Page 1

WORKSHOP MANUAL

KiSC issued 08, 2015 A

KUBOTA EXCAVATOR

KX080-4

Page 2

CONTENTS

KiSC issued 08, 2015 A

TO THE READER

TO THE READER

I INFORMATION

CONTENTS

INFORMATION

1. SAFETY FIRST ............................................ I-1

2. IN THE INTEREST OF WORK

SAFETY........................................................ I-2

3. LABELS DISPLAYED TO PROMOTE

WORK SAFETY............................................ I-6

4. MAIN SPECIFICATIONS ............................ I-12

5. DIMENSIONS ............................................. I-13

G GENERAL

CONTENTS

GENERAL

1. CHECKING EXCAVATOR

IDENTIFICATION ........................................G-1

2. ENGINE IDENTIFICATION .........................G-2

3. MUFFLER FULL ASSEMBLY

IDENTIFICATION ........................................G-5

4. GENERAL PRECAUTIONS.........................G-7

5. HANDLING PRECAUTIONS FOR

ELECTRICAL PARTS AND WIRING.........G-11

6. TIGHTENING TORQUES ..........................G-16

7. OIL AND WATER CAPACITY TABLE .......G-20

8. MAINTENANCE INTERVALS....................G-21

1 MACHINE BODY

CONTENTS

SERVICING

1. FRONT ...................................................... 1-S1

2. SWIVEL FRAME........................................ 1-S8

3. TRACK FRAME ....................................... 1-S22

4. MEASURING MACHINE

PERFORMANCE ..................................... 1-S38

5. SWIVEL GEAR BACKLASH

PERFORMANCE ..................................... 1-S40

2 ENGINE

CONTENTS

GENERAL

1. SPECIFICATIONS.....................................2-G1

2. DIMENSIONS ............................................2-G2

3. PERFORMANCE CURVES .......................2-G3

4. FAN DRIVE................................................2-G4

3 HYDRAULIC SYSTEM

CONTENTS

MECHANISM

1. DIAGRAM OF HYDRAULIC CIRCUIT...... 3-M1

2. HYDRAULIC DEVICE LAYOUT ............... 3-M3

3. PUMP ....................................................... 3-M4

4. CONTROL VALVE.................................. 3-M12

5. SWIVEL MOTOR.................................... 3-M29

6. TRAVEL MOTOR ................................... 3-M34

7. HYDRAULIC CYLINDER ........................ 3-M39

8. PILOT VALVE......................................... 3-M42

9. SHOCKLESS VALVES........................... 3-M52

10. SOLENOID VALVE................................. 3-M54

SERVICING

1. PUMP......................................................... 3-S1

2. CONTROL VALVE................................... 3-S17

3. SWIVEL MOTOR ..................................... 3-S26

4. SWIVEL JOINT ........................................ 3-S41

5. TRAVEL MOTOR..................................... 3-S49

6. CYLINDER............................................... 3-S69

7. PILOT VALVE .......................................... 3-S71

8. SHOCKLESS VALVES .......................... 3-S106

9. SWIVEL SHUTTLE VALVE ................... 3-S107

10. SOLENOID VALVE ................................ 3-S108

11. ROUTING OF HYDRAULIC HOSES .....3-S112

12. MEASURING HYDRAULIC DEVICE

PERFORMANCE ................................... 3-S133

13. HYDRAULIC DEVICE

PERFORMANCE STANDARDS............ 3-S158

14. TROUBLESHOOTING ........................... 3-S165

4 ELECTRICAL SYSTEM

CONTENTS

SERVICING

1. LAYOUT OF ELECTRICAL DEVICES

AND WIRING ROUTING ........................... 4-S1

2. METER PANEL OPERATION ................. 4-S10

3. INSPECTIONS......................................... 4-S44

4. TROUBLESHOOTING (START-UP

EQUIPMENT VERSION) .........................4-S50

5. METHODS FOR DIAGNOSING

ERRORS.................................................. 4-S51

6. TROUBLESHOOTING (METER

PANEL VERSION)................................... 4-S53

5 CABIN

CONTENTS

MECHANISM

1. AIR CONDITIONING SYSTEM................. 5-M1

2. WIPER .................................................... 5-M17

SERVICING

1. TROUBLESHOOTING............................... 5-S1

2. SERVICE SPECIFICATIONS .................... 5-S4

3. TORQUE.................................................... 5-S5

4. PRECAUTIONS WHEN REPAIRING

THE REFRIGERANT SYSTEM ................. 5-S6

5. INSPECTING AND CHARGING THE

REFRIGERANT SYSTEM ....................... 5-S11

6. INSPECTION AND DISASSEMBLY ........5-S20

7. WINDOW WASHER ................................ 5-S36

8. CABIN GLASS REMOVAL AND

MOUNTING ............................................. 5-S38

9. REMOVAL AND INSTALLATION OF

GLASS ..................................................... 5-S52

10. FRONT WINDOW .................................... 5-S57

Page 3

TO THE READER

NOTE

IMPORTANT

KiSC issued 08, 2015 A

This Workshop Manual provides service personnel with information about the mechanisms, service

and maintenance of the construction machinery. This Workshop Manual is divided into 3 sections,

General, Mechanisms and Service.

General

This section contains information such as engine and equipment ID numbers, general precautions,

maintenance schedules, inspections and maintenance items and special tools.

Mechanisms

This section describes the structure of mechanisms and explains their functions.Be sure that you

fully understand this Mechanisms section prior to performing any service work, such as troubleshooting

or when performing any disassembly or assembly work.

Service

This section contains information and procedures for performing maintenance on the backhoe, such

as troubleshooting, service specification tables, torque specifications, items to be inspected and

adjusted, disassembly and assembly procedures, as well as precautions, maintenance standard values

and usage limits.

All of the illustrations, specifications and other information in this manual were created based on the

latest model at the time of publication.

Please be aware that changes to the content may be made without prior notice.

• Corresponding model list

Machine Model Engine Model

KX080-4 V3307-CRS-T4

• Refer to the information of the engine below.

• Engine model : V2607-CR-E4B, V2607-CR-TE4B, V3307-CR-TE4B

• Web PDF-Code : No.9Y111-06740

• Hard Copy-Code : No.9Y121-06740

• CD-ROM-Code : No.9Y131-06740

© KUBOTA Corporation 2013

January, 2013

Page 4

Record of Revisions

KiSC issued 08, 2015 A

Last digit of

the Code

No.

Date Main Revised Point and Corrective Measures Remarks

1 2015.08.05

2

3

4

• Add the contents of pump assembly and disassembly,

the contents of cabin glass removal and mounting.

S. M

Page 5

I INFORMATION

KiSC issued 08, 2015 A

Page 6

INFORMATION

KiSC issued 08, 2015 A

CONTENTS

1. SAFETY FIRST .............................................................................................................................. I-1

2. IN THE INTEREST OF WORK SAFETY ........................................................................................ I-2

[1] WORKING SAFELY WITH THE EQUIPMENT MEANS ALWAYS FOLLOWING

THESE INSTRUCTIONS:......................................................................................................... I-2

(1) Precautions Before Working on the Machine ..................................................................... I-2

(2) Precautions Before Working on the Equipment.................................................................. I-3

3. LABELS DISPLAYED TO PROMOTE WORK SAFETY................................................................. I-6

[1] LOCATIONS ............................................................................................................................. I-6

[2] LABEL MAINTENANCE ......................................................................................................... I-11

4. MAIN SPECIFICATIONS.............................................................................................................. I-12

5. DIMENSIONS ............................................................................................................................... I-13

Page 7

KX080-4, WSM

SAFETY FIRST

DANGER

WARNING

CAUTION

IMPORTANT

NOTE

KiSC issued 08, 2015 A

INFORMATION

1. SAFETY FIRST

• This "Safety Alert Symbol" is used in this manual and on labels on equipment to indicate important

issues and warn of the danger of personal injury. Read and follow these warnings carefully.

• It is important that you thoroughly read these instructions and safety rules prior to working on the

equipment and that you always follow them.

• Indicates that failure to follow the warning will result in serious injury or death.

• Indicates that failure to follow the warning may result in serious injury or death.

• Indicates that failure to follow the warning may result in injury.

• Indicates that failure to follow the warning may result in damage to or a breakdown of the equipment.

• Indicates supplementary explanations that will be helpful when using the equipment.

[NOTE]

• Indicates other supplementary information to take note of.

RY9212001INI0001US0

I-1

Page 8

KX080-4, WSM

KiSC issued 08, 2015 A

INFORMATION

2. IN THE INTEREST OF WORK SAFETY

[1] WORKING SAFELY WITH THE EQUIPMENT MEANS ALWAYS

FOLLOWING THESE INSTRUCTIONS:

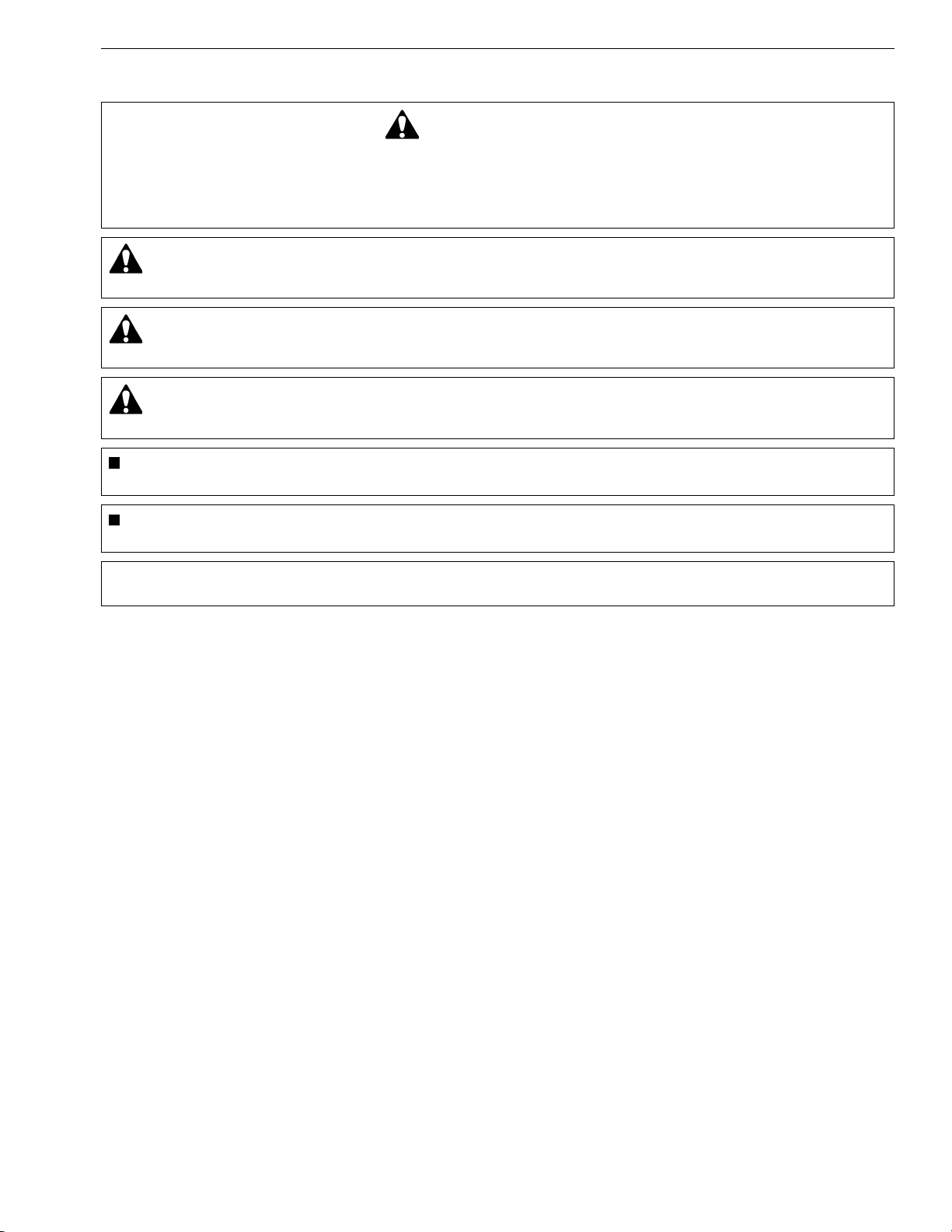

(1) Precautions Before Working on the Machine

Before starting any service or maintenance work

• Read all the general and safety instructions in this

manual, as well as the decals on your equipment.

• Always stop the engine whenever you leave the

driver's seat to inspect or clean the machine or its

devices, or to inspect or adjust parts.

• Choose a safe spot for inspecting the equipment-on

flat, hard ground.

RY9212001INI0002US0

• When performing maintenance on the equipment,

hang the DO NOT OPERATE sign where it will be

obvious from and around the driver's seat.

• When performing maintenance or repairs, always

lower attachments to the ground, stop the engine

and set the brake.

• When performing maintenance on the equipment,

always disconnect the negative battery cable.

• Before using tools, make sure you understand how

to use them correctly and use tools in good condition

and of the right size for the job.

RY9212001INI0003US0

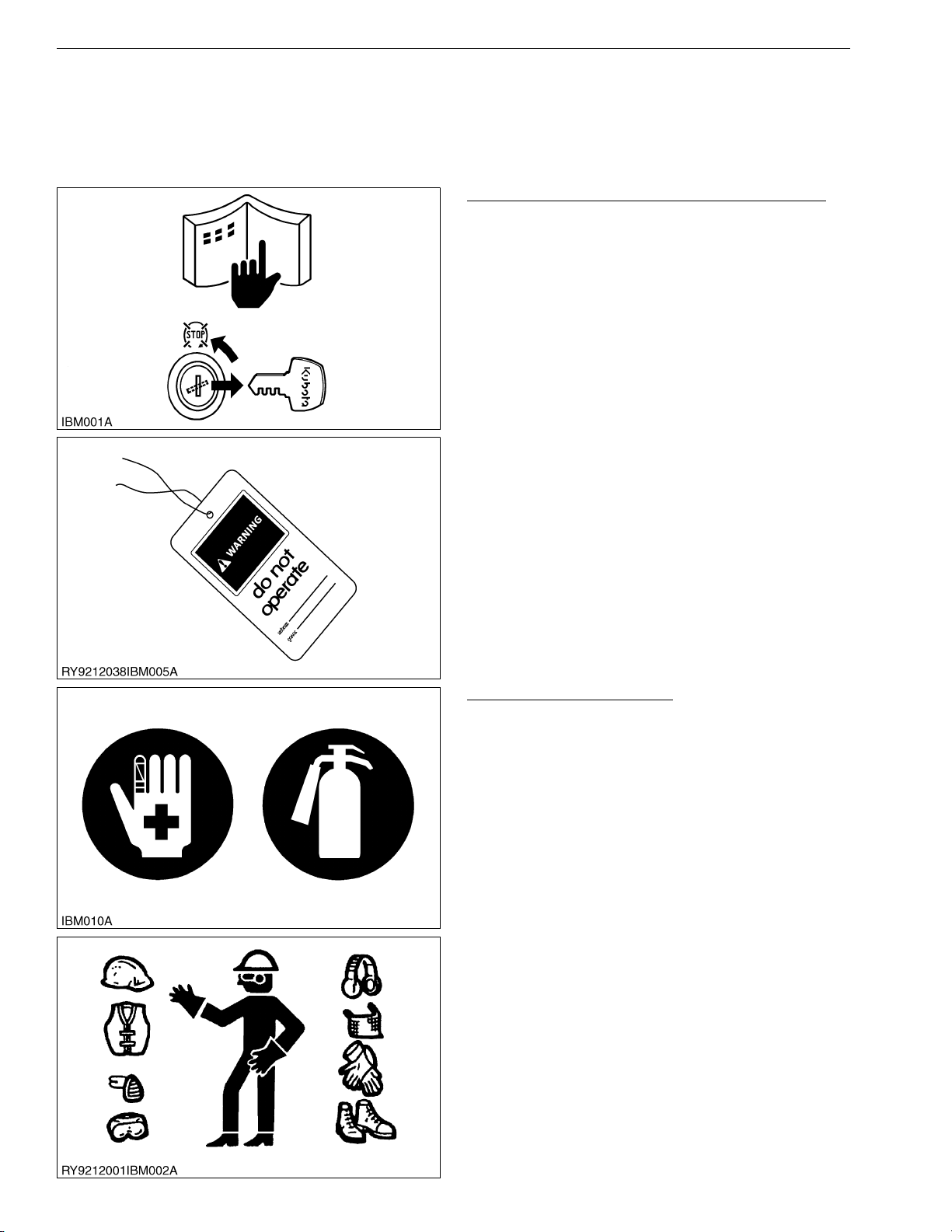

Be Ready for an Emergency

• Keep a first-aid kit and fire extinguisher close at hand

so you can use it when needed.

• Keep emergency contact information for doctors,

hospitals and ERs handy.

RY9212001INI0004US0

• Wear clothes appropriate for working on equipment.

Do not wear loose-fitting clothes as they may catch

on the machine controls.

• When working on the equipment, use all safety gear,

such as a helmet, safety glasses and shoes, that are

required by law or regulation.

• Never perform maintenance while drowsy or under

the influence of alcohol or drugs.

RY9212001INI0005US0

I-2

Page 9

KX080-4, WSM

CAUTION

KiSC issued 08, 2015 A

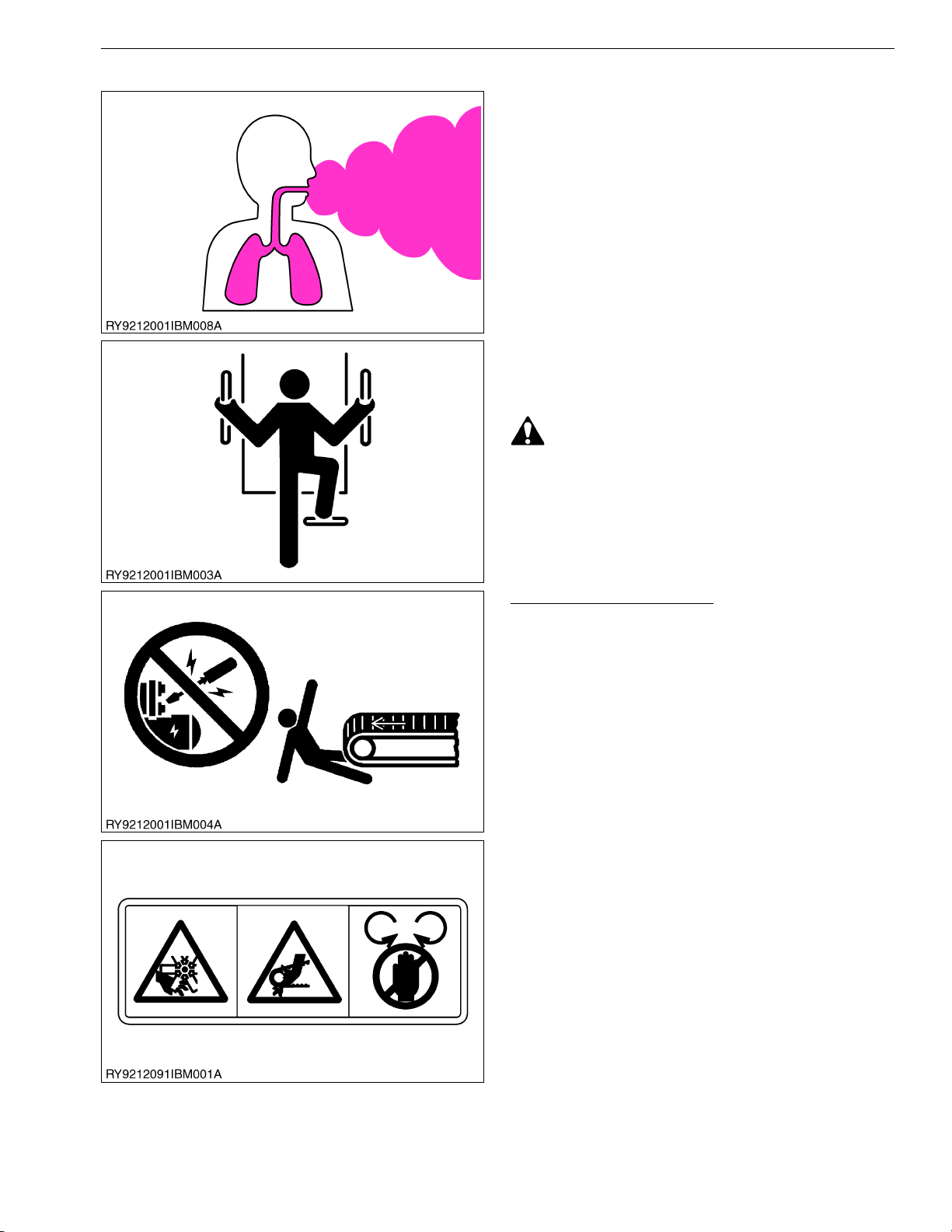

(2) Precautions Before Working on the Equipment

• Stop the machine on a hard and level location and

make sure the area around the machine is free of

obstacles and hazardous materials. When parking

the machine indoors, select a spot that can be

properly ventilated.

• When performing work such as with a hammer,

fragments may go flying, so make sure only

authorized persons are around the machine.

• Before servicing the machine, clean it off so there is

no mud, debris, oil or the like sticking to it.

• Before getting on/off of the machine, clean off

around the steps so there is no mud on them.

Always give yourself 3-point support when getting

on/off the machine.

• 3-point support means using both legs and one

hand or both hands and one leg as you climb

up/down.

INFORMATION

RY9212001INI0006US0

RY9212001INI0007US0

Starting the Machine Safely

• Before starting the engine, always sit in the driver's

seat and make sure the area is safe and clear.

• As it is dangerous, never start the engine from

anywhere but the driver's seat.

• Always check and make sure control lever(s) are not

engaged before starting the engine.

• Never start the engine by hot-wiring the starter

circuit. This is not only dangerous, but may damage

the machine.

RY9212001INI0008US0

• Whenever it is necessary to open the engine covers

or hood in order to service the machine, always prop

them open.

• If it is absolutely necessary to run the engine while

working on the machine, make sure you are clear of

all rotating or moving parts. Also take care not to

leave anything, such as tools or rags, near any

moving parts.

RY9212001INI0009US0

I-3

Page 10

KX080-4, WSM

KiSC issued 08, 2015 A

INFORMATION

• The engine, muffler, radiator, hydraulic line, etc.,

have parts that remain very hot even after the engine

has been stopped. Be sure to avoid these parts, as

touching them can result in burns. Radiator coolant,

hydraulic fluid and oil also remain hot. Therefore, do

not attempt to remove caps and plugs, etc., before

these fluids have sufficiently cooled.

• Make sure the coolant temperature has dropped

sufficiently before opening the radiator cap.

Also, since the inside of the radiator is pressurized,

when removing the cap, first loosen it to release the

pressure before removing the cap completely.

RY9212001INI0016US0

• The pressure in the hydraulic circuit stays at

pressure even after the engine stops.

Before removing parts, such as hydraulic devices

from the machine, first release the pressure. Please

note that when releasing residual pressure, the

machine itself and/or implements may move without

warning, so be very careful when releasing the

pressure.

• Oil gushing out under pressure is extremely

dangerous as it may pierce your skin or your eyes.

Similarly, oil leaking out of pinholes is not visible.

So when checking for oil leaks, always wear safety

glasses and gloves and use a piece of cardboard or

a wood block to shield yourself from oil.

RY9212001INI0011US0

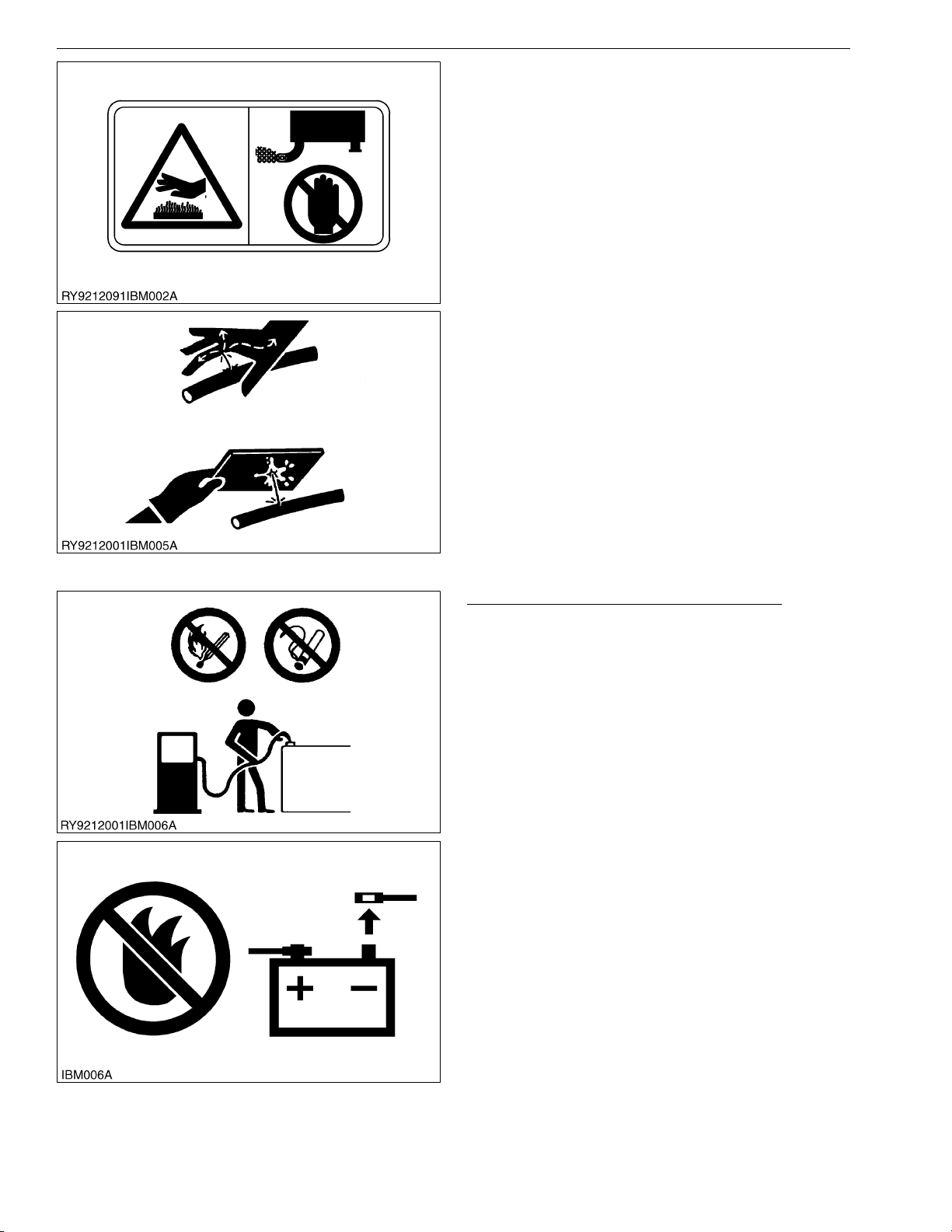

No Smoking or Open Flames while Fueling

• Fuel is extremely flammable and dangerous.

Never smoke near fuel. If fuel is spilled on the

machine, its engine, or electrical parts, it may cause

a fire. If fuel is spilled, wipe it all up immediately.

• Never smoke while filling the machine with fuel.

And always tighten the fuel cap securely and wipe up

any spilled fuel.

RY9212001INI0012US0

• Always wear safety glasses and gloves when

handling the battery.

• The gas generated by the battery is flammable.

Never weld or use tools like a grinder near the

battery. And never smoke near it.

• When disconnecting the battery, always disconnect

the negative cable first. When connecting the

battery, always connect the positive cable first.

RY9212001INI0013US0

I-4

Page 11

KX080-4, WSM

KiSC issued 08, 2015 A

INFORMATION

• Grease is under high pressure inside the hydraulic

cylinder. It is very dangerous to loosen a grease

nipple quickly as it may shoot off. Always loosen

grease nipples slowly.

• And never face a grease nipple while loosening it.

RY9212001INI0014US0

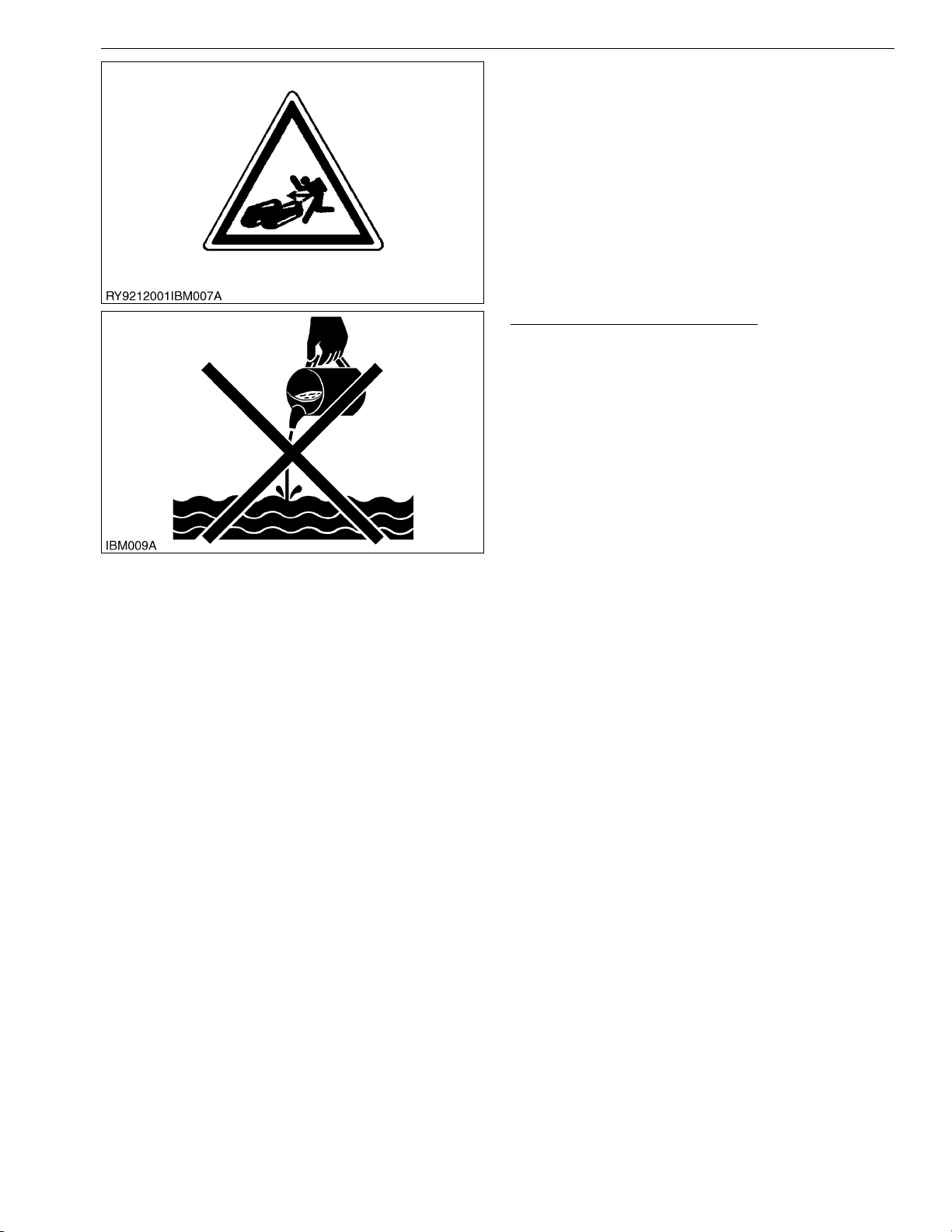

Dispose of Waste Fluids Properly

• Never dispose of waste fluids on the ground, in the

gutter, a river, pond or lake. Always dispose of

hazardous substances like waste oil, coolant and

electrolytic fluid in accordance with the relevant

environmental protection regulations.

• Keep the safety plates clean so they can be read.

If a safety plate is damaged and comes off or

becomes illegible, put a plate with the same

warnings back in its place.

RY9212001INI0015US0

I-5

Page 12

KX080-4, WSM

KiSC issued 08, 2015 A

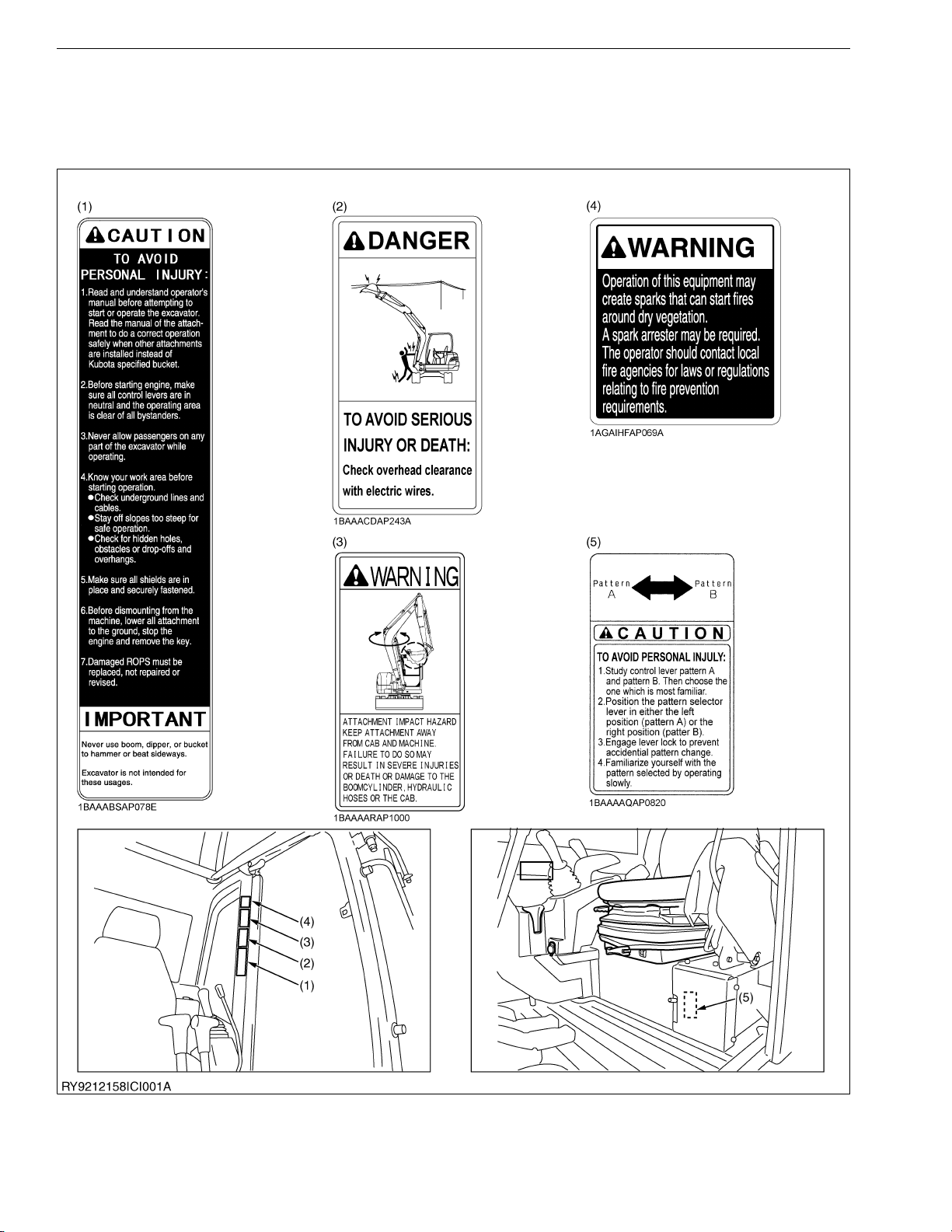

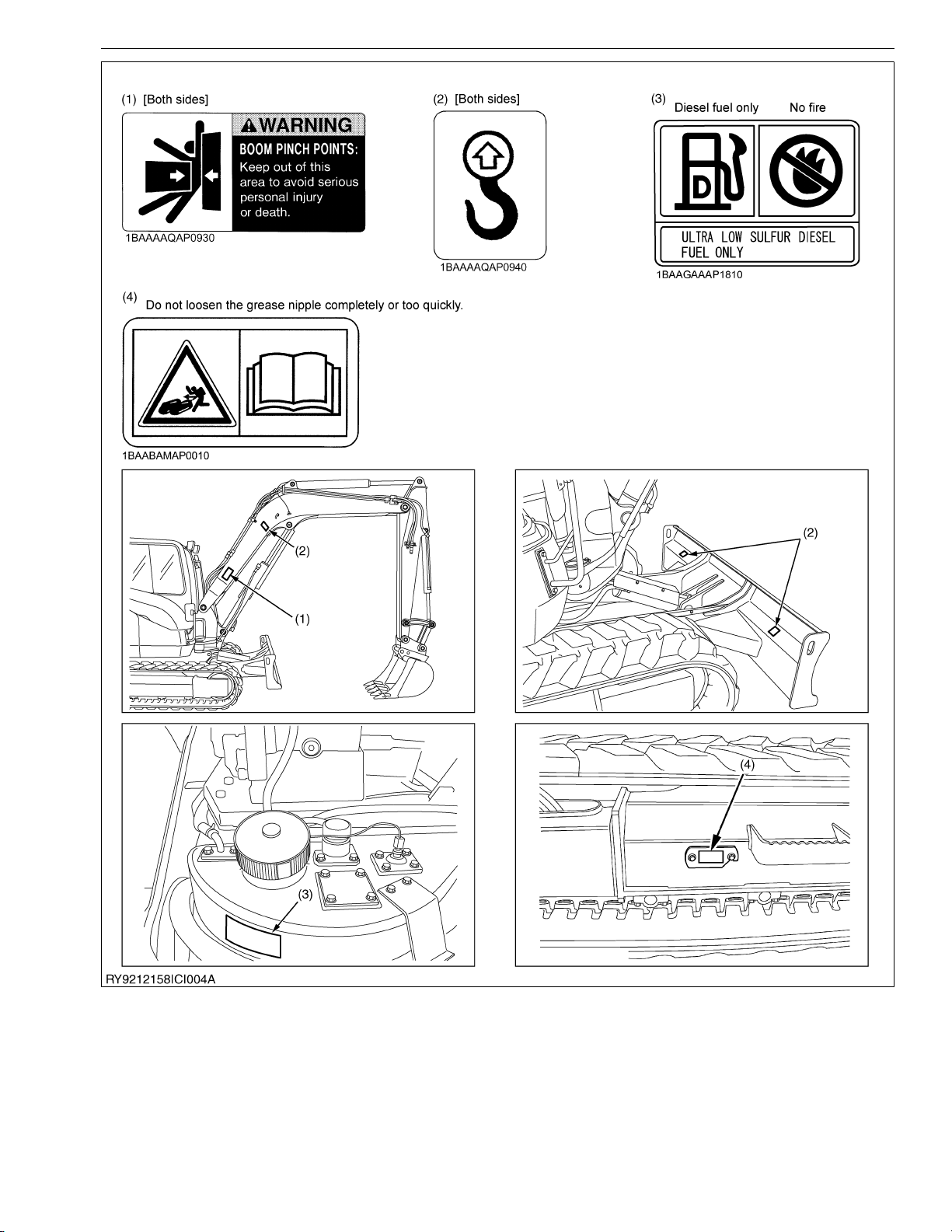

3. LABELS DISPLAYED TO PROMOTE WORK SAFETY

[1] LOCATIONS

INFORMATION

RY9212158INI0003US0

I-6

Page 13

KX080-4, WSM

KiSC issued 08, 2015 A

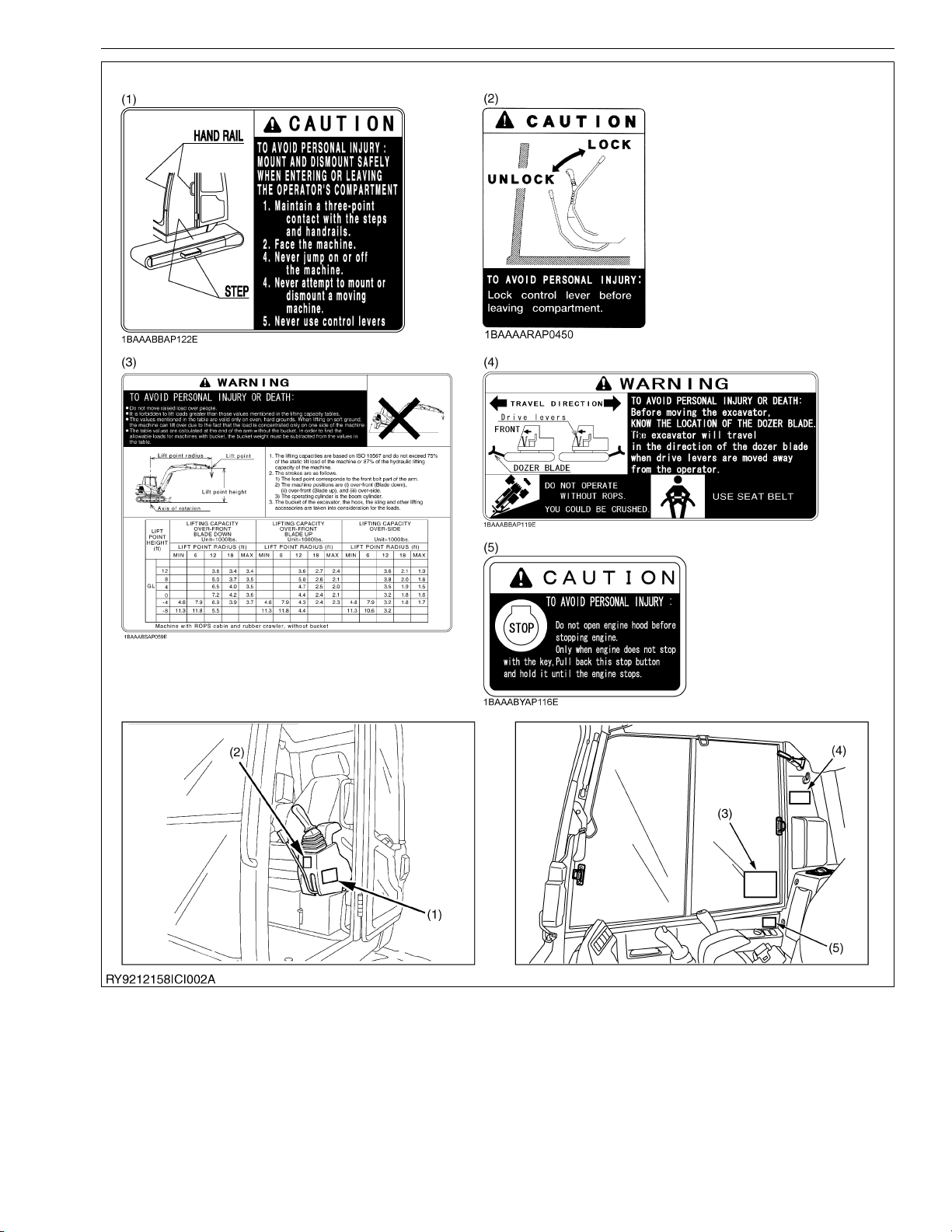

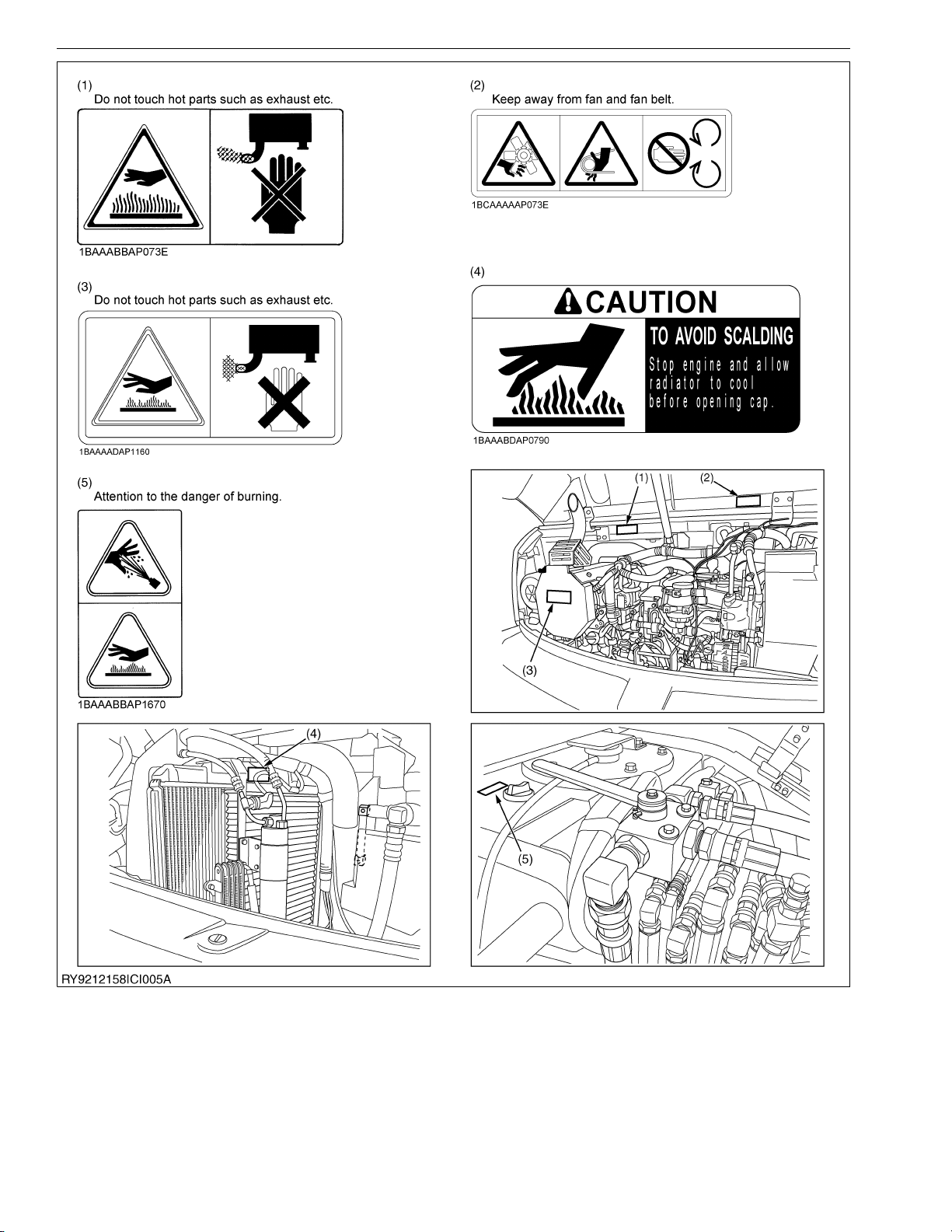

INFORMATION

RY9212158INI0004US0

I-7

Page 14

KX080-4, WSM

KiSC issued 08, 2015 A

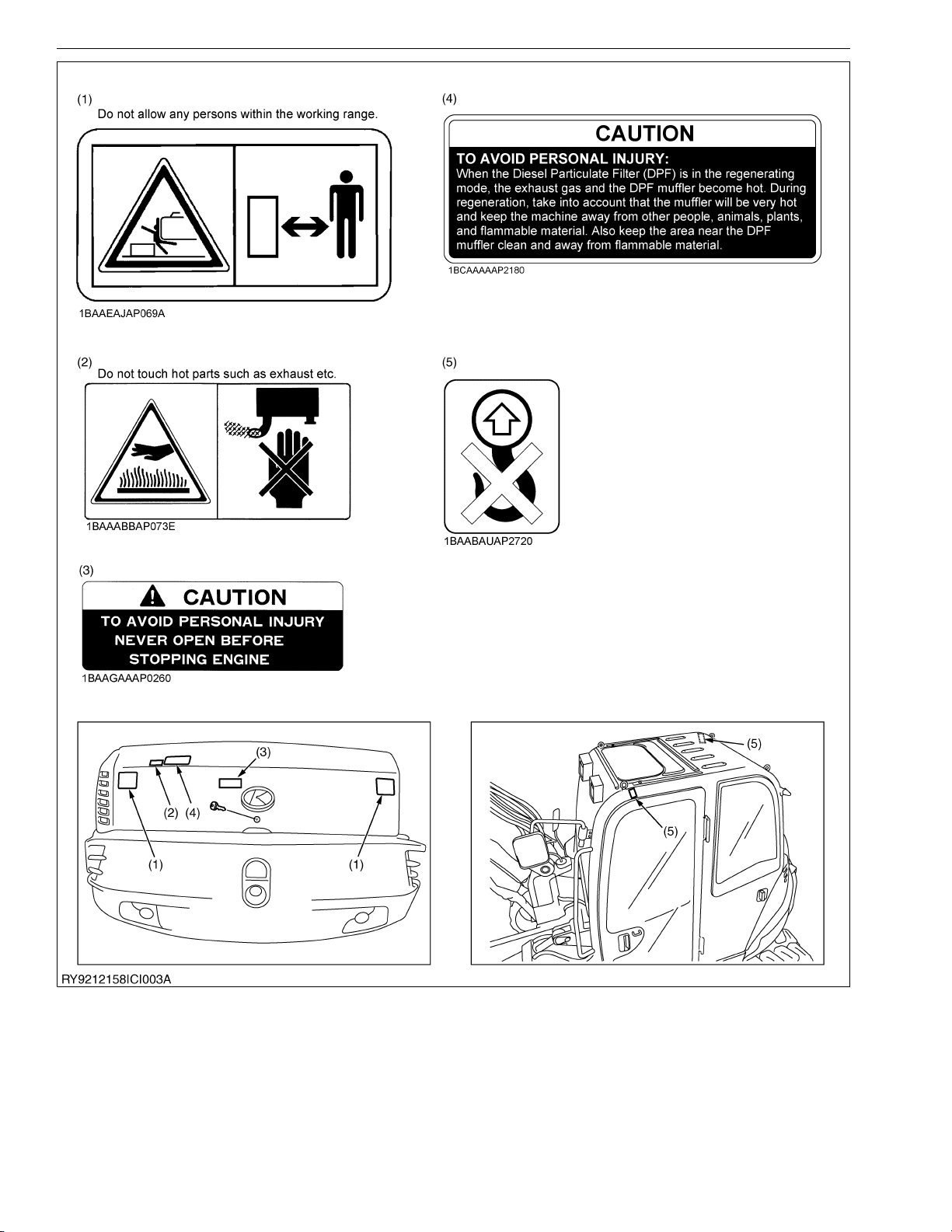

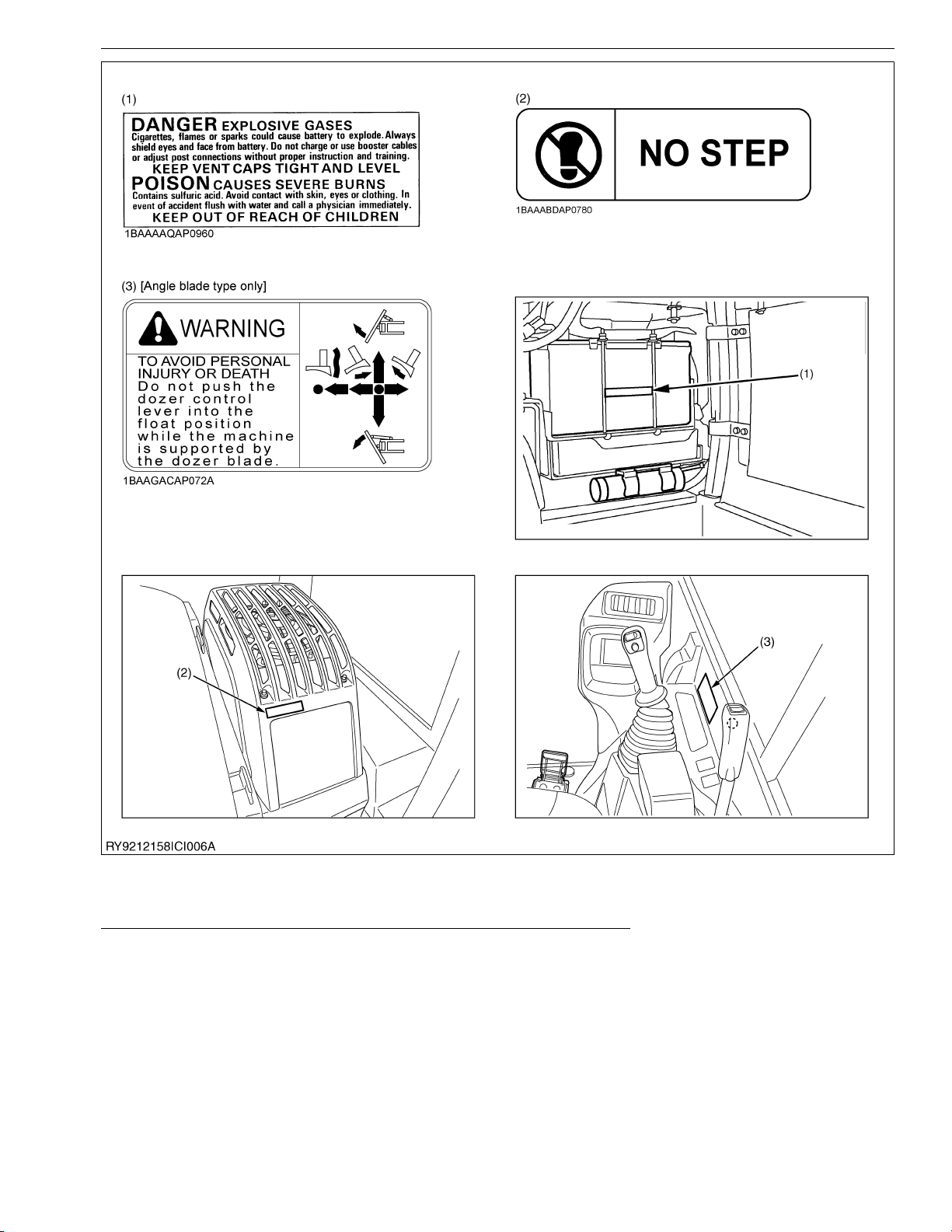

INFORMATION

RY9212158INI0005US0

I-8

Page 15

KX080-4, WSM

KiSC issued 08, 2015 A

INFORMATION

RY9212158INI0006US0

I-9

Page 16

KX080-4, WSM

KiSC issued 08, 2015 A

INFORMATION

RY9212158INI0007US0

I-10

Page 17

KX080-4, WSM

KiSC issued 08, 2015 A

INFORMATION

[2] LABEL MAINTENANCE

Thoroughly Read, Understand and Follow Safety Precautions on Labels

• Always keep labels in a clean, undamaged state.

• If labels get dirty, wipe them off with soapy water and a soft cloth.

• When using a pressure washer to clean the equipment, do not spray any labels directly as doing so may make

• If a label is damaged or lost, order a new one from your dealer and affix it as before.

• Before affixing a new label, completely wipe off any dirt or grime on the surface, allow it to dry and then affix in

• When replacing a part that has a label on it, replace the label at the same time.

RY9212158INI0008US0

If solvents such as paint thinner or engine oil are used, the text and or figures may fade away.

them peel off.

the same place.

RY9212001INI0018US0

I-11

Page 18

KX080-4, WSM

NOTE

KiSC issued 08, 2015 A

INFORMATION

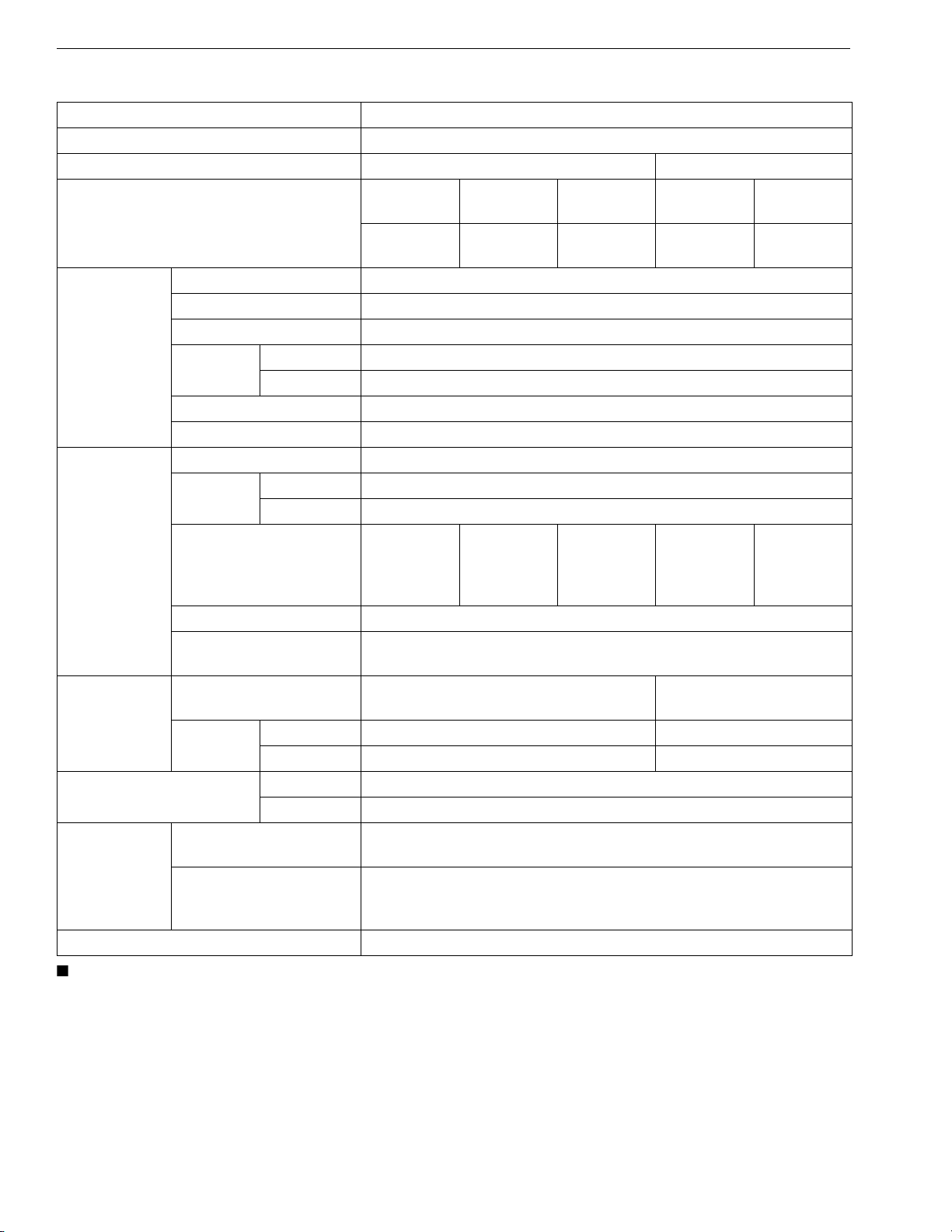

4. MAIN SPECIFICATIONS

KUBOTA EXCAVATOR

Model name KX080-4

Type Cabin Angle Blade type Cabin

Rubber

Operating weight

(including operator's weight)

tracks

8290 kg

18280 lbs

Type Water cooled 4 cycle diesel engine with 4 cylinder

Model name KUBOTA V3307-CRS-T4

Total displacement 3331 cc (203.3 cu.in.)

Engine

Engine

power

SAE gross 52.2 kW (70.0 Hp)

SAE net 48.8 kW (65.5 Hp)

Rated speed 2000 rpm

Low idling speed 1000 rpm

Unit swing speed 9.5 rpm

Travel

speed

Fast 4.9 km / h (3.1 mph)

Slow 2.7 km / h (1.7 mph)

36.0 kPa

Performance

Ground pressure

(With operator)

(0.367

kgf/cm

5.22 psi

Climbing angle *36 % (20 deg)

Angle in case of crossing

slope

Width x Height

Blade

Max

swing

Left – 0.44 rad (25 deg)

Right – 0.44 rad (25 deg)

Left 1.22 rad (70 deg)

Boom swing angle

Right 1.05 rad (60 deg)

Max. displacement

Pressure

(Theoretical)

connection for

attachments

Max. pressure

Fuel tank capacity 115 L (30.4 U.S.gal)

Steel tracks

(450 width)

8340 kg

18390 lbs

36.2 kPa

(0.369

2

)

kgf/cm

5.25 psi

2200 x 500 mm

86.6 x 19.7 in.

Steel tracks

Rubber

(600 width)

8470 kg

18670 lbs

27.6 kPa

(0.281

2

)

kgf/cm

2)

4.00 psi

8680 kg

19140 lbs

37.5 kPa

(0.382

kgf/cm

5.44 psi

*27 % (15 deg)

100 L (26.4 U.S.gal) / min

20.6 MPa

210 kgf/cm

2

2987 psi

tracks

2

)

2200 x 510 mm

86.6 x 20.1 in.

Steel tracks

(450 width)

8730 kg

19250 lbs

37.7 kPa

(0.384

kgf/cm

5.47 psi

2

)

• Above dimensions are based on the machine with KUBOTA original bucket and 2100 arm.

• Specifications subject to change without notice.

• With unloaded digging bucket.

• Firm compacted soil.

• Operators must exercise extra caution and follow instructions in the operator's manual.

• Worse condition or heavier attachment to the above will decrease climbing angle.

RY9212158INI0001US0

I-12

Page 19

KX080-4, WSM

KiSC issued 08, 2015 A

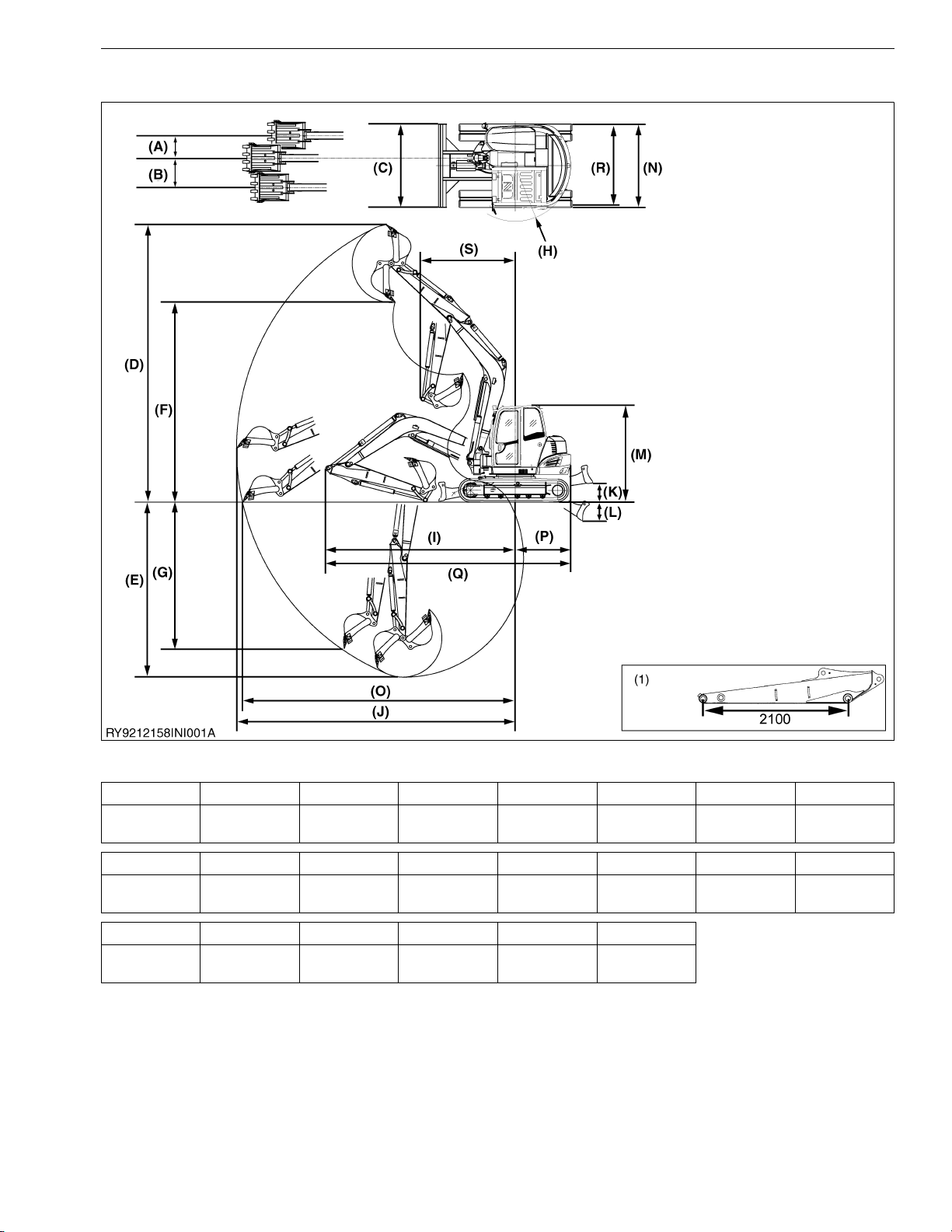

5. DIMENSIONS

INFORMATION

(1) Arm length (2100 Arm)

• Above dimensions are based on the machine with KUBOTA original bucket.

• Above dimensions are based on the machine with rubber track.

• Specifications subject to change without notice.

KX080-4

KX080-4

KX080-4

(A) (B) (C) (D) (E) (F) (G)

590 mm

23.2 in.

(H) (I) (J) (K) (L) (M) (N)

1460 mm

57.5 in.

(O) (P) (Q) (R) (S)

7170 mm

282.3 in.

770 mm

30.3 in.

4990 mm

196.5 in.

1460 mm

57.5 in.

2200 mm

86.6 in.

7330 mm

288.6 in.

6450 mm

253.9 in.

7300 mm

287.4 in.

500 mm

19.7 in.

2150 mm

84.6 in.

5250 mm

206.7 in.

500 mm

19.7 in.

2490 mm

98.0 in.

4600 mm

181.1 in.

2540 mm

100.0 in.

RY9212158INI0002US0

I-13

3850 mm

151.6 in.

2200 mm

86.6 in.

Page 20

G GENERAL

KiSC issued 08, 2015 A

Page 21

GENERAL

KiSC issued 08, 2015 A

CONTENTS

1. CHECKING EXCAVATOR IDENTIFICATION .............................................................................. G-1

2. ENGINE IDENTIFICATION .......................................................................................................... G-2

[1] MODEL NAME AND SERIAL NUMBER ................................................................................ G-2

[2] E4B ENGINE .......................................................................................................................... G-3

[3] CYLINDER NUMBER ............................................................................................................. G-4

3. MUFFLER FULL ASSEMBLY IDENTIFICATION ......................................................................... G-5

[1] PART NUMBER AND SERIAL NUMBER .............................................................................. G-5

4. GENERAL PRECAUTIONS.......................................................................................................... G-7

5. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING .................................. G-11

[1] WIRING ................................................................................................................................ G-11

[2] FUSES.................................................................................................................................. G-13

[3] CONNECTOR ...................................................................................................................... G-13

[4] WASHING THE MACHINE WITH A HIGH-PRESSURE WASHER ..................................... G-15

6. TIGHTENING TORQUES........................................................................................................... G-16

[1] TORQUES FOR GENERAL USE NUTS AND BOLTS ........................................................ G-16

[2] TORQUE FOR HYDRAULIC HOSE FITTINGS ................................................................... G-17

(1) Torque for Hydraulic Hose Fittings ................................................................................. G-17

(2) Torques of Lock-Nuts for Elbows with Male Seats and Adaptors with O-rings

(Straight Threads)........................................................................................................... G-17

[3] HOSE CLAMP SCREW TORQUE ....................................................................................... G-18

7. OIL AND WATER CAPACITY TABLE ........................................................................................ G-20

8. MAINTENANCE INTERVALS..................................................................................................... G-21

Page 22

KX080-4, WSM

KiSC issued 08, 2015 A

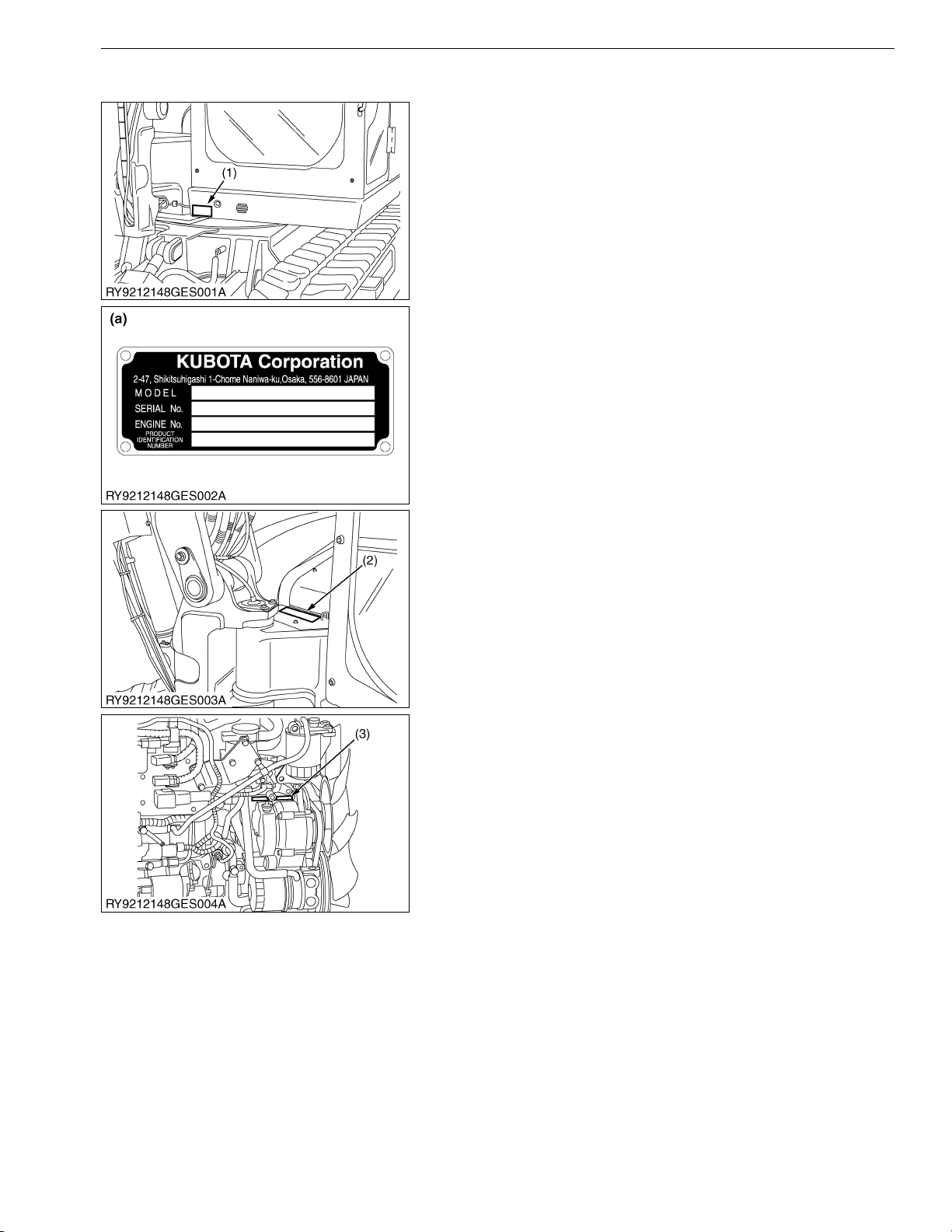

1. CHECKING EXCAVATOR IDENTIFICATION

When consulting with your local KUBOTA dealer about this

mini-excavator, please provide the model of the mini-excavator, its

frame and engine numbers and the number of hours on the hour

meter.

(1) Mini-excavator Nameplate

(Model, frame number, engine

number)

(2) Frame Number

(3) Engine Number

(a) Model Nameplate

RY9212148GEG0001US0

GENERAL

G-1

Page 23

KX080-4, WSM

KiSC issued 08, 2015 A

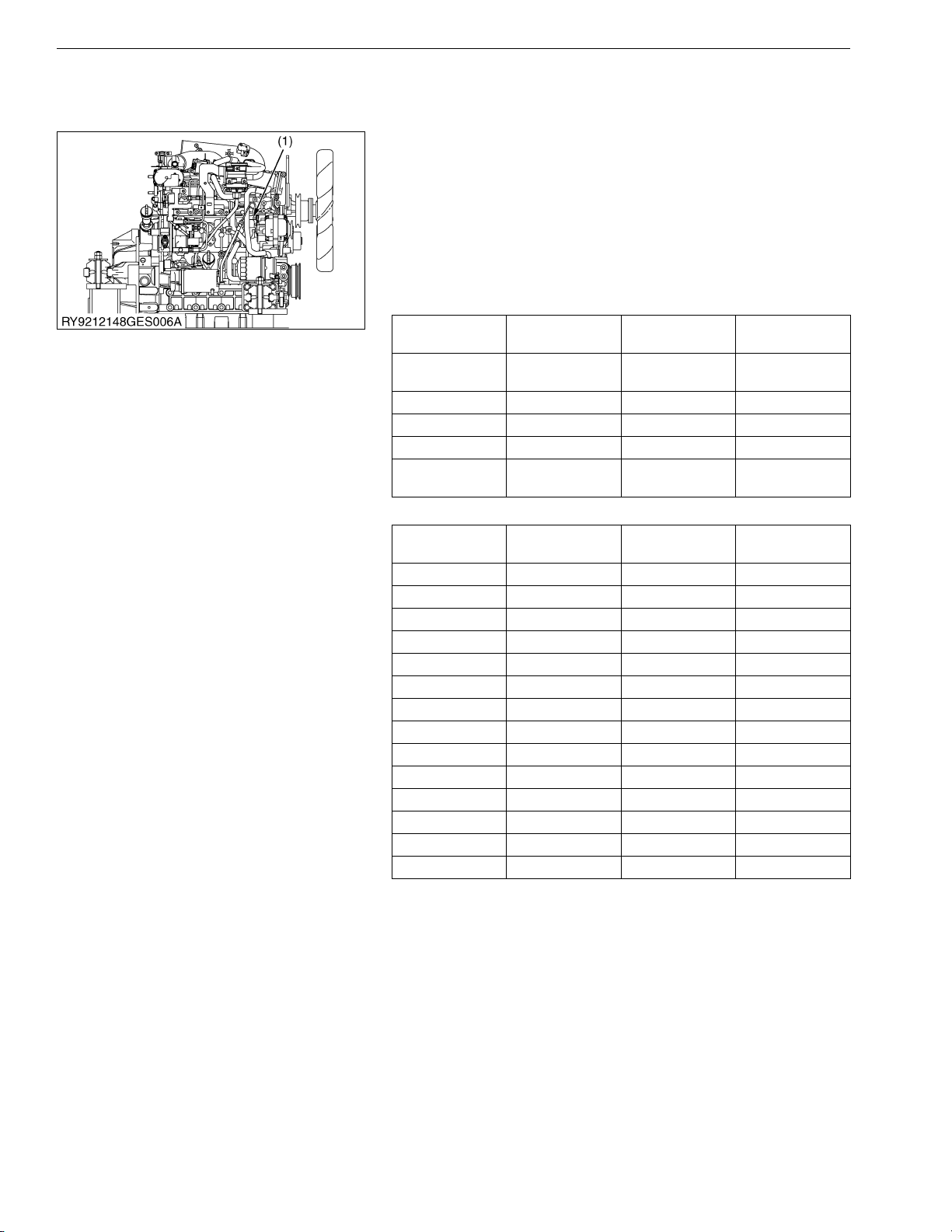

2. ENGINE IDENTIFICATION

[1] MODEL NAME AND SERIAL NUMBER

Be sure to check the engine nameplate and serial number when

you wish to consult about the engine.

The model and serial number of the engine need to be checked

prior to servicing the engine or replacing any of its parts.

Engine Serial No.

The engine serial number is the numerical ID of the engine and

is printed after the engine's model number.

The year and month of manufacture are indicated as follows.

Engine Series

Number or

Alphabet

1 05 (include: WG) 6

2V3703

308807

4 SM (include: WG) A EA, RK

5

Air Cooled

Series

Gasoline

Number or

Alphabet

B

GENERAL

Series

GZ, OC, AC, EA,

E

03 (KET

Production)

Production Year

Alphabet or

Number

1 2001 F 2015

2 2002 G 2016

3 2003 H 2017

4 2004 J 2018

5 2005 K 2019

6 2006 L 2020

7 2007 M 2021

8 2008 N 2022

9 2009 P 2023

A 2010 R 2024

B 2011 S 2025

C 2012 T 2026

D 2013 V 2027

E2014

(1) Engine Model Name and Serial

Number

Year

Alphabet or

Number

Year

(To be continued)

G-2

Page 24

KX080-4, WSM

NOTE

KiSC issued 08, 2015 A

(Continued)

Production Month and Lot Number

Month Engine Lot Number

January A0001 to A9999 from B0001

February C0001 to C9999 from D0001

March E0001 to E9999 from F0001

April G0001 to G9999 from H0001

May J0001 to J9999 from K0001

June L0001 to L9999 from M0001

July N0001 to N9999 from P0001

August Q0001 to Q9999 from R0001

September S0001 to S9999 from T0001

October U0001 to U9999 from V0001

November W0001 to W9999 from X0001

December Y0001 to Y9999 from Z0001

* Alphabetical letters "I" and "O" are not used.

(a)

e.g. V2607

(a) V2607: Engine Model Name

(b) 8: Engine Series (07 series)

(c) C: Production Year (2012)

(d) L: Production Month (June)

(e) A001: Lot Number: (0001 to 9999 or A001 to Z999)

(b)C(c)L(d)

- 8

(e)

A001

RY9212148GEG0002US0

GENERAL

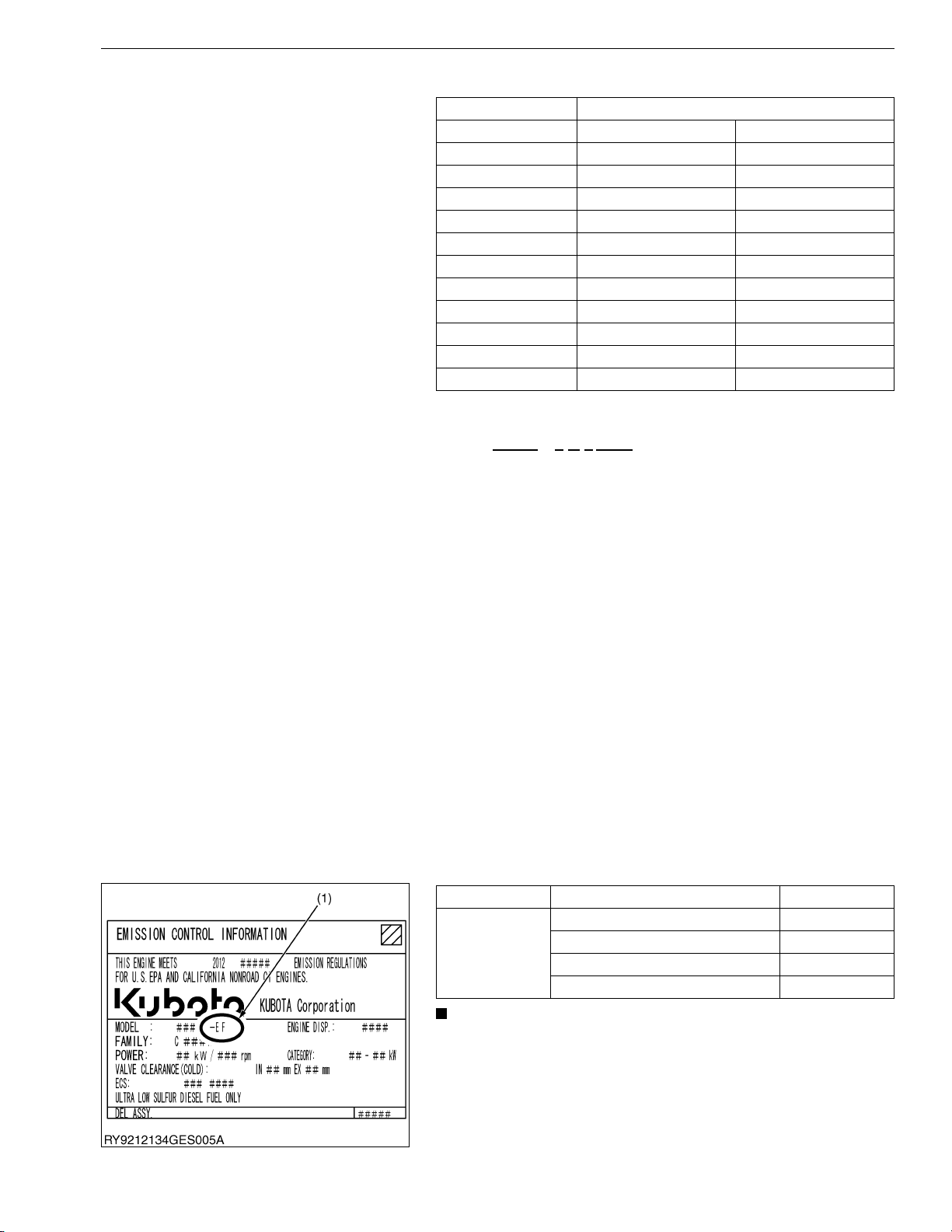

[2] E4B ENGINE

[Example: Engine Model Name V2607-CR-TE4(C)B-XXXX or V2607-CR-TIE4(C)B-XXXX]

The emission controls previously implemented in various countries to prevent air pollution will be stepped up as

Nonroad Emission Standards continue to change. The timing or applicable date of the specific Nonroad Emission

regulations depends on the engine output classification.

Over the past several years, KUBOTA has been supplying diesel engines that comply with regulations in the

respective countries affected by Nonroad Emission regulations. For KUBOTA Engines, E4B will be the designation

that identifies engine models affected by the next emission phase (See the table below).

When servicing or repairing ###-E4B series engines, use only replacement parts for that specific E4B engine,

designated by the appropriate KUBOTA Parts List and perform all maintenance services listed in the appropriate

KUBOTA Operator's Manual or in the appropriate KUBOTA Workshop Manual. Use of incorrect replacement parts or

replacement parts from other emission level engines (for example: E3B engines), may result in emission levels out

of compliance with the original E4B design and EPA or other applicable regulations.Please refer to the emission label

located on the engine head cover to identify Output classification and Emission Control Information. E4B engines are

identified with "EF" at the end of the Model designation, on the US EPA label. Please note: E4B is not marked on the

engine.

Category (1) Engine output classification EPA regulation

Less than 19 kW Tier 4

EF

• "E4B" engines are identified with "EF" at the end of the

Model designation, on the US EPA label.

"E4B" designates some Interim Tier 4 / Tier 4 models,

depending on engine output classification.

From 19 to less than 56 kW Interim Tier 4

From 56 to less than 75 kW Interim Tier 4

From 75 to less than 130 kW Interim Tier 4

RY9212148GEG0003US0

G-3

Page 25

KX080-4, WSM

KiSC issued 08, 2015 A

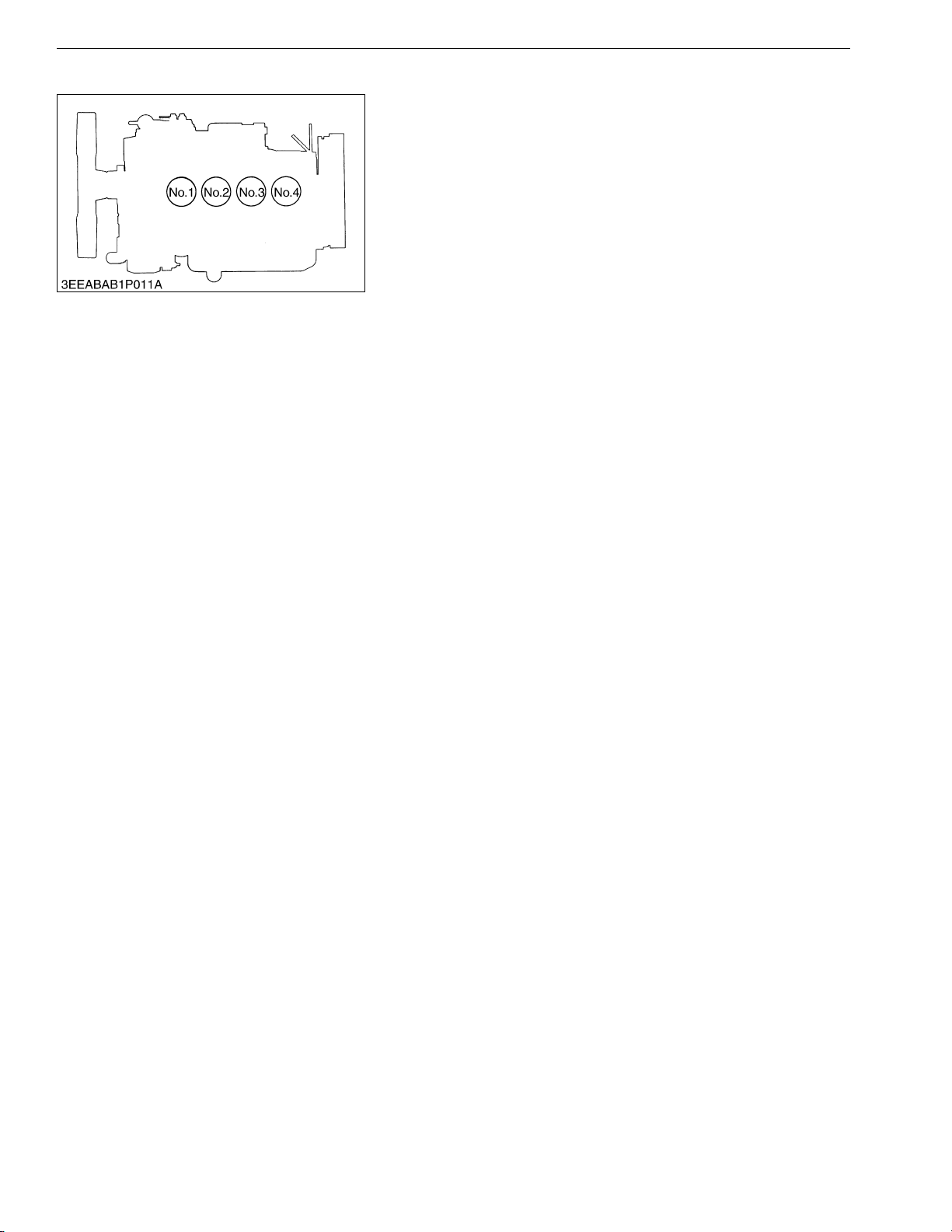

[3] CYLINDER NUMBER

GENERAL

You can see the cylinder numbers of KUBOTA diesel engine in

the figure.

The sequence of cylinder numbers is No.1, No.2, No.3 and No.4

and it starts from the gear case side.

RY9212134GEG0005US0

G-4

Page 26

KX080-4, WSM

KiSC issued 08, 2015 A

3. MUFFLER FULL ASSEMBLY IDENTIFICATION

[1] PART NUMBER AND SERIAL NUMBER

Diesel Particulate Filter (hereinafter referred to as the "DPF")

Muffler Full Assembly Serial Number

The DPF muffler full assembly serial number is an identified

number for the DPF muffler full assembly.

It shows the month and year of manufacture as below.

Year of manufacture

Alphabet or

Number

1 2001 F 2015

2 2002 G 2016

3 2003 H 2017

4 2004 J 2018

5 2005 K 2019

6 2006 L 2020

7 2007 M 2021

8 2008 N 2022

9 2009 P 2023

A 2010 R 2024

B 2011 S 2025

C 2012 T 2026

D 2013 V 2027

E 2014

Year

Alphabet or

Number

GENERAL

Yea r

Month of manufacture

Month DPF Muffler Full Assembly Lot Number

January A0001 to A9999 B0001 to BZ999

February C0001 to C9999 D0001 to DZ999

March E0001 to E9999 F0001 to FZ999

April G0001 to G9999 H0001 to HZ999

May J0001 to J9999 K0001 to KZ999

June L0001 to L9999 M0001 to MZ999

July N0001 to N9999 P0001 to PZ999

August Q0001 to Q9999 R0001 to RZ999

September S0001 to S9999 T0001 to TZ999

October U0001 to U9999 V0001 to VZ999

November W0001 to W9999 X0001 to XZ999

December Y0001 to Y9999 Z0001 to ZZ999

* Alphabetical letters "I" and "O" are not used.

(a)L(b)

(c)

e.g. C

(1) DPF Muffler Full Assembly Part Number and Serial Number

(a) Year: C indicates 2012

(b) Month: L or M indicates June

(c) Lot Number: (0001 to 9999 or A001 to Z999)

0019

RY9212148GEG0004US0

G-5

Page 27

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

You must keep the records of the filter comp (DPF) part number

and serial number before you remove the DPF for cleaning.

(1) Body (DPF Outlet) Part Number and

Serial Number

(2) Filter Comp (DPF) Part Number and

Serial Number

(3) Catalyst (DOC) Part Number and

Serial Number

RY9212148GEG0005US0

G-6

Page 28

KX080-4, WSM

KiSC issued 08, 2015 A

4. GENERAL PRECAUTIONS

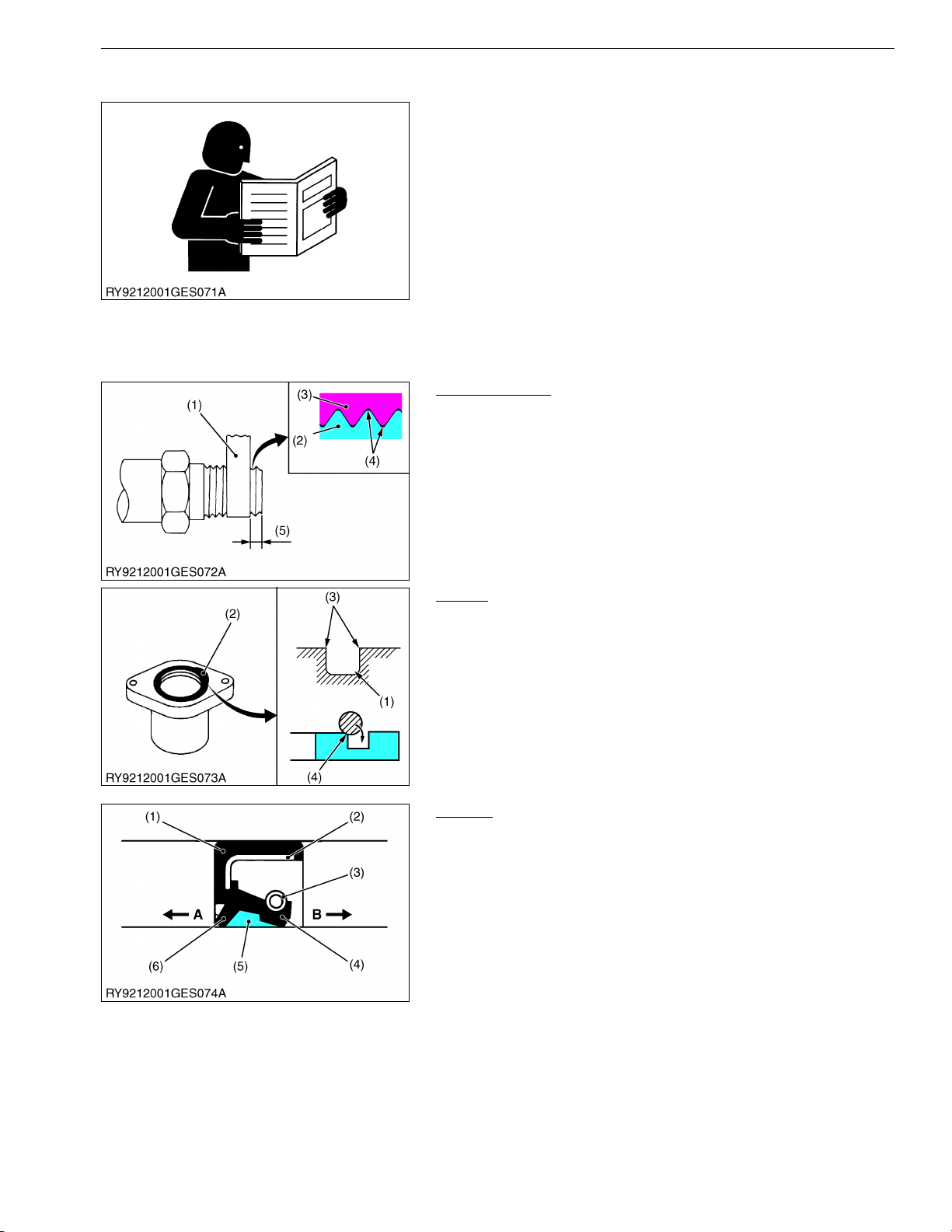

Whenever performing maintenance on the machine, always

read the Safety Precautions in this manual and the Operator's

Manual carefully, become familiar with them and perform the work

safely.

Before performing any maintenance on the machine, make sure

it is sufficiently clean and choose a sufficiently clean location to

perform any disassembly.

Before performing maintenance on the machine, always

disconnect the negative battery cable first.

Whenever a special tool is required, use the special tool that

KUBOTA recommends. Make any special tools that are not used

very frequently according to the diagrams in this manual.

Always use genuine KUBOTA parts to maintain the

performance and safety characteristics of the machine.

Plumber's Tape

• Wrap plumber's tape on the threads before tightening taper

couplings. After wrapping (2 wraps) the plumber's tape, tighten

to the specified torque. Once the coupling is tightened, do not

loosen it as this will cause an oil leak.

(1) Plumber's Tape

(2) External Thread

(3) Internal Thread

GENERAL

RY9212001GEG0011US0

(4) Gap

(5) Leave 1 to 2 Threads

RY9212001GEG0012US0

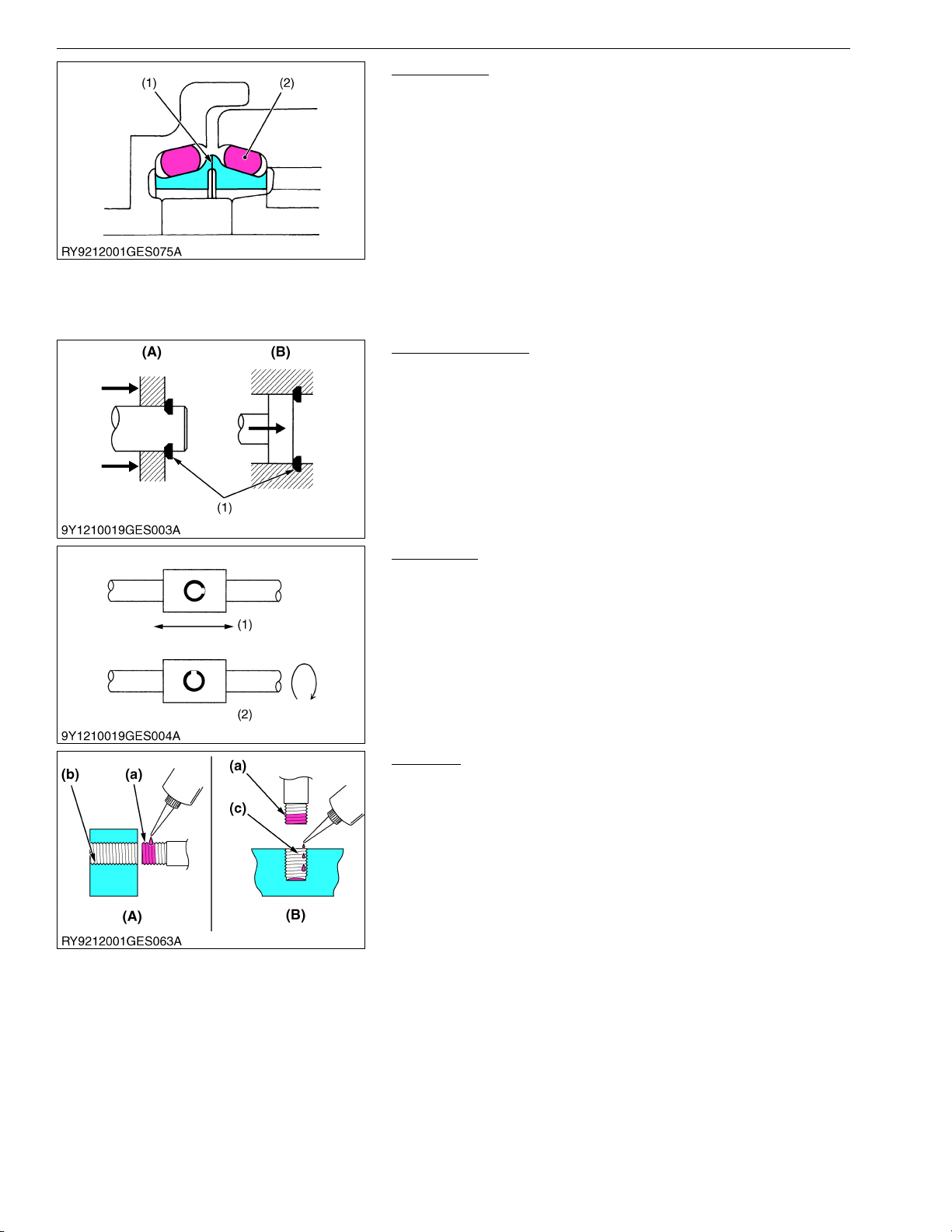

O-Ring

• Clean the groove the O-ring goes in and remove any burrs.

Apply grease on the O-ring when inserting it in the groove.

(Except floating seals)

• When putting the O-ring in the groove, be careful as it is easy at

the very end to twist the O-ring against the inside of the groove.

If it gets twisted, roll it gently with your fingertip to untwist it.

(1) O-Ring Groove

(2) O-Ring

(3) Check for Burrs

(4) If the Ring Touches This Corner, It

Will Twist

RY9212001GEG0013US0

Oil Seal

• Do not face the lip of the oil seal in the wrong direction. Face the

main lip toward the material to be sealed.

• After oil seals are replaced, apply grease to the moving parts

around the lip to prevent the dry surfaces from wearing against

each other when the engine is started. If the seal has a dust lip,

fill the gap between the lips with grease.

• As a general rule, use a press to insert the oil seal in place.

If that is not possible, use an appropriate tool to gently and

evenly tap it into place, taking care that it does not go in at a

slant. Press the seal all the way so it seats in the boss.

(1) Gasket

(2) Metal Ring

(3) Spring

(4) Main Lip

(5) Grease

(6) Dust Lip

A : Air (Outside)

B : Hydraulic Chamber (Inside)

RY9212001GEG0014US0

G-7

Page 29

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

Floating Seal

• Be sure to wipe off any oil from the O-ring or surfaces that touch

the O-ring. (For wheel motors, apply a light film)

• When putting an O-ring into a floating seal, make sure the

O-ring does not twist.

• Apply a light film of oil to surrounding surfaces when working to

get the floating seal with O-ring in place; take care that the

surrounding surfaces, O-ring and housing are parallel with each

other.

• After getting the seal in place, turn the engine over 2 or 3

revolutions, to both create a film of oil on surrounding surfaces

and to properly seat the face of the seal.

(1) Surrounding Surfaces (2) O-Ring

RY9212001GEG0015US0

Snap Ring Related

• When installing external or internal snap rings, orient them as

shown in the diagram so the angled side faces the direction of

force.

(1) Position so the Angled Part

Receives the Force

(A) External

(B) Internal

RY9212001GEG0016US0

Spring Pins

• When driving a spring pin, face the split in the direction that

receives the force, as shown in the diagram.

(1) With Lateral Movement (2) With Rotational Movement

RY9212001GEG0017US0

Adhesive

• Clean and dry the area where adhesive will be applied with a

solvent so it is free of moisture, oil and dirt.

• Apply adhesive all around the threads of the bolt except the first

set of threads at the tip and fill the grooves between the threads.

If the threads or the grooves are large, adjust the amount of

adhesive accordingly and apply it all around the bolt hole as

well.

(A) Bolt Through-Hole (Nut)

(B) Pocket Bolt Hold

(Capsule Shape, etc.)

(a) Apply Here

(b) Do Not Apply

(c) Drip On

RY9212001GEG0018US0

G-8

Page 30

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

Tightening Bolts and Nuts

• Tighten bolts and nuts to their specified torque.

• Tighten nuts and bolts alternately top/bottom (a) (b), left/right so

the torque is distributed evenly.

(A) Top/Bottom Alternately

(B) Across Diagonally

(C) Diagonally Across the Center

RY9212001GEG0019US0

Assembling Hydraulic Hoses

• Tighten to their specified torque.

• Before assembling, wipe the inside of metal fittings clean of any

dirt.

• After assembly, put the fitting under normal pressure and check

that it does not leak.

RY9212001GEG0020US0

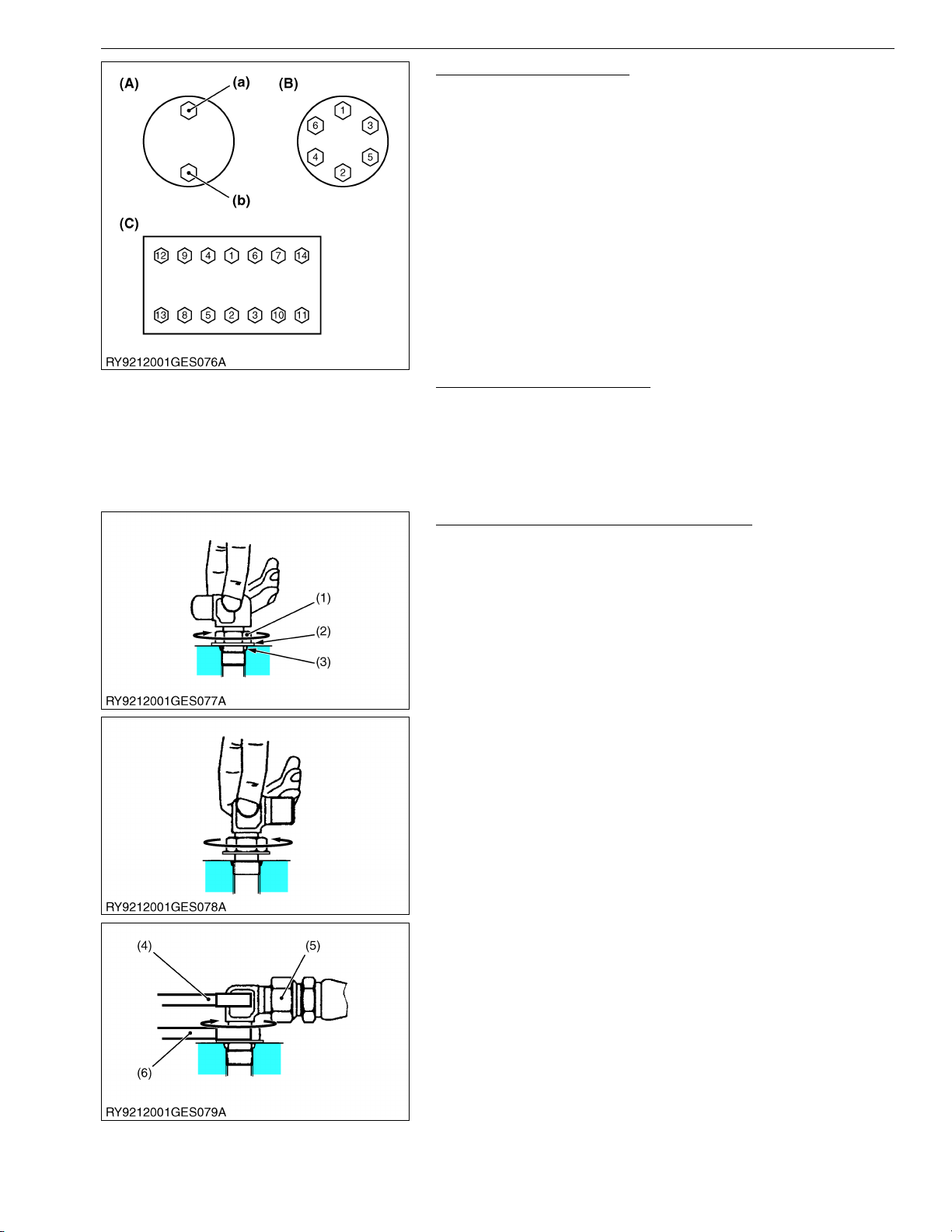

Elbow with Male Seat Assembly Procedure

When assembling an elbow with male seat, adhere to the

following procedures to prevent deformation of O-rings and leaks.

1. Connecting to Valves

• Clean the blow with male seat and the surface of the seal

opposite and mount with the lock-nut on top.

• Finger tighten till it touches the washer.

2. Positioning

• Turn the mouth of the elbow back so it faces the right

direction. (not back over 1 turn)

3. Fasten

• Tighten the lock-nut to the specified torque with a wrench.

(1) Lock-Nut

(2) Washer

(3) Seal (O-Ring)

(4) Wrench for Holding

(5) Hose

(6) Torque Wrench for Tightening

RY9212001GEG0021US0

G-9

Page 31

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

Installing and Removing Quick Couplings

• To remove a quick hose coupling, push the fitting in the direction

of the arrow and pull on the plastic part in the opposite direction.

• To attach a quick coupler, push it in firmly in the direction of the

arrow. Then check that it will not pull off.

(1) Plastic Part (2) Fitting

RY9212001GEG0022US0

Connecting the face sealing (ORS) type hose

1. Remove the protective cap from the adapter and make sure the

O-ring is installed in its groove. (If the O-ring is missing, fit the

specified-size in position.)

2. Shift the hose's cap nut in the direction of arrow until the O-ring

contact face stretched out of the cap nut.

3. Bring the hose's O-ring contact face in close contact with the

joint's O-ring.

Make sure they do not come off each other.

4. Tighten up the cap nut to the specified torque.

(1) Protective cap

RY9212038GEG0005US0

G-10

Page 32

KX080-4, WSM

IMPORTANT

KiSC issued 08, 2015 A

GENERAL

5. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING

Follow the precautions below for handling electrical parts and

wiring to ensure safety and prevent damage to the machine and

nearby equipment.

• Inspect electrical wiring for damage and/or loose

connections.

• Do not alter or rewire any electrical parts or wiring.

• Always remove the negative battery cable first when

disconnecting the battery and attach the positive cable first

when connecting it.

(1) Battery Cable (-) Side (2) Battery Cable (+) Side

RY9212001GEG0023US0

[1] WIRING

• Tighten wiring terminals securely.

(1) Correct (Tightened Securely) (2) Incorrect (Poor Contact if Loose)

RY9212001GEG0024US0

• Keep wiring away from hazards.

(1) Hazardous Positioning

(2) Wiring Position (Wrong)

(3) Wiring Position (Right)

(4) Hazardous Position

RY9212001GEG0025US0

• Immediately repair or replace old or damaged wiring.

(1) Damaged

(2) Torn

(3) Electrical Tape

RY9212001GEG0026US0

G-11

Page 33

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

• Insert grommet securely.

(1) Grommet (A) Correct

(B) Incorrect

RY9212001GEG0027US0

• Clamp wiring securely but do not damage wires with the clamp.

(1) Clamp (Spiral Clamp Around Wire)

(2) Wire

(3) Clamp

(4) Welding Mark

RY9212001GEG0028US0

• Clamp wiring so it is not twisted, pulled too tight or sag too

much. However, moving parts may require play in the wiring.

(1) Wire

(2) Clamp

(A) Correct

(B) Incorrect

RY9212001GEG0029US0

• Do not pinch or bind wiring when installing parts.

(1) Wire (A) Incorrect

RY9212001GEG0030US0

• After wiring, double-check terminal protectors and clamps

before connecting battery cables.

(1) Cover (Install Covers Securely)

RY9212001GEG0031US0

G-12

Page 34

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

• Do not modify harnesses. The diameter of wires in each

harness is determined after calculating its capacity.

• Modifying harnesses may cause a malfunction or a fire.

[2] FUSES

[3] CONNECTOR

(A) Wiring Diagram

(B) Diagram of Modification

(a) Standard Wiring

(b) Modified Wiring

RY9212038ELS0008US0

• Always use fuses of the specified capacity.

Never use over or undersized fuses.

• Never use copper or steel wire in place of a fuse.

• Do not install accessories such as work lights, radios, etc., if

your machine does not have an auxiliary circuit.

• Do not install accessories as they will exceed the capacity of

fuses.

(1) Fuse

(2) Fusible Link

(3) Slow-Blow Fuse

RY9212001GEG0032US0

Connectors

The terminals of female connector are numbered from #1 on the

top right when facing it.

Male terminals are numbered from #1 on the top left.

(A) Female connector terminals (B) Male connector terminals

RY9212038ELS0010US0

• Press the lock to disconnect locking connectors.

(A) Push

RY9212001GEG0033US0

G-13

Page 35

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

• Hold the connectors when separating them.

• Do not pull on the wire harness to separate the connectors.

(A) Correct (B) Incorrect

RY9212001GEG0034US0

Pull on the harness from the connector and make sure the

harness does not come off. (Pull with 3 kgf (30 N, 7 lbf) or less of

force)

(A) Pull (B) Loosened Crimping

RY9212038ELS0011US0

• Straighten bent prongs and make sure none are sticking out or

missing.

• Remove corrosion from terminals with sandpaper.

(1) Missing Terminal

(2) Bent Prong

(3) Sandpaper

(4) Corrosion

RY9212001GEG0035US0

• Do not touch the terminals of connectors with bare hands.

(A) Do not touch

RY9212038ELS0012US0

• Female connectors must not be spread too far open

(A) Correct (B) Incorrect

RY9212001GEG0036US0

G-14

Page 36

KX080-4, WSM

CAUTION

KiSC issued 08, 2015 A

GENERAL

• The plastic covers of connectors must cover them completely.

(1) Cover (A) Correct

(B) Incorrect

RY9212001GEG0037US0

[4] WASHING THE MACHINE WITH A HIGH-PRESSURE WASHER

Using a high-pressure washer incorrectly can lead to personal

injury and/or damage, break or cause parts of the machine to fail,

so use the power washer properly according to its operator's

manual and labels.

• Stand at least 2.0 meters from the machine and adjust the

nozzle for a wide spray so it does not cause any damage.

If you blast the machine with water or wash it from too

close a distance,

1. It may cause a fire due to damaged or cuts in the insulation

of electrical wiring.

2. An injury may result if hydraulic oil gushes out under high

pressure, due to damaged hydraulic hoses.

3. It may damage, break or cause parts of the machine to fail.

(Ex.)

(1) Stickers or labels may come off

(2) Electrical parts or the engine may fail due to water in them.

(3) Damage glass, resins, etc. or the rubber of oil seals.

(4) Tear off paint or the film from plating

(1) Do Not Blast with Water

(2) Never Wash from Too Close

(A) Blasting

(B) Wide Spray

(C) Less Than 2.0 m (80 in.)

(D) Over 2.0 m (80 in.)

RY9212001GEG0038US0

G-15

Page 37

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

6. TIGHTENING TORQUES

[1] TORQUES FOR GENERAL USE NUTS AND BOLTS

Screws, bolts and nuts whose tightening torques are not specified in this Workshop Manual should be

tightened according to the table below.

Indication on top of bolt

Indication on top of nut

Material of opponent part Ordinariness Aluminum Steel Aluminum Steel

Unit N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft

7.9

0.8

M6

M8

M10

M12

M14

M16

M18

M20

to

9.3

18

to

20

40

to

45

63

to

72

108

to

125

16

to

191

246

to

284

334

to

392

to

0.95

1.8

to

2.1

4.0

to

4.6

6.4

to

7.4

11

to

12.8

7

17

to

19.5

25

to

29

34

to

40

No-grade or 4T 7T 9T

No-grade or 4T

5.8

7.9

0.8

5.8

9.81

1.0

7.24

7.9

0.8

5.8

12.3

to

to

to

to

to

to

to

to

to

to

6.8

8.8

0.9

6.5

13

17

1.7

to

to

15

19

32

29

to

to

33

34

47

to 53–––

79.6

to

–––

92.5

123

to

–––

141

181

to

–––

209

246

to

–––

289

to

2.0

3.2

to

3.5

13

to

14

24

to

25

11. 2

24

to

27

48

to

55

78

to

90

124

to

147

197

to

225

275

to

318

368

to

431

1.15

2.4

to

2.8

4.9

to

5.7

7.9

to

9.2

12.6

to

15

20

to

23

28

to

32.5

37.5

to

44

8.31

18

to

20

36

to

41

58

to

66

91.2

to

108

145

to

166

203

to

235

272

to

318

8.8

0.9

18

1.8

to

to

20

2.1

40

4.0

to

to

44

4.5

63

6.4

to

to

72

7.4

––

–––

–––

–––

to

6.5

14.2

13

30

to

to

15

34

29

61

to

to

32

70

47

103

to

to

53

117

167

–

to

196

260

to

304

344

to

402

491

to

568

RY9212032GEG0001US0

6T

1.25

to

1.45

3.0

to

3.5

6.2

to

7.2

10.5

to

12

17

to

20

26.5

to

31

35

to

41

50

to

58

9.05

to

10.4

22

to

25

45

to

52

76

to

86.7

123

to

144

192

to

224

254

to

296

362

to

419

G-16

Page 38

KX080-4, WSM

KiSC issued 08, 2015 A

[2] TORQUE FOR HYDRAULIC HOSE FITTINGS

(1) Torque for Hydraulic Hose Fittings

Union nut (metal seal type) Union nut (ORS type)

7.8 to 11.8 N·m

1/8

1/4

3/8

1/2

3/4

1 - 1/4

0.8 to 1.2 kgf·m

5.7 to 8.7 lbf·ft

24.5 to 29.2 N·m

2.5 to 3.0 kgf·m

18.1 to 21.7 lbf·ft

37.2 to 42.1 N·m

3.8 to 4.3 kgf·m

27.5 to 31.1 lbf·ft

58.8 to 63.7 N·m

6.0 to 6.5 kgf·m

43.4 to 47.0 lbf·ft

117.6 to 127.4 N·m

12.0 to 13.0 kgf·m

86.8 to 94.0 lbf·ft

220.5 to 230.3 N·m

22.5 to 23.5 kgf·m

162.7 to 169.8 lbf·ft

––

35.2 to 43.1 N·m

9/16UNF

11/16UNF

13/16UNF

1-14UNS

––

3.6 to 4.4 kgf·m

26.0 to 31.8 lbf·ft

60.0 to 73.5 N·m

6.1 to 7.5 kgf·m

44.3 to 54.2 lbf·ft

70.6 to 86.2 N·m

7.2 to 8.8 kgf·m

52.1 to 63.6 lbf·ft

105.8 to 129.4 N·m

10.8 to 13.2 kgf·m

78.0 to 98.4 lbf·ft

GENERAL

RY9212148GEG0006US0

(2) Torques of Lock-Nuts for Elbows with Male Seats and Adaptors with

O-rings (Straight Threads)

15.0 to 16.5 N·m

Tightening torque

(1) Lock-nut

(2) Washer

1/8

1/4

3/8

1/2

3/4, 1

1-1/4

7/8 - 14UNF

(3) Seal (O-ring)

1.5 to 1.7 kgf·m

11.1 to 12.2 lbf·ft

24.5 to 29.4 N·m

2.5 to 3.0 kgf·m

18.1 to 21.7 lbf·ft

49.0 to 53.9 N·m

5.0 to 5.5 kgf·m

36.1 to 39.8 lbf·ft

58.8 to 63.7 N·m

6.0 to 6.5 kgf·m

43.4 to 47.0 lbf·ft

117.6 to 127.4 N·m

12.0 to 13.0 kgf·m

86.8 to 94.0 lbf·ft

220.5 to 230.3 N·m

22.5 to 23.5 kgf·m

162.8 to 170.0 lbf·ft

55.9 to 60.8 N·m

5.7 to 6.2 kgf·m

41.2 to 44.8 lbf·ft

RY9212148GEG0007US0

G-17

Page 39

KX080-4, WSM

KiSC issued 08, 2015 A

[3] HOSE CLAMP SCREW TORQUE

Type 1

GENERAL

Tightening torque

10- 14 6C040-58721

12- 16 09318-89016

19- 25 09318-89024

31- 40 09318-89039

36- 46 09318-89045

44- 53 09318-89052

51- 59 09318-89058

86- 96 RD809-42241

2.5 to 3.4 N·m

25 to 35 kgf·cm

1.8 to 2.5 lbf·ft

2.5 to 3.4 N·m

25 to 35 kgf·cm

1.8 to 2.5 lbf·ft

2.5 to 3.4 N·m

25 to 35 kgf·cm

1.8 to 2.5 lbf·ft

2.5 to 3.4 N·m

25 to 35 kgf·cm

1.8 to 2.5 lbf·ft

2.5 to 3.4 N·m

25 to 35 kgf·cm

1.8 to 2.5 lbf·ft

3.9 to 4.9 N·m

40 to 50 kgf·cm

2.9 to 3.6 lbf·ft

3.9 to 4.9 N·m

40 to 50 kgf·cm

2.9 to 3.6 lbf·ft

2.5 to 3.4 N·m

25 to 35 kgf·cm

1.8 to 2.5 lbf·ft

RY9212001GEG0045US0

G-18

Page 40

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

Type 2

Tightening torque

13- 20 RB101-63631

15- 25 RC101-64581

19- 28 R1401-63211

22- 32 R1401-63151

26- 38 68311-72821

32- 44 RD411-63821

44- 56 35820-15181

50- 65 RC401-63191

58- 75 36919-04591

60- 80 RD809-63101

68- 85 RD809-63061

77- 95 69284-63171

2.5 to 3.4 N·m

25 to 35 kgf·cm

1.8 to 2.5 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

4.9 to 5.9 N·m

50 to 60 kgf·cm

3.6 to 4.3 lbf·ft

RY9212001GEG0046US0

G-19

Page 41

KX080-4, WSM

KiSC issued 08, 2015 A

7. OIL AND WATER CAPACITY TABLE

Item KX080-4 Notes

Engine oil (when filter changed) 9.7 L (2.6 U.S.gal) API type, CJ-4

Coolant 10.5 L (2.77 U.S.gal)

Reserve tank 1.3 L (0.34 U.S.gal)

Fuel (full) 115 L (30.4 U.S.gal) JIS #3 diesel

Hydraulic oil

Travel motor 1.35 L (0.36 U.S.gal) Gear oil SAE#90 (API GL-4)

Idler assy 80 ml (4.88 cu.in.)

Carrier rollers 80 ml (4.88 cu.in.)

Grease – EP2

Total volume (Std. spec.) 146 L (38.6 U.S.gal)

Inside tank (gauge middle) 75 L (20.0 U.S.gal)

Antifreeze Kubota LLC-N-50F

Mixture ratio 50%

Tellus oil S2M46

Engine oil SAE #30CD (monograde)Track rollers 80 ml (4.88 cu.in.)

RY9212158GEG0001US0

GENERAL

G-20

Page 42

KX080-4, WSM

KiSC issued 08, 2015 A

8. MAINTENANCE INTERVALS

GENERAL

No. Check points Measures

check Daily check

1 Coolant

2 Fuel check Daily check

3 Engine oil

4 Hydraulic oil

Bucket and

bucket link pin

/ Dozer angle

Grease front

5

attachments

6 Radiator and oil cooler check Daily check

7 Washer liquid check Daily check

8 Engine and electrical wiring check Daily check

9 Water separator drain

10 Fuel tank drain

11 Battery condition check

Greasing swing bearing

12

teeth

13 V-belt tension

14 Radiator hoses and clamps

Air filter

15

element

16 Greasing swing ball bearing –

Fuel filter cartridge replace

17

18 Engine oil filter replace

19 Drive unit oil change

Hydraulic return filter

20

cartridge

Hydraulic suction filter

21

element

Filter in the pilot hydraulic

22

system

23 Injector tip check

pin and angle

cylinder boss

Boom swing

fulcrum

Others –

Outer

element

Inner element replace

change

check Daily check

change

check Daily check

change

check Daily check

adjust

check

replace

clean

replace

replace

replace

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 1000

– Daily check

–

–

Hour meter indication

Interval

every

2 years

every

500 hrs

every

1000 hrs

every

100 hrs

every

250 hrs

every

50 hrs

every

50 hrs

every

50 hrs

every

50 hrs

every

200 hrs

every

200 hrs

every

2 years

every

200 hrs

every

1000 hrs

every

1000 hrs

every

hrs

200

every

500 hrs

every

500 hrs

every

500 hrs

every

500 hrs

every

1000 hrs

every

1000 hrs

every

1500 hrs

*1

*2

@replace

*2

*2

@

*4

*4

*4 @

G-21

Page 43

KX080-4, WSM

KiSC issued 08, 2015 A

GENERAL

No. Check points Measures

24 Oil separator element replace

25 EGR cooler check

26 Front idler and track roller oil change

27 Alternator and starter motor check

28 EGR system check

29 Turbo charger check

30 DPF clean

Boost sensor and AFS

31

(Air flow sensor)

32 Condition of DPF muffler check

DPF differential pressure

33

sensor and piping for gas

leak

DPF exhaust gas

34

temperature sensor

35 EGR and piping for gas leak check

36 Radiator system rinse

37 Fuel line and intake air line

Closed breather related

38

rubber piping

DPF differential pressure

39

sensor rubber piping (Front

and back)

Suction pipe downstream the

40

AFS

Boost sensor pressure

41

rubber piping

42 EGR cooler hose replace

check

check

check

check

replace

replace

replace

replace

replace

Hour meter indication

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 1000

Interval

every

1500 hrs

every

1500 hrs

every

2000 hrs

every

2000 hrs

every

3000 hrs

every

3000 hrs

every

3000 hrs

every

1 year

every

1 year

every

1 year

every

1 year

every

1 year

every

2 years

every

200 hrs

every

2 years

every

2 years

every

2 years

every

2 years

every

2 years

every

y

ears

2

*4 @

*4

*4

*4

*4

*4

*4

*4

*4

*4

*4

*4

*4

@

*3

*4

*4

*4

*4

*4

G-22

Page 44

KX080-4, WSM

IMPORTANT

NOTE

IMPORTANT

KiSC issued 08, 2015 A

GENERAL

Air conditioner

No. Check points Measures

clean

1 Air filter

replace

2 Air-conditioner condenser check

Air-conditioner pipes and

3

hose

4 Refrigerant (gas) check

check

replace

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 1000

Hour meter indication

Interval

every

200 hrs

every

1000 hrs

every

200 hrs

every

1year

every

2 years

service as

required

*2

*2

*4

• : First operation

• *1 : When using a hydraulic hammer, change hydraulic oil and return filter according to the table on

"Hydraulic Oil Change (Including Exchange of the Suction Filter in the Hydraulic Tank) under "EVERY

1000 SERVICE HOURS" in the chapter "REGULAR CHECKS AND MAINTENANCE WORK".

*2 : Clean and replace the air filter more frequently if used under dusty conditions. When the filter is very

dirty from dusty conditions, replace the filter.

*3 : Replace only if necessary.

*4 : Consult your local KUBOTA Dealer for this service.

• The items listed above (@ marked) are registered as emission related critical parts by KUBOTA in the

U.S.EPA nonroad emission regulation. As the engine owner, you are responsible for the performance of

the required maintenance on the engine according to the above instruction. Please see the Warranty

Statement in detail.

RY9212158GEG0002US0

Engine Oil:

• Oil used in the engine should have an American Petroleum Institute (API) service classification and

Proper SAE Engine Oil according to the ambient temperatures.

Above 25 °C (77 °F) SAE30 or SAE 10W-30, SAE 15W-40

0 to 25 °C (32 to 77 °F) SAE20 or SAE 10W-30, SAE 15W-40

Below 0 °C (32 °F) SAE10W or SAE 10W-30, SAE 15W-40

• Refer to the following table for the suitable API classification engine oil and the fuel.

Fuel used

Ultra Low Sulfur Fuel [< 0.0015 % (15 ppm)] CJ-4

Engine oil classification (API classification)

Oil class of engines except external DPF

Fuel:

• Use the ultra low sulfur diesel fuel only [below 0.0015 % (15 ppm)] for these engines.

• Cetane number of 45 minimum. Cetane number greater than 50 is preferred, especially for temperatures below

-20 °C (-4 °F) or elevations above 1500 m (5000 ft).

• Diesel fuels specified to EN 590 or ASTM D975 are recommended.

• No. 2-D is a distillate fuel of lower volatility for engines in industrial and heavy mobile service. (SAE J313 JUN87)

• Indicated capacities of water and oil are manufacture's estimate.

• If you use different fuel or engine oil, the cleaning interval of the DPF (3000 hours) can't be secured and

the DPF will be clogged for a shorter time than expected.

• Filters must trap fuel and lubricant sulfate additives (Zn, Pb, Na, K, Ca, Mg, Cu, Ba, P, etc.) as ash during

combustion. Fuel must be controlled carefully to prevent the additives being mixed into fuel such as fuel

tank anti-oxidants, water remover, anti-freeze and so on.

RY9212158GEG0003US0

G-23

Page 45

1 MACHINE BODY

KiSC issued 08, 2015 A

Page 46

SERVICING

KiSC issued 08, 2015 A

CONTENTS

1. FRONT ........................................................................................................................................ 1-S1

[1] BOOM ASSEMBLY/DISASSEMBLY .....................................................................................1-S1

[2] TABLE OF DIMENSIONS .....................................................................................................1-S3

(1) Bucket..............................................................................................................................1-S3

(2) Front Pin ..........................................................................................................................1-S4

(3) Front Bushings ................................................................................................................1-S5

(4) Arm ..................................................................................................................................1-S6

(5) Blade ...............................................................................................................................1-S7

2. SWIVEL FRAME..........................................................................................................................1-S8

[1] WEIGHT ASSEMBLY/DISASSEMBLY ................................................................................. 1-S8

[2] CABIN REMOVAL AND MOUNTING ....................................................................................1-S8

[3] FUEL TANK ASSEMBLY/DISASSEMBLY ..........................................................................1-S11

[4] HYDRAULIC OIL TANK ASSEMBLY/DISASSEMBLY........................................................1-S14

[5] ASSEMBLY/DISASSEMBLY OF ENGINE RELATED COMPONENTS..............................1-S16

(1) DPF Muffler ...................................................................................................................1-S16

(2) Engine ...........................................................................................................................1-S18

[6] ASSEMBLING OPERATING LEVERS ................................................................................1-S21

(1) Travel Lever...................................................................................................................1-S21

(2) Blade Lever ...................................................................................................................1-S21

(3) Limit Switch ...................................................................................................................1-S21

3. TRACK FRAME .........................................................................................................................1-S22

[1] SWIVEL BEARING ASSEMBLY/DISASSEMBLY ............................................................... 1-S22

[2] TRACK ................................................................................................................................1-S23

(1) Assembly/Disassembly of the Rubber Track.................................................................1-S23

(2) Assembly/Disassembly of Iron Tracks...........................................................................1-S24

(3) Steel Track Removal/Installation Tools .........................................................................1-S27

[3] FRONT IDLER.....................................................................................................................1-S30

(1) Assembly/Disassembly of Front Idler ............................................................................1-S30

(2) Assembly/Disassembly of the Front Idler ......................................................................1-S30

[4] GREASE CYLINDER ..........................................................................................................1-S32

(1) Assembly/Disassembly of the Grease Cylinder............................................................. 1-S32

(2) Components ..................................................................................................................1-S32

[5] TENSIONER........................................................................................................................1-S33

(1) Tensioner Assembly/Disassembly................................................................................. 1-S33

[6] TRACK ROLLERS...............................................................................................................1-S34

(1) Track Roller Assembly/Disassembly .............................................................................1-S34

(2) Components ..................................................................................................................1-S34

[7] CARRIER ROLLERS...........................................................................................................1-S35

(1) Carrier Roller Assembly/Disassembly ...........................................................................1-S35

(2) Components ..................................................................................................................1-S3

TABLE OF DIMENSIONS ................................................................................................... 1-S36

[8]

(1) Rubber Track.................................................................................................................1-S36

(2) Steel Track ....................................................................................................................1-S36

(3) Idler Sprocket ................................................................................................................1-S37

(4) Carrier Rollers and Track Rollers .................................................................................. 1-S37

4. MEASURING MACHINE PERFORMANCE ..............................................................................1-S38

[1] MEASURING FRONT PERFORMANCE ............................................................................ 1-S38

(1) Measuring Swivel Gear Backlash..................................................................................1-S38

(2) Measuring Swivel Bearing Play ..................................................................................... 1-S39

5

Page 47

5. SWIVEL GEAR BACKLASH PERFORMANCE .........................................................................1-S40

KiSC issued 08, 2015 A

Page 48

KX080-4, WSM

CAUTION

KiSC issued 08, 2015 A

MACHINE BODY

1. FRONT

[1] BOOM ASSEMBLY/DISASSEMBLY

• Wear protective gear, such as a helmet, eye protection, etc., during assembly/disassembly.

• For group work, decide on signals for communication, make sure everyone understands and uses them

and be very careful about safety.

• Never put your finger in the pin hole when aligning the pin with the hole.

• When hoisting anything heavy, always determine its center of gravity before hoisting it.

• When working with a sling, use a cloth or the like in places that may be hit hard by the nylon sling.

RY9212148MBS0012US0

1. Lower the front to the ground.

Remove the AUX lines from each bracket and disconnect the

bucket cylinder hoses.

(1) AUX line (2) Bucket cylinder hose

RY9212148MBS0017US0

2. Suspend the arm cylinder temporarily and remove the pin on the

rod side.

Operate the crane and lower the arm cylinder onto a block on

top of the boom.

(1) Arm Cylinder (2) Block

RY9212148MBS0018US0

3. Suspend the arm and bucket temporarily with the crane, then

remove the linkage pin between the arm and the boom and then

remove the bucket and the arm.

Weight Approx. 510 kg (1120 lbs)

(1) Pin

RY9212148MBS0019US0

4. Set the end of the boom on the ground.

Suspend the boom cylinder temporarily and remove the pin on

the rod side.

Operate the crane and lower the boom cylinder onto a stand.

(1) Pin (2) Cylinder stand

RY9212148MBS0020US0

1-S1

Page 49

KX080-4, WSM

KiSC issued 08, 2015 A

MACHINE BODY

5. Remove all the arm cylinder and bucket cylinder hoses.

(1) Arm cylinder hose (2) Bucket cylinder hose

RY9212148MBS0021US0

6. Suspend the boom temporarily and remove the pin at the base

of the boom.

(1) Pin

RY9212148MBS0022US0

7. Operate the crane and remove the boom.

Boom weight Approx. 500 kg (1102 lbs)

RY9212148MBS0023US0

8. Perform the procedure in reverse for assembly.

RY9212148HYS0096US0

1-S2

Page 50

KX080-4, WSM

NOTE

KiSC issued 08, 2015 A

[2] TABLE OF DIMENSIONS

(1) Bucket

• Kubota Japan bucket

MACHINE BODY

No. KX080-4 No. KX080-4 No. KX080-4 No. KX080-4

(1)

(2)

(3)

(4)

(5)

(6)

600 mm

23.62 in.

620 mm

24.41 in.

328 mm

12.91 in.

200 mm

7.87 in.

44 mm

1.73 in.

20 mm

0.79 in.

(7)

(8)

(9)

(10)

(11)

(12)

105 mm

4.13 in.

120 mm

4.72 in.

60 mm

2.36 in.

538 mm

21.18 in.

902.5 mm

35.53 in.

7.5 mm

0.30 in.

1-S3

(13)

(14)

(15)

(16)

(17)

(18)

300 mm

11. 8 1 i n.

205 mm

8.07 in.

25 mm

0.98 in.

37.5 mm

1.48 in.

164.5 mm

6.48 in.

82 mm

3.23 in.

(19)

(20)

(21)

(22)

(23)

(24)

RY9212148MBS0033US0

462 mm

18.19 in.

90 mm

3.54 in.

22 mm

0.87 in.

14 mm

0.55 in.

222 mm

8.74 in.

111 m m

4.37 in.

Page 51

KX080-4, WSM

KiSC issued 08, 2015 A

(2) Front Pin

MACHINE BODY

Item

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

100 × 474 mm

3.94 × 18.66 in.

70 × 183 mm

2.76 × 7.20 in.

70 × 168 mm

2.76 × 6.61 in.

80 × 437 mm

3.15 × 17.20 in.

70 × 200 mm

2.76 × 7.87 in.

70 × 226 mm

2.76 × 8.90 in.

70 × 332 mm

2.76 × 13.07 in.

60 × 226 mm

2.36 × 8.90 in.

60 × 175 mm

2.36 × 6.89 in.

60 × 333 mm

2.36 × 13.11 in.

60 × 151 mm

2.36 × 5.94 in.

60 × 275 mm

2.36 × 10.83 in.

60 × 275 mm

2.36 × 10.83 in.

60 × 167 mm

2.36 × 6.57 in.

70 × 144 mm

2.76 × 5.67 in.

85 × 295 mm

3.35 × 11.61 in.

50 × 167 mm

1.97 × 6.57 in.

50 × 167 mm

1.97 × 6.57 in.

KX080-4

(Pin dia. X length)

• The pin usage limit is when the wear

exceeds 1.0mm (0.039 in.) from the

factory spec. from new.

(a) Pin diameter

(b) Length

RY9212158MBS0001US0

1-S4

Page 52

KX080-4, WSM

KiSC issued 08, 2015 A

(3) Front Bushings

MACHINE BODY

Item Point used

Swing bracket top

(1)

Swivel frame, vertical

Swing bracket bottom

(2) Cylinder

Swing bracket top

(3)

Cylinder

Swing bracket bottom

Swing bracket ends

(4)

Boom ends

Swing bracket right

(5)

Cylinder

Swing bracket left

(6) Cylinder

KX080-4

(I.D. X O.D. X Length)

100 × 115 × 64 mm

3.94 × 4.53 × 2.52 in.

100 × 115 × 110 mm

3.94 × 4.53 × 4.33 in.

100 × 115 × 61 mm

3.94 × 4.53 × 2.40 in.

70 × 82 × 65 mm

2.76 × 3.23 × 2.56 in.

70 × 82 × 45 mm

2.76 × 3.23 × 1.77 in.

70 × 82 × 65 mm

2.76 × 3.23 × 2.56 in.

70 × 82 × 36 mm

2.76 × 3.23 × 1.42 in.

80 × 95 × 80 mm

3.15 × 3.74 × 3.15 in.

80 × 95 × 80 mm

3.15 × 3.74 × 3.15 in.

70 × 82 × 49 mm

2.76 × 3.23 × 1.93 in.

70 × 82 × 75 mm

2.76 × 3.23 × 2.95 in.

70 × 82 × 49 mm

2.76 × 3.23 × 1.93 in.

70 × 82 × 75 mm

2.76 × 3.23 × 2.95 in.

Item Point used

(7) Arm ends

(8) Cylinder

(9) Cylinder

(10) Arm ends

(11) Bucket link

(12) Cylinder

(13) Arm ends

Bucket link

(14)

Cylinder

(15) Blade

(16) Blade

(17) Cylinder

(18) Angle fulcrum, vertical

KX080-4

(I.D. X O.D. X Length)

70 × 82 × 80 mm

2.76 × 3.23 × 3.15 in.

60 × 70 × 75 mm

2.36 × 2.76 × 2.95 in.

60 × 70 × 75 mm

2.36 × 2.76 × 2.95 in.

60 × 80 × 65 mm

2.36 × 3.15 × 2.56 in.

60 × 70 × 60 mm

2.36 × 2.76 × 2.36 in.

60 × 70 × 65 mm

2.36 × 2.76 × 2.56 in.

60 × 70 × 60 mm

2.36 × 2.76 × 2.36 in.

60 × 70 × 52 mm

2.36 × 2.76 × 2.05 in.

60 × 70 × 65 mm

2.36 × 2.76 × 2.56 in.

60 × 70 × 88 mm

2.36 × 2.76 × 3.46 in.

70 × 82 × 60 mm

2.76 × 3.23 × 2.36 in.

50 × 60 × 60 mm

1.97 × 2.36 × 2.36 in.

85 × 100 × 60 mm

3.35 × 3.94 × 2.36 in.

• The usage limit for bushings is when the wear exceeds 1.0 mm (0.039 in.) from the factory spec. from new.

RY9212158MBS0002US0

1-S5

Page 53

KX080-4, WSM

KiSC issued 08, 2015 A

Bushing shape

(4) Arm

MACHINE BODY

(A) Flanged bushing

(B) Normal bushing

(a) I.D.

(b) O.D.

(c) Length

RY9212148MBS0036US0

(A) Arm tip (B) Bucket link 1

No. KX080-4 No. KX080-4 No. KX080-4 No. KX080-4

(1)

(2)

(3)

(4)

(5)

260 mm

10.24 in.

1840 mm

72.44 in.

451 mm

17.76 in.

279 mm

10.98 in.

370 mm

14.57 in.

(6)

(7)

(8)

(9)

(10)

1745 mm

68.70 in.

403 mm

15.87 in.

428 mm

16.85 in.

13 mm

0.51 in.

188 mm

7.40 in.

1-S6

(11)

(12)

(13)

(14)

(15)

66 mm

2.60 in.

200 mm

7.87 in.

70 mm

2.76 in.

67 mm

2.64 in.

80 mm

3.15 in.

(16)

(17)

(18)

(19)

(20)

RY9212148MBS0037US0

70 mm

2.76 in.

200 mm

7.87 in.

76 mm

2.99 in.

70 mm

2.76 in.

Page 54

KX080-4, WSM

KiSC issued 08, 2015 A

(5) Blade

No. Item KX080-4

(a) I.D. X Length

(b) I.D. X Length

(c) Width

(d) Height

(e) Length

Tip height - plate

(f)

thickness

Distance between

(g)

supports

70 × 98 mm

2.76 × 3.86 in.

70 × 28 mm

2.76 × 1.10 in.

2200 mm

86.61 in.

500 mm

19.69 in.

1448 mm

57.01 in.

90 × t 16 mm

3.54 × t 0.63 in.

698 mm

27.48 in.

RY9212148MBS0038US0

MACHINE BODY

No. Item KX080-4 No. Item KX080-4

(a) I.D. X Length

(b) I.D. X Length

(c) I.D. X Length

(d) Width

(e) Height

(f) Length

70 × 98 mm

2.76 × 3.86 in.

70 × 28 mm

2.76 × 1.10 in.

85 × 289 mm

3.35 × 11.38 in.

2200 mm

86.61 in.

510 mm

20.08 in.

1754.5 mm

69.07 in.

(g) Tip height - plate thickness

(h) Distance between supports

(i) Cutting edge

(j) Cutting edge

(k) Cutting edge

(l) Cutting edge

1-S7

160 × t 15.9 mm

6.30 × t 0.63 in.

698 mm

27.48 in.

60 mm

2.36 in.

153 mm

6.02 in.

306 mm

12.05 in.

732 mm

28.82 in.

RY9212158MBS0003US0

Page 55

KX080-4, WSM

CAUTION

CAUTION

KiSC issued 08, 2015 A

2. SWIVEL FRAME

[1] WEIGHT ASSEMBLY/DISASSEMBLY

1. Remove the left and rear hoods.