Kubota G26-2, G23-2 Workshop Manual

WORKSHOP MANUAL

KiSC issued 02, 2014 A

G23-2,G26-2

TO THE READER

KiSC issued 02, 2014 A

This Workshop Manual tells the servicing personnel about the mechanism, servicing and

maintenance of the G23-2 and G26-2. It contains 4 parts: "Information", "General", "Mechanism" and

"Servicing".

Information

This section contains information below.

• Safety First

• Safety Label

• Specification

• Dimension

General

This section contains information below.

• Engine Identification

• Model Identification

• General Precautions

• Maintenance Check List

• Check and Maintenance

• Special Tools

Mechanism

This section contains information on the structure and the function of the unit. Before you continue

with the subsequent sections, make sure that you read this section.

Refer to the latest version of Workshop Manual (Code No. 9Y021-01870) for the diesel engine

mechanism that this workshop manual does not include.

Servicing

This section contains information below.

• Troubleshooting

• Servicing Specifications

• Tightening Torques

• Checking, Disassembling and Servicing

All illustrations, photographs and specifications contained in this manual are of the newest

information available at the time of publication.

KUBOTA reserves the right to change all information at any time without notice.

Since this manual includes many models, information or illustrations and photographs can show

more than one model.

January, 2013

© KUBOTA Corporation 2013

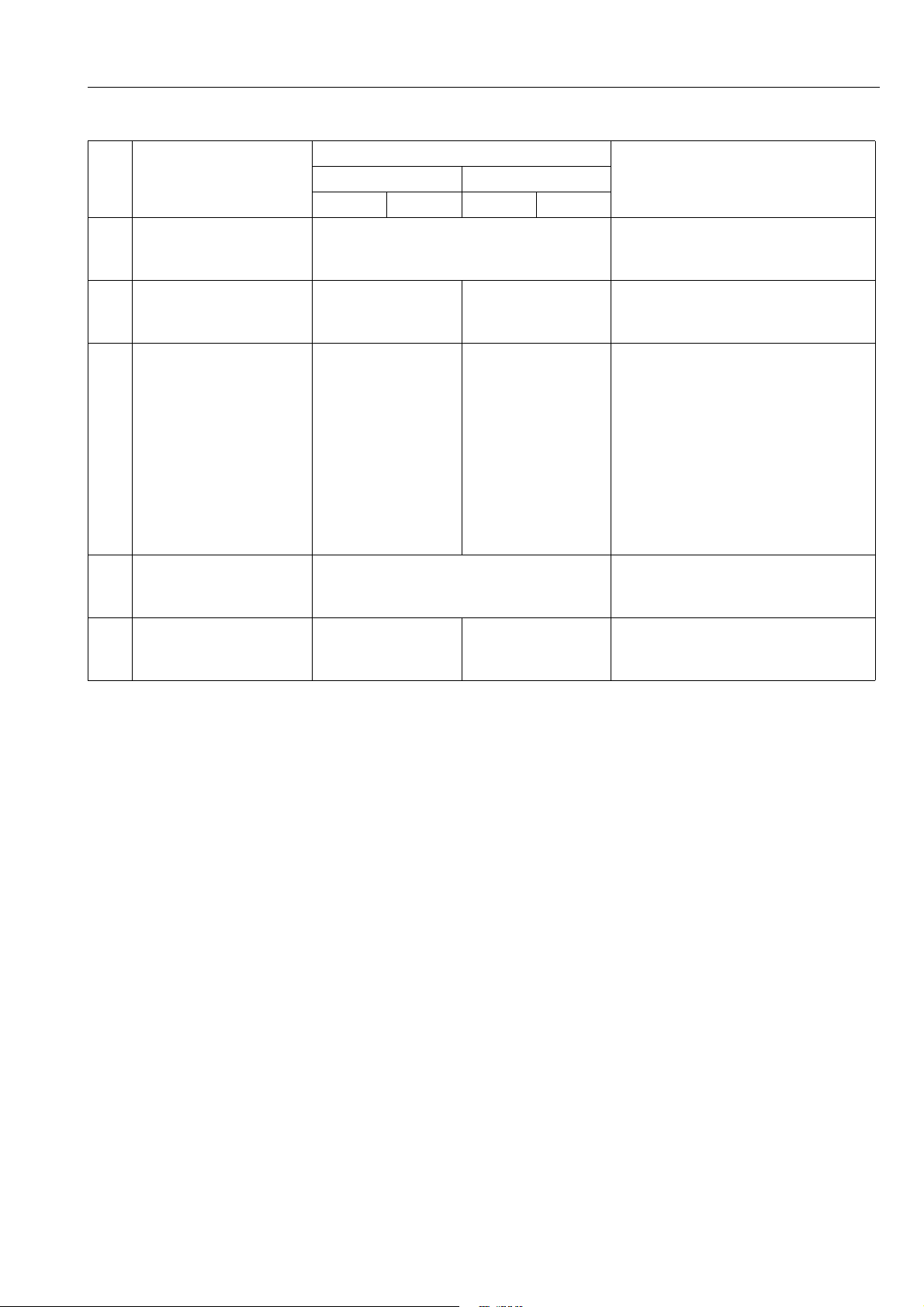

Record of Revisions

KiSC issued 02, 2014 A

For pdf, use search function {Search word} to find all the revised locations.

Last digit

of the

Code No.

Issue

month

Main Revised Point and Corrective Measures {Search word}

1 2014.02 Correcting the errors. G-41,

Correcting of part names. 1-S23,

Reference

Page

2-S33

1-S30,

2-S26,

3-S7,

5-S10,

5-S17,

6-M2,

8-S4

I INFORMATION

KiSC issued 02, 2014 A

INFORMATION

KiSC issued 02, 2014 A

CONTENTS

1. SAFETY FIRST .............................................................................................................................. I-1

2. SAFETY DECALS .......................................................................................................................... I-4

3. SPECIFICATIONS.......................................................................................................................... I-9

4. DIMENSIONS ............................................................................................................................... I-10

G23-2, G26-2, WSM

SAFETY FIRST

DANGER

WARNING

CAUTION

IMPORTANT

NOTE

KiSC issued 02, 2014 A

INFORMATION

1. SAFETY FIRST

• This symbol, the industry's "Safety Alert Symbol", is used throughout this manual and on labels on the

machine itself to warn of the possibility of personal injury. Read these instructions carefully.

• It is essential that you read the instructions and safety regulations before you try to repair or use this

unit.

• Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

• Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

• Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

• Indicates that equipment or property damage could result if instructions are not followed.

• Gives helpful information.

WSM000001INI0001US1

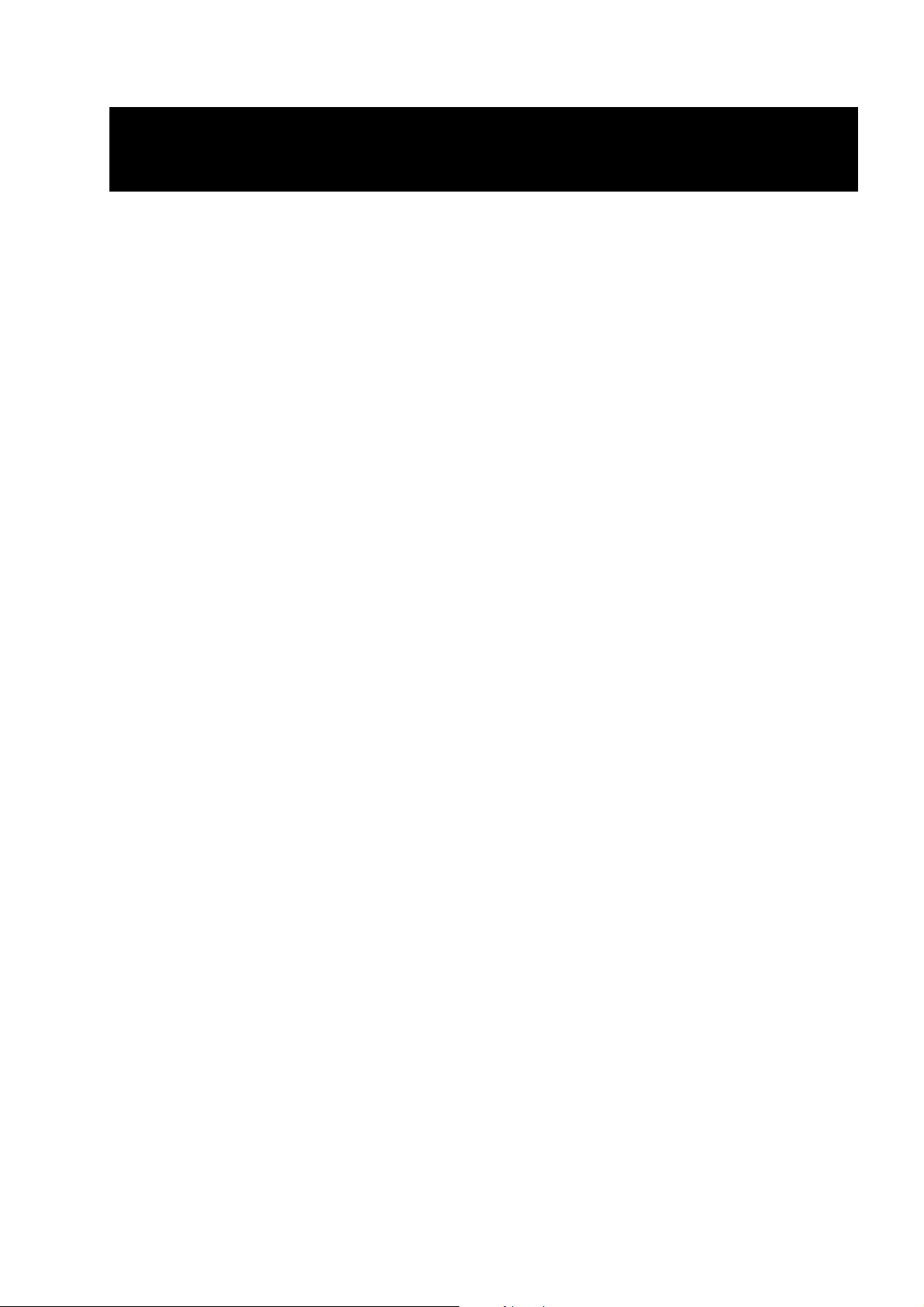

BEFORE YOU START SERVICE

• Read all instructions and safety instructions in this

manual and on your machine safety decals.

• Clean the work area and machine.

• Park the machine on a stable and level ground, and

set the parking brake.

• Lower the implement to the ground.

• Stop the engine, then remove the key.

• Disconnect the battery negative cable.

• Hang a "DO NOT OPERATE" tag in the operator

station.

WSM000001INI0010US0

START SAFELY

• Do not do the procedures below when you start the

engine.

– short across starter terminals

– bypass the safety start switch

• Do not alter or remove any part of machine safety

system.

• Before you start the engine, make sure that all shift

levers are in neutral positions or in disengaged

positions.

• Do not start the engine when you stay on the ground.

Start the engine only from operator's seat.

WSM000001INI0015US0

I-1

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

INFORMATION

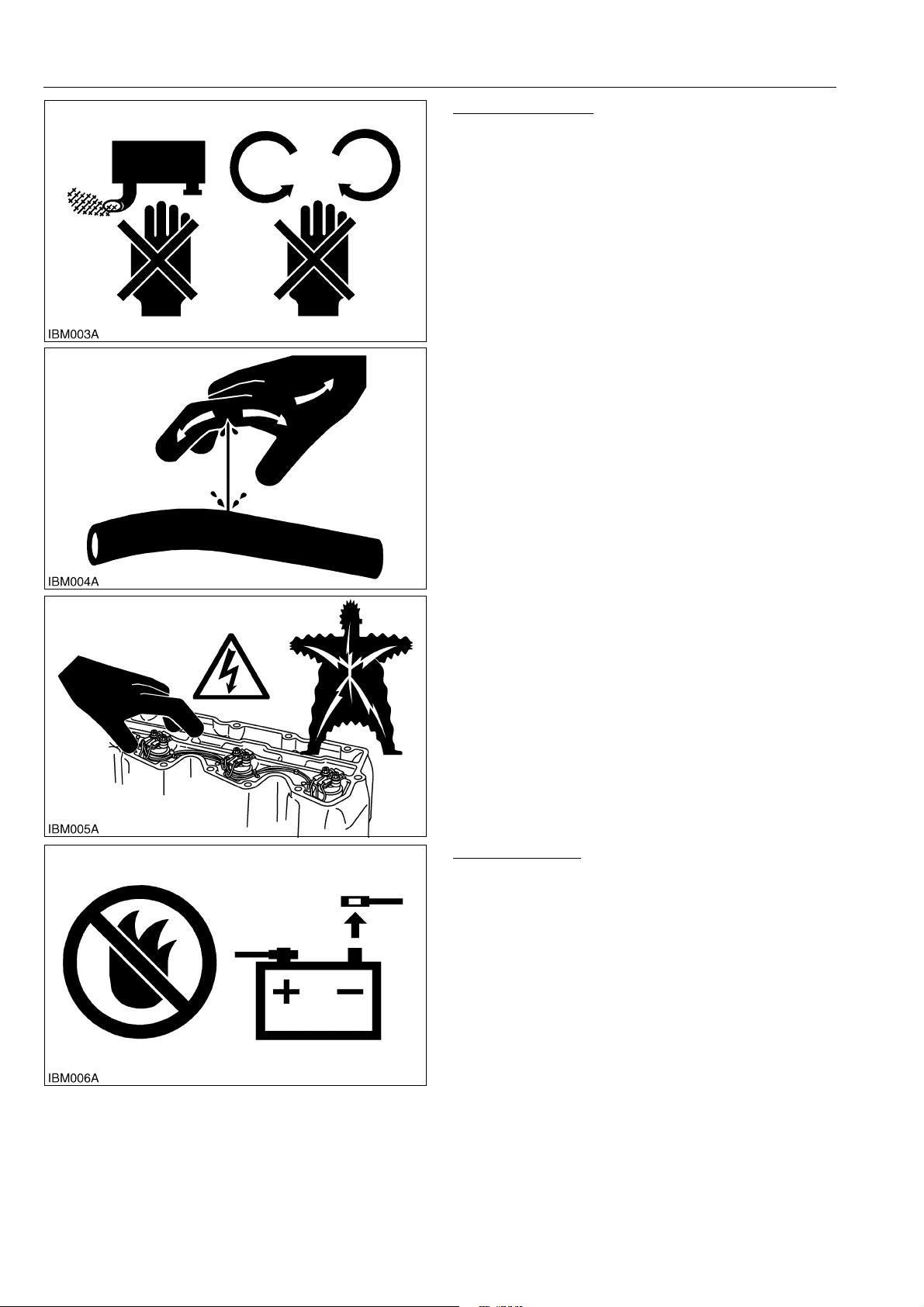

OPERATE SAFELY

• Do not use the machine after you consume alcohol

or medication or when you are tired.

• Put on applicable clothing and safety equipment.

• Use applicable tools only. Do not use alternative

tools or parts.

• When 2 or more persons do servicing, make sure

that you do it safely.

• Do not operate below the machine that only a jack

holds. Always use a safety stand to hold the

machine.

• Do not touch the hot parts or parts that turn when the

engine operates.

• Do not remove the radiator cap when the engine

operates, or immediately after it stops. If not, hot

water can spout out from the radiator. Only remove

the radiator cap when it is at a sufficiently low

temperature to touch with bare hands. Slowly loosen

the cap to release the pressure before you remove it

fully.

• Released fluid (fuel or hydraulic oil) under pressure

can cause damage to the skin and cause serious

injury. Release the pressure before you disconnect

hydraulic or fuel lines. Tighten all connections before

you apply the pressure.

• Do not open a fuel system under high pressure.

The fluid under high pressure that stays in fuel lines

can cause serious injury. Do not disconnect or repair

the fuel lines, sensors, or any other components

between the fuel pump and injectors on engines with

a common rail fuel system under high pressure.

• Put on an applicable ear protective device (earmuffs

or earplugs) to prevent injury against loud noises.

• Be careful about electric shock. The engine

generates a high voltage of more than DC100 V in

the ECU and is applied to the injector.

WSM000001INI0012US0

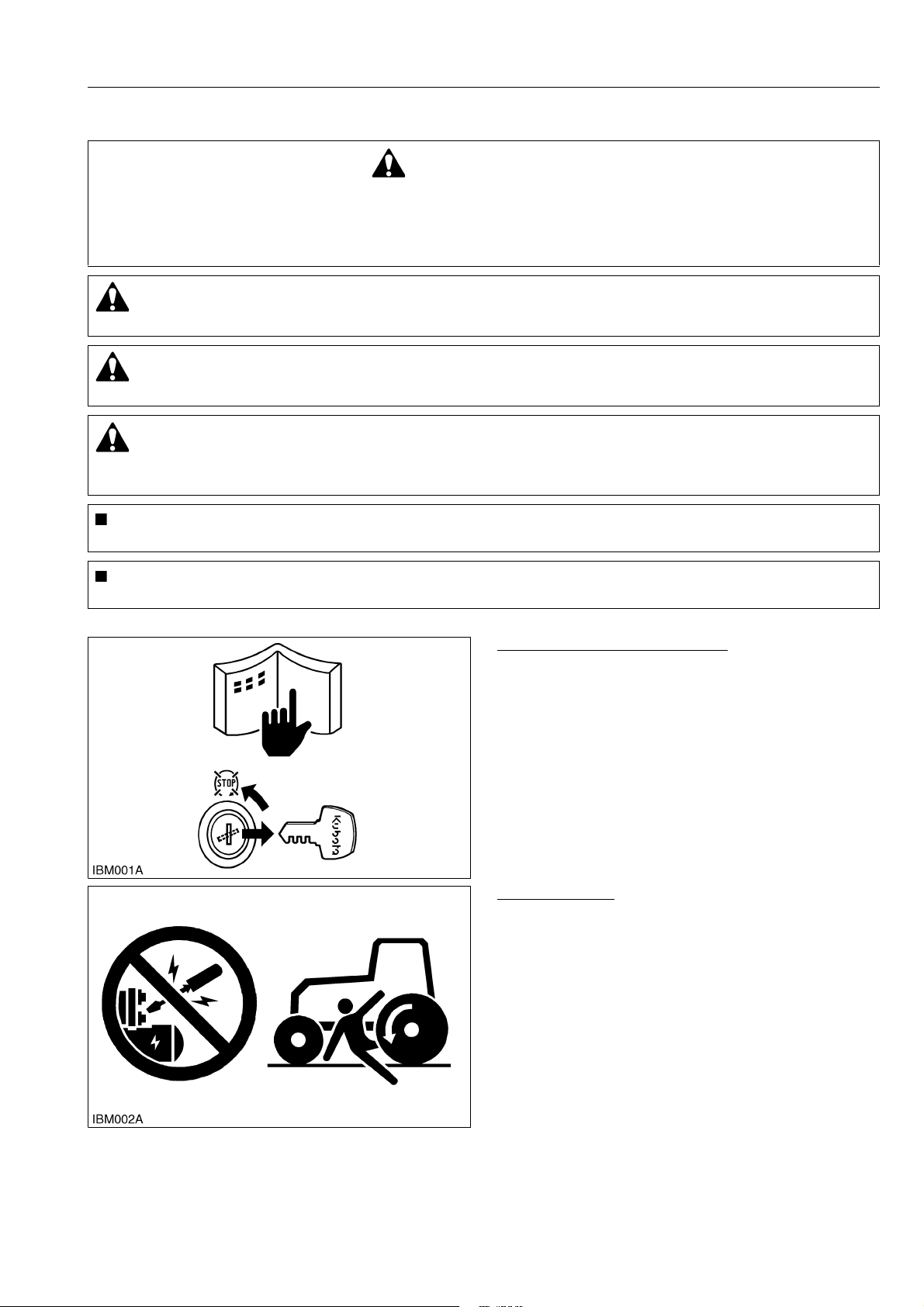

PREVENT A FIRE

• Fuel is very flammable and explosive under some

conditions. Do not smoke or let flames or sparks in

your work area.

• To prevent sparks from an accidental short circuit,

always disconnect the battery negative cable first

and connect it last.

• The battery gas can cause an explosion. Keep the

sparks and open flame away from the top of battery,

especially when you charge the battery.

• Make sure that you do not spill fuel on the engine.

WSM000001INI0005US0

I-2

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

INFORMATION

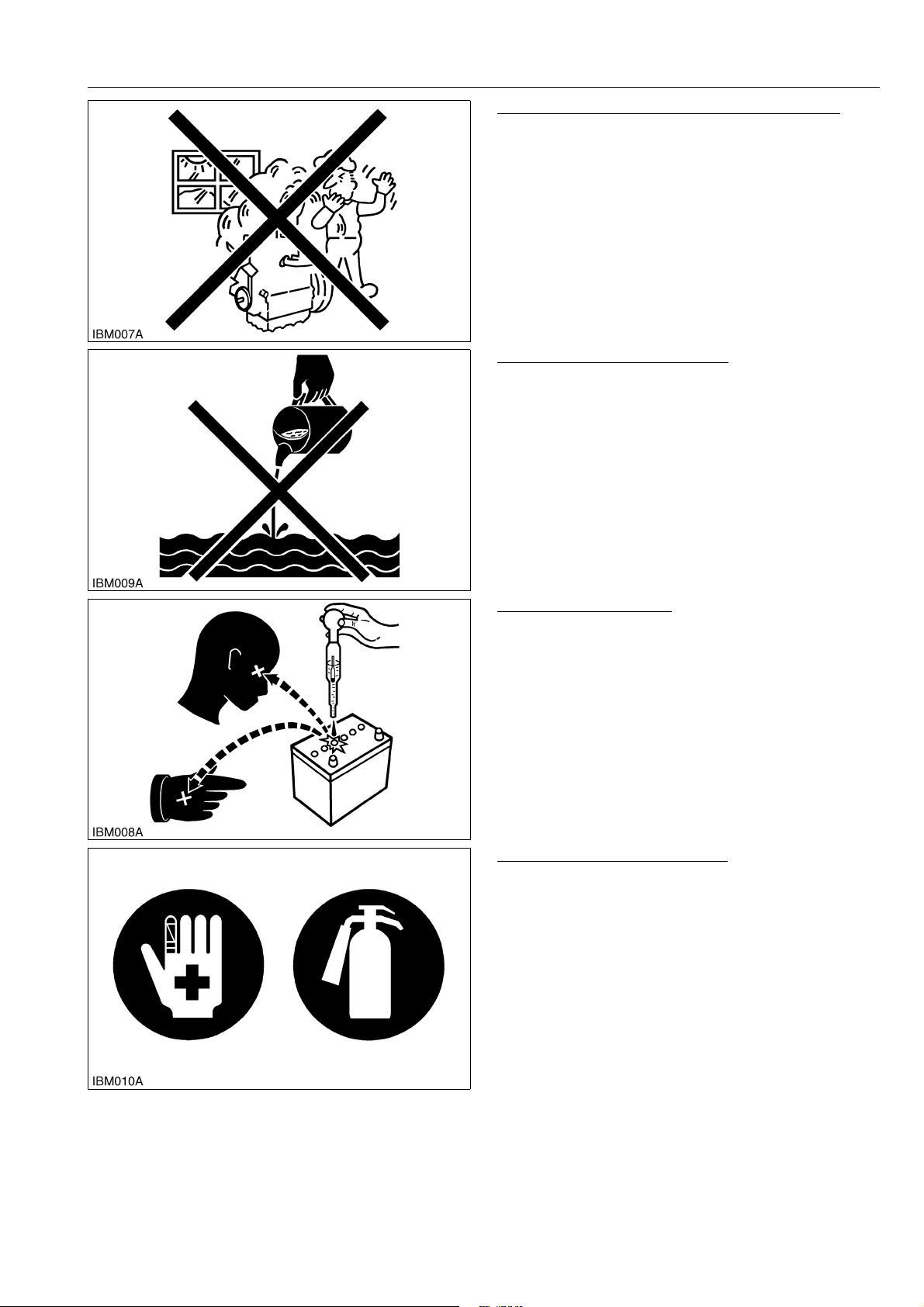

KEEP A GOOD AIRFLOW IN THE WORK AREA

• If the engine is in operation, make sure that the area

has good airflow. Do not operate the engine in a

closed area. The exhaust gas contains poisonous

carbon monoxide.

WSM000001INI0006US0

DISCARD FLUIDS CORRECTLY

• Do not discard fluids on the ground, down the drain,

into a stream, pond, or lake. Obey related

environmental protection regulations when you

discard oil, fuel, coolant, electrolyte and other

dangerous waste.

WSM000001INI0007US0

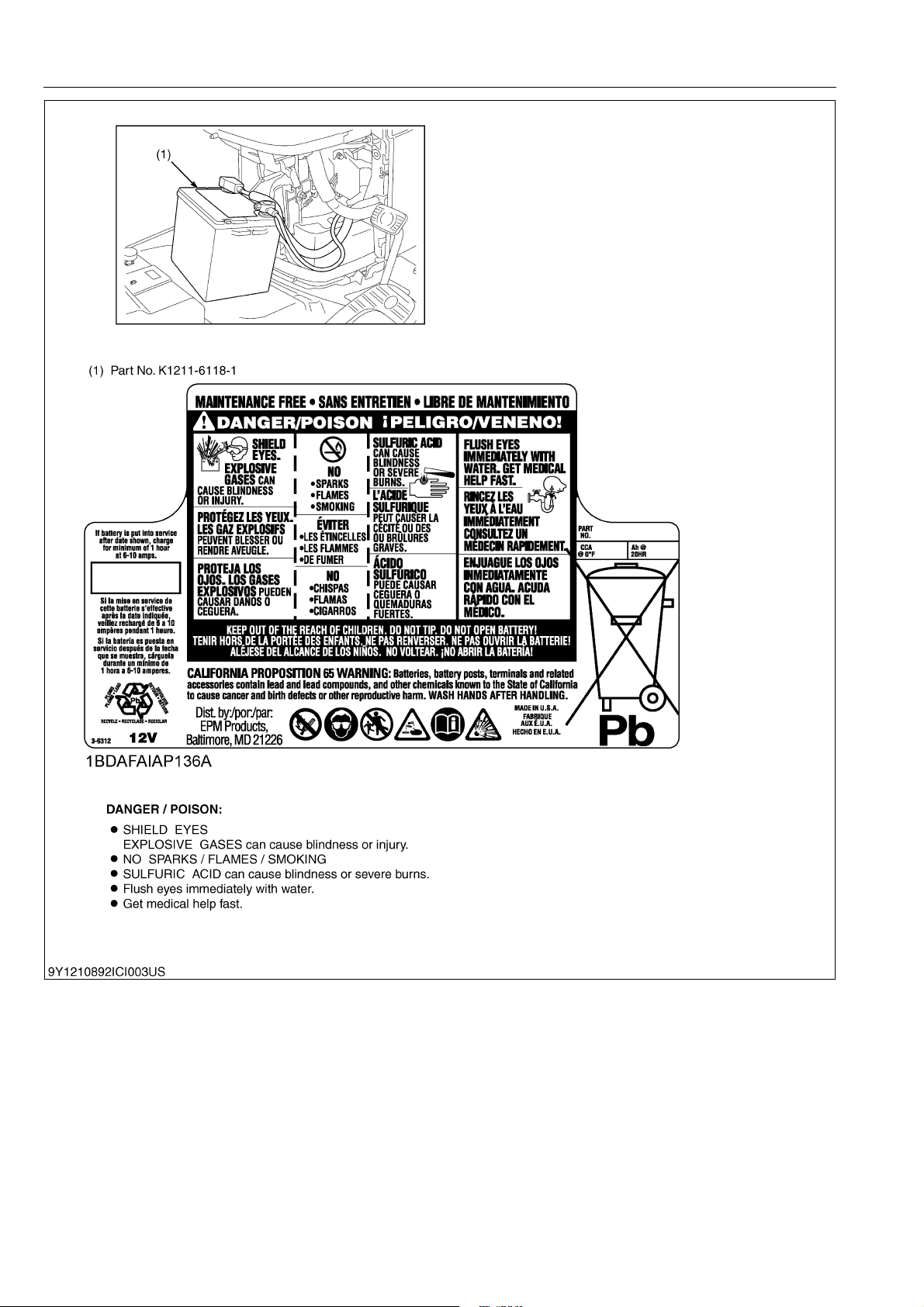

PREVENT ACID BURNS

• Keep electrolyte away from your eyes, hands and

clothing. Sulfuric acid in battery electrolyte is

poisonous and it can burn your skin and clothing and

cause blindness. If you spill electrolyte on yourself,

clean yourself with water, and get medical aid

immediately.

WSM000001INI0008US0

PREPARE FOR EMERGENCIES

• Keep a first aid kit and fire extinguisher ready at all

times.

• Keep the emergency contact telephone numbers

near your telephone at all times.

WSM000001INI0009US0

I-3

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

INFORMATION

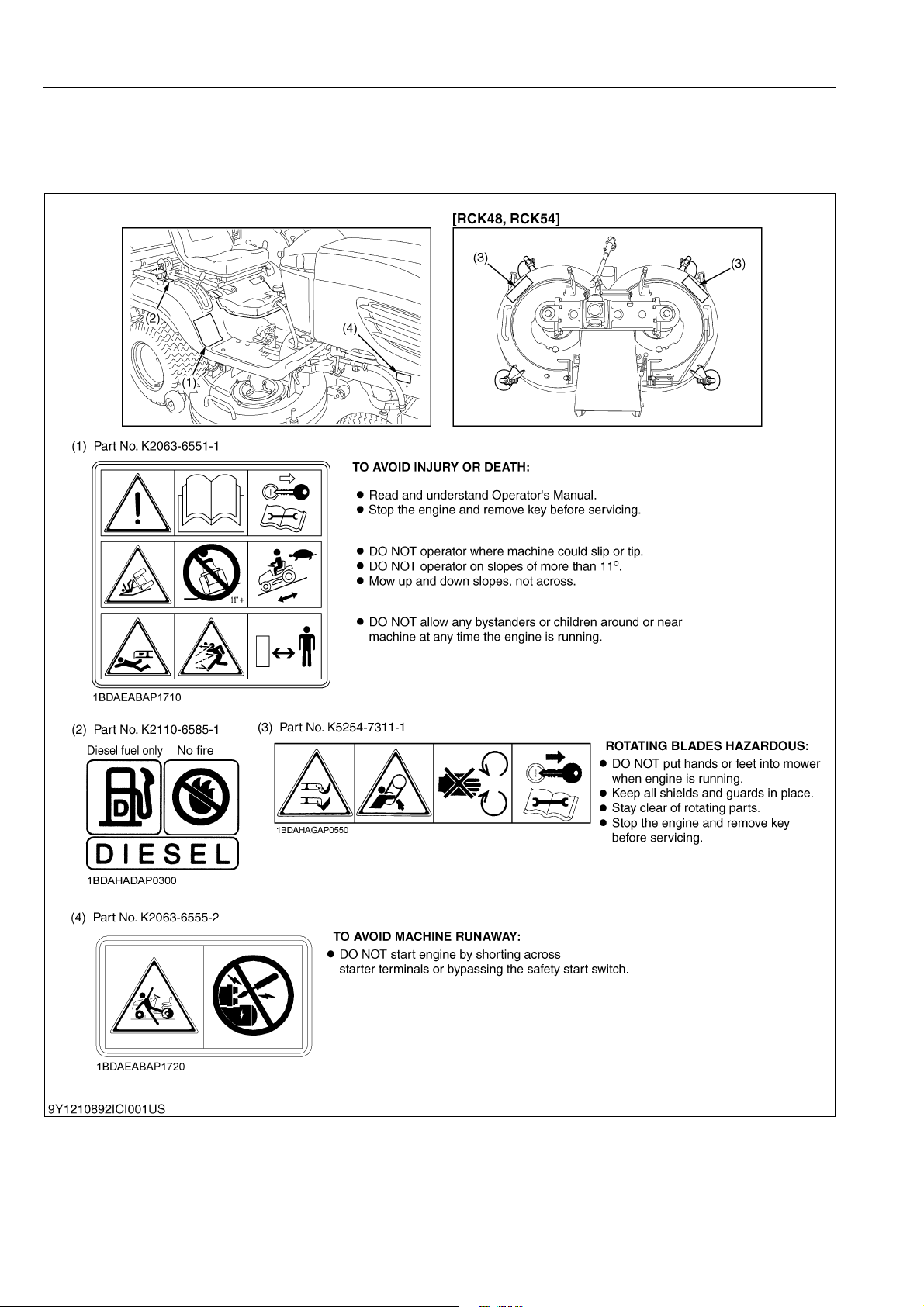

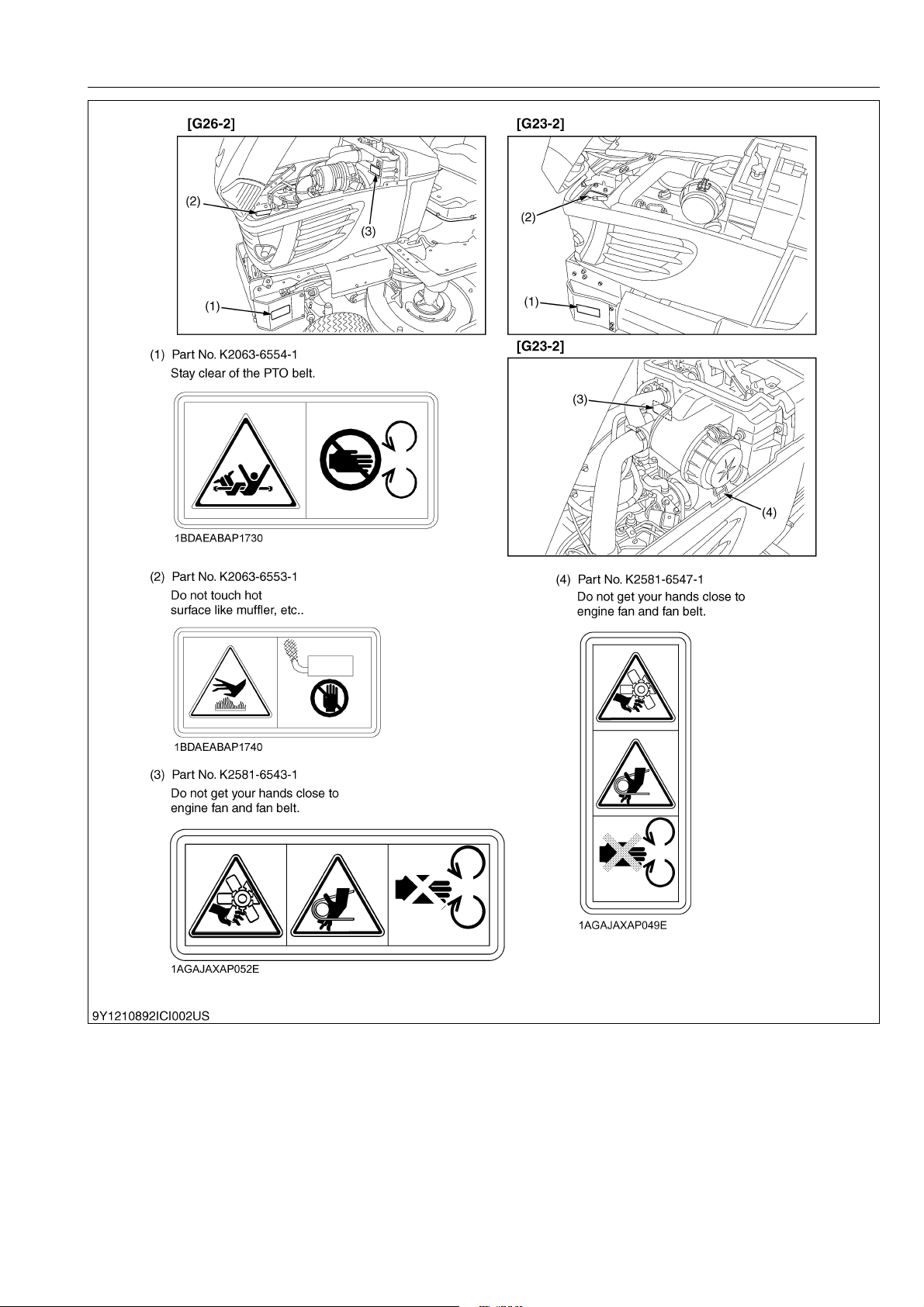

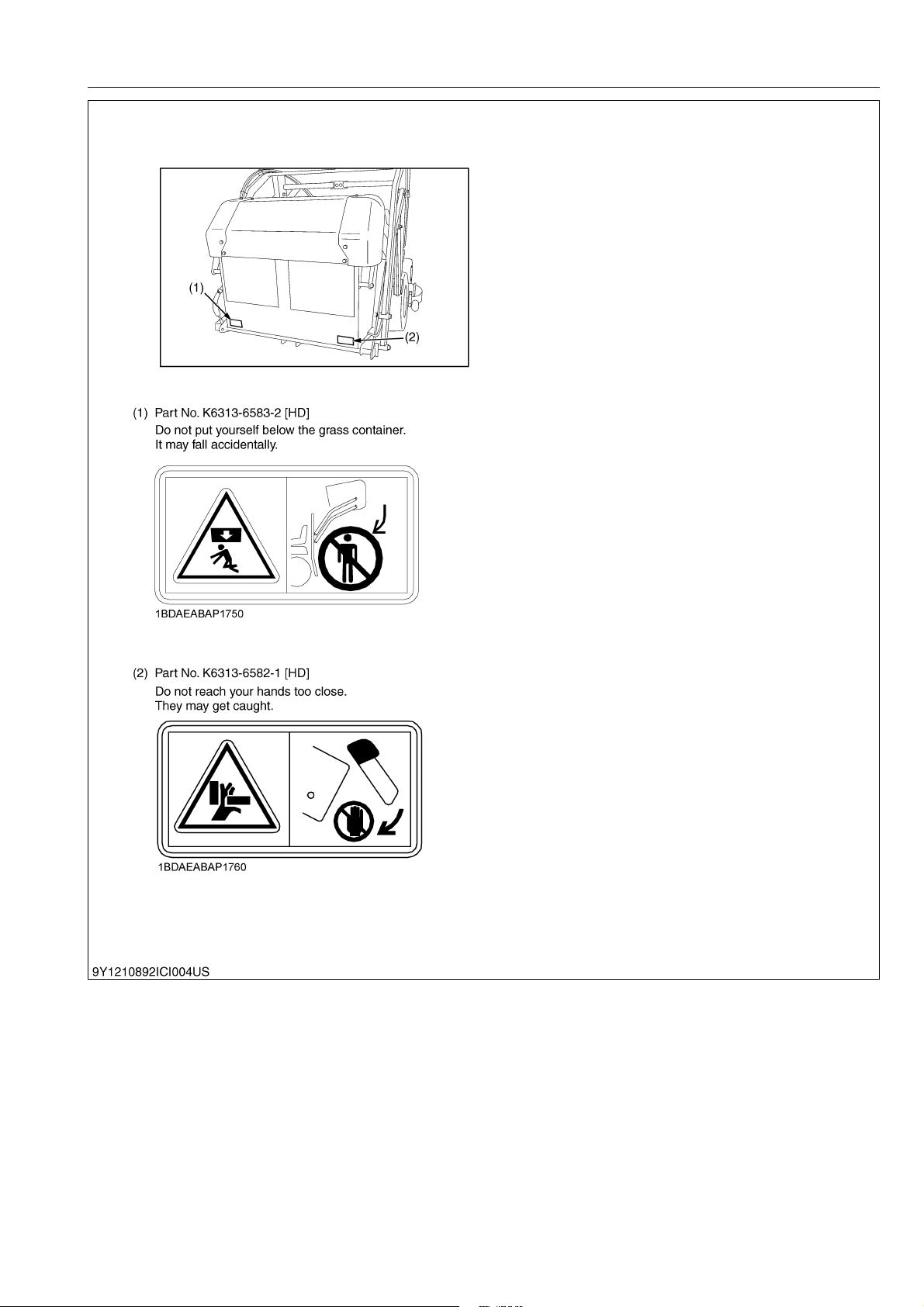

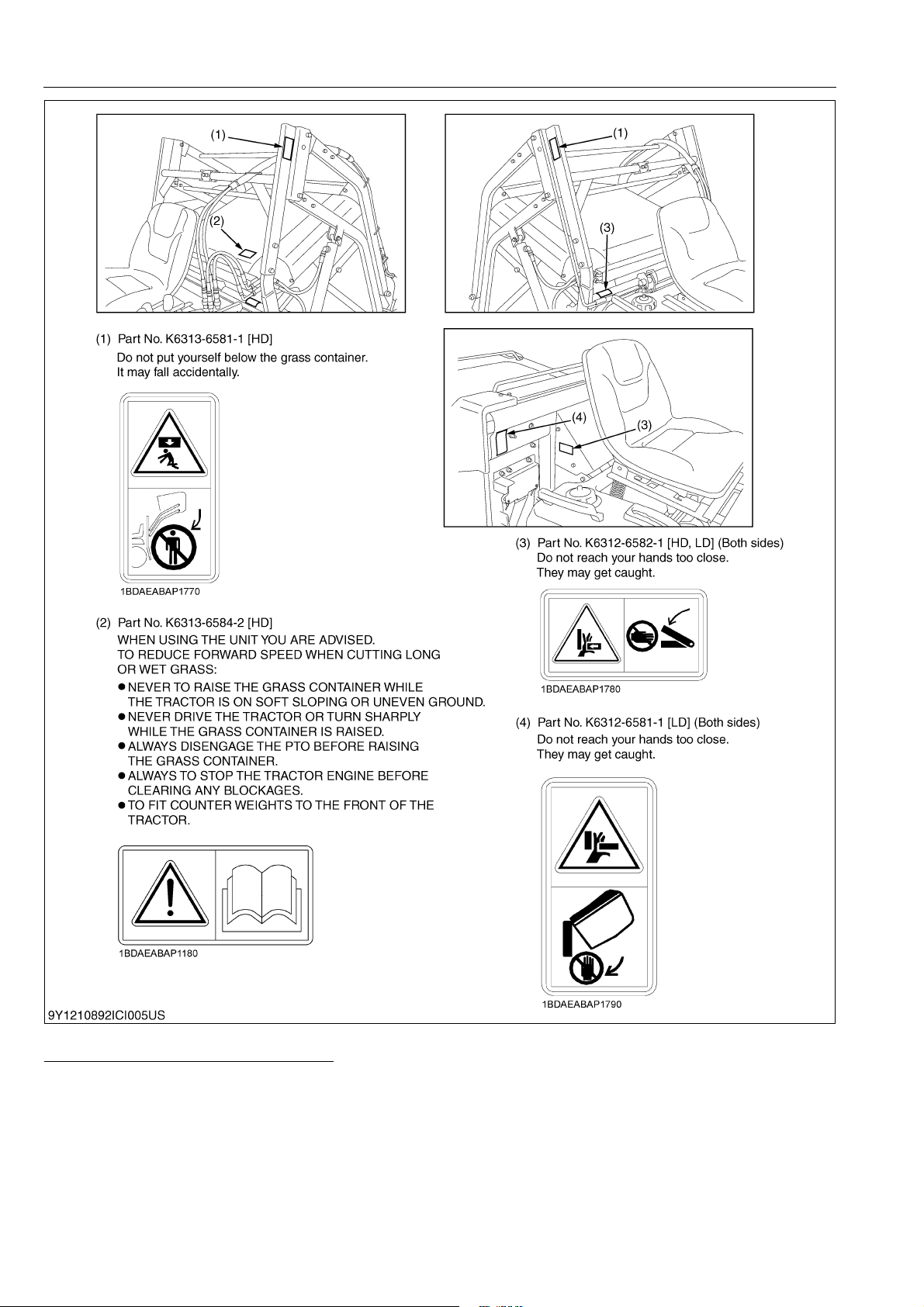

2. SAFETY DECALS

The following safety decals (pictorial safety labels) are installed on the machine. If a decal becomes

damaged, illegible or is not on the machine, replace it. The decal part number is listed in the parts list.

WSM000001INI0014US0

9Y1210892INI0001US0

I-4

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

INFORMATION

9Y1210892INI0002US0

I-5

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

INFORMATION

9Y1210892INI0003US0

I-6

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

INFORMATION

9Y1210892INI0004US0

I-7

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

INFORMATION

9Y1210892INI0005US0

CARE OF PICTORIAL SAFETY LABELS

1. Keep pictorial safety labels clean and free from obstructing material.

2. Clean pictorial safety labels with soap and water, dry with a soft cloth.

3. Replace damaged or missing pictorial safety labels with new labels.

4. If a component with pictorial safety label(s) affixed is replace with new part, make sure new label(s) is (are)

attached in the same location(s) as the replace component.

5. Mount new pictorial safety labels by applying on a clean dry surface and pressure any bubbles to outside edge.

9Y1210892INI0006US0

I-8

G23-2, G26-2, WSM

NOTE

KiSC issued 02, 2014 A

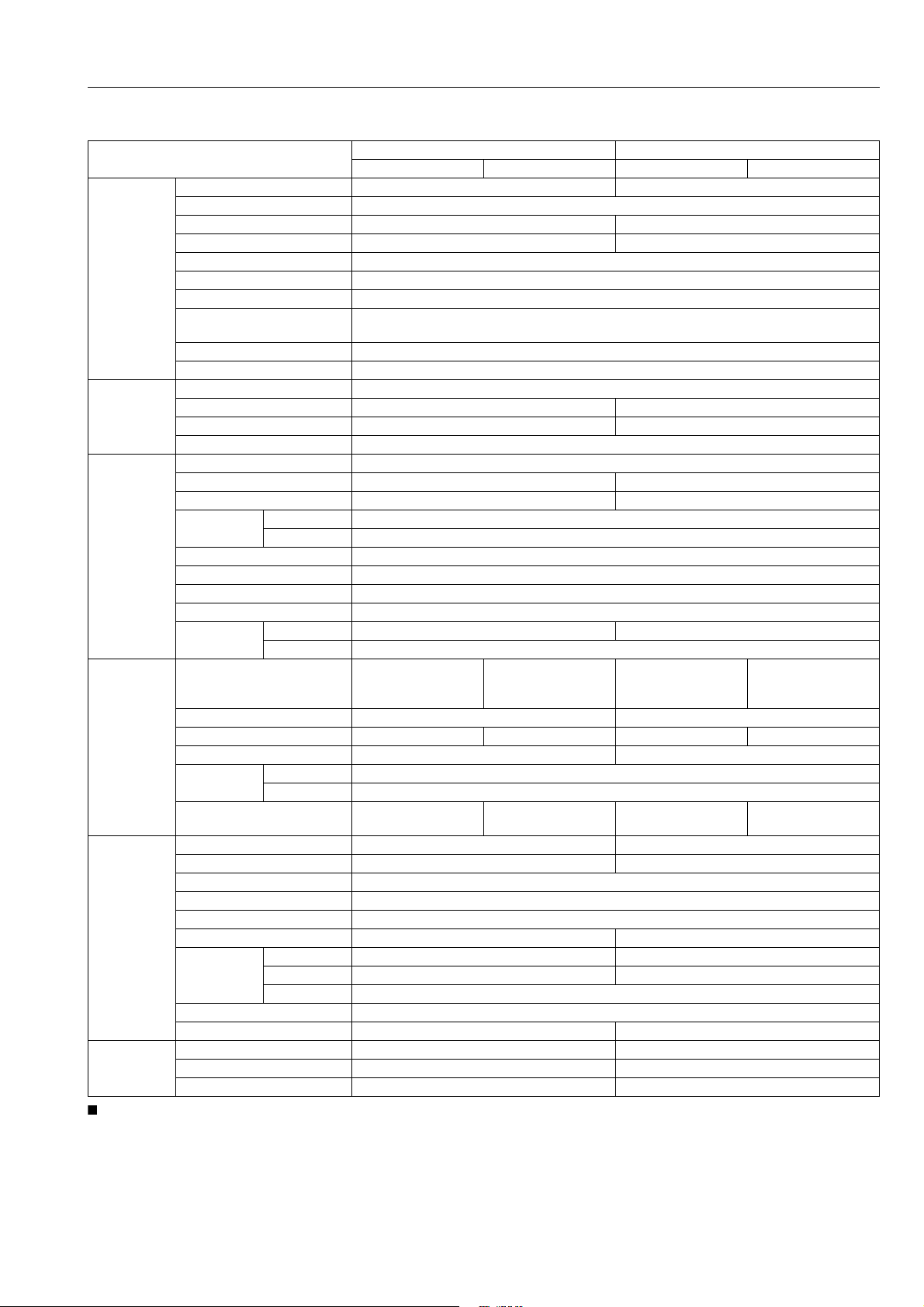

3. SPECIFICATIONS

INFORMATION

Engine

Capacities

Machine

Dimensions

Mower

Grass

collector

Model

Model D902-E3-GT D1005-E3-GT

Type Liquid-cooled diesel

Total displacement 898 cm

Gross power 17.1 kW (23.3 HP) 18.8 kW (25.5 HP)

Number of cylinders 3

Starter Electric starter with battery

Battery 12V, RC: 80 min, CCA: 535A

Fuel

Preheating system Super glow

Engine stop Key stop

Fuel tank 20 L (5.3 U.S.gals, 4.4 Imp.gals)

Engine oil 3.1 L (3.3 U.S.qts, 2.7 Imp.qts) 3.5 L (3.7 U.S.qts, 3.1 Imp.qts)

Radiator coolant 3.1 L (3.3 U.S.qts, 2.7 Imp.qts) 3.3 L (3.5 U.S.qts, 2.9 Imp.qts)

Hydrostatic transmission oil 11 L (12 U.S.qts, 9.7 Imp.qts)

PTO Shaft drive

PTO clutch Belt tension Wet disks

PTO brake Shoe Wet disks

Tyres

Steering type Hydrostatic type power steering

Brakes Wet Discs

Travel speed control Foot pedal

Transmission Hydrostatic

Traveling

speeds

Overall length

(with grass collector), without

front weight bracket for HD

Overall width (with mower) 1226 mm (48.27 in.) 1418 mm (55.83 in.)

Overall height 1350 mm (53.15 in.) 1600 mm (62.99 in.) 1350 mm (53.15 in.) 1600 mm (62.99 in.)

Wheel base 1390 mm (54.72 in.) 1460 mm (57.18 in.)

Tyead

Weight (Without mower deck

and grass collector)

Model RCK48-G23-2 RCK54-G26-2

Cutting width 1219 mm (48.0 in.) 1372 mm (54.0 in.)

Cutting height 25 to 102 mm (1.0 to 4.0 in.)

Adjustment of cutting height Dial gauge

Mounting method Quick joint, parallel linkage

Weight (Approx.) 120 kg (265 lbs) 135 kg (298 lbs)

Dimensions

Discharge direction Rear

Gear box oil 1.9 L (2.0 U.S.qts, 1.7 Imp.qts) 2.1 L (2.2 U.S.qts, 1.8 Imp.qts)

Model GCK-G23LD GCK-G26HD

Container capacity 560 L (148 U.S.gals, 123 Imp.gals) 640 L (169 U.S.gals, 141 Imp.gals)

Weight (Approx.) 35 kg (77 lbs) 220 kg (485 lbs)

Front 16 × 7.50-8

Rear 24 × 12.00-12

Forward 0 to 15.5 km/h (0 to 9.6 mph) 0 to 17.0 km/h (0 to 10.6 mph)

Reverse 0 to 10.0 km/h (0 to 6.2 mph)

2980 mm (117.3 in.) 3160 mm (124.4 in.) 3035 mm (119.5 in.) 3215 mm (126.6 in.)

Front 900 mm (35.4 in.)

Rear 840 mm (33.1 in.)

Total length 895 mm (35.2 in.) 980 mm (38.6 in.)

Total width 1266 mm (49.8 in.) 1418 mm (55.8 in.)

Total height 400 mm (15.8 in.)

LD HD LD HD

535 kg (1180 lbs) 500 kg (1100 lbs) 565 kg (1250 lbs) 535 kg (1180 lbs)

G23-2 G26-2

3

(54.8 cu.in.) 1001 cm3 (61.1 cu.in.)

Diesel fuel No. 1 [below – 10 °C (14 °F)]

Diesel fuel No. 2 [above – 10 °C (14 °F)]

• The company reserves the right to change the specifications without notice.

9Y1210892INI0007US0

I-9

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

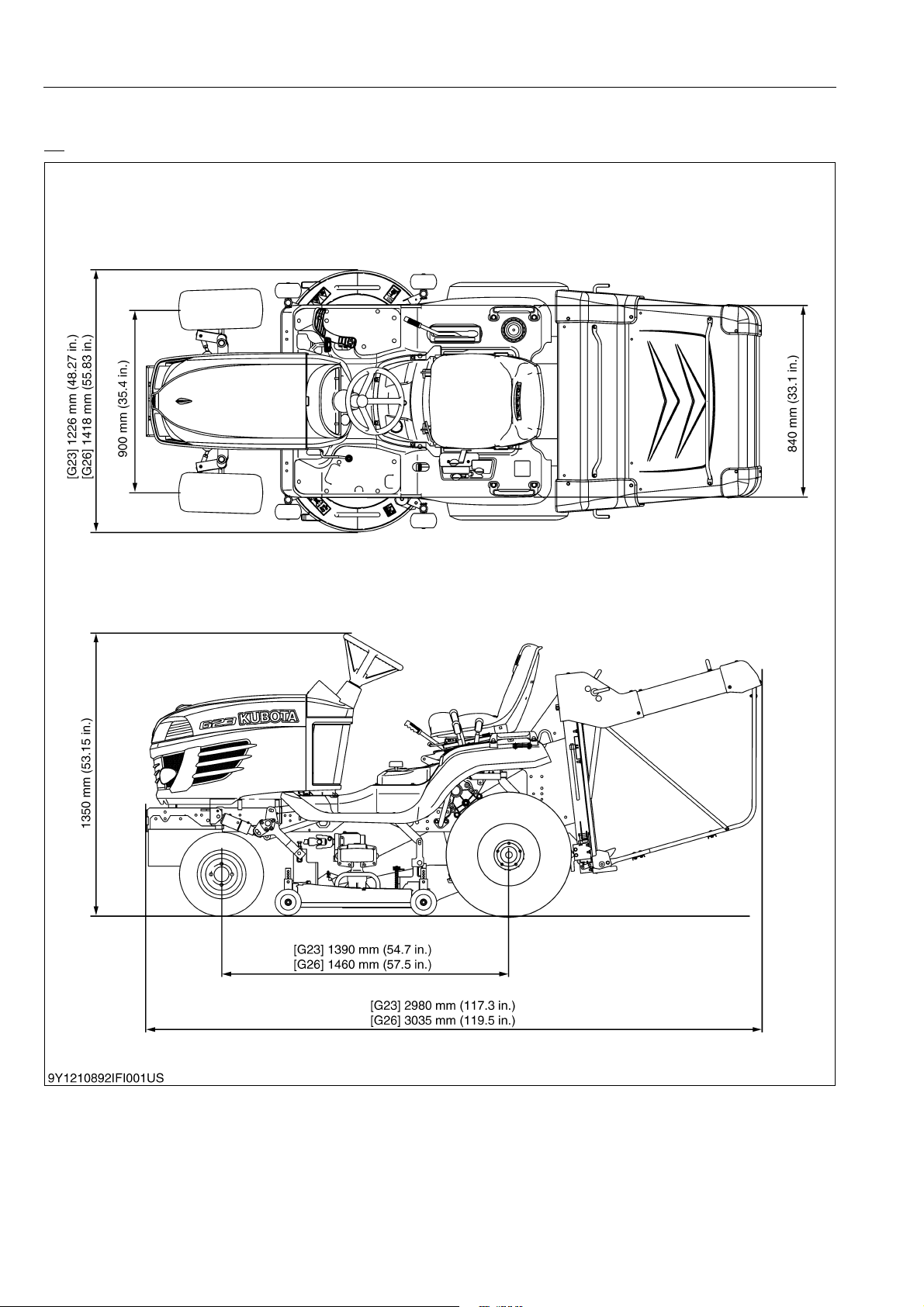

4. DIMENSIONS

LD

INFORMATION

9Y1210892INI0008US0

I-10

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

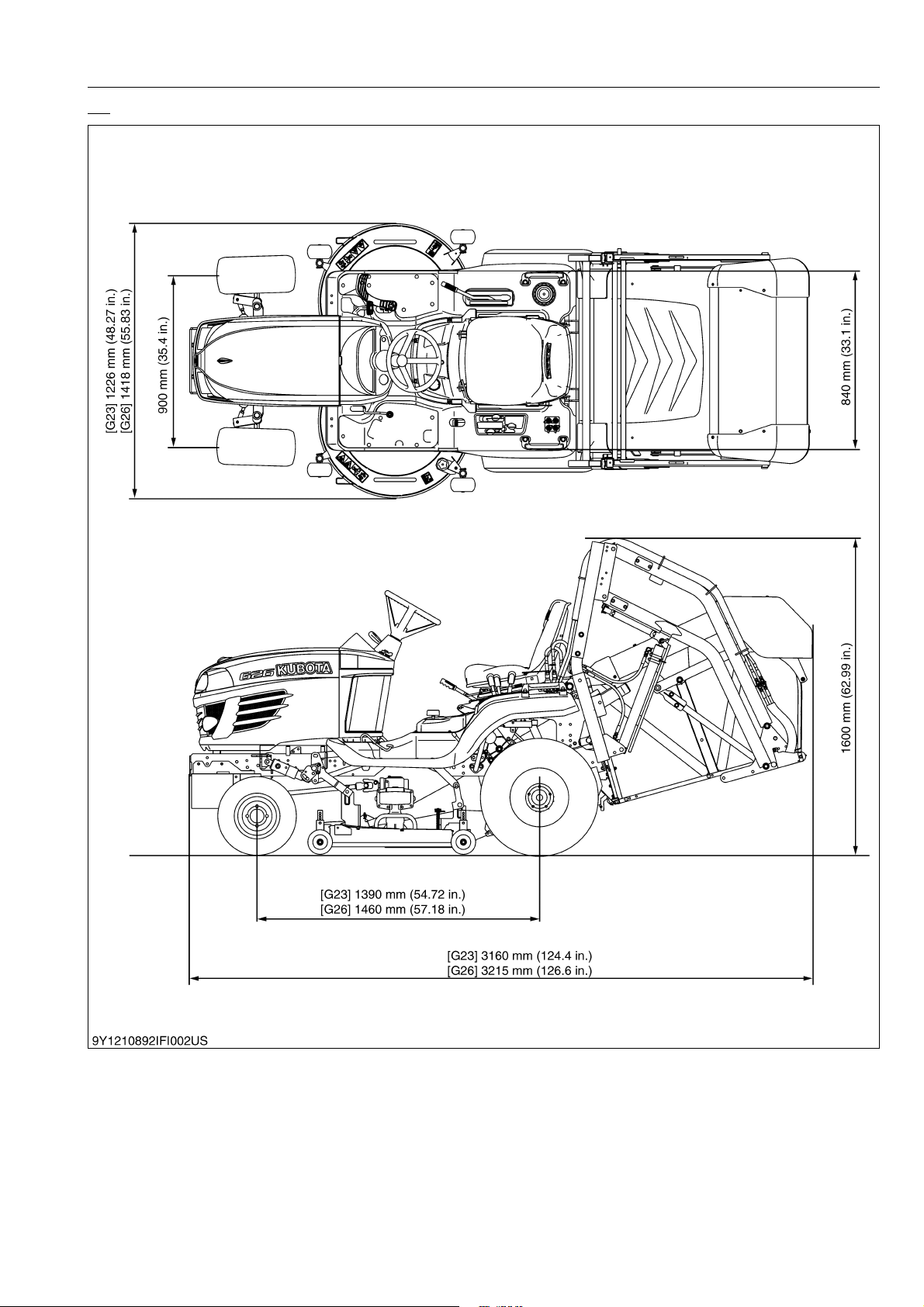

HD

INFORMATION

9Y1210892INI0009US0

I-11

G GENERAL

KiSC issued 02, 2014 A

GENERAL

KiSC issued 02, 2014 A

CONTENTS

1. MACHINE IDENTIFICATION........................................................................................................G-1

[1] SERIAL NUMBER .................................................................................................................. G-1

[2] CYLINDER NUMBER ............................................................................................................. G-2

2. GENERAL PRECAUTIONS.......................................................................................................... G-3

3. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING .................................... G-4

[1] WIRING .................................................................................................................................. G-4

[2] BATTERY ............................................................................................................................... G-6

[3] FUSE ...................................................................................................................................... G-6

[4] CONNECTOR ........................................................................................................................ G-6

[5] HANDLING OF CIRCUIT TESTER ........................................................................................ G-7

[6] COLOR OF WIRING ..............................................................................................................G-8

4. LUBRICANTS, FUEL AND COOLANT......................................................................................... G-9

5. TIGHTENING TORQUES ........................................................................................................... G-12

[1] GENERAL USE SCREWS, BOLTS AND NUTS .................................................................. G-12

[2] STUD BOLTS ....................................................................................................................... G-12

[3] AMERICAN STANDARD SCREWS, BOLTS AND NUTS WITH UNC OR UNF

THREADS ............................................................................................................................ G-13

[4] PLUGS ................................................................................................................................. G-13

6. MAINTENANCE CHECK LIST ................................................................................................... G-14

7. CHECK AND MAINTENANCE ................................................................................................... G-16

[1] DAILY CHECK...................................................................................................................... G-16

(1) Walking Around the Machine.......................................................................................... G-16

(2) Mower............................................................................................................................. G-19

(3) While Sitting on the Operator's Seat .............................................................................. G-19

(4) Turning the Key Switch "ON".......................................................................................... G-19

(5) Starting the Engine ......................................................................................................... G-19

(6) Others............................................................................................................................. G-20

[2] CHECK POINTS OF INITIAL 50 HOURS ............................................................................ G-20

[3] CHECK POINTS OF EVERY 50 HOURS ............................................................................ G-22

[4] CHECK POINTS OF EVERY 100 HOURS .......................................................................... G-37

[5] CHECK POINT OF EVERY 150 HOURS ............................................................................. G-39

[6] CHECK POINTS OF EVERY 200 HOURS .......................................................................... G-40

[7] CHECK POINTS OF EVERY 400 HOURS .......................................................................... G-45

[8] CHECK POINT OF EVERY 1500 HOURS ........................................................................... G-46

[9] CHECK POINT OF EVERY 3000 HOURS ........................................................................... G-46

[10]CHECK POINT OF EVERY 1 YEAR .................................................................................... G-46

[11]CHECK POINTS OF EVERY 2 YEARS ............................................................................... G-47

.......

[12]OTHERS.......................................................................................................................

8. SPECIAL TOOLS ....................................................................................................................... G-55

[1] SPECIAL TOOLS FOR ENGINE .......................................................................................... G-55

[2] SPECIAL TOOLS FOR MACHINE ....................................................................................... G-60

9. TYRE PRESSURE AND WHEEL ............................................................................................... G-62

[1] TYRE PRESSURE ............................................................................................................... G-62

[2] WHEEL................................................................................................................................. G-62

10. IMPLEMENT LIMITATIONS ....................................................................................................... G-63

. G-51

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

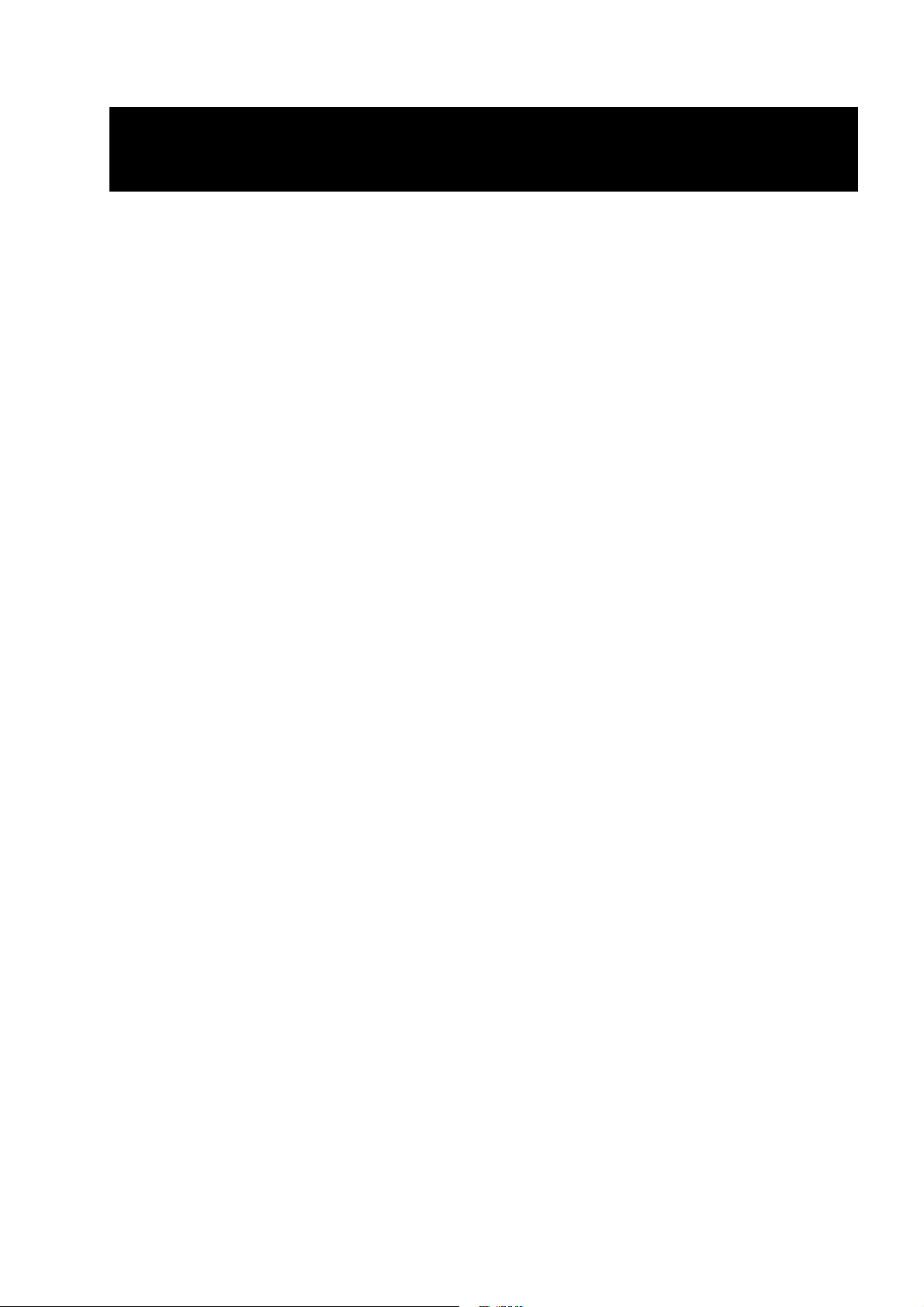

1. MACHINE IDENTIFICATION

[1] SERIAL NUMBER

When contacting your local KUBOTA distributor, always specify

engine serial number, tractor serial number and hour meter reading.

GENERAL

(1) Machine Serial Number

(2) Engine Serial Number

(3) Mower Serial Number

(4) Grass Catcher Serial Number (LD)

(5) Grass Catcher Serial Number (HD)

(6) Hour Meter / Tachometer

9Y1210892GEG0001US0

G-1

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

[2] CYLINDER NUMBER

GENERAL

You can see the cylinder numbers of KUBOTA diesel engine in

the figure. The sequence of cylinder numbers is No. 1, No. 2 and

No. 3 and it starts from the gear case side.

WSM000001GEG0056US0

G-2

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

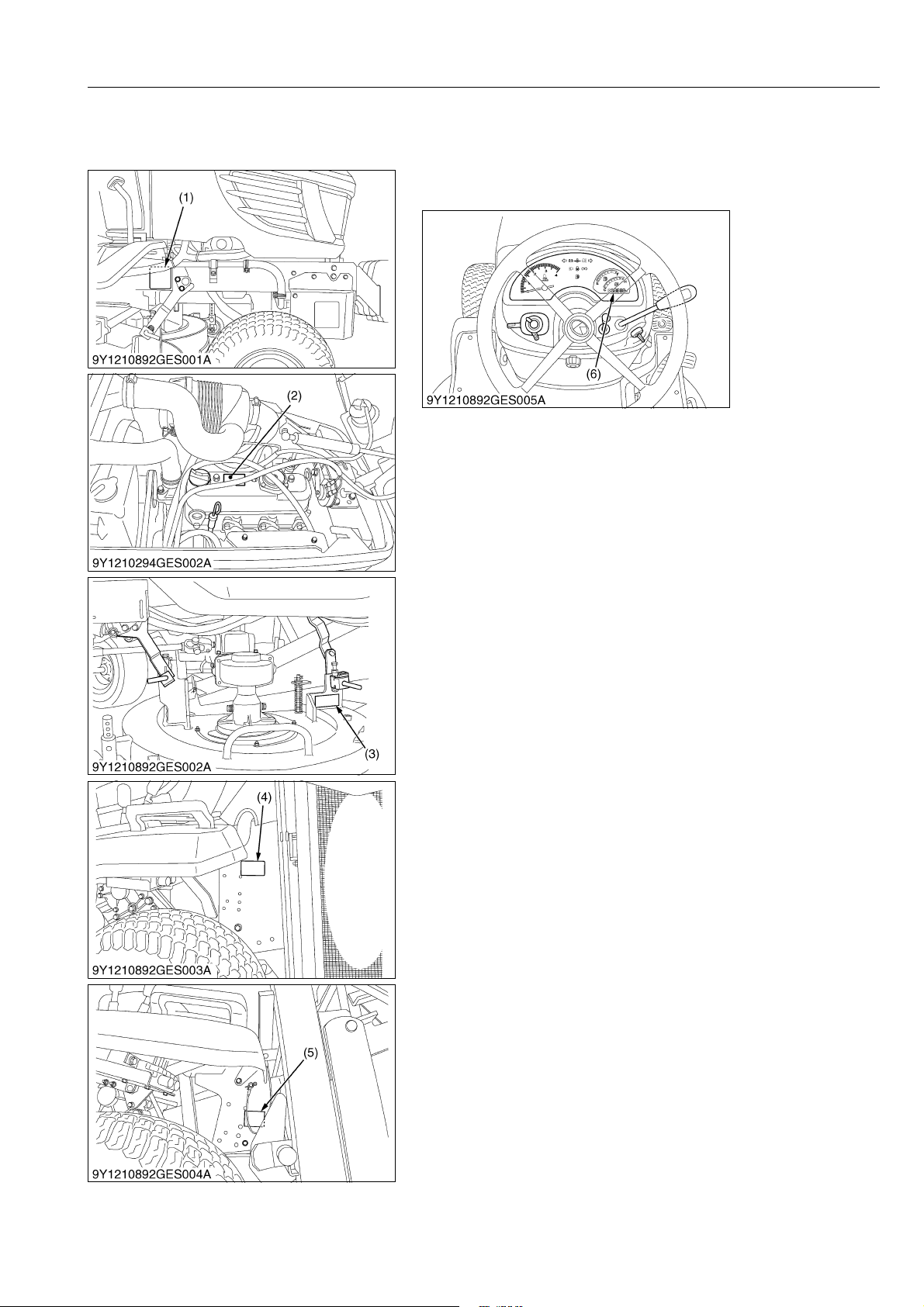

2. GENERAL PRECAUTIONS

• When you disassemble, carefully put the parts in a clean area

to make it easy to find the parts. You must install the screws,

bolts and nuts in their initial position to prevent the reassembly

errors.

• When it is necessary to use special tools, use KUBOTA special

tools. Refer to the drawings when you make special tools that

you do not use frequently.

• Before you disassemble or repair machine, make sure that you

always disconnect the ground cable from the battery first.

• Remove oil and dirt from parts before you measure.

• Use only KUBOTA genuine parts for replacement to keep the

machine performance and to make sure of safety.

• You must replace the gaskets and O-rings when you assemble

again. Apply grease (1) to new O-rings or oil seals before you

assemble.

• When you assemble the external or internal circlips, make sure

that the sharp edge (3) faces against the direction from which

force (2) is applied.

• When inserting spring pins, their splits must face the direction

from which a force is applied. See the figure on the left side.

• To prevent damage to the hydraulic system, use only specified

fluid or equivalent.

(1) Grease

(2) Force

(3) Sharp Edge

(4) Axial Force

(5) Rotating Movement

GENERAL

(A) External Circlip

(B) Internal Circlip

WSM000001GEG0092US0

G-3

G23-2, G26-2, WSM

IMPORTANT

KiSC issued 02, 2014 A

GENERAL

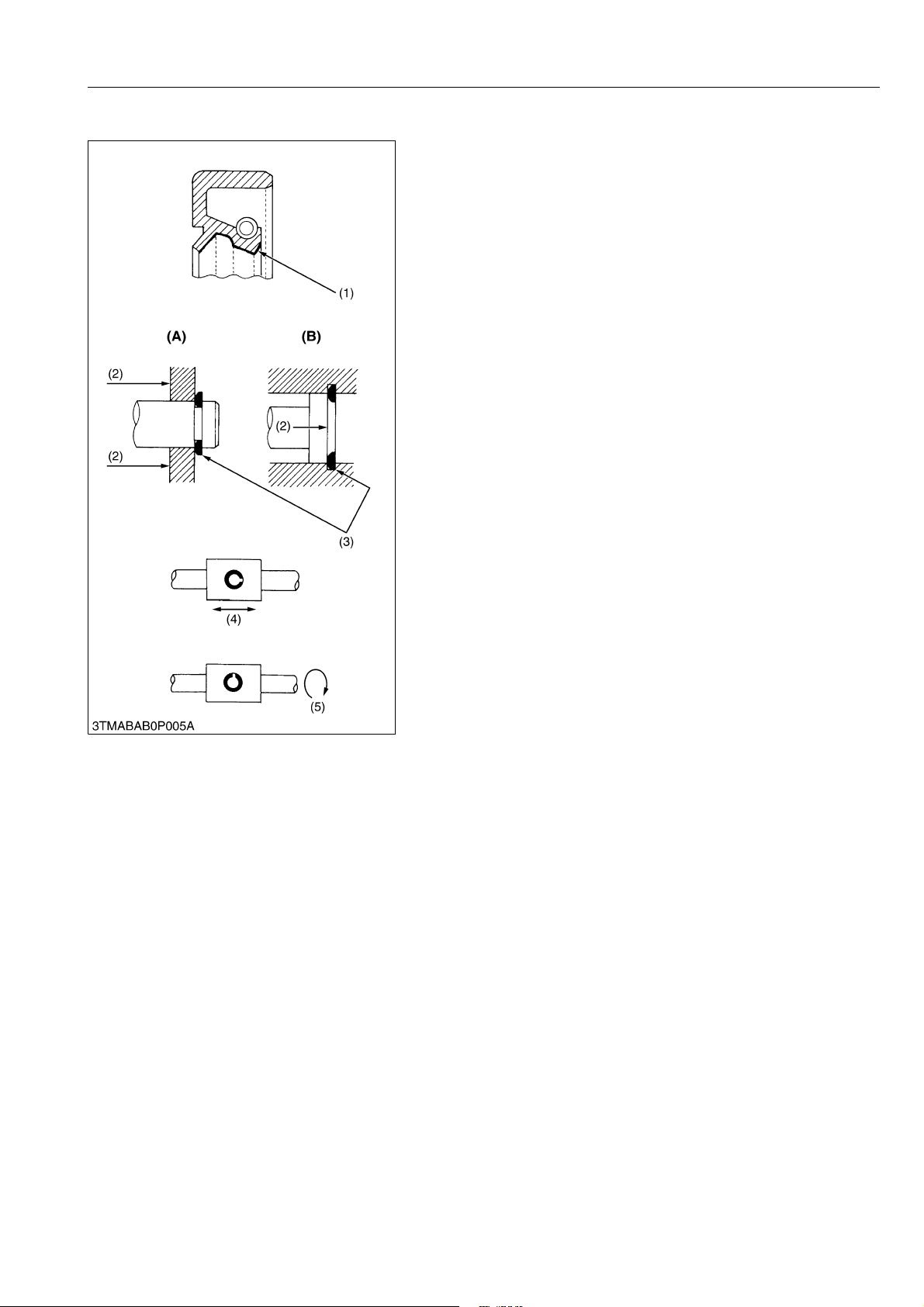

3. HANDLING PRECAUTIONS FOR ELECTRICAL PARTS AND WIRING

To ensure safety and prevent damage to the machine and

surrounding equipment, obey the following precautions in handling

electrical parts and wiring.

• Check electrical wiring for damage and loosened

connection every year. To this end, educate the customer

to do his or her own check and at the same time

recommend the dealer to perform periodic check for a fee.

• Do not try to modify or remodel any electrical parts and

wiring.

• When removing the battery cables, disconnect the negative

cable first. When installing the battery cables, connect the

positive cable first.

(1) Negative Terminal (2) Positive Terminal

WSM000001GEG0062US0

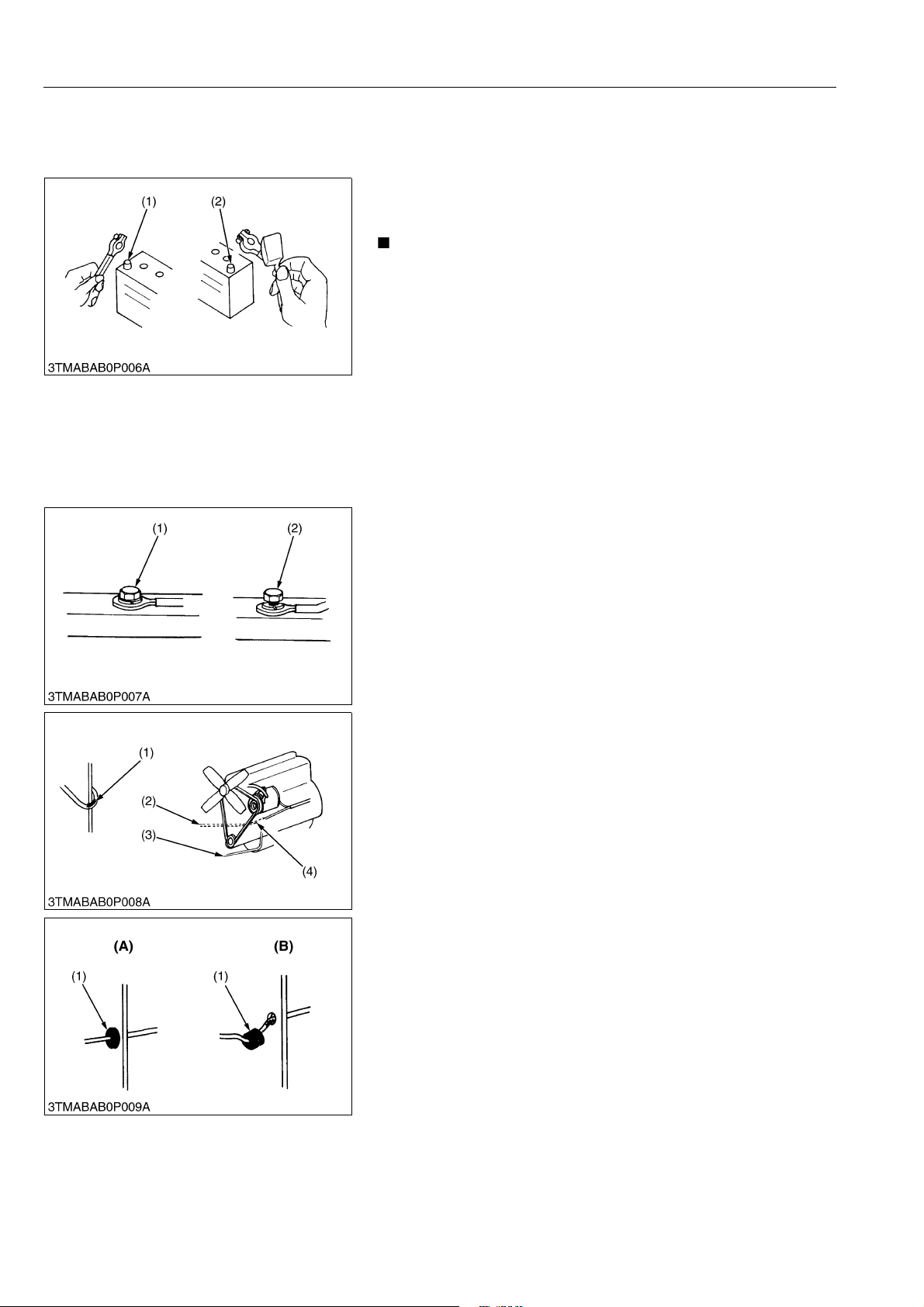

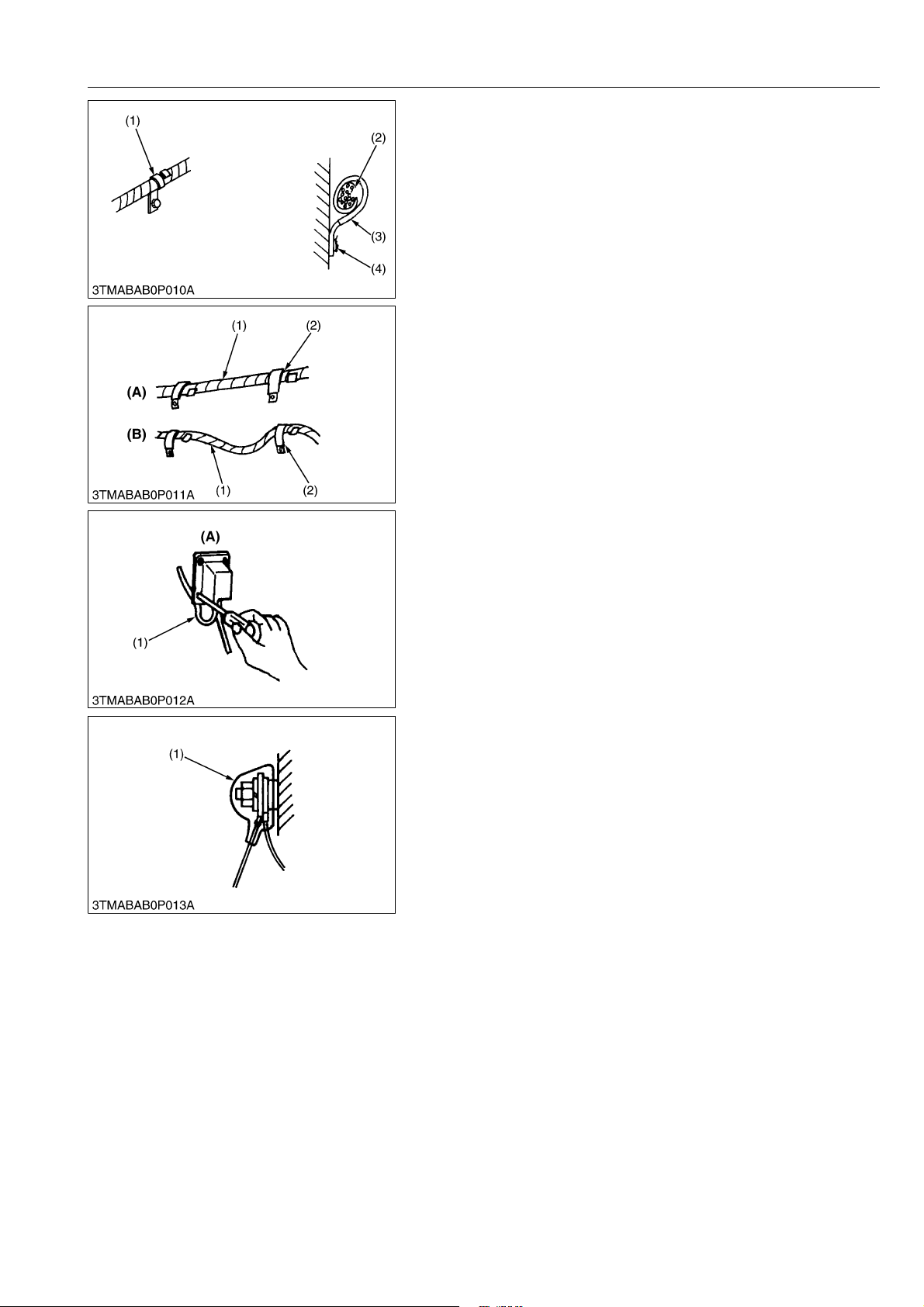

[1] WIRING

• Securely tighten wiring terminals.

(1) Correct

(Securely Tighten)

(2) Incorrect

(Loosening Leads to Faulty Contact)

WSM000001GEG0063US0

• Do not let wiring contact dangerous part.

(1) Dangerous Part (Sharp Edge)

(2) Wiring (Incorrect)

(3) Wiring (Correct)

(4) Dangerous Part

• Securely insert grommet.

(1) Grommet (A) Correct

(B) Incorrect

WSM000001GEG0064US0

WSM000001GEG0066US0

G-4

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

GENERAL

• Securely clamp, being careful not to damage wiring.

(1) Clamp

(Wind Clamp Spirally)

(2) Wire Harness

(3) Clamp

(4) Welding Dent

WSM000001GEG0067US0

• Clamp wiring so that there is no twist, unnecessary sag, or

excessive tension, except for movable part, where sag be

required.

(1) Wiring

(2) Clamp

(A) Correct

(B) Incorrect

WSM000001GEG0068US0

• In installing a part, be careful not to get wiring caught by it.

(1) Wiring (A) Incorrect

WSM000001GEG0069US0

• After installing wiring, check protection of terminals and

clamped condition of wiring.

(1) Cover

(Securely Install Cover)

WSM000001GEG0070US0

G-5

G23-2, G26-2, WSM

CAUTION

KiSC issued 02, 2014 A

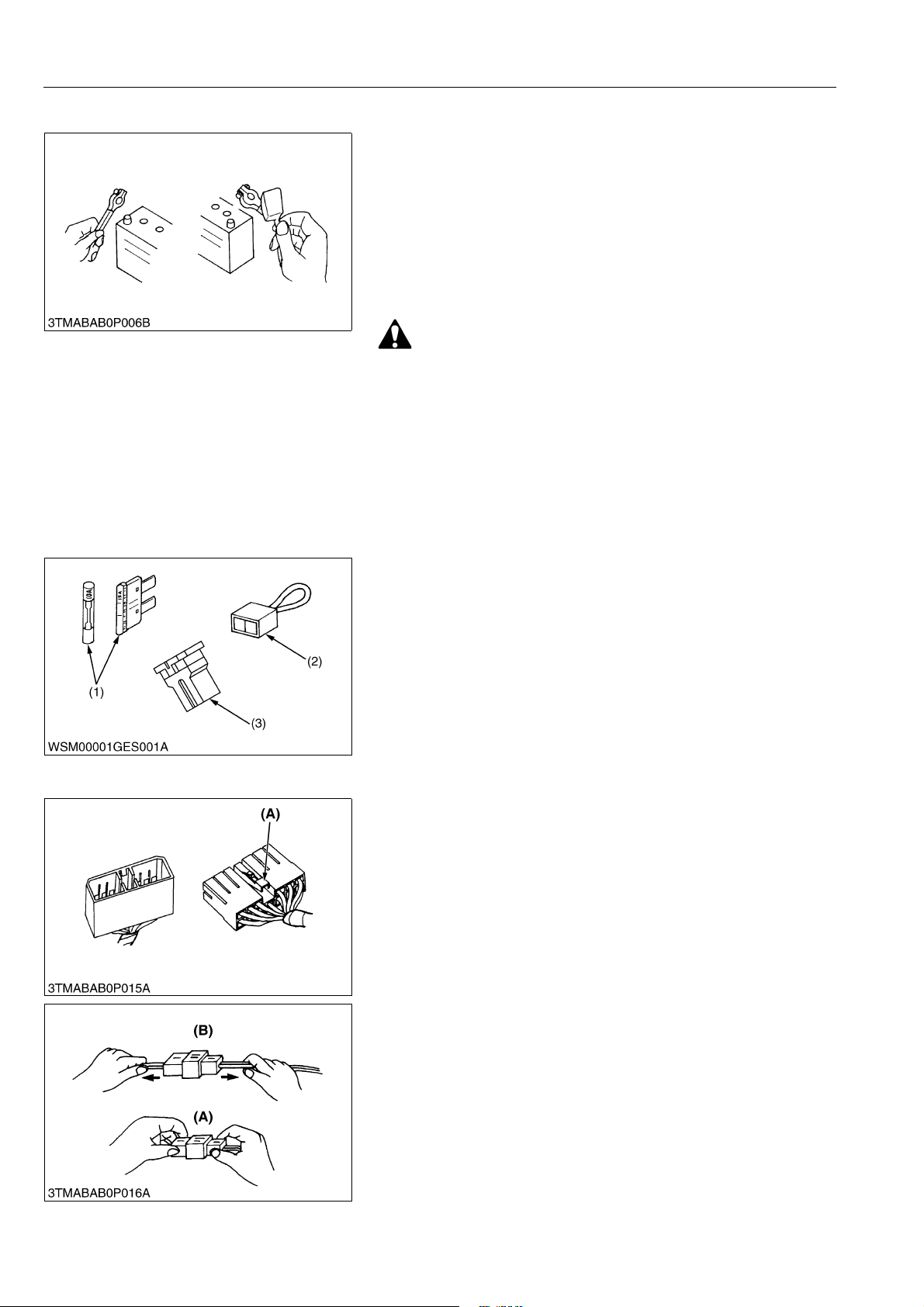

[2] BATTERY

GENERAL

• Be careful not to confuse positive and negative terminal posts.

• When you remove battery cables, disconnect negative cable

first. When you install battery cables, check for polarity and

connect positive cable first.

• Do not install any battery with capacity other than is specified

(Ah).

• After you connect cables to battery terminal posts, apply high

temperature grease to them and securely install terminal covers

on them.

• Do not allow dirt and dust to collect on battery.

• Be careful not to let battery liquid spill on your skin and

clothes. If contaminated, wash it off with water

immediately.

• Before you recharge the battery, remove it from the

machine.

• Before you recharge, remove cell caps.

• Recharge in a well-ventilated place where there is no open

flame nearby, as hydrogen gas and oxygen are formed.

WSM000001GEG0071US0

[3] FUSE

[4] CONNECTOR

• Use fuses with specified capacity.

Neither too large nor small capacity fuse is acceptable.

• Never use steel nor copper wire in place of fuse.

• Do not install working light, radio set, etc. on machine which is

not provided with reserve power supply.

• Do not install accessories if fuse capacity of reserve power

supply is exceeded.

(1) Fuse

(2) Fusible Link

(3) Slow Blow Fuse

WSM000001GEG0072US0

• For connector with lock, push lock to separate.

(A) Push

WSM000001GEG0073US0

• In separating connectors, do not pull wire harnesses.

• Hold connector bodies to separate.

(A) Correct (B) Incorrect

WSM000001GEG0074US0

G-6

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

GENERAL

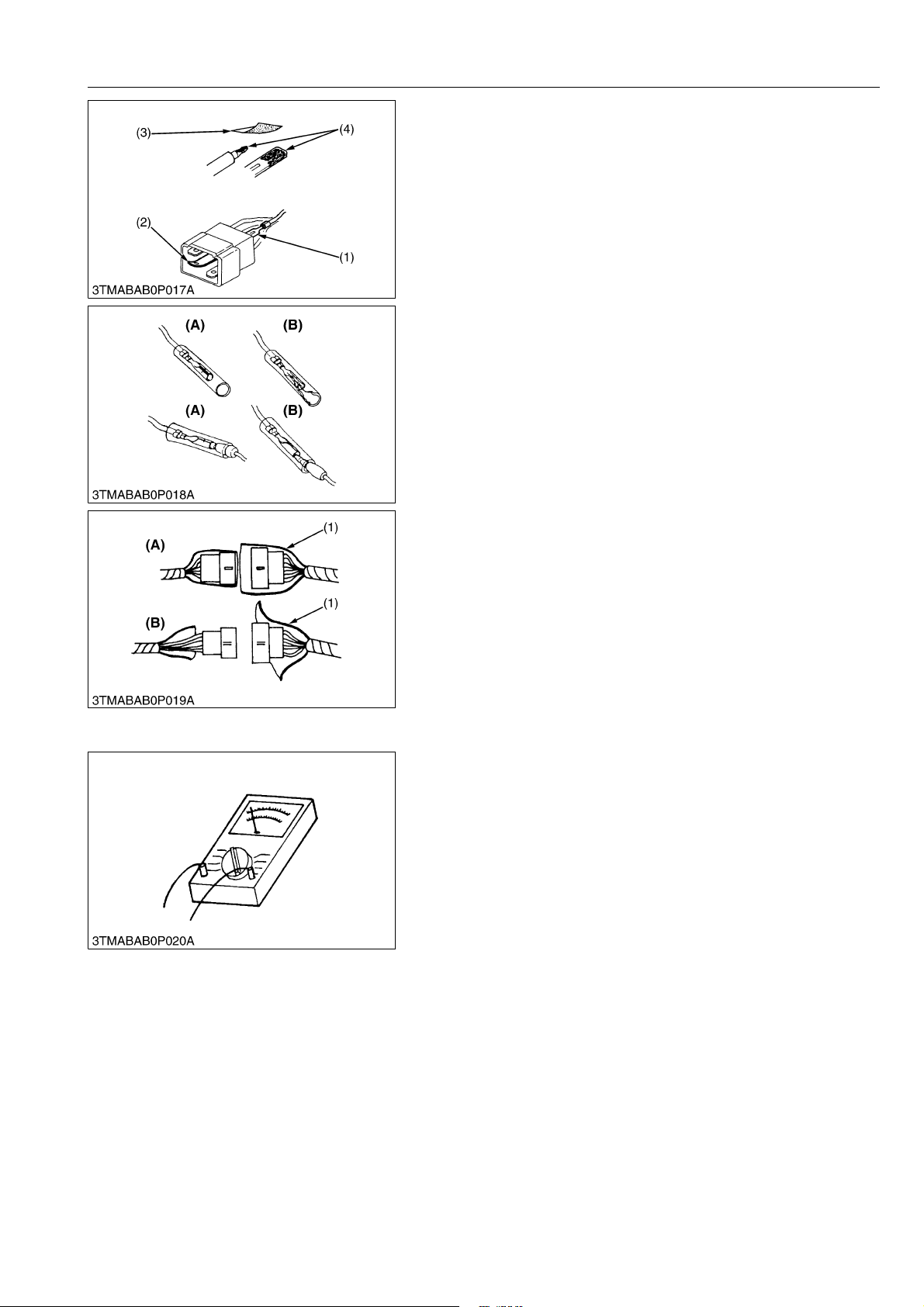

• Use sandpaper to remove rust from terminals.

• Repair deformed terminal. Make sure that there is no terminal

being exposed or displaced.

(1) Exposed Terminal

(2) Deformed Terminal

(3) Sandpaper

(4) Rust

WSM000001GEG0075US0

• Make sure that there is no female connector being too open.

(A) Correct (B) Incorrect

WSM000001GEG0076US0

• Make sure that plastic cover is large enough to cover whole

connector.

(1) Cover (A) Correct

(B) Incorrect

WSM000001GEG0077US0

[5] HANDLING OF CIRCUIT TESTER

• Use tester correctly following manual provided with tester.

• Check for polarity and range.

WSM000001GEG0078US0

G-7

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

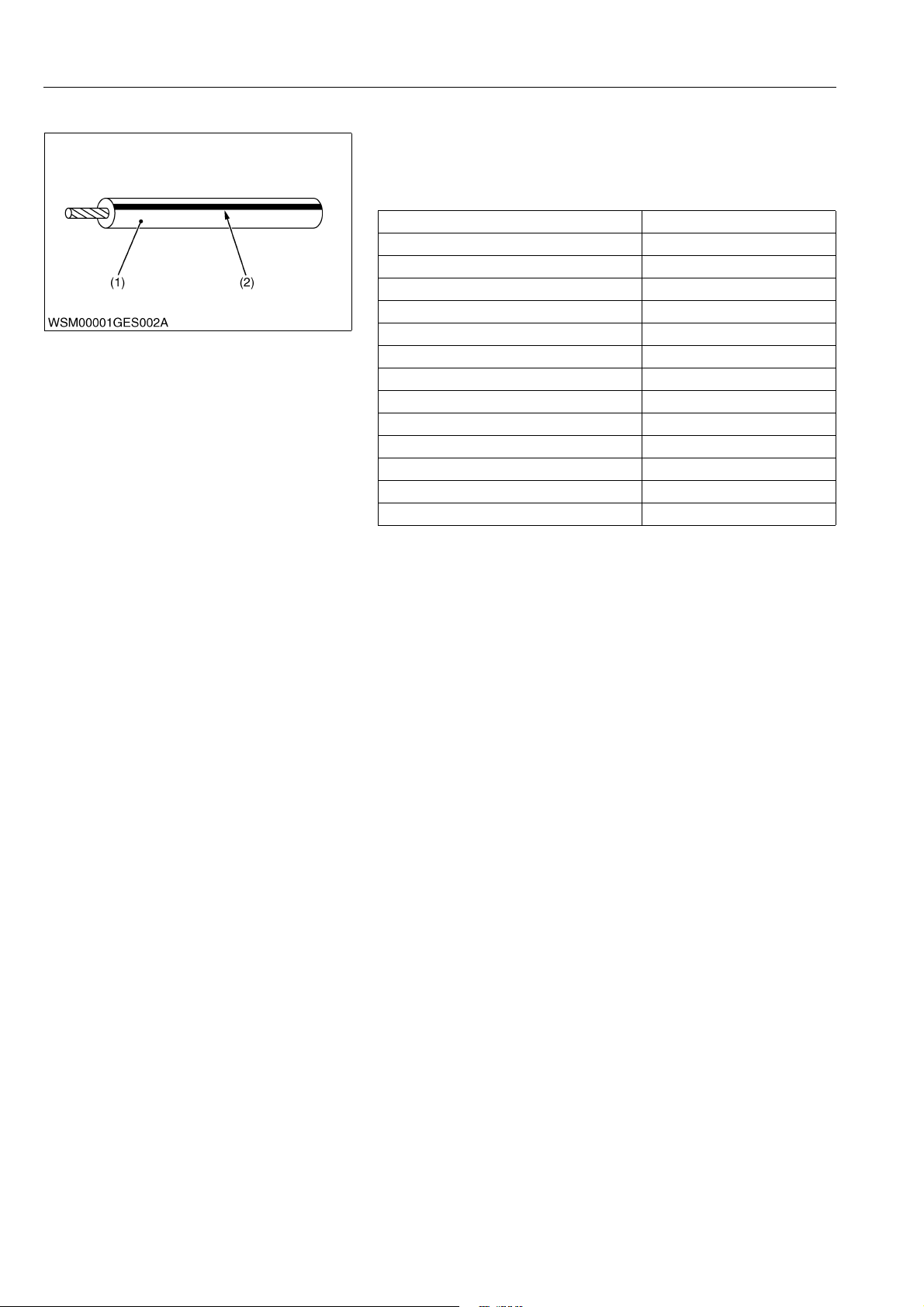

[6] COLOR OF WIRING

GENERAL

• Colors of wire are specified to the color codes.

• This symbol of "/" shows color with stripe(s).

(An example)

Red stripe on white color: W/R

Color of wiring Color code

Black B

Brown Br

Green G

Gray Gy or Gr

Blue L

Light Green Lg

Orange Or

Pink P

Purple Pu or V

Red R

Sky Blue Sb

White W

Yellow Y

(1) Wire Color (2) Stripe

WSM000001GEG0079US0

G-8

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

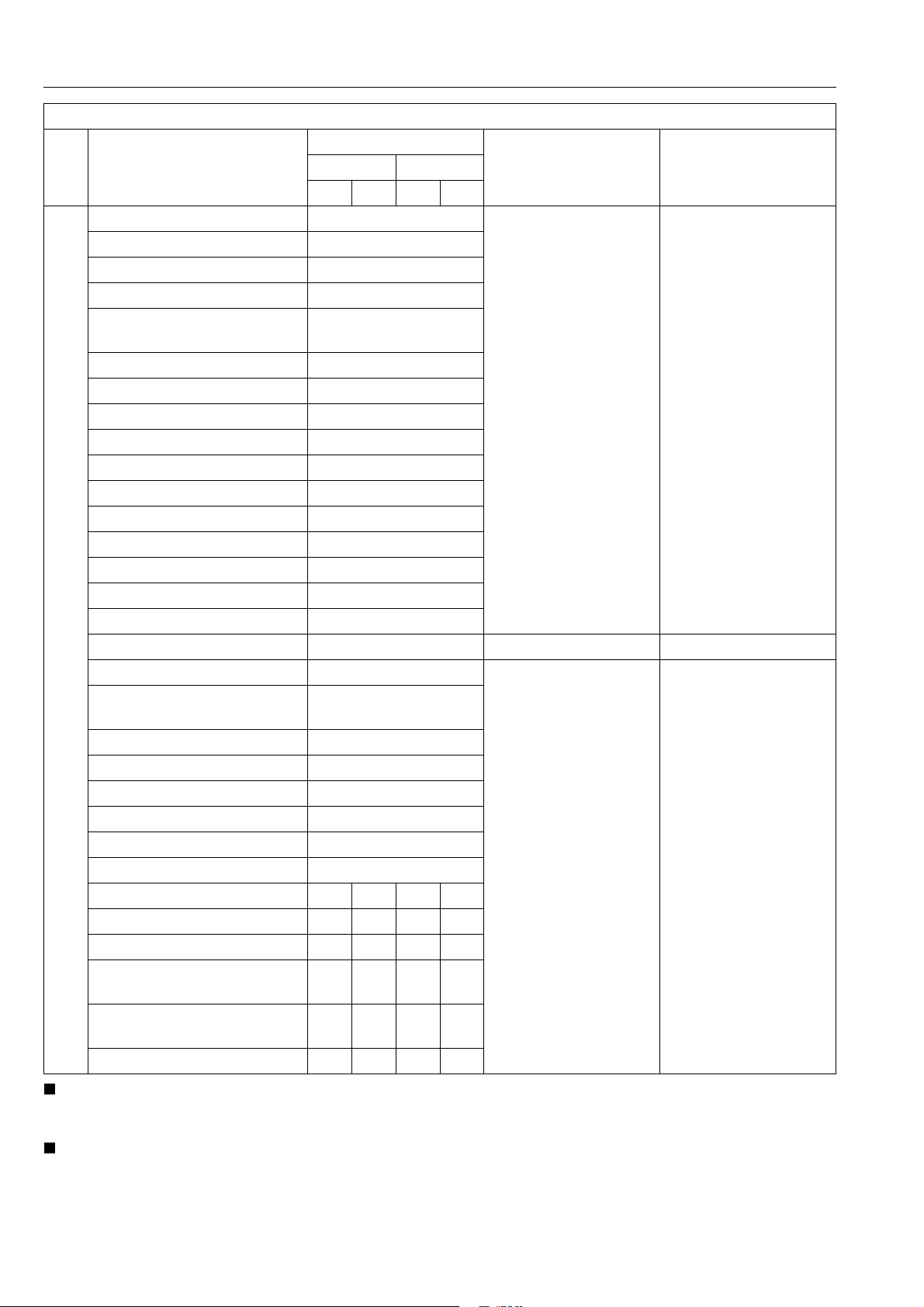

4. LUBRICANTS, FUEL AND COOLANT

Capacities

No. Place

LD HD LD HD

1Fuel

Coolant

2

(with recovery tank)

3 Engine crankcase

4 Transmission case

5 Mower gear box

3.1 L

3.3 U.S.qts

2.7 Imp.qts

3.1 L*

3.3 U.S.qts

2.7 Imp.qts

1.9 L

2.0 U.S.qts

1.7 Imp.qts

20 L

5.3 U.S.gals

4.4 Imp.gals

3.3 L

3.5 U.S.qts

2.9 Imp.qts

3.5 L*

3.7 U.S.qts

3.1 Imp.qts

11 L

12 U.S.qts

9.7 Imp.qts

2.1 L

2.2 U.S.qts

1.8 Imp.qts

• No. 2-D diesel fuel

• No. 1-D diesel fuel if temperature

is below –10 °C (14 °F)

Fresh clean water with anti-freeze

Engine oil

API Service Classification CD, CE

or CF

• Above 25 °C (77 °F)

SAE30W,

SAE10W-30 or 15W-40

• 0 to 25 °C (32 to 77 °F)

SAE20, SAE10W-30 or 15W-40

• Below 0 °C (32 °F)

SAE10W,

SAE10W-30 or 15W-40

KUBOTA UDT or SUPER UDT fluid*

KUBOTA UDT or SUPER UDT fluid*

GENERAL

LubricantsG23-2 G26-2

G-9

G23-2, G26-2, WSM

NOTE

IMPORTANT

KiSC issued 02, 2014 A

No. Place

Front axle (King pin) 2

Front axle (Centre pin) 1

Mower link 10

Brake pedal link 6

HST speed change pedal

dumper

HST pedal boss 1

Tension PTO arm 1

PTO (Spline) 1

Parking lock pedal link 2

Cruise control link 2

Differential lock pedal link 4

Under duct pivot 4

Sensor system pivot 2

Duct cleanup system link 4

Seat adjuster 2

Seat pivot 2

6

Throttle cable 1 Moderate amount Oil

Mower universal joint 3

Mower universal joint

(Grease fitting)

Mower lift cylinder 5

Mower lift arm front (RH) 1

Mower lift link front 3

Mower lift arm rear (LH, RH) 4

Mower lift pin front (LH, RH) 2

Mower lift link rear (LH, RH) 4

Dump cylinder 2–2–

Grass container rotation pivot4–4–

Lock lever (LH, RH) 2–2–

Grass container pivot

(Grease fitting) (LH, RH)

Grass container lift cylinder

(LH, RH)

Dump pivot (LH, RH) –2–2

Greasing

No. of greasing point

LD HD LD HD

2

2

–10–10

–4–4

Capacity Type of greaseG23-2 G26-2

Until grease overflows

Until grease overflows

GENERAL

Multipurpose EP2

grease

(NLGI Grade No.2)

Multipurpose EP2

grease

(NLGI Grade No.2)

• * Oil amount when the oil level is at the upper level of the oil lever gauge.

• Check the oil lever of the transmission case with the mower lifted up and grass catcher lowered.

• To prevent serious damage to hydraulic system, use only KUBOTA genuine fluid or its equivalent.

9Y1210892GEG0002US0

G-10

G23-2, G26-2, WSM

NOTE

KiSC issued 02, 2014 A

GENERAL

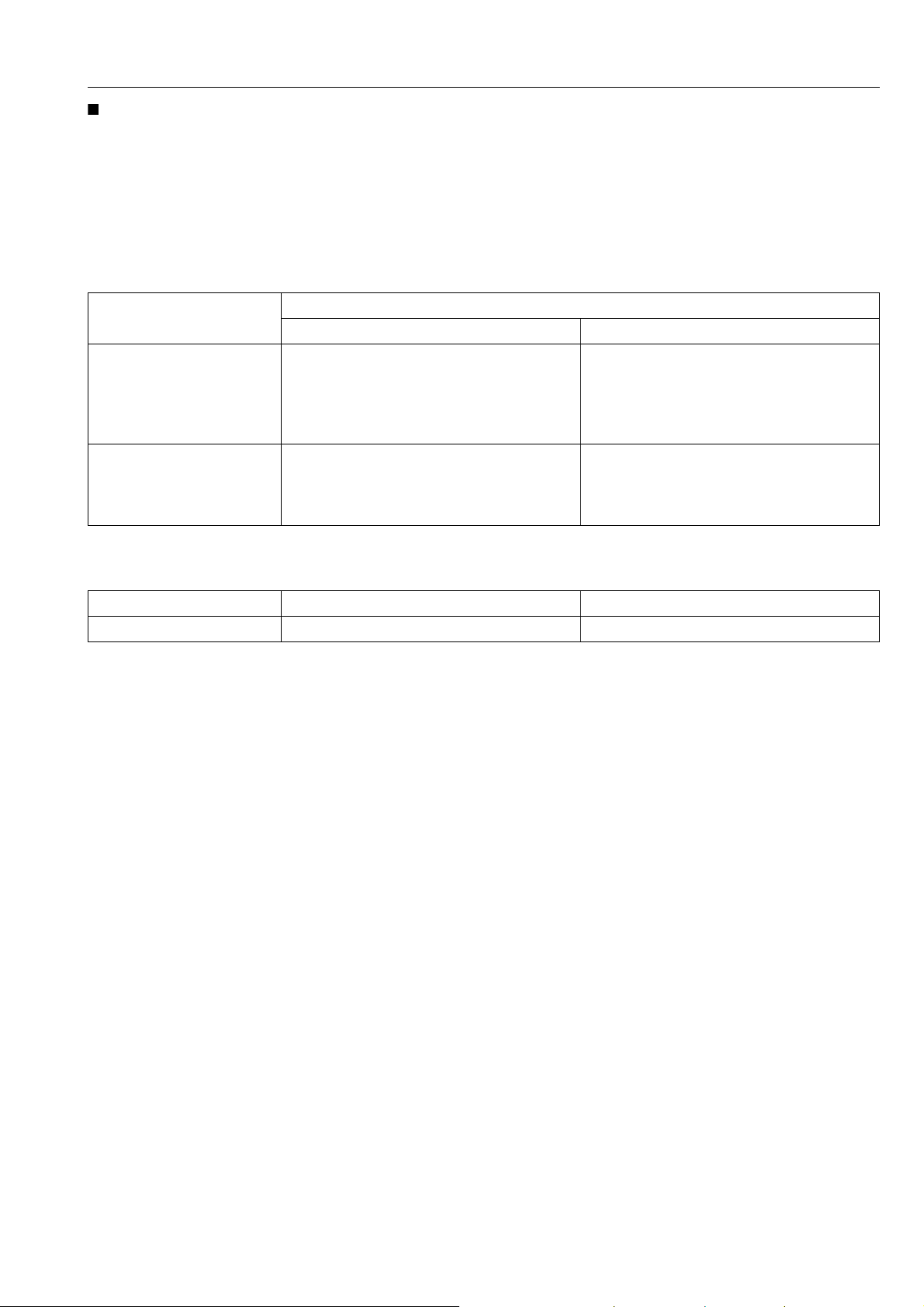

Engine Oil

• Oil used in the engine should have an American Petroleum Institute (API) service classification and

Proper SAE Engine Oil according to the ambient temperatures as shown above :

• With the emission control now in effect, the CF-4 and CG-4 lubricating oils have been developed for use

of a low-sulfur fuel on on-road vehicle engines. When an off-road vehicle engine runs on a high-sulfur

fuel, it is advisable to employ the "CF or better" lubricating oil with a high Total Base Number (TBN of 10

minimum).

• Refer to the following table for the suitable API classification engine oil according to the engine type (with

internal EGR, external EGR or non-EGR) and the fuel (low-sulfur or high-sulfur fuel).

Fuel used

Engine oil classification (API classification)

Oil class of engines except external EGR Oil class of engines with external EGR

CF

High Sulfur Fuel

[≥ 0.05 % (500 ppm)]

(If the "CF-4, CG-4, CH-4, or CI-4"

lubricating oil is used with a high-sulfur

fuel, change the lubricating oil at shorter

—

intervals. (approximately half))

Low Sulfur Fuel

[< 0.05 % (500 ppm)] or

Ultra Low Sulfur Fuel

[< 0.0015 % (15 ppm)]

CF, CF-4, CG-4, CH-4 or CI-4

CF, CI-4

(Class CF-4, CG-4 and CH-4 engine oils

cannot be used on EGR type engines)

EGR: Exhaust Gas Re-circulation

• The CJ-4 engine oil is intended for DPF (Diesel Particulate Filter) Type engines, and cannot be used on

this machine.

except external EGR with external EGR

Models G23-2, G26-2 –

Fuel

• Cetane number of 45 minimum. Cetane number greater then 50 is preferred, especially for temperatures

below −20 °C (−4 °F) or elevations above 1500 m (5000 ft).

• If diesel fuel with sulfur content greater than 0.5 % (5000 ppm) sulfur content in used, reduce the service

interval for engine oil and filter by 50%.

• NEVER use diesel fuel with sulfur content greater than 0.05% (500 ppm) for EXTERNAL EGR type engine.

• DO NOT use diesel fuel with sulfur content greater than 1.0% (10000 ppm).

• Diesel fuels specified to EN 590 or ASTM D975 are recommended.

• No.2-D is a distillate fuel of lower volatility for engine in industrial and heavy mobile service. (SAE J313

JUN87)

Transmission oil

• The oil used to lubricate the transmission is also used as hydraulic fluid. To insure proper operation of

the hydraulic system and to complete lubrication of the transmission, it is important that a multi-grade

transmission fluid is used in this system. We recommend the use of KUBOTA UDT or SUPER UDT fluid

for optimum protection and performance.

Do not mix different brands together.

Indicated capacities of water and oil are manufacturer's estimate.

9Y1210892GEG0003US0

G-11

G23-2, G26-2, WSM

KiSC issued 02, 2014 A

GENERAL

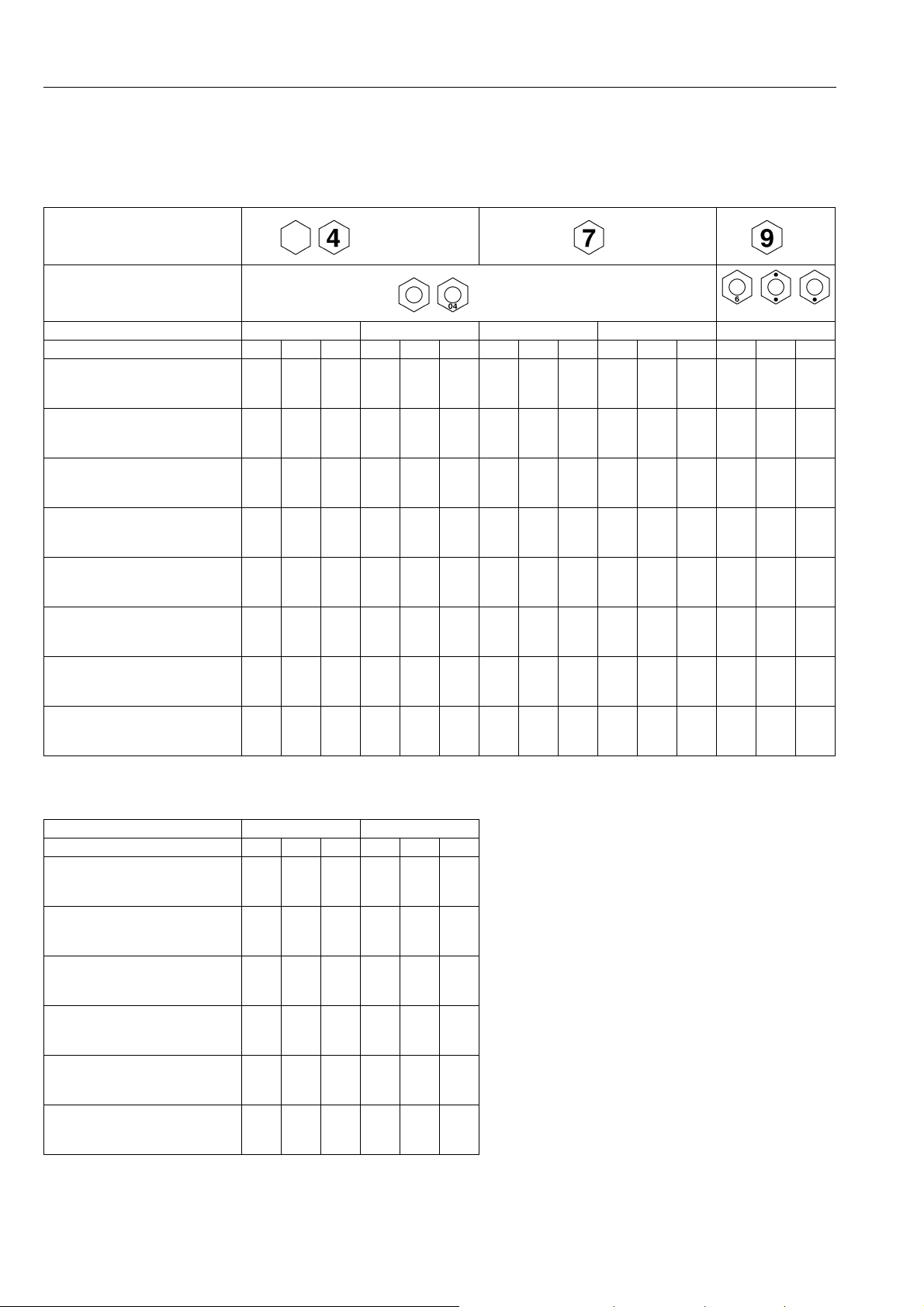

5. TIGHTENING TORQUES

[1] GENERAL USE SCREWS, BOLTS AND NUTS

Tighten screws, bolts and nuts whose tightening torques are not specified in this Workshop Manual

according to the table below.

Indication on top of bolt

Indication on top of nut

Material of opponent part Ordinariness Aluminum Ordinariness Aluminum Ordinariness

Unit N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft

7.9

0.80

M6

M8

M10

M12

M14

M16

M18

M20

to

9.3

18

to

20

40

to

45

63

to

72

108

to

125

16

to

191

246

to

284

334

to

392

to

0.95

1.8

to

2.1

4.0

to

4.6

6.4

to

7.4

11. 0

to

12.8

7

17.0

to

19.5

25.0

to

29.0

34.0

to

40.0

No-grade or 4T 7T 9T

No-grade or 4T

5.8

7.9

0.80

5.8

9.81

1.00

7.24

7.9

0.80

5.8

to

to

to

1.7

to

2.0

3.2

to

3.5

to

6.5

13

to

14

24

to

25

6.8

8.8

0.90

13

17

to

to

15

19

32

29

to

to

33

34

47

to 53–––

79.6

to

92.5

–––

123

to

–––

141

181

to

–––

209

246

to

–––

289

to

11. 2

24

to

27

48

to

55

78

to

90

124

to

147

197

to

225

275

to

318

368

to

431

to

1.15

2.4

to

2.8

4.

9

to

5.7

7.9

to

9.2

12.6

to

15.0

20.0

to

23.0

28.0

to

32.5

37.5

to

44.0

to

8.31

18

to

20

36

to

41

58

to

66

91.2

to

108

145

to

166

203

to

235

272

to

318

to

to

8.8

0.90

18

1.8

to

to

20

2.1

40

4.0

to

to

44

4.5

63

6.4

to

to

72

7.4

––

–––

–––

–––

12.3

to

to

6.5

14.2

13

30

to

to

15

34

29

61

to

to

32

70

47

103

to

to

53

117

167

–

to

196

260

to

304

344

to

402

491

to

568

WSM000001GEG0001US0

6T

1.25

to

1.45

3.0

to

3.5

6.2

to

7.2

10.5

to

12.0

17.0

to

20.0

26.5

to

31.0

35.0

to

41.0

50.0

to

58.0

9.05

to

10.4

22

to

25

45

to

52

76.0

to

86.7

123

to

144

192

to

224

254

to

296

362

to

419

[2] STUD BOLTS

Material of opponent part Ordinariness Aluminum

Unit N·m kgf·m lbf·ft N·m kgf·m lbf·ft

12

1.2

8.7

M8

M10

M12

M14

M16

M18

to

15

25

to

31

30

to

49

62

to

73

98.1

to

112

172

to

201

to

1.6

2.5

to

3.2

3.0

to

5.0

6.3

to

7.5

10.0

to

11. 5

17.5

to

20.5

8.9

to

to

11

11

18

20

to

to

23

25

22

to 3631 3.2 23

46

to 54–––

72.4

to

83.1

–––

127

to

–––

148

0.90

to

1.2

2.0

to

2.6

6.5

to

8.6

15

to

18

WSM000001GEG0002US0

G-12

Loading...

Loading...