Page 1

Agility 50 - 125

Page 2

50 4T R10 50 4T R12 125

MOTORE MONOCIL INDRICO ORIZZO NTALE 4 TEMPI

RAFF REDDAMENTO ARIA FOR ZATA

CILINDR ATA 49cc 125cc

POTEN ZA

2,4kW (3 ,3CV) a 8.50 0 giri/min 2,4kW (3 ,3CV) a 7.500 giri /min 6,9kW (9,4 CV) a 7.500 giri/ min

COPPIA 3,2 Nm a 7.000 gir i 9,6 Nm a 6.50 0 giri

EMISSIO NI EURO 2 EURO 3

AVVIA MENTO E LETTRICO E K ICK STARTER

FRIZION E CE NTRIFUGA AU TOMATICA A SECC O

TRAS MISSIONE CINGHIA T RAPEZOIDA LE - INGRANA GGI

SOSPEN SIONI

ANT. FORC ELLA TELESC OPICA IDRAULI CA ø 31

POST. MONO BRACCIO OSCIL LANTE AM MORTIZZATO RE IDRAULICO RE GOLABILE

FRENI

ANT. DISCO ø 180mm

POST. TAMBUR O ø 110mm

PNEUMAT ICI

ANT. - POST. 90 /90-10

ANT. 120/ 70-12

POST. 130/ 70-12

DIMENSIO NE 1.830 x 69 0 x 1.070mm 1.830 x 69 0 x 1.130mm 1.835 x 690 x 1.125mm

MASS A 8 4kg 92kg 105kg

COLORI argent o nero argent o nero rosso giallo

giallo

Agility 50 - 125

2616-0 40407KYMCO S I RISERVA DI APPO RTARE VARIAZ IONI TECNIC HE, ESTET ICHE O DI ALTRA N ATURA SENZ A L’OBBLIGO DI ALCU N PREAVVIS O.

KYMCO RACC OMANDA2 ANNI DI GAR ANZIA 1 ANNO DI ASS ISTENZA CREDITO PERSONA LIZZATO

S e r v i z i F i n a n z i a r i

SCOOTER TARGATICICLOMOTO RI 4T

Page 3

AGILITY 50

PREFACE

This Service Manual describes the

technical features and servicing

procedures for the KYMCO AGILITY

50

Section 1 contains the precautions for all

operations stated in this manual. Read

them carefully before starting any

operation.

Section 2 is the removal/installation

procedures for the frame covers which

are subject to higher removal/installation

frequency during maintenance and

servicing operations.

Section 3 describes the inspection/

adjustment procedures, safety rules and

service information for each part, starting

from periodic maintenance.

Sections 6 through 17 give instructions

for disassembly, assembly and inspection

of engine, chassis frame and electrical

equipment.

Most sections start with an assembly or

system illustration and troubleshooting

for the section. The subsequent pages

give detailed procedures for the section.

KWANG YANG MOTOR CO., LTD.

OVERSEAS SALES DEPARTMENT

OVERSEAS SERVICE SECTION

TABLE OF CONTENTS

GENERAL INFORMATION 1

FRAME COVERS/EXHAUST MUFFLER 2

INSPECTION/ADJUSTMENT 3

LUBRICATION SYSTEM 4

FUEL SYSTEM 5

ENGINE REMOVAL/INSTALLATION 6

CYLINDER HEAD/VALVES 7

CYLINDER/PISTON 8

ENGINE

DRIVE AND DRIVEN PULLEYS/KICK

STARTER

9

FINAL REDUCTION 10

CRANKCASE/CRANKSHAFT 11

FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12

CHASSIS

REAR WHEEL /REAR BRAKE /REAR

SUSPENSION

13

BATTERY/CHARGING SYSTEM/A.C.

GENERATOR

14

IGNITION SYSTEM 15

STARTING SYSTEM 16

ELECTRICAL

EQUIPMEN

T

LIGHTS/INSTRUMENTS/SWITCHES 17

Our company reserves the right to

make any alteration in the design.

The information and contents included

in this manual may be different from

the motorcycle in case specifications

are changed.

Page 4

1. GENERAL INFORMATION

1-1

AGILITY 50

Location of Engine Serial Numbe

r

1

ENGINE SERIAL NUMBER

1

ENGINE SERIAL NUMBER...................1- 1 LUBRICATION POINTS .......................1-13

SPECIFICATIONS ...................................1- 2 CABL E & H A R N E S S R O UTI N G............1-15

SERVICE PRECAUTIONS......................1- 3 WIRING DIAGRAM................................1-20

TORQUE VALUES..................................1-11 TROUBLESHOOTUNG ..........................1-21

SPECIAL TOOLS.....................................1-12

AGILITY 50

Page 5

1. GENERAL INFORMATION

1-2

AGILITY 50

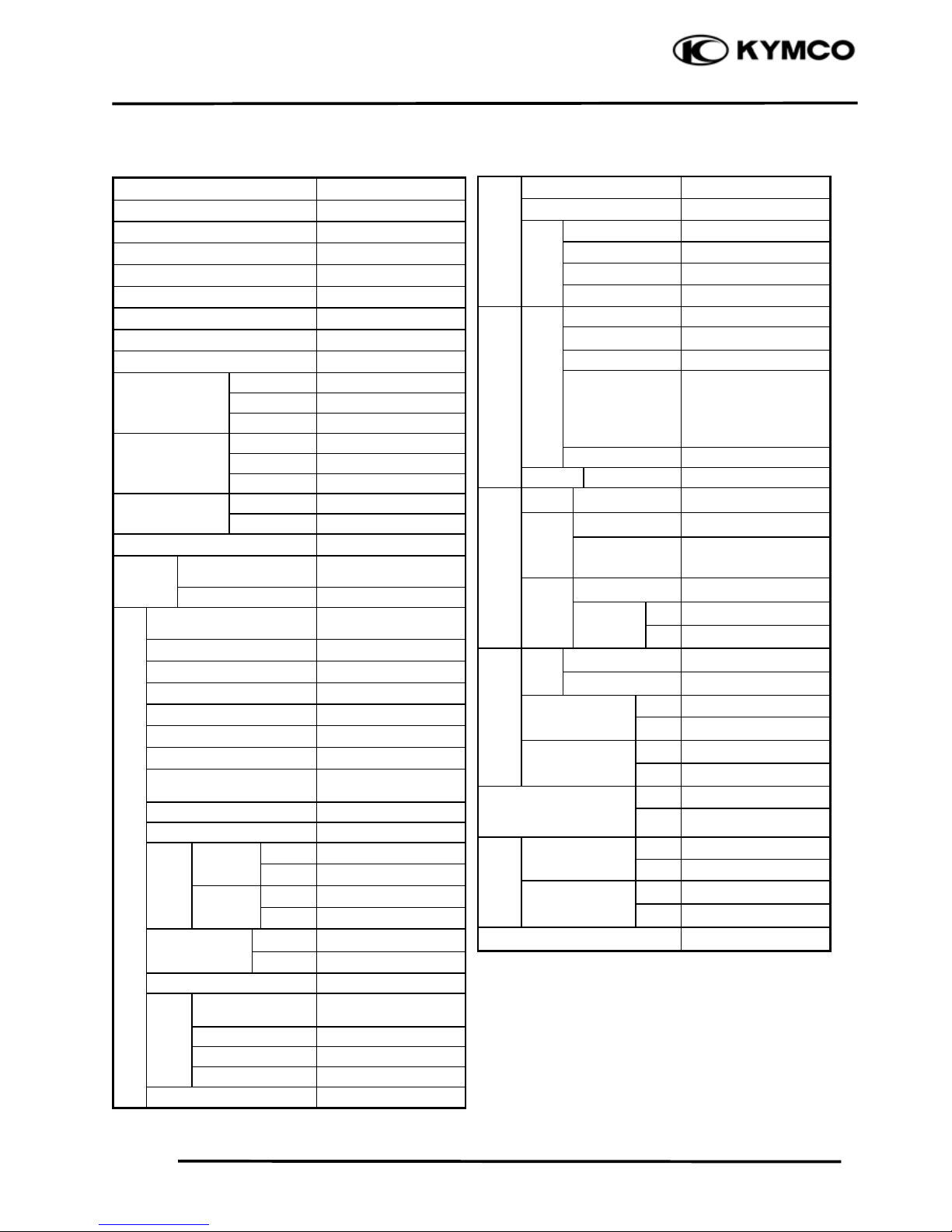

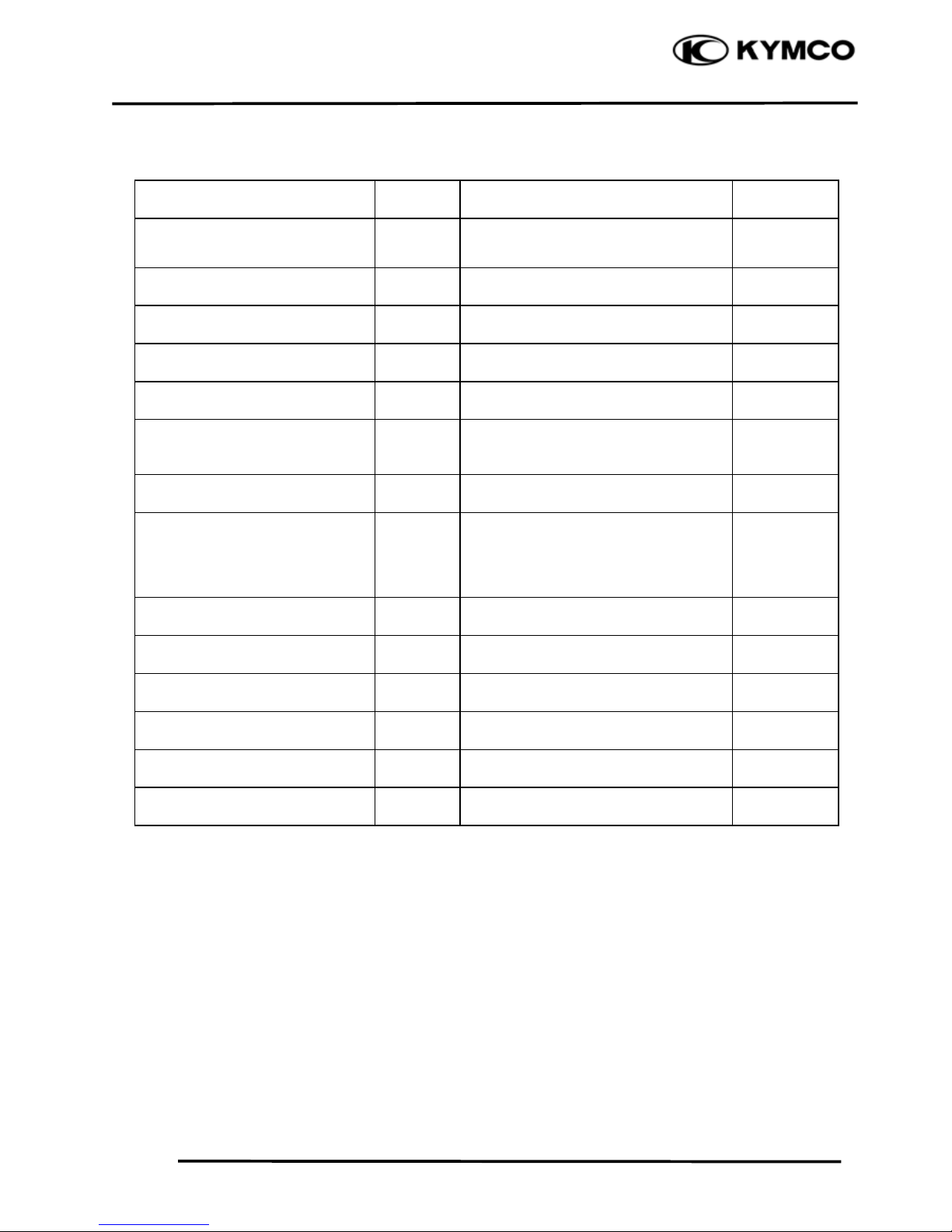

SPECIFICATIONS

Motorcycle Name & Type AGILITY 50

Name & Model No. KG10SA

Overall length (mm) 1830

Overall width (mm) 690

Overall height (mm) 1130

Wheel base (mm) 1325

Engine type O.H.C.

Displacement 49.5cc

Fuel Used 92# nonleaded gasoline

Front wheel 37.5

Net weight (kg) Rear wheel 55

Total 92.5

Front wheel 38

Gross weight(kg) Rear wheel 59

Total 97

Front wheel 120/70 -12 56J

Tires

Rear wheel 130/70 -12 56J

Ground clearance (mm) 112

Perform-

Braking distance (m)

4 (Initial speed

20km/h)

ance

Min. turning radius (m) 1.99

Starting system

Starting motor &

kick starter

Type Gasoline, 4-stroke

Cylinder arrangement Single cylinder

Combustion chamber type Semi-sphere

Valve arrangement O.H.C.

Bore x stroke (mm) I39.0 x 41.4

Compression ratio 11

Compression pressure

(kg/cm²-rpm)

18

Max. output 3.5/7500kw/(r/min)

Max. torque 0.35/7000kg m/rpm

Open 3q

Port

Intake

Close 7q

Engine

timin

g

Open 9q

Exhaust

Close 1q

Intake 0.04

(cold) (mm)

Exhaust 0.04

Idle speed (rpm) 1700Ô100rpm

Lubrication type

Forced

p

ressure &

wet sump

Oil pump type Inner/outer rotor type

Oil filter type Full-flow filtration

Lubrication

System

Oil capacity 0.8 liter

Cooling Type Forced air cooling

Air cleaner type & No Paper element, wet

Fuel capacity 5.0 liter

Type CVK

Piston dia. (mm)

Venturi dia.(mm) I17equivalent

Carburetor

Throttle type Butterfly type

Type CDI

Ignition timing BTDC28q/4000rpm

Contact breaker Non-contact point type

Spark plug

NGK

C7HSA

Spark plug gap 0.6Д0.7mm

Battery Capacity 12V4AH

Clutch Type Dry multi-disc clutch

Type Non-stage transmission

Operation

Automatic centrifugal

type

Type Two-stage reduction

Reduction 1st

0.8-3.1

ratio

2nd

11.05

Front Caster angle 27q

Axle

Trail length

Tire pressure

Fron

t

1.75

(kg/cm²)

Rear 2.25

Turning Left 45q

angle

Right 45q

FrontDISK (180mm) brake

Brake system

type

Rear Drum (110mm) brake

Fron

t

TELESCOPE

Suspension type

Rear Unit Swing

Front 80

Shock absorber

distance

Rear

82

Frame type Under Bone

Fuel S

y

stem

Electrical E

q

ui

p

ment

I

g

nition S

y

stem

Power Drive System

Transmis-

sion Gear

Reduction

Gear

Moving Device

Damping

Device

Page 6

1. GENERAL INFORMATION

1-3

AGILITY 50

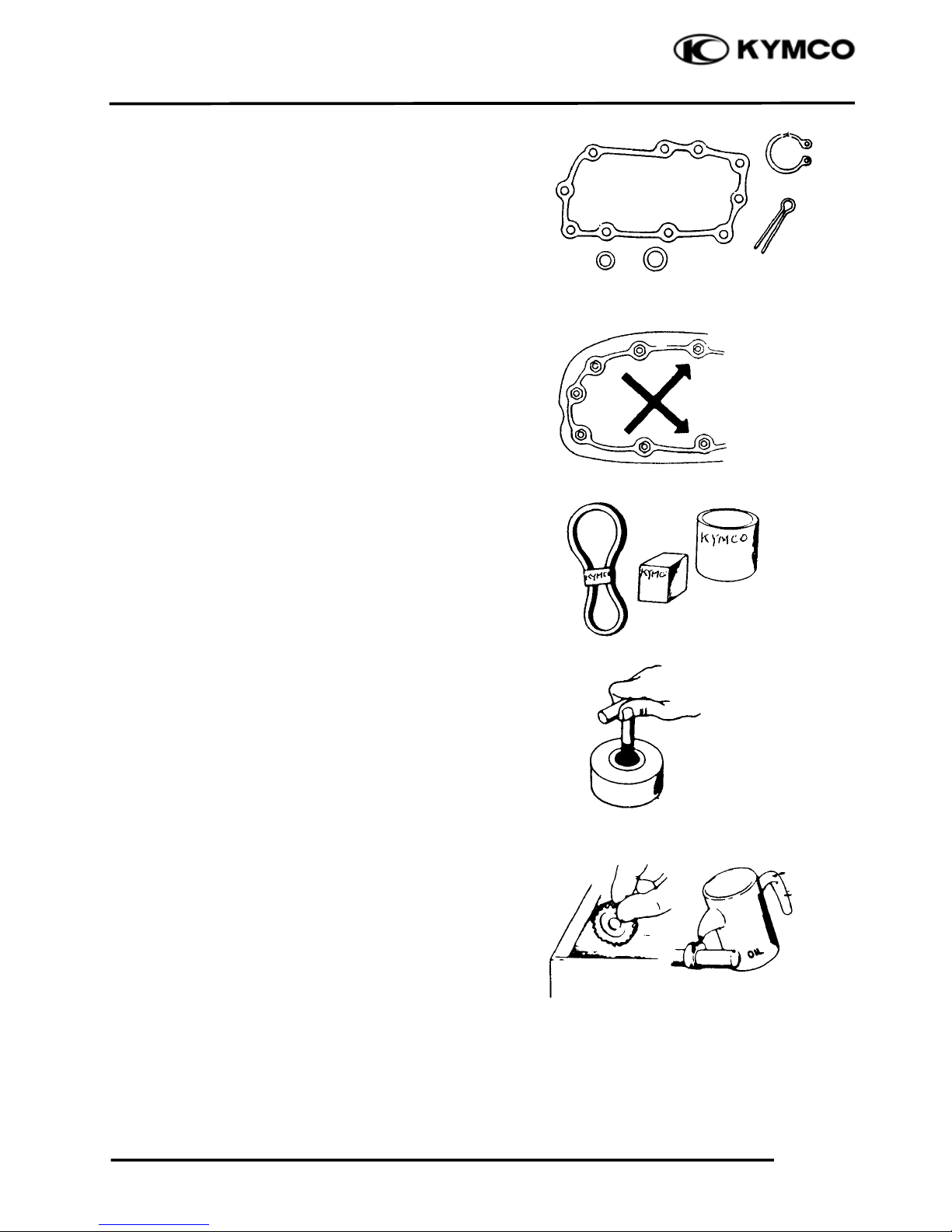

SERVICE PRECAUTIONS

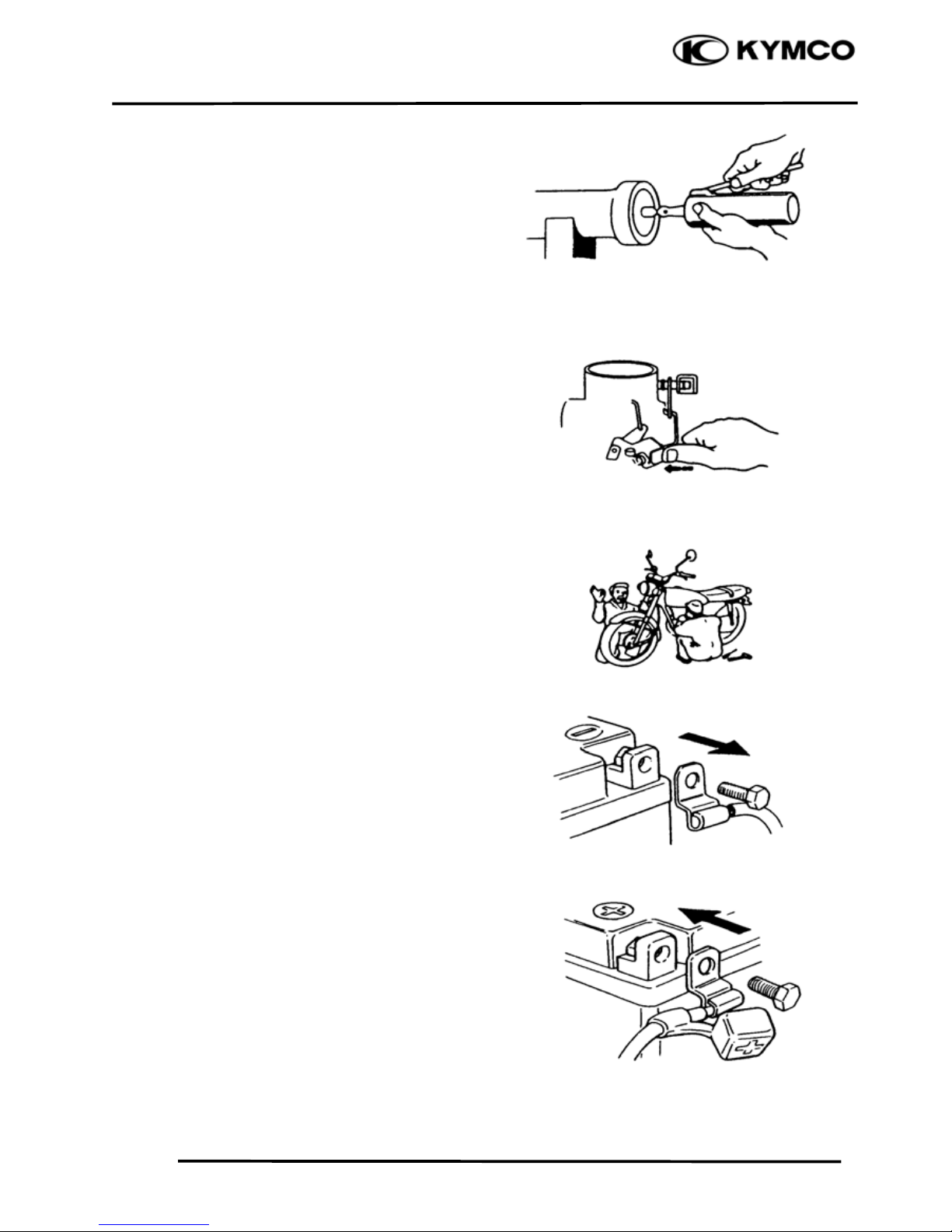

Make sure to install new gaskets, O-rings,

circlips, cotter pins, etc. when

reassembling.

When tightening bolts or nuts, begin with

larger-diameter to smaller ones at several

times, and tighten to the specified torque

diagonally.

Use genuine parts and lubricants

.

When servicing the motorcycle, be sure to

use special tools for removal and

installation.

After disassembly, clean removed parts.

Lubricate sliding surfaces with engine oil

before reassembly.

Page 7

1. GENERAL INFORMATION

1-4

AGILITY 50

Apply or add designated greases and

lubricants to the specified lubrication

points.

After reassembly, check all parts for proper

tightening and operation.

When two persons work together, pay

attention to the mutual working safety.

Disconnect the battery negative (-) terminal

before operation.

When using a spanner or other tools, make

sure not to damage the motorcycle surface.

After operation, check all connecting

points, fasteners, and lines for proper

connection and installation.

When connecting the battery, the positive

(+) terminal must be connected first.

After connection, apply grease to the

battery terminals.

Terminal caps shall be installed securely.

Page 8

1. GENERAL INFORMATION

1-5

AGILITY 50

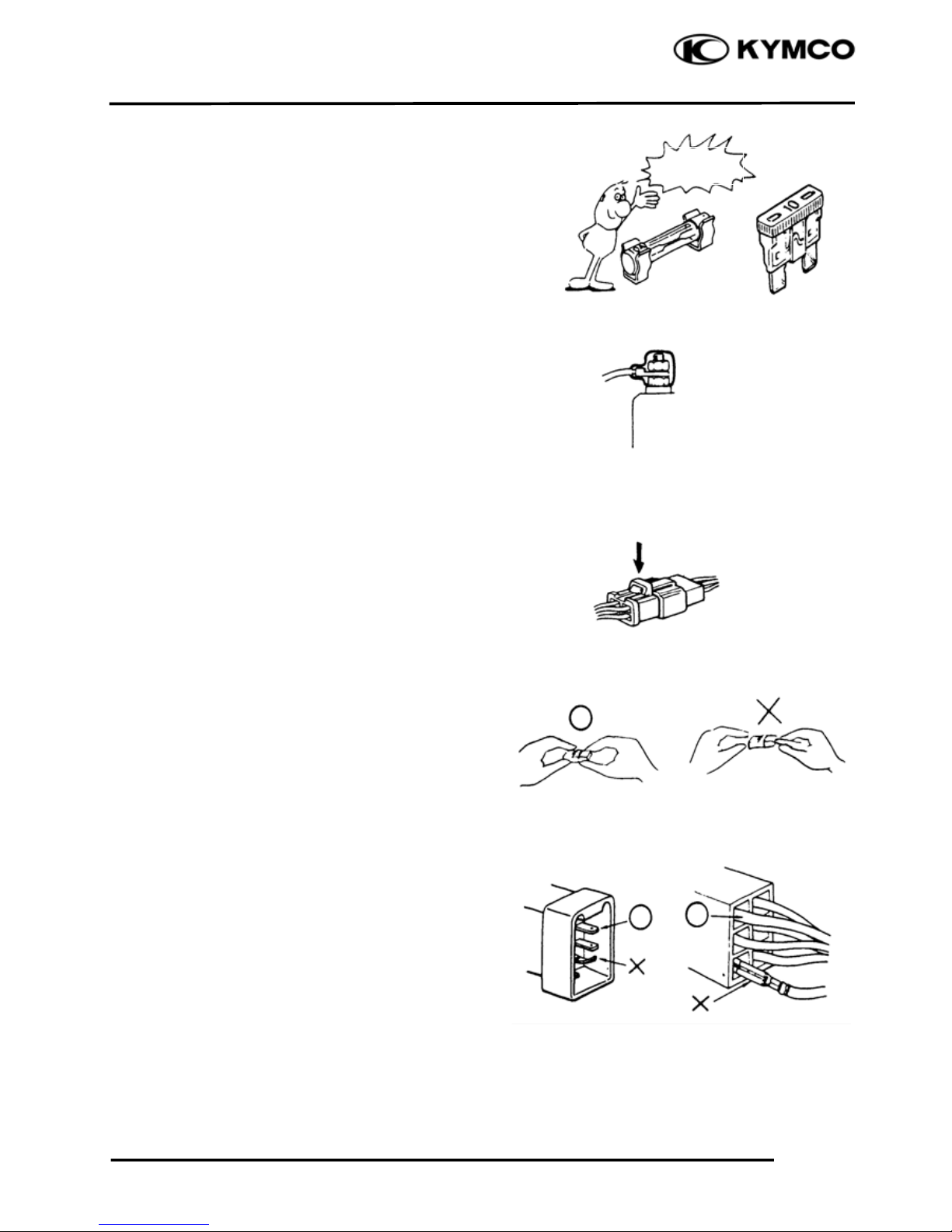

If the fuse is burned out, find the cause and

repair it. Replace it with a new one

according to the specified capacity.

After operation, terminal caps shall be

installed securely.

When taking out the connector, the lock on

the connector shall be released before

operation.

Hold the connector body when connecting

or disconnecting it.

Do not pull the connector wire.

Check if any connector terminal is bending,

protruding or loose.

Confir

m

Capacity

Page 9

1. GENERAL INFORMATION

1-6

AGILITY 50

The connector shall be inserted

completely.

If the double connector has a lock, lock

it at the correct position.

Check if there is any loose wire.

Before connecting a terminal, check for

damaged terminal cover or loose

negative terminal.

Check the double connector cover for

proper coverage and installation.

Insert the terminal completely.

Check the terminal cover for proper

coverage.

Do not make the terminal cover opening

face up.

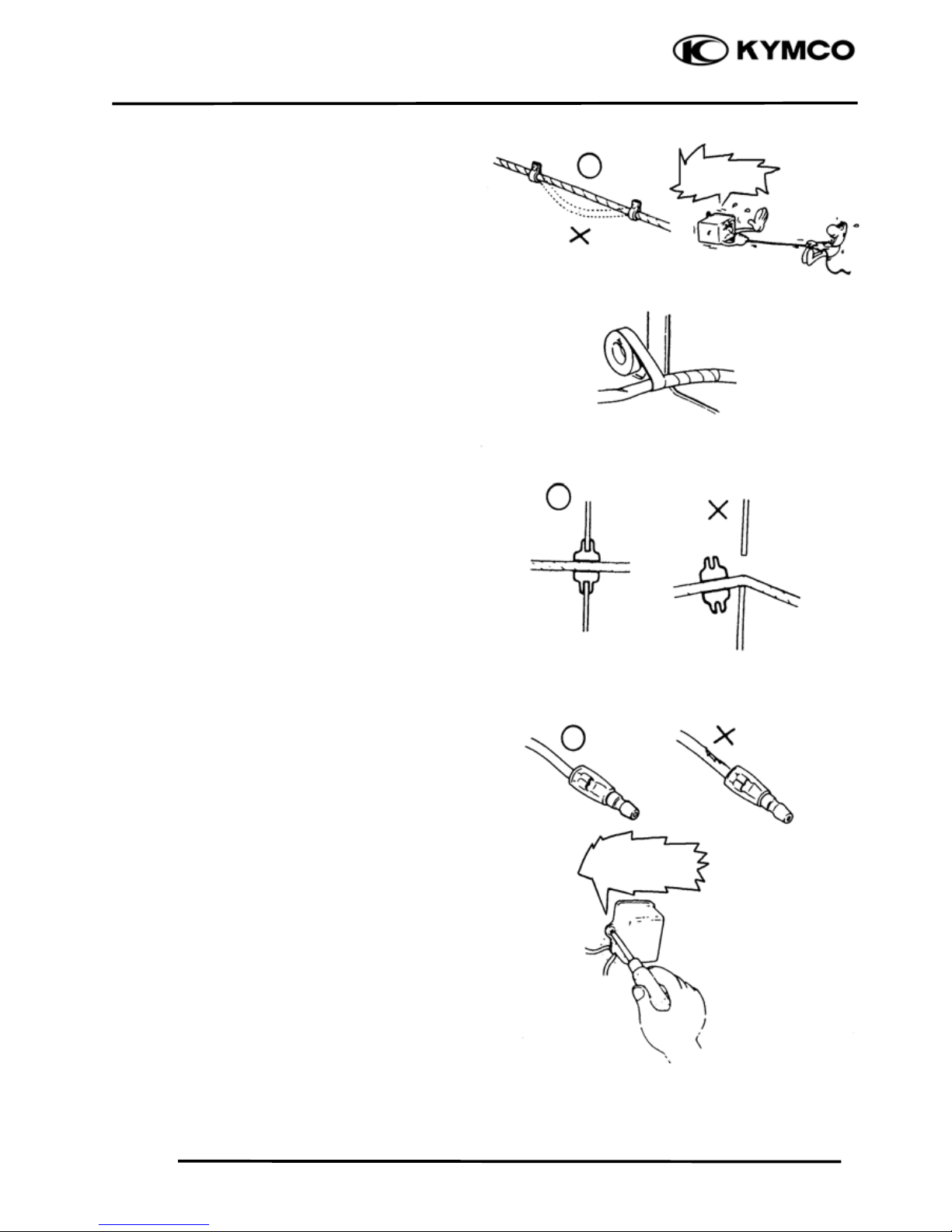

Secure wire harnesses to the frame with

their respective wire bands at the

designated locations.

Tighten the bands so that only the insulated

surfaces contact the wire harnesses.

Snapping!

Page 10

1. GENERAL INFORMATION

1-7

AGILITY 50

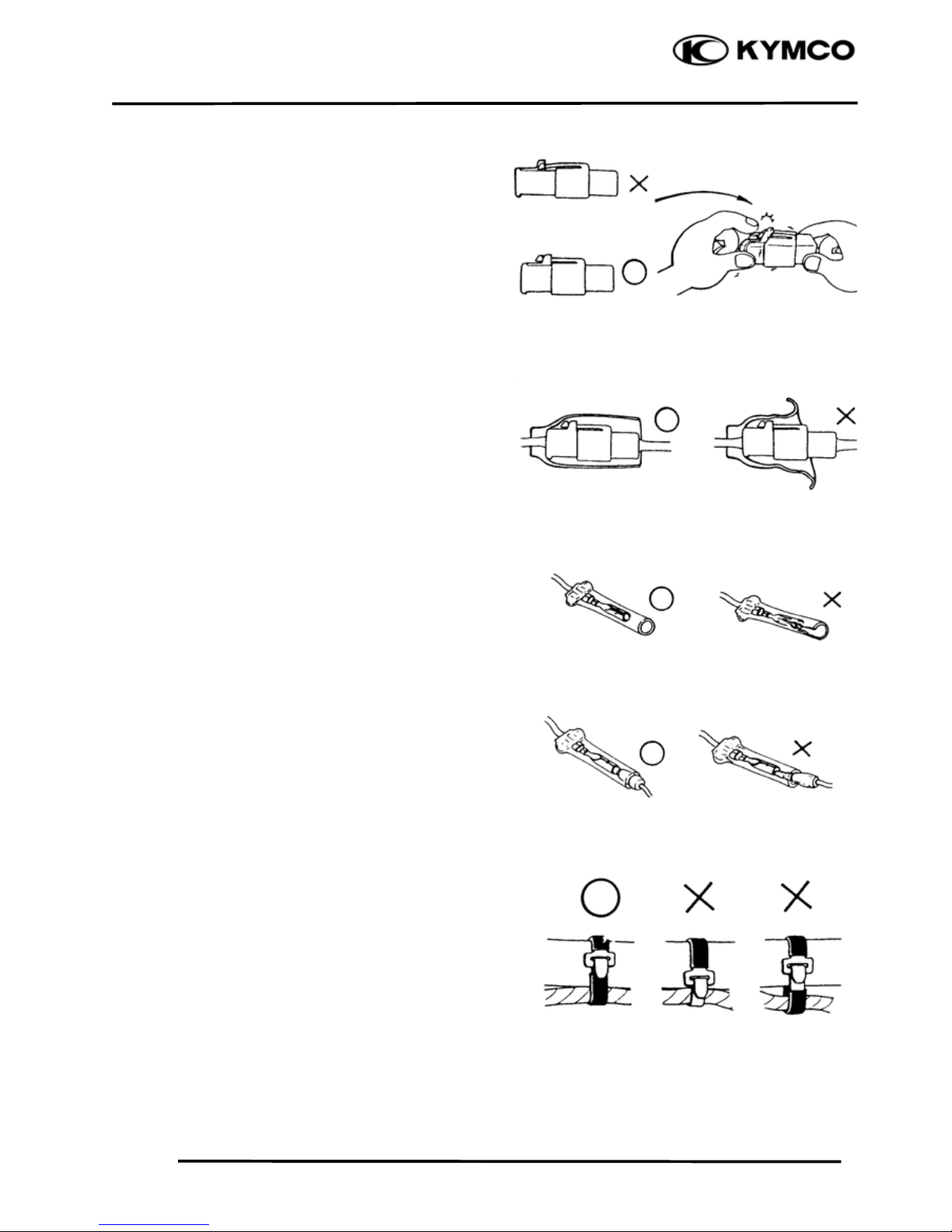

After clamping, check each wire to make

sure it is secure.

.

Do not squeeze wires against the weld or

its clamp

After clamping, check each harness to

make sure that it is not interfering with any

moving or sliding parts.

When fixing the wire harnesses, do not

make it contact the parts which will

generate high heat.

Route wire harnesses to avoid sharp edges

or corners. Avoid the projected ends of

bolts and screws.

Route wire harnesses passing through the

side of bolts and screws. Avoid the

projected ends of bolts and screws.

N

o Contact !

Page 11

1. GENERAL INFORMATION

1-8

AGILITY 50

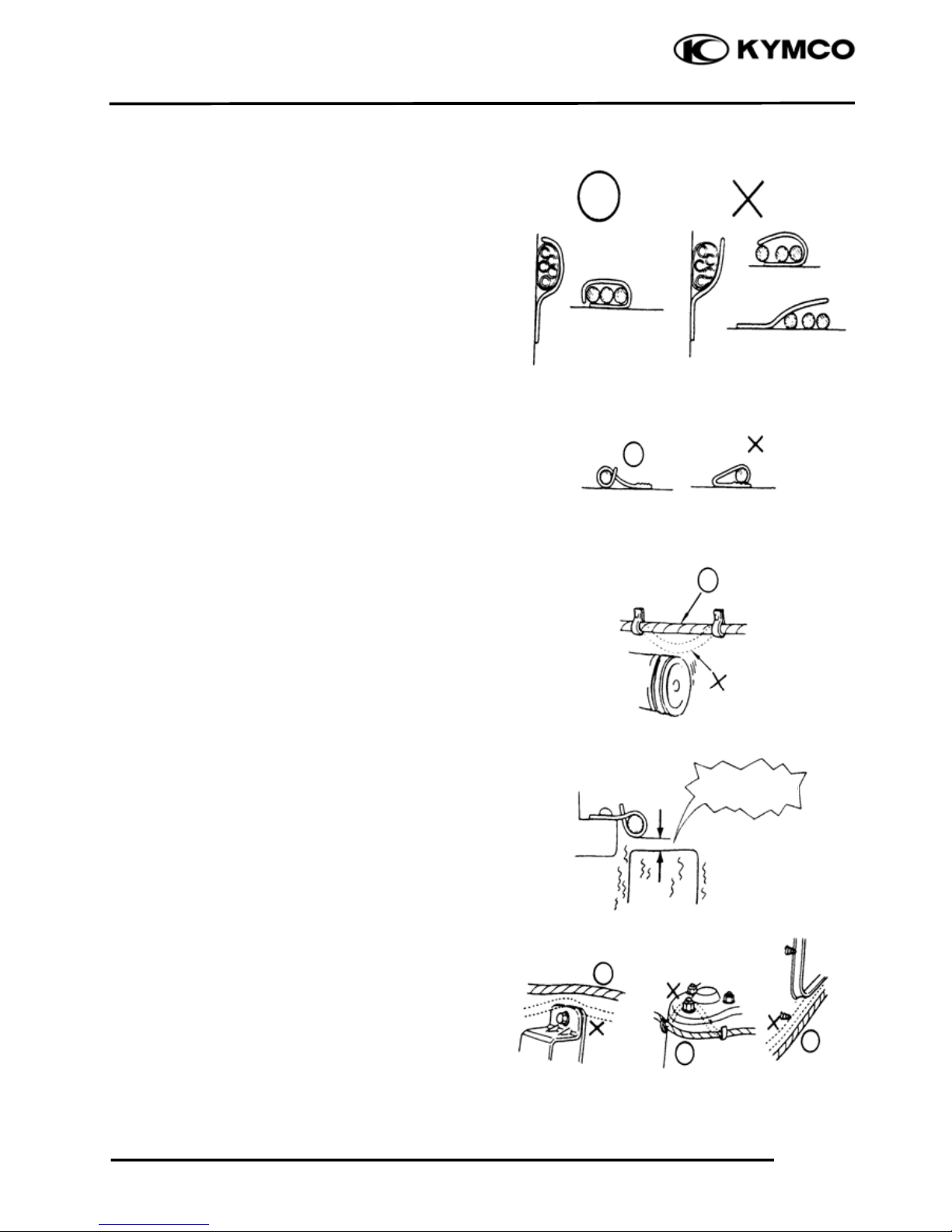

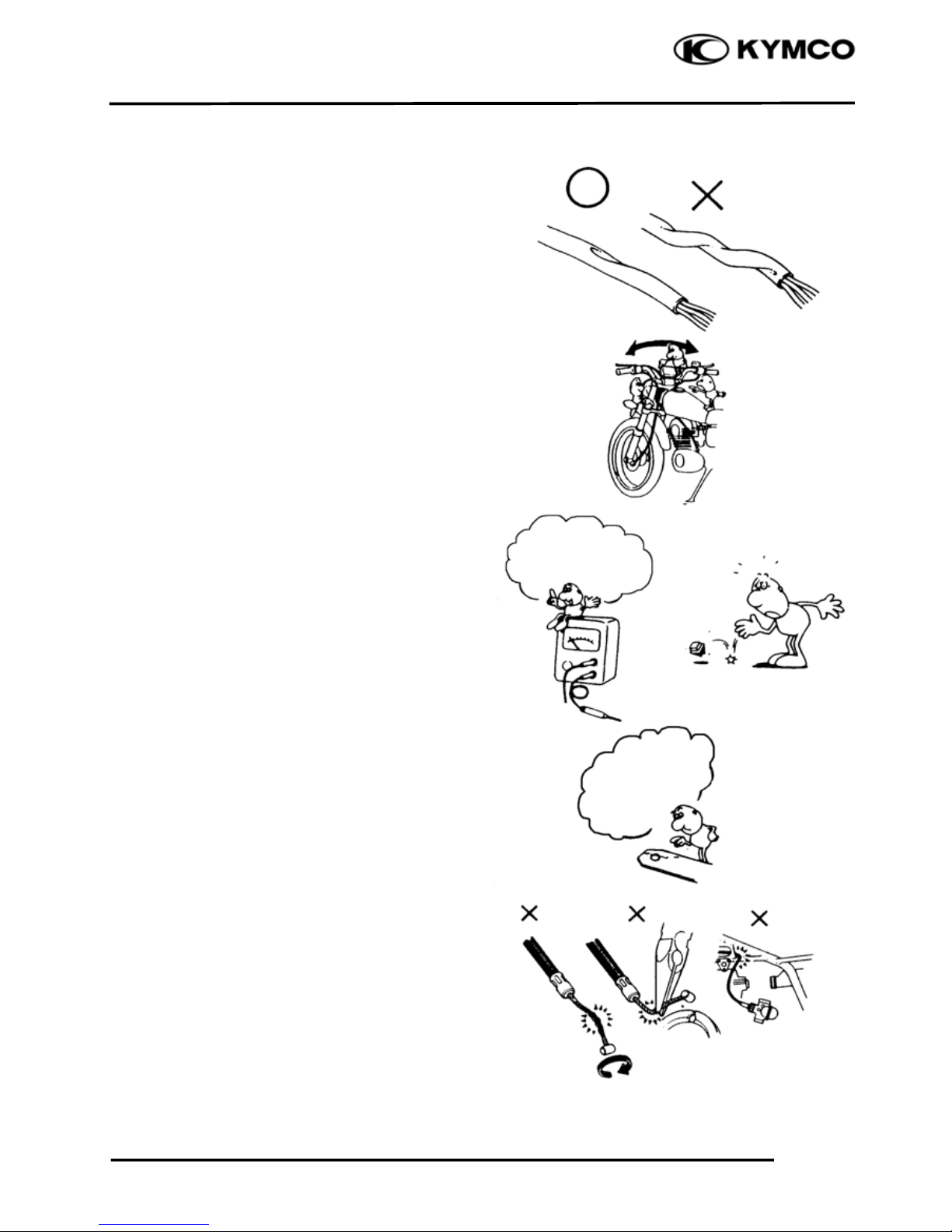

Route harnesses so they are neither

pulled tight nor have excessive slack.

.

Protect wires and harnesses with electrical

tape or tube if they contact a sharp edge or

corner

When rubber protecting cover is used to

protect the wire harnesses, it shall be

installed securely.

Do not break the sheath of wire.

If a wire or harness is with a broken sheath,

repair by wrapping it with protective tape

or replace it.

When installing other parts, do not press or

squeeze the wires.

Do not pull

too ti

g

ht!

Do not press o

r

squeeze the wire.

Page 12

1. GENERAL INFORMATION

1-9

AGILITY 50

After routing, check that the wire harnesses

are not twisted or kinked.

Wire harnesses routed along with

handlebar should not be pulled tight, have

excessive slack or interfere with adjacent

or surrounding parts in all steering

positions.

When a testing device is used, make sure to

understand the operating methods

thoroughly and operate according to the

operating instructions.

Be careful not to drop any parts.

When rust is found on a terminal, remove

the rust with sand paper or equivalent

before connecting.

Do not bend or twist control cables.

Damaged control cables will not operate

smoothly and may stick or bind.

Do you understand

the instrument? Is

the instrument set

correctly?

Remove Rust !

Page 13

1. GENERAL INFORMATION

1-10

AGILITY 50

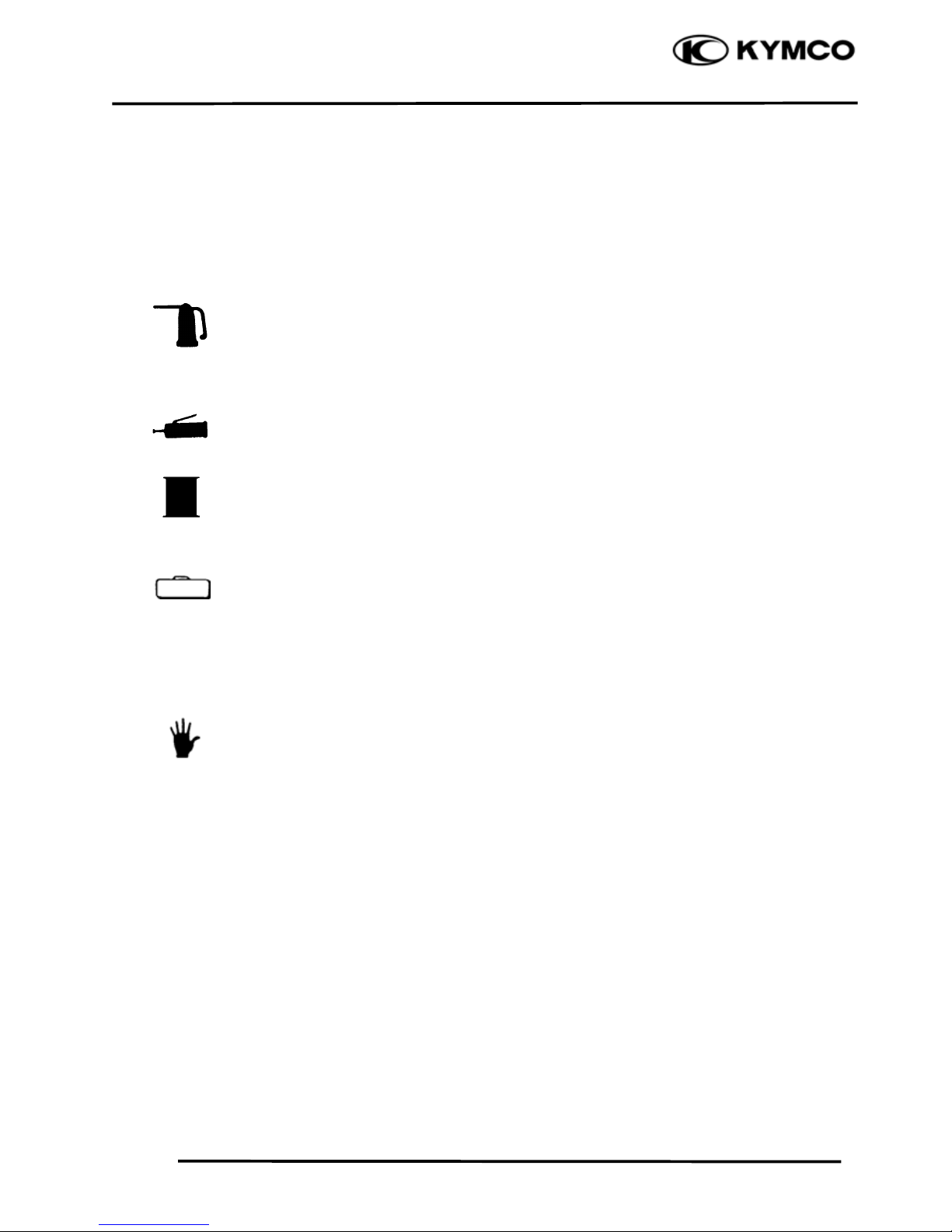

Symbols:

The following symbols represent the

servicing methods and cautions included in

this service manual.

: Apply engine oil to the

specified points. (Use

designated engine oil for

lubrication.)

: Apply grease for lubrication.

: Transmission Gear Oil (90#)

: Use special tool.

: Caution

: Warning

(Ö12-3) :Refer to page 12-3.

Engine Oil

Grease

Gear Oil

Special

*

Page 14

1. GENERAL INFORMATION

1-11

AGILITY 50

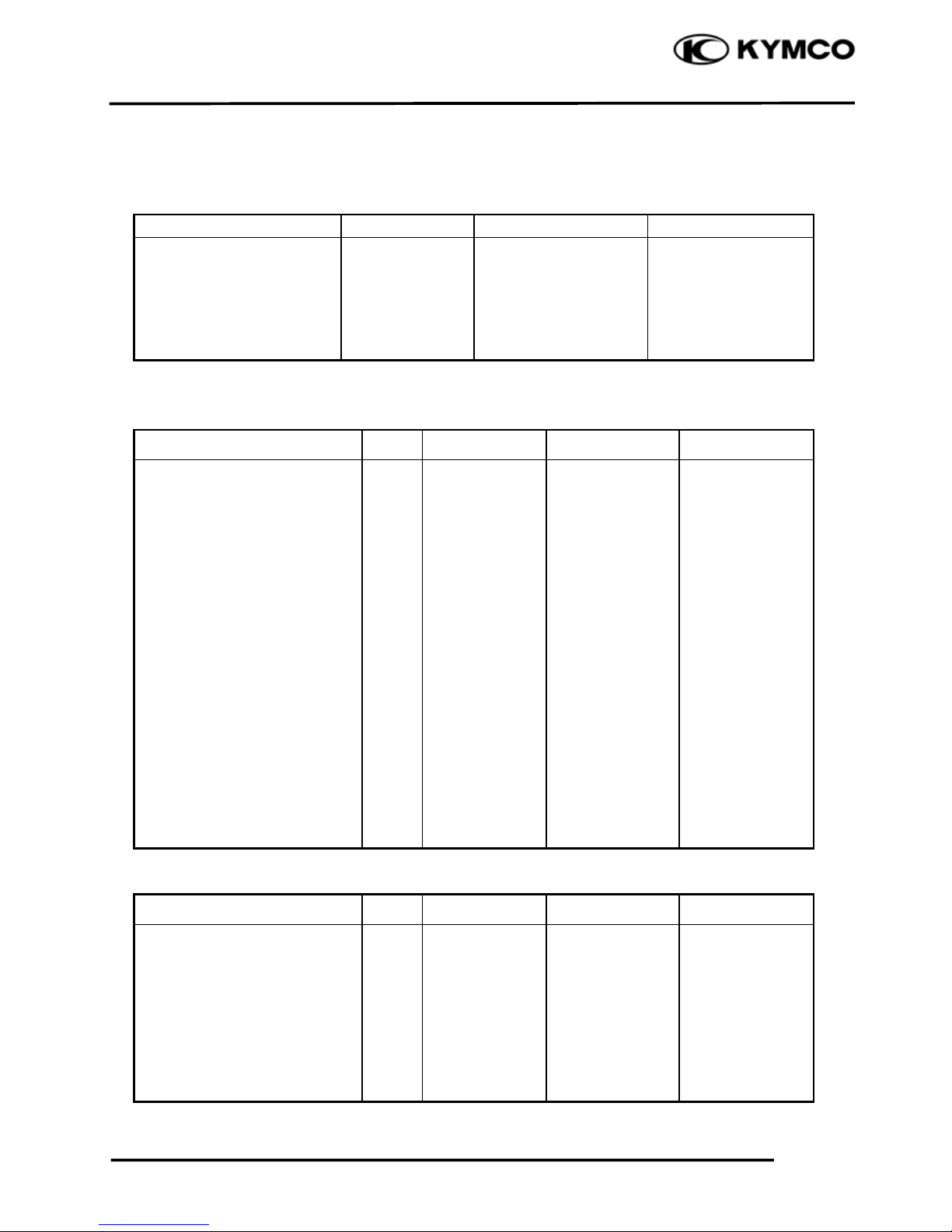

TORQUE VALUES

STANDARD TORQUE VALUES

Ite

m

Torque (kg-m

)

Ite

m

Torque (kg-m

)

5mm bolt, nut

6mm bolt, nut

8mm bolt, nut

10mm bolt, nut

12mm bolt, nut

0.45-0.6

0.6-1.2

1.8-2.5

3.0-4.0

5.0-6.0

5mm screw

6mm screw, SH bolt

6mm flange bolt, nut

8mm flange bolt, nut

10mm flange bolt, nut

0.35-0.5

0.7-1.1

1.0-1.4

2.4-3.0

3.5-4.5

Torque specifications listed below are for important fasteners.

ENGINE

Item Q‘ty Thread dia.(mm) Torque (kg-m) Remarks

Cylinder head bolt A

Cylinder head bolt B

Oil filter screen cap

Exhaust muffler lock bolt

Cylinder head flange nut

Valve adjusting lock nut

Cam chain tensioner slipper bolt

Oil bolt

Clutch outer nut

Clutch drive plate nut

Starter motor mounting bolt

Oil pump bolt

Drive face nut

Spark plug

A.C. generator stator bolt

Cam chain tensioner bolt

2

4

1

2

4

2

1

1

1

1

2

3

1

1

2

1

6

6

30

6

7

3

8

8

10

28

6

4

10

10

6

6

0.7-1.1

0.7-1.1

1.0-2.0

0.7-1.1

1.2-1.6

0.07-0.09

0.4-0.7

1.1-1.5

3.5-4.5

5.0-6.0

0.8-1.2

0.1-0.3

5.5-6.5

1.0-1.4

0.8-1.2

0.8-1.2

Double end bolt

Double end bolt

Apply oil to

threads

FRAME

Item Q‘ty Thread dia.(mm) Torque (kg-m) Remarks

Steering stem lock nut

Front axle nut

Rear axle nut

Rear shock absorber upper bolt

Rear shock absorber lower bolt

Speedometer cable set screw

Rear shock absorber lock nut

1

1

1

1

1

1

1

25.4

10

14

10

8

5

8

8.0-12.0

5.0-7.0

11.0-13.0

4.0-5.0

2.0-3.0

0.45-0.6

3.0-3.6

U-nut

U-nut

U-nut

Apply locking agent

Page 15

1. GENERAL INFORMATION

1-12

AGILITY 50

SPECIAL TOOLS

Tool Name Tool No. Remarks Ref. Page

10-3

10-4Bearing puller 10.12.15.18 mm E037 10.12.15.18mm bearing

12-6

Bushing remover L E032 11102 bush engine hanger rubber

Bushing remover S EO19 11203 bush rear cushion under rubber

Crankshaft bearing puller E030 91005 radial bearing

Crankshaft protector E029 13000 crankshaft comp 12mm.14mm

Clutch spring compressor E027 2301a driven pully assy

9-9

9-12

Cushion assemble & disassemble

tool

F004 52400 cushion assy 13-4

Flywheel holder E017

31110 fl

y

wheel comp.2310a pully ass

y

driven

9-5

9-9

9-13

14-7

14-9

Flywheel puller E002 Left hand thread 27mm

14-7

Long socket wrench 32mm 8angle F002 50306 steering stem

12-21

12-22

Oil seal & bearing installer E014 Oil seal & bearing install

Tool boox E033 Special tools storage

Tappet adjuster E036 90012 screw tappet 3-5

7-7

Valve spring compressor E038 Valve spring

7-8

Page 16

1. GENERAL INFORMATION

1-13

AGILITY 50

LUBRICATION POINTS

ENGINE

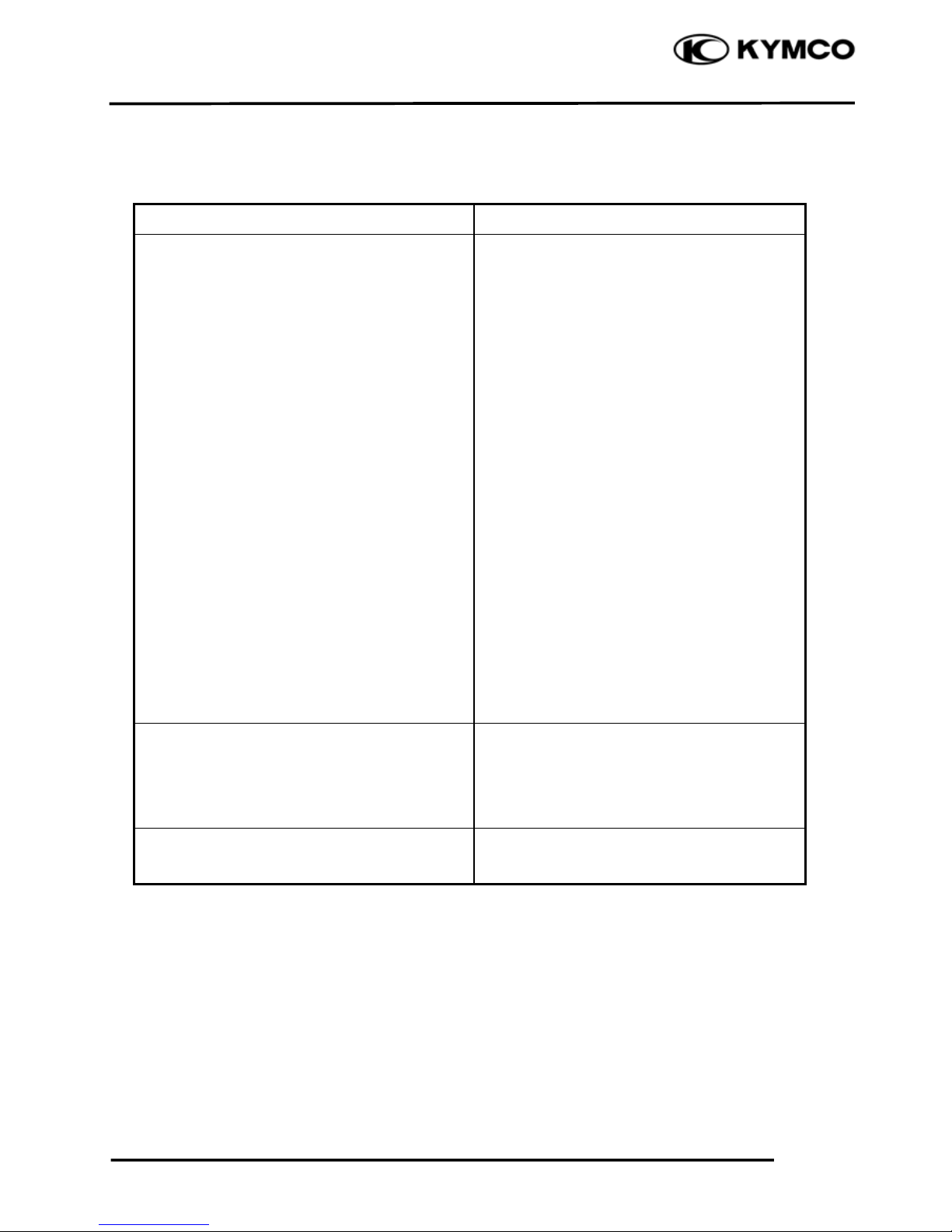

Lubrication Points Lubricant

Valve guide/valve stem movable part

Cam lobes

Valve rocker arm friction surface

Cam chain

Cylinder lock bolt and nut

Piston surroundings and piston ring grooves

Piston pin surroundings

Cylinder inside wall

Connecting rod/piston pin hole

Connecting rod big end

Crankshaft R/L side oil seal

Starter reduction gear engaging part

Countershaft gear engaging part

Final gear engaging part

Bearing movable part

O-ring face

Oil seal lip

xGenuine KYMCO Engine Oil (SAE15W-40)

xAPISG Engine Oil

Starter idle gear

Friction spring movable part/shaft movable part

Shaft movable grooved part

Kick starter spindle movable part

High-temperature resistant grease

A.C. generator connector

Transmission case breather tube

Adhesive

Page 17

1. GENERAL INFORMATION

1-14

AGILITY 50

FRAME

The following is the lubrication points for the frame.

Use general purpose grease for parts not listed.

Apply clean engine oil or grease to cables and movable parts not specified.

This will avoid abnormal noise and rise the durability of the motorcycle.

Rear Wheel Bearings

Main Stand Pivot

Speedometer Gear/ Front Wheel

Bearings/ Brake Cam/ Anchor Pin

/Front Shock Absorber Lower

Mount Bushings/Pivot

Grease

Grease

Grease

Engine Oil

Rear Brake Cable

Brake Cam

/

Anchor Pin

Grease

Grease

Front Brake Leve

r

Pivot

Front Brake Cable

/

Speedometer Cable/

Throttle Cable

Engine/ Oil

Page 18

1. GENERAL INFORMATION

1-15

AGILITY 50

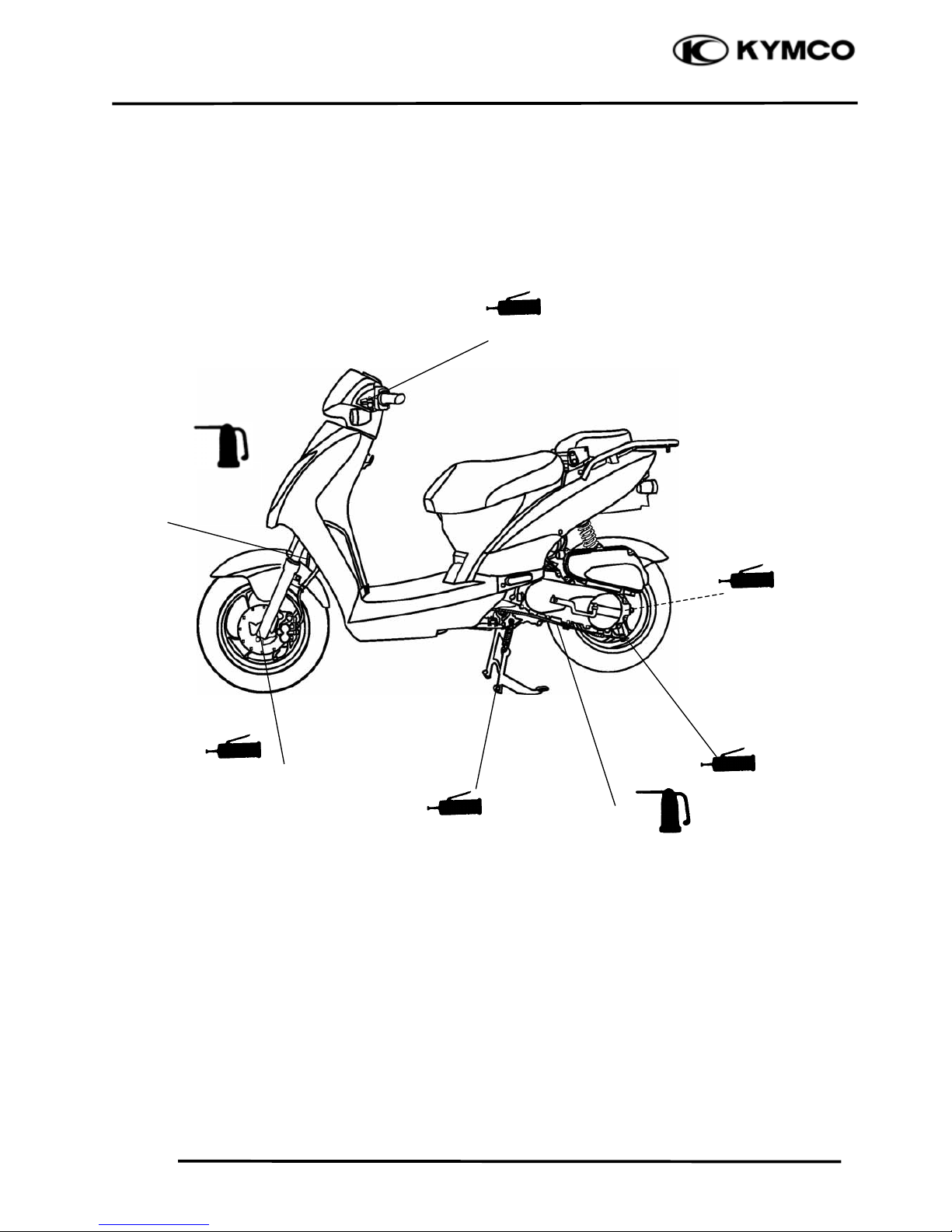

CABLE & HARNESS ROUTING

Front Stop Switch Wire

Rear Stop Switch Wire

Throttle Cable

Regulator/Rectifie

r

Rear Brake Cable

Speedometer Cable

Horn

Ignition Switch

Winke

r

Front Brake Fluid Tube

Brake Master Cylinde

r

Page 19

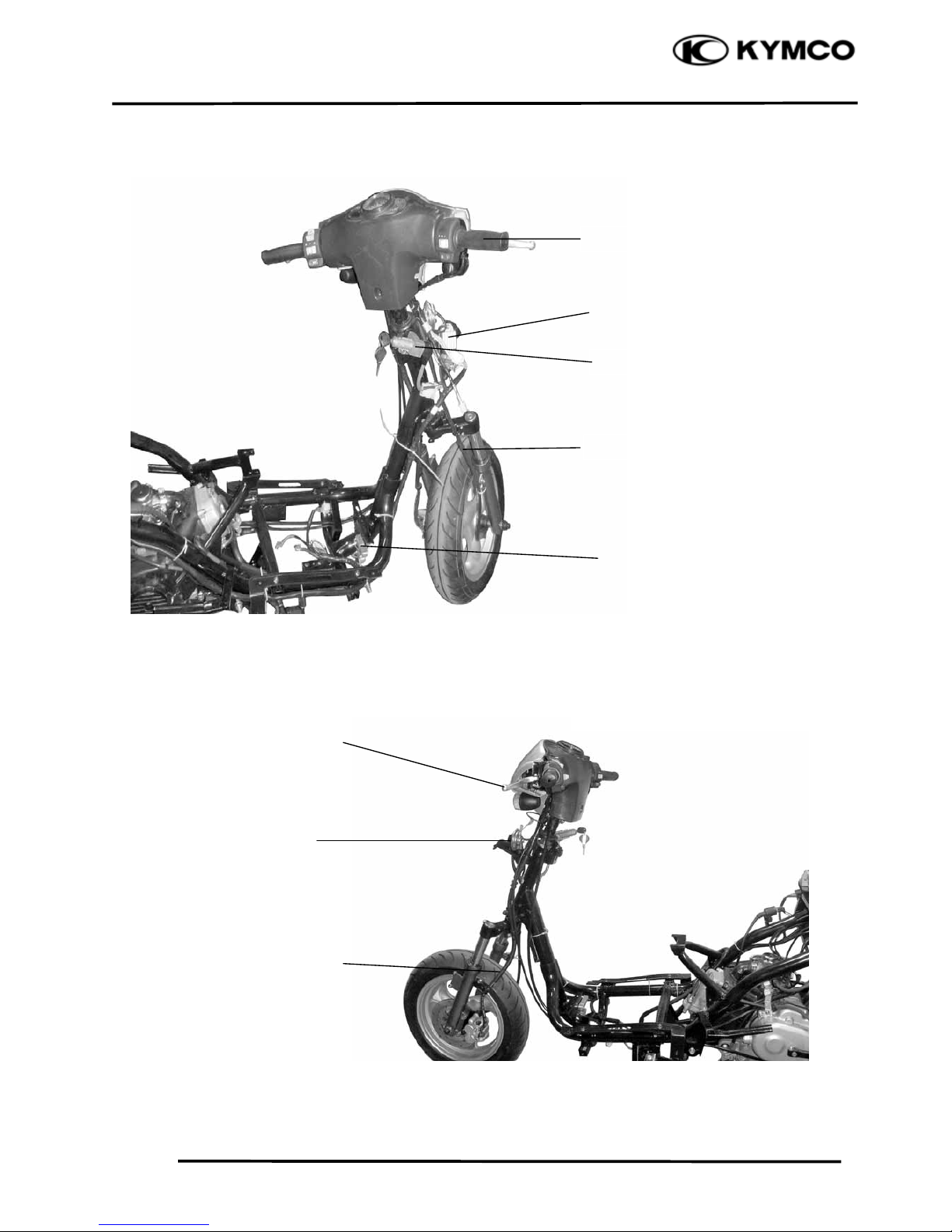

1. GENERAL INFORMATION

1-16

AGILITY 50

Regulator/Rectifie

r

Speedometer Cable

Ignition Switch

Throttle Grip

Rear Brake Leve

r

Front Brake Fluid Tube

Headlight Resisto

r

Horn

Page 20

1. GENERAL INFORMATION

1-17

AGILITY 50

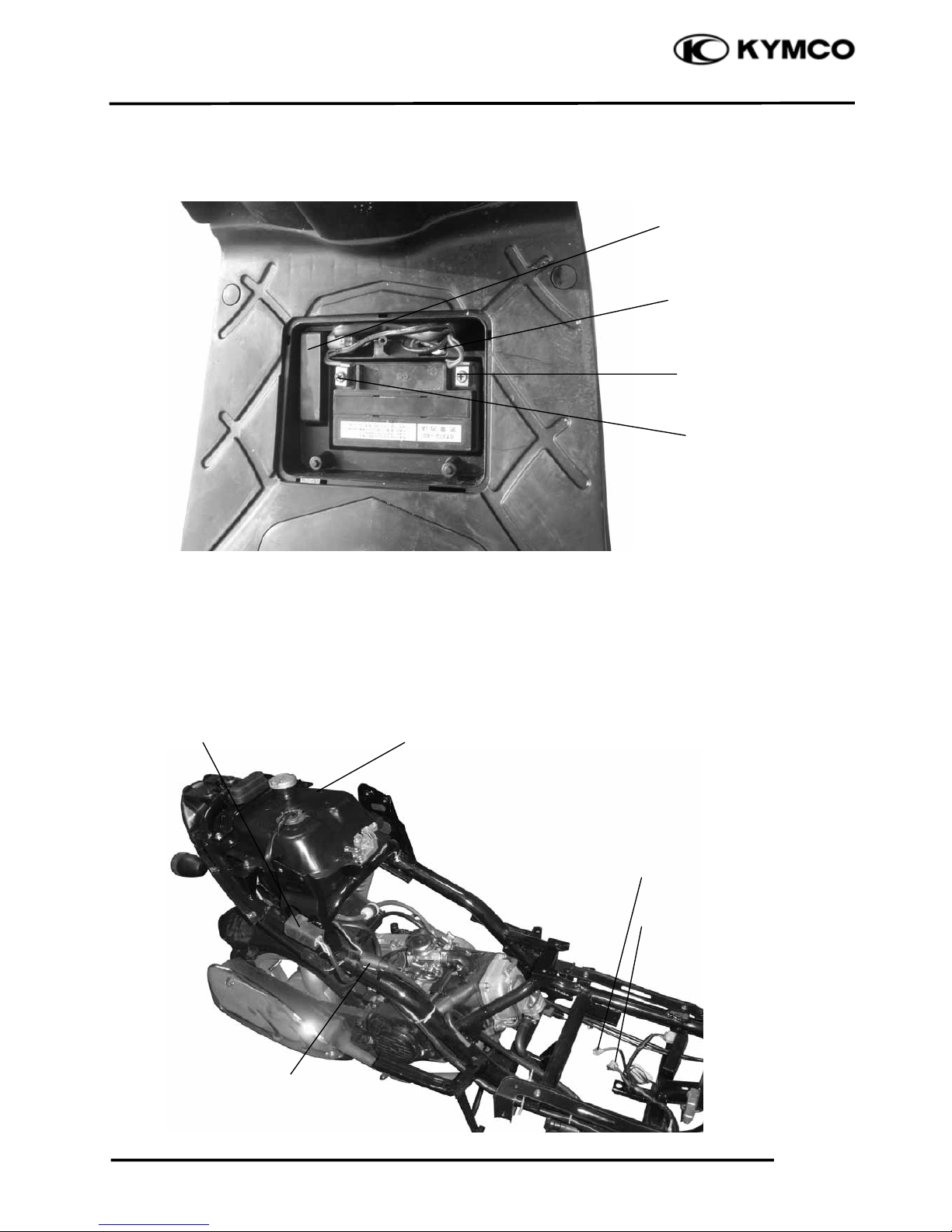

Starter Relay

Fuse

Battery (+) Cable

Battery (-) Cable

CDI Unit

Battery (+) Cable

Battery (-) Cable

Fuel Tan

k

Ignition Coil

Page 21

1. GENERAL INFORMATION

1-18

AGILITY 50

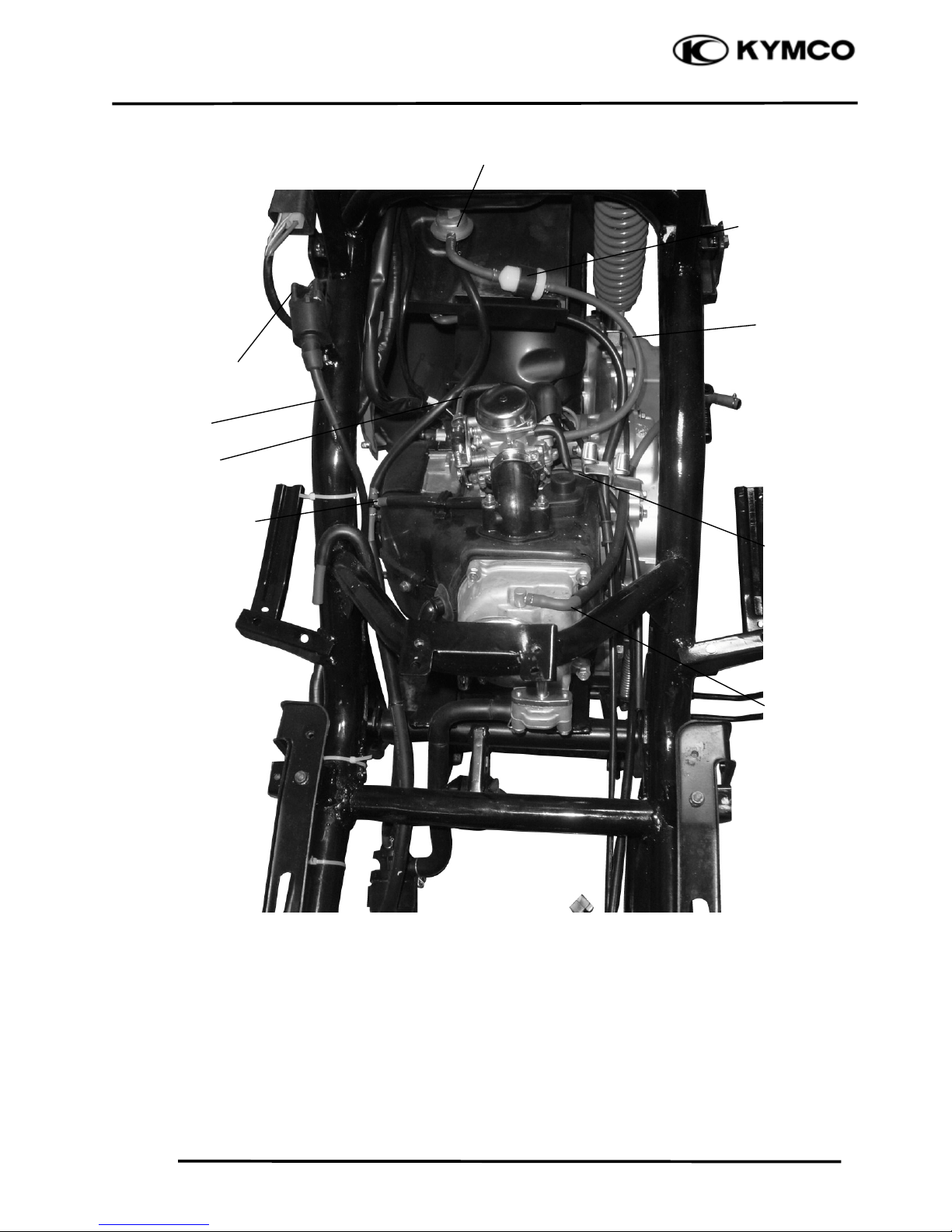

Throttle Cable

Vacuum Tee

Carbureto

r

Overflow Tube

Fuel Tube

Crankcase Breathe

r

Tube

Ignition Coil

Primary Wire

Ignition Wire

Fuel Filte

r

Auto Cock Assy Fuel

Page 22

1. GENERAL INFORMATION

1-19

AGILITY 50

Throttle Cable

Fuel Tube

Vacuum Tube

Auto Bystarte

r

Crankcase Breathe

r

Tube

Ignition Coil

Wire

Crankcase Breathe

r

Tube

Throttle Cable

Vacuum Tube

Fuel Unit

Reed Valve

Secondary Ai

r

Inlet Tube

Air Injection

Cut-off

Valve

Page 23

1. GENERAL INFORMATION

1-20

AGILITY 50

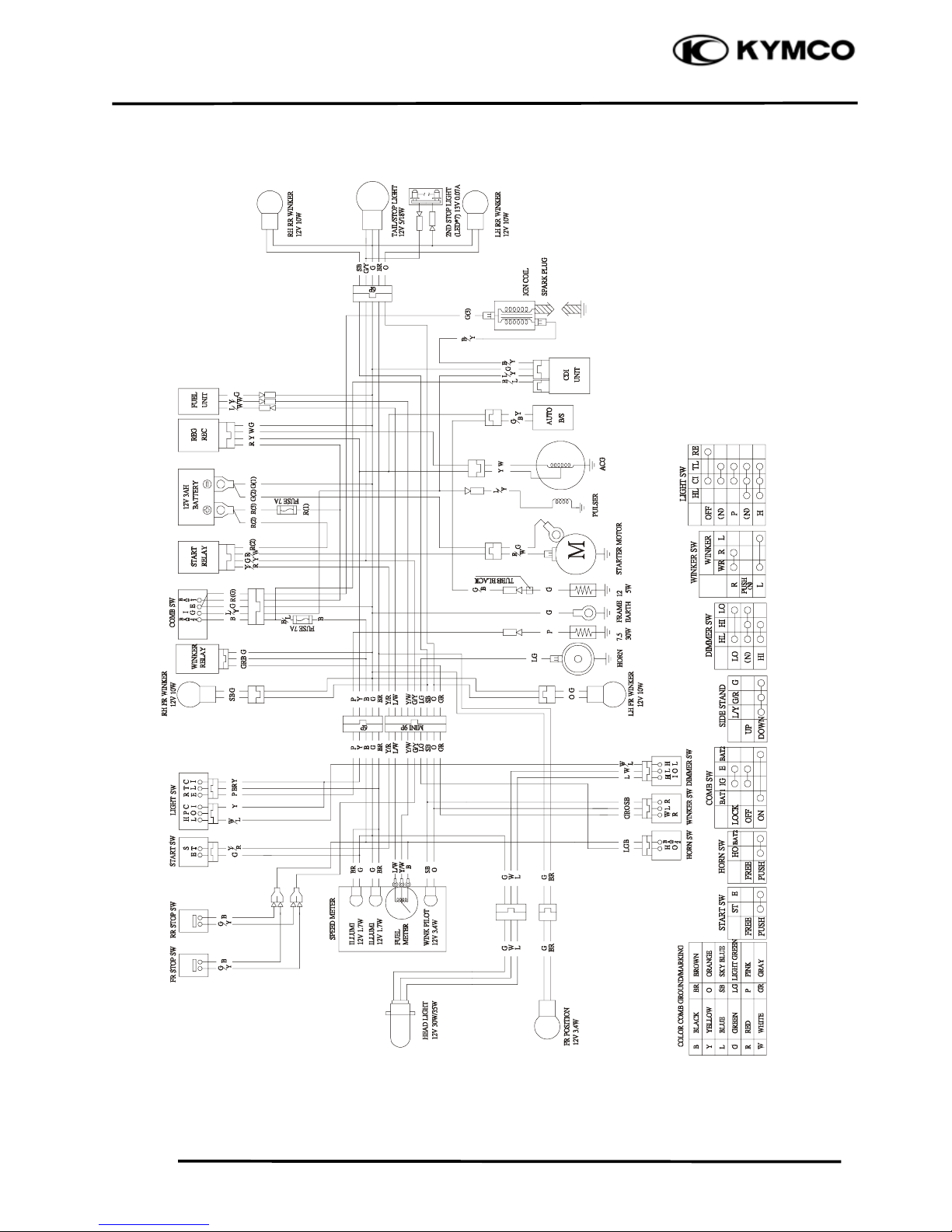

WIRING DIAGRAM

Page 24

1. GENERAL INFORMATION

1-21

AGILITY 50

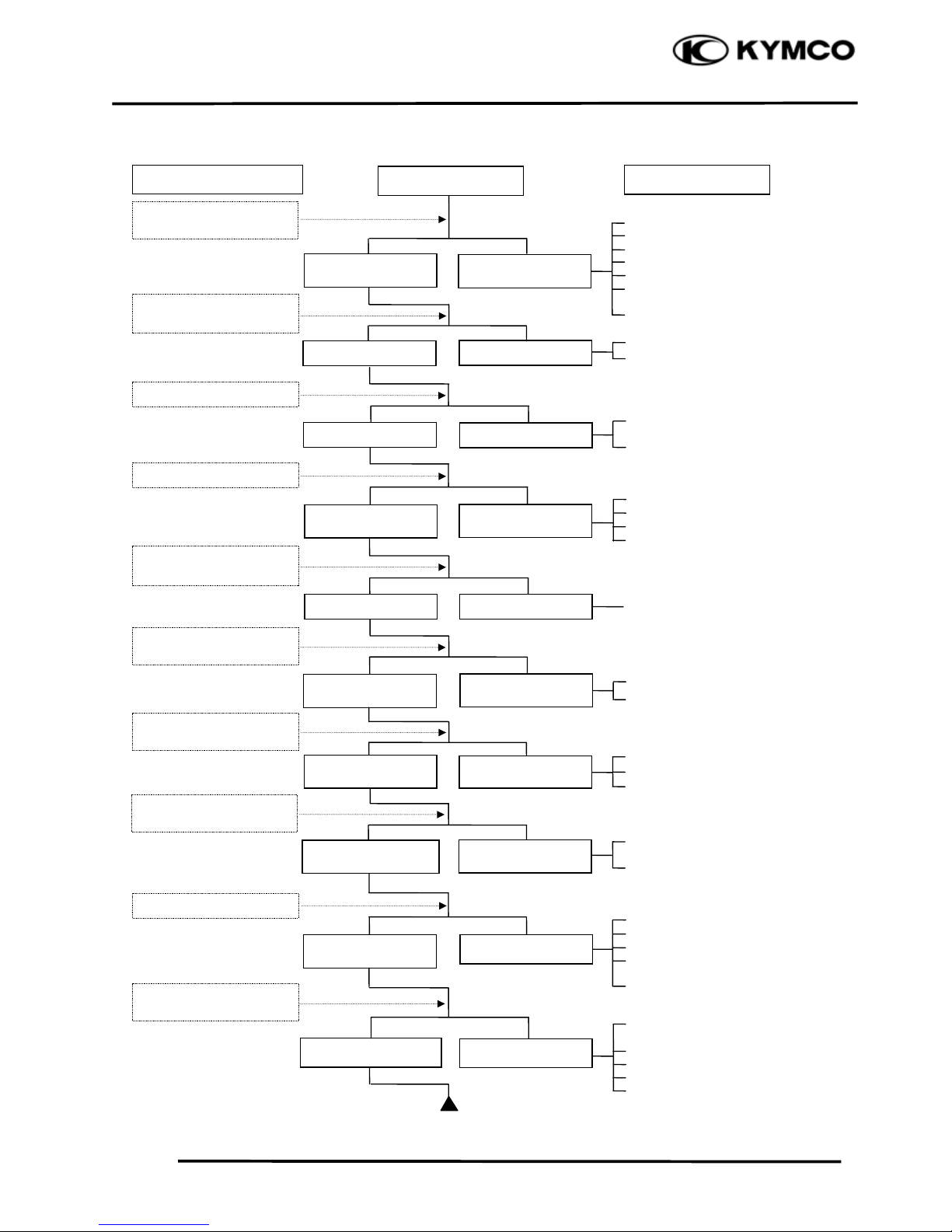

TROUBLESHOOTING

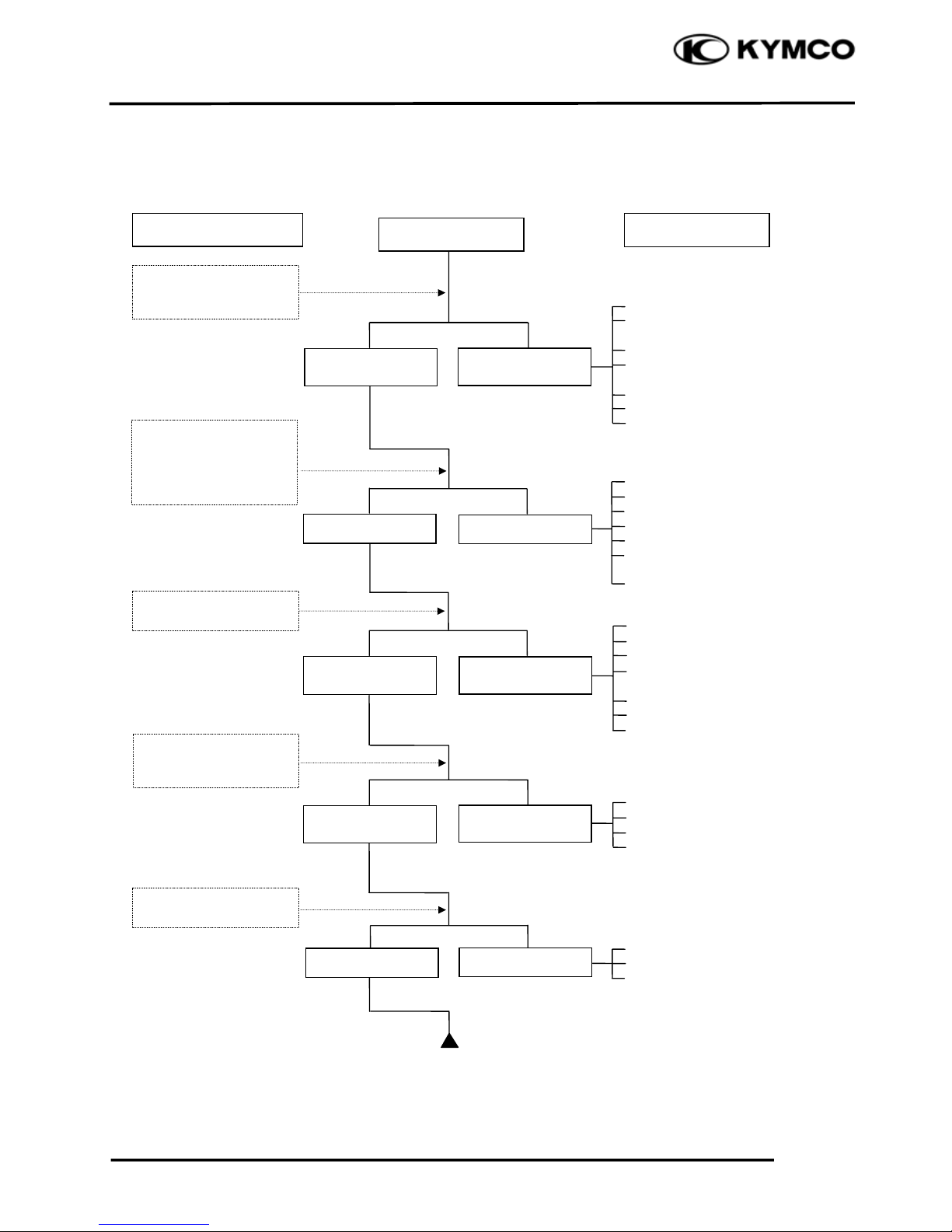

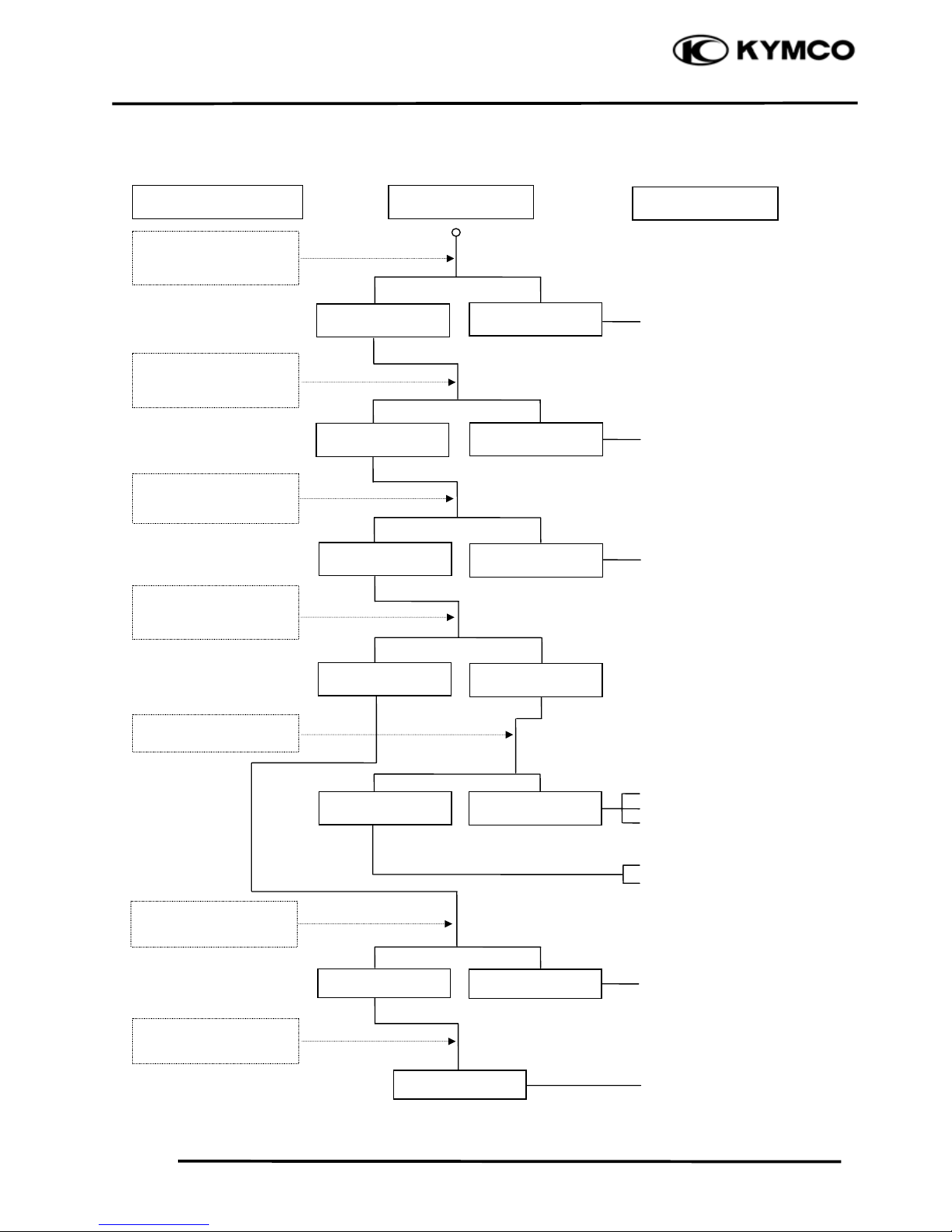

ENGINE WILL NOT START OR IS HARD TO START

Empty fuel tank

Clogged fuel line between fuel

tank and carburetor

Clogged float oil passage

Clogged fuel tank cap breather

hole

Clogged fuel filter

Clogged fuel strainer

Faulty auto fuel

valve

Faulty spark plug

Fouled spark plug

Faulty CDI unit

Faulty pulser coil

Broken or shorted ignition coil

Broken or shorted high-tension

wire

Faulty ignition switch

Faulty starter clutch

Valve clearance too small

Improper valve and seat contact

Worn cylinder, piston and piston

rings

Leaking cylinder head gasket

Seized valve

Improper valve timing

Faulty auto bystarter

Air leaking through intake pipe

Incorrect ignition timing

Incorrectly adjusted pilot screw

Flooded carburetor

Faulty auto bystarter

Throttle valve excessively open

Check if fuel reaches

carburetor by loosening

drain screw

Remove spark plug and

install it into spark plug

cap to test spark by

connecting it to engine

ground

Inspection/Adjustment

Probable Cause

Spark jumps

Normal

compression

Engine does no

t

fire

Weak or no spark

Low or no

compression

Engine fires bu

t

does not start

Test cylinde

r

compression

Start engine by following normal starting

p

rocedure

Remove spark plug and

inspect again

Symptom

Fuel reaches

carburetor

Fuel does no

t

reach carburetor

Wet spark plug

Dry spark plug

Page 25

1. GENERAL INFORMATION

1-22

AGILITY 50

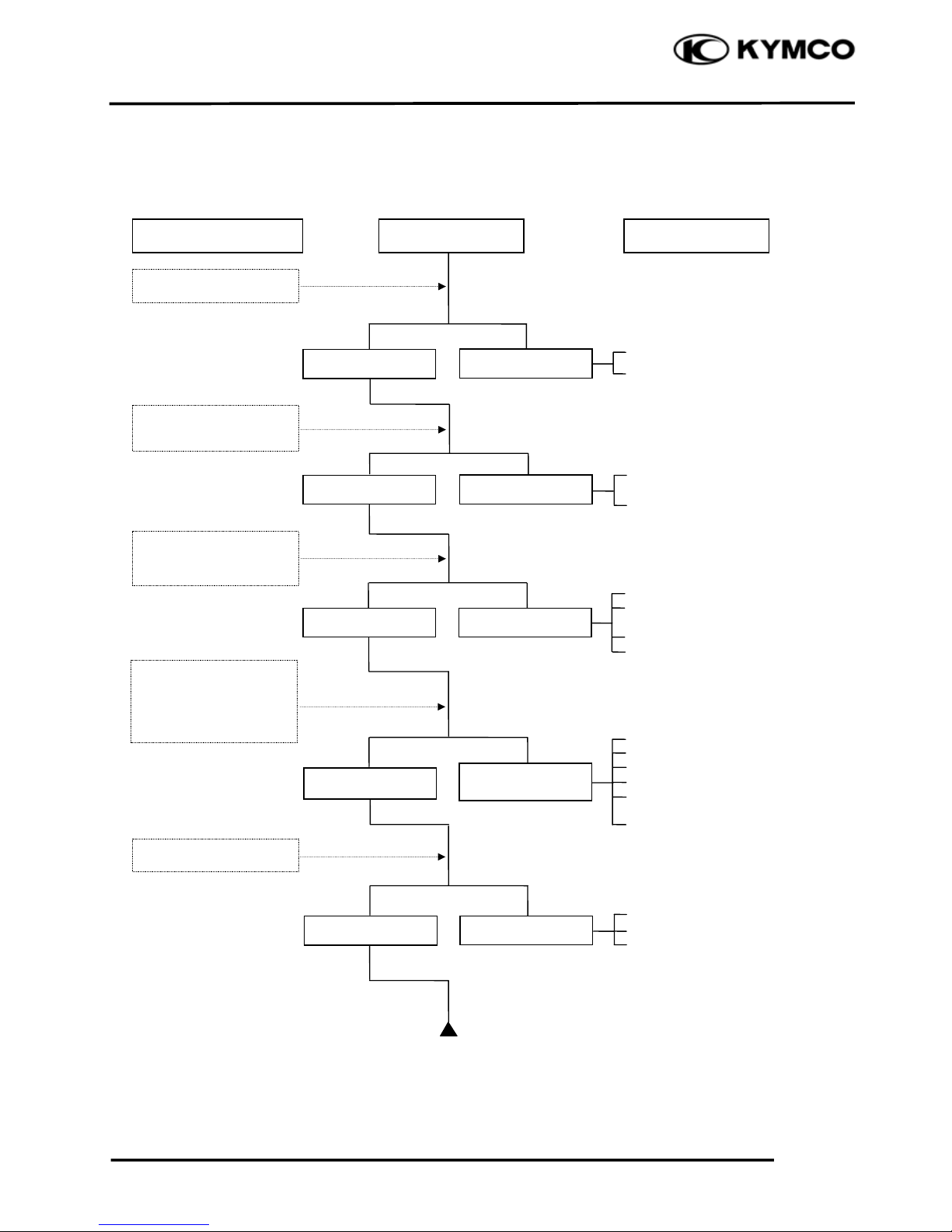

ENGINE LACKS POWER

Clogged air cleaner

Poor quality fuel (Restricted)

Clogged fuel tank cap breather hole

Clogged exhaust muffler

Faulty auto bystarter

Split carburetor vacuum piston

diaphragm

Faulty auto fuel valve

Faulty CDI unit

Faulty pulser coil

Improper valve clearance

adjustment

Worn valve seat (valve stem too

protruding

Improper valve and seat contact

Worn cylinder and piston rings

Leaking cylinder head gasket

Improper valve timing

Clogged carburetor jets

Fouled spark plug

Incorrect heat range plug

Oil level too high

Oil level too low

Oil not changed

Clogged oil pipe

Faulty oil pump

Worn cylinder and piston rings

Mixture too lean

Poor quality fuel

Excessive carbon buildup in

combustion chamber

Ignition timing too early

Excessive carbon build-up in

combustion chamber

Poor quality fuel

Clutch slipping

Mixture too lean

Ignition timing too early

Start engine and accelerate

lightly for observation

Inspection/Adjustment

Symptom

Probable Cause

Engine speed

Correct timin

g

Engine speed does no

t

increase sufficientl

y

Incorrect timin

g

Check ignition timing

using a timing light

Test cylinder compression

Check carburetor fo

r

clogging

Rapidly accelerate or run

at hi

g

h speed

Remove spark plug and

inspec

t

Check if engine overheats

Check valve clearance

Correc

t

Incorrec

t

N

ormal

com

p

ression

Abnormal

compression

Remove oil dipstick and

check oil level and condition

Remove cylinder head oil

pip

e bolt and inspec

t

Engine overheats

Engine does no

t

overheats

Plug not fouled o

r

discolored

Plug fouled o

r

discolored

Correct and no

t

contaminated

Incorrect o

r

contaminated

Valve train lubricated

prop

erl

y

Valve train no

t

lubricated properl

y

Engine does not knock

Engine knocks

Not clogged

Clogged

Page 26

1. GENERAL INFORMATION

1-23

AGILITY 50

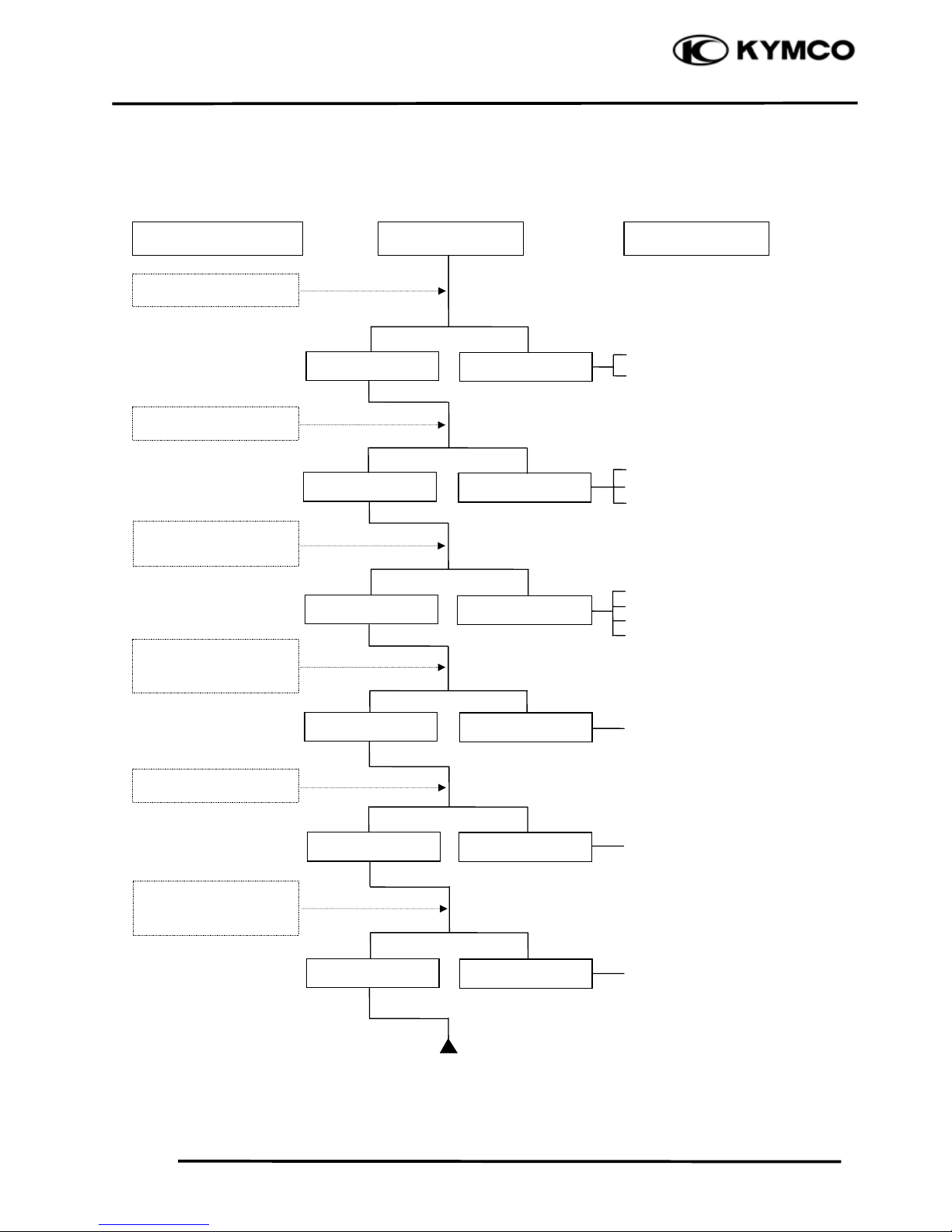

POOR PERFORMANCE (ESPECIALLY AT IDLE AND LOW SPEEDS)

Faulty CDI unit

Faulty pulser coil

Mixture too rich (turn screw

out)

Mixture too lean (turn screw in)

Deteriorated O-ring

Carburetor not securely

tightened

Damaged insulator rubber

Broken vacuum tube

Faulty or fouled spark plug

Faulty CDI unit

Faulty A.C. generator

Faulty ignition coil

Broken or shorted spark plug

wire

Faulty ignition switch

Faulty air cut-off valve

Damaged vacuum tube

Clogged or damaged air vent

hole

Remove spark plug and

install it into spark plug

cap to test spark by

connecting it to engine

g

round

Inspection/Adjustment Symptom Probable Cause

Check ignition timing

Check air cut-off valve

Check carburetor gaske

t

for air leaks

Check carburetor pilo

t

screw adjustment

Correct timing

Incorrect timing

Correctly adjusted

No air leak

Air leaks

Good spark

Weak or inter-

mittent spark

Good

Faulty

Incorrectly adjusted

Page 27

1. GENERAL INFORMATION

1-24

AGILITY 50

POOR PERFORMANCE (AT HIGH SPEED)

Faulty CDI unit

Faulty pulser coil

Improperly adjusted valve clearance

Worn camshaft

Worn valve seat

Empty fuel tank

Clogged fuel tube or filter

Faulty charcoal canister

Faulty auto fuel valve

Clean and unclog

Cam timing gear aligning marks

not aligned

Faulty spring

Inspection/Adjustment Symptom Probable Cause

Check ignition timing

Check carburetor jets

for clogging

Check fuel pump fo

r

fuel supply

Correct timing

Incorrect timing

Check valve spring

tension

Check valve clearance

Fuel flows freely

Fuel flow restricted

Correc

t

Incorrec

t

Not clogged

Clogged

Correctly adjusted

Incorrectly adjusted

Not weakened

Weak spring

Check valve timing

Page 28

1. GENERAL INFORMATION

1-25

AGILITY 50

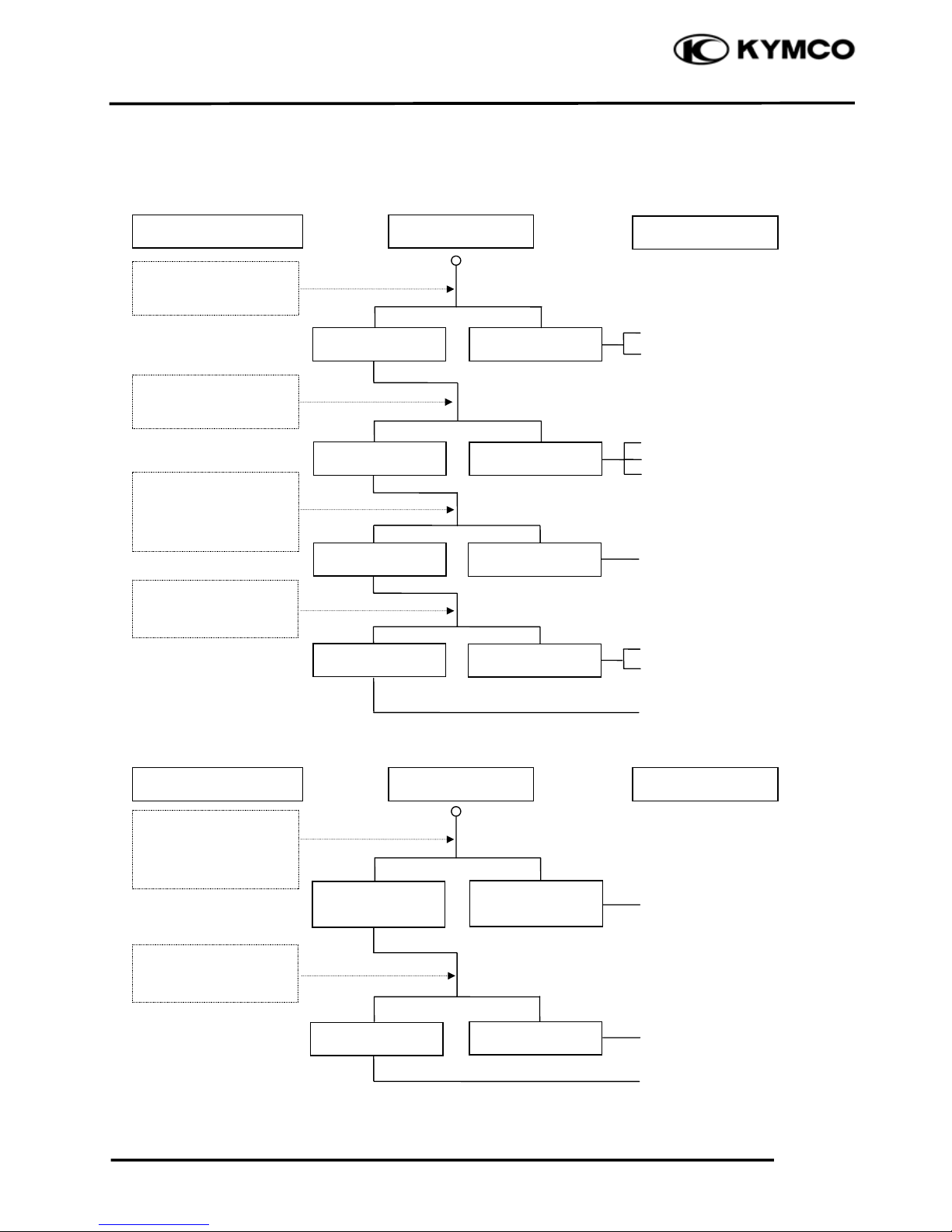

POOR CHARGING (BATTERY OVER DISCHARGING OR OVERCHARGING)

Undercharging

Dead battery

Faulty battery

Faulty A.C. generator coil

Broken yellow wire

Loose connector

Broken red wire

Faulty regulator/rectifier

Poorly connected coupler

Faulty A.C. generator

Overcharging

Broken green wire

Poorly connected coupler

Faulty regulator/rectifier

Start engine and tes

t

limit voltage between

b

attery terminals

Connect battery (+) wire

to regulator/rectifier

coupler red wire and

battery (-) wire to engine

g

round and test voltage

Inspection/Adjustment

Inspection/Adjustment

Symptom

Symptom

Probable Cause

Probable Cause

Normal voltage

B

attery has voltage

with ignition

switch “ON”

Normal

Voltage does no

t

B

attery has no

voltage with ignition

switc

h

“ON”

Resistance too high

Normal voltage

No voltage

Measure resistance

between AC generator

coil terminals

Normal

Abnormal

Check regulator/rectifier

coupler for loose

connection

Normal

Abnormal

Connect battery (+) wire

to regulator/rectifier

coupler green wire and

battery (-) wire to engine

g

round and test voltage

Check regulator/rectifier

coupler for loose

connection

Page 29

1. GENERAL INFORMATION

1-26

AGILITY 50

NO SPARK AT SPARK PLUG

Faulty old spark plug

Loose spark plug cap

Poorly connected coupler

Faulty ignition switch

Faulty pulser coil

Faulty ignition coil

Broken wire harness

Poorly connected coupler

Faulty CDI unit

Faulty ignition coil

Replace with a new

spark plug and inspect

a

g

ain

Check CDI unit coupler

for looseness

Inspection/Adjustment Symptom

Probable Cause

Normal

Abnormal

Normal

Abnormal

Normal

Abnormal

Abnormal

Measure resistance

between CDI unit

cou

p

ler wire terminals

Check related parts

Check ignition coil with

a CDI unit tester

Weak or no spark

Not loose

Good spark

Loose

Good

Good

Check spark plug cap

and high-tension wire

for looseness

Check CDI unit with a

CDI unit tester

Page 30

2. FRAME COVERS/EXHAUST MUFFLER

2-0

AGILITY 50

2 SCHEMATIC DRAWING

2

Page 31

2. FRAME COVERS/EXHAUST MUFFLER

2-1

AGILITY 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

xWhen removing frame covers, use special care not to pull them by force because the cover joint

claws may be damaged.

Items Related for Removal

xHandlebar front cover Handlebar rear cover

Headlight wire connector

xHandlebar rear cover Speedometer cable and instrument light

wire connectors, etc.

xFrame body cover Met-in box, rear grip, rear turn signal

lights, floor board

xFloor board Frame body cover

Battery and wire connectors

xFront tool box Front cover, floor board

TORQUE VALUES

Exhaust muffler joint lock nut 1.0~1.4kgf-m

Exhaust muffler lock bolt 3.0~3.6kgf-m

SERVICE INFORMATION...................... 2-1 EXHAUST MUFFLER REMOVAL .........2-5

FRAME COVERS ..................................... 2-2

Page 32

2. FRAME COVERS/EXHAUST MUFFLER

2-2

AGILITY 50

FRAME COVERS

FRONT COVER REMOVAL

Remove the screw on the front of the front

cover.

Remove the six screws on the back of the

front cover.

Remove the front cover.

The installation sequence is the reverse of

removal.

HANDLEBAR FRONT/REAR COVER

REMOVAL

HANDLEBAR FRONT COVER REMOVAL

Remove the handlebar front cover screw.

Remove the two screws attaching the

handlebar front cover.

Disconnect the headlight wire connector and

remove the handlebar front cover.

HANDLEBAR REAR COVER REMOVAL

Disconnect the speedometer cable, right and

left handlebar switch couplers, and the stop

switch wire connectors.

Remove the bolt attaching the handlebar rear

cover.

Remove two screws inside the handlebar rear

cover and remove the handlebar rear cover.

The installation sequence is the reverse of

removal.

Bol

t

Screw

Handlebar Front Cove

r

Screw

Front Cove

r

Screws

Handlebar Rear Cove

r

Handlebar Front Cove

r

Screws

Page 33

2. FRAME COVERS/EXHAUST MUFFLER

2-3

AGILITY 50

MET-IN BOX REMOVAL

Open the seat and remove the two nuts and

three bolt attaching the met-in box.

Remove the met-in box .

FRAME BODY COVER REMOVAL

Remove the center cover.

Remove the three bolts attaching the rear

carrier.

Remove the rear carrier.

Remove the four bolts on the rear seat.

Remove the rear seat

Remove the six screws on the rear part of the

frame body cover.

Remove the two screws on the front of the

frame body cover.

Bol

t

Rear Carrie

r

Screws

Bolts

Center Cove

r

Bolts

Screws

Bolts

Page 34

2. FRAME COVERS/EXHAUST MUFFLER

2-4

AGILITY 50

Discornnect the seat lock wire.

Remove the frame body cover.

The installation sequence is the reverse of

remove

Remove the three bolts attaching each of the

right and left side covers.

Remove the right and left side covers.

FLOOR BOARD REMOVAL

Remove the rear carrier and rear seat. (Ö2-3)

Remove the met-in box. (Ö2-3)

Remove the frame body cover. (Ö2-4)

Remove the eight bolts attaching the floor

board.

Remove the floor board.

BOTTOM PROTECTOR COVER

REMOVAL

Remove the sixbolts on the bottom protector

cover.

Remove the bottom protector cover.

Bolts

Frame Body

Bottom Protector Cove

r

Bolts

Floor Board.

Seat Lock Wire

During removal, do not pull the joint

claws forcedly to avoid damage.

When installing, be sure to connect the

seat lock wire.

*

Page 35

2. FRAME COVERS/EXHAUST MUFFLER

2-5

AGILITY 50

LEG SHIELD REMOVAL

Remove the bolt leg shield.

Remove the ignition switch decorative ring

Remove the leg shield.

F RONT FENDER REMOVAL

Remove the two bolts attaching the front

fender bracket.

Remove the front fender.

EXHAUST MUFFLER REMOVAL

Remove the two exhaust muffler joint lock

nuts.

Remove the two exhaust muffler lock bolts.

Remove the exhaust muffler.

Remove the exhaust muffler joint packing

collar.

When installing, first install the exhaust

muffler packing collar and then install the

exhaust muffler.

First install and tighten the exhaust muffler

joint lock nuts. Then, install and tighten the

exhaust muffler lock bolts.

Torques:

Exhaust muffler lock bolt: 3.0~3.6kgf-m

Exhaust muffler joint lock nut: 1.0~1.4kgf-m

Bolts

Lock Nu

t

Front Fende

r

Bolts

Leg shield

Be sure to install a new exhaust muffle

r

packing collar.

*

Bol

t

Decorative Ring

Page 36

3. INSPECTION/ADJUSTMENT

3-0

AGILITY 50

3

SERVICE INFORMATION

GENERAL

l WARNING

xBefore running the engine, make sure that the working area is well-ventilated. Never run the

engine in a closed area. The exhaust contains poisonous carbon monoxide gas which may

cause death to people.

xGasoline is extremely flammable and is explosive under some conditions. The working area

must be well-ventilated and do not smoke or allow flames or sparks near the working area or

fuel storage area.

SPECIFICATIONS

ENGINE

Throttle grip free play : 2Д6mm

Spark plug gap : 0.6Д0.7mm

Spark plug : NGK C7HSA

Valve clearance : IN: 0.04mm

:EX: 0.04mm

Idle speed : 1900 Ô100rpm

Engine oil capacity:

At disassembly : 0.85 liter

At change : 0.7 liter

Gear oil capacity :

At disassembly : 0.11 liter

At change : 0.10 liter

3

SERVICE INFORMATION....................3-0 FINAL REDUCTION GEAR OIL.......3- 7

MAINTENANCE SCHEDULE...............3-2 DRIVE BELT.........................................3- 7

FUEL FILTER..........................................3-3 BRAKE SHOE.......................................3- 8

THROTTLE OPERATION.....................3-3 BRAKE ADJUSTING NUT..................3- 8

AIR CLEANER ........................................3-4 HEADLIGHT AIM ...............................3- 9

SPARK PLUG ..........................................3-4 CLUTCH SHOE WEAR.......................3- 9

VALVE CLEARANCE............................3-5 SUSPENSION ........................................3- 9

CARBURETOR IDLE SPEED...............3-5 NUTS/BOLTS/FASTENERS................3-10

IGNITION TIMING................................3-6 WHEELS/TIRES...................................3-10

CYLINDER COMPRESSION................3-6 STEERING HANDLEBAR..................3-11

Page 37

3. INSPECTION/ADJUSTMENT

3-1

AGILITY 50

Cylinder compression : 16 kg/cm

2

Ignition timing: BTDC 28Ę/4000rpm

CHASSIS

Front brake free play: 10Д20mm

Rear brake free play : 10Д20mm

TIRE PRESSURE

1 Rider 2 Riders

Front 1.5kg/cm

2

1.75kg/cm

2

Rear 2.0kg/cm

2

2.25kg/cm

2

TIRE SIZE:

Front : 120/70-12

Rear : 130/70-12

TORQUE VALUES

Front axle nut 5.0Д7.0kgf-m

Rear axle nut 11Д13kgf-m

Page 38

3. INSPECTION/ADJUSTMENT

3-2

AGILITY 50

MAINTENANCE SCHEDULE

Perform the periodic maintenance at each scheduled maintenance period.

I: Inspect, and Clean, Adjust, Lubricate or Replace if necessary.

A: Adjust C: Clean R: Replace T : Tighten

Regular Service Mileage (km)

Frequenc

y

Item

comes

first

Ö

Ø

1000

Engine oil

R

New

Motorcycle

300k

m

RRR

R

RR

Engine oil filter

screen

CC

Fuel filter screen R

Gear oil Note 3

R

New

motorcycle

300k

m

R

R

Valve clearance A A A A

Carburetor I I C

Air Cleaner Note 2,3 Replace at every2000km

Spark plug Clean at every 3000km and replace if necessary

Brake system I IIIIIIIII I I

Drive belt I

Suspension I I I

Nut, bolt, fastener I

Tire I I I

Steering head bearing I I I

xIn the interest of safety, we recommend these items should be serviced only by an authorized

KYMCO motorcycle dealer.

Note: 1. For higher odometer readings, repeat at the frequency interval established here.

2. Service more frequently when riding in dusty or rainy areas.

3. Service more frequently when riding in rain or at full throttle.

Whicheve

r

Page 39

3. INSPECTION/ADJUSTMENT

3-3

AGILITY 50

FUEL FILTER

Remove the met-in box. (Ö2-3)

Check the fuel lines and replace any parts

which show signs of deterioration, damage or

leakage.

THROTTLE OPERATION

Check the throttle grip for smooth movement.

Measure the throttle grip free play.

Free Play: 2Д6mm

Major adjustment of the throttle grip free play

is made at the carburetor side.

Adjust by loosening the lock nut and turning

the adjusting nut.

Minor adjustment is made with the adjusting

nut at the throttle grip side.

Slide the rubber cover out and adjust by

loosening the lock nut and turning the

adjusting nut.

Lock Nu

t

Adjusting Nu

t

Fuel Filte

r

Do not smoke or allow flames or sparks

in your working area.

*

Fuel Line

Lock Nu

t

Adjusting Nu

t

2Д6m

m

Page 40

3. INSPECTION/ADJUSTMENT

3-4

FILLY LX 50

AIR CLEANER

AIR CLEANER REPLACEMENT

Remove the air cleaner case cover screws and

the cover by removing the seven screws.

Remove the air cleaner element by removing

the four screws.

Check the element and replace it if it is

excessively dirty or damaged.

CHANGE INTERVAL

More frequent replacement is required when

riding in unusually dusty or rainy areas.

SPARK PLUG

Remove the spark plug.

Check the spark plug for wear and fouling

deposits.

Clean any fouling deposits with a spark plug

cleaner or a wire brush.

Specified Spark Plug:

CHAMPION-P-RZ9HC

Measure the spark plug gap.

Spark Plug Gap: 0.6Д0.7mm

Cracks

Damage

Gap, Wear, and

Fouling Deposits

xThe air cleaner element has a viscous

type paper element. Do not clean it

with any fluid.

xBe sure to install the air cleaner

element and cover securely.

*

When installing, first screw in the spar

k

plug by hand and then tighten it with a

spark plug wrench.

*

Screws

Air Cleaner Case Cove

r

Air Cleaner Elemen

t

Washe

r

Deformation

Page 41

3. INSPECTION/ADJUSTMENT

3-5

AGILITY 50

VALVE CLEARANCE

Remove the frame cover. (Ö2-3)

Remove the six bolts on the cylinder head

cover.

Remove the cylinder head cover. (Ö7-3)

Remove the cylinder head cover..

Turn the flywheel counterclockwise so that

the “T” mark on the flywheel aligns with the

index mark on the crankcase to bring the

round hole on the camshaft gear facing up to

the top dead center on the compression

stroke.

Inspect and adjust the valve clearance.

Valve Clearance: IN : 0.04mm

EX: 0.04mm

Loosen the lock nut and adjust by turning the

adjusting nut

Tappet Adjuster

CARBURETOR IDLE SPEED

Remove the inspection cover.

Warm up the engine before this operation.

Start the engine and connect a tachometer.

Turn the throttle stop screw to obtain the

specified idle speed.

Idle Speed: 1900Ô100rpm

When the engine misses or run erratic, adjust

the pilot screw.

Throttle Stop Screw

Inspect and adjust valve clearance while

the engine is cold (below 35Ċ).

*

Special

xCheck the valve clearance again afte

r

the lock nut is tightened.

*

xThe engine must be warm for accurate

idle speed inspection and adjustment.

*

Cylinder Head Cove

r

Bolts

Round Hole

Tappet Adjuste

r

Feeler Gauge

Page 42

3. INSPECTION/ADJUSTMENT

3-6

FILLY LX 50

IGNITION TIMING

Remove the right of the fan cover.

Check the ignition timing with a timing light.

When the engine is running at idle speed, the

ignition timing is correct if the “F” mark on

the flywheel aligns with the index mark on

the crankcase.

Also use a timing light to check the advance.

Raise the engine speed to 4,000rpm and the

index mark on the crankcase cover should be

aligned with the advance mark on the

flywheel.

CYLINDER COMPRESSION

Warm up the engine before compression test.

Remove the met-in box and center cover.

(Ö2-3)

Remove the spark plug.

Insert a compression gauge.

Open the throttle valve fully and push the

starter button to test the compression.

Compression: 16kg/cm2rpm

If the compression is low, check for the

following:

ΘLeaky valves

ΘValve clearance to small

ΘLeaking cylinder head gasket

ΘWorn piston rings

ΘWorn piston/cylinder

If the compression is high, it indicates that

carbon deposits have accumulated on the

combustion chamber and the piston head.

Compression Gauge

Timing Ligh

t

The CDI unit is not adjustable. If the

ignition timing is incorrect, check the

ignition system. (Ö15-5)

*

Timing Hole Cap

Advance Mark

“F” Mark

Page 43

3. INSPECTION/ADJUSTMENT

3-7

AGILITY 50

FINAL REDUCTION GEAR OIL

OIL LEVEL CHECK

Stop the engine and remove the oil check bolt.

The oil level shall be at the oil check bolt

hole.

If the oil level is low, add the recommended

oil to the proper level.

Recommended Oil: SAE90#

Install the oil check bolt.

OIL CHANGE

Remove the oil check bolt.

Remove the oil drain bolt and drain the oil

thoroughly.

Install the oil drain bolt.

Torque: 0.8~1.2kgf-m

Fill with the recommended oil.

Oil Capacity: At disassembly : 0.11 liter

At change : 0.10 liter

Reinstall the oil check bolt and check for oil

leaks.

Torque:0.8~1.2kgf-m

DRIVE BELT

Remove the left crankcase cover. (Ö9-2)

Inspect the drive belt for cracks or excessive

wear.

Replace the drive belt with a new one if

necessary and in accordance with the

Maintenance Schedule.

Drive Bel

t

Oil Check Bolt/Sealing Washe

r

Place the motorcycle on its main stan

d

on level ground for oil level check.

*

Make sure that the sealing washer is in

good condition.

*

Oil Check Bolt Hole

Oil Drain Bolt/ Sealing Washe

r

Make sure that the sealing washer is in

good condition.

*

Page 44

3. INSPECTION/ADJUSTMENT

3-8

FILLY LX 50

BRAKE SHOE

Replace the brake shoes if the arrow on the

wear indicator plate aligns with the punch

mark on the brake panel when the brake is

fully applied.

Refer to page 12-7 and 13-3 for brake shoe

replacement.

REAR BRAKE

Measure the rear brake lever free play.

Free Play: 10Д20mm

BRAKE ADJUSTING NUT

If the free play do not fall within the limit,

adjust by turning the adjusting nut.

BRAKE FLUID

Turn the steering handlebar upright and check

if the rear brake fluid level should be between

the upper and lower level lines.

Specified Brake Fluid: DOT-4f

Arrows

Adjusting Nu

t

Punch Mark

Upper Line

Lower Line

Page 45

3. INSPECTION/ADJUSTMENT

3-9

AGILITY 50

If the free play do not fall within the limit,

adjust by turning the adjusting nut.

HEADLIGHT AIM

Turn the ignition switch ON and start the

engine.

Turn on the headlight switch.

Adjust the headlight aim by turning the

headlight aim adjusting screw.

CLUTCH SHOE WEAR

Start the engine and check the clutch

operation by increasing the engine speed

gradually.

If the motorcycle tends to creep, or the engine

stalls, check the clutch shoes for wear and

replace if necessary. (Ö9-11)

SUSPENSION

FRONT

Fully apply the front brake lever and check

the action of the front shock absorbers by

compressing them several times.

Check the entire shock absorber assembly for

oil leaks, looseness or damage.

Adjusting Screw

Adjusting Nu

t

clutc

h

Front Cove

r

Page 46

3. INSPECTION/ADJUSTMENT

3-10

FILLY LX 50

REAR

Check the action of the rear shock absorber

by compressing it several times.

Check the entire shock absorber assembly for

oil leaks, looseness or damage.

Jack the rear wheel off the ground and move

the rear wheel sideways with force to see if

the engine hanger bushings are worn.

NUTS/BOLTS/FASTENERS

Check all important chassis nuts and bolts for

looseness.

Tighten them to their specified torque values

if any looseness is found. (Ö1-11)

WHEELS/TIRES

Check the tires for cuts, imbedded nails or

other damages.

Check the tire pressure.

TIRE PRESSURE

1 Rider 2 Riders

Front 1.5kg/cm

2

1.75kg/cm

2

Rear 2.00kg/cm

2

2.25kg/cm

2

TIRE SIZE

Front: 120/70-12

Rear : 130/70-12

Check the front axle nut for looseness.

Check the rear axle nut for looseness.

If the axle nuts are loose, tighten them to the

specified torques.

Torques: Front : 5.0Д7.0kgf-m

Rear : 11Д13kgf-m

Tire pressure should be checked when

tires are cold.

*

Front Axle Nu

t

Page 47

3. INSPECTION/ADJUSTMENT

3-11

AGILITY 50

STEERING HANDLEBAR

Check that the control cables do not interfere

with handlebar rotation.

Raise the front wheel off the ground and

check that the steering handlebar rotates

freely.

If the handlebar moves unevenly, binds, or

has vertical movement, adjust the steering

head bearing.

Page 48

4. LUBRICATION SYSTEM

4-0

AGILITY 50

Oil PumpOil Filter Screen

Crankshaft

4 LUBRICATION SYSTEM

4

Rocker Arm Shaft

Page 49

4. LUBRICATION SYSTEM

4-1

AGILITY 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

xThe maintenance of lubrication system can be performed with the engine installed in the frame.

xUse care when removing and installing the oil pump not to allow dust and foreign matters to

enter the engine and oil line.

xDo not attempt to disassemble the oil pump. The oil pump must be replaced as a set when it

reaches its service limit.

xAfter the oil pump is installed, check each part for oil leaks.

SPECIFICATIONS

Item Standard (mm) Service Limit (mm)

Inner rotor-to-outer rotor clearance 0.12

Oil pump Outer rotor-to-pump body clearance 0.12

Rotor end-to-pump body clearance 0.05Д0.10 0.2

TROUBLESHOOTING

Oil level too low Poor lubrication pressure

xNatural oil consumption x Oil level too low

xOil leaks x Clogged oil filter or oil passages

xWorn or poorly installed piston rings x Not use the specified oil

xWorn valve guide or seal

SERVICE INFORMATION.......................4-1 ENGINE OIL/OIL FILTER ......................4-2

TROUBLESHOOTING .............................4-1 OIL PUMP................................................. 4-3

Page 50

4. LUBRICATION SYSTEM

4-2

AGILITY 50

ENGINE OIL/OIL FILTER

OIL LEVEL

Remove the oil dipstick and check the oil

level with the oil dipstick.

If the level is near the lower level, fill to the

upper level with the specified engine oil.

OIL CHANGE

Remove the drain bolt to drain the engine oil

thoroughly.

Remove the oil filter screen cap and clean the

oil filter screen with compressed air.

Check the filter screen O-ring for damage and

replace if necessary.

Install the oil filter screen, spring and filter

screen cap.

Torque: 1.0~2.0kgf-m

Fill the crankcase with the specified engine

oil to the proper level.

Oil Capacity: At disassembly : 0.85 liter

At change : 0.70 liter

Check for oil leaks and then start the engine

and let it idle for few minutes.

Recheck the oil level.

Oil Dipstick

O-ring

Oil Filter Screen Cap

xPlace the motorcycle upright on level

ground for engine oil level check.

xRun the engine for 2Д3 minutes and

check the oil level after the engine is

stopped for 2Д3 minutes.

*

The engine oil will drain more easily

while the engine is warm.

*

Page 51

4. LUBRICATION SYSTEM

4-3

AGILITY 50

Bol

t

Right Crankcase Cove

r

Oil Pump Drive Gear

Circlip

Oil Pump Gear

Oil Pump

Bolts

O-rings

OIL PUMP

REMOVAL

Remove the A.C. generator flywheel. (Ö14-7)

Remove the A.C. generator stator and pulsar

coil. (Ö14-6)

Remove the eight right crankcase cover bolts

and the right crankcase cover.

Remove the gasket and dowel pins.

Remove the oil pump drive gear circlip.

Remove the oil pump gear.

Remove the oil pump mounting bolts.

Remove the oil pump.

Remove the two O-rings.

Inspect the two O-rings for damage or

deterioration.

Page 52

4. LUBRICATION SYSTEM

4-4

AGILITY 50

Screws

Outer Rotor

Oil Pump Boby

Outer Rotor

Inner Rotor

DISASSEMBLY

Remove the three oil pump boby screws.

Disassembly the oil pump.

INSPECTION

Measure the pump boby-to-outer rotor

clearance.

Service Limit: 0.12mm

Measure the inner rotor-to-outer rotor

clearance.

Service Limit: 0.12mm

Measure the rotor end-to- pump boby

clearance.

Service Limit: 0.2mm

Oil Pump Boby

Page 53

4. LUBRICATION SYSTEM

4-5

AGILITY 50

Pump Cove

r

Screws

Inner Rotor

O-rings

Bolts

Outer Rotor

Pum

p

Shaf

t

Oil pump

ASSEMBLY

Install the outer rotor, inner rotor and pump

shaft into the pump boby.

Install the pump cover and tighten the screws

to secure the pump cover.

INSTALLATION

First install the two O-rings onto the oil pump

base.

Install the oil pump into the crankcase.

After the oil pump is installed, tighten the

three mounting bolts.

Install the pump shaft by aligning the flat

on the shaft with the flat in the inner

rotor.

*

Fill the oil pump with engine oil before

installation.

*

Page 54

4. LUBRICATION SYSTEM

4-6

AGILITY 50

Bolts

Right Crankcase Cove

r

Pump Driven Gear

Circlip

Install the pump driven gear and secure it

with the circlip.

Torque: 0.8Д1.2kg-m

Install the right crankcase cover and tighten

the eight bolts.

Torque: 0.8~1.2kgf-m

Diagonally tighten the bolts in 2Д3

times.

*

Page 55

5. FUEL SYSTEM

5-0

AGILITY 50

5

5

Page 56

5. FUEL SYSTEM

5-1

AGILITY 50

Fuse

12V Battery

Regulato

r

/Rectifier

L/Y

W

Auto Bystarte

r

Ignition Switch

CDI Unit

B

G

Y

Y

Lighting

System

Resistor

5

:

5W

G/B

.

Page 57

5. FUEL SYSTEM

5-2

AGILITY 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

xWhen disassembling the carburetor, be sure to service the vacuum piston and float chamber.

xDo not bend or twist control cables. Damaged control cables will not operate smoothly.

xWhen disassembling fuel system parts, note the locations of O-rings. Replace them with new

ones during assembly.

xBefore float chamber disassembly, loosen the drain screw to drain the residual gasoline into a

clean container.

xAfter the carburetor is removed, plug the intake manifold side with a clean shop towel to prevent

foreign matters from entering.

xRemove the vacuum diaphragm before cleaning the carburetor air and fuel passages with

compressed air to avoid damaging the vacuum diaphragm.

xWhen the motorcycle is not used for over one month, drain the residual gasoline from the float

chamber to avoid erratic idling and clogged slow jet due to deteriorated fuel.

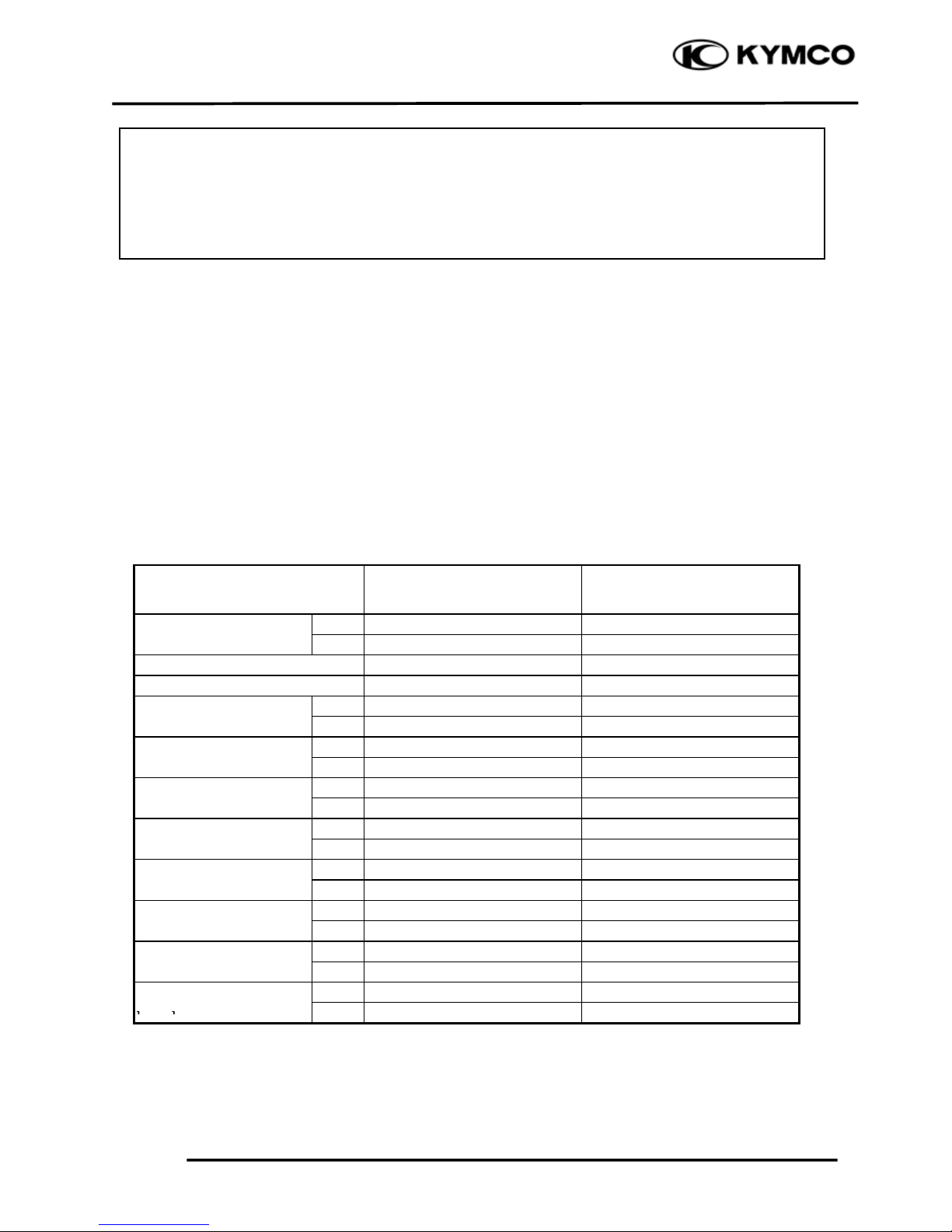

SPECIFICATIONS

Item

Standard

Venturi dia. (mm) 20

Type CVK

Float level (mm) 17

Main jet Commonly: #82 Speed limits vehicle: #80

Slow jet #35

Idle speed 2000rpm±100

Throttle grip free play 2Д6mm

Pilot screw opening 2r

1

/2

Gasoline is very dangerous. When working with gasoline, keep sparks and flames away

from the working area.

Gasoline is extremely flammable and is explosive under certain conditions. Be sure to

work in a well-ventilated area.

SERVICE INFORMATION.......................5-2 ACCELERATING PUMP.......................5-10

TROUBLESHOOTING..............................5-3 CARBURETOR INSTALLATION.........5-11

CARBURETOR REMOVAL.....................5-4 PILOT SCREW ADJUSTMENT ............5-12

AUTO BYSTARTER.................................5-4 FUEL TANK............................................5-13

AIR CUT-OFF VALVE .............................5-6 FUEL UNIT .............................................5-14

VACUUM CHAMBER..............................5-6 AIR CLEANER .......................................5-14

FLOAT CHAMBER...................................5-8

Page 58

5. FUEL SYSTEM

5-3

AGILITY 50

TROUBLESHOOTING

Engine is hard to start Misfiring during acceleration

xNo spark at plug (ÖSection 15) x Faulty ignition system

xCompression too low x Lean mixture

xNo fuel to carburetor x Faulty accelerating pump

Clogged fuel filter Engine idles roughly, stalls or runs poorly

Restricted fuel line x Clogged fuel system

Faulty float valve x Ignition malfunction

Incorrectly adjusted float level x Rich or lean mixture

xEngine flooded with fuel x Contaminated fuel

Clogged air cleaner x Intake air leak

Fuel overflowing x Incorrect idle speed

xIntake air leak x Incorrectly adjusted pilot screw

xContaminated fuel x Clogged idle system or auto bystarter passages

xFaulty auto bystarter x Incorrectly adjusted float level

xClogged idle system or auto bystarter passages Lean mixture

Rich mixture x Clogged fuel jets

xFaulty auto bystarter x Faulty float valve

xFaulty float valve x Float level too low

xFloat level too high x Clogged fuel system

xClogged air jets x Intake air leak

xDirty air cleaner x Improper vacuum piston operation

xFlooded carburetor x Improper throttle operation

Backfiring at deceleration

xLean mixture in idle system

xImproper air cut-off valve operation

Page 59

5. FUEL SYSTEM

5-4

AGILITY 50

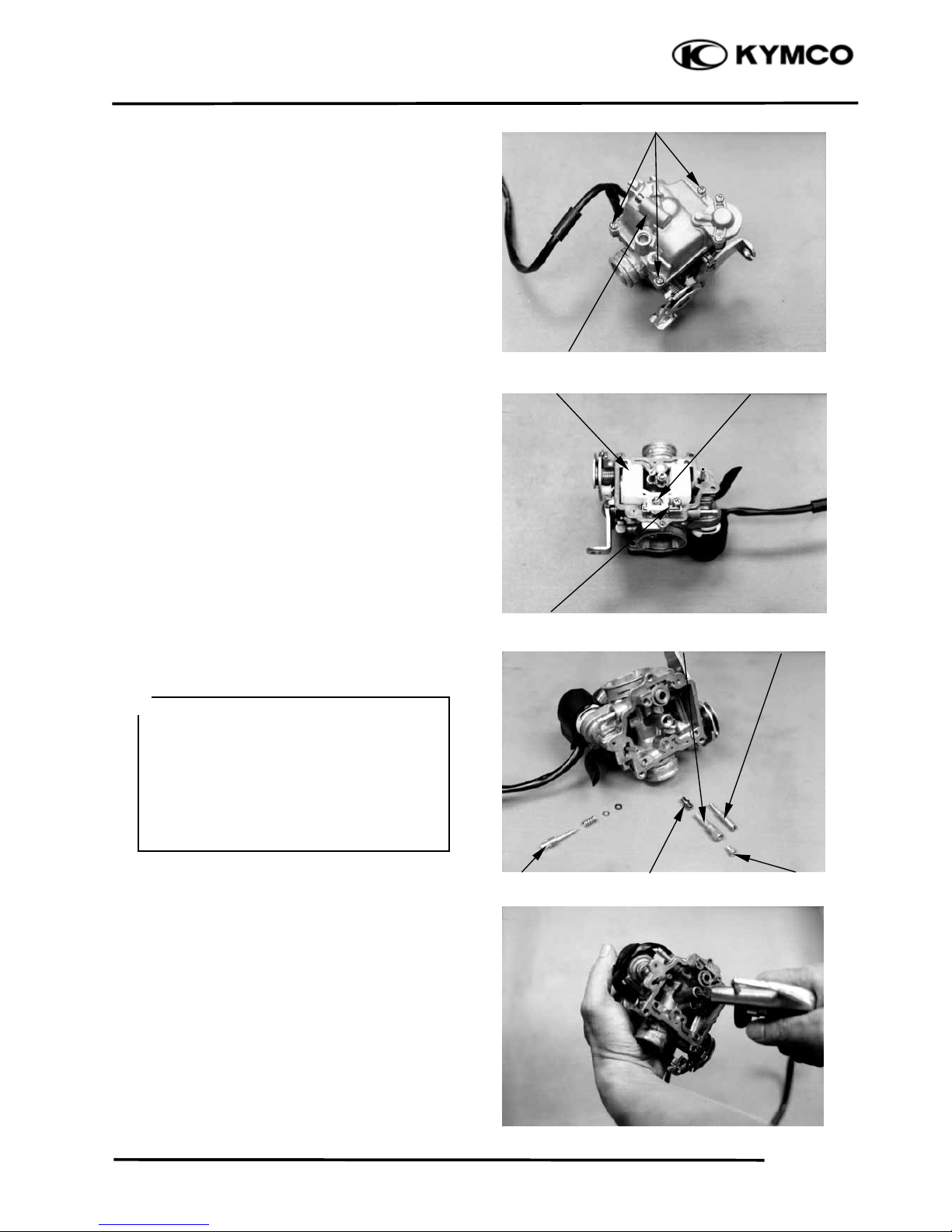

CARBURETOR REMOVAL

Remove the frame right side cover. (Ö2-4)

Disconnect the auto bystarter wire

connector.

Remove the met-in box. (Ö2-3)

Loosen the drain screw and drain the fuel

from the float chamber.

Disconnect the fuel tube and vacuum tube at

the carburetor.

Loosen the throttle cable adjusting nut and

lock nut, and disconnect the throttle cable

from the carburetor.

Loosen the carburetor intake manifold band

and air cleaner connecting tube band screws

and then remove the carburetor.

AUTO BYSTARTER

OPERATION INSPECTION

Measure the resistance between the auto

bystarter wire terminals.

Resistance:10: max. (10 minutes

minimum after stopping the engine)

If the reading is not within the limit, replace

the auto bystarter with a new one.

Adjusting Nu

t

Fuel Tube

Intake Manifold

Band

Air Cleaner Connectin

g

Tube Band

Throttle Cable

Lock Nu

t

A

uto Bystarter Wire

A

uto Bystarte

r

Page 60

5. FUEL SYSTEM

5-5

AGILITY 50

Connect a hose to the fuel enriching circuit of

the carburetor. Connect the auto bystarter

yellow wire to the positive (+) terminal of a

battery and green wire to the negative (-)

terminal. Wait 5 minutes and blow the hose

with mouth or vacuum pump. If the passage

is blocked, the auto bystarter is normal.

Disconnect the auto bystarter from the

battery. Wait 30 minutes and blow the hose

with mouth or vacuum pump. If air can be

blown into the hose, the auto bystarter is

normal.

REMOVAL

Remove the set plate screws and set plate.

Remove the auto bystarter from the

carburetor.

AUTO BYSTARTER INSPECTION

Check the auto bystarter valve and needle

for nicks, wear or damage.

If any faulty part is found, replace the auto

bystarter as a set.

INSTALLATION

Insert the auto bystarter into the carburetor

body until it bottoms.

Position the set plate into the groove in the

auto bystarter and tighten the screws.

Auto Bystarte

r

Screws

Bystarter Needle

Bystarter Valve

Auto Bystarte

r

Screws

Set Plate

Vacuum Pump

Adopte

r

Set Plate

xBe sure to install the auto bystarter an

d

set plate properly.

xInstall the set plate with its bottom face

facing down.

*

Page 61

5. FUEL SYSTEM

5-6

AGILITY 50

AIR CUT-OFF VALVE

DISASSEMBLY

Remove the two screws attaching the

throttle cable set plate and the set plate.

Remove the two screws attaching the air

cut-off valve.

Remove the spring and vacuum diaphragm.

Check the vacuum diaphragm for cracks or

damage and check each passage for

clogging.

ASSEMBLY

Install the vacuum diaphragm onto the

carburetor.

Install the spring and air cut-off valve cover.

Install the throttle cable set plate and tighten

the two screws.

VACUUM CHAMBER

DISASSEMBLY

Remove the two vacuum chamber cover

screws and the cover.

Remove the spring and vacuum diaphragm/

piston.

Spring

Spring

Throttle Cable Set Plate

Vacuum Diaphragm/Piston

Air Cut-off Valve Cove

r

Cove

r

Screws

O-rin

g

Screws

Screws

xBe sure to set the vacuum diaphrag

m

lip into the groove on the carburetor.

xWhen installing the air cut-off valve

cover, make sure that the vacuum

diaphragm is properly installed.

*

Diaphrag

m

Vacuum Chamber Cove

r

Spring

Page 62

5. FUEL SYSTEM

5-7

AGILITY 50

Remove the needle holder and jet needle.

INSPECTION

Inspect the needle for stepped wear.

Inspect the vacuum piston for wear or

damage.

Inspect the diaphragm for deterioration and

tears.

ASSEMBLY

Install the vacuum piston/diaphragm in the

carburetor body.

Install the spring and then install the

vacuum chamber cover.

Tighten the two screws.

Vacuum Chamber Cove

r

Vacuum Diaphrag

m

Jet Needle

Vacuum Diaphrag

m

Be careful not to damage the vacuu

m

diaphragm.

*

xBe careful not to damage the diaphragm.

xHold the vacuum piston while

tightening the vacuum chamber cover.

*

Page 63

5. FUEL SYSTEM

5-8

AGILITY 50

FLOAT CHAMBER

DISASSEMBLY

Remove the three float chamber screws and

the float chamber.

Loosen the float pin screw.

Remove the float pin, float and float valve.

Remove the main jet, needle jet holder,

needle jet, slow jet and pilot screw.

Clean the removed fuel jets with detergent

oil and blow them open with compressed

air.

Blow compressed air through all passages

of the carburetor body.

Pilot Screw

Float ValveFloa

t

Float Pin

Float Chambe

r

Slow Je

t

Main Je

t

N

eedle Jet Holde

r

N

eedle Je

t

Screws

xBe careful not to damage the fuel jets

and pilot screw.

xBefore removing, turn the pilot screw

in and carefully count the number of

turns until it seats lightly and then

make a note of this.

xDo not force the pilot screw against its

seat to avoid seat damage.

*

Page 64

5. FUEL SYSTEM

5-9

AGILITY 50

INSPECTION

Inspect the float valve and valve seat for

damage or clogging.

Inspect the float valve and valve seat

contact area for stepped wear or

contamination.

ASSEMBLY

Install the slow jet, needle jet, needle jet

holder, main jet and pilot screw.

Standard Opening: 2r

1

/2

turns

Install the float valve, float and float pin.

Secure the float pin with the screw.

FLOAT LEVEL INSPECTION

Measure the float level.

Float Level: 17.0mm

This installation sequence is the reverse of

removal.

Float Level Gauge

Float Valve

xCheck the operation of the float valve

and float before this inspection.

xMeasure the float level by placing the

float level gauge on the float chamber

face parallel with the main jet.

*

Float Pin

Pilot Screw

Slow Je

t

Main Je

t

N

eedle Jet Holde

r

N

eedle Je

t

Valve Sea

t

Floa

t

Screw

Worn or contaminated float valve an

d

valve seat must be replaced because it

will result in float level too high due to

incomplete airtightness.

*

Return the pilot screw to the original

position as noted during removal.

*

Page 65

5. FUEL SYSTEM

5-10

AGILITY 50

ACCELERATING PUMP

DISASSEMBLY

Remove the two accelerating pump cover

screws and accelerating pump cover.

Remove the spring and accelerating pump

diaphragm.

INSPECTION

Inspect the accelerating pump diaphragm

for cracks, damage or deterioration.

Replace if necessary.

Check each accelerating pump fuel passage

for clogging

Clean and blow them open with compressed

air.

Install the accelerating pump in the reverse

order of removal.

Compressed Ai

r

Screws

Diaphrag

m

Diaphrag

m

Compressed Ai

r

Be careful not to damage the diaphragm

during installation.

*

Page 66

5. FUEL SYSTEM

5-11

AGILITY 50

CARBURETOR INSTALLATION

Tighten the drain screw.

Install the carburetor onto the intake

manifold, aligning the tab on the carburetor

with the cutout in the intake manifold.

Tighten the intake manifold band screw.

Install the air cleaner connecting tube and

tighten the band screw.

Connect the throttle cable to the throttle

wheel on the carburetor.

Tighten the lock nut.

Connect the fuel tube and vacuum tube to

the carburetor.

Connect the auto bystarter wire connector.

Perform the following inspections and

adjustments:

-Throttle grip free play (Ö3-3)

-Carburetor idle speed (Ö3-5)

Auto Bystarter Wire Connecto

r

Fuel Tube

Connecting Tube Band

Throttle Cable

Throttle Cable

Lock Nut

Adj

usting Nut

Page 67

5. FUEL SYSTEM

5-12

AGILITY 50

PILOT SCREW ADJUSTMENT

*

ADJUSTMENT

A tachometer must be used when adjusting

the engine speed.

Turn the pilot screw clockwise until it seats

lightly and back it out to the specification

given.

Standard Opening: 2r

1

/2

turns

Warm up the engine and adjust the throttle

stop screw to obtain the specified idle

speed.

Idle Speed: 1900Ô100rpm

Turn the pilot screw in or out slowly to

obtain the highest engine speed.

Slightly accelerate several times to make

sure that the idle speed is within the

specified range.

If the engine misses or runs erratic, repeat

the above steps.

Pilot Screw

Throttle Stop Screw

xThe pilot screw is factory pre-set an

d

no adjustment is necessary. During

carburetor disassembly, note the

number of turns of the pilot screw and

use as a reference when reinstalling it.

xPlace the motorcycle on its main stand

on level ground for this operation.

*

xThe carburetor must be adjusted when

the engine is warm and the auto

bystarter is closed.

xDo not force the pilot screw against its

seat to prevent damage.

*

Page 68

5. FUEL SYSTEM

5-13

AGILITY 50

FUEL TANK REMOVE

Remove the net-in box. (Ö2-3)

Remove the frame center cover.

Remove the frame body cover. (Ö2-3)

Remove the four bolts on the fuel tank, take

the upper seat lock off.

Disconnect the fuel unit wire connector.

Remove the fuel tank.

The installation sequence is the reverse of

removal.

FUEL STRAINER REMOVAL

Remove the fuel strainer from the fuel tank.

INSPECTION

Inspect if the fuel strainer is clogged and

clean it with compressed air.

INSTALLATION

Install the fuel strainer with its arrow mark

toward the fuel pump.

Bolts

xWhen removing the fuel strainer, do

not allow flames or sparks near the

working area and drain the residual

gasoline into a container.

*

Seat Loc

k

Arrow Mar

k

Fuel Straine

r

Fuel

Tank

Fuel Unit Wite

Connector

Page 69

5. FUEL SYSTEM

5-14

AGILITY 50

FUEL UNIT

REMOVAL

Remove the related parts.

Disconnect the fuel unit wire connector.

Turn the fixed plate on the fuel unit,take the

fuel unit off.

INSTALLATION

Inspet if the fuel unit is damaged,or harden.

Assemble the fuel unit in the reverse order

of disassembly.

AIR CLEANER

Loosen the air cleaner connecting tube band

screw.

Disconnect the clinhead cover breather tube

from the air cleaner.

Remove the two bolts and air cleaner case.

Fuel Unit Wire

Align Mark

Fuel Unit

Fuel Tank

Do not bend the float arm on the fuel

unit,otherwise the figure on the fuel

meter will not correct.

*

xAlign the groove on the fuel unit with

the angle on the fuel tank.

xInspect if the fuel tank leaked after

installing and filling the gasoling.

*

b

olts

air cleane

r

Page 70

5. FUEL SYSTEM

5-15

AGILITY 50

The installation sequence is the reverse of removal.

Page 71

6. ENGINE REMOVAL/INSTALLATION

6-0

FILLY LX 50

6

6

Page 72

6. ENGINE REMOVAL/INSTALLATION

6-1

FILLY LX 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

xA floor jack or other adjustable support is required to support and maneuver the engine. Be

careful not to damage the motorcycle body, cables and wires during engine removal.

xUse shop towels to protect the motorcycle body during engine removal.

xParts requiring engine removal for servicing:

Crankcase

Crankshaft

SERVICE INFORMATION...................... 6-1 ENGINE INSTALLATION.......................6-4

ENGINE REMOVAL................................ 6-2

Page 73

6. ENGINE REMOVAL/INSTALLATION

6-2

FILLY LX 50

ENGINE REMOVAL

Disconnect the battery negative cable.

Remove the frame body cover. (Ö2-3)

Disconnect the spark plug high tension wire.

Disconnect the auto bystarter wire connector.

Disconnect the A.C. generator wire

connector.

Disconnect the starter motor cable and earth

cable from the starter motor.

Remove the fuel tube.

Remove the spark plug cap.

Disconnect the vacuum tube.

Loosen the throttle cable adjusting nut and

lock nut, and disconnect the throttle cable

from the carburetor.

Auto Bystarter Wire Connecto

r

Vacuum Tube

Spark Plug High Tension Wire

Band

N

egative Cable

S

tarter Motor Cable

Earthr Cable

Lock Nut

Adjusting Nut

Page 74

6. ENGINE REMOVAL/INSTALLATION

6-3

FILLY LX 50

Loosen the drive belt air cleaner connecting

tube band screw and remove the connecting

tube.

Remove the rear brake adjusting nut,

connector pin rear brake cable.

Remove the rear shock absorber upper mount

bolt.

Remove the engine mounting bolt and move

the motorcycle forward to separate it from the

engine.

Support the motorcycle with a floor jack.

Rear Shock Absorber Upper Mount Bol

t

connecting tube

Air Tube Band

Adjusting Nut

Engine Mounting Bol

t

Engine Hange

r

Bracket Bolt

Page 75

6. ENGINE REMOVAL/INSTALLATION

6-4

FILLY LX 50

ENGINE HANGER BRACKET

REMOVAL

Remove the return spring from the main

stand.

Remove the main stand.

Remove the engine hanger bracket bolts and

engine hanger bracket.

Inspect the engine hanger bushings and

stopper spring for wear or damage.

ENGINE HANGER BRACKET

INSTALLATION

Install the engine hanger bracket to the

chassis and tighten the bolt.

Install the main stand onto the engine and

install the return spring.

ENGINE INSTALLATION

Install the engine and tighten the engine

mounting bolt.

Torque: 4.5~5.5kgf-m

Tighten the rear shock absorber upper mount

bolt.

Torque: 4.5~5.5kgf-m

Bushing

Engine Mounting Bol

t

Return Sprin

g

Main Stand

Return Sprin

g

Main Stand

Stopper Spring

Engine Hanger Bracket Bol

t

Page 76

6. ENGINE REMOVAL/INSTALLATION

6-5

FILLY LX 50

Install the removed parts in the reverse order

of removal.

After installation, inspect and adjust the

following:

xThrottle grip free play (

Ö

3-3)

xRear brake adjustment (

Ö

3-8)

Rear Shock Absorber Upper Mount Bol

t

Route the wires and cables properly.

*

Page 77

7. CYLINDER HEAD/VALVES

7-0

AGILITY 50

7

7

Page 78

7. CYLINDER HEAD/VALVES

7-1

FILLY LX 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

xThe cylinder head can be serviced with the engine installed in the frame.

xWhen assembling, apply molybdenum disulfide grease or engine oil to the valve guide movable

parts, valve arm and camshaft sliding surfaces for initial lubrication.

xThe camshaft is lubricated by engine oil through the cylinder head engine oil passages. Clean and

unclog the oil passages before assembling the cylinder head.

xAfter disassembly, clean the removed parts and dry them with compressed air before inspection.

xAfter removal, mark and arrange the removed parts in order. When assembling, install them in

the reverse order of removal.

SPECIFICATIONS

Item

Standard (mm) Service Limit (mm)

IN 0.04

EX 0.04

Cylinder head compression 14kg/cm

2

Cylinder head warpage 0.05

IN 26.438 26.038

EX 25.807 25.407

IN 10.000-10.015 10.10

EX 10.000-10.015 10.10

Valve rocker arm shaft IN 9.972-9.987 9.91

O.D.

EX 9.972-9.987 9.91

IN 1.0 1.8

EX 1.0 1.8

IN 4.975-4.990 4.9

EX 4.955-4.970 4.9

IN 5.000-5.012 5.03

EX 5.000-5.012 5.03

Valve stem-to-guide IN 0.010-0.037 0.08

clearance

EX 0.030-0.057 0.1

Inne

r

31.1 30.1

Oute

r

34.35 33.3

SERVICE INFORMATION......................7-1 CYLINDER HEAD DISASSEMBLY.......7-7

TROUBLESHOOTING ............................7-2 CYLINDER HEAD ASSEMBLY.............7-8

CAMSHAFT REMOVAL.........................7-3 CYLINDER HEAD INSTALLATION .....7-8

CYLINDER HEAD REMOVAL..............7-5 CAMSHAFT INSTALLATION................7-9

Valve clearance (cold)

Camshaft cam height

Valve rocker arm I.D.

Valve seat width

Valve stem O.D.

Valve guide I.D.

Valve spring free

Page 79

7. CYLINDER HEAD/VALVES

7-2

AGILITY 50

TORQUE VALUES

Cylinder head nut 1.8~2.2kgf-m Apply engine oil to threads

Valve clearance adjusting nut 0.7~1.1kgf-m Apply engine oil to threads

SPECIAL TOOLS

Valve spring compressor

TROUBLESHOOTING

xThe poor cylinder head operation can be diagnosed by a compression test or by tracing engine

top-end noises.

Poor performance at idle speed White smoke from exhaust muffler

xCompression too low x Worn valve stem or valve guide

x Damaged valve stem seal

Compression too low

xIncorrect valve clearance adjustment Abnormal noise

xBurned or bend valves x Incorrect valve clearance adjustment

xIncorrect valve timing x Sticking valve or broken valve spring

xBroken valve spring x Damaged or worn camshaft

xPoor valve and seat contact x Worn cam chain guide

xLeaking cylinder head gasket x Worn camshaft and rocker arm

xWarped or cracked cylinder head

x Poorly installed spark plug

Compression too high

xExcessive carbon build-up in combustion

chamber

Page 80

7. CYLINDER HEAD/VALVES

7-3

FILLY LX 50

CAMSHAFT REMOVAL

Remove the center cover. (Ö2-3)

Remove the frame center.

Remove the four cylinder head cover bolts to

remove the cylinder head cover.

Remove the cam chain tensioner sealing bolt

and spring.

Remove the two bolts attaching the cam chain

tensioner and the tensioner.

Turn the flywheel counterclockwise so that

the “T” mark on the flywheel aligns with the

index mark on the crankcase to bring the

round hole on the camshaft gear facing up to

the top dead center on the compression

stroke.

Remove the two cylinder head bolts.

Remove the four cylinder head nuts and

washers.

Remove the camshaft holder.

Cylinder Head Cove

r

Sealing Bol

t

Round Hole

Camshaft Gea

r

Bolts

Diagonally loosen the cylinder head nuts

in 2 or 3 times.

*

Punch Marks

Washe

r

Nut

Page 81

7. CYLINDER HEAD/VALVES