Page 1

Service Handbook

Waterclean 600 CD,

LP/MP, PI

1.024-...

5.905-521

08.2004

Page 2

FOREWORD WTC 600 LP / MP

Foreword

Good servicing and maintenance requires comprehensive, practical training and clearly organised

documents.

This is why we offer all servicing engineers regular basic training and further qualification courses

for the whole product range.

In addition, we compile service manuals for the main units which can be used as instructions to start

with and as a reference work later on.

In addition, we issue regular Service Information about on-going developments of our products.

The texts and pictures can only be copied and duplicated or passed on to third parties after obtaining

explicit permission from:

ALFRED KÄRCHER GmbH & Co.

CUSTOMER SERVICE TRAINING

P. O. Box 160

D-71349 Winnenden

www.kaercher.com

2

Service Handbook 08.2004

Page 3

WTC 600 LP / MP CONTENTS

Contents

1 General..........................................................................................7 - 10

1.1 Introduction ........................................................................................................... 7

1.2 Marking of Instructions ........................................................................................ 7

1.3 Intended Use.......................................................................................................... 7

1.4 Safety Instructions................................................................................................ 8

1.4.1 Quality of the Untreated W ater .................................................................................8

1.4.2 Chlorination of Drinking Water..................................................................................8

1.4.3 Disposal of Chemicals ............................................................................................. 8

1.4.4 Handling Electricity / Protection Class .....................................................................9

1.5 General installation notes .................................................................................. 10

1.6 Units and Designations .......................................................................................11

2 Description ................................................................................ 11 - 20

2.1 Overview .............................................................................................................. 11

2.2 Flow Diagram ...................................................................................................... 13

2.3 Description of the System.................................................................................. 14

2.3.1 Modular Design ......................................................................................................14

2.3.1.1 Pre-chlorination Module......................................................................................... 14

2.3.1.2 Flocculation Module............................................................................................... 14

2.3.1.3 Mediafilter- and Activated Carbon Filter ................................................................ 15

2.3.1.4 RO System, Pump and Fine Filter ........................................................................ 15

2.3.1.5 Control Panel and Display ..................................................................................... 15

2.3.1.6 Anti Scalant and Post Chlorination ........................................................................ 15

2.3.1.7 Pressure-increase Pump ...................................................................................... 16

2.3.2 Safety Installations .................................................................................................16

2.3.3 Operating Modes....................................................................................................17

2.3.3.1 Automatic Operation (Standard Operating Mode) ................................................. 17

2.3.3.2 Manual Operation .................................................................................................. 17

2.4 Technical Data WTC 600 LP/MP ......................................................................... 18

2.5 Consumption Materials ...................................................................................... 20

2.5.1 Chemicals for Metering Container ..........................................................................20

2.5.2 Cleaning Chemicals ...............................................................................................20

2.5.3 Filter .......................................................................................................................20

3 Operation of the System .......................................................... 21 - 43

3.1 Assembly and Starting Operation ..................................................................... 21

3.2 Mixing Chlorine, Flocculation Agent and Antiscalant ..................................... 22

3.2.1 Initial Starting of Operation .....................................................................................22

3.2.2 Pre-chlorination ......................................................................................................22

3.2.3 Antiscalant..............................................................................................................24

3.2.4 Metering Amounts and Mixing of the Post Chlorination ..........................................25

3.2.5 Flocculation Agent..................................................................................................25

3.2.5.1 Mixing of the flocking test solution..........................................................................25

Service Handbook 08.2004

3

Page 4

CONTENTS WTC 600 LP / MP

Contents

3.2.5.2 Perfor m flocking test...............................................................................................26

3.2.5.3 Evaluate flocking test .............................................................................................26

3.3 Connecting the Equipment ................................................................................ 27

3.3.1 Connections, Valves and Indicators.......................................................................27

3.3.1.1 Pressure-increase Module .................................................................................... 28

3.3.1.2 RO Module with Preliminary Filters....................................................................... 28

3.3.2 Electrical Connections ........................................................................................... 29

3.3.2.1 Pressure-increase Pump ...................................................................................... 29

3.3.2.2 Preliminary Filter ................................................................................................... 29

3.3.2.3 Metering Station .................................................................................................... 29

3.3.2.4 Float Switch........................................................................................................... 31

3.3.2.5 Reverse Osmosis System .................................................................................... 31

3.4 Starting Operation ............................................................................................... 31

3.4.1 Metering Station .....................................................................................................31

3.4.2 Media filter and activated carbon filter ....................................................................32

3.4.2.1 Initial Filling............................................................................................................ 32

3.4.2.2 Starting Operation ................................................................................................. 32

3.4.2.3 Backwashing / Regeneration ................................................................................ 32

3.4.2.4 Programming......................................................................................................... 33

3.4.3 Starting Operation of the RO System ....................................................................35

3.4.3.1 Operating Levels and Passwords ......................................................................... 35

3.4.3.2 Menu Selection...................................................................................................... 35

3.4.3.3 Selection of an Option ........................................................................................... 35

3.4.3.4 Selecting Several Arguments at the Same............................................................ 36

3.4.3.5 Adjusting Operating Parameters and Balancing Values .........................................36

3.4.3.6 Acknowledging Data Inputs .................................................................................. 36

3.4.3.7 Operational Interruptions....................................................................................... 36

3.4.3.8 Initial startup ...........................................................................................................38

3.4.4 Normal Operation ...................................................................................................40

3.4.4.1 Operating Messages for Normal Operation .......................................................... 41

3.4.5 Putting Out of Operation.........................................................................................42

3.4.6 Disinfection.............................................................................................................43

4 Maintenance.............................................................................. 44 - 62

4.1 Fine Filter ............................................................................................................. 44

4.2 Metering Station WTC 600 CD............................................................................ 44

4.3 Reverse Osmosis Module (RO Module) ............................................................ 45

4.3.1 RO Filter Replacement...........................................................................................45

4.4 Cleaning in Case of Malfunction........................................................................ 46

4.4.1 Design of the Flushing and Disinfection Equipment ...............................................47

4.4.2 Disinfection.............................................................................................................49

4.4.3 Acidic and Alkaline Cleaning ..................................................................................50

4.4.3.1 Cleaning Solution for Acidic Cleaning ................................................................... 51

4

Service Handbook 08.2004

Page 5

WTC 600 LP / MP CONTENTS

Contents

4.4.3.2 Cleaning Solution for Alkaline Cleaning................................................................. 51

4.4.4 Conserving.............................................................................................................51

4.4.4.1 Draining and rinse the metering stations ................................................................51

4.4.4.2 Conserve RO systems ..........................................................................................51

4.4.4.3 Draining the pre-filter ..............................................................................................53

4.4.5 Removing the Preservation After Longer Operational Interruptions.......................53

4.4.6 Rinsing the pre-filter ...............................................................................................54

4.4.7 Replacing the activated carbon or filter sand .........................................................55

4.5 Malfunction, Cause and Corrective Action ....................................................... 57

4.5.1 Metering Station LED and Indicator LEDs at the Switch Cabinet...........................57

4.5.2 Malfunction Indication at the Operating Panel ........................................................58

4.5.3 Malfunctions of the RO Control and Metering Pump ..............................................59

4.5.4 Malfunctions – Sand and Activated Carbon Filter, Fine Filter and Flocculation......60

4.6 Maintenance Plan ................................................................................................ 61

4.6.1 Maintenance During Operation...............................................................................61

4.6.2 Maintenance Plan Service .....................................................................................62

Appendix ................................................................................... 63 - 84

RO control manufacture settings .......................................................................... 63

RO control program structure ............................................................................... 65

RO 1000: User manual...........................................................................................67

Operating Record for the WTC 600 LP/MP ........................................................... 84

List of key words .............................................................................86 - 88

Service Handbook 08.2004

5

Page 6

WTC 600 LP / MP

6

Service Handbook 08.2004

Page 7

WTC 600 LP / MP GENERAL

1 General

1.1 Introduction

This service manual contains basic instructions and information which are to be observed upon

set-up, operation and maintenance.

Therefore, it is imperative that the service manual is read by the installer as well as by the

responsible specialist staff prior to installation and starting of operation. Please observe not only

the general safety instructions listed in the section “Safety Instructions”, but also the special

safety instructions included in the other sections.

1.2 Marking of Instructions

The safety instructions contained in these operating instructions, which in case of

non-observance can cause dangerous situations for persons, are specially marked

with the general symbol for dange.

The safety instructions contained in these operating instructions, which in case of

non-observance can cause poisoning, cauterizing, etc. for persons, are specially

marked with the death’s-head symbol.

CAUTION

NOTE

Instructions that are attached directly to the equipment must be observed under all means and

kept in completely readable condition.

Following this symbol are recommendations or tips which make working easier and

provide for secure operation.

Following this symbol are recommendations or tips which make working easier and

provide for secure operation.

1.3 Intended Use

The equipment is intended for the conditioning of untreated water into drinking water .

The retention degree of harmful chemical substances and biological pathogens or contaminants

is very high.

The quality of the produced drinking water ultimately depends on the contamination degree and

salt content of the untreated water .

- Prior to the initial starting of operation, we recommend carrying out an analysis of the

untreated water .

- Continuous drinking-water quality can be ensured only when the equipment is controlled

regularly.

- The respective national or international drinking water regulations are to be observed.

Under consideration of these rules of conduct, water produced from this system can quite safely

be classified as drinking water.

Service Handbook 08.2004

7

Page 8

GENERAL WTC 600 LP / MP

1.4 Safety Instructionse

1.4.1 Quality of the Untreated Water

Sufficient quality of the untreated water must be ensured!

Faultless drinking water is achieved only when all filters of the equipment are

maintained regularly .

1.4.2 Chlorination of Drinking Water

When applying post chlorination, the limit values set by national laws must be maintained. The chemicals used have a caustic and fire-promoting effect.

Dangers:

- Danger of fire in case of contact with combustible materials.

- Toxic gas develops when coming in contact with acids.

- Heat or direct sunlight decomposes the chemical: Chlorine and oxygen are released.

- Caustic effects to the eyes, skin and respiratory system result.

Safety Instructions:

- Wear acid-resistant protective equipment (goggles, gloves) and when dust is produced,

breathing mask protection with a filter.

- Keep an eye wash bottle (small) readily available.

- Provide for adequate room ventilation and a washing facility.

- Store the chemicals in a cool, dry place, not below 5 °C.

- Store chemicals in a location out of the reach of children.

In Case of Accidents:

- In case of contact with the eyes, rinse immediately and thoroughly with fresh water and

consult a doctor.

- Use water to extinguish; avoid impact and friction.

- If solutions are spilt, flush the area with a sufficient amount of fresh water .

1.4.3 Disposal of Chemicals

It is generally recommended to admit resulting disinfection solutions, preservation solutions, etc.

into a neutralizing system.

If this should not be possible, the disinfection solution, after clarification with the relevant

authority (mayor’s office, district administration office, etc.) is to be neutralized and can

afterwards be led into the public sewer system.

8

Service Handbook 08.2004

Page 9

WTC 600 LP / MP GENERAL

1.4.4 Handling Electricity / Protection Class

Be aware of dangerous electrical voltage!

For work on components/assemblies which are marked with this symbol, protective

measures are to be taken:

- Switch off the power

- Secure against restarting

- Check and assess that no voltage is given.

The electrical connection of the equipment may be carried out only by a qualified

electrician.

The power supply cable must be fitted with a protective conductor

(protection class I).

1.5 General installation notes

- Only use food safe components and resources on the drinking water side

- Pay special attention to hygienic cleanliness when installing drinking water pipes.

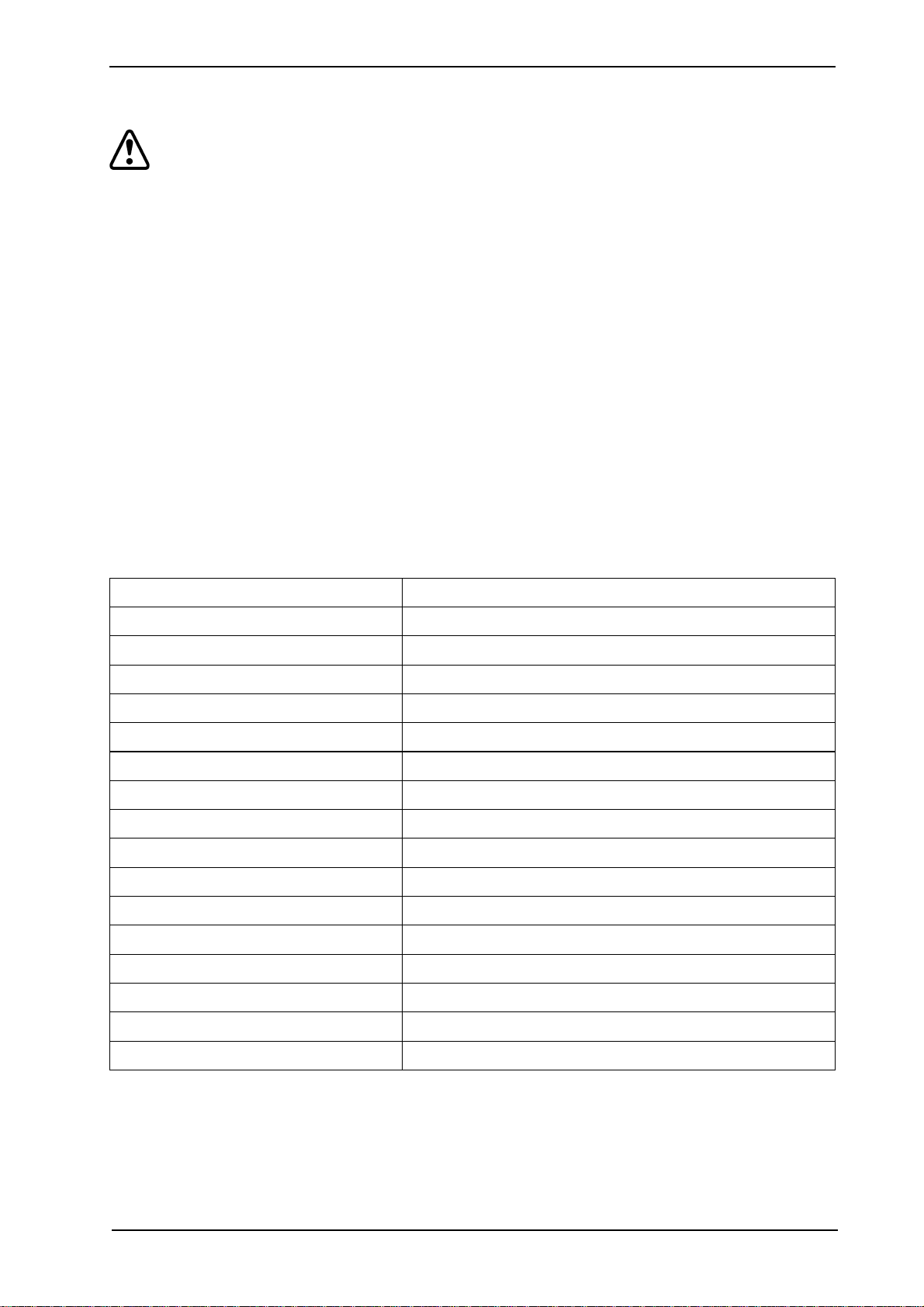

1.6 Units and Designations

Unit Designation

bar bar (pressure)

di/da Diameter, inside / diameter, outside

g/h Gram per hour

H z Hz (frequency)

l Liter

l/h Liter per hou

mg/h Milligram per hour

mg/l Milligram per lite

ml Milliliter

V AC Volt (AC)

W Watt (power)

°dH Degree of hardness (water hardness)

µS/cm Microsiemens per cm (spec. conductance value

ETL Spare parts list

LW Conductance value

SLP Circuit Diagram

Table 1 Units and their meaning

NOTE

Service Handbook 08.2004

1000 milliliter = 1 liter; 1000 mg = 1

9

Page 10

DESCRIPTION WTC 600 LP / MP

2 Description

2.1 Overview

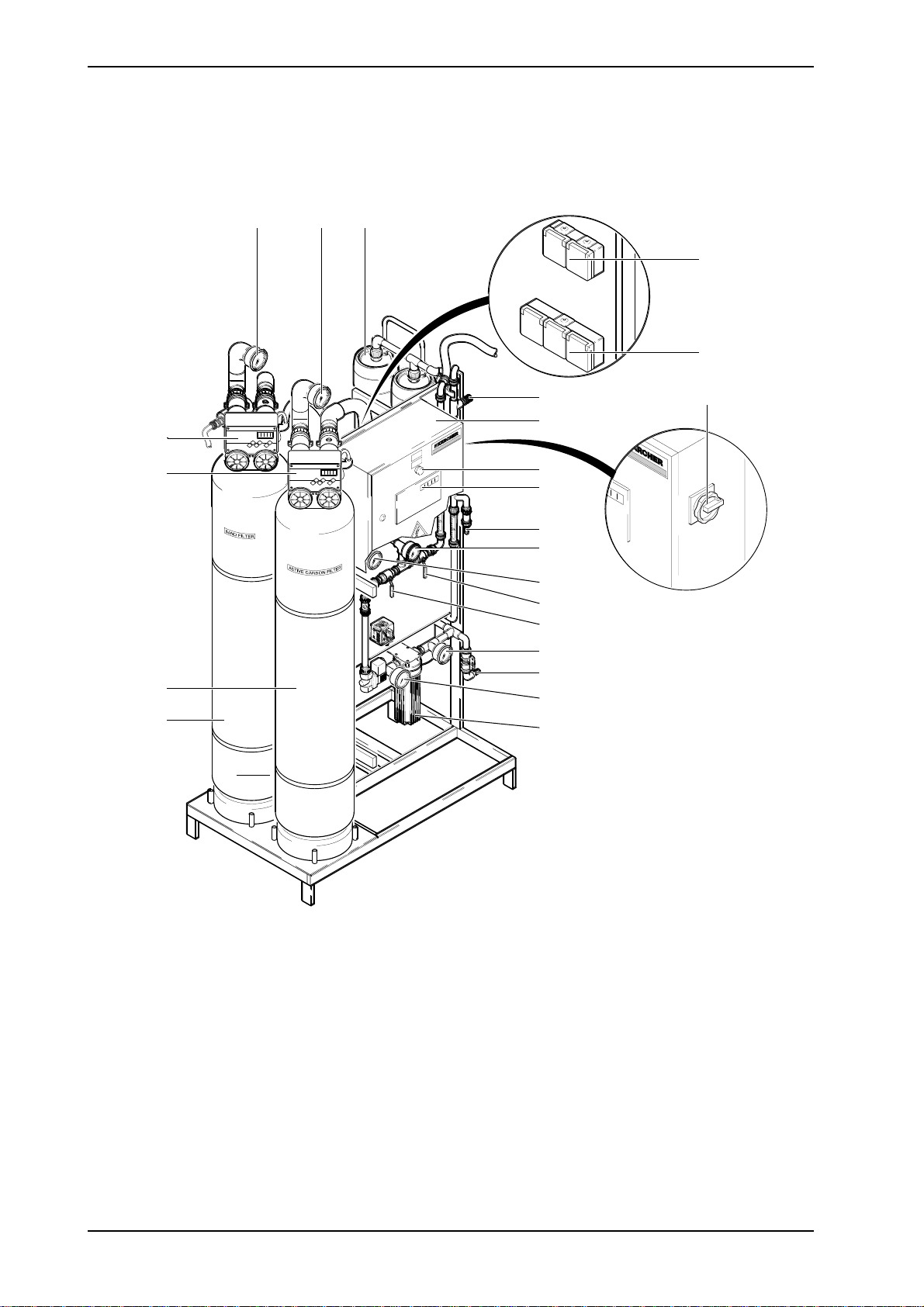

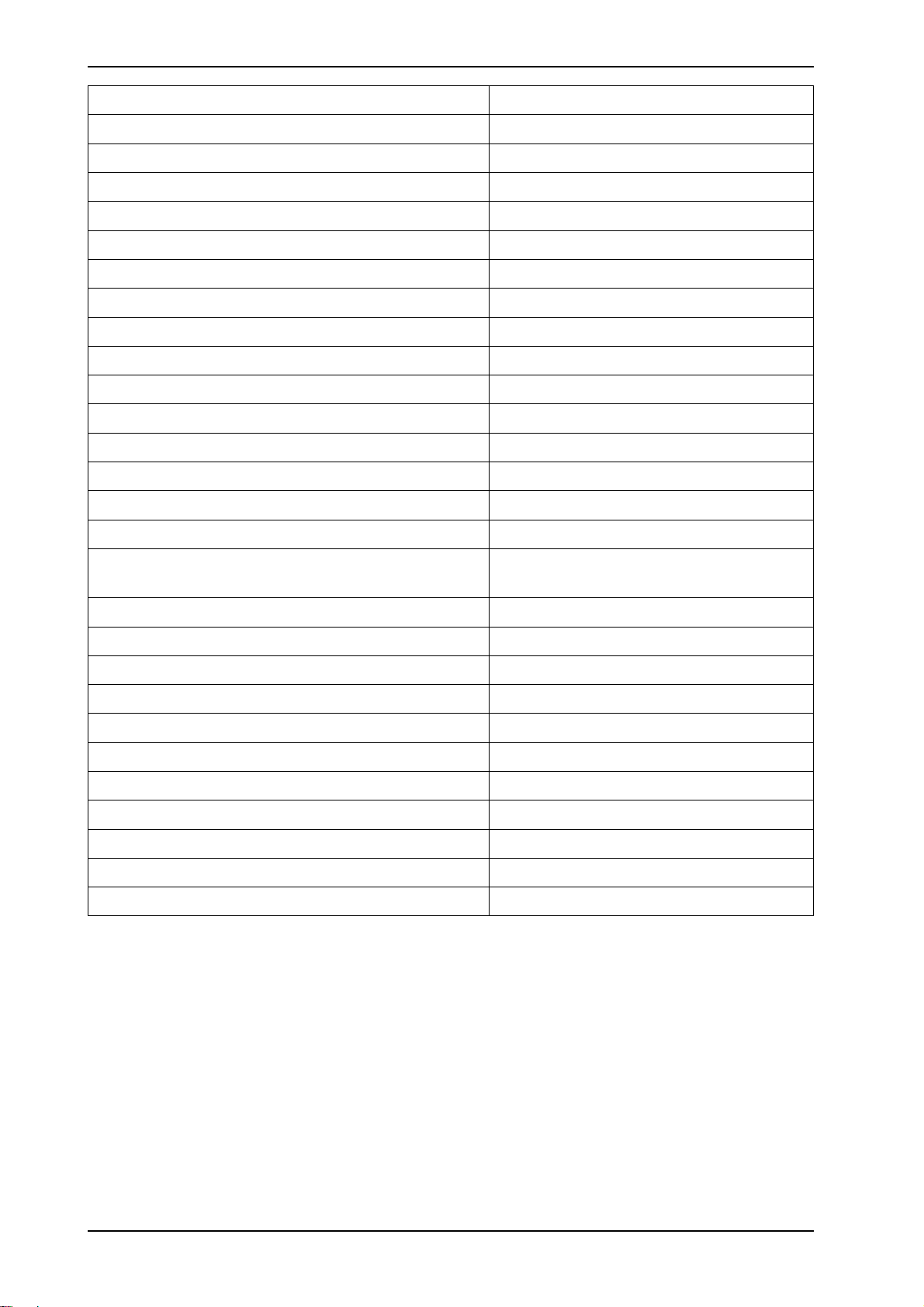

1.2 2.1 4.12, 4.13

f

g

2.2

1.3

4.23

c

b

a

d

4.24

4.21

4.14

4.11

4.15

4.17

4.4

4.3

4.7

4.5, 4.6

e

Figure 1 Overview of components

10

Service Handbook 08.2004

Page 11

WTC 600 LP / MP DESCRIPTION

Legend for figure 1 and figure 2:

1.1 Pre-chlorination metering point

1.2 Manometer - media filter inlet pressure

1.3 Media filter

1.4 Differential pressure switch

1.5 Concussion restrictor

1.6 Flocculation metering point

2.1 Manometer - activated carbon filter

inlet pressure

2.2 Activated carbon filter

4.1 Antiscalant metering point

4.2 Non-return valve

4.3 Untreated water sampling tap

4.4 Manometer - fine filter input pressure

4.5 Fine filter housing

4.6 Fine filter candle

4.7 Manometer - fine filter output pressure

4.11 Manometer, pump pressure

4.12 Membrane pressure pipe

4.13 Membrane

4.14 Manometer - concentrate pressure

4.15 Concentrate control valve

4.16 Concentrate flowmeter

4.17 Pressure control valve

4.18 High-pressure pump

4.19 Conductivity and temperature

measuring cell - drinking water

4.20 Drinking water flowmeter

4.21 Drinking water sampling tap

4.22 Non-return valve

4.23 Post chlorination metering point

4.24 Reverse osmosis control

6.1 Pre-chlorination metering

4.8 Input solenoid valve

4.9 Manostat

4.10 High-pressure pump

Items 1.1 to 6.4 are attached to the components as reference numbers.

a Media filter control

b Control, activated carbon filter

c Control cabinet

d Manual / automatic rotary switch

e Master switch

f Media and activated charcoal

plug sockets

g Power outlets (3x) for metering

stations

6.2 Antiscalant metering

6.3 Post chlorination metering

6.4 Flocculation metering

Service Handbook 08.2004

11

Page 12

DESCRIPTION WTC 600 LP / MP

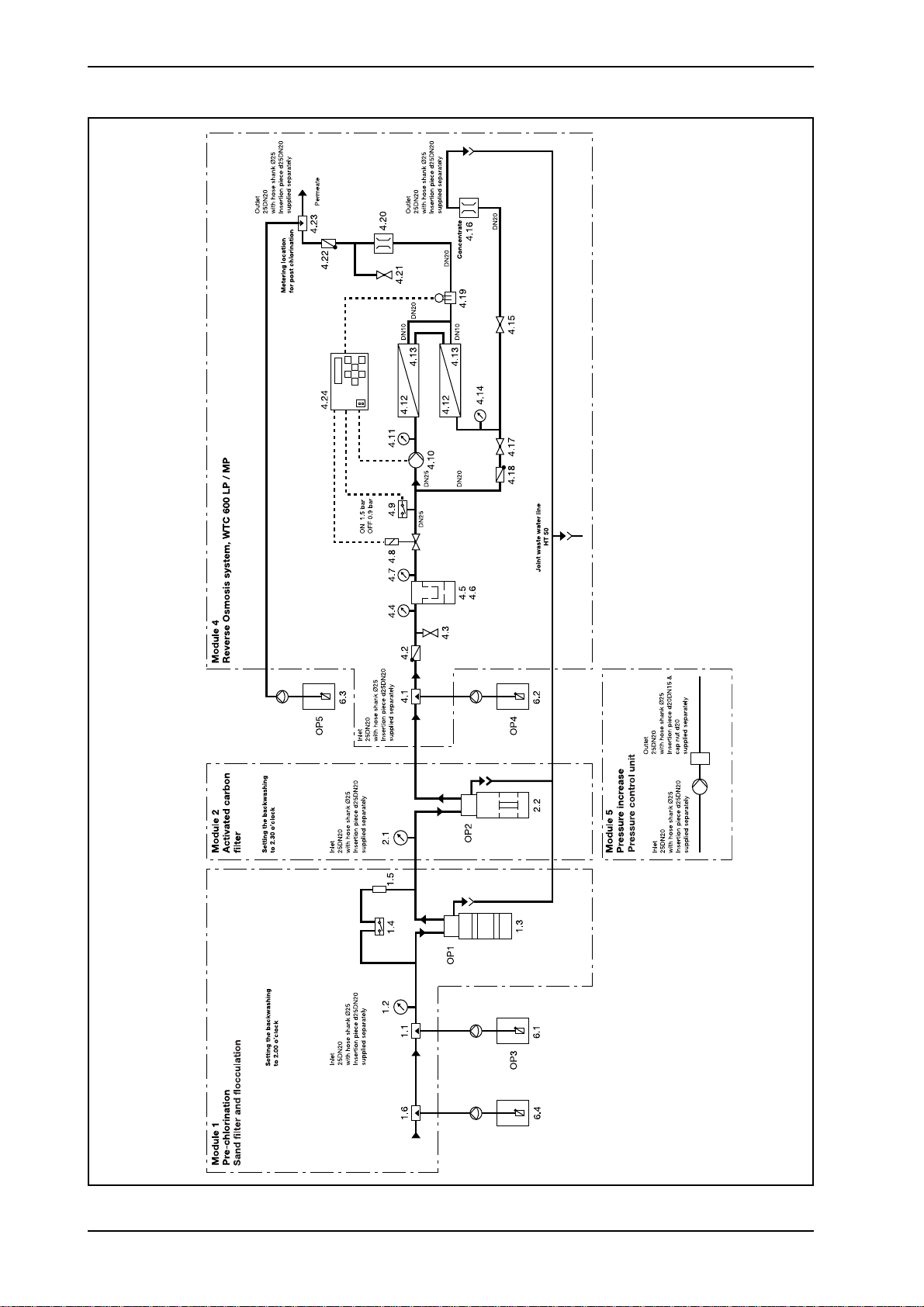

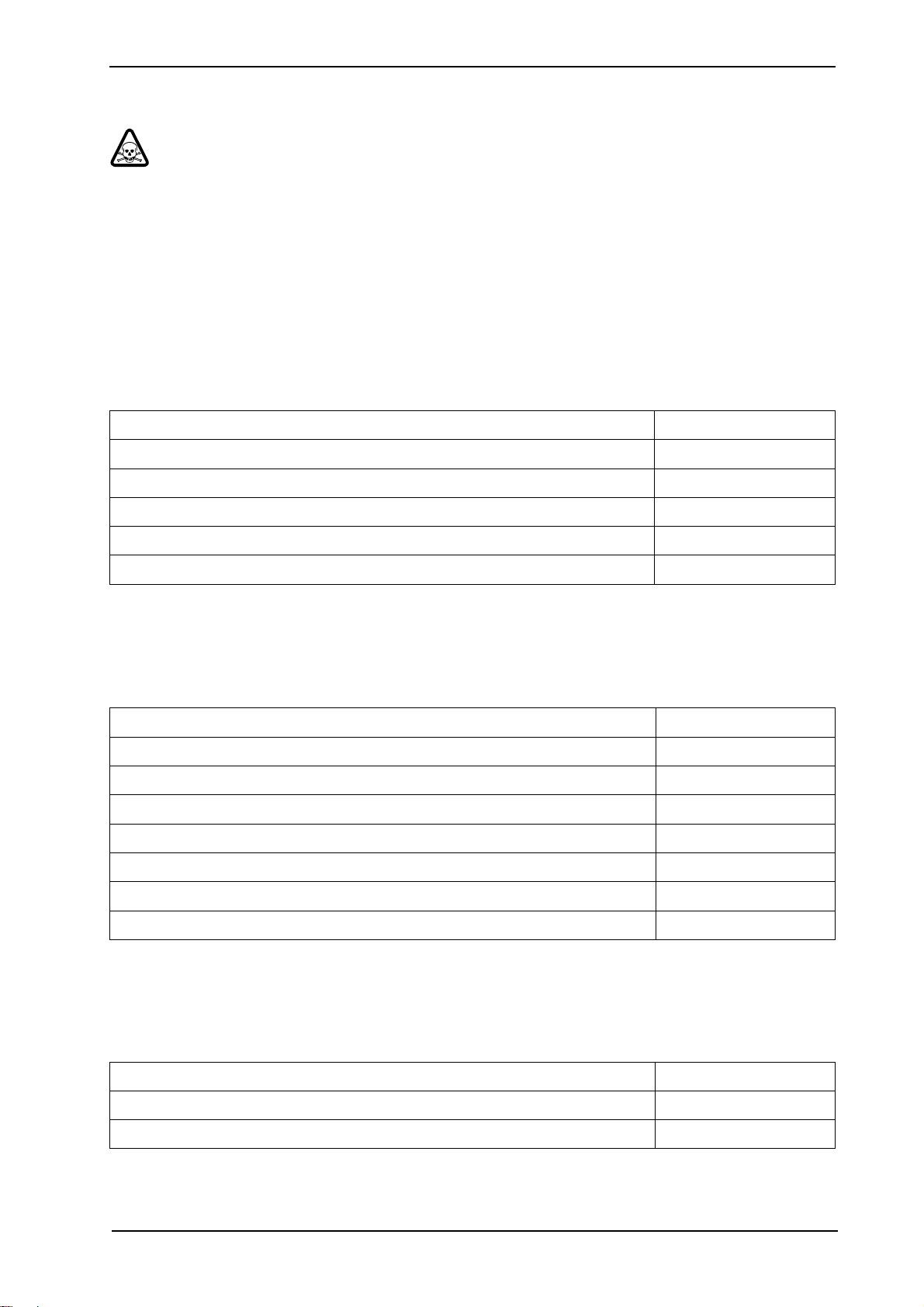

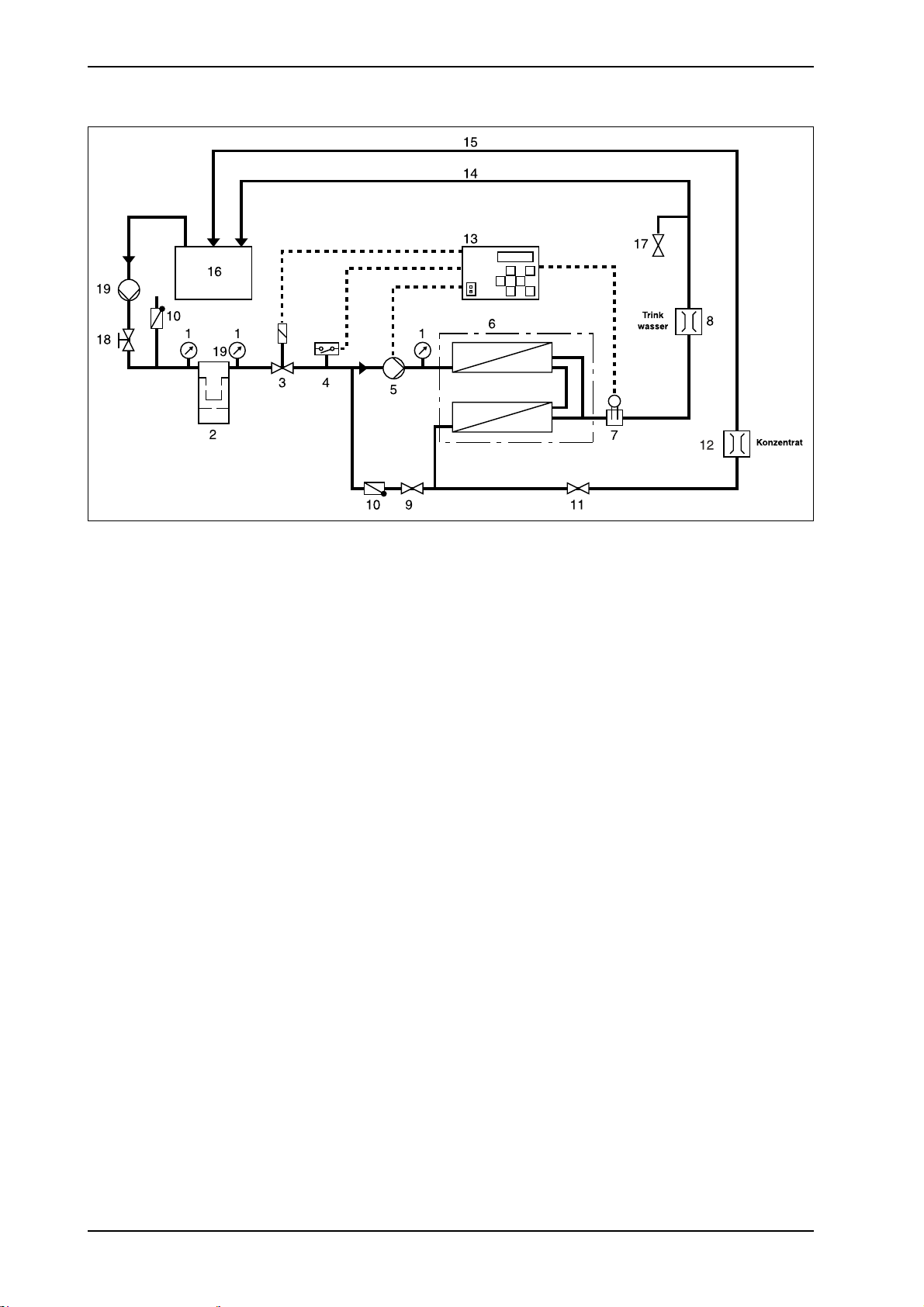

2.2 Flow Diagram

Figure 2 Flow diagram of the complete reverse osmosis system (RO system)

12

Service Handbook 08.2004

Page 13

WTC 600 LP / MP DESCRIPTION

2.3 Description of the System

2.3.1 Modular Design

The installation is a drinking water conditioning system. Its core application is the

emineralization of brackish water with a salt content up to 2000 ppm (WTC 600 LP), respectively

up to 5000 ppm (WTC 600 MP).

The design of the system is modular, and can be adapted accordingly to the local conditions

depending on the application conditions as well as the composition of the untreated water:

- Media filter and flocculation – module 1

- Activated carbon filter – module 2

- Reverse osmosis system – module 4

- Pressure-increase pump – module 5

- Metering stations

The RO system is designed for stationary use.

2.3.1.1 Pre-chlorination Module

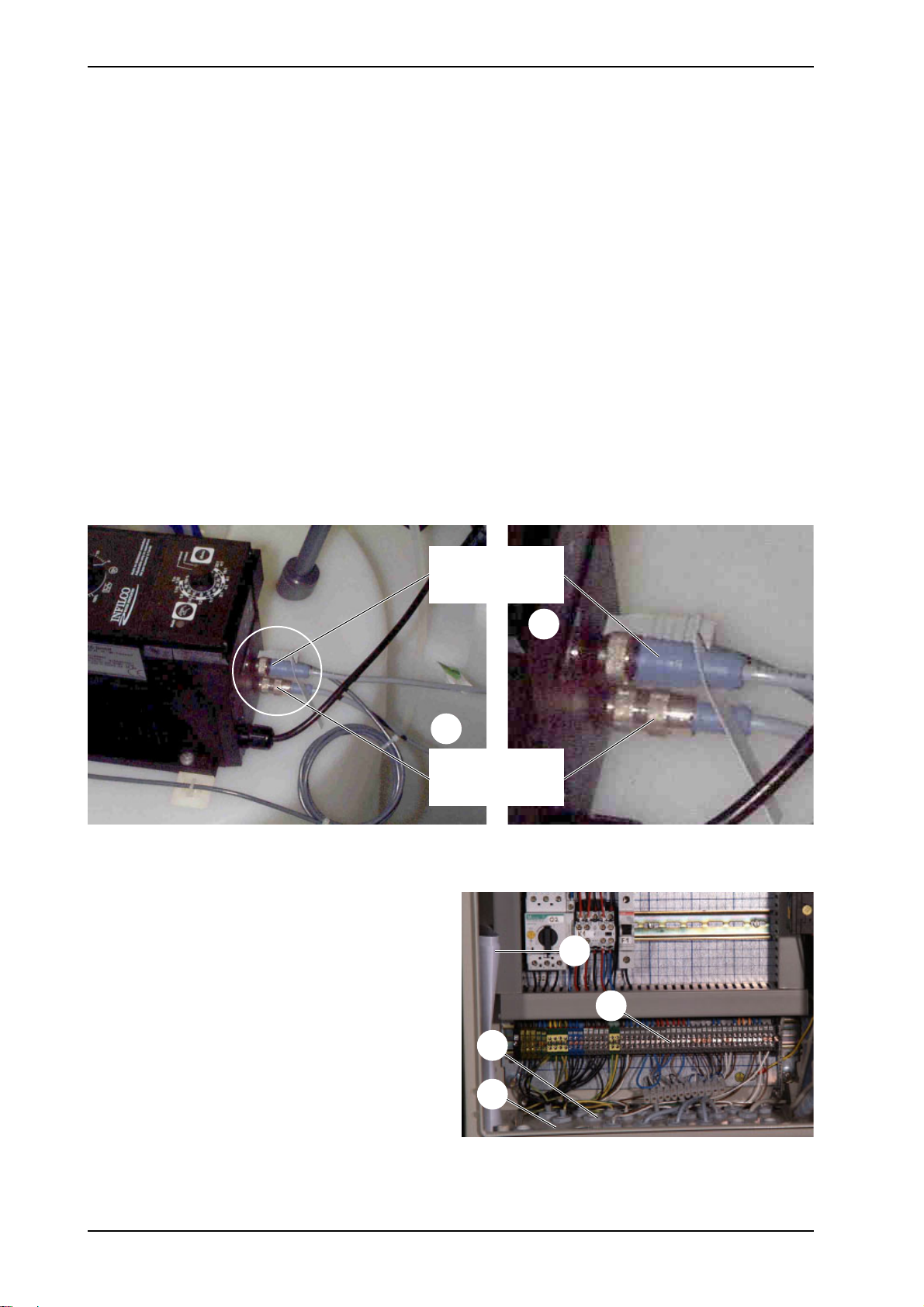

The WTC 600 CD metering station, consisting

of metering container (3/1) and pump (3/2), is

connected to the sand filter module for prechlorination if required.

2

1

Figure 3 WTC 600 CD

2.3.1.2 Flocculation Module

The WTC 600 CD metering station (see figure 3) with injection adapter is connected to the sand

filter module for pre-flocculation if required.

The exact requirement of flocculation agent is to be determined when starting operation (see

Section 3.2.5).

Service Handbook 08.2004

13

Page 14

DESCRIPTION WTC 600 LP / MP

2.3.1.3 Mediafilter- and Activated Carbon Filter

The pre-filter units of the RO system consist of the media filter and the activated carbon filter.

The filter fillings consist of support pebbles and filter sand according to DIN 19623, as well as

activated carbon.

The filters are each controlled by means of a central control valve with microprocessor control

and located at the top of the filter.

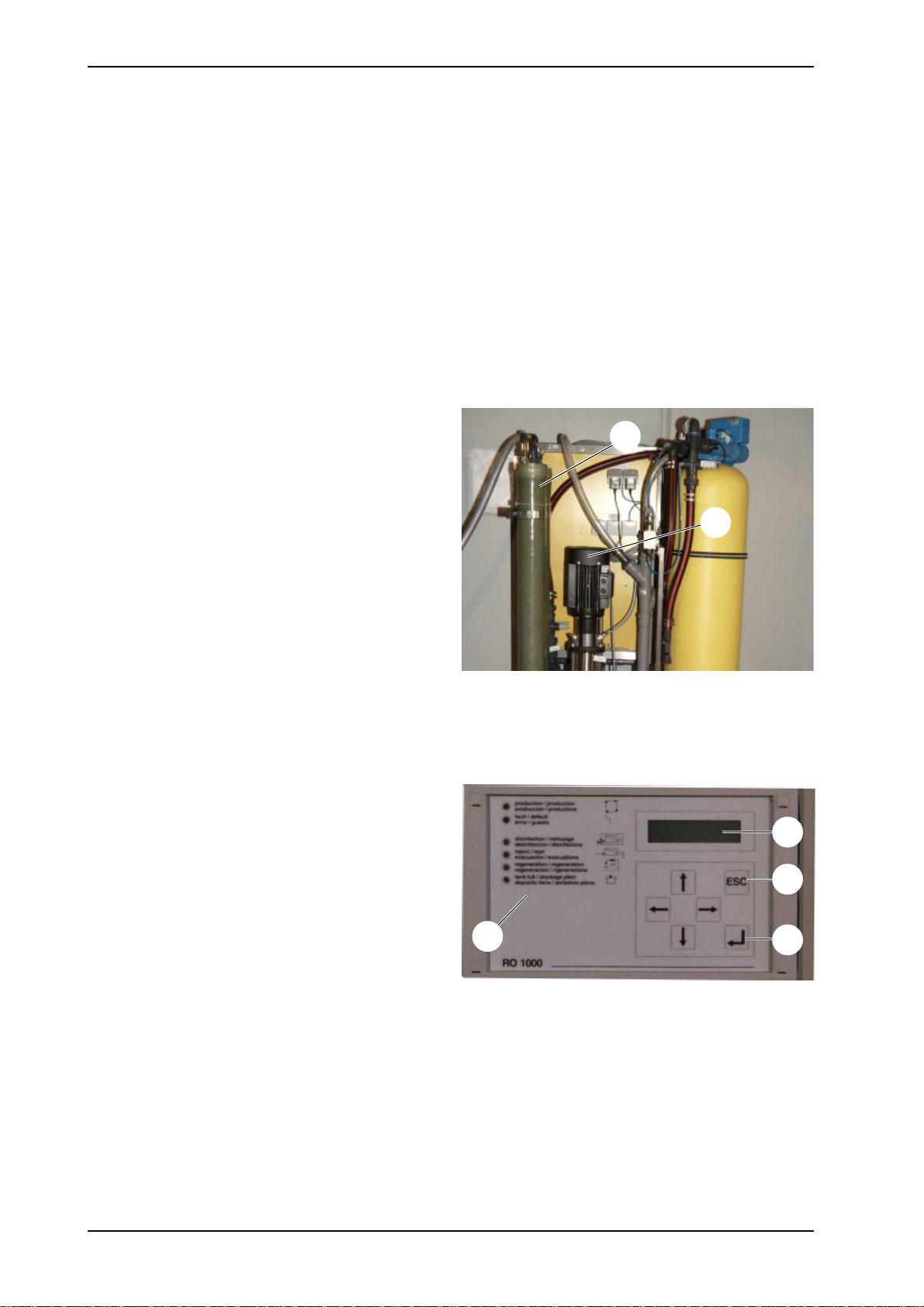

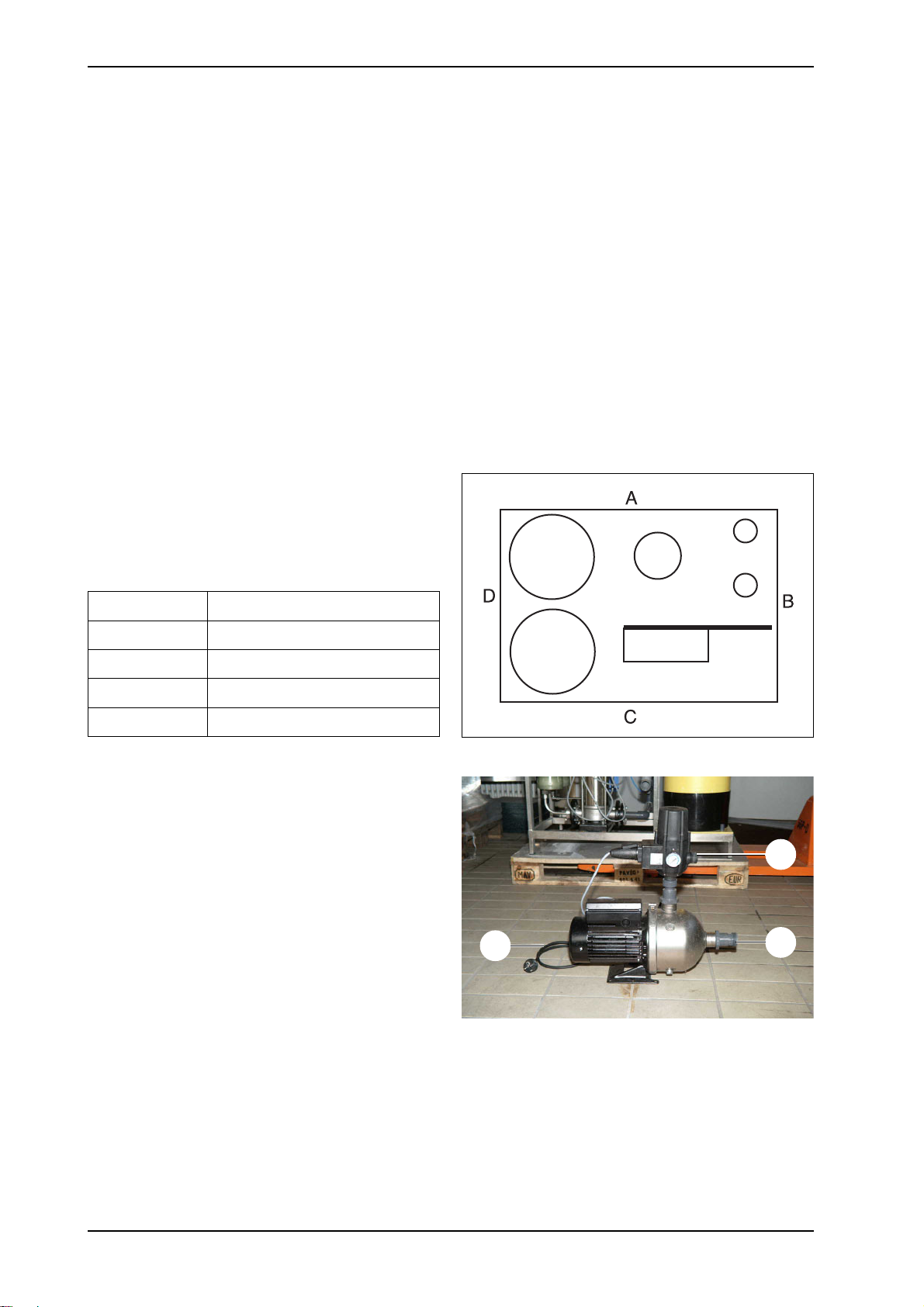

2.3.1.4 RO System, Pump and Fine Filter

The fine filter is located on the front side of the

equipment. It is connected directly in front of

1

the RO system.

The RO pump (4/2) pumps the pre-filtered

water through two RO filters (4/1) which are

connected in series.

2

2.3.1.5 Control Panel and Display

The control panel is used for data input in the

control and as LED indicator for the operating

modes and malfunction indications (5/1).

Parameters are entered with the arrow

pushbuttons. Data input is acknowledged with

the ENTER pushbutton (5/4) and cancelled

with the ESC pushbutton (5/3).

Programming conditions, etc., are indicated in

the display (5/2).

2.3.1.6 Anti Scalant and Post Chlorination

Figure 4 RO pump

1

Figure 5 Control panel and display

2

3

4

For hardness stabilization of the untreated water and post chlorination of the drinking water a

WTC 600 CD metering station is connected to the RO module in the same manner as for prechlorination.

14

Service Handbook 08.2004

Page 15

WTC 600 LP / MP DESCRIPTION

2.3.1.7 Pressure-increase Pump

If required, the WTC 600 PI pressure-increase

pump (6/1) is connected between untreated

1

water supply and RO system. It is used for

pressure increase of the untreated water.

NOTE

A pressure-increase pump should

be used for a water pressure (flow

pressure) ⱕ 2 bar.

CAUTION

Observe mechanical protection as

well as protection of the

connection cable against water!

Figure 6 WTC 600 PI

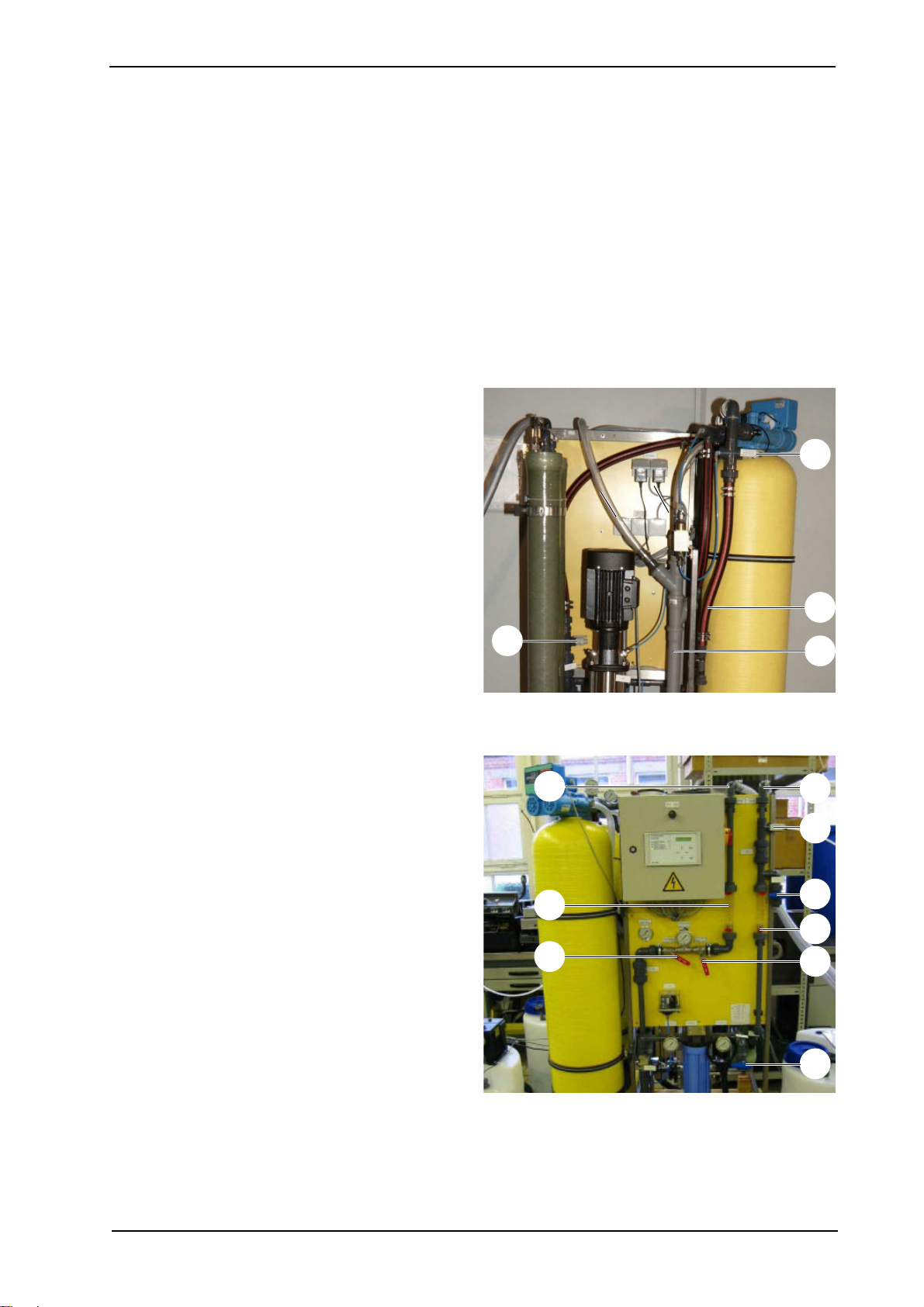

2.3.2 Safety Installations

Emergency Stop

The emergency stop switch (7/4) (main switch) is located on the side of the switch box.

RC Protective Switch

RC protective switch (external): i ⱕ 30 mA

Circuit Breaker

Automatic circuit breaker (7/3) 10 A for power limitation of the power outlets, etc

Motor Protection Switch

The motor protection switch (7/2) is factory-set depending on the power consumption of the RO

pump (compare circuit diagram (7/1)) and must be checked:

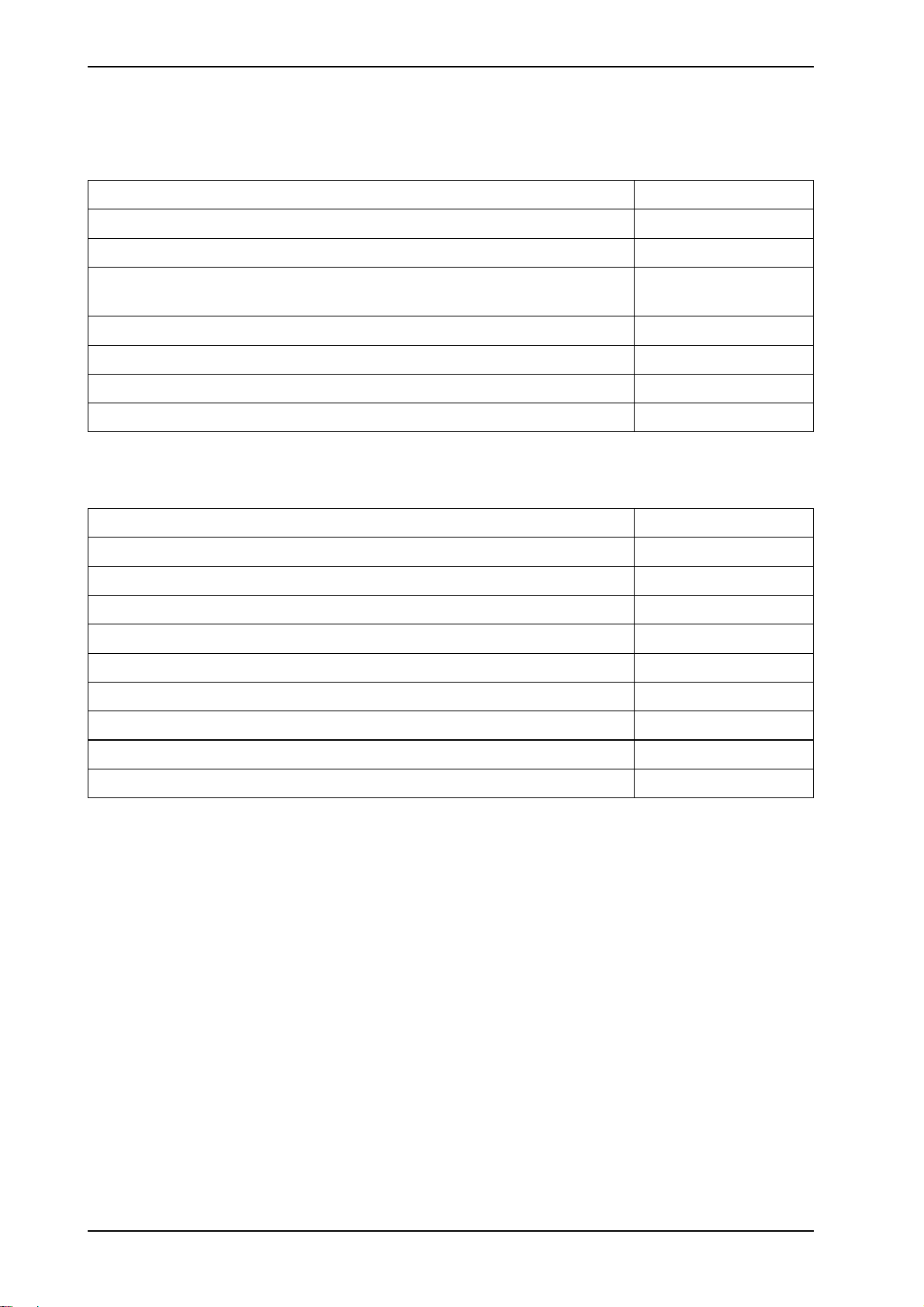

WTC 600 Nominal output Actual power Motor protection

RO pump consumption switch setting

LP 400 V 2.2 kW 1.5 kW 4 A

MP 400 V 2.2 kW 2.2 kW 5.1 A

LP 230V 2.2 kW 1.5 kW 10 A

MP 230 V 2.2 kW 2.2 kW 14 A

Table 2 Setting of motor protection switch

Service Handbook 08.2004

15

Page 16

DESCRIPTION WTC 600 LP / MP

Microfuses

Two microfuses (7/6) for protection of the

control electronics (7/5) are located on the

control board for the electronics:

2

1

3

4

5

- 5x20 6,3 A time-delay

- 5x20 0,1 A time-delay.

Figure 7 Switch cabinet and control electronic

6

2.3.3 Operating Modes

2.3.3.1 Automatic Operation (Standard Operating Mode)

After switching on the main switch, the system is fully automatic controlled through the

electronic control system and the float switch in the drinking water tank. The mode selector

switch is in the “Auto” position.

The control system usually operates in the normal plane in the operating mode operation.

With the exception of an error acknowledgement (only in case of pre-selection Vwacknowledgement by actuating the ESC key button), no further operating by the operator is

possible; this is to protect the control system against unintended / unauthorized manipulations.

NOTE

By entering the respective password, the user level or the technician level for input

of operating parameters, etc. is cleared (see section 3.4.3.1). The program structure

is given in the appendix, Figure 21.

NOTE

Operating parameters and setting values are listed on the data sheet by the

manufacturer (cf. Tables 34 and 35).

2.3.3.2 Manual Operation

The float switch in the drinking water tank is deactivated by the manual / automatic rotary switch

("Manual" position), so that the plant can run continuously.

CAUTION

Manual operation is not standard operating mode, as the system does not switch off

automatically.

16

Service Handbook 08.2004

Page 17

WTC 600 LP / MP DESCRIPTION

2.4 Technical Data WTC 600 LP/MP

Parameter WTC 600 LP WTC 600 MP

Ambient temperature +1°C - +50°C

Storage temperature (delivery) to -10°C

Humidity <100% r.F.

Supply voltage 3*400V 50 Hz

1*230V 50 Hz

Pre-filter controls: prim / sec. 230 V/12 V 50 Hz

Metering pumps 230 V 50-60Hz

Wiring 3 Ph, N, PE

Electrical protection 16 A

Connected electrical load 2.2 kW 2.2 kW

Effective electrical power consumption 1.5 kW 2.2 kW

Mechanical protection / protection against water

1)

1)

Switch cabinet IP44

Pump and valves IP44

Metering pump IP44

Power outlets (plug inserted) < IP44

Minimum temperature of untreated water +5°C

Maximum temperature of untreated wate +35°C

Reference temperature +15°C

pH-value, untreated water 6-9.5

pH-value during cleaning 3-11

System input pressure and flow 2-6 bar at min. 2 m³/h

Capacity range 15000 l/day (±10%)

Maximum drinking water capacity 650 l/h

Dimensions: H x W x D

WTC 600 LP/MP 1800 x 660 x 720 mm

WTC 600 LP/MP - A 1800 x 1120 x 720 mm

WTC 600 LP/MP - AM 1800 x 1120 x 720 mm

Weight in delivery condition (without filter container)

WTC 600 LP/MP 135 kg

WTC 600 LP/MP - A 155 kg

WTC 600 LP/MP - AM 175 kg

Table 3 Technical Data

1)

depending on the system version

Service Handbook 08.2004

17

Page 18

DESCRIPTION WTC 600 LP / MP

Filter Container

Volume per container 103 l

Filling capacities, Mediafilter

Support pebbles 2.0 - 3.15 mm 15 kg

Filter sand 0.4 - 0.8 mm 100 kg

Filter amounts, activated carbon filter

Support pebbles 1 - 2 mm 15 kg

Activated carbon filter F100 32 kg

Water connections

Inlet threaded connection hose nozzle Outer diameter d25

Drinking water threaded connection hose nozzle Outer diameter d25

Concentrate threaded connection hose nozzle Outer diameter d25

Outlet for flushing water HT pipe d50

Canal connection (supplied by customer) > DN 50

Hydraulic Data

Maximum allowable flow rate in filteroperation 1,3 m3/h

Amount of waste water produced during 2 m³/h, ca. 670 liter per backwashing

backwashing

Allowable Operating Conditions

Maximum pressure 6 bar

Metering Pump

Feed capacity at max. counter-pressure (10 bar) 1 l/h

Metering Container:

Weight with pump 10 kg

Connections

Hose connections (PE) di/do 4/6

Hose connection, ventilation (PVC) di/do 4/6

Float Switch

Minimum hysteresis 300 l

Table 4 Technical Data

18

Service Handbook 08.2004

Page 19

WTC 600 LP / MP DESCRIPTION

2.5 Consumption Materials

Swear protective equipment and observe safety instructions!

2.5.1 Chemicals for Metering Container

For mixing of the metering solution, use the measuring cup with the handle (250 ml or 1000 ml).

NOTE

NOTE

Product ItemNo.

Chlorinated lime 6.291-505.0

Sterilization agen RM 852 6.291-772.0

RM 5000 hardness stabilization 6.290-991.0

RM 5001 Flockulents, 10 l 6.294-703.0

RM 5001 Flockulents, 60 l 6.294-716.0

Table 5 Kärcher Original Products

2.5.2 Cleaning Chemicals

Product Item No.

RM Kleen MCT 511 6.294-008.0

Explanations of the units, see Chapter 1.6.

A metering container from the WTC 600 CD metering station has a volume of 75 liter.

RM Kleen MCT 103 6.294-009.0

RM P3 Oxonia Active 6.294-010.0

RM 1,2 Propandiol, 5 l 6.290-910.0

Sulfite 5 kg 6.769-040.0

Soda 6.287-014.0

RM 511 Vaporapid bio-descaling acid 6.290-239.0*

Table 6 Cleaning Chemicals * Attention! Note national variants!

2.5.3 Filter

Product Item No.

Filter element 5µ 6.414-466.0

Replacement set, metering pump 6.762-172.0

Table 7 Filter Elements

Service Handbook 08.2004

19

Page 20

OPERATION OF THE SYSTEM WTC 600 LP / MP

3 Operation of the System

3.1 Assembly and Starting Operation

Assembly Chapter

Checking the scope of delivery (delivery note)

Placing the equipment in the set-up location and positioning

Connecting the untreated water to the WTC 600 LP/MP; connecting 2.2, 3.3.2.1, 3.3.1

the WTC 600 PI in between, if required (depending on delivery scope)

Installing the piping for backwashing and drinking water 2.2

Installing the float switch 3.3.2.4

Filling and connecting the sand filter and the activated carbon filter 3.4.2

Connecting the electrical system SLP, 3.3.2

Table 8 Assembly work to be carried out upon starting operation

Starting Operation Chapter

Establishing the untreated water supply 2.2

Manually actuating the sand filter backwashing 3.4.2

Manually actuating the activated carbon filter backwashing 3.4.2

Flushing the reverse osmosis 3.4.3.7

Filling the chemicals container 3.2

Adjusting the flow rates 3.4.3.8

Filling out the metering table in the operating instructions

Instructing the operator (operating instructions)

Table 9 Overview of start-up work

A water analysis with the following values must exist for commissioning of the WTC 600:

- Total hardness GH in °dH

- Iron Fe in mg/l

- Manganese Mn in mg/l

- Ammonium NH

or NH3 in mg/l

4

- System yield determined by the sales department (Normal case: 75%, in special cases 50%).

20

Service Handbook 08.2004

Page 21

WTC 600 LP / MP OPERATION OF THE SYSTEM

3.2 Mixing Chlorine, Flocculation Agent and Antiscalant

3.2.1 First fill of the metering tanks

The first time they are filled, the metering tanks are filled with 30 litres of chlorine-free water.

This is taking from the reverse osmosis at the drinking water sampling tap (1/12).

For the first fill of the metering tank, the system is switched to disinfection mode and set to the

following flow rates:

- Drinking water: 100 l/h

- Concentrate: 600 l/h

CAUTION

Use the prescribed system yield (50% or 75%) and the water analysis to determine each of the

chemical quantities for a 30 litre metering solution according to Chap. 3.2 to 3.5, add to the tanks

and mix well.

Switch the system to operation mode.

3.2.2 Pre-chlorination

CAUTION

1.Take the system yield (50% or 75%) from the evaluation of the untreated water analysis.

2.Take the analysis values for iron (Fe), manganese (Mn) and ammonium (NH3 or NH4 ) in mg/l

from the untreated water analysis.

3.Iron content: ____ x 0,4 = ______

During the disinfection operating mode, all confirmation queries are switched off!

Observe the pressure downstream of the fine filer: as soon as it is less than 2 bar

pressure, immediately switch off the system. The high-pressure pump is running dry!

Only use drinking water to dilute the original chlorine product upstream of the

chlorination point. This water is taken from the drinking water tap (1/4.21).

Manganese content: ____ x 0,6 = ______

Ammonium content: ____ x 8,0 = ______

Basic requirement: 1,2

Total: ==========

4.For 50% yield:

Total x 192 = ____ ml RM 852 per 10 litre metering solution

OR

T otal x 512 = ____ ml calcium h ypochlorite (1ml corresponds to 1.05g) per 10 litres metering solution

Service Handbook 08.2004

21

Page 22

OPERATION OF THE SYSTEM WTC 600 LP / MP

5.For 75% yield:

Total x 128 = _____ ml RM 852 per 10 litre metering solution

OR

T otal x 348 = _____ ml calcium h ypochlorite (1ml corresponds to 1.05g) per 10 litres metering solution

These values are entered in the customer's operating instructions.

Calculation example:

- Yield 75%

- Iron (Fe) 1.0 mg/l

- Manganese (Mn) 1.0 mg/l

- Ammonium (NH

) 0.2 mg/l

4

Iron content: 1,0 x 0 ,4 = 0 ,4

Manganese content: 1,0 x 0,6 = 0,6

Ammonium content: 0,2 x 8,0 = 1,6

Basic requirement: 1,2

Total: 3,8

For 75% yield:

Total x 128 = 486 ml RM 852 per 10 litre metering solution

OR

Total x 348 = 129 ml calcium hypochlorite (1ml corresponds to 1.05g) per 10 litres metering solution

22

Service Handbook 08.2004

Page 23

WTC 600 LP / MP OPERATION OF THE SYSTEM

3.2.3 Antiscalant

The drinking water for the metering solution is taken from the sampling tap for drinking

water (1/4.21).

The antiscalant metering quantity can be set with a very good approximation using the following

table. The optimum quantity can only be calculated using a calculation program after a precise

water analysis has been carried out. The typical metering range lies between 2 and 5 mg/l.

Where water hardnesses are higher than 28°dH, special design is necessary.

If this design is not possible, the following setting is recommended: 5 mg/l RM5000 and 50%

yield, until the precise design is available.

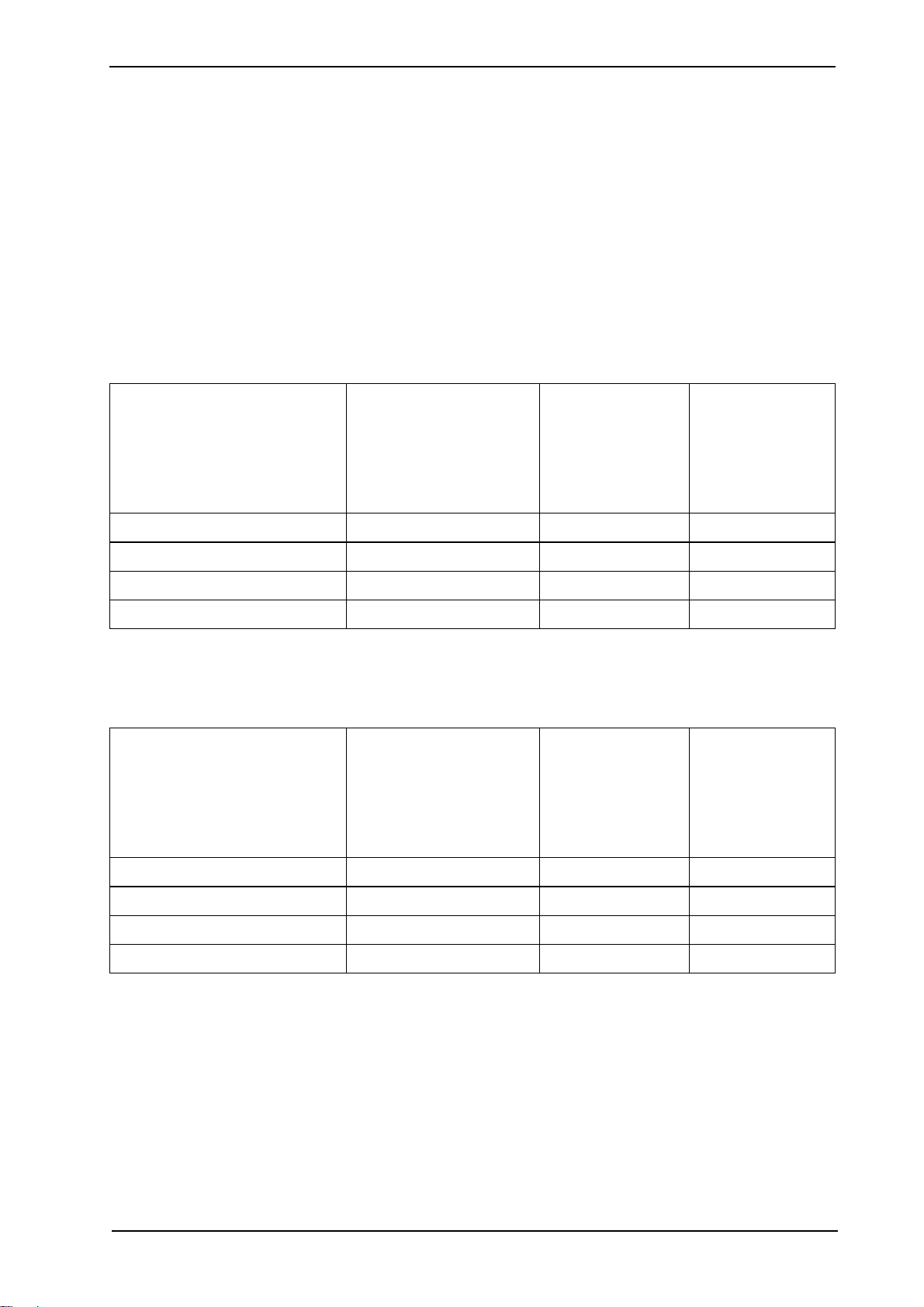

Range of Water Hardness Antiscalant [mg/l] Metered Run-down

amount of Tank Service

RM 5000 [ml] Life [h]

per 10 l

Metering

Solution

1 (0°-7° dH) 2,5 58 214

2 (7°-14° dH) 3 69 214

3 (14°-21° dH) 4 92 214

4 (21°-28° dH) 5 115 214

Table 10 Metering of antiscalant at 75% yield

Range of Water Hardness Antiscalant [mg/l] Metered Run-down

amount of Tank Service

RM 5000 [ml] Life [h]

per 10 l

Metering

Solution

1 (0°-7° dH) 2,5 87 214

2 (7°-14° dH) 3 104 214

3 (14°-21° dH) 4 138 214

4 (21°-28° dH) 5 173 214

Table 11 Metering of antiscalant at 50% yield

1 °dH = 1,79 °frH

1 °dH = 17,9 mg CaCO3/l

1 °frH = 10,0 mg CaCO3/l

Service Handbook 08.2004

23

Page 24

OPERATION OF THE SYSTEM WTC 600 LP / MP

3.2.4 Metering Amounts and Mixing of the Post Chlorination

The chlorine quantity given matches a chlorine content of 0.3mg/l in the drinking water.

The following quantities of RM 852 or calcium hypochlorite are each required for 10 litres of

metering solution:

- RM 852 Sterilization Agent: 32 ml

- Chlorinated Lime: 17 ml (= 18 g)

Example: 75 litres ready mixed metering solution (one metering tank) consists of 7.5 x 32 = 240 ml

RM 852 or 7.5 x 17 = 128ml (=136 g) calcium hypochlorite and chlorine-free drinking water

(cf. Chapter 3.2.3 for extraction).

The quantities must be adjusted accordingly for higher or lower chlorine contents.

Example: Chlorine content: 1.2 mg/l

- RM 852: 4 x 32 ml = 128 ml

- Chlorinated Lime: 4 x 17 = 68 ml

3.2.5 Flocculation Agent

The exact demand in flocculents can only be determined by test. Therefore a test solution is

mixed first, then the raw water is flocked and finally the dosing quantity is evaluated.

3.2.5.1 Mixing of the flocking test solution

Auxiliaries:

- Measuring cup with 500-ml-scale 6.277-001.0 (within service kit)

- Desalinated water (refill water for car batteries)

- Flocculent RM 5001 6.294-716.0 resp. 6.294-703

- Measuring cup 25 ml 6.394-425.0 (within service kit)

- Dropping bottle 50 ml,PE 6.394-426.0 (within service kit)

- Plastic eating spoon.

Work Steps:

1. Give 25 ml flocculent RM 5001 into measuring cup

2. Fill up with desalinated water to 500 ml

3. Stir up thoroughly with plastic eating spoon

4. Give 50 ml of this into a clean dropping bottle, close bottle

5. Cast away the remainder.

24

Service Handbook 08.2004

Page 25

WTC 600 LP / MP OPERATION OF THE SYSTEM

3.2.5.2 Perform flocking test

Auxiliaries:

- Transparent cup, 1 litre with marking at 0.5 litre 6.277-001.0

- Dropping bottle with test solution 6.394-426.0

- Plastic eating spoon.

Work Steps:

1. Measure pH-value of water, has to be between 6 and 9

2. Pour 0.5 Liter raw water into cup

3. Give 10 drops of flocking test solution into spoon

4. Fill flocking test solution into cup, at this stir strongly for 5 seconds

5. Leave cup: flocking has to start within 1 minute and settle significantly.

NOTE

If analysis is not possible on the spot, take out 2 litres of test solution and store in refrigerator at

ca. 4°C until analysis. Cooling maintains cloudiness by suspended matter.

NOTE

3.2.5.3 Evaluate flocking test

Adjustment of dosing pump flocking means:

- Stroke: 40%

- Frequency: 70%.

The required amount of flocculation agent RM 5001 is then calculated as follows:

- For 50% yield: number of drops x 120 = ml RM 5001 per 10 litres metering solution

- For 75% yield: number of drops x 80 = ml RM 5001 per 10 litres metering solution

If no flockung has start repeat test and change quantity of flocking test solution (first

more test solution, if not successful repeat with less test solution).

Shake well before measurement in labor atory.

Calculation example:

The flocculation test gave 11 drops of flocculation test solution to 500ml up to ideal flocculation,

the yield is 75%:

11 drops x 80 = 880 ml RM 5001 per 10 litres of metering solution

Service Handbook 08.2004

25

Page 26

OPERATION OF THE SYSTEM WTC 600 LP / MP

3.3 Connecting the Equipment

3.3.1 Connections, Valves and Indicator s

Depending on the local untreated water supply, the WTC 600 LP/MP is connected directly to the

off-site supply or supplemented through a WTC 600 PI pressure-increase module.

The following constructional measures must be observed:

- The off-site untreated water supply must be equipped with a shut-off device (supplied by user

/ customer).

- All pipes / lines (untreated water , backwashing, concentrate and drinking water) to be installed

without mechanical tension.

- Drinking water line to be installed with free run-out and no further shut-off devices.

- Backwashing line to be installed with steady drop (under no circumstances inclined upward).

For easy and secure operation and maintenance of the system, minimum clearances

from the walls are to be observed:

Page Minimum clearances [cm]

A50

B10

C70

D50

Table 12 Minimum clearances

Figure 8 Minimum clearances WTC 600 LP/MP

2

1

Figure 9 Water connections, WTC 600 PI

3

Installation space (incl. working space for maintenance and operation, not including piping):

WTC 600 LP and MP: width x depth: 1300 x 1900mm

WTC 600 LP-A, LP-AM, MP-A, MP-AM: width x depth: 1700 x 1900 mm

WTC 600 CD: width x depth: 500 x 1100 mm

WTC 600 PI: width x depth: 600 x 200 mm

26

Service Handbook 08.2004

Page 27

WTC 600 LP / MP OPERATION OF THE SYSTEM

3.3.1.1 Pressure-increase Module

Connection to the RO system (9/2) Hose shank d25

Connection to the untreated water (9/3) Hose shank d25

CAUTION

Observe mechanical protection of the electrical connection cable (9/1) as well

as protection against water!

The fan wheel of the pump must be at least 20 cm away from the next wall.

CAUTION

Otherwise damage to the motor caused by heat build-up must be considered.

3.3.1.2 RO Module with Preliminary

Filters

In the delivery condition, blind discs are

installed for means of preservation to the

screwed connection above the Antiscalant

(10/1) metering line as well as to the drinking

water connection (11/4) and to the concentrate

connection (11/3). These are to be removed

before starting operation.

Metering line connection for pre-chlorination

(10/2)

2

3

1

4

Untreated water connection (10/3) hose shank

d25

Concentrate drain (10/4) HT-pipe d50

Drinking water connection (11/4) hose shank

d25

Metering line connection for post chlorination

(11/5)

Sampling valve for drinking water (11/6)

Sampling valve for untreated water (11/9)

Pressure control valve (11/1)

Flow meter, concentrate (11/2)

Flow meter, drinking water (11/7)

Concentrate control valve (11/8)

Figure 10 Connections, rear

3

2

1

Figure 11 Connections, front

4

5

6

7

8

9

Service Handbook 08.2004

27

Page 28

OPERATION OF THE SYSTEM WTC 600 LP / MP

3.3.2 Electrical Connections

3.3.2.1 Pressure-increase Pump

230 V external, via connection cable.

3.3.2.2 Preliminary Filter

In delivery condition, the preliminary filters are connected to the power outlets (1/f) on the rear

side of the RO equipment.

3.3.2.3 Metering Station

The pumps of the projected metering stations are connected to the power outlets (1/g).

NOTE

The cable from the float switch must be inserted in the metering pump unit.

Digital input

(release)

1

Alarm output

(empty alarm)

Figure 12 Alarm output and digital input of the metering pumps

2

For connection of the control cables in the

electrical switching cabinet, the blind

connections in the flange plate (13/4) are

replaced by the enclosed cable screw fittings

(13/3).

Connect the control cables in accordance with

T ab le 13.

NOTE

The complete connecting

diagrams / plans (13/1) are located

in the switch cabinet.

NOTE

The connections for signal inputs

that are not required are bridged at

the connecting terminal (13/2).

28

1

2

3

4

Figure 13 Connections, metering stations

Service Handbook 08.2004

Page 29

WTC 600 LP / MP OPERATION OF THE SYSTEM

Metering Type Function Signal Line Connecting

Container Terminal,

El. Cabinet

Pre-chlorination Alarm output (12/1 not required white -----

blue -----

Empty signal brown 14

black 15

Digital input (12/2) Release brown 8

blue 9

not required white -----

black -----

Antiscalant Alarm output (12/1) not required white -----

blue -----

Empty signal brown 16

black 17

Digital input (12/2) Release brown 10

blue 11

not required white -----

black -----

Post chlorination Alarm output (12/1) not required white -----

blue -----

Empty signal brown 18

black 19

Digital input (12/2) Release brown 12

blue 13

not required white -----

black -----

Table 13 Connection assignment: Empty message and releasing of the metering containers at

the RO control

CAUTION

Electrically insulate cable ends that are not used with insulating terminals.

Service Handbook 08.2004

29

Page 30

OPERATION OF THE SYSTEM WTC 600 LP / MP

3.3.2.4 Float Switch

Connect the signal lines of the enclosed float switch to clamps 6/7 (8S3 option) of the

connecting terminal – compare wiring diagram in the switching box. Upon installation, adjust a

switching hysteresis of at least 300 liters between the switching-on and switching-off point.

3.3.2.5 Reverse Osmosis System

The WTC 600 LP/MP is connected to the following power supply:

- 400 V / 50Hz, 3Ph + N + PE or 230 V / 50Hz, 1Ph + N + PE (depending on type of system)

- Fuse protection 16 A

- RC protective switch 30 mA from source of power supply (check if in existence or have

confirmed in writing).

3.4 Starting Operation

Operation of the individual equipment components is started in the following sequence:

- Fill the preliminary filter and start operation by bac kwashing (3.4.2)

- De-conserve reverse osmosis (3.4.3.7)

- Fill metering container and start operation (3.4.1)

- Start the operation of the reverse osmosis (3.4.3.8)

3.4.1 Metering Station

NOTE

Operating mode on “Manual” (14/2)!

Change the operating mode by pressing the

"Mode" key (14/2).

Modul Lift Frequency Meter-

Prechlorination 40% 70% 3.2.2

Pushbutton for venting in “continuous operation” (14/3).

4

(14/1) (14/4) ing

2

3

1

Antiscalant 40% 50% 3.2.3

Post

clorination 40% 70% 3.2.4

Flocculation 40% 70% 3.2.5

Table 14 Checking pump settings

NOTE

30

Adjust the lift only when the

pump is running. Danger of

damaging!

Figure 14 Metering station

Service Handbook 08.2004

Page 31

WTC 600 LP / MP OPERATION OF THE SYSTEM

3.4.2 Media and Activated Carbon Filter

3.4.2.1 Initial Filling

Remove the central control valve and position the central pipes with the lower nozzle in the

middle of the tank floor. Fill the tank up to a third with water. Place the filling funnel (4.901-090.0)

in the opening and fill the filter bed with a shovel (6.812-049.0) in accordance with T ab le 15:

Filter Support pebbles Filter sand / Activated carbon

Media filter 15 kg Grain size 2,0-3,15 mm 100 kg Grain size 0,4-0,8 mm

Activated carbon 15 kg Grain size 1-2 mm 32 kg Actvated carbon grain F100

Table 15 Completely fill the tank with water

Align the central pipe in the middle of the container opening and reinsert the central control valve

again after removing the cover. Connect the hydraulic connections again.

3.4.2.2 Starting Operation

After filling, the filters must be backwashed. For this the complete system is to be connected

hydraulically and electrically, and to be switched on at the main switch. The reverse osmosis

system must be in the Switched Off operating mode (compare 3.4.3 – 3.4.5). The

backwashing is initiated manually with the MANUAL REGEN pushbutton (15/4) and takes

approx. 15 minutes. The procedure can be followed on the display of the controller:

- Step 1C: Backwashing; duration approx. 10 min

- Step 2C and 3C: Without function

- Step 4C: Initial filtration; duration approx. 3 min

Afterwards the filter is ready for operation.

3.4.2.3 Backwashing / Regeneration

For cleaning of the filters, the flow direction of the water is reversed so that the settled debris

particles are moved to the outlet of the flushing water.

The filters are equipped with different devices for actuation of backwashing:

Activated carbon filter:

- Time-controlled: 1 x per night Standard: 2:30 a.m.

- Manually: any time

Media filter:

- Pressure difference: upon contamination of the filter Standard: 1 bar difference

- Time-controlled: 1 x per night Standard: 2:00 a.m.

- Manually: any time

Service Handbook 08.2004

31

Page 32

OPERATION OF THE SYSTEM WTC 600 LP / MP

3.4.2.4 Programming

To start the programming, the covered

pushbutton (15/1) to the left of the “TIME OF

DAY” pushbutton (15/2) is to be pressed (a

circular indentation can be felt under the front

foil).The changing of the flashing positions is

carried out with the “ADVANCE” pushbutton

43

(15/3).

1

NOTE

If a different adjustment than the

factory-setting is required, enter

2

and acknowledge by pressing

“MANUAL REGEN” (15/4).

Figure 15 XP Controller

When pressed continuously, the number values run through in double digits from the current

value to 99; by briefly pressing the pushbutton, the indication changes upward by the value 1.

Moving on to the next enter position is done by pressing the pushbutton mentioned in the 2nd

column in Table 17.

TIME OF DAY 1. Sets the time

2. Starts the programming of time steps

ADVANCE 1. For changing of parameters during proggramming

2. Calls up the diagnosis (see Table 24) - press for 10 sec

MANUAL REGEN 1. Activates a manual regeneration

2. Runs step by step through the regeneration steps

Covered pushbutton Left of the „TIME OF DAY“ pushbutton. Starts the programming.

Table 16 Input, preliminary filter control

Position Indication Description

At the media filter:

1 Covered pushbutton 0. 2 00 Media filter back-washing at 02.00 (minutes)

2 Covered pushbutton 0. 2 00 Media filter back-washing at 02.00

(full hours)

At the activated carbon filter

1 Covered pushbutton 0. 2 30 Backwashing of activated carbonfilter at

02.30 (minutes)

2 Covered pushbutton 0. 2 30 Backwashing of activated carbonfilter at

02.30 (full hours)

At both filters

3 Covered pushbutton FF01 Time interval (in days) between 2 backwa

shings; FF01 means one backwashing per

day

4 Covered pushbutton 200.0 Without function

5 Covered pushbutton 200.0 Without function

1)

Table 17 Programming table

32

for sand filter and activated carbon filter

Service Handbook 08.2004

Page 33

WTC 600 LP / MP OPERATION OF THE SYSTEM

Position Indication Description

6 Covered pushbutton 0000. Without function

7 Covered pushbutton 0000. Without function

8 Covered pushbutton AA14 Without function

9 Covered pushbutton AA02

10 Covered pushbutton AA02

11 TIME OF DAY 1C10 Backwashing period 10 minutes

12 Covered pushbutton 2C00 0 minutes

13 Covered pushbutton 3C00 0 minutes

14 Covered pushbutton 4C03 Initial filtration 3 minutes

15 Covered pushbutton 4d10 Leave programming mode

1)

Table 18 Programming table

1)

For changing of any given value from the programming table, the complete menu must be run

for media filter and activated carbon filter

through. The enter position flashes and the value is changed with the ”ADVANCE“ pushbutton!

Indication Description

02.30 Day time

F-00 Days since the last regeneration

0.0.0.0. Number of regeneration

Table 19 Statistical indications – diagnosis

NOTE

Briefly pressing the “ADVANCE” pushbutton after selecting runs you through the

diagnosis indication.

Service Handbook 08.2004

33

Page 34

OPERATION OF THE SYSTEM WTC 600 LP / MP

3.4.3 Starting Operation of the RO System

3.4.3.1 Operating Levels and Passwords

Normal Level:

In this level, the operating mode, the operating condition as well as the current measuring and

operating values are indicated on the display (5/2) with the help of changing (rotating) masks

(see figure 16).

NOTE

User Level:

The user level enables operation as well as adjustment of the most important functions and

operating settings/parameters as well as the calibration of the LF sensors.

User password:

T echnician Level:

The technician level is an extended user level. Apart from the functions of the user level, it

enables the manipulation of all operating settings/parameters as well as a hardware test with the

help of a diagnosis function.

Technician password: ESC ESC

NOTE

NOTE

NOTE

The user operates the equipment in normal level. Entering a password is not

required.

To enter a password, the respective key sequence must be entered in the normal

level within one minute.

For settings and menus of the RO 1000 control system, see figure 22.

Enter the settings of the projected system in the diagram on page 64!

3.4.3.2 Menu Selection

The menu consists of several lines which are arranged below each other in a list. Two menu

lines each are depicted on the display of the control.

In order to call up the function of a menu point, first select the desired menu point with help of the

pushbutton and the pushbutton.

By pressing the RETURN pushbutton, the function of this menu point is called up . A menu is

ended by pressing the ESC pushbutton (returning you to the normal level). For nested menus,

the ESC pushbutton brings you back to the previous menu.

3.4.3.3 Selection of an Option

Options are selected with the pushbutton and the pushbutton. By pressing the RETURN

pushbutton, the current option is stored as the new operating setting. A selection can be

cancelled by pressing the ESC pushbutton.

34

Service Handbook 08.2004

Page 35

WTC 600 LP / MP OPERATION OF THE SYSTEM

3.4.3.4 Selecting Several Arguments at the Same

For this a series of “0” (argument inactive) and “1” (argument active) appears on the bottom line

of the display. With help of the pushbutton and the pushbutton, a cursor can be moved

between the individual characters. The activation / inactivation of an argument is carried out with

the pushbutton and the pushbutton respectively. Storing is carried out through pressing the

RETURN pushbutton (Example: See Chapter 3.4.3.7).

3.4.3.5 Adjusting Operating Parameters and Balancing Values

For adjustment of operating parameters (e. g. via a menu), the name of the operating parameter

appears in the upper line and the current value is shown in the bottom line. A flashing cursor

marks the respective changeable figure, which can be adjusted to the desired value by pressing

the pushbutton and the pushbutton. With help of the pushbutton and the pushbutton,

the marking can be slid to the respective other figure. Storing is carried out through pressing the

RETURN pushbutton; the input can be cancelled by pressing the ESC pushbutton.

3.4.3.6 Acknowledging Data Inputs

To avoid input errors, acknowledgments are required at various menu locations. They request

the user again to acknowledge changes of operational settings / parameters and adjustments as

correct.

For acknowledgment the pushbutton and afterwards the RETURN pushbutton must be

pressed.

3.4.3.7 De-conserving

The RO system leaves the factor y conserved. Therefore, the conservation liquid must be

flushed out before the initial startup.

Initial situation:

The pre-filters have been put into service. The filter insert has been inserted at the fine filter 5µ.

After all the water pipes and float switch have been connected, the drinking water pipe to the

tank must be undone and temporarily fed to the wastewater sewer.

Work steps:

- Master switch on: system is in switched off operating mode

- Temporarily lay the drinking water pipe in the sewer

- Flush / purge system:

- Pressure regulating valve (4.17) fully open (lever horizontal)

- Concentrate regulating valve (4.15) half open (45°).

The following message must be indicated on the display:

RO 1000 V 01.34

Stop

Otherwise press the ESC pushbutton 5 times.

Then enter user password (cf. Chap. 3.4.3.1).

Service Handbook 08.2004

35

Page 36

OPERATION OF THE SYSTEM WTC 600 LP / MP

Indication:

-Press the pushbutton.

Indication:

Press the RETURN pushbutton.

Indication:

-Press the pushbutton.

Indication:

Press the RETURN pushbutton.

Indication:

-Press the pushbutton.

Indication:

Press the RETURN pushbutton.

> 1 Error ack. <

2 Operating mode

1 Error ack.

> 2 Operating mode <

Operating mode

Operation

Operating mode

Switched off

Execute ?

> no < yes

Execute ?

no > yes <

Indication:

Press the RETURN pushbutton.

Indication:

-Press the pushbutton.

Indication:

System in disinfection operating mode.

Set the concentrate flow to 600l/h at the concentrate regulating valve (4.15).

CAUTION

CAUTION

During disinfection operating mode, all confirmation queries are switched off!

Observe the pressure downstream of the fine filter (manometer 4.7): As soon as it is

less than 2 bar pressure immediately switch off the system. High-pressure pump

running dry!

1 Error ack.

> 2 Operating mode <

Operating mode

Switched off

Operating mode

Disinfection

Leave the system to run in this condition for 20 minutes, then switch to switched off operating

mode (cf. 3.4.5).

36

Service Handbook 08.2004

Page 37

WTC 600 LP / MP OPERATION OF THE SYSTEM

3.4.3.8 Initial startup

- Set the equipment to the operation operating mode (see 3.4.4)

- Set the drinking water capacity to 600 l/h

- For very cold water, the drinking water capacity of 600 l/h is not achieved: Then adjust the

maximum pump pressure of 21 bar (MP) or 14 bar (LP)

- Adjust the concentrate capacity to 200 l/h (for very cold water possibly somewhat more)

Closing the pressure control valve (11/1) Closing the concentrate control valve

(11/8)

Pump pressure and concentrate pressure Pump pressure and concentrate pressure

increase increase

Drinking water amount increases Drinking water amount increases

Concentrate amount increases Concentrate amount decreases

Conducting capacity increase Conducting capacity increase

Table 20 Operating performance of the reverse osmosis when changing the pressure control

and concentrate control valve

CAUTION

Untreated Drinking water Concentrade Yield

water capacity capacity

1200 l/h 600 l/h 600 l/h 50%

800 l/h 600 l/h 200 l/h 75%

Table 21 Typical yields at maximum drinking water capacity and untreated water temperature

NOTE

For all changes of the settings to the system, the following values may not be

exceeded under any circumstances:

- Maximum pump pressure 21 bar (MP) or 14 bar (LP)

- Drinking water amount, 650 liters per hour maximum.

of 15 °C

The drinking water capacity must never be set at more than 650 l/h, meaning that at

higher / lower feed-water temperature, the pump pressure and concentrate pressure

must be decreased / increased respectively by means of the ball valves (compare

figure 11).

Check the conductance value according to the reading on the display.

Demineralization rate: 94 – 99 %.

- Switch off the system at the main switch.

- Connect drinking water line in tank.

- Switch on the system at the main switch: Drinking water is produced and fills the tank.

- Tank filled: The level float switches off the solenoid v alve and the pump until the switch of the

level float signals empty and the RO system switches on again.

Service Handbook 08.2004

37

Page 38

OPERATION OF THE SYSTEM WTC 600 LP / MP

Checking the pressure control device (shut the untreated water supply for this):

The RO system must switch off after a short time.

THE “Fault” LED must light at the operating panel – Lack of pressure is indicated on the

display (5/2).

- Afterwards, open the untreated water supply again.

- Delete the malfunction indication with the ESC pushbutton (5/3)

- Enter operator password

- Use

- -Press pushbutton

- Use the

- Use the key to change to warn value

- Use

CAUTION

- Press the key: Display jumps back to "6 LF limits"

- Press ESC, display is in initial condition

- System has been checked and is ready for use.

keys to call up menu item "6 LF limits"

keys to set the limiting value (upper limiting value of the drinking water

conductivity): 20% of the untreated water conductivity value

keys to set the warn value (warning value of the drinking water conductivity):

15% of the untreated water conductivity value

The upper limiting value must not exceed the statutorily permissible drinking water

conductivity! In case of doubt, take the statutory limiting value as the limiting value

and enter the warning as half the statutory limiting value!

38

Service Handbook 08.2004

Page 39

WTC 600 LP / MP OPERATION OF THE SYSTEM

3.4.4 Normal Operation

Switch on the RO 1000 control; the following

message appears on the display:

RO 1000 V 01.34

Switched off

NOTE

The system has been switched off

in the user or technician level.

Switching on without password is

not possible!

When the following rotating masks appear:

RO 1000 V 01.34

production on

Figure 16 User indication in normal operation

W-Temp:

12.3°C

perm: 12 µS/cm

The system is ready to start, meaning the equipment can produce.

Otherwise enter the user password (compare with Chapter 3.4.3.1).

Indication:

> 1 ackn. failure <

Press the pushbutton one time.

2 operat. mode

Indication:

1 ackn. failure

Press the RETURN pushbutton.

> 2 operat. mode <

Indication:

operation mode

Press the pushbutton.

STOP

hours meter

1111 h 11 min

Indication:

Press the RETURN pushbutton.

Indication:

Press the pushbutton.

Indication:

Press the RETURN pushbutton.

Indication:

Press the ESC pushbutton.

Service Handbook 08.2004

operation mode

OPERATION

are you sure ?

>no< yes

are you sure ?

no >yes <

1 ackn. failure

> 2 operat. mode <

39

Page 40

OPERATION OF THE SYSTEM WTC 600 LP / MP

Indication:

The equipment produces and starts with

rejection. Operating conditions:

- „Production“ LED lights.

- “Reject“ LED lights.

After the reject period has run off, normal production with rotating indication:

RO 1000 V 01.34

Production on

When the RO equipment starts, the intake valve for untreated water is opened and the RO

pump starts after the preset time and given pressure.

3.4.4.1 Operating Messages for Normal Operation

1. System does not produce because tank is full:

W-Temp:

12.3°C

perm: 12 µS/cm

RO 1000 V 01.34

Disposal

hours meter

1111 h 11 min

- The “tank full” LED lights at the operating panel.

- Indication: “K. Displacement” and afterwards “Production off” on the display.

Cause: The float switch in the drinking water tank has switched.

2. System does not produce during regeneration / flushing:

- The “regeneration” LED lights at the operating panel.

- Indication: “Forced stop” on the display.

Cause: One of the preliminary filters is being cleaned.

3. The system does not produce at malfunction indication: Metering station empty

- The “fault” LED lights.

- Indication: Hard w ater .

Cause: Empty sensor in the metering container delivers signal.

Corrective action: Refill metering container with chemical and acknowledge.

NOTE

The malfunction indication can be acknowledged by pressing the ESC pushbutton;

the rotating indications for normal operation appear again (see above).

40

Service Handbook 08.2004

Page 41

WTC 600 LP / MP OPERATION OF THE SYSTEM

3.4.5 Putting Out of Operation

CAUTION

NOTE

NOTE

The system is switched off e. g., when putting out of operation for extended periods. For out-ofoperation periods exceeding 14 days, the equipment must be conserved (see Chapter 4.4.4).

Enter user password for this (compare with Chapter 3.4.3.1):

Indication:

Press the pushbutton.

Indication:

Press the RETURN pushbutton.

Normally, do not switch off with the main switch (a possibly active flushing program

may be interrupted).

The RO system working in normal operation is switched off only via the float switch

when the drinking water tank is full.

The current operating mode is also maintained in the switched off condition, meaning

after switching on again, the control system is in the same operating mode as before

switching off last with the main switch.

> 1 ackn. failure <

2 operat. mode

1 ackn. failure

> 2 operat. mode <

Indication:

Press the pushbutton.

Indication:

Press the RETURN pushbutton.

Indication:

Press the pushbutton.

Indication:

Press the RETURN pushbutton.

Indication:

Press the ESC pushbutton.

Indication:

operation mode

OPERATION

operation mode

Stop

are you sure ?

>no< yes

are you sure ?

no > yes <

1 ackn. failure

> 2 operat. mode <

RO 1000 V 01.34

Stop

The equipment is switched off now.

Service Handbook 08.2004

41

Page 42

OPERATION OF THE SYSTEM WTC 600 LP / MP

3.4.6 Desinfection

Enter user password (compare with Chapter 3.4.3.1):

Indication:

Press the pushbutton one time.

Indication:

Press the RETURN pushbutton.

Indication:

Press the pushbutton.

Indication:

Press the RETURN pushbutton.

Indication:

Press the pushbutton.

Indication:

Press the RETURN pushbutton.

> 1 ackn. failure <

2 operat. mode

1 ackn. failure

> 2 operat. mode <

operation mode

OPERATION

operation mode

STOP

are you sure ?

>no< yes

are you sure ?

no > yes <

Indication:

Press the RETURN pushbutton.

Indication:

Press the pushbutton.

Indication:

System in disinfection operation mode.

CAUTION

CAUTION

During the disinfection operation mode, all safety quest are switched off!

Observe the pressure after the fine filter: If less than 2 bar, switch off the equipment

immediately. High-pressure pump running dry!

1 ackn. failure

> 2 operat. mode <

operation mode

STOP

operation mode

Desinfection

42

Service Handbook 08.2004

Page 43

WTC 600 LP / MP MAINTENANCE

4 Maintenance

4.1 Fine Filter

The manometers (17/1 and 17/3) are located

in front of and behind the fine filter unit (17/2). If

the differential pressure is more than 0.8 bar,

the fine filter is to be cleaned or replaced:

- Stop the untreated water supply until the

system is in the lack of pressure operating

condition.

- Switch off the main switch.

- Release the pressure in the equipment

(open the sampling valve for untreated

water).

- Replace filter.

NOTE

Replace the fine filter every 3

months.

NOTE

Use the special filter wrench!

4.2 Metering Station WTC 600 CD

1

Figure 17 Replacing the fine filter

2 3

Every 4 weeks:

Clean the inside of the metering tank and thoroughly rinse with chlorine-free drinking water.

When working on the metering head or on the connections and lines, wear protective

clothing (goggles, gloves)!

Before any maintenance, disconnect the pump from mains (pull mains plug)!

Every 12 months (or when malfunctions occur):

Cleaning the suction and pressure valves

- Unscrew valve and take out inner part of valve.

- With a thin wire pin (nail or similar), carefully remove the valve inner part in flow direction (see

arrow mark on valve body).

- Disassemble the inner part (seat, O-ring, balls, ball cages) and clean; replace if necessary.

- Reassemble valve again and screw in.

CAUTION

Observe direction of flow (arrow)!

Tighten valve by hand only (danger of damaging!)

1)

Feinfilter 5µ: Art.-Nr. 6.414-466.0

Service Handbook 08.2004

43

Page 44

MAINTENANCE WTC 600 LP / MP

Replacing the membrane

- Set the pump lift adjustment knob (8/1) to 100 %.

- Unscrew the 4 screws, size 6 mm, at the metering head and remove the metering head.

- Unscrew the membrane to the left.

- Reattach the sealing membrane1), intermediate ring and support disc again.

- Screw in new membrane.

- Bring the push rod to the “end of suction stroke” position by switching the mains voltage on/

off.

- Reassemble metering head and tighten screws over cross (tightening torque 4 Nm).

- Bleed the pump (8/3) and put into operation again.

- After 48 hours of operation, retighten the metering head screws (tightening torque 4 Nm).

4.3 Reverse Osmosis Module (RO Module)

4.3.1 RO Filter Replacement

The RO filters are to be replaced when

cleaning and disinfection as a measure to

increase the capacity have been without

success.

Filter replacement:

- Select the switching off operating mode and

release the system pressure.

- Loosen the connections (concentrate

connection (18/2), drinking water connection

(18/1) and supply (18/5)) and unscrew

pressure tube (18/4) with tube clamps (19/5)

from the frame.

CAUTION

Do not loosen the tube clamps

because of height adjustment.

- Release securing rings (19/1).

- Unscrew connections (19/2).

- Screw extractor tool into thread of drinking

water connection (19/3) and carefully lever

out using pipe pliers.

1

2

3

4

4

- Remove adapter from lid, clean and insert.

- Take out filter and remove low er lid.

NOTE

1)

Membrane replacement set: Item No. 6.762 172.0

Do not interchange lids.

44

5

Figure 18 RO-Modul

Service Handbook 08.2004

Page 45

WTC 600 LP / MP MAINTENANCE

1)

- Apply Propandiol

- Insert a new filter (19/7) at the supply

opening (end without seal first!).

to the rubber seals.

67

1

- Attach all adapters.

2

- Insert lid (19/4) in such a manner that the

threads of the openings are flush with the

nuts of the clamp (19/5).

- Install securing rings and screw in

4

connections.

- Fasten module to frame and connect pipe

3

lines.

- Flush the equipment for 10 minutes

(3.4.3.7).

5

- Switch to the operation operating mode:

Figure 19 Assembly and disassembly of the RO

- The equipment values must correspond with

filter

those of the initial start-up.

4.4 Cleaning in Case of Malfunction

The following measured variables or their change from the original values (cf. operating

certificate) are indicators for the need for cleaning or disinfecting the system.

The WTC 600 service kit (2.901.044.0) is intended for cleaning the WTC 600. Apart from the

cleaning chemicals and a wet-dry vacuum, it contains all the equipment needed for cleaning and

conserving the WTC 600 LP and MP.

The cleaning chemicals must be ordered separately.

The system should be cleaned if the following differences occur compared to the initial startup

- The drinking water flow drops by 200l/h at the same pressure

- The conductivity doubles at the same pressure and temperature

- The differential pressure between the pump pressure and concentrate pressure increases

by more than 2 bar .

NOTE

NOTE

Alkali cleaning with RM MCT 511 first, then acid cleaning with RM MCT 103.

Only disinfect if cleaning is unsuccessful.

1)

Propandiol: Item No. 6.290-910.0

Service Handbook 08.2004

45

Page 46

MAINTENANCE WTC 600 LP / MP

4.4.1 Design of the Flushing and Disinfection Equipment

Figure 20 Diagram of connection principle for cleaning conserving and disinfection of the RO equipment

1. Manometer

2. Fine filter

3. Solenoid valve

4. Pressure switch

5. RO Pump

6. Pressure tube /

module

7. Measuring cell

8. Flow meter (drinking water)

9. Pressure control valve

10. Check valve

11. Concentrate control valve

12. Flow meter (concentrate)

13. Electrical control system

14. Drinking water to the

flushing tank

15. Concentrate to the

flushing tank

16. Flushing tank

17. Sampling valve for

drinking water

18. Sampling valve for

untreated water

19. Flushing pump

Aids:

- Cleaning tank

- Four connection hoses

- Conductive capacity measuring unit for measurement comparison after flushing

- Protective clothing (goggles, gloves, apron)

- External pump as flushing pump

Starting Position:

- RO equipment set to switched off operating mode and switched off with main switch.

46

Service Handbook 08.2004

Page 47

WTC 600 LP / MP MAINTENANCE

Work Steps:

1. Fill 30 liters of chorine-free drinking water into the flushing container (20/16).

2. Switch on master switch and set RO system to "Switched off" operating mode.

3. Close the untreated water inlet; depressurise system:

- Use connection hoses and flushing pump (20/19) to connect the flushing tank with the

untreated water sampling tap

- Feed the drinking water adapter and connection hose from the drinking water outlet (20/8)

to the flushing tank

- Feed the concentrate adaptor and connection hose from the concentrate outlet (20/12) to

the flushing tank

- Unplug the earthing-contact plugs of the metering pumps.

- Switch the flushing pump on.