Page 1

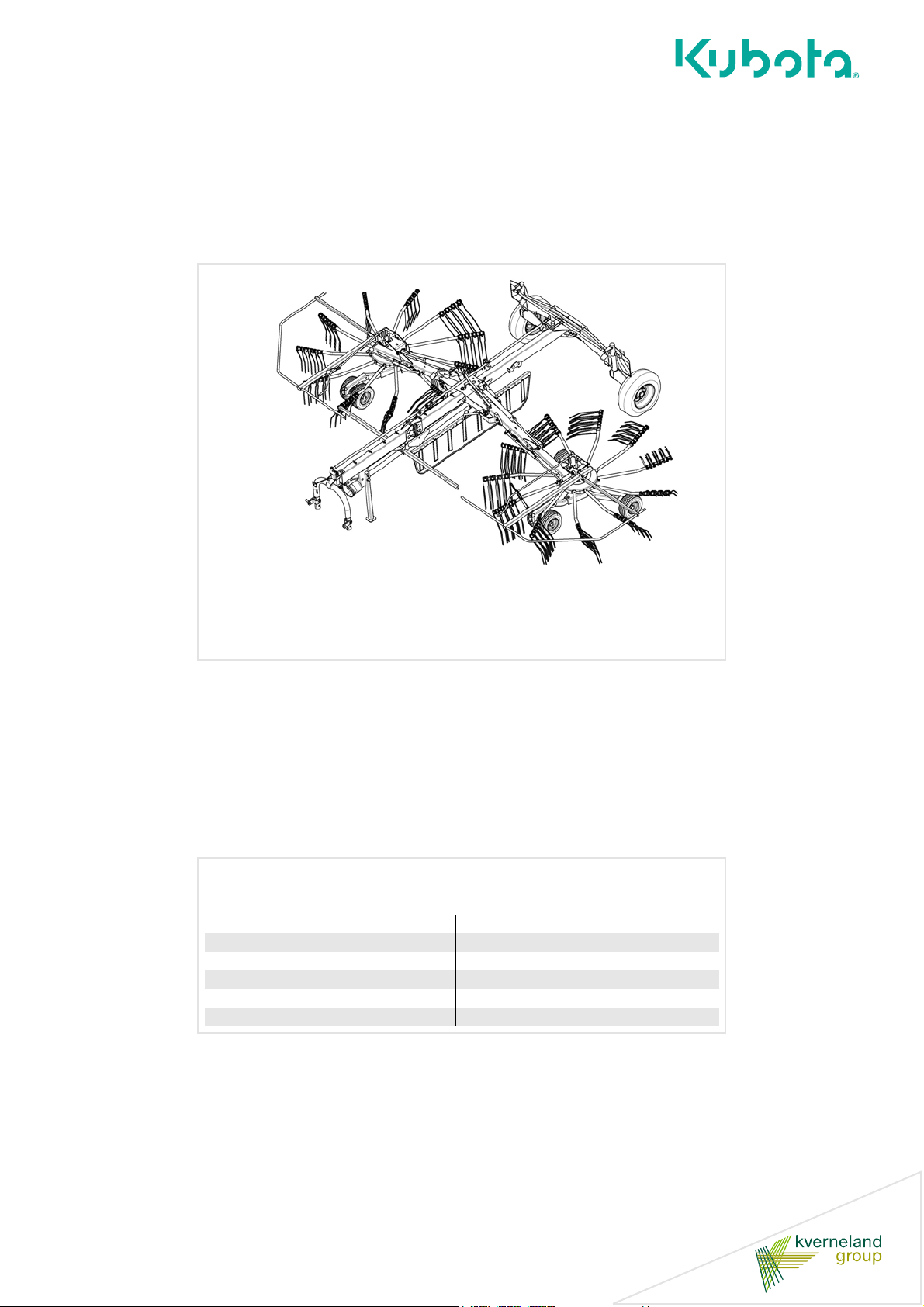

RA2072

RA2072 Hydro

Operator’s manual

Original operator’s manual

Edition 04.2015

Date of print 06.2015

Language EN-US

Machine number VF69670236 –

Model VF6967

Document number VF16662027.EN-US

Page 2

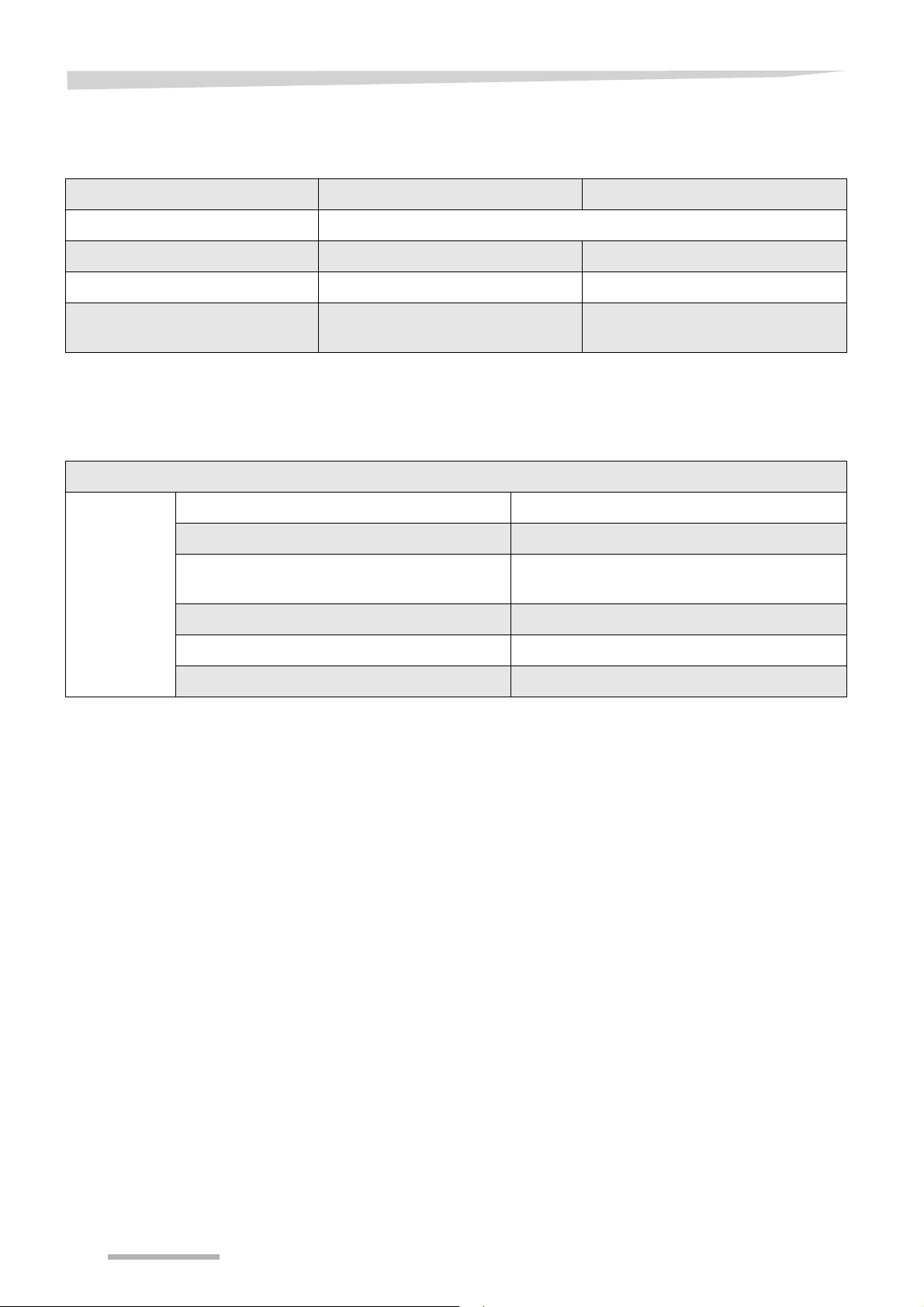

Machine identification

In order for your dealer to assist you as efficiently as possible, you will need to provide some information about

your machine. Please enter the details here.

Designation

Operating width

Weight

Machine

number

Accessories

Address of

supplier

RA2072 RA2072 Hydro

6.20 - 7.30 m (20.30 - 23.95 ft)

1 640 kg (2 557 lbs)

VF6967 _ _ _ _

Address of

manufacturer

Kverneland Group Kerteminde AS

Taarupstrandvej 25

DK-5300 Kerteminde

Denmark

Tel: +45 65 19 19 00

Copyright by Kverneland Group Gottmadingen N. V., Germany. Reproduction, transfer to other media, translation or the use of extracts or parts

of this manual without the explicit permission of Kverneland, is not permitted. All rights reserved. The contents of this operator’s manual are subject

to change without notice. The right to technical revision is reserved.

Page 3

Table of contents

Preface ....................................................... 5

Target group for

this operator’s manual 5

Symbols used 6

Table of contents

Preparations on the field .......................... 68

Safety 68

General 69

Lowering the machine 69

Safety ......................................................... 8

For your safety 9

DANGER, WARNING and CAUTION labels

10

Who is allowed to

operate the machine? 16

General safety information 16

Coupling 19

Hydraulics 19

Road transport 20

Operation 22

Uncoupling 23

Care and maintenance 24

Further regulations 25

Getting to know the machine .................. 26

Range of application 26

Features 26

Designation of components 27

Technical specifications 28

Pilotbox – Hydro version 32

Function

overview 33

Delivery and assembly ............................. 39

Checking the scope of delivery 39

Checking tandem axle [+] 40

Length of PTO shaft 41

Steering 43

Coupling the machine .............................. 44

Safety 44

General 44

Coupling the lower link 45

Swivelling in the parking stand 46

Coupling the PTO shaft 47

Wheel chocks 48

Connections 49

Preparing for use ...................................... 55

Safety 55

General 56

Adjusting the machine 56

Frame pitch 57

Rotor pitch 57

Working depth 61

Road transport .......................................... 62

Safety 62

General 63

Prior to road transport 63

Road transport 67

Operation ................................................... 73

Safety 73

General 74

Crop processing 74

Using the machine 75

Working speed 81

Adjusting the swath width 81

Driving on headlands 82

Check list for operation 83

Cleaning and care ..................................... 84

Safety 84

General 85

Cleaning 85

Care 85

Parking and storage .................................. 86

Safety 86

General 86

Uncoupling the machine 87

After the end of the season 87

Maintenance ............................................... 88

Safety 88

General 89

Screwed connections 92

Lubrication points for grease 94

Lubricating the PTO shafts 95

Filling quantities 96

Tires 96

Hydraulics 97

Checking sliding elements 98

Accessories ............................................... 100

Tine saver 100

Hydraulic single lift 100

Tandem axles 101

Spare wheel 101

Fault elimination ........................................ 102

Troubleshooting 102

Emergency manual function 104

Circuit diagrams ........................................ 105

Hydraulic circuit diagram 105

Pilotbox circuit diagram 107

Lighting equipment circuit

diagram – USA 108

Decommissioning ..................................... 109

Disposal 109

EC Declaration of Conformity .................. 110

Conforms to

3

Page 4

Table of contents

EC Directive

2006/42/EC 110

Index .......................................................... 111

4

Page 5

Preface

Target group for

this operator’s

manual

Preface

\ WARNING

Simplified illustrations for better understanding

Illustrations of the machine in the operator’s manual are shown

without protective equipment – or with the protective equipment

open – for better understanding. Be sure to observe the safety

information and follow the handling instructions in the operator’s

manual. Otherwise, serious or fatal injury may be caused as a

result.

This operator’s manual is intended for trained agriculturists and

persons who are otherwise qualified for agricultural activities and have

received instruction in working with this machine.

Minimum age

For your safety

Demonstration and

training

Children under the age of 16 are not permitted to operate the machine.

You must familiarise yourself with the contents of this operator’s

manual before assembly or initial operation of the machine. In this

way, you will achieve optimum work results and operational safety.

The operator’s manual forms an integral part of the machine and must

always be kept at hand. This will ensure that you:

• avoid accidents.

• comply with warranty conditions.

• have a fully functional machine in good working order at all times.

Your dealer will provide instruction on operation and care of the

machine.

Information for the employer

All personnel are to be regularly, but at least once a year, instructed

on the use of the machine, in accordance with the regulations of the

national organisation for Health and Safety at Work. Untrained or

unauthorised persons are not permitted to use the machine.

You are responsible for ensuring that the machine is operated and

maintained safely. Make sure that you and all other persons that

operate, maintain or work in close proximity with the machine are

familiar with the operating and maintenance regulations, as well as the

corresponding safety instructions in this operator’s manual.

5

Page 6

Preface

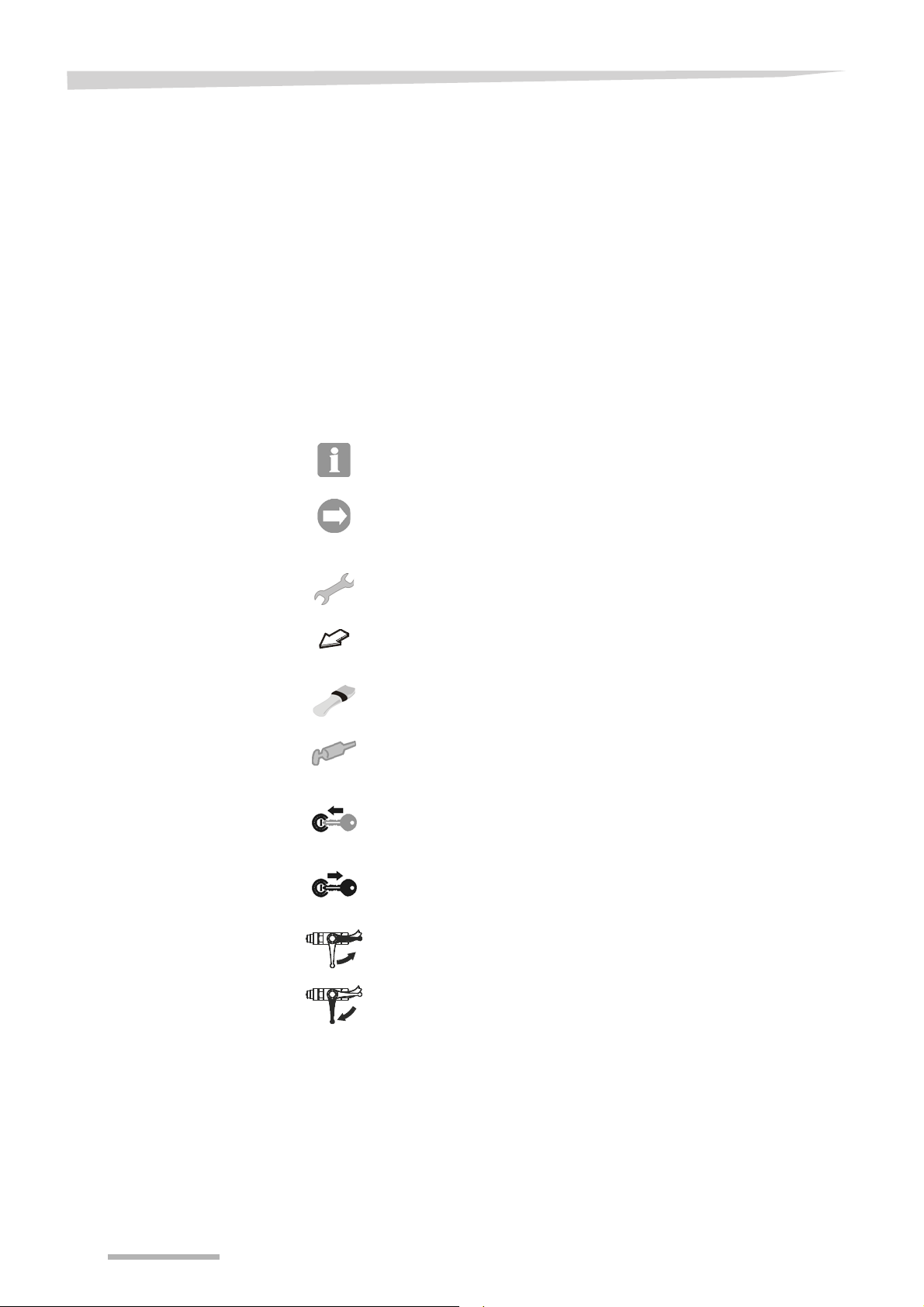

Symbols used

In this operator’s manual, the following symbols and terms have been

used:

• A bullet point accompanies each item in a list.

A triangle indicates operating functions which must be performed.

An arrow indicates a cross-reference to other sections of this

manual.

[+] A plus sign indicates additional equipment which is not included in

the standard version.

We have also used pictograms to help you find instructions more

quickly:

The "Information" pictogram indicates tips and additional information.

The “Examples” pictogram indicates examples that assist understanding of the instructions.

The spanner indicates tips for assembly or adjustment work.

This arrow in the diagram shows the direction of travel.

The brush indicates the points that must be lubricated using the brush.

The grease gun indicates the points that must be lubricated using the

grease gun.

Switch on the tractor.

Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

Open the ball valve.

Close the ball valve.

6

Page 7

Preface

7

Page 8

Safety

Safety

\

California Proposition 65

\ WARNING

Engine exhaust, some of its constituents, certain machine

components and fluids, contain or emit chemicals known to the

State of California to cause cancer and birth defects or other reproductive harm.

\ SAFETY FIRST

This symbol, the industry's "Safety Alert Symbol", is used

throughout this manual and on labels on the machine itself to warn

of the possibility of personal injury. Read these instructions

carefully. It is essential that you read the instructions and safety

regulations before you attempt to assemble or use this unit.

\ DANGER

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

\ WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

\ CAUTION

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

8

Page 9

\

Safety

For your safety

Know your equipment and it's limitations. Read this entire manual

before attempting start and operate the units.

This chapter contains general safety instructions. Each chapter of the

operator’s manual contains additional specific safety information

which is not described here. Observe the safety information:

• in the interest of your own safety.

• in the interest of the safety of others.

• to ensure the safety of the machine.

Numerous risks can result from handling agricultural machinery in the

wrong way. Therefore, always work with particular care and never

under time pressure.

Information for the employer

Inform all persons who work with the machine about this safety

information at regular intervals and in accordance with statutory regulations.

9

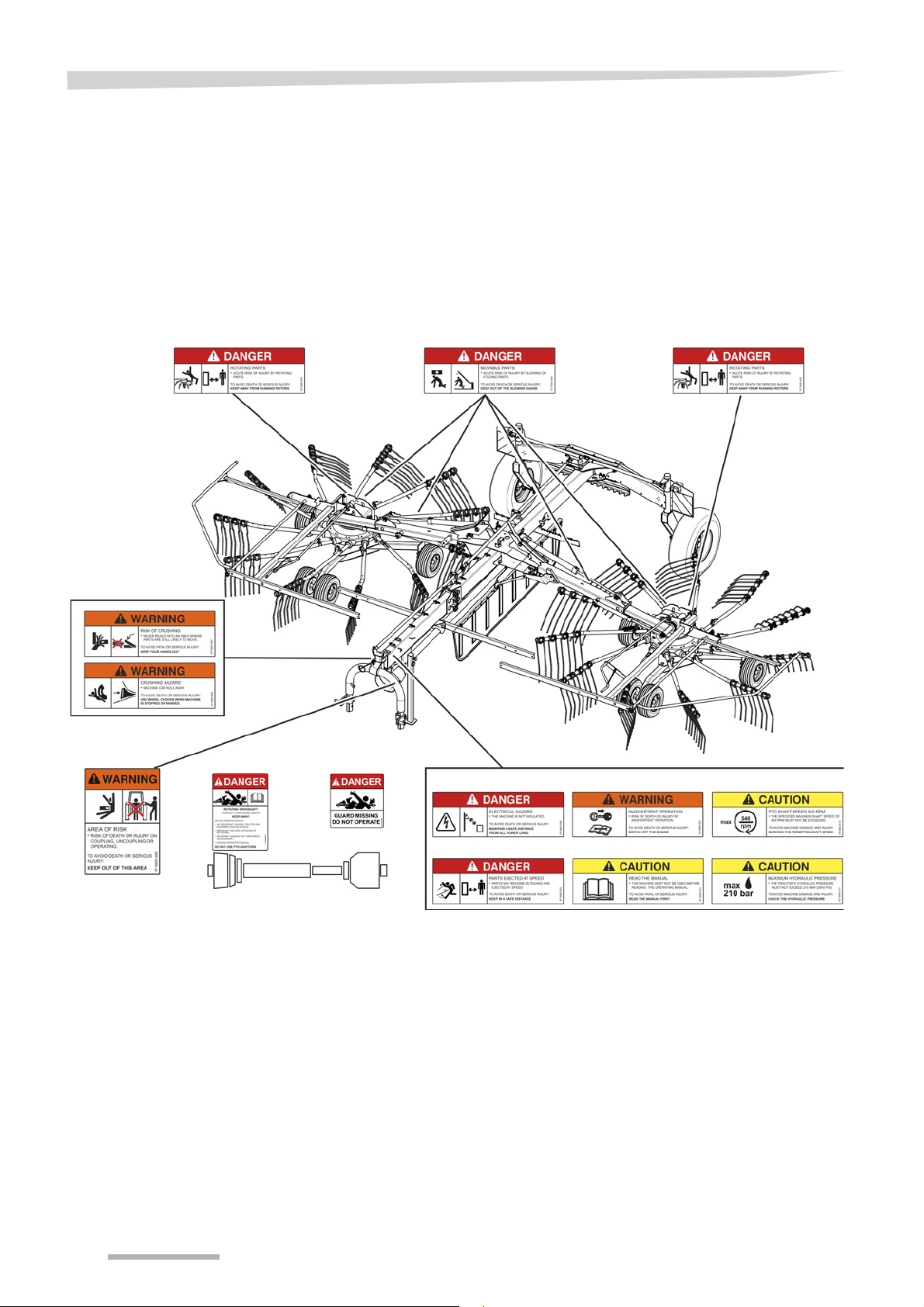

Page 10

Safety

\

DANGER, WARNING and CAUTION labels

DANGER, WARNING

and CAUTION labels

on the machine

Safety-related stickers attached to the machine indicate potential

hazards. The stickers must not be removed. Illegible or missing

stickers should be replaced. You can obtain new stickers as

replacement parts from your dealer.

10

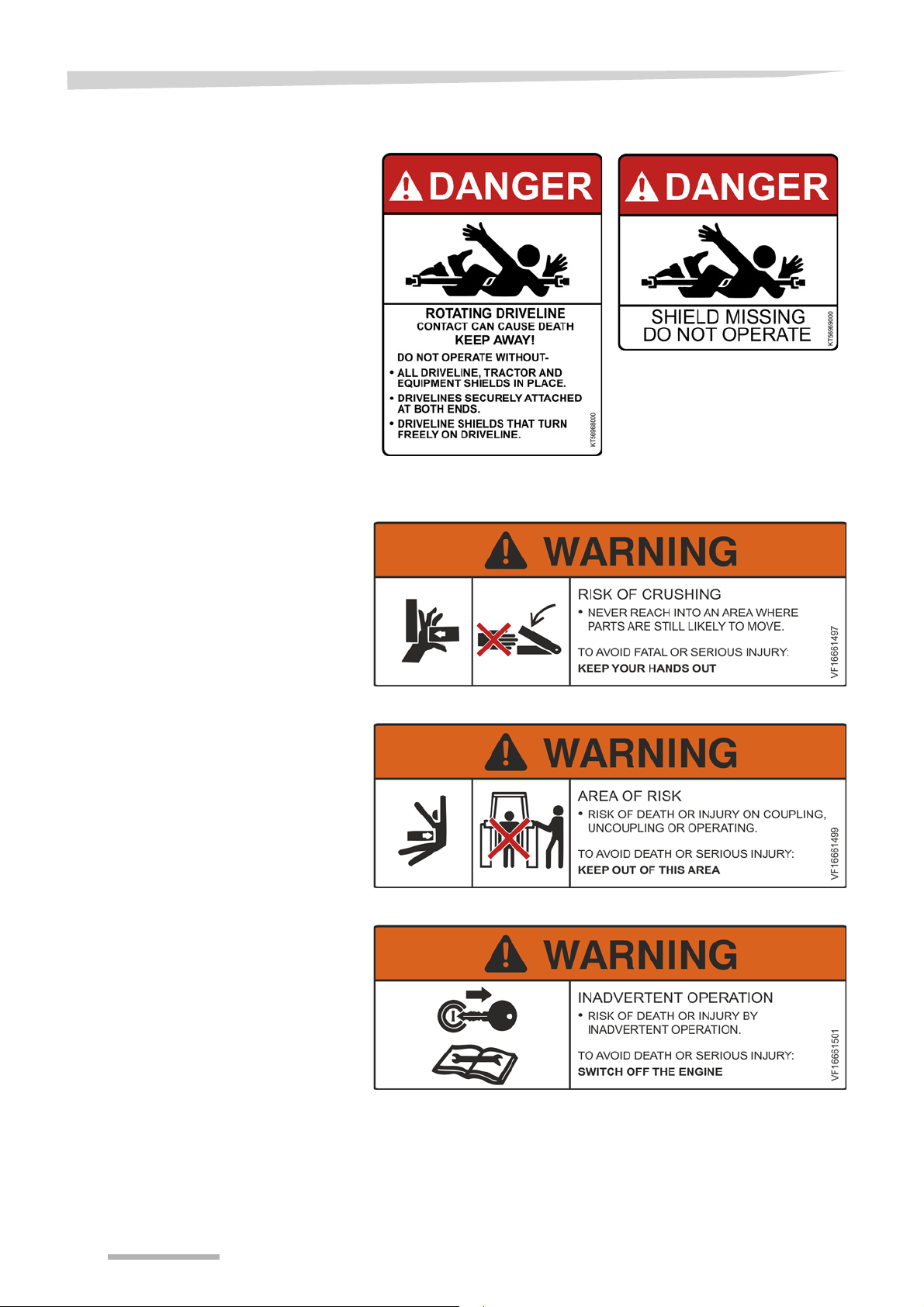

Page 11

\

Meaning of DANGER,

WARNING and CAUTION

labels

Safety

11

Page 12

Safety

Outer tube.

Inner tube.

\

12

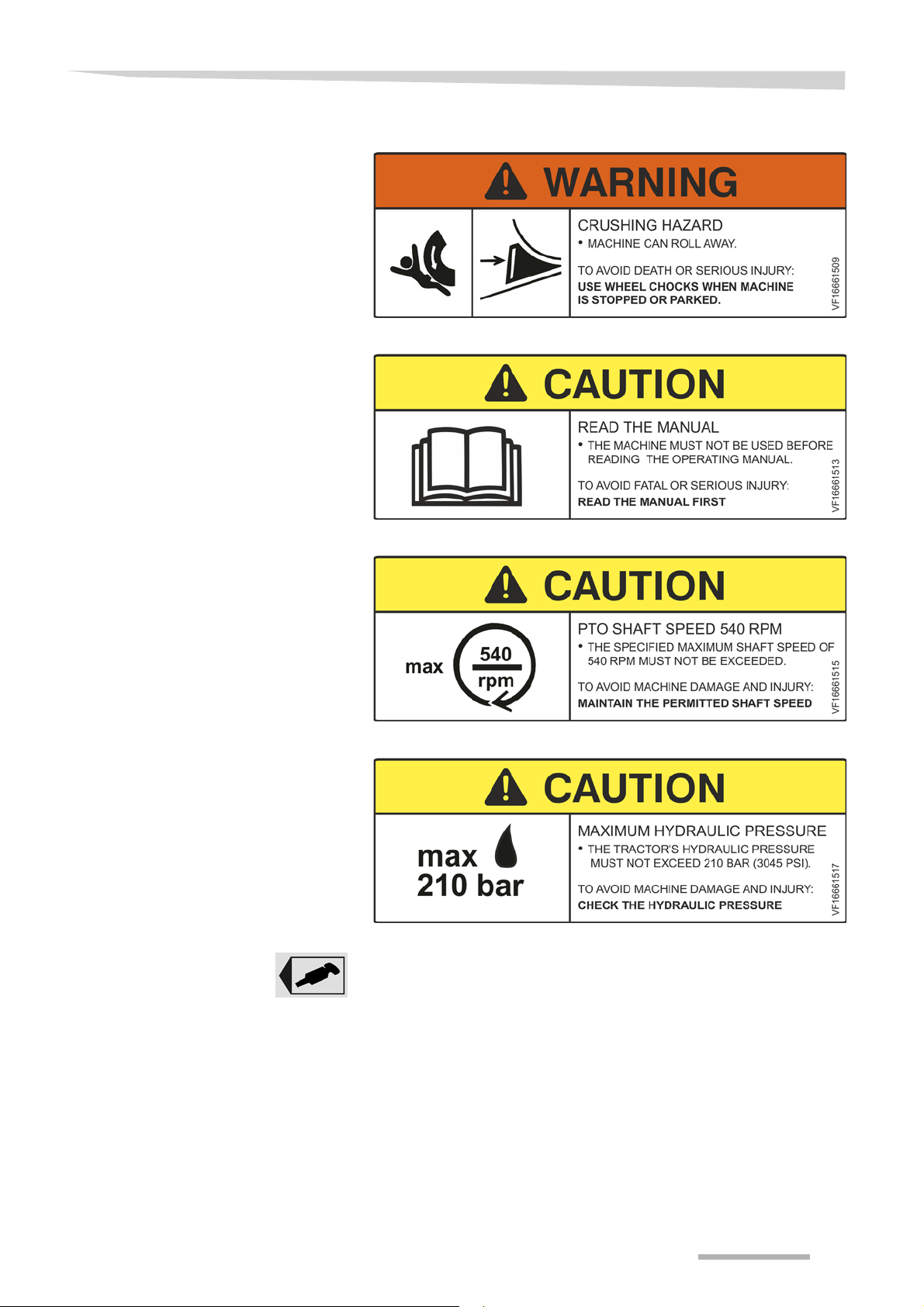

Page 13

\

Safety

Lubrication points

Hidden lubrication points are marked with an information label.

Lubricate the machine in accordance with the instructions in the

"Maintenance" chapter.

13

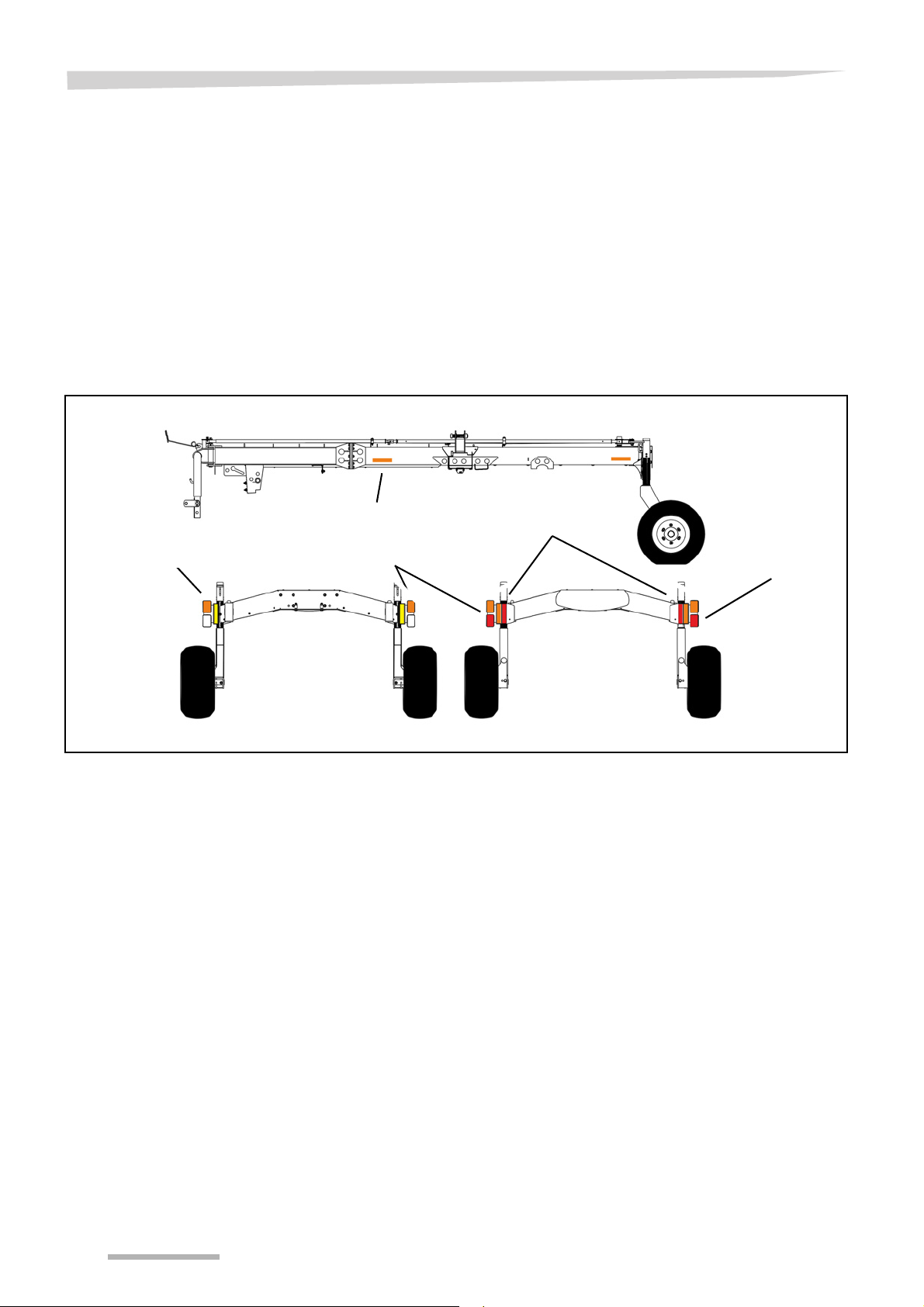

Page 14

Safety

Front view

Rear light/

brake light (red)

Indicator (amber)

Rear view

2 x yellow reflectors

2 x red reflectors

2 x amber reflectors

*SMV identification is available as an option

2 x amber reflectors

\

Signalling equipment

– USA

Signalling equipment

On the machine there are signalling equipment, signs and stickers that

serve to ensure safety in road traffic. The signalling equipment must

be in good working order at all times. The signs and stickers must not

be removed. Illegible or missing labels should be replaced. You can

obtain new labels as spare parts from your dealer.

If the implement, in the transport position, obscures the effective illumination of any flashing, extremity, tail or stop lamp on the tractor, the

implement must be fitted with lighting appropriate to take the place of

the lamp(s) obscured. See your authorized dealer for an appropriate

lighting kit.

14

Page 15

\

Safety

Signs

Additional markings are required for road transport in some U.S.

states and some Canadian provinces:

Marking for slow-moving vehicle – SMV

This SMV emblem shall be used on all slow moving machines when

operated or traveling on public roads.

• On slow moving machines with design specifications of a

maximum speed of 40 km/h (25 mph) or less, the SMV emblem

shall be used.

• On slow moving machines with design specifications of speed

greater than 40 km/h (25 mph) but not exceeding 65 km/h (40

mph):

• a SMV emblem shall be used and

• a Speed Identification Symbol (SIS) shall be used.

Marking for maximum speed

(Speed identification symbol – SIS)

The scope of this standard is primarily directed to identifying agricultural equipment that have been designed in their original equipment

configuration for specified ground speeds greater than 40 km/h (25

mph) but under 65 km/h (40 mph).

15

Page 16

Safety

\

Who is allowed to

operate the

machine?

General safety information

Qualified machine operators

Only qualified persons who have been informed of the dangers

associated with handling the machine are permitted to operate,

service or repair the machine. The necessary knowledge can be

gained in the course of agricultural vocational training, professional

training or intensive instruction.

\ WARNING

The general safety information and warning signs apply to every

phase of the life cycle of the machine and to every application.

Switch off the tractor and secure it

Before you dismount:

Disengage the PTO

Lower all implements to the ground

Place all controls in their neutral or park position

Set the parking brake

Switch off the tractor.

Remove the ignition key.

Secure the tractor against rolling away.

An unsecured tractor can run you over or trap you. Otherwise, serious

or fatal injury may be caused as a result.

Operate for the first time only after proper training

The machine may only be put into operation after proper training has

been provided by an authorized dealer. Operation without proper

training can lead to damage to the machine due to incorrect operation,

or may cause accidents.

Safety is your responsibility

Follow the safety instructions. Ensure that all operators read and

understand the manual and comply with the safety instructions.

Prevent serious or fatal accidents by following the safety instructions.

Instructions in the event of malfunctions

In the event of a malfunction:

shut down,

stop and secure the machine immediately.

Rectify the malfunction immediately yourself if qualified to do so,

or seek the assistance of an authorized dealer.

Operating a faulty machine can cause accidents or damage.

16

Page 17

\

Safety

No persons in the working area

Ensure that no persons are present in the slewing and working area

of the machine. Persons could be caught by the machine within this

area. This could result in fatal injury.

Proper working condition

Ensure that the tractor and the machine are always in proper working

condition. Make sure that the tractor brakes work in synchronisation

with the machine. Also follow the instructions in your tractor's

operator’s manual.

Switch off the tractor PTO shaft drive

Switch off the PTO shaft drive on the tractor when changing from work

to transport position (and vice versa). Wait for moving parts to come

to a stop. If this requirement is ignored, the consequence may be

damage to the machine and even life-threatening injuries.

No reversing while the drive is running

Never drive in reverse with the PTO shaft drive switched on and in the

work position if people could enter the working area of the machine.

Switch off the PTO shaft drive. Rotating, unprotected parts can

damage the machine and cause life-threatening injuries.

Specified workwear

Do not wear loose fitting or other inappropriate clothing. Loose fitting

items of clothing may become caught in rotating parts. Wear workwear

and protective clothing, request for the operating, environment and

conditions. Serious or fatal injury may be caused if these guidelines

are not followed.

No riding on the machine

Persons or objects must never be transported on the machine.

Carrying passengers, especially children, on the machine is life

threatening and prohibited. Serious or fatal injury may be caused as a

result.

Safety for children

Never assume that children will remain where you last saw them. Be

alert and shut your machine down if children into the work area. Never

allow children to play on or operate the machine.

17

Page 18

Safety

\

Never work on the machine while it is running

No operations may be performed on the machine while it is running.

Objects or persons can be caught, drawn in or crushed. Serious or

fatal injury may be caused as a result.

PTO shaft

Use only the PTO shafts specified by the manufacturer and read the

attached operator’s manual carefully. Adjust the length of the PTO

shaft as required. Incorrect PTO shaft lengths can cause damage to

the machine and personal injury.

Check and fasten the PTO shaft guard in position

The rotating PTO shaft is protected by the PTO shaft guard. Ensure

that the guard is not damaged. Fasten the PTO shaft guard in position

by connecting the chains on the machine and the tractor. Unguarded

PTO shafts can cause life-threatening injuries.

Make sure the machine is standing level

Before changing from the transport to the work position (and vice

versa), make sure the machine is standing level. Otherwise, damage

to the machine and serious or fatal injury may be caused as a result.

Do not make any modifications to the machine

No modifications of any kind may be made to the machine.

Unauthorised modifications can adversely affect the correct operation

and safety of the machine and shorten its service life. Unauthorised

modifications to the machine render the manufacturer's guarantee null

and void and free the manufacturer from all liability.

PTO shaft speed 540 rpm

The specified maximum PTO shaft speed of 540 rpm must not be

exceeded. A higher PTO shaft speed will damage the machine.

Unrestricted field of vision to the rear

After it has been coupled, ensure that you have an unrestricted view

of the machine, in both its work and transport positions. Otherwise,

dangerous situations may not be detected in time. resulting in

accidents or damage.

Safety distance from raised and unsecured loads

Never work under suspended loads. Maintain a sufficient distance

from raised and unsecured loads. Otherwise, serious or fatal injury

may be caused as a result.

Checking the angle of lock

On machines with attachment carriers, an angle of lock of 90° is

possible. This angle must not be exceeded. Otherwise, the PTO shaft

may be damaged.

18

Page 19

\

Safety

Coupling

Increased risk of injury

When the machine is being coupled to the tractor, there is an

increased risk of injury. Therefore:

• Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

• Never stand between the tractor and machine.

• Lock the PTO shaft securely on the PTO stub shafts of the tractor

and the machine.

If this requirement is ignored, the consequence may be lifethreatening injuries or damage to the machine.

Attaching electrical connections after assembly

The electrical supply to the tractor must not be connected when the

lighting equipment is being fitted. Otherwise, short circuits will occur

and the electronic system will be damaged.

Observe the operator’s manual of the PTO shaft manufacturer

Observe the operator’s manual of the PTO shaft manufacturer. It will

provide you with instructions on how to handle the PTO shaft correctly.

If these instructions are ignored, damage may be caused to the PTO

shaft and machine.

Risk of tipping

When the machine is coupled to tractors with lower link quick-release

couplings, the latter must be secured against unintentional opening. If

the quick-release couplings open unintentionally, the tractor and

machine may tip over. If this requirement is ignored, the consequence

may be damage to the machine and even life-threatening injuries.

Also follow the instructions in your tractor's operator’s manual.

Hydraulics

Hydraulic connection at zero pressure only

Only connect hydraulic hoses to the tractor hydraulic system if the

tractor and machine hydraulic system is at zero pressure. A

pressurised hydraulic system can trigger unforeseen movements on

the machine and can cause serious machine damage and personal

injury. Serious or fatal injury may be caused as a result.

High pressures in the hydraulic system

The hydraulic system is under high pressure. Regularly check all lines,

hoses, and screwed connections for leaks and externally visible

damage. Do not use hands to search for suspected leaks. Only use

suitable equipment when looking for leaks. Rectify any damage immediately. Fluid escaping under pressure can penetrate skin may result

in injuries and fires. Seek medical attention immediately if injuries

occur.

Replace hydraulic hoses every six years or earlier

Hydraulic hoses age without showing externally visible signs. Replace

hydraulic hoses every six years, or earlier if aging or degradation is

visible. Defective hydraulic lines can cause serious or fatal injuries.

19

Page 20

Safety

\

Road transport

Ensuring road safety

The machine must conform to current national traffic regulations if you

intend to drive it on public roads. Ensure the following:

• Lighting, warning and protective equipment must be fitted.

• The permissible transport widths and weights, axle loads, tire load-

bearing capacities, laden weights and national speed restrictions

must be observed.

• The maximum permissible road transport speed must be complied

with, but not exceed 40 km/h (25 mph).

• Before driving on public roads, fully fold in all guard bars and

secure the machine. All tine supports which have tips that point at

right angles to the direction of travel must be removed.

• The machine should only be towed by agricultural or forestry

tractors.

The empty weight of the tractor must be greater than the weight of the

machine. The driver and keeper of the vehicle are liable should these

conditions not be observed.

Close the ball valve

Close the ball valve before driving on the road. If the ball valve is open

and there is an operating error, the machine may drop or swing out

unexpectedly. This could cause traffic accidents and accidents with

fatal consequences.

Check tire pressures

Check tire pressure on a regular basis. Incorrect tire pressures reduce

the service life of a tire and cause unstable driving characteristics.

Accidents with serious or fatal injuries may be caused as a result.

Altered driving and braking performance

Driving and braking performance are altered when the machine is

coupled or hitched to the tractor. When cornering, take the overall

width and balancing weight of the machine into consideration. Adjust

your driving speed accordingly. A driving style which is not adapted to

conditions can cause accidents. Accidents with serious or fatal injuries

may be caused as a result.

20

Page 21

\

Safety

Speed adjustment

In poor road conditions and at high speeds, significant forces can be

generated which subject the tractor and machine material to high or

excessive stresses. Adjust your driving speed to the road conditions.

A driving style which is not adapted to conditions can cause accidents.

Accidents with serious or fatal injuries may be caused as a result.

Check hitch pins

Hitch pins must be in perfect condition. Hitch pins must show no signs

of wear and be properly secured. Otherwise, hitched machines may

detach themselves of their own accord. Accidents with serious or fatal

injuries may be caused as a result.

Check release rope on quick release couplings

Release rope must hang loose and must not allow a release in their

lowered position. Hitched machines may otherwise detach

themselves from the lower link hitching system of their own accord.

Accidents with serious or fatal injuries may be caused as a result.

21

Page 22

Safety

\

Operation

Ensure that the machine is in proper working condition

Do not operate the machine unless it is in proper working condition.

Check all key components and their correct operation before use.

Replace defective components. Defective components can cause

material damage and personal injury.

Check the protective equipment

The protective equipment must not be removed or by-passed. Check

all protective equipment before using the machine. Unprotected

machine parts can cause serious or fatal injury.

Check the immediate vicinity

Check the area immediately surrounding the machine before driving

off, and continually during operation. Make sure that you have an

adequate view. Only begin work when the immediate vicinity is cleared

of any persons or objects. Serious or fatal injury may be caused as a

result.

Retighten all nuts, bolts and screws

Regularly check that nuts and bolts are correctly tightened. Retighten

bolts if necessary. Nuts and bolts can work loose through machine

use. The machine may be damaged or accidents caused as a result.

See »Tightening bolts«, page 92 for proper torque values.

The PTO shaft continues turning after it has been switched off

After the PTO shaft drive on the tractor has been switched off, the

machine continues to run due to the moment of inertia. Maintain a

sufficient safety distance until all moving parts have come to a

complete standstill. Otherwise, damage to the machine and serious or

fatal injury may be caused as a result.

Cornering and turning manoeuvres

Centrifugal forces are in operation during cornering. The machine's

centre of gravity at the rear of the tractor is displaced. Be aware of the

turning radius and the moment of inertia. A driving style which is not

adapted to conditions can cause accidents. Accidents with serious or

fatal injuries may be caused as a result.

22

Page 23

\

Safety

Uncoupling

Increased risk of injury

There is an increased risk of injury when uncoupling the machine from

the tractor. Therefore:

• Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

• Never stand between the tractor and machine.

• Set the machine down on firm, secure and level ground.

• Ensure that the parking stand is securely locked.

• Place the PTO shaft in the holder provided.

• Secure the machine against rolling away (use wheel chocks).

• Do not disconnect hydraulic hoses until there is no pressure in the

tractor and machine hydraulic system.

• Disconnect all electrical connections.

Failure to observe these instructions can result in serious or fatal

injury.

23

Page 24

Safety

\

Care and maintenance

Observe the care and maintenance intervals

Observe the periods specified in the operator’s manual for recurrent

checks and inspections. If these periods are not observed, damage to

the machine and accidents may be caused as a result.

Use original parts

Many components have special properties that are essential for the

stability and correct operation of the machine. Only spare parts and

accessories supplied by the manufacturer have been tested and

approved. Other products may adversely affect the correct operation

of the machine and safety. Using non-OEM replacement parts renders

the manufacturer's guarantee null and void and frees the manufacturer from all liability.

When performing care and maintenance work:

• Switch off the PTO shaft drive.

• Depressurise the hydraulic system.

• Whenever possible, uncouple the tractor.

• Place all controls in neutral or park.

• Set tractor parking brake.

• Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

• Ensure the machine is standing on firm, secure and level ground,

and provide additional support, if necessary.

• Secure the machine against rolling away (use wheel chocks).

Only if these regulations are observed can safe working be ensured

during care and maintenance work.

Turn off the electrical supply

Prior to carrying out work on the electrical system, disconnect the

system from the power supply. Systems being supplied with electrical

power can cause damage to equipment and injury to persons.

Caution when cleaning with a high-pressure cleaner

Exercise caution when cleaning with a high-pressure cleaner.

Bearings, seals and pipe unions are not waterproof. In order to

prevent damage to the machine, the bearings, seals and pipe unions

must not be exposed to direct contact with the high pressure water jet.

No aggressive washing additives

Do not use any aggressive washing additives for cleaning. Uncoated

metal surfaces can be damaged.

Before carrying out welding work

Disconnect all electrical connections from the tractor when carrying

out welding on the hitched machine. Damage may otherwise be

caused to the electrical system.

Retighten all nuts, bolts and screws

All screwed/bolted connections that are loosened during maintenance

and repair operations must be retightened. Serious injury and damage

to property can be caused by loose pin and screw connections.

See »Tightening bolts«, page 92 for proper torque values.

24

Page 25

\

Safety

Further regulations

Warranty

Observe the regulations

In addition to the safety information listed above, please observe the

following:

• Accident prevention regulations in your local area.

• Generally recognised safety regulations, occupational health

requirements and road traffic regulations.

• The instructions provided in this operator’s manual.

• Standards relating to operation, maintenance and repair.

The warranty and manufacturer's liability will no longer be valid if the

instructions provided in the chapter on Safety are not observed, if

maintenance is inadequate or faulty, if the machine is used for

purposes other than those for which it was intended and if it is overstressed, or if impermissible modifications are made to the machine.

25

Page 26

Getting to know the machine

Getting to know the machine

Range of application

Proper use

Features

This product is classified as replaceable equipment in accordance

with EC directive 2006/42/EC and agricultural implement in

accordance with ASABE S390.

The machine is a twin rotor rake, which is suitable only for the raking

together of mown, stalked material (for example, hay or straw).

Any use other than the use described above - such as silo spreading,

any type of soil preparation, sweeping, or transmitting power to other

machines - is not permitted. The manufacturer and dealers are not

liable for damage caused by improper use. The risk is borne solely by

the user.

Flexible in operation

This central rake, which has a working width of approximately 6.20 m

- 7.30 m (20.30 ft - 23.95 ft) meets all the requirements of modern

crop harvesting engineering. All the important functions for field use

are controlled during operation. The following functions should be set

without leaving the tractor:

• Deposit of crop in single rotor operation via the hydraulic single lift.

• Individual working depth of both rotors.

• Swath width.

The rake can be pulled by tractors of 35 kW (47 hp) or more.

Extensive equipment

The machine is equipped with low-maintenance gearboxes and 11

arms on each rotor. The cranked tines achieve an excellent raking

quality.

The “TerraLink” support ensures outstanding adjustment to the

contours of the land.

The automatic system swivels the swath former into the selected

transport or work position.

Easy changeover from work to transport position

The rake is easily changed over from the work to the transport

position. Hydraulic cylinders lift the rotors into the transport position to

maintain the transport width of less than 2.80 m (9.2 ft).

26

Page 27

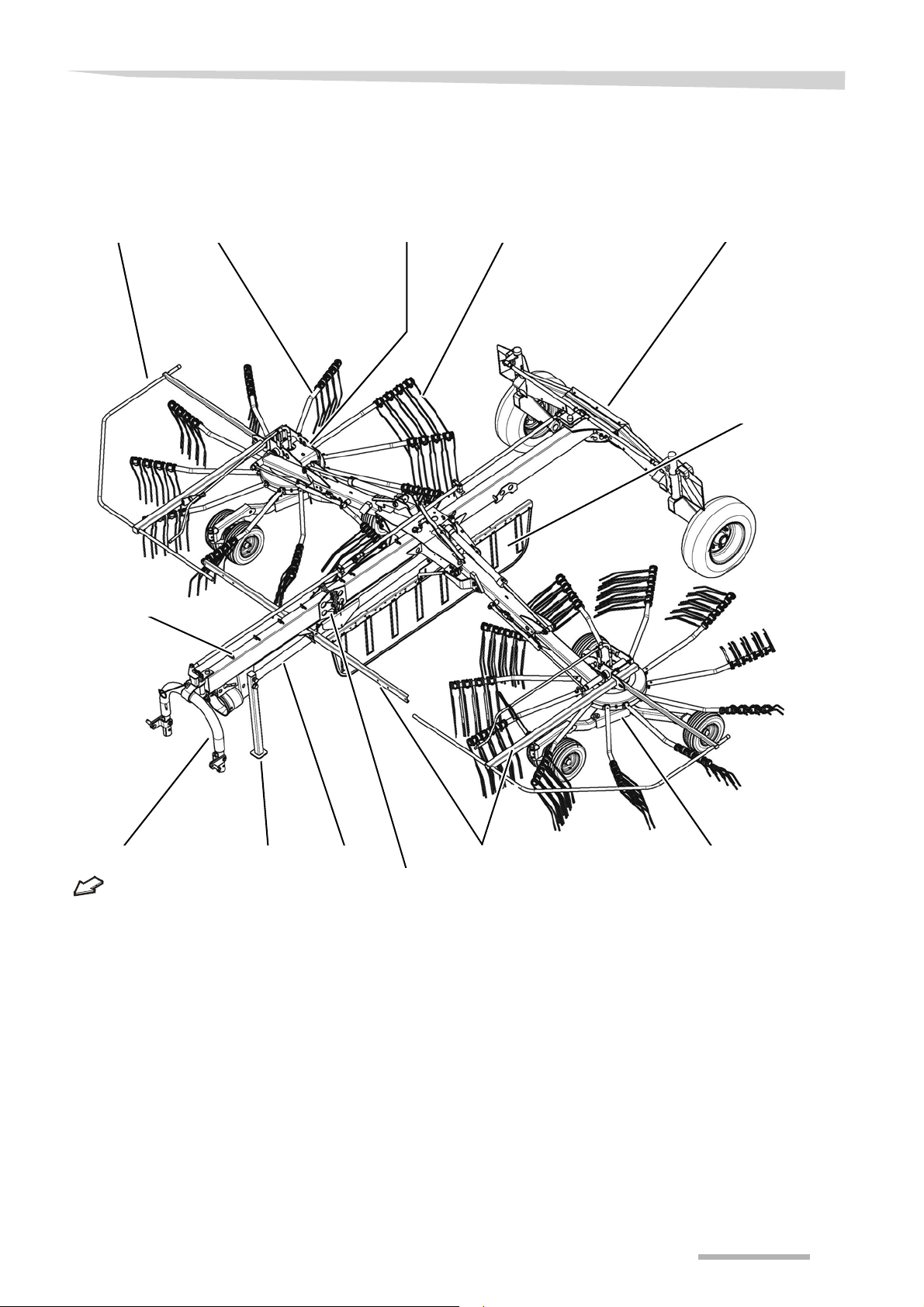

Designation of

Deflector bar

Main frame

Attachment carrier

Tine supports Tines

Swath former

Rotor gear

Sustainer

Transport chassis

Rotor chassisFront deflector bar

Tine guard stowage

compartment

Drive

components

Getting to know the machine

27

Page 28

Getting to know the machine

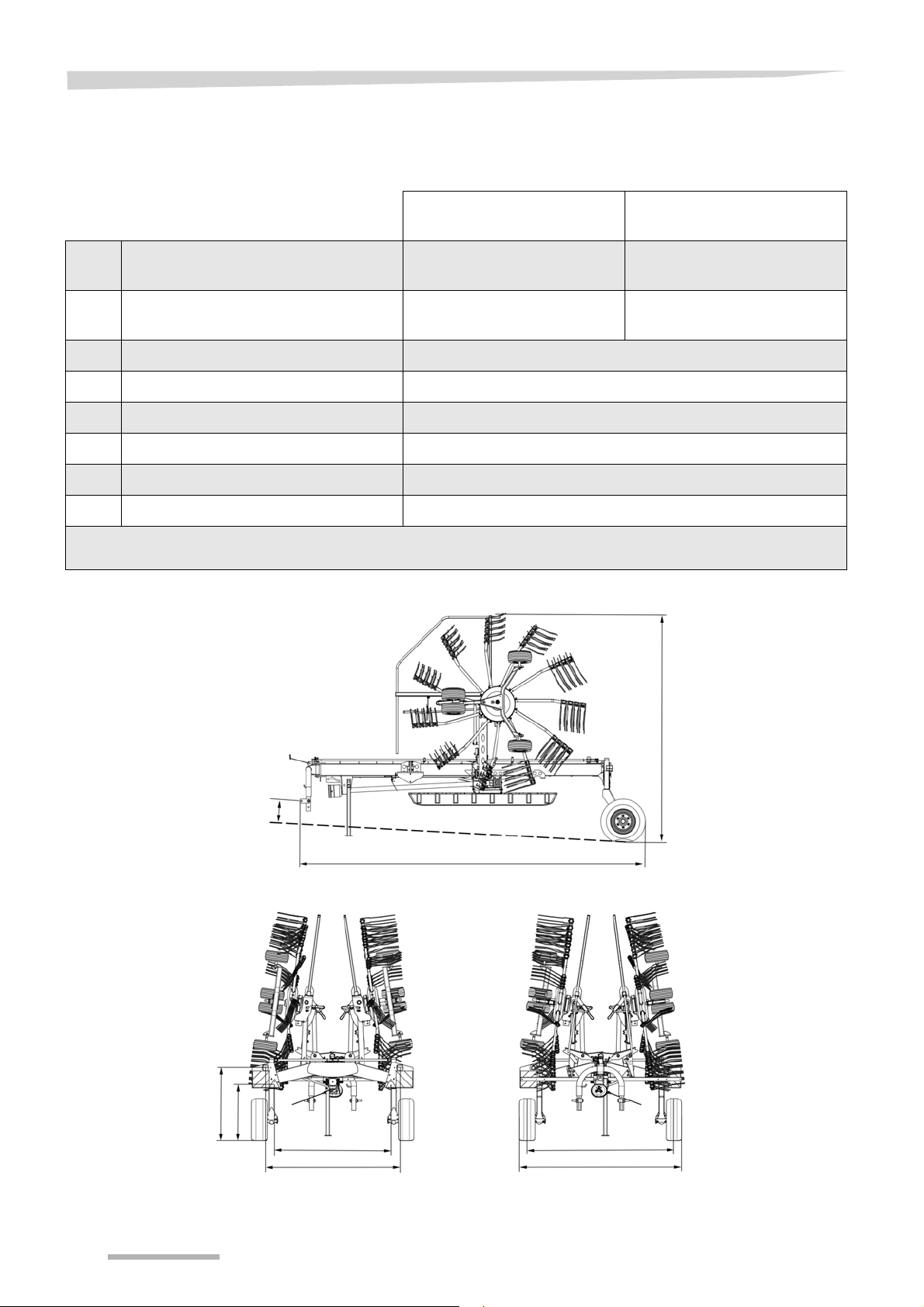

A

B

H

E

F

G

D

C

Technical specifications

Dimensions in transport position Standard

transport chassis [m]

A Length

B Height with all tine supports

C Width at transport wheels 2.80 (9.19 ft)

D Track width 2.51 (8.25 ft)

E Distance between lights 2.30 (7.55 ft)

F Height of lights 1.29 (4.23 ft)

G Height of bottom reflectors 0.35 (1.15 ft

H Distance between bottom reflectors 2.08 (6.83 ft)

* Machine attachment point (cat. 2) lowered to 200 mm from the ground (attachment carrier 40 mm).

** Machine completely lowered for transport position with hydraulic chassis.

5.90 (16.36 ft) 5.90 - 6.06**

3.65 ** - 3.90

(11.76 ft - 12.80 ft)

With hydraulic transport

chassis [m]

(16.36 ft - 21.65 ft)

3.44** - 3.90

(11.29 ft - 12.80 ft)

28

Page 29

Getting to know the machine

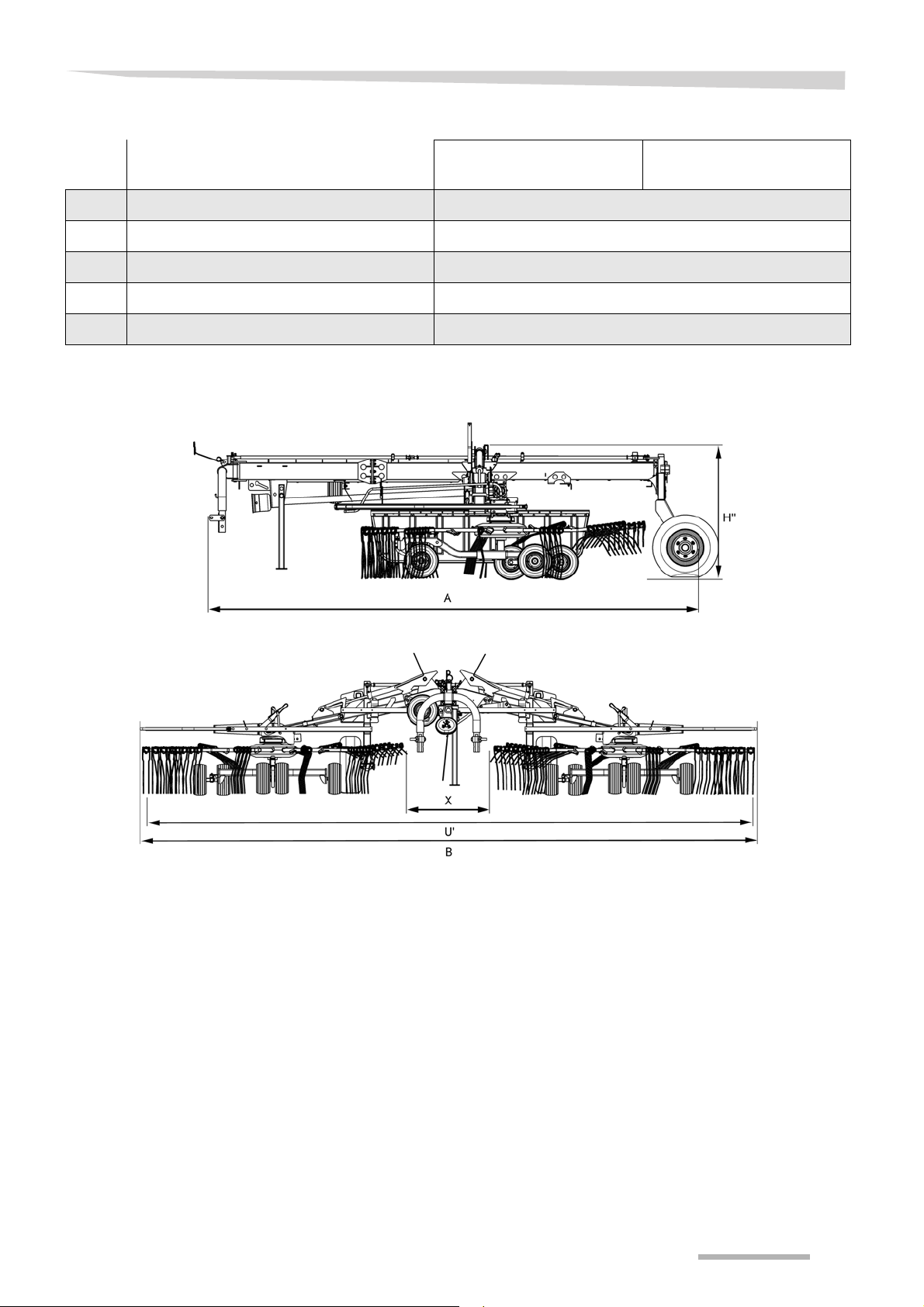

Dimensions in work position

A Length 5.90 (16.36 ft)

J Height in work position 1.79 (5.88 ft)

K Working width 6.20 - 7.30 (20.30 - 23.95 ft)

L Width 6.35 - 7.45 (20.84 ft - 24.45 ft)

M Distance between the rotors 0.20 - 1.30 (0.66 ft - 4.27 ft)

Standard

transport chassis [m]

With hydraulic transport

chassis [m]

29

Page 30

Getting to know the machine

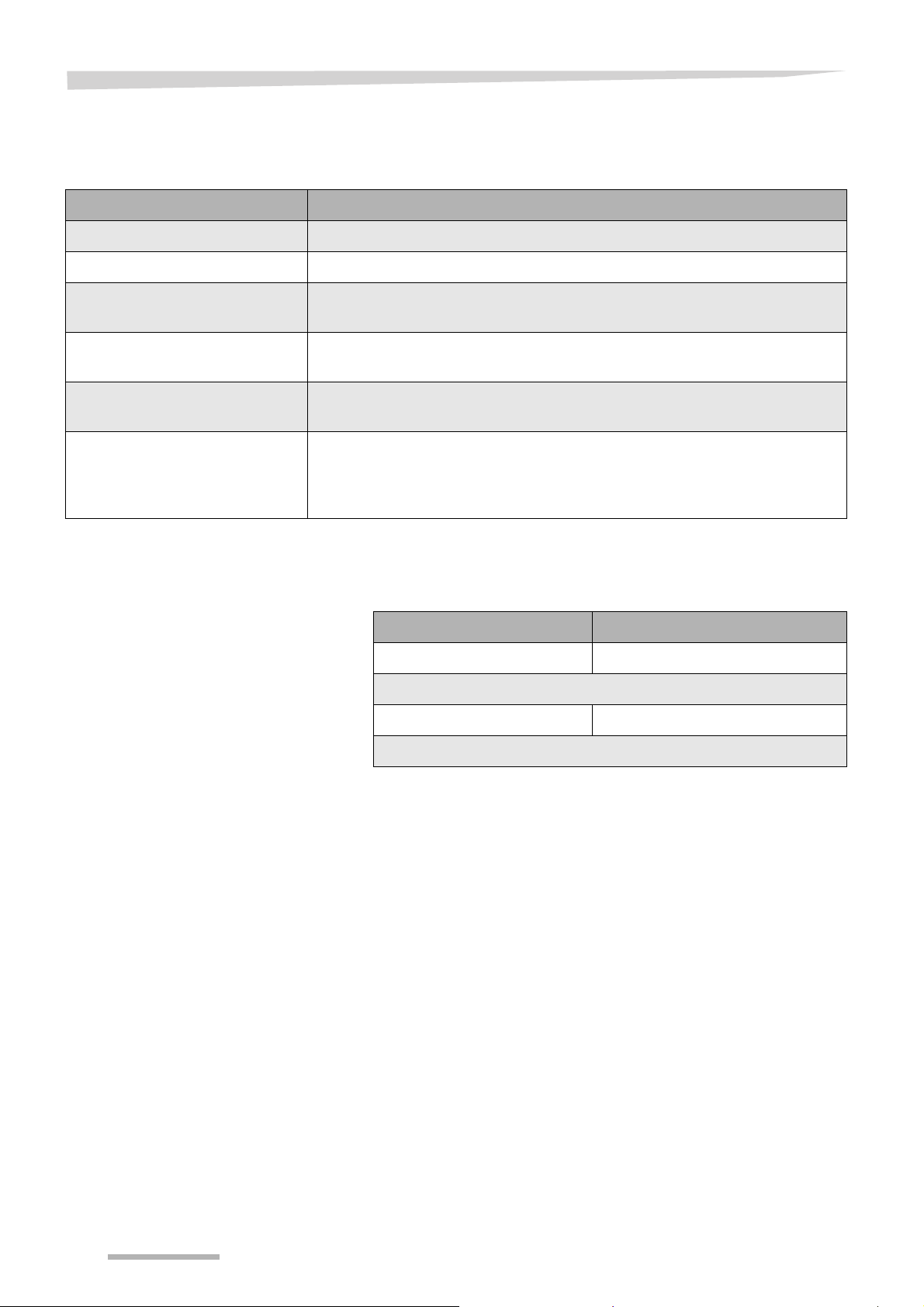

Weights

Work position Transport position

Total weight 1 640 kg (2 557 lbs)

Load supported on parking stand - 725 (1 598 lbs)

Load supported on lower link - 615 (1 356 lbs)

Transport chassis axle load

Tractor equipment

required

Output / connections

Minimum output of the tractor 35 kW (47 hp)

Lighting equipment power supply 12 V, 7-pin plug socket SAE J560

Hydraulic connections

Hydraulic pressure 150 - 210 bar (2175 - 3046 psi)

Maximum PTO shaft speed 540 rpm

Lower link Fixable in height and laterally

- Parking stand: 895 (1 973 lbs)

Lower link: 1 005 (2 216 lbs)

1 x double-acting control device

1 x single-acting control device

30

Page 31

Machine equipment

Swath deposit

Swath former with auto-swivel Standard

Rotors / tine supports / tines

Number of rotors 2

Getting to know the machine

Number of tine supports per rotor

Number of tines per tine support 4

Removable Tine supports Standard

Tine cover 6

Rotor height adjustment Mechanical

Hydraulic single lift [+]

Tine saver [+]

Wheels

Rotor chassis 16 x 6.50-8 6 PR

Tandem axles on rotor chassis [+]

Transport chassis 10,0 / 75-15,3

Safety accessories

Lighting equipment Standard

Warning signs Standard

11 swaths to the left

11 swaths to the right

PTO shaft

PTO shaft with freewheel Standard

Measurement of

airborne sound

emissions

The airborne sound emissions from the machine are below the levels

stipulated by machinery directive 2006/42/EC.

• A-weighted sound level in the workplace:

< 70 dB(A)

• Currently C-weighted sound level:

< 63 Pa (130 dB based on 20 µPa)

• A-weighted sound level on the machine:

< 80 dB(A)

31

Page 32

Getting to know the machine

On/Off switch

Control LED

3-way switch

Pilotbox – Hydro version

Protecting electrical parts against moisture

The electronic control system, pilotbox and electrical plug connections must be protected against damp and penetrating moisture.

Dampness in electronic devices can lead to leakage current,

which results in malfunction.

The rotary rake Hydro version is fitted with an electro-hydraulic control

unit – the pilotbox. The following functions can be selected from the

tractor seat and controlled using a single-acting hydraulic control device:

Preselection Function

Pilotbox

OFF

Pilotbox

ON

Raise and lower both rotors.

Extend both lift arms.

Control LED lights up. The A, B and C functions

are available.

A: Raise and lower the left rotor.

B: Raise and lower the transport chassis.

Caution: During this process, the lift arms are also

extended or retracted.

C: Raise and lower the right rotor.

Operate the rotary rake with the pilotbox as follows:

Mount the pilotbox in the tractor cab so that it is easily reachable

and secure it.

Switch it on and off with the switch. The control LED lights up when

the pilotbox is switched on.

With the switch, select the function (A, B or C) and then execute

the function with the double-acting hydraulic control device.

The pilotbox is included in the scope of delivery for the Hydro version.

The pilotbox is not included in the scope of delivery for the standard

version.

32

Page 33

Getting to know the machine

Standard

Standard

Standard

Standard

Function

overview

Standard version

Steering Machine position Function

• Single-acting hydraulic control

device on the tractor.

• Single-acting hydraulic control

device on the tractor.

The table below provides a summary of the functions. Be sure to

follow the other instructions and note the safety information in the

operating manual.

Transport

• Machine in work position.

• Switch off the PTO shaft drive.

• Clean the machine.

• Use the single-acting hydraulic control device on the tractor to move the

machine to the transport position.

Work position

• Switch off the PTO shaft drive.

• Use the single-acting hydraulic control device on the tractor to release

the lift arm locking mechanism.

• Pull the cable on the mechanical

lock and keep tensioned.

• Fold the rotors in fully with the single-acting hydraulic control device

on the tractor.

• Single-acting hydraulic control

device on the tractor.

• Single-acting hydraulic control

device on the tractor.

• Cable-controlled ball valve for

right rotor.

Headlands

• Using the single-acting hydraulic

control device on the tractor, raise

both rotors to the headland position,

then lower them.

Swathing with left rotor [+]

• The right rotor remains in the headland position.

• Raise the machine to the headland

position using the single-acting hydraulic control device.

• Pull the cable on the right cable-controlled ball valve once.

• Lower the left rotor using the singleacting hydraulic control device on

the tractor.

33

Page 34

Getting to know the machine

Standard

Standard

Standard

Standard

Standard

Steering Machine position Function

• Single-acting hydraulic control

device on the tractor.

• Cable-controlled ball valve for

left rotor.

• Single-acting hydraulic control

device on the tractor.

• Cable-controlled ball valve for

right rotor.

• Single-acting hydraulic control

device on the tractor.

• Cable-controlled ball valve for

left rotor.

Swathing with right rotor [+]

• The left rotor remains in the headland position.

• Raise the machine to the headland

position using the single-acting hydraulic control device.

• Pull the cable on the left cable-controlled ball valve once.

• Lower the right rotor using the single-acting hydraulic control device

on the tractor.

Lowering the left rotor [+]

• Remove the right side shaft.

• Raise the machine to the transport

position using the single-acting hydraulic control device.

• Pull the cable on the right cable-controlled ball valve once.

• Lower the left rotor using the singleacting hydraulic control device on

the tractor.

Lowering the right rotor [+]

• Remove the left side shaft.

• Raise the machine to the transport

position using the single-acting hydraulic control device.

• Pull the cable on the left cable-controlled ball valve once.

• Lower the right rotor using the single-acting hydraulic control device

on the tractor.

• Double-acting hydraulic control

device on the tractor.

Swath width

• Raise the machine to the headland

position using the tractor's doubleacting hydraulic control device.

• Adjust the swath width using the

double-acting hydraulic control device on the tractor.

• Lower the machine to the work position using the tractor's double-acting

hydraulic control device.

• Crank on left rotor. Working depth of left rotor

• Switch off the PTO shaft drive.

• Switch off the tractor and secure it.

• Set the working depth using the

crank on the left rotor.

34

Page 35

Getting to know the machine

Standard

Steering Machine position Function

• Crank on right rotor. Working depth of right rotor

• Switch off the PTO shaft drive.

• Switch off the tractor and secure it.

• Set the working depth using the

crank on the right rotor.

35

Page 36

Getting to know the machine

Hydro

Hydro

Hydro

Hydro

Hydro version

Steering Machine position Function

• Pilotbox switched off.

• Single-acting hydraulic control

device on the tractor.

• Pilotbox switched off.

• Single-acting hydraulic control

device on the tractor.

The table below provides a summary of the functions. Be sure to

follow the other instructions and note the safety information in the

operating manual.

Transport

• Machine in work position.

• Switch off the PTO shaft drive.

• Clean the machine.

• Move the machine into its transport

position using the tractor's doubleacting hydraulic control device.

Work position

• Switch off the PTO shaft drive.

• Use the single-acting hydraulic control device on the tractor to release

the lift arm locking mechanism.

• Pull the cable on the mechanical

lock and keep tensioned.

• Fold in the rotors using the tractor's

double-acting hydraulic control device.

• Pilotbox switched off.

• Single-acting hydraulic control

device on the tractor.

• Pilotbox switched off.

• Double-acting hydraulic control

device on the tractor.

Headlands

• Using the tractor's double-acting hydraulic control device, raise both rotors to the headland position, then

lower them.

Swath width

• Raise the machine to the headland

position using the tractor's doubleacting hydraulic control device.

• Adjust the swath width using the

double-acting hydraulic control device on the tractor.

• Lower the machine to the work position using the tractor's double-acting

hydraulic control device.

36

Page 37

Getting to know the machine

Hydro

Hydro

Hydro

Hydro

Steering Machine position Function

• Pilotbox switched on.

• Select position A on the

pilotbox.

• Single-acting hydraulic control

device on the tractor.

• Pilotbox switched on.

• Select position C on the

pilotbox.

• Single-acting hydraulic control

device on the tractor.

Swathing with left rotor [+]

• Switch the pilotbox on.

• Select position A on the pilotbox.

• Using the tractor's single-acting hydraulic control device, raise the right

rotor and then lower it.

Swathing with right rotor [+]

• Switch the pilotbox on.

• Select position C on the pilotbox.

• Using the tractor's single-acting hydraulic control device, raise the left

rotor and then lower it.

• Pilotbox switched on.

• Select position A on the

pilotbox.

• Single-acting hydraulic control

device on the tractor.

• Pilotbox switched on.

• Select position C on the

pilotbox.

• Single-acting hydraulic control

device on the tractor.

Lowering the left rotor [+]

• Remove the right side shaft.

• Raise the machine to the transport

position using the single-acting hydraulic control device.

• Switch the pilotbox on.

• Select position A on the pilotbox.

• Lower the left rotor using the singleacting hydraulic control device on

the tractor.

Lowering the right rotor [+]

• Remove the left side shaft.

• Raise the machine to the transport

position using the single-acting hydraulic control device.

• Switch the pilotbox on.

• Select position C on the pilotbox.

• Lower the right rotor using the single-acting hydraulic control device

on the tractor.

37

Page 38

Getting to know the machine

Hydro

Hydro

Hydro

Hydro

Steering Machine position Function

• Pilotbox switched on.

• Select position B on the

pilotbox.

• Single-acting hydraulic control

device on the tractor.

• Pilotbox switched on.

• Select position B on the

pilotbox.

• Single-acting hydraulic control

device on the tractor.

Lower the transport chassis [+]

• Switch the pilotbox on.

• Select position B on the pilotbox.

• Lower the transport chassis using

the tractor's double-acting hydraulic

control device.

• Caution: During this process, the lift

arms are also retracted.

Raise the transport chassis [+]

• Switch the pilotbox on.

• Select position B on the pilotbox.

• Raise the transport chassis using

the tractor's double-acting hydraulic

control device.

• Caution: During this process, the lift

arms are also extended.

• Crank on left rotor. Working depth of left rotor

• Switch off the PTO shaft drive.

• Switch off the tractor and secure it.

• Set the working depth using the

crank on the left rotor.

• Crank on right rotor. Working depth of right rotor

• Switch off the PTO shaft drive.

• Switch off the tractor and secure it.

• Set the working depth using the

crank on the right rotor.

38

Page 39

Delivery and assembly

The operator’s manual and spare

part manual can be found in the

document box on the machine.

Delivery and assembly

Checking the scope of delivery

Delivery is in the fully assembled state

The machine is delivered fully assembled. Using the check list, check

the loose parts on delivery. If any parts of the machine have not been

fitted or are missing, please contact your dealer.

\ WARNING

Do not assemble the machine yourself

Trained personnel are required to assemble the machine. Do not

perform assembly work yourself. The following points are required

to be met for the machine to be in proper condition:

• Observance of the sequence of work steps.

• Compliance with tolerances and torques.

• Knowledge of work safety during assembly.

Incorrect assembly can result in damage to the machine or

accidents.

If parts are missing or have been damaged during transportation,

please inform the dealer, importer or manufacturer immediately.

Operator’s manual

Check list for parts which were

supplied loose

PTO shaft for drive 1

PTO shaft for auxiliary drive 2

Tine support placing swaths on the left 11

Tine support placing swaths on the right 11

Swath former 1

Operator’s manual 1

Spare part manual 1

Additional equipment See delivery note

The operator’s manual belongs with the machine and must always be

kept on board. A document box for the operator’s manual and spare

part manual is mounted on the main frame.

Quantity

39

Page 40

Delivery and assembly

Narrow track

Wide track

Checking tandem axle [+]

\ WARNING

Ensure that the tandem axle is positioned correctly

Ensure that the tandem axles are positioned correctly. If they are

positioned incorrectly, this will cause damage to the machine.

Check that the tandem axles [+] are aligned correctly.

• The wide track is at the front in relation to the direction of travel.

• The narrow track is at the back in relation to the direction of

travel.

40

Page 41

Delivery and assembly

Length of PTO shaft

Safety

The length of the PTO shaft was selected at the factory to suit almost

all types of tractor. Only in exceptional cases is a correction of the PTO

shaft length required on individual tractors. Check the length of the

PTO shaft on each tractor prior to first use.

A manufacturer's operator’s manual for the PTO shaft is enclosed.

This includes detailed information on the relevant version of the PTO

shaft and must be observed.

\ WARNING

Switch off the tractor and secure it

Before you dismount:

Disengage the PTO

Lower all implements to the ground

Place all controls in their neutral or park position

Set the parking brake

Switch off the tractor.

Remove the ignition key.

Secure the tractor against rolling away.

An unsecured tractor can run you over or trap you.

Otherwise, serious or fatal injury may be caused as a result.

Checking the length

of the PTO shaft

Checking the angle of lock

The PTO shaft has a wide hinge joint giving the tractor a steering

angle of up to 80°. Make sure that the PTO shaft is not damaged

during sharp cornering. This would result in damage to the

machine.

Correct length

A PTO shaft that is too long must not be used. This would result in

damage to the drive bearings of the tractor and the machine.

Couple the machine to the tractor without the PTO shaft.

Lower the lower link of the tractor.

Set the combination (tractor and machine) to the smallest steering

angle.

Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

41

Page 42

Delivery and assembly

Marking on the guard tube

1

2

3

4

5

Shortening the PTO

shaft

Pull the PTO shaft apart and connect one half to the tractor PTO

shaft drive and one to the machine and secure them.

Place the two shaft halves next to each other and:

• Check for a minimum of 250 mm (10 in) overlap (b).

• Check that the PTO shaft is not blocked at each end

Shorten both the sliding tube and guard tube to the same size.

Deburr the ends of the tubes.

Remove the shavings.

Grease the sliding surfaces well.

Minimum distance (a) = 20 mm (1 in).

Fitting the PTO shaft

Make sure that you fit the PTO shaft in the correct installation position.

There is a marking on the guard tube of the PTO shaft.

Check the length of the PTO shaft and shorten it if necessary.

Place the PTO shaft onto the PTO stub shaft of the machine.

Secure the PTO shaft with a locking pin.

Remove the locking screw (1) between the guard tube (2) and the

guard cone (3).

Twist the guard cone (3) and the guard tube (2) in opposite

directions so that the "noses" of the slide ring (4) are positioned

directly over the slots on the guard cone (3).

Pull the guard cone (3) and guard tube (2) back until the single joint

(5) is accessible.

Connect the PTO shaft to the machine.

Push the guard cone (3) and guard tube (2) back over the single

joint (5).

Tighten the locking screw (1).

Secure the guard cone to the gear box using a jubilee clip.

42

Page 43

Delivery and assembly

Track arm

Steering arm

Track rod

Steering rod

Steering

Checking the

steering

The following applies to all instructions below:

Please note the following instructions and safety information:

»Coupling the machine«. Page 44.

»Coupling the lower link«, page 45.

»Coupling the PTO shaft«, page 47.

\ WARNING

Never carry out work on the steering

Contact your dealer if specifications differ. Never carry out any

work on the steering or track yourself.

This can result in traffic accidents and accidents causing serious

or fatal injuries.

The steering is fitted and calibrated in the factory. Check the

adjustment of the steering with a hitched machine.

Drive along a straight line with the entire combination (tractor with

hitched machine). For example, a straight kerb.

Check if the machine follows the tractor in the same track.

If the machine is pulled at an offset angle behind the tractor, the

tracking must be checked and adjusted. This work must be carried out

by a dealer.

Checking the track

If the machine rolls at an offset angle to the tractor when driving a

straight line, the directional stability is set incorrectly. Proceed as

follows:

See chapter »Checking the track«, page 99.

Consult your dealer. Never carry out any work on the steering or

tracking yourself.

43

Page 44

Coupling the machine

Coupling the machine

Safety

\ WARNING

Observe the safety information

Disregard for safety information can lead to serious or fatal injury.

See chapter »Safety«, page 8.

Increased risk of injury

When the machine is being coupled to the tractor, there is an

increased risk of injury. Therefore:

• Never stand between the tractor and machine.

• Secure the tractor against rolling away.

Failure to observe these instructions can result in serious or

fatal injury.

General

The machine is equipped at the factory for coupling to the lower link of

the three-point power lift system.

The following work steps are described in this section:

• »Coupling the lower link«

• »Swivelling in the parking stand«

• »Coupling the PTO shaft«

• »Wheel chocks«

• »Electrical connections«

• »Hydraulic connections«

44

Page 45

Coupling the lower

Pin

Lynch pin

Catch

Lower link

link

Tractors with quickrelease couplings

Coupling the machine

\ WARNING

Follow the instructions for the quick-release coupling

Follow the instructions below for tractors with quick-release

couplings. If this requirement is ignored, the consequence may be

damage to the machine and even life-threatening injuries.

Slide collecting trays suitable for the tractor onto the lower link

hitching system of the machine.

To couple the machine, raise the lower link until the catch engages.

Secure the quick-release coupling with lynch pins.

Secure the catch with pins.

Follow the instructions for »Tractors without quick-release

coupling«.

Tractors without

quick-release

coupling

The following applies to all tractors, with or without quick-release

couplings:

Couple the machine to the lower link - in accordance with the

operator’s manual of the tractor manufacturer - lift slightly and

secure.

Slightly raise the lower link.

Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

Swivel in the parking stand.

See »Swivelling in the parking stand«, page 46.

With the lower link in the work position, lift it off the ground until the

main frame of the machine is tilted approximately 1 degree

forwards.

Engage the lower link at the sides.

Adjust the lower link such that a uniform ground clearance is

maintained.

Note the instructions and warnings in the operator’s manual of the

tractor manufacturer for tractors with lower link quick-release

couplings.

45

Page 46

Coupling the machine

Pin

Parking stand

Swivelling in the parking stand

After coupling the machine to the tractor, raise and secure the parking

stand.

Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

Pull the pin on the parking stand.

Swivel in the parking stand.

Release the pin on the parking stand and lock it in place.

46

Page 47

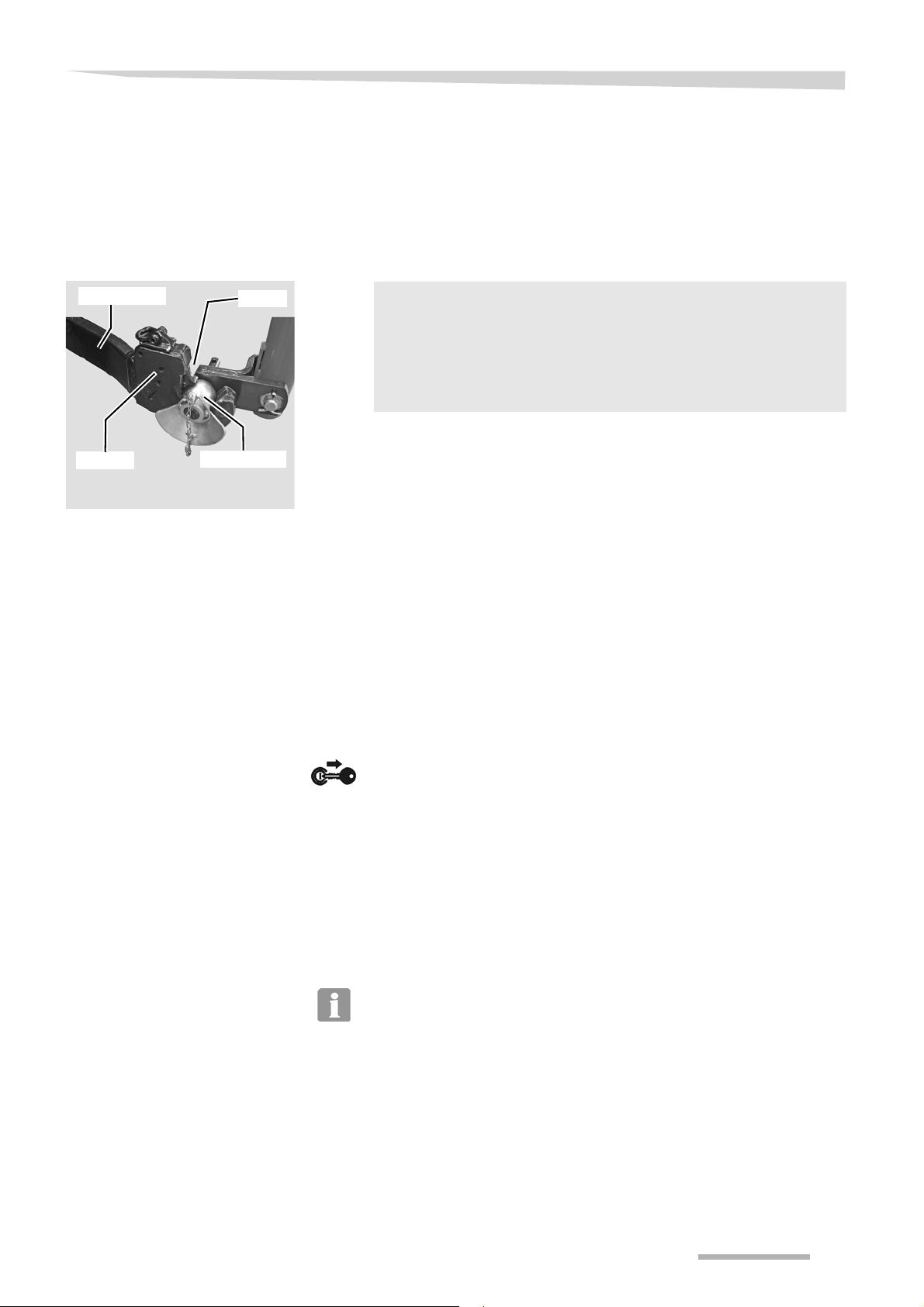

Coupling the machine

Tractor

Wide angle joint with

freewheel assembly

PTO shaft

Chain

Wide angle joint

Coupling the PTO shaft

Make sure that you fit the PTO shaft in the correct installation position.

There is a marking on the guard tube of the PTO shaft.

\ WARNING

Do not use force

When coupling the PTO shaft, do not use a hammer or any similar

tools. Using these types of tool can severely damage the PTO

shaft. A damaged PTO shaft can cause damage to the tractor and

the machine.

Check whether the PTO shaft must be shortened before coupling.

Shorten the PTO shaft if necessary.

»Length of PTO shaft«, page 41

Check that the tractor's PTO stub shaft is clean and lubricated.

Couple the PTO shaft to the tractor and the machine.

Ensure that the PTO shaft is engaged on the shaft ends.

Secure the guard tubes so that they cannot rotate at the same

time.

Couple the wide-angle joint to the machine's PTO stub shaft.

47

Page 48

Coupling the machine

Wheel chock

Wheel chocks

\ WARNING

Use wheel chocks

Never remove the wheel chocks before the machine has been

coupled to the tractor. Persons could be run over by the machine

or the tractor. Serious or fatal injury would be caused as a result.

Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

Remove the wheel chocks from in front of the wheels.

Place them in the brackets provided on the left and right behind the

warning plates on the transport chassis and engage them securely.

48

Page 49

Connections

Left-hand lighting equipment

Amber

Red

2 x reflectors

(red and amber)

Electrical

Coupling the machine

connections

Lighting equipment –

USA

\ WARNING

Checking the electrical cables

Check the electrical cables. The electrical cables must not chafe

or hang loose. Electrical cables that have been torn away or worn

through must be replaced. Damage to the machine may be

caused as a result.

The machine is fitted with lighting equipment for road transport. The

lighting equipment is mounted on the left and right-hand side of the

rear guard bar and connected to the tractor by a 7-pin plug. The corresponding connection must be present on the tractor (SAE J560).

If your tractor does not have the corresponding connection, this must

be retrofitted. Consult your dealer.

The lighting equipment is controlled by the lighting controls in the tractor.

The lamps on the machine are only switched on when either the parking

lights or the headlight of the tractor is switched on.

SAE J560 plug

arrangement

PIN Cable Connection to

1 White Earth; all lights

2 Black Not used

3 Yellow Left indicator (amber)

4 Red Brake lights

5 Green Right indicator (amber)

6 Brown Rear lights (red)

7 Blue Not used

Connect the plug for the 12 V power supply to the 7-pin plug socket

on the tractor.

49

Page 50

Coupling the machine

Function overview of

lighting equipment – USA

Tractor lights Left amber Left red Right red Right amber

Headlight “OFF” — Off Off —

Headlight “ON” — Dimmed Dimmed —

Amber indicator light “OFF” Off — — Off

Amber indicator light “ON” Flashing (same

frequency as right)

Brake lights

(for tractors with brake lights)

Amber indicator light “ON”

No turning indicated

(tractor with brake lights)

Amber indicator light “ON”

No turning indicated

(no tractor brake lights)

Turning left indicated Higher flashing

— Bright Bright —

Flashing (same

frequency as right)

Flashing (same

frequency as right)

frequency

Check that the lighting equipment is functioning using the following

table.

Device lights

— — Flashing (same

frequency as left)

Bright Bright Flashing (same

Off Off Flashing (same

Depending on tractor

equipment: Off, dimmed

or flashing in sync with

the left-hand light

Off or dimmed Illuminated, no flashing

frequency as left)

frequency as left)

Turning right indicated Illuminated, no flashing Off or dimmed Depending on tractor

equipment: Off, dimmed

or flashing in sync with

the right-hand light

Observe local regulations governing lighting equipment for travelling

on the road. Consult your dealer if the lighting equipment does not

function as stated.

Higher flashing

frequency

50

Page 51

Pilotbox [+]

Pilotbox

Coupling the machine

\ WARNING

Switch off the pilotbox for all tasks on the machine

Always switch off the pilotbox when coupling or uncoupling and

when carrying out service or maintenance work or any task on the

machine. If the pilotbox is switched on and accidentally actuated,

unexpected machine movements may be triggered. This can

cause accidents with fatal consequences.

Mount the pilotbox in the driver's cab so that it is secure and easily

reachable.

Pilotbox Solenoid valve connec-

tion

A Y1 Raise and lower the left-hand lift arm.

B Y2 Raise and lower the transport chassis.

C Y3 Raise and lower the right-hand lift arm.

The pilotbox is included in the scope of delivery for the Hydro version.

The pilotbox is not included in the scope of delivery for the standard

version.

Function

51

Page 52

Coupling the machine

Hydraulic

connections

\ WARNING

Check hoses and couplings

Check all hydraulic hoses for damage before connecting them.

Check all hydraulic couplings for firm seating after connecting

them. Defective hydraulic hoses and poorly fitting hydraulic

connections can trigger unanticipated movements in the machine,

causing severe damage to the machine as well as personal injury.

Serious or fatal injury may be caused as a result.

Secure the tractor's control devices

In the transport position, secure the control devices on the tractor

against unintended actuation and lock them if possible. Unintentional activation of a control device can trigger unpredictable

movements of the machine and cause serious machine damage

and personal injury. Serious or fatal injury may be caused as a

result.

Check the routing of the hydraulic hoses

Close or disconnect the quick couplings with great care. Remove

any dirt or air which has entered the hydraulic system. The

hydraulic system may otherwise be seriously damaged. Material

damage or personal injury may be caused as a result.

Hydraulic connection at zero pressure only

Only connect hydraulic hoses to the tractor hydraulic system if the

tractor and machine hydraulic system is at zero pressure. A

hydraulic system which is under pressure can cause unforeseen

movements on the machine.

Avoid mixing oils

If the machine is used on different tractors, an impermissible

mixing of oil may occur. Impermissible oil mixtures can destroy

tractor components.

High pressures in the hydraulic system

The hydraulic system is under high pressure. Regularly check all

lines, hoses, and screwed connections for leaks and externally

visible damage. Do not use hands to search for suspected leaks.

Only use suitable equipment when looking for leaks. Rectify any

damage immediately. Fluid escaping under pressure can

penetrate skin may result in injuries and fires. Seek medical

attention immediately if injuries occur.

52

Page 53

Connecting the

Red

Yellow

hydraulic couplings

Coupling the machine

\ WARNING

Make sure the connection is correct

Ensure that the hydraulic system is connected correctly,

Otherwise, damage to the machine and personal injury may be

caused as a result.

Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

Close the ball valve.

Roll up the control ropes and store them in the tractor cab.

Connect the hydraulic coupling of the machine to the single-acting

control device when it is set to the floating position.

Connect the hydraulic coupling on the machine to the double-

acting control device.

The rotors are raised and lowered and single-swath mode is controlled

using the single-acting control unit (hydraulic connection not colourcoded).

The swath width is controlled using the double-acting control device.

Hydraulic line Marking

Single-acting hydraulic control device

pressure line

Double-acting hydraulic control device

Pressure line

Double-acting hydraulic control device

Return line

Black

Red

Yellow

53

Page 54

Coupling the machine

Hydro version

The rotors are raised and lowered via the single-acting hydraulic

control device. Single swath operation is controlled by switching on

and actuating the pilotbox.

The swath width is controlled using the double-acting hydraulic control

device. Raising and lowering the transport chassis is controlled by

switching on and actuating the pilotbox.

Hydraulic line Marking

Double-acting hydraulic control device

pressure line

Double-acting hydraulic control device

return line

Single-acting hydraulic control device

pressure line

Red

Yellow

Black

54

Page 55

Preparing for use

Safety

Preparing for use

\ WARNING

Observe the safety information

Disregard for safety information can lead to serious or fatal injury.

See chapter »Safety«, page 8.

Securing the machine

Secure the machine against unintentional starting and rolling

away. Use wheel chocks. The machine must stand on a level, firm

and secure surface and be supported during the work, if

necessary. Unsecured or non-supported machines can cause

accidents. Otherwise, serious or fatal injury may be caused as a

result.

No persons in the working area

Ensure that no persons are present in the slewing and working

area of the machine. Persons could be caught by the machine

within this area. This could result in fatal injury.

Remove tine supports

When carrying out adjustment work on the machine, tine supports

which hinder work on the machine must be removed. Tine

supports that are not removed can cause serious injuries.

Avoid the hazard area

The rotors are considered a hazard area. Do not stand in the

hazard area. The rotors may lower or turn. This could result in fatal

injury.

Unfold fully and evenly

Ensure that the side devices are evenly unfolded. If there is a malfunction, fold the side devices back in and repeat the process at a

higher engine speed. The hydraulic cylinders must be completely

extended in the work position, otherwise the machine may be

damaged.

55

Page 56

Preparing for use

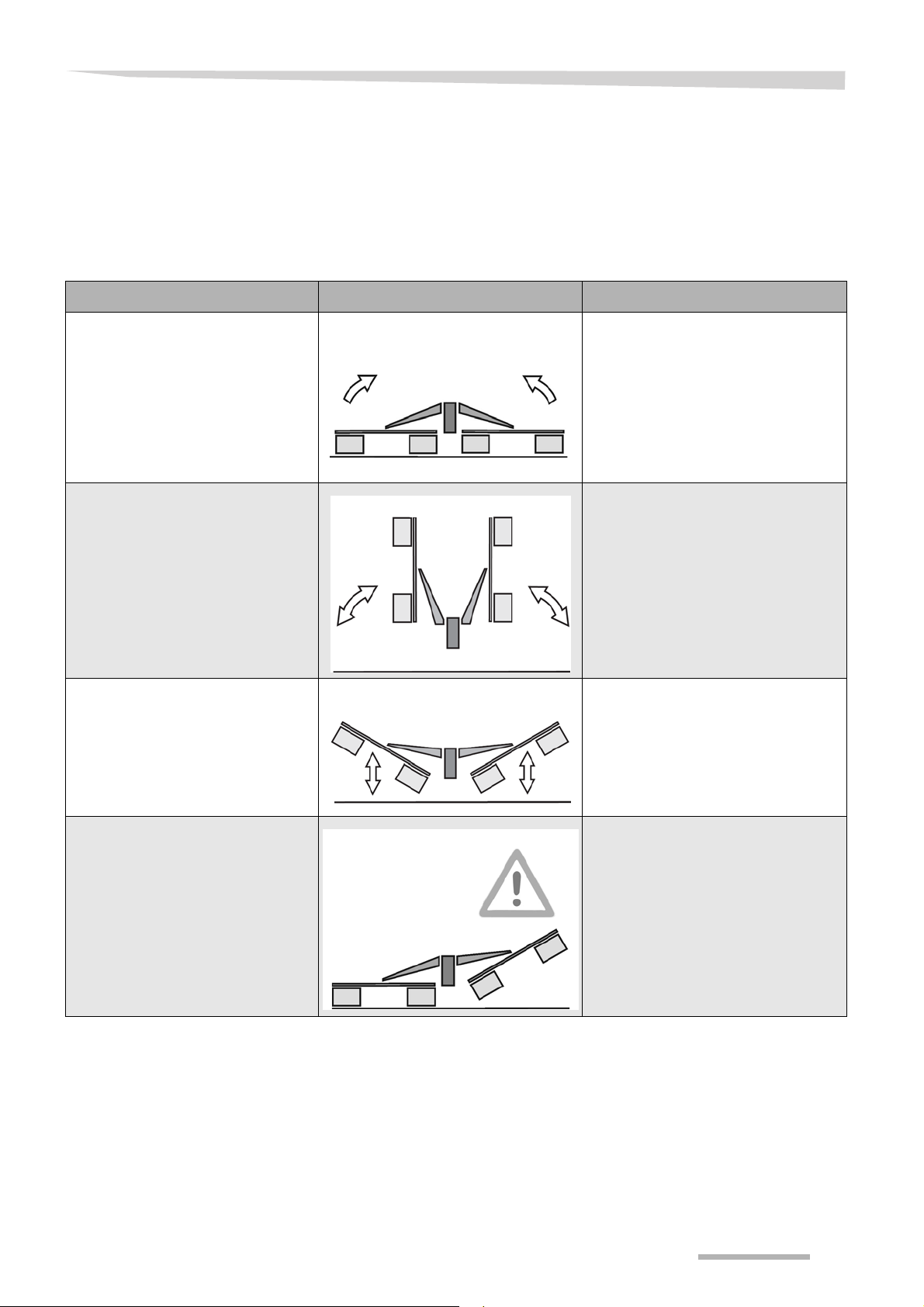

Frame pitch

Rotor pitch

Working depth

Rotor pitch

Lifting the tines

20 mm (0.8 in)

20 mm (0.8 in)

0 mm

0 mm

1°

Early lifting

Late lifting

Working depth

General

Adjusting the machine

The following applies when performing all adjustment work:

Check the tire pressure.

Secure the machine.

Lower the machine to the work position.

Undo the appropriate bolts.

Make the required adjustment.

Retighten the bolts.

Fit and secure the tine supports.

The following work steps are described in this section:

• »Adjusting the machine«

• »Frame pitch«

• »Rotor pitch«

• »Working depth«

The machine is preset at the factory. The following illustration shows

an overview of the basic settings. Detailed information can be found

on the following pages.

56

Page 57

Frame pitch

1°

Rotor pitch

Preparing for use

For improved pick-up of the crop, use the three-point power lift system

to incline the main frame approx. 1° further to the front.

Use the three-point power lift system to incline the main frame

approx. 1° further to the front.

\ WARNING

Close the ball valve

Close the ball valve before working on the machine or carrying out

any adjustment work. If the ball valve is open and there is an

operating error, the machine can lower itself and cause serious

injuries.

The rotors are inclined transversely to the chassis. The rotor is already

inclined transversely ex-factory. If the crop is not picked up cleanly, the

raking quality can be improved by adjusting the rotor pitch.

The optimum raking quality is achieved when the tips of the tines in

the front working area and before the crop is deposited have the

lowest possible ground clearance (see adjacent illustration).

57

Page 58

Preparing for use

20 mm (0.8 in)

20 mm (0.8 in)

Tines

Crop pick-up increases the distance (a) between the tines and the ground.

0 mm 0 mm

a

a

a

a

Adjusting the rotor

pitch

Before carrying out any adjustment work, you must secure the

machine:

Move the machine to the headland position using the tractor's

control device.

Close the ball valve.

Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away

Secure the rotors using supports.

Remove the tine supports.

Then carry out one of the following steps:

Adjust the rotor pitch for a single axle

»Adjust the rotor pitch for a single axle«, page 59.

– or –

Adjust the rotor pitch for a tandem axle [+]

»Adjust the rotor pitch for a tandem axle [+]«, page 60.

58

Page 59

Preparing for use

M 20 nut at

250 Nm (185 ft.lbs)

Pin

Axle plate

Adjust the rotor pitch for a

single axle

Loosen the M 20 nut.

Remove the M 20 nut and washer.

Remove the wheel.

Fit the wheel in the desired position.

Put the washer and M 20 nut back on.

Retighten the M 20 nut.

Fit and secure the tine supports.

The inner wheels (on the swath former side) must be fitted one hole

higher than the outer wheels.

Tighten the bolt to at least 250 Nm (185 ft.lbs). The axle plate must sit

securely on the pin.

59

Page 60

Preparing for use

M 20 nut at 250 Nm

Securing pin

Axle plate

Stop plate

Securing pin

Adjust the rotor pitch

for a tandem axle [+]

Remove the M 20 nut.

Remove the tandem axle.

Fit the tandem axle in the desired position.

Fit the securing pin in the opposite hole.

Tighten the M 20 nut to 250 Nm (185 ft.lbs).

Fit and secure the tine supports.

The inner tandem axle (on the swath former side) must be fitted one

hole higher than the outer tandem axle so that the rotor on the swath

former side is inclined.

Tighten the M 20 nut to at least 250 Nm (185 ft.lbs). The axle plate

must sit securely on the stop plate of the securing pin.

60

Page 61

Working depth

Tines

Working depth

Crank

Retainer

Preparing for use

\ WARNING

Never set the tines too deep

If the tines are set too deep:

• The tines are overstressed.

• The tines will soil the crop.

• This can result in damage to the machine.

Adjust the working depth as follows:

Fully lower the machine using the hydraulic control device on the

tractor and advance approximately 2 metres (7 ft).

Shut off the engine, set the parking brake, remove the ignition key

and secure the tractor against rolling away.

Check the working depth to the ground.

Adjusting the

working depth

The working depth is set using the crank on the rotor.

Release the crank retainer on the rotor chassis and adjust the

working depth by turning the crank.

• Basic setting: the tines lightly touch the ground.

• Ten turns of the crank equate to a rotor tine height adjustment

of about 15 mm (0.6 in). The thread is left-handed.

After adjusting, secure the crank against turning using the retainer.

Adjust the working width on the second rotor in the same way.

Readjust the working depth to suit the field conditions if necessary.

Tines that are set too low will soil the crop. The load on the rotor tines

and the drive is increased.

• If necessary, adjust the working depth to the field again.

61

Page 62

Road transport

Road transport

Safety

Before transporting the machine on public roads, please read the

following safety information. Compliance is mandatory and will help

you to avoid accidents.

\ WARNING

Observe the safety information

Observe the safety information. Disregard for safety information

can lead to serious or fatal injury. See chapter »Safety«, page 8.

Ensuring road safety

The machine must conform to current national traffic regulations if

you intend to drive it on public roads. Ensure the following:

• Lighting, warning and protective equipment must be fitted.

• The permissible transport widths and weights, axle loads, tire

load-bearing capacities, laden weights and national speed

restrictions must be observed.

• The maximum permissible road transport speed must be

complied with, but not exceed 40 km/h (25 mph).

• The machine should only be towed by agricultural or forestry

tractors.

• The empty weight of the tractor must be greater than the weight

of the machine.

The driver and keeper of the vehicle are liable should these

conditions not be observed.

Observe the contour of the terrain

Move the machine onto ground that is as flat as possible before

changing from the working to the transport position. Avoid inclines

on which the combination (tractor and machine) could slip or

overturn. There is an increased risk of tipping and injury in a

position at right angles to the direction of the slope.

Observe transport width

Observe the permissible transport widths. Put the machine in the

transport position and attach lights, warning signs and protective

equipment. The driver and keeper of the vehicle are liable for any

non-compliance with national traffic regulations.

Close the ball valve