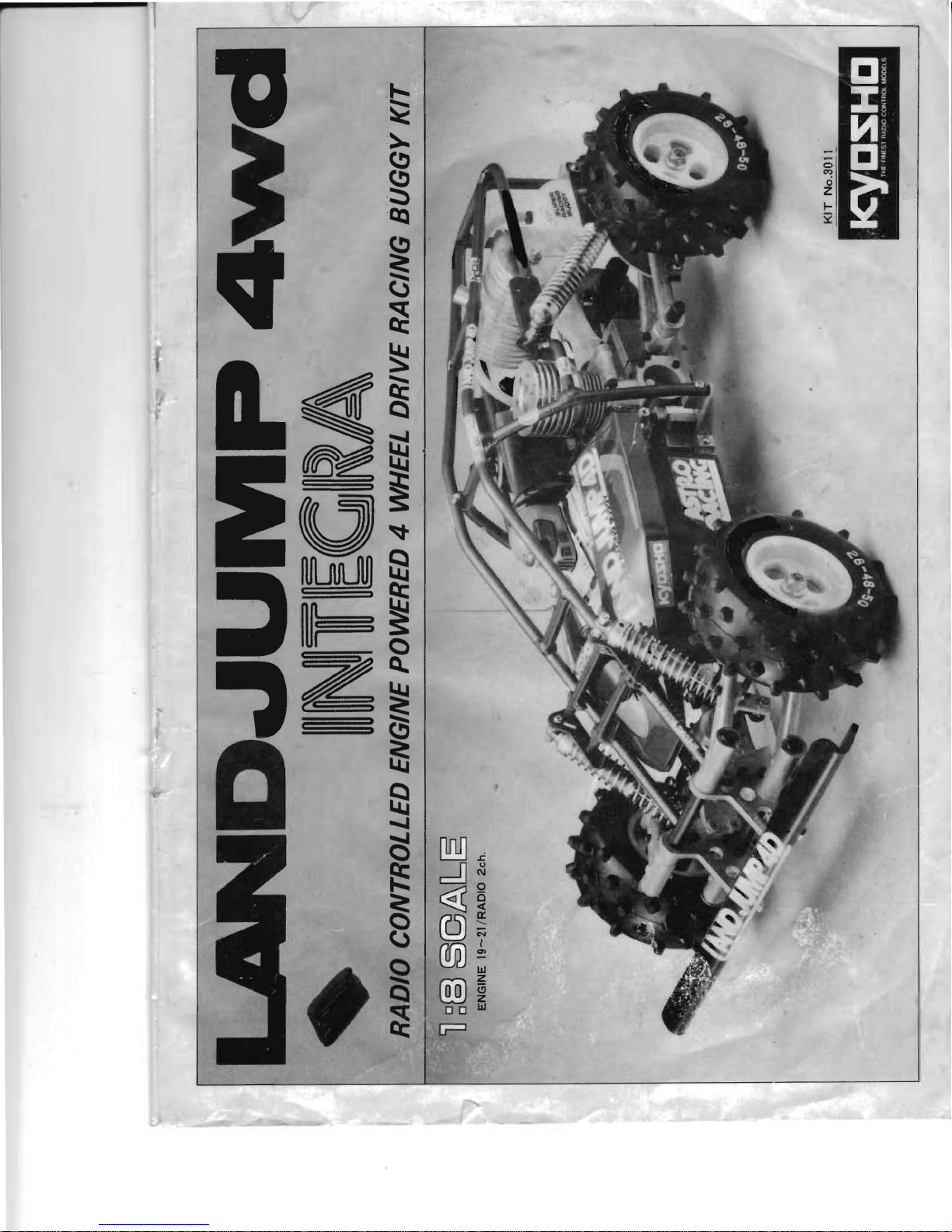

Kyosho Landjump 4wd, Landjump 4wd INTEGRA User Manual

LAND

JUMP

4D

No.2397

============

4

Wheel

Drive

Buggy

===================

TECHNICAL

DATA

Length

...........

.

515

rrm

Break

..............

.

Di

s k

Break

Wi

dth

............

.

270

mm

Gear

Rati 0

••••••••••.

8.5:1 -

10:1

Height

...........

.

200

rrm

Front

Sus

..........

.

Doub

1 e

Tra ili

ng

Chassis

Heigh

.. ..

.

40

mm

Rear Sus. . .

........

.

Semi

Trailing

Wheel

Base

.....

. . .

315

mm

Weight

..............

.

3.4

kg

Front Tire

.......

.

11

O¢

x

48

rT1l1

Proportional

System

..

2ch

Rear

Tire ... . ... . .

11

O¢

x 48

rrm

Engine

..............

. .

19 -.21

Drive

System

.....

.

Side

Winder

&

Chain

Drive

Thank

you

very

much

for

purchasing the

RIC

Car

"LAND

JU~1P

4D".

To

be

able

to assemble your

"LAND

JUMP

4D"

properly

so

it

will

run

with

maximum

performance,

we

recommend

that

you

proceed with the assembly

work

following

closely

this

instruction

booklet.

By

reading

this

instruction

booklet to the

end

throughly before

you

start

to

assemble

and

keeping in

mind

the general construction of the

car,

it·will

enable

you

to get

started

with the assembly

work

very smoothly.

If

you

are going to use

a

new

engine,

by

BREAKING

IN

the engine in accordance with the

instruction

sheet

that

comes

with the engine,

it

will enable

you

to

get

long engine

life

and

miximum

performance.

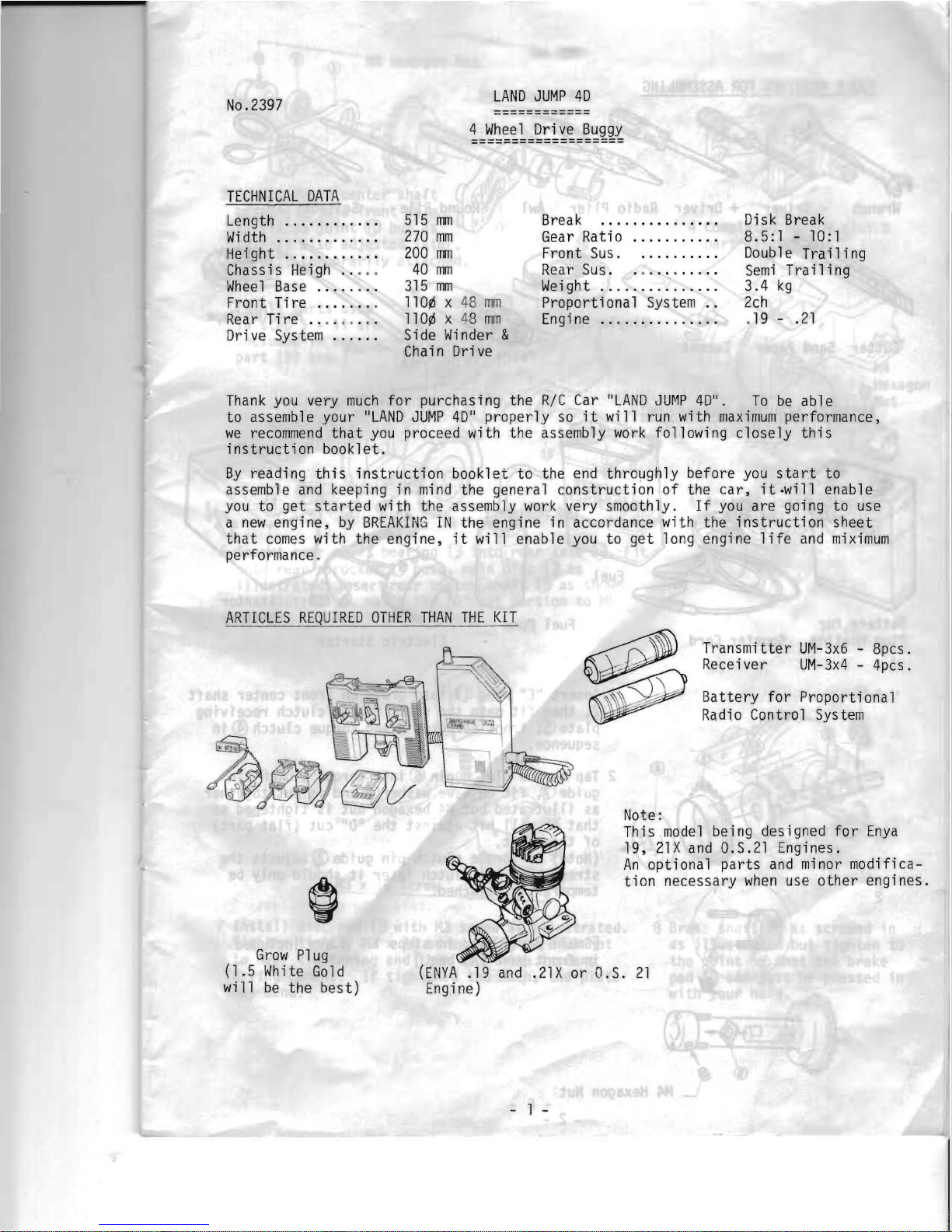

ARTICLES

REQUIRED

OTHER

THAN

THE

KIT

Transmitter

UM-3x6

- 8pcs.

Receiver

UM-3x4

- 4pcs.

Battery

for

Proportional

Radio

Control

System

Note:

This

model

being designed

for

Enya

19,

21X

and

0.S.21 Engines.

An

optional

parts

and

minor modifica-

tion

necessary

when

use

other

engines.

Grow

P1

ug

(1 . 5

Wh

ite

Go

1d

(ENYA

.19

and

.21X

or O.S.

21

will

be

the best)

Engine)

- 1 -

2

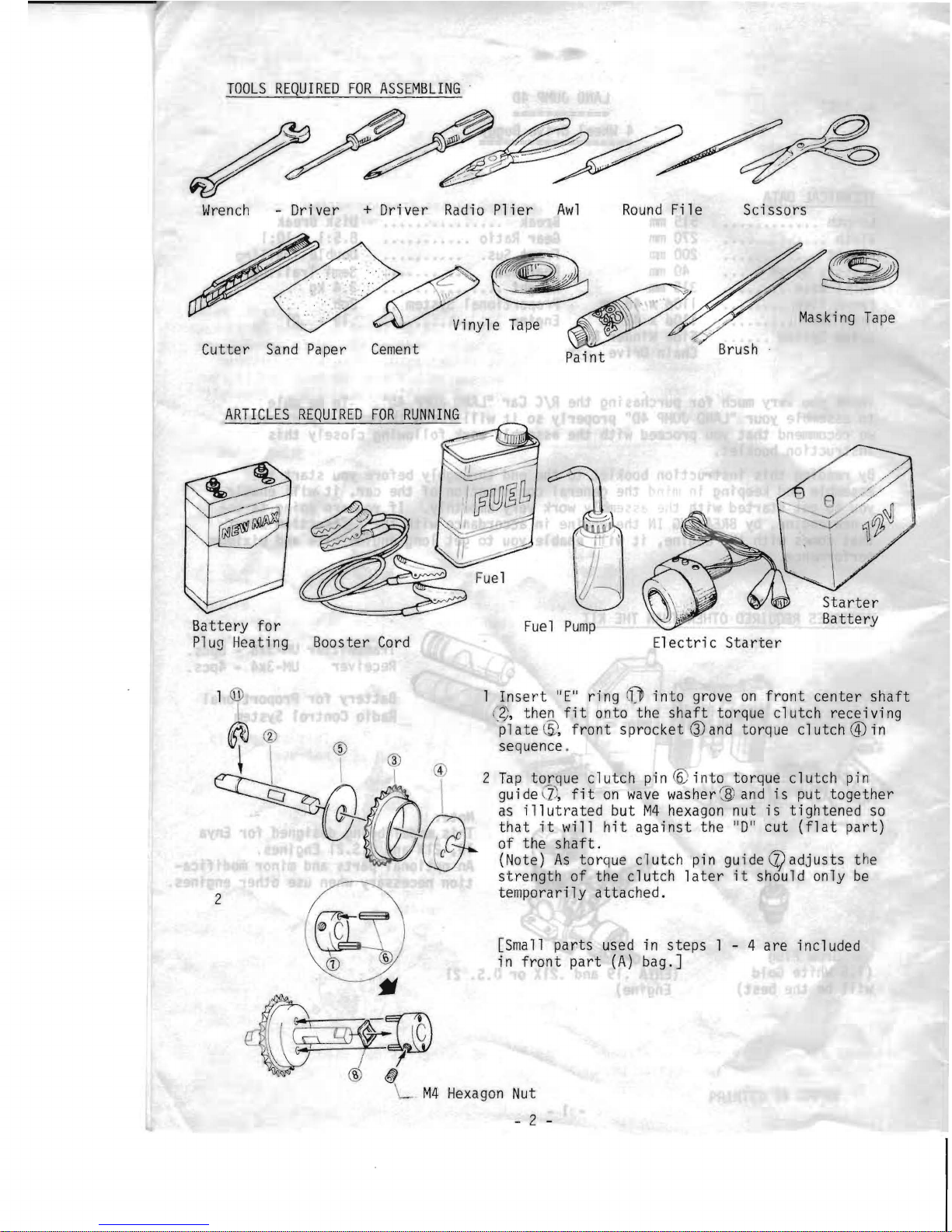

TOOLS

REQUIRED

FOR

ASSEMBLING

.

Wrench

- Driver + Driver

Radio

Plier

Awl

Round

File

Scissors

..

;>

A>(~

~

Masking

Tape

~;nYle

T~P~

~

.

Cutter

Sand

Paper

Cement

Pa

i nt

ARTICLES

REQUIRED

FOR

RUNNING

Battery

for

Fue1 Pump

Plug

Heating Booster

Cord

Electric

Starter

1 Ins e

rt

"E"

ring

OJ

into

grove

on

front

center

shaft

(

2),

then

fit

onto the

shaft

torque cl utch recei

vi

ng

plate

®.

front

sprocket

Q)

and

torque

clutch@in

sequence .

Tap

torque clutch pin

~

into

torque

clutch

pin

guide \l;,

fit

on

wave

washer '])

and

is

put

together

as

illutrated

but

M4

hexagon

nut

is

tightened

so

that

it

l'Ii11

hit

against

the

"0"

cut

(flat

part)

of the

shaft.

(Note)

As

torque clutch pin guideCZ)adjusts t he

strength

of

the clutch l a

ter

it

should only

be

temporarily attached.

[Small parts used in steps 1 - 4 are included

in

front

part

(A)

bag.]

_

M4

Hexagon

Nut

- 2 -

~

~

®

CD

M4

Hexagon

Nut

rr~

.

\ .

~""~

~

M4

Hexagon

Nut

~ '~/&-

~

1

\

/

~

I .

®

~

i I

o~

C

__

~

I

:c

l~(bt~

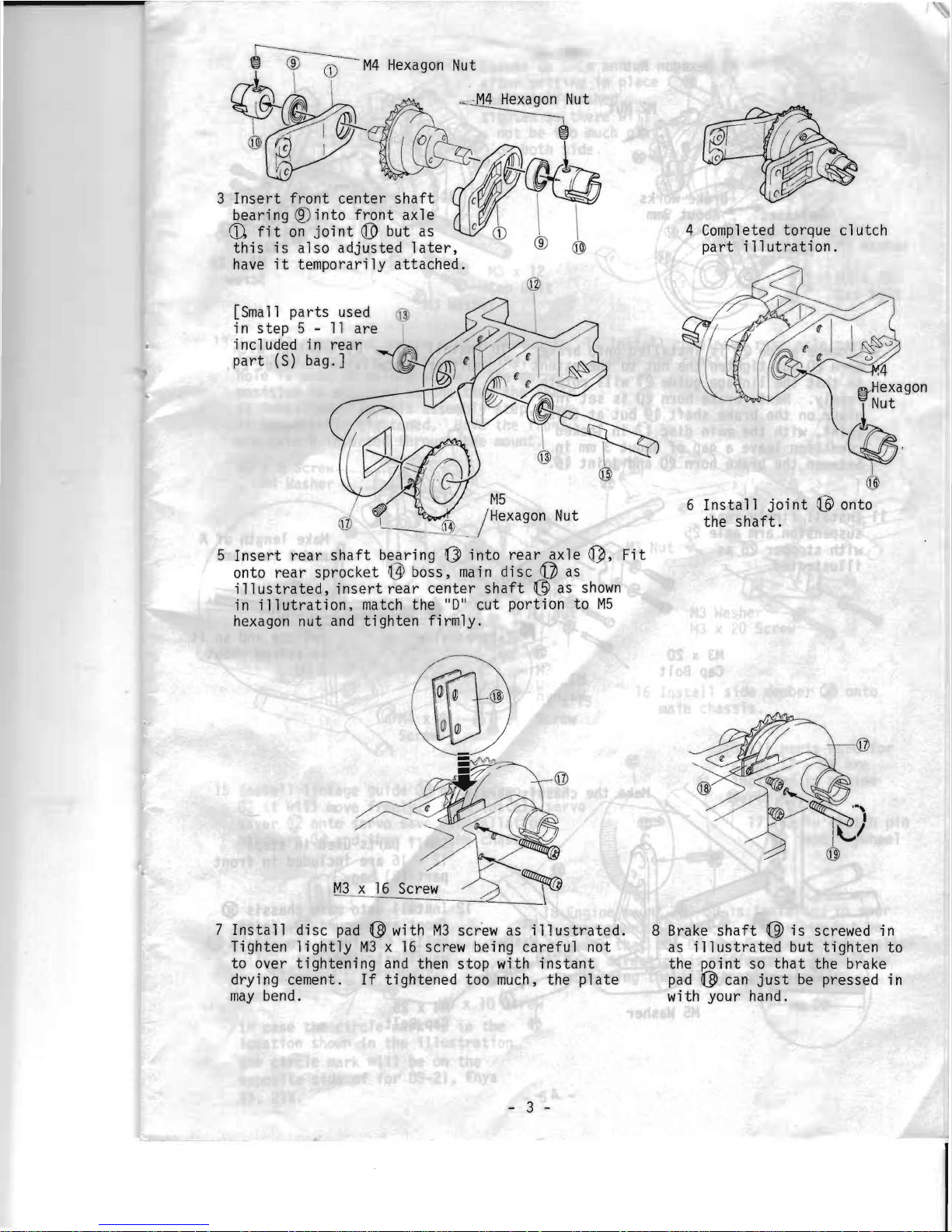

3

Insert

front

center

shaft

~

'\

'f

l:k1!}

bearing

®into

front

axle \ \ \

ffi

fit

on

joint@

but as

CD

C

this

is

also adjusted

later,

® ®

have

it

temporarily

attached.

[Small

instep 5 incl

uded

in

part

(S) bag.]

parts

used

~

11

a re I

rear

~

~

M5

. /

Hexagon

Nut

5

Insert

rear

shaft

bearing ~ into

rear

axle

~,

Fit

onto

rear

sprocket ~boss,

main

disc

Q}

as

ill

us

tra

ted,

insert

rea r

center

shaft

(3l

as

shown

in

illutration,

match

the

"0"

cut portion to

M5

hexagon

nut

and

tighten

firmly.

4 Completed torque clutch

part

illutration.

~~

i

~~

--

j

/

@tHexagon

,,ret

~.

i

@

6

Install

joint

t~

onto

the

shaft.

7

Install

disc

pad ~with

M3

screw as

illustrated.

8

Brake

shaft ~ is

screwed in

Tighten

lightly

M3 x 16

screw being careful not

as

illustrated

but

tighten

to

to over

tightening

and

then stop with

instant

the point so

that

the brake

drying cement.

If

tightened too

much,

the

plate

pad ~can

just

be

pressed in

may

bend.

with your hand.

- 3 -

C

I c

~

~

\\

~

M5

Washer

@

M3 x 25

Screw

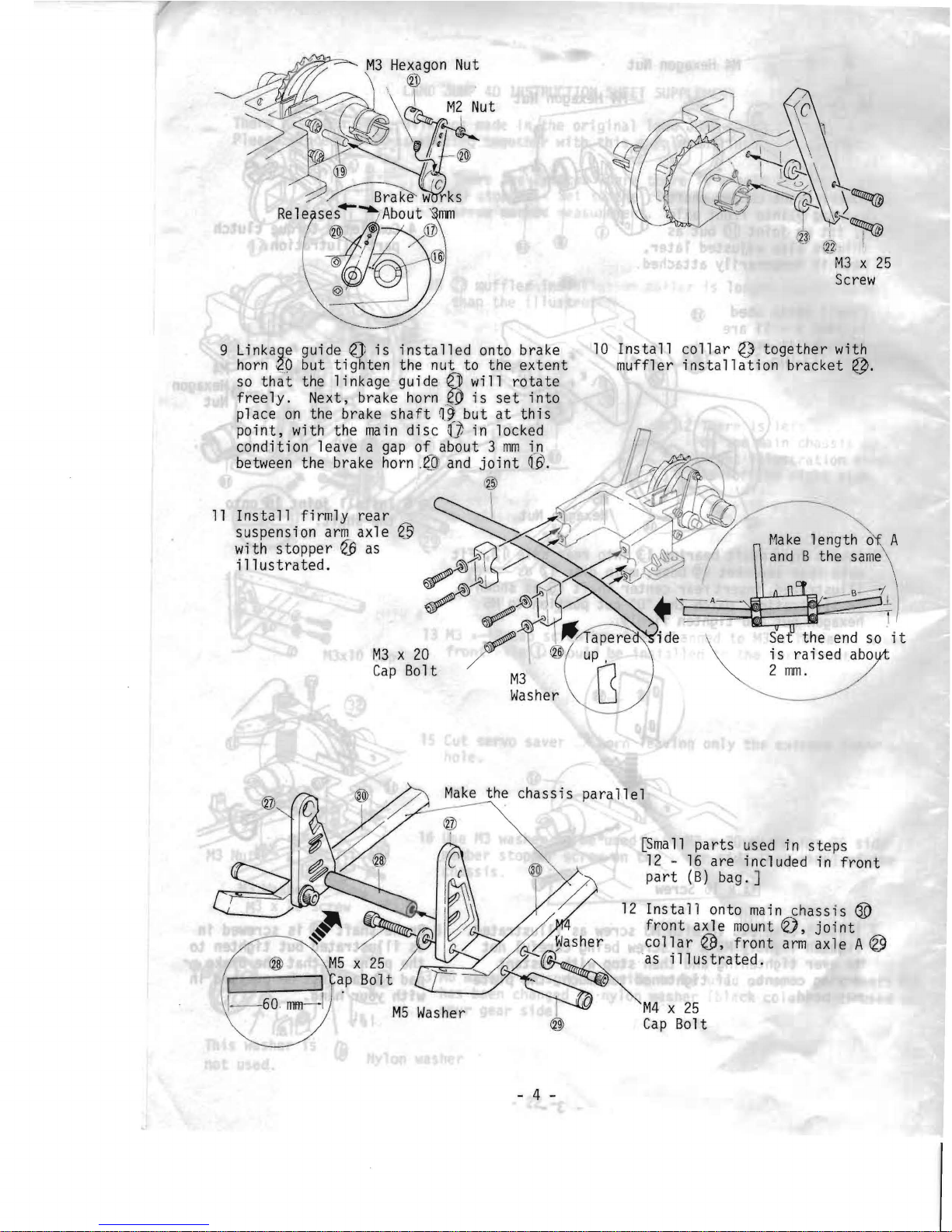

9 Linkage guide

eJ

is

installed

onto brake

10

Install

collar

~

together

with

horn

~O

but

tighten

the nut to the

extent

muffler

installation

bracket

~.

so

that

the 1i

nkage

gu ide

e)J

wi

11

rota

te

freely.

Next, brake horn

eO

is

set

into

place

on

the brake

shaft

n,~

but

at

this

point,

with the

main

disc

Q]

in locked

condition leave a

gap

of

about 3

mm

i~

between the brake

horn ,(0:

and

joint

161.

®

11

Install

firmly

rear

~

\

'-...

~

~

~

}

~~

A~

~

Y

~

"

~

"

suspension

arm

axle

~

~~

~

Make

length 0 A

with stopper

ell

as

~

'>....

~

and

B the

same

illustrated.

~1

J)/

~

~

~f'

+

~W)

===

up

r)

L':l

end

so

it

M3

x

20

/ @

is

raised

aboi)'t

Cap

Bolt

M3

2

mm.

/

Washer

~~~

~

the chassis

parallel

~mall

parts

used in steps

~

12 -16

are included in

front

,

part

(B)

bag. ]

~

12

Install

onto

main

chass is

GO

I

l'l

front

axle

mount

0,

joint

~

~asher

collar

~,

front

arm

axle A

~

/

~as

illustrated

.

G.

_

..

~

M4 x 25

~

Cap

Bolt

- 4 -

0

,ce

and

after

setting

in place

has

been

finished,

there will

too

much

p1a1

Nut

-

M3 x 20

Cap

Bolt

/

~

\

(

~~

ighten

so

r~

not

be

~

on

Loosen

up

~

both

side,

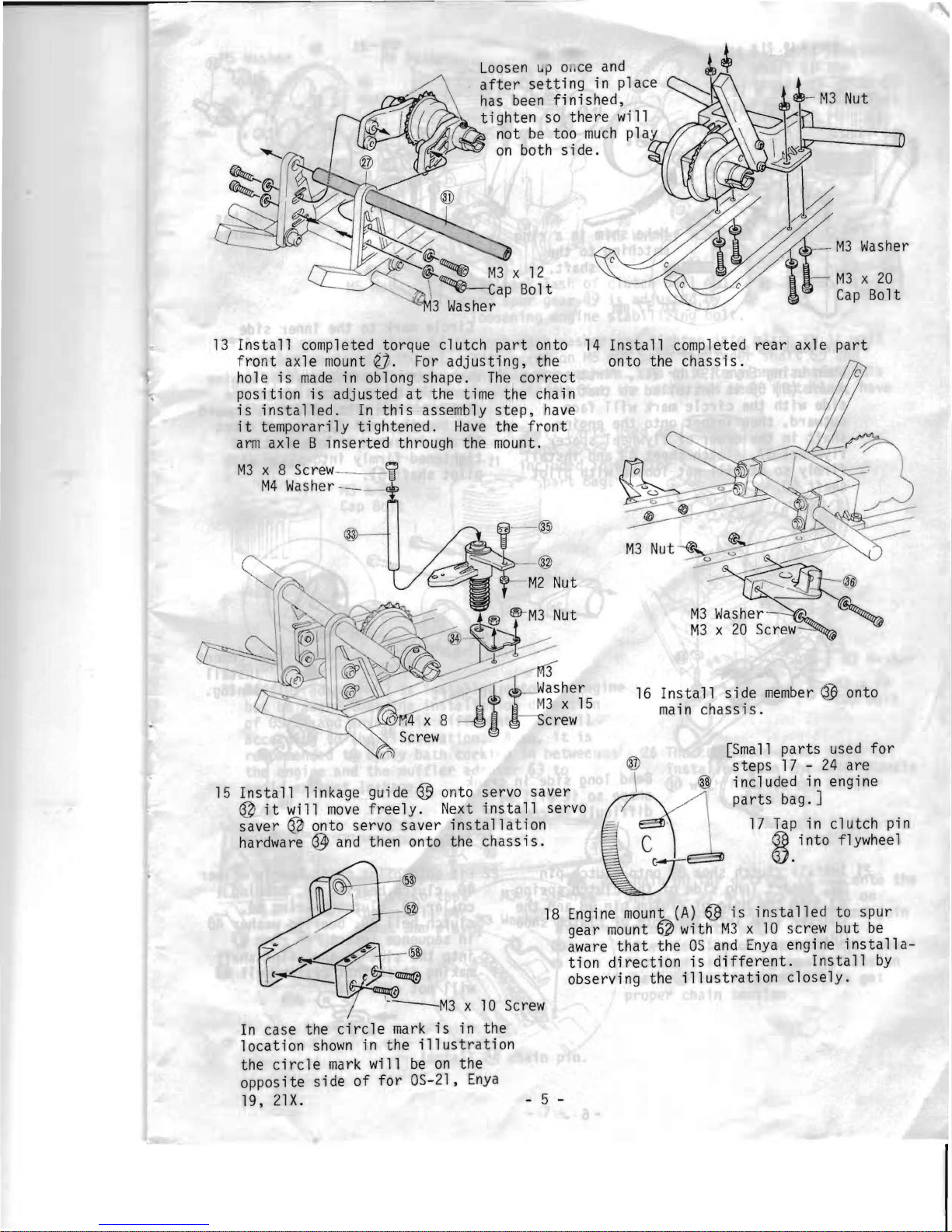

13

Install

completed torque clutch

part

onto

14

Install

completed

rear

axle

part

front

axle

mount

e).

For

adjusting,

the onto the

chassis.

hole

is

made

in oblong shape.

The

correct

position

is

adjusted

at

the time the chain

is

installed.

In

this

assembly

step,

have

it

temporarily tightened.

Have

the

front

arm

axle B

lnserted

through the

mount.

M3

x 8

Screw

-------

li

M4

Washer --_

16

Install

side

member ~ onto

main

chassis.

@

[Small

parts

used

for

1(>

steps

17 -24

are

included in engine

15

Install

linkage guide

G5

onto servo saver

parts

bag. ]

~

it

will

move

freely.

Next

install

servo

saver

~

onto servo saver

installation

17

Tap

in clutch pin

hardware

~

and

then onto the

chassis.

~.into

flywheel

"

....

,\_-

®l

- @

18

Engine

mount

(A)

~

is

installed

to spur

gear

mount ~with

M3 x 10

screw but

be

aware

that

the

OS

and

Enya

engine

installa-

tion

direction

is

different.

Install

by

observing the

illustration

closely.

x

10

Screw

In

case the

circle

mark

is

in the

location

shown

in the

illustration

the

circle

mark

will

be

on

the

opposite side

of

for

OS-2l.

Enya

19.

21X.

-5-

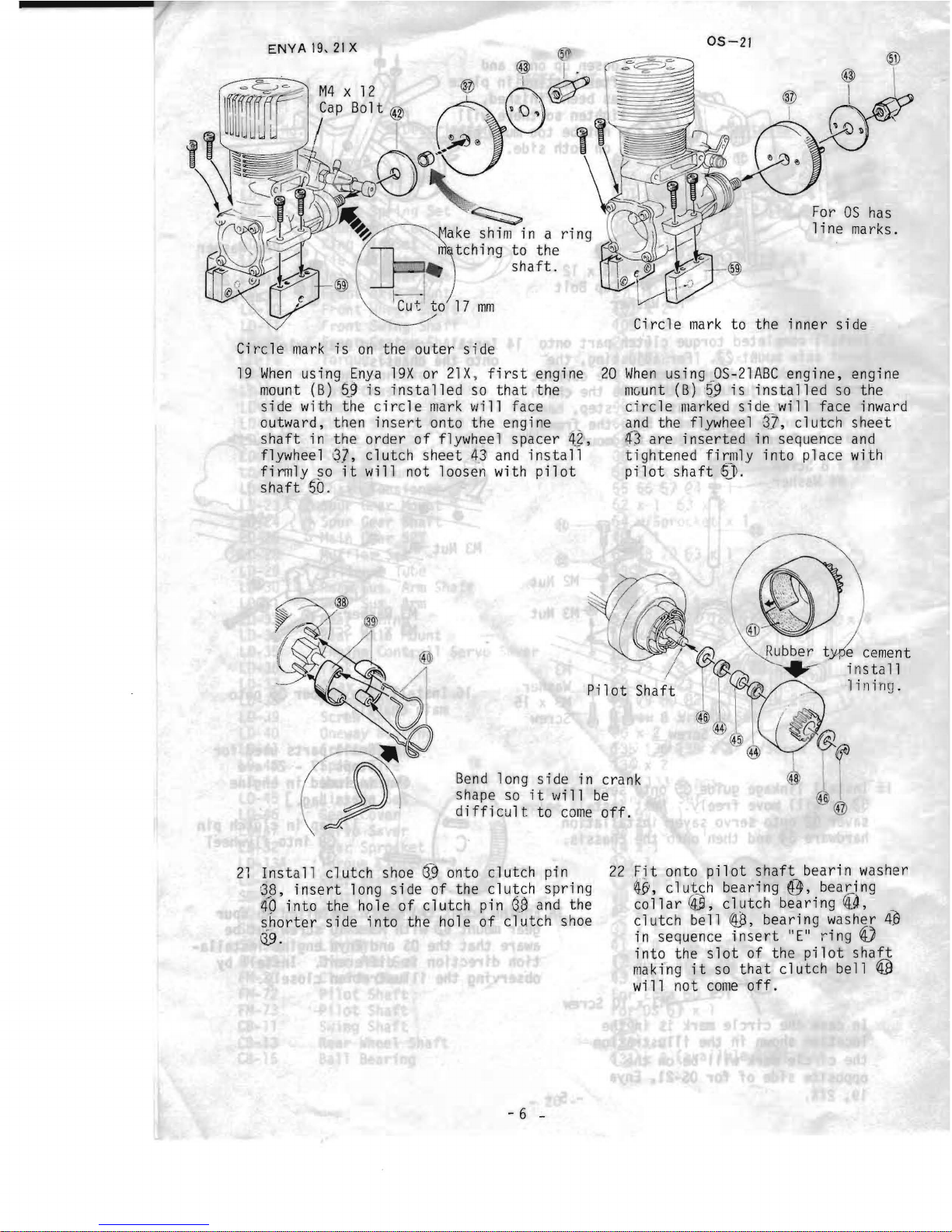

05-21

Circle

mark

to the inner

side

mm

For

OS

has

1 ine marks.

20

When

using .pS-21

ABC

engine. engine

mcunt

(B)!?9

is

installed

so the

circle

marked

side

will

face inward

and

the flywheel 3-

]:

,

clutch

sheet

43

are

inserted

in sequence

and

tightened

firmly

into

place with

pilot

shaft

~).

Circle

mark

is

on

the outer

side

19

When

using

Enya

19X

or

21X , first

engine

mount

(B)

~~

is

installed

so

that

the

side

with the

circle

mark

will

face

outward, then

insert

onto the engine

shaft

in the

order

of

flY\'Iheel spacer

4~'

,

flywheel

'

~J,

clutch

sheet

4)

and

install

fi

rmly

50

it

will not loosen with

pil

ot

shaft '50

.

e

be

off

.

cement

install

lining.

Bend

long

side

in crank

shape

so

it

will

difficult

to

come

21

Install

cl utch shoe

Q9

onto cl utch

pi

n

22

Fjt

onto

pilot

shaft

bearin washer

G8.

insert

long

side

of the

clutch

spring

~y,

clutch

bearing

@.

bearing

(0

into

the hole

of

clutch

pin

88

and

the

collar~.

clutch

bearing

~~.

shorter

side

into

the hole

of

clutch

shoe

cl utch

bellW.

bearing washer

4£1

\19.

in sequence

insert

"E"

ring

~

into

the

slot

of the

pilot

shaft

making

it

so

that

clutch

bell

©

will

not

come

off.

- 6 -

r~6

Washer

_,;

M6

Washer

r15

Nut

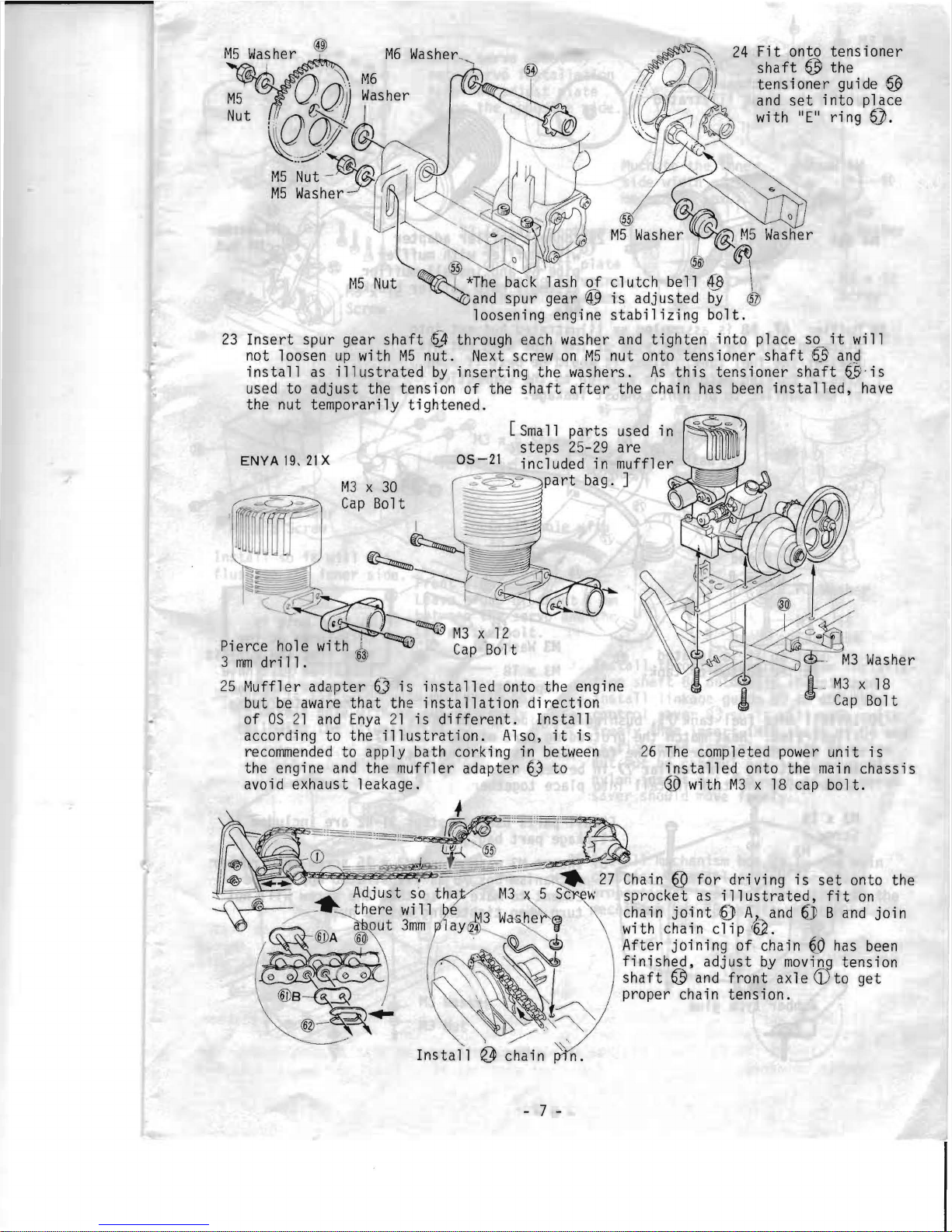

23

Insert

spur gear

shaft

~4

through each washer

and

tighten

into

place

s~

it

will

not loose,n

up

with

M5

nut.

Next

screw

on

M5

nut onto tens ioner

shaft

6.S

and

install

as

illustrated

by

inserting

the washers.

As

this

tensioner

shaft

(~'is

used

to

adjust

the tension of the

shaft

after

the chain

has

been

installed,

have

the nut temporarily

tightened.

ENYA

19,

21

X

05-21

M3 x

30

Cap

Bolt

25

~luffl

e r

adapter

Q)

is

installed

onto the engine

but

be

aware

that

the

installation

direction

of

OS

21

and

Enya

21

is

different.

Install

according to the

illustration.

Also,

it

is

recommended

to apply bath corking in between

the engine

and

the muffler adapter ~ to

avoid exhaust leakage.

h~

'.

~

~

"_~A

- @-

~

r

./"

~

'

~

.

;:~

~s~

'

~,

3

'. --:

- . . . -

..

Adjust

~o

th

_

___

~

here

wlll

a out

3mm

~

A

@W

()

0 @ @ ( 0 0

®e~

@j

-

'"

~

~

~

.

~

M3 ~5

Srn'N

e

M3

W

ar

he~@J

ay@--.....

lJ

.

~~~

Install

~

chain n.

- 7 -

~

.:

., ~~

'

~~'>->b

I

~\

\~;

'. t .

.

~

" '

''

~

~

/'

'0

'

26

The

completed

power

unit

is

installed

onto the

main

chassis

dO

with

M3 x 18

cap

bolt.

27

Chain ® for

driving

is

set

onto the

sprocket as i.

ll

ustrated,

fit

on

chain

joint

0

A"

and

6"J

B

and

join

wi

th

cha

inc

1i P '

62.

After

joining

of

chain

~O

has

been

finished,

adjust

by

moving

tension

shaft

@

a~d

fron~

axle

CD

to get

proper chaln tenSlOn.

Loading...

Loading...