Page 1

FILE: IM_091-141_Rev_B

DATE: 10-02-03

INSTRUCTION MANUAL

LOAD MANAGER P

A battery protector for vehicles with equipment that

Is operated with the engine not running

MODEL# 091-141

INPUT: 12 Volts D.C.

MODEL# 091-141-24

INPUT: 24 Volts D.C.

3 YEAR WARRANTY

Page 2

INTRODUCTION

The model 091-141 LOAD MANAGER P is designed to disconnect loads when

the battery voltage drops below a certain threshold. In addition a "Shutdown

Timer" is provided so that the load is disconnected 1 to 2 hours after the engine

is shutdown. This provides the ideal control for the computer or radio in police

cars, rescue vehicles, command vehicles or any application where these devices

might be used with the engine not running. If the operator forgets to shut down

the computer or radio, the battery is protected, as the Load Manager P will turn

off the power before the battery is drained.

12VDC Operation:

The factory pre-set voltage for shutdown is 11.0 volts, but can be

potentiometer adjusted up to 12.85 volts. The factory pre-set shutdown

time is 1 hour (when engine is not running). This time can also be

potentiometer adjusted up to 2 hours.

24VDC Operation:

The factory pre-set voltage for shutdown is 22.0 volts, but can be

potentiometer adjusted from 21.25 to 24.75 volts. The factory pre-set

shutdown time is 1 hour (when engine is not running). This time can also

be potentiometer adjusted up to 2 hours.

Shutdown Timer:

Enabled (factory default) when diode CR4 is installed on Printed Circuit

Board Assembly (refer to Figure 3). Disabling the Shutdown Timer by

removing CR4 will allow load power supply regardless of engine

running/not running status. The load will, however, still be managed as a

function of vehicle battery voltage per voltage shutdown described above.

The Load Manager Model Number will be followed by "DIS" if the Shutdown

Timer is disabled at the factory per customer order.

Page 3

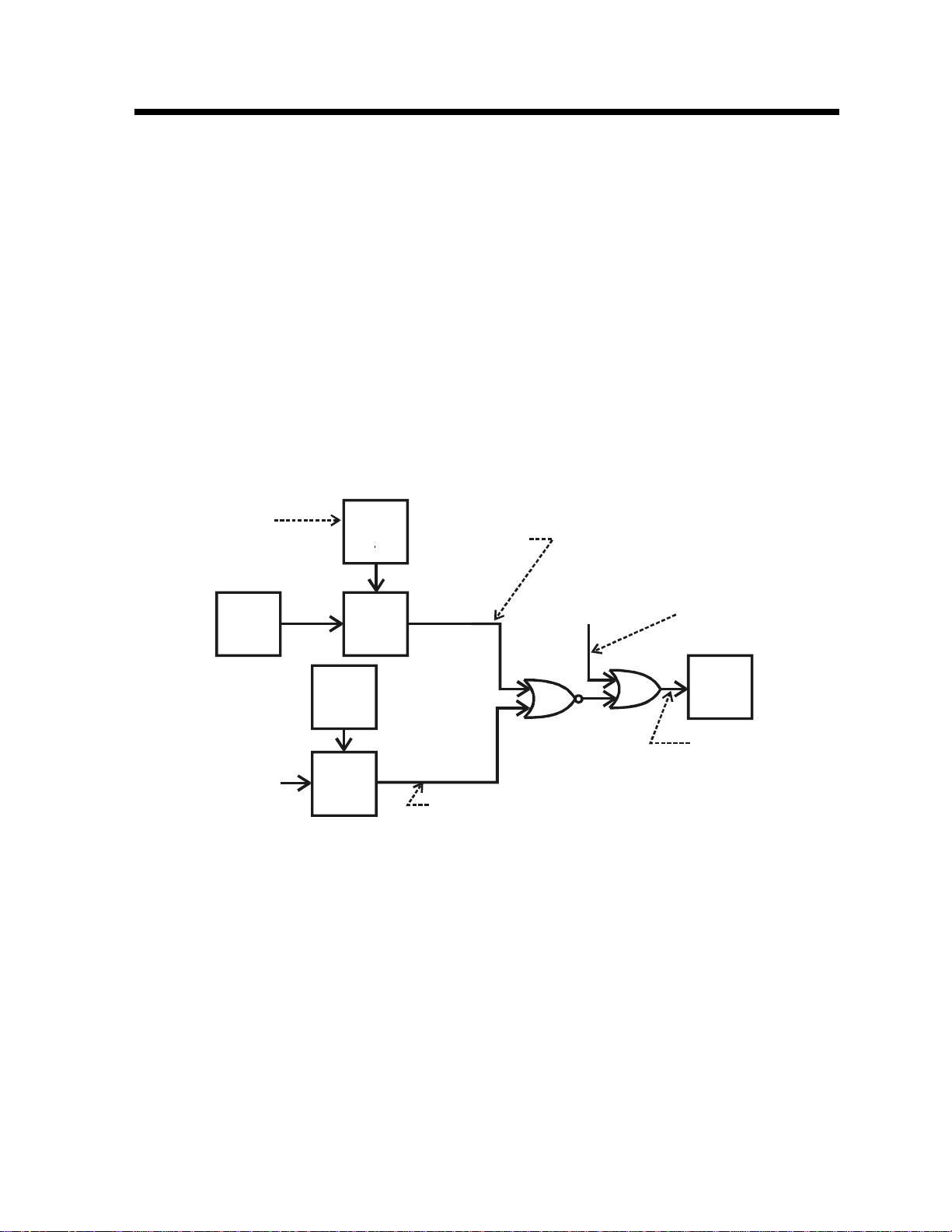

PRINCIPLES OF OPERATION

The Load Manager P is basically a low voltage disconnect which removes power

from the load when the voltage sensed drops below the preset threshold of 11.0

volts for 12VDC operation and 22.0 volts for 24VDC operation. A starter override

is provided to prevent disabling the load while the engine is cranking. This

eliminates re-booting the computer if cranking the engine drops the battery

voltage below the threshold. When the device detects that the engine is not

running a timer is started. After the set time has elapsed the load will be

deenergized. If during the timing cycle, the battery voltage drops below its set

point, the load will be immediately deenergized. Starting the engine at any time

during the timing cycle will reset the timer. A block diagram appears in figure 1.

FACTORY ADJUSTED

TO 1 HOUR

ENGINE

OFF

SENSOR

V

Bat

PRE-SET

ADJUST

TRIMMER

TIMER

1 HOUR

2 HOURS

VOLTAGE

PRE-SET

ADJUST

TRIMMER

VOLTAGE

DETECTOR

TIME

AND ENGINE IS “OFF”

TO

>

T

T

IF TRUE

Sp

STARTER

SWITCH “ON”

V

<

V

IF TRUE

Bat Sp

Figure 1

BLOCK DIAGRAM, LOAD MANAGER P

TRUE WHILE

ENGINE IS

“CRANKING”

POWER

RELAY

IF THIS LINE IS

TRUE, THEN THE

POWER RELAY

IS ENERGIZED

Page 4

INSTALLATION

WIRING:

Figure 2 illustrates the wiring of the Load Manager P. Wire the unit using the

wire gauges shown in figure 2.

RADIO &

COMPUTER

+

LOADS

-

SIZE FUSE

FOR 25% HIGHER

THAN ACTUAL

LOAD

#12 AWG, RED

#12 AWG, ORANGE

NO

C

#12 AWG, BLACK

FROM

12 or 24

VOLT

BATTERY

1

#20 AWG, RED

#20 AWG, BLACK

FROM

STARTER

SWITCH

(0PTIONAL)

23

4

#20 AWG,

YELLOW

Figure 2

INSTALLATION WIRING, LOAD MANAGER P

ALIGNMENT:

Refer to Figure 3 for all component locations and measurement points.

12VDC Operation:

R102 is normally set maximum counter-clockwise for an 11.0 volt threshold.

R102 can be adjusted in a clockwise direction to obtain a higher threshold

voltage. Maximum clockwise is 12.85 volts.

24VDC Operation:

R102 is normally set approximately 70% of full counter-clockwise for a 22.0 volt

threshold. R102 can be adjusted in a clockwise direction to obtain a higher

threshold voltage. Maximum clockwise is 24.75 volts, maximum counterclockwise is 21.25VDC.

R103 is normally set maximum counter-clockwise for a 1-hour time threshold.

R103 can be adjusted in a clockwise direction to obtain a longer time threshold.

Maximum clockwise is 2 hours.

Page 5

Shutdown Timer

Enable Diode

TIME ADJUSTMENT R1 03

MAX. CCW = 1 HOUR (NORMAL)

MAX. CW = 2 HOURS

VOLTAGE ADJUST, R102, 12VD C

R101

R7

C11

R103

+

U3

TIME

C10

R2

CR1

R9

REF

V

U2

+

C9

CR4

C8

+

+

C3

Q1

A3

R4

VOLTS

A1

+

A2

R1

R102

R5

R8

MAX CCW = 11 VOLTS (NORMAL)

MAX CW = 12.85 VO LTS

U1

R3

C1

+

C2

R11

S1

RUN

C13

TEST

+

C6

+

K1

+

B091-141-001

Q2

A4

+

C5

R10

R12

C7

CR3

R6

J1

KUSSMAUL ELECTRONICS

C12

CR2

Figure 3

VOLTAGE ADJUST, R102, 24VD C

MAX CCW = 21 .2 5 VOLTS

MAX CW = 24.75 VOLTS

70% MAX CCW = 22.0 VOL TS (NORMAL)

ALIGNMENT & PROGRAMMING, LOAD MANAGER P

Page 6

SPECIFICATION AND OUTLINE

Temperature Environment: 0 to 50 deg C.

Main Input Power: 12VDC Battery, [24VDC Battery]

Input Current: 90 [40] milliamperes, relay ON

9 [5] milliamperes, relay OFF

Load Output Power: 12VDC @ 30 amperes maximum.

[14VDC @ 30 Amperes maximum]

Low Voltage Dropout of Load: 11.0 to 12.85 volts (potentiometer adjustable,

Factory set for 11 volts).

[21.25 to 24.75 volts (potentiometer adjustable,

Factory set for 22.0 volts)]

Load Power Restoration Voltage: .5 [.75] volt higher than the Low Voltage

dropout of load.

Time Dropout of Load: 1 to 2 hours (potentiometer adjustable, factory

set for 1 hour).

Starter Inhibit: The Load will not drop out due to low voltage

while the engine is being started.

Weight: 0.5 lbs

5.10

3/16" DIA.

2.95

4,50

1.55

OUTLINE, LOAD MANAGER P

Page 7

INSTALLATION RECORD & WARRANTY

Date Installed________________________________________

Installed By___________________________________________

Vehicle Identification_________________________________

Vehicle Owner________________________________________

WARRANTY

All products of Kussmaul Electronics Company Inc. are warranted to be free of

defects of material or workmanship. Liability is limited to repairing or replacing at

our factory, without charge, any material or defects that become apparent in

normal use within 3 years from the date the equipment was shipped. Equipment

is to be returned, shipping charges prepaid and will be returned, after repair,

shipping charges paid.

Kussmaul Electronics Company, Inc. shall have no liability for damages of any

kind to associated equipment arising from the installation and /or use of the

Kussmaul Electronics Company, Inc. products. The purchaser, by the

acceptance of the equipment, assumes all lia bility for any damages which may

result from its installation, use or misuse, by the purchaser, his or its employees

or others.

Loading...

Loading...