Kubota L185, L245, L235, L285, L295 Shop Manual

...

SHOP MANUAL

KUBOTA

Models

L185-L235-L245-L275-L285-L295-L305-L345-L355

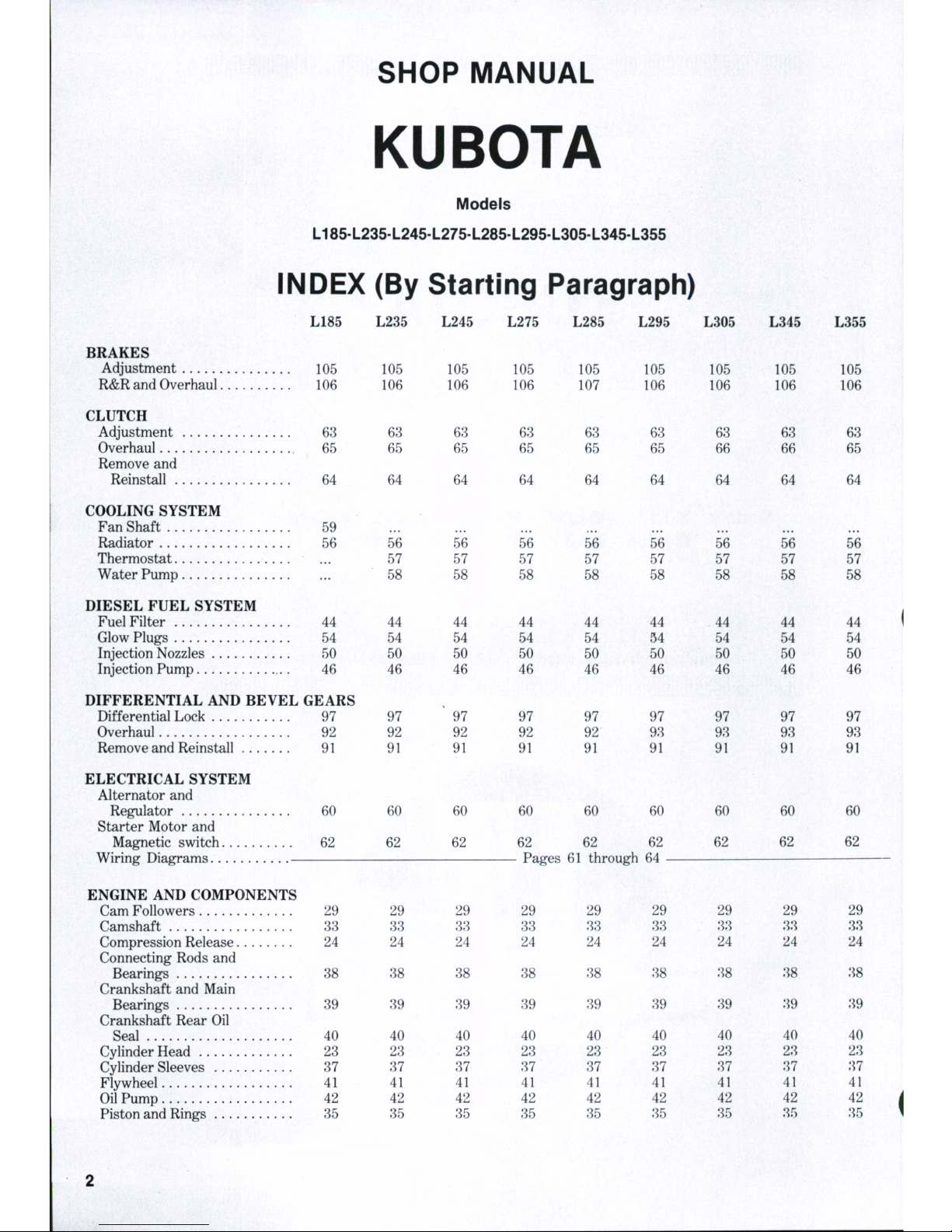

INDEX (By Starting Paragraph)

L185 L235 L245 L275 L285 L295 L305

L345

BRAKES

Adjustment 105

R&R and Overhaul 106

CLUTCH

Adjustment 63

Overhaul 65

Remove and

Reinstall 64

COOLING SYSTEM

Fan Shaft 59

Radiator 56

Thermostat

Water Pump

DIESEL FUEL SYSTEM

Fuel Filter 44

Glow Plugs 54

Injection Nozzles 50

Injection Pump 46

DIFFERENTIAL AND BEVEL GEARS

Differential Lock 97

Overhaul 92

Remove and Reinstall 91

ELECTRICAL SYSTEM

Alternator and

Regulator 60

Starter Motor and

Magnetic switch 62

Wiring Diagrams

ENGINE AND COMPONENTS

Cam Followers 29

Camshaft 33

Compression Release 24

Connecting Rods and

Bearings 38

Crankshaft and Main

Bearings 39

Crankshaft Rear Oil

Seal 40

Cylinder Head 23

Cylinder Sleeves 37

Flywheel 41

Oil Pump 42

Piston and Rings 35

64

38

39

64

38

39

64 64 64 64

38

39

38

39

38

39

38

39

64

L355

105

106

63

65

105

106

63

65

105

106

63

65

105

107

63

65

105

106

63

65

105

106

63

66

105

106

63

66

105

106

63

65

64

56

57

58

44

54

50

46

97

92

91

60

62

29

33

24

56

57

58

44

54

50

46

' 97

92

91

60

62

29

33

24

56

57

58

44

54

50

46

97

92

91

60

62

29

33

24

56

57

58

44

54

50

46

97

92

91

60

62

js

6 1

through

29

33

24

56

57

58

44

54

50

46

97

93

91

60

62

64

29

33

24

56

57

58

44

54

50

46

97

93

91

60

62

29

33

24

56

57

58

44

54

50

46

97

93

91

60

62

29

33

24

56

57

58

44

54

50

46

97

93

91

60

62

29

33

24

38

39

40

23

37

41

42

35

40

23

37

41

42

35

40

23

37

41

42

35

40

23

37

41

42

35

40

23

37

41

42

35

40

23

37

41

42

35

40

23

37

41

42

35

40

23

37

41

42

35

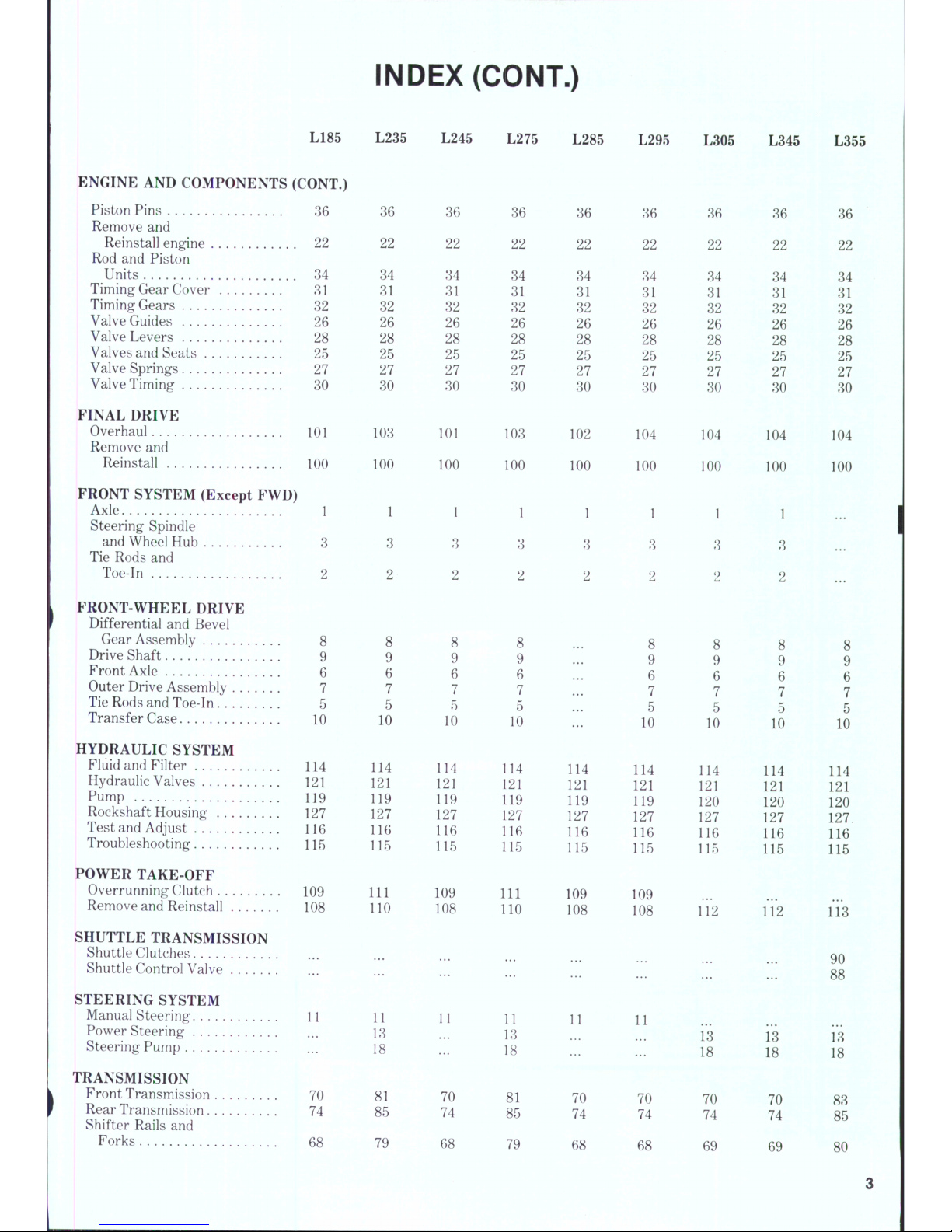

INDEX (CONT.)

L185

L235 L245

L275

L285

L295 L305 L345

L355

ENGINE AND COMPONENTS (CONT.)

Piston Pins 36

Remove and

Reinstall engine 22

Rod and Piston

Units 34

Timing Gear Cover 31

Timing Gears 32

Valve Guides 26

Valve Levers 28

Valves and Seats . 25

Valve Springs 27

Valve Timing 30

FINAL DRIVE

Overhaul 101

Remove and

Reinstall 100

FRONT SYSTEM (Except FWD)

Axle 1

Steering Spindle

and Wheel Hub 3

Tie Rods and

Toe-In 2

FRONT-WHEEL DRIVE

Differential and Bevel

Gear Assembly 8

Drive Shaft 9

Front Axle 6

Outer Drive Assembly 7

Tie Rods and Toe-In 5

Transfer Case 10

HYDRAULIC SYSTEM

Fluid and Filter 114

Hydraulic Valves 121

Pump 119

Rockshaft Housing 127

Test and Adjust 116

Troubleshooting 115

POWER TAKE-OFF

Overrunning Clutch 109

Remove and Reinstall 108

SHUTTLE TRANSMISSION

Shuttle Clutches

Shuttle Control Valve

STEERING SYSTEM

Manual Steering 11

Power Steering

Steering Pump

TRANSMISSION

Front Transmission 70

Rear Transmission 74

Shifter Rails and

Forks 68

22

34

31

32

26

28

25

27

30

103

100

1

3

2

8

9

6

7

5

10

114

121

119

127

116

115

111

110

36

22

34

31

32

26

28

25

27

30

101

100

1

3

2

8

9

6

7

5

10

114

121

119

127

116

115

109

108

36

22

34

31

32

26

28

25

27

30

103

100

1

3

2

8

9

6

7

5

10

114

121

119

127

116

115

111

110

36

22

34

31

32

26

28

25

27

30

102

100

1

3

2

114

121

119

127

116

115

109

108

36

22

34

31

32

26

28

25

27

30

104

100

1

3

2

8

9

6

7

5

10

114

121

119

127

116

115

109

108

36

22

34

31

32

26

28

25

27

30

104

100

1

3

2

8

9

6

7

5

10

114

121

120

127

116

115

112

36

22

34

31

32

26

28

25

27

30

104

100

1

3

2

8

9

6

7

5

10

114

121

120

127

116

115

112

36

22

34

31

32

26

28

25

27

30

104

100

...

8

9

6

7

5

10

114

121

120

127

116

115

113

11

13

18

81

85

11

70

74

00 CO —'

81

85

11

70

74

11

70

74

13

18

70

74

13

18

70

74

90

88

13

18

83

85

79

68 79

68

68

69 69

80

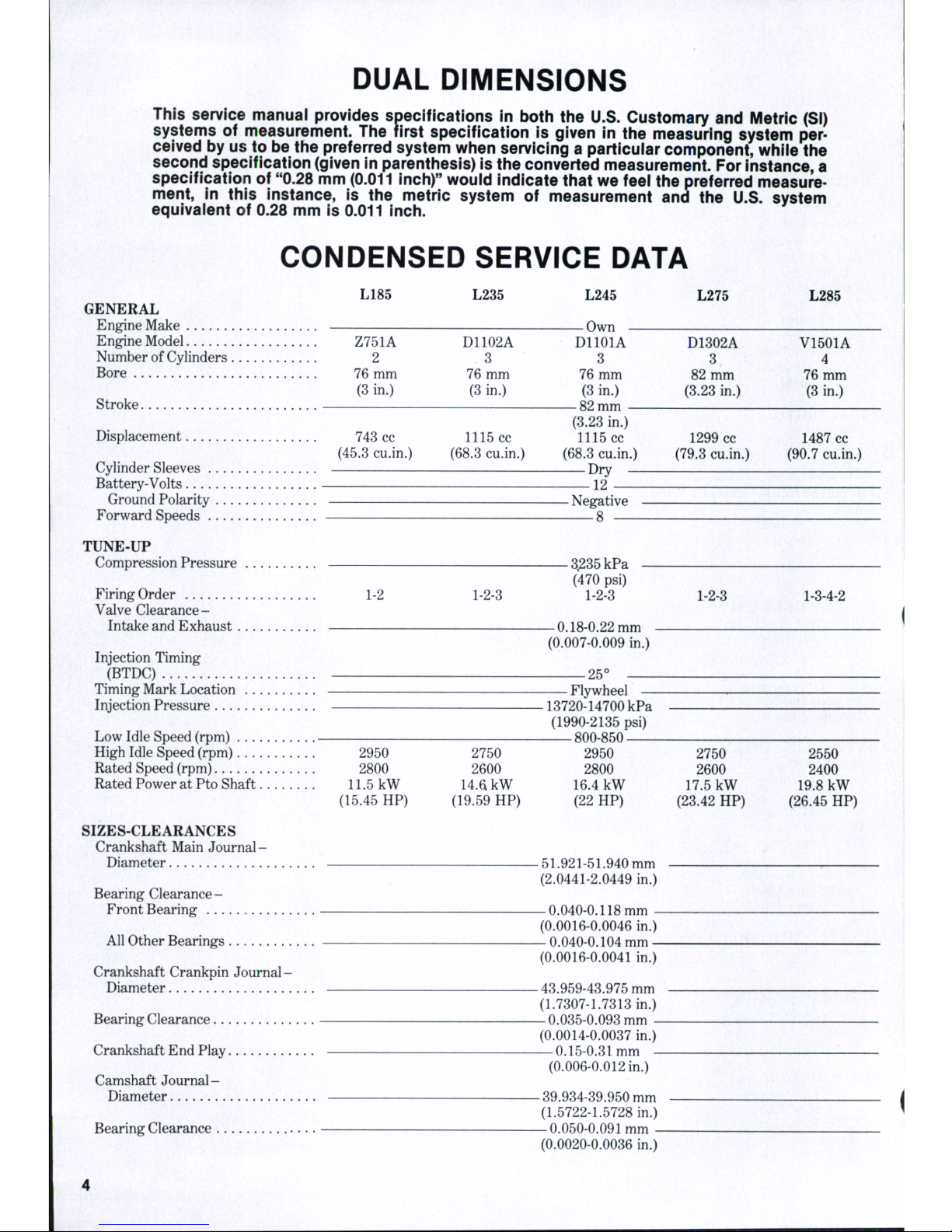

DUAL DIMENSIONS

This service manual provides specifications in both the U.S. Customary and Metric (SI)

systems of measurement. The first specification is given in the measuring system perceived by us to be the preferred system when servicing a particuiar component, whiie the

second specification (given in parenthesis) is the converted measurement. For instance, a

specification of "0.28 mm (0.011 inch)" wouid indicate that we feei the preferred measurement, in this instance, is the metric system of measurement and the U.S. system

equivaient of 0.28 mm is 0.011 inch.

CONDENSED SERVICE DATA

L185 L235

GENERAL

Engine Make

Engine Model Z751A D1102A

Number of Cylinders 2 3

Bore 76 mm 76 mm

(3 in.) (3 in.)

Stroke

Displacement 743 cc 1115 cc

(45.3 cu.in.) (68.3 cu.in.)

Cylinder Sleeves

Battery-Volts

Ground Polarity

Forward Speeds

TUNE-UP

Compression Pressure —

FiringOrder 1-2 1-2-3

Valve Clearance-

Intake and Exhaust

Injection Timing

(BTDC) - . .

Timing Mark Location

Injection Pressure

Low Idle Speed (rpm)

High Idle Speed (rpm) 2950 2750

Rated Speed (rpm) 2800 2600

Rated Power at Pto Shaft 11.5 kW

14.61

kW

(15.45 HP) (19.59 HP)

SIZES-CLEARANCES

Crankshaft Main Journal-

Diameter

Bearing Clearance -

Front Bearing

All Other Bearings

Crankshaft Crankpin Journal -

Diameter

Bearing Clearance

Crankshaft End Play

Camshaft Journal -

Diameter

Bearing Clearance

L24S

Own —

DllOlA

3

76 mm

(3 in.)

—

82

mm —

(3.23 in,)

1115 cc

(68.3 cu.in.)

Dry —

12

—

Negative

8

L275 L285

-

3,235

kPa

(470 psi)

1-2-3

—

0.18-0.22

mm

(0.007-0.009 in.)

-25°

-

Flywheel

-13720-14700 kPa

(1990-2135 psi)

800-850

2950

2800

16.4 kW

(22 HP)

-51.921-51.940 mm

(2.0441-2.0449 in.)

-0.040-0.118 mm (0.0016-0.0046 in.)

—

0.040-0.104

m m -

(0.0016-0.0041 in.)

-43.959-43.975 mm

(1.7307-1.7313 in.)

-0.035-0.093 mm (0.0014-0.0037 in.)

—

0.15-0.31

mm -

(0.006-0.012 in.)

-39.934-39.950 mm

(1.5722-L5728 in.)

—

0.050-0.091

mm -

(0.0020-0.0036 in.)

D1302A

3

82 mm

(3.23 in.)

V1501A

4

76 mm

(3 in.)

1299 cc

(79.3 cu.in.)

1487 cc

(90.7 cu.in.)

1-2-3

1-3-4-2

2750

2600

17.5 kW

(23.42 HP)

2550

2400

19.8 kW

(26.45 HP)

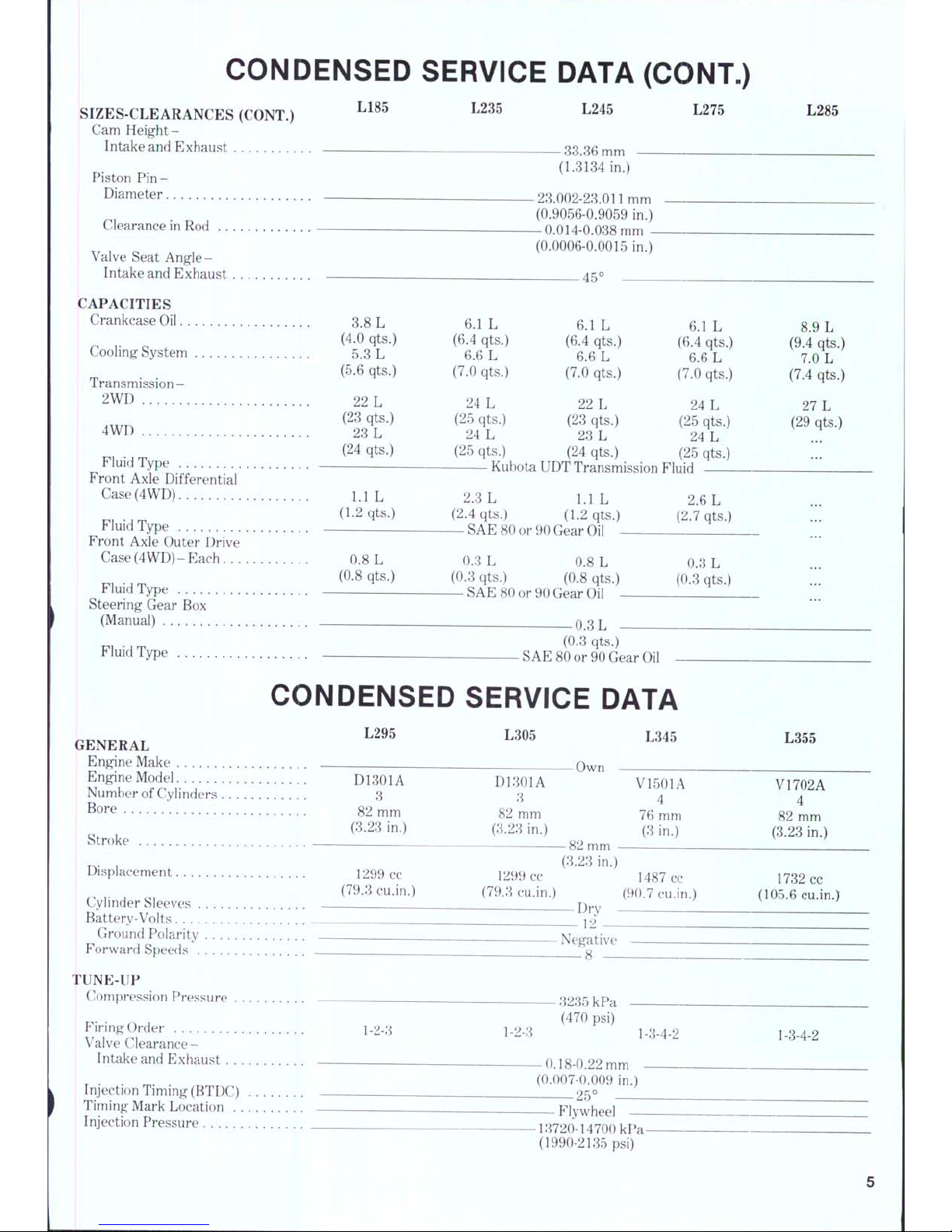

CONDENSED SERVICE DATA (CONT.)

SIZES-CLEARANCES (CONT.)

^^^ ^ ^^^^ ^^^^ ^275

Cam He ig ht -

Intake

and

Exhaust

.

33.36

mm

(1.3134

in.)

Piston

Pin-

I^ia'^eter

23.002-23.011

mm

(0.9056-0.9059

in.)

Clearance

in Rod

-0.014-0.038

mm

(0.0006-0.0015

in.)

Valve Seat An gl e-

Intake

and

Exhaust

. 450

CAPACITIES

CrankcaseOil

3.8 L 6.1 L 6.1 L 6.1 L

r. ,• c. (4.0 qts.) (6.4 qts.) (6.4 qts.) (6.4 qts.)

CoolmgSystem

5.3 L 6.6 L 6.6 L 6.6 L

.

. (5.6 qts.) (7.0 qts.) (7.0 qts.) (7.0 qts.)

Iransmission-

2WD

22 L 24 L 22 L 24 L

,,,,^

(23 qts.) (25 qts.)

(23

qts.)

(25

qts.)

4WD

23 L 24 L 23 L 24 L

^,

.^

^ (24 qts.) (25 qts.) (24 qts.) (25 qts.)

PluidType

—

Kubota UDT Transmission Fluid

-

Front Axle Differential

Case(4WD)

1.1 L 2.3 L 1,1 L 2.6 L

™

. . ^ (1.2 qts.) (2.4 qts.) (1.2 qts.) (2.7 qts.)

FluidType

SAE

80

or

90 Gear Oil

Front Axle Outer Drive

Case (4WD)-Each

0.8 L 0.3 L 0.8 L 0.3 L

(0-8

qts.)

(0.3

qts.)

(0.8

qts.)

(0.3

qts.)

FluidType

SAE

80

or

90 Gear Oil

Steering Gear

Box

(Manual)

^0.3L

T.T

. (^-3 qt s. )

FluidType

SAE

80

or

90 Gear Oil

CONDENSED SERVICE DATA

L295

GENERAL

Engine Make

^__^

Engine Model D1301A

Number

of

Cylinders

3

Bore

' 82 mm

(3.23

in.)

Stroke

Displacement

1299 cc

(79.8 cu.in.)

Cylinder Sleeves

Battery-Volts

Ground Polarity

Forward Speeds

TUNE-UP

Compression Pressure

Firing Order

1-2-3

Valve Clearan ce-

Intake

and

Exhaust

Injection Timing (BTDC)

Timing Mark Location

Injection Pressure

L305

L345

-Own

D1301A

3

82

mm

(8.28

in.)

-82 mm

V1501A

4

76

mm

(8

in.)

(8.28

in.)

1299

CC

1487

CC

(79.8 cu.in.)

(90.7

cu.in.)

Dry

.

12

L285

8.9 L

(9.4

qts.)

7.0

L

(7.4

qts.)

27

L

(29

qts.)

L355

V1702A

4

82

mm

(8.28

in.)

1782

CC

(105.6 cu.in.)

-

Negative

8

—

1-2-8

-8285kPa

(470

psi)

1-8-4-2

1-8-4-2

-0.18-0.22mm

(0.007-0.009

in.)

25°

-

Flywheel

-18720-14700

kPa-

(1990-2185

psi)

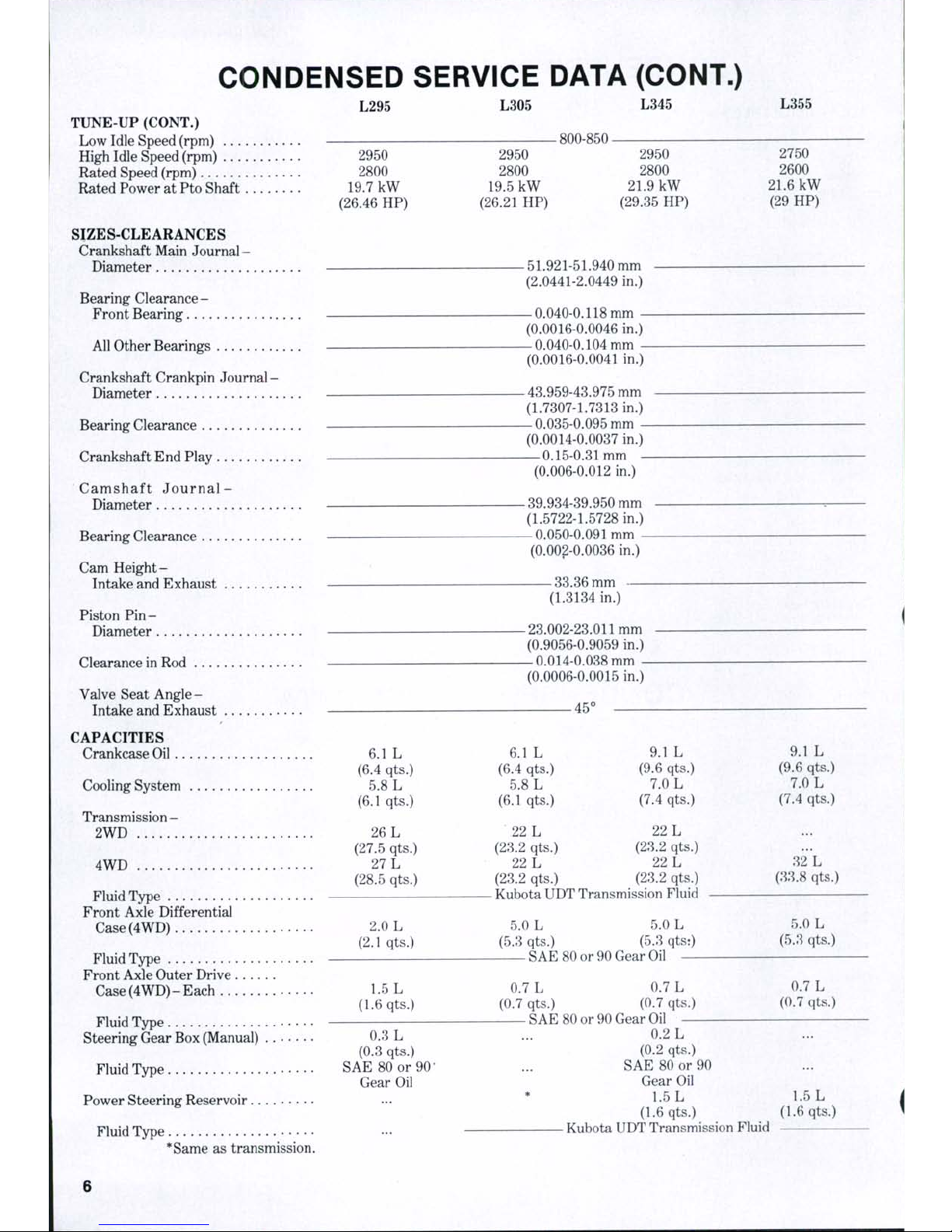

CONDENSED SERVICE DATA (CONT.)

L295

TUNE-UP (CONT.)

Low Idle Speed (rpm)

High Idle Speed (rpm) . . .

Rated Speed (rpm)

Rated Power at Pto Shaft

2950

2800

19.7 kW

(26.46 HP)

SIZES-CLEARANCES

Crankshaft Main Journal -

Diameter

Bearing Clearance-

Front Bearing

All Other Bearings

Crankshaft Crankpin Journal-

Diameter

Bearing Clearance

Crankshaft End Play

Camshaft J o u rn a l -

Diameter

Bearing Clearance

Cam Height-

Intake and Exhaust

Piston Pin-

Diameter

Clearance in Rod

Valve Seat A ng le -

Intake and Exhaust

CAPACITIES

Crankcase Oil 6.1 L

(6.4 qts.)

Cooling System 5.8 L

(6.1 qts.)

Transmission -

2WD 26 L

(27.5 qts.)

4WD 27 L

(28.5 qts.)

Fluid Type

Front Axle Differential

Case(4WD) 2.0 L

(2.1 qts.)

Fluid Type

Front Axle Outer Drive

Case(4WD)-Each 1.5 L

(1.6 qts.)

Fluid Type

Steering Gear Box (Manual) 0.3 L

(0.3 qts.)

Fluid Type SAE 80 or 90'

Gear Oil

Power Steering Reservoir

Fluid Type

*Same as transmission.

L305

L345

-800-8502950

2800

19.5 kW

(26.21 HP)

2950

2800

21.9 kW

(29.35 HP)

-51.921-51.940 mm

(2.0441-2.0449 in.)

-0.040-0.118 mm (0.0016-0.0046 in.)

—

0.040-0.104

mm -

(0.0016-0.0041 in.)

—

43.959-43.975 mm

(1.7307-1.7313 in.)

—

0.035-0.095

mm -

(0.0014-0.0037 in.)

—

0.15-0.31

mm -

(0.006-0.012 in.)

-39.934-39.950 mm

(1.5722-1.5728 in.)

—

0.050-0.091

mm -

(0.002-0.0036 in.)

-33.36 mm

(1.3134 in.)

-23.002-23.011 mm

(0.9056-0.9059 in.)

—

0.014-0.038

mm -

(0.0006-0.0015 in.)

-45°

6.1 L :

(6.4 qts.)

(6.1 qts.) • :

22 L

(23.2 qts.)

22 L

(23.2 qts.)

-

Kubota UDT Transmission Fluid

5.0 L 5.0 L

(5.3 qts.) (5.3 qts:)

SAE 80 or 90 Gear Oil —

9.1

(9.6

7.C

(7.4

22

(23.2

22

(23.2

L

qts.)

)L

qts.)

L

qts.)

L

qts.)

0.7 L 0.7 L

(0.7 qts.) (0.7 qts.)

SAE 80 or 90 Gear

Oil

—

0.2 L

L355

2750

2600

21.6 kW

(29 HP)

9.1 L

(9.6 qts.)

7.0 L

(7.4 qts.)

32 L

(33.8 qts.)

5.0 L

(5.3 qts.)

0.7 L

(0.7 qts.)

(0.2 qts.)

SAE 80 or 90

Gear Oil

1.5 L

(1.6 qts.)

Kubota UDT Transmission Fluid

1.5 L

(1.6 qts.)

6

SHOP MANUAL

Paragraphs 1-3

FRONT SYSTEM

(TWO-WHEEL DRIVE)

FRONT AXLE

All Models So Equipped

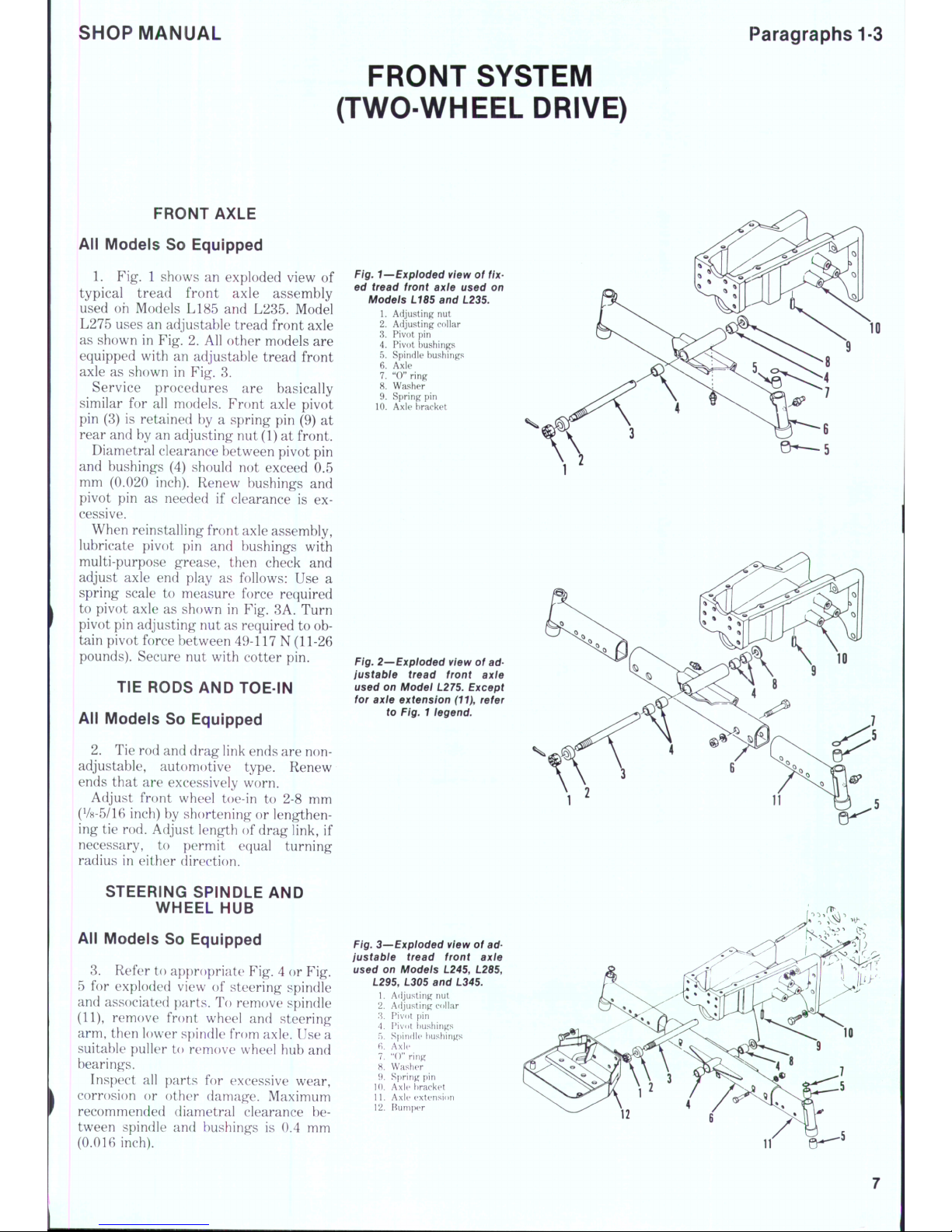

1.

Fig. 1 shows an exploded view of

typical tread front axle assembly

used oh Models L185 and L285. Model

L275 uses an adjustable tread front axle

as shown in Fig. 2. All other models are

equipped with an adjustable tread front

axle as shown in Fig. 8.

Service procedures are basically

similar for all models. Front axle pivot

pin (8) is retained by a spring pin (9) at

rear and by an adjusting nut (1) at front.

Diametral clearance between pivot pin

and bushings (4) should not exceed 0.5

mm (0.020 inch). Renew bushings and

pivot pin as needed if clearance is excessive.

When reinstalling front axle assembly,

lubricate pivot pin and bushings with

multi-purpose grease, then check and

adjust axle end play as follows: Use a

spring scale to measure force required

to pivot axle as shown in Fig. 8A. Turn

pivot pin adjusting nut as required to obtain pivot force between 49-117 N (11-26

pounds). Secure nut with cotter pin.

TIE RODS AND TOE-IN

All Models So Equipped

2.

Tie rod and drag link ends are nonadjustabie, automotive type. Renew

ends that are excessively worn.

Adjust front wheel toe-in to 2-8 mm

(V8-5/16 inch) by shortening or lengthening tie rod. Adjust length of drag link, if

necessary, to permit equal turning

radius in either direction.

STEERING SPINDLE AND

WHEEL HUB

All Models So Equipped

8. Refer to appropriate Fig. 4 or Fig.

5 for exploded view of steering spindle

and associated parts. To remove spindle

(11),

remove front wheel and steering

arm, then lower spindle from axle. Use a

suitable puller to remove wheel hub and

bearings.

Inspect al! parts for excessive wear,

corrosion or other damage. Maximum

recommended diametral clearance between spindle and bushings is 0.4 mm

(0.016 inch).

Fig. 1—Expioded view of

fix-

ed tread front axle used on

Motfe/s L185 and L235.

1.

Adjusting nut

2.

Adjusting collar

3.

Pivot pin

4.

Pivot bushings

5.

Spindle bushings

6. Axle

7.

"0" ring

8. Washer

9. Spring pin

10.

Axle bracket

en—5

Fig.

2—Expioded view of ad-

justabie tread front axie

used on Modei

L275.

Except

for axle extension

(11),

refer

to Fig. 1 legend.

Fig.

3—Expioded view of adjustabie tread front axle

used on Modeis L245, L285,

L295, L305 and L345.

1.

Af ljusting nut

2.

Ad justi ng collar

3.

Pivot i)in

4.

Pivot bu shings

f).

Spin dle bu shing s

fi. A xle

7.

" ()" ring

8. Wa sher

9. Sp ring pin

10.

Axle b racke t

11.

Axk* e xtens ion

12.

[^um[)er

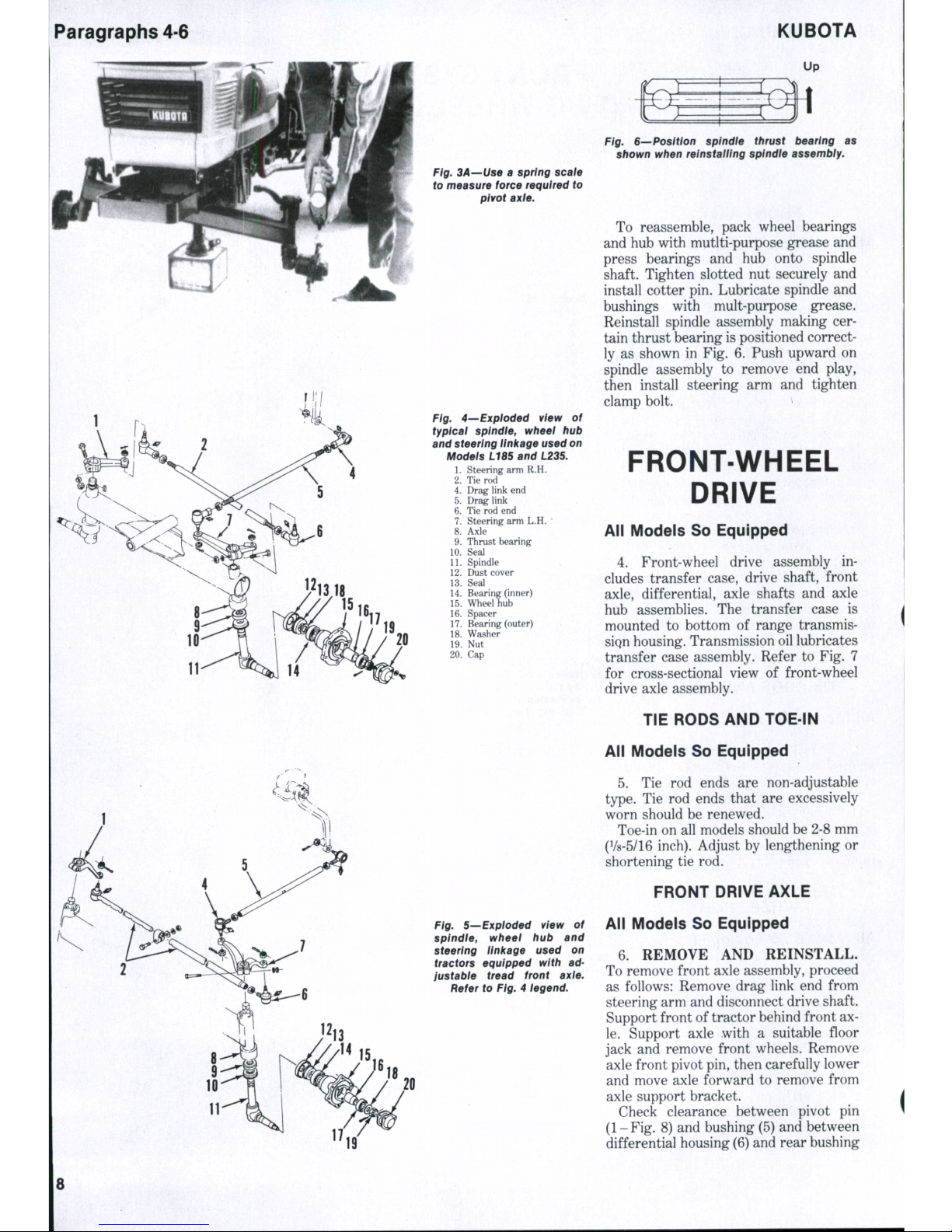

Paragraphs 4-6

KUBOTA

^

11

Fig. BA—Use a spring scafe

to measure force required to

pivot axie.

Fig. 4—'Expioded view of

typicai spindie, wheei hub

and steering iinkage used on

Modeis L18S and L23S.

1.

Steering arm R.H.

2.

Tie rod

4.

Drag link end

5.

Drag link

6. Tie rod end

7.

Steering arm L.H.

*

8. Axle

9. Thrust bearing

10.

Seal

11.

Spindle ,

12.

Dust cover

13.

Seal

14.

Bearing (inner)

15.

Wheel hub

16.

Spacer

17.

Bearing (outer)

18.

Washer

19.

Nut

20.

Cap

Fig. 5—Expioded view of

splndie, wheei hub and

steering ilni(age used on

tractors equipped with ad-

justabie tread front axie.

Refer to Fig. 4 iegend.

Fig. S—Position spindie thrust bearing as

shown when reinstaiiing spindie assembiy.

To reassemble, pack wheel bearings

and hub with mutlti-purpose grease and

press bearings and hub onto spindle

shaft. Tighten slotted nut securely and

install cotter pin. Lubricate spindle and

bushings with mult-purpose grease.

Reinstall spindle assembly making certain thrust bearing is positioned correctly as shown in Fig. 6. Push upward on

spindle assembly to remove end play,

then install steering arm and tighten

clamp bolt. >

FRONT-WHEEL

DRIVE

All Models So Equipped

4.

Front-wheel drive assembly includes transfer case, drive shaft, front

axle,

differential, axle shafts and axle

hub assemblies. The transfer case is

mounted to bottom of range transmissiQn housing. Transmission oil lubricates

transfer case assembly. Refer to Fig. 7

for cross-sectional view of front-wheel

drive axle assembly.

TIE RODS AND TOE-IN

All Models So Equipped

5.

Tie rod ends are non-adjustable

type.

Tie rod ends that are excessively

worn should be renewed.

Toe-in on all models should be 2-8 mm

(1/8-5/16 inch). Adjust by lengthening or

shortening tie rod.

FRONT DRIVE AXLE

All Models So Equipped

6. REMOVE AND REINSTALL.

To remove front axle assembly, proceed

as follows: Remove drag link end from

steering arm and disconnect drive shaft.

Support front of tractor behind front ax-

le.

Support axle with a suitable floor

jack and remove front wheels. Remove

axle front pivot pin, then carefully lower

and move axle forward to remove from

axle support bracket.

Check clearance between pivot pin

(1-Fig. 8) and bushing (5) and between

differential housing (6) and rear bushing

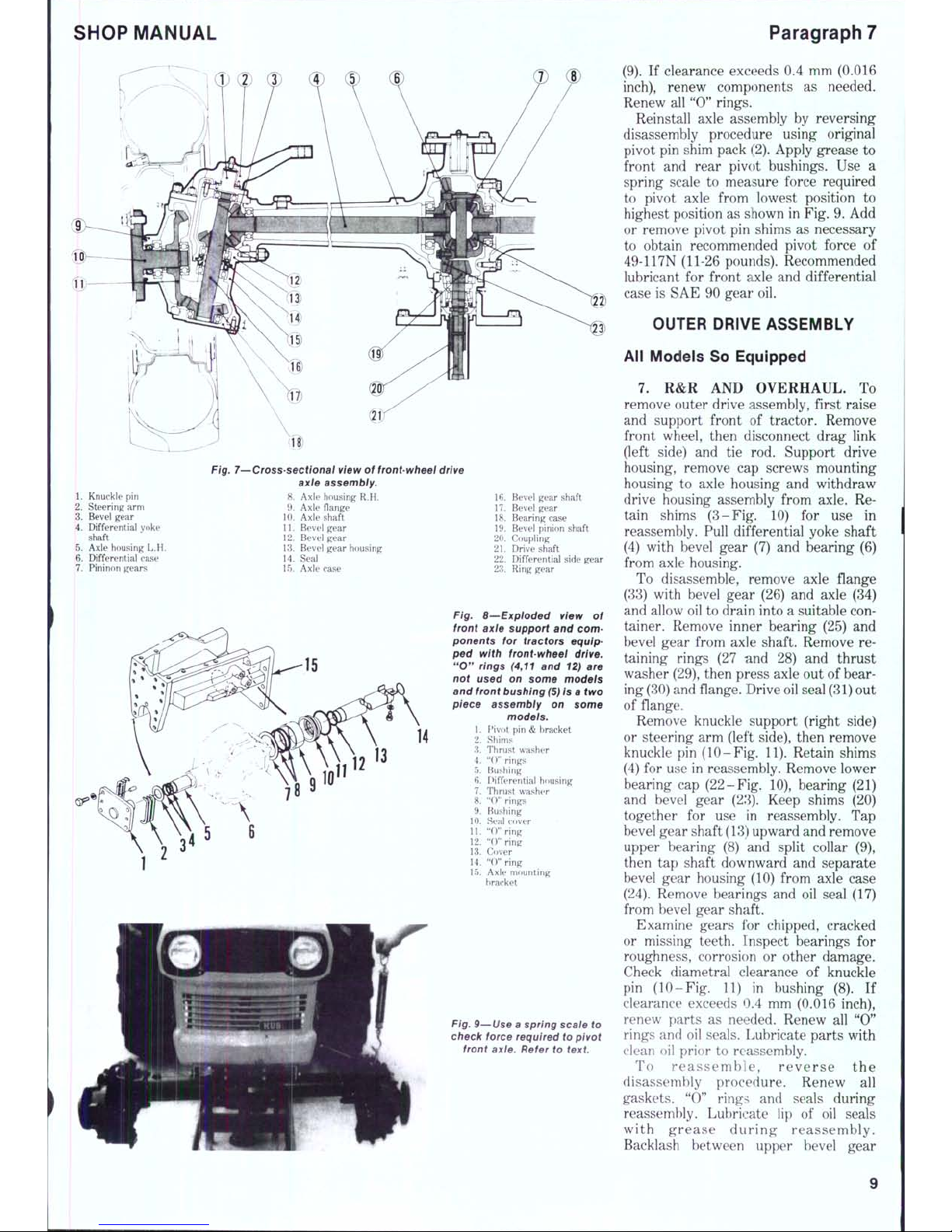

SHOP MANUAL

Paragraph

7

Fig. 7—Cross-sectional view

of

front-wheel

drive

axie assembly.

1. Knuckle

pin 8.

Axle housing

R.H.

2.

Steering arm 9. Axle flange

3.

Bevel gear 10. Axle shaft

4.

Differential yoke 11. Bevel gear

shaft ' 12. Bevel gear

5.

Axle housing L.H. 13. Bevel gea r housing

6. Differential ease 14. Seal

7.

Pininon g ears 15. Axle case

16.

Bevel gear shaft

17.

Bevel gear

18.

Bearing case

19.

Bevel pinion shaft

20.

Coupling

21.

Drive shaft

22.

Differential side gear

23.

Ring gear

Fig. 8—Expioded view

of

front axte support

and

com-

ponents

for

tractors equip-

ped with front-wheel drive.

"0" rings (4,11

and

12)

are

not used

on

some models

and

front

bushing

(5)

is a two

piece assembly

on

some

models.

1.

Pivot pin & bracket

2.

Shims

3.

Thrust washer

4.

"()" rings

5.

Bushing

6. Differential housing

7.

Thrust washer

8. "(T' rings

9. Bushing

10.

Seal cover

11.

"0 " ring

12.

"O "ring

13.

Cover

14.

"0 " ring

15.

Axle mounting

bracket

Fig.

9—Use a spring scale

to

check force required

to

pivot

front axle. Refer

to

text

(9).

If

clearance exceeds

0.4 mm

(0.016

inch),

renew components

as

needed.

Renew

all

"0" rings.

Reinstall axle assembly

by

reversing

disassembly procedure using original

pivot

pin

shim pack (2). Apply grease

to

front

and

rear pivot bushings.

Use a

spring scale

to

measure force required

to pivot axle from lowest position

to

highest position

as

shown

in

Fig.

9.

Add

or remove pivot

pin

shims

as

necessary

to obtain recommended pivot force

of

49-117N (11-26 pounds). Recommended

lubricant

for

front axle

and

differential

case

is

SAE

90

gear

oil.

OUTER DRIVE ASSEMBLY

All Models

So

Equipped

7.

R&R AND

OVERHAUL,

To

remove outer drive assembly, first raise

and support front

of

tractor. Remove

front wheel, then disconnect drag link

(left side)

and tie rod.

Support drive

housing, remove

cap

screws mounting

housing

to

axle housing

and

withdraw

drive housing assembly from axle.

Re-

tain shims (3-Fig.

10) for use in

reassembly. Pull differential yoke shaft

(4) with bevel gear

(7) and

bearing

(6)

from axle housing.

To disassemble, remove axle flange

(33) with bevel gear

(26) and

axle

(34)

and allow

oil

to

drain into a suitable

con-

tainer. Remove inner bearing

(25) and

bevel gear from axle shaft. Remove

re-

taining rings

(27 nnd 28) and

thrust

washer (29), then press axle

out

of

bear-

ing

(30)

and

flange. Drive oil seal

(31)

out

of flange.

Remove knuckle support (right side)

or steering

arm

(left side), then remove

knuckle

pin

(10-Fig.

11).

Retain shims

(4)

for

use

in

reassembly. Remove lower

bearing

cap

(22-Fig.

10),

bearing

(21)

and bevel gear

(23).

Keep shims

(20)

together

for use In

reassembly.

T'ap

bevel gear shaft

(13)

upward

and

remove

upper bearing

(8) and

split collar

(9),

then

tap

shaft downward

and

separate

bevel gear housing

(10)

from axle case

(24).

Remove bearings

and oil

seal

(17)

from bevel gear shaft.

Examine gears

for

chipped, cracked

or missing teeth. Inspect bearings

for

roughness, corrosion

or

other damage.

Check diametral clearance

of

knuckle

pin (1 0-Fig.

11) in

bushing

(8). If

clearance exceeds

0.4 mm

(0.016 inch),

renew parts

as

needed. Renew

all " 0"

rings

and oil

seals. Lubricate parts with

clean

oil

prior

to

reassembly.

To rea s semb le, r e ver s e

the

disassembly procedure. Renew

all

gaskets.

"0"

rings

and

seals during

reassembly. Lubricate

lip of oil

seals

with gre ase d ur ing reas sembly.

Backlash between upper bevel gear

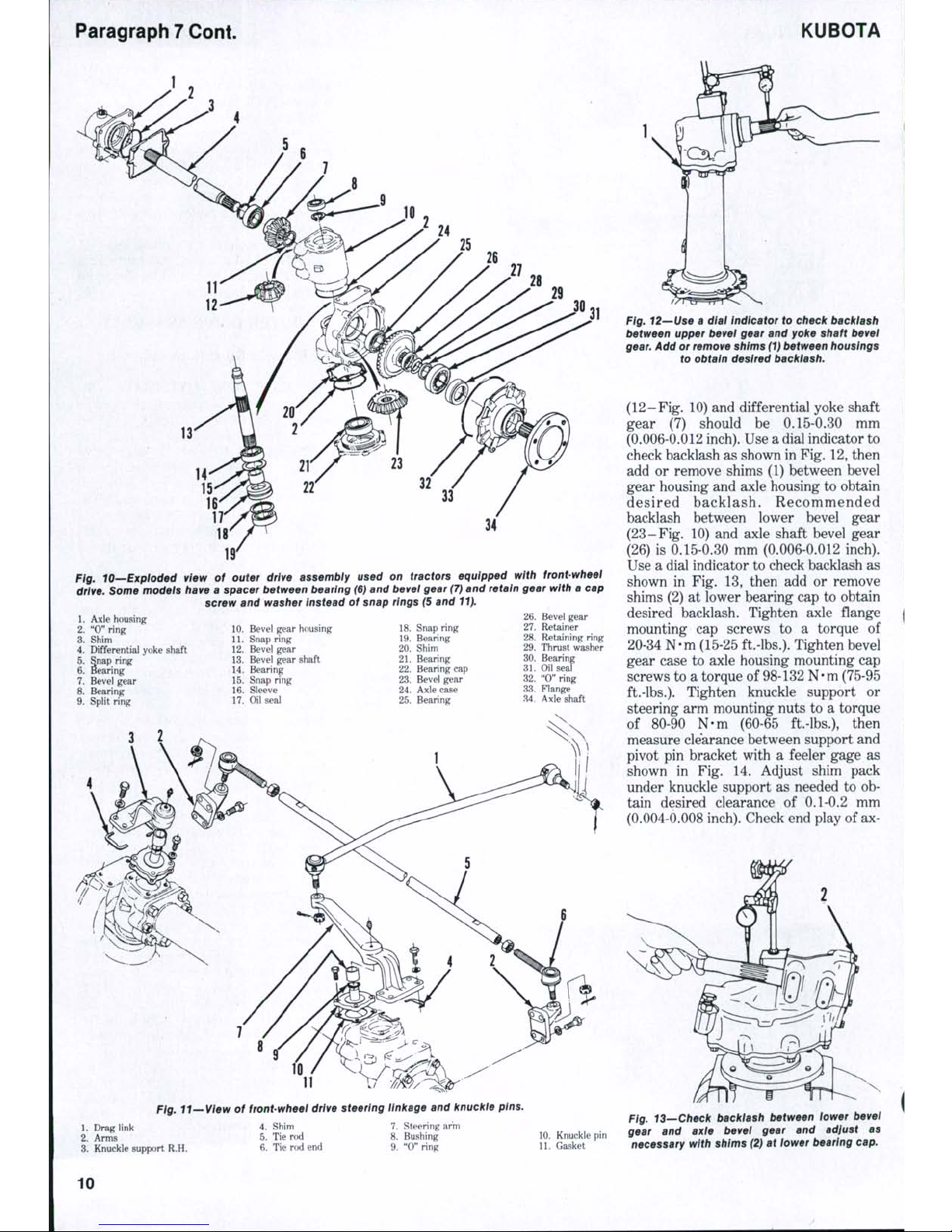

Paragraph 7 Cont.

KUBOTA

34

Fig. lO—Bxploded view of outer drive assembiy used on tractors equipped with front-wheel

drive. Some modeis have a spacer between bearing (6) and bevel gear (7) and retain gear with a cap

screw and washer Instead of snap rings (5 and 11).

1.

Axle housing

2.

"0" ring

3.

Shim

4.

Differential yoke shaft

5.

Snap ring

6. Bearing

7.

Bevel gear

8. Bearing

9. Split ring

10.

Bevel gear housing

11.

Snap ring

12.

Bevel gear

13.

Bevel gear shaft

14.

Bearing

15.

Snap ring

16.

Sleeve

17.

Oil seal

18.

Snap ring

19.

Bearing

20.

Shim

21.

Bearing

22.

Bearing cap

23.

Bevel gear

24.

Axle case

25.

Bearing

26.

27.

28.

29.

30.

31.

32.

33.

M.

Bevel gear

Retainer

Retaining ring

Thrust washer

Bearing

Oil seal

"0"

ring

Flange

Axle shaft

11

Pfg.

tt~ We i¥ of front-wheel drive steering linkage and knuckle pins.

1.

Drag link

2.

Arms

3.

Knuckle support R.H.

Fig. 12—Use a dial indicator to check backiash

between upper bevel gear and yoke shaft bevei

gear.

Add or remove shims (1) between housings

to obtain desired backlash.

(12-Fig. 10) and differential yoke shaft

gear (7) should be 0.15-0.30 mm

(0.006-0.012 inch). Use a dial indicator to

check backlash as shown in Fig. 12, then

add or remove shims (1) between bevel

gear housing and axle housing to obtain

desired ba cklash. Recom mended

backlash between lower bevel gear

(23-Fig. 10) and axle shaft bevel gear

(26) is 0.15-0.30 mm (0.006-0.012 inch).

Use a dial indicator to check backlash as

shown in Fig. 13, then add or remove

shims (2) at lower bearing cap to obtain

desired backlash. Tighten axle flange

mounting cap screws to a torque of

20-34 N-m (15-25 ft.-lbs.). Tighten bevel

gear case to axle housing mounting cap

screws to a torque of 98-132 N-m (75-95

ft.-lbs.).

Tighten knuckle support or

steering arm mounting nuts to a torque

of 80-90 N-m (60-65 ft.-lbs.), then

measure clearance between support and

pivot pin bracket with a feeler gage as

shown in Fig. 14. Adjust shim pack

under knuckle support as needed to ob-

tain desired clearance of 0.1-0.2 mm

(0.004-0.008 inch). Check end play of ax-

4.

Shim

5.

Tie rod

6. Tie rod end

7.

Steering arm

8. Bushing

9. "0" ring

10.

Knuckle pin

11.

Gasket

Fig. 13—Check backlash between iower bevel

gear and axle bevei gear and adjust as

necessary with shims (2) at lower bearing cap.

10

SHOP MANUAL

Paragraph 8

Fig. 14—Use a feeier gage to check knuckle pin

to support clearance. Add or remove knuckie

support mounting shims to obtain desired

ciearance.

le shaft using a dial indicator as shown

in Fig. 15. Maximum allowable end play

is 0.5 mm (0.020 inch). If end play is ex-

cessive, check condition of thrust

washer (29-Fig. 10) and retainer (27).

Refill unit with SAE 90 gear oil.

DIFFERENTIAL AND BEVEL

GEAR ASSEMBLY

All Models So Equipped

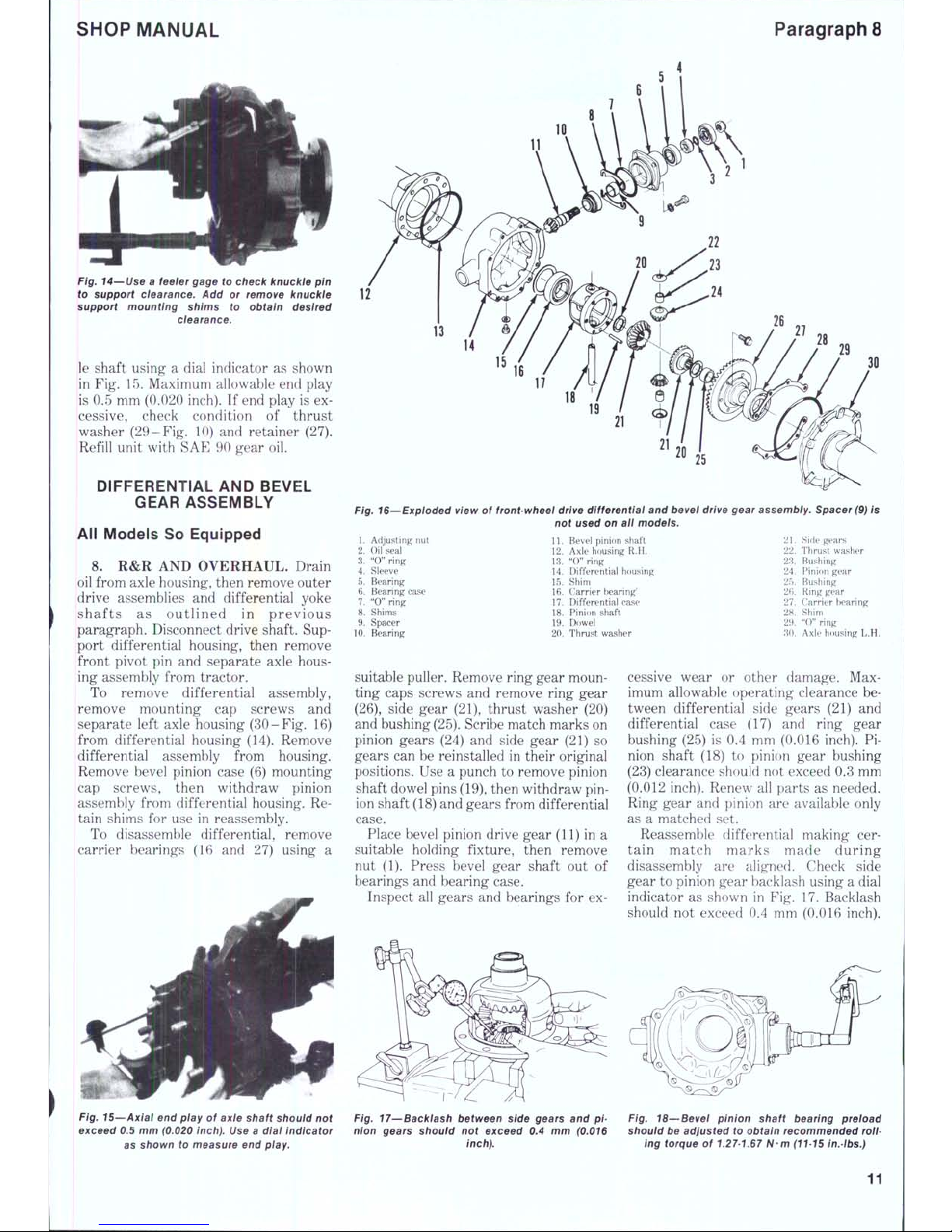

8. R&R AND OVERHAUL. Drain

oil from axle housing, then remove outer

drive assemblies and differential yoke

shafts as outlined in previous

paragraph. Disconnect drive shaft. Support differential housing, then remove

front pivot pin and separate axle hous-

ing assembly from tractor.

To remove differential assembly,

remove mounting cap screws and

separate left axle housing (30-Fig. 16)

from differential housing (14). Remove

differential assembly from housing.

Remove bevel pinion case (6) mounting

cap screws, then withdraw pinion

assembly from differential housing. Retain shims for use in reassembly.

To disassemble differential, remove

carrier bearings (16 and 27) using a

21

20

25

Fig. 16--Exploded view of front-wheel drive differentiai and bevei drive gear assembiy. Spacer (9) is

not used on ail modeis.

1.

Adjusting nut

2.

Oil seal

3.

"0" ring

4.

Sleeve

5.

Bearing

6. Bearing ease

7.

"0" ring

8. Shims

9. Spacer

10.

Bearing

11.

Bevel pinion shaft

12.

Axle housing R.H.

13.

"0" ring

14.

Differential housing

15.

Shim

16.

Carrier bearing'

17.

Differential case

18.

Pinion shaft

19.

Dowel

20.

Thrust washer

21.

Side gears

22.

Thrust washer

23.

Bushing

24.

Pinion gear

25.

Bushing

2fi.

Ring gear

27.

Carrier tearing

28.

Shim

29.

"0" ring

'M).

Axle housing L.H.

suitable puller. Remove ring gear mounting caps screws and remove ring gear

(26),

side gear (21), thrust washer (20)

and bushing

(25).

Scribe match marks on

pinion gears (24) and side gear (21) so

gears can be reinstalled in their original

positions. Use a punch to remove pinion

shaft dowel pins

(19),

then withdraw pin-

ion shaft

(18)

and gears from differential

case.

Place bevel pinion drive gear (11) in a

suitable holding fixture, then remove

nut (1). Press bevel gear shaft out of

bearings and bearing case.

Inspect all gears and bearings for ex-

cessive wear or other damage. Maximum allowable operating clearance between differential side gears (21) and

differential case (17) and ring gear

bushing (25) is 0.4 mm (0.016 inch). Pinion shaft (18) to pinion gear bushing

(23) clearance should not exceed 0.3 mm

(0.012 inch). Renew all parts as needed.

Ring gear and pinion are available only

as a matched set.

Reassemble differential making certain match mark s made during

disassembly are aligned. Check side

gear to pinion gear backlash using a dial

indicator as shown in Fig. 17. Backlash

should not exceed 0.4 mm (0.016 inch).

Fig. 15—Axial end piay of axie shaft shouid not

exceed 0.5 mm (0.020 inch). Use a dial indicator

as shown to measure end

piay.

Fig. 17^Backiash between side gears and pinion gears shouid not exceed 0.4 mm (0.016

inch).

Fig. 18—'Bevei pinion shaft bearing preload

should be adjusted to obtain recommended

roil-

ing torque of

1.27-167

N-m (11-15 in.tbs.)

11

Paragraph 8 Cont.

KUBOTA

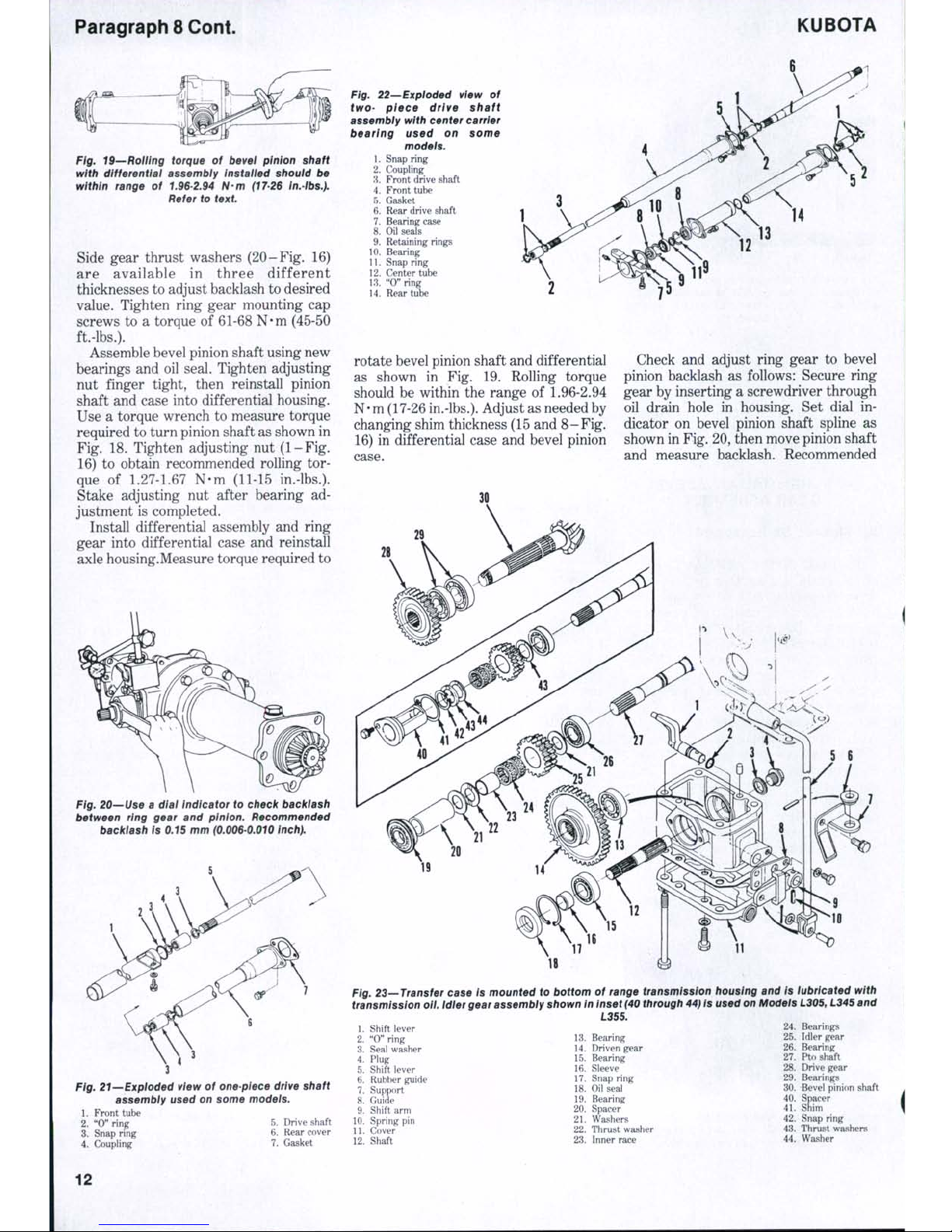

Fig. 19—Rolling torque of bevel ptnton shaft

with differential assembly Instatted shouid be

within range of 1.96-2.94 N-m (17-26 tn.-tbs.).

Refer to text

Side gear thrust washers (2 0-Fig. 16)

are available in three different

thicknesses to adjust backlash to desired

value. Tighten ring gear mounting cap

screws to a torque of 61-68 N-m (45-50

ft.-lbs.).

Assemble bevel pinion shaft using new

bearings and oil seal. Tighten adjusting

nut finger tight, then reinstall pinion

shaft and case into differential housing.

Use a torque wrench to measure torque

required to turn pinion shaft as shown in

Fig. 18. Tighten adjusting nut (1-Fig.

16) to obtain recommended rolling tor-

que of

1.27-1.67

N-m (11-15 in.-lbs.).

Stake adjusting nut after bearing ad-

justment is completed.

Install differential assembly and ring

gear into differential case and reinstall

axle housing.Measure torque required to

Fig. 20—Use a diai indicator to check backlash

between ring gear and pinion. Recommended

backlash Is 0.15 mm

(0.006-0.010

inch).

Fig. 21—Exploded view of one piece drive shaft

assembly used on some modets.

1.

Front tube

2.

"0" ring 5. Drive shaft

3.

Snap ring 6. Rear cover

4.

Coupling 7. Gasket

Ftg. 22—Exploded view of

two-

piece drive shaft

assembly

with center carrier

bearing used on some

models.

1.

Snap ring

2.

Coupling

3.

Front drive shaft

4.

Front tube

5.

Gasket

6. Rear drive shaft

7.

Bearing case

8. Oil seals

9. Retaining rings

10.

Bearing

11.

Snap ring

12.

Center tube

13.

"0" ring

14.

Rear tube

rotate bevel pinion shaft and differential

as shown in Fig. 19. Rolling torque

should be within the range of

1.96-2.94

N-m (17-26

in.-lbs.).

Adjust as needed by

changing shim thickness (15 and 8- Fig.

16) in differential case and bevel pinion

case.

Check and adjust ring gear to bevel

pinion backlash as follows: Secure ring

gear by inserting a screwdriver through

oil drain hole in housing. Set dial indicator on bevel pinion shaft spline as

shown in Fig. 20, then move pinion shaft

and measure backlash. Recommended

II

Fig. 23—Transfer case is mounted to bottom of range transmission housing and is lubricated with

transmission ott.

Idler

gear assembly shown in Inset

(40

through

44)

is used on Modeis

L305,

L345

and

L355.

1.

Shift lever

2.

"0" ring

3.

Seal washer

4.

Plug

5.

Shift lever

6. Rubber guide

7.

Support

8. Guide

9. Shift arm

10.

Spring pin

11.

Cover

12.

Shaft

13.

Bearing

14.

Driven gear

15.

Bearing

16.

Sleeve

17.

Snap ring

18.

Oil seal

19.

Bearing

20.

Spacer

21.

Washers

22.

Thrust washer

23.

Inner race

24.

Bearings

25.

Idler gear

26.

Bearing

27.

Pto shaft

28.

Drive gear

29.

Bearings

30.

Bevel pinion shaft

40.

Spacer

41.

Shim

42.

Snap ring

43.

Thrust washers

44.

Washer

12

SHOP MANUAL

Paragraphs 9-12

backlash

is

0.15-0.25

mm

(0.006-0.010

inch).

If

measured backlash is excessive,

decrease shims

(15 - Fig.

16)

on differen-

tial case side and add shims (28)

of

same

thickness between left axle housing and

differential case.

If

backlash

is

insuffi-

cient, decrease shims (28) and

add

same

thickness

to

shims (15).

Complete reassembly

and

installation

of axle assembly. Refill axle housing

with

SAE 90

gear

oil.

DRIVE SHAFT

All Models

So

Equipped

9. Models L305, L345 and L355 use

a

two-piece drive shaft with a center

car-

rier bearing (Fig.

22). All

other models

use a one-piece drive shaft

as

shown

in

Fig. 21.

Removal

of

drive shaft consists

of

removing mounting screws from drive

shaft tubes, disengaging retaining rings

and sliding drive shaft

out of

couplers.

Remove center carrier bearing

and oil

seals

on

models

so

equipped.

Inspect shaft splines

and

couplers

for

excessive wear

or

other damage.

Reinstall drive shaft

by

reversing

removal procedure.

TRANSFER CASE

All Models

So

Equipped

10.

R&R AND OVERHAUL. Drive

gear (28 -

Fig.

28) and idler gear (25) are

located

in

range transmission housing.

Refer

to

appropriate transmission

sec-

tion

for

service procedures.

To service transfer case, first drain

oil

from transmission housing. Disconnect

drive shaft

and

shift linkage. Remove

transfer case mounting

cap

screws

and

lower unit from transmission housing.

To disassemble, remove

oil

seal

(18),

retaining ring

(17) and

plug

(4). Tap

shaft (12)

out

front

of

case

and

remove

gear (14). Drive pin (10) out

of

shift arm

(9)

and

remove shift lever (1).

To reas s embl e , reve r se

the

disassembly procedure. Apply liquid

gasket maker

to

surfaces

of

drive case

mounting gasket when reinstalling.

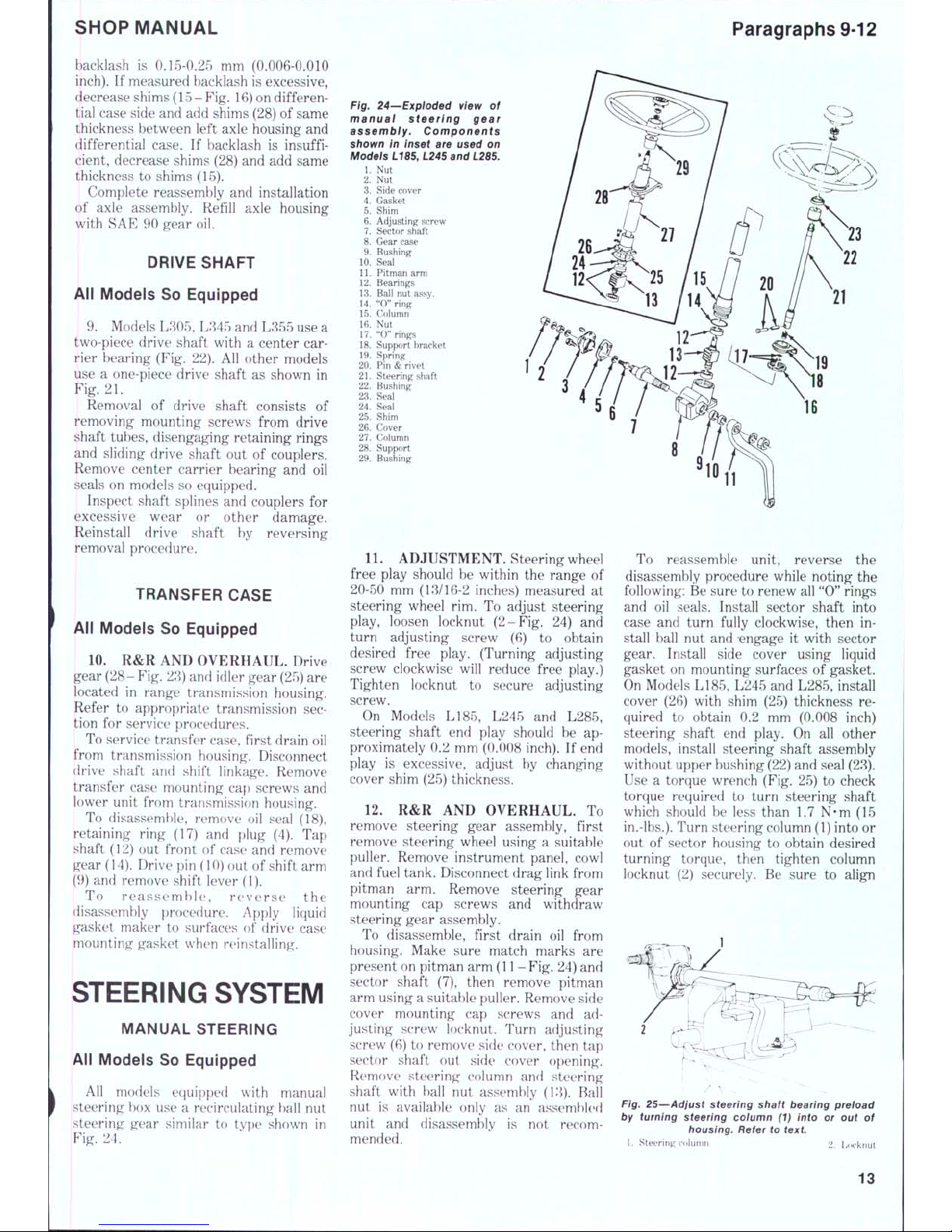

STEERING SYSTEM

MANUAL STEERING

All Models

So

Equipped

All models equipped with manual

steering box

use a

recirculating ball

nut

steering gear similar

to

type shown

in

P^ig.

24.

Fig. 24—Exploded view

of

manual steering gear

assembiy. Components

shown

in

inset

are

used

on

Models L185, L245 and

L28S.

1.

Nut

2.

Nut

3.

Side cover

4.

Gasket

5.

Shim

6. Adjusting screw

7.

Sector shaft

8. Gear case

9. Bushing

10.

Seal

11.

Pitman arm

12.

Bearings

13.

Ball nut assy.

14.

" 0" ring

15.

Column

16.

Nut

17.

" 0" rings

18.

Support bracket

19.

Spring

20.

Pin & rivet

21.

Ste ering shaft

22.

Bushing

23.

Seal

24.

Seai

25.

Shim

26.

Cover

27.

Column

28.

Support

29.

Bushing

11.

ADJUSTMENT. Steering wheel

free play should

be

within

the

range

of

20-50

mm

(13/16-2 inches) measured

at

steering wheel

rim. To

adjust steering

play, loosen locknut (2-Fi g.

24) and

turn adjusting screw

(6) to

obtain

desired free play. (Turning adjusting

screw clockwise will reduce free play.)

Tighten locknut

to

secure adjusting

screw.

On Models LI85, L245

and

L285,

steering shaft

end

play should

be ap-

proximately

0.2

mm (0.008 inch).

If

end

play

is

excessive, adjust

by

changing

cover shim (25) thickness.

12.

R&R AND

OVERHAUL.

To

remove steering gear assembly, first

remove steering wheel using a suitable

puller. Remove instrument panel, cowl

and fuel tank. Disconnect drag link from

pitman

arm.

Remove steering gear

mounting

cap

screws

and

withdraw

steering gear assembly.

To disassemble, first drain

oil

from

housing. Make sure match marks

are

present on pitman arm

(1 1 -

Fig.

24) and

sector shaft

(7),

then remove pitman

arm using a suitable puller. Remove side

cover mounting

cap

screws

and adjusting screw locknut. Turn adjusting

screw (6)

to

remove side cover, then

tap

sector shaft

out

side cover opening.

Remove steering column

and

steering

shaft with hall

nut

assembly (13). Ball

nut

is

available only

as an

assernhknl

unit

and

disassembly

is not

recom-

mended.

To reassemble unit, reverse

the

disassembly procedure while noting^

the

following: Be sure

to

renew all "0" rings

and

oil

seals. Install sector shaft into

case

and

turn fully clockwise, then

in-

stall ball

nut and

-engage

it

with sector

gear. Install side cover using liquid

gasket

on

mounting surfaces

of

gasket.

On Models L185, L245 and L285, install

cover

(26)

with shim

(25)

thickness

re-

quired

to

obtain

0.2 mm

(0.008 inch)

steering shaft

end

play.

On all

other

models, install steering shaft assembly

without upper bushing (22) and seal (23).

Use a torque wrench (Fig. 25)

to

check

torque required

to

turn steering shaft

which should

be

less than

1.7 N-m (15

in.-lbs.).

Turn steering column (1) into

or

out

of

sector housing

to

obtain desired

turning torque, then tighten column

locknut

(2)

securely.

Be

sure

to

align

Fig. 25—Adjust steering shaft bearing preload

by turning steering coiumn

(1)

into

or out of

housing. Refer

to

text

1.

Steering colunm 2 Ijocknut

13

Paragraphs 13-14 KUBOTA

match marks when reinstalling pitman

arm. Refill unit with approximately 0.2

L (% pint) of SAE 90 gear oil.

Reinstall steering unit on tractor and

adjust steering wheel free play as

previously outlined.

POWER STEERING

Integral Type

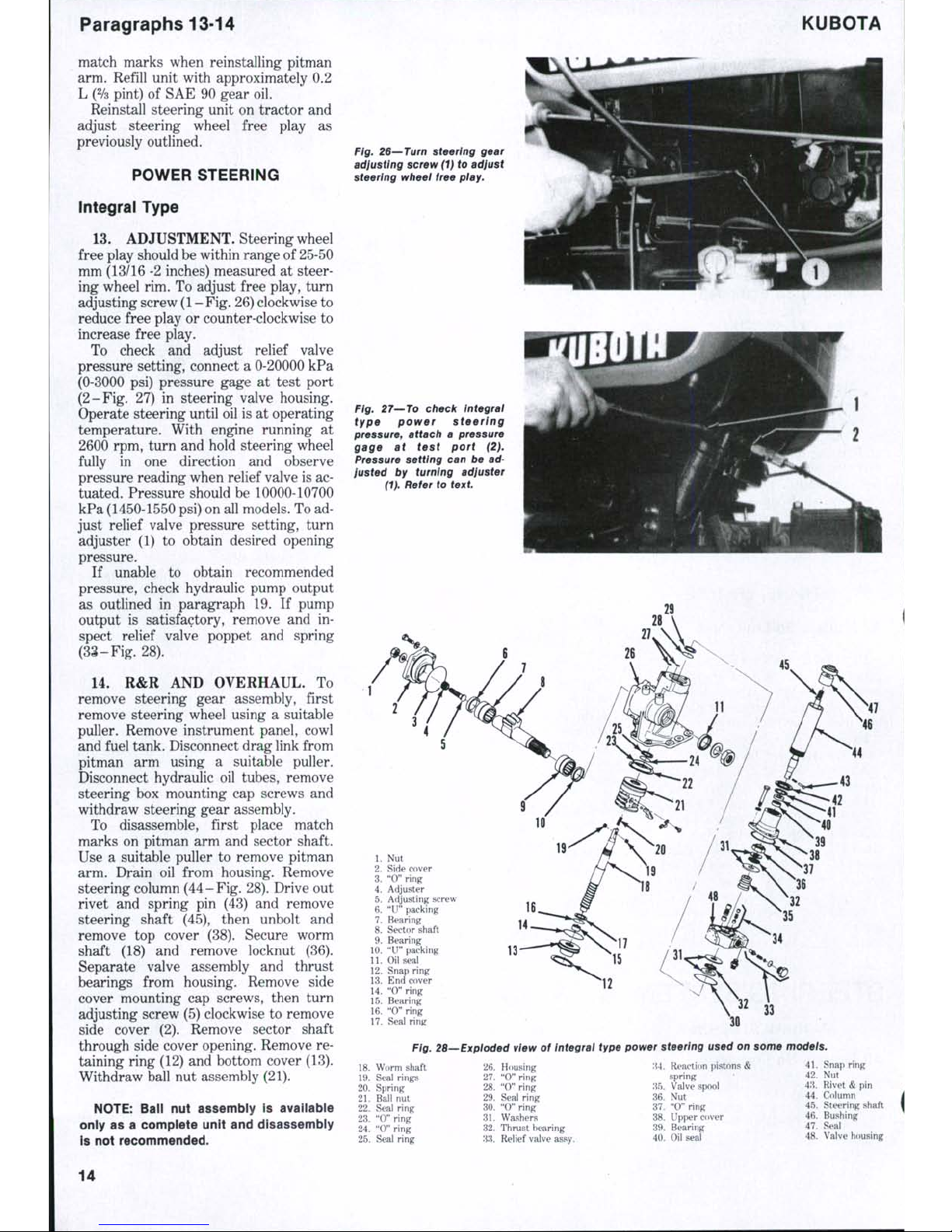

13.

ADJUSTMENT. Steering wheel

free play should be within range of 25-50

mm (13/16-2 inches) measured at steering wheel rim. To adjust free play, turn

adjusting screw

(1 - Fig.

26) clockwise to

reduce free play or counter-clockwise to

increase free play.

To check and adjust relief valve

pressure setting, connect a 0-20000 kPa

(0-3000 psi) pressure gage at test port

(2-Fig. 27) in steering valve housing.

Operate steering until oil is at operating

temperature. With engine running at

2600 rpm, turn and hold steering wheel

fully in one direction and observe

pressure reading when relief valve is ac-

tuated. Pressure should be 10000-10700

kPa (1450-1550 psi) on all models. To ad-

just relief valve pressure setting, turn

adjuster (1) to obtain desired opening

pressure.

If unable to obtain recommended

pressure, check hydraulic pump output

as outlined in paragraph 19. If pump

output is satisfactory, remove and inspect relief valve poppet and spring

(33-Fig.28).

14.

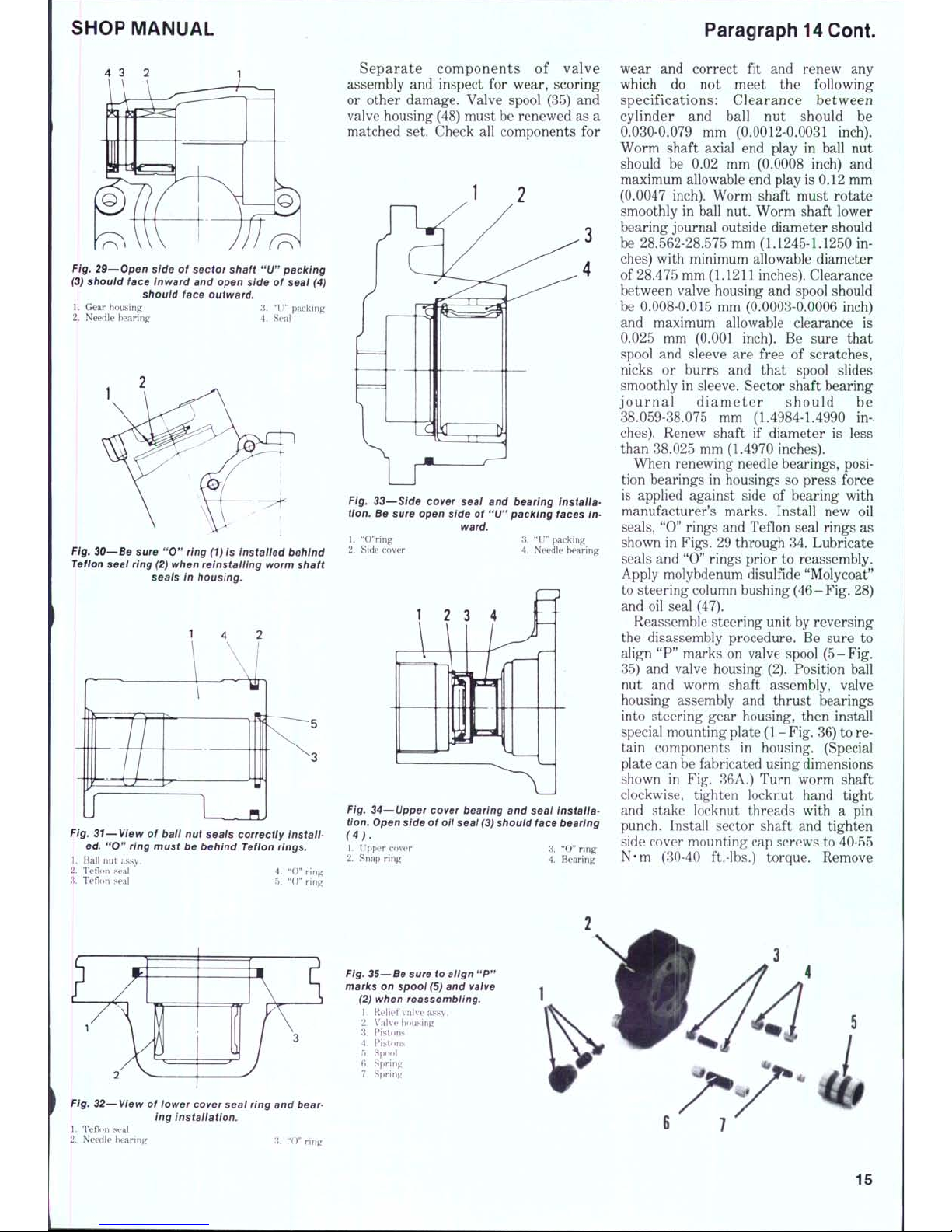

R&R AND OVERHAUL. To

remove steering gear assembly, first

remove steering wheel using a suitable

puller. Remove instrument panel, cowl

and fuel tank. Disconnect drag link from

pitman arm using a suitable puller.

Disconnect hydraulic oil tubes, remove

steering box mounting cap screws and

withdraw steering gear assembly.

To disassemble, first place match

marks on pitman arm and sector shaft.

Use a suitable puller to remove pitman

arm. Drain oil from housing. Remove

steering column

(44 - Fig.

28). Drive out

rivet and spring pin (43) and remove

steering shaft (45), then unbolt and

remove top cover (38). Secure worm

shaft (18) and remove locknut (36).

Separate valve assembly and thrust

bearings from housing. Remove side

cover mounting cap screws, then turn

adjusting screw (5) clockwise to remove

side cover (2). Remove sector shaft

through side cover opening. Remove retaining ring (12) and bottom cover (13).

Withdraw ball nut assembly (21).

NOTE:

Ball nut assembly is available

only as a complete unit and disassembly

Is not recommended.

Fig. 26—Turn steering gear

adjusting screw (1) to adjust

steering wheel free

play.

Fig. 27—To check integral

type power steering

pressure, attach a pressure

gage at test port (2).

Pressure setting can be adjusted by turning adjuster

(1).

Refer to text

1.

Nut

2.

Side cover

3.

"0" ring

4.

Adjuster

5.

Adjusting screw

6. "U" packing

7.

Bearing

8. Sector shaft

9. Bearing

10.

"U" packing

11.

Oil seal

12.

Snap ring

13.

End cover

14.

"0" ring

15.

Bearing

16.

"0" ring

17.

Seal ring

14

13-

'^^

12

33

Ftg. 28—Exploded view of Integral type power steering used on some models.

18.

W orm sh aft

19.

Seal ri ngs

20.

Spr ing

21.

Ball n ut

22.

Seal ri ng

23.

" 0" rin g

24.

" 0" ri ng

25.

Seal ring

26.

Hou sing

27.

" 0" ri ng

28.

"O" rin g

29.

Seal r ing

30.

" 0" ri ng

31.

W ashe rs

32.

Thrust b earing

33.

Relie f valve ass y.

;{4.

R eaction pi stons

<!

spring

35.

Valv e spool

36.

Nu t

37.

"0 " ring

38.

Up per c over

39.

Be aring

40.

Oil seal

41.

S nap r ing

42.

Nut

43.

Rive t & pin

44.

Col umn

45.

St eeri ng sh aft

46.

Bus hing

47.

Se al

48.

Valv e housing

14

SHOP MANUAL

Paragraph 14 Cont.

4 3 2

Fig.

29—Open side of sector shaft

"U"

packing

(3)

should face Inward and open side of seal (4)

should face outward.

1.

Gear housing 3. "I!" packing

2.

Needle bearing 4. Seal

Fig.

30—Be sure

"O"

ring (1)

is installed behind

Teflon

seai

ring (2)

when reinstailing worm shaft

seals in housing.

Fig. 31—View of baii nut seais correctly instail-

ed.

"O"

ring must be behind Tefion rings.

1.

Ball nut assy.

2.

Teflon seal ' 4. "0" ring

3.

Teflon seal 5. "()" ring

Separate components of valve

assembly and inspect for wear, scoring

or other damage. Valve spool (35) and

valve housing (48) must be renewed as a

matched set. Check all components for

Fig. 33—Side cover seai and bearing Installation.

Be sure open side of

"U"

packing faces

in-

ward.

3.

"IJ" packing

4.

Needle bearing

1.

"O'Ving

2.

Side cover

1

2

3

4

ifi

1!

J

Fig. 34—Upper cover bearing and seal installa-

tion.

Open side of oii seai

(3)

shouid face bearing

(4).

1.

nppor cover 3. "O" ring

2.

Snap ring 4. Bearing

wear and correct fit and renew any

which do not meet the following

specifications: Clearance between

cylinder and ball nut should be

0.030-0.079 mm (0.0012-0.0031 inch).

Worm shaft axial end play in ball nut

should be 0.02 mm (0.0008 inch) and

maximum allowable end play is 0.12 mm

(0.0047 inch). Worm shaft must rotate

smoothly in ball nut. Worm shaft lower

bearing journal outside diameter should

be 28.562-28.575 mm (1.1245-1.1250 inches) with minimum allowable diameter

of 28.475 mm (1.1211 inches). Clearance

between valve housing and spool should

be 0.008-0.015 mm (0.0003-0.0006 inch)

and maximum allowable clearance is

0.025 mm (0.001 inch). Be sure that

spool and sleeve are free of scratches,

nicks or burrs and that spool slides

smoothly in sleeve. Sector shaft bearing

journal dia m eter should be

38.059-38.075 mm (1.4984-1.4990 inches).

Renew shaft if diameter is less

than 38.025 mm (1.4970 inches).

When renewing needle bearings, position bearings in housings so press force

is applied against side of bearing with

manufacturer's marks. Install new oil

seals,

"0" rings and Teflon seal rings as

shown in Figs. 29 through 34. Lubricate

seals and "0" rings prior to reassembly.

Apply molybdenum disulfide "Molycoat"

to steering column bushing(46-Fig. 28)

and oil seal (47).

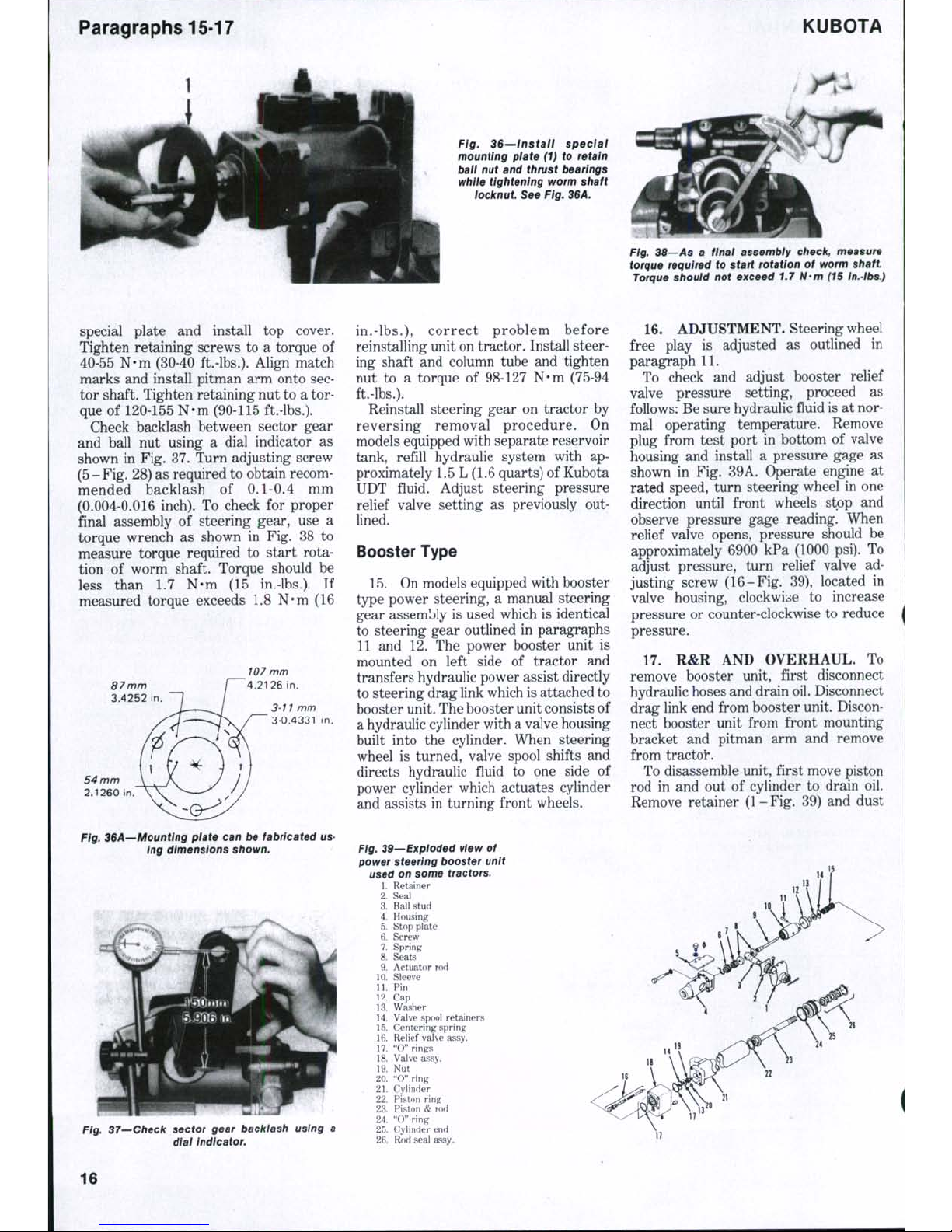

Reassemble steering unit by reversing

the disassembly procedure. Be sure to

align "P" marks on valve spool (5-Fig.

35) and valve housing (2). Position ball

nut and worm shaft assembly, valve

housing assembly and thrust bearings

into steering gear housing, then install

special mounting plate

(1 - Fig.

36) t o re-

tain components in housing. (Special

plate can be fabricated using dimensions

shown in Fig. 36A.) Turn worm shaft

clockwise, tighten locknut hand tight

and stake locknut threads with a pin

punch. Install sector shaft and tighten

side cover mounting cap screws to 40-55

N-m (30-40 ft.-lbs.) torque. Remove

Fig.

32—View of iower cover seai

ring

and bear-

ing installation.

1.

Teflnn sea!

2.

Needle bearing :i. "O" ring

Fig.

35—Be sure to aiign

"P"

marks on spool

(5)

and valve

(2) when reassembiing.

1.

Relief valve assy.

2.

Valve housing

3.

F^istons

4.

F^i.stons

5.

Spool

6. Spring

7.

Spring

6

7

15

Paragraphs 15-17

KUBOTA

Fig. 36—Install speciai

mounting plate (1) to retain

ball nut and thrust bearings

while tightening worm shaft

tocknut See Fig. 36A.

Fig, 38—As a finai assembly check, measure

torque required to start rotation of worm shaft

Torque should not exceed 1.7 N-m (15 In.-lbs.)

special plate and install top cover.

Tighten retaining screws to a torque of

40-55 N-m (30-40 ft.-lbs.). Align match

marks and install pitman arm onto sector shaft. Tighten retaining nut to a torque of 120-155 N-m (90-115 ft.-lbs.).

Check backlash between sector gear

and ball nut using a dial indicator as

shown in Fig. 37. Turn adjusting screw

(5-Fig. 28) as required to obtain recommended backlash of 0.1-0.4 mm

(0.004-0.016 inch). To check for proper

final assembly of steering gear, use a

torque wrench as shown in Fig. 38 to

measure torque required to start rotation of worm shaft. Torque should be

less than 1.7 N-m (15 in.-lbs.). If

measured torque exceeds 1.8 N-m (16

Ftg. 36A—Mounting plate can be fabricated us-

ing dimensions shown.

37—Check sector gear backlash using a

dtat Indicator.

in.-lbs.),

c orrect problem before

reinstalling unit on tractor. Install steering shaft and column tube and tighten

nut to a torque of 98-127 N-m (75-94

ft.-lbs.).

Reinstall steering gear on tractor by

reversing removal procedure. On

models equipped with separate reservoir

tank, refill hydraulic system with ap-

proximately 1.5 L (1.6 quarts) of Kubota

UDT fluid. Adjust steering pressure

relief valve setting as previously out-

lined.

Booster Type

15.

On models equipped with booster

type power steering, a manual steering

gear assembly is used which is identical

to steering gear outlined in paragraphs

11 and 12. The power booster unit is

mounted on left side of tractor and

transfers hydraulic power assist directly

to steering drag link which is attached to

booster unit. The booster unit consists of

a hydraulic cylinder with a valve housing

built into the cylinder. When steering

wheel is turned, valve spool shifts and

directs hydraulic fluid to one side of

power cylinder which actuates cylinder

and assists in turning front wheels.

Fig. 39—Exploded view of

power steering booster unit

used on some tractors.

1.

Retainer

2.

Seal

3.

Ball stud

4.

Housing

5.

Stop plate

6. Screw

7.

Spring

8. Seats

9. Actuator rod

10.

Sleeve

11.

Pin

12.

Cap

13.

Washer

14.

Valve spool retainers

15.

Centering spring

16.

Reliefvalve assy.

17.

"O" rings

18.

Valve assy.

19.

Nut

20.

"0" ring

. 21. Cylinder

22.

Piston ring

23.

Piston & rod

24.

"0" ring

25.

Cylinder end

26.

Rod seal assy.

16.

ADJUSTMENT. Steering wheel

free play is adjusted as outlined in

paragraph 11.

To check and adjust booster relief

valve pressure setting, proceed as

follows: Be sure hydraulic fluid is at normal operating temperature. Remove

plug from test port in bottom of valve

housing and install a pressure gage as

shown in Fig. 39A. Operate engine at

rated speed, turn steering wheel in one

direction until front wheels stop and

observe pressure gage reading. When

relief valve opens, pressure should be

approximately 6900 kPa (1000 psi). To

adjust pressure, turn relief valve adjusting screw (16-F ig. 39), located in

valve housing, clockwise to increase

pressure or counter-clockwise to reduce

pressure.

17.

R&R AND OVERHAUL. To

remove booster unit, first disconnect

hydraulic hoses and drain oil. Disconnect

drag link end from booster unit. Disconnect booster unit from front mounting

bracket and pitman arm and remove

from tractor.

To disassemble unit, first move piston

rod in and out of cylinder to drain oil.

Remove retainer ( 1-Fig. 39) and dust

16

SHOP MANUAL

I

seal (2) from spool housing (4). Remove

retaining cap screws, then separate

spool valve assembly, valve housing and

cylinder assembly. Remove nut (19)

securing valve spool, then separate

valve spool, center spring (15) and retainers (14) from actuator rod (9).

Remove stud adjusting screw (6), spring

(7),

seats (8), stud (3) and sleeve (10)

from housing

(4).

Count number of turns

required to remove relief valve adjuster

screw (16) from valve body. Unscrew

piston rod retainer (25) and withdraw

piston and rod assembly. Remove and

discard all seals and "0" rings.

Clean and inspect all parts for excessive wear, scoring or other damage.

Renew components which do not meet

following specifications: Maximum

allowable clearance between valve spool

and housing is 0.04 mm (0.0016 inch).

Maximum allowable clearance between

piston and cylinder bore should not exceed 0.2 mm (0.008 inch).

To reassemble booster unit, reverse

the disassembly procedure. Renew all

seals and "0" rings. Lubricate all parts

with clean hydraulic oil prior to

reassembly. Tighten cylinder rod end

(25) to torque of 79-98 N-m (60-70

ft.-lbs.).

When reinstalling relief valve

assembly, turn adjuster screw into valve

Fig. 39A—TO check relief

vaive opening pressure on

booster type

steering^

Install

a pressure gage in valve

housing test port as shown.

Refer to text

body same number of turns required for

removal. Apply light coat of grease to

valve sleeve and ball stud (3). Reassemble valve spool and centering spring being careful not to damage "0" ring in cap

(12).

Tighten retaining nut to a torque of

7.8 N-m (70 in.-lbs.) Assemble actuator

housing, valve housing and cylinder

assembly and tighten mounting cap

screws evenly to a torque of 19.6 N-m

(15 ft.-lbs.).

To reinstall booster unit, reverse the

removal procedure. Operate steering in

both directions several times to purge

air from system. Check and adjust relief

valve pressure setting as outlined in

paragraph 16.

STEERING PUMP

18.

Hydraulic power supply for

power steering system on Models L235,

L275 and L305 is the hydraulic system

pump mounted on right side of engine.

Pump output is first routed to a flow

divider valve which directs a priority

flow of

oil

to power steering, the remaining pump flow is directed to hitch control valve.

On Models L345 and L355, a separate

hydraulic pump is used for steering

Paragraphs 18-20

system. The pump is mounted in tandem

behind hydraulic hitch system pump. All

pumps are located on right side of

engine and are driven by engine fuel

camshaft.

All Models So Equipped

19.

PRESSURE TEST. To check

pump discharge pressure, disconnect

pump pressure outlet pipe and connect a

20000 kPa (3000 psi) pressure gage with

flow control valve as shown in Fig. 40 or

41.

Direct return hose from flow control

valve back into reservoir.

CAUTION:

With test equipment connected as outlined, pressure reiief vaive

wiil be eiiminated. BE SURE fiow controi

vaive is fuiiy open before starting engine.

DO NOT ciose controi vaive further after

specified pressure is reached. Otherwise,

pump damage wiii occur.

With flow control valve open, start

engine and operate until fluid reaches

operating temperature. Set engine

speed at 2600 rpm., then slowly close

flow control valve until pump delivery

pressure is within range of 13250-14700

kPa (1920-2130 psi). If specified

pressure cannot be obtained, hydraulic

pump should be removed and repaired

or renewed.

Models L235, L275 and L305

20.

R&R AND OVERHAUL. To

remove hyd rau lic p ump , fir st

thoroughly clean pump and hydraulic

lines.

Disconnect hydraulic lines from

pump. Remove pump mounting cap

screws and withdraw pump assembly.

On Models L235 and L275, remove

hydraulic filter and base. On all models,

place a scribe mark across pump sections,

then remove end cover (10-Fig.

42 or 43). Carefully separate pump com-

Fig. 40—Pressure gage and

flow control valve connected

to check hydraulic pump

discharge pressure on

Modeis L235, L275 and L305.

1.

H ydraul ic pu mp

2.

I*r(.'ssure gag e

'A. F^low co ntrol val ve

4.

R etur n to res ervoir

Fig. 41—On Models L345 and L355, connect test

gage and fiow control vatve as shown to check

output of steering pump (2).

17

Paragraph 21

KUBOTA

ponents noting location so parts can be

reinstalled in their original position.

Remove oil seal from pump front plate if

renewal is necessary.

Inspect all parts for excessive wear,

scoring or other damage. The only parts

available are seal rings and front oil seal.

Renew pump if the following specifications are not met. Clearance between

gear outside diameter and case inside

diameter should not exceed 0.15 mm

(0.006 inch). Maximum allowable

clearance between bushing and gear

shaft is 0.12 mm (0.005 inch).

Lubricate all parts with clean oil during reassembly. Renew all seal rings and

front oil seal. Assemble pump sections

aligning match marks made during

disassembly. Tighten end cover mounting cap screws evenly to a torque of

32-39 N-m (24-29 ft.-lbs.).

Be sure oil supply and discharge tube

"0"

rings are in place when reconnecting

to pump. Check fluid level of reservoir

and add recommended hydraulic oil if

necessary. Start engine and turn steering from side to side to purge air from

system.

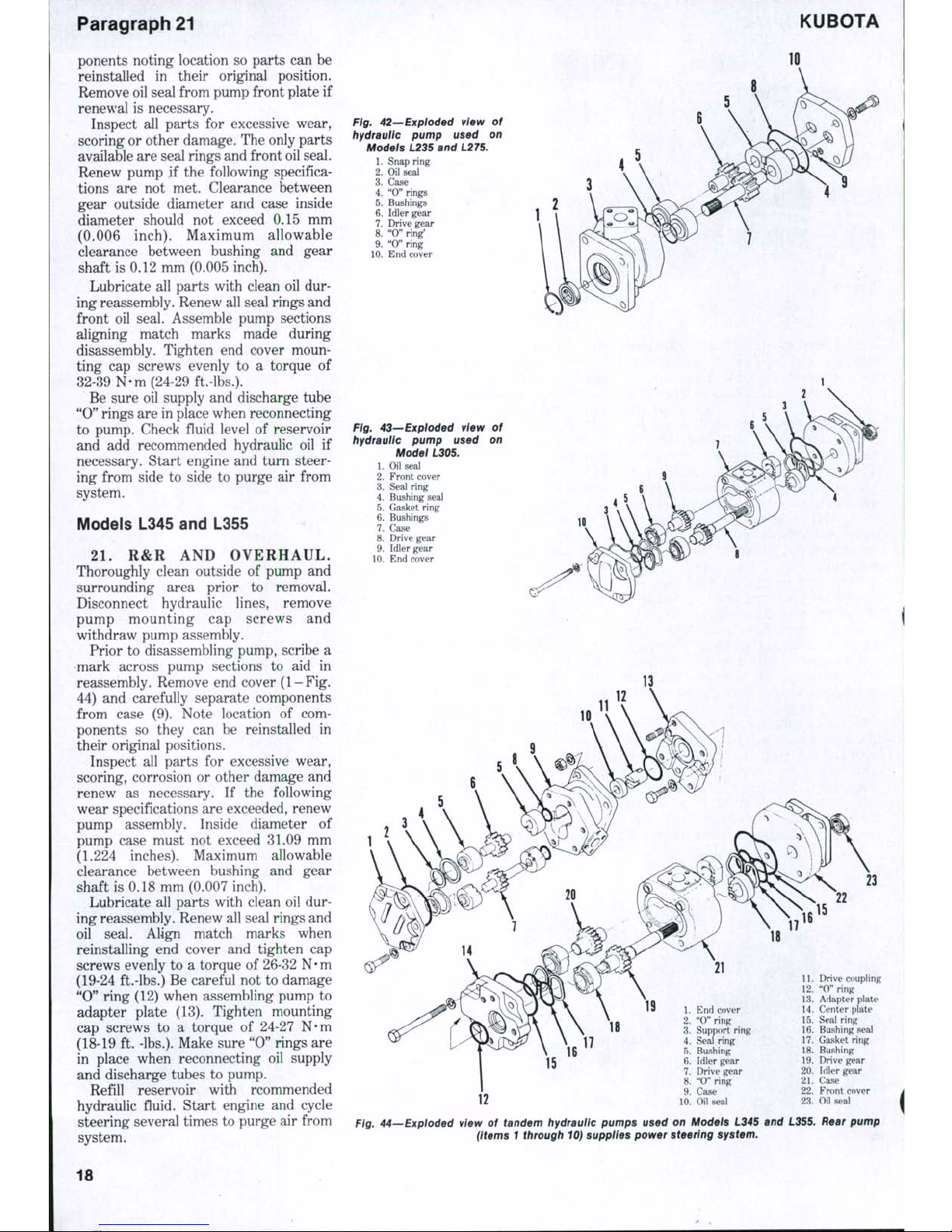

Models L345 and L355

21.

R&R AND OVERH AUL .

Thoroughly clean outside of pump and

surrounding area prior to removal.

Disconnect hydraulic lines, remove

pump mounting cap screws and

withdraw pump assembly.

Prior to disassembling pump, scribe a

mark across pump sections to aid in

reassembly. Remove end cover (1- Fig.

44) and carefully separate components

from case (9). Note location of components so they can be reinstalled in

their original positions.

Inspect all parts for excessive wear,

scoring, corrosion or other damage and

renew as necessary. If the following

wear specifications are exceeded, renew

pump assembly. Inside diameter of

pump case must not exceed 31.09 mm

(1.224 inches). Maximum allowable

clearance between bushing and gear

shaft is 0.18 mm (0.007 inch).

Lubricate all parts with clean oil during reassembly. Renew all seal rings and

oil seal. Align match marks when

reinstalling end cover and tighten cap

screws evenly to a torque of 26-32

N • m

(19-24 ft.-lbs.) Be careful not to damage

"0"

ring (12) when assembling pump to

adapter plate (13). Tighten mounting

cap screws to a torque of 24-27 N-m

(18-19 ft. -lbs.). Make sure "0" rings are

in place when reconnecting oil supply

and discharge tubes to pump.

Refill reservoir with rcommended

hydraulic fluid. Start engine and cycle

steering several times to purge air from

system.

Fig. 42—Expioded view of

hydraulic pump used on

Models 1235 and L275.

1.

Snap ring

2.

Oil seal

3.

Case

4.

"0" rings

5.

Bushings >

6. Idler gear

7.

Drive gear

8. "0" ring'

9. "O"ring

10.

End cover

Ftg. 43—Exploded vtew of

hydraulic pump used on

Model L305.

1.

Oil seal

2.

Front cover

3.

Seal ring

4.

Bushing seal

5.

Gasket ring

6. Bushings

7.

Case

8. Drive gear

9. Idler gear

10.

End cover

IS

15

16

1.

End cover

2.

"0" ring

3.

Support ring

4.

Seal ring

5.

Bushing

6. Idler gear

7.

Drive gear

8. "0" ring

9. Case

10.

Oil seal

11.

Drive coupling

12.

"0" ring

13.

Adapter plate

14.

Center plate

15.

Seal ring

16.

Bushing seal

17.

Gasket ring

18.

Bushing

19.

Drive gear

20.

Idler gear

21.

Case

22.

Front cover

23.

Oil seal

Fig. 44—Expioded vtew of tandem hydrauiic pumps used on Models L345 and L355. Rear pump

(Items 1 through 10) supplies power steering system.

18

SHOP MANUAL

Paragraphs 22-24

ENGINE AND COMPONENTS

R&R ENGINE

All Models

22.

To remove engine and clutch as a

unit, first drain cooling system, engine

oil,

transmission oil, power steering

reservoir (if equipped) and front wheel

drive differential housing (if equipped).

Remove front axle assembly as follows:

Remove hood, side panels and upper

support rail (if equipped), muffler and

battery. Disconnect radiator hoses and

air cleaner hose. Disconnect drag link

end using a suitable puller. On front

wheel drive models, unbolt and remove

drive shaft. On all models, support

tractor under clutch housing and support front end unit with a suitable hoist

or splitting stand. Remove front axle

bracket mounting cap screws, then roll

front end away from engine. To

separate engine from clutch housing,

disconnect wiring to engine as necessary

Disconnect fuel supply line, fuel return

line and hydraulic hoses and tubes.

Disconnect throttle control linkage,

engine stop rod (if equipped), hourmeter cable and decompression cable.

Support engine with a suitable hoist,

remove cap screws securing flywheel

housing to clutch housing and separate

engine from transmission.

To reinstall engine, reverse the

removal procedure. Tighten clutch housing mounting cap screws to a torque of

49-54 N-m (36-41 ft.-lbs.). Tighten front

axle bracket fasteners to the following

torques: MIO nut to 61-71 N-m (45-50

ft.-lbs.),

MIO bolt to 48-56 N-m (;-i6-41

ft.-lbs.) and M12 nut or bolt ot 78-90

N-m (58-66 ft.-lbs.).

CYLINDER HEAD

All Models

23.

To remove cylinder head, first

drain cooling system and disconnect battery cables. Remove hood, muffler and

side covers (if equipped). Remove upper

radiator hose, coolant return hose and

intake manifold hose. Disconnect decompressor control cable. Remove injection

lines and nozzle assemblies and cap all

exposed fittings to prevent entry of dirt.

Remove alternator adjusting bracket.

Remove valve lever cover. Remove

valve levers an(i shaft assembly and

withdraw push ro(is. Remove cap screws

and nuts securing cylinder head and lift

head off cylinder block.

One or more shims may he installed

between gasket and cylinder head to ad-

just clearance between cylinder head

and piston tops. Identify shims when

cylinder head is removed, then install an

equal number of shims when head is

reinstalled. To check piston to head

clearance, insert a soft lead wire

through injection nozzle holder hole.

Rotate crankshaft by hand until lead

wire is fiattened by piston top. Measure

thickness of fiattened wire to determine

top clearance which should be 0.7-0.9

mm (0.028-0.035 inch).

NOTE:

Because of minimum amount of

clearance that exists between vaives and

piston tops, ioosen vaive iever adjusting

screws before reinstailing vaive ievers

and shaft assembiy to prevent possibie

damage to vaives.

Check cylinder head surface for

distortion using a straightedge and

feeler gage. If a 0.05 mm (0.002 inch)

feeler gage can be inserted between

cylinder head and straightedge, head

surface should be refaced with a surface

grinder. A maximum of 0.5 mm (0.020

inch) of material may be removed to true

cylinder head surface. Refer to

paragraph 25 for valve head recession

specifications.

When installing cylinder head, use

new head gasket and install shims (if used) between gasket and cylinder head.

Be sure sealing surfaces are clean and

dry. Apply light coat of engine oil to

threads of retaining nuts and cap

screws. Tightening torque on all models

is 73.5-78.4 N-m (55-58 ft.-lbs.). On all

models, tighten nuts and cap screws

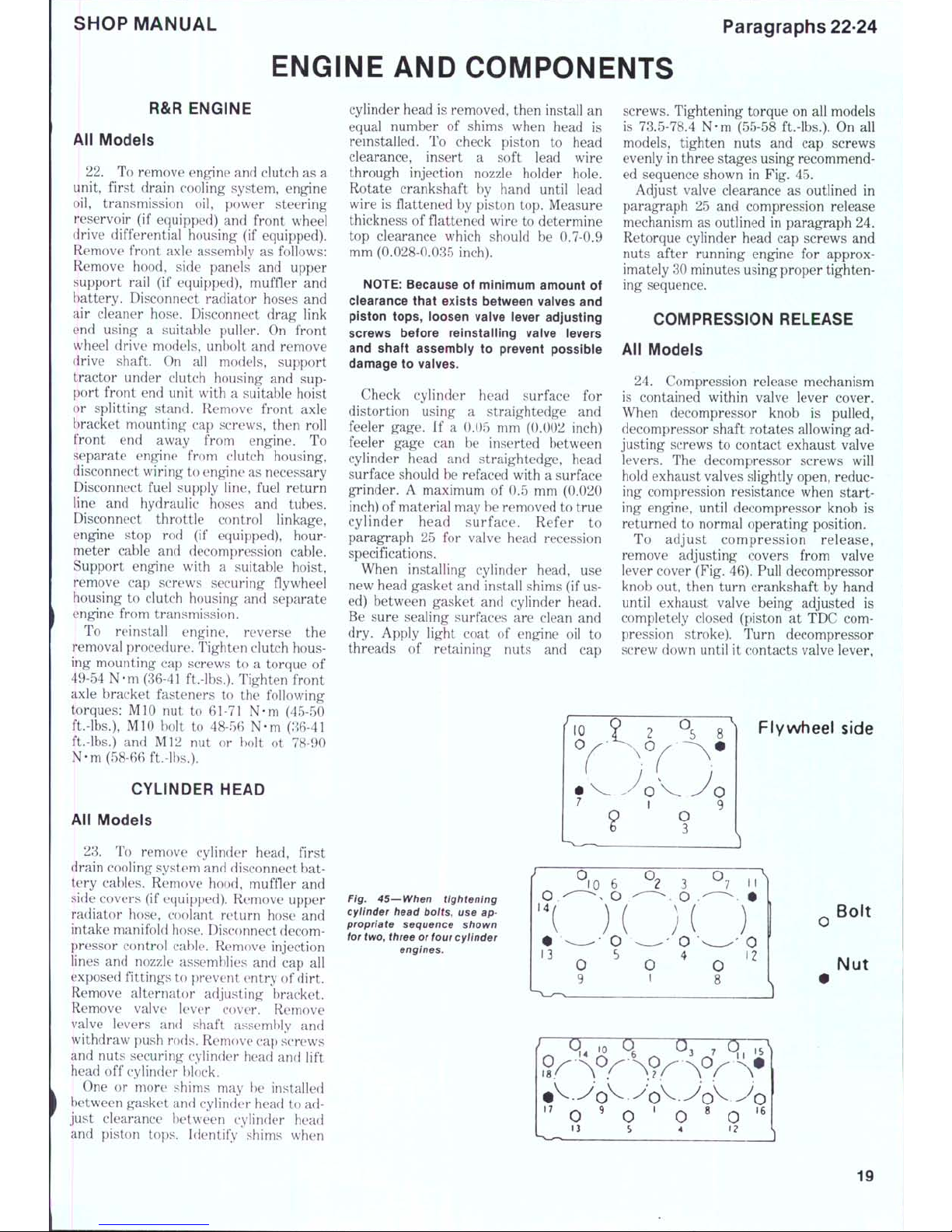

evenly in three stages using recommended sequence shown in Fig. 45.

Adjust valve clearance as outlined in

paragraph 25 and compression release

mechanism as outlined in paragraph 24.

Retorque cylinder head cap screws and

nuts after running engine for approximately 30 minutes using proper tightening sequence.

COMPRESSION RELEASE

All Models

24.

Compression release mechanism

is contained within valve lever cover.

When decompressor knob is pulled,

decompressor shaft rotates allowing ad-

justing screws to contact exhaust valve

levers. The decompressor screws will

hold exhaust valves slightly open, reducing compression resistance when starting engine, until decompressor knob is

returned to normal operating position.

To adjust compression release,

remove adjusting covers from valve

lever cover (Fig. 46). Pull decompressor

knob out, then turn crankshaft by hand

until exhaust valve being adjusted is

completely closed (piston at TDC compression stroke). Turn decompressor

screw down until it contacts valve lever.

Flywheel side

Fig. 45—When tightening

cyiinder head boits, use appropriate sequence shown

for two, three or four cylinder

engines.

Bolt

Nut

19

Paragraphs 25-26

KUBOTA

Compression release

position

Ftg. 46—Cross-sectional

view of decompressor mechanism and adjustment point

0.750 to 1.125mm

0.0295 to 0.0443 in.

then turn screw down an additional 1 to

IV2 turns to obtain specified valve opening of 0.750-1.125 mm (0.030-0.044

inch).

Tighten locknut while holding ad-

justing screw. Repeat adjustment pro-

cedure for remainder of exhaust valves.

NOTE:

After adjustment is completed,

puil knob out and turn cranlcshaft by hand

to make certain valves do not contact

piston tops.

VALVES AND SEATS

All Models

25.

Intake and exhaust valves are

not interchangeable. All valves seat

directly in cylinder head. Valve face and

seat angles are 45 degrees for all valves.

Recommended valve seat width is 2.1

mm (0.080 inch). Valve stem diameter is

7.960-7.975 mm (0.3134-0.3140 inches)

t

for all valves. Face of valves should be

recessed

1.1-1.3

mm (0.043-0.051 inch)

below surface of cylinder head. Maximum allowable recession is 1.6 mm

(0.063 inch).

Whenever valves are renewed or

reseated, be sure to adjust compression

release mechanism as previously outlined.

Valve clearance, gap between valve

stem end and valve lever, is adjusted

with engine cold on all models. Recommended g ap is 0.18-0.22 mm

(0.007-0.009 inch) for both intake and

exhaust on all models.

CAUTION:

Due to close ciearance between valves a pistons, severe damage

can resuit from inserting feeler gage be-

tween vaive stem and vaive iever with

engine running. DO NOT attempt to adjust

vaive clearance with engine running.

To adjust valve clearance, proceed as

follows: Loosen valve lever adjusting

screw locknuts. Rotate crankshaft by

hand to position number one piston at

top dead center of compression stroke.

Using a feeler gage to measure

clearance, adjust valves for number one

cylinder. Adjust remaining valves in se-

quence of firing order after positioning

each piston at top dead center of compression stroke.

VALVE GUIDES

All Models

26.

Intake and exhaust valve guides

are semi-finished and must be reamed

after installation in cylinder head. Intake and exhaust valve guides are not in-

terchangeable as exhaust guide is

equipped with a "carbon scraper" at

lower end of guide (Fig. 47). Press new

guides into cylinder head until guide

shoulder is seated against surface of

head. All models are equipped with cuptype stem seals which fit over stem end

of valve guide.

Desired operating clearance of valve

stem in guide is 0.04-0.07 mm

(0.0016-0.0028 inch). Maximum

14

Fig. 48—Exploded vtew of

valves and valve lever

assembly.

1.

Intake valve

2.

Exhaust valve

3.

Valve stem seal

4.

Spring

5.

Retainer

6. Keepers

7.

Cap

8. Snap ring

9. Washer

10.

Bushing

11.

Adjusting screw

12.

Spring

13.

Valve lever

14.

Bracket

15.

Shaft

10

Fig. 47—Exhaust valve guide is equipped with a

"carbon scraper" (C) and is not interchangeable

with Intake guide. Note scraper area when

measuring inside diameter

(A

and B) of guides.

20

Loading...

Loading...