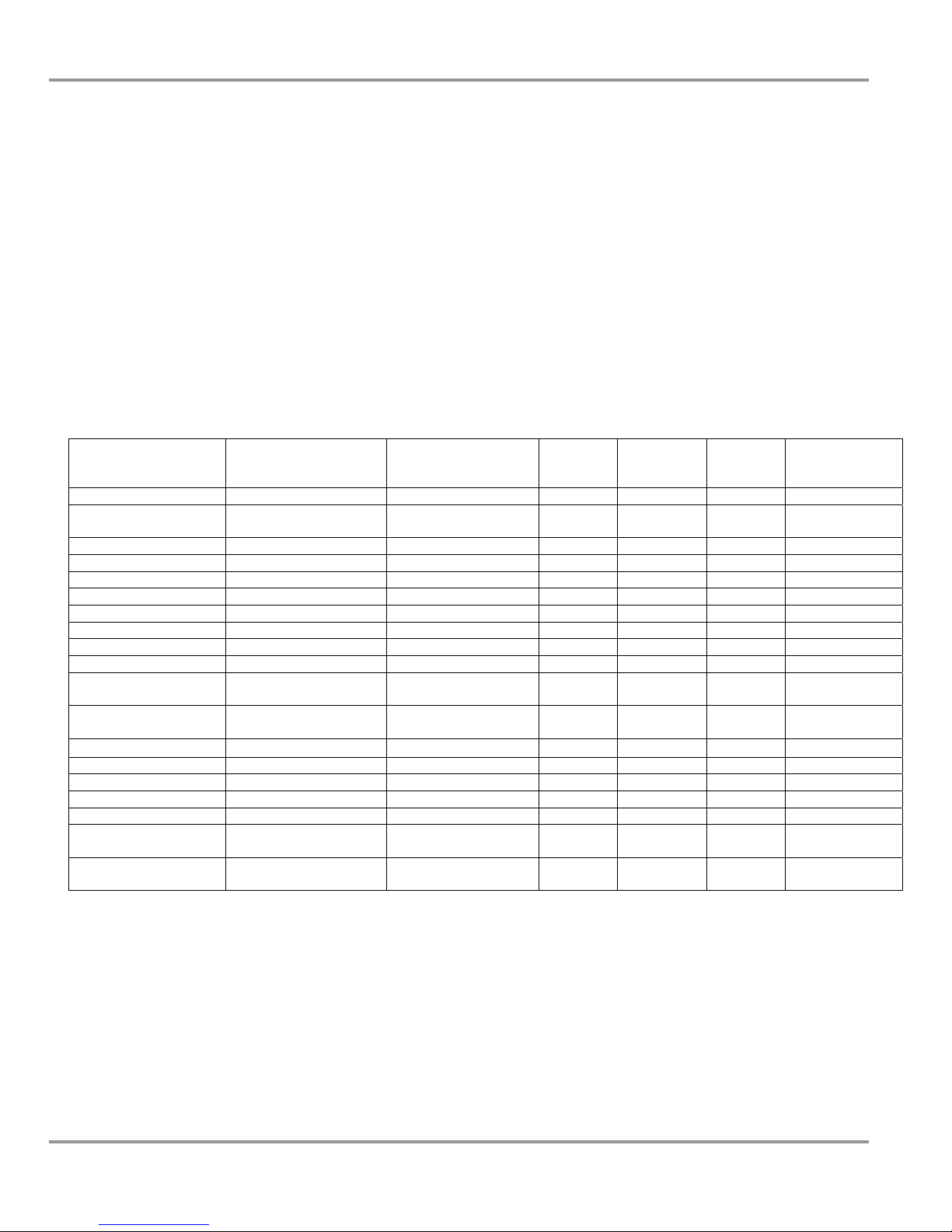

Model No. Voltage

6963200 100-115V 2' 22.7" 9.4" 29" 43.7"

6963220 208-230V 2' 22.7" 9.4" 29" 43.7”

6963300 100-115V 3' 22.7" 9.4" 29" 43.7"

6963301 100-115V 3' 32" 12" 29" 53"

6963302 100-115V 3' 32" x 360° 12" 29" 53"

6963320 208-230V 3' 22.7" 9.4" 29" 43.7"

6963321 208-230V 3' 32" 12" 29" 53"

6963322 208-230V 3' 32" x 360° 12" 29" 53"

6963400 100-115V 4' 22.7" 9.4" 29" 43.7"

6963401 100-115V 4' 32" 12" 29" 53"

6963402 100-115V 4' 32" x 360° 12" 29" 53"

6963403 100-115V 4' 35" 12" 35.5" 56"

6963420 208-230V 4' 22.7" 9.4" 29" 43.7"

6963421 208-230V 4' 32" 12" 29" 53"

6963422 208-230V 4' 32" x 360° 12" 29" 53"

6963423 208-230V 4' 35" 12" 35.5" 56"

6963501 100-115V 5' 32" 9.4" 29" 53"

6963503 100-115V 5' 35" 9.4" 35.5" 56"

6963521 208-230V 5' 32" 9.4" 29" 53"

6963523 208-230V 5' 35" 9.4" 35.5" 56"

6963601 100-115V 6' 32" 12" 29" 53"

6963603 100-115V 6' 35" 12" 35.5" 56"

6963621 208-230V 6' 32" 12" 29" 53"

6963623 208-230V 6' 35" 12" 35.5" 56"

Enclosure

Width

Internal

Working

Height

Sash

Opening

Exterior

Depth

Exterior

Height

Face

Velocity

(fpm)

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

60

80

100

Airflow

Exhaust

Volume

(CFM)

85

115

145

85

115

145

130

175

220

170

230

285

170

230

285

130

175

220

170

230

285

170

230

285

175

235

295

230

305

380

230

305

380

230

305

380

175

235

295

230

305

380

230

305

380

230

305

380

220

295

370

220

295

370

220

295

370

220

295

370

350

465

580

350

465

580

350

465

580

350

465

580

Noise

Pressure

(dbA)

50

54

59

50

54

59

46

52

56

52

57

62

52

57

62

46

52

56

52

57

62

52

57

62

53

57

62

57

62

67

57

62

67

59

62

67

53

57

62

57

62

67

57

62

67

59

62

67

57

62

67

57

62

67

57

62

67

57

62

67

57

61

66

57

61

66

57

61

66

57

61

66

Product Service 1-800-522-7658

5

Chapter 2: Prerequisites

Electrical Requirements

Standard duplex electrical receptacles should be nearby for connecting the

Paramount Ductless Enclosure and other equipment. The enclosures include iris

pass-through ports to allow electrical cords through the back of the enclosure

without leaving a large hole for contaminants to escape. (See Appendix C for

amperage.)

There is no provision for controlling a remote blower for exhausting air from the

Paramount Ductless Enclosure. If remote blower control is required, a qualified

electrician may connect a wall-mounted power outlet switch receptacle nearby so

that the switch controls both the remote blower and the outlet. The power cord

for the Paramount is then plugged into this outlet.

Space Requirements

The dimensions for the different models are shown in the chart in Chapter 2 and

detailed in Appendix B: Dimensions. To convert inches to millimeters, multiply

by 25.4.

6

Product Service 1-800-522-7658

CChhaapptteerr 33::

GGeettttiinngg SSttaarrtteedd

Now that the site for your Paramount Ductless Enclosure is properly

prepared, you are ready to unpack, inspect, install, and validate your system.

Read this chapter to learn how to:

• Unpack and move the enclosure.

• Set up the enclosure with the proper supporting structure and work

surface.

• Install carbon filters and/or HEPA filters.

• Connect the electrical supply.

• Set Filter Life and Filter Check Timers.

• Reset or change the face velocity, if necessary.

• Validate the enclosure.

• Seal the enclosure to the work surface.

• If applicable, connect to an exhaust system.

Depending upon which model you are installing, you may need common

mechanical and electrical installation tools in addition to 5/16", 3/8", 7/16",

and 1/2" wrenches, ratchets, sockets, a nut driver set, a flat-blade screwdriver,

a Phillips screwdriver, and a carpenter level to complete the instructions in

the chapter.

Note: Each enclosure model weighs between 125 to 350 lbs. (55 to 152 kg).

The shipping container allows for lifting with a mechanical lift truck or

floor jack. If you must lift the enclosure manually, follow safe-lifting

guidelines. Do not lift by the front air foil.

Product Service 1-800-522-7658

7

Chapter 3: Getting Started

Unpacking the Enclosure

We recommend that you do not remove the enclosure from its shipping

container until it is ready to be placed into its final location. Move the unit

by placing a flat, low dolly under the shipping skid, or by using a floor jack.

Carefully remove the shrink-wrap or carton on the enclosure and inspect it

for damage that may have occurred in transit. If damaged, notify the delivery

carrier immediately and retain the entire shipment intact for inspection by the

carrier.

Note: The United States Interstate Commerce Commission rules require that

claims be filed with the delivery carrier within fifteen (15) days of delivery.

Note: Do not return goods without the prior authorization of Labconco.

Unauthorized returns will not be accepted.

Note: If the enclosure was damaged in transit, you must file a claim directly

with the freight carrier. Labconco Corporation and its dealers are not

responsible for shipping damages.

Do not discard the packing material until you have checked all of the

components and tested the enclosure.

Do not move the enclosure by tilting it onto a hand truck.

Set Up the Ductless Enclosure on a Supporting

Structure and Work Surface

When installing the enclosure onto a chemical-resistant work surface or

benchtop, ensure that the structure can safely support the combined weight of

the enclosure and any related equipment. See Chapter 7: Accessorizing the

Paramount Ductless Enclosure for appropriate work surfaces, stands,

and cabinets. The work surface should be at least as wide as the enclosure

to properly support it. The front of the enclosure should be aligned within

0.3" of the front of the work surface as shown in Figure 3-1. Mounting holes

are provided in the Labconco accessory work surfaces to secure the

enclosure. RTV Silicone sealant can be applied to seal the work surface to

the enclosure.

Work Surface Specifications

The work surface should be smooth, rigid, and durable. The surface should

be non-porous and resistant to the powders, solvents and chemicals used in

conjunction with the Paramount Ductless Enclosure.

8

Product Service 1-800-522-7658

Chapter 3: Getting Started

Work Surface and Enclosure Installation

1. Level the base cabinets and the work surface. Work surface should be

placed flush with the front of the stand or base cabinet as shown in

Figure 3-1.

2. Identify and position the work surface ensuring the mounting holes

will align with the four screw locations on the base of the enclosure.

(Rear mounting holes are located close to the rear edge.)

3. Secure the work surface to the base cabinet with a structural adhesive

or silicone sealant.

4. Before moving the enclosure, insert the supplied mounting screws in

the four holes. Allow a minimum of 1/8" clearance under the head of

the screw for positioning the enclosure. For the stainless work

surfaces, use a #10-24 x 3/8" hex washer head screw (Labconco part

number 1885806).

5. Place the enclosure on the work surface and slide the rear flange and

front air foil flanges under the mounting screw heads.

6. Tighten the four screws to complete the installation.

7. If desired, apply RTV silicone to seal the work surface and enclosure.

Product Service 1-800-522-7658

9

Chapter 3: Getting Started

Figure 3-1

Paramount Ductless Enclosure Installation

10

Product Service 1-800-522-7658

Chapter 3: Getting Started

Install Carbon Filters and/or HEPA Filters

Refer to Figure 3-2 for a view of the filter loading compartment with the

front panel removed. The Paramount Ductless Enclosure ships without

filters that must be ordered separately. It is highly recommended that

an extra set of new filters be on hand on a continuous basis.

To remove the front panel, use a Phillips screwdriver to loosen the two

screws holding the front panel in position; slide the front panel forward and

then up to remove. The filter loading compartment is hinged and supported

by gas spring cylinders. Lift the handle up and remove the cardboard

packing. The cardboard packing will be replaced with filters that always

stack two high.

The Paramount Ductless Enclosure has seven different filter types identified

below:

6938100 HEPA Filter, 15" x 18" x 1.5", 99.99% efficient particulate on 0.3 micron

6938200 Activated Carbon Filter, Organic Vapor 7.5 lbs.

6938201 Impregnated Carbon Filter Acid-Sulfur 10 lbs.

6938202 Impregnated Carbon Filter, Ammonia-Amine 11 lbs.

6938203 Impregnated Carbon Filter, Formaldehyde-Formalin 10 lbs.

6938204 Mixed Bed Carbon Filter, Org. Vap., Acid-Sul., Ammon, Form (25% Mix) 10 lbs.

6938205 Impregnated Carbon Filter, Radioisotope 10 lbs.

All impregnated Carbon Filters, specific chemical treated, have an organic

vapor capacity of 25%. Mixed Bed Carbon Filters have an organic vapor

capacity of 50%. For example, the Impregnated Acid Filter has 25% of 10

pounds or 2.5 pounds of organic vapor capacity. Thus, a common application

using solvents with acids would require one Activated Carbon Filter for

organic vapors and one Impregnated Acid Filter for acid vapors.

Any combination of two filter types may be used. Filters are always loaded

with the gasket side up. If placing the Paramount Ductless Enclosure in a

clean room, always place the HEPA filter above the carbon filter to eliminate

any trace carbon particles from entering the clean room. Load the stacked

filters into the individual filter compartments. The Paramount model sizes,

filter compartments, and number of filters are listed below for installation

convenience.

Paramount

Size

2' 1 2 15 lbs.

3' 2 4 30 lbs.

4' 3 6 45 lbs.

5' 3 6 45 lbs.

6' 4 8 60 lbs.

Filter

Compartments

Required

No. of Filters

Total Organic

Vapor Filter Weight

Product Service 1-800-522-7658

11

Chapter 3: Getting Started

To install the filters, push the stacked filters to the stop in the rear of each

filter compartment. After loading the stacked filters into the compartments,

close the gas spring cylinders by pulling the handle down and compressing

the filter gaskets. Filter installation is complete.

Figure 3-2

Filter Installation

Connect the Electrical Supply

Simply connect the 115V power cord supplied to the IEC electrical supply

plug on the back of the enclosure. For 230V, the same procedure applies

except it is shipped without a plug. Install the appropriate plug for your

electrical specifications per local codes. (See Appendix C for amperage.)

Set Filter Life and Filter Check Timers

Once the filters are installed and electrical power is connected, it is necessary

to set the Filter Life Timers in the Filter Setup menus described in Chapter 5:

Using the Ductless Enclosure. Consult the separate Paramount Chemical

Guide, Appendix E: Estimated Filter Life Calculation, and/or Labconco

Specialist to determine the filter capacity. Through the use of all three

sources, set the Filter Life Timers.

12

Product Service 1-800-522-7658

Chapter 3: Getting Started

Initial Safety-First™ Vapor Sensor Warm Up Period

The Safety-First™ Vapor Sensor includes a 5V, 0.28W integrated heater and

any detectable gas that accumulates during shipment must be driven off the

organic sensor over an initial 10-30 minute warm up period with the blower

activated. Refer to the Diagnostic Program Screen for Organic Sensor on

page 32 in Chapter 5 to view the display of the millivolt levels of the Vapor

Sensor. With new filters installed, the Organic Sensor should read between

1300-1500 millivolts after the initial 10-30 minute warm up period with the

blower running. All filters should be changed upon completion of work once

the Organic Sensor sees an increase of 400-500 millivolts with the display

indicating “Replace Filters.”

Reset or Change the Airflow Face Velocity

(If Necessary)

The face velocity for the Paramount Ductless Enclosure has been preset at the

factory between 75-80 fpm. Important Note: Transport, altitude, and

temperature differences may require a reset of the “Calibration” of the

“Pressure Sensor” as outlined in Chapter 5: Using the Ductless Enclosure.

When “Calibration” of the “Pressure Sensor” is reset, it is best to try the

previously calibrated values of motor speed and airflow face velocity and

then confirm the average face velocity through the enclosure sash opening.

Adjust the motor speed and airflow face velocity as necessary after

confirmation. Average face velocity measurements are made using a

calibrated thermal anemometer and taking an average across the sash opening

at 5" directly below the sash handle.

Additionally, the same “Calibration” menu in Chapter 5 should be used to

change the face velocity to another value. For most applications, 75-80 fpm

is ideal. However, there are some requirements for 100 fpm. Furthermore,

the face velocity alarm has been preset at the factory at 60 fpm. If needed,

follow the “Calibration” menu for the “Airflow Alarm” in Chapter 5 and

adjust the alarm value between 10-20 fpm below the actual face velocity.

The Paramount Ductless Enclosure has been set up to accept the SmartFlow™ feedback system. The Smart-Flow feature adjusts the motor speed

automatically for filter pressure drop, barometric pressure, and room

temperature, and maintains constant airflow velocity at the calibrated value.

Note: At altitudes above or below 900 feet, the Paramount must be

recalibrated to account for significant pressure changes that will have an

effect on face velocity. Face velocity measurements are always made using a

calibrated thermal anemometer and taking an average across the sash

opening. Follow the “Calibration” menu for “Pressure Sensor” as outlined in

Chapter 5: Using the Ductless Enclosure for recalibration of face velocity.

Product Service 1-800-522-7658

13

Chapter 3: Getting Started

Validate the Enclosure

To determine the actual face velocity at the sash opening, airflow velocity

readings are taken. Each Paramount Ductless Enclosure has been preset at

75-80 fpm. The “average face velocity” is achieved by taking readings

across the enclosure with the readings 6" from the ends and evenly spaced

every 12". Readings are measured at 5" directly below the upper sash handle.

Refer to Chapter 2 for proper airflow volumes for your particular model.

The Paramount Ductless Enclosures have been tested at Labconco’s airflow test

facility per ASHRAE 110-1995. All enclosures achieve an “as manufactured

rating” of less than 0.05 part per million (ppm) at 4 liters per minute (lpm); AM

<0.05 (Consult Labconco for individual ratings). For particulate powder

validation, Labconco had containment testing performed to validate the

enclosures for naproxen sodium powders. The Paramount Ductless Enclosures

demonstrated excellent containment when used by an operator using excellent

technique and good containment when used by an operator using marginal

technique. While no enclosure can compensate for improper technique, these

tests confirm that the Paramount Ductless Enclosures provide a safe working

environment. For copies of these validation reports, contact Labconco at 800821-5525 or 816-333-8811.

Seal the Enclosure to the Work Surface

When the enclosure has been set in place, it can be sealed at the work surface

to prevent spilled materials from collecting under the walls. A bead of

silicone sealant is recommended to seal the enclosure to the work surface.

Connecting to the Exhaust System (If Applicable)

WARNING: The weight of the exhaust ductwork system must be

supported independently of the enclosure superstructure or damage may

occur.

The exhaust system should be installed by a qualified HVAC contractor.

Normal operations with the Paramount Ductless Enclosure are exhausted into

the room and the accessory Canopy Exhaust Connection is not required. The

Canopy Exhaust Connection aids in the further removal of chemicals beyond

the filters or applications where a higher degree of powder and particulate

removal is required. However, if desired, the Canopy Exhaust Connection

(see Chapter 7) accessory has been designed to accept 6" diameter ductwork.

Review Chapter 2 for exhaust prerequisites and review Chapter 7 for ordering

blower exhaust equipment. Consult Labconco should you require help sizing

your blower for the exhaust volume and system static pressure loss. To

ensure compatibility, the selected exhaust duct material should match the

enclosure, procedures and chemical applications.

14

Product Service 1-800-522-7658

CChhaapptteerr 44::

PPeerrffoorrm

maannccee FFeeaattuurreess aanndd

SSaaffeettyy PPrreeccaauuttiioonnss

The Paramount Ductless Enclosure is a self-contained filtered enclosure that

protects the operator from specified vapors and particulates through the

revolutionary combination of features to enhance safety, performance, and

ergonomics. Carbon filters and/or HEPA filters must be installed.

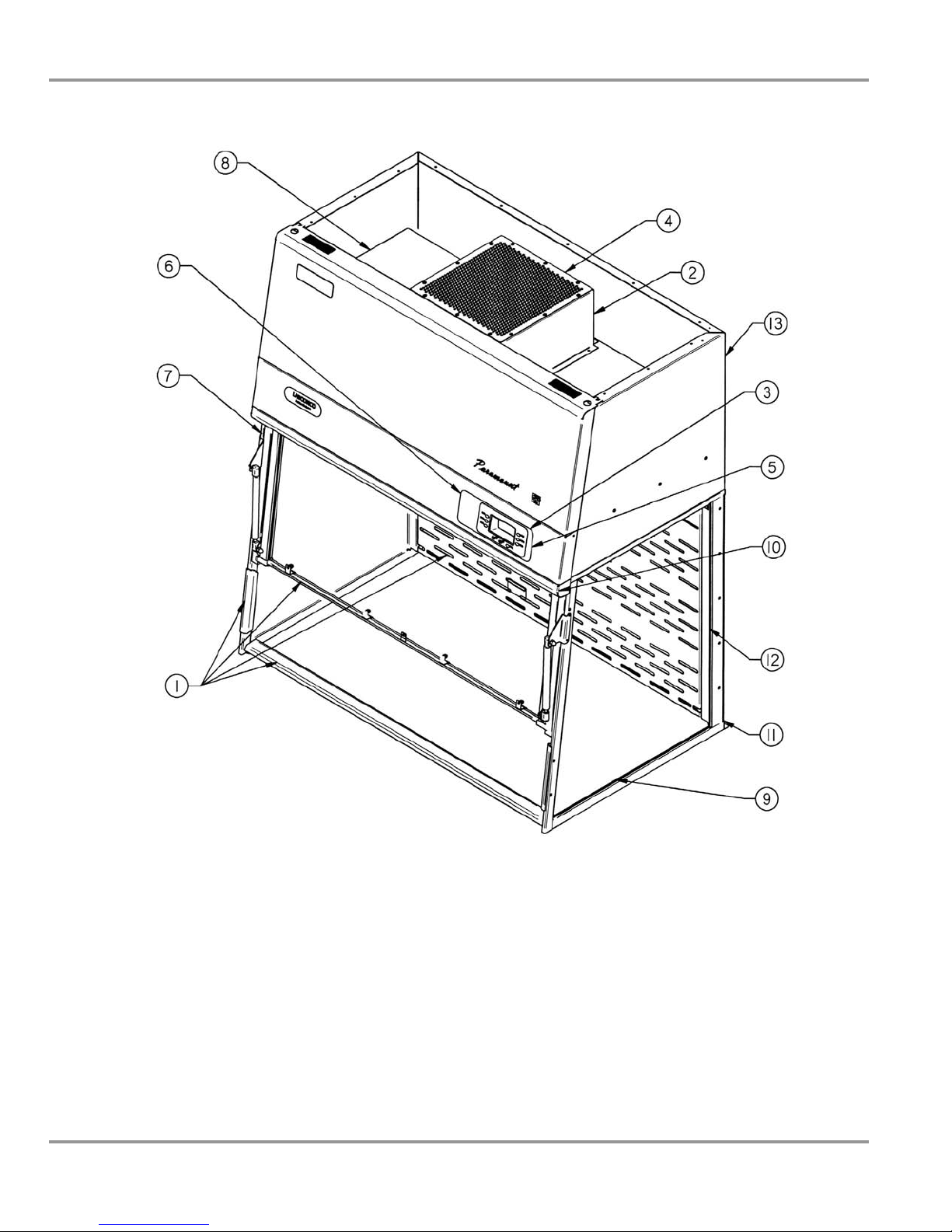

All Paramount Ductless Enclosures have the following performance features

as illustrated in Figure 4-1:

1. High Performance Containment

2. Safety-First™ Vapor Sensor

3. Smart-Flow™ Airflow Monitor

4. Quiet, Energy-Efficient ECM Impeller

5. Audible/Visual Alarms

6. Large Control Panel LCD Display

7. Ergonomic Sloped Front

8. Convenient Filter Replacement

9. Durable Construction

10. Fluorescent Light with Electronic Ballast

11. Utility Iris Ports

12. Maximum Visibility

13. Simple Electrical Connection

Product Service 1-800-522-7658

15

Chapter 4: Performance Features and Safety Precautions

16

Figure 4-1

Performance Features

Product Service 1-800-522-7658

Chapter 4: Performance Features and Safety Precautions

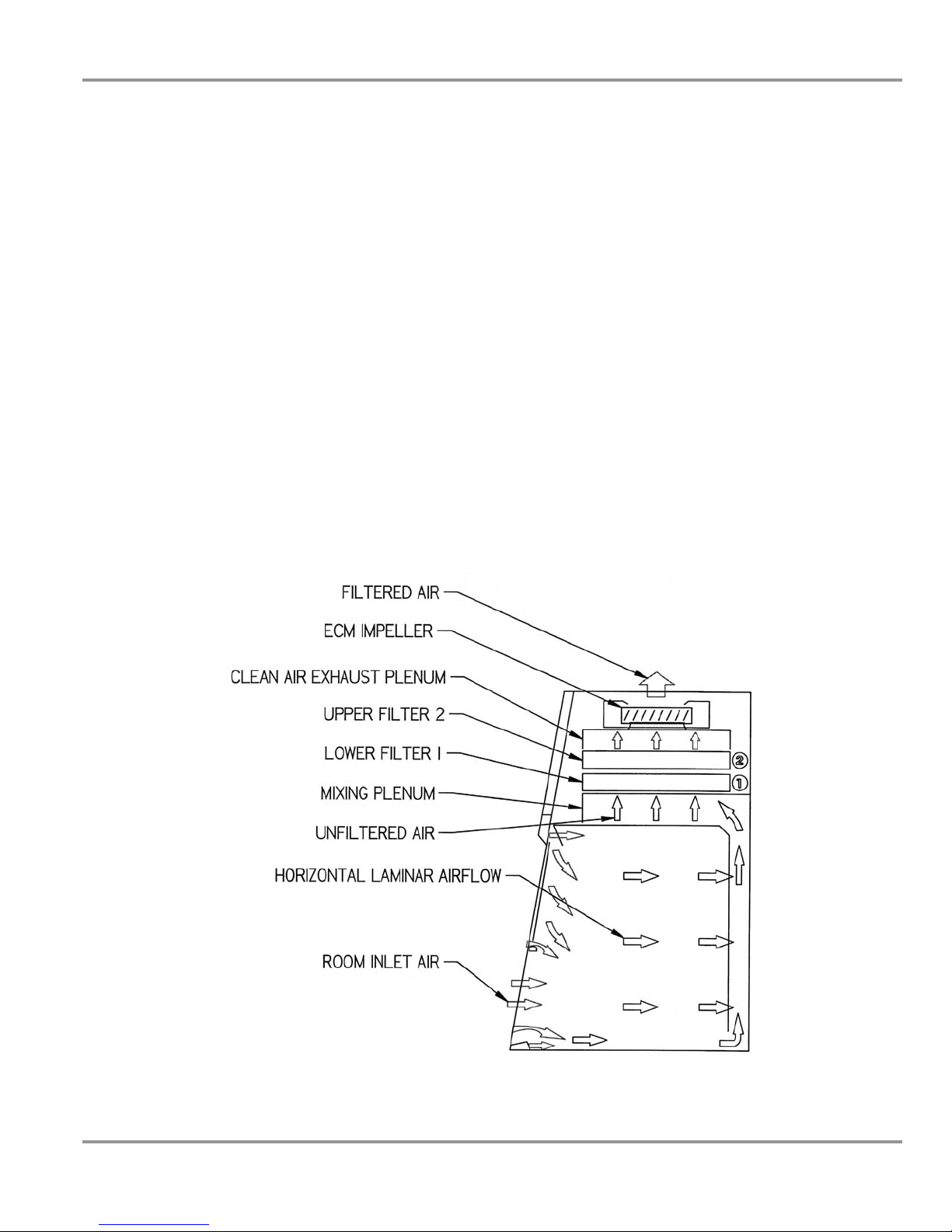

High Performance Containment

The Paramount Ductless Enclosures use patented technology to direct air into

and through the contaminated air chamber (U.S. Patent 6,461,233). The

containment enhancing and aerodynamic designs of the lower CleanSweep™ Air Foil, upper sash foil, side air foils, upper dilution air supply,

and zoned rear perforated baffle all work in concert to produce horizontal

airflow patterns that significantly reduce chemical concentrations through the

work area (illustrated in Figure 4-2). The unique lower air foil shape and

Clean-Sweep™ openings sweep the work surface and create a constant

protective barrier from contaminants. The radiused upper sash foil includes

an open air passage directly atop the sash foil into the enclosure chamber and

directs chemical concentrations away from the sash opening. The side entry

air foils allow turbulence-free air to enter the enclosure from the sides and

allow clean air to sweep the interior walls. The upper dilution air supply

provides by-pass air from above the work surface to constantly bathe the

inside of the sash and upper chamber with clean air to reduce chemical

concentrations. The zoned rear perforated baffle directs horizontal laminar

air streams to the three zones to minimize the potential for air to roll forward

preventing contaminants from moving toward the sash opening.

Product Service 1-800-522-7658

Figure 4-2

Airflow Diagram

17

Chapter 4: Performance Features and Safety Precautions

Safety-First™ Vapor Sensor

The Safety-First™ Vapor Sensor detects filter saturation in the exhaust to

alert the operator to replace the filters. The early warning provided by the

Safety-First Vapor Sensor provides the user ample time (5-10% remaining

filter life) to complete work in process before replacing the filters. The early

warning signals with an intermittent beep and the LCD display message alerts

the user to replace filters. The final warning signals with a constant alarm

and the LCD display message alerts the user to replace filters. The SafetyFirst Vapor Sensor includes a primary and secondary backup sensor for

redundant monitoring. Both sensors detect typical organic vapor solvents,

smoke particulates, ammonia gases, formaldehyde gases and hydrogen

sulfide gases. The Safety-First Vapor Sensor has an optimal detection range

of 1-10 ppm. Typical concentrations tested by Labconco for chemicals in

separate chemical families are listed in order of sensor sensitivity as follows:

Chemical Family Chemical

Aldehydes & Ketones Cyclohexanone 0.2-0.5 ppm 0.068 50 22% OV

Mixture of Aliphatic

Hydrocarbons

Particulates Cigarette smoke 0.4-1.0 ppm N/A N/A N/A OV & HEPA

Aldehydes & Ketones Acetone 0.5-1.0 ppm 4.58 250 2% OV

Aromatic Hydrocarbons Toluene 0.5-1.0 ppm 0.16 100 20% OV

Ethers Methyl Tert-Butyl Ether 0.5-1.0 ppm 0.053 50 9% OV

Sulfur Compounds Hydrogen Sulfide 0.5-2.0 ppm 0.0005 10 10% AG, Acid-Sulfur

Nitrogen Compounds Diethylamine 1.5-2.0 ppm 0.186 10 7% OV

Esters Ethyl Acetate 1.5-4 ppm 0.61 400 9% OV

Ethers Diethyl Ether 2-4 ppm 2.29 400 4% OV

Aldehydes Formaldehyde 2-4 ppm, best to use

Nitrogen Compounds Ammonia Solution

Alcohols

Acids Acetic Acid 5-6 ppm 0.016 10 4% OV

Halogens Chlorobenzene 5-8 ppm 0.741 10 20% OV

Alcohols Isopropyl Alcohol 8-11 ppm 22 200 7% OV

Aliphatic Hydrocarbons Hexane 9-15 ppm 21.9 50 11% OV

Alcohols

Mineral Acids Hydrochloric Acid Not Detected, use other

Important Note: Clean up procedures using alcohols or volatile

*

Gasoline 0.3-1.0 ppm 0.3 300 11% OV

(Ammonium Hydroxide)

Ethyl Alcohol

Methanol

*

*

Sensitivity Alert

Concentration

other detector methods

2-5 ppm 5.75 25 10% AM, Ammonia-

2.5-4 ppm 0.136 1000 1.3% OV

15-25 ppm 141 200 0.1%,

detector means

Odor

Threshold

(ppm)

0.87 0.1 ceiling,

0.77 5 17% AG, Acid-Sulfur

chemicals with low filter capacity could saturate the filters quickly.

Important Note: The vapor sensor does not detect mineral acid gases such

as hydrochloric acid, nitric acid, or sulfuric acid and other detector means

such as a mineral acid sensor or interval timed sampling with sampling tubes

must be used.

Chemical Safety Note: The chart above is only a guideline! Frequent

chemical testing or filter monitoring is recommended for other chemicals. If

chemical suitability is ever in question, always work below the acceptable

exposure limit/TWA to maximize both safety and filter performance.

Exposure

Limit TWA

(ppm)

0.016

Filter

Capacity

(%W)

10% FORM

very low

Filter Type

Amine

not recommended

18

Product Service 1-800-522-7658

Chapter 4: Performance Features and Safety Precautions

Smart-Flow™ Airflow Monitor

The Smart-Flow™ Airflow Monitor continuously monitors airflow and

displays face velocity. An audible/visual alarm alerts the user to low airflow

conditions. The Smart-Flow Airflow Monitor enables the motor speed to

automatically adjust for conditions such as temperature, barometric pressure,

and filter loading and maintain constant programmed airflow speed. The

Smart-Flow feedback maintains constant airflow speed through the use of

constant velocity pressure measurement accomplished with a pitot tube and

pressure sensor mounted on the control board. Transport, altitude, and

temperature differences require the airflow re-calibration steps as outlined in

Chapter 5 and 6. Use the “Calibration” menu in Chapter 5 to reset the

“Pressure Sensor” values for “motor speed” and “airflow face velocity.”

Quiet, Energy-Efficient ECM Impeller

The electronically commutated motorized (ECM) impeller is 95% energy

efficient providing “green” energy savings (See Appendix D). Because of

the high efficiency, the impeller runs extremely quiet for the comparative

amount of airflow volume. All Paramounts run at or below 62 dbA at 80 fpm

and most Paramounts run at or below 59 dbA at 80 fpm. By design, the ECM

impeller is located after the filters assuring an intrinsically safe design where

all contaminated air is filtered effectively. See Chapter 2: Prerequisites for

complete airflow exhaust volume, noise pressure, and face velocities of 60,

80 and 100 fpm. The ECM impeller has a programmable blower timer

should you desire additional “green” energy savings.

Audible/Visual Alarms

The audible/visual alarms remind the operator to check the filters with

sampling tubes or replace the filter. Filter replacement alarms occur in

audible/visual modes for both filter saturation activated by the Safety-First

Vapor Sensor or the final filter elapsed time. A low airflow alarm occurs

when the face velocity drops below programmed levels.

Large Control Panel LCD Display

The large (3" x 1.5") LCD message center provides continuous status reports

for each filter, displays airflow speed, and displays alarm messages for both

filters and airflow. The touchpad can be programmed for filter types, filter

check times, and filter replacement times. Audible/visual alert time messages

appear after the specified number of hours has elapsed. The audible/visual

alarm reminds the operator to check the filters with sampling tubes or replace

the filters. Filter replacement audible/visual alarms occur for both the SafetyFirst Vapor Sensor and final filter elapsed time.

Product Service 1-800-522-7658

19

Chapter 4: Performance Features and Safety Precautions

Ergonomic Sloped Front

The ergonomic slope provides maximum visibility and comfort, reduces

glare, thereby minimizing operator fatigue. The space saving design (U.S.

Patent No. D538,941) increases effective laboratory work space, because the

impeller and filters are all self-contained within the enclosure and a separate

filtered blower unit is not required.

Convenient Filter Replacement

The Paramount filter compartment was designed to make filter replacement

convenient and easy. The gas spring assisted clamping mechanism opens

effortlessly and applies uniform pressure across the entire top surface of the

filters for leak-proof, one-step filter replacement from the front of the

enclosure.

Durable Construction

Unlike comparable plastic or acrylic ductless fume hoods and enclosures, the

Paramount Ductless Enclosure is manufactured with durable tempered safety

glass and dry powder epoxy-coated aluminum and steel. The sides and sash

are made from tempered safety glass that will not easily discolor or craze like

plastic. The frame is made from dry powder epoxy-coated aluminum and

steel providing further strength and corrosion resistance to solvents and acids.

Fluorescent Light with Electronic Ballast

The fluorescent light is located above the work area, out of contact with

contaminated air and easy to service. All Paramounts have a fluorescent light

and energy saving light timer with electronic ballast. The light timer is a

programmable feature should you desire additional “green” energy savings.

Utility Iris Ports

All Paramounts have two utility iris ports that allow electrical cords and data

cords to pass through the back of the enclosure without leaving a large hole

for contaminants to escape. The enclosure ships with both solid plugs and

iris ports for your convenience.

20

Product Service 1-800-522-7658

Loading...

Loading...