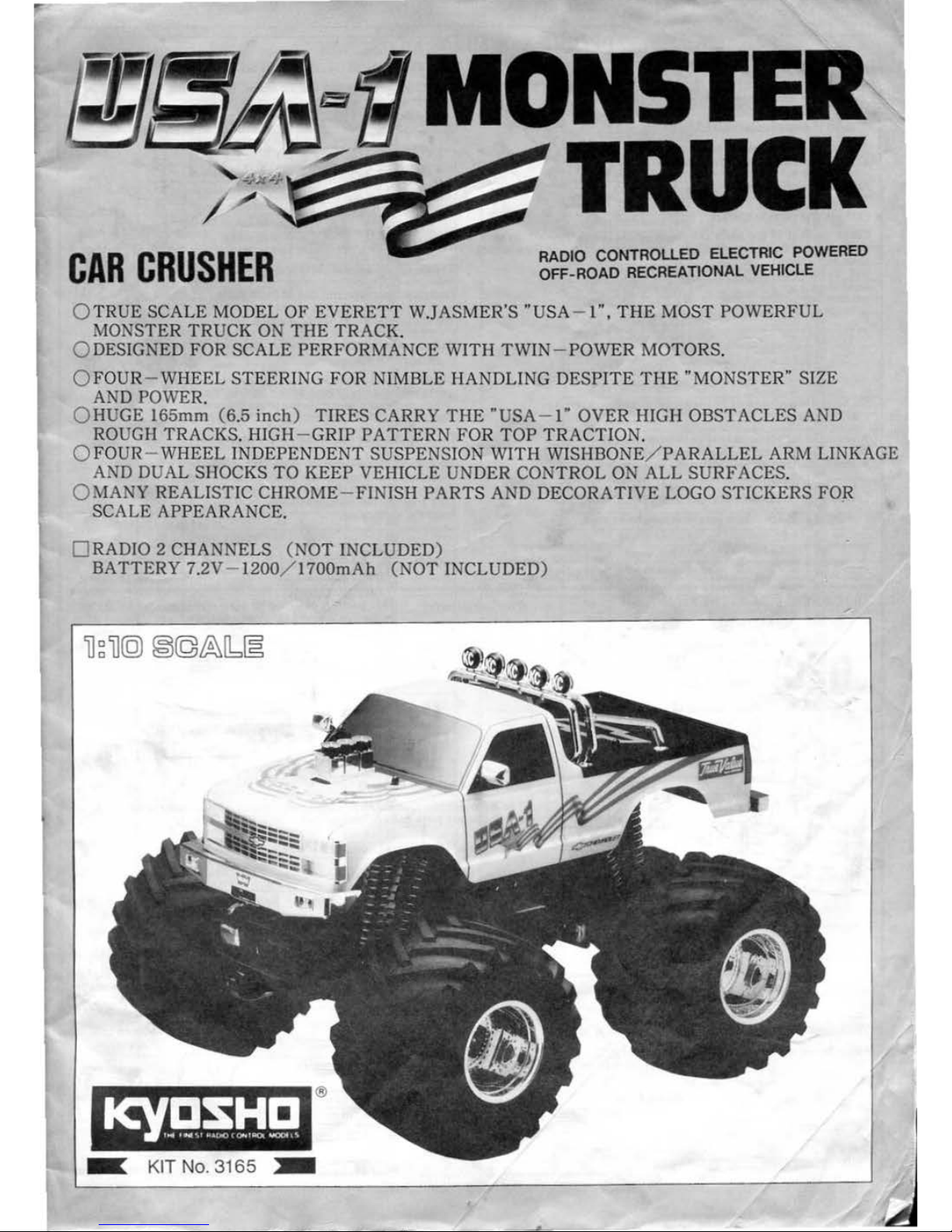

Kyosho USA-1 Monster Truck User Manual

/"'

CAR

CRUSHER

RADIO

CONTROUED

ELECTRIC POWERED

OFF- ROAD RECREATIONAL VEHICLE

Q

TRUE

SCALE

MODEL

OF

EVERETT

W.JASMER'S

"USA

- 1

", THE

MOST

POWERFUL

MONSTER

TRUCK

ON

THE

TRAC

K.

Q DESIGNED

FOR

SCA

LE PER

FORMANCE

WITH TWIN

- POWER MOTORS.

0 FOUR- WHEEL

STEER

ING

FOR

NIMBLE HANDLING

DESPITE

THE

"MONSTER"

SIZE

AND

POWER.

Q HUGE

l65mm

(6.5

inch) TIRES

CARRY

THE

"USA-1"

OVER HIGH OBSTACLES AND

ROUGH TRACKS. HIGH- GRIP

PATTERN

FOR

TOP TRACTION.

Q FOUR- WHEEL INDEPENDENT SUSPENSION

WITH

WISHBONE/

PARALLEL

ARM LINKAGE

AND

DU

AL

SHOCKS

TO

KEEP

VEHICLE UNDER

CONTROL

ON

ALL

SURF

ACES.

Q MANY REALISTIC

CHROME-FINISH

PARTS

AND DECORATIVE LOGO

STICKERS

FOR

SCALE APPEARANCE.

0 RADIO 2 CHANNELS (

NOT

INCLUDED)

BATTERY

7.2V - 1200/

1700mAh

(NOT

INCLUDED)

®

Ill[

KIT N

o. 3165

:1111

r

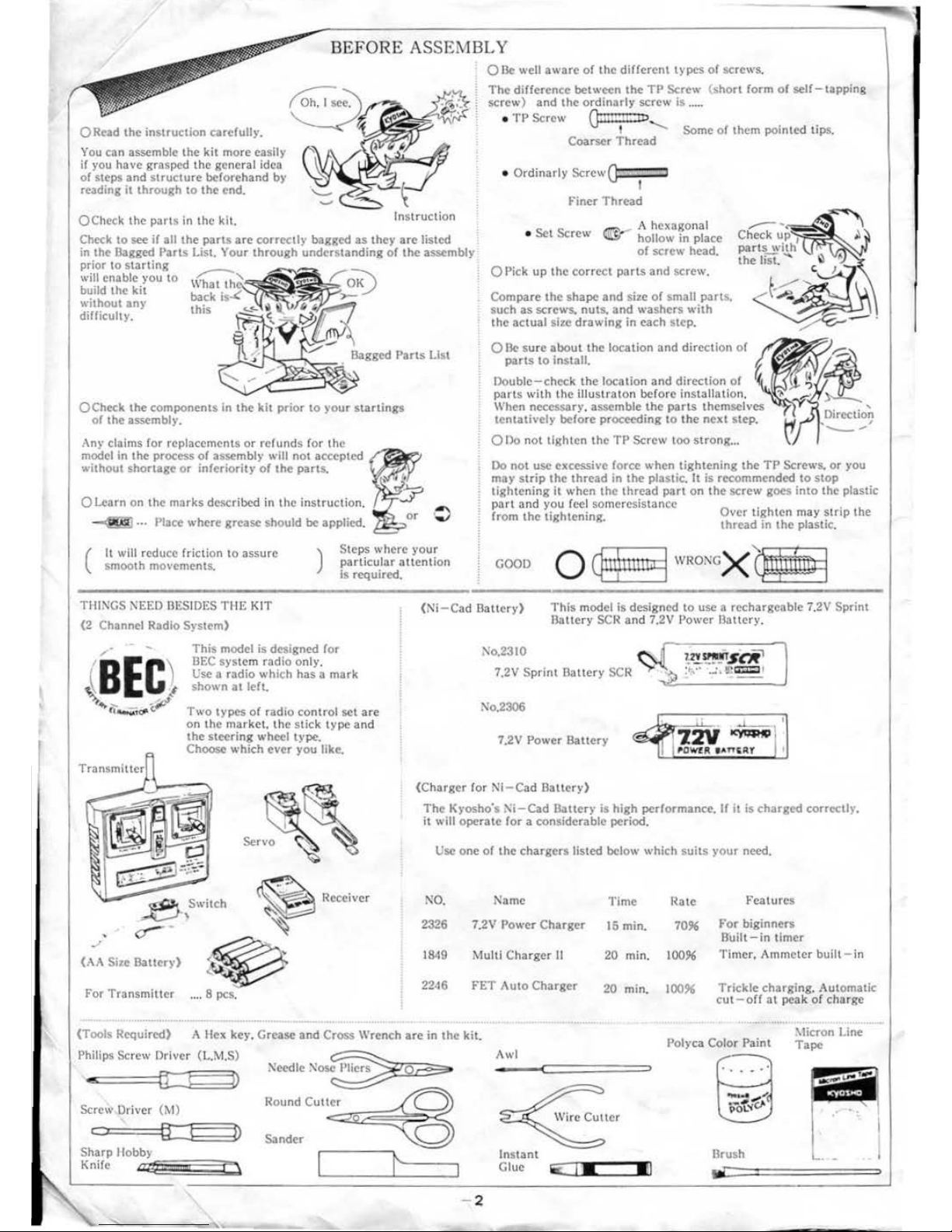

BEFORE

ASSEMBLY

ORead

the

instruction

carcfull)•.

You

can

assemble the

kit

more easily

if

you

have

grasped

the

general idea

or

steps

and

structure

beforehand by

reading it

through

to

the

end.

OCheck

the

parts

in

the

kit.

Instruct

ion

Check

to

see

if all

the

parts

are

correctly

bagged

as

they

are

listed

0

Be

well

aware

of

the

diHerent

types

or

screws.

The

difference between

the

TP

Screw (

short

form

of

self-tapping

screw)

and

the

ordinnrly

screw

is

.....

•

TP

Screw

ail!!!'!!:

ID

I Some

of

them pointed tips.

Coarser

Thread

• Ordinnrly

ScrewQ

'

Finer

Thread

=-..-

A hexagonal

•

Set

Screw

~

hollow in place

in the

Bagged

Parts

List. Your

through

understanding

of

the

assembly

of

screw

head.

prior to

starting

will

enable you

to

build the

kit

without

am·

difficulty. •

OCheck

the

components in

the

kit

prior

to )'Our

startlngs

or

the assembly.

Any

claims for replacements

or

refunds for

the

model in the process

of

assembly will

not

accepted

without

shortage

or

in!criorit)'

or

the

pans.

0 Learn on the

marks

described in

the

instruction.

-g)

... Place

where

grease

should be applied.

c=

=-

0 Pick

up

the

correct

parts

and

screw.

Compare

the

shape

and

size

of

small

parts.

such

as

screws. nuts.

and

washers

with

the

actual

size

drawing

in

each

step

.

0

Be

sure

about

the

location

and

direction

or

parts

to

install.

Double-check

the

location

and

direction

or

?;

parts

with

the

illustraton

before installation.

When necessary. assemble

the

parts

themselves

tentatively before proceeding to

the

next

step.

0

no

not tighten

the

TP

Screw too

strong

...

'

Direction

. '

--

Do

not

usc excessive force

when

tightening

the

TP

Screws.

or

you

may

strip

the

thread

in

the

plastic. It is recommended to

stop

tightening

it

when

the

thread

part

on

the

screw

goc.

into

the

plastic

part

and

you reel someresista nee . .

from

the

tightening Q,•cr tighten may

stnp

the

·

thread

in

the

plastic.

(

It

will redu

ce

friction to

assure

smooth

movements.

)

Steps

where

your

particular

attention

is required.

GOOD

TIIINGS NEED BESIDES T ilE KIT

(2

Channel Radio System)

Transrniuer

(:\A

Size

Battery)

This model

is

designed for

BEC

syste

m radio only.

Usc a radio which

has a mark

shown

at

left.

Two

types

of

radio

control

set

arc

on

the

market.

the

stick type

and

the

steering wheel type,

Choose which ever you like.

Servo

f'or

Trans

mitter

.... 8 pes.

(1-11

-Cad

Battery)

This

model is designed to usc a rechargeable

7.2V

Sprint

Battery

SCR

and

7.2V Power

Battery.

1'\o.2310

7.2V Sprint

Battery

SCR

l':o.2306

7.2V Power

Battery

(Charger

lor

NI-Cad

Ballcry)

The

Kyosho's

l'i-Cad

Dauer)'

is high performance. If it is

charged

correctly.

it will

operate

for a considerable period.

Usc

one

of

the

chargers

listed below which

suits

your

need.

NO.

Name

2326 7.

2V

Power

Charger

1849 Multi

Charger

II

2246

f'ET Auto

Charger

0

·--·-·

Time

15

min.

l~ate

Features

7096

For

biginncrs

Built-

in

timer

20 min.

10096

Timer. Ammeter

built-

in

20 min.

10096

Trickle charging. Automatic

cut

-orr

at

peak

of

charge

(Tools Required) A Hex kC)', Grease

and

Cross Wrench

are

in

the

kit.

Polyca Color Paint

:0.1icron

Line

Tape

Philips Screw Driver (L.M.S) Awl

--<====

==

• • 0

..

•

.....

cr:

!

D

Screw Driver

(M)

C=t

§

J

D

Sander

Sharp

llobb}

Knife

Brush

Instant

Glue

lii

lliC:[I

JMC=::JIIJ

I

- 2

JIJg

:>:o.

IKe}·

::

I

2

3

Ulister

4

5

6

66

001<-1

9

10

11

12

13

14

15

USI<-2

16

17

18

19

zo

Zl

22

OOA-3

23

USI<-4

24

USI<-5

25

26

27

28

29

001<-7

30

31

32

33

34

US

A-8

35

36

37

38

39

40

41

US

A-9

42

43

(4

45

46

47

48

49

USA-10

so

I

51

52

53

54

55

56

57

58

59

USA-II

60

61

62

63

64

65

67

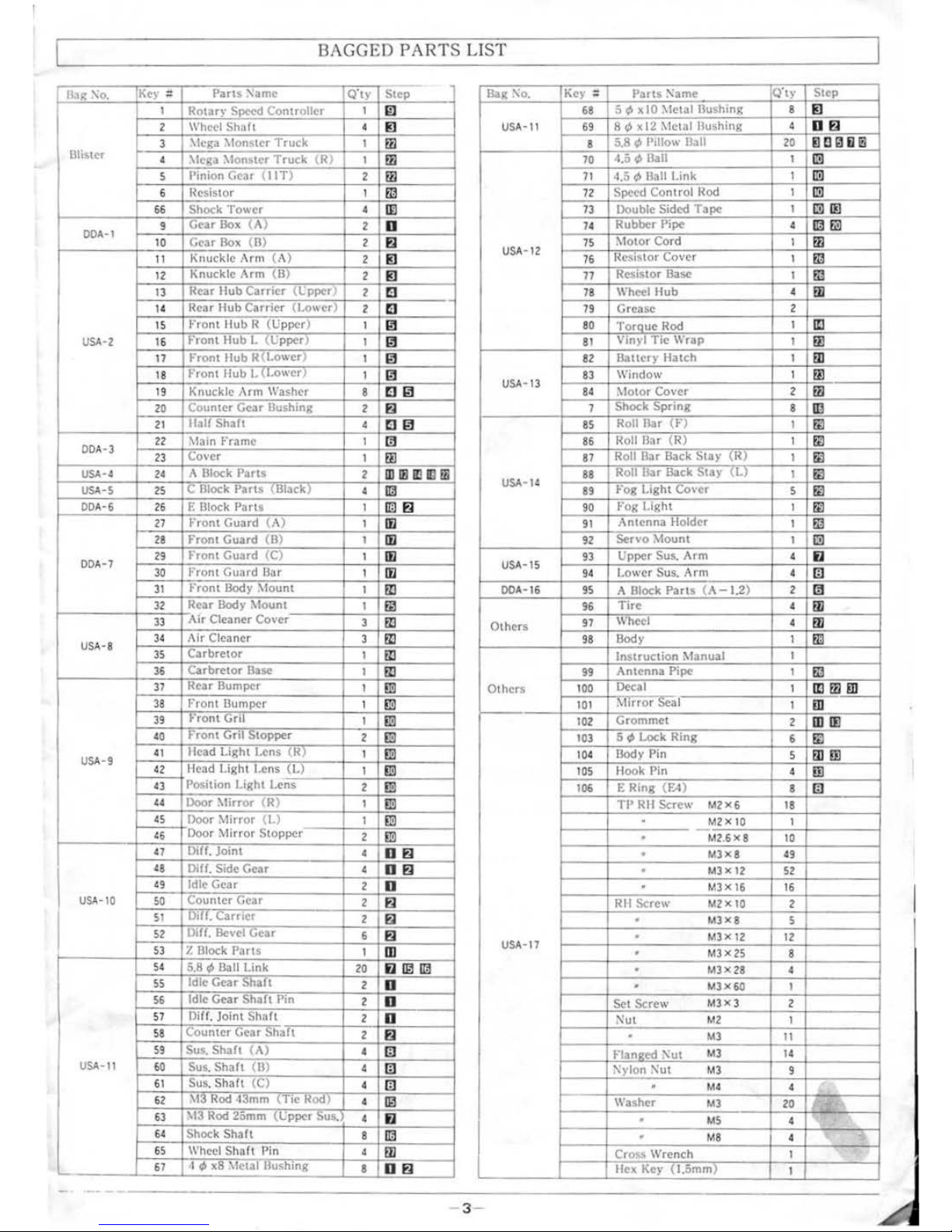

BAGGED PARTS

LIST

"

I

Q'ty

l~o1ary

Controller

I

'""""

4

'ter 1 ruck

I

\leg a :\lon,ter

Truck

( R)

I

1

Gear

(liT)

2

l~esistor

I

Shock

Tower

4

Dox

(A)

2

Box

((ll

2

Kn·~~

~

~Arm (A)

2

" '

, 1

\rm

(B)

2

Rear

Hub

lL

2

1

"~"'

llub ""'

""

C

.,

z

,.,

um

Hub

I! (Upper

)

I

1

rrun!

Hub L

n·

. '

1

1

rronl

Hub R I

1 r

ront

llub

I.

' I

1

!K

Arm

8

Gear

II

2

•

JlalfShaft

4

\lain

Frame

I

1

:\

Par,.

2

c

"'i3i'OC'k

Pa r 1 s

(i3fiiCi()

4

E

131ock

Parts

1

rrum

r:

(M

1

II

Gp>r<l

~

I

Front

Guard

(C)

1

I

front

Guard_I3(Jr

I

r

rom

Body :'-fount

I

•.u• .,

\f

ount

I

Air

Cleaner

Co,•er

3

AirO.

3

""'

uo

~•v• I

Ba,;c

I

llear

Bu

.•

1

Front

1

r

rom

vrll

1

rrunt

Gril

2

I lead Light

-(I<)

I

I I

iuh1

l."ns

{L)

I

Position

Light

Lens

2

Door

:\lirror

1 R)

I

1\

•

•v

t)

1

,

·hrror

topper

2

I Dilf.

4

Dill. Side

Gear

4

Idle

Gear

2

Counter

v•u•

2

Oil!.

Carrier

2

Dill. .1

vear

6

Z

131ock

Parts

I

8¢

Ball Link

20

lfe

v~o

;:)IIUil

2

Idle v_

-·

'"'""

Pin

2

0111.

Joint

Shall

2

vw.'

Shall

2

Sus.

Shaft~

4

Sus.

Shaft

(ll)

4

_Sus.

Shalt

{Cl

4

:\13

Rod~

\

lie

KOO_J_

4

I \13 Rod

·Sus

4

'

Shaft

8

Wheel

Shall

Pin 4

I

~XI!

..

.,

8

ji]

_

i

~

~

1l_

L

[b

b

-

~

j

j

!

~

!

l

~

1m

=I

~

i

j

~

J

D~

Bag

\o.

USI<-11

USA-12

USI<-13

USI\·14

USA-IS

I Key

::

Pans

:'\a me

68

5 ¢ x 10

\lrtnl

69

8

~

x

12

Metal Bushing

8

5.11

l

13;111

70

4.5 1

13all

71

4.5 ¢ Ball Link

72

Con 1 rol Hod

73

~

74

R

75

76

77

·Pipe

1

4

I

1

1

78

\\

nee•

Hub

4

2

f.!!!-

'-----1

79

Grease

89

~·og

l.ight

-v

· 5

90

Fog

•ht 1

91

i\1 1

92

..Cr•v

. I

93 Sus.

Arm

4

4

i

--

--i

94

Lower Sus.

Arm

~;O~

OA~-~16~~~9~5~A=~~

Parts

(A-1.2)

Z

~

:~~-rrn:~

:

Others

98

Body I

·~•;,.,

l\lanual

I

99

Antenna

npc

I @

Others

100

II 1

1

~J!!_

101

i\

irror

seal

_ill___

_

~-------t:i~o~

zcj~

~~m~e~t~=========j==

z~~~

~~:~~!=t~S~~~.t~.i~P~ikntR~in~g========t=~:=t

iil

~

~

~--~

~

1

OS

: Pin 4

8

Lm_

:------1

106

_E Ring

(E4)

IQ

TP

RH

Screw

M2

x 6

18

•

__

M~XIO

I

~--~----.-----M~2~.6~X-8

~~-

I~G~

----

---;

•

M3X8

49

•

MJX

12

52

•

MJX

16

16

Rll

M2 X 10

2

• MJX8 5

•

M3XI2

12

USA-17

MJX

25

8

•

•

M3X28 4

• M

J~

I

I

Set

!':rr~w

MJXJ

2

Nut

_!.1_2_

I

•

MJ

11

MJ

14

' :>:yton

Nut

MJ

9

M4 4 ' ,

r---~~\\'a~shc--r----~

M~J--

---i-720~~~

:--\---i

•

•

•

M8

4 ' 2

I

'\.

/

Hex

Ke~·

0.5mm)

1

3 -

•

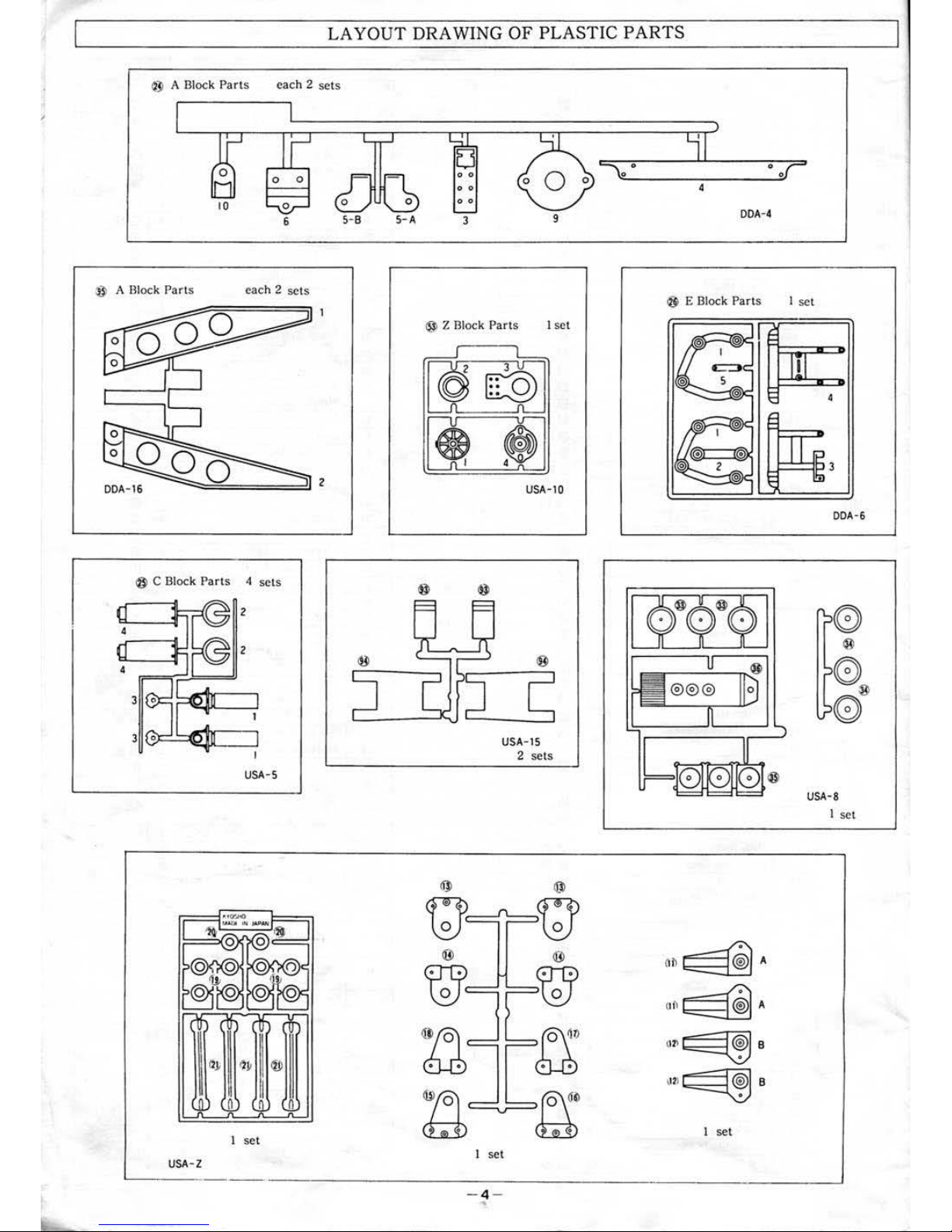

LAYOUT

DRAWING OF PLASTIC

PARTS

® A Block

Parts

each 2 sets

0 0

10

5-B

® A Block Parts each 2 sets

ooo

.JJ

0

,......

0

II

I

I

I

.....

I

I

I

~

Jl

ooo

""il

DDA

- 16

z

@ C

Block

Parts

4 sets

4

USA-5

®

I

1

se

t

USA-Z

5- A

[3

0 0

0 0

0 0

3

9

® Z

Block

Parts I set

USA-10

USA-15

2

se

ts

~

~fJ)=:'J==u;

I set

•

0

•

4

DDA-4

® E Block Parts

I

)

!!

I @7:

~

~~l

-.....:

@)c

,.

it

'

@)C

ik

® @)

®

21®lc

-......:

@

lL....i

Oh

~A

no

~

A

1

111(

~

B

~1l

~B

I

set

•

I

se

t

I

4

IP

l!:u

3

DDA-6

USA-8

I set

.__

_ _ , _

____

__

___

__

_ _

___

__

_ _

____

__

_ _

_j

- 4 -

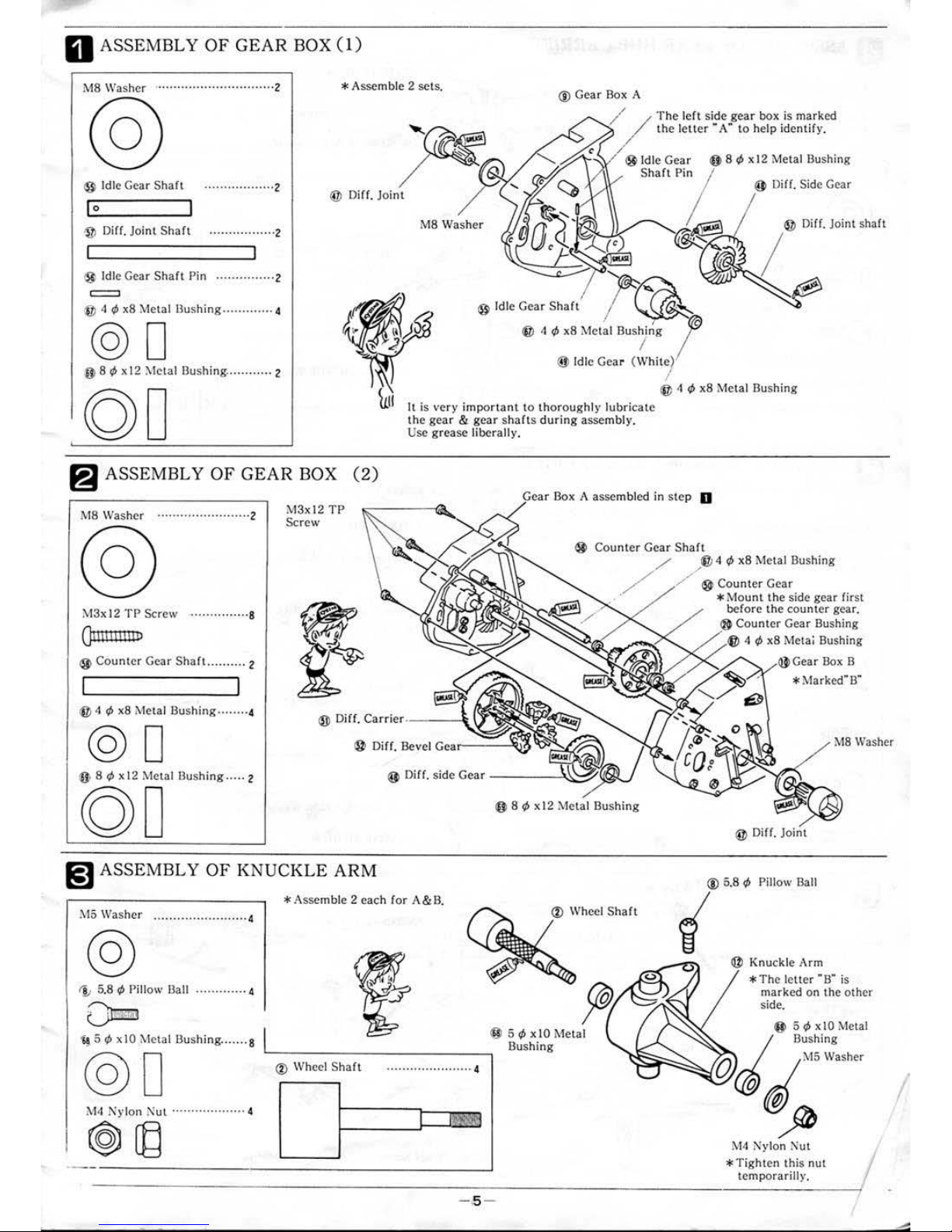

0 ASSEMBLY

OF

GEAR

BOX

(1)

M8

Washer ........ ...

...................

2

® Id le

Gea

r S

haft

··

·······

·· ·····

··2

I o

·

~

Diff

.

Joint Shaft ·················2

®

Idl

e Gear

Shaft

Pin

···············2

® tl

r/>

x8

Metal Bus

hing

.............

4

@0

@ 8

r/>

x 12

:0.1eta

I Bushing .....

.......

2

*A

ssemble 2 sets.

®Gea

r Box A

@

Di

ff.

Joint

The left side

gear box is marked

the

letter

·A·

to help

identify.

®Idle

Gear @ 8

r1>

x 12 Metal Bushing

S

haft

Pin

M8 Washer

It

is

very impor

tant

to thorough!)'

lubr

icate

the

gear

& gear s

hafts during asse

mbly.

Usc grease

liberall

y.

@ Di

ff.

Side Gear

I" o; ".

'''"'

"''"

~

ASSEMBLY

OF

GEAR

BOX

(2)

Box A a

ssem

bled in step D

M8

Washer ·······

··

··· ············2

M3

xl2

TP

Screw

® Counter Gear Shaft

.//

M3x

12

TP

Screw

··

·············8

Qt

I IIlli Ill P

®Counter

Gear Sha

ft

...

.......

2

® 4

tJ>

x8 Metal

Bushing ········4

®

Oiff. Car-r

ie•c·--

-

-\

@0

®

Diff.

Bevel

Ge;ar---~;~

@ 8

tJ>

x 12 Meta l

llushing

.....

2

00

(i] ASSEMBLY

OF

KNUCKLE

ARM

*A

ssemble 2 each for

A&

B.

l\15

Washer

••

0 • 0 0

•••••••••

• • 0 • 0 0 0 • 0 4

@

1;

5

.8

tJ>

Pillow

Ba

II

.........

....

4

O=m

1§

5

tJ>

x

10 1\letal

llushi

ng

.......

8

@ D ® Wheel Shaft

o o o o o o o o I o o o o o o o o o o o o o 4

M4

Nylon

Nut ····

···

·······

···

·· 4

@ 8

tJ>

x

12 Metal

Bushing

® Wheel

Shaft

® 5

tJ>

x

10

Metal

Bushing

4

tJ>

x8

Metal Bushing

® Co

unt

er

Gea

r

*

Mount the side gear

fir

st

before the co

unt

er gear.

Counter Gear Bushing

4

tJ>

x8 Meta; Bushing

Gear Box B

* Marked"B"

MS

Washer

@

Diff.

Joint

®

5.8

tJ>

P

ill

ow Ball

@

Kn

uckle

Arm

* The l

etter

• B" is

marked on the o

th

er

side.

® 5

r1>

x

10

Metal

Bushing

M5

Washer

@ ©

M4

Nylon

Nut

I

*

Tigh

ten

this nut

·

--

---

----------------

----

--

----------

------------

----

----

--------

------

--------

--

----~

t~e~m~po~ra

~

r~il~ly

~·

----~

- ,5 -

I

m ASSEMBLY

OF

REAR

HUB

CARRIER

*A

ssemble I set each

for

A &

13.

Tighten screws so the

knuckle

arm can move smoothly.

11

Knuckle

Arm

Washer

··

4

:.13x8

TP

RH

Screw

···

···

······

4

QUill!•

® 5.8 ¢

Pillow

Ball ·

········

·2

()mm

:\13x12TP RH

Screw·········

·4

On

11111

mo

®Half

Shah

Knuckle

Arm

(B)

assembled

in

step

l!J

.

*

Marked

• B"

on

the

other

side.

® Rear

Hub

Carrier (Lower

)

~

ASSEMBLY

OF

FRONT

HUB

CARRIER

* Assemble I

set

each

for

A &

B.

Tighten screws so the knuckle

arm can move smoot

hly.

lJ, Knuckle

Arm

Washer

..

,

M3x8

TP

RH Screw .......... 4

QIIIUI•

.-J!:1

~

M3xl2

TP

RH Screw

® 5.8 ¢

Pillow

Ball~

1:1

lf

J:')kr:

M3x8

TP

RH Screw

M3xl2

TP

RH

Screw~

ij

®

Half

Shah

V

QJ)

Knuckle

Arm

Washer

• 1 I

.1~,.

.,

®

Front

Hub

Carrier R (Upper)

~

'"""

@ (other

side)

Knuckle

Arm

A)

assembled

in

step

l!J

.

*Mark

ed

'

A·

on the

other

side.

@ Rear

Hub

Carrier

(U

pper)

I ; I

I

0\ I

® Rear

Hub

Carrier

(Lower)

L r---.._j

@

Front

Hub

Carrier R

(U

pper)

~

®Front

Hub

Carrier

R

(L

ower)

®

Front

Hub

Carrier R (Lower)

® 5.8 ¢ Pillow Ball ............ z

I

Omm

L

_j

-Pb

@ (other

side)

~

~

®

Knuckle

Arm

Washer

~

M3x8

TP

RH Screw

:\13x

12

TP

RH Screu ............. 4

01111111111

p

-

ASSEMBLY

OF

MAIN

FRAME

*I

nstall

Front

& Rear Gear Box.

M3x

16

Tl'

Rll

Screw

:\13x

16

TP

RH Screw

..........

a

()IIIIIIIIIIIIIIIP

Gear Box

assembled

in

step a

M3x8

TP

RH Screw ............

,z

~

A-2

M3 Washer

@

......•....

•.•.•.

..

4

M3

Washer

:.t3x8

TP

RH Screw

*

Temporarilly

tightened.

M3

x8

TP

RH Screw

M3xl6

TP

RH Screw

- 9-

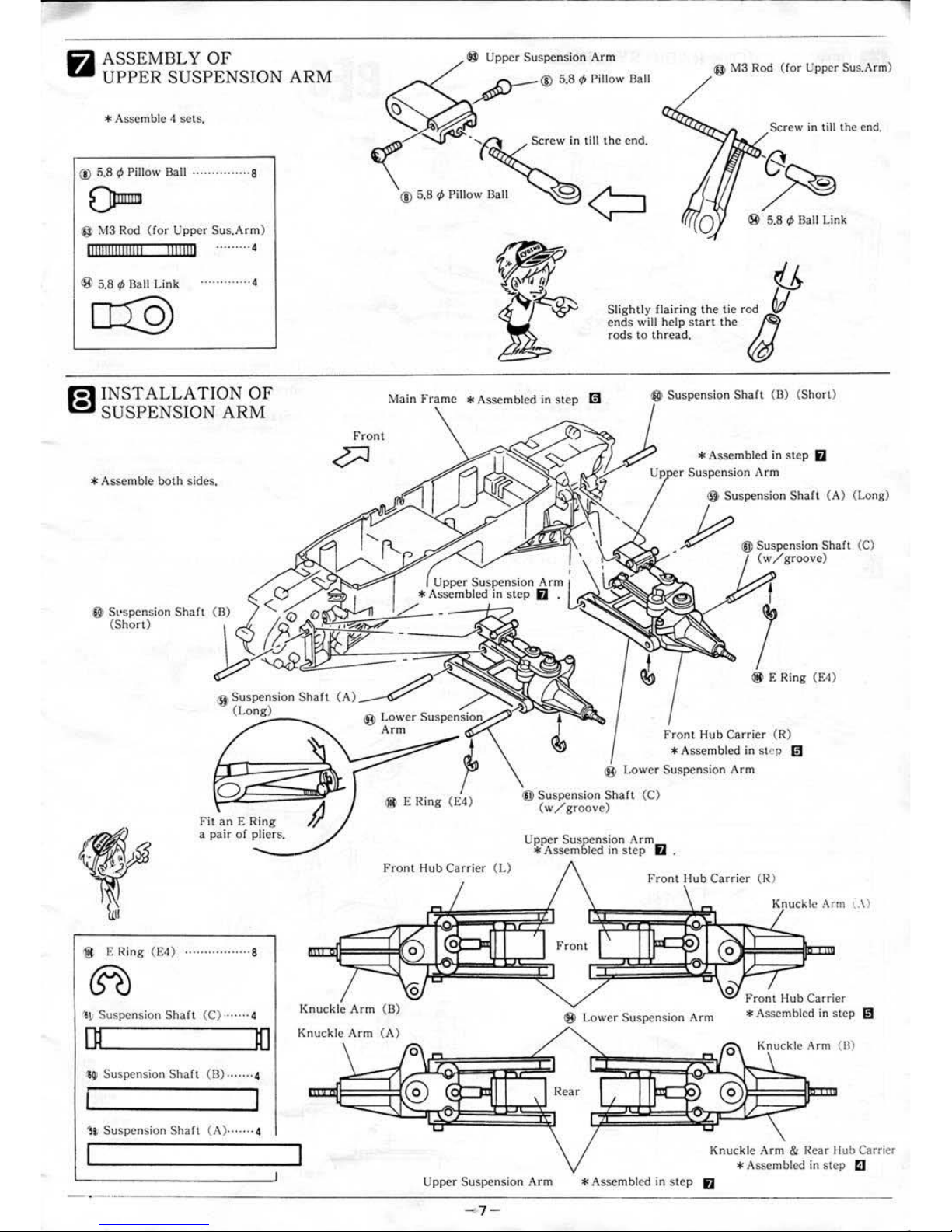

ASSEMBLY OF

UPPE

R SUSPENSION ARM

*A

ssemble 4 sets.

® 5.8 ¢ Pillow Ball · · · ·· ·· · · · · · · · · 8

Onmm

<0>

!V

I3

Rod

(ro

r U

pper

Sus.Arm)

1111111

111111111

11111111

.•....... 4

® 5.8 ¢ Ball

Link

·············

4

·"

)

Q)

@

M3

Rod

(for

Upper Sus. Arm)

Screw

in

till

the end.

ends

will help

start

the

rods

to

thread.

Screw

in

till

the

end.

® 5.8 ¢

Ba

ll

Link

~

r-1

INS

TALLATION OF

~

SUSPENSION ARM

Main

Frame * Assembled

in

step

fiJ

@ Suspension

Shah

(B)

(Short)

* Assemble

both

sides.

I}

St·spension

Shaft (B)

(S

hort

)

®Sus

pension

Shah

(Lon

g)

.:;---...

Fit

an E Ring

a

pair

or

pliers.

<g

E

Ring (E4)

···

····

···

···

····8

@1)

Front

®

Lower

Suspension

Arm

@ E

Ring

(E4)

Fr

ont Hub Carri

er

(

I.)

l

~

Suspension

Shaft

(C) ··· ··· 4

rn

10

Knuckle

Arm

(B)

Knuckle

Arm

(A)

~

Suspensio

r\

Shaft (13)

·······4

1L

Suspension

Shaft (A)·······

4

*Assembled

in

step

iJ

r Suspension

Arm

® Suspension Shaft (A)

(l-

ong)

Y

®Suspension

Shah

(C)

{

w/groove

)

@ E Ring (E4)

Front Hub

Carrier

(R)

* Assembled

in step

~

®

Low

er

Suspension

Arm

®Sus

pension S

haft

(C)

(w/groove)

Upper

Suspension Armm

* Assembled

in

step u .

Front

Hub Carri

er (R)

®

Lower

Suspension

Arm

0

\.

\ )

Fr

ont

Hub

Carrier

*A

ssembled

in

step

~

Knuckle Arm (B)

Knuckle

Arm

& Rear Hub Carrier

*A

ssembl

ed

in

step C

Upper

Suspension

Arm

*A

ssembled

in

step

iJ

- -

--------

----

------------------------

----------------

- 7 -

l

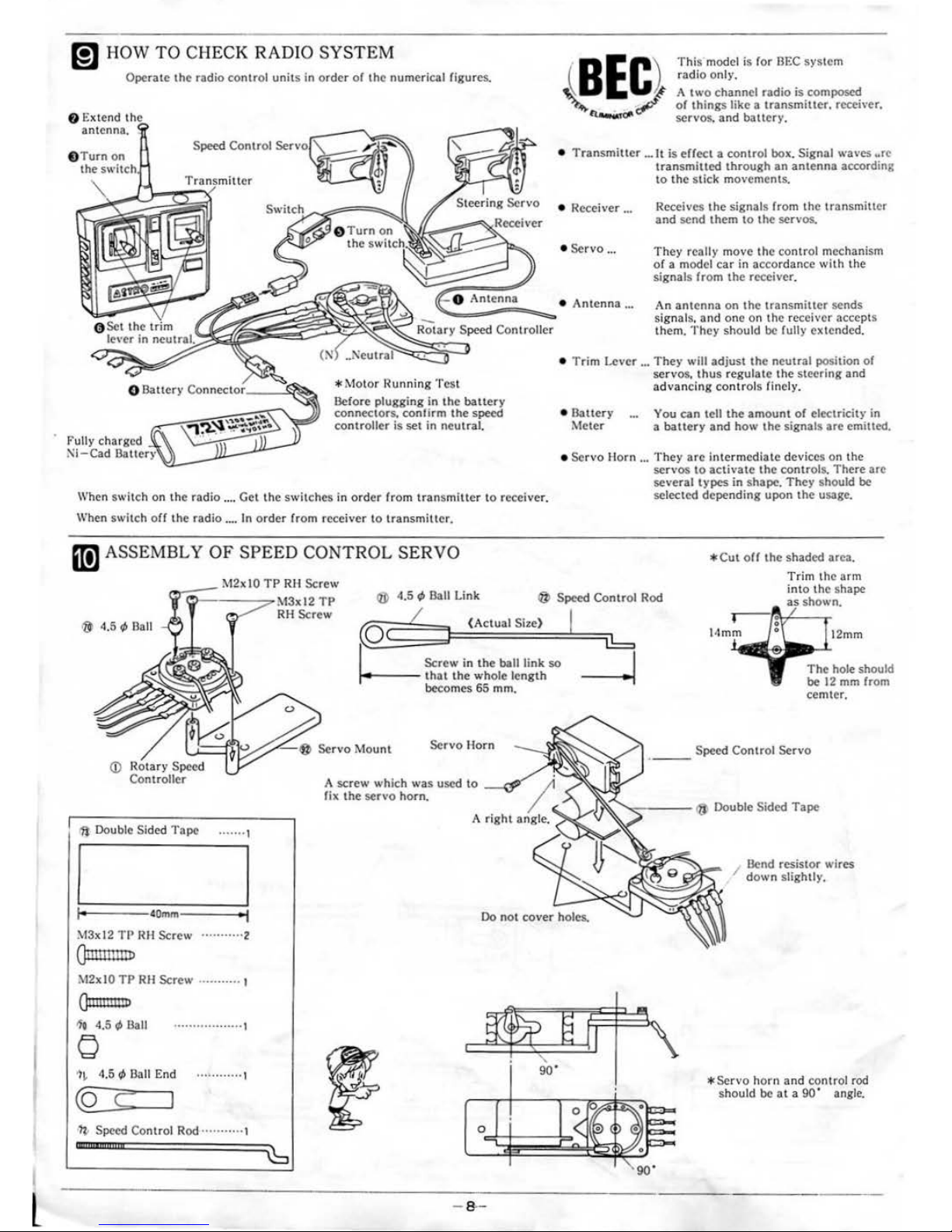

m HOW

TO

CHECK RADIO

SYSTEM

Operate

the

radio

control

units

in

order

or

the

numerical figures.

Tra

tcr

This

model is

for

BEC

system

radio only.

A

two

channel

radio

is composed

or

things

like a

transmiller.

rcceh

·er.

servos.

and

baucry.

•

Transmiuer

...

It

is

effect

a control box. Signal waves

~re

transmilled

through

an

antenna

according

to

the

stick

movements.

• Receiver

...

• Servo

...

Receives the signals from the transmiuer

and

send

them

to

the

servos.

They

really

move the control mechanism

or

a model car in nccordancc

with

the

signals

from

the

receiver.

--

"-.::,=A=n=t"'e,.n

..

n=a=""'.,•

Antenna

...

An

antenna

on

the

transmillcr

sends

signals.

and

one

on

the receiver

accepts

them. They

should

be fu lly extended.

@Set

the

le,

rer

in

ncul

Rotary Speed Controller

*

Motor

l~unning

Test

Before plugging in

the

bauery

connectors.

conlirm

the

speed

controller

is

set

in

neutral.

•

Trim

Lever

...

They

will

adjust

the

neutral

pOsition

or

servos.

thus

regulat

e the

steering

and

advancing

controls

finel

y,

•

Balte

ry

Meter

You

can

tell

the

amount

or

electricity

in

a

baltery

and

how

the

signals

are

emiued.

Fully

charged

Ni-Cad

DattN·v'\ •

Servo Horn

...

They

arc

intermediate

devices

on

the

I

scn•os

to

activate

the

controls.

There

arc

several

types

in

shape.

They

should

be

When switch

on the

radio

....

Get

the swit

ches

in

order

from

tran

smi

ucr

to

receiver. selected

depending

upOn

the

usage.

When switch orr the

radio

....

In order from

receiver

to

transmitt

er.

II!] ASSEMBLY OF

SPEED CONTROL

SERVO

7

0

:::_:l\:_:

1

:::2x::_l:.::O~T~P

R H

Screw

'I

l\13x

12

TP

@

Speed

Control Rod

@ 4.5

1/>

llnll

<D

Rotary Speed

Controller

1ft

Double Sided

Tape

....•.•

1

40mm

I

M3xl2

TP

RH

Screw

...........

2

Qll!lllll

liD

M2x 10

TP

RH

Screw

.....

.......

Qmnnnto

If~

4.5

"'

Ball

•..••••.•

.•..•.•.•

1

0

1~

4.5

1/>

Ball End

• •

•• 0 .....

0 ·1

(Q

(

I

'lt-

Speed Control Rod ....... .... ,

CDIUDIIIIIIIIID

RH

Screw

~~

Screw

in

the

ball link

so

f.----

th

at

the whole

length

becomes

65

mm.

Servo

Mount

Servo

Horn

A

screw

which was used

to

-~

1"'

fix

the

servo

horn

..

I

Do

not

cover

holes.

~

-

8-

--

*Cut

orr

the

shaded

area.

Trim the arm

into

the

shape

shown.

12mm

The

hole should

be 12 mm from

cemter

.

Speed Control

Servo

/ Bend

resistor

wires

down

sli

ght

ly.

* Servo

horn

and

control rod

should

be

at a 90

' angle.

Loading...

Loading...