Page 1

OPERATOR'S MANUAL

English (U.S.A.)

Code No. 3S205-9971-3

MODELS

M6-101·M6-111

M6-131·M6-141

M

6

---1

0

1

·

M

6

1

1

1

·

M

6

1

3

1

·

M

6

1

4

1

PRINTED IN JAPAN

KUBOTA Corporation 2015

©

READ AND SAVE THIS MANUAL

Page 2

ABBREVIATION LIST

Abbreviations Definitions

2WD

4WD

API

ASABE

ASTM

DIN

DEF

DPF

DT

fpm

GST

Hi-Lo

HST

m/s

PTO

RH/LH

ROPS

rpm

2 Wheel Drive

4 Wheel Drive

American Petroleum Institute

American Society of Agricultural and Biological Engineers, USA

American Society for Testing and Materials, USA

Deutsches Institut für Normung, GERMANY

Diesel Exhaust Fluid

Diesel Particulate Filter

Dual Traction [4WD]

Feet Per Minute

Glide Shift Transmission

High Speed-Low Speed

Hydrostatic Transmission

Meters Per Second

Power Take Off

Right-hand and left-hand sides are determined by facing

in the direction of forward travel

Roll-Over Protective Structures

Revolutions Per Minute

KUBOTA Corporation is ···

Since its inception in 1890, KUBOTA Corporation has grown to

rank as one of the major firms in Japan.

To achieve this status, the company has through the years

diversified the range of its products and services to a remarkable

extent. 30 plants and 35,000 employees produce over 1,000

different items, large and small.

All these products and all the services which accompany them,

however, are unified by one central commitment. KUBOTA makes

products which, taken on a national scale, are basic necessities.

Products which are indispensable. Products which are intended to

help individuals and nations fulfill the potential inherent in their

environment. KUBOTA is the Basic Necessities Giant.

This potential includes water supply, food from the soil and from

the sea, industrial development, architecture and construction, and

transportation.

Thousands of people depend on KUBOTA's know-how, technology,

experience and customer service. You too can depend on

KUBOTA.

r/s

SAE

SCR

SMV

Revolutions Per Second

Society of Automotive Engineers, USA

Selective Catalytic Reduction

Slow Moving Vehicle

California Proposition 65

WARNING

Engine exhaust, some of its constituents,

certain vehicle components and fluids,

contain or emit chemicals known to the

State of California to cause cancer and birth

defects or other reproductive harm.

M6-101/M6-111/M6-131/M6-141

AU . E . 3 - 4 . 6 . AK

Page 3

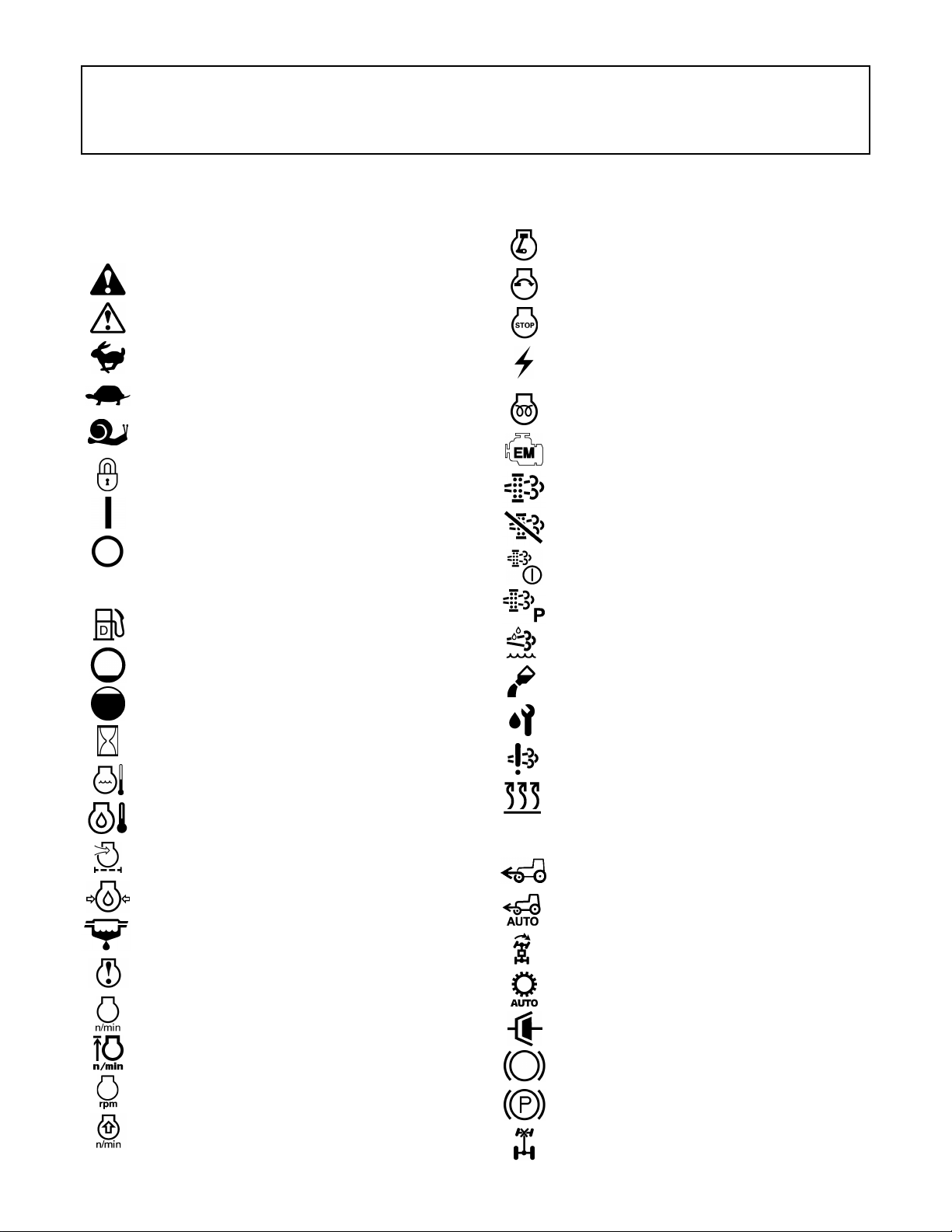

UNIVERSAL SYMBOLS

As a guide to the operation of your tractor, various universal symbols have been utilized on the instruments and controls.

The symbols are shown below with an indication of their meaning.

B General

Safety Alert Symbol

Master System Warning

Fast

Slow

Creep

Lock

ON (Engaged)

OFF (Disengaged)

B Engine-related

Diesel Fuel

Empty

Full

Hourmeter/Elapsed Operating Hours

Engine Coolant-Temperature

Low Temperature Reguration

Engine Intake/Combustion Air-Filter

Engine Oil-Pressure

Water Separator

Engine-Warning

Engine-Rotational Speed

Engine-Rev Limiter

Engine-Constant RPM management

Engine-RPM Increase

Engine-Run

Engine-Start

Engine-Stop

Electrical Power-accessories

Diesel Preheat/Glow Plugs

(Low Temperature Start Aid)

Emission Control

Regeneration

Regeneration inhibit

Regeneration (Switch)

Parked Regeneration

DEF/AdBlue-Level

DEF/AdBlue-Low Level

DEF/AdBlue-Poor Quality

DEF/AdBlue-Trouble

DEF/AdBlue-Freeze

B Vehicle body-related

4-Wheel Drive-On

4-Wheel Drive-Automatic

Bi-Speed turn

Auto-Transmission

Clutch

Brake

Parking Brake

Differential Lock-Front

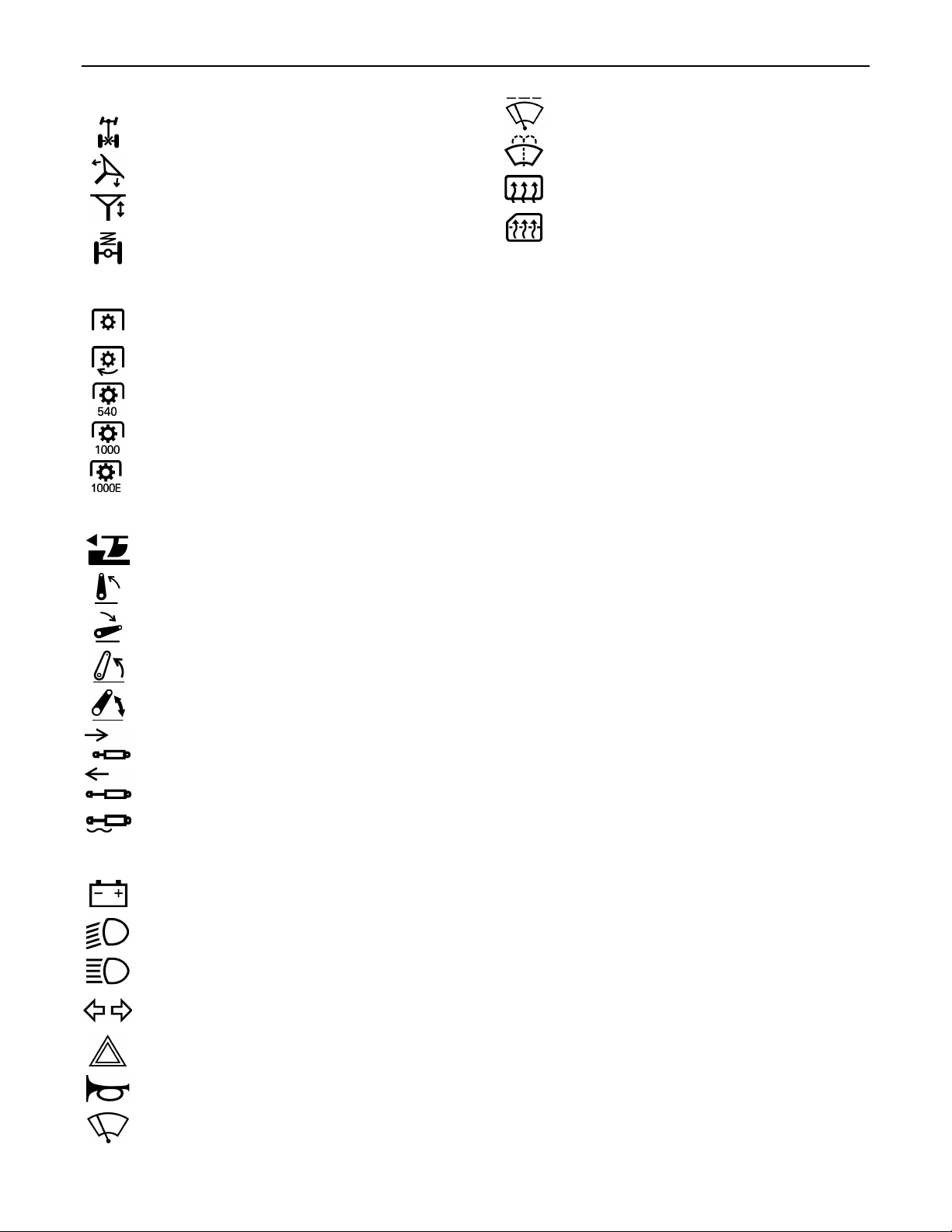

Page 4

Differential Lock-Rear

Steering Wheel-Tilt

Steering Wheel-Telescope

Front Suspension

B PTO-related

PTO-Off (Disengaged)

PTO-On (Engaged)

PTO-540 rpm

PTO-1000 rpm

PTO-1000E rpm

B Hydraulic-related

Draft Control

Windshield Wiper-Intermittent

Windshield Washer

Rear Window Defroster

Side Window Defroster

Position Control-Raised Position

Position Control-Lowered Position

3-Point Lifting/Lowering

Lift Arm-Height

Remote Cylinder-Retract

Remote Cylinder-Extend

Remote Cylinder-Float

B Electric-related

Battery Charging Condition

Headlight-Low Beam

Headlight-High Beam

Turn Signal

Hazard Warning Lights

Audible Warning Device

Windshield Wiper

Page 5

FOREWORD

You are now the proud owner of a KUBOTA Tractor. This tractor is a product of

KUBOTA quality engineering and manufacturing. It is made of fine materials and

under a rigid quality control system. It will give you long, satisfactory service. To

obtain the best use of your tractor, please read this manual carefully. It will help you

become familiar with the operation of the tractor and contains many helpful hints

about tractor maintenance. It is KUBOTA's policy to utilize as quickly as possible

every advance in our research. The immediate use of new techniques in the

manufacture of products may cause some small parts of this manual to be

outdated. KUBOTA distributors and dealers will have the most up-to-date

information. Please do not hesitate to consult with them.

3

This symbol, the industry's ''Safety Alert Symbol'', is used throughout this manual

and on labels on the machine itself to warn of the possibility of personal injury.

Read these instructions carefully. It is essential that you read the instructions and

safety regulations before you attempt to assemble or use this unit.

3

3

3

IMPORTANT :

NOTE :

DANGER :

WARNING :

CAUTION :

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

Indicates that equipment or property damage could result if

instructions are not followed.

Gives helpful information.

SAFETY FIRST

Page 6

Page 7

CONTENTS

SAFE OPERATION ............................................................................................ -1

SERVICING OF TRACTOR......................................................................................... 1

SPECIFICATIONS....................................................................................................... 3

SPECIFICATION TABLE ......................................................................................... 3

TRAVELING SPEEDS ............................................................................................. 5

IMPLEMENT LIMITATIONS ........................................................................................ 6

INSTRUMENT PANEL AND CONTROLS................................................................... 8

PRE-OPERATION CHECK ....................................................................................... 12

DAILY CHECK ....................................................................................................... 12

OPERATING THE ENGINE....................................................................................... 13

EXHAUST AFTERTREATMENT DEVICES........................................................... 13

Dual Exhaust Aftertreatment Devices............................................................................. 13

DIESEL PARTICULATE FILTER (DPF) MUFFLER............................................... 14

Handling Points...............................................................................................................14

DPF Regeneration Process............................................................................................14

Operating Procedure for Auto Regeneration Mode ........................................................ 15

Operating Procedure for Regeneration Inhibit Mode......................................................17

Operating Procedure for Parked Regeneration .............................................................. 19

Tips on Diesel Particulate Filter (DPF) Regeneration..................................................... 21

SELECTIVE CATALYTIC REDUCTION (SCR) MUFFLER ................................... 21

Outline of the SCR..........................................................................................................21

DEF/AdBlue® .................................................................................................................22

Warning Indication and its Countermeasure...................................................................22

Storing and Handling DEF/AdBlue®...............................................................................27

STARTING THE ENGINE ...................................................................................... 27

COLD WEATHER STARTING ............................................................................... 32

Block Heater (if equipped) ..............................................................................................32

STOPPING THE ENGINE...................................................................................... 32

WARMING UP ....................................................................................................... 33

Warm-up and Transmission Oil at Low Temperature Range ......................................... 33

JUMP STARTING .................................................................................................. 33

OPERATING THE TRACTOR ................................................................................... 34

OPERATING NEW TRACTOR .............................................................................. 34

Do not Operate the Tractor at Full Speed for the First 50 Hours.................................... 34

Changing Lubricating Oil for New Tractors..................................................................... 34

BOARDING AND LEAVING THE TRACTOR ........................................................ 34

STARTING ............................................................................................................. 34

Operator's Seat...............................................................................................................34

Seat Belt .........................................................................................................................36

Instructional Seat............................................................................................................36

Steering Adjustment .......................................................................................................37

Extendable Mirror ...........................................................................................................37

Light Switch ....................................................................................................................38

Page 8

CONTENTS

Turn Signal / Hazard Light Switch ..................................................................................38

Horn Button.....................................................................................................................39

Work Light Switch (Front) ............................................................................................... 39

Work Light Switch (Rear)................................................................................................ 39

Brake Pedals (Right and Left).........................................................................................40

Clutch Pedal ...................................................................................................................41

Power Shift / Range Shift Lever (PS. Lever) ..................................................................42

DHC switch.....................................................................................................................44

Shuttle Lever...................................................................................................................44

Creep Lever (if equipped)...............................................................................................45

4WD / Auto 4WD Switch................................................................................................. 45

Bi-speed Turn Switch......................................................................................................46

Hand Throttle Lever........................................................................................................49

Foot Throttle ...................................................................................................................49

Rev-limiter Control Dial................................................................................................... 49

Parking Brake Lever ....................................................................................................... 49

STOPPING............................................................................................................. 49

Stopping.......................................................................................................................... 49

CHECK DURING DRIVING ................................................................................... 50

Immediately Stop the Engine if:......................................................................................50

Easy Checker(TM).......................................................................................................... 50

Fuel Gauge.....................................................................................................................51

DEF / AdBlue® Gauge ...................................................................................................51

Coolant Temperature Gauge..........................................................................................52

Tachometer.....................................................................................................................52

LCD MONITOR ...................................................................................................... 53

Performance Monitor ...................................................................................................... 54

SIDE DIGITAL DISPLAY........................................................................................ 55

Initial Setting ...................................................................................................................55

Factory-set Screen Display.............................................................................................57

ELECTRONIC ENGINE CONTROL....................................................................... 59

Rev-limiter Control Setting.............................................................................................. 59

RPM Dual Memory Setting ............................................................................................. 59

Constant RPM Management Control.............................................................................. 62

AUTO MODE ......................................................................................................... 63

Outline ............................................................................................................................63

Operation........................................................................................................................65

Work Speed Display ....................................................................................................... 66

Changing the Field Speed .............................................................................................. 67

Sensitivity Adjustment.....................................................................................................68

Changing the Auto-Mode Setting....................................................................................68

FRONT SUSPENSION .......................................................................................... 71

Outline ............................................................................................................................71

Suspension Switch .........................................................................................................71

Ride Condition Damper Switch....................................................................................... 73

Manual Control Mode .....................................................................................................73

PARKING ............................................................................................................... 74

Parking............................................................................................................................ 74

OPERATING TECHNIQUES ................................................................................. 74

Differential Lock..............................................................................................................74

Rear Wheel Differential Lock Pedal................................................................................75

Front Wheel Differential Lock Switch..............................................................................75

Page 9

CONTENTS

Operating the Tractor on a Road....................................................................................76

Operating on Slopes and Rough Terrain........................................................................76

Transport the Tractor Safely...........................................................................................76

Directions for Use of Power Steering..............................................................................76

Trailer Electrical Outlet ...................................................................................................77

PTO ........................................................................................................................... 78

PTO OPERATION.................................................................................................. 78

PTO Clutch Control Switch.............................................................................................78

1000 rpm PTO Shaft....................................................................................................... 79

PTO Shaft Cover and Shaft Cap ....................................................................................80

3-POINT HITCH & DRAWBAR.................................................................................. 81

3-POINT HITCH ..................................................................................................... 82

Selecting the holes of Lower Links ................................................................................. 82

Adjusting Lateral Float....................................................................................................82

Selecting the Top Link Mounting Holes .......................................................................... 82

Drawbar ..........................................................................................................................82

Remote Hitch UP / DOWN Switch..................................................................................83

Lifting Rod (Left) .............................................................................................................83

Lifting Rod (Right)........................................................................................................... 84

Top Link..........................................................................................................................84

Telescopic Stabilizers.....................................................................................................84

Telescopic Lower Links ..................................................................................................85

DRAWBAR............................................................................................................. 85

Adjusting Drawbar Length ..............................................................................................85

Swing Drawbar ...............................................................................................................85

HYDRAULIC UNIT..................................................................................................... 86

3-POINT HITCH CONTROL SYSTEM................................................................... 86

Terminology....................................................................................................................86

Mode Selector Switch.....................................................................................................87

Position Control Mode ....................................................................................................87

Mixed Draft Control Mode............................................................................................... 88

Float Control ...................................................................................................................88

Bottom Limit Control Dial................................................................................................89

Lift Arm Top Limit Adjustment Dial .................................................................................89

3-Point Hitch Lowering Speed Adjustment Dial..............................................................89

3-Point Hitch Lowering Lock Lever.................................................................................90

3-P. Quick Raise / Lower Switch ....................................................................................90

3-Point Hitch's Position Lock ..........................................................................................91

REMOTE HYDRAULIC CONTROL SYSTEM........................................................ 91

Remote Control Valve.....................................................................................................91

Remote Control Valve Lever...........................................................................................91

Remote Control Valve Coupler Connecting and Disconnecting .....................................92

Adjusting the flow rate ....................................................................................................93

Remote Couplers Spillage Collector............................................................................... 94

Hydraulic Control Unit Use Reference Chart..................................................................95

TIRES, WHEELS AND BALLAST.............................................................................. 96

TIRES..................................................................................................................... 96

Inflation Pressure............................................................................................................96

Dual Tires ....................................................................................................................... 96

Page 10

CONTENTS

WHEEL ADJUSTMENT ......................................................................................... 97

Front Wheels (with 4-wheel drive) .................................................................................. 97

Adjusting Front Wheel Turning Stopper Bolt ..................................................................98

Rear Wheels...................................................................................................................99

BALLAST ............................................................................................................. 101

Front Ballast..................................................................................................................101

Rear Ballast ..................................................................................................................102

CAB OPERATION ................................................................................................... 103

DOOR AND WINDOW......................................................................................... 103

Locking and Unlocking the Door................................................................................... 103

Opening the Door .........................................................................................................103

Rear Window ................................................................................................................103

Sun Roof.......................................................................................................................104

Emergency Exit.............................................................................................................104

DOME LIGHT....................................................................................................... 104

Dome Light ...................................................................................................................104

WIPER ................................................................................................................. 104

Front Wiper / Washer Switch........................................................................................104

Rear Wiper / Washer Switch.........................................................................................105

Using the Wipers in Cold Season.................................................................................105

AIR CONDITIONER ............................................................................................. 105

Airflow...........................................................................................................................105

Air Control Vent ............................................................................................................106

Control Panel................................................................................................................106

Operation......................................................................................................................107

REAR DEFOGGER WITH TIMER (if equipped) .................................................. 109

INSTALLING THE IMPLEMENT CONTROL BOX............................................... 109

ELECTRICAL OUTLET........................................................................................ 110

Electrical Outlet.............................................................................................................110

MAINTENANCE....................................................................................................... 111

SERVICE INTERVALS ........................................................................................ 111

Maintenance Items Chart..............................................................................................113

LUBRICANTS, FUEL AND COOLANT ................................................................ 114

PERIODIC SERVICE............................................................................................... 116

HOW TO OPEN THE HOOD ............................................................................... 116

Hood .............................................................................................................................116

Side Cover....................................................................................................................116

DAILY CHECK ..................................................................................................... 117

Walk Around Inspection................................................................................................ 117

Checking and Refueling................................................................................................117

Checking the DEF/AdBlue® level and adding the fluid ................................................ 118

Checking Water Separator ...........................................................................................119

Checking Engine Oil Level............................................................................................120

Checking Transmission Fluid Level..............................................................................120

Checking Coolant Level................................................................................................ 121

Cleaning Evacuator Valve ............................................................................................121

Cleaning Grill, Radiator and Screen .............................................................................122

Checking DPF/SCR Muffler..........................................................................................123

Checking Brake Pedal .................................................................................................. 123

Checking Gauges, Meter and Easy Checker(TM) ........................................................ 124

Page 11

CONTENTS

Checking Head Light, Turn Signal / Hazard Light etc................................................... 124

Checking Seat Belt ....................................................................................................... 124

Checking Movable Parts............................................................................................... 124

INITIAL 50 HOURS .............................................................................................. 124

Changing Engine Oil..................................................................................................... 124

Replacing Engine Filter.................................................................................................124

Checking Fan / Air-conditioner Belt Tension ................................................................ 124

EVERY 50 HOURS .............................................................................................. 124

Checking Engine Start System.....................................................................................124

Checking Wheel Bolt Torque........................................................................................125

Checking Tie-rod Dust Cover .......................................................................................126

EVERY 100 HOURS ............................................................................................ 126

Lubricating Grease Fittings........................................................................................... 126

Cleaning Air Cleaner Primary Element ......................................................................... 128

Adjusting Fan Belt Tension........................................................................................... 129

Adjusting Brake Pedal ..................................................................................................129

Adjusting Parking Brake Lever .....................................................................................130

Checking Battery Condition .......................................................................................... 131

Adjusting Air-Conditioner Belt Tension.........................................................................133

EVERY 200 HOURS ............................................................................................ 133

Adjusting Toe-in............................................................................................................ 133

Draining Fuel Tank Water............................................................................................. 134

Cleaning Inner Air Filter................................................................................................134

Cleaning Fresh Air Filter...............................................................................................135

EVERY 400 HOURS ............................................................................................ 136

Checking Fan / Air-conditioner Belt Tension ................................................................ 136

Cleaning Water Separator ............................................................................................ 137

Cleaning Fuel Solenoid Pump Element........................................................................138

EVERY 500 HOURS ............................................................................................ 138

Changing Engine Oil..................................................................................................... 138

Replacing Engine Oil Filter ........................................................................................... 139

Cleaning Pre-Fuel Filter................................................................................................ 140

Replacing Fuel Filter..................................................................................................... 140

Replacing Hydraulic Oil Filter .......................................................................................141

Checking Power Steering Line .....................................................................................142

Checking Radiator Hose and Clamp ............................................................................142

Checking Fuel Line.......................................................................................................144

Checking Intake Air Line............................................................................................... 144

Checking Oil Cooler Line..............................................................................................145

Adjusting Power Shift....................................................................................................145

Checking Air Conditioner Pipe and Hose ..................................................................... 145

EVERY 600 HOURS ............................................................................................ 145

Adjusting Front Axle Pivot.............................................................................................145

Adjusting King-pin Pivot................................................................................................ 146

EVERY 1000 HOURS .......................................................................................... 146

Changing Transmission Fluid ....................................................................................... 146

Changing Front Differential Case Oil............................................................................147

Changing Front Axle Gear Case Oil ............................................................................. 147

Adjusting Engine Valve Clearance ...............................................................................147

EVERY 1000 HOURS or 1 YEAR ........................................................................ 148

Replacing Air Cleaner Primary Element and Secondary Element................................ 148

Checking Exhaust Manifold ..........................................................................................148

Page 12

CONTENTS

EVERY 1500 HOURS .......................................................................................... 148

Cleaning Fuel Injector Nozzle Tip................................................................................. 148

Checking DEF/AdBlue® Injector Tip ............................................................................ 148

Checking DEF/AdBlue® Line .......................................................................................148

Replacing Oil Separator Element .................................................................................148

Checking PCV (Positive Crankcase Ventilation) Valve ................................................ 148

Checking and Cleaning EGR Cooler ............................................................................ 148

Checking Accumulator.................................................................................................. 148

EVERY 2000 HOURS or 2 YEARS...................................................................... 149

Flushing Cooling System and Changing Coolant .........................................................149

Anti-Freeze ...................................................................................................................150

EVERY 3000 HOURS .......................................................................................... 151

Checking Turbocharger ................................................................................................ 151

Checking Supply Pump ................................................................................................151

Checking Intake Air Heater........................................................................................... 151

Checking and Cleaning EGR System........................................................................... 151

Cleaning DPF Muffler ...................................................................................................151

Checking DEF/AdBlue® injector................................................................................... 151

Replacing DEF/AdBlue® Pump Filter...........................................................................151

EVERY 8000 HOURS .......................................................................................... 152

Cleaning DPF Muffler ...................................................................................................152

EVERY 9000 HOURS .......................................................................................... 152

Replacing DEF/AdBlue® Tank Filter ............................................................................152

EVERY 1 YEAR ................................................................................................... 152

Checking Antifrost Heater for Oil Separator .................................................................152

Checking CAB Isolation Cushion.................................................................................. 152

Checking DPF Differential Pressure Sensor Pipe ........................................................ 152

Checking EGR Pipe...................................................................................................... 152

EVERY 2 YEARS................................................................................................. 152

Replacing PCV (Positive Crankcase Ventilation) Valve Hose......................................152

Replacing DPF Differential Pressure Sensor Hose ...................................................... 152

Replacing Boost Sensor Hose...................................................................................... 152

Replacing Brake Hose..................................................................................................152

Replacing Clutch Hose ................................................................................................. 152

Replacing Differential Lock Hose..................................................................................152

EVERY 3 YEARS................................................................................................. 152

Replacing Parking Brake Cable.................................................................................... 152

EVERY 4 YEARS................................................................................................. 153

Replacing Radiator Hose (Water pipes) ....................................................................... 153

Replacing Fuel Hose ....................................................................................................153

Replacing Intake Air Line.............................................................................................. 153

Replacing Oil Cooler Line.............................................................................................153

Replacing Power Steering Hose................................................................................... 153

Replacing Lift Cylinder Hose ........................................................................................153

Replacing Suspension Hose.........................................................................................153

Replacing Master Cylinder Kit ......................................................................................153

Replacing Equalizer Kit.................................................................................................153

Replacing Brake Seal 1 and 2 ...................................................................................... 153

Replacing Air Conditioner Hose....................................................................................153

SERVICE AS REQUIRED.................................................................................... 153

Bleeding Fuel System................................................................................................... 153

Bleeding Brake System ................................................................................................154

Page 13

CONTENTS

Draining Clutch Housing Water ....................................................................................154

Replacing Fuse.............................................................................................................155

Replacing Slow-Blow Fuses ......................................................................................... 157

Replacing Light Bulb.....................................................................................................159

Replacing Head Lamp ..................................................................................................159

Lubricating Points ......................................................................................................... 159

Adding Washer Liquid...................................................................................................160

Checking the Amount of Refrigerant (gas) ...................................................................160

STORAGE ............................................................................................................... 161

TRACTOR STORAGE ......................................................................................... 161

REMOVING THE TRACTOR FROM STORAGE................................................. 161

TROUBLESHOOTING............................................................................................. 162

ENGINE TROUBLESHOOTING .......................................................................... 162

POWER SHIFT/RANGE SHIFT TROUBLE SHOOTING..................................... 164

OPTIONS................................................................................................................. 166

APPENDICES.......................................................................................................... 167

SIDE DIGITAL DISPLAY...................................................................................... 167

Changing the Information Displayed.............................................................................167

Information Displayed and its Handling ........................................................................ 168

Displaying and Using the Work History ........................................................................171

Measuring the Distance................................................................................................173

Changing the Units and Dates...................................................................................... 173

INDEX .................................................................................................................. 175

Page 14

Page 15

SAFE OPERATION

-1SAFE OPERATION

Careful operation is your best insurance against an

accident.

Read and understand this manual carefully before

operating the tractor.

All operators, no matter how much experience they may

have, should read this and other related manuals before

operating the tractor or any implement attached to it. It is

the owner's obligation to instruct all operators in safe

operation.

1. BEFORE OPERATING THE TRACTOR

1. Know your equipment and its limitations. Read this

entire manual before attempting to start and operate

the tractor.

2. Pay special attention to the danger, warning and

caution labels on the tractor.

3. Do not operate the tractor or any implement attached

to it while under the influence of alcohol, medication,

controlled substances or while fatigued.

4. Before allowing other people to use your tractor,

explain how to operate and have them read this

manual before operation.

5. Never wear loose, torn, or bulky clothing around

tractor. It may catch on moving parts or controls,

leading to the risk of an accident. Use additional safety

items, e.g. hard hat, safety boots or shoes, eye and

hearing protection, gloves, etc., as appropriate or

required.

6. Do not allow passengers to ride on any part of the

tractor at anytime. The operator must remain in the

tractor seat during operation.

7. Check brakes, clutch, linkage pins and other

mechanical parts for improper adjustment and wear.

Replace worn or damaged parts promptly. Check the

tightness of all nuts and bolts regularly. (For further

details, see "MAINTENANCE" section.)

8. Keep your tractor clean. Dirt, grease, and trash build

up may contribute to fires and lead to personal injury.

9. Use only implements meeting the specifications listed

under "IMPLEMENT LIMITATIONS" in this manual or

implements approved by KUBOTA.

10.Use proper weights on the front or rear of the tractor to

reduce the risk of upsets. When using the front loader,

put an implement or ballast on the 3-point hitch to

improve stability. Follow the safe operating

procedures specified in the implement or attachment

manual.

11. The narrower the tread, the greater the risk of a tractor

upset. For maximum stability, adjust the wheels to the

widest practical tread width for your application. (See

"TIRES, WHEELS AND BALLAST" section.)

(1) Rear wheels (A) Tread Width

12.Do not modify the tractor. Unauthorized modification

may affect the function of the tractor, which may result

in personal injury.

C CAB, ROPS

1. KUBOTA recommends the use of a CAB or Roll Over

Protective Structures (ROPS) and seat belt in almost

all applications. This combination will reduce the risk

of serious injury or death, should the tractor be upset.

Check for overhead clearance which may interfere

with a CAB or ROPS.

2. If the CAB or ROPS is loosened or removed for any

reason, make sure that all parts are reinstalled

correctly before operating the tractor.

3. Never modify or repair any structural member of a

CAB or ROPS because welding, bending, drilling,

grinding, or cutting may weaken the structure.

4. A damaged CAB or ROPS structure must be replaced,

not repaired or revised.

5. If any structural member of the CAB or ROPS is

damaged, replace the entire structure at your local

KUBOTA Dealer.

6. Always use the seat belt if the tractor has a CAB or

ROPS. Do not use the seat belt if there is no CAB or

ROPS. Check the seat belt regularly and replace if

frayed or damaged.

Page 16

SAFE OPERATION-2

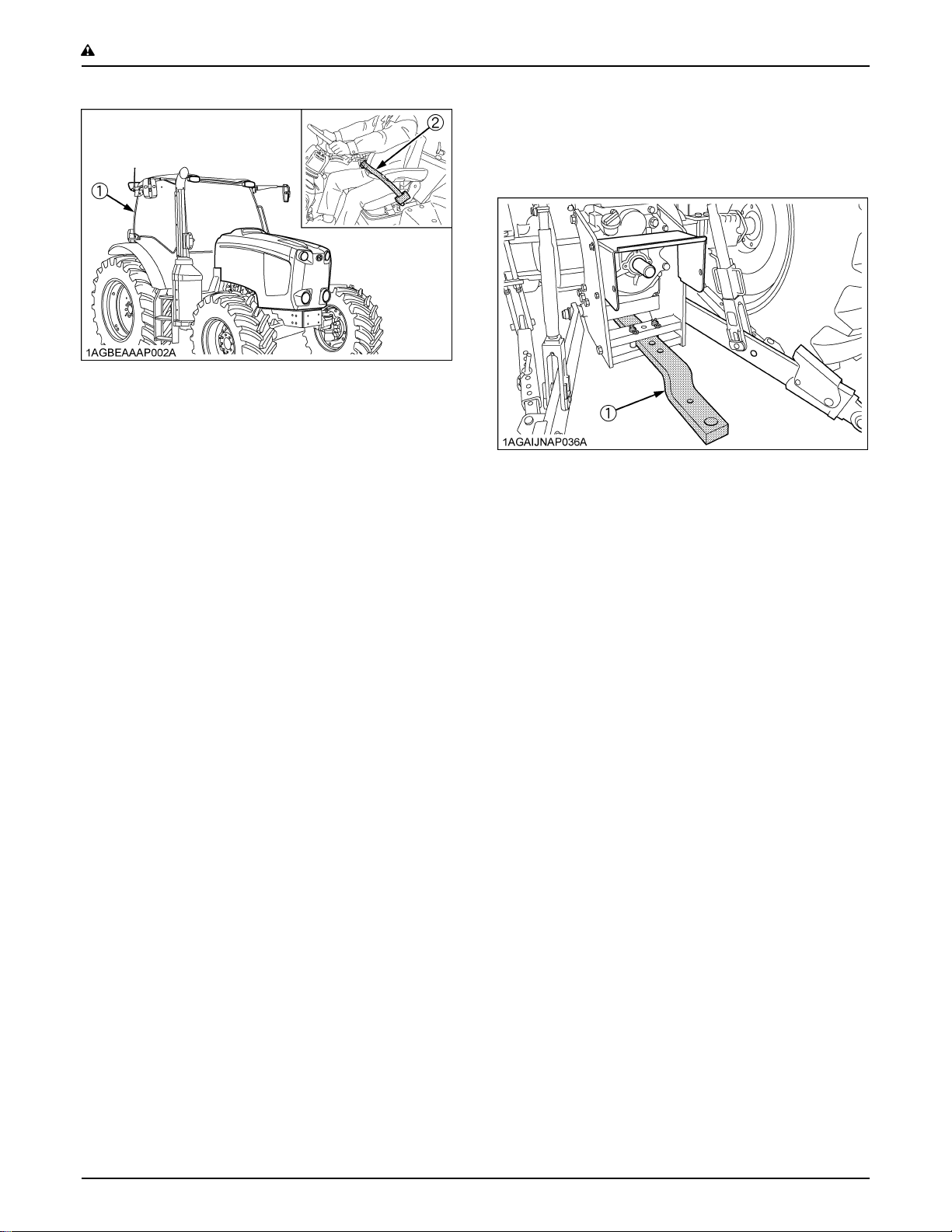

(1) CAB

(2) Seat belt

C Working

1. Pull only from the drawbar. Never hitch to axle housing

or any other point except drawbar; such arrangements

will increase the risk of serious personal injury or death

due to a tractor upset.

2. OPERATING THE TRACTOR

Operator safety is a priority. Safe operation, specifically

with respect to overturning hazards, entails understanding

the equipment and environmental conditions at the time of

use. Some prohibited uses which can affect overturning

hazards include traveling and turning with implements

and loads carried too high etc. This manual sets forth

some of the obvious risks, but the list is not, and cannot

be, exhaustive. It is the operator's responsibility to be alert

for any equipment or environmental condition that could

compromise safe operation.

C Starting

1. Always sit in the operator's seat when starting engine

or operating levers or controls. Adjust seat per

instructions in the operating the tractor section. Never

start engine while standing on the ground.

2. Before starting the engine, make sure that all levers

(including auxiliary control levers) are in their neutral

positions, that the parking brake is engaged, and that

both the clutch and the Power Take-Off (PTO) are

disengaged or "OFF".

Fasten the seat belt if the tractor has a CAB, a fixed

ROPS or a foldable ROPS in the upright and locked

position.

3. Do not start engine by shorting across starter

terminals or bypassing the safety start switch.

Machine may start in gear and move if normal starting

circuitry is bypassed.

4. Do not operate or idle engine in a non-ventilated area.

Carbon monoxide gas is colorless, odorless, and

deadly.

5. Check before each use that operator presence

controls are functioning correctly. Test safety systems.

(See "Checking Engine Start System" in "EVERY 50

HOURS" in "PERIODIC SERVICE" section.)

Do not operate unless they are functioning correctly.

(1) Drawbar

2. For trailing PTO-driven implements, set the drawbar to

the towing position.

3. Attach pulled or towed loads to the drawbar only.

4. Keep all shields and guards in place. Replace any that

are missing or damaged.

5. Avoid sudden starts. To avoid upsets, slow down

when turning, on uneven ground, and before stopping.

6. The tractor cannot turn with the rear wheel or 4-wheel

differential locked and attempting to do so could be

dangerous.

7. Do not operate near ditches, holes, embankments, or

other ground surface features which may collapse

under the tractor's weight. The risk of tractor upset is

even higher when the ground is loose or wet. Tall

grass can hide obstacles, walk the area first to be sure.

8. Watch where you are going at all times. Watch for and

avoid obstacles. Be alert at row ends, near trees, and

other obstructions.

9. When working in groups, always let the others know

what you are going to do before you do it.

10.Never try to get on or off a moving tractor.

11.Always sit in the operator's seat when operating levers

or controls.

12.Do not use "Bi-speed Turn" at high speed.

13."Bi-Speed Turn" enables short and fast turns,

therefore, become familiar with its performance before

operating in close or confined areas.

14.Do not stand between tractor and implement or trailed

vehicle unless parking brake is applied.

Page 17

-3SAFE OPERATION

C Instructional seat (if equipped)

1. Always wear your seat belt and stabilize your body by

holding the handrail on the CAB frame.

2. It is not intended to carry children nor any other person

for any other purpose.

3. The left hand door must be closed at all time whenever

the instructional seat is occupied and the tractor is in

motion.

4. Do not permit others to ride, except on the designated

instructional seat.

5. Use caution to avoid the risks of obstructing operator's

view, falling from the machine and interfering with

controls.

6. Do not start and stop the tractor suddenly, nor take

sharp turn.

7. Do not use the instructional seat if the seat belt or the

door lock fails to function.

8. Do not use the instructional seat for transport.

9. When opening and closing the door from the

instructional-seat-sitting position, move the door

slowly. This is to prevent his or her hand(s) from

getting caught by the door or his or her body to hit

against the door.

C Safety for children

Tragedy can occur if the operator is not alert to the

presence of children. Children generally are attracted to

machines and the work they do.

1. Never assume that children will remain where you last

saw them.

2. Keep children out of the work area and under the

watchful eye of another responsible adult.

3. Be alert and shut your machine down if children enter

the work area.

4. Never carry children on your machine. There is no safe

place for them to ride. They may fall off and be run

over or interfere with your control of the machine.

5. Never allow children to operate the machine even

under adult supervision.

6. Never allow children to play on the machine or on the

implement.

7. Use extra caution when backing up. Look behind and

down to make sure area is clear before moving.

C Operating on slopes

Slopes are a major factor related to loss-of-control and tipover accidents, which can result in severe injury or death.

All slopes require extra caution.

1. To avoid upsets, always back up steep slopes. If you

cannot back up the slope or if you feel uneasy on it, do

not operate on it. Stay off slopes too steep for safe

operation.

2. Driving forward out of a ditch, mired condition or up a

steep slope increases the risk of a tractor to be upset

backward. Always back out of these situations. Extra

caution is required with 4-wheel drive models because

their increased traction can give the operator false

confidence in the tractor's ability to climb slopes.

3. Keep all movement on slopes slow and gradual. Do

not make sudden changes in speed, direction or apply

brake and make sudden motions of the steering

wheel.

4. Avoid disengaging the clutch or changing gears speed

when climbing or going down a slope. If on a slope

disengaging the clutch or changing gears to neutral

could cause loss of control.

5. Special attention should be made to the weight and

location of implements and loads as such will affect the

stability of the tractor.

6. To improve stability on slope, set widest wheel tread

as shown in "TIRES, WHEELS AND BALLAST"

section.

Follow recommendations for proper ballasting.

7. To avoid free wheeling:

A Do not shift the shuttle lever while on a slope.

A Stop completely by using the brake and by

depressing the clutch pedal, then shift the shuttle

lever.

A Start off after selecting shuttle direction, by

releasing the clutch pedal.

C Driving the tractor on the road

1. Lock the 2 brake pedals together to help assure

straight-line stops. Uneven braking at road speeds

could cause the tractor to tip over.

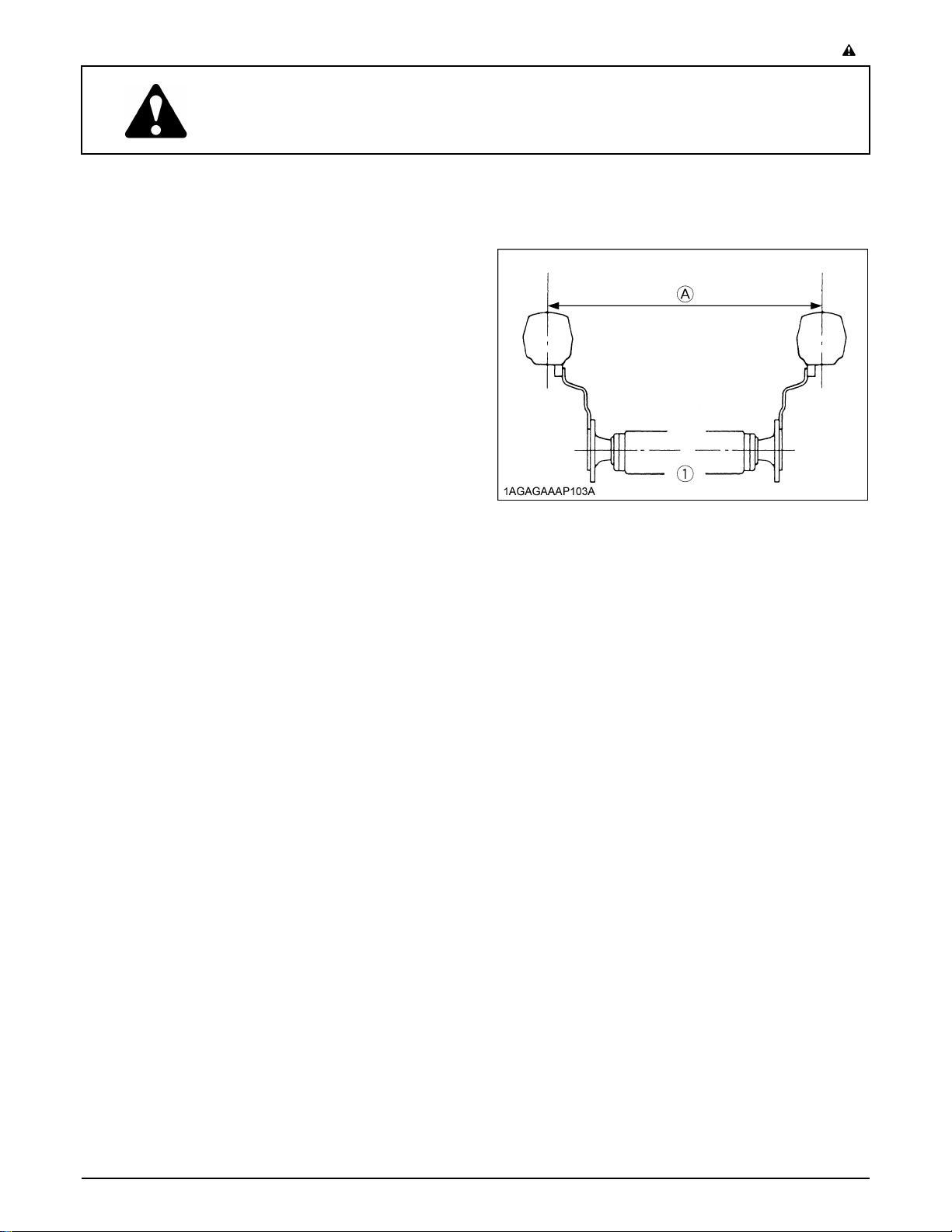

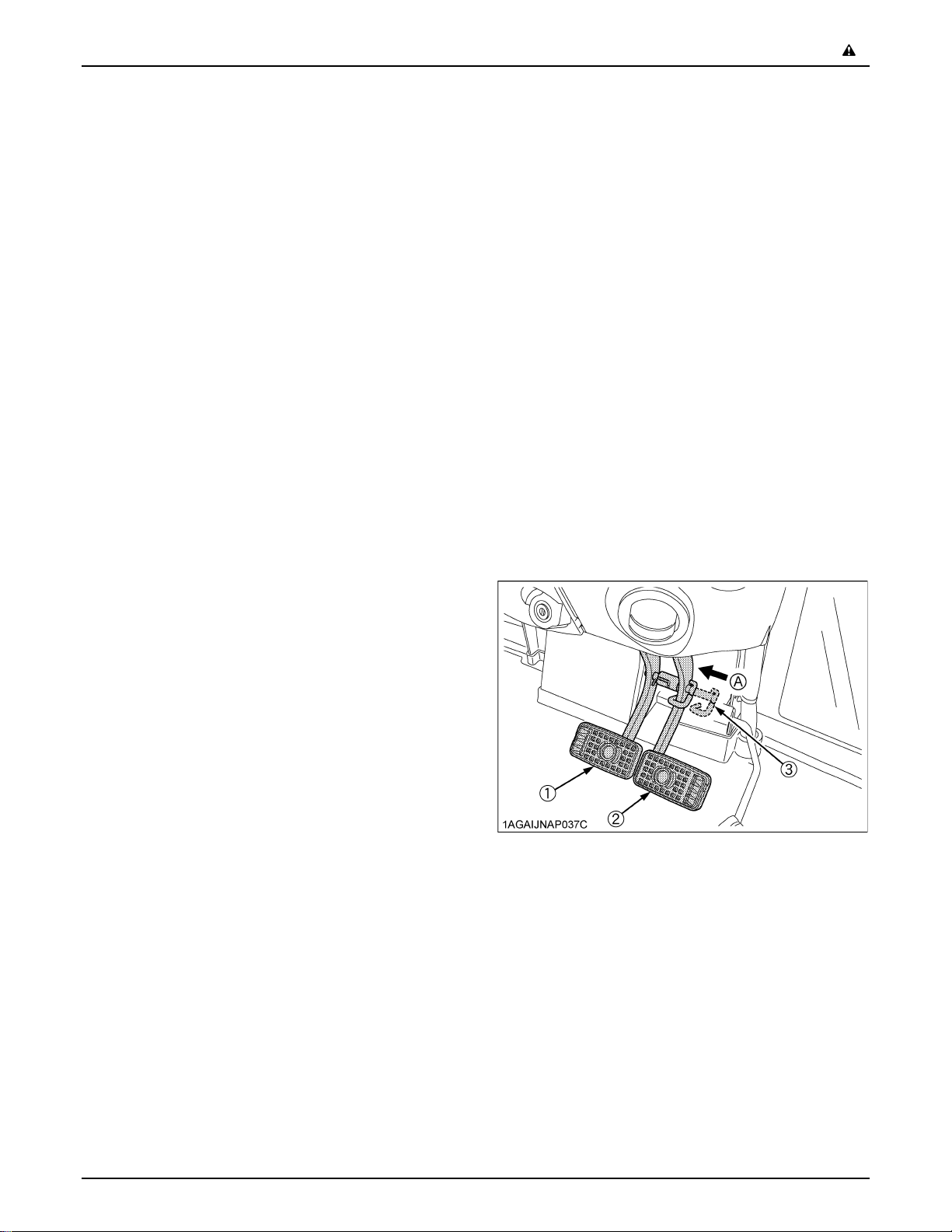

(1) Brake Pedal (LH)

(2) Brake Pedal (RH)

(3) Brake Pedal Lock

(A) Whenever travelling on the road

2. Check the front wheel engagement. The braking

characteristics are different between 2 and 4-wheel

drive. Be aware of the difference and use carefully.

3. Always slow the tractor down before turning. Turning

at high speed may tip the tractor over.

Page 18

SAFE OPERATION-4

4. Make sure that the Slow Moving Vehicle (SMV) sign is

clean and visible. Use hazard lights and turn signals as

required.

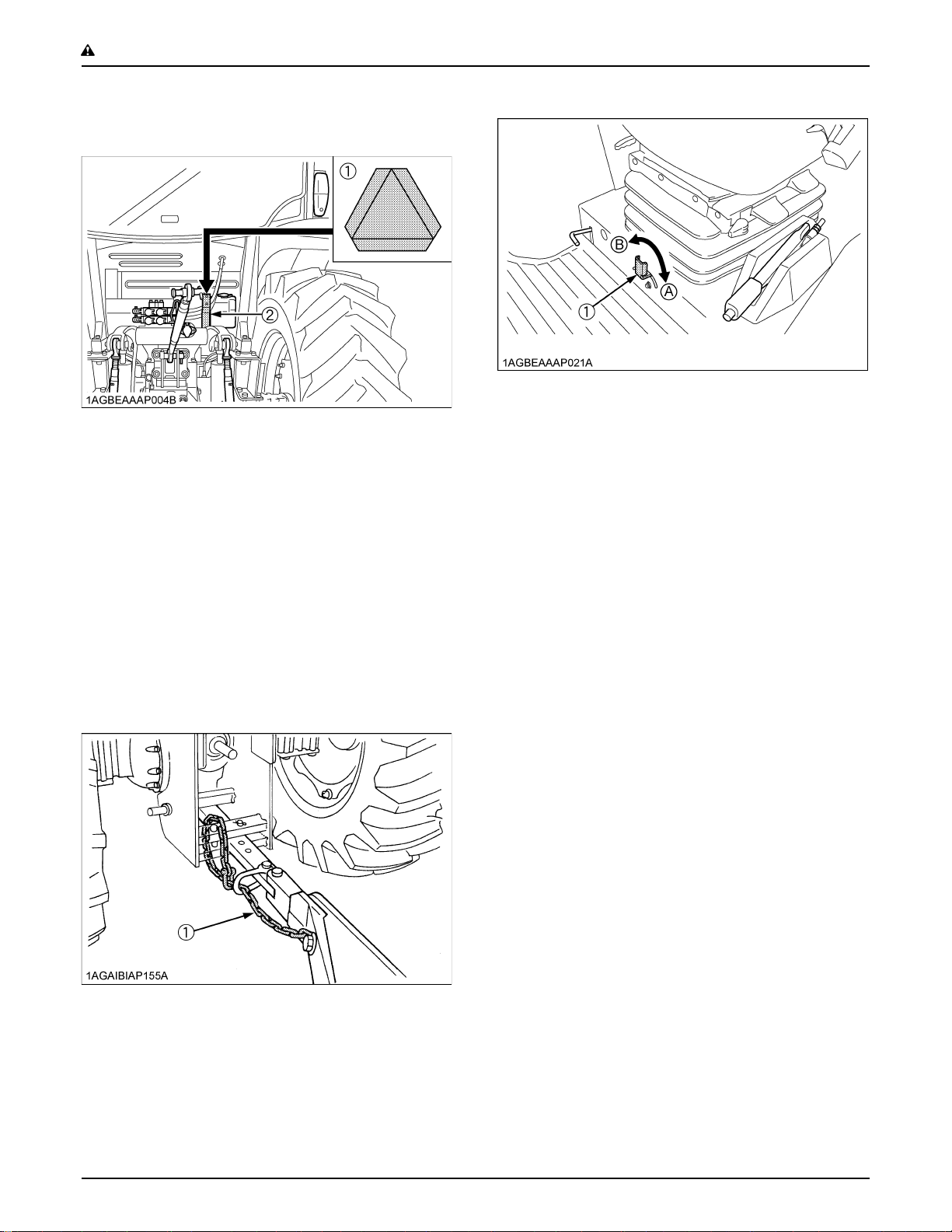

(1) SMV emblem

(2) Bracket

(1) 3-point hitch lowering lock lever (A) "LOCK"

(B) "UNLOCK"

5. Observe all local traffic and safety regulations.

6. Turn the headlights on. Dim them when meeting

another vehicle.

7. Drive at speeds that allow you to maintain control at all

times.

8. Do not apply the differential lock while traveling at road

speeds. The tractor may run out of control.

9. Avoid sudden motions of the steering wheel as they

can lead to a dangerous loss of stability. The risk is

especially great when the tractor is traveling at road

speeds.

10.Do not operate an implement while the tractor is on the

road. Lock the 3-point hitch in the raised position.

11.When towing other equipment, use a safety chain and

place an SMV emblem on it as well.

3. PARKING THE TRACTOR

1. Disengage the PTO, lower all implements to the

ground, place all control levers in their neutral

positions, set the parking brake, stop the engine,

remove the key from the ignition and lock the cab door

(if equipped). Leaving transmission in gear with the

engine stopped will not prevent tractor from rolling.

2. Make sure that the tractor has come to a complete

stop before dismounting.

3. Avoid parking on steep slopes, if at all possible park on

a firm and level surface; if not, park across a slope and

chock the wheels.

Failure to comply with this warning may allow the

tractor to move and could cause injury or death.

(1) Safety chain

12.Set the implement lowering control in the "LOCK"

position to hold the implement in the raised position.

Page 19

-5SAFE OPERATION

4. OPERATING THE PTO

1. Wait until all moving components have completely

stopped before getting off the tractor, connecting,

disconnecting, adjusting, cleaning, or servicing any

PTO driven equipment.

2. Keep the PTO shaft cover in place at all times.

Replace the PTO shaft cap when the shaft is not in

use.

(1) PTO Shaft cover

(2) PTO Shaft cap

(A) "NORMAL POSITION"

(B) "RAISED POSITION"

5. USING 3-POINT HITCH

1. Use the 3-point hitch only with equipment designed for

3-point hitch usage.

2. When using a 3-point hitch mounted implement, be

sure to install the proper counterbalance weight on the

front of the tractor.

3. To avoid injury from separation:

Do not extend lift rod beyond the groove on the

threaded rod.

(1) Groove

3. Before installing or using PTO driven equipment, read

the manufacturer's manual and review the safety

labels attached to the equipment.

To prevent PTO driven equipment from improper or

unsafe use, select the lower speed (540rpm) unless

the higher one is specifically recommended as safe by

the equipment manufacturer.

4. When operating stationary PTO driven equipment,

always apply the tractor parking brake and place

chocks behind and in front of the rear wheels. Stay

clear of all rotating parts. Never step over rotating

parts.

4. Use [UP-DOWN] switch or lever only on farm fields.

For all other application, use hydraulic lever to move

attachment.

6. SERVICING THE TRACTOR

Before servicing the tractor, park it on a firm, flat and level

surface, set the parking brake, lower all implements to the

ground, place the gear shift lever in neutral, stop the

engine and remove the key.

1. Allow the tractor time to cool off before working on or

near the engine, muffler, radiator, etc.

2. Do not remove radiator cap while coolant is hot. When

cool, slowly rotate cap to the first stop and allow

sufficient time for excess pressure to escape before

removing the cap completely. If the tractor has a

coolant recovery tank, add coolant or water to the tank,

not the radiator. (See "Checking Coolant Level" in

"DAILY CHECK" in "PERIODIC SERVICE" section.)

3. Always stop the engine before refueling. Avoid spills

and overfilling.

4. Do not smoke when working around battery or when

refueling. Keep all sparks and flames away from

battery and fuel tank. The battery presents an

explosive hazard, because it gives off hydrogen and

oxygen especially when recharging.

5. Before "jump starting" a dead battery, read and follow

all of the instructions. (See "JUMP STARTING" in

"OPERATING THE ENGINE" section.)

Page 20

SAFE OPERATION-6

6. Keep first aid kit and fire extinguisher handy at all

times.

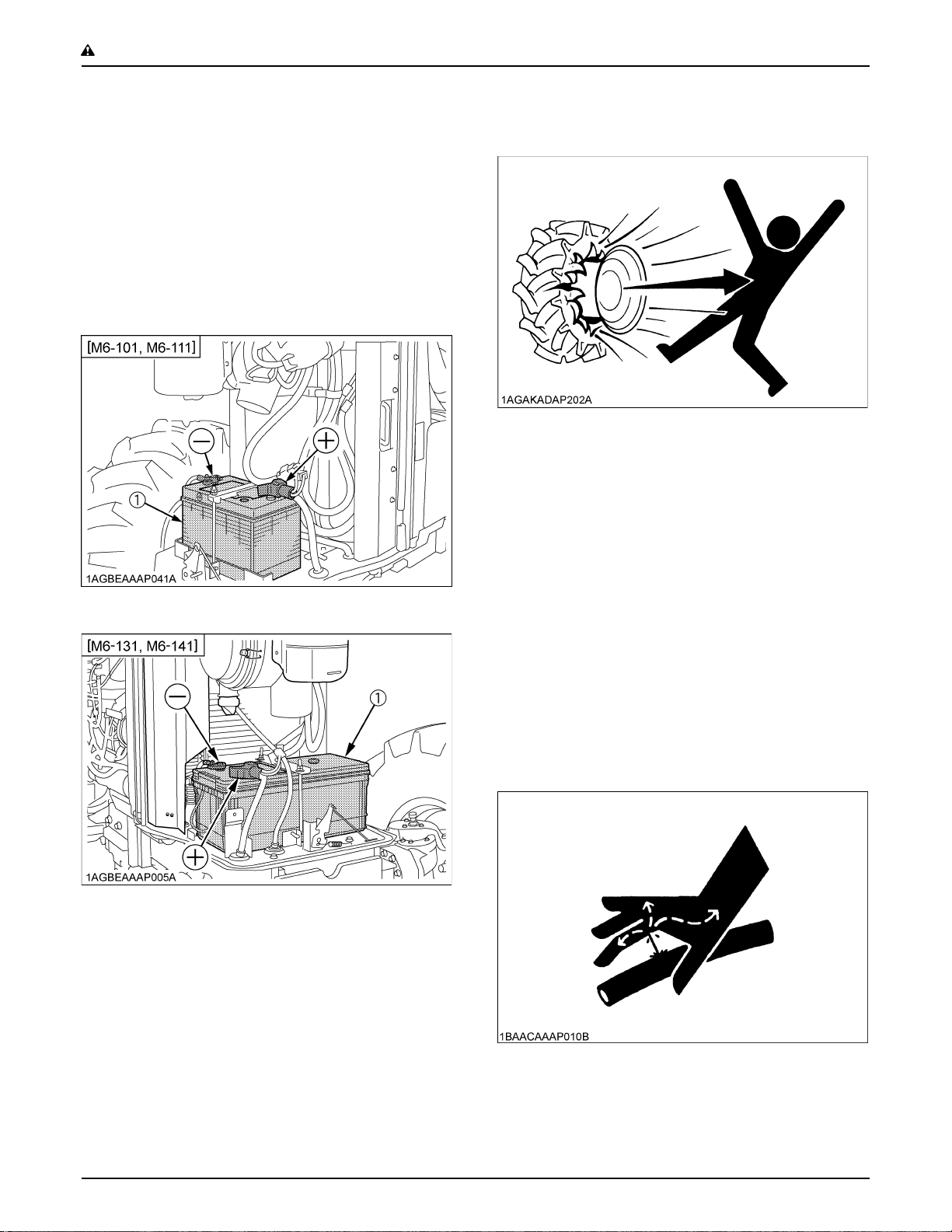

7. Disconnect the battery's ground cable before working

on or near electric components.

8. To avoid the possibility of battery explosion, do not use

or charge the refillable type battery if the fluid level is

below the LOWER ( lower limit level ) mark. Check the

fluid level regularly and add distilled water as required

so that the fluid level is between the UPPER and

LOWER levels.

9. To avoid sparks from an accidental short circuit,

always disconnect the battery's ground cable (-) first

and reconnect it last.

(1) Battery

11.Always maintain the correct tire pressure. Do not

inflate tires above the recommended pressure shown

in the operator's manual.

12.Securely support the tractor when either changing

wheels or adjusting the wheel tread width.

13.Make sure that wheel bolts have been tightened to the

specified torque.

14.Disconnect the battery's ground cable and stop the

engine to avoid the possibility of the machine runaway

due to 4WD braking system during testing, service or

repair with only rear wheels off the ground.

15.Do not work under any hydraulically supported

devices. They can settle, suddenly leak down, or be

accidentally lowered. If it is necessary to work under

tractor or any machine elements for servicing or

adjustment, securely support them with stands or

suitable blocking beforehand.

16.Escaping hydraulic fluid under pressure has sufficient

force to penetrate skin, causing serious personal

injury. Before disconnecting hydraulic lines, be sure to

release all residual pressure. Before applying

pressure to the hydraulic system, make sure that all

connections are tight and that all lines, pipes, and

hoses are free of damage.

(1) Battery

10.Do not attempt to mount a tire on a rim. This should be

done by a qualified person with the proper equipment.

Page 21

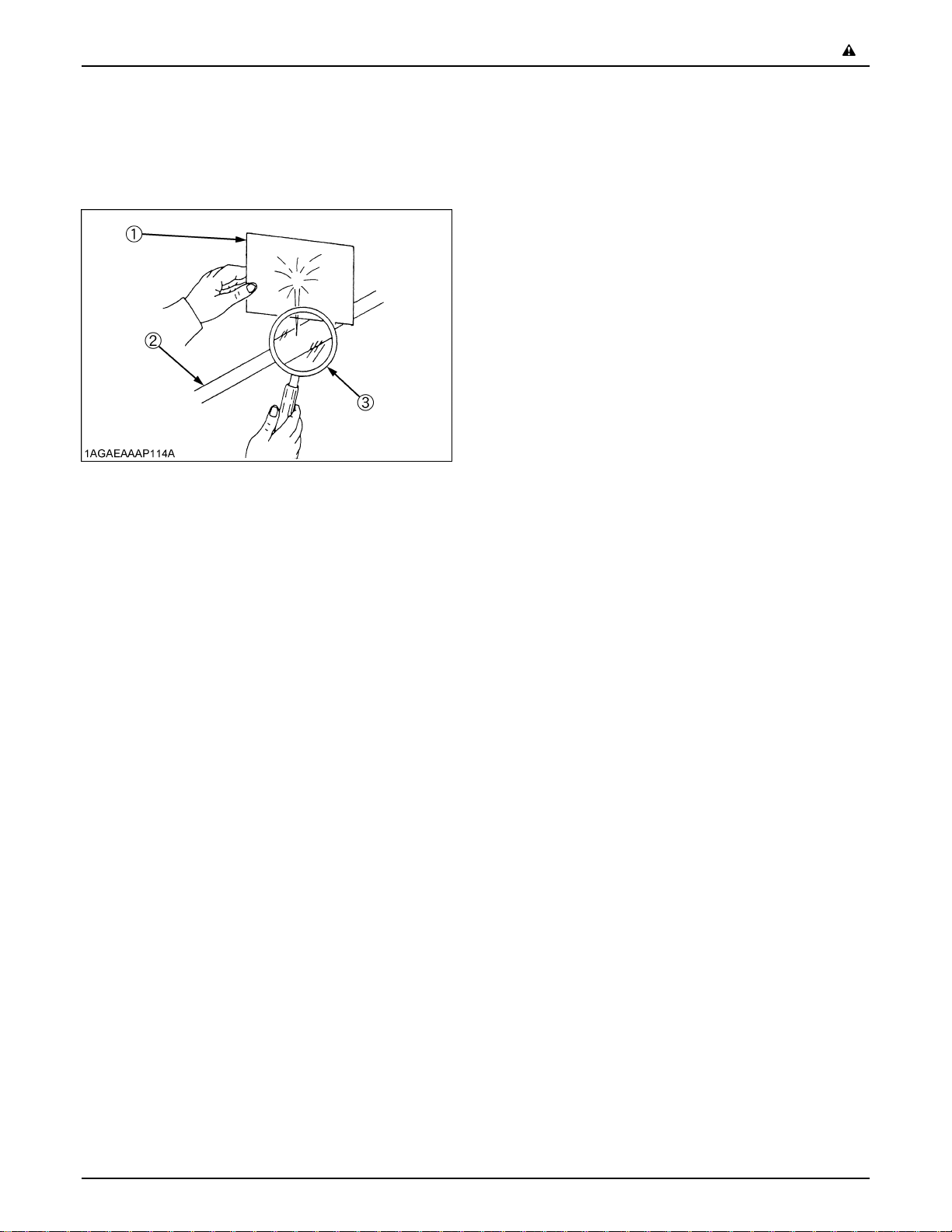

17.Fluid escaping from pinholes may be invisible. Do not

use hands to search for suspected leaks; use a piece

of cardboard or wood. Use of safety goggles or other

eye protection is also highly recommended. If injured

by escaping fluid, see a medical doctor at once. This

fluid will produce gangrene or severe allergic reaction.

(1) Cardboard

(2) Hydraulic line

(3) Magnifying glass

-7SAFE OPERATION

18.Do not open high-pressure fuel system.

High-pressure fluid remaining in fuel lines can cause

serious injury. Do not disconnect nor attempt to repair

fuel lines, sensors, or any other components between

the high-pressure fuel pump and injectors on engines

with high pressure common rail fuel system.

19.To avoid hazardous high voltage, turn the key switch

to the OFF position if it is necessary to check to repair

the computer, harness or connectors.

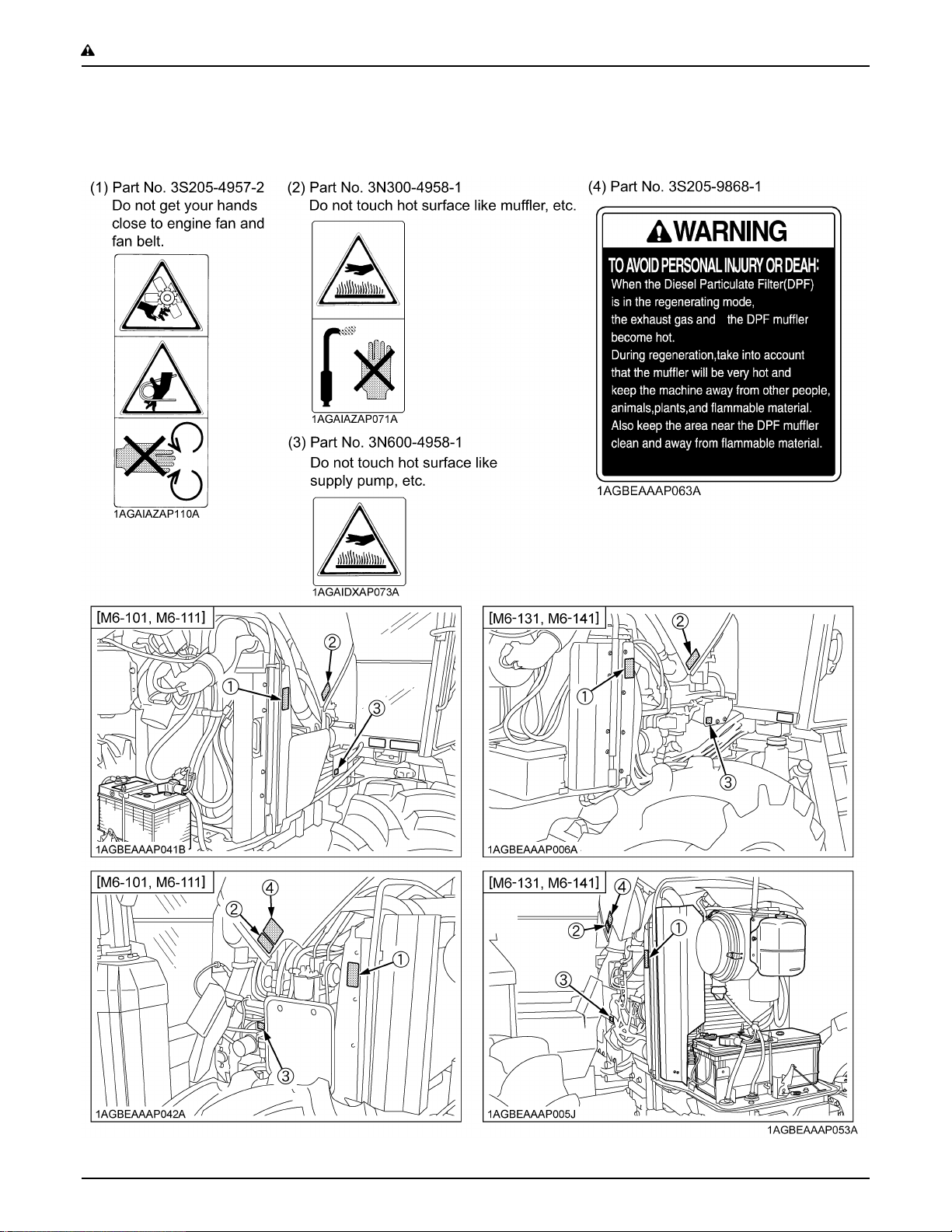

20.During Diesel Particulate Filter (hereinafter called

DPF) regenerating operations, exhaust gases and

exhaust filter components reach temperatures hot

enough to burn people, or ignite or melt common

materials.

21.Keep the tractor away from people, animals or

structures which may be susceptible to harm or

damage from hot exhaust gases.

22.To prevent fires, keep the DPF/SCR muffler and its

surroundings clear of anything flammable and keep

clean at all times. [Selective Catalytic Reduction

(hereinafter called SCR)]

23.During regeneration, white exhaust gas may be

visible. Do not allow regeneration in a non-ventilated

space.

24.During regeneration, do not leave the tractor.

25.Before servicing a tractor equipped with the front

suspension, be sure to lower the machine to the lowest

position.

26.The front suspension hydraulic circuit is still under high

pressure after the engine has stopped. Do not

disconnect the pipes and/or hoses because you may

get injured by high-pressure oil. If pipes and/or hoses

are found worn or damaged, consult your local

KUBOTA Dealer for this service.

Page 22

SAFE OPERATION-8

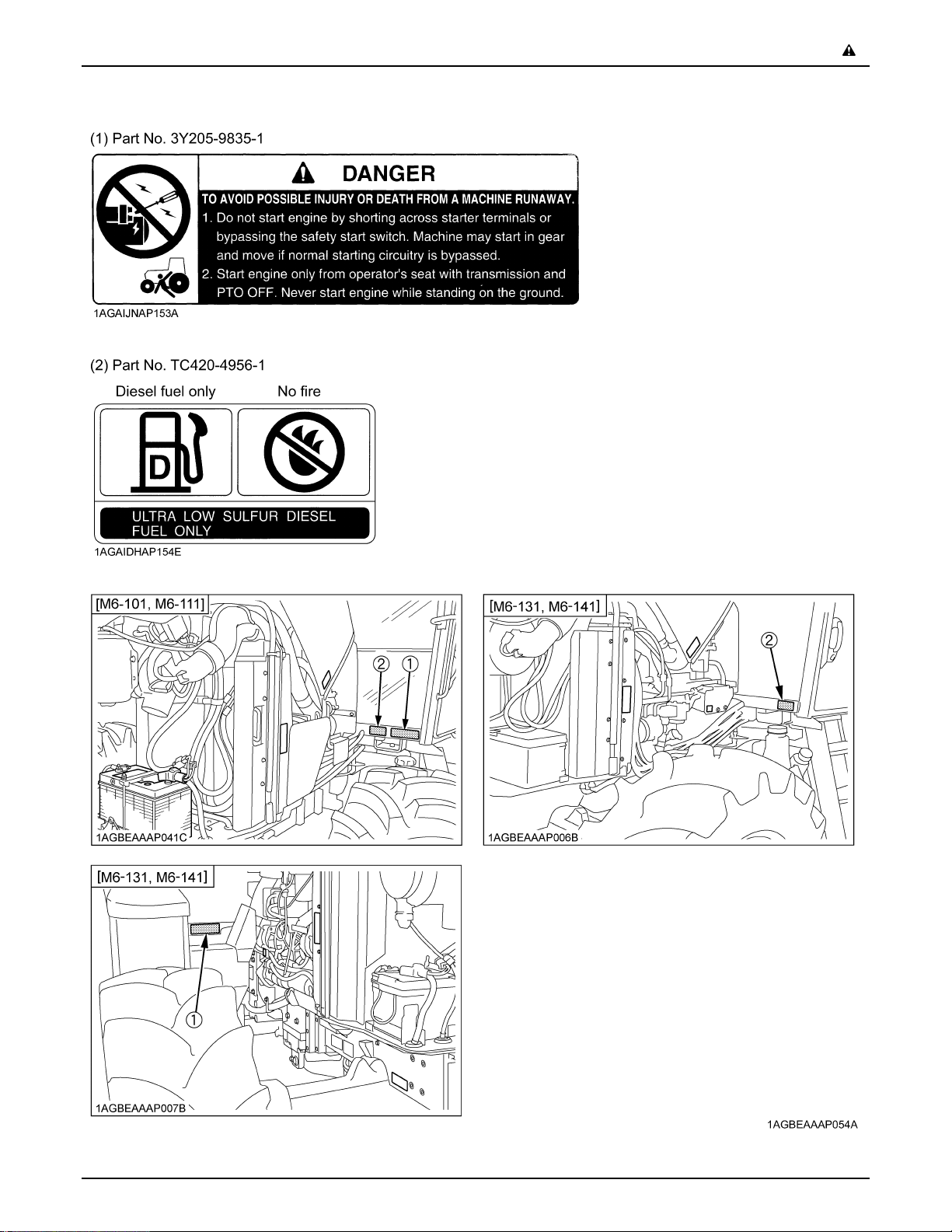

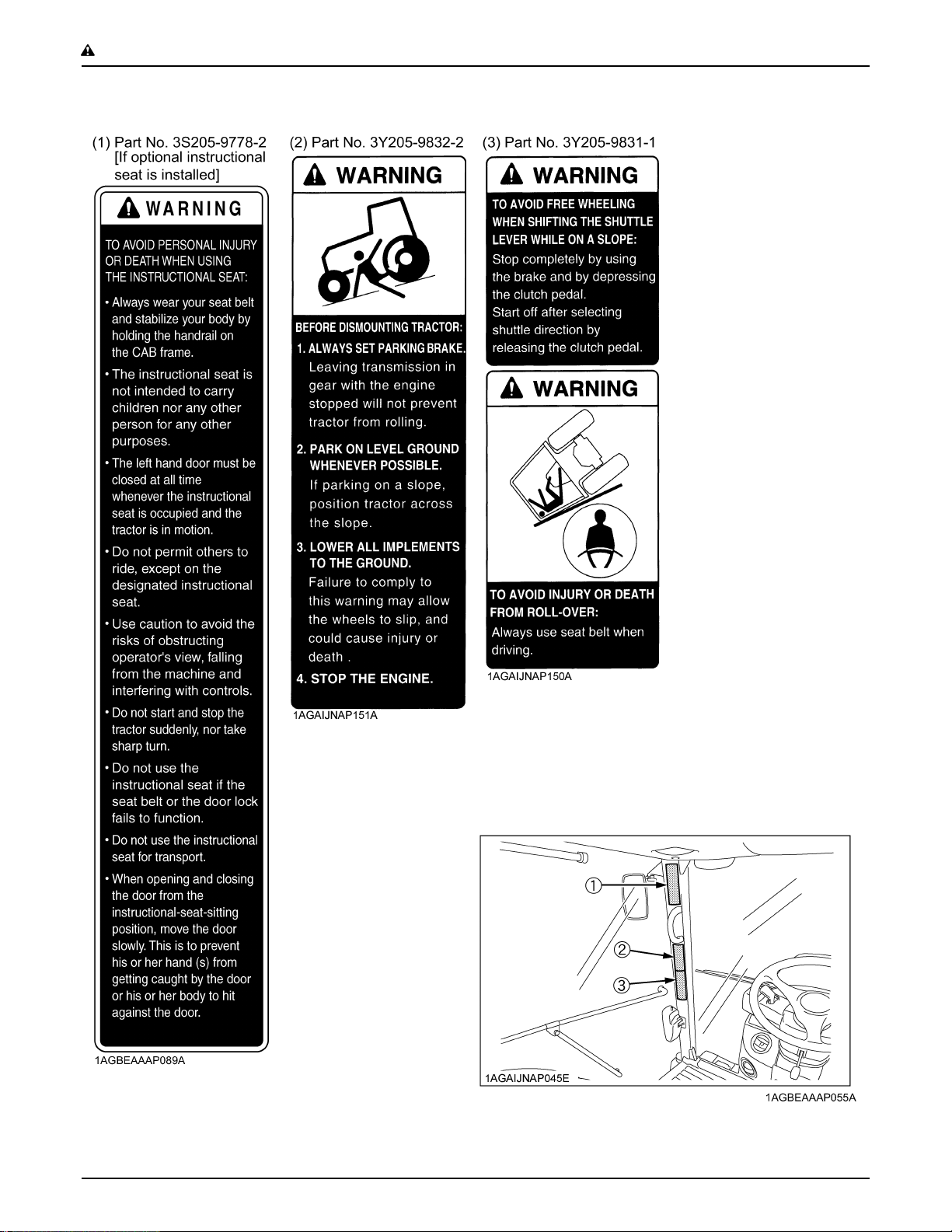

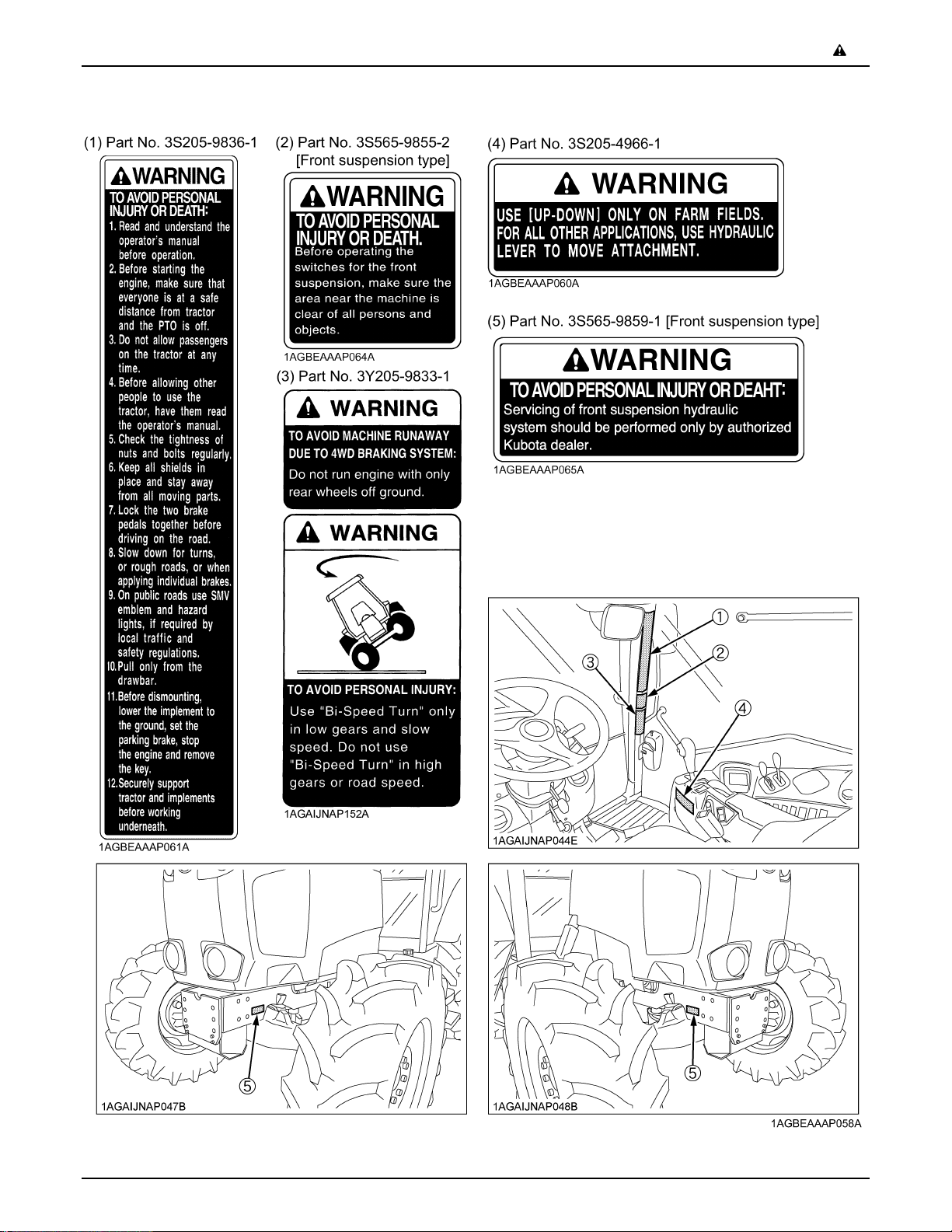

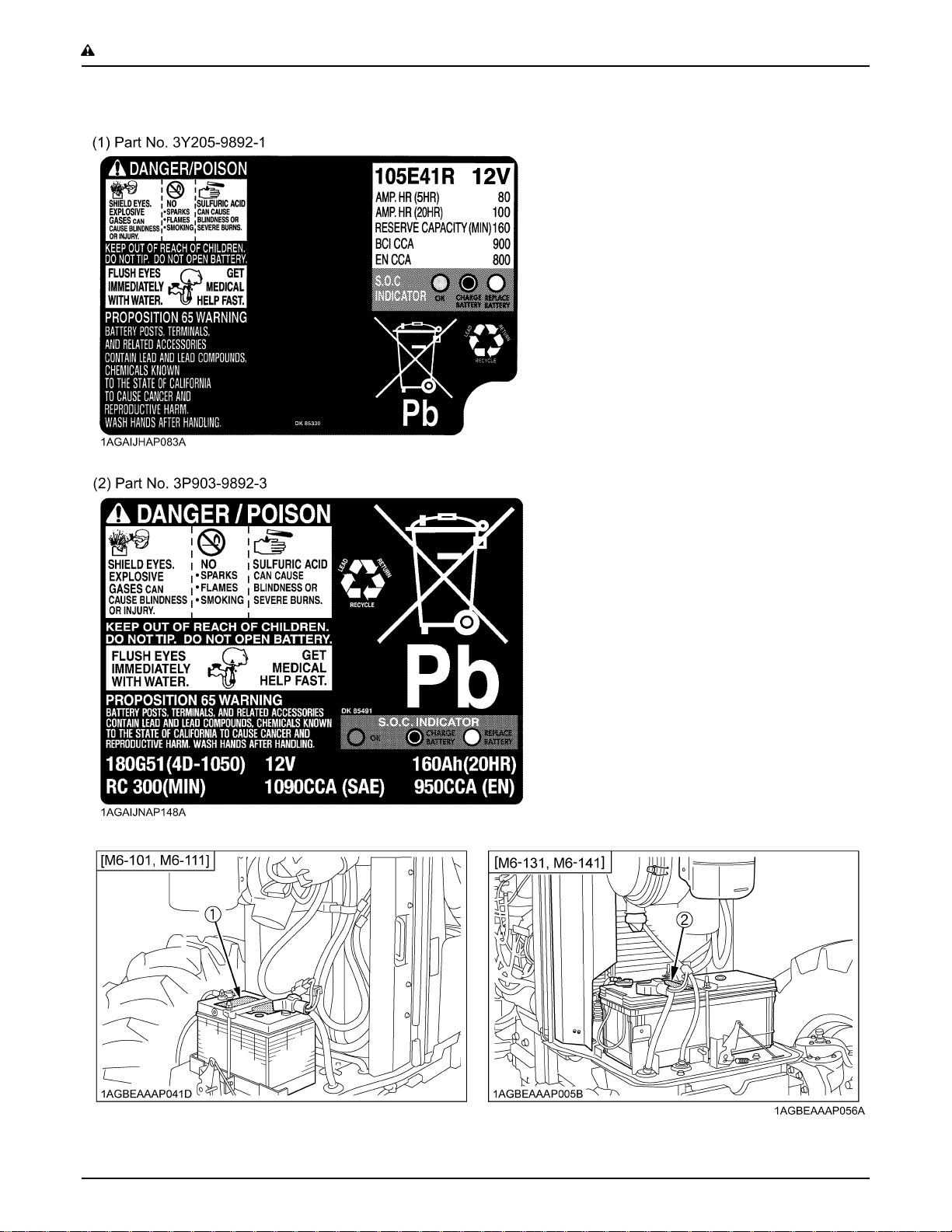

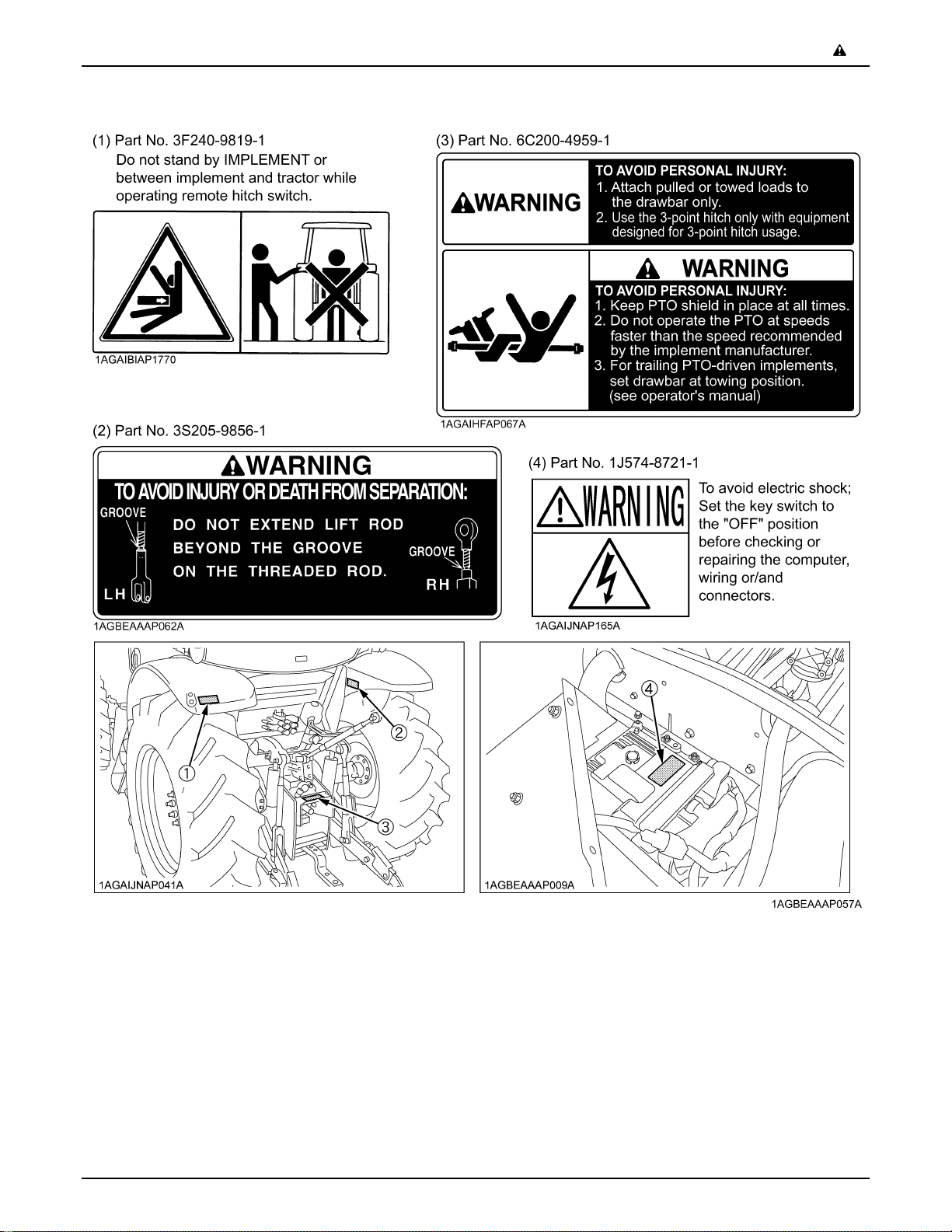

7. DANGER, WARNING AND CAUTION LABELS

Page 23

-9SAFE OPERATION

Page 24

SAFE OPERATION-10

Page 25

-11SAFE OPERATION

Page 26

SAFE OPERATION-12

Page 27

-13SAFE OPERATION

8. CARE OF DANGER, WARNING AND CAUTION LABELS

1. Keep danger, warning and caution labels clean and free from obstructing material.

2. Clean danger, warning and caution labels with soap and water, dry with a soft cloth.

3. Replace damaged or missing danger, warning and caution labels with new labels from your local KUBOTA Dealer.

4. If a component with danger, warning and caution label(s) affixed is replaced with new part, make sure new label(s) is

(are) attached in the same location(s) as the replaced component.

5. Mount new danger, warning and caution labels by applying on a clean dry surface and pressing any bubbles to outside

edge.

Page 28

Page 29

SERVICING OF TRACTOR

Your dealer is interested in your new tractor and has the

desire to help you get the most value from it. After reading

this manual thoroughly, you will find that you can do some

of the regular maintenance yourself.

However, when in need of parts or major service, be sure

to see your KUBOTA Dealer.

For service, contact the KUBOTA Dealership from which

you purchased your tractor or your local KUBOTA Dealer.

When in need of parts, be prepared to give your dealer the

tractor, CAB/ROPS and engine serial numbers.

Locate the serial numbers now and record them in the

space provided.

Type Serial No.

1SERVICING OF TRACTOR

Tractor

CAB / ROPS

Engine

Date of Purchase

Name of Dealer

(To be filled in by purchaser)

C Warranty

This tractor is warranted under the KUBOTA Limited

Express Warranty, a copy of which may be obtained from

your selling dealer. No warranty shall, however, apply if

the tractor has not been handled according to the

instruction given in the Operator's Manual even it is within

the warranty period.

C Scrapping the tractor and its procedure

To put the tractor out of service, correctly follow the local

rules and regulations of the country or territory where you

scrap it. If you have questions, consult your local

KUBOTA Dealer.

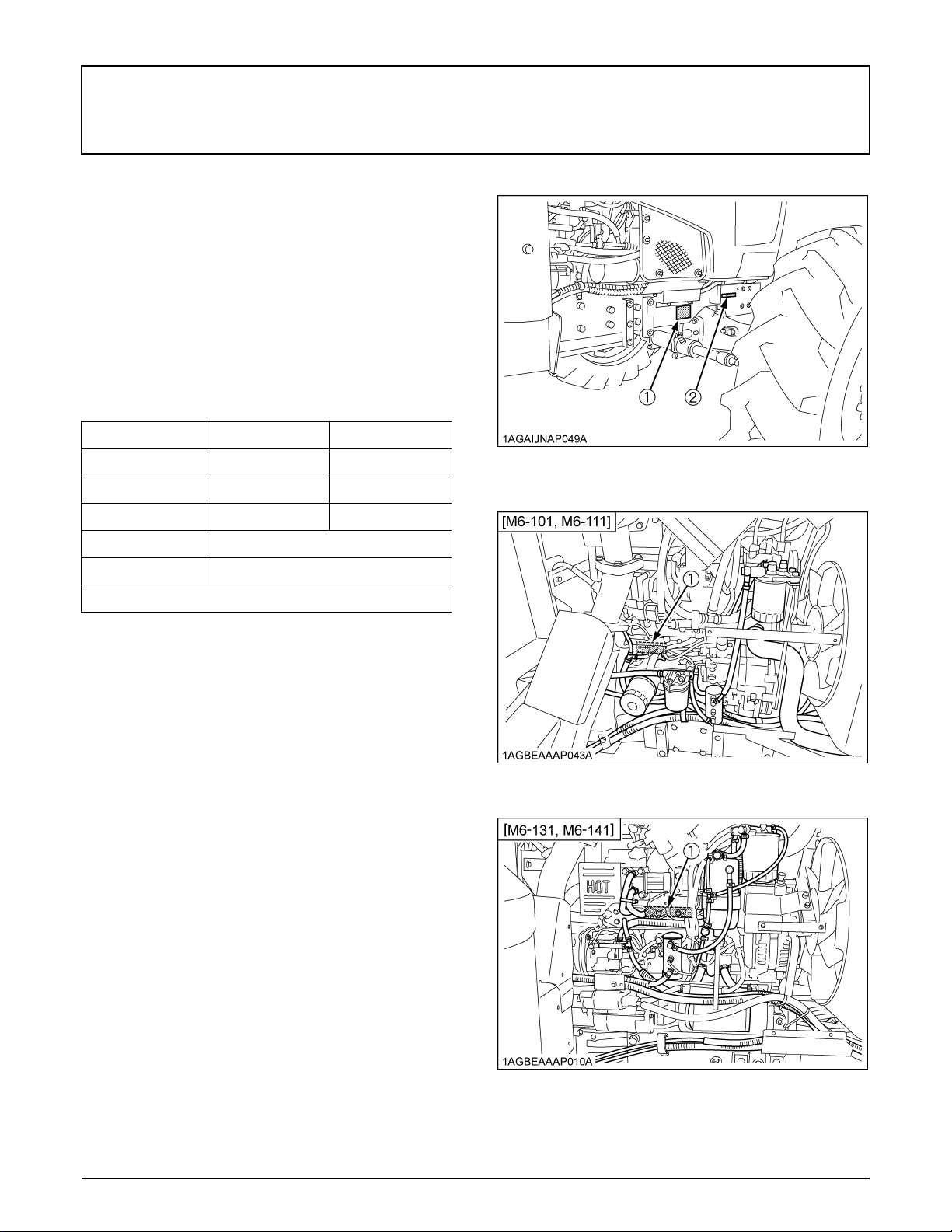

(1) Tractor identification plate

(2) Tractor serial number

(1) Engine serial number

(1) Engine serial number

Page 30

SERVICING OF TRACTOR2

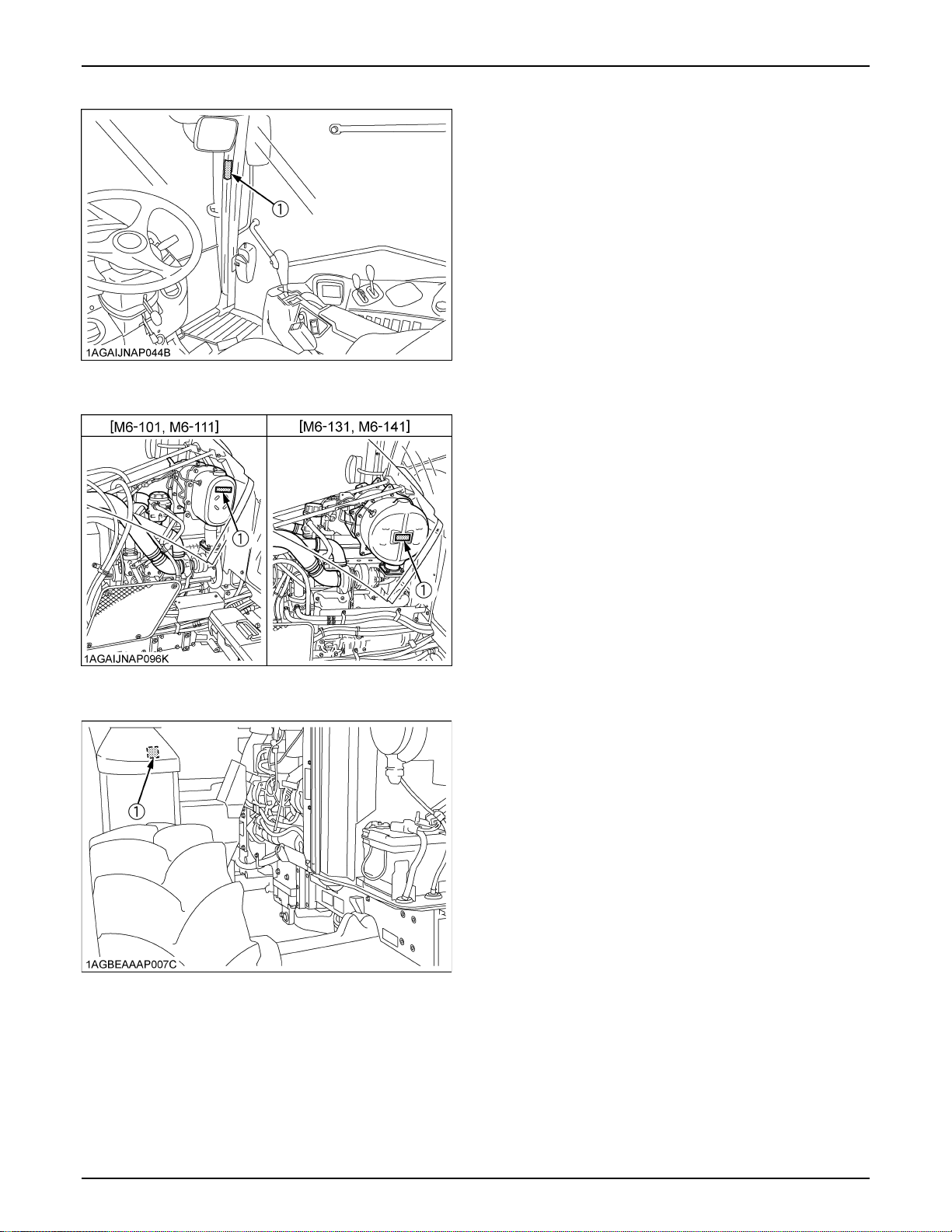

(1) CAB identification plate (CAB Serial No.)

(1) Diesel Particulate Filter (DPF) serial number

(1) Selective Catalytic Reduction (SCR) muffler serial number

Page 31

SPECIFICATIONS

SPECIFICATION TABLE

3SPECIFICATIONS

Engine

Model

Model V3800-TIEF4 V6108-TIEF4

Type

Number of cylinders 4

Total displacement cm (cu.in.) 3769 (230) 6124 (374)

Bore and stroke mm (in.) 100 x 120 (3.94 x 4.72) 118 x 140 (4.65 x 5.51)

Rated revolution rpm 2600 2200

Low idling revolution rpm 800 to 850

Net power *1 kW (HP) 74.6 (100) 81.7 (109.5) 93.2 (125) 100.7 (135)

PTO power *1

(factory observed)

Battery capacity

Fuel tank capacity L (U.S.gals.) 190 (50.2)

Engine oil capacity L (U.S.qts.) 10.5 (11.1) 14.6 (15.4)

Coolant capacity L (U.S.qts.) 10.1 (10.7) 14.6 (15.4)

kW (HP) /

rpm

M6-101 M6-111 M6-131 M6-141

4WD

Direct Injection, Water-cooled 4 Cycle Diesel,

Common Rail System, Turbocharger, Intercooler

61.1 (82) /

2600

12V, 100Ah at 20hours,

900CCA

68.6 (92) /

2600

77.6 (104) /

2200

12V, 160Ah at 20hours,

1090CCA

85.0 (114) /

2200

DEF/AdBlue®

capacity

Overall length mm (in.) 4200 (165.4) 4360 (171.7) <4350 (171.3)>

Overall width

(minimum tread)

Overall height mm (in.) 2790 (109.8) 2840 (111.8) 2875 (113.2)

Dimensions

Weight kg (lbs.) 4355 (9601) 4440 (9789) 4965 (10946) <5165 (11387)>

Traveling

system

Wheel base mm (in.) 2435 (95.9) 2690 (105.9) <2680 (105.5)>

Front mm (in.) 1580 (62.2), 1680 (66.1) 1775 (69.9), 1875 (73.8)

Tread

Crop clearance mm (in.) 370 (14.5) 425 (16.7) 450 (17.7)

Standard

tire size

Clutch Multiple wet disc, Electronic Hydraulically operated

Steering Hydrostatic Power Steering

Braking system Hydraulically operated wet disk

Differential Bevel gears with differential lock (Front, Rear)

Rear mm (in.)

Front tires 12.4R24 13.6R24 14.9R24

Rear tires 18.4R30 18.4R34 18.4R38

L (U.S.gals.) 16 (4.2)

mm (in.) 2100 (82.7) 2180 (85.8)

1520 (59.8) to

2060 (81.1)

1530 (60.2) to

2040 (80.3)

1590 (62.6) to 2090 (82.3)

Page 32

4 SPECIFICATIONS

Hydraulic

unit

PTO

Model

Hydraulic control system Electronic draft control

Pump capacity L/min (gpm) 70.9 (18.7) 77.2 (20.4)

3-point hitch Category 2

At lifting

Max.

lifting

force

Remote hydraulic control 2 standard (3rd & 4th valve optional)

System pressure

Traction system Swinging drawbar, adjustable in direction

Live PTO

(Independent)

points

24 in.

behind

lifting

point *2

Direction of turning Clockwise, viewed from tractor rear

PTO/

Engine

speed

kg (lbs.) 3900 (8598) At lower link end with links horizontal

kg (lbs.) 3100 (6834)

MPa

(kgf/cm )

rpm

M6-101 M6-111 M6-131 M6-141

4WD

19.6 (200)

6 spline: 540 / 2405

21 spline: 1000 / 2389

6 spline: 540 / 1994

21 spline: 1000 / 2050

The company reserves the right to change the specifications without notice.

NOTE: *1 Manufacturer's estimate

*2 Top link mounting: upper hole

< >: Front suspension type

Page 33

TRAVELING SPEEDS

(At rated engine rpm)

Model M6-101 M6-111 M6-131, M6-141

Tire size (Rear) 18.4R30 18.4R34 18.4R38

Range Speed (km/h) Speed (mph) Speed (km/h) Speed (mph) Speed (km/h) Speed (mph)

1 0.19 0.11 0.20 0.12 0.20 0.12

2 0.23 0.14 0.24 0.15 0.24 0.15

3 0.27 0.17 0.29 0.18 0.29 0.18

C

L

M

H

4 0.33 0.20 0.35 0.22 0.36 0.22

5 0.39 0.24 0.41 0.26 0.41 0.26

6 0.47 0.29 0.50 0.31 0.50 0.31

7 0.56 0.35 0.59 0.37 0.61 0.38

8 0.68 0.42 0.72 0.45 0.74 0.46

1 0.78 0.49 0.83 0.52 0.84 0.52

2 0.96 0.59 1.02 0.63 1.01 0.63

3 1.13 0.70 1.21 0.75 1.23 0.77

4 1.37 0.85 1.46 0.91 1.50 0.93

5 1.62 1.01 1.73 1.08 1.74 1.08

6 1.99 1.24 2.12 1.32 2.11 1.31

7 2.35 1.46 2.51 1.56 2.56 1.59

8 2.85 1.77 3.04 1.89 3.12 1.94

1 3.3 2.1 3.5 2.2 3.5 2.2

2 4.1 2.5 4.3 2.7 4.3 2.7

3 4.8 3.0 5.1 3.2 5.2 3.2

4 5.8 3.6 6.2 3.9 6.4 4.0

5 6.9 4.3 7.4 4.6 7.4 4.6

6 8.4 5.2 9.0 5.6 8.9 5.6

7 9.9 6.2 10.6 6.6 10.9 6.8

8 12.1 7.5 12.9 8.0 13.2 8.2

1 9.1 5.7 9.8 6.1 9.8 6.1

2 11.2 7.0 12.0 7.4 11.9 7.4

3 13.2 8.2 14.1 8.8 14.4 9.0

4 16.0 10.0 17.1 10.6 17.6 10.9

5 19.0 11.8 20.3 12.6 20.4 12.6

6 23.3 14.5 24.9 15.4 24.7 15.4

7 27.5 17.1 29.3 18.2 30.0 18.6

8 * 35.3 21.9 37.7 23.4 39.1 24.3

5SPECIFICATIONS

The company reserves the right to change the specifications without notice.

* At maximum engine rpm.

Page 34

6 IMPLEMENT LIMITATIONS

IMPLEMENT LIMITATIONS

The KUBOTA Tractor has been thoroughly tested for proper performance with implements sold or approved by KUBOTA.

Use with implements which are not sold or approved by KUBOTA and which exceed the maximum specifications listed

below, or which are otherwise unfit for use with the KUBOTA Tractor may result in malfunctions or failures of the tractor,

damage to other property and injury to the operator or others. [Any malfunctions or failures of the tractor resulting from use

with improper implements are not covered by the warranty.]

Tread (max. width)

Front

Without spacer With spacer

M6-101

M6-111

M6-131

M6-141

(Shown on the next page)

Lower link end max,

hydraulic lifting capacity................. W 0

Implement weight...........................The implement's weight which can be put on the lower link: W 1

Max. drawbar load..........................W 2

Trailer loading weight......................The max. loading weight for trailer (without trailer's weight): W 3

1680 mm

(66.1 in.)

1875 mm

(73.8 in.)

Implement weight W 1

and / or size

As in the following list

---

2050 mm

(80.7 in.)

Actual figures

Max. Drawbar Load W 2

1500 kg (3300 lbs.)

Rear

2060 mm

(81.1 in.)

2090 mm

(82.3 in.)

Operating

condition

IMPORTANT

A Tractor with front

spacer option is not

approved for use

with front loader.

Trailer loading weight W 3

Max. capacity

7000 kg (15400 lbs.)

8000 kg (17600 lbs.)

Lower link end

max. lifting

capacity

W 0

3900 kg

(8598 lbs.)

A Implement size may vary depending on soil operating conditions.

A Strictly follow the instructions outlined in the operator’s manual of the mounted or trailed machinery or trailer, and do

not operate the combination tractor - machine or tractor - trailer unless all instructions have been followed

A Forestry Application

Following hazards exist;

(a) toppling trees, primarily in case a rear-mounted tree grab-crane is mounted at the rear of the tractor;

(b) penetrating objects in the operator’s enclosure, primarily in case a winch is mounted at the rear of the tractor.

Optional equipments such as OPS (Operator Protective Structure), FOPS (Falling Object Protective Structure), etc. to

deal with these hazards and other related hazards are not available for this tractor. Without such optional equipment

use is limited to tractor specific applications like transport and stationary work.

Page 35

7IMPLEMENT LIMITATIONS

No. Implement Remarks

1Slurry Tank

2 Trailer

Rotary-Cutter

3Mower

4 Sprayer

5 Rotary Tiller

6 Bottom Plow

Disk

7

harrow

8Disc Plow

9 Sub Soiler

10 Cultivator

11 Front Blade *1,*2

12 Rear Blade

13 Front Loader *1,*2

14 Box Blade

15 Back Hoe *2

16 Snow Blade

Flail Mower

(Heavy)

S i c k l e B a r M a x . C u t t i n g W i d t h m m ( i n . ) 3 0 5 0 ( 1 2 0 ) 3 0 5 0 ( 1 2 0 )

3P Type

Drawbar Type Max. Harrowing Width mm (in.) 4570 (180) 4570 (180)

Max. Tank Capacity L (gals.) 5000 (1320) 6000 (1585)

Max. Load Capacity kg (lbs.) 6000 (13200) 7000 (15400)