Page 1

FreeZone

Stoppering Tray Dryers

Models

79480 Series

User’s Manual

Labconco Corporation

8811 Prospect Avenue

Kansas City, MO 64132-2696

800-821-5525, 816-333-8811

FAX 816-363-0130

E-MAIL labconco@labconco.com

HOME PAGE www.labconco.com

Please read the User’s Manual before operating the equipment.

To receive important product updates,

complete your product registration card

online at register.labconco.com

Page 2

Copyright © 2004, 2007, 2010, 2012, 2013, 2014 Labconco Corporation. All rights reserved.

Warranty

Labconco provides a warranty on all parts and factory workmanship. The warranty includes areas of

defective material and workmanship, provided such defect results from normal and proper use of the

equipment. Glassware is not warranted from breakage when dropped or mishandled.

The warranty for FreeZone® Stoppering Tray Dryers will expire one year from date of installation or

two years from date of shipment from Labconco, whichever is sooner. Warranty is non-transferable

and only applies to the owner (organization) of record.

This limited warranty covers parts and labor, but not transportation and insurance charges. In the

event of a warranty claim, contact Labconco Corporation or the dealer who sold you the product. If

the cause is determined to be a manufacturing fault, the dealer or Labconco Corporation will repair or

replace all defective parts to restore the unit to operation. Under no circumstances shall Labconco

Corporation be liable for indirect, consequential, or special damages of any kind. This statement may

be altered by a specific published amendment. No individual has authorization to alter the provisions

of this warranty policy or its amendments. Lamps and filters are not covered by this warranty.

Damage due to corrosion or accidental breakage is not covered.

The information contained in this manual and the accompanying products are copyrighted and all rights

reserved by Labconco Corporation. Labconco Corporation reserves the right to make periodic design

changes without obligation to notify any person or entity of such change.

Returned or Damaged Goods

Do not return goods without the prior authorization from Labconco. Unauthorized returns will not be

accepted. If your shipment was damaged in transit, you must file a claim directly with the freight carrier.

Labconco Corporation and its dealers are not responsible for shipping damages.

The United States Interstate Commerce Commission rules require that claims be filed with the delivery

carrier within fifteen (15) days of delivery.

Limitation of Liability

The disposal and/or emission of substances used in connection with this equipment may be governed by

various federal, state, or local regulations. All users of this equipment are required to become familiar with

any regulations that apply in the user’s area concerning the dumping of waste materials in or upon water,

land, or air and to comply with such regulations. Labconco Corporation is held harmless with respect to

user’s compliance with such regulations.

Contacting Labconco Corporation

If you have questions that are not addressed in this manual, or if you need technical assistance, contact

Labconco’s Customer Service Department or Labconco’s Product Service Department at 1-800-821-5525

or 1-816-333-8811, between the hours of 7:00 a.m. and 6:00 p.m., Central Standard Time.

Part #7353900, Rev. F

ECO J323

Page 3

T

T

AABBLLEE

O

O

FF

C

C

OONNTTEENNTTSS

CHAPTER 1: INTRODUCTION 1

Freeze Dry Process 1

Freeze Dry Rates 2

Freeze Dry Capacity 3

Samples Containing Volatile Substances 4

About This Manual 4

Typographical Conventions 5

CHAPTER 2: PREREQUISITES 6

Electrical Requirements 6

Location Requirements 7

Vacuum Pump Requirements 7

CHAPTER 3: GETTING STARTED 8

Unpacking Your Stoppering Tray Dryer 8

Stoppering Tray Dryer Components 9

Setting Up Your Stoppering Tray Dryer 9

Installing the Tray Dryer on the Freeze Dry System 10

Venting the Vacuum Pump 11

Electrical Connection 11

Chemical Resistance of Freeze Dryer Components 11

Solvent Safety Precautions 13

CHAPTER 4: USING YOUR STOPPERING TRAY DRYER 14

Stoppering Tray Dryer Controls 15

Operation Checklist 16

Operating the Stoppering Tray Dryer 17

Set-Up 17

Manual Control Operation 18

Automatic Control Operation 19

Automatic Start-Up of Freeze Dryer Vacuum 20

Programming 21

Starting the Freeze Dry Cycle 21

Changing the Program Parameters in the Middle of a Run 23

Stopping the Freeze Dry Cycle 23

Monitoring the System Operation 23

Shelf Spacing Adjustment 24

Shelf Loading 24

Page 4

Sample Freezing 25

Freeze Drying 25

Stoppering 25

Vacuum Break/Backfilling 26

Alarms 26

System Temperature Variations 26

Vacuum 26

System Temperature Set Point 27

Power Failure 27

Temperature Probe 27

CHAPTER 5: MAINTAINING YOUR STOPPERING TRAY

DRYER 28

CHAPTER 6: USING THE RS232 RECEPTACLE 30

Computer Connection for Computer Interface 30

CHAPTER 7: TROUBLESHOOTING 35

Vacuum Pump 35

Gaskets, Tubing, Connections, Sample Valves 36

System Components & Collection Chamber Isolation 37

Stoppering Tray Dryer 40

Refrigeration Module Operation 40

Access to Mechanical Components 40

Shelf and Stoppering System Removal 41

Filling the Fluid System 42

Heat Transfer Fluid Precautions 43

Heat Transfer Fluid First Aid Procedures 44

CHAPTER 8: MODIFYING YOUR STOPPERING TRAY

DRYER DISPLAY 45

Modifying the Display 45

APPENDIX A: STOPPERING TRAY DRYER COMPONENTS 47

APPENDIX B: STOPPERING TRAY DRYER DIMENSIONS 50

APPENDIX C: STOPPERING TRAY DRYER

SPECIFICATIONS 52

Electrical Specifications 52

Environmental Conditions 52

APPENDIX D: STOPPERING TRAY DRYER ACCESSORIES 53

Page 5

1

C

C

HHAAPPTTEERR

1

1

I

I

NNTTRROODDUUCCTTIIOONN

Congratulations on your purchase of a Labconco FreeZone® Stoppering Tray

Dryer, which is designed for laboratory lyophilization procedures. The refrigerant

used in the refrigeration system is CFC-free so it will not endanger the

environment. The unit is easy to install and maintain. Proper care and

maintenance of this product will result in many years of dependable service.

Freeze Dry Process

Freeze drying is an important process in sample preparation and for the

preservation and storage of biologicals, pharmaceuticals and foods. Of the

various methods of dehydration, freeze drying (lyophilization) is especially suited

for substances that are heat sensitive. Other than food processing (e.g., coffee,

whole dinners), freeze drying has been extensively used in the development of

pharmaceuticals (e.g., antibiotics) and preservation of biologicals (e.g., proteins,

plasma, viruses and cell lines). The nondestructive nature of this process has been

demonstrated by the retention of viability in freeze dried viruses and

microorganisms.

Freeze drying is a process whereby water or other solvent is removed from frozen

material by converting the frozen water directly into vapor without the

intermediate formation of liquid water. The basis for this sublimation process

involves the absorption of heat by the frozen sample in order to vaporize the ice;

the use of a vacuum pump to enhance the removal of water vapor from the surface

of the sample; the transfer of water vapor to a collector; and the removal of heat

by the collector in order to condense the water vapor. In essence, the freeze dry

process is a balance between the heat absorbed by the sample to vaporize the ice

and the heat removed from the collector to convert the water vapor into ice.

Product Service 1-800-522-7658

Page 6

Chapter 1: Introduction

2

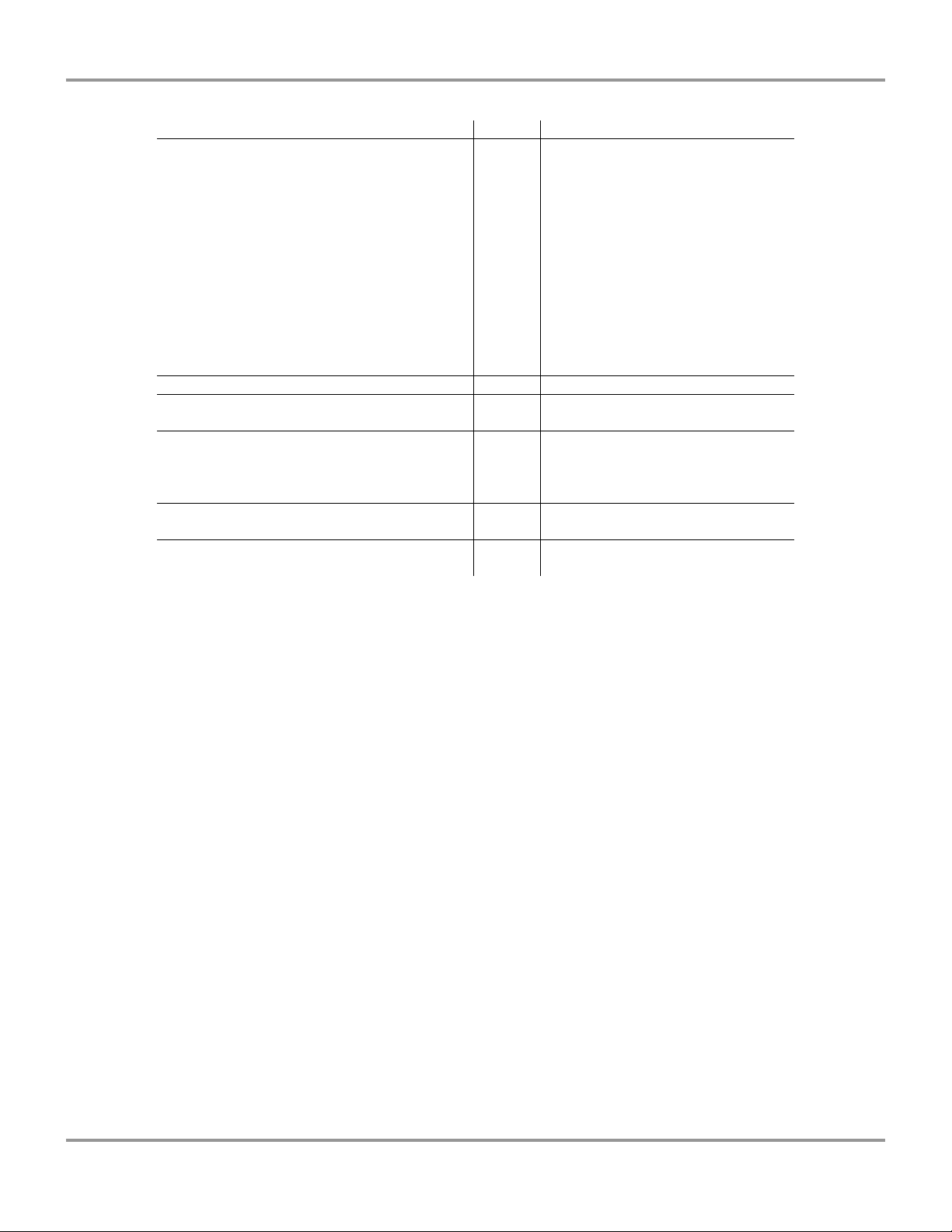

SAFE TEMPERATURE AND DRYING TIMES

FOR SELECTED MATERIALS

Material

10mm Thick

Safe

Temperature

°C

Collector

Temperature

°C

Hours

(Approx.)

Milk

-5

-40

10

Urea

-7

-40

10

Blood Plasma

-10 to -25

-40

16

Serum

-25

-40

18

Vaccinia

-30 to -40

-50

22

Influenza Vaccine

-30

-50

24

Human Tissue

-30 to -40

-50

48

Vegetable Tissue

-50

-80

60

Table 1

Freeze Dry Rates

The efficiency of the freeze drying process is dependent upon the surface area and

the thickness of the sample, the collector temperature and vacuum obtained, the

eutectic point and solute concentration of the sample. It is important to remember

these factors when trying to obtain efficient utilization of your freeze dry system.

A listing of selected materials and their approximate drying times are shown in

Table 1 for your reference.

*Total sample quantities are contingent on various freeze dryer capacities.

Up to the point of overloading the system, the greater the surface area of the

sample, the faster the rate of freeze drying. By contrast, for a given surface area,

the thicker the sample the slower the rate of freeze drying. This is based on the

fact that the heat of sublimation is usually absorbed on one side of the frozen

sample and must travel through the frozen layer to vaporize water at the other

surface. In addition, as the sample is freeze dried, the water vapor must travel

through the layer of dried material. The thicker the sample, the greater the chance

that the dried layer may collapse which would cause an additional decrease in the

rate of freeze drying.

The surface area and thickness of the sample can usually be ignored when each

sample contains only a few milliliters. However, for larger volumes, the samples

should be shell frozen to maximize the surface area and minimize the thickness of

the sample. The volume of the freeze dry flask should be two to three times the

volume of the sample.

In order for lyophilization to occur, ice must be removed from the frozen sample

via sublimation. This is accomplished by the collector and the vacuum pump.

The collector, which should be at least 15 to 20°C colder than the eutectic

temperature (melting temperature) of the sample, traps vapor as ice. Since the

vapor pressure at the collector is lower than that of the sample, the flow of water

Product Service 1-800-522-7658

Page 7

Chapter 1: Introduction

3

vapor is from the sample to the collector. Since this vapor diffusion process

occurs very slowly under normal atmospheric conditions, a good vacuum is

essential to maintain an efficient rate. In many applications, the maintenance of a

vacuum of 0.133 mBar or less is recommended.

The rate of freeze drying is directly proportional to the vapor pressure and the

vapor pressure is dependent upon both eutectic temperature and solute

concentration of the sample. For example, a solution of sodium chloride and

water would freeze dry at a slower rate than pure water. The eutectic temperature

of a sodium chloride solution is about –21°C and at this temperature the vapor

pressure is about 1/16 that of water at 0°C. Although the eutectic temperature is

not dependent upon the concentration of sodium chloride, the vapor pressure of

the water would decrease as the concentration of sodium chloride increased. This

is due to the fact that as the solute concentration increases, less of the surface area

of the frozen sample is occupied by water. In general, most solutions or

biological samples will have a eutectic temperature of –10° to –25°C. However,

if the sample contains a simple sugar such as glucose or if the sample is animal or

plant tissue, the eutectic temperature may be as low as –30° to –50°C.

Freeze Dry Capacity

The volume of a sample that can be freeze dried at one time is related to factors

discussed previously and the size and design of the freeze dry system. With any

given instrument, the capacity is based on the surface area of the sample, the

eutectic temperature and concentration of the sample and the rate and amount of

heat transferred to the frozen sample. Of these factors, the eutectic temperature is

the most important factor in determining the amount of sample that can be freeze

dried at one time, particularly when flasks are used. This is because as the

eutectic temperature decreases, the vapor pressure decreases but the rate of heat

absorption by the sample does not change. This tends to promote melting of the

sample, which leads to a marked increase in vapor pressure and ultimately

overloads the collector and vacuum pump. Samples that have eutectic

temperatures of –20°C or lower should be placed on the freeze dry system one

flask at a time so that the vacuum in the system may recover before adding

another sample to the system. If the vacuum does not recover, the capacity of the

freeze dry system has been exceeded and the sample should be removed.

If there is a problem with a particular type of sample melting when placed on the

freeze dry system, dilution of the sample with more water or providing some

insulation around the flask to decrease the rate of heat absorption by the sample

may help. If the eutectic temperature of the sample is –40 to –60°C, the freeze

dry system selected for use must be equipped with cascade type refrigeration so

that the collector temperature can be cooled to below –75°C, or a dry ice/solvent

trap may be used between the collector and the vacuum pump.

Product Service 1-800-522-7658

Page 8

Chapter 1: Introduction

4

Samples Containing Volatile Substances

In certain cases the solvent in a sample to be freeze dried may contain volatile

components such as acetonitrile, methanol, acetic acid, formic acid or pyridine.

In addition to these substances having an effect on the eutectic temperature, they

may increase the vapor pressure at the surface of the sample. Also, compared to

water, they will require the absorption of less heat for sublimation to occur.

Hence, samples that contain volatile substances will have a greater tendency to

melt, particularly when placed in flasks or exposed to room temperature. If a

sample containing a volatile substance tends to melt when placed on a freeze dry

system, dilution of the sample with more water will help keep the sample frozen.

For example, a 0.2M solution of acetic acid is much easier to freeze dry than a

0.5M solution.

About This Manual

This manual is designed to help you learn how to install, use, and maintain your

Stoppering Tray Dryer. Instructions for performing routine maintenance and

making minor modifications to your Stoppering Tray Dryer are also included.

Chapter 1: Introduction provides a brief overview of the freeze dry process,

explains the organization of the manual, and defines the typographical

conventions used in the manual.

Chapter 2: Prerequisites explains what you need to do to prepare your site before

you install your Stoppering Tray Dryer. Electrical requirements are discussed.

Chapter 3: Getting Started contains the information you need to properly unpack,

inspect and install your Stoppering Tray Dryer.

Chapter 4: Using Your Stoppering Tray Dryer discusses the basic operation of

your Stoppering Tray Dryer. Information on how to load samples and run the

Stoppering Tray Dryer is included.

Chapter 5: Maintaining Your Stoppering Tray Dryer explains how to perform

routine maintenance on your Stoppering Tray Dryer.

Chapter 6: Using the RS-232 Receptacle describes how to connect a computer

for monitoring the operation.

Chapter 7: Troubleshooting contains information about problems you may

encounter while using your Stoppering Tray Dryer, including the probable causes

of the problems, and suggested corrective actions.

Chapter 8: Modifying Your Stoppering Tray Dryer Display describes how to

calibrate the vacuum display and restore factory settings.

Product Service 1-800-522-7658

Page 9

Chapter 1: Introduction

5

!

Appendix A: Stoppering Tray Dryer Components contains labeled diagrams of the

components of the Stoppering Tray Dryer.

Appendix B: Stoppering Tray Dryer Dimensions contains comprehensive

diagrams showing the dimensions for the Stoppering Tray Dryer.

Appendix C: Stoppering Tray Dryer Specifications contains product

specifications.

Appendix D: Stoppering Tray Dryer Accessories lists the part numbers and

descriptions of all of the accessories available for your Stoppering Tray Dryer.

Typographical Conventions

Recognizing the following typographical conventions will help you understand

and use this manual:

Book, chapter, and section titles are shown in italic type (e.g., Chapter 3:

Getting Started).

Steps required to perform a task are presented in a numbered format.

Comments located in the margins provide suggestions, reminders, and

references.

Critical information is presented in boldface type in paragraphs that are

preceded by the exclamation icon. Failure to comply with the information

following an exclamation icon may result in injury to the user or permanent

damage to your Freeze Dryer.

Important information is presented in capitalized type in paragraphs that are

preceded by the pointer icon. It is imperative that the information contained

in these paragraphs be thoroughly read and understood by the user.

Product Service 1-800-522-7658

Page 10

6

C

C

HHAAPPTTEERR

2

2

P

P

RREERREEQQUUIISSIITTEESS

Before you install your Stoppering Tray Dryer, you need to prepare your site for

installation. The Stoppering Tray Dryer will mount on top of a FreeZone 6, 12 or

18 liter Freeze Dry System. This could be either a benchtop or console model.

Carefully examine the location where you intend to install your Stoppering Tray

Dryer. You must be certain that the area is level and of solid construction. An

electrical source must be located near the installation site.

Carefully read this chapter to learn:

the electrical supply requirements.

the vacuum pump requirements.

Refer to Appendix C: Stoppering Tray Dryer Specifications for complete

Stoppering Tray Dryer electrical and environmental conditions, specifications and

requirements.

Refer to the User’s Manual for the FreeZone Freeze Dry System for complete

electrical and environmental conditions, specifications and requirements.

Electrical Requirements

The Stoppering Tray Dryer requires a dedicated electrical outlet. This outlet

requires a 20 Amp circuit breaker or fuse for models rated at 115V (60 Hz). An

outlet equipped with a 15 Amp circuit breaker or fuse is required for models rated

at 230V (50/60 Hz). The power cord on 115V models is equipped with a 20 Amp

NEMA 5-20P plug. Various power cord configurations are provided with 230V

models. If this does not match with the available receptacle, remove this plug and

replace it with an approved plug of the suitable style.

Product Service 1-800-522-7658

Page 11

Chapter 2: Prerequisites

7

Location Requirements

The Freeze Dryer should be located in an area that provides an unobstructed flow

of air around the cabinet. This air cools the refrigeration system. The

refrigeration system draws air in through the front and exhausts it through the

rear. A minimum of 3" must be allowed between the rear and both sides of the

Freeze Dryer and adjacent wall surfaces. Restriction of airflow during operation

could adversely affect performance.

Refer to Appendix B: Stoppering Tray Dryer Dimensions for dimensional

drawings of the Stoppering Tray Dryer.

Vacuum Pump Requirements

A vacuum pump must be provided by the user. A vacuum pump with a

displacement of 144 liters per minute and 0.002 mBar ultimate pressure is

adequate for most samples. The inlet fitting on the vacuum pump must be

suitable for 3/4" ID vacuum hose, which is provided with the FreeZone Freeze

Dry System. It is recommended that the vacuum pump is equipped with an

exhaust filter to minimize oil mist exhausting from the vacuum pump. The

operating vacuum level may be set on the Freeze Dry System. The higher the

pressure is set, the more likely it is that oil mist will be exhausted.

Vacuum pumps used with 115V models should be equipped with an 115V, 15

Amp NEMA 5-15P plug. Vacuum pumps used with 230V models should be

equipped with a reverse IEC plug. This plug is included with 230V models. This

will allow the vacuum pump to be plugged into the receptacle on the back panel

of the Freeze Dry System. Refer to the User’s Manual for the FreeZone Freeze

Dry System for vacuum pumps available from Labconco.

Product Service 1-800-522-7658

Page 12

8

C

C

HHAAPPTTEERR

3

3

G

G

EETTTTIINNGG

S

S

TTAARRTTEEDD

!

The United

States Interstate

Commerce

Commission

rules require

that claims be

filed with the

delivery carrier

within fifteen

(15) days of

delivery.

Now that the site for your Stoppering Tray Dryer is properly prepared, you are

ready to unpack, inspect, install and test your Stoppering Tray Dryer. Read this

chapter to learn how to:

unpack and move your Stoppering Tray Dryer.

set up your Stoppering Tray Dryer.

connect the electrical supply source to your Stoppering Tray Dryer.

safely use solvents with your Stoppering Tray Dryer.

The Stoppering Tray Dryer weighs over 400 lbs. (181 Kg). The

carton allows for lifting with a mechanical lift truck or hand

truck. If you must lift the Stoppering Tray Dryer manually,

use at least four (4) persons and follow safe lifting guidelines.

Unpacking Your Stoppering Tray Dryer

Carefully unpack your Stoppering Tray Dryer and inspect it for damage that may

have occurred in transit. If your Stoppering Tray Dryer is damaged, notify the

delivery carrier immediately and retain the entire shipment intact for inspection

by the carrier.

DO NOT RETURN GOODS WITHOUT THE PRIOR

AUTHORIZATION OF LABCONCO.

UNAUTHORIZED RETURNS WILL NOT BE ACCEPTED.

Product Service 1-800-522-7658

Page 13

Chapter 3: Getting Started

9

Power Cords

Catalog #

Description

Volts

Hz

1336400

1336500

1342100

1332601

1332701

7948020

Stoppering Tray Dryer

115

60 X 7948030

Stoppering Tray Dryer

230

50 X 7948040

Stoppering Tray Dryer

230

60 X 7948060

Stoppering Tray Dryer

230

50 X 7948070

Stoppering Tray Dryer

230

50

X

Part #

Qty.

Component Description

7353900

1

User’s Manual

1880712

4

Screw ¼-20 x .75

1905621

4

Nut ¼-20

1911416

8

Washer ¼

7353403

1

Cable RS 232

IF YOUR STOPPERING TRAY DRYER WAS DAMAGED IN

TRANSIT, YOU MUST FILE A CLAIM DIRECTLY WITH THE

FREIGHT CARRIER. LABCONCO CORPORATION AND ITS

DEALERS ARE NOT RESPONSIBLE FOR SHIPPING DAMAGE.

DO NOT DISCARD THE CARTON OR PACKING MATERIAL

FOR YOUR STOPPERING TRAY DRYER UNTIL YOU HAVE

CHECKED ALL OF THE COMPONENTS AND INSTALLED

AND TESTED THE STOPPERING TRAY DRYER.

Stoppering Tray Dryer Components

Locate the model of Stoppering Tray Dryer you received in the following table.

Verify that the components listed are present and undamaged.

Plus the following:

If you did not receive one or more of the components listed for your Stoppering

Tray Dryer, or if any of the components are damaged, contact Labconco

Corporation immediately for further instructions.

Setting Up Your Stoppering Tray Dryer

After you verify receipt of the proper components, move your Stoppering Tray

Dryer to the location where you want to install it. Then, follow the steps listed

below.

Product Service 1-800-522-7658

Page 14

Chapter 3: Getting Started

10

Installing the Tray Dryer on the Freeze Dry System

The following tools are required to install the Stoppering Tray Dryer onto a

FreeZone Freeze Dry System base unit: Flat blade screwdriver or 5/16" socket

and a 7/16" wrench or socket.

Remove the four plastic hole plugs from the top of the Freeze Dry System on

which the Stoppering Tray Dryer is to be mounted. If the Freeze Dry System has

a flat gasket around the 3.0 inch vacuum port, remove it. Loosen both clamps on

the lower connection hose and slide the hose upward so the bottom edge of the

hose is above the lower edge of the stainless steel tube. Snug both clamps on the

hose to hold them in place.

Lift the Stoppering Tray Dryer into place on your Freeze Dry System while

centering the vacuum coupling over the vacuum connection port. Align the four

mounting holes in the Stoppering Tray Dryer support stand with the four holes in

the top of the Freeze Dry System.

NOTE: Do not lift the Stoppering Tray Dryer by the door or disturb

it.

Install the four bolts, nuts, and washers provided. Loosen the clamps and slide

the lower hose down over the vacuum connection port. Orient the clamps to gain

access and tighten the clamps to provide a leak-free connection.

Product Service 1-800-522-7658

Page 15

Chapter 3: Getting Started

11

!

!

The Stoppering Tray Dryer is now installed and must be tested to make certain the

system is free of leaks. To test, turn on the Freeze Dry System refrigeration and

allow the temperature to reach –40° or lower. Close the door of the Tray Dryer

and make sure the Stoppering Control is in the “LOWER” position and the Vac

Release control is in the “CLOSED” position. Start the vacuum pump and

monitor the vacuum gauge. The vacuum on the Freeze Dry System should reach

0.133 mBar within 30 minutes and should achieve an ultimate vacuum of 0.040

mBar or lower within 18 hours. If 0.040 mBar cannot be achieved, consult the

troubleshooting section of this manual and of the manual supplied with the Freeze

Dry System.

Venting the Vacuum Pump

If any materials will be placed in the Stoppering Tray Dryer

that can liberate hazardous gases when heated, the vacuum

pump exhaust must be vented to a fume hood or other

ventilation device.

Electrical Connection

Plug the power cord into the receptacle on the back of the Stoppering Tray Dryer

and plug the other end into a suitable power receptacle.

DO NOT ATTEMPT TO PLUG THE STOPPERING TRAY

DRYER INTO THE FREEZONE FREEZE DRY SYSTEM.

CAUTION: When the appropriate power cord is plugged into

the power receptacle on the rear panel of the tray dryer, the

clamp on the tray dryer receptacle should be tightened to

prevent the cord from accidentally being switched with the

freeze dryer cord located underneath the tray dryer. (The

freeze dryer may require different mains A.C. voltage and

switching these power cords may cause damage).

Chemical Resistance of Freeze Dryer

Components

The FreeZone Freeze Dry System and Stoppering Tray Dryer are designed to be

chemically resistant to most compounds that are commonly used in freeze drying

processes. However, by necessity, the Freeze Dryer is comprised of a number of

different materials, some of which may be attacked and degraded by certain

chemicals. The degree of degradation is dependent on the concentration and

exposure duration. Some of the major components of the FreeZone Freeze Dry

System that are susceptible to degradation are as follows:

Product Service 1-800-522-7658

Page 16

Chapter 3: Getting Started

12

Acids

Buffers Solvents

Component

Material

Acetic Acid 20%

Formic Acid

Trifluoroacetic Acid (TFA) Calcium Chloride

Sodium Phosphate Acetone

Acetonittirle

Carbon Tetrochloride

Cyclohexane

Dioxane

Methyl t-Butyl Ether (BTBE)

Pyridine

Valve Stem

Acetal

C D D D D

Collector*

Lid & Door

Acrylic

D D D D

Hoses,

Gaskets &

Valve

Bodies

Neoprene

C D D C C D D D C

D

Flask Top

Silicon

Rubber

C D D D D D C

D

Chamber &

Fittings

Stainless

Steel

C

* An accessory glass lid is available for the Freeze Dry Systems.

C – Moderate degradation; Limited use.

D – Severe degradation; infrequent use recommended; immediate

thorough cleaning required.

Most common compounds used in freeze drying processes, if allowed to enter

the vacuum pump, will degrade the oil and cause damage to the vacuum

pump.

Sugars and proteins typically will have minimal negative effect on any of the

materials of construction.

When using compounds in the Freeze Dryer that are hostile to the materials of

construction, it is imperative the equipment is thoroughly cleaned after use.

Rubber and plastic components that have been exposed to damaging

compounds should be removed and flushed with water.

The oil in the vacuum pump should be checked often. It must be changed if it

is cloudy, shows particles or is discolored. The useful life of vacuum pump

oil can be extended if the vacuum pump is operated for an extended period of

time after a freeze dry run. This allows contaminants to be purged from the

hot oil. This must be done with the inlet to the pump blocked off to prevent

air from free flowing through the pump. This is accomplished by closing all

sample valves on a clean, dry freeze dry system and turning on the vacuum

pump. If the pump is operated at an elevated vacuum level (> 10mBar), oil

may be expelled from the pump and damage could occur.

Product Service 1-800-522-7658

Page 17

Chapter 3: Getting Started

13

!

Another way to extend the life of the vacuum pump is to install an optional

secondary trap in the line between the Freeze Dry System and the vacuum pump.

Contact Labconco for ordering information.

With prudent maintenance the FreeZone Freeze Dry System will provide years of

service. Warranty on the affected parts will be voided if maintenance has been

obviously neglected. If you have questions about using specific compounds in the

Freeze Dry System, contact Labconco Technical Service at 1-800-821-5525 or

816-333-8811 or e-mail: labconco@labconco.com.

Solvent Safety Precautions

Solvents used in the Stoppering Tray Dryer may be flammable

or hazardous to your health. Use extreme caution and keep

sources of ignition away from the solvents. When using

flammable or hazardous solvents, the vacuum pump must be

vented to a fume hood.

Hazardous materials such as strong acids or bases, radioactive

substances and volatile organics must be handled carefully and

promptly cleaned up if spilled. If a sample is spilled in the

collector chamber it must immediately be cleaned up.

WARNING: The disposal of substances used in connection

with this equipment may be governed by various Federal, State

or local regulations. All users of this equipment are urged to

become familiar with any regulations that apply in the user’s

area concerning the dumping of waste materials in or upon

water, land or air and to comply with such regulations.

Product Service 1-800-522-7658

Page 18

14

C

C

HHAAPPTTEERR

4

4

U

U

SSIINNG

G

Y

Y

OOUURR

S

S

TTOOPPPPEERRIINNG

G

T

T

RRAAYY

D

D

RRYYEERR

!

After your Stoppering Tray Dryer has been installed as detailed in Chapter 3:

Getting Started, you are ready to begin using your Stoppering Tray Dryer. Read

this chapter to learn how to:

operate the controls.

understand the display.

connect samples.

Do not use the Stoppering Tray Dryer in a manner not

specified by the manufacturer (refer to Appendix C: Stoppering

Tray Dryer Specifications). The electrical protection properties

of the Stoppering Tray Dryer may be impaired if the

Stoppering Tray Dryer is used inappropriately.

Product Service 1-800-522-7658

Page 19

Chapter 4: Using Your Stoppering Tray Dryer

15

6

14 2

3

4

13

11

10

12

1

5 6 7 8 9

14

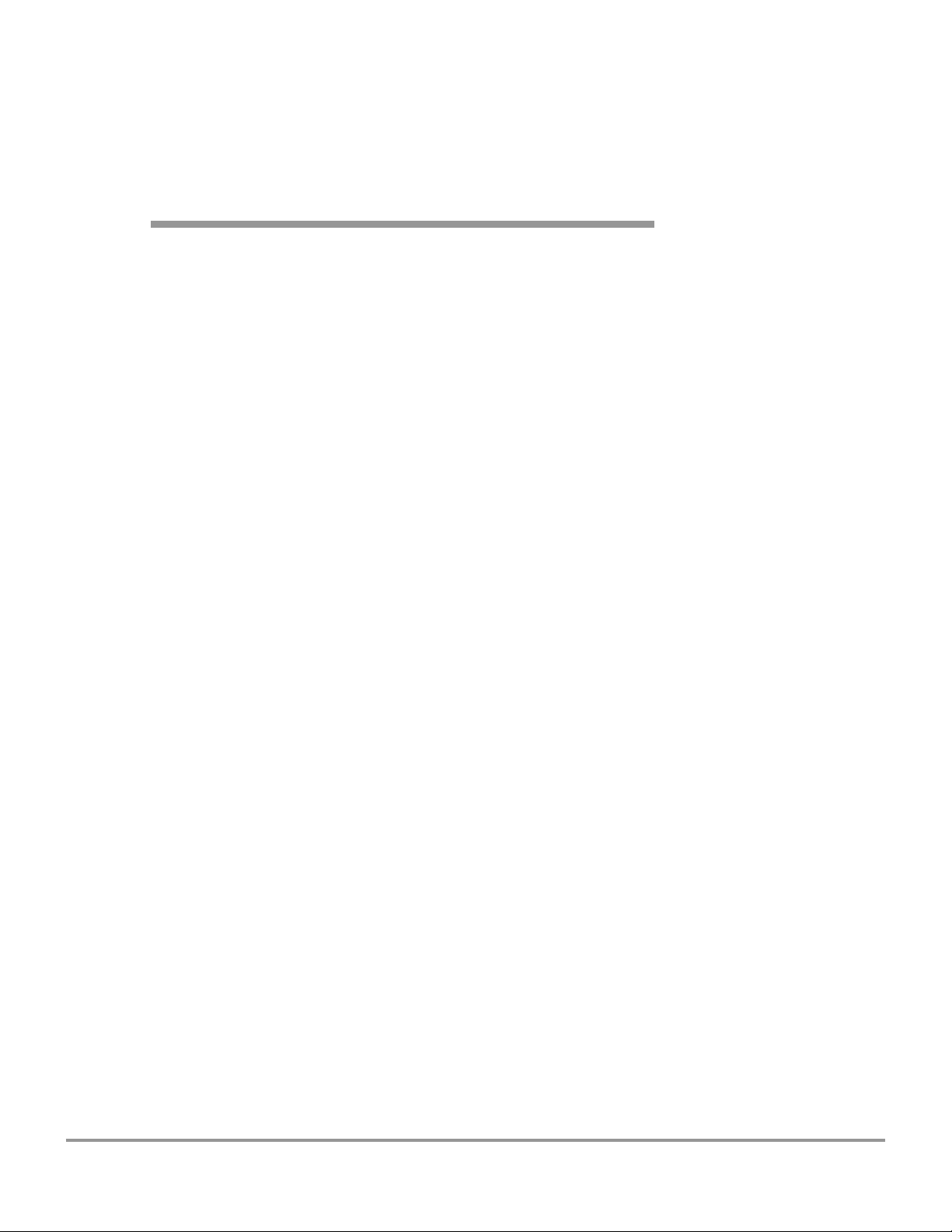

Stoppering Tray Dryer Controls

The control panel for the Stoppering Tray Dryer is shown with a description about

its function.

1. Display. Displays all necessary programming and operational data. Provides

prompts to aid in programming.

2. Display Selector. Changes format of display from “monitor’ to “auto” to

“manual” to “set up” screen.

3. Display Indicators. Amber lamps indicate which display “screen” is shown.

4. Alarm Indicator. Red LED indicates that a system alarm has occurred.

5. Decrease Switch. Used in programming to decrease a parameter set point.

6. Increase Switch. Used in programming to increase a parameter set point.

7. Enter Switch. Used in programming to enter a selected set point into memory.

Product Service 1-800-522-7658

Page 20

Chapter 4: Using Your Stoppering Tray Dryer

16

!

8. Mode Indicator. Amber lamp indicates whether the control is set to operate either

in the automatic or manual mode.

9. Mode Selector Switch. Selects the mode of operation – either manual or

automatic.

10. Run/Stop Switch. Initiates the start or stop of the lyophilization process.

11. Run/Stop Indicator. Amber lamp burns steadily while freeze drying is in

progress and turns off if either the programmed cycle is completed or the process

is terminated in mid cycle. The amber lamp flashes if freeze drying is in progress

and an out-of-specification condition exists.

12. Stoppering. Controls the stoppering up and down movement. The mechanism

will function only while the chamber is under vacuum. The stoppering action

should be closely monitored when operating this control.

13. Vacuum Release. Vents the chamber so the chamber door can be opened. This

control can also vent gas into the chamber when the gas is properly connected to

the backfill port.

14. Back Fill. A regulated tank of gas may be connected to the port to allow the

introduction of gas into the chamber after freeze drying. The port accepts 1/8"

tubing.

Ethylene Oxide is not recommended for use in this Tray Dryer for

decontamination because of its hazardous and corrosive properties.

15. Power Switch. Turns all power to Tray Dryer ON or OFF. Not shown. Located

on left side of cabinet.

Operation Checklist

The following checklist should be followed prior to each use of your Stoppering

Tray Dryer:

1. Wipe out the interior of the Stoppering Tray Dryer chamber with a soft cloth

or paper towel to remove any moisture or debris

2. Wipe the interior of the collector chamber of the Freeze Dry System with a

soft cloth or paper towel to remove any accumulated moisture.

3. Check the collector chamber drain hose on the Freeze Dry System to ensure

that the hose is free of moisture and that the drain plug is securely installed.

Product Service 1-800-522-7658

Page 21

17

TEMPERATURE UNITS:

°C °F

REFRIG TOTAL HOUR: XXXX

SERVICE HOUR: XXXX

VACUUM UNITS:

MBar Pa Torr

REFRIGERATION TOTAL HOURS: XXXX:

RESET SERVICE HOUR: ? X

4. Using a soft, lint-free cloth or paper towel, wipe the Freeze Dry System

collector chamber lid gasket and the Stoppering Tray Dryer door gasket to

remove any dirt and contaminants that could cause a vacuum leak. Vacuum

grease is not required on the door gasket or collector lid gasket to obtain a

proper vacuum seal.

Operating the Stoppering Tray Dryer

Set-Up

The display units for vacuum may be selected to be mBar, Pascal (Pa) or Torr and

the temperatures may be displayed as either °F or °C. The refrigeration operating

time may be monitored and the vacuum reading may be calibrated. To configure

your Stoppering Tray Dryer, turn the main power switch ON. Press the Display

button until the Set up LED is lit. The display will show:

Press or until the desired units are flashing.

Press ENTER.

The display will show:

Press or until the desired units are flashing.

Press ENTER

The display will show:

Press ENTER if you do not want to reset SERVICE HOURS.

Press to reset the Service Hours to 0. This allows you to keep track

of the time the refrigeration system operated since it was serviced.

The display will show:

Product Service 1-800-522-7658

Chapter 4: Using Your Stoppering Tray Dryer

Page 22

Chapter 4: Using Your Stoppering Tray Dryer

18

SET POINT TEMP –30°C

Hold for 5 seconds.

Press ENTER.

At any time the DISPLAY button can be pressed to select a different

display screen.

Manual Control Operation

(1) Turn the Power switch ON. The display will become active.

(2) Push the DISPLAY button until the Manual LED lights. This will

cause the manual display screen to be shown with the previously

entered set point temperature.

The temperature units are displayed in the units (°F or °C) selected in

the Set Up.

The temperature may be set anywhere from +40°C to –40°C in 1°C

increments.

(3) If the set point needs to be changed, press the INCREASE or

DECREASE button until the desired set point temperature is

displayed.

(4) Press ENTER. If ENTER is not pressed within 10 seconds, the set

point will revert to the previously entered set point temperature.

(5) Press MODE button until the Manual LED lights.

(6) Press RUN/STOP button. The amber LED by the button will light and

the refrigeration system and/or heater will operate.

(7) To change the set point temperature in the middle of a run, repeat steps

2, 3 and 4. The system will adjust to the new temperature set point.

(8) To monitor system operation, press DISPLAY until the Monitor LED

lights. The display will simultaneously show system temperature,

vacuum and three sample temperatures if sensors were plugged into

their jacks at the front of the chamber and inserted into sample vials.

If sensors are not plugged into their jacks, the probe temperature

display will show “- - -”.

Product Service 1-800-522-7658

Page 23

Chapter 4: Using Your Stoppering Tray Dryer

19

P1

-indicates what program is selected

PRB

-shelf probes for shelf 1, 2 and 3 (If a probe

is not installed, the display shows ---)

C

-°C F -°F

TMP

-system temperature

SEG

-indicates what segment is active and

ramping or holding.

M

-manual mode

VAC

-system vacuum level

m

-mBar

P

-Pascal

T

-Torr

R

-Ramp

H

-Hold

TR

-Time remaining in hours

P1 PRB 1=XX 2=XX 3=XXc

TMP=XX SEG=M VAC=hi m

The segment number will always indicate “M” while operating in the

manual mode. Segment numbers are used only in the automatic mode to

identify portions of the programmed cycle. Temperatures and vacuum are

displayed in the units selected during the set up procedure. Above 5.0

mBar the display will show “hi” vacuum. System temperature rather than

probe temperature is the parameter that is regulated by the controller.

(9) To stop, push RUN/STOP button, which will turn off the amber LED

over the switch, the refrigeration system and the heater. To turn off

the entire system, turn the power switch off.

Automatic Control Operation

The Stoppering Tray Dryer is equipped with a microprocessor based controller

that permits temperature to be programmed using as many as five different

segments. Each segment consists of a temperature ramp function and a

temperature hold function. There are five programs of five segments each that

store the settings. One of the five may be selected by pressing the DISPLAY

switch until the AUTO LED lights. Press the UP/DOWN keys to select the

desired program, and then press “ENTER.” The display will change to show the

parameters for this program. The ramp allows the temperature of the sample to be

increased or decreased at any desired rate within the capacity of the heating and

cooling systems of the Stoppering Tray Dryer.

A Stoppering Tray Dryer without samples on shelves is capable of cooling at a

rate of approximately .5°C/minute and can heat at approximately 1.3°C/minute.

The cooling ramp rate may be slower as the temperature approaches –40°C. Hold

temperatures may be set anywhere from +40°C to –40°C in 1°C increments.

Product Service 1-800-522-7658

Page 24

Chapter 4: Using Your Stoppering Tray Dryer

20

When the desired temperature is achieved, the hold function will maintain that

temperature for the programmed length of time. The microprocessor control has a

built in memory of the last entered program to allow the identical protocol to be

repeated by simply pushing the RUN button. A typical 3 segment program is

shown in Figure 5.

Automatic Start-Up of Freeze Dryer

Vacuum

At the end of Segment 1 Hold, if the StopperingTray Dyer is connected to the

Freeze Dry System base unit, the vacuum provided by the Freeze Dryer will start

automatically. The base unit should have the refrigeration started in manual mode

to allow it to reach temperature while the Tray Dryer is processing Segment 1 of

the program. (Do not start the base unit’s refrigeration using automatic mode.

This will not allow the Tray Dryer to start the vacuum on the Freeze Dryer).

Connect the Tray Dryer to the Freeze Dryer with cable #7353403 (this cable is

shipped with the Tray Dryer). One end of the cable plugs into the 4-pin connector

(Output to Freeze Dryer) on the back of the Tray Dryer in the lower right hand

corner of the unit (when viewing the back of the unit), and the other end of the

cable plugs into the 4-pin connector (Stoppering Tray Dryer Input) on the back of

the Freeze Dryer in the upper right hand corner of the unit (when viewing the

back of the unit).

Product Service 1-800-522-7658

Page 25

Chapter 4: Using Your Stoppering Tray Dryer

21

P1 SEG 1 RAMP 00.0°C/MN

HOLD –34°C TIME 00.0

Programming

The Tray Dryer will store up to five programs numbered 1 through 5. The five

programs, once programmed, will be retained in memory. To program a run,

select the program number that you want to use and enter the parameters as

follows.

Turn the Power switch to the ON position. Press the DISPLAY button until the

Auto LED lights.

NOTE: Values shown in this example are for reference only.

The “P” in the display will flash and the program number that will be run is

shown. To select different programs, press the UP or DOWN key to change

program number (Programs 1 through 5). When the desired program number is

displayed, press ENTER.

The display will show the parameters that were last entered for this program.

If any of the parameters are changed, the ENTER key must be pressed for the new

value to be stored. If the ENTER key is not pressed within 10 seconds after the

last parameter adjustment, the value will return to the previously stored value.

The flashing parameter name indicates the parameter that will be changed.

Pressing ENTER only will advance to the next parameter.

After the AUTO RUN cycle is started, segments with a value greater than the

segment running may have their parameters changed. Only the selected program

may be modified. To modify a different program, the system must be stopped and

the desired program selected.

Starting the Freeze Dry Cycle

After the desired cycles have been programmed, push the MODE button to

Select-AUTO. Push the RUN/STOP button to start the program running. The

RUN indicator will light. The System

Product Service 1-800-522-7658

Page 26

Chapter 4: Using Your Stoppering Tray Dryer

22

P1

-indicates what program is

selected

PRB

-shelf probes for shelf 1, 2

and 3 (If a probe is not

installed, the display shows ---)

C

-°C F -°F

TMP

-system temperature

SEG

-indicates what segment is

active and ramping

VAC

-system vacuum level

M

-mBar

P

-Pascal

T

Torr

P1 PRB 1=28 2=29 3=28 C

TMP=30 SEG=1H VAC=.030 M

P1 PRB 1=28 2=29 3=28 C

TMP=30 TR=4.55 VAC=0033 M

TR

-indicates the amount of time

remaining in the present segment. If time is 10.0 hours or

more, the time is displayed in

1/10 hours. If time is less than

10.0 hours, the time is displayed

in 1/100 hours. If the hold time

was programmed to be

indefinite, the display will show

“INDF”.

P1

-indicates what program is

selected

PBR

-shelf probes for shelf 1, 2

and 3

TMP

-system temperature

SEG

-indicates what segment is

active and holding

VAC

-system vacuum level

P1 PRB 1=28 2=29 3=28 C

TMP=30 SEG=1R VAC=.030 M

Status Display will change and the Display will change to MONITOR mode.

During the RAMP cycle of the active segment, the Status Display will be as

follows:

During the HOLD cycle of the active segment the Status Display will alternately

be as follows:

Product Service 1-800-522-7658

Page 27

Chapter 4: Using Your Stoppering Tray Dryer

23

Changing the Program Parameters in the

Middle of a Run

(1) Press DISPLAY to obtain Monitor screen. Note current operating

segment.

(2) Press DISPLAY to obtain Auto screen.

(3) Enter a segment number that will occur after the current segment that is

running.

The presently running segment cannot be modified while the system is

running.

(4) Modify as required.

(5) Press ENTER.

Stopping the Freeze Dry Cycle

1. At the end of the last programmed segment, the freeze dry system will

automatically stop. The refrigeration system and the heater will shut off.

The display will show Segment “E” (End).

2. To stop before the completion of the last programmed segment, press

RUN/STOP. The amber lamp will turn off as will the refrigeration system

and heater. The display will remain active but time functions will stop

operating.

3. The entire system can be shut off by pressing the Power Switch.

4. If the Power switch is shut off prior to stopping the cycle with the

RUN/STOP button, when the Power Switch is again turned on, the system

will resume operation and attempt to complete the programmed cycle from

the point at which it was shut off. The display mode indicator

“PROGRAM” will flash to indicate power loss during programmed run.

Monitoring the System Operation

Press the Display button until the monitor LED lights. The display will show

system temperature, system vacuum and 3 sample temperatures if sensors were

plugged into their jacks at the front of the chamber and inserted into sample vials.

If sensors are not plugged into their jacks, the probe temperature display will

show “- - -”. The temperatures and vacuum are displayed in the units selected in

Set Up. Above 5.0 mBar the display will show “HI” vacuum.

Product Service 1-800-522-7658

Page 28

Chapter 4: Using Your Stoppering Tray Dryer

24

If the temperature is warmer than +50°C, the display will show “HI”. If the

temperature is cooler than –50°C, the display will say “LO”.

Shelf Spacing Adjustment

Prior to loading the shelves with the product to be freeze dried, adjust the shelves

to the 3-shelf, 2-shelf or 1-shelf position. It is best to observe the shelf supporting

mechanism and practice while reading these procedures. In the 3-shelf position,

the spacing between the shelves will accommodate a serum bottle with the stopper

raised up to a maximum height of 75 mm (2.9 inches).

Minimum serum bottle height with lowered stopper for bottles on 3 shelves is 38

mm (1.5 inches).

For a 2-shelf system, grasp the top shelf and raise it until it latches in place. Then

raise the middle shelf approximately 1 inch until it latches in a position to allow a

two equally spaced shelf system. The spacing between shelves will accommodate

a bottle with the stopper raised up to a maximum height of 107 mm (4.2 inches).

Minimum serum bottle height with lowered stopper for a 2-shelf system is 56 mm

(2.2 inches).

For a single shelf system, raise both the top and middle shelves until they latch in

place in their top positions. The spacing for a single shelf system will

accommodate a bottle with raised stopper up to a maximum height of 196 mm

(7.7 inches), and the minimum height of a bottle with lowered stopper for

successful stoppering is 114 mm (4.5 inches).

To unlatch the shelves, press the latch protruding from the side of the shelf

support structure and move the latch until it clears the shelf and allows the shelf to

drop. The top shelf has one latched position, the middle shelf has two latched

positions, and the bottom shelf should not latch in any position.

Shelf Loading

The stoppering mechanism is capable of generating a very strong force, which can

damage the shelves or mechanism. Therefore, it is important to distribute the

serum bottles to be stoppered evenly across the entire surface of each shelf.

Your Stoppering Tray Dryer has a unique system for keeping the shelves level

and moving smoothly while stoppering. If a problem occurs during stoppering,

the system is designed to flex a small amount to lessen the possibility of damage

to the unit.

Product Service 1-800-522-7658

Page 29

Chapter 4: Using Your Stoppering Tray Dryer

25

The stoppering action should be monitored by looking through the chamber door.

Cease stoppering when all bottles appear stoppered or if a problem occurs.

Distributing the serum bottles evenly on the shelves also aids in consistent drying

of all serum bottles on each shelf.

Sample Freezing

Before the freeze dry process can occur, the products to be dried must be in a

frozen state. This can be accomplished in a freezer separate from the Stoppering

Tray Dryer or on the shelves in the Stoppering Tray Dryer. First the shelves

should be adjusted to accept the size of the selected sample containers. Next, turn

On the power switch and set the controls to cool the shelves. This is most simply

done by setting the temperature in the manual mode, although segment 1 in the

automatic mode can also be programmed to cool the shelves and start the vacuum

after the end of Segment 1. Load the samples onto the shelves after the system

temperature is below the sample eutectic temperature. If desired, place one

temperature probe in a sample vial on each shelf. The temperature can be

monitored by pressing the Display button until the Monitor LED lights.

Freeze Drying

Turn on the FreeZone Freeze Dry System base unit. Following the instructions

for the unit, this may be accomplished in either the automatic or manual mode.

When the collector temperature is less than –40°C and the vacuum is less than

0.133 mBar, the manual mode set point temperature may be adjusted or the

automatic mode program may be initiated. At no time during the primary drying

phase should the product temperature be allowed to rise higher than the eutectic

temperature.

The ice collecting coil temperature and the vacuum level should be monitored.

Higher than desired collector coil temperature or vacuum levels will inhibit or

ruin the freeze dry process.

Stoppering

The stoppering operation (when desired) is performed after the freeze dry process

is complete. To stopper, move the Stoppering control toward the “RAISE”

position. This action allows the actuator beneath the bottom shelf to inflate

causing the bottom shelf to rise. The vials on the shelf will then contact the

middle shelf causing it to rise and the top shelf will eventually be contacted and

rise. When all three shelves have raised and made contact with each other,

stoppers will be pressed into the vials. Monitor the stoppering process by looking

through the chamber door.

Product Service 1-800-522-7658

Page 30

Chapter 4: Using Your Stoppering Tray Dryer

26

When all of the vials appear to be stoppered, move the Stoppering control to the

“LOWER” position. This opens the diaphragm to the vacuum pump, which

deflates the diaphragm. Opening the vacuum release control also deflates the

stoppering diaphragm. The Stoppering control should be left in the “LOWER”

position when not stoppering.

Vacuum Break/Backfilling

To open the chamber door, the vacuum must be released. To release the vacuum,

move the Vacuum Release control to the “OPEN” position and shut off the

vacuum pump using the switch on the base unit.

Air enters the vacuum chamber through the Back Fill port. When the sound of air

through the Back Fill port is no longer audible, the chamber door is ready to open.

To backfill the chamber with a gas, connect a cylinder of the desired gas to the

Back Fill port. The port will accept 1/8" tubing. The bottle must be equipped

with a regulator set to 15 psi maximum. The gas can be metered with the

Vacuum Release control and chamber pressure monitored with the freeze dry

system’s vacuum gauge. Allow the vacuum pump to run for a few minutes while

the gas enters to permit the back fill gas to surround the freeze dried sample.

When the vacuum pump is turned off, air will enter the system through the

vacuum break valve located between the vacuum pump and the collector

chamber.

Alarms

A number of unusual events may occur during a lyophilization procedure that can

adversely effect the operation of the Stoppering Tray Dryer. If an event occurs,

the alarm indicator will flash and the beeper will sound.

The beeper will automatically mute itself after one minute. The specific alarm

can be identified observing the display. The following “out of specification”

conditions will initiate an alarm:

System Temperature Variations

Once the system temperature has stabilized for 20 minutes, if the manual set point

temperature or automatic hold temperature varies more than ±2°C as measured by

the system temperature sensor, the Red Alarm indicator and the word “TMP” on

the display will flash. Pressing Run/Stop or turning off the power switch cancels

the flashing warning.

Vacuum

Once the system vacuum is low and stabilized at a point where it changes less

than 0.020 mBar in 5 minutes, if the vacuum changes more than 0.500 mBar, the

Red Alarm indicator and the word “VAC” on the display will flash. Pressing

Run/Stop or turning off the power switch cancels the flashing warning.

Product Service 1-800-522-7658

Page 31

Chapter 4: Using Your Stoppering Tray Dryer

27

TEMPERATURE SENSOR X

CALIBRATION ERROR

System Temperature Set Point

If during a Ramp mode the system temperature stabilizes without reaching the set

point temperature, the control will enter the next Hold mode. The Red Alarm

indicator will flash and the program indicator “Px” on the display will flash.

Pressing Run/Stop or turning off the power switch cancels the flashing warning.

Power Failure

If a power failure occurs while a run is in progress, the Red Alarm indicator and

Run/Stop Indicator will flash when the power is restored. Once power is restored,

the process will continue as programmed until completion. Pressing Run/Stop or

turning off the power switch cancels the flashing warning.

Temperature Probe

When the power is turned on, the Stoppering Tray Dryer automatically checks the

calibration of all four temperature probes. If a probe is out of calibration, the

alarm LED will flash and the display will show:

Where X is:

S for the system probe

1 for sample probe 1

2 for sample probe 2

3 for sample probe 3

If this alarm occurs, the faulty probe must be replaced. If any of the sample

probes are faulty, it may be unplugged and the Stoppering Tray Dryer may be

used. The sample temperature display will show “- - - .” If the system probe is

faulty, it must be replaced before the Stoppering Tray Dryer can be used.

Product Service 1-800-522-7658

Page 32

28

C

C

HHAAPPTTEERR

5

5

M

M

AAIINNTTAAIINNIINNG

G

Y

Y

OOUURR

S

S

TTOOPPPPEERRIINNG

G

T

T

RRAAY

Y

D

D

RRYYEERR

Under normal operation, the Stoppering Tray Dryer requires little maintenance.

The following maintenance schedule is recommended:

As needed:

1. The user has the responsibility for carrying out appropriate decontamination if

2. Clean up all spills; remove liquids from the chamber.

3. Clean door and gasket using soft cloth, sponge or chamois and a mild, non-

4. Check oil level of the vacuum pump. It should be between MIN and MAX. If

5. If oil shows cloudiness, particles or discoloration, drain the pump and replace

6. Utilization of acids requires immediate cleaning and neutralization after

Monthly:

1. The rubber components on the Stoppering Tray Dryer may eventually

hazardous material is spilled on or inside the equipment. This may be done by

wiping the contaminated surfaces with a soft cloth dampened with alcohol.

Alcohol may craze the acrylic door. Before using any cleaning or

decontamination method except those recommended by Labconco, users

should check with Labconco that the proposed method will not damage the

equipment.

abrasive soap or detergent.

the oil level is less than an inch (25.4 mm) above MIN, add oil to proper level.

with fresh oil.

a run or physical damage will result.

deteriorate and require replacement. The effective life of rubber parts depends

upon both their usage and the surrounding environment. Check all rubber

hoses and gaskets and replace any that show signs of hardening, permanent set

or deterioration.

Product Service 1-800-522-7658

Page 33

Chapter 5: Maintaining Your Stoppering Tray Dryer

29

2. Using a soft cloth, sponge or chamois and a mild, non-abrasive soap or

detergent, clean the acrylic door.

3. Using a soft cloth, sponge, or chamois and a mild, non-abrasive soap or

detergent, clean the exterior surfaces of the unit. Liquid spray cleaners and

polishes may be used on the exterior surfaces. Do not use solvents to remove

stains from the exterior surfaces as they may damage the finish.

Annually:

1. Every 12 months, or more often if the Stoppering Tray Dryer is operated in a

dusty environment, the refrigeration system condenser should be cleaned.

Using a vacuum cleaner with brush attachment, clean the condenser to ensure

proper airflow for peak performance.

Decontamination

When freeze drying biological substances, it may be necessary to decontaminate

the system. A surface decontaminant should be used to clean the accessible

surfaces. The use of ethylene oxide is not recommended because of its hazardous

and corrosive nature. Contact Labconco for additional information.

Product Service 1-800-522-7658

Page 34

30

C

C

HHAAPPTTEERR

6

6

U

U

SSIINNGG

T

T

HHEE

R

R

S

S

2

2

3

3

2

2

R

R

EECCEEPPTTAACCLLE

E

The operation of the Stoppering Tray Dryer and the FreeZone Freeze Dry System

can be monitored using a computer when the Stoppering Tray Dryer is connected

to the RS232 receptacle on the rear panel of the Freeze Dry System base unit.

The computer cannot control the operation of the Freeze Dry System.

Computer Connection for Computer

Interface

Check your computer to see which type of serial port is provided, then use a

connecting cable below:

1. Computers with a 25-pin D-sub male serial connector should use Connect

Cable, Labconco part number 7537801, to connect a computer to the

Labconco Freeze Dry System.

2. Computers with a 9-pin D-sub male serial connector should use Connect

Cable, Labconco part number 7537800, to connect a computer to the

Labconco Freeze Dry System.

The purpose of the RS232 interface is to send data to a data logging computer to

monitor the state and activity of the Freeze Dry System This data is half duplex

data. The data properties are as follows:

1. Data Rate 2400 Baud

2. 8 Bit word length

3. 1 Start bit, 1 Stop bit

4. No parity is transmitted

5. Standard ASCII character set

Product Service 1-800-522-7658

Page 35

Chapter 6: Using The RS232 Receptacle

31

B

= Base Unit

T

= Collector Temperature

-48

= Collector Temperature in °Celsius

V

= Vacuum

18

=Vacuum Level in Micro Bars

SF

= Shell Freezer Temperature (if so equipped)

-41

= Shell Freezer Temperature in °C

C

=Vacuum Chamber Temperature (if so equipped)

9

=Feature not installed or out of range

PG

= Purge (if so equipped)

1

= ON

0

= OFF

TD

= Tray Dryer

PR

= Program

1

= Program 1 is selected

S

= Segment

3

= Segment 3 is operating

R

= Segment is in Ramp Mode

H

= Segment is in Hold Mode

TR

= Time Remaining of the current Hold Segment

5678

= Time Remaining in Hours

ST

= System Temperature

-40

= System Temperature in °C

P1

= Probe 1 Temperature

-39

= Probe 1 Temperature in °C

P2

= Probe 2 Temperature

999

= Probe not connected or temperature is out of range

P3

= Probe 3 Temperature

-37

= Probe 3 Temperature in °C

V

= Vacuum at Stoppering Tray Dryer

537

= Vacuum in Micro Bars

RS-232 TRANSMISSION RATE

10 SECONDS

B<T= -48 V= 18 SF = -41 C=999 PG=1 > TD<PR=1S=3R TR = 5678 ST= -40 P1 = -39 P2 = 999 P3 = -37 V = 0537>

The time between data transmissions may be varied by the user to occur at 10, 30,

60, 300 or 600 second intervals. Press the MENU button on the Freeze Dryer

base unit until the RS232 screen appears on the display.

Press select until the desired time interval is shown.

The format of the transmitted message with typical values is as follows:

Where:

Product Service 1-800-522-7658

Page 36

Chapter 6: Using The RS232 Receptacle

32

There are several commercially available software packages which can read

RS232 data and enter the data into a computer program such as a word processor

(to create a text file) or spreadsheet (to tabulate and plot the data). Consult your

laboratory supply dealer regarding the latest software available.

The following describes how to use an IBM compatible computer with Hyper

Terminal™ software (included with Windows® 95, 98, XP or 2000 operating

systems) to collect the RS232 data from your Freeze Dryer:

1. Make sure that the Freeze Dryer is properly connected to the communication

port on the computer.

2. Open Hyper Terminal™ software.

i)Windows® 95 or 98 use:

START/PROGRAMS/ACCESSORIES.

ii) Windows® 2000 or XP use:

START/PROGRAMS/ACCESSORIES/COMMUNICATIONS

The first time Hyper Terminal™ is opened a dialogue box requesting an area

code and phone number will appear. Enter the appropriate numbers and

continue.

3. The “Connection Description” dialogue box will open. Type in a user defined

name and select an icon for the new connection. Press “OK.”

Product Service 1-800-522-7658

Page 37

Chapter 6: Using The RS232 Receptacle

33

4. The “Connect To” dialogue box will open. Using the down arrow selection

button, select the communication port to which the cable has been connected.

Press “OK.”

5. The “Com X Properties” dialogue box will open. Enter the appropriate data

properties and press “OK.”

Product Service 1-800-522-7658

Page 38

Chapter 6: Using The RS232 Receptacle

34

6. When the Freeze Dryer main power switch is on, the data will be transmitted

and updated at the time intervals selected by the user.

Product Service 1-800-522-7658

Page 39

35

C

C

HHAAPPTTEERR

7

7

T

T

RROOUUBBLLEESSHHOOOOTTIINNG

G

Refer to the following if your Freeze Dry System fails to operate properly. If the

suggested corrective actions do not solve your problem, contact Labconco for

additional assistance.

FreeZone Freeze Dry Systems that are clean and dry and without samples

attached should reach a vacuum of 0.133 mBar within 30 minutes and should

achieve an ultimate vacuum of 0.040 mBar within 18 hours when the refrigeration

is operating. If the Freeze Dry System does not obtain a satisfactory vacuum,

perform the following maintenance tests.

Vacuum Pump

First make sure that the vacuum pump operates. If it fails to operate, check the

electrical connections of the Freeze Dry System to the power source and then

check the electrical connection of the vacuum pump to the Freeze Dry System. If

the vacuum pump has a power switch, make sure that it is turned on. If the

vacuum is not adequate when the vacuum pump is operating, proceed with the

following steps:

1. Check the oil and ensure it is clear and clean. If the oil looks cloudy or

has any particulates, replace the pump oil. Sometimes it may be necessary

to flush the pump with clean oil several times. To flush the pump, run the

pump 5 to 10 minutes to allow the oil to warm up. Drain the oil and refill

with clean oil. Repeat as necessary.

2. Check the oil level in the pump. Ensure it is filled to the correct level.

3. Check vacuum hose connections from the pump to the Freeze Dryer and

try running the unit.

Product Service 1-800-522-7658

Page 40

Chapter 7: Troubleshooting

36

If vacuum problems continue, consider obtaining a second vacuum gauge capable

of reading a vacuum of 0.010 mBar. It is often useful in determining if the

vacuum pump is operating properly and the vacuum sensor reading is accurate.

4. Isolate the pump by disconnecting the vacuum hose from the Freeze Dry

System. Deadhead the pump by inserting the vacuum sensor from a

secondary vacuum gauge into the end of the vacuum hose and observe the

vacuum reading obtained. Confirm that the pump is capable of achieving

an ultimate vacuum less than 0.010 mBar or approximately 10 microns. If

an inadequate vacuum reading is obtained, the pump has most likely failed

and may need to be replaced or rebuilt.

Gaskets, Tubing, Connections, Sample

Valves

1. Check all sample valves on the optional 6 port manifold shelf (if it is

installed) and ensure all valves are closed or in the vent position.

2. Check the drain line on the Freeze Dry System and ensure the drain plug is

installed and the tube appears to be in good condition.

3. Check all rubber vacuum tubing for signs of deterioration or cracking.

4. Check all connections and make sure they are secure and leak tight.

5. Check the Freeze Dry System collector lid gasket and the Stoppering Tray

Dryer door gasket for indentations, cracks or tears. Clean gaskets using a

soft, lint free cloth or paper towel.

6. The Stoppering Tray Dryer chamber and base unit collector chamber must

be dry.

7. When checking the sample valves, (if the system is so equipped), pull as

much vacuum as possible. If a vacuum indication is displayed, wiggle or

rotate the valves and watch the gauge for any fluctuations. Fluctuations

can indicate a potential vacuum leak. If the valve seems to be in good

condition, remove the valve and apply a thin coat of vacuum grease to the

stem and the outside sealing surface of the valve body, and reinstall the

valve. If the valve still seems to be the source of the problem, remove the

valve and stopper the hole with a rubber stopper. Continue checking the

other valves.

Product Service 1-800-522-7658

Page 41

Chapter 7: Troubleshooting

37

Knob & Stem

Assembly

Valve Body

Trim Ring

Manifold Assembly

The illustration below shows how the sample valve installs on a manifold.

System Components and Collection

Chamber Isolation

The following test allows you to check the pump and the connections from the

pump to the vacuum tube.

1. Place a rubber stopper in the vacuum port in the left side of the collector

chamber and another in the drain port in the bottom.

2. Restart the vacuum system and check your vacuum indication.

Insufficient vacuum indicates a bad pump or a leak in the connections

from the pump to the side of the chamber.

Product Service 1-800-522-7658

Page 42

Chapter 7: Troubleshooting

38

Areas for

Potential Leaks

Collector

Chamber

The following test is used to check the integrity at the Freeze Dry System

collection chamber. The figure below points out potential areas to locate a leak:

1. Remove the stopper from the side of the chamber and place a flat gasket

and a freeze dry flask over the connection port.

2. Fill the collection chamber with approximately 2 inches of water, enough

to cover all fittings. Replace the collection chamber lid and turn on the

vacuum pump. Allow the vacuum pump to run for approximately 5 to 10

seconds. (If the vacuum pump is left on, the water will begin to boil and

the test will not be effective). Look inside the chamber for any bubbling

while the pump is running and after you shut the pump off.

Product Service 1-800-522-7658

Page 43

Chapter 7: Troubleshooting

39

3. If bubbling is observed around the bulkhead fittings, access the bottom of

the chamber and remove the insulation. Tighten the appropriate fitting by

placing a wrench on the fitting inside the chamber and use a second

wrench to turn the nut on the bottom of the chamber. Be careful not to

damage the evaporator coils or the brazed joints to the refrigeration

system. Once the fitting is tightened, perform the test again. Should the

bubbling still be present, loosen the bulkhead fittings and apply vacuum

grease to the O-rings, then reassemble and test.

4. If bubbling was observed on the chamber surface, the chamber must be

replaced. This type of leak cannot be successfully repaired. The leading

cause of a chamber surface leak is corrosive residue left in the chamber

after use.

This test verifies that the vacuum leak is in the Stoppering Tray Dryer.

1. Remove the Stoppering Tray Dryer.

2. Position a flat gasket over the 3.0 inch diameter vacuum port and turn a

large freeze dry flask upside down to cover the connection port.

3. Start the freeze dryer and observe the vacuum indication. If the vacuum

indication is good, then the problem is in the Stoppering Tray Dryer and

you should proceed to Section IV, Stoppering Tray Dryer.

Product Service 1-800-522-7658

Page 44

Chapter 7: Troubleshooting

40

Stoppering Tray Dryer

Inspect the door and door gasket.

Inspect the coupling between the freeze dryer and the Stoppering Tray Dryer.

Remove the top left hand cover panel and inspect the valve and hose

connections to the chamber.

Remove the top right hand cover and inspect the electrical pass through and

gasket on the top of the chamber.

Refrigeration Module Operation

Under a no-load condition and depending on the ambient temperature, the

Stoppering Tray Dryer refrigeration system can achieve a system temperature of –

40°C or lower within 4 hours when the vacuum pump is running.

If any repairs are required on the refrigeration module, contact your local

laboratory supply dealer. If your laboratory supply dealer is unable to provide

assistance, please call Labconco. Repairs should only be undertaken by a

competent refrigeration technician or through an authorized Labconco service

agency.

Access to Mechanical Components

(1) To gain access to the refrigeration system, pump, tank, and the controller

and control panel components, it is necessary to remove the cover on the

left side.

(2) Remove the stainless steel front panel and control panel. Disconnect the

wires to the power switch. Remove the left cover.

(3) Additional access is available by removing the remaining screws, which

hold the rear panel in place, and lifting it off the unit.

Product Service 1-800-522-7658

Page 45

Chapter 7: Troubleshooting

41

Shelf and Stoppering System Removal

(1) The shelf and stoppering system may be removed from the chamber as an

assembly for repairs if needed.

(2) Remove the acrylic door by taking out the two hex socket head screws

located on the right hand end of the cross bar.

(3) Remove the door gasket. Carefully pull loose all of the plastic fasteners

(located around the periphery of the chamber) from the chamber. Leave

the spacer blocks behind the gasket attached to the gasket.

(4) Place a support in front of the chamber and slide the shelf and stoppering

system out approximately 2 inches.

(5) Loosen the clamp securing the stoppering diaphragm tube (located in the

lower center at the back of the chamber) and remove the tube. Slide the

assembly out of the chamber and onto the support.

(6) The assembly is now ready for repairs. Whenever possible, do not break

the fluid system.

(7) Reverse the removal procedures for installation of the shelf and stoppering

system. Make sure the fluid inlet and outlet tubes are routed on top of the

assembly.

Product Service 1-800-522-7658

Page 46

Chapter 7: Troubleshooting

42

Filling the Fluid System

1. Fluid Circulation Valve

2. Fluid Reservoir and Cap

3. Electrical Junction Block

4. Flexible Tubing

(1) Make sure the Power Switch is in the OFF position.

(2) Remove the left cover.

(3) Remove the insulation and both caps from the fluid circulation valve,

which is located directly behind the fluid reservoir (Item 1).

(4) Attach a flexible tube to the exposed port (service port). The port is 3/8" x

45° male flare (Item 4).