Kubota L3200, L3800, L2501 Operator's Manual

OPERATOR'S MANUAL

U.S.A. :KUBOTATRACTORCORPORATION

WesternDivision :

CentralDivision :

NorthernDivision :

SoutheastDivision :

Canada :KUBOTACANADALTD.

France :KUBOTAEUROPES.A.S

Italy :KUBOTAEUROPES.A.SItalyBranch

Germany :KUBOTA(DEUTSCHLAND)GmbH

U.K. :KUBOTA(U.K.)LTD.

Spain :KUBOTAESPAÑAS.A.

Australia :KUBOTATRACTORAUSTRALIAPTYLTD.

Malaysia :SIMEKUBOTASDN.BHD.

Philippines :KUBOTAPHILIPPINES,INC.

Taiwan :SHINTAIWANAGRICULTURALMACHINERYCO.,LTD.

Indonesia :P.T.KUBOTAINDONESIA

Thailand :SIAMKUBOTACORPORATIONCO.,LTD.

Korea :KUBOTAKOREACO.,LTD.

India :KUBOTAAGRICULTURALMACHINERYINDIAPVT.LTD.

Vietnam :KUBOTAVIETNAMCO.,LTD.

3401

DelAmoBlvd.,Torrance,CA

Telephone:(

Telephone :(

Telephone :(

Telephone :(

Telephone :(

590014

Telephone:(

19-25

Telephone:(

ViaGrandi,

Telephone:(

SenefelderStr.

Telephone:(

DormerRoad,Thame,Oxfordshire,OX

Telephone:(

AvenidaRecombaNo.

Telephone:(

25-29

Telephone:(

No.

3

JalanSepadu25/

Seksyen

Telephone:(

155

PanayAvenue,SouthTrian㷅leHomes,

Telephone:(

16

,Fen㷅pin㷅2ndRd,TaliaoShian㷅Kaohsiun㷅

Telephone:(

JalanSetyabudi

Telephone:(

101/19-24

Pathumthani

Telephone:(

106-24

Telephone:(

Re㷅us,Level

Telephone:(

LotBTelephone:(

310)370-3370

1175

S.GuildAvc.,Lodi,CA

209)334-9910

14855

FAABlvd.,FortWorth,TX

817)571-0900

6300

atOneKubotaWay,Groveport,OH

614)835-1100

1025

NorthbrookParkway,Suwanee,GA

770)995-8855

thAvenue,Markham,Ontario,L3S4K4,Canada

905)294-7477

,RueJulesVercruysse,Z.I.BP88,

33)1-3426-3434

2920068

PermasWay,Tru㷅anina,VIC

25,40400

Moo20,NavanakornIndustrialEstate,TambonKhlon㷅nuen㷅,AmphurKhlon㷅luan㷅,

Mon㷅san-Ri,Mankyun㷅-Up,Kimje-City,Chonrapuk-Do,KOREA

3A2

-CN,MyPhuoc3IndustrialPark,BenCatDistrict,BinhDuon㷅Province,Vietnam

PeschieraBorrome(MI)Italy

39)02-51650377

3-563110

49)6106-873-0

44)1844-214500

34)91-508-6442

61)-3-9394-4400

60)3-736-1388

63)2-9201071

886)7-702-2333

279

62)-24-7472849

12120

66)2-909-0300

82)-63-544-5822

2

Altius,OlympiaTechPark,No.1SIDCOIndustrialEstate,Guindy,Chennai

91)-44-4299-4237

84)-650-3577-507

Rod㷅au/Nieder-Roden,Germany

5

,Poli㷅noIndustriallaLa㷅una,Le㷅anes,

123

TamanPerindustrianAxis,

ShahAlam,Selan㷅orDarulEhsanMalaysia

,Semaran㷅,Indonesia

,THAILAND

90503

,U.S.A.

95240

76155

43125

30024

95101

Ar㷅enteuilCedex,France

93

UN,U.K.

3029

,Australia

1103

QuezonCity,Philippines

83107

KUBOTACorporation

28914

,TaiwanR.O.C.

(Madrid)Spain

600032

,TN,India

English (AC)

Code No. TC425-1975-1

MODELS

L3200

L3800

L

3

2

0

0

·

L

3

8

0

0

1AGAPBTAP0540

PRINTED IN JAPAN

KUBOTA Corporation 2012

©

READ AND SAVE THIS MANUAL

KUBOTA Corporation is ···

Since its inception in 1890, KUBOTA Corporation has grown to

rank as one of the major firms in Japan.

To achieve this status, the company has through the years

diversified the range of its products and services to a remarkable

extent. Nineteen plants and 16,000 employees produce over 1,000

different items, large and small.

All these products and all the services which accompany them,

however, are unified by one central commitment. KUBOTA makes

products which, taken on a national scale, are basic necessities.

Products which are indispensable. Products which are intended to

help individuals and nations fulfill the potential inherent in their

environment. KUBOTA is the Basic Necessities Giant.

This potential includes water supply, food from the soil and from

the sea, industrial development, architecture and construction, and

transportation.

Thousands of people depend on KUBOTA's know-how,

technology, experience and customer service. You too can depend

on KUBOTA.

L3200/L3800

AR. F. 3-3. 1. K

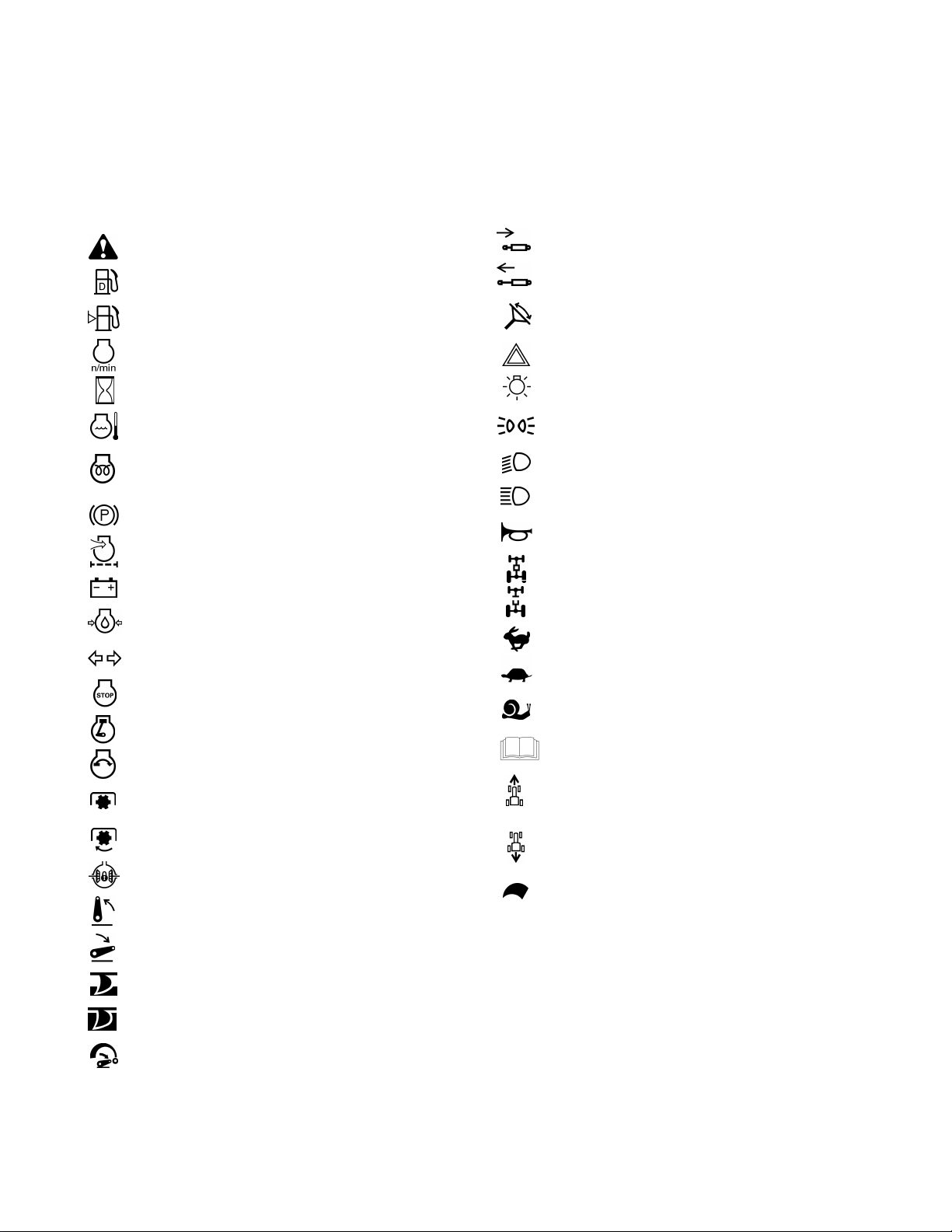

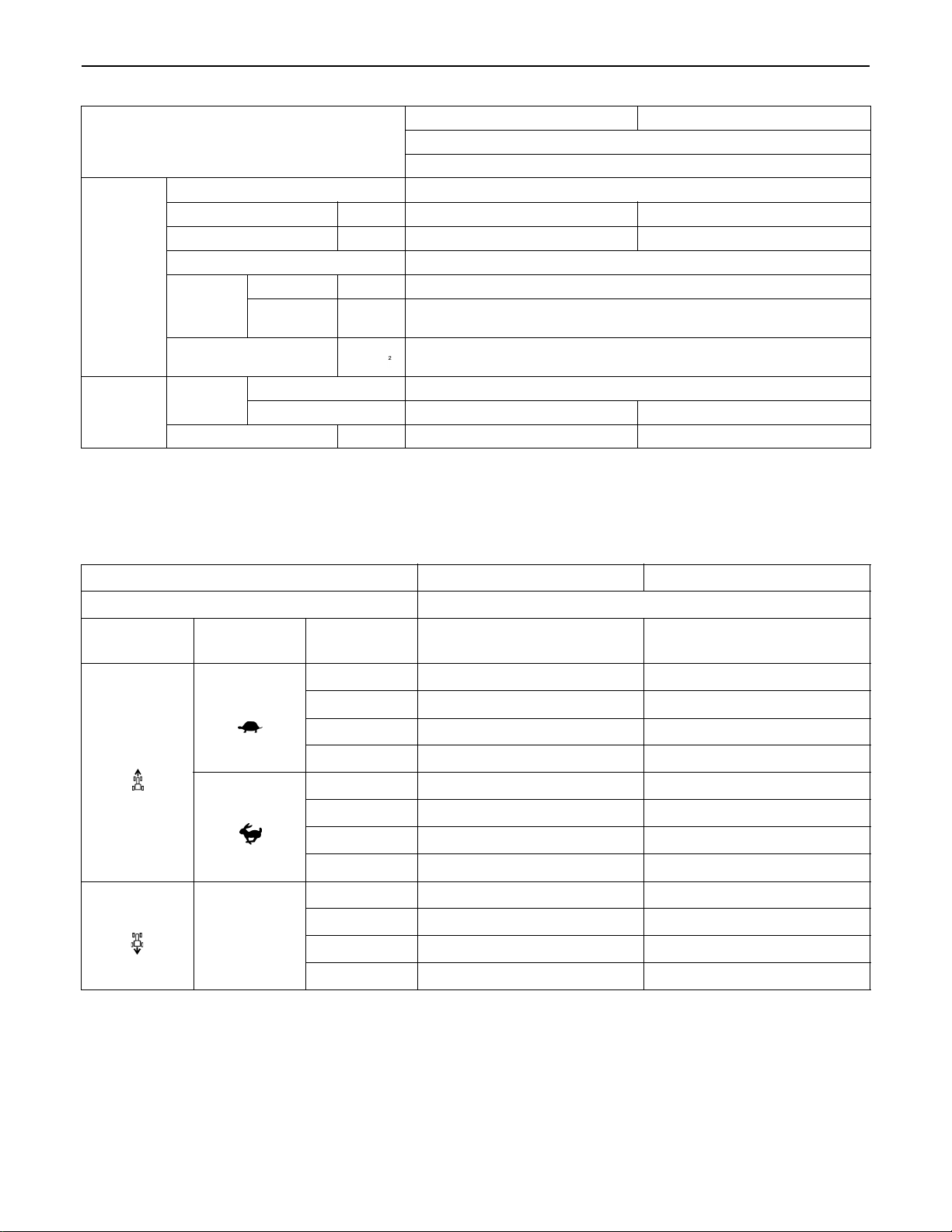

UNIVERSAL SYMBOLS

As a guide to the operation of your tractor, various universal symbols have been utilized on the instruments and

controls. The symbols are shown below with an indication of their meaning.

Safety Alert Symbol

Diesel Fuel

Fuel-Level

Engine-Rotational Speed

Hourmeter/Elapsed Operating Hours

Engine Coolant-Temperature

Diesel Preheat/Glow Plugs (Low Temperature

Start Aid)

Parking Brake

Engine Intake/Combustion Air-Filter

Battery Charging Condition

Engine Oil-Pressure

Turn Signal

Engine-Stop

Engine-Run

Starter Control

Power Take-Off Control-Off Position

Remote Cylinder-Retract

Remote Cylinder-Extend

Steering Whee-Tilt Control

Hazard Warning Lights

Master Lighting Switch

Position Lamps

Headlight-Low Beam

Headlight-High Beam

Audible Warning Device

Four-Wheel Drive-On

Four-Wheel Drive-Off

Fast

Slow

Creep

Read Operator's Manual

Tractor-Forward Movement-Overhead View of

Machine

Power Take-Off Control-On Position

Differential Lock

Position Control-Raised Position

Position Control-Lowered Position

Draft Control-Shallow Position

Draft Control-Deep Position

3-Point Lowering Speed Control

Tractor-Rearward Movement-Overhead View

of Machine

Engine Speed Control

CONTENTS

SAFE OPERATION ............................................................................................. -1

SERVICING OF TRACTOR......................................................................................... 1

SPECIFICATIONS....................................................................................................... 2

SPECIFICATION TABLE ......................................................................................... 2

TRAVELING SPEEDS ............................................................................................. 3

IMPLEMENT LIMITATIONS ........................................................................................ 4

INSTRUMENT PANEL AND CONTROLS................................................................... 6

PRE-OPERATION CHECK ......................................................................................... 8

DAILY CHECK ......................................................................................................... 8

OPERATING THE ENGINE......................................................................................... 9

STARTING THE ENGINE........................................................................................ 9

STOPPING THE ENGINE...................................................................................... 12

WARMING UP ....................................................................................................... 12

Warm-Up Transmission Oil in the Low Temperature Range ..........................................12

JUMP STARTING .................................................................................................. 12

OPERATING THE TRACTOR ................................................................................... 14

OPERATING NEW TRACTOR .............................................................................. 14

Do not Operate the Tractor at Full Speed for the First 50 Hours....................................14

Changing Lubricating Oil for New Tractors.....................................................................14

STARTING............................................................................................................. 14

Operator's Seat...............................................................................................................14

Seat Belt ......................................................................................................................... 15

Head Light Switch...........................................................................................................16

Turn Signal / Hazard Light Switch ..................................................................................16

Horn Button.....................................................................................................................17

Tractor Lights..................................................................................................................17

Brake Pedals (Right and Left)......................................................................................... 18

Clutch Pedal ...................................................................................................................19

Clutch Pedal [with Dual Clutch] ......................................................................................19

Main Gear Shift Lever & Range Gear Shift Lever...........................................................20

Front Wheel Drive Lever................................................................................................. 20

Hand Throttle Lever........................................................................................................21

Foot Throttle ...................................................................................................................21

Parking Brake ................................................................................................................. 21

STOPPING............................................................................................................. 22

Stopping..........................................................................................................................22

CHECK DURING DRIVING ................................................................................... 22

Immediately Stop the Engine if: ...................................................................................... 22

Easy Checker(TM).......................................................................................................... 22

Fuel Gauge ..................................................................................................................... 22

Coolant Temperature Gauge.......................................................................................... 23

Hourmeter/Tachometer................................................................................................... 23

PARKING............................................................................................................... 24

CONTENTS

Parking............................................................................................................................ 24

OPERATING TECHNIQUES ................................................................................. 24

Differential Lock .............................................................................................................. 24

Operating the Tractor on a Road .................................................................................... 25

Operating on Slopes and Rough Terrain........................................................................25

Directions for Use of Power Steering.............................................................................. 25

PTO ........................................................................................................................... 26

PTO OPERATION.................................................................................................. 26

PTO Gear Shift Lever ..................................................................................................... 26

Live PTO Operation ........................................................................................................ 26

PTO Shaft Cover and Shaft Cap .................................................................................... 26

THREE-POINT HITCH & DRAWBAR........................................................................ 27

3-POINT HITCH..................................................................................................... 28

Selecting the holes of Lower Links ................................................................................. 28

Selecting the top link mounting holes ............................................................................. 28

Drawbar ..........................................................................................................................28

Lifting Rod (Right)........................................................................................................... 28

Top Link ..........................................................................................................................28

Check Chains ................................................................................................................. 29

Lower link holder............................................................................................................. 29

DRAWBAR............................................................................................................. 29

Adjusting Drawbar Length ..............................................................................................29

HYDRAULIC UNIT..................................................................................................... 30

3-POINT HITCH CONTROL SYSTEM................................................................... 30

Position Control .............................................................................................................. 30

Float Control ...................................................................................................................30

3-point Hitch Lowering Speed.........................................................................................30

AUXILIARY HYDRAULICS .................................................................................... 31

Hydraulic Block Type Outlet ........................................................................................... 31

Hydraulic Control Unit Use Reference Chart .................................................................. 32

TIRES, WHEELS AND BALLAST.............................................................................. 33

TIRES..................................................................................................................... 33

Inflation Pressure............................................................................................................ 33

Dual Tires ....................................................................................................................... 33

WHEEL ADJUSTMENT ......................................................................................... 33

Front Wheels (with four wheel drive) ..............................................................................33

Rear Wheels...................................................................................................................34

BALLAST ............................................................................................................... 35

Front Ballast.................................................................................................................... 35

Rear Ballast ....................................................................................................................35

Liquid Ballast in Rear Tires............................................................................................. 35

MAINTENANCE......................................................................................................... 36

SERVICE INTERVALS .......................................................................................... 36

LUBRICANTS, FUEL AND COOLANT .................................................................. 38

PERIODIC SERVICE................................................................................................. 40

HOW TO OPEN THE HOOD ................................................................................. 40

Hood ............................................................................................................................... 40

Side Cover ......................................................................................................................40

CONTENTS

DAILY CHECK ....................................................................................................... 41

Walk Around Inspection..................................................................................................41

Checking and Refueling..................................................................................................41

Checking Engine Oil Level.............................................................................................. 41

Checking Transmission Fluid Level ................................................................................ 42

Checking Coolant Level.................................................................................................. 42

Cleaning Evacuator Valve ..............................................................................................43

Cleaning Grill, Radiator Screen and Oil Cooler ..............................................................43

Checking Brake Pedals and Clutch Pedal......................................................................43

Checking Gauges, Meter and Easy Checker(TM)..........................................................43

Checking Head Light, Turn Signal / Hazard Light etc.....................................................43

Checking Seat Belt and ROPS.......................................................................................43

Checking and Cleaning of Electrical Wiring and Battery Cables ....................................44

Checking Movable Parts ................................................................................................. 44

EVERY 50 HOURS................................................................................................ 44

Lubricating Grease Fittings.............................................................................................44

Checking Engine Start System ....................................................................................... 45

Checking Wheel Bolt Torque .......................................................................................... 46

EVERY 100 HOURS.............................................................................................. 46

Cleaning Air Cleaner Primary Element........................................................................... 46

Cleaning Fuel Filter.........................................................................................................47

Adjusting Fan Belt Tension............................................................................................. 47

Checking Fuel Line ......................................................................................................... 48

Adjusting Clutch Pedal....................................................................................................48

Adjusting Brake Pedal .................................................................................................... 49

Checking Battery Condition ............................................................................................ 49

EVERY 200 HOURS.............................................................................................. 51

Replacing Engine Oil Filter ............................................................................................. 51

Changing Engine Oil.......................................................................................................51

Checking Radiator Hose and Clamp .............................................................................. 52

Checking Intake Air Line ................................................................................................. 52

Checking Power Steering Line ....................................................................................... 53

Adjusting Toe-in.............................................................................................................. 53

EVERY 400 HOURS.............................................................................................. 54

Changing Transmission Fluid / Replacing Hydraulic Oil Filter........................................ 54

Changing Front Axle Case Oil ........................................................................................55

Replacing Fuel Filter Element......................................................................................... 55

EVERY 600 HOURS.............................................................................................. 56

Adjusting Front Axle Pivot............................................................................................... 56

EVERY 800 HOURS.............................................................................................. 56

Adjusting Engine Valve Clearance ................................................................................. 56

EVERY 1 YEAR ..................................................................................................... 56

Replacing Air Cleaner Primary Element and Secondary Element..................................56

EVERY 2 YEARS................................................................................................... 56

Flushing Cooling System and Changing Coolant ...........................................................56

Anti-Freeze .....................................................................................................................57

Replacing Radiator Hose (Water pipes) ......................................................................... 58

Replacing Power Steering Hose..................................................................................... 58

Replacing Fuel Hose ...................................................................................................... 58

Replacing Intake Air Line................................................................................................ 58

SERVICE AS REQUIRED...................................................................................... 58

Bleeding Fuel System.....................................................................................................58

CONTENTS

Draining Clutch Housing Water ...................................................................................... 59

Replacing Fuse...............................................................................................................59

Replacing Light Bulb....................................................................................................... 60

Replacing Head Lamp .................................................................................................... 60

STORAGE ................................................................................................................. 61

TRACTOR STORAGE ........................................................................................... 61

REMOVING THE TRACTOR FROM STORAGE................................................... 61

TROUBLESHOOTING............................................................................................... 62

ENGINE TROUBLESHOOTING ............................................................................ 62

OPTIONS................................................................................................................... 63

SAFE OPERATION

-1SAFE OPERATION

Careful operation is your best insurance against an

accident.

Read and understand this manual carefully before

operating the tractor.

All operators, no matter how much experience they may

have, should read this and other related manuals before

operating the tractor or any implement attached to it. It is

the owner's obligation to instruct all operators in safe

operation.

1. BEFORE OPERATING THE TRACTOR

1. Know your equipment and its limitations. Read this

entire manual before attempting to start and operate

the tractor.

2. Pay special attention to the danger, warning and

caution labels on the tractor.

3. Do not operate the tractor or any implement attached

to it while under the influence of alcohol, medication,

controlled substances or while fatigued.

4. Before allowing other people to use your tractor,

explain how to operate and have them read this

manual before operation.

5. Never wear loose, torn, or bulky clothing around

tractor. It may catch on moving parts or controls,

leading to the risk of an accident. Use additional safety

items, e.g. hard hat, safety boots or shoes, eye and

hearing protection, gloves, etc., as appropriate or

required.

6. Do not allow passengers to ride on any part of the

tractor at anytime. The operator must remain in the

tractor seat during operation.

7. Check brakes, clutch, linkage pins and other

mechanical parts for improper adjustment and wear.

Replace worn or damaged parts promptly. Check the

tightness of all nuts and bolts regularly. (For further

details, see "MAINTENANCE" section.)

8. Keep your tractor clean. Dirt, grease, and trash build

up may contribute to fires and lead to personal injury.

9. Use only implements meeting the specifications listed

under "IMPLEMENT LIMITATIONS" in this manual or

implements approved by KUBOTA.

10.Use proper weights on the front or rear of the tractor to

reduce the risk of upsets. When using the front loader,

put an implement or ballast on the 3-point hitch to

improve stability. Follow the safe operating

procedures specified in the implement or attachment

manual.

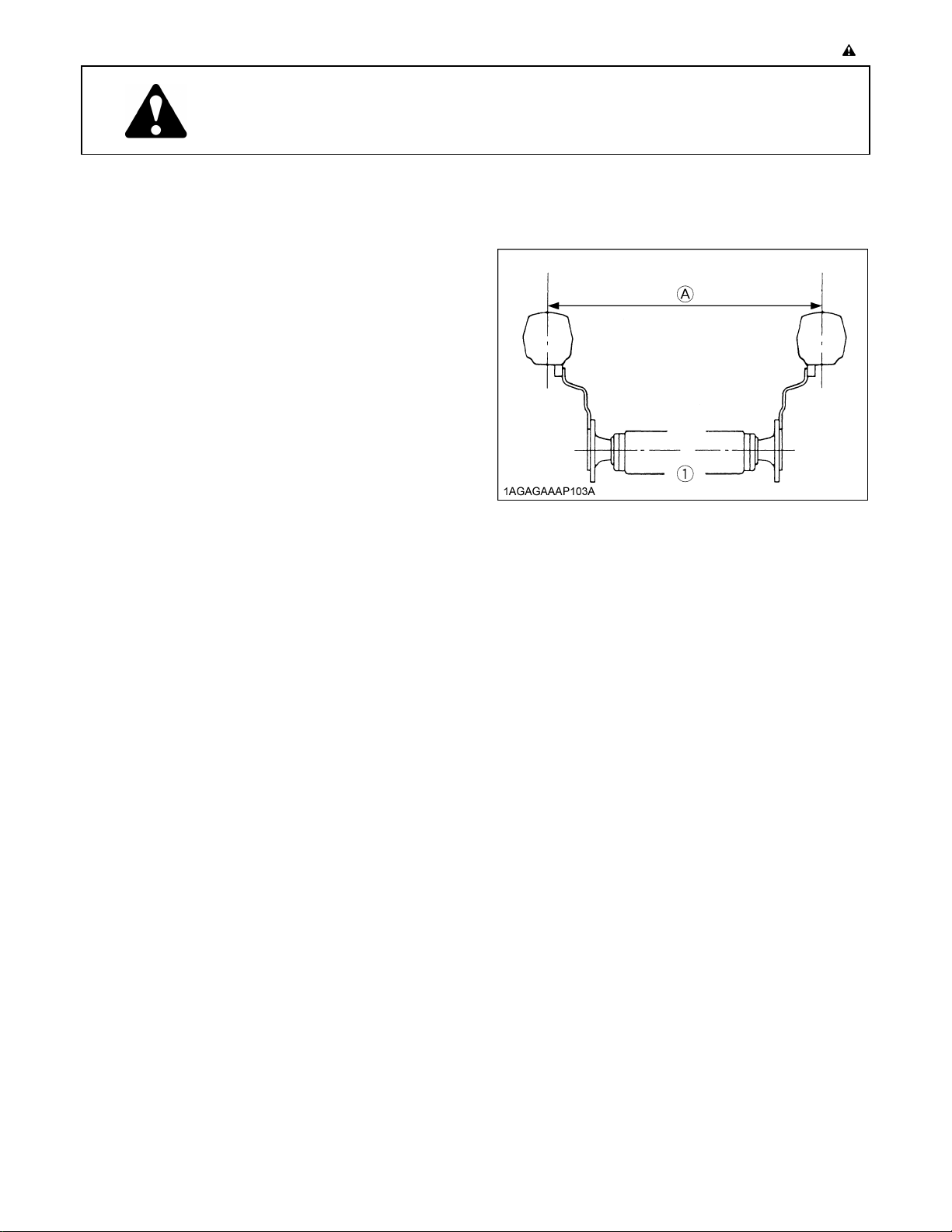

11. The narrower the tread, the greater the risk of a tractor

upset. For maximum stability, adjust the wheels to the

widest practical tread width for your application. (See

"TIRES, WHEELS AND BALLAST" section.)

(1) Rear wheels (A) Tread Width

12.Do not modify the tractor. Unauthorized modification

may affect the function of the tractor, which may result

in personal injury.

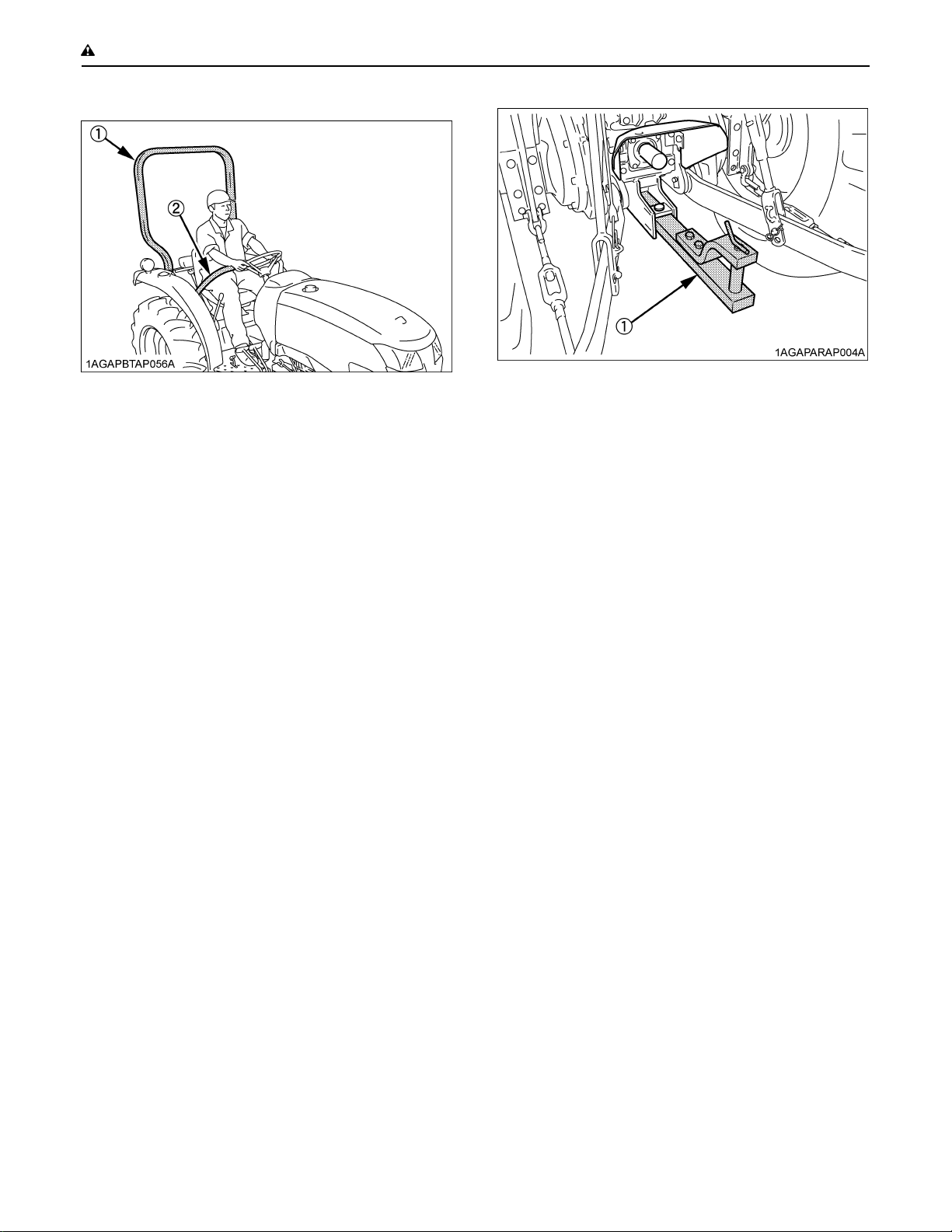

C CAB, ROPS

1. KUBOTA recommends the use of a CAB or Roll Over

Protective Structures (ROPS) and seat belt in almost

all applications. This combination will reduce the risk

of serious injury or death, should the tractor be upset.

Check for overhead clearance which may interfere

with a CAB or ROPS.

2. If the CAB or ROPS is loosened or removed for any

reason, make sure that all parts are reinstalled

correctly before operating the tractor.

3. Never modify or repair any structural member of a

CAB or ROPS because welding, bending, drilling,

grinding, or cutting may weaken the structure.

4. A damaged CAB or ROPS structure must be replaced,

not repaired or revised.

5. If any structural member of the CAB or ROPS is

damaged, replace the entire structure at your local

KUBOTA Dealer.

6. Always use the seat belt if the tractor has a CAB or

ROPS. Do not use the seat belt if there is no CAB or

ROPS. Check the seat belt regularly and replace if

frayed or damaged.

SAFE OPERATION-2

(1) ROPS

(2) Seat belt

2. OPERATING THE TRACTOR

Operator safety is a priority. Safe operation, specifically

with respect to overturning hazards, entails understanding

the equipment and environmental conditions at the time of

use. Some prohibited uses which can affect overturning

hazards include traveling and turning with implements

and loads carried too high etc. This manual sets forth

some of the obvious risks, but the list is not, and cannot

be, exhaustive. It is the operator's responsibility to be alert

for any equipment or environmental condition that could

compromise safe operation.

C Starting

1. Always sit in the operator's seat when starting engine

or operating levers or controls. Adjust seat per

instructions in the operating the tractor section. Never

start engine while standing on the ground.

2. Before starting the engine, make sure that all levers

(including auxiliary control levers) are in their neutral

positions, that the parking brake is engaged, and that

both the clutch and the Power Take-Off (PTO) are

disengaged or "OFF".

Fasten the seat belt if the tractor has a CAB, a fixed

ROPS or a foldable ROPS in the upright and locked

position.

3. Do not start engine by shorting across starter

terminals or bypassing the safety start switch.

Machine may start in gear and move if normal starting

circuitry is bypassed.

4. Do not operate or idle engine in a non-ventilated area.

Carbon monoxide gas is colorless, odorless, and

deadly.

C Working

1. Pull only from the drawbar. Never hitch to axle housing

or any other point except drawbar; such arrangements

will increase the risk of serious personal injury or death

due to a tractor upset.

(1) Drawbar

2. For trailing PTO-driven implements, set the drawbar to

the towing position.

3. Attach pulled or towed loads to the drawbar only.

4. Keep all shields and guards in place. Replace any that

are missing or damaged.

5. Avoid sudden starts. To avoid upsets, slow down

when turning, on uneven ground, and before stopping.

6. The tractor cannot turn with the differential locked and

attempting to do so could be dangerous.

7. Do not operate near ditches, holes, embankments, or

other ground surface features which may collapse

under the tractor's weight. The risk of tractor upset is

even higher when the ground is loose or wet. Tall

grass can hide obstacles, walk the area first to be sure.

8. Watch where you are going at all times. Watch for and

avoid obstacles. Be alert at row ends, near trees, and

other obstructions.

9. When working in groups, always let the others know

what you are going to do before you do it.

10.Never try to get on or off a moving tractor.

11.Always sit in the operator's seat when operating levers

or controls.

12.Do not stand between tractor and implement or trailed

vehicle unless parking brake is applied.

C Safety for children

Tragedy can occur if the operator is not alert to the

presence of children. Children generally are attracted to

machines and the work they do.

1. Never assume that children will remain where you last

saw them.

2. Keep children out of the work area and under the

watchful eye of another responsible adult.

3. Be alert and shut your machine down if children enter

the work area.

4. Never carry children on your machine. There is no safe

place for them to ride. They may fall off and be run

over or interfere with your control of the machine.

5. Never allow children to operate the machine even

under adult supervision.

6. Never allow children to play on the machine or on the

implement.

-3SAFE OPERATION

7. Use extra caution when backing up. Look behind and

down to make sure area is clear before moving.

C Operating on slopes

Slopes are a major factor related to loss-of-control and tipover accidents, which can result in severe injury or death.

All slopes require extra caution.

1. To avoid upsets, always back up steep slopes. If you

cannot back up the slope or if you feel uneasy on it, do

not operate on it. Stay off slopes too steep for safe

operation.

2. Driving forward out of a ditch, mired condition or up a

steep slope increases the risk of a tractor to be upset

backward. Always back out of these situations. Extra

caution is required with four-wheel drive models

because their increased traction can give the operator

false confidence in the tractor's ability to climb slopes.

3. Keep all movement on slopes slow and gradual. Do

not make sudden changes in speed, direction or apply

brake and make sudden motions of the steering

wheel.

4. Avoid disengaging the clutch or changing gears speed

when climbing or going down a slope. If on a slope

disengaging the clutch or changing gears to neutral

could cause loss of control.

5. Special attention should be made to the weight and

location of implements and loads as such will affect the

stability of the tractor.

6. To improve stability on slope, set widest wheel tread

as shown in "TIRES, WHEELS AND BALLAST"

section.

Follow recommendations for proper ballasting.

3. Always slow the tractor down before turning. Turning

at high speed may tip the tractor over.

4. Observe all local traffic and safety regulations.

Use the registration plate as required.

5. Turn the headlights on. Dim them when meeting

another vehicle.

6. Drive at speeds that allow you to maintain control at all

times.

7. Do not apply the differential lock while traveling at road

speeds. The tractor may run out of control.

8. Avoid sudden motions of the steering wheel as they

can lead to a dangerous loss of stability. The risk is

especially great when the tractor is traveling at road

speeds.

9. Keep the ROPS in the "UP" position and wear the seat

belt when driving the tractor on the road.

Otherwise, you will not be protected in the event of a

tractor roll-over.

10.Do not operate an implement while the tractor is on the

road. Lock the 3-point hitch in the raised position.

11.When towing other equipment, use a safety chain and

place an SMV emblem on it as well.

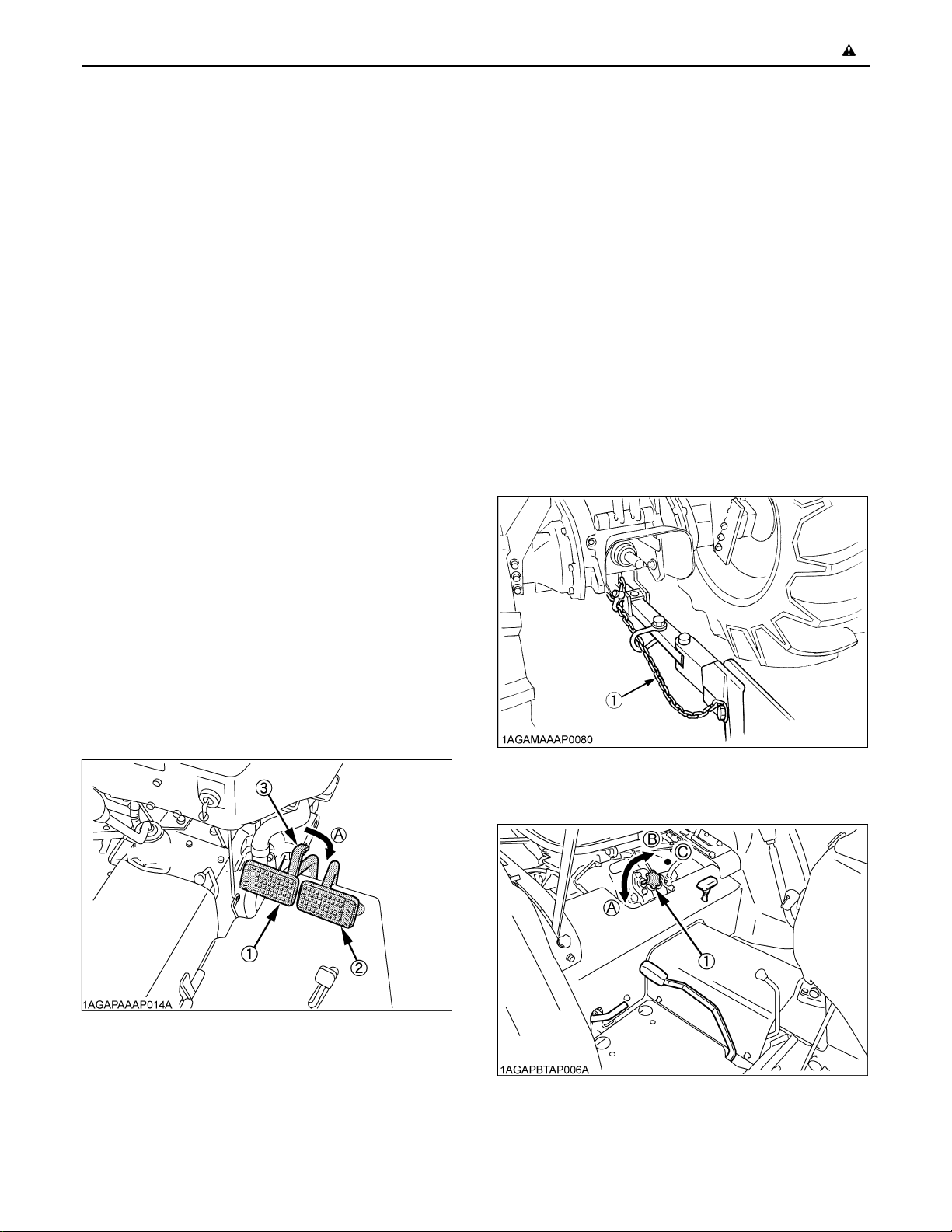

C Driving the tractor on the road

1. Lock the two brake pedals together to help assure

straight-line stops. Uneven braking at road speeds

could cause the tractor to tip over.

(1) Brake Pedal (LH)

(2) Brake Pedal (RH)

(3) Brake Pedal Lock

(A) Whenever travelling on the road

2. Check the front wheel engagement. The braking

characteristics are different between two and four

wheel drive. Be aware of the difference and use

carefully.

(1) Safety chain

12.Set the implement lowering speed knob in the "LOCK"

position to hold the implement in the raised position.

(1) 3-point hitch lowering speed knob (A) "FAST"

(B) "SLOW"

(C) "LOCK"

SAFE OPERATION-4

3. PARKING THE TRACTOR

1. Disengage the PTO, lower all implements to the

ground, place all control levers in their neutral

positions, set the parking brake, stop the engine,

remove the key from the ignition and lock the cab door

(if equipped).

2. Make sure that the tractor has come to a complete

stop before dismounting.

3. Avoid parking on steep slopes, if at all possible park on

a firm and level surface; if not, park across a slope with

chock the wheels.

Failure to comply with this warning may allow the

tractor to move and could cause injury or death.

4. OPERATING THE PTO

1. Wait until all moving components have completely

stopped before getting off the tractor, connecting,

disconnecting, adjusting, cleaning, or servicing any

PTO driven equipment.

2. Keep the PTO shaft cover in place at all times.

Replace the PTO shaft cap when the shaft is not in

use.

(1) PTO Shaft cover

(2) PTO Shaft cap

3. Before installing or using PTO driven equipment, read

the manufacturer's manual and review the safety

labels attached to the equipment.

4. When operating stationary PTO driven equipment,

always apply the tractor parking brake and place

chocks behind and in front of the rear wheels. Stay

clear of all rotating parts. Never step over rotating

parts.

(A) "NORMAL POSITION"

(B) "RAISED POSITION"

5. USING 3-POINT HITCH

1. Use the 3-point hitch only with equipment designed for

3-point hitch usage.

2. When using a 3-point hitch mounted implement, be

sure to install the proper counterbalance weight on the

front of the tractor.

6. SERVICING THE TRACTOR

Before servicing the tractor, park it on a firm, flat and level

surface, set the parking brake, lower all implements to the

ground, place the gear shift lever in neutral, stop the

engine and remove the key.

1. Allow the tractor time to cool off before working on or

near the engine, muffler, radiator, etc.

2. Do not remove radiator cap while coolant is hot. When

cool, slowly rotate cap to the first stop and allow

sufficient time for excess pressure to escape before

removing the cap completely. If the tractor has a

coolant recovery tank, add coolant or water to the tank,

not the radiator. (See "Checking Coolant Level" in

"DAILY CHECK" in "PERIODIC SERVICE" section.)

3. Always stop the engine before refueling. Avoid spills

and overfilling.

4. Do not smoke when working around battery or when

refueling. Keep all sparks and flames away from

battery and fuel tank. The battery presents an

explosive hazard, because it gives off hydrogen and

oxygen especially when recharging.

5. Before "jump starting" a dead battery, read and follow

all of the instructions. (See "JUMP STARTING" in

"OPERATING THE ENGINE" section.)

6. Keep first aid kit and fire extinguisher handy at all

times.

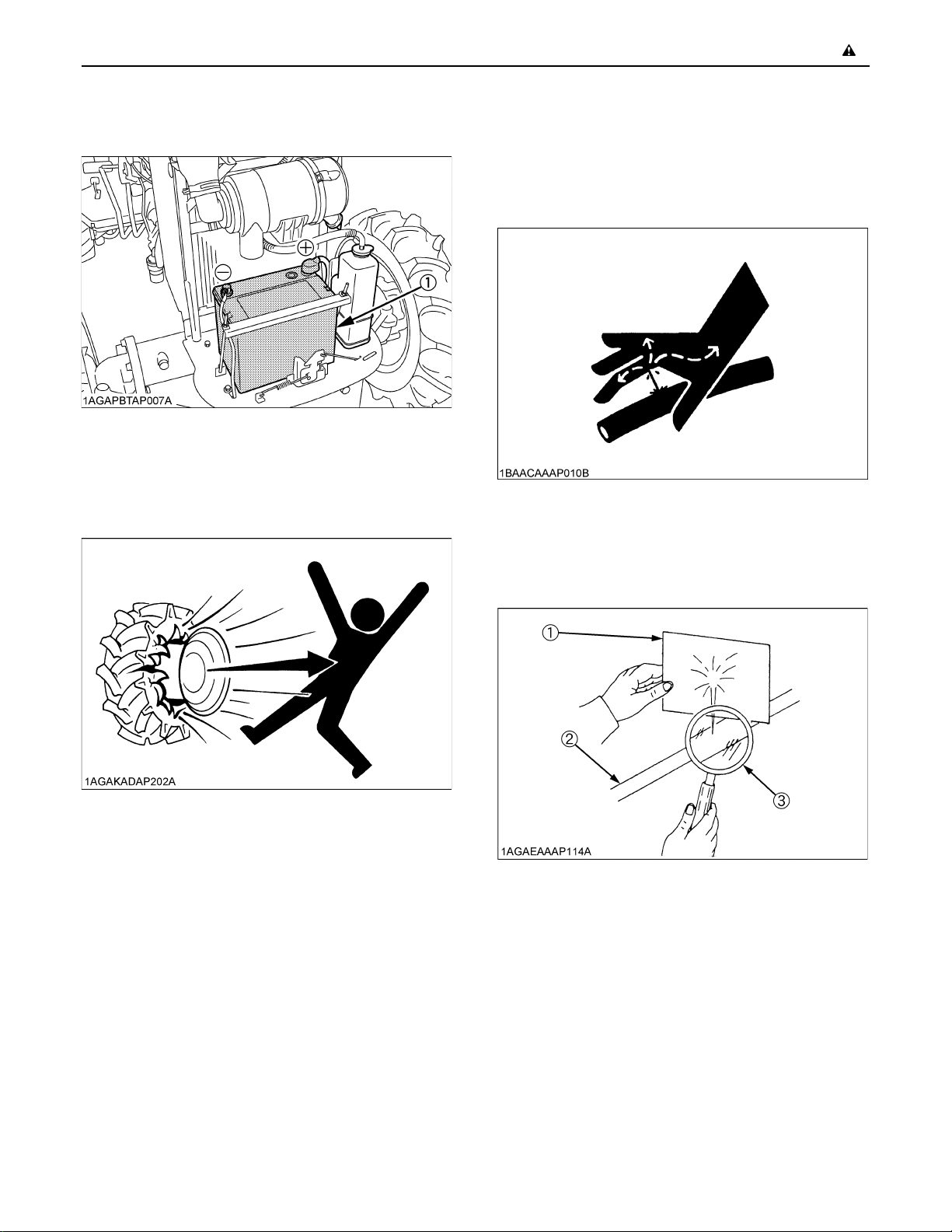

7. Disconnect the battery's ground cable before working

on or near electric components.

8. To avoid the possibility of battery explosion, do not use

or charge the refillable type battery if the fluid level is

below the LOWER ( lower limit level ) mark. Check the

fluid level regularly and add distilled water as required

so that the fluid level is between the UPPER and

LOWER levels.

-5SAFE OPERATION

9. To avoid sparks from an accidental short circuit,

always disconnect the battery's ground cable (-) first

and reconnect it last.

(1) Battery

10.Do not attempt to mount a tire on a rim. This should be

done by a qualified person with the proper equipment.

11.Always maintain the correct tire pressure. Do not

inflate tires above the recommended pressure shown

in the operator's manual.

15.Escaping hydraulic fluid under pressure has sufficient

force to penetrate skin, causing serious personal

injury. Before disconnecting hydraulic lines, be sure to

release all residual pressure. Before applying

pressure to the hydraulic system, make sure that all

connections are tight and that all lines, pipes, and

hoses are free of damage.

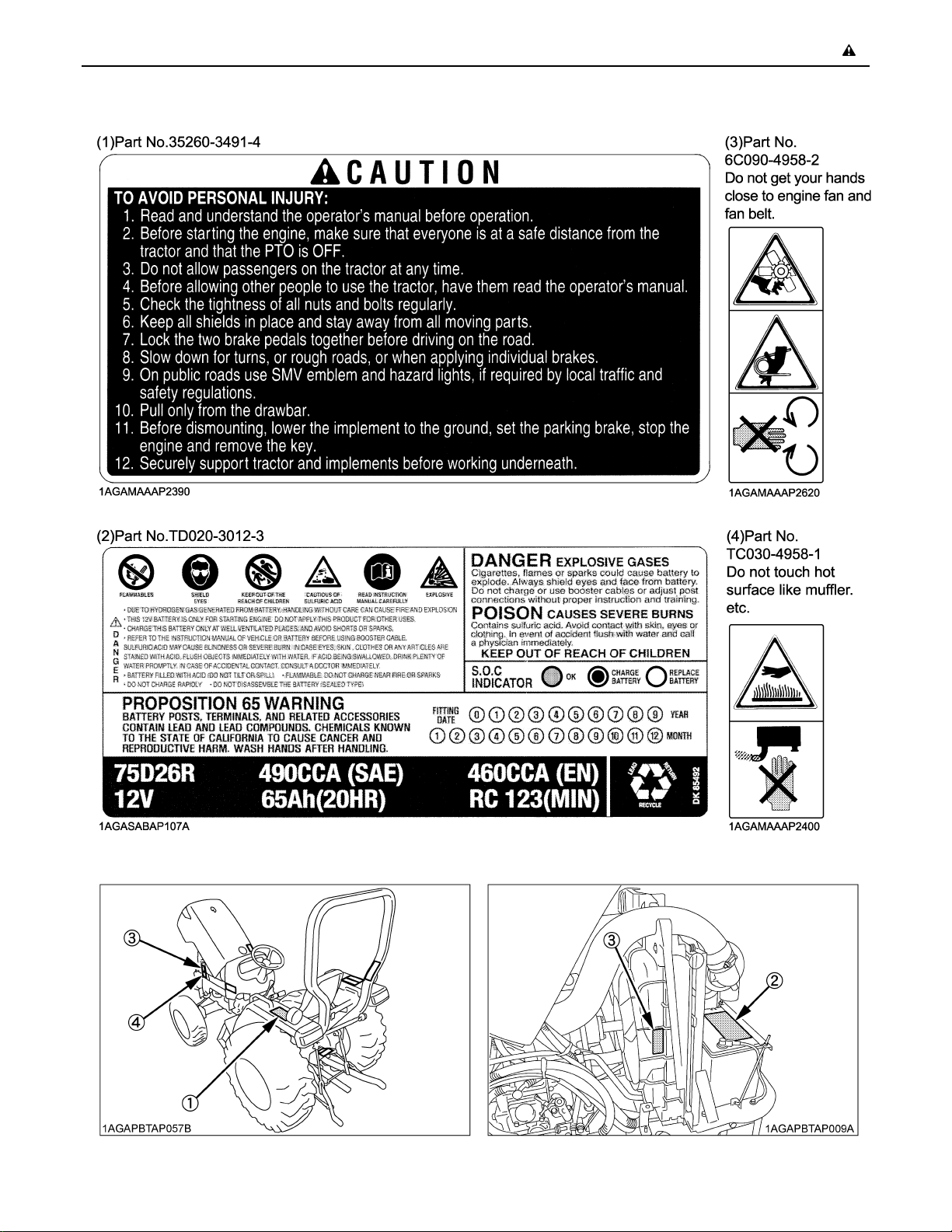

16.Fluid escaping from pinholes may be invisible. Do not

use hands to search for suspected leaks; use a piece

of cardboard or wood. Use of safety goggles or other

eye protection is also highly recommended. If injured

by escaping fluid, see a medical doctor at once. This

fluid will produce gangrene or severe allergic reaction.

12.Securely support the tractor when either changing

wheels or adjusting the wheel tread width.

13.Make sure that wheel bolts have been tightened to the

specified torque.

14.Do not work under any hydraulically supported

devices. They can settle, suddenly leak down, or be

accidentally lowered. If it is necessary to work under

tractor or any machine elements for servicing or

adjustment, securely support them with stands or

suitable blocking beforehand.

(1) Cardboard

(2) Hydraulic line

(3) Magnifying glass

SAFE OPERATION-6

7. DANGER, WARNING AND CAUTION LABELS

-7SAFE OPERATION

SAFE OPERATION-8

8. CARE OF DANGER, WARNING AND CAUTION LABELS

1. Keep danger, warning and caution labels clean and free from obstructing material.

2. Clean danger, warning and caution labels with soap and water, dry with a soft cloth.

3. Replace damaged or missing danger, warning and caution labels with new labels from your local KUBOTA Dealer.

4. If a component with danger, warning and caution label(s) affixed is replaced with new part, make sure new label(s) is

(are) attached in the same location(s) as the replaced component.

5. Mount new danger, warning and caution labels by applying on a clean dry surface and pressing any bubbles to outside

edge.

SERVICING OF TRACTOR

Your dealer is interested in your new tractor and has the

desire to help you get the most value from it. After reading

this manual thoroughly, you will find that you can do some

of the regular maintenance yourself.

However, when in need of parts or major service, be sure

to see your KUBOTA Dealer.

For service, contact the KUBOTA Dealership from which

you purchased your tractor or your local KUBOTA Dealer.

When in need of parts, be prepared to give your dealer the

tractor, CAB/ROPS and engine serial numbers.

Locate the serial numbers now and record them in the

space provided.

Type Serial No.

1SERVICING OF TRACTOR

Tractor

CAB / ROPS

Engine

Date of Purchase

Name of Dealer

(To be filled in by purchaser)

(1) Tractor serial number

(1) Engine serial number

(1) Tractor identification plate

(1) ROPS identification plate (ROPS Serial No.)

2 SPECIFICATIONS

SPECIFICATIONS

SPECIFICATION TABLE

L3200 L3800

Model

PTO power* kW (PS) 19.9 (27.1) 23.5 (31.9)

Maker KUBOTA

Model D1503-M-E3 D1803-M-E3

Type Indirect injection, Vertical, Water-Cooled 4 cycle diesel

Number of cylinders 3

Bore and stroke mm 83 X 92.4 87 x 102.4

Engine

Capacities

Dimensions

Weight (with ROPS) kg 1180 1205

Traveling

system

Total displacement L 1.499 1.826

Engine gross power* kW (PS) 23.8 (32.4) 27.9 (37.9)

Engine net power* kW (PS) 22.7 (30.8) 26.8 (36.4)

Rated revolution rps (rpm) 46.7 (2800) 45.0 (2700)

Low idling revolution rps (rpm) 15.0 to 16.7 (900 to 1000)

Maximum torque N-m 94.9 115.6

Battery 12V. RC : 123 min, CCA : 490 A

Fuel tank L 38.0

Engine crankcase (with filter) L 5.7 7.1

Engine coolant L 6.0

Transmission case L 27.5

Overall length (without 3p) mm 2800

Overall width (min.tread) mm 1400

Overall height (with ROPS) mm 2330

Overall height

(Top of steering wheel)

Wheel base mm 1610

Min. ground clearance mm 340

Tread

Tires

Turf (option)

Clutch Dry type Single stage Dry type Dual stage

Steering Integral type power steering

Transmission Gear shift, 8 forwardand 4 reverse

Brake Wet disk type

Min. turning radius (with brake) m 2.5

Front mm 1085

Rear mm 1115, 1195, 1295

AG Front 7 - 16

AG Rear 11.2 - 24

Front 212/80 - D15

Rear 355/80 - D20

mm 1475

Manual Transmission

4WD

L3200 L3800

Hydraulic unit

PTO

Model

Hydraulic control system Position control

Pump capacity (main) L / min 24.7 23.9

Pump capacity (PS) L / min 15.0 14.5

Three point hitch Category 1

At lift points kg 906

Max. lift force

System pressure

Rear PTO

PTO / Engine speed rpm 540 / 2430 540 / 2425

24 in. behind

lift points

PTO shaft size SAE 1-3 /8, 6-splines

Type Transmission driven with overrunning Live-continuous running

kg 651

MPa

(kgf / cm )

Manual Transmission

4WD

15.7 (160)

NOTE: *Manufacturer's estimate The company reserves the right to change the specifications without notice.

3SPECIFICATIONS

TRAVELING SPEEDS

Model L3200 L3800

Tire size (Rear) 11.2-24

Range gear

shift lever

Low

Forward

High

Reverse

Reverse

(At rated engine rpm)

Main gear shift

lever

km/h km/h

11.8 1.7

22.3 2.2

33.3 3.2

45.8 5.6

16.8 6.6

28.8 8.5

3 12.7 12.2

4 22.0 21.2

12.4 2.4

23.2 3.1

34.6 4.4

47.9 7.6

The company reserves the right to change the specifications without notice.

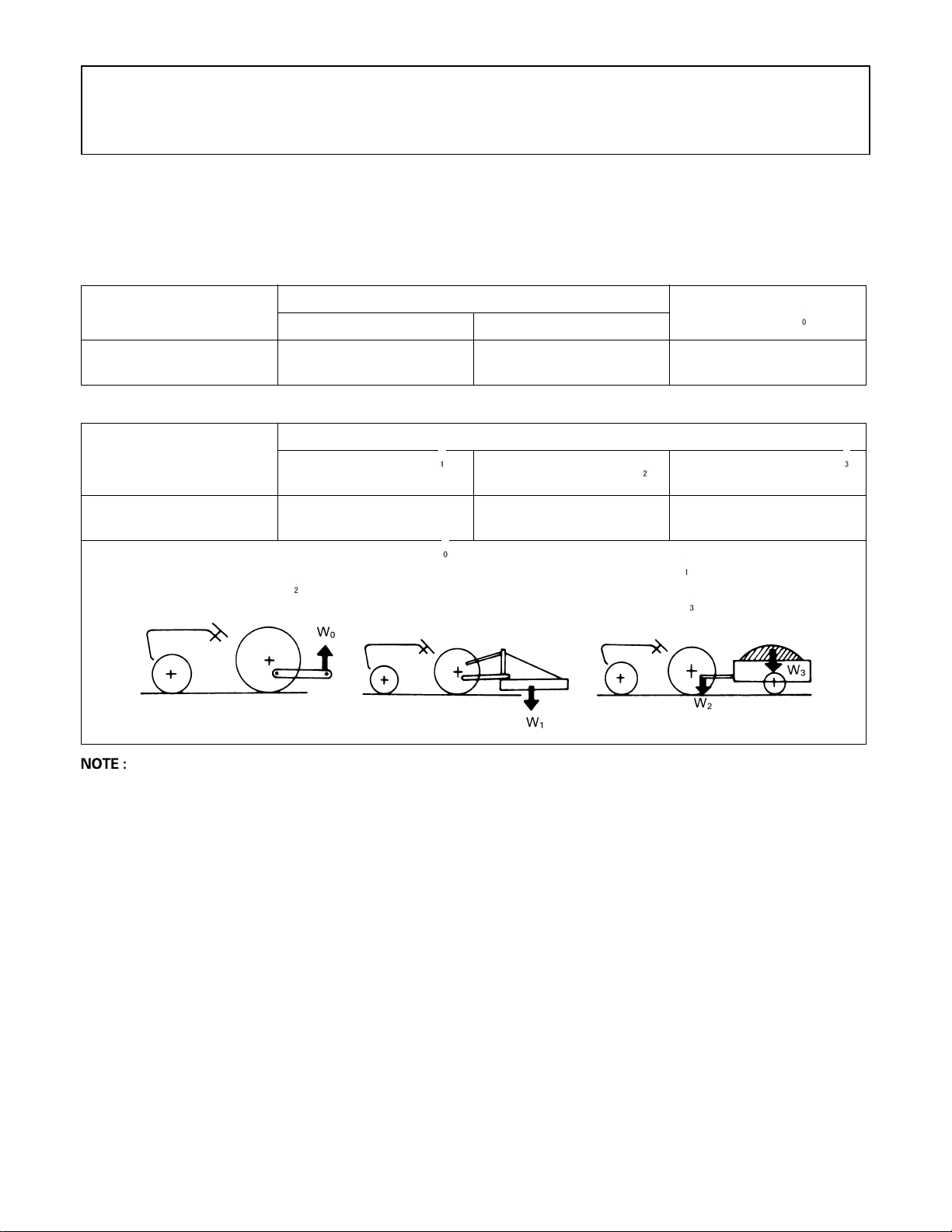

4 IMPLEMENT LIMITATIONS

IMPLEMENT LIMITATIONS

The KUBOTA Tractor has been thoroughly tested for proper performance with implements sold or approved by KUBOTA.

Use with implements which are not sold or approved by KUBOTA and which exceed the maximum specifications listed

below, or which are otherwise unfit for use with the KUBOTA Tractor may result in malfunctions or failures of the tractor,

damage to other property and injury to the operator or others. [Any malfunctions or failures of the tractor resulting from use

with improper implements are not covered by the warranty.]

Tread (max. width) with farm tires

Front Rear

L3200

L3800

L3200

L3800

Lower link end max. hydraulic lifting capacity ...........W

Implement weight .................The implement's weight which can be put on the lower link : W

Max. drawbar load ................W

Trailer loading weight ............The max. loading weight for trailer (without trailer's weight) : W

(Shown on the next page)

1085 mm 1295 mm 900 kg

Actual figures

Implement weight W

and/or size

As in the following list

Max. Drawbar Load W

330 kg 1000 kg

Lower link end max. lifting

capacity W

Trailer loading weight W

Max. capacity

A Implement size may vary depending on soil operating conditions.

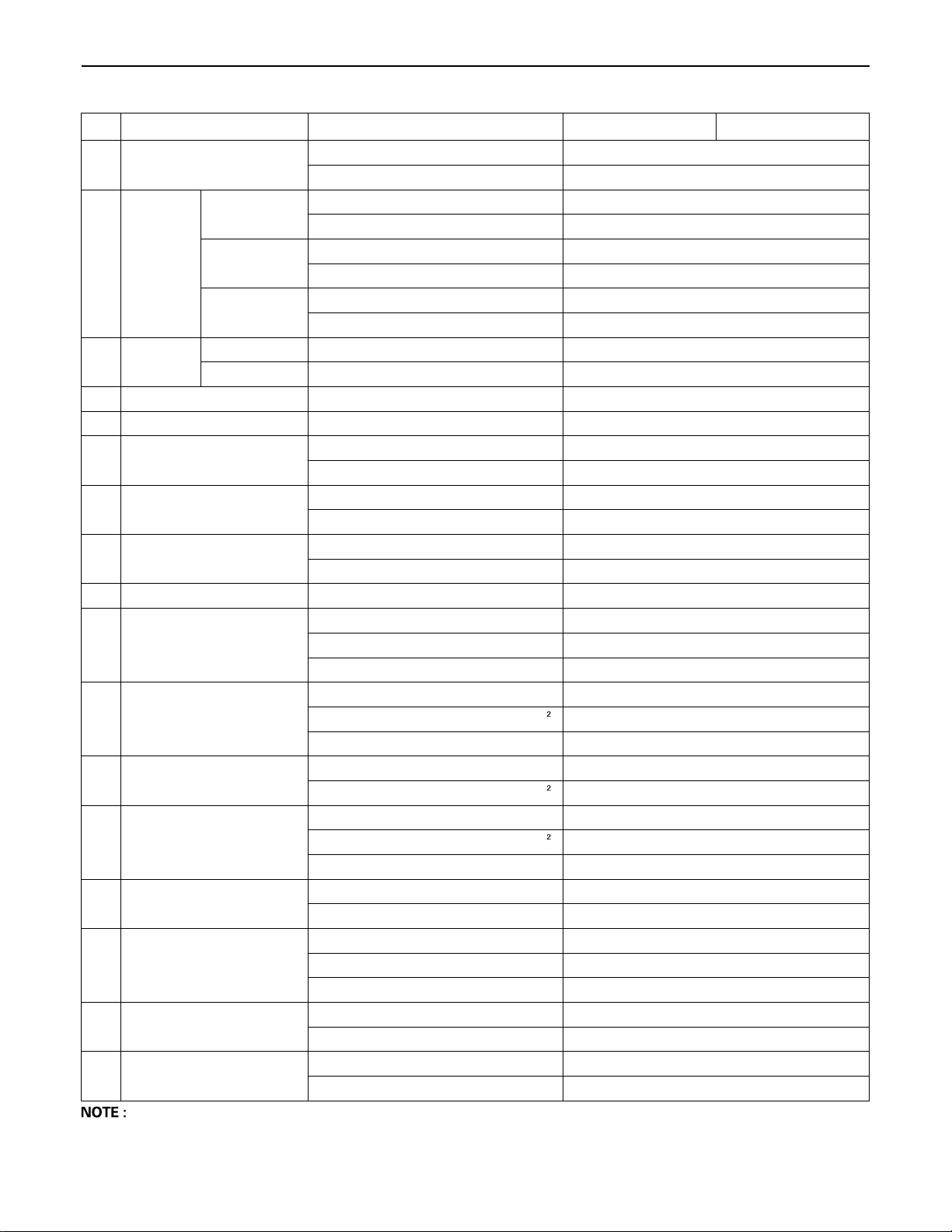

No. Implement Remarks L3200 L3800

5IMPLEMENT LIMITATIONS

1Trailer

Rotary-Cutter

2 Mower

3 Sprayer

4 Rotary Tiller Max. tilling width mm 1370

5 Bottom Plow Max. size 12 in. x 2, 16 in. x 1

6 Disk harrow : Pull type

7 Chisel Plow

8 Broad Caster

9 Manure Spreader Max. capacity kg 1000

10 Cultivator

11 Front Blade

12 Rear Blade

13 Front-end Loader

14 Box Blade

15 Backhoe

16 Snow Blade

17 Snow Blower

Flail Mower

Sickle Bar

Rear mounted Max. tank capacity L 300

Pull type Max. tank capacity L 800

Max. load capacity kg 1000

Max. drawbar load kg 330

Max. cutting width mm 1829

Max. weight kg 350

Max. cutting width mm 1270

Max. weight kg 350

Max. cutting width mm 1829

Max. weight kg 400

Max. harrowing width mm 1524

Max. weight kg 300

Max. width mm 1829

Max. weight kg 350

Max. tank capacity L 200

Max. weight kg 100

Max. width mm 1524

Number of rows 1

Max. weight kg 250

Max. cutting width mm 1829

Max. oil pressure MPa (kgf/cm ) 15.9 (162.1)

Sub frame Necessary

Max. cutting width mm 1829

Max. oil pressure MPa (kgf/cm ) 15.9 (162.1)

Max lifting capacity kg 460

Max. oil pressure MPa (kgf/cm ) 15.9 (162.1)

Sub frame Not necessary

Max. cutting width mm 1321

Max. weight kg 315

Max. digging depth mm 2288

Max. weight kg 420

Sub frame Necessary

Max. width mm 1524

Max. weight kg 300

Max. working width mm 1524

Max. weight kg 250

A Implement size may vary depending on soil operating conditions.

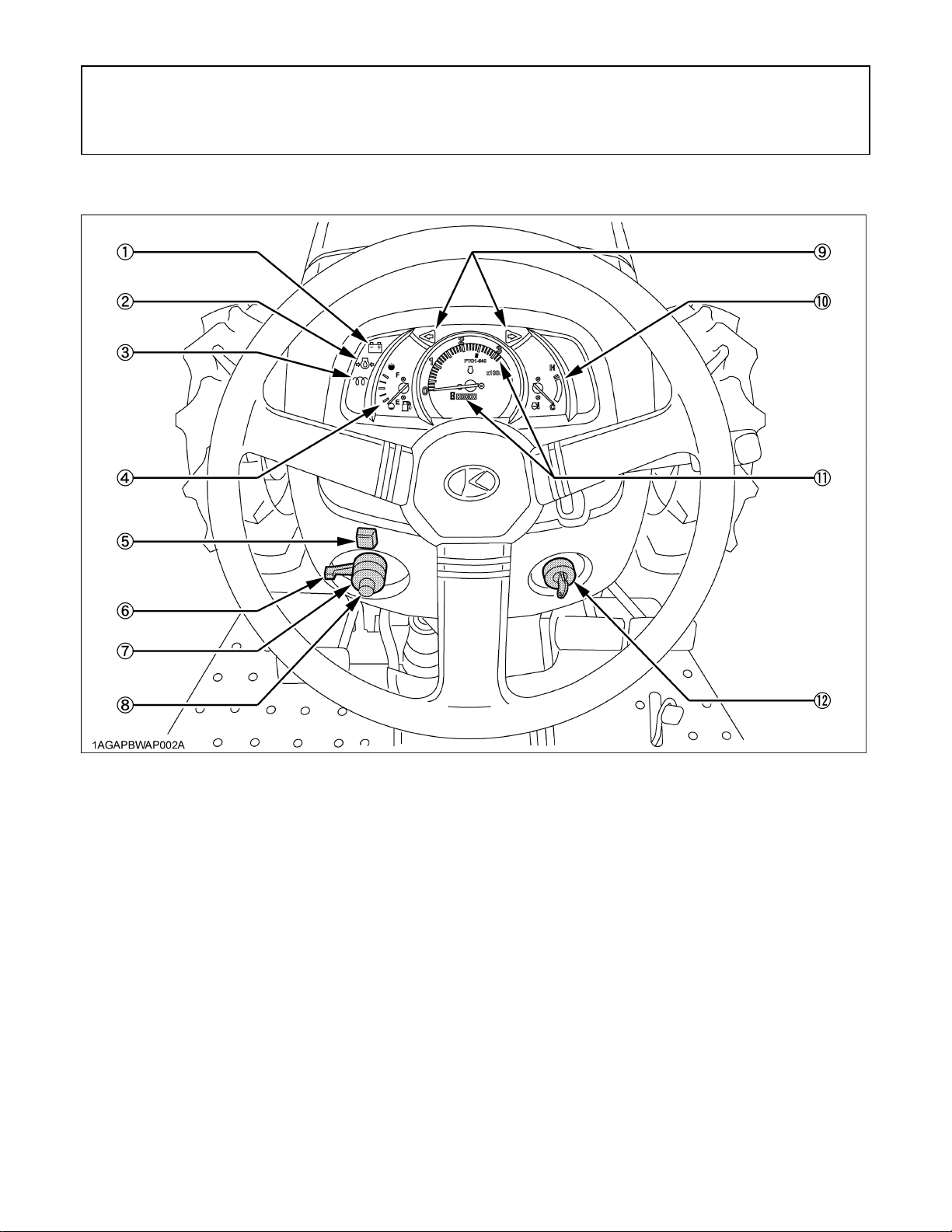

6 INSTRUMENT PANEL AND CONTROLS

INSTRUMENT PANEL AND CONTROLS

B Instrument Panel, Switches and Hand Controls

ILLUSTRATED CONTENTS

(1) Electrical charge lamp.......................... 22

(2) Engine oil pressure lamp...................... 22

(3) Glow plug indicator.............................. 9

(4) Fuel gauge........................................... 22

(5) Hazard light switch............................... 16

(6) Turn signal switch................................ 16

(7) Head light switch.................................. 16

(8) Horn button.......................................... 17

(9) Turn signal / Hazard light indicator....... 16

(10) Coolant temperature gauge................. 23

(11) Hourmeter / Tachometer...................... 23

(12) Key switch............................................ 9

B Foot and Hand Controls

7INSTRUMENT PANEL AND CONTROLS

ILLUSTRATED CONTENTS

(1) Parking brake lever.............................. 24

(2) Main gear shift lever............................. 20

(3) Clutch pedal......................................... 19,19

(4) PTO gear shift lever............................. 26

(5) 3-Point hitch lowering speed knob....... 30

(6) Front wheel drive lever......................... 20

(7) Range gear shift lever

(Shuttle shift lever)............................... 20

(8) Seat belt............................................... 15

(9) Operator's seat.................................... 14

(10) Hand throttle lever................................ 21

(11) Brake pedal.......................................... 18,21

(12) Foot throttle.......................................... 21

(13) Position control lever............................ 30

(14) Differential lock pedal........................... 24

(15) Cup holder .......................................... -

(16) Tool box ............................................ -

8 PRE-OPERATION CHECK

PRE-OPERATION CHECK

DAILY CHECK

To prevent trouble from occurring, it is important to know

the condition of the tractor well. Check it before starting.

To avoid personal injury:

A Be sure to check and service the tractor on a

level surface with the engine shut off and the

parking brake "ON" and implement lowered to

the ground.

Check item

- Walk around inspection

- Check engine oil level

- Check transmission oil level

- Check coolant level

- Clean grill and radiator screen

- Check air cleaner evacuator valve

(When used in a dusty place)

- Check brake and clutch pedal

- Check indicators, gauges and meter

- Check lights

- Check wire harness

- Check seat belt and ROPS

- Check movable parts

- Refuel

(See "DAILY CHECK" in "PERIODIC SERVICE"

section.)

- Care of danger, warning and caution labels

(See "DANGER, WARNING AND CAUTION LABELS"

in "SAFE OPERATION" section.)

Loading...

Loading...