Page 1

INSTALLATION MANUAL

FOR KYOCE RA S OLAR MODULE

KC-TYPE SERIES

Please read this manual carefully before

1. INT RODUCTIO N

As the world leader in high technology ceramic/silica

applications, Kyocera has stepped into the forefront in

development of mul ticrystalline solar modul es. Kyocera

began researching photovoltaics in 1975 and has

supplied many thousands of modules throughout the

world since 1978. Its years of experience and state-ofthe-art technology have produced qual ity sol ar modules

in a range of sizes to meet the energy needs of the

growing solar mark et.

2. POWER MODULES

Kyocera "KC" series modules come in v arious sizes to

satisfy a full range of applicati ons. E ac h module is made

of multi - crystalli ne cells manufac tured by the "casting"

method. These cel ls c ov er nearly 100% of t he modul e's

surface. To protect the cells from the most severeenvironmental conditions, they are encapsulated

between a tempered glass cover and an EVA pottant

with PVF back sheet. The entire lami nate is installed in

an anodized alum inum f ram e for structural strength and

ease of instal lation.

3. APPLICATIONS

Kyocera modules are a reliable, virtually maintenance

free power supply, designed to operate efficiently in

sunlight. Kyocera solar modules are ideal for charging

storage batteries used to power remote homes,

recreational vehicles, boats, telecommunication systems

and other elect r ic generation application.

4. MOUNTING SITE SELECTION

The solar modules should be mounted i n a location

wh e r e they will re c e ive ma ximum sunlight th r oughout the

year. In the Nor thern Hemisphere, the modules should

face south, and in the Southern Hemisphere, the

modules should face north. Modules facing 30 degr ees

away from true South (or North) will lose approximately

10 to 15 per cent of their power output . If t he module

faces 60 degrees away from true South (or Nor th), the

power loss will be 20 to 30 per cent. When choosing a

site, avoid trees, buildings or obstructions which could

cast shadows on the solar modules especially during the

winter mont hs when the arc of the sun is lowest over the

horizon.

KYOCERA CORPORATION

install ing the modules.

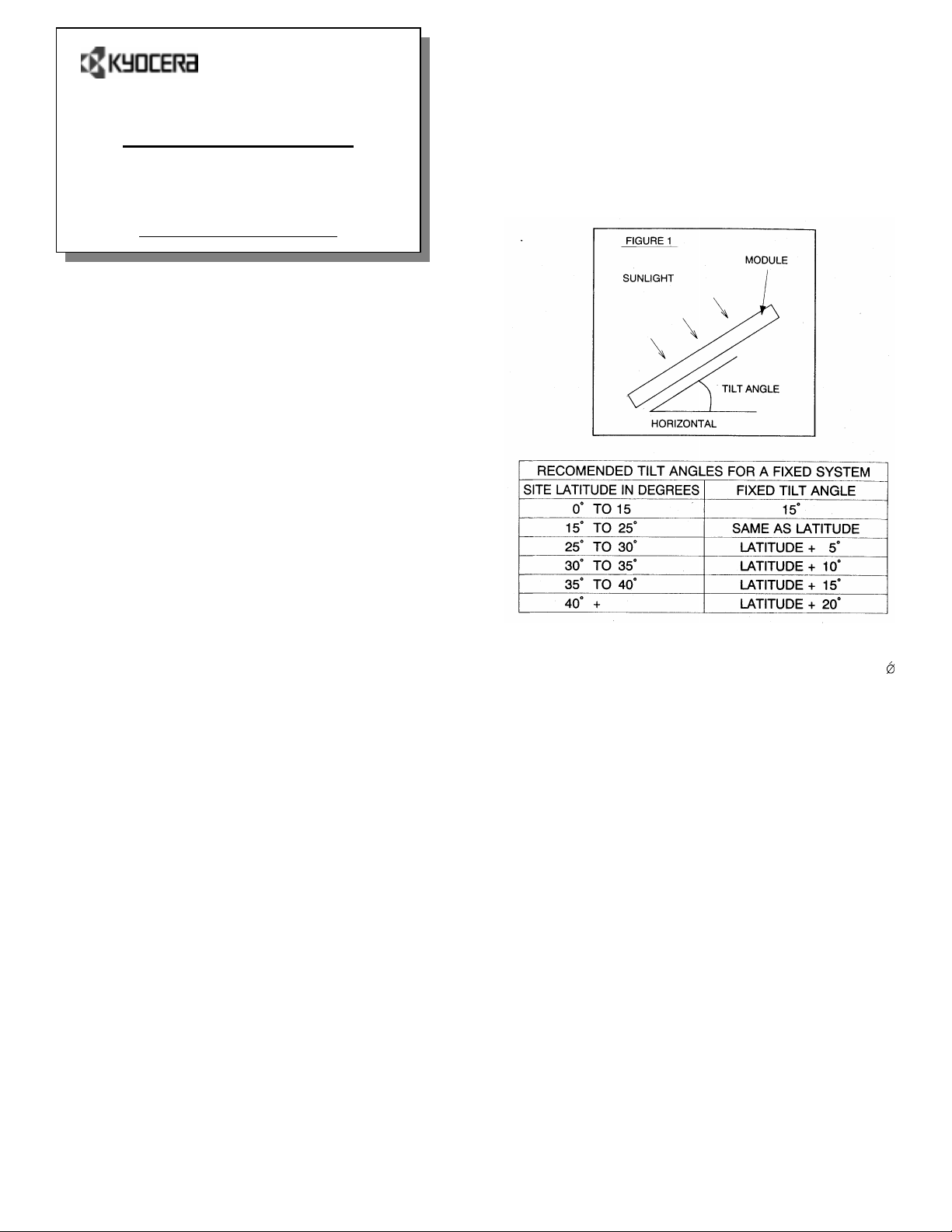

5. MODULE TILT ANGLE

Solar m odules produce the most power when they are

pointed directly at the sun. For installations where the

solar modules are mounted to a permanent structure,

the solar modules should be tilted for optimum winter

perform ance. As a rule, if the system power production

is adequate in the winter, it will be satisfactory during the

rest of the year. The module tilt angle is measured

between the solar modules and the ground (Figure 1) .

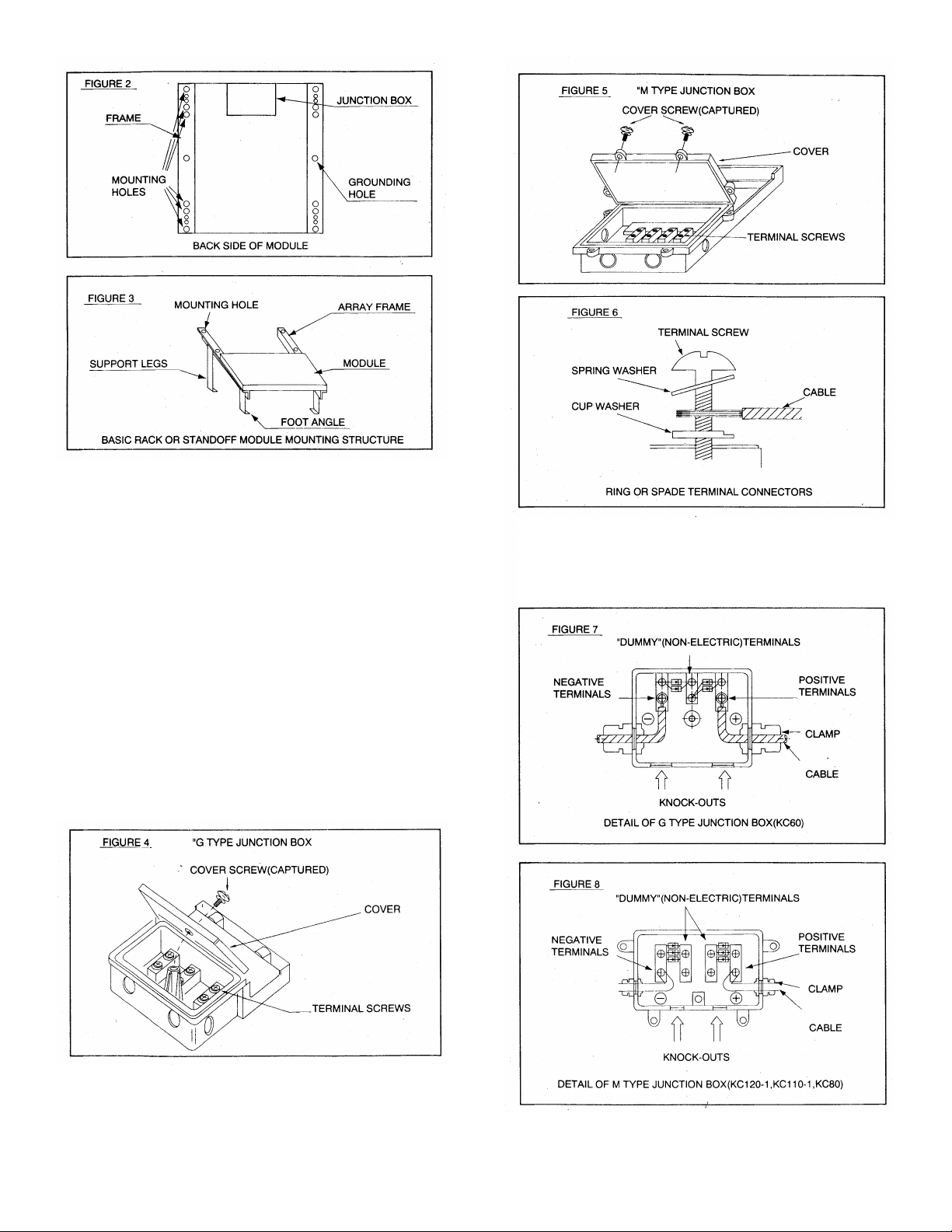

6. MOUNTING THE MODULE

The frame of each module has fourteen 7 mm Ú

diamet er mounting holes (Fi gure 2). These are used to

secure the modules to the supporting structure. The

example of a ground mounted structure is shown in

Figure 3. The four holes close to the corners of the

module are most often used for mounting. Clearance

between the module frame and the mounting surface

may be required to prevent the junction box from

touching the surf ace, and to ci rculat e cooli ng air around

the back of the module. In case the modules will be

mounted on the roof or wall of a building, the standoff

method or t he r ac k method are recommended.

STANDOFF: The modules are supported par allel t o the

surface of the building wall or roof. Clearance between

the module frames and surface of the wall or roof is

required to pre- vent wiring dam age and to allow air to

circul ate behind the m odule.

The recommended standoff height is 4.5 i n.

If ot her mounting m eans are employed, thi s may aff ect

the Listing For Fire Class Ratings.

RACK: The supporti ng fram e is used to mount modules

at correct t ilt angles. T he modules are not designed for

integral m ounti ng as part of a r oof or wall. The mounti ng

design may have an impact on the fire resistance.

(about 115 mm)

1

Page 2

7. WIRING

Most of the larger KYOCERA P OWE R M ODULES use

the "G" or " M " type junction box. This box, on the back

side of the module, is weatherproof and is designed to

be used with standard wiring or conduit connecti ons.

Wiring m ethods should be in accordance to the NEC

(National E lectric al Code). Bypass diodes and cable

clamps are included with each module when shipped

from the factory.

A. Open the "G" or "M" box cover by loosening the

screws in the cover . (Figure 4 and 5)

B. The wire ty pically used to interconnect the solar

modules should be single or two conductor, from 10

AW G(5.26 mm²) up to 14 AWG(2. 08 mm²) gauge

stranded copper wire, i n a " S UNLIGHT RESIS TANT"

jacket UF c able. This cable is suitable for appli c ations

where wiring is exposed to t he direct rays of the sun.

The maximum and minimum diameter of the cabl e that

may be used with the cable connector are 8 mm and 6

mm r espect ively. (Figure 6)

C. Using a flat blade screwdriver, remov e only the

appropriate "K NOCK-OUTS" from the sides of the

"G" or "M" box. (Figure 7 and 8)

2

Page 3

D. Read the enclosed instructions for routing wires

through the knock-outs and clam ps. (Figure 9)

E. Remove approximately ½” of insulation on the ends of

the wires and insert them under the appropriate

"POSITIVE" or "NEGATIVE" terminal screws in the

junction box. The wires should be installed with some

slack; ex c ess wire should be cut off. (Figure 7 and 8)

Install cable with appropriate hardware in accordance

with NEC Article 250 or national and inter national rules.

F. Gently tighten the terminal screws. Do not

overtighten, as the t er minal c an be damaged.

G. The output wiring f rom the f inal m odule is generally

run to a separate array junction box. In commercial

system, this wiring from the array box to the next

component (i.e. fuse box. or charge regulator, etc.) is

generally r un in conduit. T he maxim um electri cal rating

of an accept able series fuse is 4 ~ 12 amperes.

9. BLOCKING DIODES

Blocking diodes can prevent nighttime battery

discharging caused and prevent modules from loss of

array output and being damaged or destroyed by

reverse current flow.

KYOCERA modules do not contain a blocking diode

when shipped from the factory, however most battery

charging regul ators do have this feature.

10. BYPASS DIODES

Partial shading of an individual module in a 12 v olt or

higher "series" string (i.e. two or more modules) can

cause a reverse voltage across the shaded module.

Current is then forced through the shaded area by the

other modules in series.

By hav ing a by pass diode, the forced current will bypass

the shaded module in a series circuit, thereby minimizing

module heat ing and array current losses.

For 12-volt systems and higher: Each solar module

junction box has a diagram illustrating the proper

directi on for the by- pass diode to be install ed between

two of the t erm i nal screws (Figur e 11, F igur e 12). When

the solar modules are connected as individual series

strings first, and then these strings are connected in

parallel , bypass diodes should be used in each juncti on

box. This is the simplest wiring arrangement for most

installations.

At a minimum the bypass diodes must have the following

electrical charact er istics:

)$Y

• Rated Average Forward Current [I

] Above

maximum system current at highest operating

temperat ur e.

• Rated Repetit ive P eak Reverse Voltage [V

UUP

]

Above maxi mum system voltage at lowest

operating temperature.

H. Aft er compl eting the wiri ng between all box es, Close

and secure all the junction boxes.

8. GROUNDING

We recommend you attach all module frames to an earth

ground. Attach a separate ground wire to one of the

extra mounting hol es on the m odule frame wit h a self tapping screw. The rack s must also be grounded unless

they are mechanically connected by nuts and bolts to the

grounded modules.

Grounding is achieved by securing the array f rame for

both roof and field mounted applications. Additionally,

the array frame shall be installed in accordance with

NEC Art 250.

11. MAINTENANCE

Solar modules require v ery little m aintenance. It is not

un- com mon for a remote sit e to be checked but once

per year. Under most conditions, normal rainfall is

suffi ci ent t o keep the m odul e gl ass clean. I f di rt bui l d-up

becomes excessive, clean the glass with a soft cloth

using mild detergent and water. Modules that are

mounted, flat (O

Û WLOW DQJOH VKRXOG EH FOHDQHG PRUH

often, as they will not "self clean" as effectively as

modules m ounted at a 15

Û WLOW RU JUHDWHU 2QFH D \HDU

3

Page 4

check the t ightness of termi nal screws and the general

conditi on of the wiri ng.

Also, check t o be sure that m ounting hardware is tight.

Loose bolts could result in a damaged m odule or array.

12. WARNINGS

Solar modules are live electrical power sources when

ex- posed to light. Arrays of many m odules can cause

lethal shock and burn hazar ds. Sol ar m odul es should be

covered with an opaque material during installation to

avoi d shocks or burns. Do not touch liv e term inals with

bare hands. Use insulated tools for electrical

connections.

PERMIT

- Before installing your solar system, contact local

authorities to determine the necessary permit,

install ation and inspection requirem ents.

INSTALLATION AND OPERATION

• Systems should be installed by qualified

personnel only . The system inv olv es electrici ty,

and can be dangerous if the personnel are not

familiar with the appropriate safety procedures.

• Do not step on the module.

• Although KYO CERA modules are quit e rugged,

the glass can be broken (and the module will no

longer work properly) if it is dropped or hit by

tools or other objects.

• Sunlight shall not be concentrated on the

module.

• The module frames is made of anodized

alumi num, and ther efore corrosion can occur i f

the module is subject to a salt water

envi ronment wit h contact to a rac k of an- other

type of metal. ( E lectroly tic Corrosion)

GROUNDING

• All module fram es and mounting r acks must be

properly grounded in accordance with the

appropriate electrical codes.

INSPECTION

• Follow the requirements of applicable National

and local electrical safety Codes.

BATTERY

• When solar modules are used to charge

batteries, the battery must be installed in a

manner which will prote c t t h e per for ma nce o f th e

system and the safety of its users. The battery

should be away from the main flow of people

and animal traffic. Select a battery site that is

protected f rom sunlight, r ain, snow, debris, and

is well ventilated. Most batteries generate

hydrogen gas when charging, which is

explosive. Do not li ght m atches or cr eate sparks

near the battery bank. When a battery is

installed outdoors, it should be placed in an

insulated and ventilated battery case specifically

designed for t he pur pose.

NOTES The electrical characteristics are within ±10

percent of i ndi cat ed v al ues of l sc, Voc, and Pm ax under

standard test condit ions (irradiance of 1KW/ m², AM 1. 5

spectrum, and c ell temperature of 25

Under conditions, a photov oltaic module is likely to pr o-

duce more curr ent and / or voltage than repor ted at

standard test conditions. Accordingly, the values of lsc

and Voc marked on this module shoul d be multiplied by

a factor of 1.25 when determ ining com ponent voltage

ratings, conductor ampaci ties, fuse sizes, and si z es of

regulators which are connec ted to the PV output. Refer

to Secti on 690- 8 of the National Electrical Code for an

additional multiplying factor of 125 (80 per cent

derating), whic h may also be applicable.

Manufactu red by: Kyocera Corp oration

Made in Japan

Kyocera Solar, Inc.

7812 East Acoma Dr.

Scottsdal e, AZ 85260

Phone: 800-223-9580

480-948-8003

Fax: 480-483-2986

Email: info@kyocerasolar.com

Web site: www.kyocerasolar.com

Û&

4

Loading...

Loading...