Page 1

LABCONCO CORPORATION 8811 Prospect Ave, Kansas City, MO 64132

(816) 333-8811, Fax (816) 363-0130, (800) 821-5525

Labconco Small Stoppering Chamber 7569000

Introduction-

The Small Stoppering Chamber is ideal for Lyophilizing sample in small serum vials with split

stoppers. Once the samples are lyophilized the vials can then be stoppered while still under

vacuum. The chamber comes complete with PVC tubing and ½” adapter to connect directly to

the ports of Labconco’s Freeze Dry Chambers.

Installation of Small Chamber To Freeze Dry Chamber (Refer to Figure 1)

1. Place one end of the PVC Tubing over the ½ fitting on the side of the chamber and

secure with a clamp.

2. Insert the ½” Stainless Steel Adapter approximately 1” into the other end of the PVC

Tubing and secure with a clamp.

3. Insert the open end of the ½” adapter into one of the Ports on the Freeze Dryers

Chamber.

4. Position the switch on the Small Stoppering Chamber to the “CLOSE” position.

5. The Small Stoppering Chamber is now ready to use.

Figure 1

Labconco Instruction Sheet 1049200, Rev -, ECO H250 01/13 1 of 5

Page 2

Set-up

Size

Part no.

Number of

Bottles/run

Spacers

Required

Vial Dimensions

Diameter x Height

Split Stopper

Part No.

Alum Seal

Part No.

2 ml

7575000

48

2

18mm x 35mm

7576000

7577000

3ml

7575200

43

2

17mm x 28mm

7576000

7577000

5 ml

7573000

21

1

23mm x 47mm

7576200

7577100

10 ml

7573200

19

1

25mm x 54mm

7576200

7577100

20 ml

7573400

11

0

32mm x 58mm

7576200

7577100

30 ml

7573600

8

0

37mm x 63mm

7676200

7577100

1. The Small Stoppering Chamber has a stoppering travel distance of ½”(12.7mm), it can

accommodate vials that range in height from 1.38”(35mm) to 2.48”(63mm) tall by using

zero, one, or two of the spacers which are provided. Labconco offers 6 sizes of serum

vials that can be used in the Small Stoppering Chamber. See the chart below to determine

the number of spacers required for specific vials and the total number of vials the

chamber will hold of each size.

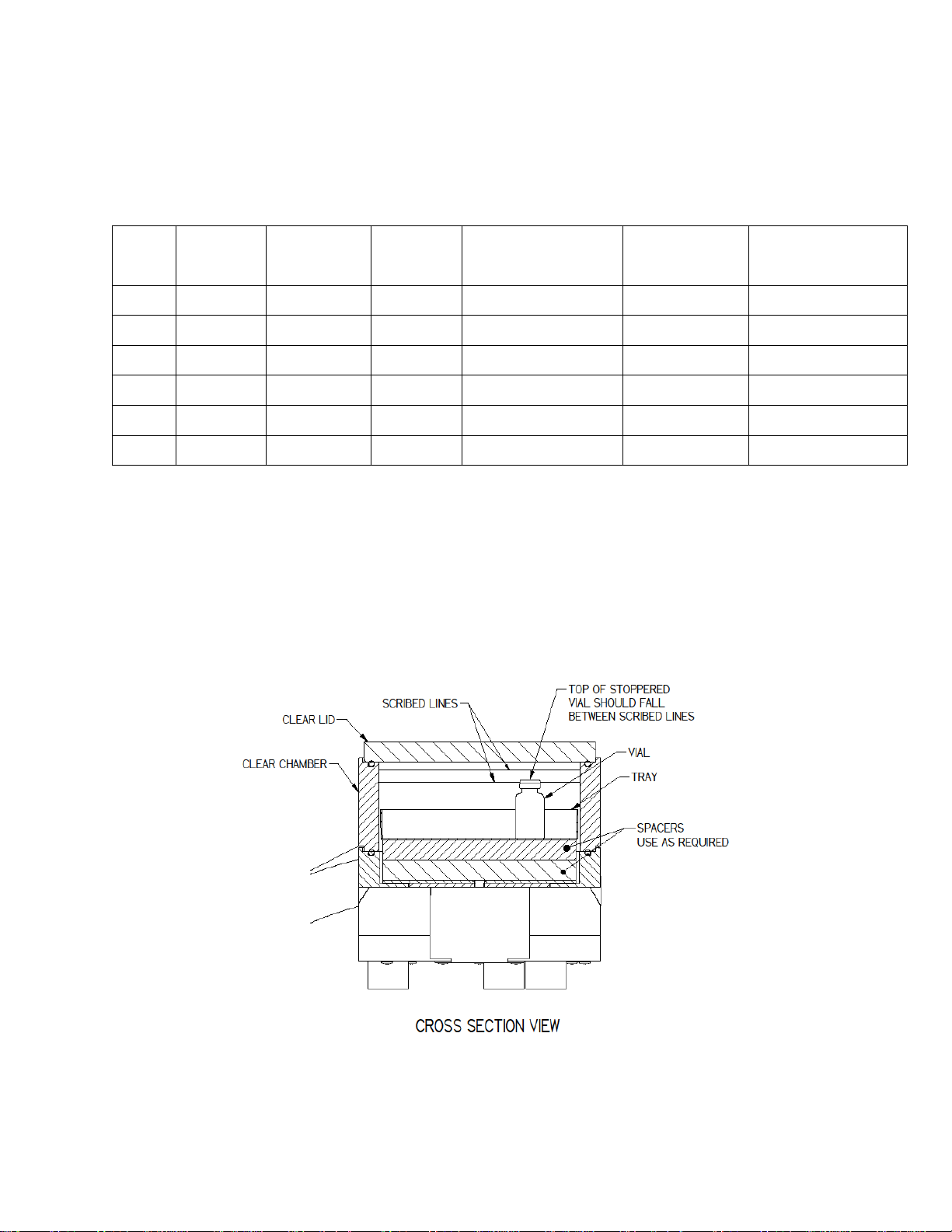

2. Once the vial size is selected place a stoppered vial in the chamber with the tray and

correct number of spacers. The top of the stopper should be located between the two

scribed lines marked on the inside diameter of the clear chamber. If the vial is lower than

the bottom line, the Stoppering device will not stopper fully. If the vial is higher than the

top line the lid will prematurely stopper the vials when it is placed on top of the chamber.

Caution: only one size (height) vial can be Lyophilized and stoppered during the same

run.

Labconco Instruction Sheet 1049200, Rev -, ECO H250 01/13 2 of 5

Figure 2

Page 3

Freeze Dry

1. The samples should be pre-frozen in the vials with the stoppers installed in the un-

stoppered position. A tray is provided so that the vials can be loaded and then placed in

the freezer. Once the samples are frozen and the Freeze Dryer is ready, the tray can

quickly be transferred to the Small Stoppering Chamber for Lyophilizing.

2. Start the Freeze Dry System as directed in the owner’s manual. When the Freeze Dry

system is started all of the Freeze Dry Ports should be in the vent position. (The bevel on

the knob should point away from the sample port). This will allow vacuum to build up in

the system.

3. When the freeze dry system is ready, make sure the switch on the Small Stoppering

Chamber in the “CLOSE” position. Place the tray with the frozen samples in the Small

Stoppering Chamber with the proper spacers. Make sure the Clear Chamber and Clear

Lid are centered and resting on their o-ring seals. Apply vacuum to the sample by rotating

the knob on the Freeze Dry Port to the vacuum position. (The bevel on the knob should

be positioned toward the sample port).

4. The vacuum should pull the Clear Chamber and Clear Lid together to seal the system.

Check the Vacuum after some time to confirm there are no vacuum leaks.

5. Lyophilization has begun.

Stoppering

1. Let the samples run until primary and secondary freeze-drying is complete.

2. To stopper the vials move the toggle switch on the Small Stoppering Chamber to the

middle position marked “STOPPER”. The vials will move up, the stoppers will press

against the clear lid and then seal the vials.

3. Once all of the vials are stoppered return the toggle switch to the closed position.

4. Release vacuum by turning the Freeze Dry Port to the vent position.

Notes:

Always vent the vacuum line before turning off the vacuum pump.

Make sure all vacuum lines are secured to prevent leaks.

Wear appropriate protective attire and eye protection.

Clean after use.

Installation of Small Chamber Cold Trap (Refer to Figure 2)

6. Place one end of the PVC Tubing over the ½ fitting on the side of the chamber and

secure with a clamp.

7. Insert the ½” Stainless Steel Adapter approximately 1” into the other end of the PVC

Tubing and secure with a clamp.

8. Insert the open end of the ½” adapter into one of the Ports on the Freeze Dryers

Chamber.

Labconco Instruction Sheet 1049200, Rev -, ECO H250 01/13 3 of 5

Page 4

9. Position the switch on the Small Stoppering Chamber to the “CLOSE” position.

10. The Small Stoppering Chamber is now ready to use.

Figure 1

Labconco Instruction Sheet 1049200, Rev -, ECO H250 01/13 4 of 5

Page 5

WarrantyWe are committed to providing our customers with quality equipment and service after the sale. Part of this

objective involves keeping you informed of changes and new product additions.

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas of defective

material and workmanship, provided such defect results from normal and proper use of the equipment.

The warranty for all Labconco products will expire one year from date of installation or two years from date of

shipment from Labconco, whichever is sooner, except the following:

Purifier® Delta™ Series Biological Safety Cabinets, which carry a three-year warranty from date of

installation or four years from date of shipment from Labconco, whichever is sooner.

Carts carry a lifetime warranty.

Glassware is not warranted from breakage when dropped or mishandled.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the event of a

warranty claim, contact Labconco Corporation or the dealer who sold you the product. If the cause is determined to

be a manufacturing fault, the dealer or Labconco Corporation will repair or replace all defective parts to restore the

unit to operation. Under no circumstances shall Labconco Corporation be liable for indirect, consequential, or

special damages of any kind. This statement may be altered by a specific published amendment. No individual has

authorization to alter the provisions of this warranty policy or its amendments. Lamps and filters are not covered by

this warranty. Damage due to corrosion or accidental breakage is also not covered.

WARNING: various federal, state or local regulations may govern the disposal and/or emission of substances used

in connection with this equipment. All users of this equipment are urged to become familiar with any regulations

that apply in the user’s area concerning the dumping of waste materials in or upon water, land or air and to comply

with such regulations.

Shipping Claims-

If a shipment is received in visibly damaged condition, be certain to make a notation on the delivering carrier’s

receipt and have his agent confirm the damage on your receipt. Otherwise, the damage claim may be refused.

If concealed damage or pilferage is discovered, notify the carrier immediately and retain the entire shipment intact

for inspection. Interstate Commerce Commission rules requires that the claim be filed with the carrier within 15

days after delivery.

NOTE: Do not return goods. Goods returned without prior authorization will not be accepted. Labconco

Corporation and its dealers are not responsible for shipping damage. The recipient must file claims directly with the

freight carrier. If authorization has been received to return this product, by accepting this approval, the user assumes

all responsibility and liability for biological and chemical decontamination and cleansing. Labconco reserves the

right to refuse delivery of any products that do not appear to have been properly cleaned and/or decontaminated

prior to return.

Contacting Labconco-

If you have any questions that are not addressed in these instructions, or if you need technical assistance, please

contact Labconco Sales Information Department at either (800) 821-5525, and Service Information at (800)-5227658 or (816) 333-8811, between the hours of 7:00 a.m. and 6:00 p.m. Central Standard Time.

Visit the Internet at http://www.labconco.com

Or

email: labconco@labconco.com

Labconco Instruction Sheet 1049200, Rev -, ECO H250 01/13 5 of 5

Loading...

Loading...