Kyocera ECOSYS M2135dn, ECOSYS M2635dn, ECOSYS M2635dw, ECOSYS M2735dw, ECOSYS M2040dn Service Manual

...Page 1

ECOSYS M2135dn

ECOSYS M2635dn

ECOSYS M2635dw

ECOSYS M2735dw

ECOSYS M2040dn

ECOSYS M2540dn

ECOSYS M2540dw

ECOSYS M2640idw

PF-1100

SERVICE

MANUAL

Published in November 2016

842S0111

2S0SM061

Rev.1

Page 2

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE OF USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

It may be illegal to dispose of this battery into the municipal waste stream. Check with your local solid waste

officials for details in your area for proper disposal.

ATTENTION

IL Y A UN RISQUE D’EXPLOSION SI LA BATTERIE EST REMPLACEE PAR UN MODELE DE TYPE

INCORRECT. METTRE AU REBUT LES BATTERIES UTILISEES SELON LES INSTRUCTIONS DONNEES.

Il peut être illégal de jeter les batteries dans des eaux d’égout municipales. Vérifiez avec les fonctionnaires

municipaux de votre région pour les détails concernant des déchets solides et une mise au rebut appropriée.

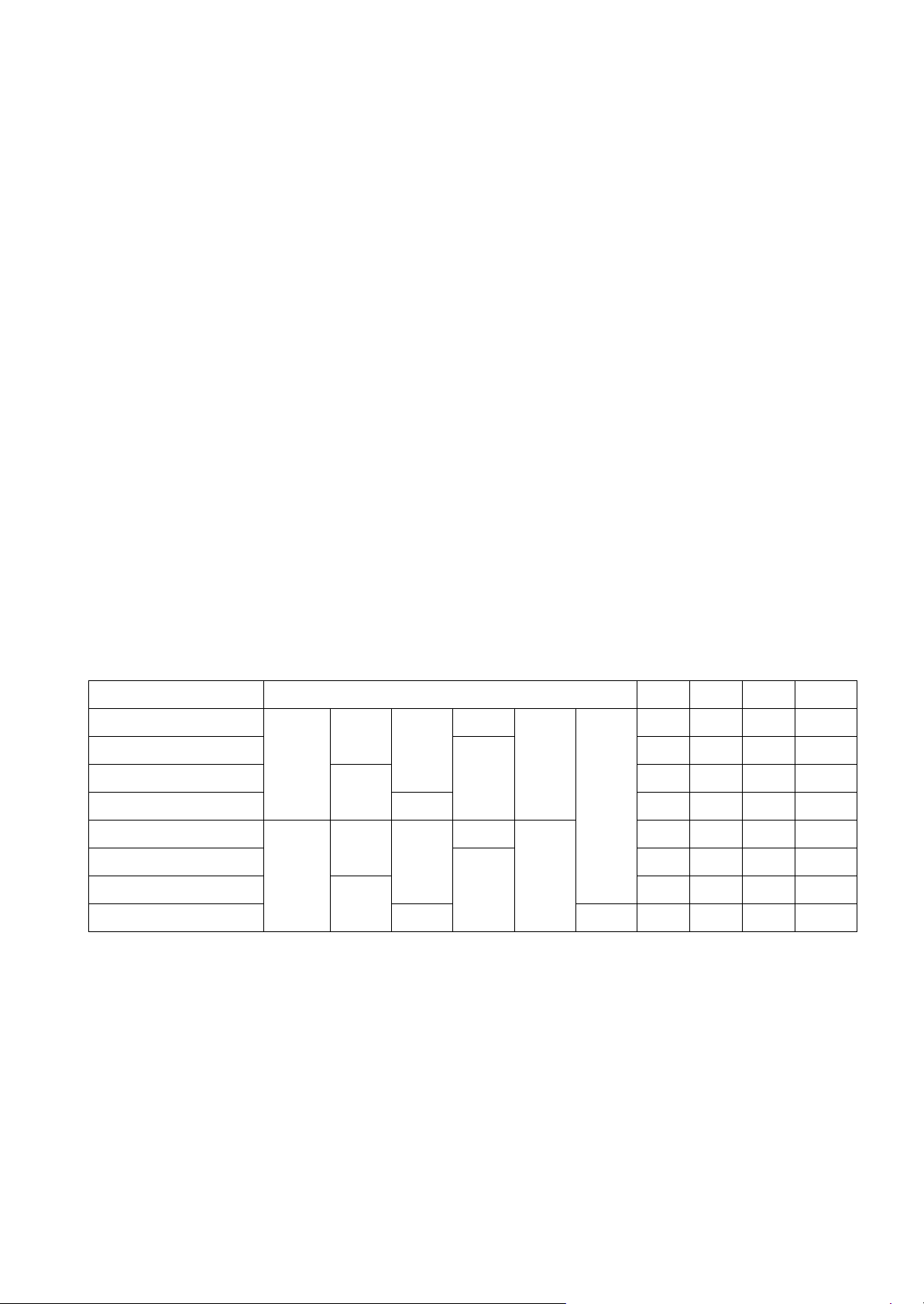

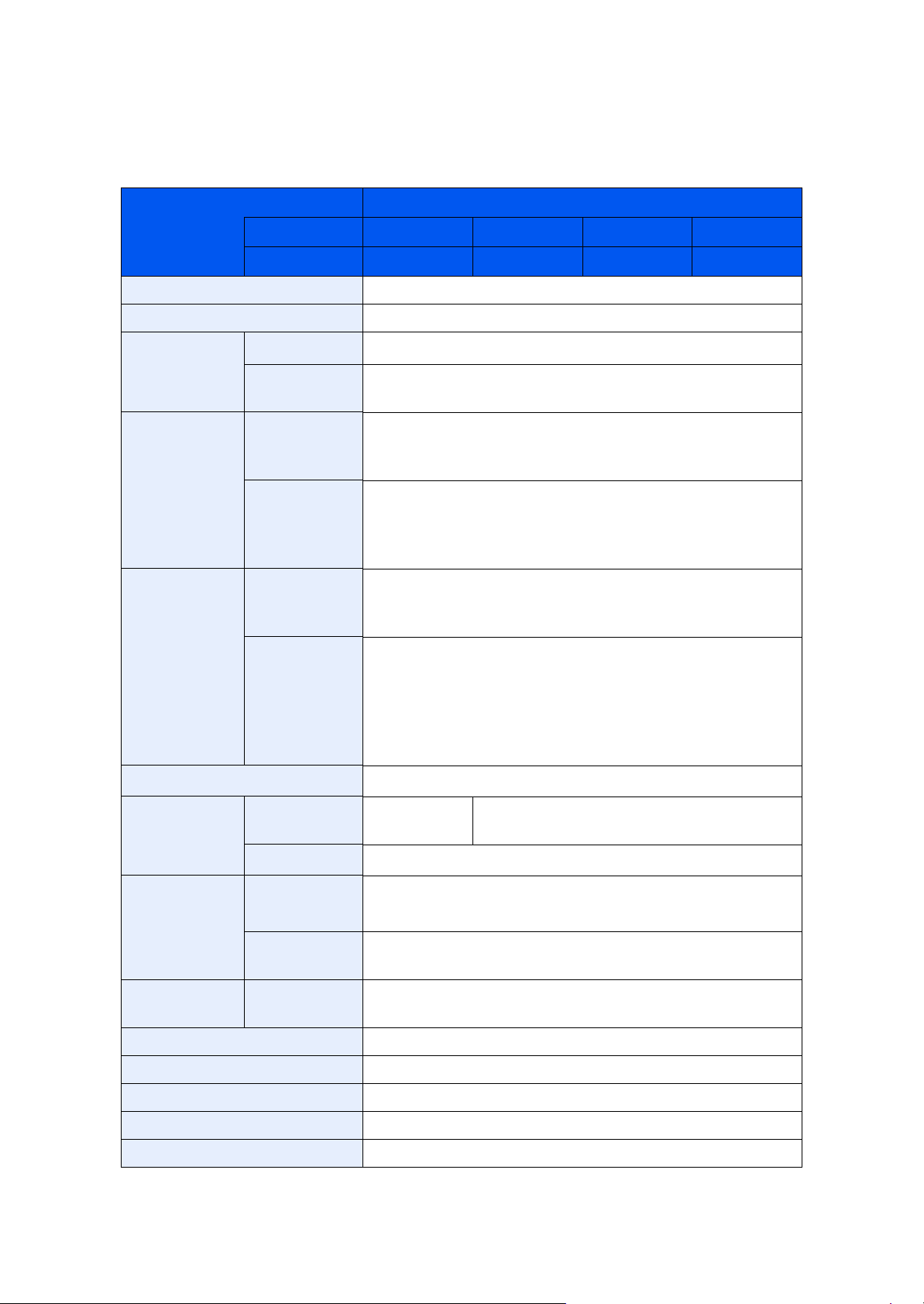

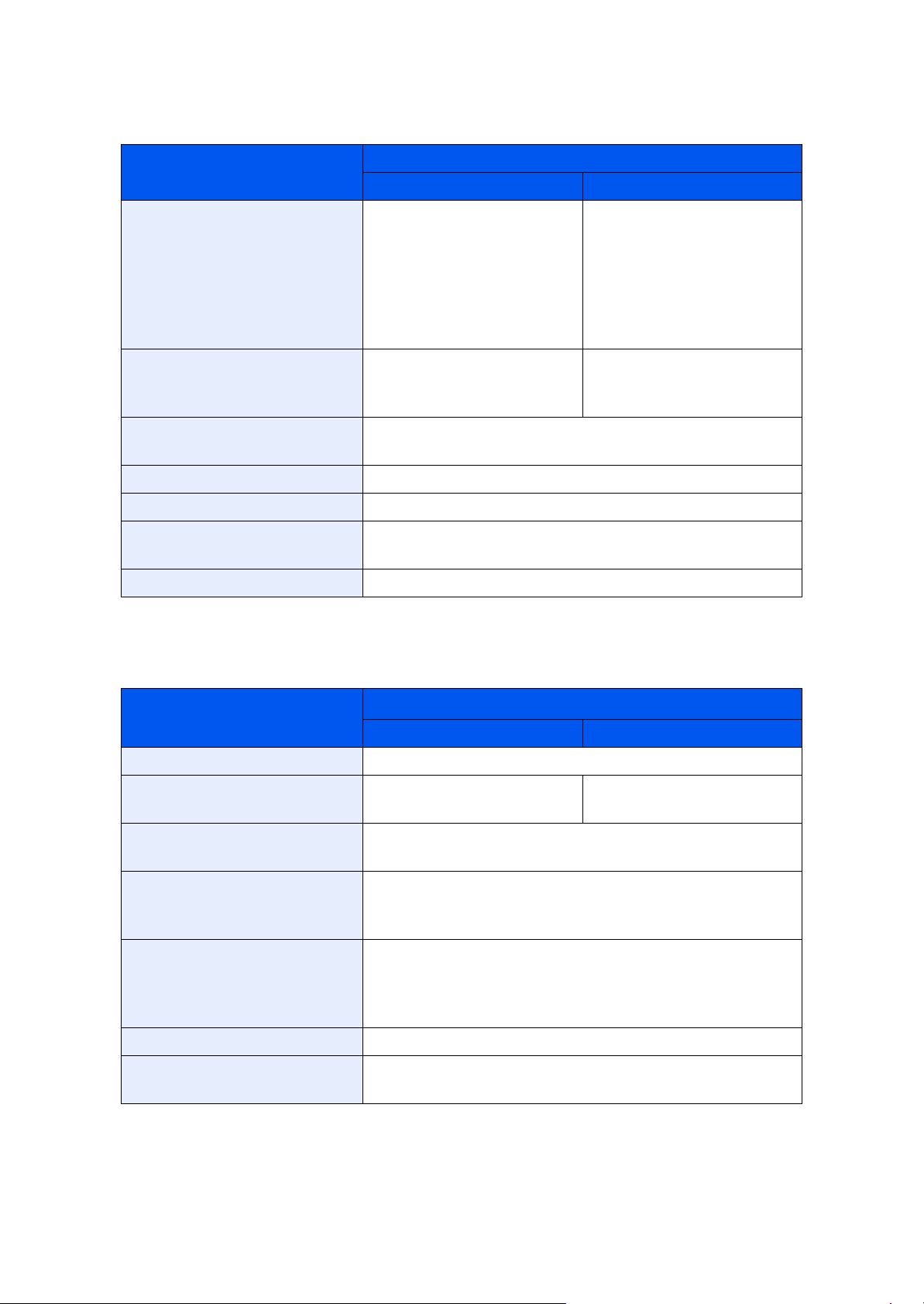

Notation of products in the manual

For the purpose of this service manual, products are identified by print speed.

Product name Manual classification KDJ KDA KDE KDAU

ECOSYS M2135dn

ECOSYS M2635dn

35 ppm

ECOSYS M2635dw

ECOSYS M2735dw TSI × × ○○

ECOSYS M2040dn

ECOSYS M2540dn

40 ppm

ECOSYS M2540dw

ECOSYS M2640idw TSI HyPAS ○○○ ○

-

Wi-Fi

-

Wi-Fi

LCD

LCD

-

ADF

FAX

-

-

DADF

FAX

× ○○ ×

××○○

× ○ ××

× ○○ ○

××○○

○○××

Page 3

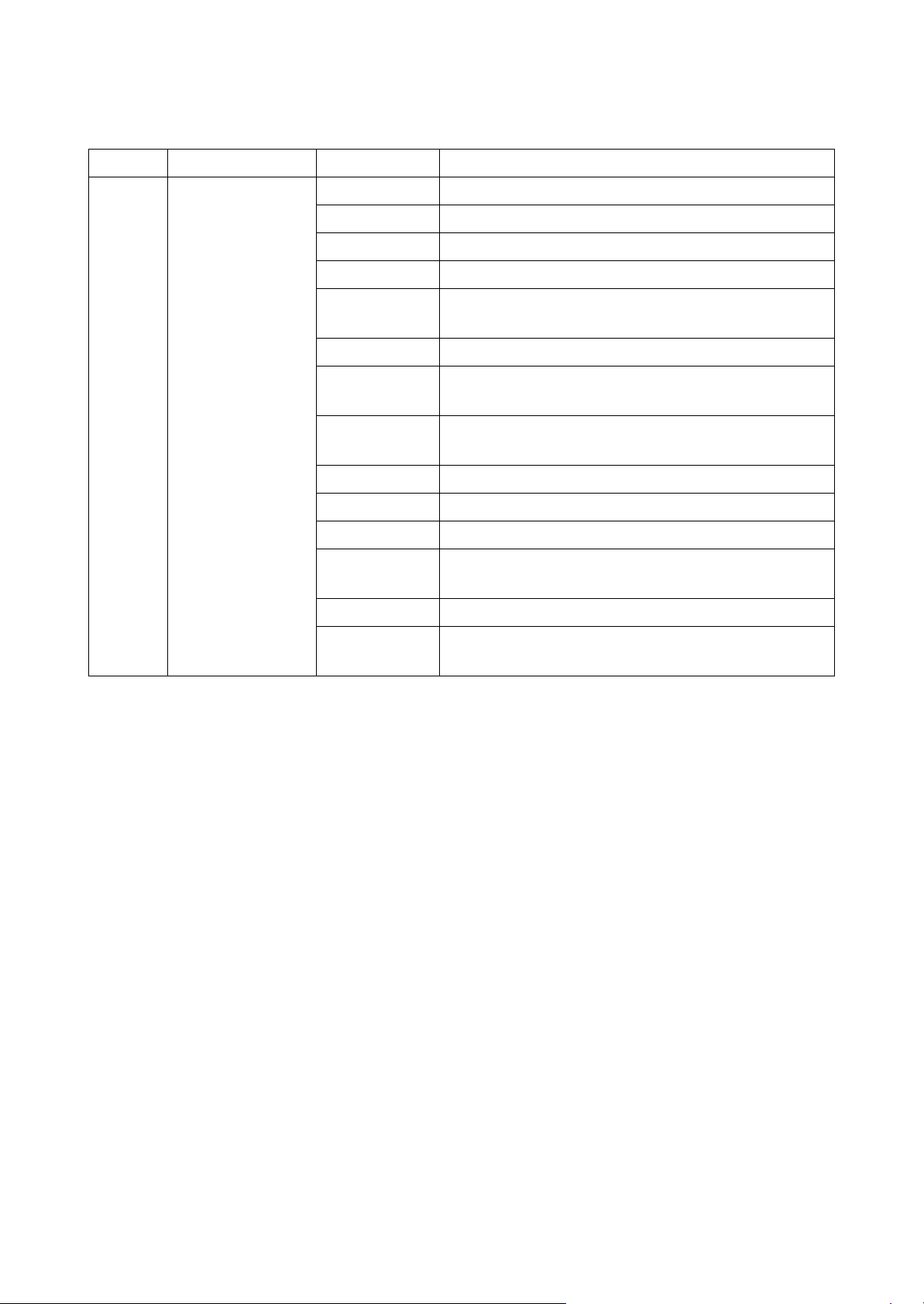

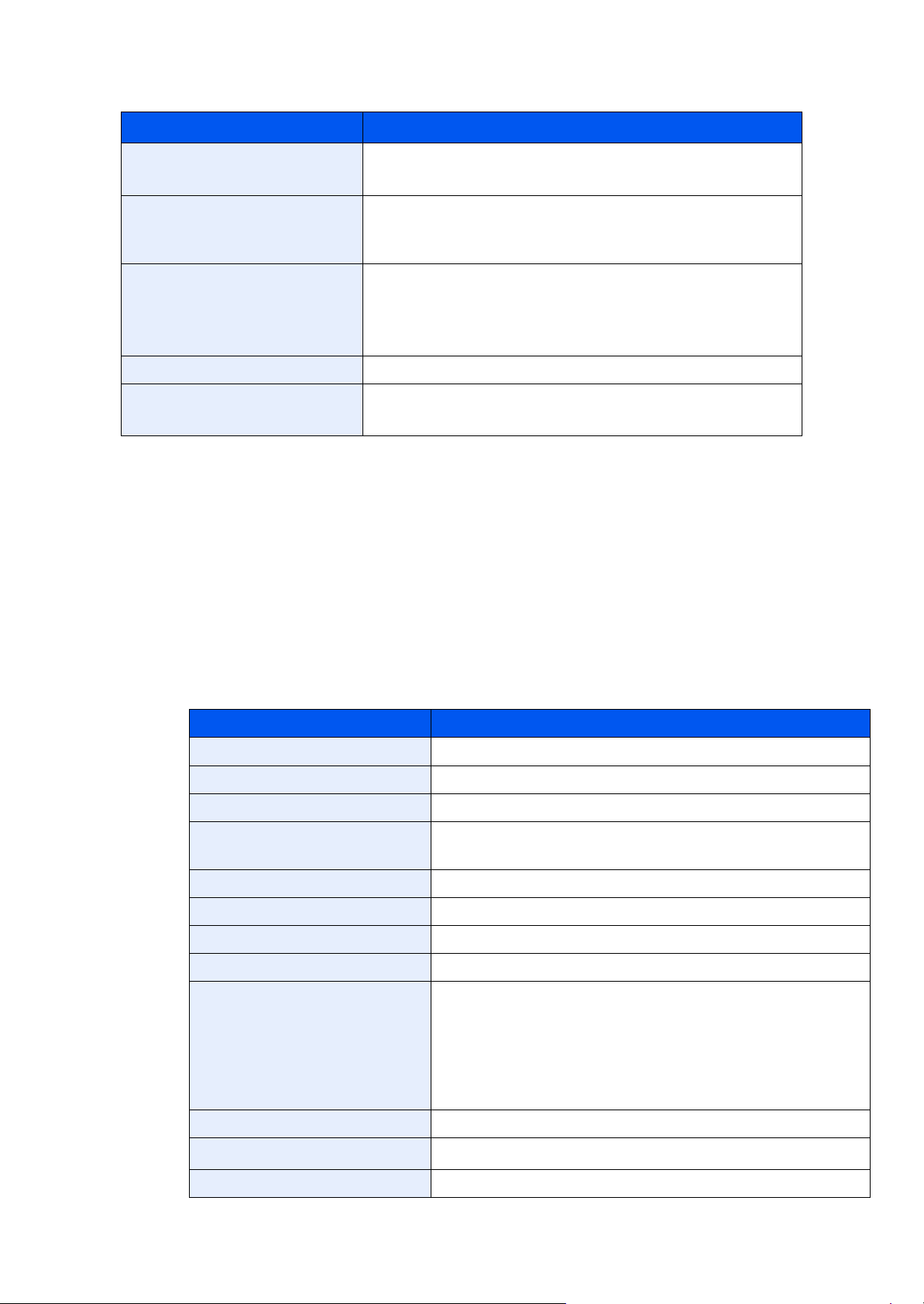

Revision history

Revision Date Pages Revised contents

1 2 November 2016 CONTENTS Chenge: Page number

1-4, 1-5 Added: FAX functions

2-4 Added: Name of parts number 7

2-9 Correction: Description of "IMPORTANT"

3-2 Correction: Item name of 3-2/3-2(1)

Added: 4. Fuser pressure release motor

3-11 Correction: Description of the thermopile

4-3, 4-4

6-9, 6-10

4-36 to 38 Correction: Correction: Procedure of detaching and

4-75 Deleted: Procedure of detaching the front cover

4-95 to 99 Added: Procedure of detaching the Wi-Fi PWB

6-68 Deleted: Destination code (22)

7-2 Correction: rear cover → cover

7-9, 7-10 Added: J4002 to J4018

7-15 to 83 Added: 7-2 Self diagnostic, 7-3 Image formation failure

Correction: Maintenance kits

rettaching the laser scanner unit

Deleted: (1-1)Step2 to 4

7-4 Electric failure, 7-5 Mechanical failure

Page 4

This page is intentionally left blank.

Page 5

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Page 6

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect com-

pliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point of attention is

shown inside the symbol.

General warning. Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action. Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required. Remove the power plug from the wall outlet.

Always ground the copier.

Page 7

1. Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check that

it is adequate for the rated current. .....................................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes, lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the proper

authorities. ..........................................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .........

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. .................

• Do not install the copier near a radiator, heater, other heat source or near flammable material. This

may cause fire. ...................................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ............

• Always handle the machine by the correct locations when moving it. .................................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may cause

the copier to move unexpectedly or topple, leading to injury. ..............................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally

ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately.

If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical atten-

tion. .....................................................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. .........................................................................................................................

Page 8

2. Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ................

• Always follow the procedures for maintenance described in the service manual and other related

brochures. ..........................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety mechanisms

and protective circuits. ........................................................................................................................

• Always use parts having the correct specifications. ............................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related brochure

when replacing them. Using a piece of wire, for example, could lead to fire or other serious acci-

dent. ...................................................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ..................................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. ...............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it

is dirty, clean it to remove the risk of fire or electric shock. .................................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ...............................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause electric

shock if handled improperly. ...............................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are safely

secured so they will not be caught in rotating sections. ......................................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. ..........

• Handle the fixing section with care to avoid burns as it can be extremely hot. ..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. ...........................................................................................................

Page 9

• Do not remove the ozone filter, if any, from the copier except for routine replacement. ......................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. ........................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. ................................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ..........

• Remove toner completely from electronic components. .....................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ......................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten connector,

trapped wire and missing screws. .......................................................................................................

• Check that all the caution labels that should be present on the machine according to the instruction

handbook are clean and not peeling. Replace with new ones if necessary. .......................................

• Handle greases and solvents with care by following the instructions below: ......................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the power

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. ...........................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet immedi-

ately. ...................................................................................................................................................

3. Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the

specified refiner; it may generate toxic gas. ........................................................................................

• Keep the machine away from flammable liquids, gases, and aerosols. A fire or an electric shock

might occur. ........................................................................................................................................

Page 10

This page is intentionally left blank.

Page 11

1 Specifications

1-1 Specifications ........................................................................................................................... 1-1

(1) Common function ................................................................................................................ 1-1

(2) Copy Functions.................................................................................................................... 1-3

(3) Printer Functions ................................................................................................................. 1-3

(4) Scanner Functions............................................................................................................... 1-4

(5) FAX Functions ..................................................................................................................... 1-4

(6) Document Processor ...........................................................................................................1-5

(7) Paper Feeder (PF-1100)(Option) ........................................................................................ 1-6

1-2 Part Names............................................................................................................................... 1-7

(1) Machine Exterior.................................................................................................................. 1-7

(2) Connectors/Interior .............................................................................................................. 1-8

(3) With Optional Equipments Attached .................................................................................... 1-9

(4) Operation Panel (TSI)........................................................................................................1-10

(5) Operation Panel Keys (LCD) ............................................................................................. 1-11

1-3 Overview of Optional Equipment ............................................................................................ 1-13

(1) Expansion Memory............................................................................................................ 1-14

(2) PF-1100 "Paper Feeder" ................................................................................................... 1-15

(3) Card Authentication Kit(B) "Card Authentication Kit"......................................................... 1-15

(4) UG-33 "ThinPrint Option" .................................................................................................. 1-15

(5) SD/SDHC Memory Card.................................................................................................... 1-15

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

CONTENTS

2 Installation

2-1 Environment ............................................................................................................................. 2-1

2-2 Installing the main unit .............................................................................................................. 2-2

(1) Unpacking and checking bundled items .............................................................................. 2-3

(1-1) Main unit..................................................................................................................... 2-3

(1-2) Paper Feeder (Option) ............................................................................................... 2-4

(2) Installing the optional equipment ......................................................................................... 2-5

(3) Connecting to other device.................................................................................................. 2-5

(4) Connecting to the cable....................................................................................................... 2-6

(4-1) LAN Cable .................................................................................................................. 2-6

(4-2) USB cable .................................................................................................................. 2-6

(5) Loading Paper ..................................................................................................................... 2-7

(6) Power-up ............................................................................................................................. 2-9

(7) Default (TSI model) ........................................................................................................... 2-10

(7-1) Setting Date and Time.............................................................................................. 2-10

(7-2) Network Settings ...................................................................................................... 2-11

(7-3) Altitude Adjustment Setting ...................................................................................... 2-12

(7) Default (LCD model)..........................................................................................................2-13

(7-1) Setting Date and Time.............................................................................................. 2-13

(7-2) Network Settings ...................................................................................................... 2-14

(7-3) Altitude Adjustment Setting ...................................................................................... 2-16

(8) Installing Software ............................................................................................................. 2-17

(9) Output Maintenance Report (Executing Maintenance mode U000) (For Service) ............ 2-18

(10) Clearing the counts (Executing Maintenance Mode U927) (For service) .......................... 2-18

(11) Terminating the maintenance mode (For service)............................................................. 2-18

(12) Installing the main unit is complete.................................................................................... 2-18

Page 12

3 Machine Design

3-1 Cross-section view ................................................................................................................... 3-1

(1) Main unit + Document processor + Paper feeder (option)................................................... 3-1

3-2 The configuration of the electrical components ........................................................................ 3-2

(1) Electric parts........................................................................................................................ 3-2

(1-1) Machine left side ........................................................................................................ 3-2

(1-2) Machine right side ...................................................................................................... 3-3

(1-3) Document processor .................................................................................................. 3-4

(1-4) Paper feeder (option) ................................................................................................. 3-4

(2) Descriptions about the major PWBs.................................................................................... 3-5

(2-1) Main/Engine PWB ...................................................................................................... 3-5

(2-2) High-voltage PWB ...................................................................................................... 3-5

(2-3) Power source PWB .................................................................................................... 3-5

(2-4) Operation panel PWB (TSI)........................................................................................ 3-6

(2-5) Operation panel PWB (LCD) ...................................................................................... 3-6

(3) Electric parts layout ............................................................................................................. 3-7

(3-1) PWBs ......................................................................................................................... 3-7

(3-2) Sensors and Switches.............................................................................................. 3-10

(3-3) Motors ...................................................................................................................... 3-13

(3-4) Others....................................................................................................................... 3-15

3-3 Drive system ........................................................................................................................... 3-17

(1) Drive system for the paper conveying ............................................................................... 3-17

(2) Each section drive ............................................................................................................. 3-18

(2-1) Primary paper feed drive .......................................................................................... 3-18

(2-2) Drum drive................................................................................................................3-18

(2-3) Developer drive ........................................................................................................ 3-19

(2-4) Fuser unit drive......................................................................................................... 3-19

3-4 Mechanical construction ......................................................................................................... 3-20

(1) Paper feed section............................................................................................................. 3-20

(1-1) Cassette paper feed section..................................................................................... 3-20

(1-2) MP tray paper feed section ...................................................................................... 3-22

(2) Optical section ................................................................................................................... 3-24

(2-1) Image scanner unit................................................................................................... 3-24

(2-2) Laser scanner unit.................................................................................................... 3-26

(3) Developer section.............................................................................................................. 3-28

(3-1) Developer unit .......................................................................................................... 3-28

(4) Drum section ..................................................................................................................... 3-30

(4-1) Main charger unit...................................................................................................... 3-30

(4-2) Cleaning ................................................................................................................... 3-30

(5) Conveying/Transfer and Separation section ..................................................................... 3-32

(6) Fuser section ..................................................................................................................... 3-34

(7) Eject and feedshift section................................................................................................. 3-36

(8) Duplex conveying section.................................................................................................. 3-38

(9) Document processor ......................................................................................................... 3-40

(10) Paper feeder (option)......................................................................................................... 3-42

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

4 Maintenance

4-1 Precautions for the maintenance ..............................................................................................4-1

(1) Precautions.......................................................................................................................... 4-1

(2) Storage and handling of the drum ....................................................................................... 4-1

(3) Storage of the toner container ............................................................................................. 4-1

Page 13

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

(4) Screening of the toner container ......................................................................................... 4-2

4-2 Maintenance parts .................................................................................................................... 4-3

(1) Maintenance kits.................................................................................................................. 4-3

(2) Executing the maintenance mode after replacing the maintenance kit ............................ 4-3

(3) Maintenance parts list.......................................................................................................... 4-3

(4) Periodic maintenance Procedures....................................................................................... 4-4

4-3 Maintenance parts replacement procedures ............................................................................ 4-5

(1) Cassette paper feed section................................................................................................ 4-5

(1-1) Detaching and reattaching the Paper feed roller........................................................ 4-5

(1-2) Detaching and reattaching the retard roller ................................................................ 4-6

(1-3) Detaching and reattaching the MP paper feed pulley ................................................ 4-8

(2) Developer section.............................................................................................................. 4-10

(2-1) Detaching and reattaching the developer unit.......................................................... 4-10

(3) Drum section ..................................................................................................................... 4-11

(3-1) Detaching and reattaching the drum unit ................................................................. 4-11

(3-2) Detaching and reattaching the main charger unit..................................................... 4-13

(4) Transfer section................................................................................................................. 4-14

(4-1) Detaching and reattaching the transfer roller unit .................................................... 4-14

(5) Fuser section ..................................................................................................................... 4-17

(5-1) Detaching and reattaching the fuser unit.................................................................. 4-17

4-4 Disassembly and Reassembly ............................................................................................... 4-21

(1) Outer covers ...................................................................................................................... 4-21

(1-1) Detaching and reattaching the left rear cover .......................................................... 4-21

(1-2) Detaching and reattaching the ISU rear cover ......................................................... 4-21

(1-3) Detaching and reattaching the ISU left cover ........................................................... 4-22

(1-4) Detaching and reattaching the ISU right cover......................................................... 4-22

(1-5) Detaching and reattaching the left cover.................................................................. 4-23

(1-6) Detaching and reattaching the right cover................................................................ 4-24

(1-7) Detaching and reattaching the front cover ............................................................... 4-26

(1-8) Detaching and reattaching the rear cover ................................................................ 4-27

(2) Optical section ................................................................................................................... 4-28

(2-1) Detaching and reattaching the laser scanner unit (LSU).......................................... 4-28

(2-2) Detaching and reattaching the image scanner unit (ISU)......................................... 4-39

(2-3) Detaching and reattaching the operation panel (TSI model).................................... 4-45

(2-4) Detaching and reattaching the operation panel (LCD model) .................................. 4-47

(2-5) Detaching and reattaching the ISU top frame .......................................................... 4-48

(2-6) Detaching and reattaching the scanner carriage assembly ..................................... 4-48

(3) Drive section...................................................................................................................... 4-49

(3-1) Detaching and reattaching the main motor .............................................................. 4-49

(3-2) Detaching and reattaching the fuser pressure release drive unit ............................. 4-54

(3-3) Detaching and reattaching the MP solenoid (front side) .......................................... 4-60

(3-4) Detaching reattaching the clutch. ............................................................................. 4-64

(3-5) Detaching and reattaching the eject solenoid .......................................................... 4-70

(4) Others................................................................................................................................ 4-83

(4-1) Detaching and reattaching the speaker.................................................................... 4-83

(4-2) Detaching and reattaching the eraser ...................................................................... 4-89

(4-3) Replacing the language sheet (TSI model) .............................................................. 4-91

(4-4) Replacing the language sheet (LCD model) ............................................................ 4-92

(4-5) Fan motor attachment direction................................................................................ 4-93

(5) PWBs................................................................................................................................. 4-94

(5-1) Detaching and reattaching the main/engine PWB.................................................... 4-94

Page 14

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

(5-2) Detaching and reattaching the high voltage PWB .................................................. 4-102

(5-3) Detaching and reattaching the low voltage power source PWB............................. 4-110

(5-4) Detaching and reattaching the FAX PWB .............................................................. 4-116

(5-5) Detaching and reattaching the Wi-Fi PWB. ............................................................ 4-124

(5-6) Detaching and reattaching the USB PWB. ............................................................. 4-126

(5-7) Detaching and reattaching the operation panel PWB (TSI model)......................... 4-138

(5-8) Detaching and reattaching the operation panel PWB (LCD model) ....................... 4-141

(6) Detaching and reattaching the document processor ....................................................... 4-143

(6-1) Detaching and reattaching the DP pick up pulley,

DP paper feed roller and DP separation pad ......................................................... 4-143

(6-2) Detaching and reattaching the DP front cover ....................................................... 4-145

(6-3) Detaching and reattaching the DP rear cover ........................................................ 4-146

(6-4) Detaching and reattaching the DP main motor ...................................................... 4-146

4-5 Maintenance parts replacement procedures (option) ........................................................... 4-148

(1) Paper feeder.................................................................................................................... 4-148

(1-1) Detaching and reattaching the PF main PWB ........................................................ 4-148

(1-2) Detaching and reattaching PF conveying motor. ................................................... 4-149

(1-3) Detaching and reattaching the PF clutch. .............................................................. 4-152

5Firmware

5-1 Firmware update (TSI model) ................................................................................................... 5-1

5-2 Firmware update (LCD model) ................................................................................................. 5-6

6 Maintenance mode

6-1 Maintenance mode ................................................................................................................... 6-1

(1) Executing the maintenance mode ....................................................................................... 6-1

(2) Maintenance modes list ......................................................................................................6-2

(2-1) Content of the maintenance mode ............................................................................. 6-5

6-2 Service modes ...................................................................................................................... 6-107

(1) TSI model ........................................................................................................................ 6-107

(1-1) Executing the service mode ................................................................................... 6-107

(1-2) Descriptions of service modes ............................................................................... 6-109

(2) LCD model....................................................................................................................... 6-113

(2-1) Executing the service mode ................................................................................... 6-113

(2-2) Descriptions of service modes ............................................................................... 6-115

7Troubleshooting

7-1 Conveying failures .................................................................................................................... 7-1

(1) Prior standard check items .................................................................................................. 7-1

(1-1) Paper jam due to the cover-open detection ............................................................... 7-2

(1-2) Paper jam due to the wave or curl in the fuser section of the damp paper ................ 7-2

(1-3) Paper jam due to the dog-ear, paper skew,

paper creases, fusing failure or the paper curl ........................................................... 7-2

(1-4) Paper jam caused by the conveying guide, paper entry guide or the feedshift guide 7-3

(1-5) Paper jam caused by incorrectly loaded paper in the cassette .................................. 7-3

(1-6) Paper jam due to the inferior paper............................................................................ 7-3

(1-7) Paper jam caused by the conveying rollers or the paper feed pulleys ....................... 7-4

(1-8) Paper jam due to the sensor ...................................................................................... 7-5

(1-9) Paper jam due to the setting / detection failure .......................................................... 7-5

(1-10) Paper jam due to the static electricity......................................................................... 7-6

Page 15

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

(1-11) Paper jam caused by installation in the environment

where paper inside the cassette is always moist. ...................................................... 7-6

(2) Paper jam indication ............................................................................................................ 7-7

(3) Paper jam detection condition ............................................................................................. 7-8

(4) First check item ................................................................................................................. 7-12

7-2 Self diagnostic ........................................................................................................................ 7-15

(1) Self diagnostic function...................................................................................................... 7-15

(2) Self diagnostic codes......................................................................................................... 7-15

(3) System Error (Fxxxx) Outline ............................................................................................ 7-32

7-3 Image formation failure ........................................................................................................... 7-37

(1) Poor image (due to DP and scanner reading) ................................................................... 7-38

(1-1) No image appears (entirely white)............................................................................ 7-39

(1-2) No image appears (entirely black)............................................................................ 7-41

(1-3) The entire image is faint ........................................................................................... 7-42

(1-4) The background is colored ....................................................................................... 7-44

(1-5) Vertical white streaks or bands appear .................................................................... 7-46

(1-6) Vertical white streaks or bands appear .................................................................... 7-47

(1-7) Horizontal black streaks appear ............................................................................... 7-49

(1-8) The image is partly dark or bright............................................................................. 7-51

(1-9) Black dots appear in the image ................................................................................ 7-53

(1-10) Characters are blurred ............................................................................................. 7-54

(1-11) Regular error images arise at the leading edge of the original and copy. ................ 7-56

(1-12) The image is partly missing...................................................................................... 7-57

(1-13) The image is blurred................................................................................................. 7-59

(1-14) Image center does not align with the original center ................................................ 7-61

(1-15) Moire ........................................................................................................................ 7-62

(1-16) Skewed image.......................................................................................................... 7-63

(1-17) Abnormal image ....................................................................................................... 7-64

(2) Poor image (Image forming factor).................................................................................... 7-65

(2-1) No image appears (entirely white)............................................................................ 7-66

(2-2) No image appears (entirely black)............................................................................ 7-67

(2-3) The entire image is faint ........................................................................................... 7-68

(2-4) It is foggy at the background image ......................................................................... 7-70

(2-5) Vertical white streaks or bands appear .................................................................... 7-71

(2-6) Vertical white streaks or bands appear .................................................................... 7-72

(2-7) There are horizontal bands in white or black............................................................ 7-73

(2-8) Uneven density vertically.......................................................................................... 7-74

(2-9) Uneven density horizontally ..................................................................................... 7-75

(2-10) Black dots appear in the image ................................................................................ 7-76

(2-11) Offset occurs ............................................................................................................7-76

(2-12) The image is partly missing...................................................................................... 7-77

(2-13) The image is blurred................................................................................................. 7-77

(2-14) Irregular horizontal white streaks appear in the image

Dots appear in the image ......................................................................................... 7-78

(2-15) Granular image (low solid image density) ................................................................ 7-79

7-4 Electric failure ......................................................................................................................... 7-80

7-5 Mechanical failure................................................................................................................... 7-83

7-6 Error codes ............................................................................................................................. 7-84

(1) Scan to SMB error code .................................................................................................... 7-84

(2) Scan to FTP error code ..................................................................................................... 7-85

(3) Scan to E-mail error code.................................................................................................. 7-86

Page 16

7-7 Error codes ............................................................................................................................. 7-88

(1) Error codes ........................................................................................................................ 7-88

(2) Error codes ........................................................................................................................ 7-89

(2-1) Error code table: U004XX Interrupted phase B ........................................................ 7-92

(2-2) Error code table: U006XX Problems with the unit .................................................... 7-93

(2-3) Error code table: U008XX Page transmission error ................................................. 7-93

(2-4) Error code table: U009XX Page reception error....................................................... 7-93

(2-5) Error code table: U010XX G3 transmission error ..................................................... 7-94

(2-6) U011XX G3 reception error...................................................................................... 7-96

(2-7) Error code table: U017XX V.34 transmission error .................................................. 7-97

(2-8) Error code table: U018XX V.34 reception error........................................................ 7-98

(2-9) Error code table: U023XX Page reception error....................................................... 7-98

(2-10) Error code table: U044XX Encrypted transmission error ......................................... 7-98

8PWBs

8-1 Description for PWB ................................................................................................................. 8-1

(1) Main/Engine PWB ............................................................................................................... 8-1

(2) High voltage PWB .............................................................................................................8-10

(3) Low voltage power supply PWB ........................................................................................ 8-12

(4) Operation panel PWB (TSI)............................................................................................... 8-14

(5) Operation panel PWB (LCD) ............................................................................................. 8-19

(6) PF main PWB (option)....................................................................................................... 8-21

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

9 Appendixes

9-1 Appendixes ............................................................................................................................... 9-1

(1) Repetitive defects gauge .....................................................................................................9-1

(2) Firmware environment commands ...................................................................................... 9-2

(3) Chart of image adjustment procedures ............................................................................. 9-10

(4) Wiring diagram .................................................................................................................. 9-13

(4-1) Standard................................................................................................................... 9-13

(4-2) PF-1100 (Options).................................................................................................... 9-17

Installation Guide

PF-1100 (250 sheets × 1 Paper Feeder)

Page 17

1 Specifications

1-1 Specifications

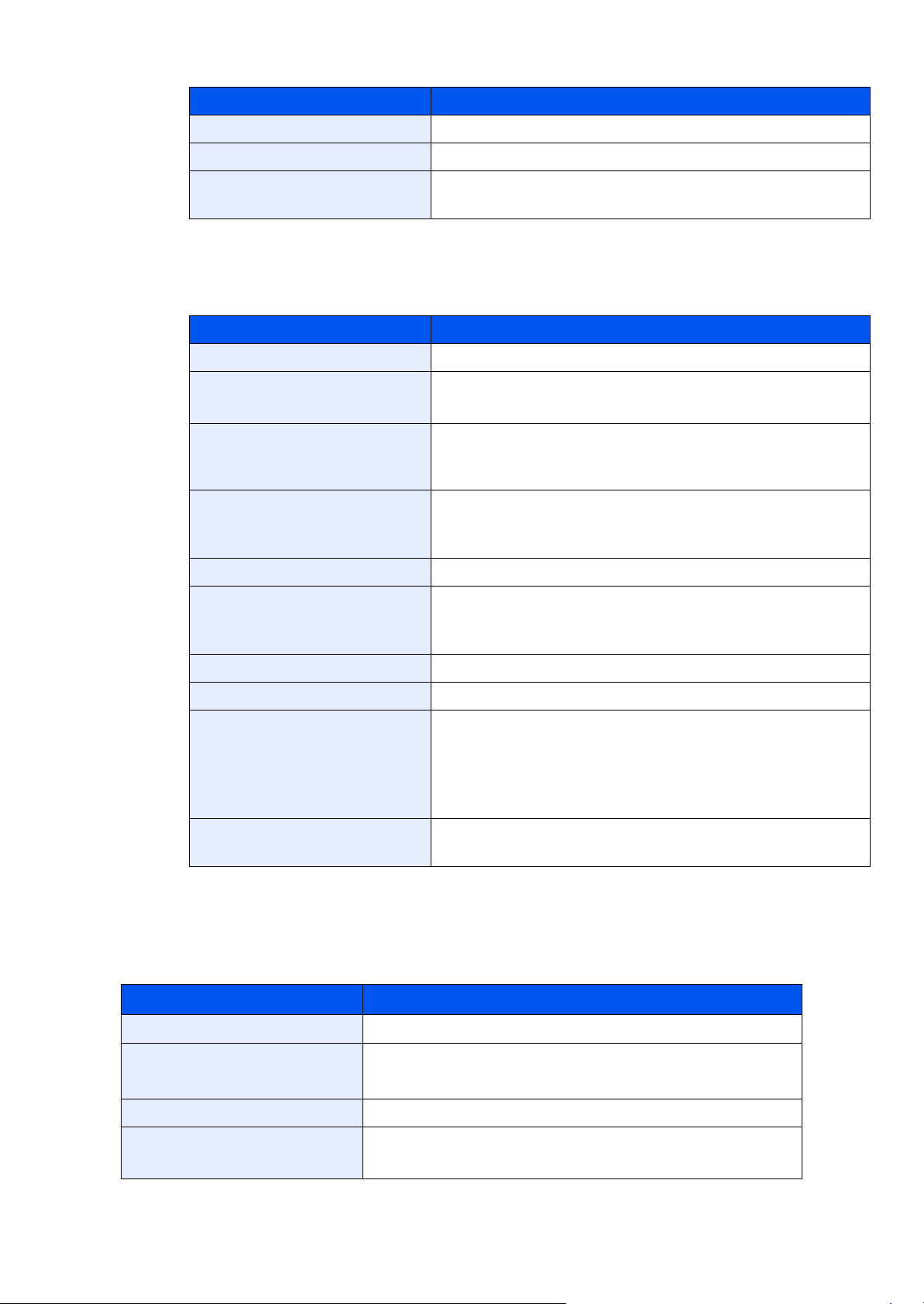

(1) Common function

Item Description

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

40 ppm model

35 ppm model

Type Desktop

Printing Method Electrophotography by semiconductor laser

Paper Weight Cassette

Multi Purpose

Tra y

Paper Type Cassette Plain, Rough, Recycled, Preprinted, Bond, Color, Prepunched,

Multi Purpose

Tra y

Paper Size Cassette A4, A5-R, A5, A6, B5, Letter, Legal, Folio, 216 × 340 mm,

Multi Purpose

Tra y

M2640idw M2540dw M2540dn M2040dn

M2735dw M2635dw M2635dn M2135dn

2

60 to 163 g/m

60 to 220 g/m², 209g/m² (Hagaki)

Letterhead, Thick, High Quality, Custom 1 to 8 (Duplex:

Same as Simplex)

Plain, Transparency (OHP film), Rough, Vellum, Labels, Recycled, Preprinted, Cardstock, Coated, Color, Prepunched, Letterhead, Envelope,

Thick, High Quality, Custom 1 to 8

Statement, Executive, Oficio II, 16K, B5(ISO),

Custom (105 x 148 to 216 x 356 mm)

A4, A5-R, A5, A6, B5, B6, Letter, Legal, Folio, 216 × 340 mm,

Statement-R,Executive, Oficio II, 16K, B5(ISO),

Envelope #10, Envelope #9, Envelope #6 3/4,

Envelope Monarch, Envelope DL, Envelope C5, Hagaki (Cardstock), Oufukuhagaki (Return postcard), youkei 4, youkei 2,

Custom (70 x 148 to 216 x 356 mm)

Printable Area Print margin for top, bottom and both sides is 4.2 mm.

Warm-up Time

(23°C/ 73.4°F,

60%)

Paper Capacity

Output Tray

Capacity

Image Write System Semiconductor laser and electrophotography (twin beams)

Scanning light source 3-color LED light source

Scanning method Flat-face scanning method with the CIS contact image sensor

Photoconductor OPC drum (diameter 30 mm)

Charging system Positive charge scorotron system

Power on 20 seconds or

less

Sleep 10 seconds or less

Cassette

Multi Purpose

Tra y

Inner tray 150 sheets (80 g/m²)

300 Sheets (64 g/m2)

250 Sheets (80 g/m2)

120 sheets (A4/Letter or smaller) (64 g/m2)

100 sheets (A4/Letter or smaller) (80 g/m2)

17 seconds or less

*1

*1

1-1

Page 18

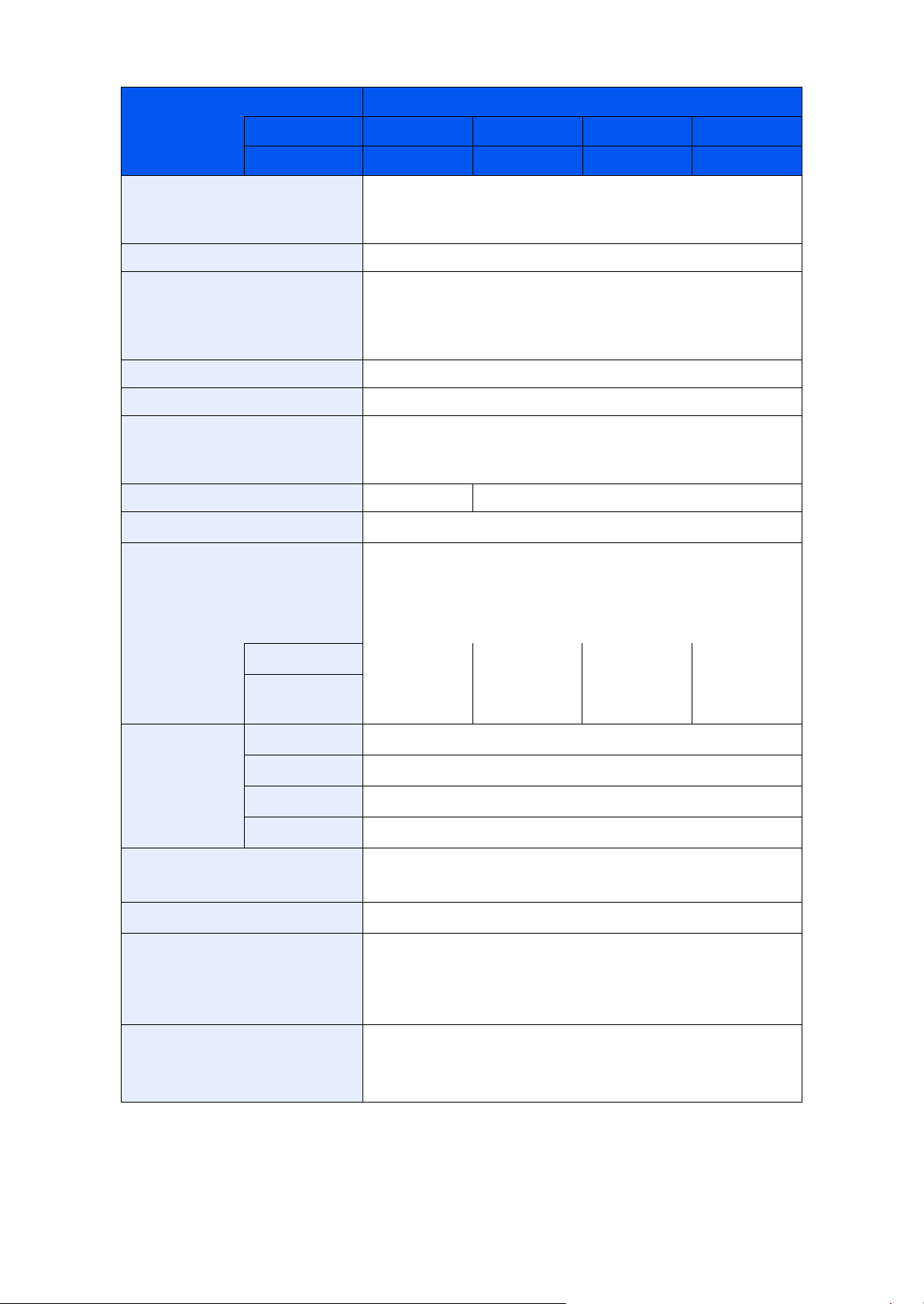

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

Item Description

40 ppm model

35 ppm model

M2640idw M2540dw M2540dn M2040dn

M2735dw M2635dw M2635dn M2135dn

Developer system Magnetic mono-component developing system

Toner: magnetic toner

Toner feed system: leveled toner feed

Transfer system Transfer roller method

Separation system Curvature separation + discharger needle (grounded) : except

100 V model

Curvature separation + discharger needle (DC voltage

impressed) : 100 V model only

Cleaning system Counter blade

Charge erasing system Exposure by cleaning lamp (LED)

Fusing system Sliding belt + foam press roller system

Heat source: halogen heater

Abnormal temperature preventing device: 2 thermocat

Operation Panel 4.3inch TSI 5-line LCD

Memory 512 MB

Interface USB Interface Connector: 1 (Hi-Speed USB)

Network interface: 1

(10 BASE-T/100 BASE-TX/1000 BASE-T)

USB Port: 1 (Hi-Speed USB)

Fax Fax: 1Fax: 1Fax: 1-

Operating

Environment

Wireless LAN Wireless LAN

support Only

Temperatur e 10 to 32.5°C/50 to 90.5°F

Humidity 10 to 80%

Wireless LAN

support Only

--

Altitude 3,500 m/11,482 ft maximum

Brightness 1,500 lux maximum

Dimension (W × D × H) 16.42" × 16.23" × 17.21"417 × 412 × 437 mm (Metric Model)

18.71" × 16.23" × 17.21"475 × 412 × 437 mm (Inch Model)

Weight (without toner container) Approx. 41.9 lb/Approx. 19 kg

Space Required (W × D) (Using multi purpose tray) 14.77" × 28.47"375 × 723 mm

(Metric Model)

(Using multi purpose tray) 14.77" × 28.47"375 × 723 mm (Inch

Model)

Power Source AC100V, 50/60Hz, 9.7A

AC120 V, 60 Hz, 8.7A

AC220 to 240V, 50 Hz, 4.4 A

*1 Up to upper limit height line in the cassette.

1-2

Page 19

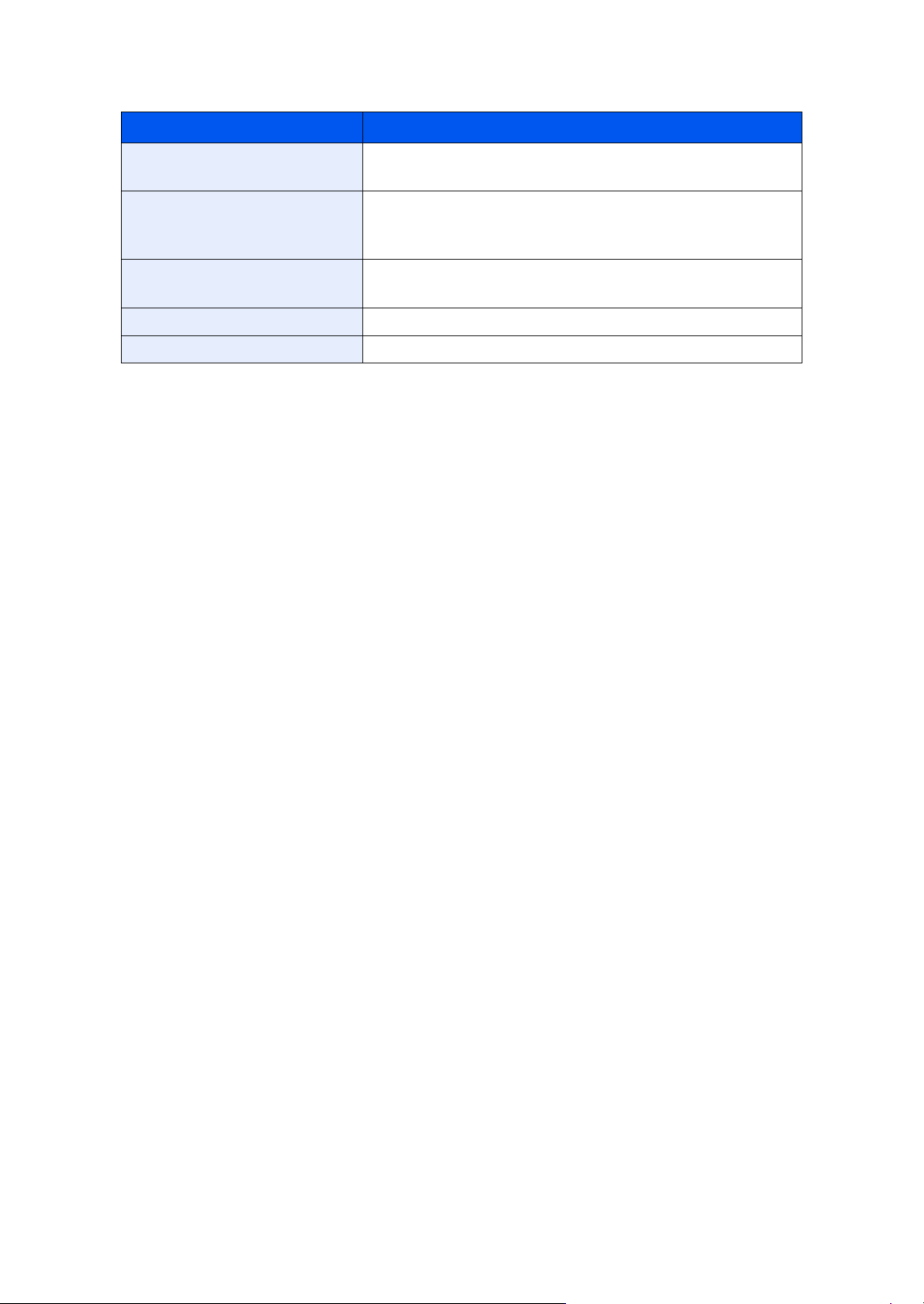

(2) Copy Functions

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

Item Description

40 ppm model 35 ppm model

Copy Speed A4/A5 40 sheets/min

Letter 42 sheets/min

Legal 34 sheets/min

B5 27 sheets/min

A5-R 19 sheets/min

A6 19 sheets/min

16K 22 sheets/min

First Copy Time

(A4, place on the platen, feed

from Cassette)

Zoom Level Manual mode: 25 to 400%, 1% increments

Continuous Copying 1 to 999 sheets

Resolution 600 × 600 dpi

Supported Original Types Sheet, Book, 3-dimensional objects (maximum original size:

Original Feed System Fixed

6.4 seconds or less 6.9 seconds or less

Auto mode:Preset Zoom

Legal/Folio)

A4/A5 35 sheets/min

Letter 37 sheets/min

Legal 30 sheets/min

B5 24 sheets/min

A5-R 17 sheets/min

A6 17 sheets/min

16K 20 sheets/min

(3) Printer Functions

Printing Speed Same as Copying Speed.

First Print Time (A4, feed from

Cassette)

Resolution 300 dpi × 300 dpi, 600 dpi × 600 dpi, 1200 dpi equivalent ×

Operating System Windows XP, Windows Server 2003, Windows Vista, Windows

Interface USB Interface Connector: 1 (Hi-Speed USB)

Page Description Language PRESCRIBE

Emulations PCL6(PCL-XL, PCL5c) KPDL3, (PostScript3 compatible),

Item Description

40 ppm model 35 ppm model

6.4 seconds or less 6.8 seconds or less

1200 dpi equivalent, 1800 dpi equivalent × 600 dpi

7, Windows 8, Windows 8.1, Windows 10, Windows Server

2008/R2, Windows Server 2012/R2, Mac OS X v10.5 or later

Network interface: 1

(10 BASE-T/100 BASE-TX/1000 BASE-T)

Wireless LAN support Only

PDF, XPS, OpenXPS

1-3

Page 20

(4) Scanner Functions

Item Description

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

Resolution

300 × 300 dpi, 200 × 200 dpi, 200 × 100 dpi, 600 × 600 dpi

*1

,

400 × 400 dpi*1, 200 × 400 dpi*1

File Format TIFF (MMR/JPEG compression), JPEG, PDF (MMR/JPEG

compression), High compressive PDF, XPS, OPEN XPS,

Encrypted PDF, PDF/A-1

Scanning Speed

*2

(A4 landscape, 300 dpi × 300 dpi, Image quality: Text/Photo

original)

1-sided B/W: 40 images/min, Color: 23 images/min

2-sided B/W: 32 images/min, Color: 16 images/min

*3

Interface Ethernet (10 BASE-T/100 BASE-TX/1000 BASE-T), USB

Transmission System

SMBv3, SMTP, FTP, FTP over SSL, USB, TWAIN

*4

, WIA*5,

WSD

*1 One-sided scanning

*2 When using the document processor (except TWAIN and WIA scanning)

*3 Simultaneous duplex scan: 40ppm model only

*4 Available Operating System: Windows XP/Windows Vista/Windows Server 2003/Windows Server 2008/

Windows Server 2008 R2/Windows 7/Windows 8/Windows 8.1/Windows 10/Windows Server 2012/Windows Server 2012 R2

*5 Available Operating System: Windows Vista/Windows Server 2008/Windows Server 2008 R2/Windows 7/

Windows 8/

Windows 8.1/Windows Server 2012/Windows Server 2012 R2/Windows 10

(5) FAX Functions

FAX Function

Compatibility G3

Communication Line Subscriber telephone line

Transmission Time Less than 3 seconds (33600 bps, JBIG, ITU-T A4-R #1 chart)

Transmission Speed 33600/31200/28800/26400/24000/21600/19200/16800/14400/

Coding Scheme JBIG/MMR/MR/MH

Error Correction ECM

Original Size Max. width: 8 1/2"/216 mm, Max. length: 14 1/32"/356 mm

Automatic Document Feed Max. 50 sheets (with document processor)

Resolution Scan:

Item Description

12000/9600/7200/4800/2400 bps

200 × 100 dpi Normal (8 dot/mm × 3.85 line/mm)

200 × 200 dpi Fine (8 dot/mm × 7.7 line/mm)

200 × 400 dpi Super (Super Fine) (8 dot/mm × 15.4 line/mm)

400 × 400 dpi Ultra (Ultra Fine) (16 dot/mm × 15.4 line/mm)

Print: 600 dpi

Gradations 256 shades (Error diffusion)

One Touch Key

100 keys

*1

, 22 keys

*2

Multi-Station Transmission Max. 100 destinations

1-4

Page 21

Substitute Memory Reception 256 sheets or more (when using ITU-T A4 #1)

Image Memory Capacity 3.5 MB (standard)(For fax transmission and reception)

Report Output Send result report, FAX RX result report, Activity report, Status

*1 TSI model

*2 LCD model

Network FAX Function

Hardware IBM PC-AT compatible computer

Interface 10BASE-T, 100BASE-TX, 1000BASE-T, Wireless LAN sup-

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

Item Description

page

Item Description

*1

port

Operating system

Windows XP, Windows Server 2003, Windows Vista, Windows 7,

Windows 8, Windows 8.1, Windows 10, Windows Server

2008/R2,Windows Server 2012/R2

Transmission Resolution

200 × 100 dpi Normal (8 dot/mm × 3.85 line/mm)

200 × 200 dpi Fine (8 dot/mm × 7.7 line/mm)

400 × 400 dpi Ultra (Ultra Fine) (16 dot/mm × 15.4 line/mm)

Document Size Letter, Legal, Statement, A4, A5, Folio, B5(JIS)

FAX Del ayed Transmit Based on settings in the Network FAX Driver (setting is possi-

ble to any 1 minute increment within the subsequent 24 hour

period)

Transmit and Print Fax transmission and print out at the machine is available

Broadcast Transmission Max. 100 destinations

Job Accounting Requires the input of a Login User Name and Password in the

Network FAX Driver when User Login, is turn ON in the fax

machine.

Requires the input of an Account ID in the Network FAX Driver

when Job Accounting, is turned ON in the fax machine.

Cover Page A format can be selected using the Network FAX Driver or a

template can be created.

*1 Wi-Fi model only

(6) Document Processor

Item Description

Supported Original Types Sheet originals

Paper Size Maximum: Folio/Legal

Paper Weight 50 to 160 g/m2

Loading Capacity

*1 Up to upper limit height line in the document processor

Minimum: Statement/A6

50 sheets (50 to 80 g/m²) maximum

Thick (120 g/m²) : 25 sheets

1-5

*1

Page 22

(7) Paper Feeder (PF-1100)(Option)

Item Description

Paper Supply Method Friction roller feeder

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

(No. Sheets: 250, 80 g/m2, 1 cassette)

Paper Size

A4, A5-R, A5, B5, A6, Letter, Legal, Folio, 216 × 340 mm,

Statement, Executive, Oficio II, 16K, B5(ISO),

Custom (105 x 148 to 216 x 356 mm)

Supported Paper Paper weight: 60 to 163 g/m²

Media types: Plain, Recycled, Material

Dimensions (W) × (D) × (H) 14.77" × 15.48" × 3.94" 375 × 393 × 100 mm

Weight Approx. 6.4 lb/Approx. 2.9 kg

1-6

Page 23

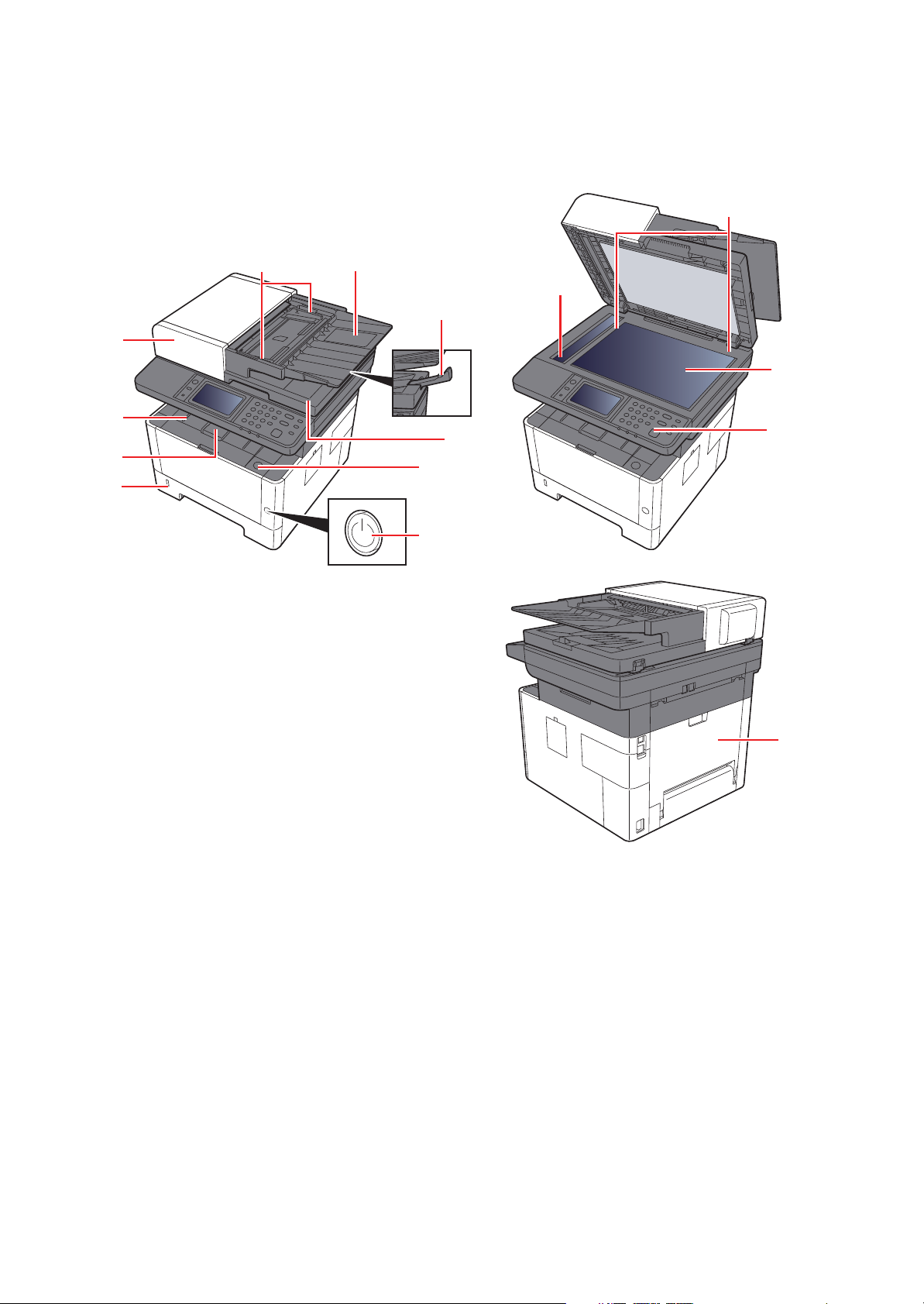

1-2 Part Names

(1) Machine Exterior

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

14

10

9

11

8

1

13

2

7

3

6

12

4

5

1 Document Processor

2 Inner Tray

3 Eject Stopper

4 Cassette 1

5 Power Switch

6 Front Cover Open Button

7 Original Eject Table

8 Original Stopper

15

9 Original Tray

10 Original Width Guides

11 Slit Glass

12 Operation Panel

13 Contact glass

14 Original Size Indicator Plates

15 Rear cover

1-7

Page 24

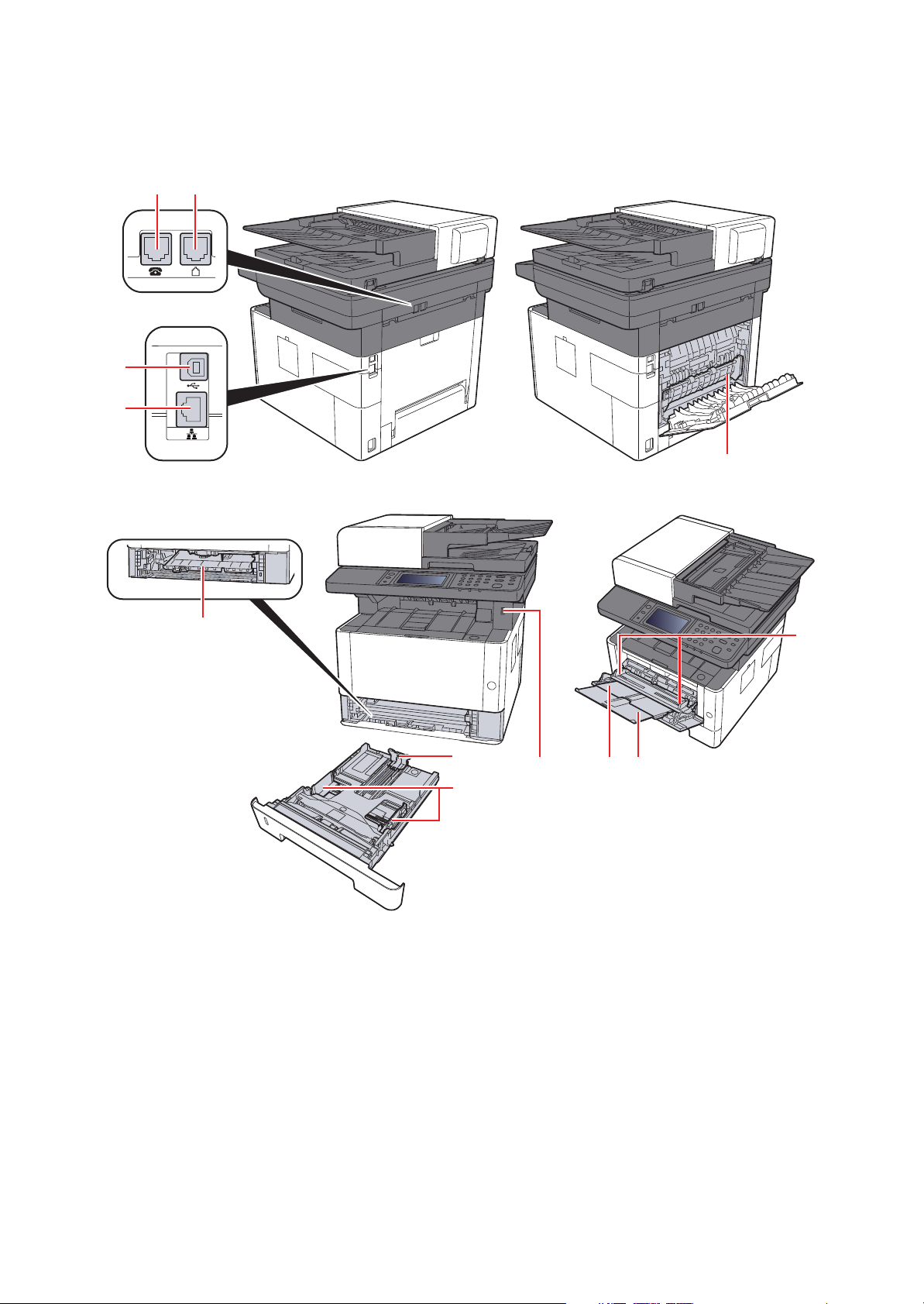

(2) Connectors/Interior

1 2

3

4

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

12

5

1. TEL Connector

2. LINE Connector

3. USB Interface Connector

4. Network Interface Connector

5. Feed Cover

6. Paper Length Guide

6

8

7

7. Paper Width Guides

8. USB Memory Slot

9. Multi Purpose Tray

10. Sub Tray

11. Paper Guides

12. Fuser Cover

11

9 10

1-8

Page 25

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

14

13

13. Toner Container Release Button

14. Toner Container

(3) With Optional Equipments Attached

1

1. Cassette 2

2. Cassette 3

2

1-9

Page 26

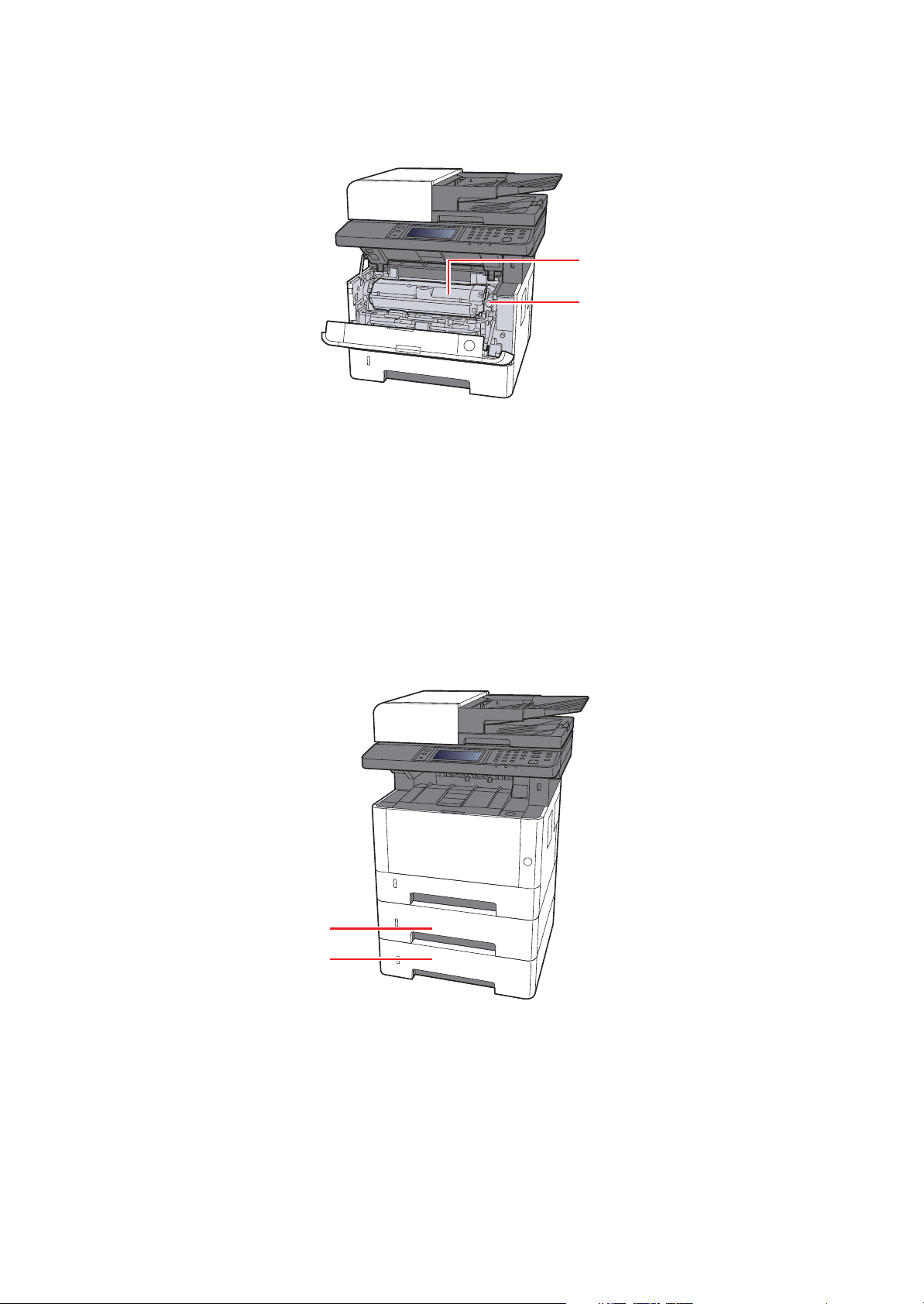

(4) Operation Panel (TSI)

Select the function.

nimdAemoH

Copy

Status

10:10

Send

Job Box

FAX

Removable

Memory

Task Screen

Sub

Address

Box

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

1 17

3 4 5 6 7 9

2 8 1210 11

16 15

14 13

1. [Home] key: Displays the Home screen.

2. [Status/Job Cancel] key: Displays the Status/Job Cancel screen.

3. [System Menu/Counter] key: Displays the System Menu/Counter screen.

4. Touch panel: Displays icons for configuring machine settings.

5. [Processing] indicator: Blinks while printing or sending/receiving.

6. [Memory] indicator: Blinks while the machine is accessing the machine memory or fax memory.

7. [Attention] indicator: Lights or blinks when an error occurs and a job is stopped.

8. [Enter] key: Finalizes numeric key entry, and finalizes details during setting of functions. Operates linked with the onscreen [OK].

9. [Start] key: Starts copying and scanning operations and processing for setting operations.

10. [Stop] key: Cancels or pauses the job in progress.

11. [Quiet Mode] key: Lower print and scan speed for quiet processing.

12. [Authentication/Logout] key: Authenticates user switching, and exits the operation for the current user (i.e. log out).

13. [Energy Saver] key: Puts the machine into Sleep Mode. Recovers from Sleep if in Sleep Mode.

14. [Reset] key: Returns settings to their default states.

15. [Clear] key: Clears entered numbers and characters.

16. [Quick No. Search] key: Specifies registered information such as address numbers and user IDs by number.

17. Numeric keys: Enter numbers and symbols.

1-10

Page 27

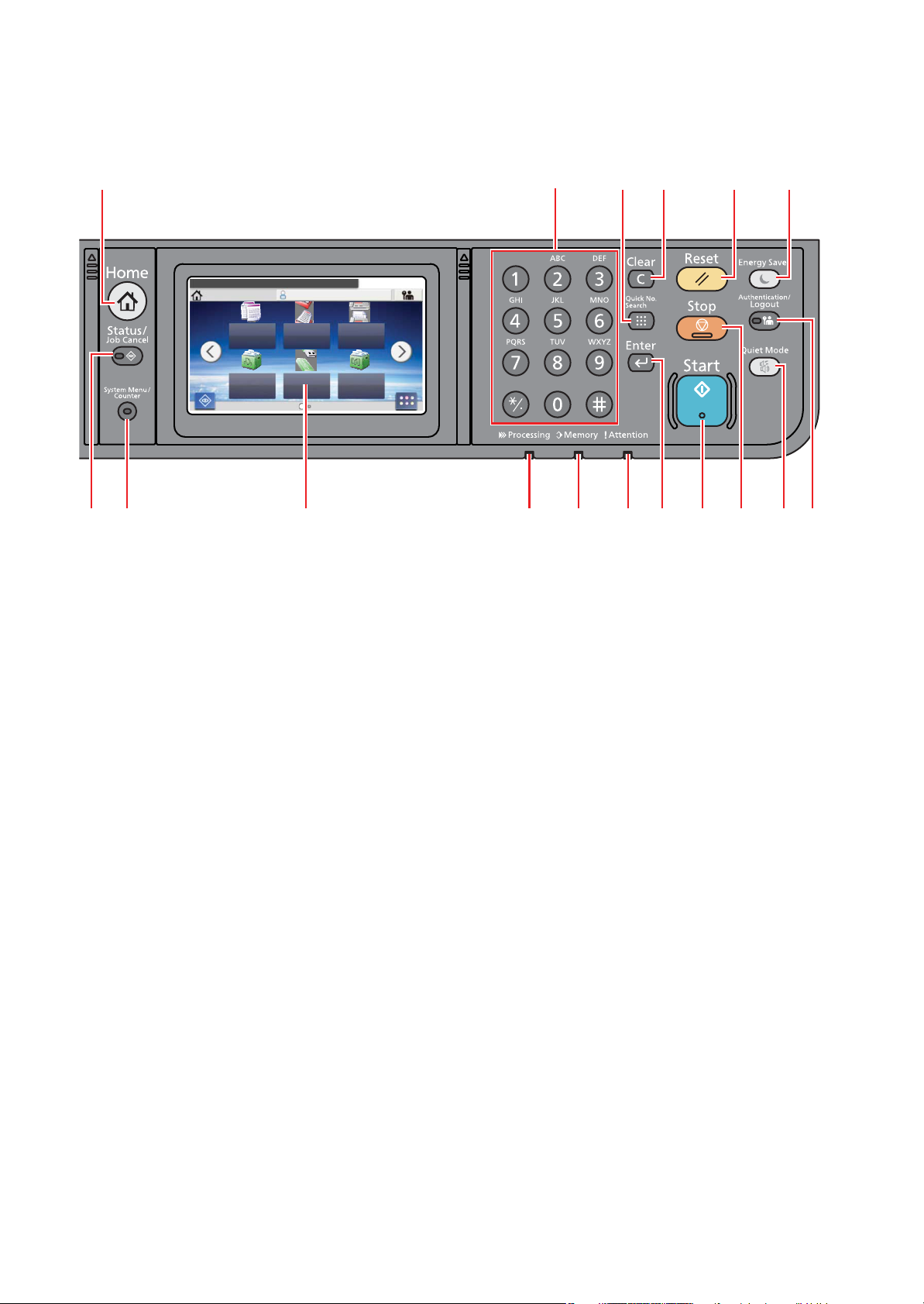

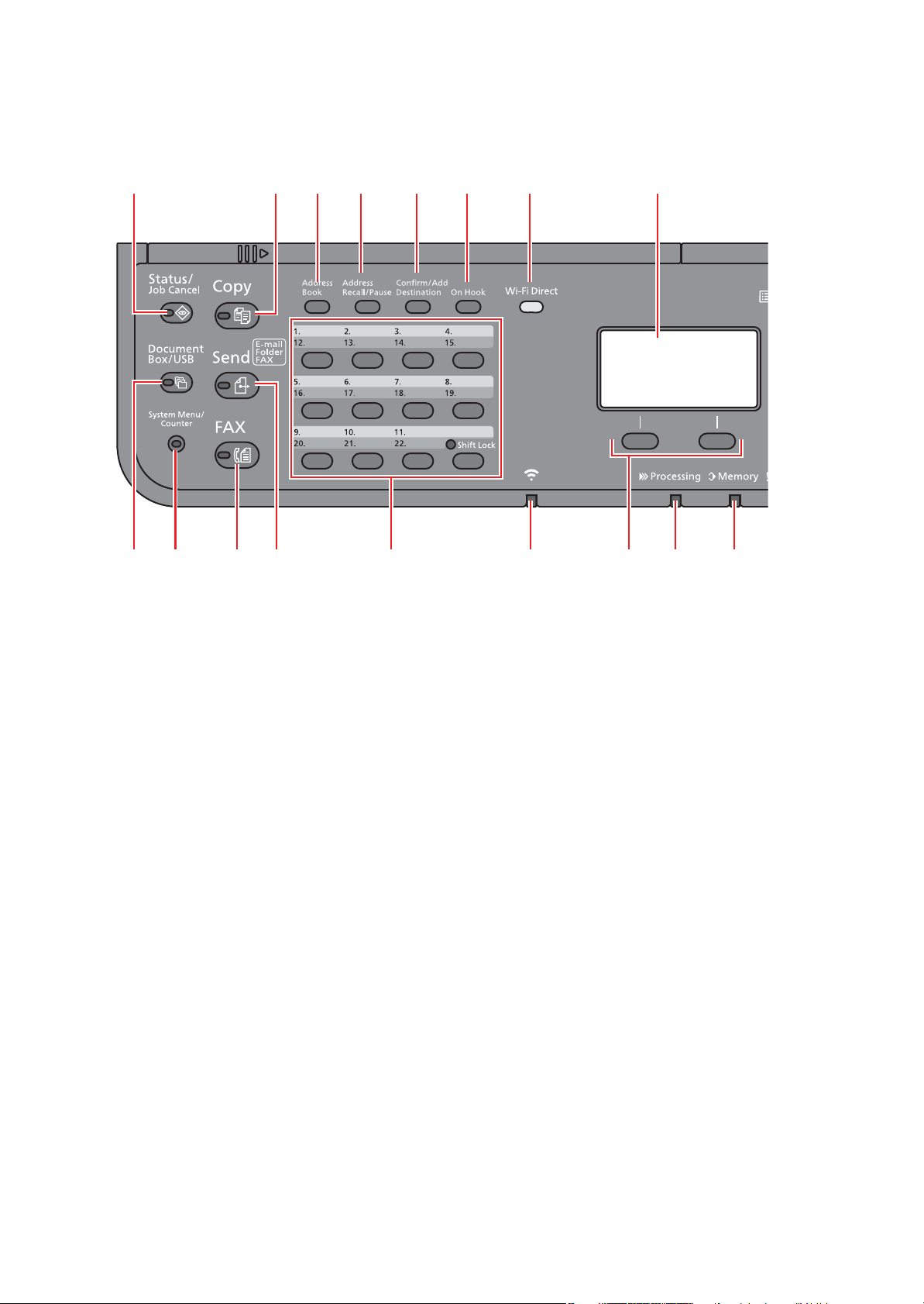

(5) Operation Panel Keys (LCD)

1

3 4 6 7 9 10

15 14 13 1216 11

8

17

2 5

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

1. [Status/Job Cancel] key: Displays the Status/Job Cancel screen.

2. [Document Box/USB] key: Displays the Document Box/USB screen.

3. [System Menu/Counter] key: Displays the System Menu/Counter screen.

4. [FAX] key: Displays the FAX screen.

5. [Send] key: Displays the screen for sending. You can change it to display the Address Book screen.

6. One Touch keys: Recalls the destination registered for One Touch Keys.

7. [Wi-Fi] indicator : Blinks during Wi-Fi connection.

8. Select keys: Selects the menu displayed at the bottom of the message display.

9. [Processing] indicator: Blinks while printing or sending/receiving.

10. [Memory] indicator: Blinks while the machine is accessing the machine memory or fax memory.

11. Message display: Displays the setting menu, machine status, and error messages.

12. [Wi-Fi Direct] key: Set Wi-Fi Direct, and show information necessary for connection and the connection status.

13. [On Hook] key: Switches between on-hook and off-hook when manually sending a FAX.

14. [Confirm/Add Destination] key: Confirms the destination or adds a destination.

15. [Address Recall/Pause] key: Calls the previous destination. Also used to enter a pause when entering a FAX number.

16. [Address Book] key: Displays the Address Book screen.

17. [Copy] key: Displays the Copy screen.

1-11

Page 28

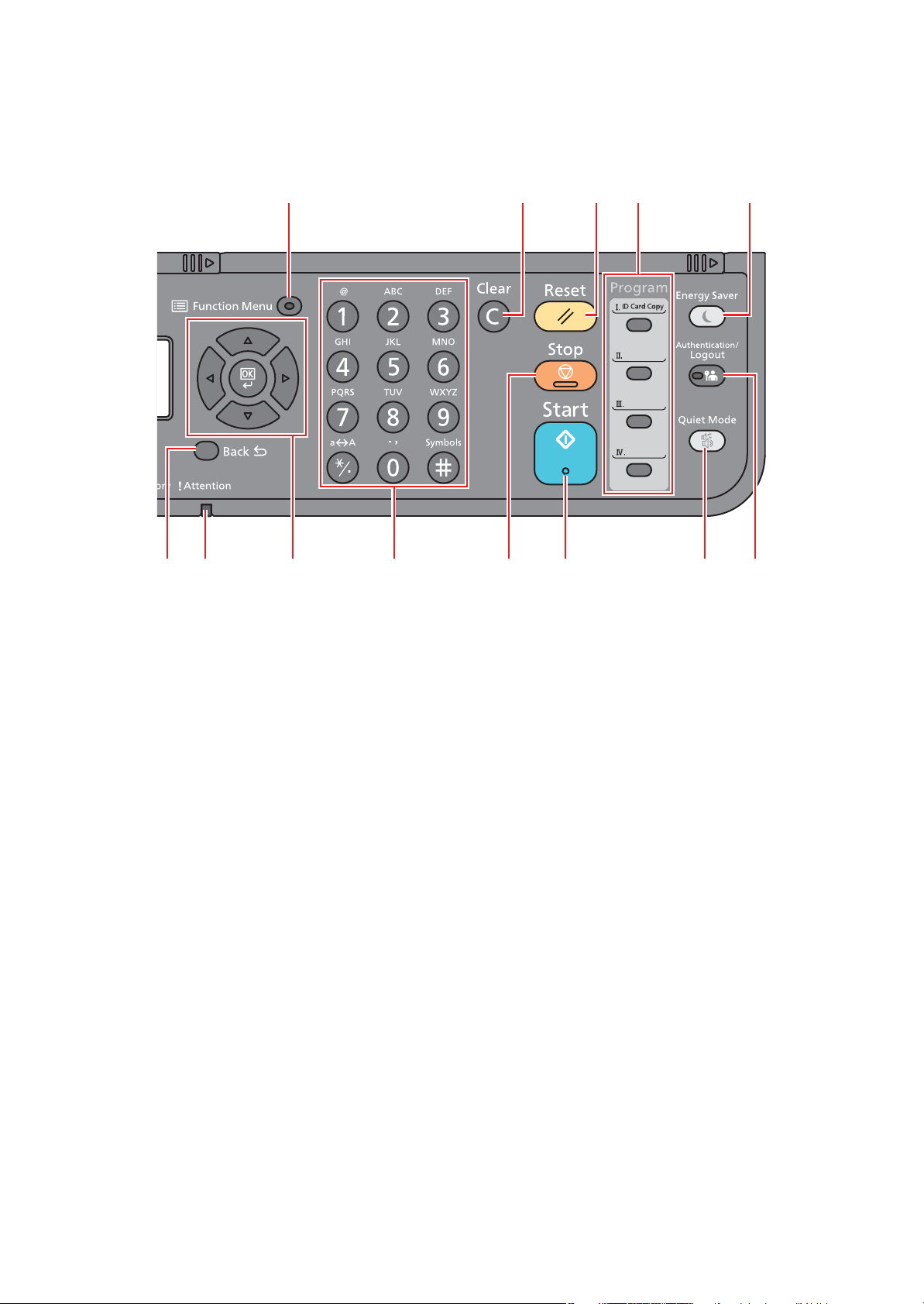

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

18

20 21, 22 23 25 26 27

28

29

24

3031

19

18. [Function Menu] key: Displays the function menu screen.

19. [Back] key: Returns to the previous display.

20. [Attention] indicator: Lights or blinks when an error occurs and a job is stopped.

21. Arrow keys: Increments or decrements numbers, or selects menu in the message display. In addition, moves the

cursor when entering the characters.

22. [OK] key: Finalizes a function or menu, and numbers that have been entered.

23. Numeric keys: Enter numbers and symbols.

24. [Stop] key: Cancels or pauses the job in progress.

25. [Start] key: Starts copying and scanning operations and processing for setting operations.

26. [Quiet Mode] key: Lower print and scan speed for quiet processing.

27. [Authentication/Logout] key: Authenticates user switching, and exits the operation for the current user (i.e. log out).

28. [Energy Saver] key: Puts the machine into Sleep Mode. Recovers from Sleep if in Sleep Mode.

29. Program keys: Used to register or recall programs.

30. [Reset] key: Returns settings to their default states.

31. [Clear] key: Clears entered numbers and characters.

1-12

Page 29

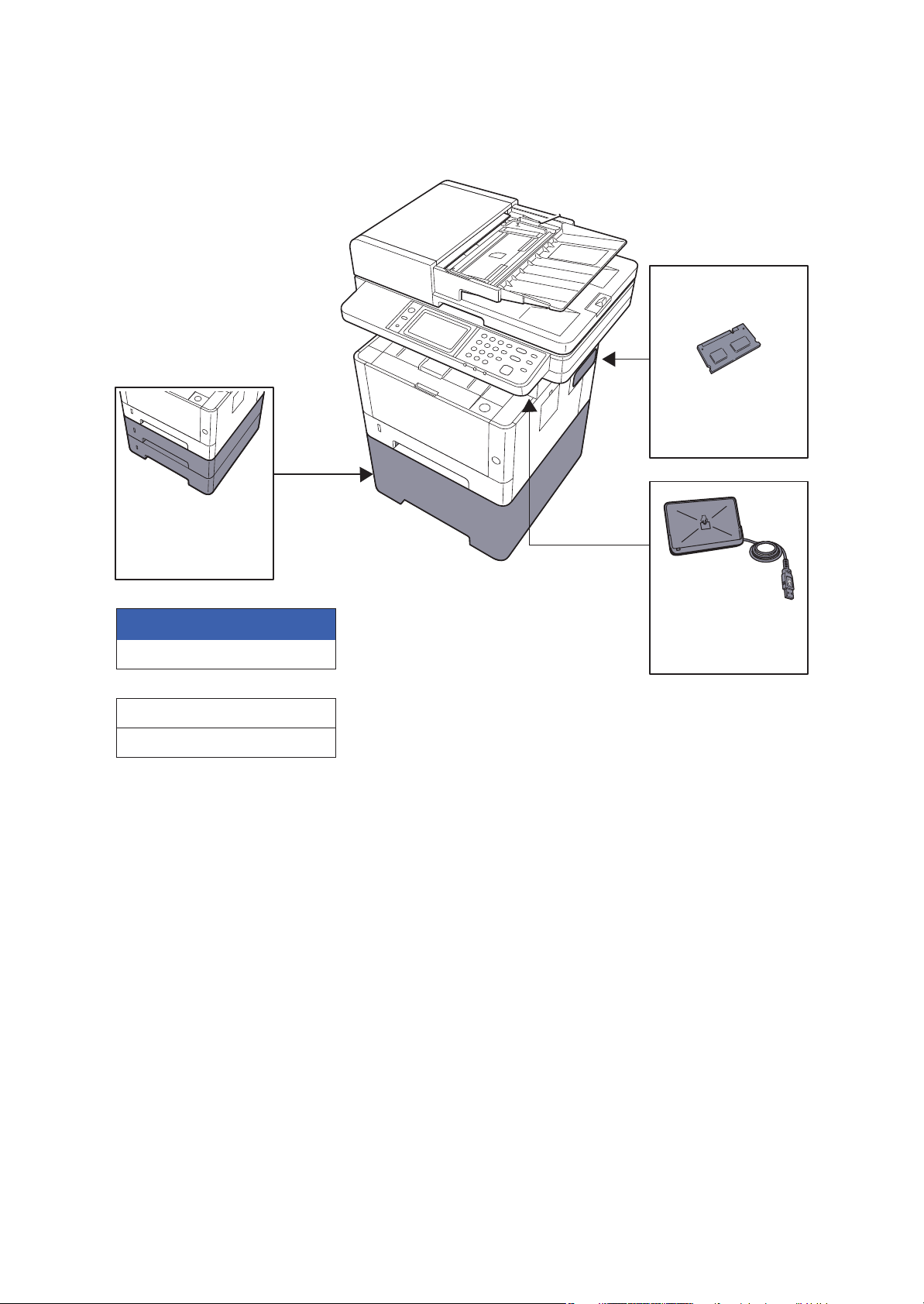

1-3 Overview of Optional Equipment

(1) Expansion Memory

Software option

(4) UG-33

(5) SD/SDHC Memory Card

(6) USB Keyboad

(3) Card Authentication

Kit (B)

The following optional equipment is available for the machine.

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

(2) PF-1100

1-13

Page 30

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

(1) Expansion Memory

The machine can perform the more multiple jobs simultaneously by adding more memories. You can increase the

machine's memory up to 1,536 MB by plugging in the optional memory modules.

Precautions for Handling the Memory Modules

To protect electronic parts, discharge static electricity from your body by wearing an antistatic wrist strap, if possible,

when you install the memory modules. If you do not have a wristband, touch a metal object to discharge static electricity

before inserting the memory.

Installing the Memory Modules

1. Turn off the machine and disconnect the power cord and interface cable.

2. Remove the cover.

3. Remove the memory module from its package.

4. With the memory connection terminal pointing toward the socket, align the cut-out part with the socket terminal and

insert directly in at an angle.

5. Carefully press the inserted memory down and into the machine.

6. Replace the covers.

1-14

Page 31

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

(2) PF-1100 "Paper Feeder"

Maximum two 250-sheet paper feeder can be installed.

(3) Card Authentication Kit(B) "Card Authentication Kit"

User login administration can be performed using ID cards. To do so, it is necessary to register ID card information on

the previously registered local user list.

(4) UG-33 "ThinPrint Option"

This application allows print data to be printed directly without a print driver.

(5) SD/SDHC Memory Card

SD/SDHC memory card is a micro chip card that can save optional fonts, macros, forms.

The machine is equipped with a slot for an SDHC memory card with a maximum size of 32 GB, and an SD memory card

with a maximum size of 2 GB.

Installing the Memory Modules

1. Turn off the machine and disconnect the power cord and interface cable.

2. Remove the cover.

3. Insert the SD/SDHC memory card into the SD/SDHC memory card slot.

4. Replace the covers.

1-15

Page 32

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

500mm or more

300mm or more 300mm or more

400mm or more

300mm or more

2 Installation 2-1 Environment

Installation environment

1. Temperature: 50 to 90.5°F (10 to 32.5°C) (But humidity should be 70% or less when the temperature is 90.5°F

(32.5°C).)

2. Humidity: 10 to 80%(But the temperature should be 86°F (30°C) or less when humidity is 80%.)

3. Power AC100V 50/60Hz 9.7A or more

AC120V 60Hz 8.7A or more

AC220 to 240V 50HzA 4.4A or more

4. Frequency fluctuation: 50Hz+/-2% or 60Hz+/-2%

Installation location

The operative environmental conditions are as follows:

Adverse environmental conditions may affect the image quality. It is recommended to use the machine as follows:

Humidity: 36 to 65% Temperature: 60.8 to 80.6°F or less (16 to 27°C).

Avoid the following locations when selecting a site for the machine.

Avoid locations near a window or with exposure to direct sunlight

Avoid locations with vibrations

Avoid locations with rapid temperature fluctuations

Avoid locations with direct exposure to hot or cold air

Avoid poorly ventilated locations

If the floor is delicate, when this machine is moved after installation, the floor material may be damaged by the casters.

During operation, some ozone is released, but the amount does not cause any ill effect to one's health.

If, however, the machine is used over a long period of time in a poorly ventilated room or when making an extremely

large number of copies, the smell may become unpleasant. To maintain the appropriate environment for copy work, it is

suggested that the room be properly ventilated.

Installation space

Figure 2-1

2-1

Page 33

2-2 Installing the main unit

Installation procedures

START

Unpacking and checking bundled items

Optional unit installation

Connecting the Other Dvices

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

Connecting the Interface Cable

Loading Paper

Turn the power on

Default Setting

Installing Software

Output a report

(Maintenance mode U000)

Maintenance report

User status report

Clearing the counts

(maintenance mode U927)

Exiting from the Maintenance mode

Output a Status report

Completion of installing the main unit

IMPORTANT

Default setting will take about 10 minutes for the toner installation.

Do not execute the maintenance mode during the initial setting drive.

2-2

Page 34

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

12

14

11

7

5

4

2

1

13

6

10

9

3

8

1. Right upper pad

2. Left upper pad

3. AC power cord

4. Product storage bag

5. Main unit

6. Front upper pad

7. Accessories box

8. Documents

9. Left bottom pad

10. Front bottom pad

11. Lower right pad

12. Lower left pad

13. inner frame

14. Outer box

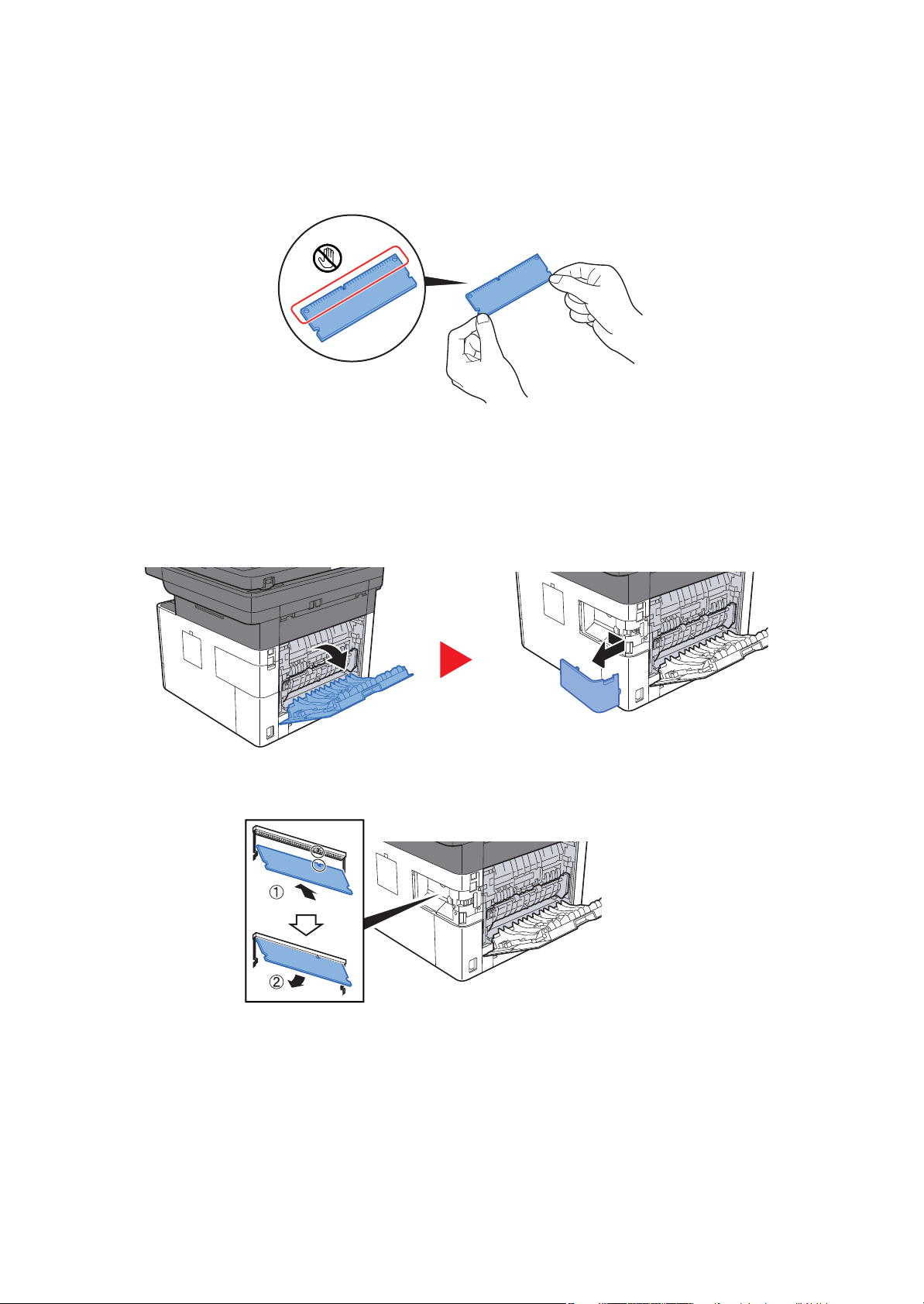

(1) Unpacking and checking bundled items

(1-1) Main unit

Take out the main unit and accessories from the packing case.

Remove the tape and cushioning materials for packing from the main unit.

Figure 2-2

Note: Make sure to install the main unit on a level surface.

2-3

Page 35

(1-2) Paper Feeder (Option)

1

6

5

2

4

3

7

1. Left pad

2. Right pad

3. Main unit protective sheet

4. Paper Feeder

5. Main unit storage bag

6. Outer box

7. Cassette spacer

Take the paper feeder out of the packing case.

Remove the packing tape from the paper feeder.

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

Figure 2-3

2-4

Page 36

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

(2) Installing the optional equipment

Install the necessary optional equipment in the main unit by referring to the installation procedures.

(3) Connecting to other device

Prepare the cables necessary to suit the environment and purpose of the machine use.

When Connecting the Machine to the PC via USB

USB

When Connecting the Machine to the PC on the Network

Network

Network

NOTE

When using wireless LAN, it is not necessary to connect the network cable. It is necessary to change the initial setting of

the machine unit from System Menu to use the wireless LAN.

Cables that Can Be Used

Connection environment Function Necessary Cable

Connect a LAN cable to the

machine.

Connect a USB cable to the

machine.

IMPORTANT

When not using the USB2.0 compatible cable, it causes a failure.

Printer/Scanner/Network FAX LAN cable (10BASE-T, 100BASE-TX,

1000BASE-T)

Printer/Scanner (TWAIN/WIA) USB2.0 compatible cable (Hi-Speed USB compli-

ant, Max. 5.0m or less. with shield)

2-5

Page 37

(4) Connecting to the cable

(4-1) LAN Cable

1. Connect the LAN cable to the network interface connector.

2. Connect the other end of the cable to the hub or the PC.

3. Power on the machine and set the network.

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

(4-2)USB cable

1. Connect the USB cable to the USB interface connector.

2. Connect the other end of the cable to the PC.

3. Turn the power switch of the main unit on.

2-6

Page 38

(5) Loading Paper

1. Pull the cassette out of the main unit.

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

NOTE

When the bottom plate is lifted, push it until locked.

2. Adjust the paper length guide of the cassette.

2-7

Page 39

NOTE

In case of using Folio, Oficio ?or Legal

3. Adjust the paper width guides of the cassette

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

4. Load paper.

5. Insert the cassette slowly into the main unit as far as it goes.

6. Set the paper size and the paper type from the system menu.

IMPORTANT

Load it with the printing side facing down

Before loading paper in the cassette, fan the paper taken from a new package to separate it.

Before loading the paper, be sure that it is not curled or folded. Such paper may cause paper jams.

Load paper below the maximum paper level.

If the paper is loaded without adjusting the paper length guide and the paper width guides, it causes the skew paper

feeding and the paper jam.

2-8

Page 40

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA-1

Precaution for Loading Paper

Separate the paper taken out of the package in the following procedures before loading it in the cassette.

Separate paper and align the edge of the paper in a flat place.

In addition, note the following.

In case of paper fold or curl, stretch it in a straight line. Such paper may cause a jam.

If paper is left in the high humidity environment after taking the paper out of the package, it causes a trouble with moisture. Keep paper remaining paper in the cassette into the sealed paper storage bag. Also, keep paper left on the MP tray

into the sealed paper storage bag.

If the machine is not used for a prolonged period, keep paper out of the cassette in the sealed storage bag in order to

protect it from humidity.

(6) Power-up

1. Turn the power switch on.

IMPORTANT

Initial Setup will take up to 10min to complete toner installation.

Do not execute maintenance mode during this period.

2-9

Page 41

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

(7) Default (TSI model)

Before using this machine, configure such settings as date and time, network configuration, and energy saving functions

as needed. The Machine Setup Wizard is launched when the equipment is turned on for the first time after being

installed. Also, configure the following settings if necessary.

NOTE

The default settings of the machine can be changed in System Menu.

Refer to the operation guide of the main unit about the items which can set from the system menu.

(7-1) Setting Date and Time

Follow the steps below to set the local date and time at the place of installation.

When you send an E-mail using the transmission function, the date and time as set here will be printed in the header of

the E-mail message. Set the date, time and time difference from GMT of the region where the machine is used.

NOTE

The correct time can be periodically set by obtaining the time from the network time server.

See page Command Center RX User Guide.

1. Displays the screen.

[System menu / counter] key > [Date/Timer/Energy Saver]

2. Configure the settings.

Select [Time Zone] > [Date/Time] > [Date Format] in this order for settings.

Item Descriptions

Time Zone Set the time difference from GMT. Choose the nearest listed location from

the list. If you select a region that utilizes summer time, configure settings

for summer time.

Date/Time Set the date and time for the location where you use the machine. If you

perform Send as E-mail, the date and time set here will be displayed on the

header.

Value: Year (2000 to 2037), Month (1 to 12), Day (1 to 31), Hour (00 to 23),

Minute (00 to 59), Second (00 to 59)

Date Format Select the display format of year, month, and date. The year is displayed in

Western notation.

Value: Month/Day/Year, Day/Month/Year, Year/Month/Day

2-10

Page 42

2S0/2S1/2S2/2S3/2S4/2S5/2SG/2SH/3RA

(7-2)Network Settings

Wired network setting

The machine is equipped with network interface, which is compatible with network protocols such as TCP/IP (IPv4),

TCP/IP (IPv6), NetBEUI, and IPSec. It enables network printing on the Windows, Macintosh, UNIX and other platforms.

Set up TCP/IP (IPv4) to connect to the Windows network.

Be sure to connect the network cable before configuring the settings.

If the user administration is effective, this can be changed by logging in with administrator privileges.

If the user login administration is not effective, the user authentication screen appears. Enter a login user name and

password, and select [Login].

The default login user name and login password at the factory shipment is set as below.

Login User Name: 4000 or 3500

Login Password: 4000 or 3500

TCP/IP (IPv4) Settings

1. Displays the screen.

[System menu / counter] key > [System/Network] > [Network] > [Wired Network Settings] > [TCP/IP Setting] >

[IPv4]

[Wired setting] > [TCP/IP setting] > [IPv4 setting]

2. Configure the settings.