Page 1

LABCONCO 1000

GUARDIAN DIGITAL MONITOR

Operating and Instruction Manual

Model: Guardian 1000 / 1

• Digital display

• 3 Relay inputs

• 3 Relay outputs

• Com port

Used for alarm indication and

monitoring on Fume Hoods

05/03/04

1

Page 2

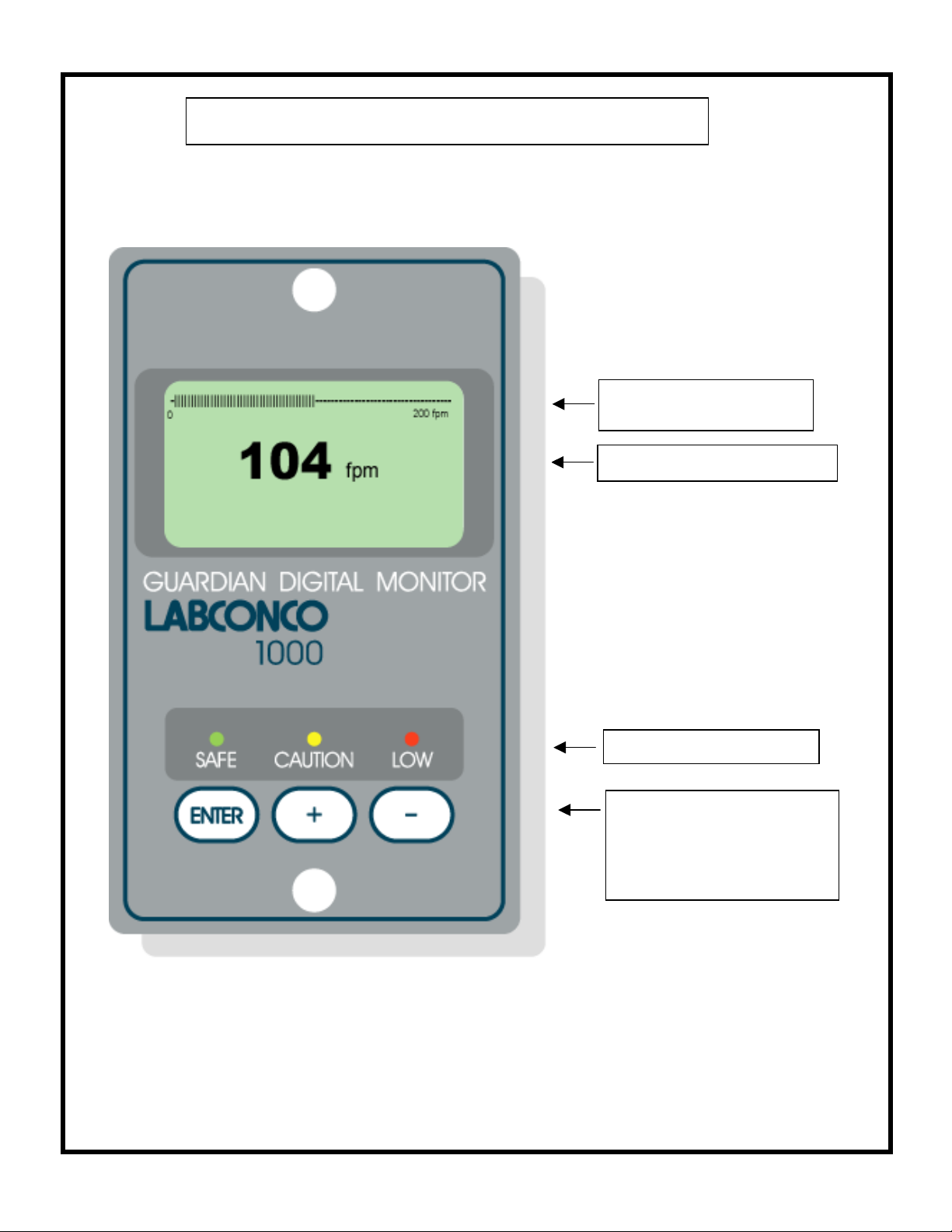

OPERATOR DISPLAY PANEL

Velocity Bar Graph or

Alarm Time Line

Velocity display fpm or m/sec

LED indicators

Function and up/down buttons

for Menu Configuration and

Calibration.

ENTER – also used as

Mute button for audible alarm

Note :- Access to the Calibration and Configuration menus is password protected and is factory

set. To access and or change the password contact the supplier for the Engineers Password and

enter the Passwords in the Main Menu or alternatively use a Laptop connected to the Com port

and the Upload/Download software provided

2

Page 3

Connection details :-

V

OUTPUT

RELAY

R1

RS 232

Com Port

IDC

14-way

Connector

for remote

Interface Box

( Optional )

SM6 or Inline

Airflow Sensor

Flying lead with RJ11

plug connection for PCB

and SM6 airflow sensor

12V DC

Notes :-

1. The Remote Interface Box is an optional extra. This is supplied

complete with a 2m long ribbon cable with IDC plugs. The box is

designed to allow termination of external cables rated at 220V and

includes the following connection points :-

3 – Input connections – Input 1 , Input 2 , Input 3

3 - Relay outputs - Output relays R1 , R2 , R3

2. Output 1 is an optional extra output giving a 0 –10 V DC signal

proportional to the Fume Hood face velocity over the range

of 0 – 200 fpm

TEL

MADE IN ENGLAND

www.tel-uk.com

AFA 1000 USA

SENSOR

REFER TO

INSTALLATION

INSTRUCTIONS

BEFORE

CONNECTING

Sash High

Proximity switch

( Optional )

0-10

OUTPUT

1

INPUT

Blu

Blk

Brn

Flying lead with plug

connection for PCB

15 V DC

Sash High

Micro - switch

( Optional )

120V

PSU

s/w

-

INPUT 3

+

INPUT 2

INPUT 1

15V DC

POWER

SUPPLY

120V / 15V DC

Plug – in power

adapter for 120V

socket

3

Page 4

1.1 General Description

All systems comprise of the following components :-

1 – SM6 Airflow Sensor,

1 – AFA1000 /1 Alarm unit,

1 – AC power supply

If the Sash Alarm System option is included there will also be a sash micro switch or proximity

switch.

Operator Features

--- the alarm has the following operator features :-

Digital Display

The digital display is a back-lit, full graphic unit with a visual display of approx 56 x 27 mm.

The display operates through the software allowing the generation of figures, wording and Icons.

The display shows the fume cupboard face velocity in m/sec or fpm when enabled or the

alternative with no velocity reading but showing AIR FAIL / AIR SAFE as continuous display.

All of the above are configurable via the alarm key pad.

An ‘ event time line ’ segmented into 20 x 3 minute segments will scroll across the display

( when enabled) .This takes the form of a graphical ‘ blip’ that will progress from the right hand

side to the left hand side – representing events that have occurred during the past hour. On the

standard alarm this will be limited to airflow alarms but other alarms are available.

Using the diagnostics software and an associated computer via the com port on the alarm the

event data can be transferred to a data logger.

The alternative to the event time line is a dynamic ‘ bar graph ’ representing the face velocity

The display shows a Horn icon ( with line through it ) when the audible alarm is in the Muted

condition

Sash High – will be displayed when the Sash alarm is enabled and the sash is raised above

the max safe working opening.

This display will alternate on/off with the velocity reading.

Ext Alarm – will be displayed when the external alarm input is activated ( when enabled )

This display will alternate on/off with the velocity reading

Air Fail - will be displayed if the airflow is less than the Low air alarm point.

This display will alternate on/off with the velocity reading

High Air - will be displayed if the airflow is more than the High air alarm point.

This display will alternate on/off with the velocity reading

Set-back - will be displayed if the night set-back function is activated ( when enabled )

This display will alternate on/off with the velocity reading

Disabled - will be displayed if the alarm disable function is activated ( when enabled )

This display will alternate on/off with the velocity reading

4

Page 5

LED Indicators ---- the alarm unit has three LED indicators : Red -- Alarm

Amber -- Caution

Green -- Safe

Audible Alarm sounder

Mute facility

Enter

--- the alarm has an Enter button -- this is multi-functional as follows : Press Enter momentarily when alarm is sounding will mute the alarm

Press Enter for 5 secs will gain access to Calibration and Configuration

menus ( both menus password protected )

-- the alarm has an audible alarm sounder with local or remote

+ / - -- the alarm has + / - buttons that can be used to scroll through the calibration and

configuration menu or to select options or values

External Connections

Input 1 --- volt free relay input configurable for normally closed or normally open relays

This input can be configured as : Alarm disable

Night set-back

External alarm

Sash High

High / Low

Input 2 --- volt free relay input configurable for normally closed or normally open relays

This input can be configured as : Alarm disable

Night set-back

External alarm

Sash High

High / Low

Input 3 --- volt free relay input configurable for normally closed or normally open relays

This input can be configured as : Alarm disable

Night set-back

External alarm

Sash High

High / Low

-- the alarm unit will have the following connection points :-

5

Page 6

Output 1 --- volt free relay output configurable as normally closed or normally open relays.

Output 2 --- volt free relay output configurable as normally closed or normally open relays.

Output 3 --- volt free relay output configurable as normally closed or normally open relays.

Com Port --- to enable connection to Laptop or PC for full diagnostics , logging or setting

up and for communications to building computer system ( BMS)

Power supply --- low voltage DC power supply

Airflow Sensor --- connection socket for the face velocity airflow sensor.

6

Page 7

1.2 Alarm Configuration / Calibration

The alarm can be configured via a Laptop or PC using a variety of ‘set up ’ programs each

designed for a particular application with a combination of inputs , outputs and push buttons.

This configuration can be changed via the alarm key pad using the menu system if required or

re-configured by re-connection of the laptop or PC.

This allows the fume hood manufacturer to stock standard units and configure the alarms

to suit the application.

The configuration of the various functions and the calibration of the alarm face velocity display is

menu driven. Access to the menu will be via password ( 4 digit number ) and will be two level.

The first level will be for calibration of the unit and the second level will be for ‘engineers’ to set up

the configuration of the alarm.

NOTE:- If you enter the Calibration or Configure Menu by accident :-

press the + & - buttons at the same time to escape back to the Main Menu

The menus and sub–menus are in ‘ plain language ’ and incorporate brief instructions where

appropriate.

See menu operation document

1.3 Start up

When unit is powered up the following sequence of events occur :-

1. The 12V DC power is applied to the airflow sensor and a delay on timer ( 30 sec ) is initiated.

2. The alarm then performs a self test on the display and all indicators etc ( approx 5 sec )

3. The display show a ‘ Welcome note ’ – with the fume cupboard manufacturer company name

( if configured ) for the rest of the initial 30 sec delay time. During this time the airflow sensor

is stabilising

4. During the whole of the 30 sec period all alarms and relay outputs are inhibited.

5. At the end of the 30 sec delay the unit performs one of two options : a. If the alarm calibration has been previously completed – the unit goes to

normal operating mode ( Run )

b. If the unit has not been calibrated the unit displays

‘ Unit requires Set up -- press Enter to access Set up menu ’

The set up menu allows calibration or configuration via the password protection

During the set-up all alarms and output relays are inhibited.

7

Page 8

1.4 Events / actions

Safe airflow

• Meter reading above warning level ( e.g. > 90fpm )

• Green LED on

Warning airflow

• Meter reads between warning level and air fail level ( e.g. > 80fpm and < 90fpm )

• Amber LED on

Low airflow

• Meter reads below alarm level for longer than the warning to low air delay time

• AIR FAIL toggles on / off with display

• Red LED on ( Flashing )

• Audible alarm sounds -- can be muted via Enter pushbutton

• Low air relay operates ( if configured )

Reset : -- when airflow rises 4fpm above Low air level for longer than the low air to

warning air delay time the Low air alarm resets automatically

High airflow

If configured :-

• High Air toggles on / off with display

• Audible alarm sounds – can be muted via Enter pushbutton)

Audible alarm Mute

• When the audible alarm is muted via the Enter button - an Icon ( horn with forward slash) is

shown on the display.

Sash High

• When the input configured as Sash High is activated

• Amber LED on

• Sash High – toggles on / off with velocity display

• Audible alarm sounds

• Audible can be muted via Enter pushbutton -- this silences the alarm and initiates a repeat

timer ( if configured ). After the delay time the alarm re-sounds ( and can be re-muted).

During this time the Amber LED flashes on / off.

• Sash High relay operates ( if configured )

Reset when Sash lowered to safe position and input de-activated.

8

Page 9

High / Low

• When input configured as High/Low is activated

• Display Icon shows High or Low

• High / Low relay operates ( if configured )

This function is designed for two speed fan operation or two position damper operation switched

via a micro switch or proximity switch activated at a given position on the sash.

Night set-back

• When input configured as Night set-back is activated

• Night set-back Icon is displayed

• Red LED on ( Flashing)

• Reduced Low air alarm ( if configured )

• Audible alarm muted

• Mute Icon shown on display

External alarm

• When input configured as External alarm is activated

• Red LED on ( Flashing) – ( if configured )

• External Alarm toggles on /off with display -- ( if configured )

• Audible alarm sounds – can be muted via Enter pushbutton

• External alarm relay operates ( if configured)

Alarm disable

• When input configured as Alarm disable is activated

• Alarm disabled is displayed

• Red LED on ( Flashing)

• Audible alarm muted

• Mute Icon shown on display

9

Page 10

2.1 Quick Start Installation

Follow the instructions below for installing and commissioning the unit. :-

1. Fit the alarm to the Fume Hood using the cut-out details provided with the unit

--- see page 12

2. Fit the airflow sensor to the Fume Hood using the cut out and installation details provided

--- see page 12 ,13 & 14

3. Connect the ‘telephone style’ airflow sensor plug-in cable to the sensor and the back of

the alarm unit --- see typical connection diagram on page 15 & 16

4. Plug in the power adapter to a Mains AC power socket and connect the flying lead to the

alarm unit --- see typical connection diagram on page 15 & 16

Power up the unit and wait at least 30 secs while the sensor temperature stabilises.

5.

6.

If the unit has not been calibrated the unit will display ‘ Requires setup ’ – press ENTER

to continue and in the Main Menu use the +/- buttons on the alarm facia select ‘ SETUP ‘

and then press the ENTER button.

7. In the Setup Menu select ‘CALIBRATION’ and press the ENTER button

8. At this stage you will be requested to enter the PASSWORD. Use the +/- buttons to

select the individual digits in turn and then press ENTER.

If the password is correct the unit will go to the calibration mode. If the password is not

correct you will be requested to try again --- on the third wrong password entry the

calibration menu will lock out for 10 mins

9. When in the calibration mode follow the instructions on the display screen to carry out the

calibration of the unit. See ‘Calibration Notes’ below for hints on successful calibration.

When the calibration is complete the unit will return to the Main Menu.

10. Use the +/- buttons on the alarm facia select ‘ RUN ’ and then press the ENTER button.

The unit will now function and display the measured Fume Hood face velocity

10

Page 11

2.2 Calibration Notes :-

1. When using a standard Fume Hoods with Vertical Sliding sashes open the sash to the

normal max safe working height for the Low Air sample.

2. For the Higher Air sample close the sash to approx 50% of the opening used for the

Lower Air sample. If the Higher air sample value is too close to the Lower Air sample the

alarm will detect this and ask you to repeat with a higher value. To do this close the sash

a little more and repeat the sample. Avoid closing the sash below 100mm.

3. The face velocity readings on the open sash may vary at different points on the

measuring grid by up to 20fpm. This is quite acceptable in terms of the fume cupboard

performance so long as no individual point is below the designated Low Air alarm point

.The figure entered for the calibration point can be taken as the average value of all the

measuring grid readings or could be taken as the individual lowest point on the grid. For

most fume cupboards this low point is on the bottom row in the centre and is a convenient

position to measure and for future reference when checking the alarm during annual

maintenance.

4.

Take time when measuring the face velocities for the calibration procedure to allow for

the velocities across the open sash to stabilise. If the velocities are changing or are

turbulent during the sampling period the alarm will detect this and ask you to repeat the

sample.

5. When using a Fume Hood with Horizontal Sliding sashes open the sashes to the normal

max safe working opening for the Low Air sample.

6. When calibrating or re-calibrating the alarm it is important to ensure that the ‘Vent kit’ is

connected to the SM6 sensor on the fume hood. If the vent kit is not connected the

sensor will not ‘see’ a change in the airflow during the calibration procedure and when

switched to the Run condition the display will show a fixed reading that will not change

when the fume cupboard velocity changes.

If in normal running after successful calibration the vent kit becomes disconnected the air

flow across the sensor will fall and the alarm will go into the AIR FAIL condition.

This only applies during the calibration mode.

11

Page 12

3.0 Dimensions

T

Se

ews provided

Alarm Panel

Dimensions

40.5mm

(1.59 ″)

40.5mm

(1.59 ″)

29mm

(1.14″)

111mm

(4.37 ″)

81mm

(3.19″)

Front

View

Panel Cutout

Dimensions

3.00″ x 2.00″

132mm

(5.2 ″)

76.2mm

(3.00″)

R1

232

IDC

50.8mm

(2.00″)

EL

48mm

(1.89 ″)

Rear

View

lf tapping scr

111mm

(4.37″)

s

1

2

(2.91 ″)

15V

(1.14″)

2 x Fixing Holes

2.5mm dia

for 2 x No. 6

NOT TO SCALE

74mm

29mm

19mm

″)

(0.75

Side

View

9.75mm

(0.38 ″)

12

Page 13

3.0 Dimensions

(

)

(

(

″

)

(

″

)

(

″

)

74mm

(2.91″)

12mm

(0.47″)

17mm

10mm

(0.39″)

SM6 Sensor

Dimensions

( Rear view )

74mm

(2.91″)

12mm

0.47″)

10mm

0.39″

20mm

0.79

12mm Dia.

(0.47″)

SM1 cable

for

25mm

0.98

27mm

1.06

25mm

SM6 Sensor

Panel Cutout

Dimensions

( Front view )

2 x Holes for self tapping fixing

screw.

[ 4mm (0.157″)Fixing Hole

provided on SM6 sensor ]

30mm Dia

(1.18″)

Sensor Hole for

Vent Tube

13

Page 14

4.0 SM6 Airflow Sensor Installation

100mm

100mm

SM6 Airflow Sensor

( See exploded view below )

Normal Sash

wor king h eig ht.

eg. 500mm

25mm

Male

bush

Fume hood

inner skin

25mm

Female adapter

25mm Tube

Fume hood

SM6 Sensor

Open to the

laboratory

outer skin

It is very important to position the SM6 airflow sensor in the correct position to give long term stable reading of the face

velocity. Please read the INSTALLATION NOTES below and if in doubt contact us for further advice.

INSTALLATION NOTES :-

1. The SM6 sensor must be positioned where it can " see " the room pressure of the laboratory.The back connection

spigot of the sensor is designed to accept a 25mm OD tube which should be connected to the inner chamber of

the fume hood. (This tube and fittings is known as the " vent kit " )

The ideal position for the end of the 25mm tube for most fume hoods is 100mm back from the sash glass

and 100mm higher than the normal sash opening height through the inner side wall.

2. If possible mount the sensor on the front of the fume hood and use a short length of tube. Tube lengths of

more than 1metre or smaller diameter will restrict the airflow through the sensor. This will lead to too much

sensitivity being required to calibrate the unit which can lead to some instability of the reading or incorrect

readings at low velocities.

3. For fume hoods with a single skin side wall or a double skin with a small gap between them it may not be

possible to achieve the ideal sensing position using a flexible tube.

With a single skin side wall it is possible to fix the sensor on the outside of the fume cupboard and connect directly

to the inner chamber in the ideal position. This method can only be used for up to two fume cupboards when they

are positioned side by side ( using the two outer walls ).

An alternative method is to mount the sensor on the front of the fume hood and connect using a short flexible

tube to a rigid wall tube attached to the inner side wall. The open end of this rigid wall tube should be positioned in

the ‘ideal position’ ie. 100mm back from the sash and 100mm higher than the normal sash opening.

Fume hoods with a high internal height can present a difficulty because the tube length to reach the ideal

position may be longer than 1 metre. In this case it is better to use a tube no longer than 1 metre which may result

in a sensing position higher than the ideal.

When fitting a sensor to a ’narrow wall’ fume hood for the first time it may be necessary to try various

combinations of rigid and flexible tube to find the best combination and position.

4. The sensor should not be mounted in a position were it is subject to draughts from the laboratory air input or

ventilation system.

NOTE:- ALTERNATIVE IN-LINE SENSOR AVAILABLE Type SM6 FOR FUME HOODS WITH INTERNAL

ACCESS PANEL ON SIDE WALL

14

Page 15

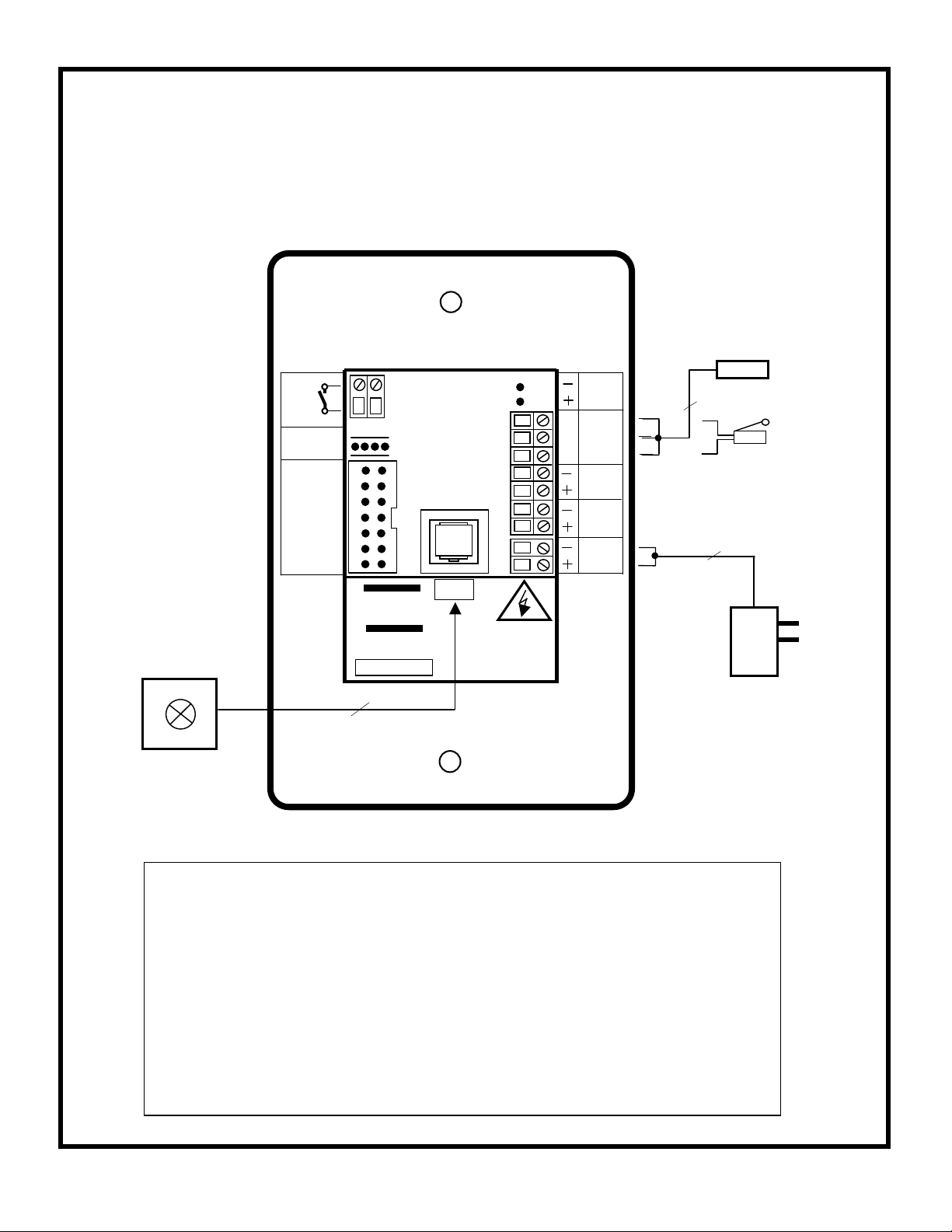

5.0 Typical Wiring Diagram --- (Alarm only)

V

OUTPUT

RELAY

R1

RS 232

Com Port

IDC

14-way

Connector

for remote

Interface Box

( Optional )

SENSOR

TEL

MADE IN ENGLAND

www.tel-uk.com

AFA 1000 USA

REFER TO

INSTALLATION

INSTRUCTIONS

BEFORE

CONNECTING

SM6 or Inline

Airflow Sensor

Flying lead with RJ11

plug connection for PCB

and SM6 airflow sensor

12V DC

Note :

Output 1 is an optional extra output giving a 0 –10 V DC

signal proportional to the Fume Hood face velocity over the

range of 0 – 200 fpm. ( Not included with the standard alarm )

s/w

-

+

0-10

OUTPUT

1

INPUT 3

INPUT 2

INPUT 1

15V DC

POWER

SUPPLY

INPUT

Blu

Blk

Brn

Flying lead with plug

connection for PCB

15 V DC

Sash High

Proximity switch

( Optional )

Sash High

Micro - switch

( Optional )

120V

PSU

120V / 15V DC

Plug – in power

adapter for 120V

socket

15

Page 16

5.1 Typical Wiring Diagram with Optional Relay Interface Unit

V

V

V

Flying lead

Ribbon cable with IDC

plug connection for PCB

and Relay Interface Unit

SM6 or Inline

Airflow Sensor

Optional Relay Interface Unit in ABS enclosure mounted on top of Fume Hood to

allow up to external cable connections to be terminated.

Rated at 220V 5A

0-10

-

s/w

+

0-10

OUTPUT

1

INPUT 3

INPUT 2

INPUT 1

15V DC

POWER

SUPPLY

INPUT

OUTPUT

1

INPUT 1

INPUT 2

INPUT 3

0-10

OUTPUT

2

Blu

Blk

Brn

OUTPUT

RELAY

R1

OUTPUT

RELAY

R2

OUTPUT

RELAY

R3

OUTPUT

RELAY

R1

RS 232

Com Port

IDC

14-way

Connector

for remote

Interface Box

( Optional )

www.tel-uk.com

Flying lead with RJ11

plug connection for PCB

and SM6 airflow sensor

12V DC

TEL

MADE IN ENGLAND

AFA 1000 USA

Relay

Interface

Unit

SENSOR

REFER TO

INSTALLATION

INSTRUCTIONS

BEFORE

CONNECTING

-

s/w

+

Sash High

Proximity switch

( Optional )

Sash High

Micro - switch

( Optional )

Flying lead with plug

connection for PCB

15 V DC

120V

PSU

120V / 15V DC

Plug – in power

adapter for 120V

socket

16

Page 17

6.0 LIMITATION OF WARRANTY AND LIABILITY

Seller warrants that this product, under normal use and service as described in the operator’s manual shall be free from

defects in workmanship and material for a period of twelve (12) months, or the length of time specified in the operator’s

manual, from the date of shipment to the customer. This limited warranty is subject to the following exclusion :-

The foregoing is IN LIEU OF all other warranties and is subject to the conditions and LIMITATIONS stated herein. NO

OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR PURPOSE OR MERCHANTABILITY IS

MADE.

THE EXCLUSIVE REMEDY OF THE USER OR PURCHASER, AND THE LIMIT OF LIABILITY OF SELLER FOR ANY

AND ALL LOSSES, INJURIES, OR DAMAGES IN CONNECTION WITH THIS PRODUCT ( INCLUDING CLAIMS BASED

ON CONTRACT NEGLIGENCE, STRICT LIABILITY, OTHER TORT, OR OTHERWISE ) SHALL BE THE RETURN OF

THE PRODUCT TO THE FACTORY OR DESIGNATED LOCATION AND THE REFUND OF THE PURCHASE PRICE,

OR, AT THE OPTION OF THE SELLER, THE REPAIR OR REPLACEMENT OF THE PRODUCT. IN NO EVENT SHALL

SELLER BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES.SELLER SHALL NOT BE

RESPONSIBLE FOR INSTALLATION, DISMANTLING, REASSEMBLY OR REINSTALLATION COSTS OR CHARGES.

NO ACTION, REGARDLESS OF FORM, MAY BE BROUGHT AGAINST THE SELLER MORE THAN ONE YEAR AFTER

THE CAUSE OF ACTION HAS ACCRUED.

The purchaser and all users are deemed to have accepted the terms of this LIMITATION OF WARRANTY AND

LIABILITY, which contains the complete and exclusive limited warranty of Seller. This LIMITATION OF WARRANTY AND

LIABILITY may not be amended or modified nor may any of its terms be waived except by a writing signed by an

authorised representative of the Seller.

a. Batteries and certain other components when indicated in specifications are warranted for a period of

90 days from the date of shipment to the customer.

b. With respect to any repair services rendered, Seller warrants that the parts repaired or replaced will

be free from defects in workmanship and material, under normal use, for a period of 90 days from the

date of shipment to the customer

c. Seller does not provide any warranty on finished goods manufactured by others. Only the original

manufacturer’s warranty applies.

d. Unless specifically authorised in a separate writing by Seller, Seller makes no warranty with respect

to, and shall have no liability in connection with, any goods which are incorporated into other

products or equipment by the Buyer. All goods returned under warranty shall be at the Buyer’s risk of

loss, Seller’s factory prepaid, and will be returned at Seller’s risk of loss, Buyer’s factory prepaid.

7.0 Contact us :-

For further information on our range of airflow alarms and controls please

contact us at :-

HSE

Temperature Electronics Ltd

Export sales :-

TEL

Tel

e-mail: xportsales@exportsales.com

web site: www.tel-uk.com

HOLLAND SAFETY EQUIPMENT

726 McKinley Ave.

Libertyville, Illinois 60048

Phone

e-mail: info@hollandsafety.com

web site: www.hollandsafety.com

: + 44 161 257 2541 Fax : + 44 161 228 8817

: 847- 680-9930 Fax : 847-680-9938

17

Page 18

FILE NUMBER

AFA 1000 / 1 -- ALARMS -- ( Velocity )

The AFA1000 alarm has been factory set to the listed parameter settings. To change

any parameter setting press and hold the enter button until the "Main Menu" screen is

displayed, select "Configure" to view the parameters and use the +/- and Enter buttons

FOR FULL INSTALLATION / CALIBRATION / CONFIGURATION DETAILS PLEASE

Menu

ON DISPLAY UNITS

ON LOW AIR ALARM FPM 60

ON LOW AIR CUTOFF

ON CUTOFF SPEED FPM 30

ON

ALARM TO WARNING AIR HYSTERESIS FPM

ON HIGH AIR ALARM

ON HIGH AIR ALARM FPM 295

ON LOWER AIR SAMPLE FLUCTUATIONS % 3

ON HIGHER AIR SAMPLE FLUCTUATIONS % 3

ON LOWER/HIGHER AIR SAMPLE DIFFERENCE FPM 20

ON WARN TO ALARM AIR TIME SECONDS 5

ON ALARM TO WARN AIR TIME SECONDS 1

ON SHOW AIR FLOW

ON SHOW TIME LINE

ON AUDIBLE ALARM

ON SENSOR DIFFERENCE

REFER TO THE DATA BOOKLET PROVIDED.

Configuration Menu: -

Calibration Config

WARNING AIR ALARM FPM 63

to change the settings.

NO = SHOW BAR GRAPH

TYPE

CUSTOMER

Units Default Settings

M/SEC

FPM

OFF

ON

YES

NO

YES ON

NO

YES

ENABLED ENABLED

NOT ENABLED

%

FACTORY DEFAULTS

FPM

ON

3

OFF

OFF

10

Configuration Menu

ON INPUT 1

ACTIVE ON CLOSING CONTACT ACTIVE ON CLOSING CONTACT

ACTIVE ON OPENING CONTACT

ON INPUT 1 - FUNCTION

NOT ACTIVE

NONE

ALARM DISABLE

NIGHT SET-BACK NIGHT SET-BACK

EXTERNAL ALARM

SASH HIGH

HIGH/LOW

2

Page 19

ON INPUT 2

ACTIVE ON CLOSING CONTACT

ON INPUT 2 - FUNCTION

ON INPUT 3

ON INPUT 3 - FUNCTION

ON OUTPUT RELAY 1 ACTIVATION

ON OUTPUT RELAY 2 ACTIVATION

ON OUTPUT RELAY 3 ACTIVATION

ON LOW AIR ALARM - RELAY

ON DISABLE ALARM - RELAY

ON SASH HIGH REPEAT TIMER

ON SASH REPEAT TIME MIN 5

ON SASH HIGH RELAY

ON HIGH / LOW RELAY

ON NIGHT SET-BACK

ON NIGHT SET BACK REDUCED ALARM FPM 49

ON NIGHT SET-BACK RELAY

ACTIVE ON OPENING CONTACT

ACTIVE ON CLOSING CONTACT ACTIVE ON CLOSING CONTACT

ACTIVE ON OPENING CONTACT

CONTACT CLOSES ON ACTIVATION Contact closes on activation

CONTACT OPENS ON ACTIVATION

CONTACT CLOSES ON ACTIVATION Contact closes on activation

CONTACT OPENS ON ACTIVATION

CONTACT CLOSES ON ACTIVATION Contact closes on activation

CONTACT OPENS ON ACTIVATION

NOT ACTIVE Not active

NONE None

ALARM DISABLE

NIGHT SET-BACK

EXTERNAL ALARM

SASH HIGH

HIGH/LOW

NOT ACTIVE

NONE

ALARM DISABLE

NIGHT SET-BACK

EXTERNAL ALARM

SASH HIGH SASH HIGH

HIGH/LOW

NONE

OUTPUT RELAY 1

OUTPUT RELAY 2

OUTPUT RELAY 3

NONE None

OUTPUT RELAY 1

OUTPUT RELAY 2

OUTPUT RELAY 3

ON ON

OFF

NONE None

OUTPUT RELAY 1

OUTPUT RELAY 2

OUTPUT RELAY 3

NONE None

OUTPUT RELAY 1

OUTPUT RELAY 2

OUTPUT RELAY 3

MAINTAIN LOW AIR ALARM Maintain Low Air alarm

REDUCE LOW AIR ALARM

NONE None

OUTPUT RELAY 1

OUTPUT RELAY 2

OUTPUT RELAY 3

OUTPUT RELAY 3

3

Page 20

ON EXTERNAL ALARM - LED

ON EXTERNAL ALARM - DISPLAY ICON

ON EXTERNAL ALARM - RELAY

ON

OFF

ON

OFF

NONE None

OUTPUT RELAY 1

OUTPUT RELAY 2

OUTPUT RELAY 3

OFF

OFF

FACTORY PASSWORDS USER PASSWORD

ALARM SERIAL NUMBER

CONFIG

0000

CALIBRATION

0000

CONFIG

CALIBRATION

4

Loading...

Loading...