Page 1

RA1042T

Operator‘s manual

Original operator‘s manual

Edition 09.2013

Date of print 09.2014

Language EN-EU

Machine number VF65982451 –

Model VF6598

Document number VF16660942.EN-EU

Page 2

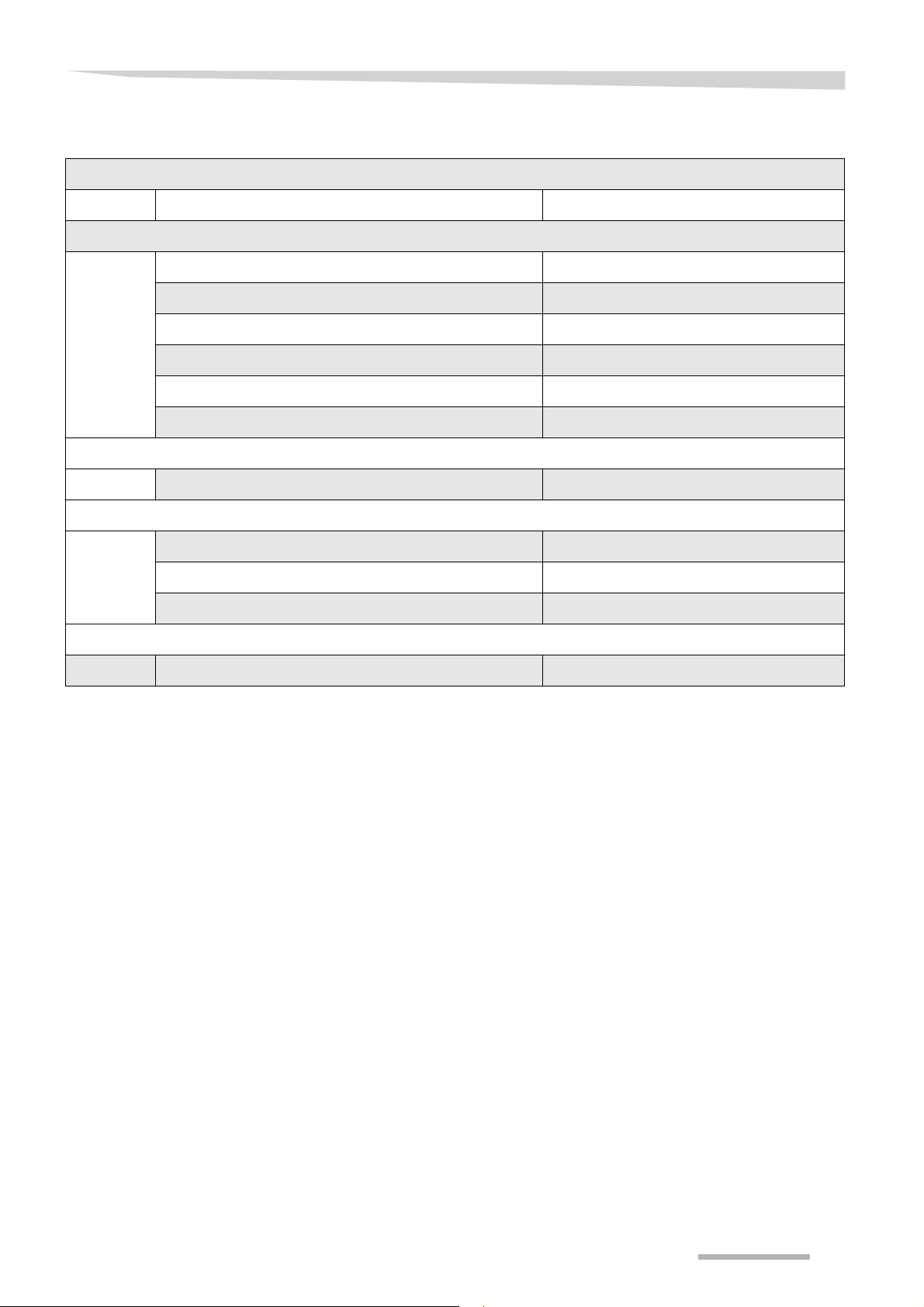

Machine identification

In order for your dealer to assist you as efficiently as possible, you will need to provide some information about

your machine. Please enter the details here.

Designation

Working width

Weight

Machine

number

Accessories

Supplier's

address

RA1042T

4.20 m

570 kg

VF6598_ _ _ _

Manufacturer's

address

Kverneland Group Kerteminde AS

Taarupstrandvej 25

DK-5300 Kerteminde

Denmark

Tel: +45 65 19 19 00

Copyright by Kverneland Group Gottmadingen N. V., Germany. Reproduction, transfer to other media, translation or the use of extracts or parts

of this manual without the explicit permission of Kverneland, is not permitted. All rights reserved. The contents of this operating manual are subject

to change without notice. The right to technical revision is reserved.

Page 3

Table of contents

Preface ....................................................... 4

Target group for this

operating manual 4

Symbols used 5

Table of contents

Cleaning and care ..................................... 56

Safety 56

Cleaning 57

Care 57

Safety ......................................................... 6

For your safety 6

Who is allowed to operate the machine? 10

General

safety information 10

Coupling 13

Hydraulics 13

Road transport 14

Operation 16

Uncoupling 17

Care and maintenance 18

Further regulations 19

Familiarising yourself with the machine 20

Range of application 20

Features 20

Designation of components 21

Technical specifications 22

Delivery and assembly ............................. 26

Checking the scope of delivery 26

Length of PTO shaft 27

Coupling the machine .............................. 29

Safety 29

General 29

Coupling the machine 30

Connecting the electrics [+] 34

Connecting the hydraulics 37

Preparing for use ...................................... 38

Safety 38

General 38

Rotor pitch 39

Working depth 40

Parking and storage .................................. 58

Safety 58

General 58

Uncoupling the machine 59

After the end of the season 60

Maintenance ............................................... 61

Safety 61

General 63

Screwed connections 65

Lubrication points for grease 67

Lubricating the PTO shafts 68

Filling quantities 69

Tyres 69

Hydraulics 70

Additional equipment ................................ 71

Optional accessories 71

Fault elimination ........................................ 74

Faults 74

Circuit diagrams ........................................ 75

Hydraulic system connection diagram 75

Lighting equipment circuit diagram 76

Decommissioning ..................................... 77

Environment 77

EC Declaration of Conformity .................. 78

Conforms to

EC Directive

2006/42/EC 78

Index ........................................................... 80

Road transport .......................................... 42

Safety 42

General 43

Prior to road transport 43

Road transport 47

Preparations on the field ......................... 48

Safety 48

General 48

Basic settings 49

Operation ................................................... 52

Safety 52

General 53

Swathing 54

Swath deposit 55

Driving on headlands 55

3

Page 4

Preface

Preface

Target group for this

operating manual

Minimum age

For your safety

Training

This operating manual is intended for trained agriculturists and

persons who are otherwise qualified for agricultural activities and have

received instruction in working with this machine.

Children under the age of 16 are not permitted to operate the machine.

You must familiarise yourself with the contents of this operating

manual before assembly or initial operation of the machine. In this

way, you will achieve optimum work results and operational safety.

The operating manual forms an integral part of the machine and must

always be kept to hand. This will ensure that you:

• avoid accidents.

• comply with warranty conditions.

• have a fully functional machine in good working order at all times.

Your will receive training from your dealer concerning using the

controls and care of the machine.

Information for the employer

All personnel are to be regularly, but at least once a year, instructed

on the use of the machine, in accordance with the regulations of the

national organisation for Health and Safety at Work. Untrained or

unauthorised persons are not permitted to use the machine.

You are responsible for ensuring that the machine is operated and

maintained safely. Make sure that you and all other persons that

operate, maintain or work in close proximity with the machine are

familiar with the operating and maintenance regulations, as well as the

corresponding safety instructions in this operating manual.

4

Page 5

Preface

Symbols used

In this operating manual, the following symbols and terms have been

used:

• A bullet point accompanies each item in a list.

A triangle indicates operating functions which must be performed.

An arrow indicates a cross-reference to other sections of this

manual.

[+] A plus sign indicates additional equipment which is not included in

the standard version.

We have also used pictograms to help you find instructions more

quickly:

The "Information" pictogram indicates tips and additional information.

The “Examples” pictogram indicates examples that assist understanding of the instructions.

Caution

The warning triangle indicates important safety information. Failure

to observe this safety information can result in:

• Serious faults in the correct operation of the implement.

• Damage to the machine.

• Personal injury or accidents.

The spanner indicates tips for assembly or adjustment work.

Switch on the tractor.

Switch off the tractor and secure it against rolling away.

The arrow in the diagram shows the direction of travel.

5

Page 6

Safety

Safety

For your safety

This chapter contains general safety instructions. Each chapter of the

operating manual contains additional specific safety information which

is not described here. Observe the safety information:

• in the interest of your own safety.

• in the interest of the safety of others.

• to ensure the safety of the machine.

Numerous risks can result from handling agricultural machinery in the

wrong way. Therefore, always work with particular care and never

under time pressure.

Information for the employer

Inform all persons who work with the machine about this safety

information at regular intervals and in accordance with statutory regulations.

6

Page 7

Safety

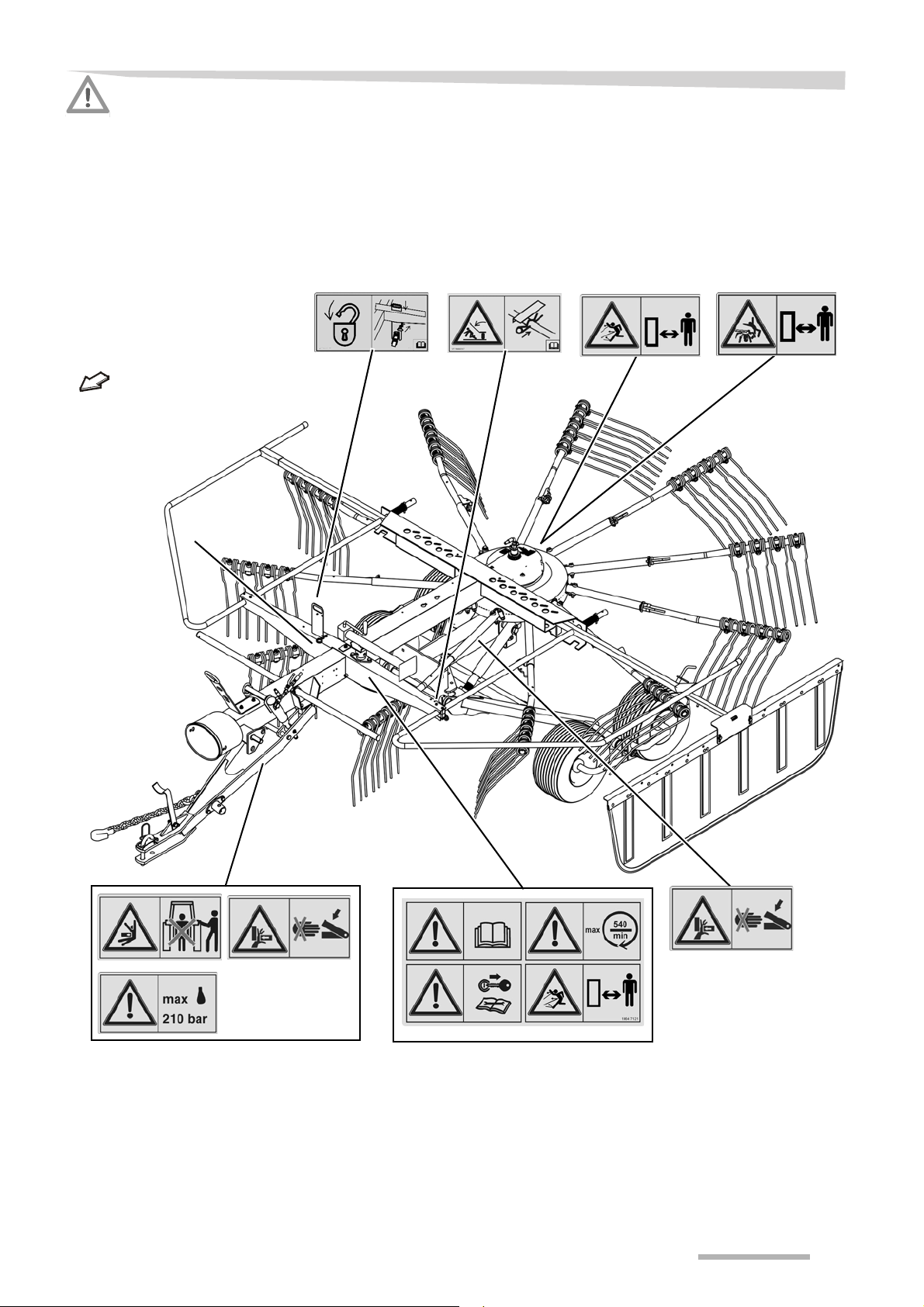

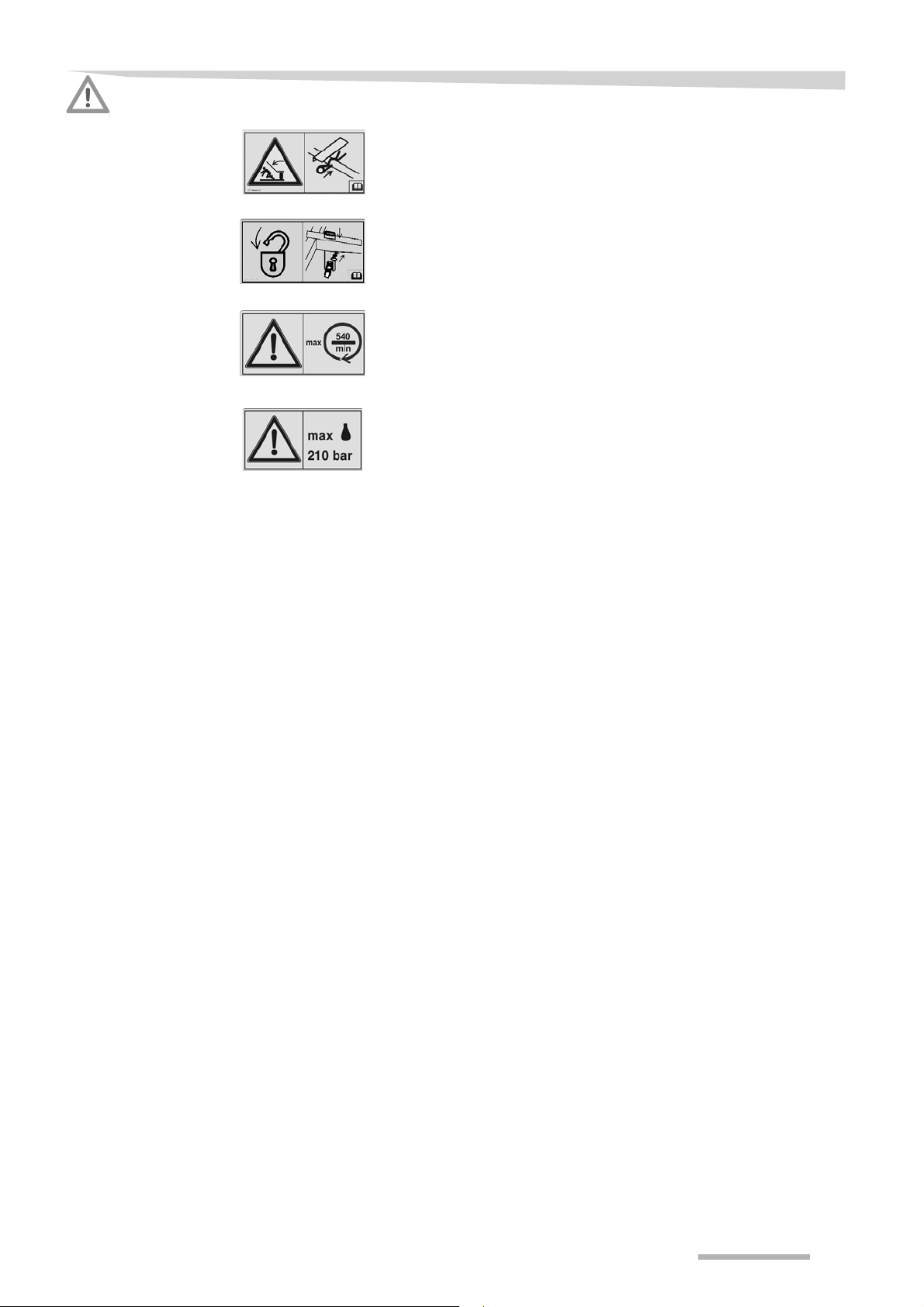

Warning signs

Warning signs on the

machine

Safety-related stickers attached to the machine indicate potential

hazards. The stickers must not be removed. Illegible or missing

stickers should be replaced. You can obtain new stickers as

replacement parts from your dealer.

7

Page 8

Safety

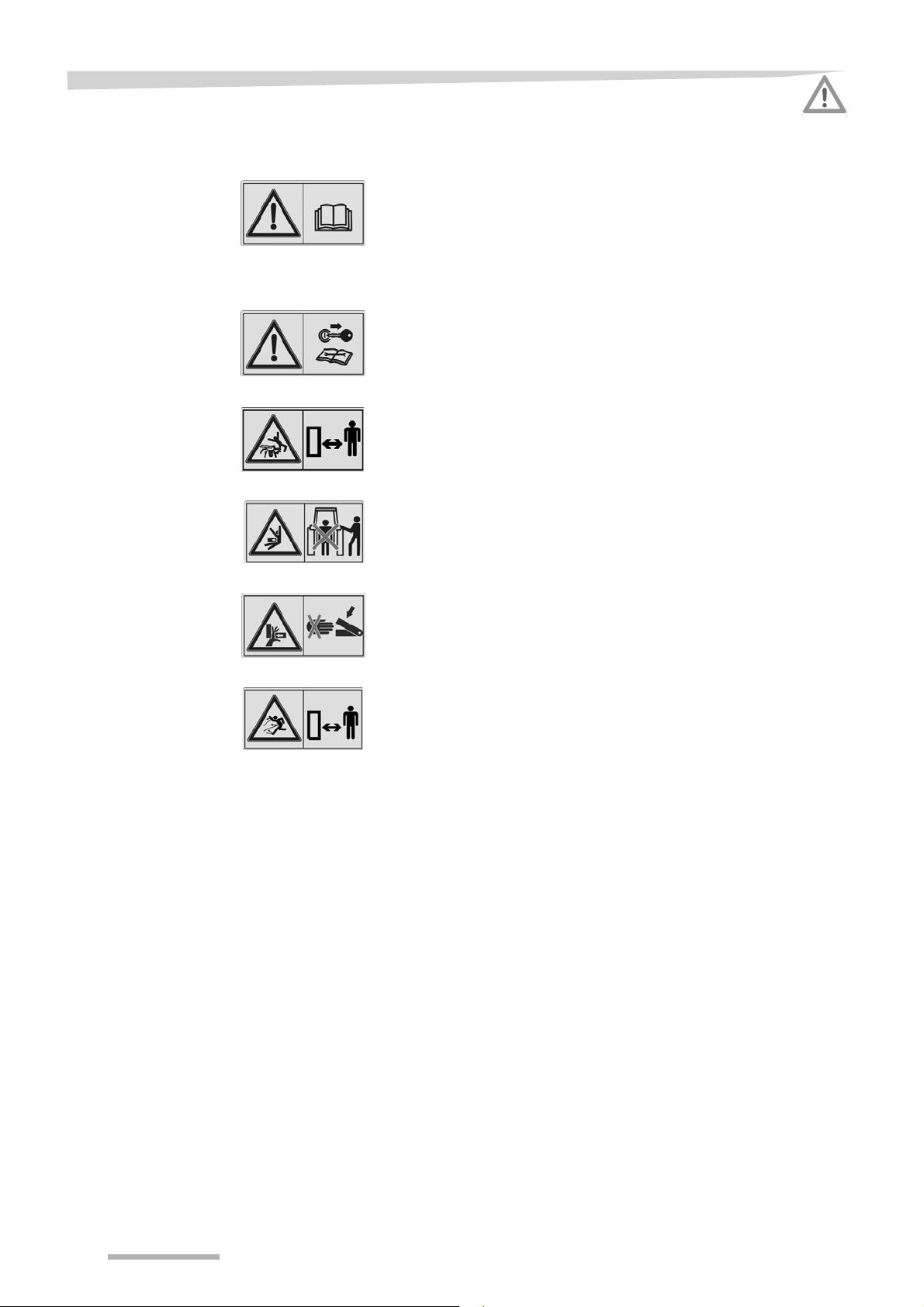

Meaning of warning

signs

Read the operating manual

Read and follow the operating and safety instructions before using the

machine for the first time. The machine must not be used for the first

time until the operating manual has been read and understood. This

applies in particular to the safety information. Otherwise, serious or

fatal injury may be caused as a result.

Switch off the engine

Only perform maintenance, repair and adjustment work when the

machine is shut down. Otherwise, serious or fatal injury may be

caused as a result.

Distance from the rotor

Maintain a safe distance from the rotor when it is rotating. Nobody may

remain in close proximity to the machine when tedders and rakes are

running. Otherwise, serious or fatal injury may be caused as a result.

Distance from the tractor

When the machine is being coupled, uncoupled or operated, there

should be no-one between the tractor and the machine. Otherwise,

serious or fatal injury may be caused as a result.

Risk of crushing

Never reach into an area where there is a risk of crushing if parts in

that area are still likely to move. Otherwise, serious or fatal injury may

be caused as a result.

Caution, parts ejected at speed

Hazard caused by parts which may become detached when the drive

is in operation, and ejected at speed. Maintain a safe distance.

Otherwise, serious or fatal injury may be caused as a result.

8

Page 9

Safety

Secure the swath former after it is folded up

Secure the swath former after it is folded up. The swath former may

fold down unexpectedly. Otherwise, serious or fatal injury may be

caused as a result.

Securing the rotors

Secure the rotor in the transport position. The rotor may turn unexpectedly due to centrifugal forces. Otherwise, serious or fatal injury

may be caused as a result.

PTO shaft speed 540 rpm

The specified maximum PTO shaft speed of 540 rpm must not be

exceeded. Otherwise, damage to the machine may be caused as a

result.

Do not exceed the maximum hydraulic pressure

The tractor's hydraulic pressure on the machine's hydraulic system

must not exceed 210 bar. Otherwise, damage to the machine may be

caused as a result.

9

Page 10

Safety

Who is allowed to operate the machine?

General

safety information

Only qualified persons may operate the machine

Only qualified persons who have been informed of the dangers

associated with handling the machine are permitted to operate,

service or repair the machine. The necessary knowledge can be

gained in the course of agricultural vocational training, professional

training or intensive instruction.

The general safety information and warning signs apply to every

phase of the life cycle of the machine and to every application.

Switch off the tractor and secure it

Before you dismount:

Switch off the tractor.

Remove the ignition key.

Secure the tractor against rolling away.

An unsecured tractor can run you over or trap you. Otherwise, serious

or fatal injury may be caused as a result.

Operate for the first time only after proper training

The machine may only be put into operation after proper training has

been provided by an employee from a dealership or the manufacturer,

or by a factory representative. Operation without proper training can

lead to damage to the machine due to incorrect operation, or may

cause accidents.

Safety is your responsibility

Follow the safety instructions. Ensure that all operators comply with

the safety instructions. Prevent serious or fatal accidents by following

the safety instructions.

Instructions in the event of malfunctions

In the event of a malfunction, shut down, stop and secure the machine

immediately. Rectify the malfunction immediately yourself or seek the

assistance of a workshop. Operating a faulty machine can cause

accidents or damage.

No persons in the working area

Ensure that no persons are present in the slewing and working area

of the machine. Persons could be caught by the machine within this

area. This could result in fatal injury.

Perfect working condition

Ensure that the tractor and the machine are always in perfect working

condition. Make sure that the tractor brakes work in synchronisation

with the machine. Also follow the instructions in your tractor's

operating manual.

10

Page 11

Safety

Switch off the tractor PTO shaft drive

Switch off the tractor's PTO shaft drive when changing from work to

transport position (and vice versa). Wait for moving parts to come to a

stop. If this requirement is ignored, the consequence may be damage

to the machine and even life-threatening injuries.

No reversing while the drive is running

Never drive in reverse with the PTO shaft drive switched on and in the

work position if people could enter the working area of the machine.

Switch off the PTO shaft drive. Rotating, unprotected parts can

damage the machine and cause life-threatening injuries.

Specified workwear

Do not wear loose fitting clothing. Loose fitting items of clothing may

become caught in rotating parts. Wear workwear and protective

clothing, as specified by the Accident Prevention and Insurance Association. Serious or fatal injury may be caused as a result.

No riding on the machine

Persons or objects must never be transported on the machine.

Carrying passengers on the machine is life-threatening and

prohibited. Serious or fatal injury may be caused as a result.

11

Page 12

Safety

Never work on the machine while it is running

No operations may be performed on the machine while it is running.

Objects or persons can be caught, drawn in or crushed. Serious or

fatal injury may be caused as a result.

PTO shaft

Use only the PTO shafts specified by the manufacturer and read the

attached operating manual carefully. Adjust the length of the PTO

shaft as required. Incorrect PTO shaft lengths can cause damage to

the machine and personal injury.

Check and fasten the PTO shaft guard in position

The rotating PTO shaft is protected by the PTO shaft guard. Ensure

that the guard is not damaged. Fasten the PTO shaft guard in position

by connecting the chains on the implement and the tractor. Unguarded

PTO shafts can cause life-threatening injuries.

Make sure the machine is standing level

Before changing from the transport to the work position (and vice

versa), make sure the machine is standing level. Otherwise, damage

to the machine and serious or fatal injury may be caused as a result.

Do not make any modifications to the machine

No modifications of any kind may be made to the machine. Unauthorised modifications can adversely affect the correct operation and

safety of the machine and shorten its service life. Unauthorised modifications to the machine render the manufacturer's guarantee null and

void and free the manufacturer from all liability.

PTO shaft speed 540 rpm

The specified maximum PTO shaft speed of 540 rpm must not be

exceeded. A higher PTO shaft speed will damage the machine.

Unrestricted field of vision to the rear

After it has been coupled, ensure that you have an unrestricted view

of the machine, in both its work and transport positions. At the very

least, use the panorama mirror provided by the tractor manufacturer.

Otherwise, dangerous situations may not be detected in time.

resulting in accidents or damage.

12

Page 13

Safety

Coupling

Increased risk of injury

When the machine is being coupled to the tractor, there is an

increased risk of injury. Therefore:

• Secure the tractor against rolling away, shut off the engine and

remove the ignition key.

• Never stand between the tractor and machine.

• Lock the PTO shaft securely on the PTO stub shafts of the tractor

and the machine.

If this requirement is ignored, the consequence may be damage to the

machine and even life-threatening injuries.

Attaching electrical connections after assembly

The electrical supply to the tractor must not be connected when the

lighting equipment is being fitted. Otherwise, short circuits will occur

and the electronic system will be damaged.

Observe the operating manual of the PTO shaft manufacturer

Observe the operating manual of the PTO shaft manufacturer. It will

provide you with instructions on how to handle the PTO shaft correctly.

If these instructions are ignored, damage may be caused to the PTO

shaft and machine.

Hydraulics

Hydraulic connection at zero pressure only

Only connect hydraulic hoses to the tractor hydraulic system if the

tractor and machine hydraulic system is at zero pressure. A

pressurised hydraulic system can trigger unpredictable movements of

the machine and can cause serious damage to the machine and

personal injury. Serious or fatal injury may be caused as a result.

High pressures in the hydraulic system

The hydraulic system is under high pressure. Regularly check all lines,

hoses, and screwed connections for leaks and externally visible

damage. Only use suitable equipment when looking for leaks. Rectify

any damage immediately. Oil escaping under pressure may result in

injuries and fires. Seek medical attention immediately if injuries occur.

Replace hydraulic hoses every six years

Hydraulic hoses age without showing externally visible signs. Replace

hydraulic hoses every six years. Defective hydraulic lines can cause

serious or fatal injuries.

13

Page 14

Safety

Road transport

Ensuring road safety

The machine must conform to current national traffic regulations if you

intend to drive with it on public roads. Ensure the following:

• Lighting, warning and protective equipment must be fitted.

• The permissible transport widths and weights, axle loads, tyre

load-bearing capacities, laden weights and national speed restrictions must be complied with.

• The maximum permissible road transport speed must be complied

with, but not exceed 50 km/h.

• Before driving on public roads, fully fold in all guard bars and

secure the machine. All tine supports which have tips that point at

right angles to the direction of travel must be removed.

• The machine should only be towed by agricultural or forestry

tractors.

The empty weight of the tractor must be greater than the weight of the

machine. The driver and keeper of the vehicle are liable should these

conditions not be observed.

Close the ball valve

Close the ball valve before driving on the road. If the ball valve is open

and there is an operating error, the machine may drop or swing out

unexpectedly. This could cause traffic accidents and accidents with

fatal consequences.

Check tyre pressures

Check tyre pressure on a regular basis. Incorrect tyre pressures

reduce the service life of a tyre and cause unstable driving characteristics. Accidents with serious or fatal injuries may be caused as a

result.

Altered driving and braking performance

Driving and braking performance are altered when the machine is

coupled or hitched to the tractor. When cornering, take the overall

width and balancing weight of the machine into consideration. Adjust

your driving speed accordingly. A driving style which is not adapted to

conditions can cause accidents. Accidents with serious or fatal injuries

may be caused as a result.

14

Page 15

Safety

Speed adjustment

In poor road conditions and at high speeds, significant forces can be

generated which subject the tractor and machine material to high or

excessive stresses. Adjust your driving speed to the road conditions.

A driving style which is not adapted to conditions can cause accidents.

Accidents with serious or fatal injuries may be caused as a result.

Check hitch pins

Hitch pins must be in perfect condition. Hitch pins must show no signs

of wear and be properly secured. Otherwise, hitched machines may

detach themselves of their own accord. Accidents with serious or fatal

injuries may be caused as a result.

15

Page 16

Safety

Operation

Operate for the first time only after proper training

The machine may only be put into operation after proper training has

been provided by an employee from a dealership or the manufacturer,

or by a factory representative. Operation without training can lead to

damage to the machine due to incorrect operation, or cause

accidents.

Ensure that the machine is in perfect working condition

Do not operate the machine unless it is in perfect working condition.

Check all key components and their correct operation before use.

Replace defective components. Defective components can cause

material damage and personal injury.

Check the protective equipment

The protective equipment must not be removed or by-passed. Check

all protective equipment before using the machine. Unprotected

machine parts can cause serious or fatal injury.

Check the immediate vicinity

Check the area immediately surrounding the machine before driving

off, and continually during operation. Make sure that you have an

adequate view. Only begin work when the immediate vicinity is cleared

of any persons or objects. Serious or fatal injury may be caused as a

result.

Retighten all nuts, bolts and screws

Regularly check that nuts and bolts are correctly tightened. Retighten

bolts if necessary. Nuts and bolts can work loose when the machine is

used. Damage to the machine or accidents may be caused as a result.

The PTO stub shaft continues turning after it has been switched

off

After the PTO stub shaft drive on the tractor has been switched off, the

machine continues to run due to the moment of inertia. Maintain a sufficiently safe distance until all moving parts have come to a complete

standstill. Otherwise, damage to the machine and serious or fatal

injury may be caused as a result.

Cornering and turning manoeuvres

Centrifugal forces are in operation during cornering. The machine's

centre of gravity at the rear of the tractor is displaced. Be aware of the

turning radius and the moment of inertia. A driving style which is not

adapted to conditions can cause accidents. Accidents with serious or

fatal injuries may be caused as a result.

16

Page 17

Safety

Uncoupling

Increased risk of injury

There is an increased risk of injury when uncoupling the machine from

the tractor. Therefore:

• Secure the tractor against rolling away, turn off the engine and

remove the ignition key.

• Never stand between the tractor and machine.

• Set the machine down on firm, secure and level ground.

• Ensure that the parking stand is securely locked.

• Place the PTO shaft in the holder provided.

• Secure the machine against rolling away (use wheel chocks).

• Do not disconnect hydraulic hoses until there is no pressure in the

tractor and machine hydraulic system.

Failure to observe these instructions can result in serious or fatal

injury.

17

Page 18

Safety

Care and maintenance

Observe the care and maintenance intervals

Observe the periods specified in the operating manual for recurrent

checks and inspections. If these periods are not observed, damage to

the machine and accidents may be caused as a result.

Use original parts

Many components have special properties that are essential for the

stability and correct operation of the machine. Only spare parts and

accessories supplied by the manufacturer have been tested and

approved. Other products may adversely affect the correct operation

of the machine and safety. Using non-OEM replacement parts renders

the manufacturer's guarantee null and void and frees the manufacturer from all liability.

When performing care and maintenance work:

• Switch off the PTO shaft drive.

• Depressurise the hydraulic system.

• Whenever possible, uncouple the tractor.

• Switch off the tractor and remove the ignition key.

• Ensure the machine is standing on firm, secure and level ground,

and provide additional support, if necessary.

• Secure the machine against rolling away (use wheel chocks).

Only if these regulations are observed can safe working be ensured

during care and maintenance work.

Turn off the electrical supply

Prior to carrying out work on the electrical system, disconnect the

system from the power supply. Systems being supplied with electrical

power can cause damage to equipment and injury to persons.

Caution when cleaning with a high-pressure cleaner

Exercise caution when cleaning with a high-pressure cleaner.

Bearings, seals and pipe unions are not waterproof. In order to

prevent damage to the machine, the bearings, seals and pipe unions

must not be exposed to direct contact with the high-pressure water jet.

18

Page 19

Safety

No aggressive washing additives

Do not use any aggressive washing additives for cleaning. Uncoated

metal surfaces can be damaged.

Before carrying out welding work

Disconnect all electrical connections from the tractor when carrying

out welding on the hitched machine. Damage may otherwise be

caused to the electrical system.

Retighten all nuts, bolts and screws

All pin and screwed connections that are loosened during

maintenance and repair operations must be retightened. Serious

injury and damage to equipment can be caused by loose pin and

screwed connections.

Further regulations

Warranty

Observe the regulations

In addition to the safety information listed above, please observe the

following:

• Accident prevention regulations.

• Generally recognised safety regulations, occupational health

requirements and road traffic regulations.

• The instructions provided in this operating manual.

• Regulations relating to operation, maintenance and repair.

The warranty and manufacturer's liability will no longer be valid if the

instructions provided in the chapter on Safety are not observed, if

maintenance is inadequate or faulty, if the machine is used for

purposes other than those for which it was intended and if it is overstressed, or if impermissible modifications are made to the machine.

19

Page 20

Familiarising yourself with the machine

Familiarising yourself with the mac hine

Range of application

Proper use

Features

This product is classified as replaceable equipment in accordance

with EC directive 2006/42/EC.

The machine is a single-wheel rake, which is suitable only for the

raking together of mown, stalked material (for example, hay or straw).

Any use other than the use described above - such as silo spreading,

any type of soil preparation, sweeping, or transmitting power to other

machines - is not permitted. The manufacturer and dealers are not

liable for damage caused by improper use. The risk is borne solely by

the user.

Flexible in operation

This single-wheel rake meets all the requirements of modern crop

harvesting engineering. Important functions for field use are controlled

during active operation.

The rake can be pulled by tractors of 15 kW (20 hp) or more.

Extensive equipment

The machine is equipped with a low-maintenance gear box and 11 tine

supports on each rotor. The cranked tines achieve an excellent raking

quality.

Easy changeover from work to transport position

The rake is easily changed over from the work to the transport

position.

Raise height of 50 centimetres

For road transport and on headlands, the machine can be quickly raised

by roughly 50 centimetres. For working, lower the rotary rakes hydraulically from transport position back to work position.

20

Page 21

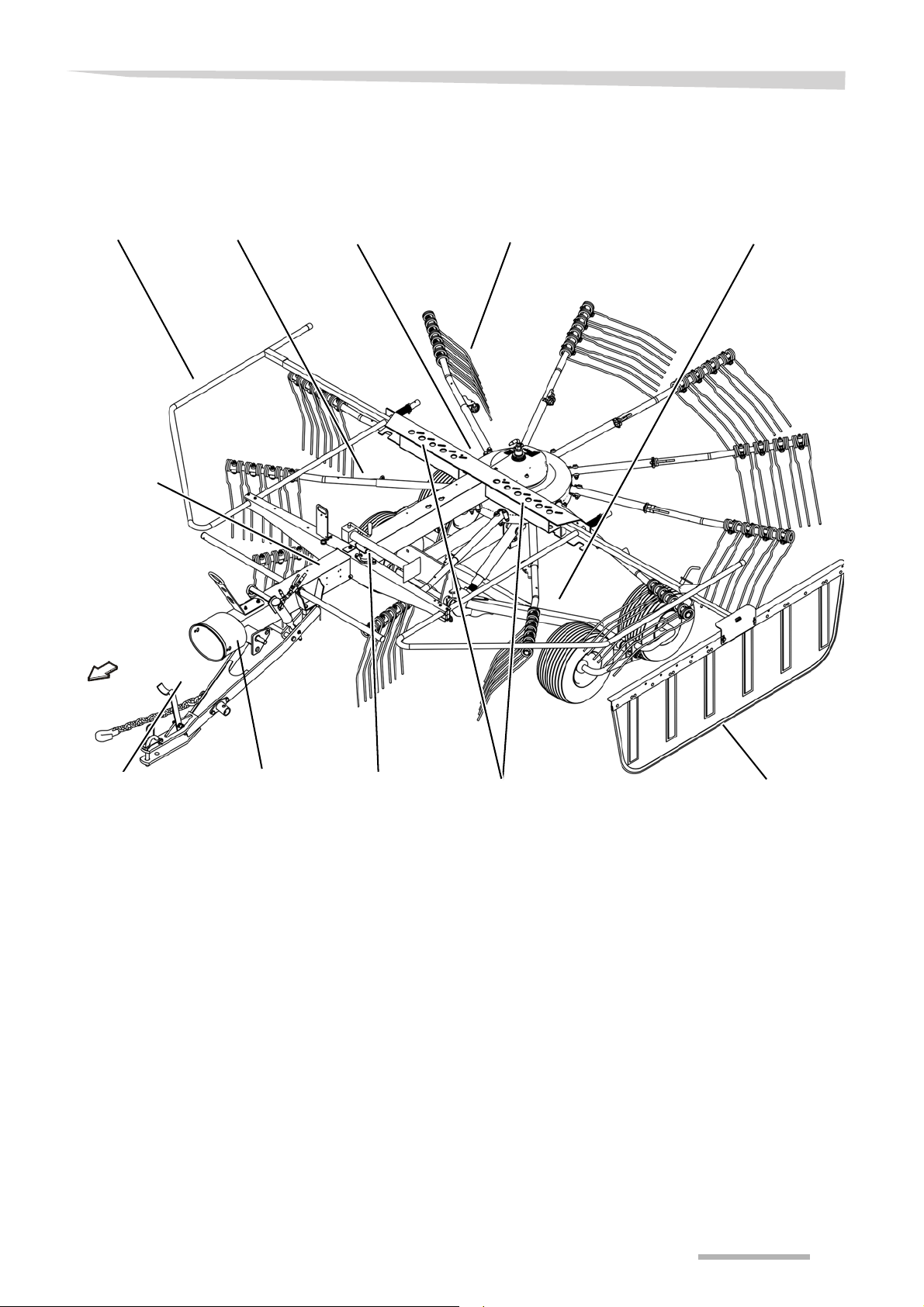

Familiarising yourself with the machine

Guard bar

Main frame

Tine support TinesRotor gear Rotor chassis

Swath former

Transport holder for

tine supports

Parking

stand [+]

DriveDrawbar

Designation of components

21

Page 22

Familiarising yourself with the machine

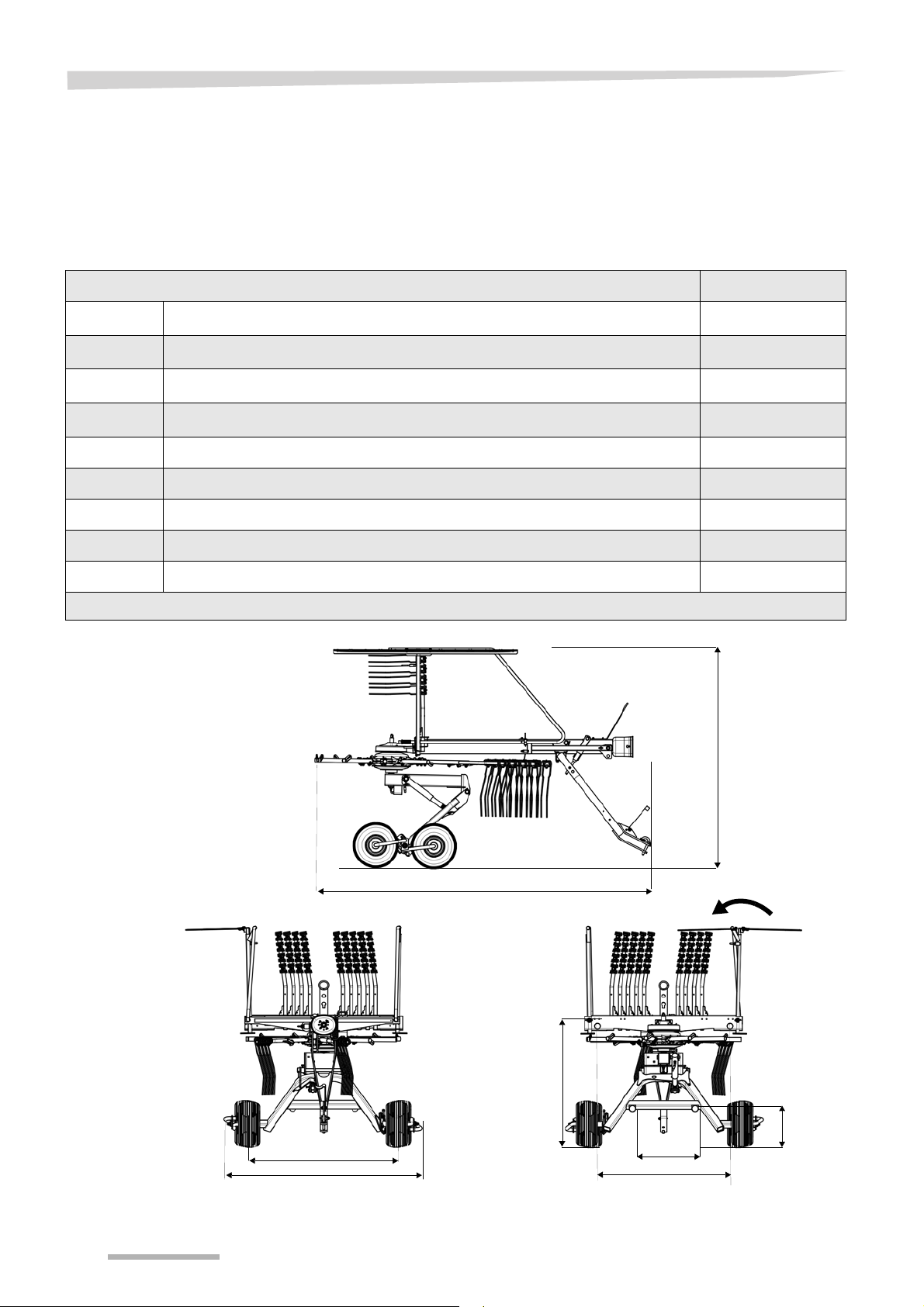

L

R

H

R

T

WT (WR)

O

S

P

R

Technical specifications

Dimensions in

transport position

[m]

L

R

H

R

W

R

W

T

T Track width 1.60

O Height of top reflectors 1.25

P Distance between top reflectors 1.70

R Height of bottom reflectors 0.40

S Distance between bottom reflectors 0.65

* Swath former in transport position

Length in transport position for road transport

Height in transport position for road transport

Width in transport position for road transport

Width in transport position from tyre to tyre

4.00

2.30

2.00* (2.45)

2.00

22

Page 23

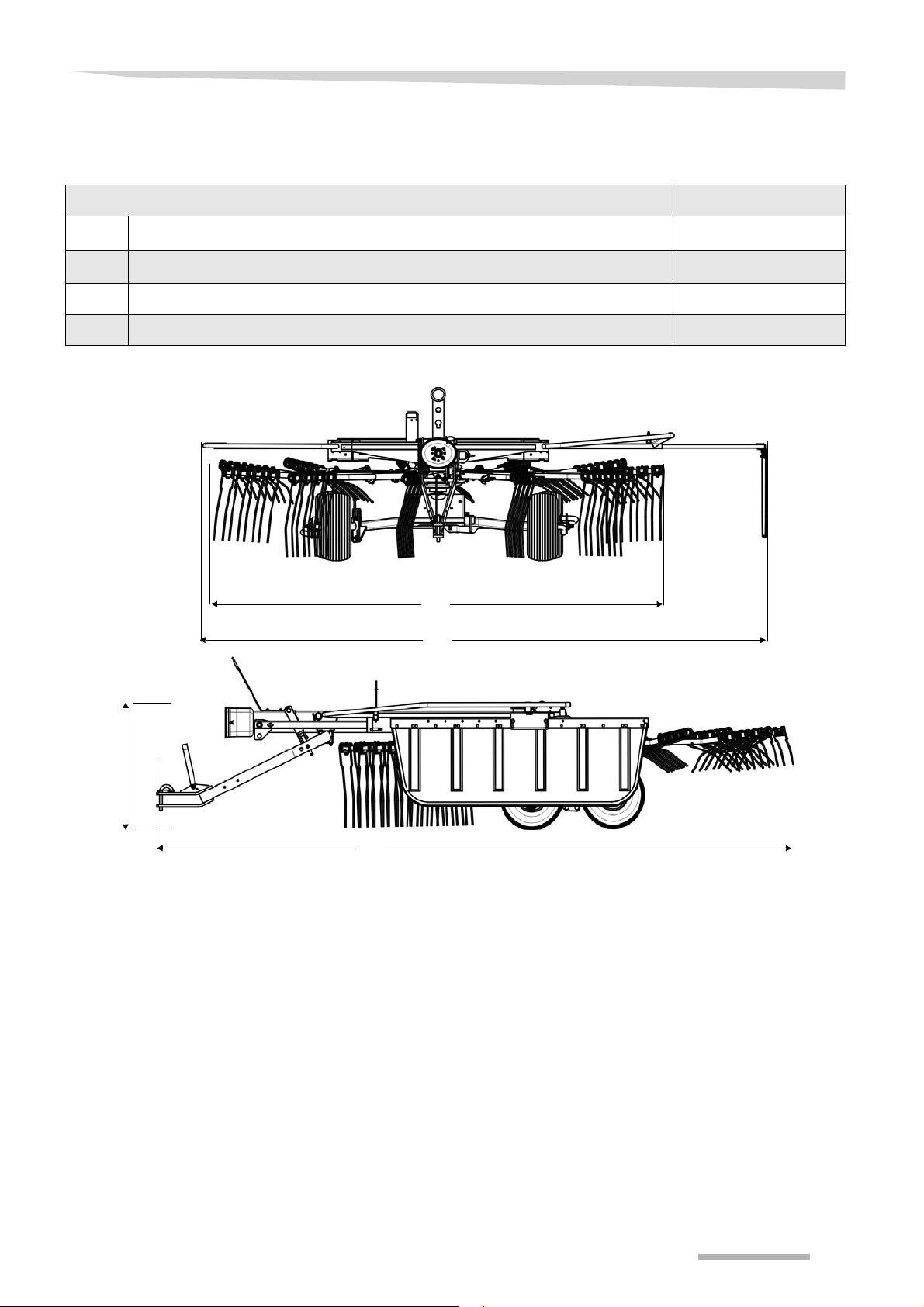

Familiarising yourself with the machine

L

W

H

W

RD

SE

Dimensions in work

position

[m]

L

W

H

W

RD Rotor diameter 3.35

SE Width with swath former fully extended 4.20

Length in work position

Height in work position

4.75

1.25

23

Page 24

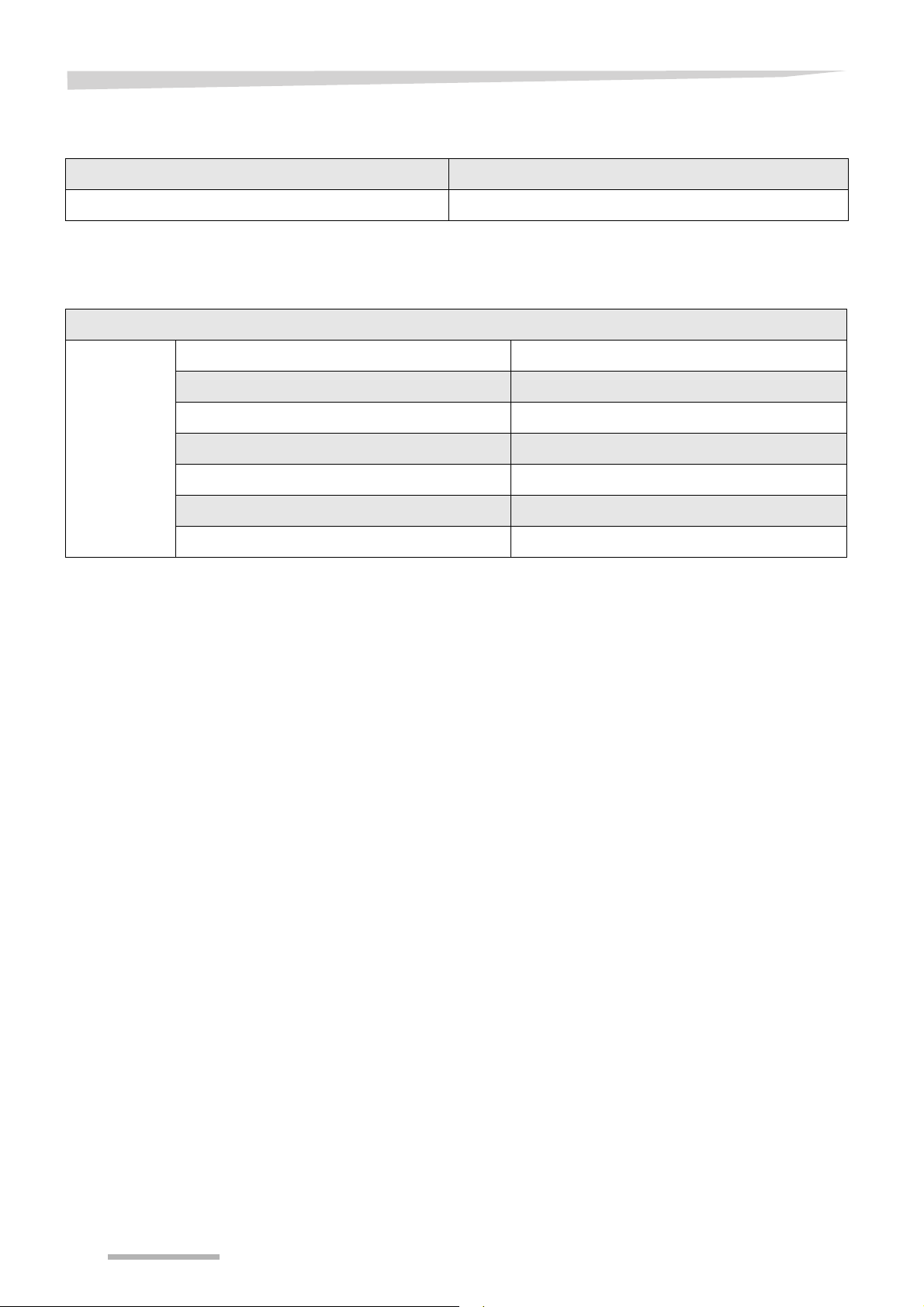

Familiarising yourself with the machine

Weights

Total weight 570 kg

Load supported on parking stand 150 kg

Tractor equipment

required

Output / connections

Minimum output of the tractor 15 kW (20 hp)

Lighting equipment power supply 12 V, 7-pin plug socket ISO 1724

Hydraulic connections 1 x single-acting hydraulic control device

Hydraulic pressure 150 - 210 bar

Maximum PTO shaft speed 540 rpm

Pending attachment In accordance with ISO 6489-3

Alternatively: lower link and lift link drawbar Fixable in height and laterally

24

Page 25

Familiarising yourself with the machine

Machine equipment

Swath deposit

Swath former Standard

Rotors / tine supports / tines

Number of rotors 1

Number of tine supports per rotor 11

Number of tines per tine support 4

Removable tine arms Standard

Rotor height adjustment Hydraulic/mechanical

Tine saver [+]

Wheels

Rotor chassis with tandem axle 18 x 8.50-8 PR 6

Safety accessories

Safety chain Standard

Lighting equipment [+]

Warning signs [+]

PTO shaft

PTO shaft (wide-angle, double-ended) Standard

Measurement of

airborne sound

emissions

The airborne sound emissions from the machine are below the levels

stipulated by machinery directive 2006/42/EC.

• A-weighted sound level in the workplace:

< 70 dB(A)

• Currently C-weighted sound level:

< 63 Pa (130 dB based on 20 µPa)

• A-weighted sound level on the machine:

< 80 dB(A)

25

Page 26

Delivery and assembly

Delivery and assembly

Checking the scope of delivery

Delivery is in the fully assembled state

The machine is delivered fully assembled. Using the check list, check

the loose parts on delivery. If any parts of the machine have not been

fitted or are missing, please contact your dealer.

Do not assemble the machine yourself

Trained personnel are required to assemble the machine. Do not

perform assembly work yourself. The following points are required

to be met for the machine to be in proper condition:

• Observance of a sequence of worksteps.

• Compliance with tolerances and torques.

• Knowledge of work safety during assembly.

Incorrect assembly can result in damage to the machine or

accidents.

If parts are missing or have been damaged during transportation,

please inform the dealer, importer or manufacturer immediately.

Check list for parts which were

supplied loose

Quantity

PTO shaft for drive 1

Tine support placing swaths on the

left

Swath former 1

Operating manual 1

Spare part manual 1

Additional equipment See delivery note

11

26

Page 27

Delivery and assembly

Length of PTO shaft

Safety

The length of the PTO shaft was selected at the factory to suit almost

all types of tractor. Only in exceptional cases is a correction of the PTO

shaft length required on individual tractors. Check the length of the

PTO shaft on each tractor prior to first use.

A manufacturer's operating manual for the PTO shaft is enclosed. This

includes detailed information on the relevant version of the PTO shaft

and must be observed.

Switch off the tractor and secure it

Before you dismount:

Switch off the tractor.

Remove the ignition key.

Secure the tractor against rolling away.

An unsecured tractor can run you over or trap you.

Otherwise, serious or fatal injury may be caused as a result.

Checking the angle of lock

The PTO shaft has a wide hinge joint giving the tractor a steering

angle of up to 80°. Make sure that the PTO shaft is not damaged

during sharp cornering. This would result in damage to the

machine.

Correct length

A PTO shaft that is too long must not be used. This would result in

damage to the drive bearings of the tractor and the machine.

27

Page 28

Delivery and assembly

Marking on the guard tube

Checking the length

of the PTO shaft

Shortening the PTO

shaft

Couple the machine to the tractor without the PTO shaft.

Lower the lower link of the tractor.

Set the combination (tractor and machine) to the smallest steering

angle.

Switch off the tractor and secure it against rolling away.

Pull the PTO shaft apart and connect one half to the tractor PTO

shaft drive and one to the machine and secure them.

Place the two shaft halves next to each other and:

• Check for a minimum of 200 mm overlap (b).

• Check that the PTO shaft is not blocked at one end

(minimum distance (a) = 20 mm).

Shorten the slide tube and guard tube by the same dimension.

Deburr the ends of the tube.

Remove the swarf.

Grease the sliding surfaces well.

Fitting the PTO shaft

Make sure that you fit the PTO shaft in the correct installation position.

There is a marking on the guard tube of the PTO shaft.

Check the length of the PTO shaft and shorten it if necessary.

Place the PTO shaft onto the PTO stub shaft of the machine.

Secure the PTO shaft with a locking pin.

28

Page 29

Coupling the machine

Safety

Coupling the machine

Observe the safety information

Observe the safety information. Disregard for safety information

can lead to serious or fatal injury. See chapter »Safety«, page 6.

Increased risk of injury

When the machine is being coupled to the tractor, there is an

increased risk of injury. Therefore:

• Never stand between the tractor and machine.

• Secure the tractor against rolling away.

• Actuate the three-point power lift system slowly and carefully.

Failure to observe these instructions can result in serious or

fatal injury.

General

The machine is equipped at the factory for coupling to the pending

attachment or a lift link drawbar.

The following worksteps are described in this section:

• »Coupling the machine«

• »Coupling the PTO shaft«

• »Connecting the electrics [+]«

• »Connecting the hydraulics«

29

Page 30

Coupling the machine

Fixing pin

Safety chain

Coupling the

machine

G

enuine fixing pins from the manufacturer

Use only genuine fixing pins from the manufacturer. These have

the required strength. Other pins can break. Damage to the

machine or accidents may be caused as a result.

The rotary rake is coupled to the pending attachment or a lift link

drawbar with a fixing pin and secured with a safety splint.

See »Coupling to the pending attachment«, page 31.

– or –

See »Coupling to the lift link drawbar«, page 32.

A freely turnable lift link drawbar is available as an optional accessory

for coupling to lower links of category I-II.

Safety chain for USA

and Canada

See »Lift link drawbar [+]«, page 71.

In the USA and Canada, it is obligatory to secure the rotary rake to the

tractor with a safety chain.

Observe national regulations concerning the length and fitting of the

safety chain.

30

Page 31

Coupling to the

Height-adjustable parking stand

Safety splint

Fixing pin

pending attachment

Coupling the machine

Lock the height adjustment of the lower link

Lock the height adjustment of the lower link. Comply with the

tractor operating manual. Unintentionally raising the lower links

can irreparably damage the PTO shaft.

Lock the lateral setting of the lower links

Fix the lower links after coupling the implement. Lateral free

movement of the lower links causes unstable drive properties

during transport journeys and can cause accidents.

For coupling to a pending attachment in accordance with ISO 6489-3,

proceed as follows:

(A) Distance between the PTO shaft drive and the drawbar hitching

point: approximately 356 mm.

(B) Height between the PTO shaft drive and the drawbar hitching

point: approximately 203 – 305 mm.

(C) Fix the lower link height at a distance of approximately 400 mm

from the ground.

Couple the rotary rake to the pending attachment with a fixing pin.

Secure the fixing pin with a safety splint.

Take the height-adjustable parking stand out of the transport

holder bracket and fit it to the drawbar.

See »Coupling to the lift link drawbar«, page 32.

The working depth is adjusted on the chassis.

Chapter »Preparing for use«, section »Rotor pitch«, page 39

31

Page 32

Coupling the machine

50 mm

Pin

PTO shaft

Safety splint

Fixing pin

Transport holder

Parking stand

Coupling to the lift

link drawbar

The factory-supplied PTO shaft only allows for coupling to the pending

attachment. The PTO shaft supplied is too short for coupling to the lift

link drawbar. For a longer PTO shaft, please contact your dealer.

Ensure the minimum spacing

In the work position, the space between the PTO shaft and the pin

must never be less than 50 mm. Otherwise the PTO shaft may be

damaged, for example when driving over an undulation in the

ground. Damaged PTO shafts can cause injury to persons or

damage the machine.

Couple the rotary rake to the lift link drawbar with a fixing pin.

Secure the fixing pin with a safety splint.

Take the height-adjustable parking stand out of the transport

holder bracket and fit it to the drawbar.

See »Coupling to the lift link drawbar«, page 32.

Stowing the heightadjustable parking

stand [+]

After coupling, remove the height-adjustable parking stand [+] and fit

and secure it to the transport holder.

Switch off the tractor and secure it.

Pull the pin on the parking stand.

Remove the parking stand.

Fit the parking stand to the transport holder and secure it with a

fixing pin.

32

Page 33

Adjusting the

Spindle

Drawbar cylinder

Spindle

20 mm

Drawbar cylinder

drawbar cylinder

Coupling the machine

The drawbar cylinder is used to adjust the height of the drawbar and

the machine pitch so that the crop can be picked up satisfactorily. The

drawbar cylinder is adjusted differently depending on the equipment:

Proceed as follows.

Operation without optional support wheel:

Fully screw in the spindle on the drawbar cylinder.

Set the tractor's hydraulic control device to the floating position.

When the optionally available support wheel is used, the spindle on

the drawbar cylinder must be adjusted to compensate for the ground

undulations.

Operation with optional support wheel:

Unscrew the spindle on the drawbar cylinder by about 20 mm.

Spanner size "17" on the spindle

In the case of the optional support wheel, ensure that a lift of at least

10 mm is always guaranteed for the drawbar cylinder.

33

Page 34

Coupling the machine

Marking on the guard tube

7-pin plug

Coupling the PTO

shaft

When coupling the PTO shaft, make sure it is in the correct position.

Check whether the PTO shaft must be shortened before coupling.

Shorten the PTO shaft if necessary.

»Length of PTO shaft«, page 27

Check that the tractor's PTO stub shaft is clean and lubricated.

Couple the PTO shaft to the tractor and the machine.

• Fit the wide-angle joint on the tractor side.

Ensure that the PTO shaft is engaged on the shaft ends.

Secure the guard tubes so that they cannot rotate at the same

time.

Couple the single joint with slip clutch to the machine's PTO stub

shaft.

Connecting the electrics [+]

Lighting equipment

[+]

Check the electrical cables

Check the electrical cables. The electrical cables must not chafe

or hang loose. Electrical cables that have been torn away or worn

through must be replaced. Otherwise, this will cause damage to

the machine.

Attach the following electrical cables to the tractor:

Connect the plug for the 12 V power supply to the 7-pin plug socket

on the tractor.

34

Page 35

Illuminated warning

Left-hand lighting equipment

Orange Red

signs USA [+]

Coupling the machine

The optional warning sign kit with lighting equipment for the USA is

available for operation in the USA and Canada. The lighting

equipment is mounted on the left and right-hand side of the rear guard

bar and connected to the tractor by a 7-pin plug. The corresponding

connection must be present on the tractor (SAE J560).

If your tractor does not have the corresponding connection, this must

be retrofitted. Consult your dealer.

The lighting equipment is controlled by the lighting controls in the tractor.

The lights are only on if the tractor is in park position or the tractor's

headlights are switched on.

Connect the plug for the 12 V power supply to the 7-pin plug socket

on the tractor.

Check that the lighting equipment is functioning using the following

table:

Device lights

Tractor lights Left orange Left red Right red Right orange

Headlight “OFF” — Off Off —

Headlight “ON” — Dimmed Dimmed —

Orange indicator light “OFF” Off — — Off

Orange indicator light “ON” Flashing (same

Brake lights

(for tractors with brake lights)

Orange indicator light

“ON”

No turning indicated

(tractor with brake lights)

Orange indicator light

“ON”

No turning indicated

(no tractor brake lights)

Turning left indicated Higher flashing

Turning right indicated Illuminated, no flashing Off or dimmed Depending on tractor

frequency as right)

— Bright Bright —

Flashing (same

frequency as right)

Flashing (same

frequency as right)

frequency

— — Flashing (same

Bright Bright Flashing (same

Off Off Flashing (same

Depending on tractor

equipment: Off, dimmed

or flashing in sync with

the left-hand light

Off or dimmed Illuminated, no flashing

equipment: Off, dimmed

or flashing in sync with

the right-hand light

frequency as left)

frequency as left)

frequency as left)

Higher flashing

frequency

Observe local regulations governing lighting equipment for travelling

on the road. Consult your dealer if the lighting equipment does not

function as stated.

35

Page 36

Coupling the machine

Power adapter USA

Power adapter

USA [+]

A specific power adapter is available for the USA.

36

Page 37

Coupling the machine

Connecting the hydraulics

Check hoses and couplings

Check all hydraulic hoses for damage before connecting them.

Check all hydraulic couplings for firm seating after connecting

them. Defective hydraulic hoses and poorly fitting hydraulic

connections can trigger unpredictable movements of the machine,

causing severe damage to the machine as well as personal injury.

Serious or fatal injury may be caused as a result.

Secure the tractor's control devices

In the transport position, secure the tractor's control devices

against unintended actuation and lock them if possible. Unintentional activation of a control device can trigger unpredictable

movements of the machine and cause serious machine damage

and personal injury. Serious or fatal injury may be caused as a

result.

Check the routing of the hydraulic hoses

Close or disconnect the quick-release couplings with great care.

Remove any dirt or air which has entered the hydraulic system.

The hydraulic system may otherwise be seriously damaged.

Material damage or personal injury may be caused as a result.

Avoid mixing oils

If the machine is used on different tractors, an impermissible

mixing of oil may occur. Impermissible oil mixtures can irreparably

damage tractor components.

Connecting the

hydraulic couplings

Ensure the connection is correct

Make sure that the hydraulics are connected correctly. Otherwise,

injuries and damage to the machine may be caused as a result.

Close the ball valve.

Set the tractor hydraulics to “free float”.

Switch off the tractor and secure it.

Connect the machine's hydraulic coupling to the single-acting

hydraulic control device.

37

Page 38

Preparing for use

Preparing for use

Safety

The following applies to all preparations for operation:

Observe the safety information

Observe the safety information. Disregard for safety information

can lead to serious or fatal injury. See chapter »Safety«, page 6.

Secure the machine

Secure the machine against unintentional starting and rolling

away. Use wheel chocks. The machine must stand on a level, firm

and secure surface and be supported during the work, if

necessary. Unsecured or non-supported machines can cause

accidents. Otherwise, serious or fatal injury may be caused as a

result.

No persons in the working area

Ensure that no persons are present in the slewing and working

area of the machine. Persons could be caught by the machine

within this area. This could result in fatal injury.

Remove tine supports

When carrying out adjustment work on the machine, tine supports

which hinder work on the machine must be removed. Tine

supports that are not removed can cause serious injuries.

General

The following applies when performing all adjustment work:

Check the tyre pressure.

Secure the machine.

Lower the machine to the work position.

Undo the appropriate bolts.

Make the required adjustment.

Retighten the bolts.

Fit and secure the tine supports.

The following worksteps are described in this section:

• »Rotor pitch«

• »Working depth«

38

Page 39

Rotor pitch

3 x M12 bolts to 85 Nm

Adjusting screw

20 mm

Crop pickup increases the distance between the tines

and the ground.

0 mm

Adjusting the rotor

pitch

Preparing for use

Close the ball valve

Close the ball valve before working on the machine or carrying out

any adjustment work. If the ball valve is open and there is an

operating error, the machine can lower itself and cause serious

injuries.

The rotors are inclined transversely to the chassis. The rotor is already

inclined transversely ex-factory. If the crop is not picked up cleanly, the

raking quality can be improved by adjusting the rotor pitch.

The optimum raking quality is achieved when the tines in the front

working area and before the crop is deposited have the lowest

possible ground clearance (see adjacent illustration).

It is possible to adjust the position of the rotors laterally to the direction

of travel.

Move the machine to the headland position using the tractor's con-

trol device.

Close the ball valve.

Switch off the tractor and secure it.

Remove the tine supports above the right-hand wheel carrier.

Slightly loosen the three bolts on the wheel carrier.

Move the wheel carriers into the required position using the adjust-

ing screw (see illustration below).

Retighten the bolts to a tightening torque of 85 Nm.

Fit and secure the tine supports.

39

Page 40

Preparing for use

Working depth

Adjusting nut

Catch

Chassis cylinder

Working depth

Checking the

working depth

When working, the machine is raised and lowered hydraulically. The

machine is lowered as far as the preadjusted depth. The basic setting

for the working depth is adjusted using an adjusting screw on the

chassis cylinder.

Check the preset working depth as follows:

Fully lower the machine using the tractor's hydraulic control device.

Switch off the tractor and secure it.

Check the working depth to the ground.

The ideal working depth depends on several factors. Decisive, among

others, are:

• The soil condition and the stubble length.

• The type and quantity of fodder

If the tines are positioned too low, the crop is contaminated and the

stress and wear on the tines, and thus on the drive, increases.

If necessary, adjust the working depth to the field again.

Adjusting the

working depth

The chassis cylinder is used to adjust the chassis end stop in the work

position. Start with a horizontal chassis basic setting at a hitch height

of 400 mm. The chassis pitch depends on the ground conditions and

the crop. Adjust the working depth as follows:

Use the tractor's hydraulic control device to move the machine into

the headland position.

Switch off the tractor and secure it.

Close the ball valve.

Release the adjusting nut below the chassis using the catch and

use the adjusting nut to adjust the working depth.

Use the catch to prevent the adjusting nut from moving.

Switch on the tractor.

Lower the machine.

Switch off the tractor and secure it.

Check the working depth and readjust it if required.

Two turns of the adjusting nut change the height by 15 mm on the

tines.

40

Page 41

Adjusting the

M22 nut

Drawbar cylinder

Drawbar cylinder

Lift = 10 mm

approx. 400 mm

M16 nut

Drawbar cylinder

Draw shackle

M16 nut

drawbar height

Preparing for use

The drawbar cylinder is used to adjust the height of the drawbar and

the machine pitch so that the crop can be picked up satisfactorily.

Proceed as follows.

Using the nut on the drawbar cylinder, adjust the working depth so

that the tines lightly touch the ground (approx. 400 mm to the

pending attachment).

When using the optional support wheel, ensure that a lift of at least

10 mm is guaranteed for the drawbar cylinder.

41

Page 42

Road transport

Road transport

Safety

Before transporting the machine on public roads, please read the

following safety information. Compliance is mandatory and will help

you to avoid accidents.

Observe the safety information

Observe the safety information. Disregard for safety information

can lead to serious or fatal injury. See chapter »Safety«, page 6.

Ensuring road safety

The machine must conform to current national traffic regulations if

you intend to drive with it on public roads. Ensure the following:

• Lighting, warning and protective equipment must be fitted.

• The permissible transport widths and weights, axle loads, tyre

load-bearing capacities, laden weights and national speed

restrictions must be complied with.

• The maximum permissible road transport speed must be

complied with, but not exceed 50 km/h.

• The machine should only be towed by agricultural or forestry

tractors.

• The empty weight of the tractor must be greater than the weight

of the machine.

The driver and keeper of the vehicle are liable should these

conditions not be observed.

Clean the machine before travelling on the road

Before travelling on the road, remove all coarse dirt, crop residues

and clods of earth from the machine and clean it. Crops or dirt that

drop onto the road can cause slippery road conditions. There is

otherwise the risk of traffic accidents and accidents with fatal consequences.

Observe the contour of the terrain

Move the machine onto ground that is as flat as possible before

changing from work to transport position. Avoid inclines on which

the combination (tractor and machine) could slip or overturn. There

is an increased risk of tipping and injury in a position at right angles

to the direction of the slope.

Close the ball valve

Close the ball valve before driving on the road. If the ball valve is

open and there is an operating error, the machine may drop or swing

out unexpectedly. This could cause traffic accidents and accidents

with fatal consequences.

42

Page 43

Road transport

Swath former holder

General

Prior to road transport

The following worksteps are described in this section:

• »Prior to road transport«

• »Folding in the guard bars«

• »Folding the machine into the transport position«

• »Checking the machine«

• »Road transport«

When driving on public roads, the machine must be in the transport

position. To prepare the machine for road transport, carry out the

following steps:

»Moving the swath former to the transport position«

»Folding in the guard bars«

»Removing the tine supports«

»Placing the tine supports in the transport holder«

»Folding the machine into the transport position«

»Checking the machine«

Moving the swath

former to the

transport position

Move the machine onto ground that is as flat as possible before

changing from work to transport position.

For the transport position with the lowest transport width, pull the

swath former out of the holder, turn it 180° and push it fully back in and

secure it.

The swath former consists of a board and a holder.

In the work position, release the T-bolt from the swath former.

Completely pull the swath former out of the holder.

Turn the swath former 180° and push it back into the holder the

other way round.

Secure the swath former with the T-bolt.

43

Page 44

Road transport

Pressure spring

Safety splint

Front transverse carrier

Folding in the guard

bars

No persons within the slewing range

There is an acute risk of injury within the slewing range from

machine parts which are slewing or folding. Otherwise, serious or

fatal injury may be caused as a result.

Before removing the tine supports, move all the protective devices

around the rotors from the work to the transport position, and lock

them in place. Fold in the guard bar as follows:

Lower the machine to the work position using the tractor's single-

acting hydraulic control device.

Switch off the tractor and secure it.

Pull the swath former out of the holder.

Fully insert the swath former.

Left guard bar

Pull the left guard bar with swath former forwards, against the

resistance of the pressure spring, and fold upwards to 90°.

Lock the guard bar in the vertical position.

Secure the guard bar on the front support using a safety splint.

Right guard bar

Pull the right guard bar forwards, against the resistance of the

pressure spring, and fold upwards by 90°.

Lock the guard bar in the vertical position.

Secure the guard bar on the front support using a safety splint.

44

Page 45

Removing the tine

Transport holder

Rotor securing device

Lynch pin

Tine support

Rear hole

Transport holder

Lynch pin

Tine support

supports

Road transport

Remove any crops and coarse dirt.

Remove the tine supports from the rotor and secure them in the

transport holder (see adjacent illustration).

Do not remove one of the tine supports and secure using a rotor

securing device.

Placing the tine supports

in the transport holder

Loosen and remove the lynch pin from the tine support.

Pull off the tine support.

Insert the tine support into the transport holder.

Secure the tine support with a lynch pin.

45

Page 46

Road transport

Folding the machine

into the transport

position

Observe the instructions in »Prior to road transport«, page 43.

Raise the rotor using the chassis hydraulics until the transport

position is reached.

Do not raise the machine beyond the maximum permitted reflector

height.

Checking the

machine

Prior to driving on the road, check the machine against the check list:

PTO shaft drive off?

Guard bar folded in?

Tine supports in the transport holder and secured?

Tyre pressures correct?

Lower link secured at the sides?

Crop residue and dirt removed?

Lighting cables routed so that they are not strained and cannot

become caught in the tractor's wheels when cornering?

Machine in transport position?

Transport locking device locked?

Lighting equipment in good working order?

46

Page 47

Road transport

Road transport

Follow the instructions below for road transport. There is

otherwise the risk of traffic accidents and accidents with fatal

consequences.

Before pulling away, check the immediate vicinity. Always

make sure that you have a clear field of vision and, in

particular, look out for children within the operating area of the

machine.

Lock the control devices on the tractor before driving on public

roads.

Do not transport people or objects on the machine.

Adjust your speed to road conditions.

Do not exceed a maximum speed of 50 km/h. Comply with the

national speed limits.

Ensure sufficient steering and braking capability. Driving char-

acteristics, steering, and braking capability are all influenced if

the machine is coupled (increased braking distance as a result

of greater inertia).

There is a danger of tipping on slopes and if corners are taken too

fast.

47

Page 48

Preparations on the field

Preparations on the fiel d

Safety

The following applies for all preparations on the field:

Observe the safety information

Observe the safety information. Disregard for safety information

can lead to serious or fatal injury. See chapter »Safety«, page 6.

Switch off the tractor and secure it

Before you dismount:

Switch off the tractor.

Remove the ignition key.

Secure the tractor against rolling away.

An unsecured tractor can run you over or trap you. Otherwise,

serious or fatal injury may be caused as a result.

Secure the machine

Secure the machine against unintentional starting and rolling

away. Use wheel chocks. The machine must stand on a level, firm

and secure surface and be supported during the work, if

necessary. Unsecured or non-supported machines can cause

accidents. Otherwise, serious or fatal injury may be caused as a

result.

No persons in the working area

Ensure that no persons are present in the slewing and working

area of the machine. Persons could be caught by the machine

within this area. This could result in fatal injury.

General

Close the ball valve

Close the ball valve before adjusting. If the ball valve is open and

there is an operating error, the machine may drop or swing out

unexpectedly. This may cause damage to the machine or

accidents with fatal consequences.

The following worksteps are described in this section:

• »Lowering the machine«

• »Fitting the tine supports«

• »Folding out the guard bars«

• »Adjusting the swath former«

48

Page 49

Preparations on the field

Lynch pin

Tine support

Rear hole

Basic settings

Lowering the

machine

Fitting the

tine supports

After road transport, the machine is brought into the work position on

the field.

Switch on the tractor.

Lower the rotor using the chassis hydraulics until the work position

is reached.

Switch off the tractor and secure it.

Remove the tine supports from the transport holder.

Attach the tine supports to the bushed bearing tube and secure

with lynch pins.

49

Page 50

Preparations on the field

Pressure spring

Safety splint

Front transverse

carrier

Folding out the guard

bars

No persons within the slewing range

There is an acute risk of injury within the slewing range from

machine parts which are slewing or folding. Otherwise, serious or

fatal injury may be caused as a result.

After the tines have been attached, all protective devices must be

moved from transport to work position. Fold out the guard bar as

follows:

Left guard bar

Remove the safety splint from the front support.

Pull the left guard bar with swath former forwards, against the

resistance of the pressure spring, and fold downwards by 90°.

Right guard bar

Remove the safety splint from the front support.

Pull the right guard bar forwards, against the resistance of the

pressure spring, and fold downwards by 90°.

Observe the instructions in chapter »Preparing for use«, section

»Working depth« on page 40.

50

Page 51

Preparations on the field

T-bolt

Swath former

Bolts

Swath former

Bolts

Adjusting the swath

former

Adjusting the swath

width

Adjusting the swath

former in relation to the

direction of travel

The swath former is pulled into the correct position and secured when

changing from the transport to the work position.

For the work position, pull the swath former out of the holder, turn it

180° and push it fully back in and secure it.

The swath width can be adjusted as follows:

Undo the T-bolt.

Pull out the swath former to the desired width.

Tighten the T-bolt in the new position and secure.

It is possible to adjust the direction of travel of the swath former as

follows:

Adjusting the swath

former's height

Remove the bolts.

Move the swath former into the desired position.

Fit the bolts and tighten them in the new position.

It is possible to adjust the height of the swath former as follows:

Loosen the bolts.

Adjust the height of the swath former.

Tighten the bolts in the new position.

51

Page 52

Operation

Operation

Safety

Observe the safety information

Observe the safety information. Disregard for safety information

can lead to serious or fatal injury. See chapter »Safety«, page 6.

No riding on the machine

Persons or objects must never be transported on the machine.

Carrying passengers on the machine is life-threatening and

prohibited. Serious or fatal injury may be caused as a result.

No persons in the working area

Ensure that no persons are present in the slewing and working

area of the machine. Persons could be caught by the machine

within this area. This could result in fatal injury.

Maximum PTO stub shaft speed 540 rpm

The PTO stub shaft speed must not exceed 540 rpm and must be

adapted to the condition of the crop. Higher revolution rates can

cause damage to the machine.

Only allow the PTO shaft clutch to respond for a short time

Do not allow the slip clutch to respond for longer than 3 seconds.

If the clutch responds for a longer period of time, it will become

worn and the disconnect torque will drop.

Do not compress the PTO shaft

The PTO shaft between the tractor and machine must not be

compressed when in the work position or transport position. If

compressed, PTO shafts can cause damage to the machine and

tractor.

Observe the contour of the terrain

Pay even more attention when driving on an incline. Avoid inclines

on which the combination (tractor and machine) could slip or

overturn. There is an increased risk of tipping and injury in a

position at right angles to the direction of the slope.

Changes in the centre of gravity

When in work position, the machine's centre of gravity changes.

Pay even more attention when driving on an incline. Avoid inclines

on which the combination (tractor and machine) could slip or

overturn. There is an increased risk of tipping and injury in a

position at right angles to the direction of the slope.

52

Page 53

Operation

General

The following worksteps are described in this section:

• »Swathing«

• »Driving on headlands«

Suitable working speeds

Select a driving speed (approx. 4 to 12 km/h) at which the crop is

picked up cleanly and completely. The working speed depends on the

machine settings and the particular crop.

Swath width

The swath width depends on the working width, working speed, rotor

settings as well as crop condition.

53

Page 54

Operation

Swathing

Requirements

No persons in the working area

Ensure that no persons are present in the slewing and working

area of the machine. Persons could be caught by the machine

within this area. This could result in fatal injury.

After setting the machine as described in chapter »Preparations on

the field« page 48, you can start swathing.

The machine is set correctly as follows:

• Swath former adjusted.

• Tine supports are attached and secured.

• Rotor securing device on the rotor released.

• Tractor's lower links are set to floating position.

• Machine in work position.

Start work as follows:

Switch on the tractor.

Open the ball valve.

Check that there is nobody in the working area of the machine.

Switch on the PTO shaft at a low engine speed.

Slowly increase the speed. Do not exceed the maximum speed of

540 rpm.

Select a driving speed at which the crop is picked up cleanly and

completely.

Start swathing at the edge of the field and at headlands to avoid subsequently driving over the crop.

The slip clutch of the machine may also respond at low speed if

resistance is increased due to excess crop or obstacles.

54

Page 55

Operation

Work position

Headland

position

Swath deposit

The following swath deposits are possible:

Single swath Swath turning

Double swath Multiple swath

Driving on headlands

The rotor can be raised for crossing swaths that have already been

harvested.

Raise the machine to the headland position using the tractor's

single-acting hydraulic control device.

Lower the machine again, in order to create a new swath.

55

Page 56

Cleaning and care

Cleaning and care

Safety

The following applies to all cleaning and care work:

Observe the safety information

Observe the safety information. Disregard for safety information

can lead to serious or fatal injury. See chapter »Safety«, page 6.

Secure the machine

• Before starting cleaning operations, always switch off the

tractor's PTO shaft drive and secure it against unintentional

restarting.

• Secure the machine against rolling away by using chocks.

• The machine must be standing on firm and level ground and, if

necessary, be supported during the work.

Unsecured or non-supported machines can cause accidents.

No persons in the working area

Ensure that no persons are present in the slewing and working

area of the machine. Persons could be caught by the machine

within this area. This could result in fatal injury.

Do not clean bearings or hydraulic parts with high-pressure

cleaners

Do not clean bearings or hydraulic parts with high-pressure

cleaners. The high-pressure cleaner removes the grease film from

the bare metal surfaces. Metal surfaces treated in this way can

corrode. After each cleaning procedure, lubricate the bearing

points and grease uncoated parts.

Clean the bearings and hydraulic parts with care

Exercise caution when cleaning with a high-pressure cleaner.

Bearings, seals and pipe unions are not waterproof. In order to

prevent damage to the machine, the bearings, seals and pipe

unions must not be exposed to direct contact with the highpressure water jet.

56

Page 57

Cleaning and care

Cleaning

After cleaning

Care

Lower the machine to the work position.

After each use, clean the machine of any coarse dirt and crop

residue.

Do not clean the bearings and piston rods of hydraulic cylinders

using a high-pressure cleaner.

Lubricate all bearings after cleaning.

For a long service life, we recommend the following:

Apply a protective layer of oil to all uncoated work tools. Only use

approved, biodegradable oil, e.g. rapeseed oil.

Repair any paint damage.

57

Page 58

Parking and storage

Machine in park position

Parking and storage

Safety

General

When setting down and parking the machine, special safety

precautions have to be observed:

Observe the safety information

Observe the safety information. Disregard for safety information

can lead to serious or fatal injury. See chapter »Safety«, page 6.

Keep children away from the machine

Forbid children from playing on or around the machine. Select a

parking area to which no unauthorised persons have direct

access. Metal edges and machine work tools can cause serious

injury.

Make sure the machine is standing level

Before changing from the transport to the work position (and vice

versa), make sure the machine is standing level. The machine

could roll away, particularly on hillside locations. Damage to the

machine and serious or fatal injury may be caused as a result.

The machine must be uncoupled in the reverse order to that in which

it was coupled.

Chapter »Folding the machine into the transport position« page 46.

Chapter»Coupling the machine«, section »Coupling« page 13.

58

Page 59

Parking and storage

Transport holder

Parking stand

Uncoupling the machine

To uncouple the machine from the tractor, proceed as follows:

Set the machine down on a firm, level surface and lower it to the

work position.

Secure the tractor against rolling away, turn off the engine and re-

move the ignition key.

Secure the machine against rolling away by using chocks.

Pull off the PTO shaft and place it on the holder provided.

Close the ball valve and release the hydraulic couplings.

Place hydraulic couplings in storage pockets.

Remove the tine supports.

Disconnect the lighting connectors and place them in the storage

pockets.

Fasten the height-adjustable parking stand to the drawbar, secure

it, and relieve the drawbar with the parking stand.

Wind the electrical cables onto the hook.

Unhitch the machine.

59

Page 60

Parking and storage

After the end of the season

After the end of the season and if the machine is to be stored for a long

period of time, perform the following work:

Clean the machine thoroughly.

Check all the screwed connections and tighten the bolts.

Repair or replace any damaged components.

Repair any paint damage.

Lubricate the machine in accordance with the lubrication schedule.

Check the tyre pressures.

Replace missing warning signs and stickers.

60

Page 61

Maintenance

Maintenance

Safety

The following applies to all maintenance work:

Observe the safety information

Observe the safety information. Disregard for safety information

can lead to serious or fatal injury. See chapter »Safety«, page 6.

Requirements for maintenance work

Only perform the maintenance work if you have the required

expert knowledge and suitable tools. The absence of technical

knowledge or suitable tools can cause accidents and injuries.

Protect the machine against unintended starting

The following conditions must be observed for carrying out repairs

and maintenance work and rectifying malfunctions on the machine

when it is coupled:

• Switch off the tractor PTO shaft drive.

• Switch off the tractor engine.

• Remove the ignition key.

Serious accidents may be caused if the machine starts unintentionally.

Use OEM replacement parts

Many components have special properties that are essential for

the stability and correct operation of the machine. Only spare parts

and accessories supplied by the manufacturer have been tested

and approved. Other products may adversely affect the correct

operation of the machine and safety. The use of non-OEM

replacement parts renders the manufacturer's guarantee null and

void and frees the manufacturer from all liability.

Secure moving parts

Moving parts must be secured with lifting gear against sliding,

folding or swivelling. Otherwise, serious injury to persons or

damage to the machine may be caused as a result.

Disconnect electrical connections before performing welding

work

Disconnect all electrical connections from the tractor when

carrying out welding on the hitched machine. Otherwise, electrical

and hydraulic systems will be damaged as a result.

61

Page 62

Maintenance

Protective measures

when handling oils or

lubricants

Additives in oils and lubricants may have adverse effects on health. As

marking in accordance with the hazardous goods regulation is not

necessary, please always ensure the following:

Avoid skin contact

Avoid skin contact with these materials. Protect your skin by

means of protective skin cream or oil-resistant gloves. Contact

can result in skin damage.

Do not use oils for cleaning

Do not use oils or lubricants to clean your hands. Swarf and

abraded material in these materials can also result in injuries.

Change out of soiled clothing

Change out of clothing that is heavily soiled with oil as soon as

possible. Oils can be hazardous to your health.

• Used oil must be collected and disposed of.

• If the skin is damaged by oil or lubricant, seek medical advice

immediately.

62

Page 63

Maintenance

Front

Left

Right

Rear

Top

Bottom

Rotary direction right

General

Direction information

This information relates to general maintenance work. For all

maintenance work, the machine must be locked in the work position.