Laars Lite 2 LC, Lite 2 LC 125, Lite 2 LC 175, Lite 2 LC 250, Lite 2 LC 325 Installation And Operation Manual

...

Installation and Operation Data

FOR YOUR SAFETY - This product must be installed and serviced by a professional service technician, qualified in pool heater installation. Improper installation and/or operation could create carbon monoxide gas in flue gases which

could cause serious injury, property damage, or death. Improper installation and/

or operation will void the warranty.

Installation and

Operation Manual

Laars Lite 2

™

Model LC (Australia)

Pool and Spa Heater

Natural Gas

Propane (Outdoor Only)

WARNING: If these instructions are not followed exactly, a fire or explosion

may result, causing property damage, personal injury, or death.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity

of this or any other appliance.

Outdoor

Configuration

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified service technician.

H0216300B

WHAT TO DO IF YOU SMELL GAS

TABLE OF CONTENTS

SECTION 1.

General Information

1A. Introduction................................................... 1

1B. Description ................................................... 1

1C. Warranty....................................................... 1

SECTION 2.

Installation Instructions

2A. General Information ..................................... 1

2B. Outdoor Installation ..................................... 2

2B-1. Heater Clearance ......................................... 2

2C. Indoor Installation ......................................... 3

2C-1. Heater Clearance ......................................... 3

2C-2. Combustion and Ventilation Air Supply ........ 4

2D. Gas Supply and Piping ................................. 4

2E. Electric Wiring .............................................. 4

2E-1. Auxiliary Time Clock Wiring ......................... 4

2E-2. Remote Operation ........................................ 5

2F. Water Piping ................................................ 5

2G. Pressure Relief Valve................................... 6

2H. Pressure Switch............................................ 6

2J. Pressure Switch Adjustment......................... 6

2K. Automatic Chlorinators ................................. 6

2L. Temperature Rise ......................................... 7

SECTION 4.

Maintenance

4A. General ..................................................... 12

4B. Gas Pressure Tests................................... 12

4C. Electrical Troubleshooting......................... 13

4C-1. Control System Troubleshooting Sequence ... 13

4D. Gas Valve Replacement ........................... 20

4E. Gas Burner Removal ................................ 20

4E-1. Pilot Burner Removal ................................ 21

4F. Heat Exchanger Water Passages Inspection . 21

4G. Cleaning the Heat Exchanger ................... 22

4H. Automatic Flow Control Valve .................. 22

SECTION 5.

Assembly Instructions

5A. Reversible Water Connections ................. 23

SECTION 6.

LLC (Australia) Parts List

Exploded View of Heater...........................26

Parts List and Numbers.............................27

6A. Capacities and Dimensions....................... 28

SECTION 3.

Operating Instructions

3A. Start-Up Procedure ...................................... 8

3B. Temperature Controls .................................. 8

3C. Lighting and Shutdown ................................. 9

3C-1. Lighting the Heater ....................................... 9

3C-2. Filter Pump Operation .................................. 9

3C-3. Shutdown...................................................... 9

3D. Spring and Autumn Operation ...................... 9

3E. Winterizing ................................................. 10

3F. Water Chemistry ........................................ 10

3F-1. For Pool ...................................................... 10

3F-2. For Spa ....................................................... 10

3F-2a. Corrosion .................................................... 10

3F-2b. Testing........................................................ 10

3G. Therapeutic Spa Safety Rules.................... 11

3H. Swimming Pool Energy Saving Tips .......... 11

3J. Periodic Inspection ..................................... 12

Model LC (Australia) Pool and Spa Heater

Page 1

SECTION 1.

General Information

1A. Introduction

This manual provides information for the proper

installation, operation and maintenance of the Laars

Lite 2 Model LC (Australia) pool heater. The heater is

approved by the Australian Gas Association for use

with natural and propane gases. Installation should be

carried out in accordance with these instructions, the

gas authority and local government regulations.

The Installation, Operation, and Maintenance

manual must be followed exactly.

1B. Description

The Model LC (Australia) gets electrical power

from an external 240 volt (V) source. The Model LC

(Australia) provides a dual thermostat Flex-Temp

control system for pool/spa combinations or preheat

convenience. All Laars Lite 2 Model LC (Australia)

heaters meet stringent energy requirements such as

those instituted by the United States which require

intermittent ignition devices.

Waterpik Technologies designed this appliance to

heat only fresh water swimming pools and spas. Do

not use it as a heating boiler or general service water

heater. For special applications, consult your Australian Waterpik Technologies dealer.

Waterpik Technologies ships the heater with the

water connections on the right side. It could be necessary, or helpful, to switch the connections to the left

side to improve access for service. Instructions for

making this change can be found in Section 5. The

procedure should only be done by authorized personnel.

1C. Warranty

Waterpik Technologies sells the Laars Lite 2

Model LC (Australia) heater with a limited factory

warranty. A copy of the warranty is on the back cover

of this manual and is included in the plastic bag.

The home owner should fill out the warranty

registration card included in the plastic bag and return

it to the Australian distributor.

The warranty does not cover damage caused by

improper installation or field modification, or to the

heat exchanger by corrosive water. Section 3F explains

proper pool water chemistry.

SECTION 2.

Installation Instructions

WARNING

Improper installation or maintenance can

cause nausea or asphyxiation from carbon

monoxide and flue gases which could result in

severe injury or death.

2A. General

All gas-fired products require correct installation to

assure safe operation. The requirements for pool

heaters include the following:

1. Appropriate site location (clearances).

2. Noncombustible surface.

3. Sufficient combustion air and ventilation air.

4. Adequate venting (products of combustion).

5. Properly sized gas pipe.

6. Adequate water flow.

Install the heater at least 1.5 meters (m) from the

inside wall of the pool or spa unless it is separated

from the pool or spa by a solid fence, wall, or other

permanent barrier.

The Gas Installation Code AG601 offers general

guidelines for combustion air, ventilation air, and

flueing. Follow these guidelines to make sure the

installation is safe and efficient.

Pick a heater location that will supply enough air

for proper flue clearance, and allow space for maintenance access. Recommended clearances are specified

in Section 2B and 2C.

Locate the heater in an area where condensate

leakage from the heater or connections will not damage

the area around the appliance or the structure. If such a

location cannot be avoided, install a suitable drain pan

under the heater. This pan must not restrict air flow.

Install the heater on a noncombustible surface.

That means a surface made up of steel, iron, brick, tile,

concrete, slate, glass or plaster.

You can install the heater on a combustible floor

by putting a noncombustible base under the heater. Do

not install heater on carpeting. Combustible floor is a

floor made of, or surfaced with wood, compressed

paper, plant fibres or other materials that will ignite

and burn.

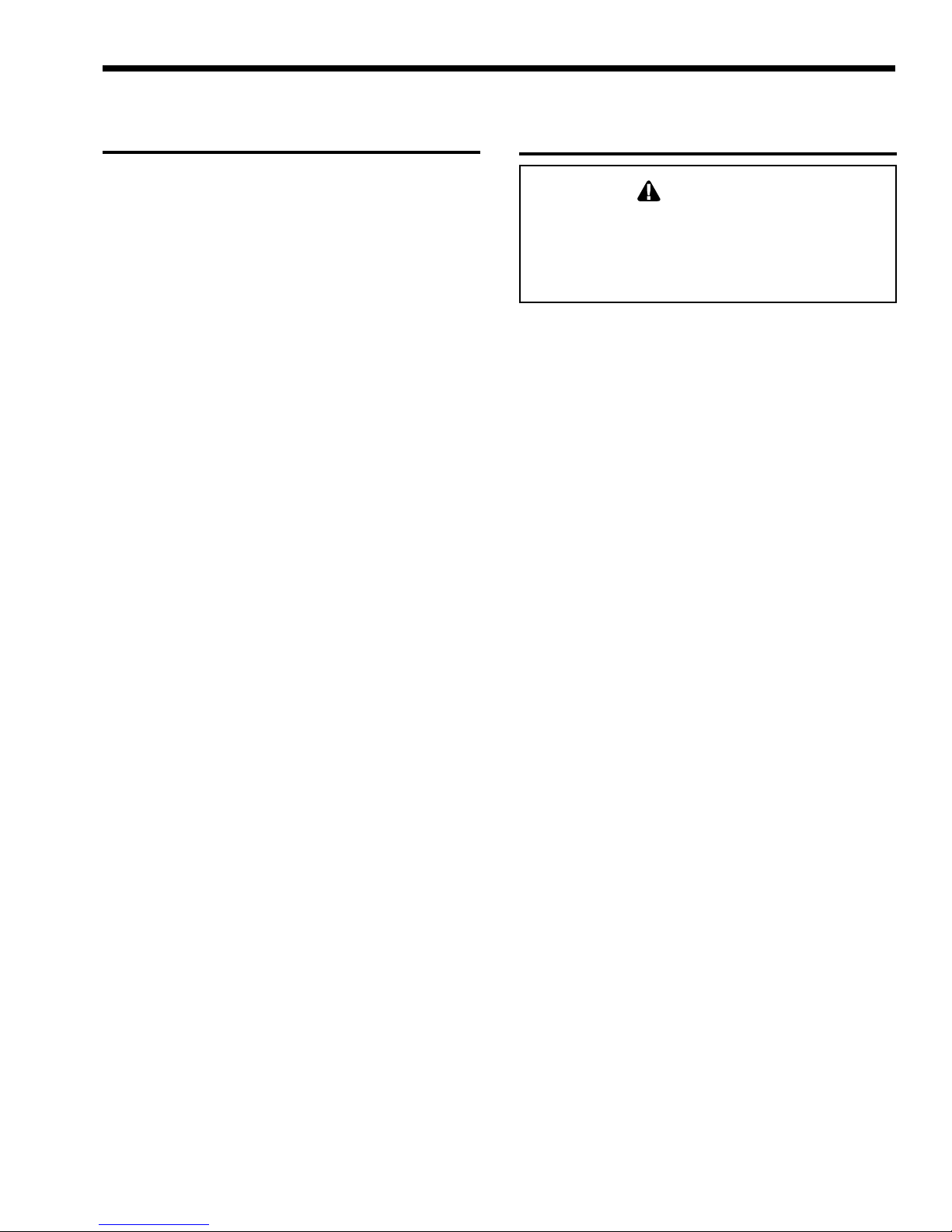

It is recommended that the noncombustible base

be a platform under the heater constructed of hollow

masonry no less than 100 millimeters (mm) thick,

covered with sheet metal at least 0.75 mm thick. The

masonry must be laid with ends unsealed, and joints

matched to provide a free circulation of air from side

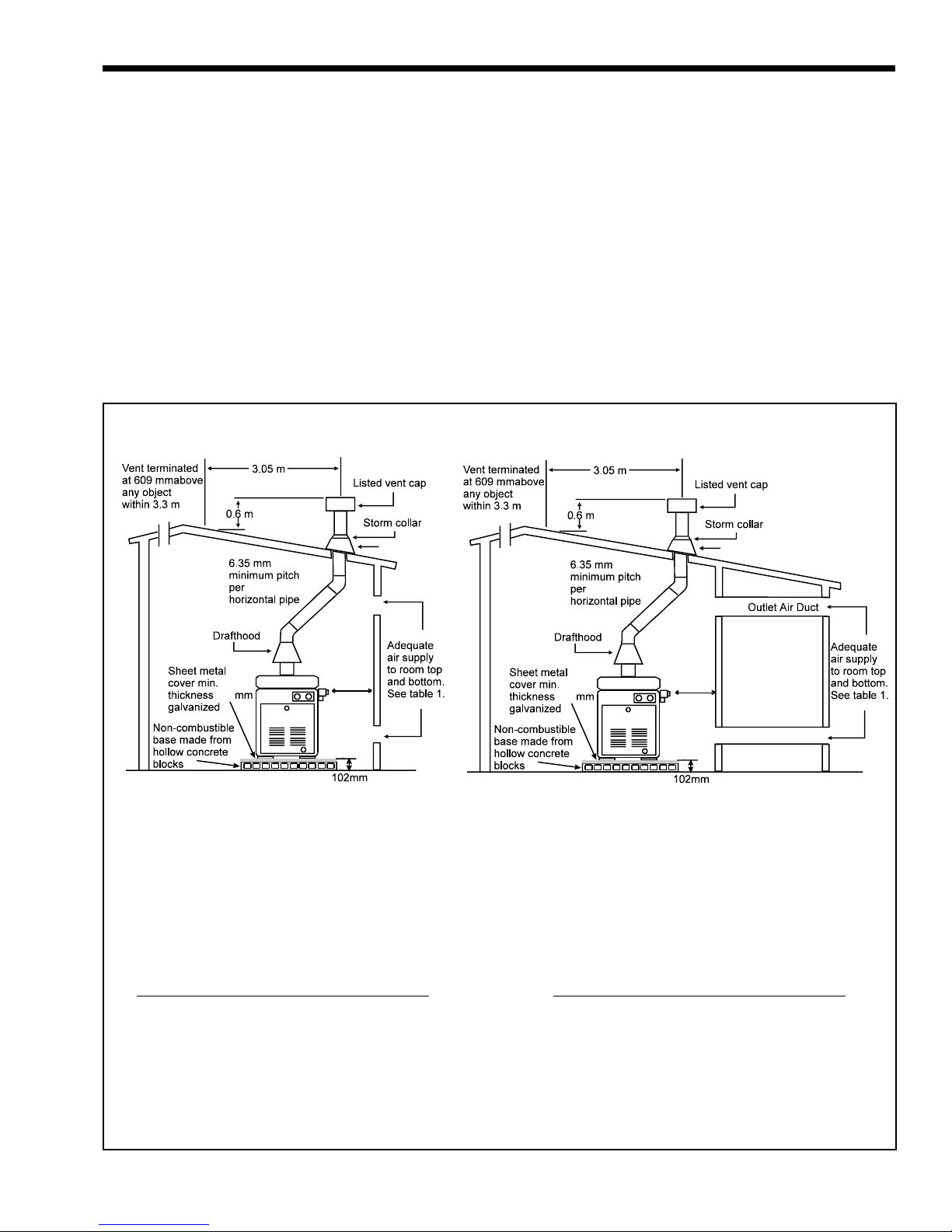

to side through the masonry (see Fig. 1).

Page 2

Safe operation at the proper gas manifold pressure requires correct sizing of supply gas pipe. The

Gas Installation Code AG601 also offers general

criteria for gas piping (see Section 2D).

If the above installation requirements are not

followed, the fuel used in these appliances could

produce and expose you to substances that are known

to cause cancer or reproductive harm.

Install the heater in accordance with all local

codes and ordinances and the most recent edition of the

Gas Installation Code AG601.

Do not operate this heater outdoors at temperature below -7°C.

WARNING

The heater must be tested to ensure

operation is satisfactory before the installer

leaves.

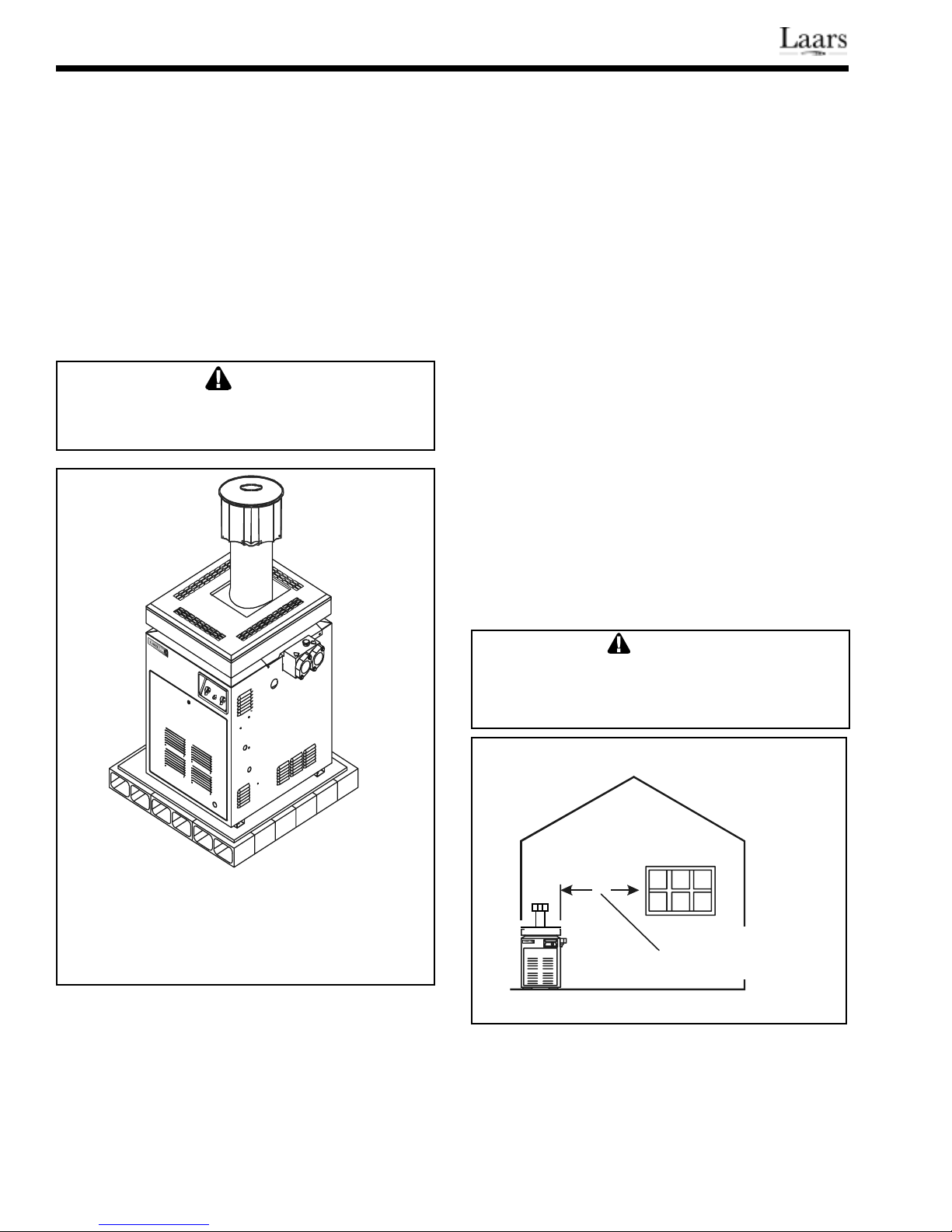

2B. Outdoor Installation

2B-1. Heater Clearance

Locate the heater in an open, unroofed area, (see

Fig. 2) and maintain the following clearances:

Blank side and 150 mm Minimum

rear of heater

Piping side 300 mm Minimum

Front of heater 450 mm Minimum

Floor Noncombustible*

*If you are installing the heater on a combustible

surface, use an approved noncombustible base.

Do not install the heater in a location where

leaves or other combustible materials can gather

around the base or on the top.

Do not locate the heater close to sprinklers; the

water could damage the controls and the electronics.

If you are installing the heater under an overhang,

there must be a minimum clearance of 1.5 meters

above the top of the heater. The area under the overhang must be open on three sides. Protect the heater

from direct water drainage.

Notes:

1. Blocks must provide solid base and be braced so they

cannot slip out of place.

2. Air openings in blocks must be arranged to provide

unrestricted opening through entire width or length of

base.

Figure 1. Non-Combustible Platform

Special Precautions for Propane Gas Heaters

Propane gas is heavier than air, so do not

install pool heater using propane gas in pits or other

locations where gas might collect. Locate the heater a

safe distance from propane gas storage and filling

equipment. Consult local codes and fire protection

authorities about specific installation restrictions.

WARNING

Minimum clearances between the heater and

any opening into the building must be

maintained.

Size 12 5-500 mm

All O ther Sizes - 1500 mm

Figure 2. Outdoor Heater Locations

IMPORTANT: High wind conditions may

cause downdrafting problems in the heater. To minimize downdrafting problems in high wind areas, locate

the heater at least 900 mm from vertical surfaces, such

as nearby buildings and walls.

Model LC (Australia) Pool and Spa Heater

Page 3

2C. Indoor Installation

The Laars Lite 2 Model LC (Australia) heater is

design-certified for indoor installation only when

equipped with a draft hood. Check the rating plate or

the parts list (Section 6) for the correct Laars draft

hood part numbers. Install the draft hood without

modification.

Connect the draft hood to a vent pipe which stops

at least 0.6 m above the highest point of the roof or

other object that is within 3 m of the flue. Install a

listed cap which allows a full equivalent opening for

flue products (see Fig. 3).

Roof jack

2C-1. Heater Clearance

Top of Heater 1.1 m Minimum

Blank side and 150 mm Minimum

rear of heater

Piping side 300 mm Minimum

Front of heater 450 mm Minimum

Floor Noncombustible*

*If you are installing the heater on a combustible

surface, an approved noncombustible base must be

installed.

Roof jack

305 mm of

0.75

NOTE:

1. The draft hood must sit directly on top of the heater as shown and must not be altered in any manner.

2. An approved flue cowl must be fitted.

3. Use approved roof fitting.

300 mm

Piping side

150 mm

Blank side

& Rear

Table 1. Direct Air Openings

Required Net Free Opening Area (cm2)

Directly from Outside

Model At Top At Bottom

125 393 393

175 552 552

250 789 789

325 1023 1023

400 1260 1260

305 mm of

0.75

300 mm

Piping side

150 mm

Blank side

& Rear

Table 2. Ducted Air Openings

Required Net Free Opening Area (cm2)

Ducted from Outside

Model At Top At Bottom

125 786 786

175 1104 1104

250 1578 1578

325 2046 2046

400 2520 2520

Figure 3. Indoor Installation Venting and Flueing

Page 4

2C-2. Combustion and Ventilation Air

Supply

All indoor installations must have openings to

outside air for combustion and ventilation. Tables 1

and 2 (see Fig. 3) show the net free opening areas

required at both ceiling and floor for the different

heater sizes. Waterpik Technologies does not recommend indoor installations that do not provide combustion air from outside the building.

NOTE: Check with louver manufacturers for Net

Free Area of louvers. Correct for screen resistance to

the Net Free Area if a screen is installed. Check all

local codes applicable to combustion air.

If the heater is installed in a residential garage,

the burners must be 450 mm above the garage floor.

See the Gas Installation Code AG601 for more information.

Warning

The conversion of this appliance from natural

gas to propane gas, or propane to natural,

must be done by an authorized person.

Waterpik Technologies provides kits and

detailed instructions for converting the heater.

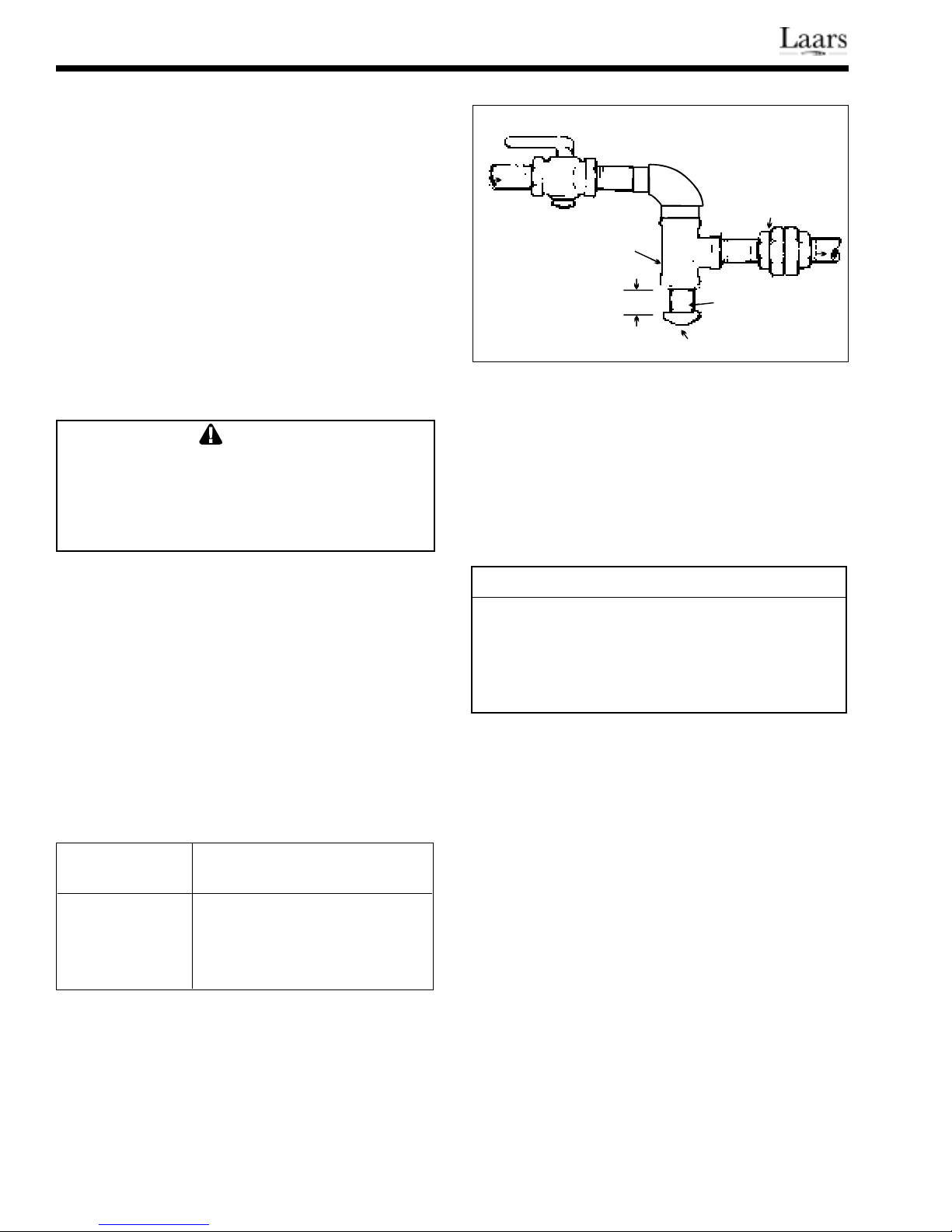

Manual Shutoff

Valve

Gas Supply

Inlet

T-Fitting

75 mm Min.

Cap

Figure 4. Proper Design For Sediment Trap / Drip Leg

Nipple

Union

To

Equipment

Inlet

testing if the test pressure is higher than 1/2 psig (3.7

kPa). If the test pressure is equal to or less than 1/2

psig (3.7 kPa), close the manual shut-off valve on the

heater during the piping pressure test.

If the supply gas pressure (Table 4) is less than

required, check for undersized pipe between the meter

and the heater, a restrictive fitting, or an undersized

gas meter.

Table 4. Supply Gas Pressure

2D. Gas Supply and Piping

Heaters shipped from the factory are certified to

operate at an altitude of zero to 600 m for natural gas,

to 1500 m for propane gas. The heater rating plate is

marked for use at specific altitudes.

If the supply gas pressure is less than required,

check for undersized pipe between the meter and the

heater, a restrictive fitting, or an undersized gas meter.

Waterpik Technologies recommends the gas inlet

pipe sizes in Table 3. Check local codes for compliance before installing the heater.

Table 3. Recommended Gas Inlet Pipe Sizes

Heater Distance from the meter

Size

125 20 mm 25 mm 32 mm

175 25 mm 32 mm 32 mm

250 & 325 32 mm 32 mm 40 mm

400 32 mm 40 mm 50 mm

NOTE: For propane gas, use one size smaller pipe except

on Model 125 which requires 20 mm from 0 to 15 m.

Install a union on the gas supply line outside the

heater jacket, including a drip leg and a manual shutoff valve (see Fig. 4). Do not use a restrictive gas cock.

Before operating the heater, test all gas connections for leaks with a soap solution. Do not use an

open flame. Disconnect the heater and its individual

shut-off valve from the gas piping during pressure

0 to 15 m 16 to 30 m 31 to 60 m

Minimum Maximum

Natural Gas 1.13 kPa 2.5 kPa

Propane Gas 2.50 kPa 3.5 kPa

NOTE: The minimum value listed for input adjustment.

Do not exceed the maximum supply pressure.

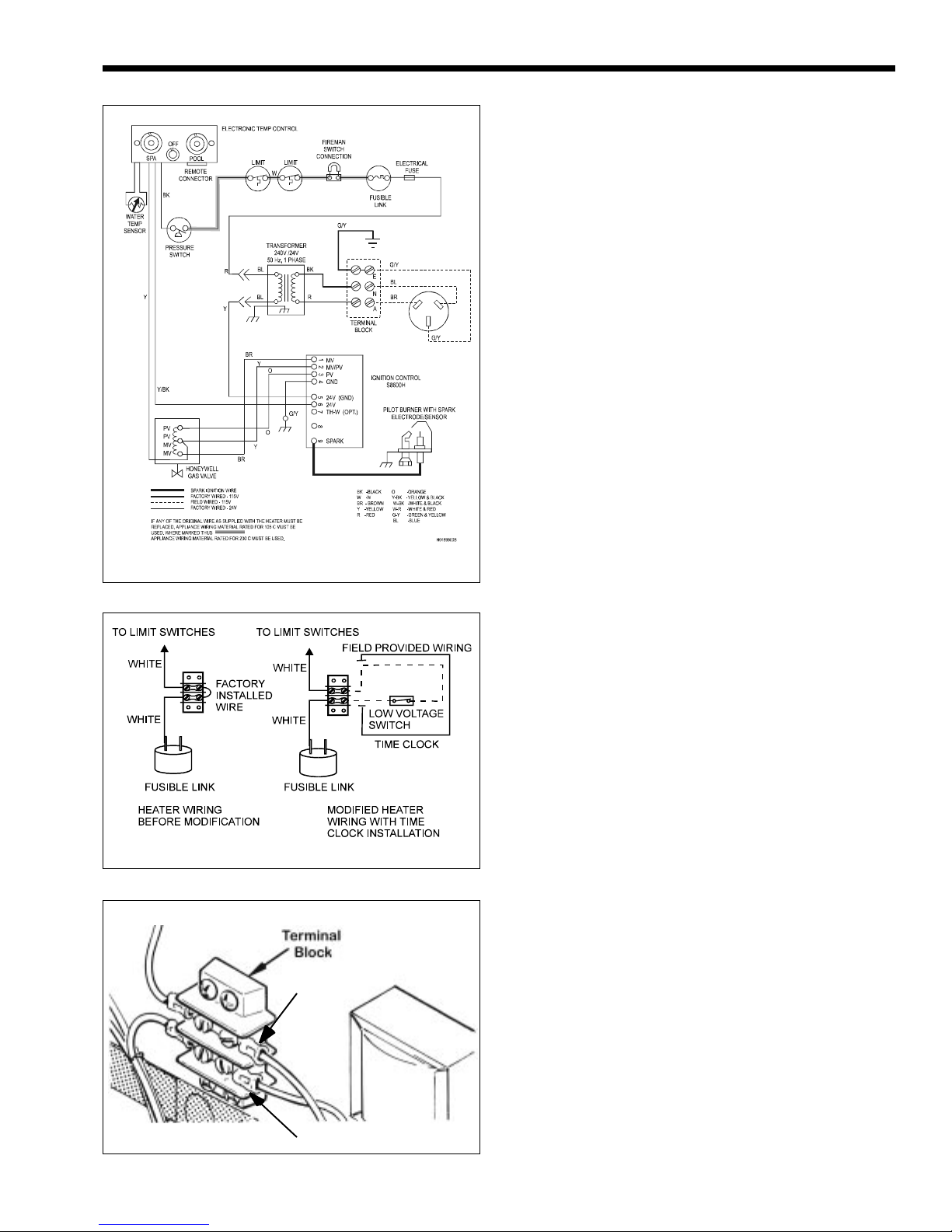

2E. Electric Wiring

The unit is fitted with a flexible electric cord and

3-pin plug for connection to a 240V 10 ampere (A)

power outlet. The power outlet must be effectively

earthed. See Figure 5 for the Model LC (Australia)

heater wiring.

NOTE: The pool heating system must have a manual

reset high limit installed in accordance with AS2610,

Section 2.7 (see Fig. 9). Contact a local installer or

distributor.

NOTE: No external junction box is required.

2E-1. Auxiliary Time Clock Wiring

If you install a time clock to control the filter

pump operation, the clock should have its own low

voltage (Fireman's) switch that turns off the heater

before turning off the pump. The switch should shut

off the heater about 15 minutes before the filter pump

shuts off.

Model LC (Australia) Pool and Spa Heater

Figure 5. LC Wiring Diagram

Page 5

To install a time clock switch into the heater

wiring, follow these steps (see Fig. 6):

1. Remove the heater door.

2. Remove the factory-installed wire between

terminals 1 and 2 on the terminal block (see Fig. 7).

3. Connect the wires from the time clock auxiliary switch to the two terminals. Use 14 gauge copper

wire with insulation at least 1.2 mm thick, and temperature rating of 221°F (105°C) or greater.

2E-2. Remote Operation

The Model LC (Australia) pool/spa heater

controls can be wired for remote operation. Two

Waterpik Technologies remote control models are

available through the local dealer or distributor. The

CS-07 remote control permits switching from one

temperature controller to the other and turning the

heater on and off from a remote location. The CS-08

includes the same features as the CS-07 plus a remote

temperature controller.

An interrupt (On-Off) type remote can be connected by removing the jumper wire on the terminal

block located in the control compartment (see Fig. 7)

and connecting the two wires from the remote to the

two terminals on the terminal block. This type of

remote control will turn the heater on or off, but will

not switch between the two temperature controllers on

the Flex-Temp control panel.

To connect a 3-wire remote (not supplied by

Waterpik Technologies), order a wire harness assembly (part No. E0120000) which connects to the FlexTemp control panel. Installation instructions are

included with the wire harness assembly.

Suggested Time Clocks: Intermatic or Paragon

Figure 6. Time Clock Wiring

Terminal 1

Terminal 2

Figure 7. Fireman's Switch Connection

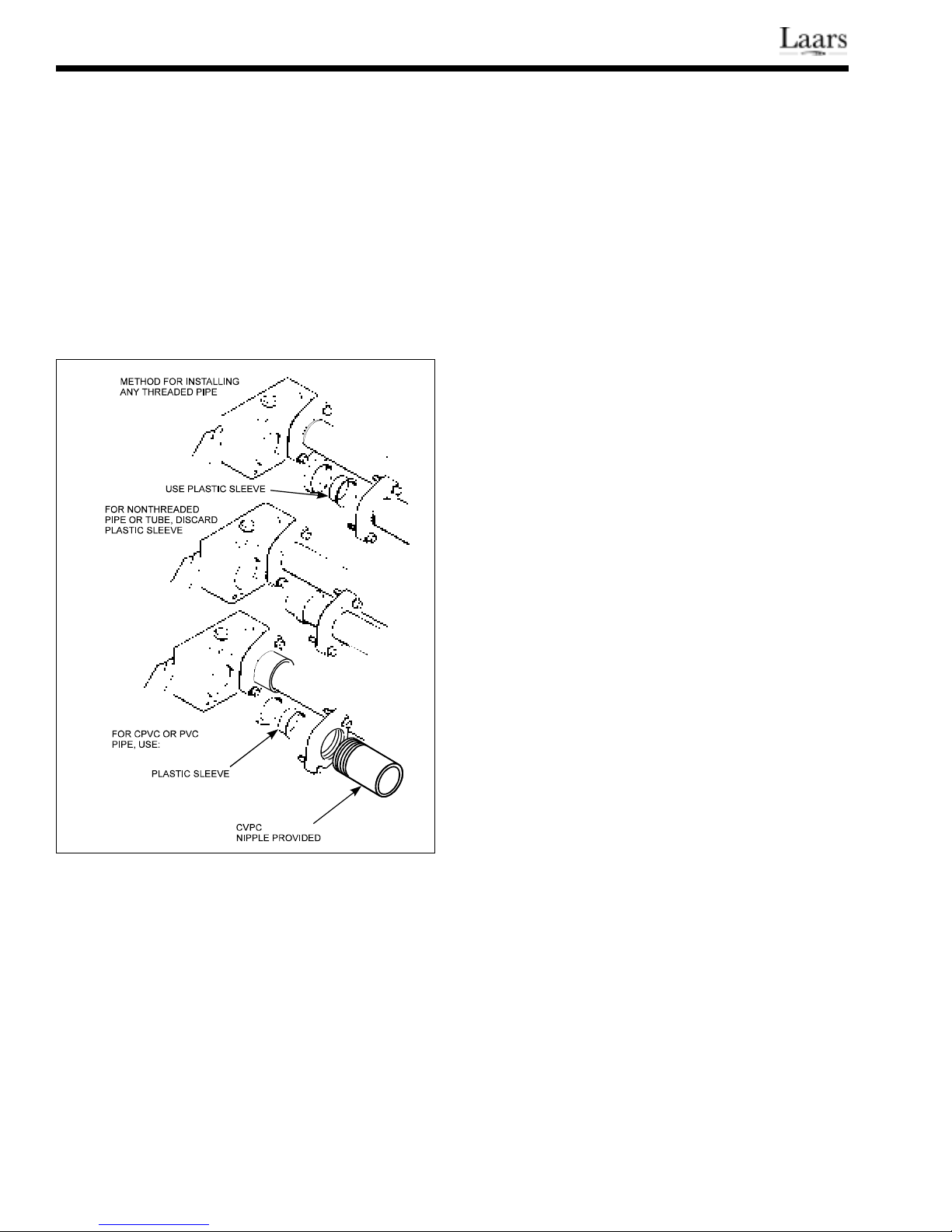

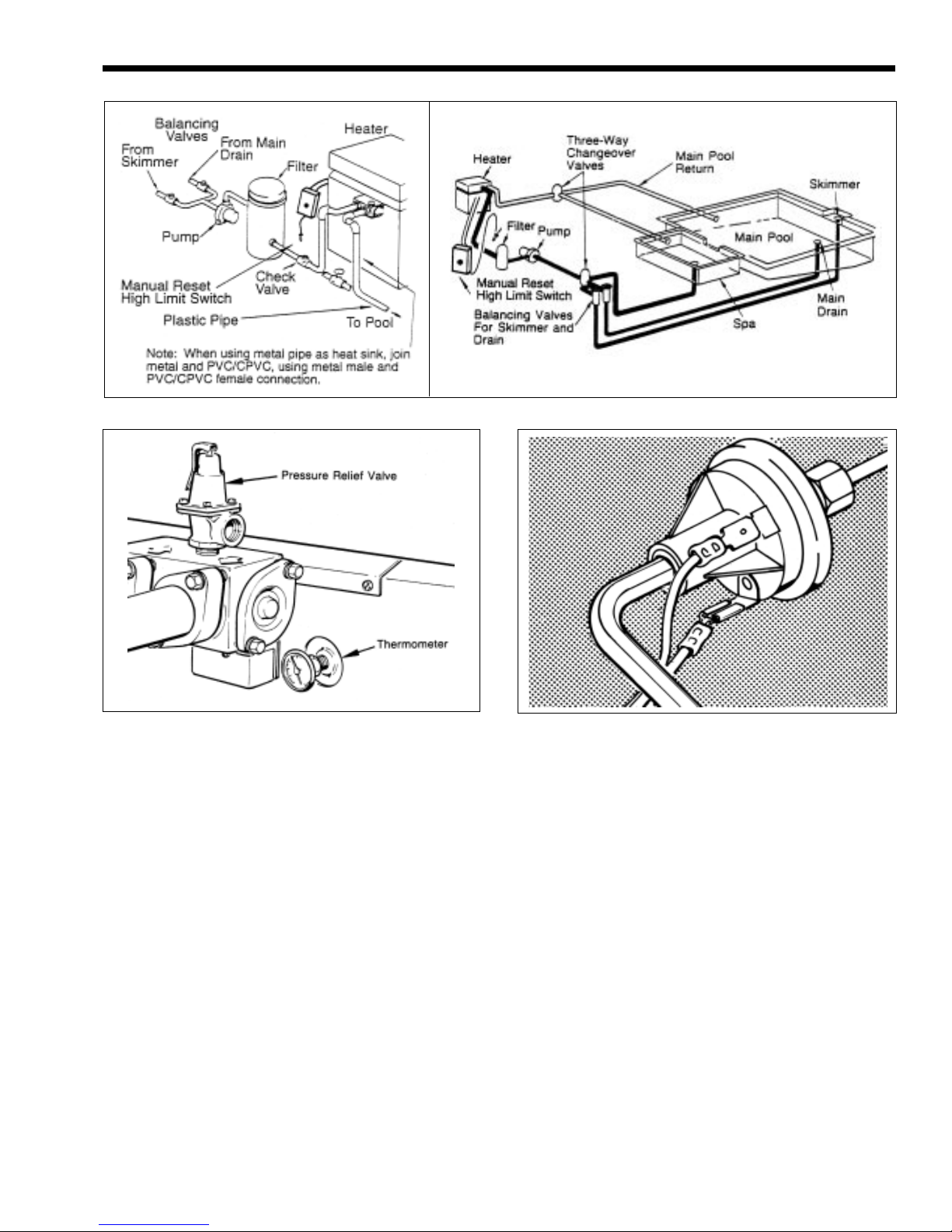

2F. Water Piping

The heater has 50 mm universal header

couplings. You can connect threaded 50 mm iron or

copper pipe, unthreaded 38 mm iron or copper pipe

using the special gaskets packaged with these

instructions, and CPVC pipe by first fitting the

CPVC nipples provided with the heater into the coupling

(see Fig. 8).

You can connect high-temperature plastic piping

(CPVC Schedule 80) to the inlet/outlet header if local

codes allow it, and the controls keep the filter pump

running at least 15 minutes after the heater is turned off.

NOTE: Do not use PVC plastic materials in pipes,

fittings, grids and other elements of the filter system

unless a metal "heat sink" pipe is used between the

filter and the heater (see Fig. 9).

NOTE: The pool heating system must have a

manual reset high limit installed in accordance with

AS2610, Section 2.7 (see Fig. 9). Contact a local

installer or distributor.

Page 6

Install a check valve if there is any chance of

"back-siphoning" when the pump stops. Do not install

any other valve or variable restriction in the piping

between the heater outlet and the pool, unless it is

being used as a diverter valve.

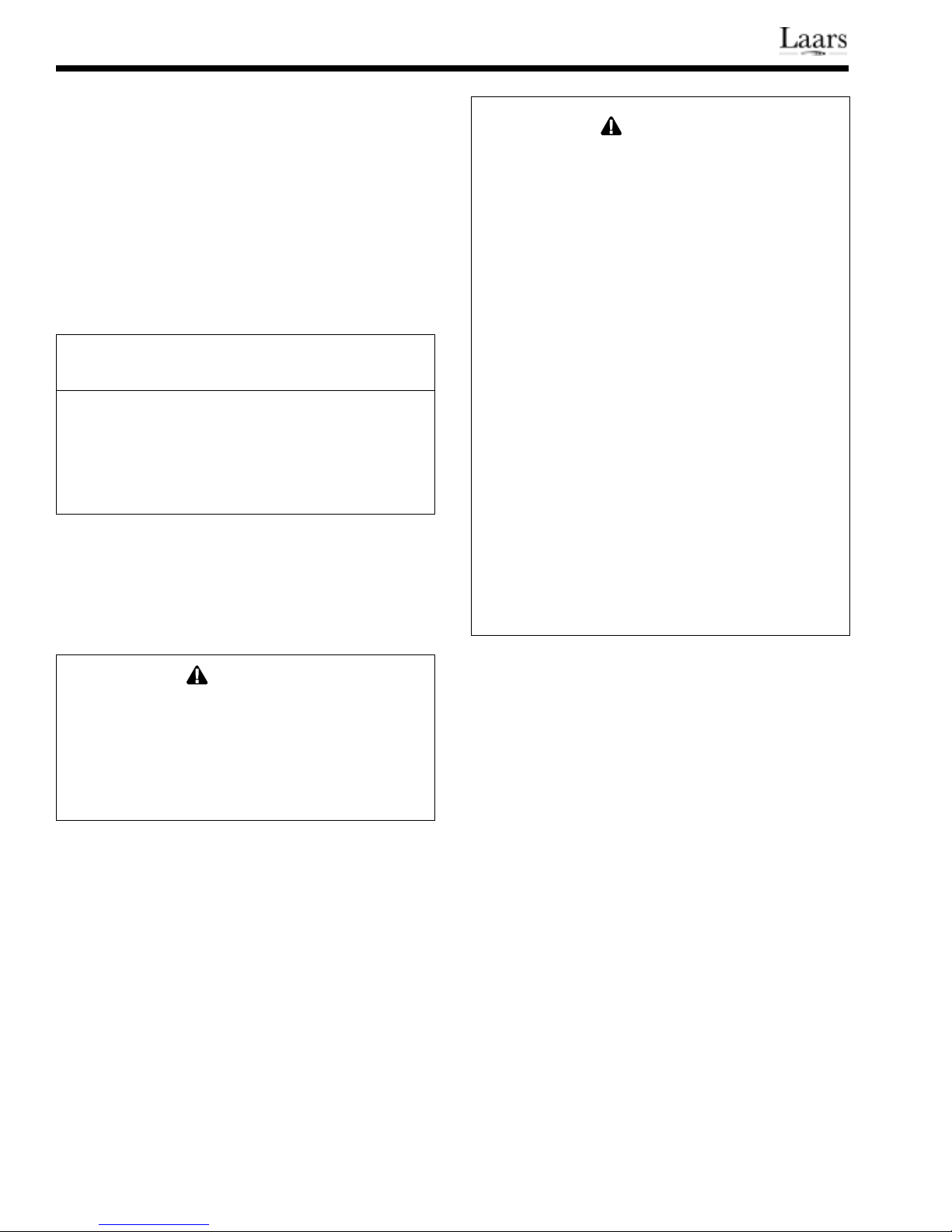

2G. Pressure Relief Valve

A pressure relief valve is not supplied with the

heater, but local plumbing codes may require it. To

install a pressure relief valve, replace the 3/4" brass

plug on top of the input/output header with the valve

(see Fig. 10). The valve setting should be at or below

the maximum working pressure of any component in

the filter system

NOTE: Do not make the pressure switch adjustment if

the heater is installed more than 4.6 m below or 1.8 m

above the pool surface. Consult Waterpik Technologies for recommendations.

On some installations, the piping from the heater

to the pool is very short. The back pressure could be

too low to trigger the pressure switch. If this happens,

it may be necessary to install a directional fitting, or

elbows where the return line enters the pool. This will

increase back pressure enough for the heater to operate

properly.

2J. Pressure Switch Adjustment

The pool filter must be clean before making this

adjustment. The heater does not have to be firing.

1. Turn the rotary switch to OFF, and make sure the

pressure switch is at its lowest setting. This is

done by rotating the adjuster counter clockwise as

far as it will go (see Fig. 11).

2. Start the filter pump and confirm by means of

hearing an audible click or with an ohmmeter that

the pressure switch closes. If the switch fails to

close, replace it with a switch that has a lower

minimum setting.

Figure 8. Piping Connections

2H. Pressure Switch

The pressure switch is preset at the factory for

normal pool installations. Do not adjust the pressure

switch unless any of the following conditions exist:

1. If the top of the heater is 900 mm or more below

the surface of the pool.

2. If any part of the filter system piping is 900 mm

or more above the top of the heater jacket.

If either of these conditions exist, follow the

instructions in Section 2J.

3. Turn the adjuster clockwise to open the contacts

(see Fig. 11).

4. With the pump still running, reduce the pressure

setting 7 to 14 kPa psi to reclose the contact.

5. Turn off the pump and make sure the pressure

switch contacts open. The contact must open

right away when the pump shuts off.

It may be necessary to repeat these steps to get a

proper setting. The switch must be set so that the

heater will not fire unless the pump is running. If a

proper setting cannot be reached, contact the factory

service department.

Elevated spas are a special problem if the water

surface is more than 2.4 m above the heater, because

the pressure switch has a limit of 35 kPa. A special

pressure switch is available from the factory for these

installation.

When the water surface is more than a few feet

below the heater, use a pressure switch with a minimum setting of 7 kPa.

2K. Automatic Chlorinators

(Chemical Feeders)

A high concentration of chlorine (or other chemi-

cal) in the pool heater can be very destructive. Heater

damage caused by chemical concentration is not

covered by the Waterpik Technologies warranty. See

Section 3F for recommended levels.

Model LC (Australia) Pool and Spa Heater

Figure 9. Typical Installation

Page 7

Figure 10. Thermometer and Pressure Relief Valve

IMPORTANT: Equip the chlorinator with an

antisiphoning device so that chlorine will not siphon

into the heater after the pump shuts off.

Wire the chlorinator so it cannot operate unless

the filter pump is running. If the chlorinator has an

independent clock control, be sure the filter and

chlorinator clocks are synchronized.

If the chlorinator is equipped with its own pump,

install it so that it introduces the chlorine downstream

from the heater, and, if possible, below the level of the

heater outlet fitting.

2L. Temperature Rise

When the installation is complete, the installer

should take a temperature rise. Use the figures in Table

5 to confirm proper water flow through the heater.

An automatic, built-in bypass valve maintains

proper flow through the heater at flow rates up to 475

liters per minute (L/min). If the system filter-flow rate

is higher than 475 L/min, install a manual bypass

valve. Figure 9 shows a valve installed between the

Figure 11. Pressure Switch Adjustment

heater inlet and outlet. To set the bypass valve, follow

this procedure.

1. Clean the pool filter if necessary.

2. With the filter pump off, remove the drain valve

located on the right side of the inlet/outlet header.

Install a 1/4 inch Pete's plug and thermometer

(see Fig. 10).

3. Close the manual bypass valve.

4. Turn off the heater by moving the rotary switch

to OFF.

5. Start the filter pump.

6. After 3 minutes, note and record the thermometer

reading (this is pool water temperature).

7. Follow the procedures on the Lighting and

Shutdown label located inside the control compartment to turn the heater on.

8. Let the heater run for at least five minutes before

noting and recording the new thermometer

reading. The difference between this reading and

the first one is the temperature rise.

Page 8

9. If the temperature rise is outside the MIN-MAX.

numbers in Table 5, gradually open the bypass

valve until there is an acceptable temperature

rise.

10. Be sure the thermometer reading stays the same

for at least 3 minutes.

11. Once the temperature rise is correct, wire the

bypass valve in place to prevent tampering.

Table 5. Temperature Rise and Minimum

Flow Rates

TEMPERATURE RISE,°C MIN. FLOW

SIZE MIN. MAX. L/MIN

125 15 20 76

175 19 24 76

250 19 24 95

325 16 21 114

400 17 22 114

SECTION 3.

Operating Instructions

LIGHTING AND SHUTDOWN INSTRUCTIONS ARE

ON THE LABEL ATTACHED INSIDE THE CONTROL

COMPARTMENT DOOR.

WARNING

PROPANE GAS: To avoid possible injury, fire

and explosion, read and follow these

precautions and all instructions on this

appliance before lighting the pilot. If this

appliance uses Propane gas which is heavier

than air, it will remain at ground level if there is

a leak. Before lighting, sniff at ground level. If

you smell gas, follow these rules:

1. DO NOT light matches. DO NOT turn

electric lights or switches on or off in

area. DO NOT use an electric fan to

remove the gas from area.

2. Shut off gas at propane tank.

3. Telephone gas company and fire

department for instructions. Give your

name, address and phone number.

If your propane tank runs out of fuel, turn off

gas at the appliance. After the tank is refilled,

the appliance must be relit according to the

instructions located on the inside of the door.

DO NOT attempt repairs on the gas control or

appliance. Tampering is dangerous and voids

all warranties.

WARNING

Flue pipes, draft hoods and heater tops get

hot! These surfaces can cause serious burns,

so do not touch these surfaces while the

heater is in operation. Adding a flue cap

reduces the temperature on the top.

3A. Start-Up Procedure

With any new pool or spa installation, operate the

filter pump with the heater off long enough to completely clean the water. This will remove any installation

residue from the water. Make sure the filter is clean

before starting the heater.

When raising the temperature of a cold pool,

remove all time clock settings. This lets the filter system

and heater operate continuously until the water reaches

the temperature setting on the thermostat. When that

happens, the heater will automatically shut off, but the

filter pump will keep running. Even though the heater

will be operating, the outlet piping will not feel hot to

the touch.

NOTE: Keep all objects off the top of the heater.

Blocking air flow could damage the heater and void the

warranty.

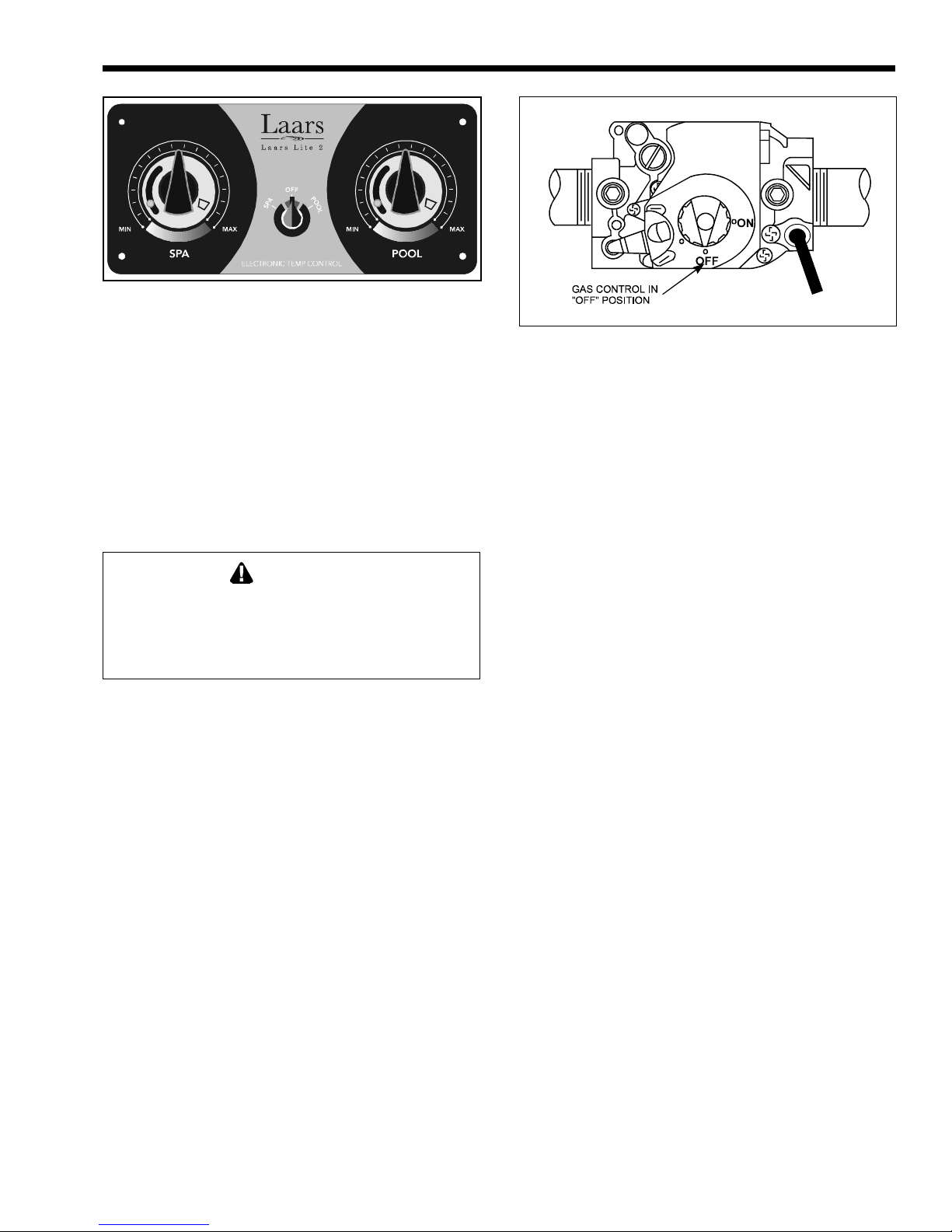

3B. Temperature Controls

The temperature controls on the Model LC

(Australia) are calibrated at the factory, and cover a

range from 21°C to 40°C. Always use an accurate pool

thermometer to verify the actual pool water temperature. Once the correct position for the control knob is

found, use the TEMP-LOK to keep it from going any

higher by putting the tab next to the knob, then tightening the screw.

The heater has dual temperature controls which

allows two different temperature settings selected by

the rotary switch in the middle of the panel. The owner

can set one control for normal use and the other for

standby, or one can be set for a pool and the other for

a spa. Positioning the rotary switch in the middle turns

off the heater (see Fig. 12).

IMPORTANT: The temperature controls cannot be

calibrated in the field. If the control is faulty, shut

down the heater and replace the control according to

the instructions in Section 4. DO NOT use the rotary

switch to completely shut down the heater. Shut down

the heater completely by removing the access door and

turning the main gas valve OFF.

Model LC (Australia) Pool and Spa Heater

C

Figure 12. LC (Australia) Temperature Controls

3C. Lighting and Shutdown

3C-1. Lighting the Heater

Full lighting and shutdown instructions can also

be found attached to the inside of the control compartment door.

To restart the heater in the Spring, have a professional service technician reassemble the heater as

follows:

WARNING

For your safety when starting the heater, keep

your head and face well away from the lower

firebox opening to prevent any risk of personal

injury.

Turn off all electrical power to the heater at the

main junction box. Open the control compartment door

and turn the gas valve OFF. Turn the rotary switch on

the temperature control panel OFF. WAIT FIVE

MINUTES BEFORE TRYING TO LIGHT THE

HEATER.

The LC (Australia) heater does not need manual

pilot lighting. It is done automatically by the ignition

control when the thermostat calls for heat.

1. Turn the gas valve control knob counter-

clockwise to ON (Fig. 13).

2. Replace the control compartment door.

Page 9

Figure 13. LC (Australia) Gas Valve

On propane heaters, if the pilot does not ignite

within 15 seconds, the system locks out and turns off

power to the whole system.

To check the lockout on the ignition control, turn

the gas valve knob OFF. Set the thermostat to call for

heat. Sparking occurs after a few seconds, but since

there is no supply gas, the pilot cannot light. Sparking

continues for about 15 seconds until lockout occurs

and the ignition control shuts down the system. To

reactivate the system, turn the thermostat to its lowest

setting, wait 10 seconds, then turn the thermostat to its

original setting.

1. Turn the gas valve knob to ON.

2. Replace the control compartment door.

3. Position the rotary switch to ON and follow

the lighting instructions above.

3C-2. Filter Pump Operation

The filter pump must continue running for at

least 15 minutes after the heater shuts off to prevent

damage to the system piping.

3C-3. Shutdown

For a complete shutdown, turn the switch on the

control panel to OFF, turn off all electrical power to

the heater at the main junction box, and set the thermostat to its lowest setting. Open the control compartment

door and turn the gas valve knob clockwise to OFF.

Turn any external gas valves OFF.

3. Turn on electrical power to the heater.

4. Turn on the filter pump.

5. Set the appropriate temperature control to the

desired setting, and turn the rotary switch to

that control. Until the water reaches a temperature of about 21°C, it is normal to have some

water accumulating in the base of the heater.

6. Set the time clock if one is installed.

3D. Spring and Autumn Operation

During periods of cold but not freezing weather,

turn the temperature control counterclockwise to the

MIN setting. This will prevent damage, yet still permit

bringing the pool water back up to the desired temperature in the least amount of time.

In areas subject to only short freeze periods, turn

off the heater and run the filter pump continuously for

the length of the cold period.

If the pool is not going to be heated for a long

period, shut the heater off (see Section 3C-3).

Loading...

Loading...