Page 1

NT 361 Eco M A / NT 611 Eco M A

www.karcher.com 5.960-422 A2006372 07/03

Page 2

NT 361 Eco M A / NT 611 Eco M A

Inhaltsverzeichnis DE Seite

Inbetriebnahme 5

Betriebsanleitung 7

Kärcher-Niederlassungen 121

Technische Daten / Schaltplan / Ersatzteilliste 122/123/124

Filtersysteme / Zubehör 126/127

Vor erster Inbetriebnahme Betriebsanleitung und Sicherheitshinweise Nr. 5.956-251

unbedingt lesen! Dieses Gerät ist für den gewerblichen Gebrauch geeignet, z.B. in

Hotels, Schulen, Krankenhäusern, Fabriken, Läden, Büros und Vermietergeschäften.

Lists of contents EN Page

Commissioning 5

Operating Instructions 16

Kärcher branches 121

Technical Data / Wiring diagram / Spare Parts List 122/123/124

Filter systems / Accessories 126/127

Prior to initial startup, operating manual and safety instructions

no. 5.956-251 must be consulted! This machine is suitable for industrial use, for

instance in hotels, schools, hospitals, factories, shops, offices and on hire.

Tables des matières FR Page

Mise en service 5

Notice d'utilisation 25

Filiales Kärcher 121

Caractéristiques techniques / Schéma de câblage /

Liste des pièces de rechange 122/123/124

Systèmes de filtres / Accessoires 126/127

Avant la première mise en service, lire absolument le mode d’emploi et les. 5.956-251

remarques de sécurité! Cet appareil est adapté à l'usage professionnel, p. ex. dans les

hôtels, les écoles, les hôpitaux, les usines, les magasins, les bureaux et les locations.

Indici IT Pagina

Messa in funzione 5

Istruzioni per l'uso 34

Filiali Kärcher 121

Dati tecnici / Schema elettrico / Elenco pezzi di ricambio 122/123/124

Sistemi del filtro / Accessori 126/127

Prima della prima messa in funzione leggere assolutamente le istruzioni per l’uso

e le avvertenze per la sicurezza n. 5.956-251! Questo apparecchio è adatto per settori

commerciali, per es. hotel, scuole, ospedali, fabbriche, negozi, uffici e noleggi.

Inhoudsopgave NL Pagina

Inbedrijfstelling 5

Gebruiksaanwijzing 43

Kärcher – filialen 121

Technische gegevens / Schakelschema / Reserveonderdelenlijst 122/123/124

Filtersystemen / Accessoires 126/127

Vóór de eerste ingebruikneming de gebruiksaanwijzing en de

veiligheidsinstructies nr.: 5.956-251 beslist lezen!

Dit apparaat is geschikt voor professioneel gebruik, bijv. in hotels,

scholen, ziekenhuizen, winkels, kantoren en verhuurbedrijven.

Índices ES Paginación

Puesta en servicio 5

Instrucciones de servicio 52

Filiales de Kärcher 121

Datos técnicos / Diagrama de conexiones / Lista de piezas de requesto 122/123/124

Sistemas de filtros / Accesorios 126/127

Las instrucciones de servicio y las indicaciones de seguridad núm. 5.956-251 se

deben leer imprescindiblemente antes de la primera puesta en servicio!

Este aparato es apropiado para el uso a escala industrial, p. ej. en hoteles, centros

escolares, hospitales, fábricas, tiendas comerciales, oficinas y empresas dedicadas al

alquiler.

2

Page 3

NT 361 Eco M A / NT 611 Eco M A

Índices PT Página

Colocação em funcionamento 5

Manual de instruções 61

Filiais da Kärcher 121

Dados técnicos / Esquema de ligações / Lista de pecas sobresselentes 122/123/124

Sistemas de Filtro / Acessórios 126/127

Antes da primeira colocação em funcionamento, ler atentamente. o manual de

instruções e as indicações de segurança nº5.956-251!

Este aparelho destina-se ao uso industrial, nomeadamente em hotéis, escolas,

hospitais, fábricas, lojas, escritórios e empresas de aluguer.

РЯнбкет ресйечпмЭнщн

РЯнбкет ресйечпмЭнщн EL

РЯнбкет ресйечпмЭнщнРЯнбкет ресйечпмЭнщн

ИЭуз уе лейфпхсгЯб 5

ПдзгЯет лейфпхс гЯбт 70

БнфйрспущреЯет Kärcher 121

ФечнйкЬ чбсбкфзсйуфйкЬ/Кхклщмбфйкь дйЬгсбммб/бнфбллбкфйкб 122/123/124

УхуфЮмбфб цЯлфсщн / еобсфЮмбфб 126/127

Рсйн брь фзн рсюфз иЭуз лейфпхсгЯбт дйбвЬуфе прщудЮрпфе

Рсйн брь фзн рсюфз иЭуз лейфпхсгЯбт дйбвЬуфе прщудЮрпфе

Рсйн брь фзн рсюфз иЭуз лейфпхсгЯбт дйбвЬуфе прщудЮрпфеРсйн брь фзн рсюфз иЭуз лейфпхсгЯбт дйбвЬуфе прщудЮрпфе

фйт ПдзгЯет чсЮузт кбй ХрпдеЯоейт буцЬлейбт. бс. 5.956-251 !

фйт ПдзгЯет чсЮузт кбй ХрпдеЯоейт буцЬлейбт. бс. 5.956-251 !

фйт ПдзгЯет чсЮузт кбй ХрпдеЯоейт буцЬлейбт. бс. 5.956-251 !фйт ПдзгЯет чсЮузт кбй ХрпдеЯоейт буцЬлейбт. бс. 5.956-251 !

БхфЮ з ухукехЮ еЯнбй кбфЬллзлз гйб фзн ербггелмбфйкЮ чсЮуз, р.ч. уе

БхфЮ з ухукехЮ еЯнбй кбфЬллзлз гйб фзн ербггелмбфйкЮ чсЮуз, р.ч. уе

БхфЮ з ухукехЮ еЯнбй кбфЬллзлз гйб фзн ербггелмбфйкЮ чсЮуз, р.ч. уеБхфЮ з ухукехЮ еЯнбй кбфЬллзлз гйб фзн ербггелмбфйкЮ чсЮуз, р.ч. уе

оенпдпчеЯб, учплеЯб, нпупкпмеЯб, есгпуфЬуйб, кбфбуфЮмбфб, гсбцеЯб кбй

оенпдпчеЯб, учплеЯб, нпупкпмеЯб, есгпуфЬуйб, кбфбуфЮмбфб, гсбцеЯб кбй

оенпдпчеЯб, учплеЯб, нпупкпмеЯб, есгпуфЬуйб, кбфбуфЮмбфб, гсбцеЯб кбйоенпдпчеЯб, учплеЯб, нпупкпмеЯб, есгпуфЬуйб, кбфбуфЮмбфб, гсбцеЯб кбй

ефбйсеЯет дбнейумпэ ухукехюн.

ефбйсеЯет дбнейумпэ ухукехюн.

ефбйсеЯет дбнейумпэ ухукехюн.ефбйсеЯет дбнейумпэ ухукехюн.

Indholdfortegnelser DA Side

Idrifttagning 5

Driftsvejledning 80

Kärcher agenturer 121

Tekniske data / Strømskema / Reservedelsliste 122/123/124

Filtersystemer / Tilbehør 126/127

Inden første idrifttagning skal driftsvejledningen og sikkerhedshenvisningerne

nr. 5.956-251 læses!

Dette apparat er beregnet til erhvervsmæssig brug, f.eks. i hoteller, skoler,

sygehuse, fabrikker, forretninger, kontorer og udlejningsforretninger.

EL уелЯдб

ELEL

уелЯдб

уелЯдбуелЯдб

Innholdsfortegnelser NO Side

Igangsetting 5

Bruksveiledning 88

Kärcher filialer 121

Tekniske data / Koplingsskjema / Reservedelsliste 122/123/124

Filtersystemer / Tilbehør 126/127

Før første gangs bruk må bruksanvisning og sikkerhetsanvisning

nr. 5.956-251 ubetinget leses!

Denne maskinen er egnet til bruk i næringslivet, f.eks. i hoteller, skoler,

sykehus, fabrikker, butikker, kontorer og utleiebutikker.

Innehållsförteckningar SV Sid

Idrifttagning 5

Driftinstruktion 96

Kärcher filialer 121

Tekniska data / Kopplingsschema / Reservdelslista 122/123/124

Filtersystem / Tillbehör 126/127

Läs noga instruktionsboken och säkerhetsanvisningarna

nr.: 5.956-251 innan aggregatet tas i bruk!

Denna apparat är lämplig för användning inom näringslivet, t.ex. hotell, skolor,

sjukhus, fabriker, butiker, kontor och uthyrningsaffärer.

Sisällysluettelo FI Sivu

Käyttöönotto 5

Käyttöohje 104

Kärcher-toimipisteet 121

Tekniset tiedot / Kytkentäkaavio / Varaosalista 122/123/124

Suodatinjärjestelmät / Lisävarusteet 126/127

Ennen ensimmäistä käyttöönottoa on käyttöohje ja

turvallisuusohjeet numero. 5.956-251 ehdottomasti luettava!

Tämä laite soveltuu ammattimaiseen käyttöön esim. hotelleissa, kouluissa,

sairaaloissa, tehtaissa, myymälätiloissa, toimistoissa ja vuokrausliikkeissä.

3

Page 4

NT 361 Eco M A / NT 611 Eco M A

Spis treści PL Strona

Uruchomienie 5

Instrukcja obsługi 112

Filie firmy Kärcher 121

Dane techniczne / Schemat ideowy / Lista części zamiennych 122/123/124

Systemy filtracyjne / Wyposażenie dodatkowe / 126/127

Przed pierwszym uruchomieniem należy koniecznie przeczytać.

Instrukcję obsługi i wskazówki dotyczące bezpieczeństwa nr 5.956-251!

do zasysania substancji płynnych.

Urządzenie to przeznaczone jest do użytku przemysłowego, np. w hotelach,

szkołach, szpitalach, fabrykach, sklepach, biurach i wypożyczalniach.

4

Page 5

NT 361 Eco M A

5

Page 6

NT 611 Eco M A

6

Page 7

Operating Instructions NT 361 Eco M A / NT 611 Eco M A English

Important

The unit is designed to extract dry,

non-inflammable, health

hazardous dusts at machines and

apparatus; dust classification "M"

according to

EN 60 335-2-69: 1999 annex AA.

"H2 suitable for extracting wood

dust to a residual dust efficiency of

2; 0,2 mg/m³ reliably maintained."

Warning:

— An adequate ventilation rate (L)

is required when the exhaust

air is pumped back into the

area. To enable maintaining the

required limit values the

permissible returned volume

flow is a maximum of 50% of

the fresh air volume flow (room

volume V

L

W

required: L

x ventilation rate

R

). No special ventilation

W

=1h

-1

— This device contains harmful

dust. Emptying and

maintenance operationss,

including disposal of the dust

collector, is permissible only by

skilled personnel wearing

appropriate safety clothing and

protection.

— Do not operate the device

without the entire filtration

system.

Operating instructions

The device has two operating

modes:

— Industrial vacuuming mode

(Socket not in use)

— Dust removal (Socket in use)

! Connect suction hose and,

depending on operating

method, fit vacuuming nozzle

or connect it to the dust-

producing unit.

Warning!

Do not operate the vacuuming

device without the filter element,

otherwise the vacuum motor will

be damaged. This will present a

health risk due to the increased

amount of fine dust expelled!

Horn

— The horn (2) sounds when the

paper filter bag ist full

Note:

— The horn (2) is activated if the

pressure decreases

! The scale (1) must therefore

be adjusted to the

corresponding cross-sectional

size of the vacuum hose.

Dry suction

Manual mode

Danger!

All dusts up to the M dust

classification can be vacuumed

with the unit.

Danger!

— The unit is designed as a

mobile industrial vacuum

cleaner for vacuuming and

dust-removing operations to

remove dry, non-inflammable,

MAC-value dusts.

— The device is fitted with a

gauge to indicate any variations

in the operating pressure and

includes a cleaning function.

This ensures that the air speed

inside the vacuum hose never

falls to below 20 m/s during the

vacuuming process.

— The flat folded filter and the

paper filter bag must never be

removed during vacuuming.

16

Page 8

Operating Instructions NT 361 Eco M A / NT 611 Eco M A English

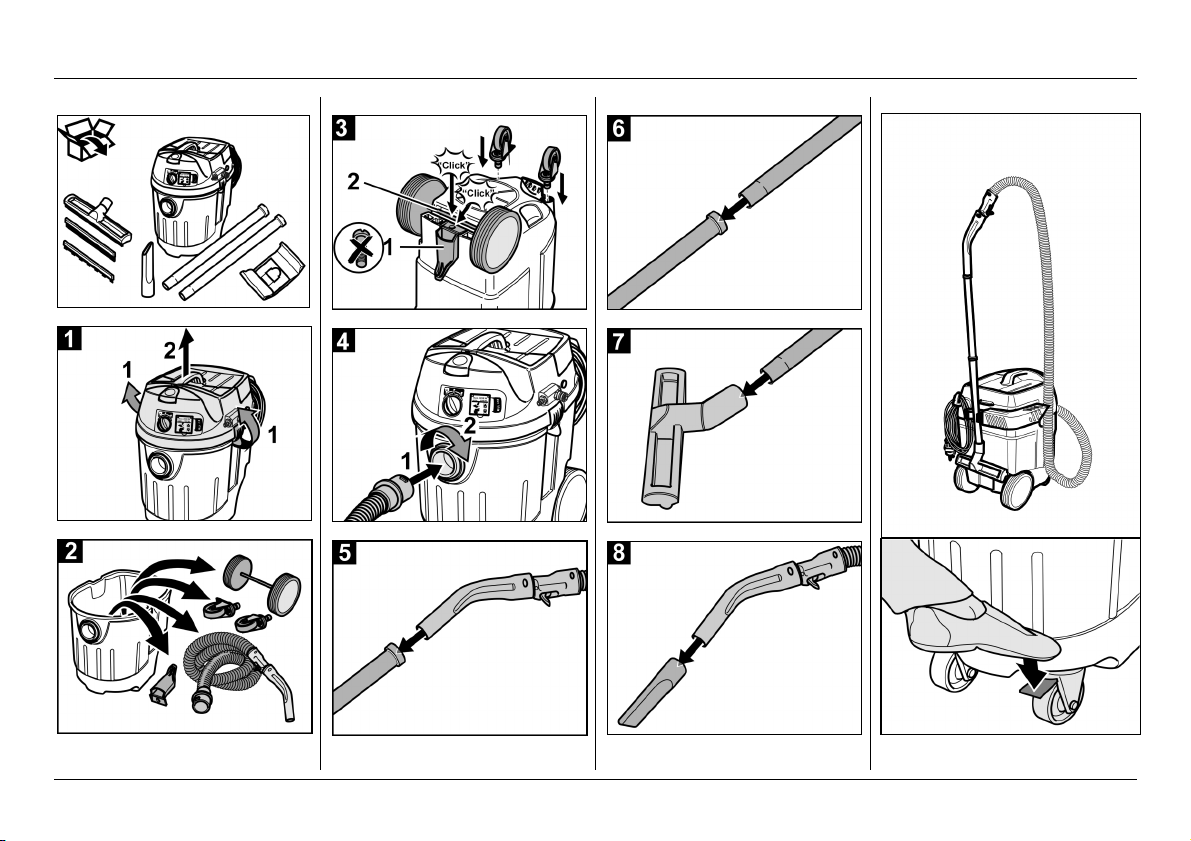

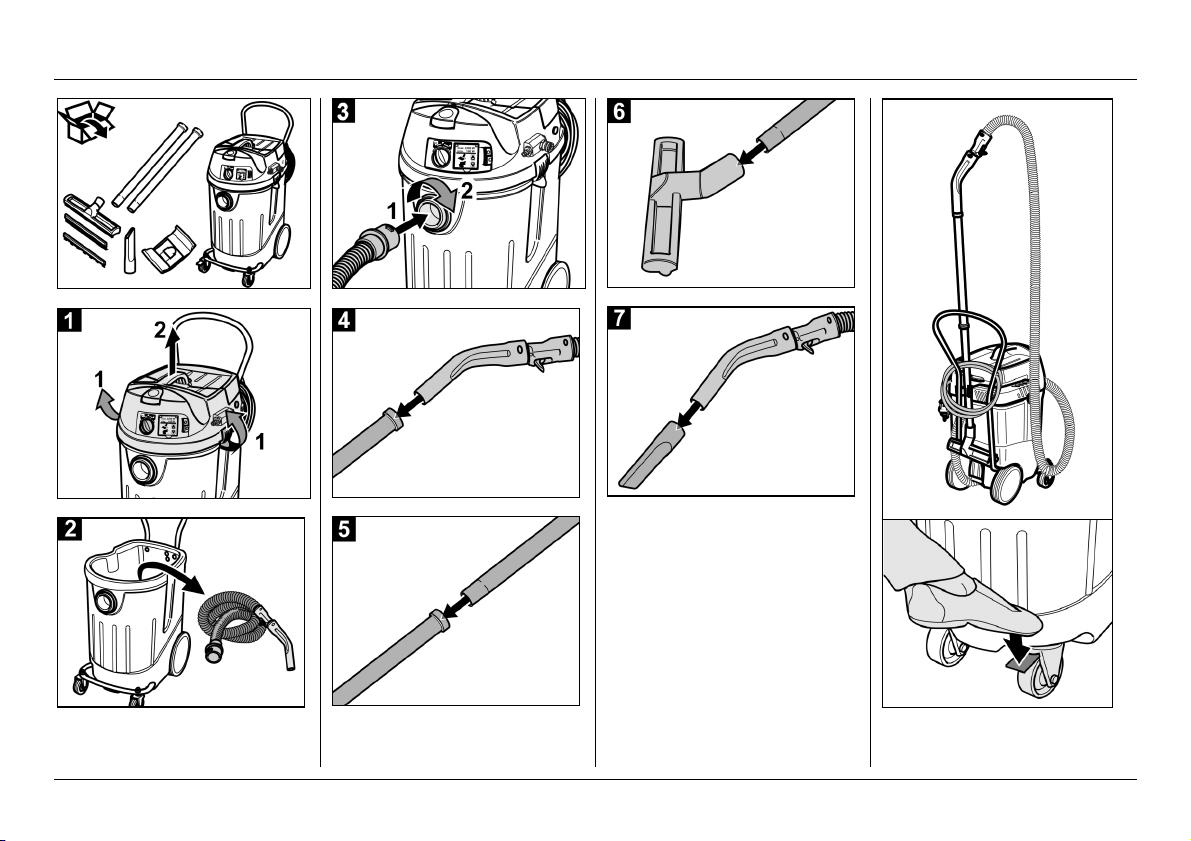

Fitting the paper filter bag

! Unlock and remove the suction

head

! Attach the paper filter bag

! Replace the suction head and

lock it in place

! Insert power plug

! Switch on the machine and

start using it

Automatic operation with

a pneumatic and/or a

power tool

! Switch unit to automatic

operation (3)

! Plug power tool’s power plug

into vacuum cleaner (4) or

connect pneumatic tool (2) and

open compressed air supply

! Switch on the machine (1)

Note:

— The vacuum cleaner is

automatically started and

stopped when the power toool

is turned on and off.

— The vacuum cleaner has a

starter delay of up to 0,5 s and

an after-running time of up to

15 s.

— See page – technical data - for

connected performance data of

the tools.

! Adapt the connection sleeve to

the electric tool's terminal

connection.

17

Page 9

Operating Instructions NT 361 Eco M A / NT 611 Eco M A English

! Remove the pipe bend from the

suction hose

! Install the connection sleeve to

the suction hose

! Connect connecting sleeve to

power tool

For pneumatic tool

! Connect air hose

Optional accessories for

connecting pneumatic

tools

Suction hose with integrated air

hose

2.860-197

Suction hose with an integrated

pneumatic hose especially for

Festo air tools

2.860-198

Warning!

Use hose 2.860-198 only if it is

attached to an air tool. Direct

vacuuming of dirt causes damage

to the hose.

Grinding accessory set

2.639-484

Grinding accessory set,

electically conducting

2.639-485

18

Page 10

Operating Instructions NT 361 Eco M A / NT 611 Eco M A English

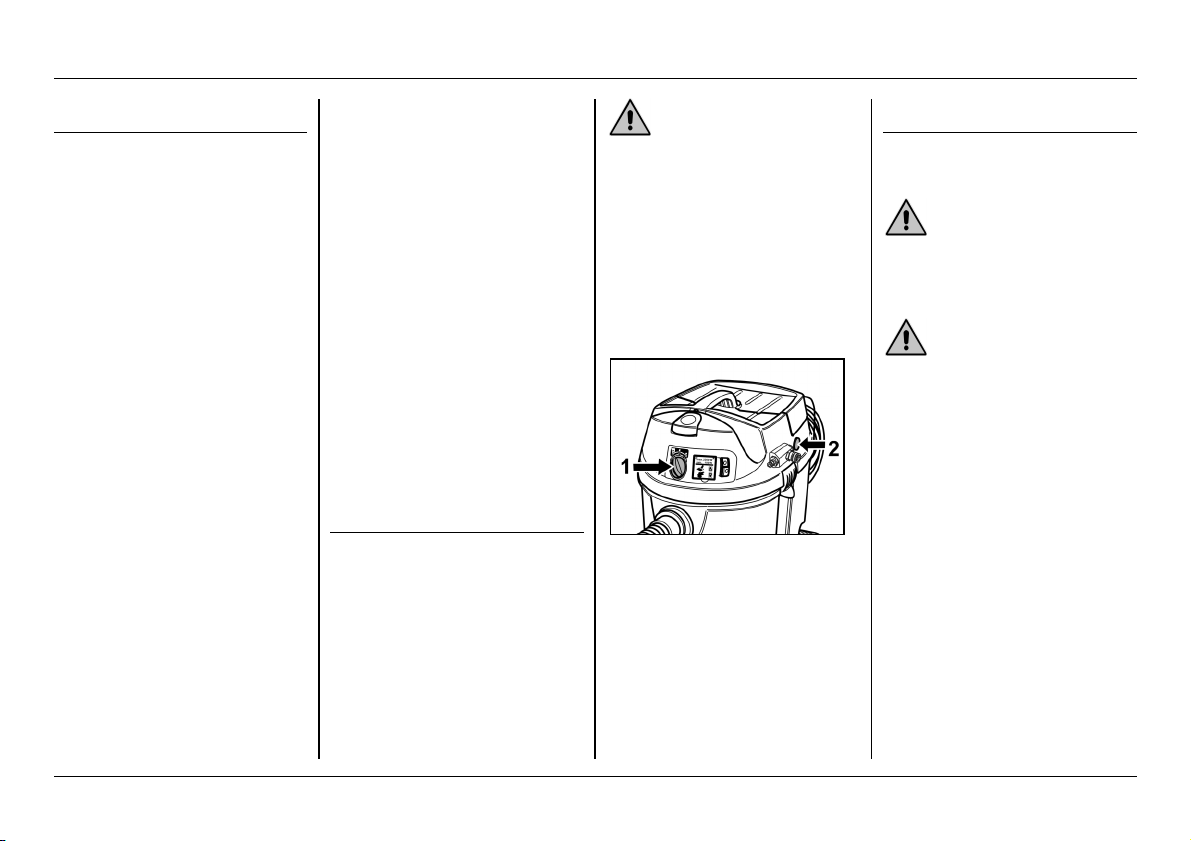

— The minimum volume flow is

adjusted using the rotary

switch (1).

— The vacuum hose cross-

sectional size is indicated on

the scales (2).

— Various vacuum hose cross-

sectional sizes are required for

use on different-sized

connection point cross sections

on the machinery.

Note:

— If the vacuuming device is

operated at different locations

(i.e. a machine is conected to

the suction point), the

integrated monitoring device

must be adjusted to the

connected (dust-producing)

machine. This means that the

user must be warned if the

minimum volume flow required

for vacuuming falls below

20 m/s.

— The specified minimum volume

flow in relation to the vacuum

can be found on the name

plate.

Filter de-duster

Power Filter Clean

Your vacuum cleaner is provided

with a new type of filter cleaner –

especially effective for fine dust.

The flat pleated filter is

automatically cleaned (pulsing

sound) by an air blast if you press

the remote control at the hand grip

for several seconds.

Switch Power Filter Clean on

Slide setting (1) - downwards

Warning!

Use the Power Filter Clean at

regular intervals both during and

after completion of the vacuuming

operation. The dust-producing

machine must be switched off

whilst the filter is being cleaned.

19

Page 11

Operating Instructions NT 361 Eco M A / NT 611 Eco M A English

Wet-vacuuming

Fitting rubber lips

! Fit the rubber lip seals

Note:

The profiled surface of the rubber

squeegees must be on the

outside.

! Remove the paper filter bag

! Insert power plug

! Switch on the machine and

start using it

! Drain dirty water using the

drain hose

(Applies only to

NT 611 Eco M A)

Warning!

— During vacuuming it is not

permitted to ever remove the

flat pleated filter.

— The paper filter bag and the

membrane filter (optional

accessories) respectively must

always be removed for

vacuuming wet dirt.

— When dielectric liquids are

vacuumed (for example. drilling

emulsions, oils and grease),

the device is not switched off

when the container is full. The

fill level must be regularly

checked and the container

emptied before it is too full.

Switch Power Filter Clean off

Setting of the slide (1) - upwards.

Note:

— It is advisable to switch off the -

Power Filter Clean – function

when vacuuming wet dirt with

the upholstery or the crevice

nozzles or mainly water out of a

container.

— The appliance turns itself

automatically off when the max.

liquid level has been reached.

— Switch the appliance off and

empty the container.

— Clean and dry the flat pleat

filter and the electrodes as well

as the container after finishing

wet vacuuming jobs.

20

Page 12

Operating Instructions NT 361 Eco M A / NT 611 Eco M A English

After completion of an

operation

! Empty dirt collector

! To clean the device, vacuum

and wipe the inside and outside

! Store unit in a dry room and

secure it against unauthorised

use

Care and maintenance

Danger!

Always pull out the mains plug

when working on the suction

machine.

Dust extracting machines are

safeguards for the prevention or

elimination of hazards as defined

in § 39 in the "General

Regulations" of BGV A1.

! For maintenance the user must

take the unit apart, clean and

service it, as far as this is

possible, without causing a

hazard to maintenance

personnel or third parties.

Appropriate precautionary

measures include

decontamination prior to taking

it apart. Take precautions to

provide local filtered forced

ventilation where the unit is

taken apart. Cleaning the

maintenance surface and the

provision of suitable protection

for personnel.

! The outside of the device

should be cleaned thoroughly

and any harmful substances

removed. Alternatively a sealed

coating can be applied before

the device is removed from the

danger area. It is important to

assume that all parts of the

device are contaminated when

the are removed from the

danger area.

! All articles soiled during

maintenance and repair work

that cannot be satisfactorily

cleaned must be thrown away.

These parts must be placed in

sealed bags and disposed of in

accordance with current

regulations relating to the

disposal of such waste

materials.

Danger!

Safety devices which are designed

to prevent or eliminate dangerous

situations must be serviced

regularly. This means that the

safety functions of the devices

must be subjected to a thorough

inspection, e.g. checking for leaks

and damage to the filter, and

testing the monitoring function.

This must be carried out by the

manufacturer or a trained person

at least once a year.

No outside help is required for

carrying out basic maintenance

and cleaning.

! The outer surface of the device

and the inside of the container

should be cleaned regularly

using a damp cloth.

Danger!

It is important to observe the

following instructions in order to

minimise health risks whilst

carrying out maintenance work.

A respiratory mask P2 or more

protection and also disposable

clothing must be worn when

carrying out maintenance work

e.g. changing the filter).

21

Page 13

Operating Instructions NT 361 Eco M A / NT 611 Eco M A English

Replace the flat pleat

filter

! Open the filter cover (1) and

remove the flat folded filter (2).

(See imprint on filter element

packaging)

! Dispose of the used filter

element in a dust-tight, sealed

bag in accordance with legal

stipulations.

! Remove any accumulations of

dirt on the clean-air side

! Replace the flat pleat filter

! Close filter cover, it must

audibly engage

— The vacuuming device is fitted

with a paper filter bag which

has a sliding seal.

NT 361 Eco M A

(manufacture no.: 6.904-210,

5 pieces)

NT 611 Eco M A

(manufacture no.: 6.904-208,

5 pieces)

! If the paper filter bag is full and

the volume flow falls below the

minumum level the bag must

be changed.

At the end of its service life the

device must be disposed of in

accordance with legal

stipulations.

Change the paper filter

bag

! Insert the connecting sleeve (1)

into the suction connector

ensurung that it fits tightly

! Slide in the connecting

sleeve (1) up to the contact

point

! Firmly close the suction

connection with the connecting

sleeve (1) by turning it

clockwise

Note:

A proper fit is ensured by the

"bayonet connection".

! Remove the paper filter bag by

pulling it towards the rear (1)

! Pull sliding cover (2) upwards

and tightly seal the paper filter

bag as it is removed. (See

imprint on filter element

packaging)

! Dispose of the used filter

element in a dust-tight, sealed

bag in accordance with legal

stipulations.

22

Page 14

Operating Instructions NT 361 Eco M A / NT 611 Eco M A English

Clean electrodes

! Unlock and remove the suction

head

! Clean electrodes

! Replace the suction head and

lock it in place

Fault instructions

If a fault occurs (e.g. a torn filter),

the device must be switched off

immediately.

The fault must be remedied before

restarting.

The suction turbine does not

run

! Check the cable, plug, fuse and

socket.

! Switch on the machine.

The suction turbine switches off

! Empty the container.

The suction turbine does not

restart following emptying of

the container

! Switch the appliance off and

wait for 5 s, switch it on again

after 5 s.

! Clean the electrodes as well as

the space between them.

The suction power decreases

— Remove the parts clogging up

the suction nozzle, the suction

tube, the Power Filter Clean

handle, the suction hose or the

flat pleat filter.

! Change the paper filter bag.

! Actuate the filter

cleaner: Power Filter Clean

several times at the handle.

! Engage the filter cover

properly.

! Replace the flat pleat filter.

Dust ejects when sucking

! Check the proper mounting

position of the flat pleat filter.

! Replace the flat pleat filter.

Automatic cut-out (wet suction)

defective

! Clean the electrodes as well as

the space between them.

! Constantly check fill level when

vacuuming electrically nonconductive liquids.

Power Filter Clean switches

regularly

! Detach blocked suction nozzle

or end of hose.

! Stop continuous vacuuming

from liquid-containing container

or switch off - Power Filter

Clean – function (see chapter

on wet vacuuming).

! Remove the parts clogging up

the suction nozzle, the suction

tube, the Power Filter Clean

handle, the suction hose or the

flat pleat filter.

! Replace the flat pleat filter.

23

Page 15

Operating Instructions NT 361 Eco M A / NT 611 Eco M A English

EC conformity

declaration

We hereby declare that the

machine specified below

as the marketed desigh, the

machine specified below

complies with the relevant

fundamental safety and health

requirements of the EC directives

listed below.

Modification of the machine

without our approval invalidates

this declaration.

Product: Wet/dry vacuum

Type: 1.145-xxx 1.146-xxx

1.184-xxx

Relevant EC directives

EC machine directive (98/37/EC)

EC low voltage directive

(73/23/EEC) amended by

93/68/EEC

EC directive on electromagnetic

compatability (89/336/EEC)

amended by 91/263/EEC,

92/31/EEC, 93/68/EEC

Applied harmonised standards

DIN EN 60335-1

DIN EN 60335-2-69

DIN EN 61000-3-2:2000

DIN EN 61000-3-3:1995 +

A1:2001

DIN EN 55014-2:1997

DIN EN 55014-1:2000 + A1:2001

Applied national standards

GS-HO-07

Internal measures ensure that the

in series produced units always

comply with the requirements of

current EC directives and applied

standards. The signatories act for

and in authority of management.

5.957-652 (02/02)

Alfred Kärcher Limited

Partnership.

Registered office: Winnenden.

Registration court: Waiblingen,

HRA 169.

Personally liable partner. Kärcher

Reinigungstechnik GmbH.

Registered office Winnenden,

2404 Waiblingen Company

Register, HRB

Managing directors:

Dr. Bernhard Graf,

Hartmut Jenner, Georg Metz

Alfred Kärcher GmbH & Co. KG

Cleaning Systems

Alfred-Kärcher-Strasse 28-40

P.O.Box 160

D-71349 Winnenden

Phone: ++49 7195 14-0

Fax :++49 7195 14-2212

24

Page 16

NT 361 Eco M A / NT 611 Eco M A

AT

Alfred Kärcher Ges. m.b.H.

Lichtblaustraße 7

A-1220 Wien

AU

Kärcher (Pty.) Ltd.

2/158 Browns Road

Noble Park 3174

Melbourne, Vict.

BE, LU, NL

Kärcher Benelux

Industrieweg 12

2320 Hoogstraden

BR

Kärcher Industria e Comércio Ltda.

Av. Prof. Benedicto Montenegro

Paulinia – Estado de Sao Paulo

CEP 13.140-000

CA

Kärcher Cleaning Systems Inc.

1770 Alstep Drive

Mississauga, Ontario L5S1W1

CH

Kärcher Variorapid AG

Industriestr. 16

CH - 8101 Dällikon

CZ

Kärcher spol. S. r. a.

Za Mototschnou

155 00 Praha – Stodůlky

DE

Alfred Kärcher GmbH & Co. KG

Vertrieb Deutschland

Friedrich - List - Straße 4

D - 71364 Winnenden

DK

Kärcher A/S

Gejihavegaard 5

DK – 6000 Kolding

ES

Kärcher S.A.

Pol. Industrial Font del Radium

Calle Doctor Trueta 6-7

n°419

E - 08400 Granollers (Barcelona)

FR

Kärcher S.A.

Z.A. des Petits Carreaux

5, avenue des Coquelicots

F - 94865 Bonneuil s. Marne/CEDEX

FI

Kärcher Oy

Yrittäjäntie 17

FIN - 01800 Klaukkala

GB

Kärcher (U.K.) Ltd.

Kärcher House

Beaumont Road

Banbury Oxon, OX 16 7TB

GR

Kärcher S.A.

Cleaning Systems

99 Aristoutelous & Ioanninon

GR - 136 71 Aharnes

HU

Kärcher Hungaria Kft.

H-2051 Biatorbagy (Vendelpark)

Tormasret ut 2

Tel.: +36/23530 Fax.: +36/23530-341

E-mail: info@kaercher.hu

HK

Kärcher Ltd.

Unit 10, 17/FL. APEC Piaza

49 Hoi Yuen Road

Kwun Tong, Kowloon

IT

Kärcher S.p.A.

Via Elvetia 4

I - 25050 Cantello (VA)

JP

Kärcher (Japan) Co., Ltd.

Irene Kärcher Building

No. 2, Matsusaka-Daira 3-chome

Taiwa-cho, Kurokawa-gun

Miyagi, 981-34, Japan

NO

Kärcher AS

PO Box 114 Grorud

N - 0905 Oslo

PT

Neoparts

Comercio e Indústria Autómovel, Lda

Largo Vitorino Damásio. 10

1200 Lisabon

PL

Kärcher Poland Ltd.

Sp. zo. o.

Ul. Godlewskiego 22

30-198 Kraków

SE

Kärcher AB

Box 24

S - 42502 Hisings - Kärra

USA

Alfred Kärcher Inc.

P.O. Box 6510

1600 Cottontail Lane

Somerset, NJ 08875

ZA

Kärcher (Pty.) Ltd.

P.O. Box 2417

Kempton Park 1620

121

Page 17

NT 361 Eco M A / NT 611 Eco M A

EUR: 230 V / 1~50-60 Hz

7,5 m

H07RN-F3 x 1,5 mm²

EUR: 6.648-584

68 dB(A)

P max: 1380 W

P nenn: 1200 W

1.184-xxx 34 l

1.146-xxx 55 l

1.184-xxx 20 l

1.146-xxx 44 l

1.184-xxx 125 m³/h

1.146-xxx 125 m³/h

1.184-xxx max. 210 mbar

1.146-xxx max. 210 mbar

1.184-xxx:

510 mm x 430 mm x 535 mm

1.146-xxx:

570 mm x 370 mm x 860 mm

1.184-xxx 10,5 kg

1.146-xxx 15,0 kg

P: 100-2200 W

min. 4 bar

max. 6 bar

min. 200 l/min.

0,5 m²

-10 °C - +40 °C

Umgebungstemperatur, Ambient

temperature, Température ambiante,

Temperatura del entorno

30 % - 90 %

rel. Luftfeuchtigkeit, rel, humidity,

humidité relative, rel. Humedad del

aire

Typenschild,Type plate

Plaque signalétique, Placa de tipo

A: Seriennummer, Serial number,

Numéro de série, Número de serie

B: Baujahr, Year of construction,

Année de construction, Año de

la construcción

122

Page 18

NT 361 Eco M A / NT 611 Eco M A

100/120 V 1~50/60 Hz

230/240 V 1~50/60 Hz

B1 Elektroden

Electrodes

Electrodes

C1 Entstörkondensator

Suppression Capacitor

Condensateur Antiparasites

H2 Summer

Buzzer

Vibreur Sonde

M1 Saugturbine

Suction Turbine

Turbine d’aspiration

N1 Platine

Circuit Board

Platine

N2 Platine M oder H Sauger

Circuit M or H suction apparatus

Platine M ou H aspirateur

S1 Schalter Turbine

Switch Suction Turbine

Interrupteur de Turbine

S2 Umschalter Betriebsart

Switch

Inverseur

X1 Stecker

Plug

Fiche

X2 Steckkupplung

X7 Plug-In Coupling

Raccord Prise

X6 Steckdose

Socket

Prise de Courant

*S3 Reedschalter

Reed switch

Reed Interrupteur

123

Page 19

NT 361 Eco M A / NT 611 Eco M A

124

Page 20

NT 361 Eco M A / NT 611 Eco M A

125

Page 21

NT 361 Eco M A / NT 611 Eco M A

* BIA C geprüft;

Rückhaltevermögen

* BIA C approved; Retention

Contrôle BIA C; Conservation

≥

99,9 %

Flachfaltenfilter *

Flat pleated filter *

Filtre plat à plis *

Papierfiltertüte 2-lagig *

Paper filter bag

double layered *

Sachet filtre à 2 épaisseurs *

Membranfilter

Diaphragm filter

Filtre à membrane

Spezialfiltertüte / nass

Special filter bag / wet

Sachet filtre spécial / mouillé

Flachfaltenfilter * (PES)

Flat pleated filter * (PES)

Filtre plat à plis * (PES)

≥

99,9 %

Bestell-Nr.

Order No.

Numéro de référence

99,9 %*

NT 361 Eco/TE

NT 361 Eco M

NT 361 Eco M A

NT 361 Eco TEA

≥

6.904-206

6.904-210

6.904-212

6.904-171

6.904-190

NT 561 Eco/TE

NT 561 Eco M

NT 611 Eco/TE

NT 611 Eco M A

NT 611 Eco TEA

6.904-206 1 X X X

6.904-208 5 X X

6.904-212 1 X X X

6.904-211 5 X X

6.904-190 1 X

Menge

Quantity

Quantité

Normalstäube

Normal dust

Poussières normales

Feinstäube

Fine dust

Poussières fines

Abrasive Stäube

Abrasive dust

Poussières

abrasives

Flüssigkeiten /

nasser Schmutz

Liquids / wet dirt

Liquides / saletès

humides

126

Page 22

Zubehör /Accessories/Accessoires NT 361 Eco M A / NT 611 Eco M A

4.440-626

4.440-653

4.440-627

4.440-654

4.440-420

4.440-478

6.906-208

6.906-241

6.906-242

6.906-237

6.906-277

2.639-483

2.639-484

2.639-485

5.453-042

5.453-052

5.031-718

5.031-939

6.900-514

Ø

[m m ]

CDN 35

CDN 35 EL

CDN 35

CDN 35 EL

C 35

C 35 EL

C 35

C 35

C 35

C 35

C 35 EL

DN 35

DN 35/27

DN 35/27 EL

C 35 EL

C 35 EL

DN 35

DN 35 EL

DN 35

2,5

2,5

2,5

2,5

2,5

4,0

10,0

0,45

3,5

3,5

0,5

[m ]

[m m ]

6.905-875

6.903-037

6.900-231

6.900-109

6.906-387

6.905-531

6.900-385

6.902-104

6.900-697

6.900-425

EL = elektrisch leitend

electrical conductive

conducteur électrique

Ø

[m m ]

DN 35

DN 35

DN 35

DN 35

DN 35

DN 35

DN 35

DN 35

DN 35

DN 35

C = Clip-Verbindung

Clip connection

Connexion de clip

[m ]

[m m ]

360

370

400

250

270

0,165

0,25

0,20

0,25

DN = Konus-Verbindung

Cone connection

Connexion de cône

127

Loading...

Loading...