Page 1

User’sManual

OpenCombination(Macro)

KjeldahlSystems

Models

21232Series

21233Series

To receive important product updates,

complete your product registration card

online at register.labconco.com

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Please read the User’s Manual before operating the equipment.

Page 2

Copyright © 2010, 2013, 2014 Labconco Corporation. All rights reserved.

The information contained in this manual and the accompanying products are copyrighted and all

rights reserved by Labconco Corporation. Labconco Corporation reserves the right to make periodic

design changes without obligation to notify any person or entity of such change.

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas of

defective material and workmanship, provided such defect results from normal and proper use of the

equipment.

The warranty for all Labconco products will expire one year from date of installation or two years

from date of shipment from Labconco, whichever is sooner, except the following;

• Purifier® Logic® Biological Safety Cabinets and PuriCare® Lab Animal Research Stations

carry a three-year warranty from date of installation or four years from date of shipment from

Labconco, whichever is sooner.

• SteamScrubber® & FlaskScrubber® Glassware Washers carry a two-year warranty from date

of installation or three years from date of shipment from Labconco, whichever is sooner.

• Blood Drawing Chairs carry a ten year warranty.

• Carts carry a lifetime warranty.

• Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the

event of a warranty claim, contact Labconco Corporation or the dealer who sold you the product. If

the cause is determined to be a manufacturing fault, the dealer or Labconco Corporation will repair or

replace all defective parts to restore the unit to operation. Under no circumstances shall Labconco

Corporation be liable for indirect, consequential, or special damages of any kind. This statement may

be altered by a specific published amendment. No individual has authorization to alter the provisions

of this warranty policy or its amendments. Lamps and filters are not covered by this warranty.

Damage due to corrosion or accidental breakage is not covered.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight

carrier. Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the

delivery carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed

by various federal, state, or local regulations. All users of this equipment are required to become

familiar with any regulations that apply in the user’s area concerning the dumping of waste materials

in or upon water, land, or air and to comply with such regulations. Labconco Corporation is held

harmless with respect to user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-8215525 or 1-816-333-8811, between the hours of 7:00 a.m. and 6:00 p.m., Central Standard Time.

Part #2081400, Rev. W

ECO H982

Page 3

T

AABBLLEE

T

CHAPTER 1: INTRODUCTION 1

Components Shipped 1

General Description 2

Performance 3

Component Identification 3

CHAPTER 2: INSTALLATION 6

General Installation Notes 6

Location 6

Electrical 7

Tap Water Supply 8

Distillation Manifold 8

Acid Fume Blower Exhaust System 9

Blower Airflow Exhaust Volume Requirement & Velocity Test 9

Digestion Rack Drip Shield 10

Glassware Installation 11

CHAPTER 3: NORMAL OPERATION & ROUTINE

Normal Operation Start-Up 12

Clean-Up and Cosmetic Guidelines 13

Fume Removal Manifold Suction Adjustment 13

Exhaust Systems Maintenance 13

Drip Shield 14

APPENDIX A: REPLACEMENT PARTS 15

APPENDIX B: DIMENSIONS & AIRFLOW REQUIREMENTS 16

APPENDIX C: TOTAL KJELDAHL NITROGEN METHOD 17

O

O

MAINTENANCE 12

FF

C

C

OONNTTEENNTTSS

Page 4

Page 5

CChhaapptteerr 11::

IInnttrroodduuccttiioonn

Components Shipped

Carefully check the contents of your Open Combination Kjeldahl System for

shipping damage while it is still on the shipping pallet. Do not discard the

packaging material until the contents have been checked and the equipment

has been approved for installation.

The Open Combination Kjeldahl Nitrogen System has been shipped in one

complete crate to minimize damage that may occur in transit.

Make sure to inspect the product thoroughly prior to installation and report

any damage that may have occurred in transit (see Warranty page for

instructions).

Figure 1-1

Product Service 1-800-522-7658

1

Page 6

Chapter 1: Introduction

General Description

Labconco’s Open Combination (Macro) Kjeldahl Nitrogen System is

designed to facilitate the determination of Total Nitrogen content within

materials such as feeds, grains, soils, fertilizers, plant tissue, water, organic

wastes, and food products. The expression ‘Macro’ identifies the size of

sample vessel and the sample size that can be used with this equipment.

Other Kjeldahl systems are available, which use smaller sample vessels and

require smaller sample sizes. The apparatus can be used for the digestion

and/or distillation of all types of nitrogen containing samples. The system

consists of the Lower Digestion rack and Upper Distillation rack. Both are

used in standardized (Macro) Kjeldahl Nitrogen Determination Methods.

This Kjeldahl system is not enclosed, excess heat and personnel safety during

the digestion and distillation reactions should be considered when selecting

an installation location. High temperature acid digestion and caustic

distillation comprise the two-step Kjeldahl Nitrogen determination method.

2123202 Six Place Open Combination Macro-Kjeldahl System

2

Product Service 1-800-522-7658

Page 7

Chapter 1: Introduction

Performance

The Open Combination Kjeldahl Digestion and Distillation Systems have

been designed for use in the determination of nitrogen (or ammonia)

concentrations. By calculation, nitrogen can be converted to protein values

for products such as plant tissues, meats and other food substances. Nitrogen

determinations with the Open Combination (Macro) Kjeldahl Systems can

accommodate sample sizes up to 5 grams due to the size of the

digestion/distillation flasks. However, higher levels of organic content within

a specific sample type will require smaller sample sizes due to the vigorous

digestion reaction. Detailed procedures developed by professional laboratory

organizations such as American Association of Analytical Chemists (AOAC)

and American Association of Cereal Chemists (AACC) should always be

consulted for step by step analytical procedures when operating this

equipment. For methodology precision and accuracy please consult the

specific published method for the type of sample or substance that will be

analyzed.

Component Identification

1. Electric Heaters. 600-watt heaters are used in both the lower digestion

and upper distillation rack of the unit. Infinite control switches regulate

each of the heaters. The curved heater elements are provided and allow

for the round base of the Kjeldahl Flasks, providing faster and more

evenly distributed heat. The heating element assembly on the digestion

rack can be moved closer to or away from the acid fume removal

manifold to accommodate different size Kjeldahl flasks. All heaters and

temperature controllers are wired to a common electrical box for

connection to a facility electrical service.

2. Lower Fume Removal Manifold. Located in back of the digestion

heater elements, this manifold is manufactured from chemical resistant

chlorinated polyvinyl chloride and fitted with heat resistant PTFE nipples

designed to prevent leakage of the hot sulfuric acid fumes created during

the digestion process. The nipple design extends into the flask opening,

and efficiently removes excess acids fumes during the digestion process.

The flasks are oriented at a 45 degree angle to the fume removal manifold

to promote the condensation and refluxing of the acid fumes back down

into the digestion flask. This refluxing process prevents the samples from

boiling dry during the 45+ minute digestion process.

Product Service 1-800-522-7658

3

Page 8

Chapter 1: Introduction

3. Acid Fume Piping Exhaust System. Located on the left side of the unit,

this exhaust piping removes excess sulfuric acid fumes from the digestion

flasks. Attention - The Exhaust Piping must be connected to a remote

blower to remove acid fumes. The unit does NOT have an integral

blower. The remote blower creates suction and draws acid fumes through

the CPVC digestion manifold and exhaust piping provided and pulls the

fumes under negative pressure out through a duct work system connected

to the remote blower and ultimately the building’s exterior. The 6"

exhaust stack on the left side of the unit must be connected to a leak-tight

PVC ductwork system that vents 10 ft (3 meters) above the building roof.

4. Temperature Gauge The condensation rack behind the upper distillation

heating elements requires cooling water. The temperature of the

distillation cooling water can be adjusted to promote condensation and

suit individual requirements with the flow control valve handle, located

below the distillation heaters. Water temperature is indicated on the

thermometer, which is located at the water outlet of the distillation

manifold. The water connections are 3/4" NPT and the supply line should

be 1/2" minimum for proper water flow through the unit. For facilities

where the ground water temperature exceeds 80°F (27°C), a recirculation

water chiller system will be required to achieve sufficient condensation

results.

5. Distillation Condensation Manifold Epoxy coated steel outer columns

with stainless steel inner condensation columns provide long life. Each of

the six column manifold features 3/4" NPT tap water inlet and outlets for

easy plumbing connections.

4

Product Service 1-800-522-7658

Page 9

4

Chapter 1: Introduction

5

1

3

2

1

Figure 1-2

Product Service 1-800-522-7658

5

Page 10

CChhaapptteerr 22::

IInnssttaallllaattiioonn

General Installation Notes

The Open Combination Macro-Kjeldahl System is shipped fully assembled.

Exhaust duct work, remote blower (if required), electrical service, water supply

and drain connections should be completed by a licensed contractor.

The customer will need to purchase their preferred size of Kjeldahl Flasks, with

one-hole-rubber-stoppers and distillate receiving flasks. The glass Connecting

Bulbs and Delivery Tubes are provided with each Kjeldahl System.

Connecting Bulbs and Delivery Tubes

are included with Macro Kjeldahl Systems.

For installation of the Connecting Bulbs

and Delivery Tubes see section on Glassware

Installation and Figure 2-8.

Use caution when you remove the protective packaging material taped to the

heater runways as fragile components are involved. Levelers are shipped

installed, as are the distillation cooling water thermometers.

Figure 2-1

Location

If possible, the apparatus should be uncrated in the room in which it is to be

placed. Open Combination Macro-Kjeldahl Systems are heavy and cannot be

disassembled to reduce their overall size. Special arrangements should be made in

advance for moving the systems to their final location within a facility. Special

instruction tags are attached to the apparatus; they must not be removed until the

installation has been completed.

The Open Combination Kjeldahl System does not include a safety enclosure. It is

strongly advised to install this Kjeldahl in a location segregated away from

normal Laboratory personnel traffic. High heats along with boiling acids and

caustics present a safety hazard to personnel in close proximity to the Open

Combination Kjeldahl System. Also recommended is spot exhaust ventilation for

the final installation location to remove excess heat produced by the Kjeldahl

digestion and distillation heaters.

6

Product Service 1-800-522-7658

Page 11

Chapter 2: Installation

Electrical

Open Combination Macro-Kjeldahl Systems have been wired at the factory per

the product model number ordered by the customer. Labconco model numbers

ending in -11 are 115 volts. Model number ending in -12 are 230 volts. Models

ending in -13 are 230 volt, three phase. Amperage requirements vary depending

on the number of heaters per the digestion rack. The tables below provide the

voltage and amperage electrical requirements for the Open Combination MacroKjeldahl Systems. A qualified electrician will need to connect the facility

electrical supply to the main breaker box with its individual circuit breakers and

the remote blower to the on/off switch (if desired) on the unit. The following

basic steps should be followed:

1. Remove circuit breaker box cover panel.

2. Main line lead connection terminals are identified and connections

must be made accordingly.

3. Line leads to the apparatus must conform to local electrical codes.

4. The Remote Blower can be wired to the on/off switch on the unit to

control the remote blower from the unit. Remote Blower MUST be on

before using the unit.

5. Provide an electrical ground to the apparatus per code.

6. Before applying power to apparatus, check the electrical panel and

breakers for loose connections.

7. Reinstall box cover panel.

8. Power the breaker box and reset breakers to check circuits in the

apparatus.

9. All electrical wiring and connections must conform to local codes and

should be performed by qualified electricians. An earth ground must

be provided.

P/N AC Electrical Code 6-PL 12-PL 18-PL

-11 115v, single phase, 60 Hz 65 amp

-12 230v, single phase, 60 Hz 35 amp 66 amp 96 amp

-13 208/230v, three phase, 60 Hz 20 amp 38 amp 56 amp

Product Service 1-800-522-7658

Figure 2-2

7

Page 12

Chapter 2: Installation

Tap Water Supply

NOTE: ALL PLUMBING CONNECTIONS AND COMPONENTS MUST

BE FREE OF FOREIGN MATERIAL BEFORE FINAL CONNECTIONS

ARE MADE.

Distillation Manifold

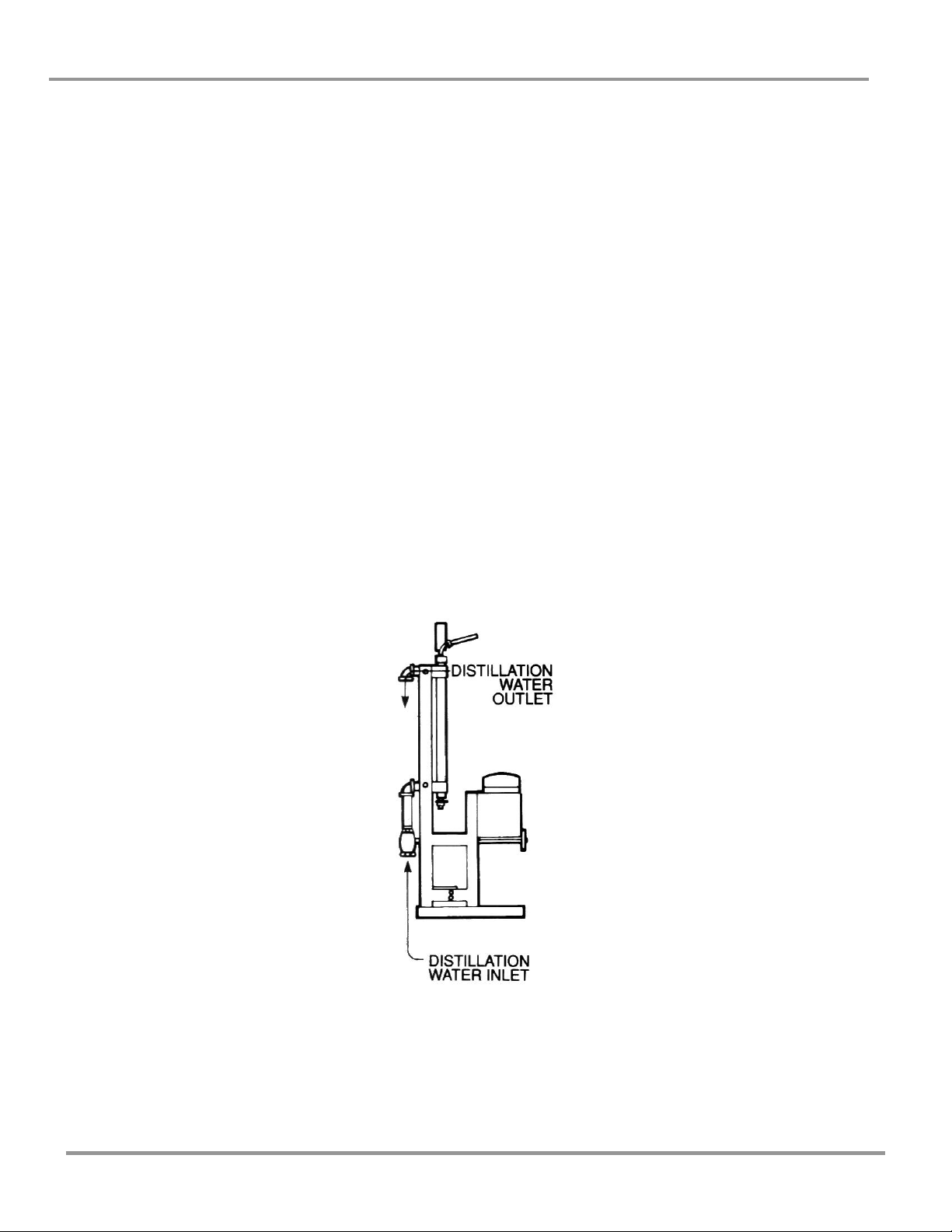

The Open Combination Macro-Kjeldahl Systems feature an upper distillation rack

with individual condensation columns, these are connected together by a common

manifold (6 columns per manifold). The tap water inlet and outlet connections are

3/4" NPT and the supply line should be minimum 1/2" ID for proper water flow

and heat removal capacity through the condensation columns (6-8 gallons/23-30

liters per minute). Open Combination Macro-Kjeldahl Systems with 12 or 18

heaters per rack will include two or three, 6 column manifolds which are

connected together in series.

The plumbing line for the outlet of the distillation manifold must be free of back

pressure to avoid flow restriction of the cooling water.

Water discharged from the distillation manifold is not acid contaminated and

standard drain lines may be used for its removal.

Distillation Manifold Tap Water Connections

Figure 2-3

8

Product Service 1-800-522-7658

Page 13

Chapter 2: Installation

Acid Fume Blower Exhaust System

The exhaust duct connection on top of the damper is sized for use with 6" nominal

(6-5/8" O.D.) vent duct. The exhaust piping assembly is supplied with a short

piece of 6" PVC pipe and a flexible coupling with clamps to connect to the

dedicated duct work exhaust. The flexible coupling must be sealed air-tight to the

exhaust duct work.

All exhaust duct work must be acid-resistant and sealed air-tight. Use only acidresistant sealant on duct work joints.

The bottom of the piping assembly is fitted with a condensate drain and corrosion

resistant tubing. This condensate (identified above and on the next page) can be

collected in a closed acid proof container, which should be emptied regularly or it

may be plumbed to an acid resistant drain line. The condensate is concentrated

acid and care must be exercised when handling it.

Flexible 6”

Coupling

Damper

Piping

Assembly

Drain Line

Figure 2-6

Blower Airflow Exhaust Volume Requirement &

Velocity Test

Cubic feet per minute = 25

Average airflow velocity = 117 feet per minute

The Kjeldahl’s airflow volume test is based on the "Pitot Traverse in Inlet Duct"

method described in the ANSI/ASHRAE 51-1999 standard. Duct velocity

measurements are taken at 48" from the flexible coupling using a 6 point duct

traverse pattern (Industrial Ventilation 24th Edition p. 9-10).

Product Service 1-800-522-7658

9

Page 14

Chapter 2: Installation

(Duct Area in Square Feet) x (Average Airflow Velocity in feet per minute)

= (Air Volume CFM)

(Pi) x (radius²) x (117 FPM) = 25 CFM

The exhaust stack rising from the piping assembly must be vented to the outside

atmosphere via acid-resistant, sealed duct work and a remote blower (not

included). If the remote blower pulls more than 25 CFM at the measurement

point (48” above flexible coupling), close the damper shown in Fig. 2-6 to reduce

airflow to the recommended 25 CFM.

WARNING: Acid-resistant duct must be used on the exhaust connection on

your Kjeldahl Apparatus.

Highly corrosive fumes produced from boiling sulfuric acid will flow through

the ductwork, so acid-resistant duct must be used. Polyvinyl chloride (PVC)

or fiberglass duct is recommended. The exhaust duct work must be supported

independent of the Kjeldahl System to avoid distortion of the piping assembly.

Digestion Rack Drip Shield

The digestion heaters are located in a drip shield and constructed of stainless steel

which is resistant to acid attack. Liquid acid spills that occur can be drained to an

acid-resistant container with the drip tube located on the left side of the digestion

rack.

Duct Acid Drip Tube

Digestion Rack Drip Tube

10

Figure 2-7

Product Service 1-800-522-7658

Page 15

k

Glassware Installation

Connecting

Bulb

Distillation

Flask

Chapter 2: Installation

Rubber

Tubing

Distillation

Manifold

Delivery

Tube

Receiving

Flas

Figure 2-8

Product Service 1-800-522-7658

11

Page 16

CChhaapptteerr 33::

NNoorrm

maall OOppeerraattiioonn && RRoouuttiinnee

MMaaiinntteennaannccee

Normal Operation Start-Up

1. The KNA apparatus is designed for use with either 500 or 800-ml

Kjeldahl Flasks. The digestion heaters are free to move forward or

backward on the runway to accommodate either size flask.

2. Turn the heat controllers to the setting on both the Digester and

Distillation racks if both racks will be used simultaneously. Wait

approximately 5 to 10 minutes to insure proper preheating. Sample

chemistry limits the boiling temperature of the sample, so the high heat

setting may be used.

3. Start the acid fume removal blower or water aspirator (depending on

model number purchased). Place a small piece of tissue paper over the

nipple on the digestion manifold. Suction should be

sufficient to hold 2" x 2" (51 mm x 51 mm) tissue paper

in place.

4. Begin the distillation cooling water and check for leaks.

For correct operation of the condensers, the temperature

of the cooling water should not exceed 80°F (27°C).

Watch your thermometer and regulate water flow by

the control valve

5. The inner stainless steel condensing tubes on the

distillation apparatus should be rinsed out by boiling

nitrogen free water in Kjeldahl flasks attached to the

condensation columns before commencing a distillation

procedure.

A generalized Kjeldahl Total Nitrogen method is present in

Appendix C. The method does not detail sample

preparation or preservation procedures, which may be

required depending on specific types of samples.

12

Product Service 1-800-522-7658

Page 17

Chapter 3: Normal Operation & Routine Maintenance

Clean-Up and Cosmetic Guidelines

• Keeping the Open Macro Kjeldahl System clean will preserve the

appearance and improve life of the equipment.

• The equipment can be kept clean by washing with a weak solution of

sodium hydroxide and rinsing with clear water.

• Sulphate, a salt of Sulfuric Acid, may build up between the channel

support and the fume removal manifold. Neutralize this with a weak

solution of sodium hydroxide periodically to keep the unit clean.

Fume Removal Manifold Suction Adjustment

The suction along the fume removal manifold is adjusted as follows:

Blower Exhaust System

No adjustment is required on the suction pressure at the manifold when used.

The remote blower should be inspected annually for debris, proper operation,

and checked for adequate airflow as specified on pages 11-12 of this manual.

Exhaust Systems Maintenance

Sometimes the suction in the nipples is reduced due to obstruction within the

exhaust system. These obstructions can usually be washed from the fume

pipe, piping assembly by boiling water in a number of flasks placed on the

digestion heaters. The remote blower should be turned on and operating

correctly to draw the steam through the fume pipe.

Product Service 1-800-522-7658

13

Page 18

Chapter 3: Normal Operation & Routine Maintenance

Drip Shield

The drip shield is constructed of stainless steel and is resistant to most acid

attack. Acid spills can however cause discoloration and eventual marring of

the surface unless the following proper procedures are followed in their clean

up.

1. Promptly wash down all major acid spills contained by the shield.

2. Periodically clean the stainless surface with any residential stainless

steel sink cleaning compound.

3. After cleaning, renew the bright shiny appearance by lightly sanding

with 220 grade emery paper.

14

Product Service 1-800-522-7658

Page 19

AAppppeennddiixx AA::

RReeppllaacceem

meenntt PPaarrttss

Electrical Heaters and Motor/Blower Parts

Part Number

1315400 Heater Control, Infinite (115Volts)

1315500 Heater Control, Infinite (230Volts)

2011500 Core Plate Casting, (package of 6)

2023200 Heater Base Casting (electric or gas)

2033100 Heater element, 115V, 600 W, (package of 6)

2033200 Heater element, 230V, 600 W, (package of 6)

2023100 Heater Top ceramic casting (electric or gas)

2031800 Heater lead wire assembly, (package of 6 pairs)

1870200 Knob for Infinite Heater Control

1317100 Blower Motor Switch

1850500 Adjustable sheave (pulley) for belt drive blower only

2056600 Ceramic nipple

2053000 Water ejector nozzle

1967000 Clamp, hose

2144600 Flex sleeving

1662200 Grommet 1/2 ID x 1-1/2 OD

2165800 PTFE nipple

1880128 Plastic screws for PTFE nipple

Description

Miscellaneous Replacement Parts

Part Number Description

1620500 Tubing, rubber condenser connecting, per foot

2152402 Distillation manifold – 6 place stainless steel

2038800 Wire, No 14 Black, SEWF-2, 30 ft length

2038900 Wire No. 14 White, SEWF-2, 30 ft length

2031700 Heater terminal assembly, package of 24

2146400 Assembly inlet & outlet manifold (12 unit only)

2081300 Connector bulb/caustic trap, package of 6

2128800 Delivery tube, package of 6

2078800 Kit, Replacement Fume Pipe

Product Service 1-800-522-7658

15

Page 20

AAppppeennddiixx BB::

meennssiioonnss && AAiirrffllooww

DDiim

RReeqquuiirreem

meennttss

B-1

16

Model A (inches) Heater Max (kW)

6 Place Combo 41.8 7

12 Place Combo 71.8 14

Product Service 1-800-522-7658

Page 21

AAppppeennddiixx CC::

TToottaall KKjjeellddaahhll NNiittrrooggeenn MMeetthhoodd

Titrimetric Determination

Various scientific associations offer approved Kjeldahl methods. These

methods are available at their websites. The AOAC International (Official

Methods of Analysis

Methods

EPA Methods for Chemical Analysis of Water and Wastes), International Standards

(

Organization, The National Forage Testing Association, and United States

Department of Agriculture.

This methodology is for reference only. It is not a citable document. It is

based on data we believe to be reliable. It is offered in good faith but without

guarantee.

1. Scope and Application

2. Definitions

3. Apparatus

Product Service 1-800-522-7658

), American Oil Chemists Society, Environmental Protection Agency

1.1. This method determines the Total Kjeldahl Nitrogen (TKN) in water,

and organic substances. There are three steps within the method: 1.

the digestion procedure – which converts organic nitrogen to

ammonia, 2. the distillation procedure - transferring ammonia from

the digested sample to an ammonia trapping solution 3. Sample

titration – the quantification of ammonia in the trapping solution.

NOTE 1: Some compounds containing nitrogen may not be converted;

such as amines, nitro-compounds, hydrazones, oximes,

semicarbazones and some tertiary amines.

1.2. This method is described for use with Kjeldahl equipment using

Macro-Size glassware (500 - 800 ml flasks).

2.1. TKN is defined as the sum of free-ammonia and organic nitrogen

compounds, converted to ammonium sulfate (NH4)2SO4 by acid

digestion.

3.1. Digestion Apparatus: A Kjeldahl digestion apparatus with multiple

600 watt electric burners, using 500 - 800 ml flasks and a fume

removal manifold system.

3.2. Distillation Apparatus: A Kjeldahl distillation apparatus with

multiple 600 watt electric burners, using 500 - 800 ml flasks. The

distillation system includes connecting bulbs to prevent mechanical

carryover of NaOH during distillation, water cooled condensers and

), Association of American Cereal Chemists (Approved

17

Page 22

Appendix C: Total Kjeldahl Nitrogen Method

distillate receiving vessels, such as 250 ml Erlenmeyer flasks. The

equipment is available as a combined system, featuring both

digestion and distillation apparatus. The preheated burners should

bring 250 ml of water at 25° C to a rolling boil with in 5 minutes.

Condensation columns should cool distillate to 75° F (23.8°C).

3.3. Titration Class A Burets, 25-50 ml. for dispensing Standardized Acid

solution.

3.4. Analytical balance, sensitive to 0.0001grams.

4. Reagents

4.1. Purified water, nitrogen free.

4.2. Sulfuric acid, H

concentrated, Specific Gravity of 1.84. (95-

2SO4

98%, nitrogen free)

4.3. Copper sulfate, CuSO

4.4. Potassium sulfate, K

anhydrous. Nitrogen free. (catalyst)

4,

. Nitrogen free. (boiling point elevator)

2SO4

4.5. Sodium hydroxide NaOH, reagent grade Specific Gravity 1.3,

nitrogen free. 45% solution, (dissolve pellets, 450g NaOH in distilled

water and dilute to 1 liter).

4.6. Boiling stones, Antibumping agent, aluminum oxide stones, (Hengar

granules).

4.7. Mixed color indicator: 0.75 g of Methyl Red and 0.5 g Methylene

Blue in 300 ml of 95% ethanol. (Prepare fresh every 30 days)

4.8. Boric acid H

saturated solution, (dissolve granules, 40 g boric

3BO3,

acid, in purified water and dilute to 1 liter). Add 3 ml of the mixed

color indicator solution to the 1 liter of boric acid solution.

4.9. Sulfuric acid, H

standardized solution: (0.02 N) Prepare a stock

2SO4,

solution of approximately 0.1 N sulfuric acid by diluting 3 ml of conc.

H2SO4 (sp. Gr. 1.84) to 1 liter with CO2-free distilled water. Dilute 200

ml of this solution to 1 liter with CO2-free distilled water.

Alternatively, premade standardized acid and base solutions with a

certified specification ranges are commercially available through most

Scientific Equipment Dealers. If the Sulfuric Acids standard solutions

are prepared, their normality must be determined analytically.

5. Digestion

5.1. The distillation condensation columns should be cleaned before use

by distilling a 1:1 mixture of distilled water and sodium hydroxide

until the distillate is ammonia-free. Then repeat this cleaning

procedure if the apparatus is out of service long enough to

accumulate ammonia (> 4 hours).

5.2. Digestion

5.2.1. Place a homogenous measured sample (0.250 – 1.000

gram) into a 500 - 800 ml Kjeldahl flask. Weigh or

measure the sample to the nearest 0.1 mg/ml.

5.2.2. Add to each flask:

20 ml sulfuric acid, 0.04 g CuSO4, 15g K2SO4 potassium

sulfate, 8-10 boiling stones. Place flask on the digestion

burner in inclined position (promotes acid refluxing), with

18

Product Service 1-800-522-7658

Page 23

Appendix C: Total Kjeldahl Nitrogen Method

the flask neck on the fume removal system. If necessary

lower the burner heat setting to prevent sample from

foaming up into neck of flask. Once, the sample comes to

a smooth rolling boil return heat setting to maximum.

When digestion sample clears (no black specs with pale

green tint color), continue to boil for an equal length of

time as required to reach the clear point, (total time

approx. 1 hr). If black specs occur in the flask neck, rotate

the flask 180 degrees to allow refluxing acid to rinse the

internal flask surface. Allow digestion mixture to cool and

carefully add 50 ml of distilled water to prevent K2S04 salt

solids from forming. All salt crystals must be dissolved

before proceeding to the next step. If necessary partially

reheat sample and agitate to dissolve crystals.

6. Distillation

6.1. The distillation burners should be preheated and condenser cooling

water turned on. The receiving flask should be in-place with enough

boric acid H3BO3 plus the mixed indicator solution to submerge the

tip of condenser delivery tube well below the level of the boric acid

receiving solution in the receiving flask. (Erlenmeyer 250 ml flasks

recommended)

6.2. In a fume hood, carefully adding of 100 ml of 45% sodium

hydroxide solution without mixing to make the digested sample

alkaline. Tilt the flask in to the hood while adding the sodium

hydroxide to the sulfuric acid digestion solution. Slowly add the

heavy sodium hydroxide solution down the neck of the flask. The

heavier sodium hydroxide solution will slip under the aqueous

sulfuric acid solution without mixing and with out loss of freeammonia. Do not mix until the flask has been connected to the

distillation apparatus.

6.3. Immediately connect the flask to a condenser using the rubber

stopper on the distillation connecting bulb attached to a condenser

column.

6.4. Vigorously swirl the Kjeldahl flask to mix contents thoroughly; heat

until all NH

has been distilled (>8-10 minutes). During the ammonia

3

transfer the receiving solution with change color from purple to

green. Lower receiving flask and let liquid drain from condenser tip.

Turn off distillation burners.

6.5. For nitrogen concentrations above 1 mg/1, the ammonia can be

determined titrimetrically. For concentrations below this level,

colorimetric or potentiometric determination methods are

recommended.

Product Service 1-800-522-7658

19

Page 24

Appendix C: Total Kjeldahl Nitrogen Method

7. Titration

7.1. Depending on the samples expected nitrogen level and the sensitivity

of the titration desired, select the appropriate standardized H2SO

4

solution (0.02 or 0.10 normal). High or low nitrogen concentrations

will require standardized H2SO4 solutions with stronger or weaker

normalitys. Titrations should require at least 15 ml of titrant to be

accurate. Fill a class A. buret to the zero line with the standardized

H2SO4 solution. Titrate the H3BO3 receiving solution with

standardized H2SO4 solution to first trace of the original purple

color. A white stirring plate will aid color visualization of end

point. Record ml H2SO4 titrated to the at least nearest 0.05 ml. Match

the endpoint against a sample blank containing the same volume of

distilled water and H3BO3 solution.

8. Calculation

For Dry Samples% Nitrogen =

% Nitrogen, = (ml H2SO4, sample - ml H2SO4, blank ) x Normality H2SO

x

4

1.4007/ weight of sample in grams. (1.4007 = a single factor that takes into

account the molecular weight of Nitrogen, the conversion of milli-equivalent results of

V*N, and the conversion to %)

% Nitrogen, = (ml H2SO4, sample - ml H2SO4, blank) x normality H2SO4 x

1400.7 x 100/ weight of sample in milligrams.

For Liquid Samples: calculate Total Kjeldahl Nitrogen, in mg/1, in the

original sample as follows:

Milligrams Total Nitrogen per Liter = (ml H2SO4, sample - ml H2SO4,

blank) x normality H2SO4 x 14.007x 1000/ volume of sample in milliliters.

If desired to determine % protein instead of % nitrogen, the calculated % N is

multiplied by a factor, the magnitude of the factor depending on the sample

matrix.

Common Protein Factors

5.7 – bread, wheat and wheat flour

6.25 – other grains

6.38 – milk

6.25 – unknown source

Total Kjeldahl Nitrogen Method Overview

Digestion is accomplished by boiling a homogeneous sample in concentrated

sulfuric acid. The end result is an ammonium sulfate solution. The general

equation for the digestion of an organic sample is shown below:

Organic N + H

(NH

)SO4 + H2O + CO4 + other sample matrix byproducts

4

20

2SO4

→

Product Service 1-800-522-7658

Page 25

Appendix C: Total Kjeldahl Nitrogen Method

Distillation: Excess base is added to the digestion product to convert NH4 to

NH3 as indicated in the following equation. The NH3 is recovered by

distilling the reaction product.

ammonium

sulfate

(NH4)2SO4 + 2NaOH

heat

→

2NH3 + Na2SO4 + 2H2O

ammonia

gas

Titration quantifies the amount of ammonia in the receiving solution. The

amount of nitrogen in a sample can be calculated from the quantified amount

of ammonia ion in the receiving solution.

There are two types of titration—back titration and direct titration. Both

methods indicate the ammonia present in the distillate with a color change.

In the direct titration, boric acid is used as the receiving solution instead of a

standardized mineral acid, the chemical reaction is:

ammonia

gas

NH3 + H3BO

boric

acid

ammoniumborate complex

→

3

NH4 + H2BO

3

excess

boric acid

+ H3BO3

(color change occurs)

The boric acid captures the ammonia gas, forming an ammonium-borate

complex. As the ammonia collects, the color of the receiving solutions

changes.

ammoniumborate

complex

2NH4 + H2BO

sulfuric

acid

ammonium

sulfate

-

+ H2SO4 (NH4)2SO4+ 2H3BO3

3

boric

acid

(color change occurs in reverse)

The boric acid method has the advantages that only one standard solution is

necessary for the determination and that the solution has a long shelf life.

Product Service 1-800-522-7658

21

Loading...

Loading...