Kubota GL6000, GL7000, GL9000, GL11000 Workshop Manual

WORKSHOP MANUAL

KiSC issued 05, 2015 A

DIESEL GENERATOR

GL6000,GL7000,

GL9000,GL11000

TO THE READER

KiSC issued 05, 2015 A

This Workshop Manual has been prepared to provide servicing personnel with

information on the mechanism, service and maintenance of KUBOTA Generator GL

Series. It is divided into three parts, “General”, “Mechanism” and “Servicing”.

General

Information on the general precautions, check and maintenance and special tools.

Mechanism

Information on the construction and function are included. This part should be

understood before proceeding with troubleshooting, disassembling and servicing.

Servicing

There are troubleshooting, servicing specification lists, checking and adjusting,

disassembling and assembling, and servicing which cover procedures, precautions,

factory specifications and allowable limits.

All information illustrations and specifications contained in this manual are based on

the latest product information available at the time of publication.

The right is reserved to make changes in all information at any time without notice.

© KUBOTA Corporation 2004

June 2004

Record of Revisions

KiSC issued 05, 2015 A

For pdf, use search function {Search word} to find all the revised locations.

Last digit

of the

Code No.

Issue

month

Main Revised Point and Corrective Measures {Search word}

3 2015.04 GL9000 / GL11000 Generator changed.

Reference

Page

GL6000, GL7000, GL9000, GL11000, WSM

SAFETY FIRST

KiSC issued 05, 2015 A

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

This symbol, the industry’s “Safety Alert Symbol”, is used throughout this manual and on labels on

the machine itself to warn of the possibility of personal injury. Read these instructions carefully.

It is essential that you read the instructions and safety regulations before you attempt to repair or use

this unit.

DANGER : Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING : Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION : Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

IMPORTANT : Indicates that equipment or property damage could result if instructions are not

followed.

NOTE : Gives helpful information.

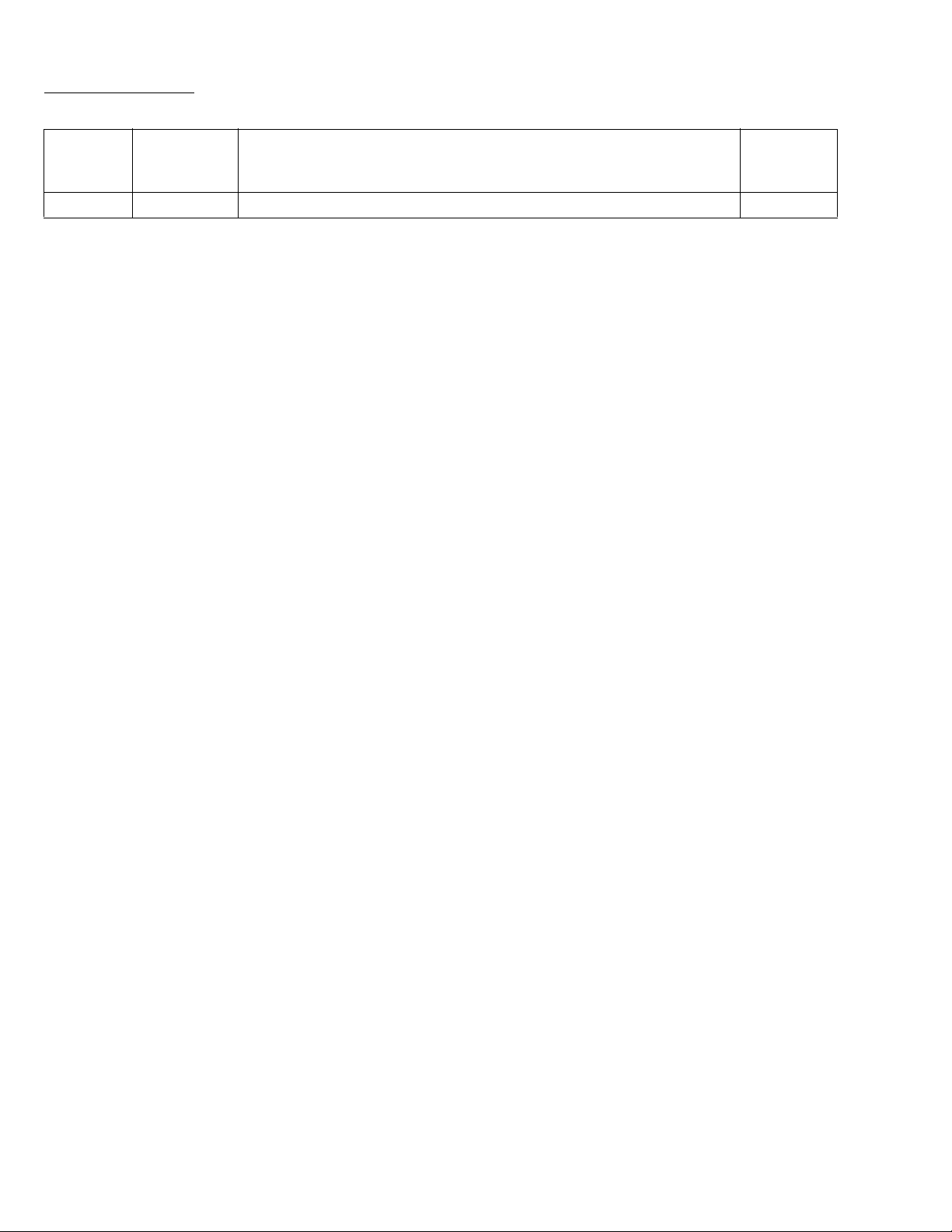

BEFORE SERVICING AND REPAIRING

• Read all instructions and safety instructions in this

manual and on your generator safety decals.

• Clean the work area and generator.

• Park the generator on a firm and level ground.

• Allow the engine to cool before proceeding.

• Stop the engine, and remove the key.

• Disconnect the battery negative cable.

1

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

SAFETY INSTRUCTIONS

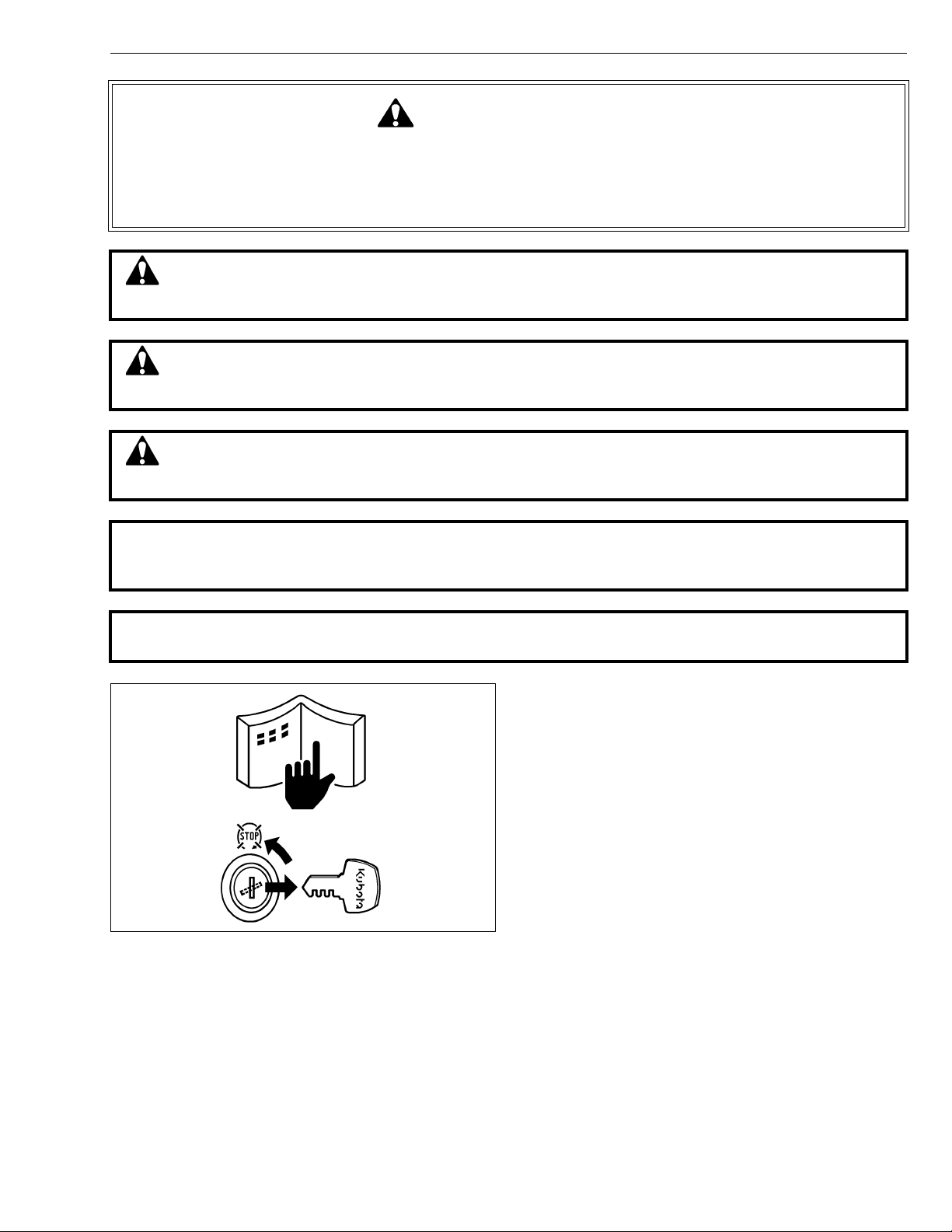

SAFETY STARTING

• Do not start the engine by shorting across starter

terminals or bypassing the safety start switch.

• Unauthorized modifications to the engine may impair

the function and / or safety and affect engine life.

SAFETY WORKING

• Do not work on the generator while under the

influence of alcohol, medication, or other substances

or while fatigued.

• Wear close fitting clothing and safety equipment

appropriate to the job.

• Use tools appropriate to the work. Makeshift tools,

parts, and procedures are not recommended.

• When servicing is performed together by two or more

persons, take care to perform all work safely.

• Do not touch the rotating or hot parts while the engine

is running.

• Never remove the radiator cap while the engine is

running, or immediately after stopping. Otherwise, hot

water will spout out from radiator. Only remove

radiator cap when cool enough to touch with bare

hands. Slowly loosen the cap to first stop to relieve

pressure before removing completely.

• Escaping fluid (fuel or hydraulic oil) under pressure

can penetrate the skin causing serious injury. Relieve

pressure before disconnecting hydraulic or fuel lines.

Tighten all connections before applying pressure.

• Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable

or uncomfortable loud noises.

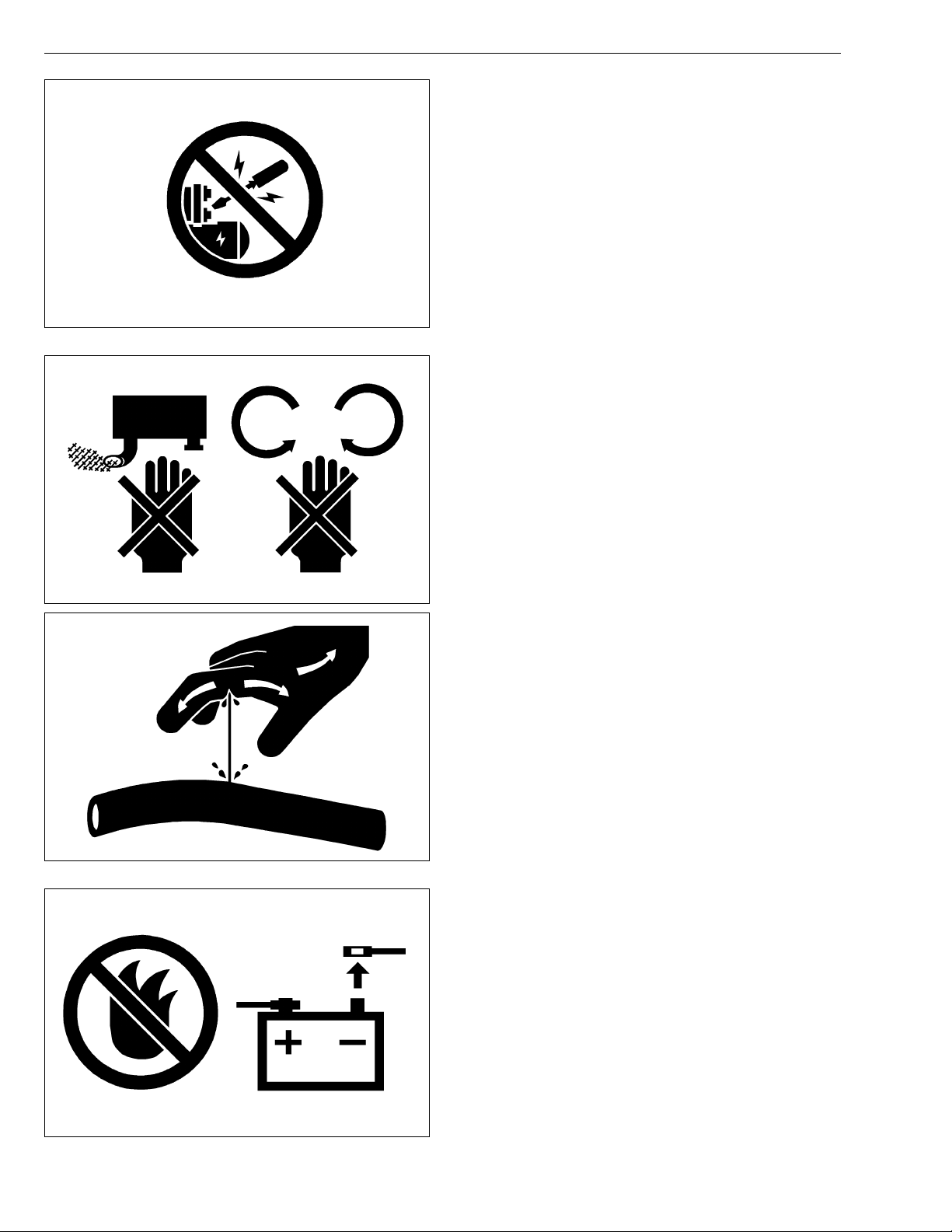

AVOID FIRES

• Fuel is extremely flammable and explosive under

certain conditions. Do not smoke or allow flames or

sparks in your working area.

• To avoid sparks from an accidental short circuit,

always disconnect the battery negative cable first and

connect it last.

• Battery gas can explode. Keep sparks and open

flame away from the top of battery, especially when

charging the battery.

• Make sure that no fuel has been spilled on the engine.

2

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

SAFETY INSTRUCTIONS

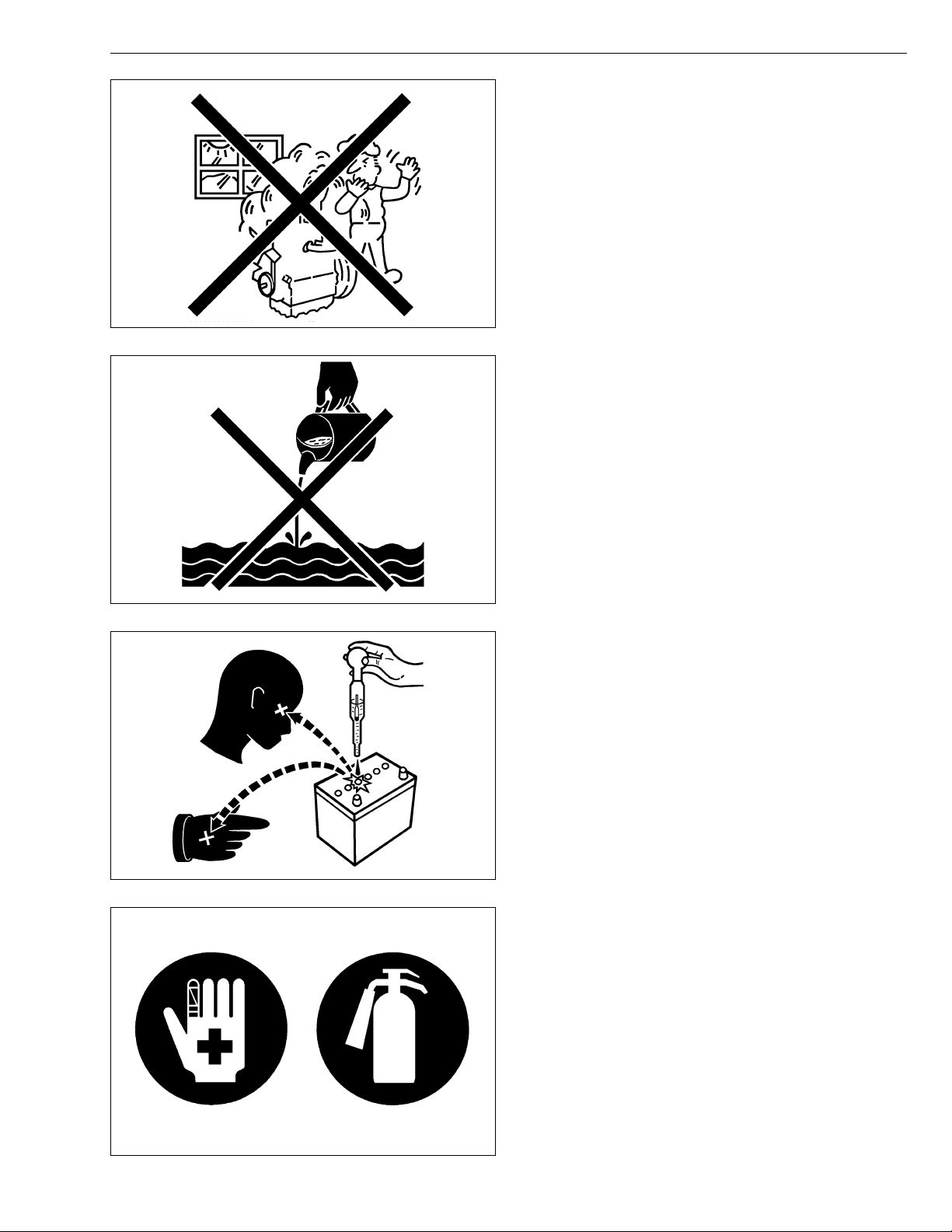

VENTILATE WORK AREA

• If the engine must be running to do some work, make

sure the area is well ventilated. Never run the engine

in a closed area. The exhaust gas contains poisonous

carbon monoxide.

DISPOSE OF FLUIDS PROPERLY

• Do not pour fluids into the ground, down a drain, or

into a stream, pond, or lake. Observe relevant

environmental protection regulations when disposing

of oil, fuel, coolant, electrolyte and other harmful

waste.

PREVENT ACID BURNS

• Sulfuric acid in battery electrolyte is poisonous. It is

strong enough to burn skin, clothing and cause

blindness if splashed into eyes. Keep electrolyte

away from eyes, hands and clothing. If you spill

electrolyte on yourself, flush with water, and get

medical attention immediately.

PREPARE FOR EMERGENCIES

• Keep a first aid kit and fire extinguisher handy at all

times.

• Keep emergency numbers for doctors, ambulance

service, hospital and fire department near your

telephone.

3

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

SAFETY INSTRUCTIONS

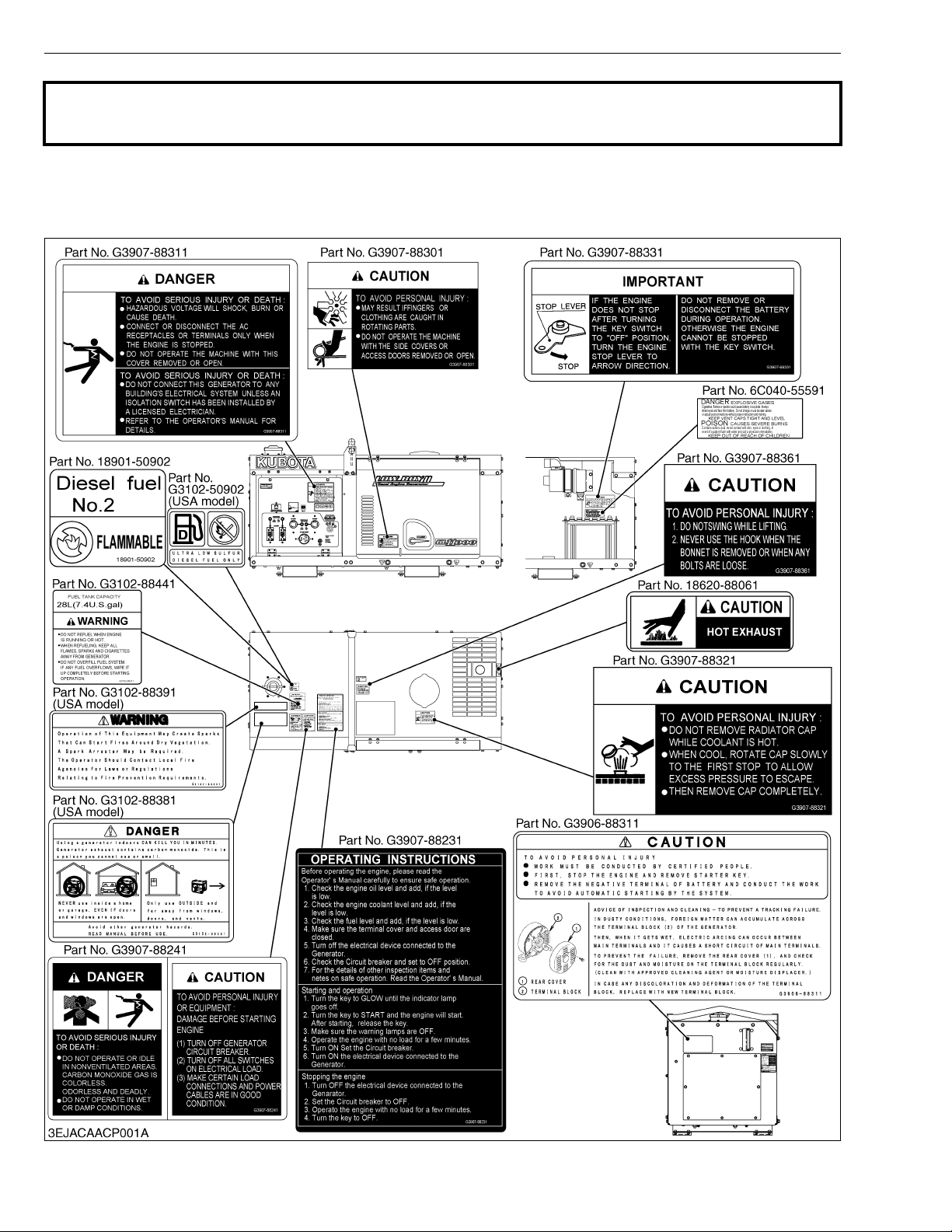

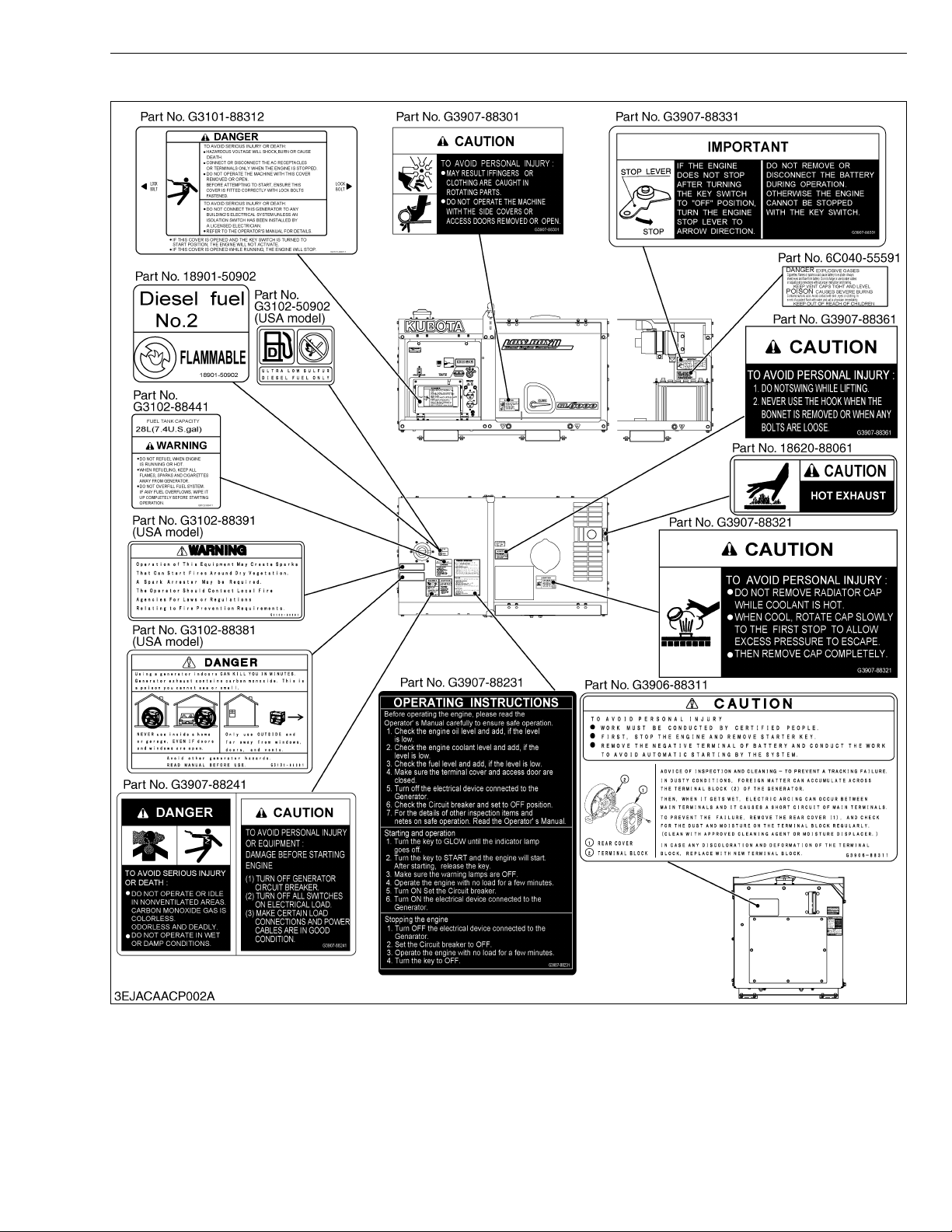

SAFETY DECALS

The following safety decals are installed on the generator.

If a decal becomes damaged, illegible or is not on the generator, replace it. The decal part number is listed

in the parts list.

[Receptacle Type]

4

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

[Terminal Type]

SAFETY INSTRUCTIONS

5

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

SPECIFICATIONS

Model GL6000-STD GL6000-AUS

Frequency 50 Hz

Rated output 5.5 kW

Maximum output 6.0 kW

Rated voltage 220 V 240 V

Generator

Engine

Continuous operating hours (at rated load) 12 hrs

Net weight kg (lbs) 235 kg (518 lbs)

Output

* Conversion Formula : HP = 0.746 kW, PS = 0.7355 kW

Rated current 25 A 22.9 A

Phrase and wire 1 - 2

Number of poles 2

Power Factor 1

Insulation Stator coil: B Rotor coil: F

Design Vertical, liquid cooled, 4 cycle, diesel

Model name Z482-E2B-SEC-2

Rated output 6.9 kW

Speed 3000 min

Number of cylinder Bore x Stroke

Displacement 0.479 L (29.23 cu.in.)

Fuel tank capacity 28 L (7.4 U.S.gals)

Crankcase oil capacity 2.2 L (0.58 U.S.gals)

Starting system Electric type 12 V / 0.8 kW

Battery 38B20R 12 V x 28 Ah / 5 Hr

Receptacle 6-15R 2 15A 2

Te rm i n al 2 P –

2 - 67 x 68 mm (2 - 2.52 x 2.68 in.)

-1

SPECIFICATIONS

(rpm)

W1028103

6

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

Model GL7000-USA GL7000-USA-TM GL7000-STD

Frequency 60 Hz

Rated output 6.5 kW

Maximum output 7.0 kW

Rated voltage 120 / 240 V 110 / 220 V

Generator

Engine

Continuous operating hours (at rated load) 10 hrs

Net weight kg (lbs) 235 kg (518 lbs)

Output

* Conversion Formula : HP = 0.746 kW, PS = 0.7355 kW

Rated current 54.2 / 27.1 A 59.1 / 29.5 A

Phrase and wire 1 - 4

Number of poles 2

Power Factor 1

Insulation Stator coil: B Rotor coil: F

Design Vertical, liquid cooled, 4 cycle, diesel

Model name Z482-E2B-SEC-3

Rated output 8.1 kW

Speed 3600 min

Number of cylinder Bore x Stroke

Displacement 0.479 L (29.23 cu.in.)

Fuel tank capacity 28 L (7.4 U.S.gals)

Crankcase oil capacity 2.2 L (0.58 U.S.gals)

Starting system Electric type 12 V / 0.8 kW

Battery 38B20R 12 V x 28 Ah / 5 Hr

Receptacle L14-30R

L6-30R

L5-30R

5-20RA (GFCI)

Terminal – 3P

2 - 67 x 68 mm (2 - 2.52 x 2.68 in.)

-1

(rpm)

5-20RA (GFCI) 5-15R x 2

SPECIFICATIONS

W1030469

7

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

Model GL9000-STD GL9000-AUS

Frequency 50 Hz

Rated output 8.0 kW

Maximum output 8.8 kW

Rated voltage 220 V 240 V

Generator

Engine

Continuous operating hours (at rated load) 8.5 hrs

Net weight kg (lbs) 280 kg (617 lbs)

Output

* Conversion Formula : HP = 0.746 kW, PS = 0.7355 kW

Rated current 36.4 A 33.3 A

Phrase and wire 1 - 2

Number of poles 2

Power Factor 1

Insulation Stator coil: B Rotor coil: F

Design Vertical, liquid cooled, 4 cycle, diesel

Model name D722-E2B-SEC-2

Rated output 10.3 kW

Speed 3000 min

Number of cylinder Bore x Stroke

Displacement 0.719 L (48.89 cu.in.)

Fuel tank capacity 28 L (7.4 U.S.gals)

Crankcase oil capacity 3.4 L (0.90 U.S.gals)

Starting system Electric type 12 V / 1.0 kW

Battery 55B24R 12 V x 36 Ah / 5 Hr

Receptacle 6-15R 2 15A 3

Te rm i n al 2 P –

3 - 67 x 68 mm (3 - 2.52 x 2.68 in.)

-1

SPECIFICATIONS

(rpm)

W1030823

8

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

Model GL11000-USA GL11000-USA-TM GL11000-STD

Frequency 60 Hz

Rated output 10.0 kW

Maximum output 11.0 kW

Rated voltage 120 / 240 V 110 / 220 V

Generator

Engine

Continuous operating hours (at rated load) 7 hrs

Net weight kg (lbs) 280 kg (617 lbs)

Output

* Conversion Formula : HP = 0.746 kW, PS = 0.7355 kW

Rated current 83.3 / 41.7 A 90.9 / 45.5 A

Phrase and wire 1 - 3

Number of poles 2

Power Factor 1

Insulation Stator coil: B Rotor coil: F

Design Vertical, liquid cooled, 4 cycle, diesel

Model name D722-E2B-SEC-2

Rated output 12.2 kW

Speed 3600 min

Number of cylinder Bore x Stroke

Displacement 0.719 L (48.89 cu.in.)

Fuel tank capacity 28 L (7.4 U.S.gals)

Crankcase oil capacity 3.4 L (0.90 U.S.gals)

Starting system Electric type 12 V / 1.0 kW

Battery 55B24R 12 V x 36 Ah / 5 Hr

Receptacle CS6369 (50 A)

L6-30R

L5-30R

5-20R (GFCI) 2

3 - 67 x 68 mm (3 - 2.52 x 2.68 in.)

-1

(rpm)

5-20R (GFCI) 5-15R 2

SPECIFICATIONS

W1031698

9

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

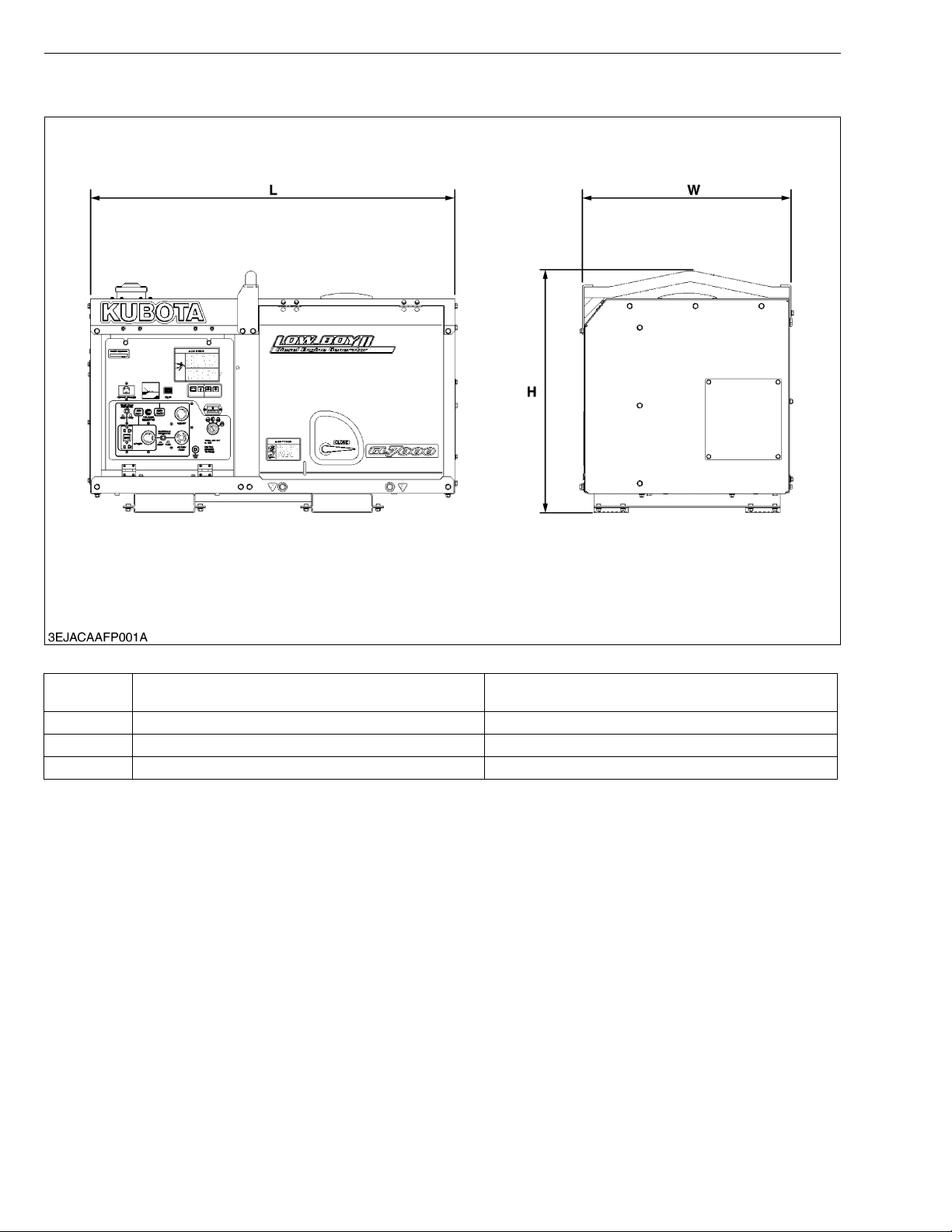

DIMENSIONS

DIMENSIONS

GL6000-STD, GL6000-AUS,

GL7000-STD, GL7000-USA, GL7000-USA-TM

L 1066 mm (42.0 in.) 1281 mm (50.4 in.)

W 618 mm (24.3 in.) 618 mm (24.3 in.)

H 698 mm (27.5 in.) 698 mm (27.5 in.)

GL9000-STD, GL9000-AUS, GL11000-STD,

GL11000-USA, GL11000-USA-TM

W1038971

10

GENERAL

KiSC issued 05, 2015 A

CONTENTS

1. IDENTIFICATION............................................................................................. G-1

[1] MODEL NAME AND ENGINE SERIAL NUMBER ................................ G-1

[2] E4B ENGINE............................................................................................. G-2

[3] CYLINDER NUMBER ............................................................................... G-3

2. PRECAUTION.................................................................................................. G-4

3. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING .. G-5

[1] WIRING ..................................................................................................... G-5

[2] BATTERY................................................................................................... G-7

[3] FUSE.......................................................................................................... G-7

[4] CONNECTOR ............................................................................................ G-7

[5] HANDLING OF CIRCUIT TESTER ......................................................... G-8

4. LUBRICANTS, FUEL AND COOLANT ......................................................... G-9

5. TIGHTENING TORQUES ............................................................................. G-11

[1] GENERAL USE SCREWS, BOLT AND NUTS ................................... G-11

[2] STUD BOLTS.......................................................................................... G-11

6. MAINTENANCE CHECK LIST ..................................................................... G-12

7. CHECK AND MAINTENANCE ..................................................................... G-14

[1] DAILY CHECK ........................................................................................ G-14

[2] CHECK POINTS OF INITIAL 50 HOURS ........................................... G-15

[3] CHECK POINT OF EVERY 50 HOURS ............................................. G-16

[4] CHECK POINT OF EVERY 100 HOURS ........................................... G-16

[5] CHECK POINT OF EVERY 200 HOURS ........................................... G-18

[6] CHECK POINT OF EVERY 300 HOURS ........................................... G-19

[7] CHECK POINT OF EVERY 400 HOURS ........................................... G-19

[8] CHECK POINTS OF EVERY 500 HOURS......................................... G-20

[9] CHECK POINT OF EVERY 800 HOURS ........................................... G-22

[10]CHECK POINT OF EVERY 1000 HOURS ......................................... G-23

[11]CHECK POINT OF EVERY 1500 HOURS ......................................... G-23

[12]CHECK POINT OF EVERY 1 YEAR................................................... G-24

[13]CHECK POINT OF EVERY 2 YEARS ................................................ G-24

8. SPECIAL TOOLS.......................................................................................... G-26

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

1. IDENTIFICATION

[1] MODEL NAME AND ENGINE SERIAL NUMBER

When contacting your local KUBOTA distributor, always specify

the model name and serial numbers of both engine and generator.

The engine model and its serial number need to be identified

before the engine can be serviced or parts replaced.

Engine Serial Number

The engine serial number is an identified number for the engine.

It is marked after the engine model number.

It indicates month and year of manufacture as follows.

• Year of manufacture

Alphabet or

Number

4 2004 G 2016

5 2005 H 2017

6 2006 J 2018

7 2007 K 2019

8 2008 L 2020

9 2009 M 2021

A 2010 N 2022

B 2011 P 2023

C 2012 R 2024

D 2013 S 2025

E 2014 T 2026

F 2015 V 2027

Year

Alphabet or

Number

G GENERAL

Yea r

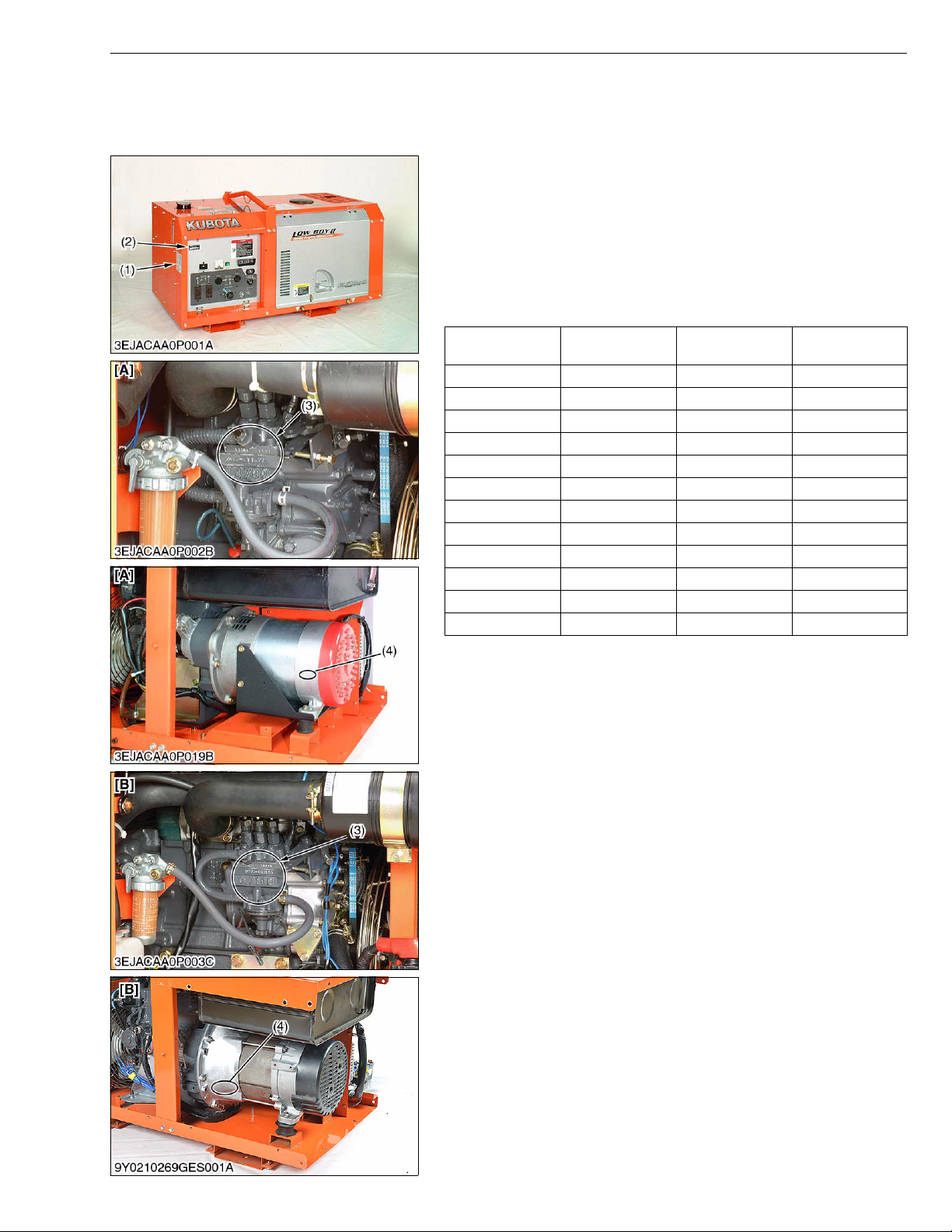

(1) Model Name

(2) Serial Number

(3) Engine Model Name and Serial

Number

(4) Generator Model Name and Serial

Number

[A] GL6000, GL7000

[B] GL9000, GL11000

W1035676

G-1

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

G GENERAL

• Month of manufacture

Month

January A0001 ~ A9999 B0001 ~

February C0001 ~ C9999 D0001 ~

March E0001 ~ E9999 F0001 ~

April G0001 ~ G9999 H0001 ~

May J0001 ~ J9999 K0001 ~

June L0001 ~ L9999 M0001 ~

July N0001 ~ N9999 P0001 ~

August Q0001 ~ Q9999 R0001 ~

September S0001 ~ S9999 T0001 ~

October U0001 ~ U9999 V0001 ~

November W0001 ~ W9999 X0001 ~

December Y0001 ~ Y9999 Z0001 ~

e.g. D722-5A0001

"5" indicates 2005 and "A" indicates January.

So, 5A indicates that the engine was manufactured in January, 2005.

0001 ~ 9999 10000 ~

Engine Serial Number

W1011076

[2] E4B ENGINE

[Example : Engine Model Name D902-E4B-XXXX]

The emission controls previously implemented in various countries to prevent air pollution will be stepped up as

Non-Road Emission Standards continue to change. The timing or applicable date of the specific Non-Road Emission

regulations depends on the engine output classification.

Over the past several years, KUBOTA has been supplying diesel engines that comply with regulations in the

respective countries affected by Non-Road Emission regulations. For KUBOTA Engines, E4B will be the designation

that identifies engine models affected by the next emission phase (See the table below).

When servicing or repairing ###-E4B series engines, use only replacement parts for that specific E4B engine,

designated by the appropriate E4B KUBOTA Parts List and perform all maintenance services listed in the appropriate

KUBOTA Operator's Manual or in the appropriate E4B KUBOTA Workshop Manual. Use of incorrect replacement

parts or replacement parts from other emission level engines (for example: E2B engines), may result in emission

levels out of compliance with the original E4B design and EPA or other applicable regulations. Please refer to the

emission label located on the engine head cover to identify Output classification and Emission Control Information.

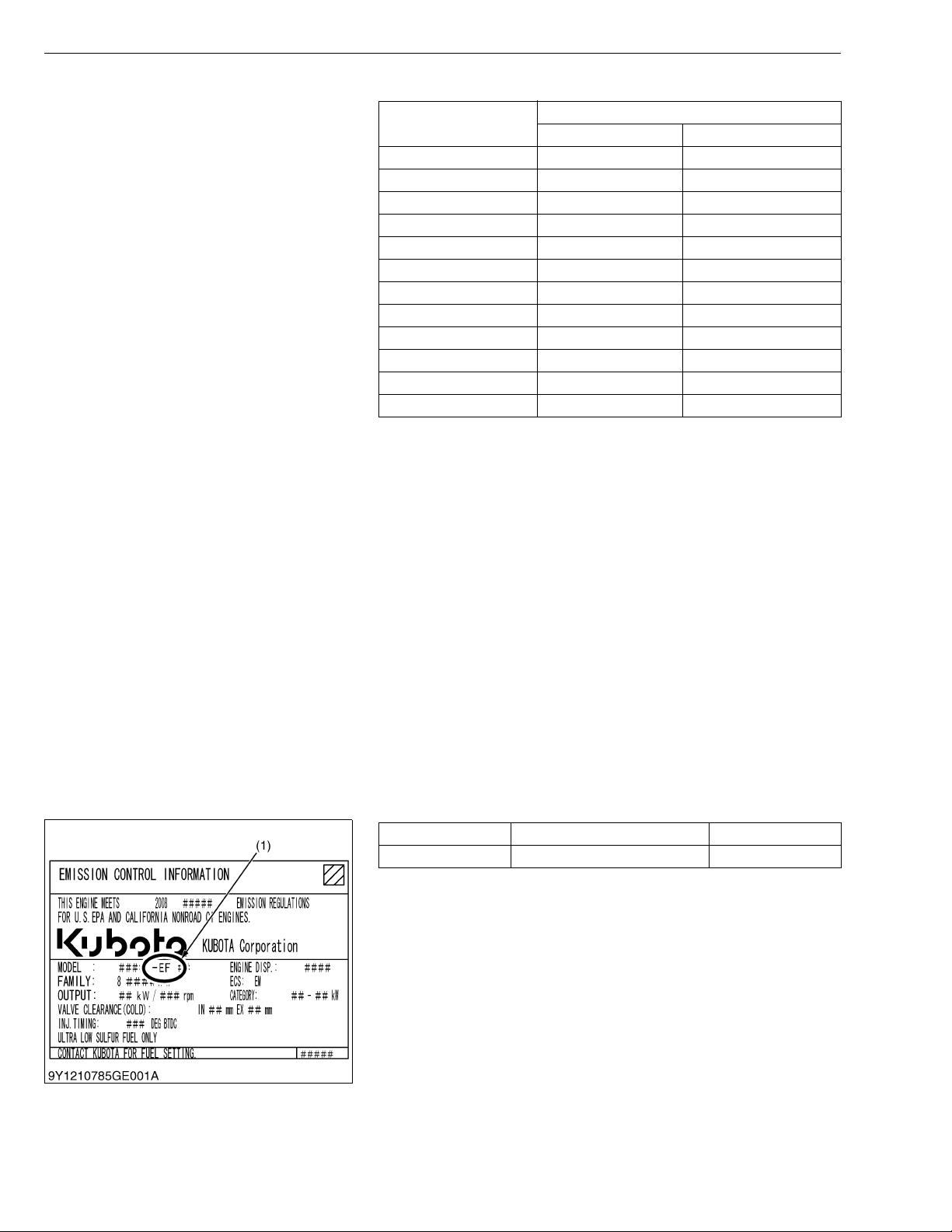

E4B engines are identified with "EF" at the end of the Model designation, on the US EPA label. Please note : E4B is

not marked on the engine.

Category (1) Engine output classification EPA regulation

EF Less than 19 kW Tier 4

(1) "E4B" engines are identified with "EF" at the end of the Model designation, on

the US EPA label.

"E4B" designates Tier 4, depending on engine output classification.

W1030236

G-2

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

[3] CYLINDER NUMBER

G GENERAL

The cylinder numbers of KUBOTA diesel engine are designated

as shown in the figure.

The sequence of cylinder numbers is given as No.1, No.2 and

No.3 starting from the gear case side.

W1011077

G-3

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

2. PRECAUTION

G GENERAL

• During disassembly, carefully arrange removed parts in a clean

area to prevent confusion later. Screws, bolts and nuts should be

replaced in their original position to prevent reassembly errors.

• When special tools are required, use KUBOTA genuine special

tools. Special tools which are not frequently used should be

made according to the drawings provided.

• Before disassembling or servicing live wires, make sure to

always disconnect the grounding cable from the battery first.

• Remove oil and dirt from parts before measuring.

• Use only KUBOTA genuine parts for parts replacement to

maintain engine performance and to ensure safety.

• Gaskets and O-rings must be replaced during reassembly. Apply

grease to new O-rings or oil seals before assembling.

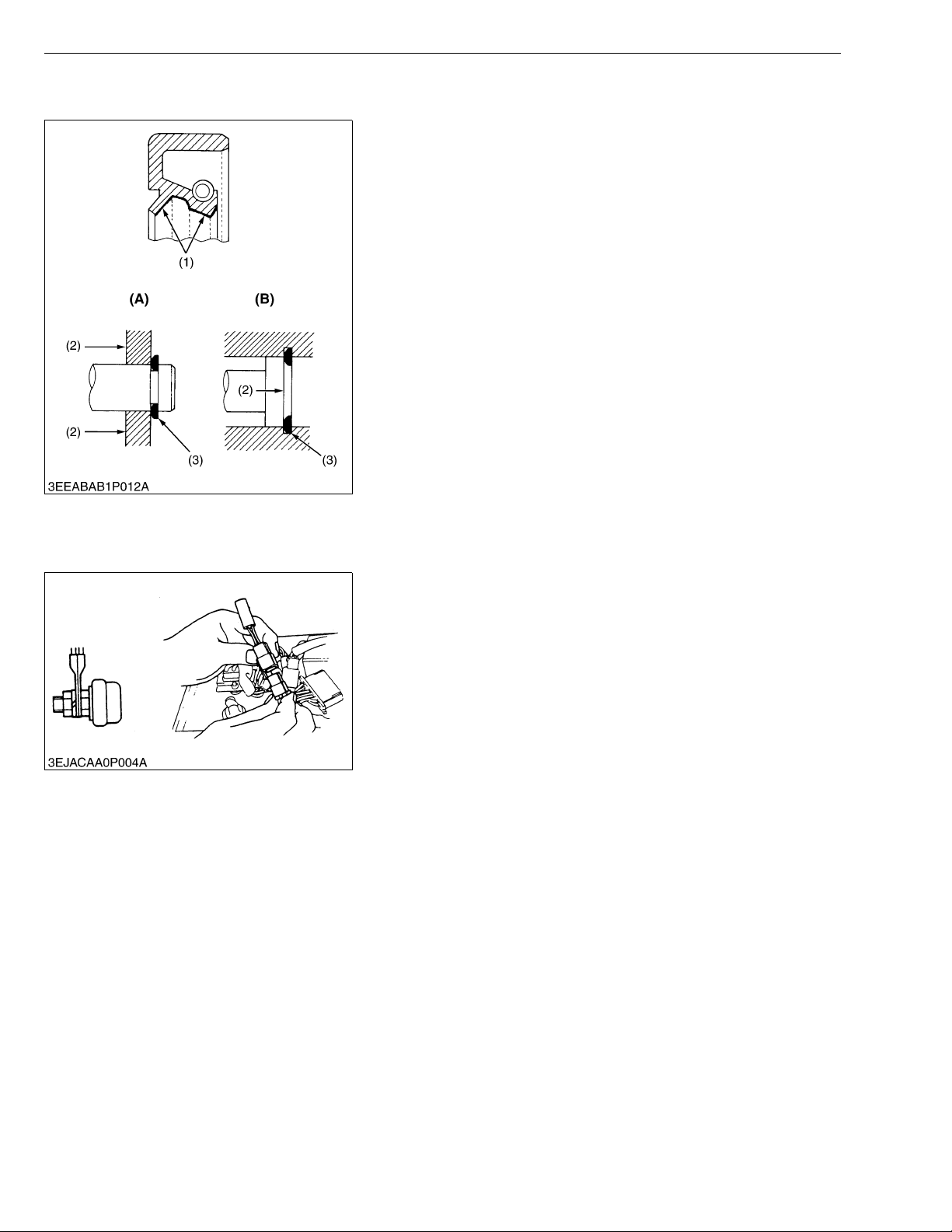

• When reassembling external or internal snap rings, position them

so that the sharp edge faces against the direction from which

force is applied.

• Be sure to perform run-in the serviced or reassembled engine.

Do not attempt to give heavy load at once, or serious damage

may result to the engine.

(1) Grease

(2) Force

(3) Place the Sharp Edge against the

Direction of Force

(A) External Snap Ring

(B) Internal Snap Ring

W10109040

• Before checking any generator or engine electrical component,

be sure to check that all terminals and connectors are tight.

• After the individual component inspection, also inspect the wire

leads for continuity; that might be the cause of the problem.

• The rotor and stator must be protected when disassembling and

reassembling.

If they are damaged, no power can be generated.

• To maintain the generator's performance and ensure safety, use

only KUBOTA genuine parts for replacement.

• Use extreme caution when working on electrical components.

Electrical shocks cause injury or death.

W10262580

G-4

GL6000, GL7000, GL9000, GL11000, WSM

IMPORTANT

KiSC issued 05, 2015 A

G GENERAL

3. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS

AND WIRING

To ensure safety and prevent damage to the machine and

surrounding equipment, heed the following precautions in handling

electrical parts and wiring.

• Check electrical wiring for damage and loosened

connection every year. To this end, educate the customer to

do his or her own check and at the same time recommend

the dealer to perform periodic check for a fee.

• Do not attempt to modify or remodel any electrical parts and

wiring.

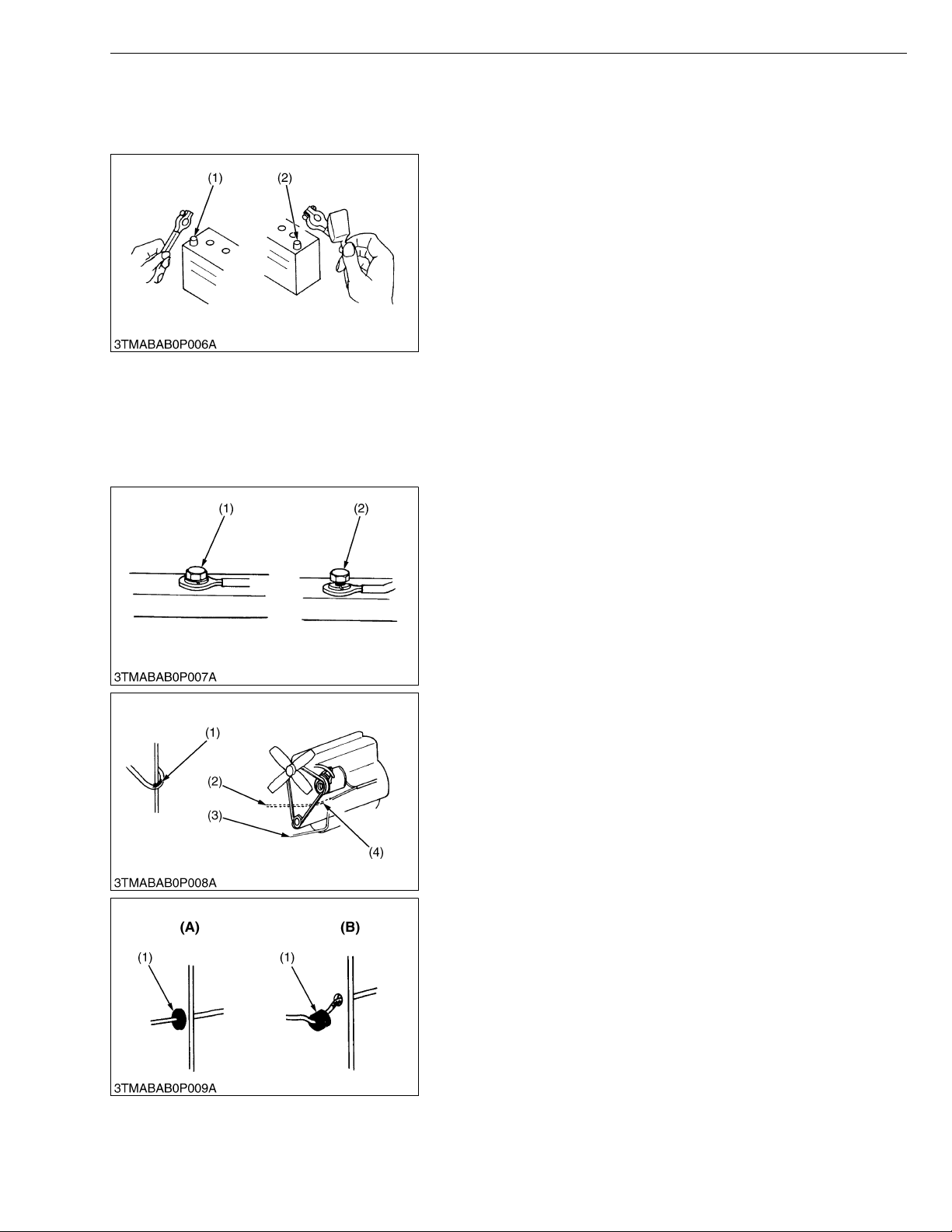

• When removing the battery cables, disconnect the negative

cable first. When installing the battery cables, connect the

positive cable first.

(1) Negative Terminal (2) Positive Terminal

W10111140

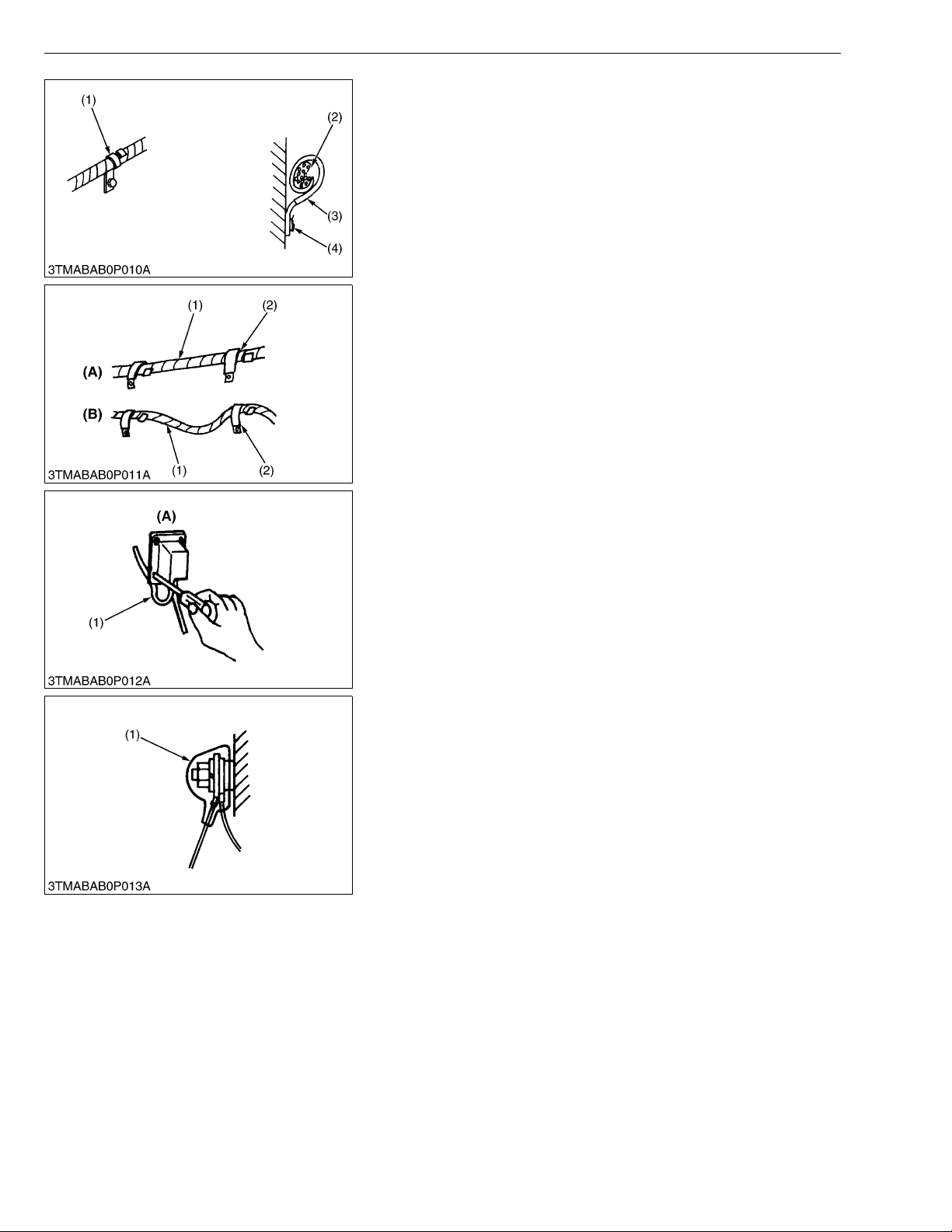

[1] WIRING

• Securely tighten wiring terminals.

(1) Correct

(Securely Tighten)

(2) Incorrect

(Loosening Leads to Faulty Contact)

W10112160

• Do not let wiring contact dangerous part.

(1) Dangerous Part

(2) Wiring (Incorrect)

(3) Wiring (Correct)

(4) Dangerous Part

• Securely insert grommet.

(1) Grommet (A) Correct

(B) Incorrect

W10113130

W10113880

G-5

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

G GENERAL

• Securely clamp, being careful not to damage wiring.

(1) Clamp

• Wind Clamp Spirally

(2) Wire Harness

(3) Clamp

(4) Welding Dent

W10114580

• Clamp wiring so that there is no twist, unnecessary sag, or

excessive tension, except for movable part, where sag be

required.

(1) Wiring

(2) Clamp

(A) Correct

(B) Incorrect

W10115870

• In installing a part, take care not to get wiring caught by it.

(1) Wiring (A) Incorrect

W10116700

• After installing wiring, check protection of terminals and clamped

condition of wiring, only connect battery.

(1) Cover

• Securely Install Cover

W10117350

G-6

GL6000, GL7000, GL9000, GL11000, WSM

CAUTION

KiSC issued 05, 2015 A

[2] BATTERY

G GENERAL

• Take care not to confuse positive and negative terminal posts.

• When removing battery cables, disconnect negative cable first.

When installing battery cables, check for polarity and connect

positive cable first.

• Do not install any battery with capacity other than is specified

(Ah).

• After connecting cables to battery terminal posts, apply high

temperature grease to them and securely install terminal covers

on them.

• Do not allow dirt and dust to collect on battery.

• Take care not to let battery liquid spill on your skin and

clothes. If contaminated, wash it off with water immediately.

• Before recharging the battery, remove it from the machine.

• Before recharging, remove cell caps.

• Do recharging in a well-ventilated place where there is no

open flame nearby, as hydrogen gas and oxygen are formed.

W10118160

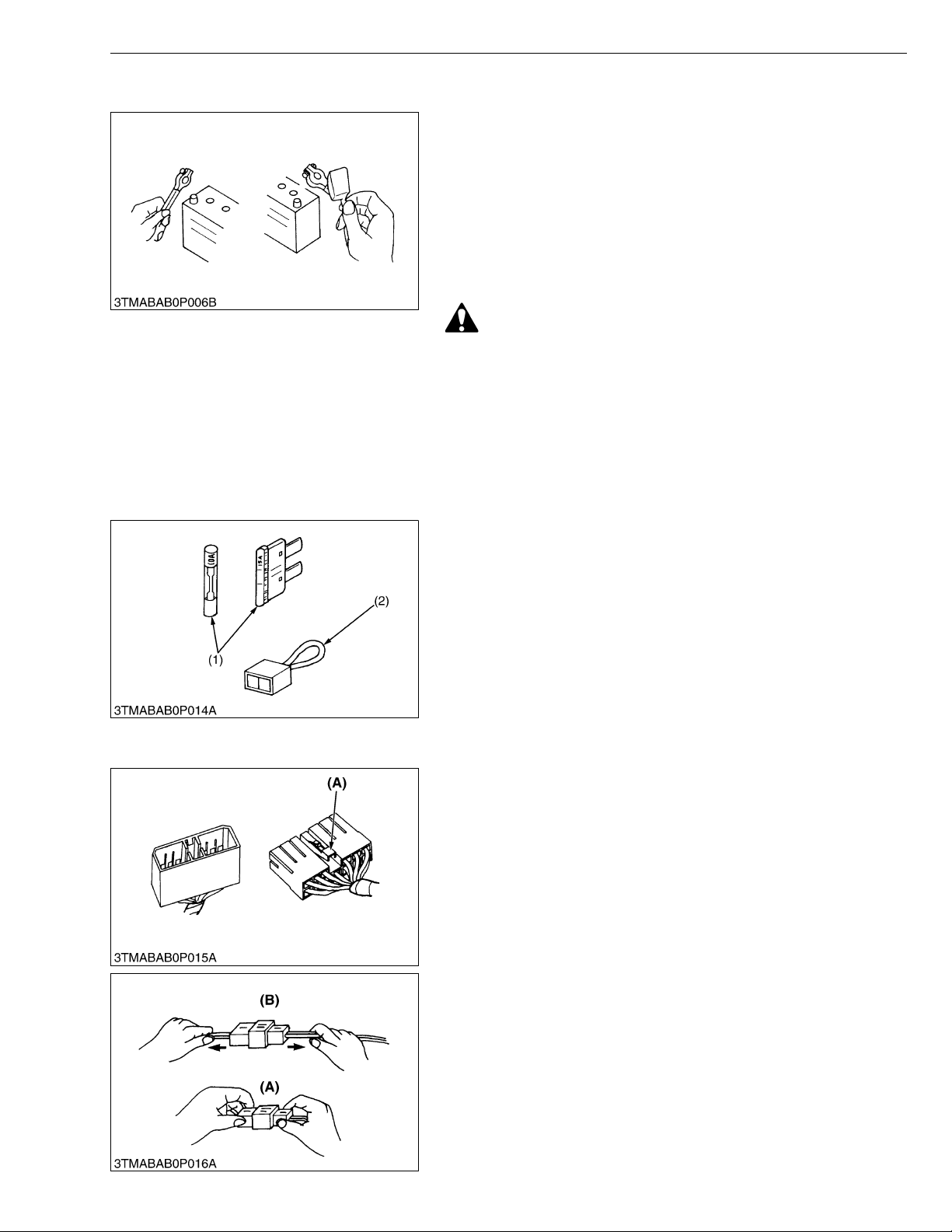

[3] FUSE

[4] CONNECTOR

• Use fuses with specified capacity.

Neither too large or small capacity fuse is acceptable.

• Never use steel or copper wire in place of fuse.

• Do not install working light, radio set, etc. on machine which is not

provided with reserve power supply.

• Do not install accessories if fuse capacity of reserve power

supply is exceeded.

(1) Fuse (2) Slow Blow Fuse

W10120920

• For connector with lock, push lock to separate.

(A) Push

W10122110

• In separating connectors, do not pull wire harnesses.

• Hold connector bodies to separate.

(A) Correct (B) Incorrect

W10122720

G-7

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

G GENERAL

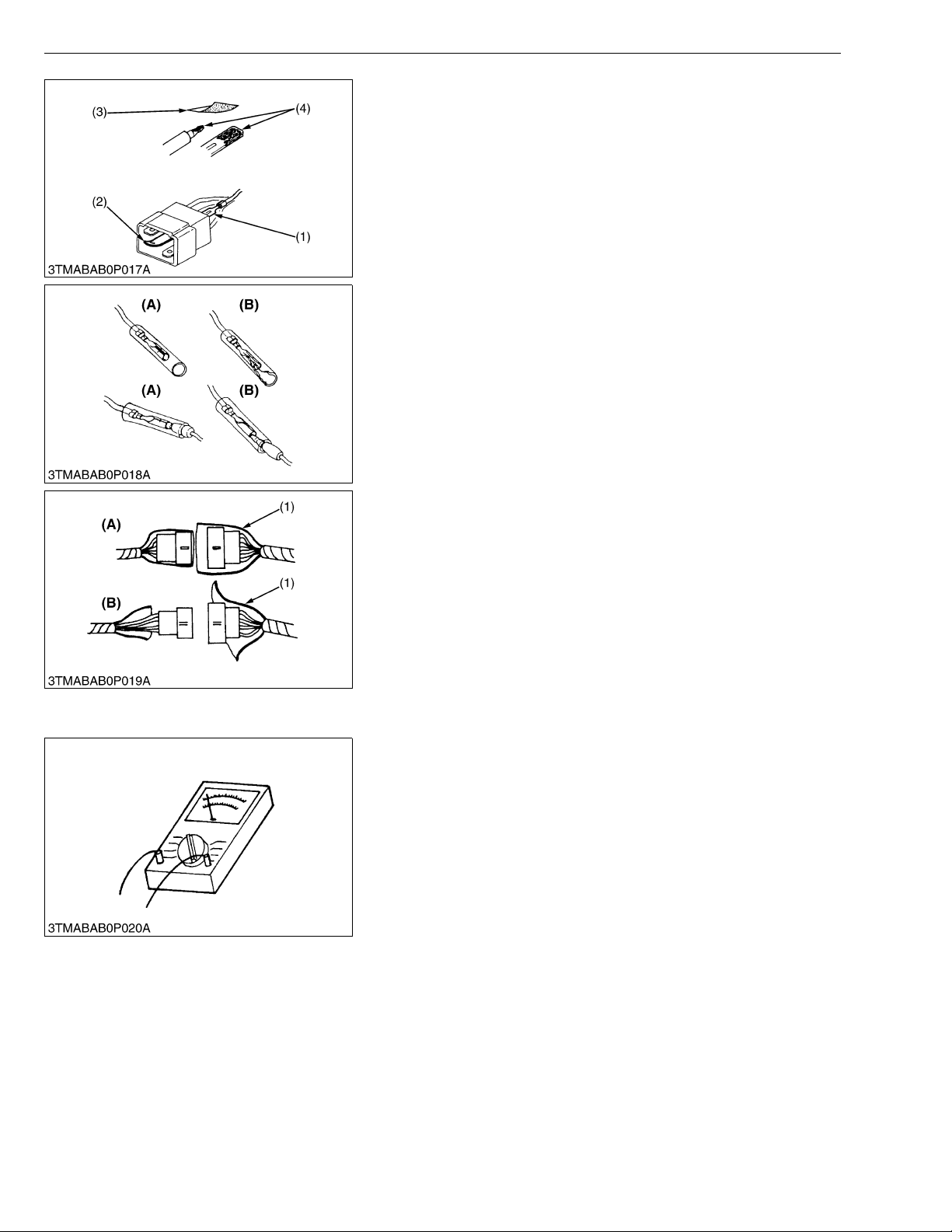

• Use sandpaper to remove rust from terminals.

• Repair deformed terminal. Make certain there is no terminal

being exposed or displaced.

(1) Exposed Terminal

(2) Deformed Terminal

(3) Sandpaper

(4) Rust

W10123460

• Make certain that there is no female connector being too open.

(A) Correct (B) Incorrect

W10124300

• Make certain plastic cover is large enough to cover whole

connector.

(1) Cover (A) Correct

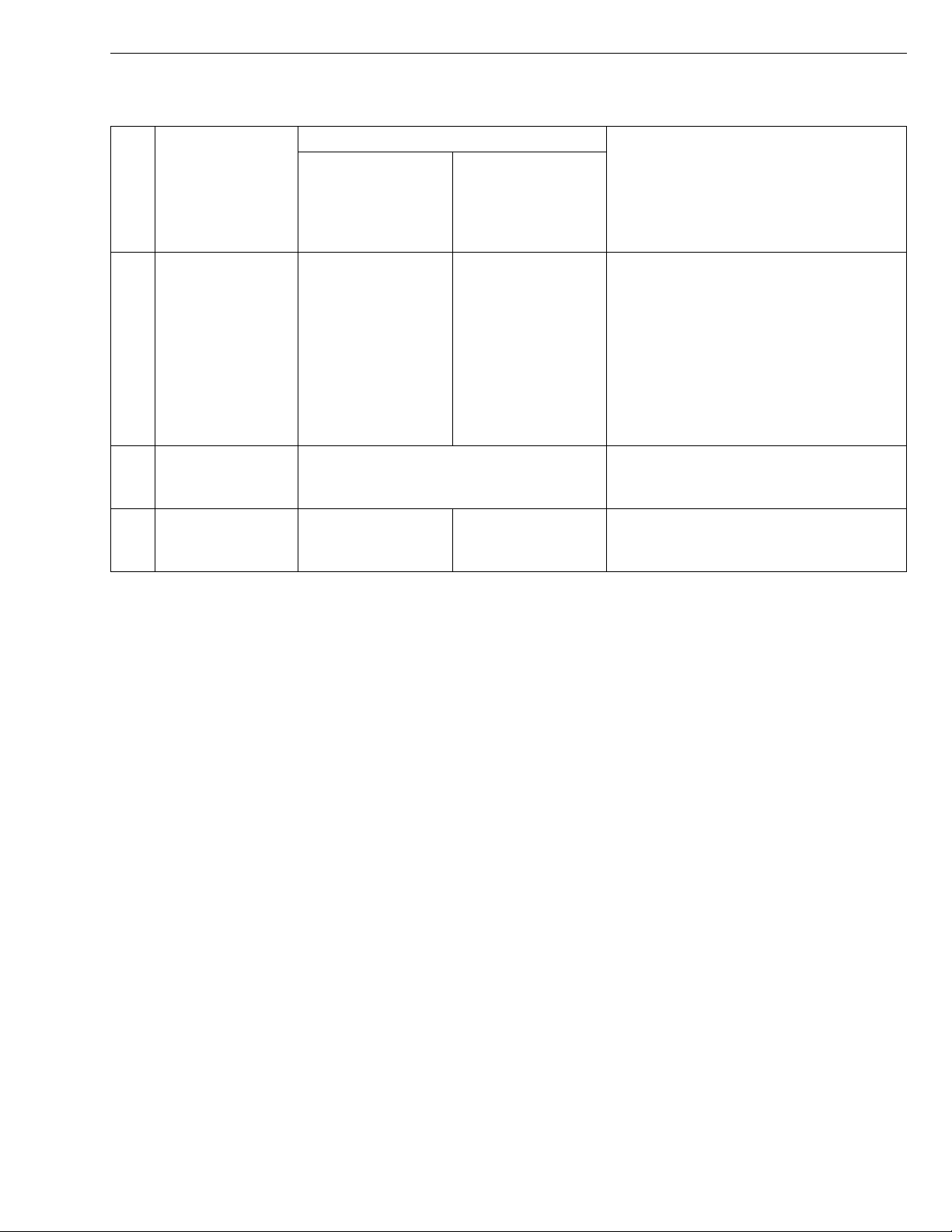

[5] HANDLING OF CIRCUIT TESTER

• Use tester correctly following manual provided with tester.

• Check for polarity and range.

(B) Incorrect

W10125190

W10126840

G-8

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

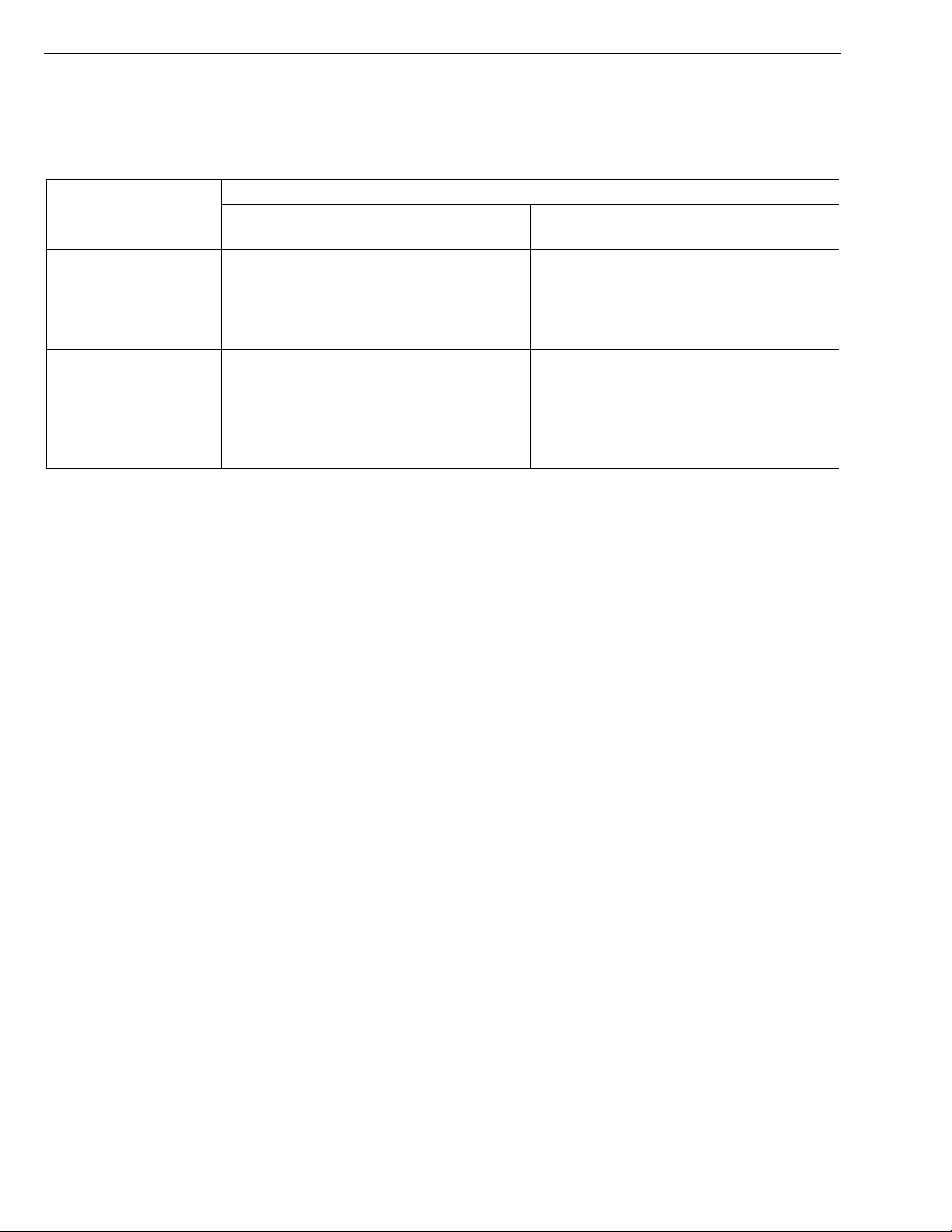

4. LUBRICANTS, FUEL AND COOLANT

Capacity

No. Place

1 Engine oil

2Fuel

3 Coolant

GL6000-STD

GL6000-AUS

GL7000-STD

GL7000-USA

GL7000-USA-TM

2.2 L

2.3 U.S.qts.

1.9 Imp.qts.

7.4 U.S.gals.

6.2 Imp.gals.

3.7 L

3.9 U.S.qts.

3.3 Imp.qts.

GL9000-STD

GL9000-AUS

GL11000-STD

GL11000-USA

GL11000-USA-TM

3.4 L

3.6 U.S.qts.

3.0 Imp.qts.

28 L

4.1 L

4.3 U.S.qts.

3.6 Imp.qts.

Higher than CF class (API)

Above 25 °C (77 °F) : SAE10W-30,

SAE10W-30,

SAE30

0 to 25 °C (32 to 77 °F) : SAE10W-30,

SAE10W-40,

SAE20

Below 0 °C (32 °F) : SAE10W-30,

SAE10W-40,

SAE10

Refer to NOTE

Clean water (Soft water)

Use antifreeze 50 / 50

G GENERAL

Lubricants, fuel and coolant

G-9

GL6000, GL7000, GL9000, GL11000, WSM

NOTE

KiSC issued 05, 2015 A

G GENERAL

Engine Oil :

• Refer to the following table for the suitable American Petroleum Institute (API) classification of engine oil

according to the engine type (with internal EGR, external EGR or non-EGR) and the Fuel Type Used :

(Low Sulfur, Ultra Low Sulfur or High Sulfur Fuels).

Engine oil classification (API classification)

Fuel Type

High Sulfur Fuel

[0.05 % (500 ppm)

Sulfur Content <

0.50 % (5000 ppm)]

CF

(If the "CF-4, CG-4, CH-4, or CI-4" engine

oil is used with a high-sulfur fuel, change

the engine oil at shorter intervals.

(approximately half))

Engines with non-EGR

Engines with internal EGR

Engines with external EGR

–

Low Sulfur Fuel

[Sulfur Content <

0.05 % (500 ppm)] or

Ultra Low Sulfur Fuel

[Sulfur Content <

CF, CF-4, CG-4, CH-4 or CI-4

CF or CI-4

(Class CF-4, CG-4 and CH-4 engine oils

cannot be used on EGR type engines.)

0.0015 % (15 ppm)]

EGR : Exhaust Gas Re-circulation

• CJ-4 classification oil is intended for use in engines equipped with DPF (Diesel Particulate Filter) and is

Not Recommended for use in KUBOTA E3 specification engines.

• Oil used in the engine should have API classification and Proper SAE Engine Oil Viscosity according to

the ambient temperatures where the engine is operated.

• With strict emission control regulations now in effect, the CF-4 and CG-4 engine oils have been developed

for use with low sulfur fuels, for On-Highway vehicle engines. When a Non-Road engine runs on high sulfur

fuel, it is advisable to use a "CF or better" classification engine oil with a high Total Base Number (a

minimum TBN of 10 is recommended).

Fuel :

• Cetane Rating : The minimum recommended Fuel Cetane Rating is 45. A cetane rating greater than 50 is

preferred, especially for ambient temperatures below 20 °C (4 °F) or elevations above 1500 m (5000 ft).

• Diesel Fuel Specification Type and Sulfur Content % (ppm) used, must be compliant with all applicable

emission regulations for the area in which the engine is operated.

• Use of diesel fuel with sulfur content less than 0.10 % (1000 ppm) is strongly recommended.

• If high-sulfur fuel (sulfur content 0.50 % (5000 ppm) to 1.0 % (10000 ppm)) is used as a diesel fuel, change

the engine oil and oil filter at shorter intervals. (approximately half)

• DO NOT USE Fuels that have sulfur content greater than 1.0 % (10000 ppm).

• Diesel fuels specified to EN 590 or ASTM D975 are recommended.

• No.2-D is a distillate fuel of lower volatility for engines in industrial and heavy mobile service. (SAE J313

JUN87)

• Since KUBOTA diesel engines of less than 56 kW (75 hp) utilize EPA Tier 4 and Interim Tier 4 standards,

the use of low sulfur fuel or ultra low sulfur fuel is mandatory for these engines, when operated in US EPA

regulated areas. Therefore, please use No.2-D S500 or S15 diesel fuel as an alternative to No.2-D, and use

No.1-D S500 or S15 diesel fuel as an alternative to No.1-D for ambient temperatures below 10 °C (14 °F).

1) SAE : Society of Automotive Engineers

2) EN : European Norm

3) ASTM : American Society of Testing and Materials

4) US EPA : United States Environmental Protection Agency

5) No.1-D or No.2-D, S500 : Low Sulfur Diesel (LSD) less than 500 ppm or 0.05 wt.%

No.1-D or No.2-D, S15 : Ultra Low Sulfur Diesel (ULSD) 15 ppm or 0.0015 wt.%

G-10

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

G GENERAL

5. TIGHTENING TORQUES

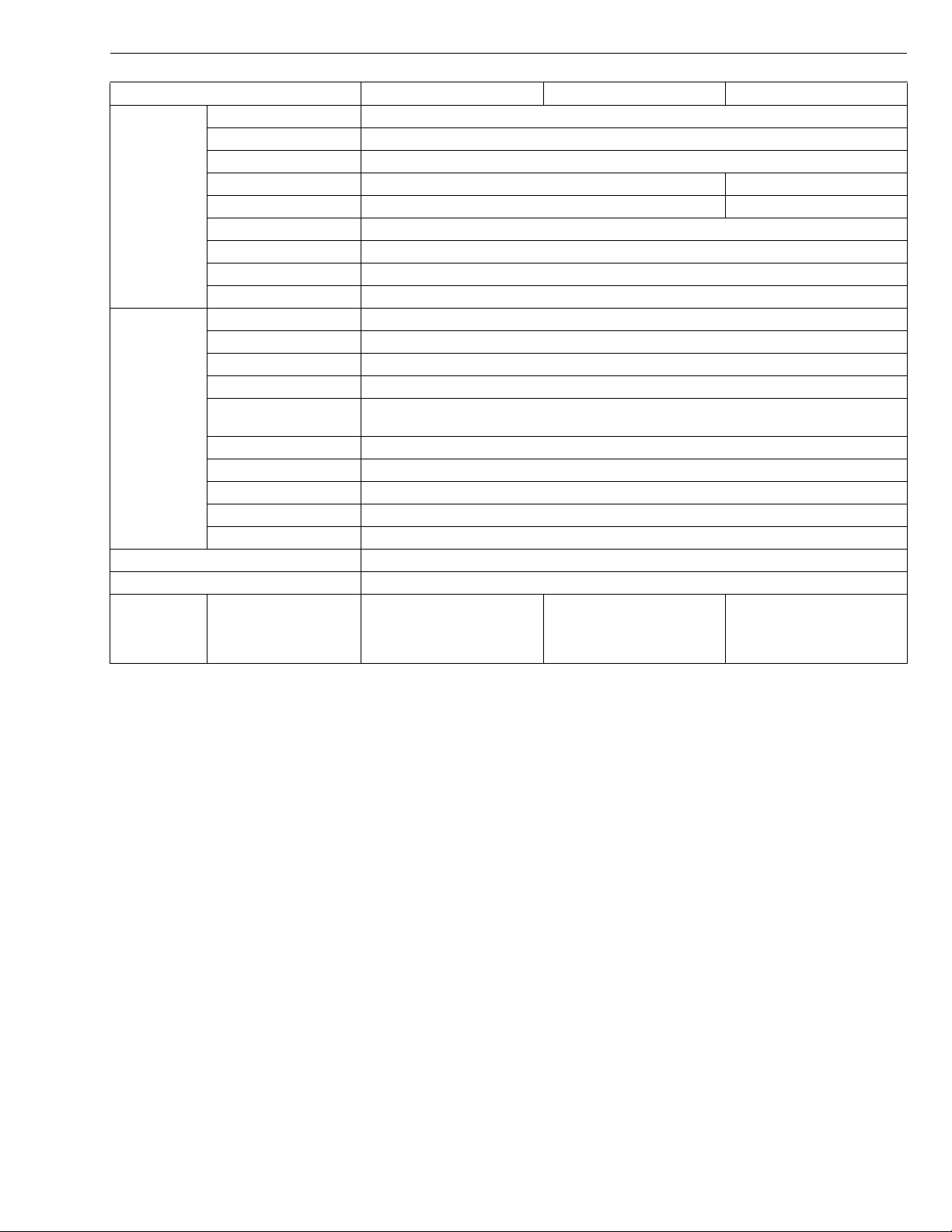

[1] GENERAL USE SCREWS, BOLT AND NUTS

Screws, bolt and nuts whose tightening torque are not specified in this Workshop Manual should be tightened

according to the table below.

Indication on top of

bolt

Material of bolt SS400, S20C S43C, S48C

Material of opponent part Ordinariness Aluminum Ordinariness Aluminum

Unit

Diameter

M4

(4 mm, 0.16 in.)

M5

(5 mm, 0.20 in.)

M6

(6 mm, 0.24 in.)

M8

(8 mm, 0.31 in.)

M10

(10 mm, 0.39 in.)

M12

(12 mm, 0.47 in.)

M14

(14 mm, 0.55 in.)

No-grade or 4T 7T

N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft

1.00

2.90

1.90

3.60

7.85

9.31

17.7

20.5

39.3

45.1

62.8

72.5

108

125

to

to

to

to

to

to

to

0.10

to

0.30

0.20

to

0.40

0.80

to

0.95

1.8

to

2.1

4.0

to

4.6

6.4

to

7.4

11. 0

to

12.8

0.70

to

2.10

1.40

to

2.70

5.79

to

6.87

13.1

to

15.1

29.0

to

33.2

46.3

to

53.5

79.6

to

92.5

---------

---------

7.85

8.82

16.7

19.6

31.4

34.3

0.80

to

0.90

1.7

to

2.0

3.2

to

3.5

–––

–––

to

to

to

5.79

to

6.50

12.3

to

14.4

23.2

to

25.3

9.81

to

11. 2

23.6

to

27.4

48.1

to

55.8

77.5

to

90.2

124

to

147

1.00

to

1.15

2.4

to

2.8

4.9

to

5.7

7.9

to

9.2

12.6

to

15.0

7.24

to

8.31

17.4

to

20.2

35.5

to

41.2

57.2

to

66.5

91.2

to

108

7.85

8.82

17

20

39.3

44.1

62.8

72.5

0.80

to

to

to

to

–––

.7

.5

to

0.90

1.8

to

2.1

4.0

to

4.5

6.4

to

7.4

W1034542

5.79

to

6.50

13.1

to

15.1

29.0

to

32.5

46.3

to

53.5

[2] STUD BOLTS

Material of opponent

part

Unit

Diameter

M8

(8 mm, 0.31 in.)

M10

(10 mm, 0.39 in.)

rdin

O

N·m kgf·m lbf·ft N·m kgf·m lbf·ft

11. 8

to

15.6

24.6

to

31.3

ariness Aluminum

1.2

8.68

8.82

to

1.6

2.5

to

3.2

to

11. 5

18.1

to

23.1

to

11. 8

19.7

to

25.4

0.90

to

1.2

2.0

to

2.6

6.51

to

8.67

14.5

to

18.8

W1048139

G-11

GL6000, GL7000, GL9000, GL11000, WSM

CAUTION

KiSC issued 05, 2015 A

G GENERAL

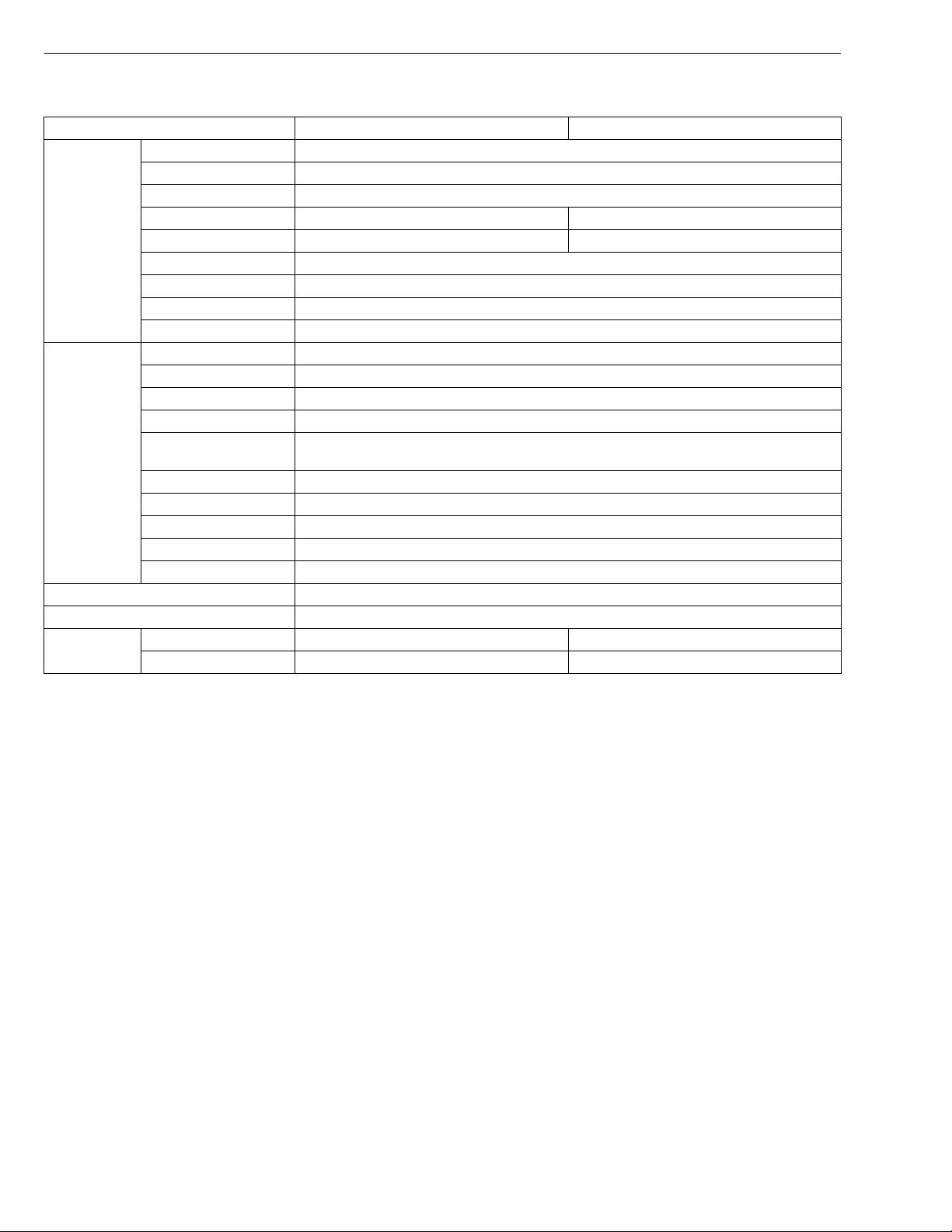

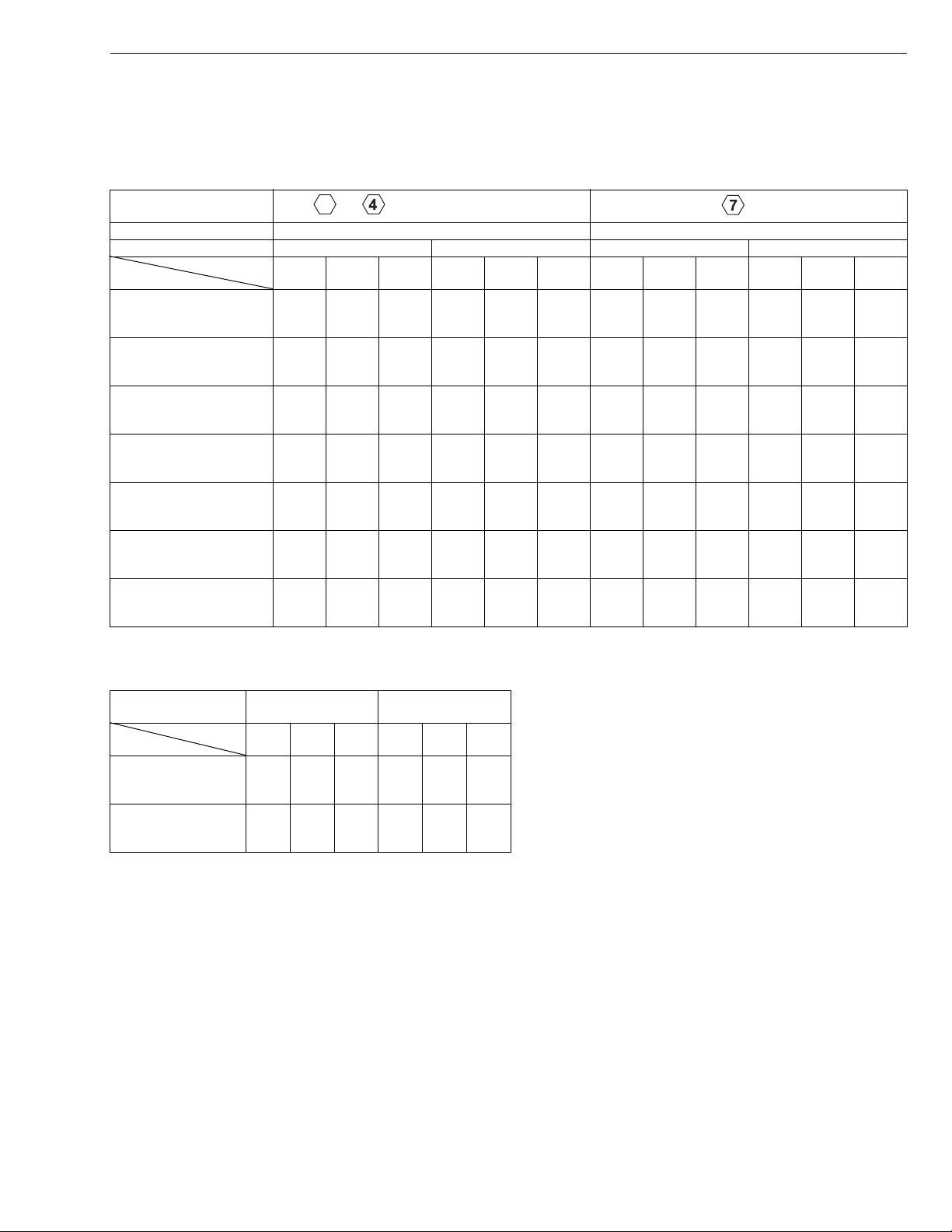

6. MAINTENANCE CHECK LIST

Observe the following for service and maintenance.

The lubricating oil change intervals listed in the table below are for classes CG, CE and CD lubricating oil of API

classification with a low-sulfur fuel in use. If the CF-4 of CG-4 lubricating oil is used with a high-sulfur fuel, change the

lubricating oil at shorter intervals than recommended in the table below depending on the operating condition.

• When checking and servicing the generator, be sure to level and stop the engine.

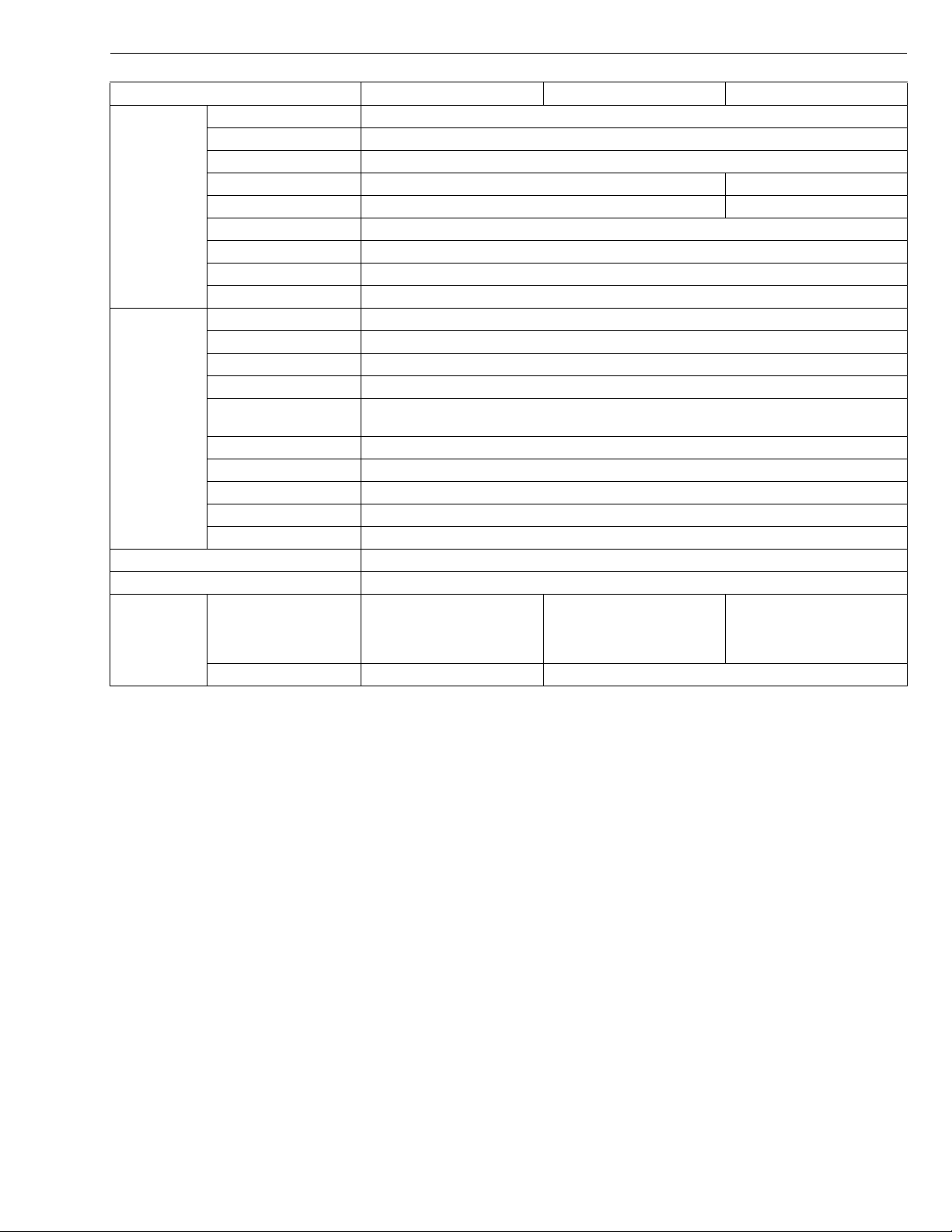

Period

No.

Item

Engine oil

1

Radiator coolant (L.L.C.)

2

Air cleaner element

3

4 Fan belt

Fuel line

5

(Fuel hose and clamp bands)

6 Battery

Radiator hose and clamp bands

7

8 Oil filter cartridge Change G-15, 18

Fuel filter element

9

Valve clearance

10

Water jacket (Radiator interior)

11

Generator's brush ware

12

ator's slip-r

Gener

13

Generator's ball bearing

14

Damage in electric wiring and

15

loose connections

Fuel injection pressure

16

Nozzle spraying condition

17

Nozzle valve seat tightness

18

ing

Check G-14

Change G-15, 16

Check G-14

Change G-24

Clean G-17

Change G-24

Check G-17

Change G-23

Check G-16

Change G-25

Check G-15, 17

Change G-25

Check G-18

Change G-25

Clean G-18

Change G-19

Check G-22

Clean G-20

Check G-19

Check G-19

Check G-23

Check 2-M8

Check G-23

Check G-23

Check G-23

Daily

Initial

50

hours

Every

50

hours

Every

100

hours

Every

200

hours

Every

300

hours

Every

400

hours

Every

500

hours

Reference

page

G-12

GL6000, GL7000, GL9000, GL11000, WSM

KiSC issued 05, 2015 A

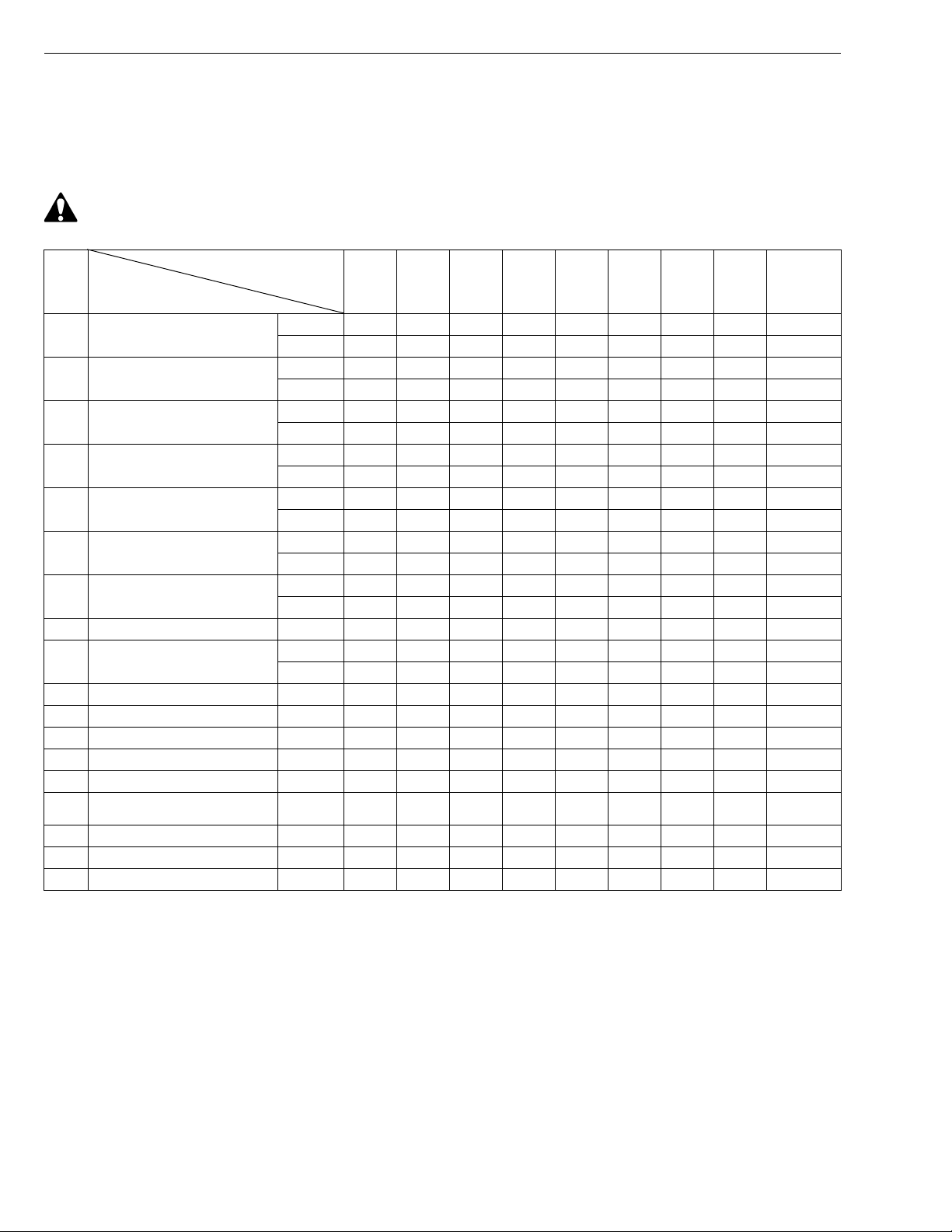

G GENERAL

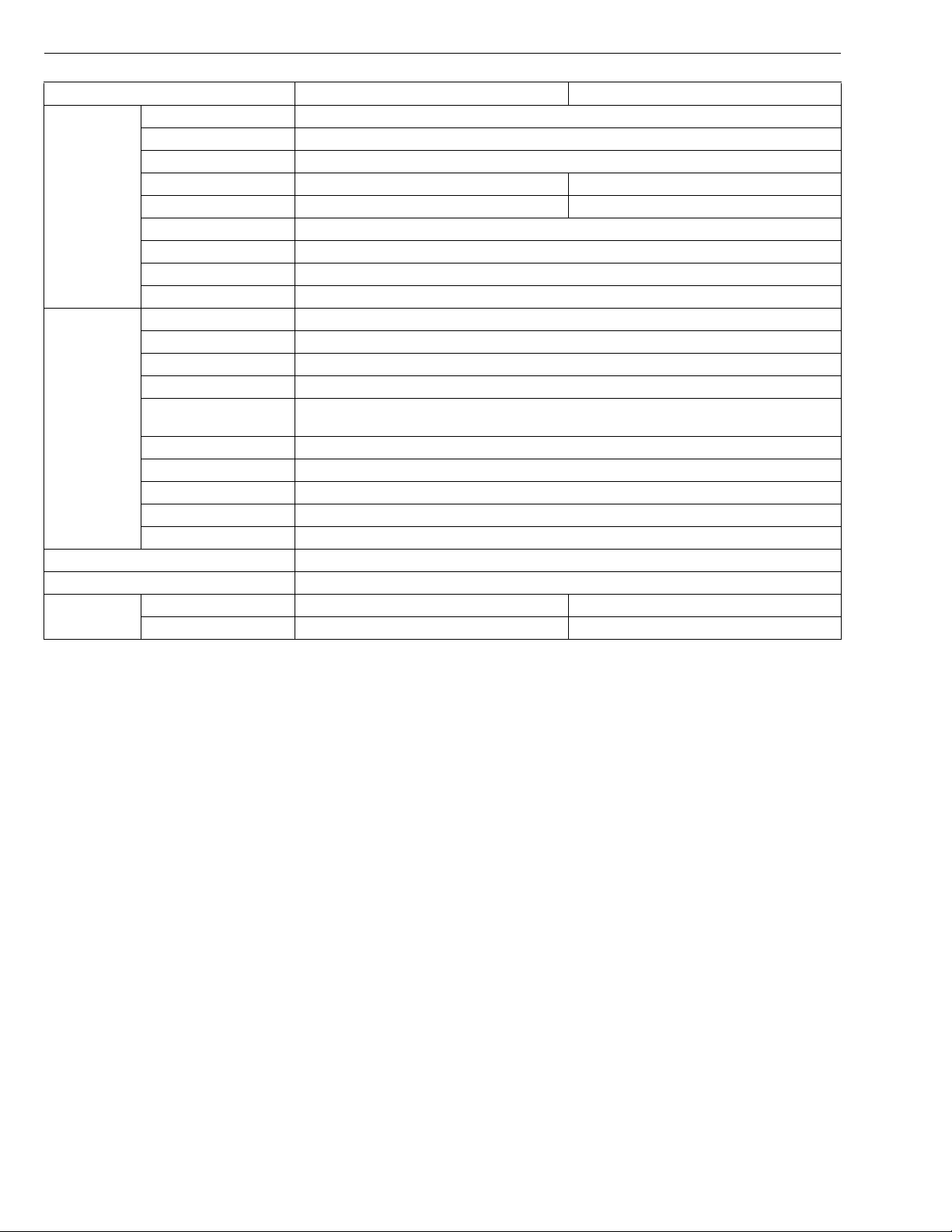

Period

No.

Item

Engine oil

1

Radiator coolant (L.L.C.)

2

Air cleaner element

3

4 Fan belt

Fuel line

5

(Fuel line and clamps)

6 Battery

Radiator hose and clamps

7

8 Oil filter cartridge Change G-15, 18

Fuel filter element

9

Valve clearance

10

Water jacket (Radiator interior)

11

Generator's brush ware

12

Generator's slip-ring

13

Generator's ball bearing

14

Damage in electric wiring and

15

loose connections

Fuel injection pressure

16

Nozzle spraying condition

17

Nozzle valve seat tightness

18

Check G-14

Change G-15, 16

Check G-14

Change G-24

Clean G-17

Change G-24

Check G-17

Change G-23

Check G-16

Change G-25

Check G-15, 17

Change G-25

Check G-18

Change G-25

Clean G-18

Change G-19

Check G-22

Clean G-20

Check G-19

Check G-19

Check G-23

Check 2-M8

Check G-23

Check G-23

Check G-

Every

800

hours

Every

1000

hours

Every

1500

hours

Every 1

year

Every 2

year

Reference

page

23

W1036740

G-13

GL6000, GL7000, GL9000, GL11000, WSM

CAUTION

IMPORTANT

CAUTION

KiSC issued 05, 2015 A

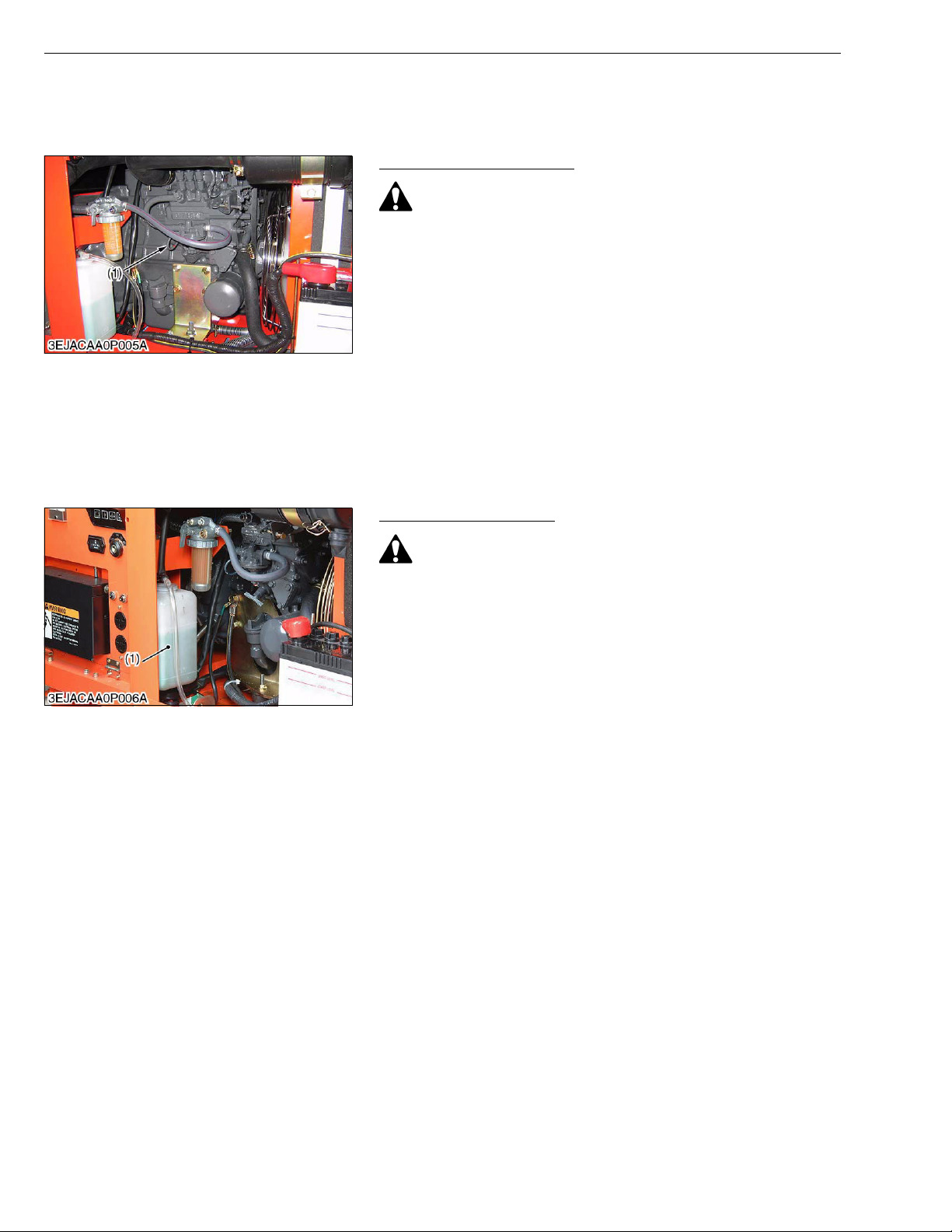

7. CHECK AND MAINTENANCE

[1] DAILY CHECK

Checking Engine Oil Level

• Be sure to stop the engine before checking the engine oil

level.

1. Level the engine and check the oil level on the gauge (1).

2. If the level below the lower mark, add new engine oil to the upper

mark.

• When using an oil of different maker or viscosity from the

previous one, drain an old oil.

• Never mix two different type's of oil.

• Use the proper SAE Engine oil according to ambient

temperatures.

Refer to "4. LUBRICANTS, FUEL AND COOLANT" (G-9).

(1) Gauge

Checking Coolant Level

G GENERAL

W1021730

• Do not remove the radiator cap while operating or

immediately after stopping. Otherwise, hot water will spout

out from the radiator. Wait for more than ten minutes to cool

the radiator, before opening the cap.

1. Remove the radiator cap and check to see that the coolant level

is just below the port.

2. If low, add coolant to the radiator.

3. Check the reserve tank (1) and keep the coolant level between

the “FULL” and “LOW” marks.

4. If low, add coolant to the reserve tank (1).

(1) Reserve Tank

W1040218

G-14

GL6000, GL7000, GL9000, GL11000, WSM

CAUTION

IMPORTANT

CAUTION

IMPORTANT

KiSC issued 05, 2015 A

[2] CHECK POINTS OF INITIAL 50 HOURS

Changing Engine Oil

• Be sure to stop engine before changing engine oil.

1. After warming up, stop the engine.

2. Place an oil pan underneath the engine.

3. Remove the oil drain plug (1) to drain the dirty engine oil

completely.

4. Inspect the drain plug gasket. Replace it damaged.

5. Reinstall the drain plug.

6. Fill the new engine oil up to the upper mark on the gauge.

• When using an oil of different maker or viscosity from the

previous one, drain an old oil.

• Never mix two different type's of oil.

• Use the proper SAE Engine oil according to ambient

temperatures.

Refer to "4. LUBRICANTS, FUEL AND COOLANT" (G-9).

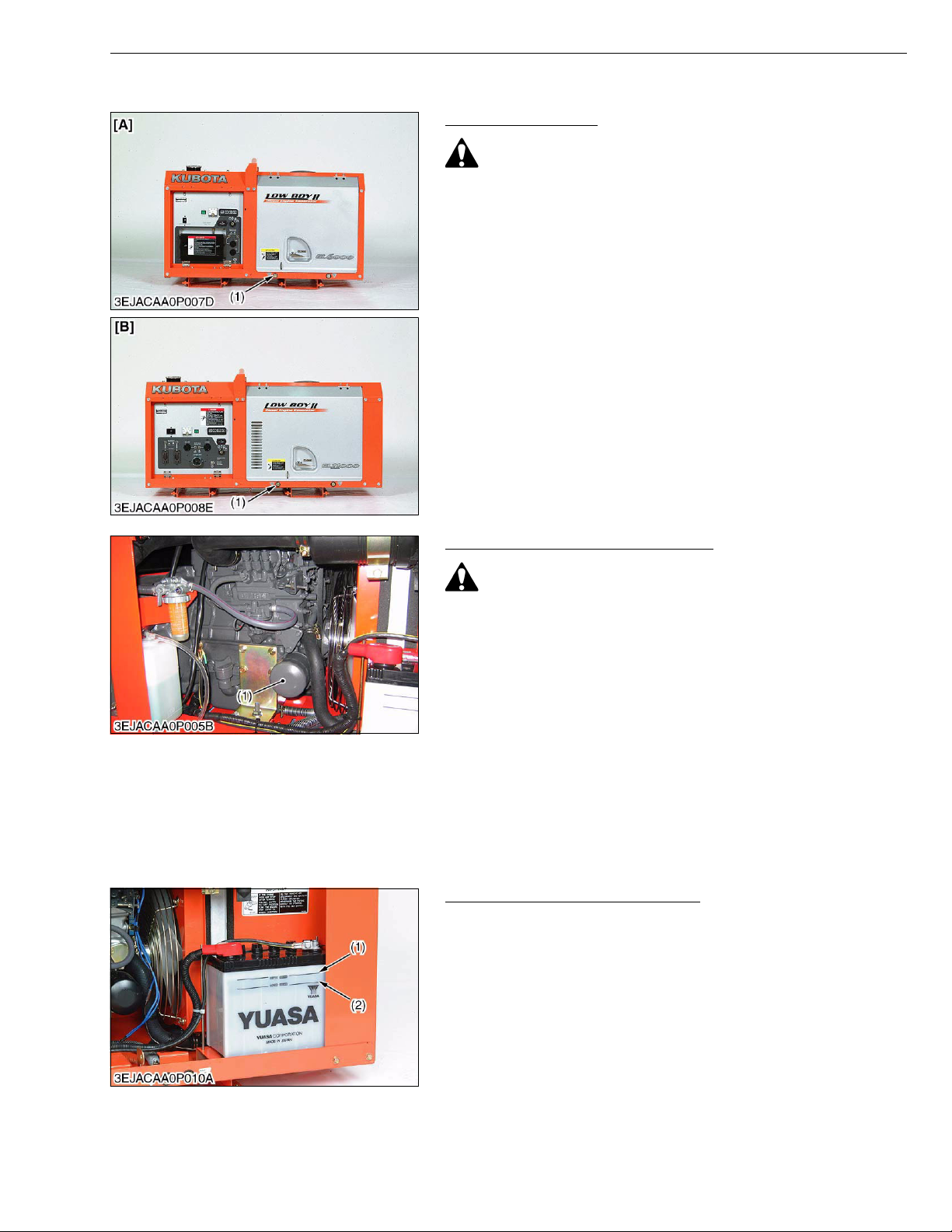

(1) Oil Drain Plug [A] GL6000, GL7000

G GENERAL

[B] GL9000, GL11000

W1016604

Changing Engine Oil Filter Cartridge

• Be sure to stop the engine before changing the engine oil

filter cartridge.

1. Remove the engine oil filter cartridge (1) with the filter wrench.

2. Apply engine oil slightly to the rubber gasket of new cartridge.

3. Install the new cartridge, screwing it in by hand.

Over-tightening may cause deformation of the rubber gasket.

4. After the cartridge has been changed, the engine oil level

normally lowers a little. Add engine oil to proper level.

• To prevent serious damage to the engine, replacement

element must be highly efficient. Use only a KUBOTA

genuine filter or its equivalent.

(1) Engine Oil Filter Cartridge

W1017137

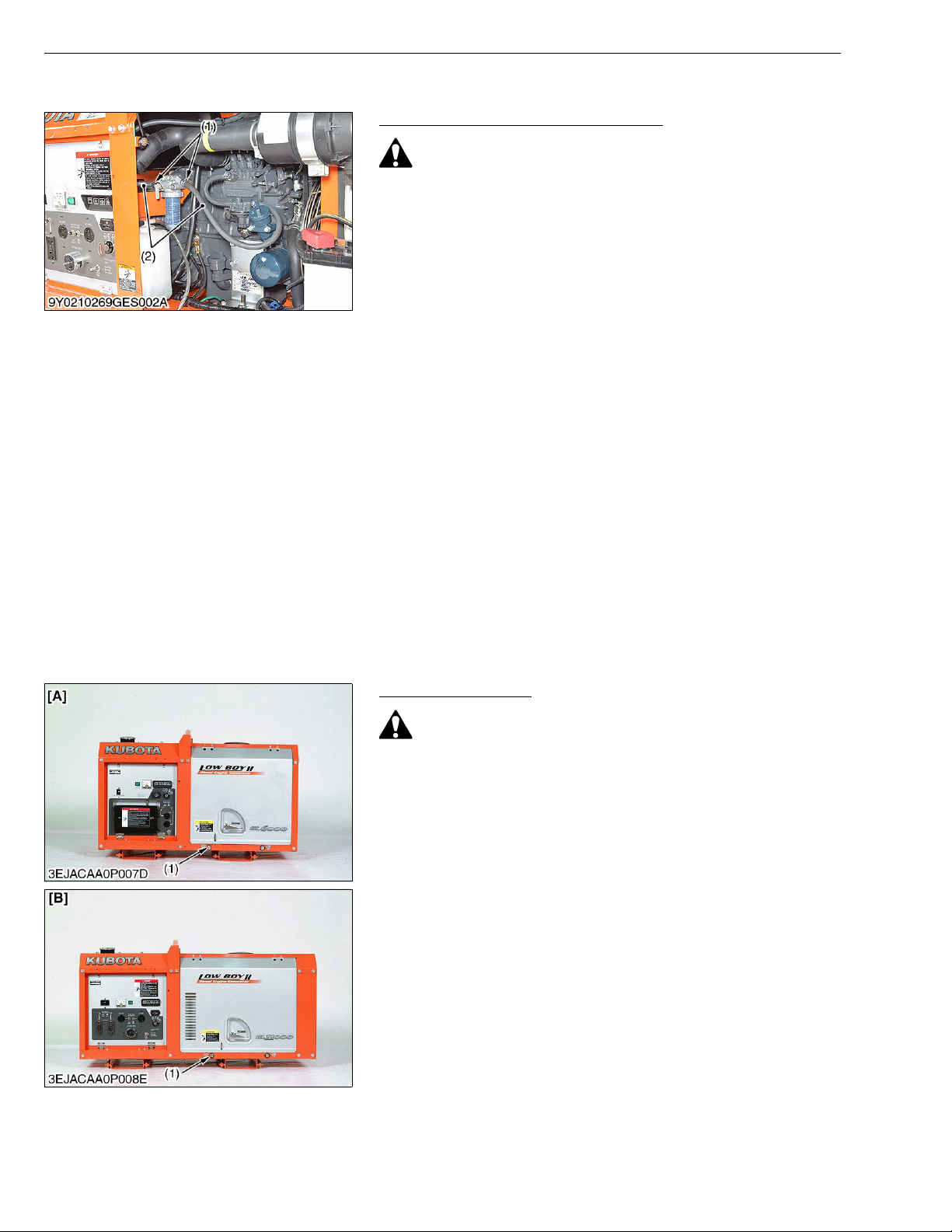

Checking Battery Electrolyte Level

1. Check the battery electrolyte level.

2. If the level is below than lower level line (2), add the distilled water

to pour level of each cell.

3. If the battery can not be charged even though the electrolyte level

is correct, replace the battery.

(1) Upper Level Line (2) Lower Level Line

W1041720

G-15

GL6000, GL7000, GL9000, GL11000, WSM

CAUTION

IMPORTANT

CAUTION

IMPORTANT

KiSC issued 05, 2015 A

[3] CHECK POINT OF EVERY 50 HOURS

Checking Fuel Hose and Clamp Bands

• Stop the engine when attempting the check and change

prescribed below.

• Remember to check the fuel line periodically. The fuel line

is subject to wear and aging, fuel may leak out onto the

running engine, causing a fire.

1. Check to see that all fuel lines (2) and hose clamps (1) are tight

and not damaged.

2. If fuel lines (2) and hose clamps (1) are found worn or damaged,

replace or repair them at once.

3. The fuel line (2) is made of rubber and ages regardless of period

of service. Replace the fuel line (2) together with the hose clamp

(1) every two years and securely tighten.

4. However if the fuel lines (2) and hose clamps (1) are found

damaged or deteriorated earlier than two years, then change or

remedy.

• When the fuel line is disconnected for change, close both

ends of the fuel line with a piece of clean cloth or paper to

prevent dust and dirt from entering. Entrance of dust and

dirt causes malfunction of the fuel injection pump. In

addition, particular care must be taken not to admit dust and

dirt into the fuel pump.

(1) Hose Clamp (2) Fuel Line

G GENERAL

W1035921

[4] CHECK POINT OF EVERY 100 HOURS

Changing Engine Oil

• Be sure to stop engine before changing engine oil.

1. After warming up, stop the engine.

2. Place an oil pan underneath the engine.

3. Remove the oil drain plug (1) to drain the dirty engine oil

completely.

4. Inspect the drain plug gasket. Replace it damaged.

5. Reinstall the drain plug.

6. Fill the new engine oil up to the upper mark on the gauge.

• When using an oil of different maker or viscosity from the

previous one, drain an old oil.

• Never mix two different types' of oil.

• Use the proper SAE Engine oil according to ambient

temperatures.

Refer to "4. LUBRICANTS, FUEL AND COOLANT" (G-9).

(1) Oil Drain Plug [A] GL6000, GL7000

[B] GL9000, GL11000

W1014131

G-16

Loading...

Loading...