Page 1

INSTRUCTION MANUAL

AIR EJECT

AUTOMATIC AIR LINE DISCONNECT

MODEL #091-28HP

BOOK# 091-28-1

20 PSI MIN.

175 PSI MAX.

1 YEAR WARRANTY

KUSSMAUL ELECTRONICS CO., INC.

170 CHERRY AVE., WEST SAYVILLE, N.Y. 11796

TEL: in NY 631-567-0314 TOLL FREE: 800-346-0857 FAX: 631-567-5826

Page 2

INTRODUCTION

The Air Eject is a specially designed pneumatic cylinder with an integral solenoid valve

which, when the vehicle is started, disconnects the air line connected to it. The Air

Eject is supplied with the following components:

1. Cylinder Assy

2. Check Valve

3. Gasket

4. Mounting Screws

5. Mating Female Connector

6. Bezel

INSTALLATION

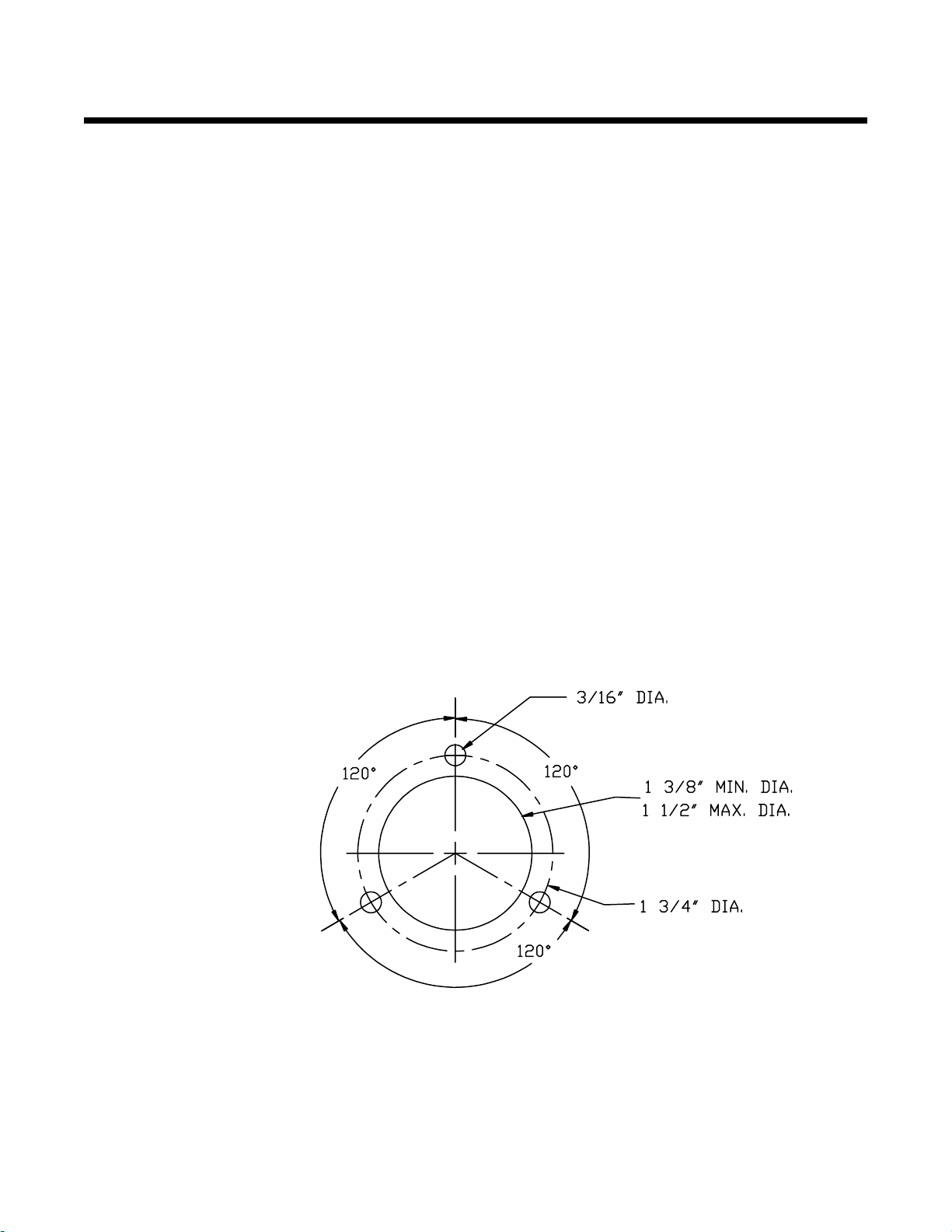

Note: The 1 3/8" diameter hole is critical. If this hole is too

HOLE TEMPLATE

small it will prevent piston from striking Female connector.

Page 3

INSTALLATION

1. In order to accurately locate the 3 mounting holes first locate the center of the large

hole and mark with a center punch mark. Using a compass scribe 1 3/4" dia. circle. Locate

the bezel over this scribed circle, mark the 3 mounting holes & center punch each hole.

2. Drill 3 mounting holes, 3/16" diameter. Drill 1 center hole using hole saw or conduit

punch. 1 3/8" diameter.

3. Mount the Cylinder Assembly as illustrated.

NOTE LOCATION OF ARROW

ON CHECK VALVE

ARROW MARK IS VERY SMALL

OUPUT TO

VECHICLE'S

AIR SYSTEM

CYLINDER

ASSEMBLY

SCREWS

BEZEL

GASKET

TRUCK WALL

MOUNTING AIR EJECT

4. Install the check valve being certain that the arrow on the check valve points away from

the cylinder assembly.

5. Connect tubing as required to vehicle’s air system.

Page 4

WIRING

1. Wire the solenoid valve to the vehicle’s starting circuit. Be certain that the solenoid is

energized only while the vehicle is cranking and deenergized at all other times.

TO STARTER

SWITCH

BATTERY

+

STARTER

_

STARTER

SOLENOID

TO CHASSIS

GROUND

TO CHASSIS

GROUND

WIRING AIR EJECT

AIR

EJECT

MAINTENANCE

The Air Eject is a precision device designed and manufactured for many years of reliable

service. Periodic servicing, cleaning and lubricating are important.

It is suggested that the cylinder assembly be inspected regularly and cleaned and lubricated

at a minimum once every six months.

In applications where contamination by water and road dirt are excessive, more frequent

servicing may be required.

Lubrication should be only with non-petroleum based lubricants such as Dow Corning DC4 Silicone grease, Silicone or Teflon spray.

Page 5

INSTALLATION RECORD & WARRANTY

Date Installed

Installed By

Vehicle Identification

Vehicle Owner

WARRANTY

All products of Kussmaul Electronics Company Inc. are warranted to be

free of defects of material or workmanship. Liability is limited to repairing or

replacing at our factory, without charge, any material or defects which

become apparent in normal use within 1 year from the date the equipment

was shipped. Equipment is to be returned, shipping charges prepaid and will

be returned, after repair, shipping charges paid.

Kussmaul Electronics Company, Inc. shall have no liability for damages

of any kind to associated equipment arising from the installation and /or use

of the Kussmaul Electronics Company, Inc. products. The purchaser, by the

acceptance of the equipment, assumes all liability for any damages which

may result from its installation, use or misuse, by the purchaser, his or its

employees or others.

ALSO AVAILABLE

NEW

MODEL 091-28-AK

WEATHERPROOF ADAPTER KIT

The Weatherproof Adapter Kit provides a recessed mounting for the Air Eject and a gasketed cover which automatically closes when the air line is ejected . A rugged

polypropylene sleeve covering the female coupler permits easy manual removal of the air line and protects the

coupler from damage during automatic release.

NEW COVER

The weatherproof adapter kit

comes with a new cover that has

an Air Eject label inserted on the

front

Loading...

Loading...