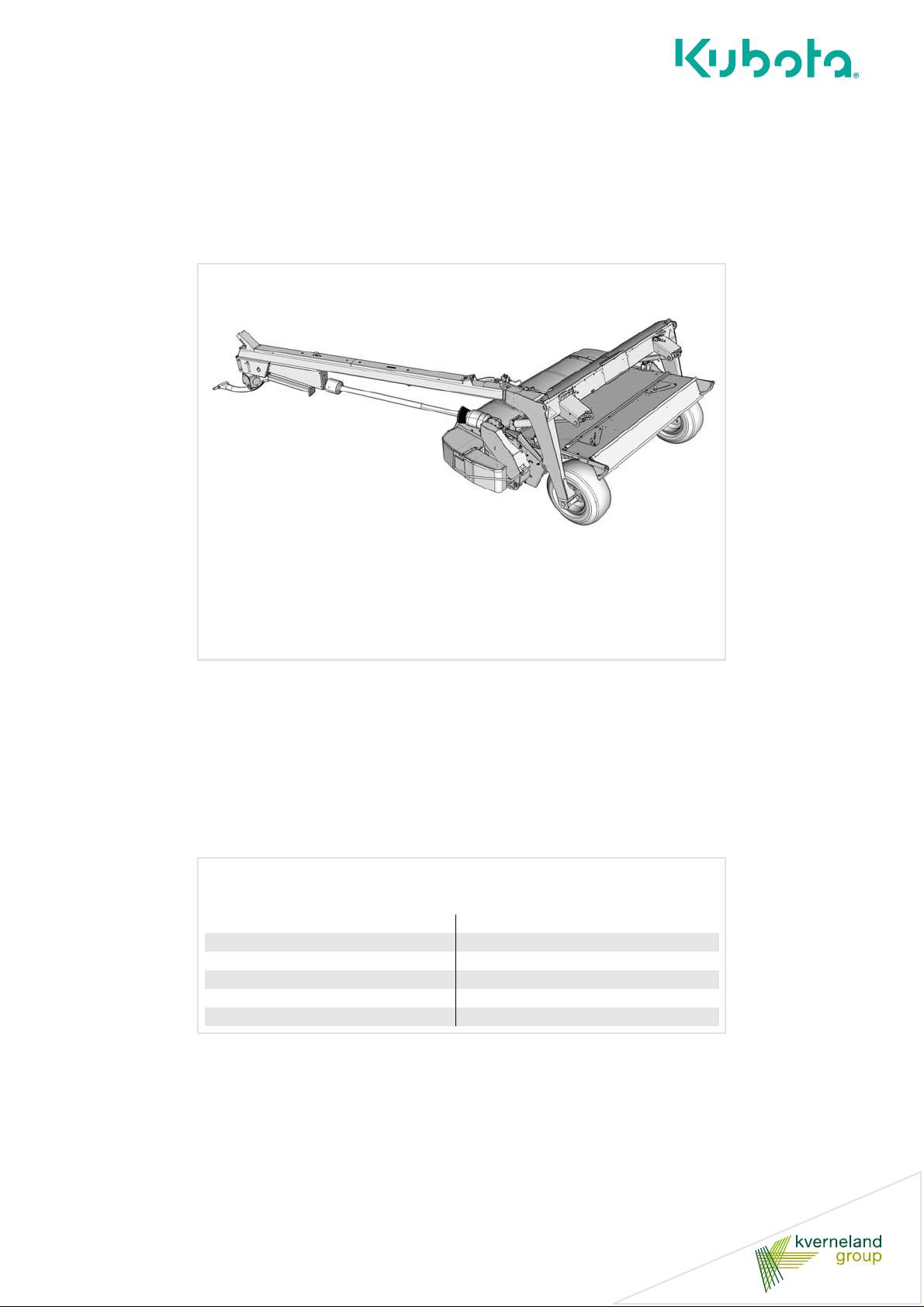

Kubota DMC 8028, DMC 8032, DMC 8036R, DMC 8536R Operator's Manual

DMC 8028-8032-8036R-

8536R

Operator’s manual

Translated from the original operator’s manual

Revision 02

Date printed 08.2015

Language EN-US

Machine number KT457127

Document number A132379640

Index 2015-09

Machine identification

In order for your dealer to assist you as efficiently as possible, you will need to provide some information about

your machine. Please enter the details here.

Designation

Operating width

Weight

Machine

number

Accessories

Address of

supplier

DMC 8028-8032-8036R-8536R

8028: 2,8 m (9’ 2”) // 8032: 3,2 m (10’ 6”),

8036-8536: 3,6 m (11’ 10’’)

8028: 1910 kg (4212 lbs) // 8032: 2061 kg (4544 lbs)

8036: 2247 kg (4955 lbs) // 8536: 2515 kg (5546 lbs)

Address of

manufacturer

Kverneland Group Kerteminde AS

Taarupstrandvej 25

DK-5300 Kerteminde - Denmark

Tel. / fax: +45 65 19 19 00 / +45 65 19 19 99

web: www.kvernelandgroup.com

Copyright Kverneland Group Kerteminde AS, Denmark. Copying, reproduction in any form, translation, or use of excerpts or parts of this document

are not permitted without specif ic permission from Kvernel and. All rights reserved . The contents of this manual may be ch anged without prior

warning. Rights reserved for technical amendments and printing errors in this manual.

Table of contents

Preface ....................................................... 4

Target group for the Instruction Manual 4

The meaning of the symbols 5

Safety ......................................................... 7

For your own safety 7

Who can operate the machine? 13

Attachment 13

Load capacity 14

Transport on public roads 15

Use 16

Disconnection 18

Maintenance 19

Further safety instructions 21

Blank page ................................................ 22

About the machine ................................... 23

The machine's field of application 23

Machine characteristics 24

Synopsis 25

Technical data 27

Tractor requirements 33

Table of contents

For your own safety 101

General instructions 103

Lubrication 108

Service - check 114

Replacement 163

Extra equipment ........................................ 206

Spreading device 206

High skids 207

Rotor RPM 207

Weights 208

P.T.O. shaft 208

Hour counter 209

Chain for locking the lift arms 209

Attachment for tractor 209

Troubleshooting ........................................ 210

Electric and hydraulic system 210

Cutterbar 210

P.T.O. shaft 211

Warranty ..................................................... 212

Guidelines for warranty 212

Preparation ................................................ 34

Preparing the machine 34

Length of P.T.O. shaft 35

Assembly - attachment ............................ 43

Attachment of the tractor 44

P.T.O. shaft 49

Lighting equipment 50

Hydraulics 52

Connection 53

Initial startup of machine 54

Machine in the transport mode 61

Transport on public roads ....................... 65

Safety 65

Before traveling on public roads 65

Checking the machine 66

Traveling on public roads 66

Operation ................................................... 67

Safety 67

Before operating 68

Operation 69

Cleaning .................................................... 96

Before cleaning 96

Cleaning 97

After cleaning 97

Disposal ..................................................... 213

Metal parts 213

Rubber parts 213

Plastic 213

Hydraulic oil and lubricants 213

Electronic parts 213

EU Declaration of Conformity .................. 214

EU Directive 2006/42/EC 214

Notes .......................................................... 215

Technical information ............................... 216

Conversion table 216

Lubricants 216

Torque moment 217

Index ........................................................... 218

Parking and Storage ................................. 98

Before storage 98

Parking/disconnection of the machine 98

Storage 100

Maintenance .............................................. 101

3

Preface

Preface

Target group for the Instruction Manual

Minimum age

For your own safety

For the employer

\ NOTICE

Simplified illustrations to improve understanding

All of the illustrations of the machine in this instruction manual

show it without the guards or with the protective equipment open

to improve understanding.

Ensure that the safety instructions are complied with and the

instructions in the instruction manual are followed.

Failure to do so can endanger lives.

This manual is intended for trained farmers and others who are

qualified to work in agriculture and who are familiar with assembling

equipment.

Children under the age of 16 are not permitted to operate the machine .

Read this instruction manual thoroughly prior to assembly and use of

the machine. This will allow you to work under optimal conditions and

in safety.

Every employee must be trained in how to use this machinery at

regular intervals (at least once a year) in accordance with the

employer's insurance guidelines. Untrained or unauthorized persons

must not use this machine.

Instructions

Your dealer will assist you with the instructions on how to use and

maintain this machinery.

4

Preface

The meaning of the symbols

We have used different symbols to make the text clear . An explanation

follows:

• A dot symbol marks a list of instructions or information.

A triangle marks an action you must carry out.

→ An arro w re fe rs yo u to othe r par ts of the text.

We have also used pictograms to help you find relevant places in the

text.

Denotes tips or instructions on use.

Denotes information that requires particular atte ntio n.

A spanner indicates tips for assembling and settings.

This pictogram indicates that the tractor can be started.

This pictogram indicates that the tractor must be stopped, the

handbrake applied and the ignition key removed.

5

Preface

California Proposition 65

\ WARNING

Engine exhaust, some of its constituents, certain machine

components and fluids, contain or emit chemicals known to the

State of California to cause cancer and birth defects or other

reproductive harm.

\ SAFETY FIRST

This symbol, the industry's "Safety Alert Symbol", is used

throughout this manual and on labels on the machine itself to warn

of the possibility of personal injury.

Read these instructions carefully. It is essential that you read the

instructions and safety regulations before you attempt to

assemble or use this unit.

\ DANGER:

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

\ WARNING:

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

\ CAUTION:

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

6

Safety

Safety

For your own safety

Get to know your equipment and its limitations. Read the entire

manual before attempting to start and operate the device.

This chapter includes general safety instructions. In addition, each

chapter in the instruction manual includes specific safety instructions

not set out here. The safety instructions must be followed

• For your own safety.

• For the safety of others.

• To ensure the safety of the machine.

When working with agricultural machinery, incorrect handling can

pose a number of dangers. Therefore, you should always be very

careful and never rush your work under pressure.

The operator must be receive regular training

Make sure that persons working with the machine are regularly

reminded of these safety instructions.

The safety instructions should be followed in accordance with local

statutes concerning agricultural machines.

7

Safety

WARNING

UNEXPECTED MOVEMENT

• MACHINE PARTS MAY STILL

ROTATE AFTER ENGINE IS

SWITCHED OFF.

TO AVOID FATAL OR SERIOUS

INJURY:

KEEP AWAY UNTIL PARTS

STOP MOVING

VF16661510

CAUTION

READ THE MANUAL

•

THE MACHINE MUST NOT BE

USED BEFORE READING

THE OPERATING MANUAL.

TO AVOID FATAL OR SERIOUS

INJURY:

READ THE MANUAL FIRST

VF16661512

WARNING

VF16661558

PRE-LOADED SPRING

SPRING MAY UNEXPECTEDLY EXPAND IN

CASE OF INCORRECT INSTALLATION.

TO AVOID SERIOUS INJURY:

SERVICE BY TRAINED PERSONNEL ONLY

DANGER

KEEP AWAY - ROTATING BLADES

TO AVOID SERIOUS INJURY OR DEATH

FROM BLADE CONTACT AND THROWN OBJECTS:

KEEP ALL PERSONS CLEAR OF OPERATING MOWER AND MOWING AREA.

KEEP CURTAIN GUARD IN PLACE AND IN GOOD CONDITION.

DO NOT OPERATE MOWER WITH CURTAIN GUARD REMOVED.

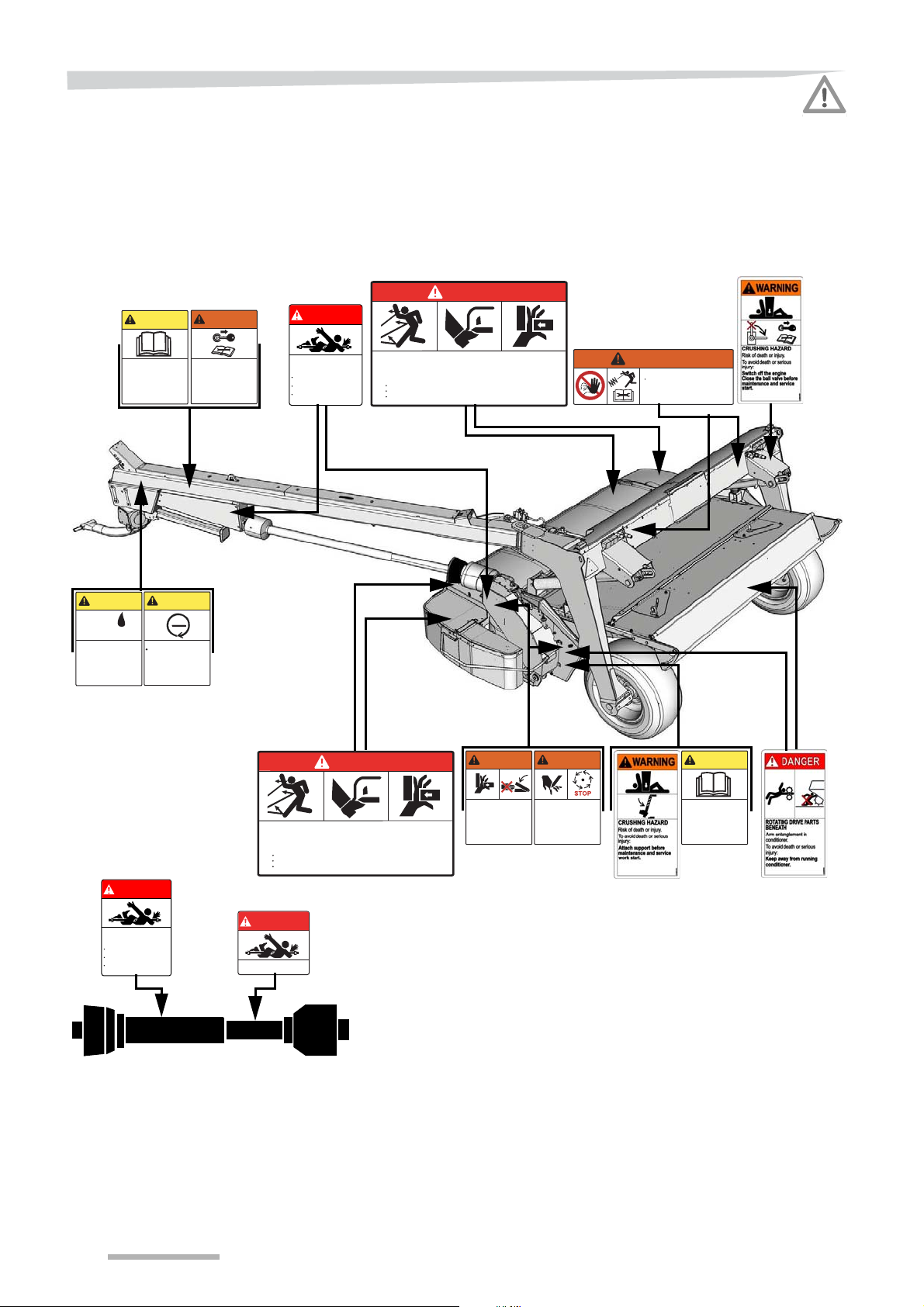

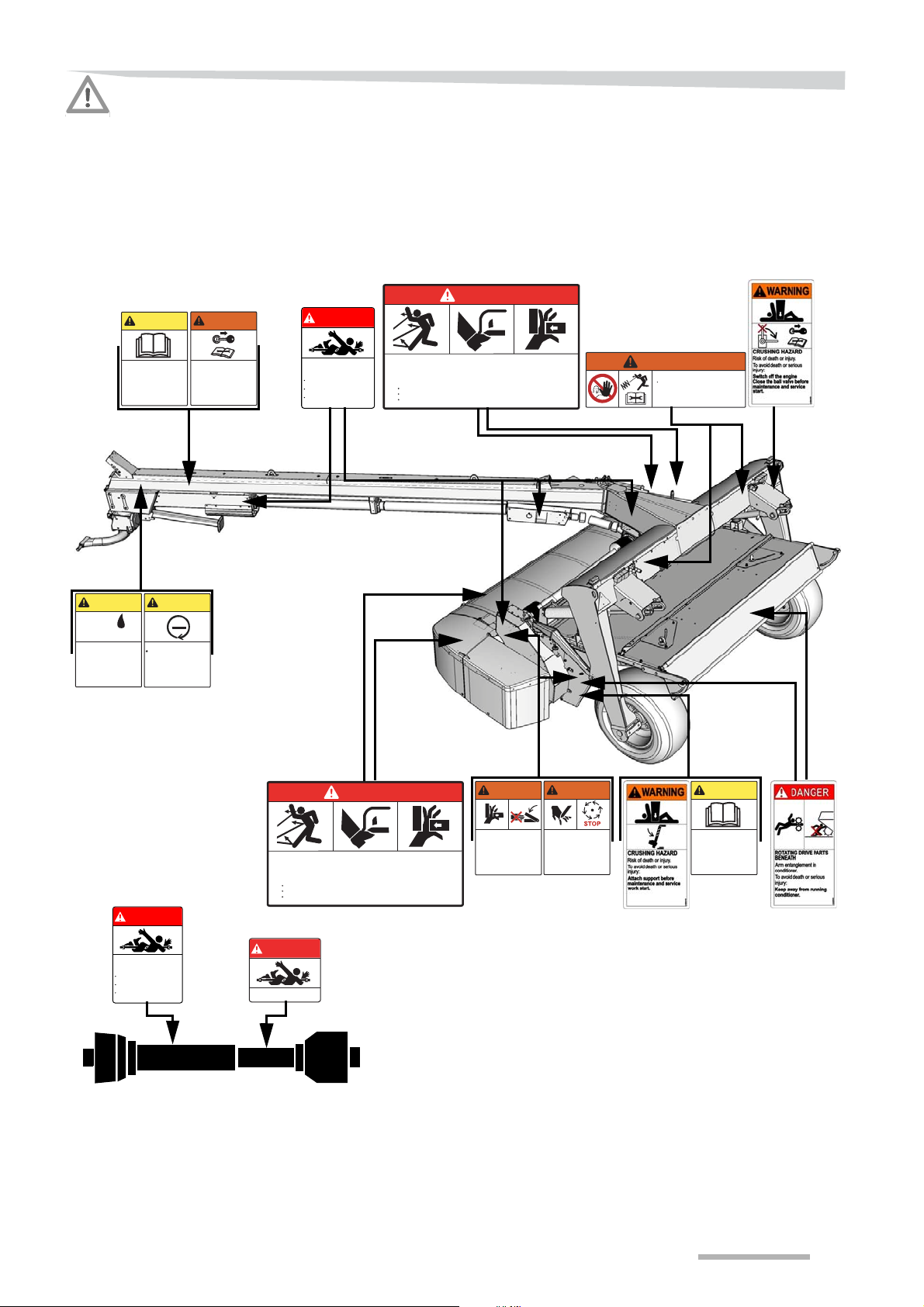

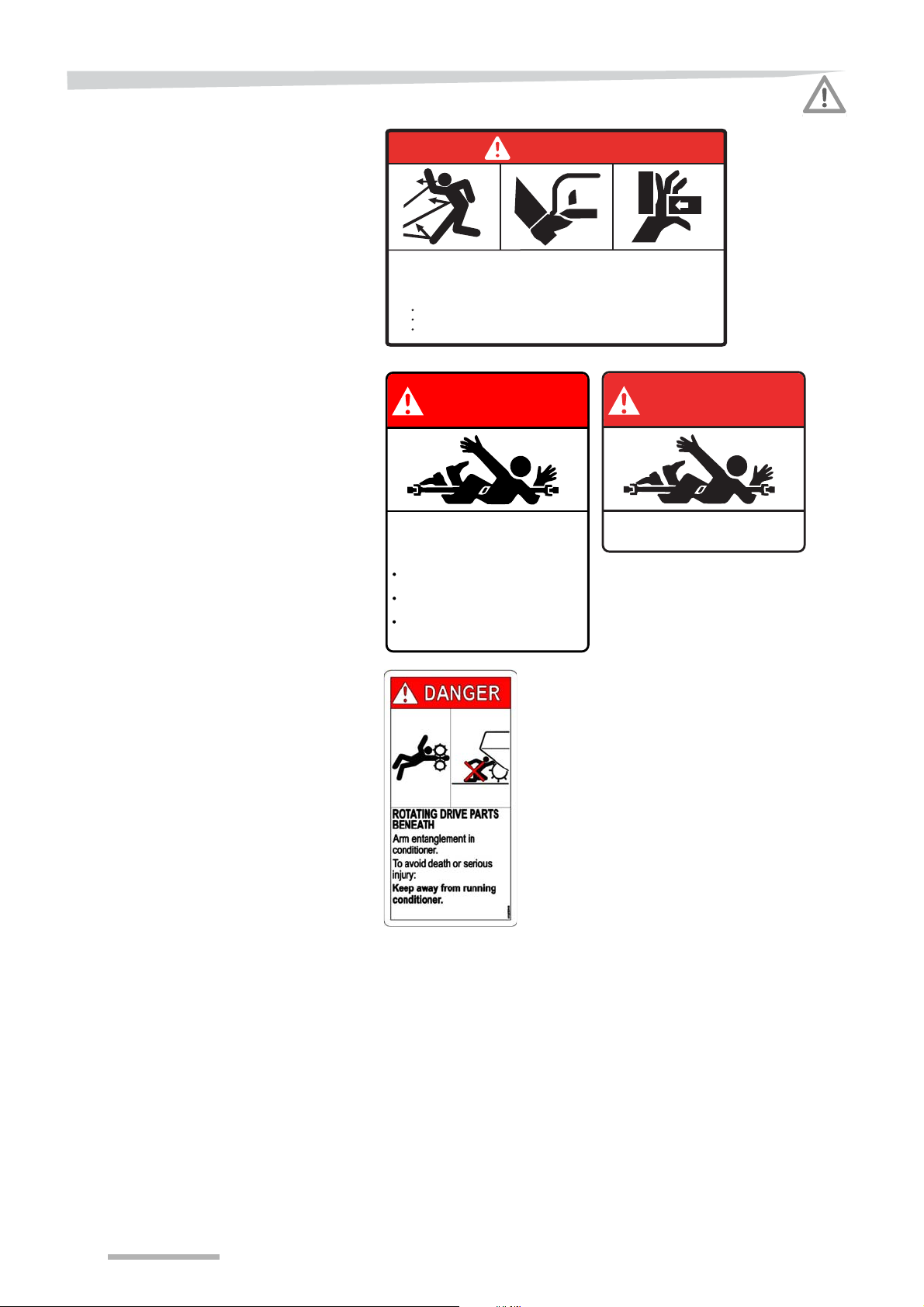

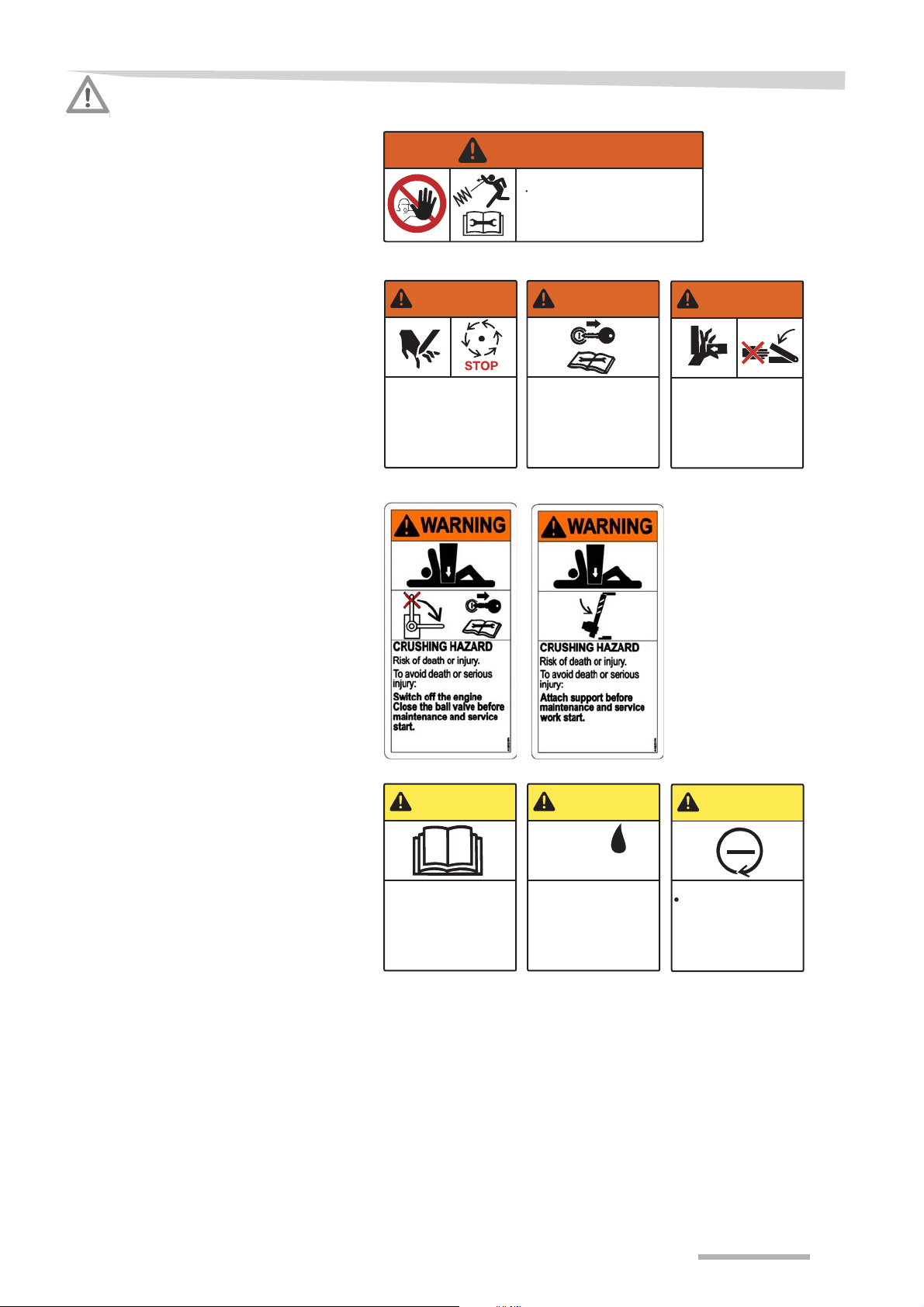

Safety labels

80xx model

CAUTION

READ THE MANUAL

•

THE MACHINE MUST NOT BE

USED BEFORE READING

THE OPERATING MANUAL.

TO AVOID FATAL OR SERIOUS

INJURY:

READ THE MANUAL FIRST

INADVERTENT OPERATION

• RISK OF DEATH OR INJURY BY

INADVERTENT OPERATION.

TO AVOID DEATH OR SERIOUS

INJURY:

SWITCH OFF THE ENGINE

VF16661512

WARNING

VF16661500

DANGER

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUTALL DRIVELINE, TRACTOR AND

EQUIPMENT SHIELDS IN PLACE.

DRIVELINES SECURELY ATTACHED

AT BOTH ENDS.

DRIVELINE SHIELDS THAT TURN

FREELY ON DRIVELINE.

56.968.000

On the machine, you will find labels relating to your safety. These

labels must not be removed. If the labels become illegible or det ached,

new labels can be ordered and affixed in the appropriate areas.

DANGER

KEEP AWAY - ROTATING BLADES

TO AVOID SERIOUS INJURY OR DEATH

FROM BLADE CONTACT AND THROWN OBJECTS:

KEEP ALL PERSONS CLEAR OF OPERATING MOWER AND MOWING AREA.

KEEP CURTAIN GUARD IN PLACE AND IN GOOD CONDITION.

DO NOT OPERATE MOWER WITH CURTAIN GUARD REMOVED.

50030644

CAUTION

max

210 bar

MAXIMUM HYDRAULIC

PRESSURE

• THE TRACTOR’S HYDRAULIC

PRESSURE MUST NOT

EXCEED 210 BAR (3045 PSI).

TO AVOID MACHINE DAMAGE AND

INJURY:

CHECK THE HYDRAULIC PRESSURE

DANGER

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUTALL DRIVELINE, TRACTOR AND

EQUIPMENT SHIELDS IN PLACE.

DRIVELINES SECURELY ATTACHED

AT BOTH ENDS.

DRIVELINE SHIELDS THAT TURN

FREELY ON DRIVELINE.

56.968.000

CAUTION

1000

max

RPM

PTO SHAFT SPEED 1000 RPM

THE SPECIFIED MAXIMUM

SHAFT SPEED OF 1000 RPM

MUST NOT BE EXCEEDED.

TO AVOID MACHINE DAMAGE

AND INJURY:

MAINTAIN THE PERMITTED

VF16661516

SHAFT SPEED

50030644

VF16661744

DANGER

SHIELD MISSING

DO NOT OPERATE

56.969.000

WARNING

RISK OF CRUSHING

•

NEVER REACH INTO AN AREA

WHERE PARTS ARE STILL

LIKELY TO MOVE.

TO AVOID FATAL OR SERIOUS

INJURY:

KEEP YOUR HANDS OUT

50030645

VF16661496

8

85xx model

56.968.000

50030644

DANGER

ROTATING DRIVELINE

KEEP AWAY!

CONTACT CAN CAUSE DEATH

DO NOT OPERATE WITHOUTALL DRIVELINE, TRACTOR AND

EQUIPMENT SHIELDS IN PLACE.

DRIVELINES SECURELY ATTACHED

AT BOTH ENDS.

DRIVELINE SHIELDS THAT TURN

FREELY ON DRIVELINE.

CAUTION

READ THE MANUAL

•

THE MACHINE MUST NOT BE

USED BEFORE READING

THE OPERATING MANUAL.

TO AVOID FATAL OR SERIOUS

INJURY:

READ THE MANUAL FIRST

WARNING

INADVERTENT OPERATION

• RISK OF DEATH OR INJURY BY

INADVERTENT OPERATION.

TO AVOID DEATH OR SERIOUS

INJURY:

SWITCH OFF THE ENGINE

VF16661512

VF16661500

DANGER

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH

KEEP AWAY!

DO NOT OPERATE WITHOUTALL DRIVELINE, TRACTOR AND

EQUIPMENT SHIELDS IN PLACE.

DRIVELINES SECURELY ATTACHED

AT BOTH ENDS.

DRIVELINE SHIELDS THAT TURN

FREELY ON DRIVELINE.

56.968.000

DANGER

KEEP AWAY - ROTATING BLADES

TO AVOID SERIOUS INJURY OR DEATH

FROM BLADE CONTACT AND THROWN OBJECTS:

KEEP ALL PERSONS CLEAR OF OPERATING MOWER AND MOWING AREA.

KEEP CURTAIN GUARD IN PLACE AND IN GOOD CONDITION.

DO NOT OPERATE MOWER WITH CURTAIN GUARD REMOVED.

50030644

WARNING

PRE-LOADED SPRING

SPRING MAY UNEXPECTEDLY EXPAND IN

CASE OF INCORRECT INSTALLATION.

TO AVOID SERIOUS INJURY:

SERVICE BY TRAINED PERSONNEL ONLY

Safety

VF16661558

CAUTION

max

210 bar

MAXIMUM HYDRAULIC

PRESSURE

• THE TRACTOR’S HYDRAULIC

PRESSURE MUST NOT

EXCEED 210 BAR (3045 PSI).

TO AVOID MACHINE DAMAGE AND

INJURY:

CHECK THE HYDRAULIC PRESSURE

CAUTION

1000

max

RPM

PTO SHAFT SPEED 1000 RPM

THE SPECIFIED MAXIMUM

SHAFT SPEED OF 1000 RPM

MUST NOT BE EXCEEDED.

TO AVOID MACHINE DAMAGE

AND INJURY:

MAINTAIN THE PERMITTED

VF16661516

SHAFT SPEED

VF16661744

DANGER

KEEP AWAY - ROTATING BLADES

TO AVOID SERIOUS INJURY OR DEATH

FROM BLADE CONTACT AND THROWN OBJECTS:

KEEP ALL PERSONS CLEAR OF OPERATING MOWER AND MOWING AREA.

KEEP CURTAIN GUARD IN PLACE AND IN GOOD CONDITION.

DO NOT OPERATE MOWER WITH CURTAIN GUARD REMOVED.

DANGER

SHIELD MISSING

DO NOT OPERATE

56.969.000

50030645

WARNING

RISK OF CRUSHING

•

NEVER REACH INTO AN AREA

WHERE PARTS ARE STILL

LIKELY TO MOVE.

TO AVOID FATAL OR SERIOUS

INJURY:

KEEP YOUR HANDS OUT

WARNING

UNEXPECTED MOVEMENT

• MACHINE PARTS MAY STILL

ROTATE AFTER ENGINE IS

SWITCHED OFF.

TO AVOID FATAL OR SERIOUS

INJURY:

KEEP AWAY UNTIL PARTS

VF16661496

STOP MOVING

VF16661510

CAUTION

READ THE MANUAL

•

THE MACHINE MUST NOT BE

USED BEFORE READING

THE OPERATING MANUAL.

TO AVOID FATAL OR SERIOUS

INJURY:

READ THE MANUAL FIRST

VF16661512

9

Safety

DANGER

KEEP AWAY - ROTATING BLADES

TO AVOID SERIOUS INJURY OR DEATH

FROM BLADE CONTACT AND THROWN OBJECTS:

KEEP ALL PERSONS CLEAR OF OPERATING MOWER AND MOWING AREA.

KEEP CURTAIN GUARD IN PLACE AND IN GOOD CONDITION.

DO NOT OPERATE MOWER WITH CURTAIN GUARD REMOVED.

DANGER

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH

DO NOT OPERATE WITHOUTALL DRIVELINE, TRACTOR AND

EQUIPMENT SHIELDS IN PLACE.

DRIVELINES SECURELY ATTACHED

AT BOTH ENDS.

DRIVELINE SHIELDS THAT TURN

FREELY ON DRIVELINE.

56.968.000

KEEP AWAY!

50030644

DANGER

SHIELD MISSING

DO NOT OPERATE

56.969.000

50030645

10

WARNING

VF16661744

THE SPECIFIED MAXIMUM

SHAFT SPEED OF 1000 RPM

MUST NOT BE EXCEEDED.

TO AVOID MACHINE DAMAGE

AND INJURY:

MAINTAIN THE PERMITTED

SHAFT SPEED

PTO SHAFT SPEED 1000 RPM

1000

RPM

max

CAUTION

PRE-LOADED SPRING

SPRING MAY UNEXPECTEDLY EXPAND IN

CASE OF INCORRECT INSTALLATION.

TO AVOID SERIOUS INJURY:

SERVICE BY TRAINED PERSONNEL ONLY

Safety

VF16661558

WARNING

UNEXPECTED MOVEMENT

• MACHINE PARTS MAY STILL

ROTATE AFTER ENGINE IS

SWITCHED OFF.

TO AVOID FATAL OR SERIOUS

INJURY:

KEEP AWAY UNTIL PARTS

STOP MOVING

WARNING

INADVERTENT OPERATION

• RISK OF DEATH OR INJURY BY

INADVERTENT OPERATION.

TO AVOID DEATH OR SERIOUS

INJURY:

SWITCH OFF THE ENGINE

VF16661510

WARNING

RISK OF CRUSHING

•

NEVER REACH INTO AN AREA

WHERE PARTS ARE STILL

LIKELY TO MOVE.

TO AVOID FATAL OR SERIOUS

INJURY:

KEEP YOUR HANDS OUT

VF16661500

VF16661496

CAUTION

READ THE MANUAL

•

THE MACHINE MUST NOT BE

USED BEFORE READING

THE OPERATING MANUAL.

TO AVOID FATAL OR SERIOUS

INJURY:

READ THE MANUAL FIRST

CAUTION

max

210 bar

MAXIMUM HYDRAULIC

PRESSURE

• THE TRACTOR’S HYDRAULIC

PRESSURE MUST NOT

EXCEED 210 BAR (3045 PSI).

TO AVOID MACHINE DAMAGE AND

INJURY:

CHECK THE HYDRAULIC PRESSURE

VF16661512

VF16661516

11

Safety

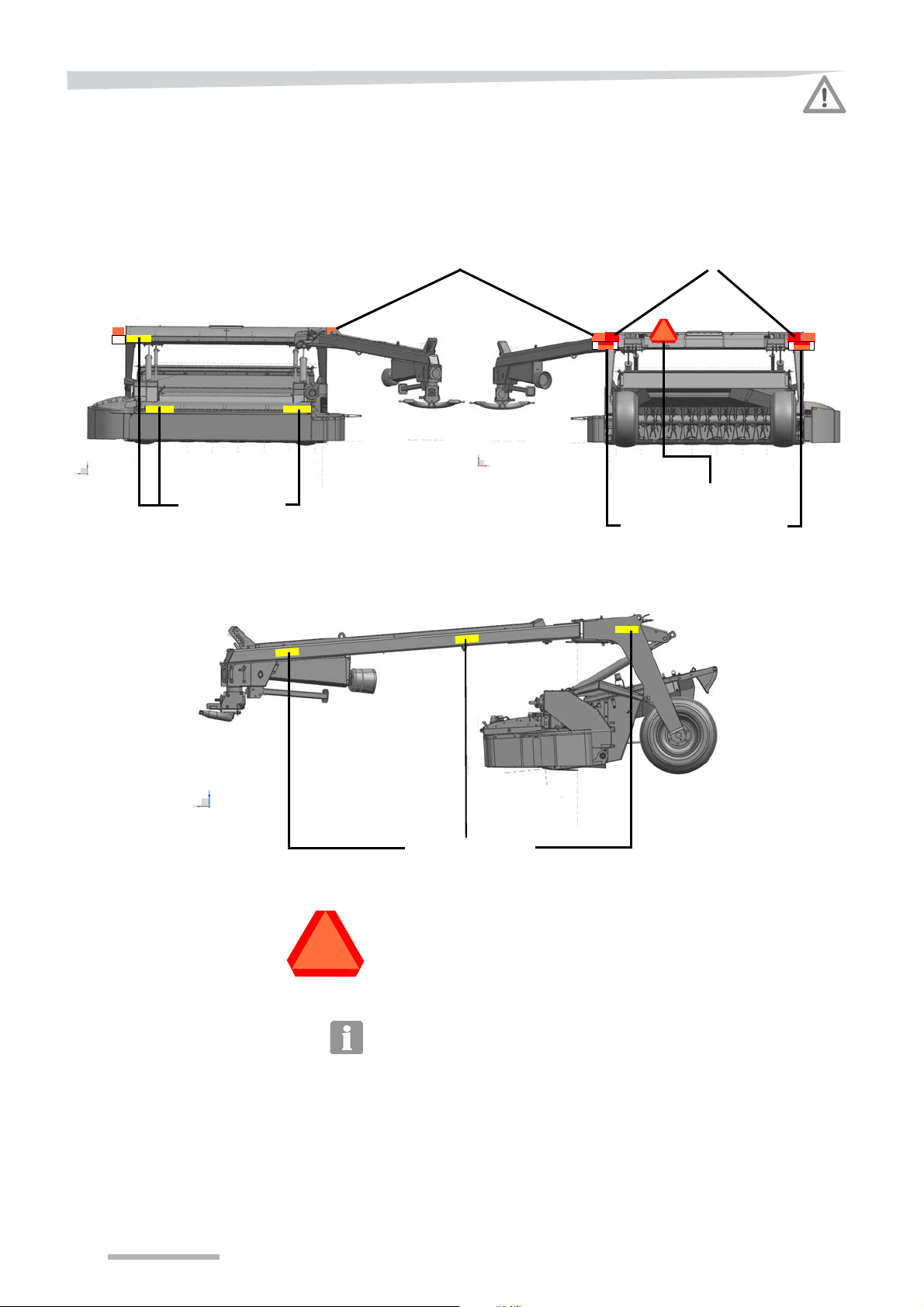

Indicators (amber)

Rear lights/brake lights (red)

SMV sign

2 x red reflectors

2 x amber reflectors

Yellow reflector

Yellow reflector

Lighting and

reflective devices USA

The machine is equipped with lighting and reflective devices as a

standard, which serve to ensure safety on the roads.

Lighting and reflective equipment shall be in good and sound condition

at all times. Lights and labels must not be removed from the machine.

Illegible or missing labels must be replaced. You can get new labels

as spare parts from your dealer.

Transport on public

roads

Reflector for slow moving vehicle – SMV

This triangular sign must be placed in the center of the back of the

tractor or machine; thus, it is always visible when the machine is in

being transported. This sign is required on machines moving at a

speed of less than 25 mph (40 km/h) on public roads.

This machine must be transported on public roads at speeds of less

than 40 km/h (25 mph) only.

→ »Speed when driving on public roads« page 66

12

Safety

r

95-015 fr

Who can operate the machine?

Attachment

This machine should only be operated by trained farmers and others

who are qualified to work in agriculture and who are familiar with

assembling equipment.

Untrained or unauthorized persons must not use this machine.

Correct attachment of the machine

The machine must be correctly attached according to the in structions.

The machine can become detached from the tractor if the att ach ment

is not done properly.

95-021 f

Incorrect attachment can lead to accidents.

When attaching the machine to the tractor you must therefore:

• Make sure that the tractor can not roll.

• Make sure that the tractor and the machine belong to the same

category.

• Never stand between the tractor and the machine during

attachment.

• Use the hydraulic three/point suspension slowly and carefully.

Paying full attention to the above mentioned points ensures your

safety and that of others.

Failure to follow the above instructions may result in serious injury.

P.T.O. shaft check

Refer to the manufacturer's servicing and maintenance instructions

with regard to the P.T.O shaft.

Make the electrical connection after attachment

When fitting the lighting device, the power supply to the tractor must

be turned off.

This will prevent short circuits and damage to the electric circuit.

There is a risk of burns and other serious injuries if the electrical

systems short circuit.

13

Safety

fr

95-006-2 fr

95-006-1 fr

95-006-3 fr

Only connect the hydraulics when the system is depressurized

Y ou should only co nnect the hydraulic hoses to the tractor's h ydraulics

when the hydraulic systems on both the tractor and the machine are

depressurized.

There is a risk that the machine will move accidentally.

Unintentional movement of the machine may result in serious injuries.

The hydraulic system should be checked regularly

All hoses and fittings should be checked regularly for visible damage.

Hydraulic hoses also wear without any visible damage.

Defective hydraulic hoses can cause injury or fire.

95-009

Color marking of the hydraulic connections

The hydraulic connections between the tractor and the machine must

be marked in different colors.

By marking the hydraulic connection s, you prevent the machine from

being incorrectly operated.

Incorrect operation or unintentional movement of the machine may

result in serious injuries.

Load capacity

kg

HP/kW

Compliance with total weight, axle pressure, carrying capacity of

the tires and minimum weight

Neither the tractor's total weight, axle pressure or th e carrying capacity

of the tires may be exceeded on front/mounted and rear- mounted

machines.

To ensure the maneuverability of the tractor, the load on the front axle

must be at least 20% of the tractor's weight.

Failure to do so can result in a loss of control and cause accidents.

Be careful when working around the P.T.O shaft

When working on the P.T.O. shaft, the tractor's P.T.O. outlet must be

disconnected, the tractor must be stopped and the ignition key

removed.

This prevents the P.T.O. shaft fr om suddenly beginning to rotate.

If the tractor and the P.T.O. shaft have not been connected in

accordance with the instructions, serious accidents causing injury to

limbs can occur.

Weight/power ratio between machine and tractor

The machine may only be connected to a tractor of the correct size

and power.

The tractor's size and P.T.O. outlet must correspond to the power

consumption of the machine and its weight.

Wrong weight/power ratio can result in damage to both machine and

tractor.

14

Safety

95-012 fr

fr

fr

Transport on public roads

Ensure that the machine meets the Road Traffic Act's requirements concerning its condition

When driving on public roads, the machine must comply with the Ro ad

Traffic Act's current requirements.

This ensures your safety and that of other road us er s.

Failure to meet the requirements can result in accidents.

Compliance with the Road Traf fic Act's current requirements includes,

for example:

• Installation of lights, warning and safety equipment.

• Compliance with permitted transport width, weight, axle pressure,

tire carrying capacity and total weight.

Carrying passengers on the machine is prohibited

It is dangerous and illegal to carry passengers on the machine.

The machine is not approved for personal transportation.

Transporting persons on the machine may result in serious injuries

and death.

Attached machines change the driving and braking abilities of

the tractor

Be aware of the changed driving and braking abilities when driving

with machines attached.

95-011

You should be especially aware of the machine's width and length

when driving around bends and turns.

Serious accidents and a loss of control may result if this is not taken

into account.

Adjust the speed according to the road conditions

Adjust driving speed according to the conditions on the road.

Poor road conditions and high speeds can lead to parts of the tractor

and machine being overloaded.

95-011

Driving too fast can lead to accidents and damage both the machine

and the tractor.

15

Safety

fr

95-031 fr

fr

fr

Use

The operator should receive careful instructions befo re using the

machine

The machine may be put to use only once the operator has received

thorough instructions; carefully read and understand this Instruction

95-002-1

Manual.

Thorough machine instruction allows safe usage.

Insufficient training may lead to incorrect usage of the machine and

accidents.

Check that the machine has no technical faults

Only use the machine if it has no technical faults.

This ensures that the machine is operating correctly and safely.

A machine with technical faults and defects can be dangerous.

Do not remove the protective guards

Check that all protective guards are in place before use.

This ensures that the machine will give maximum protection to the

operator.

95-093

If the safety guards are removed or not used, it may result in serious

injuries and accidents.

Check the tire pressure regularly

Check of the tire pressure in regular intervals..

This ensures the machine is being driven under optimum conditio ns

and prevents accidental banking on curves or corners.

95-011

Careening on bends and turns can lead to accidents.

Carrying passengers on the machine is prohibited

It is dangerous and illegal to carry passengers on the machine.

The machine is not approved for personal transportation.

Transporting persons on the machine may result in serious injuries

and death.

16

Safety

fr

95-006-1 fr

fr

95-031 fr

Check the surrounding area before starting to use the machine

Check the surrounding area before driving and using the machine.

This prevents persons and animals in the vicinity from being harmed.

If the surrounding area is not checked, it may result in serious injuries

to persons or animals.

Keep away from the machine

No unauthorized persons should be close to the machine during

operation.

This will ensure that no dangerous situations can arise.

Persons close to the machine during operation are at risk of being

severely injured.

Safety for children

Never assume that children will remain where you last saw them.

Be alert and shut your machine down if children is in the work area.

Never allow children to play on or operate the machine .

Checking bolts on moving parts

Check that all bolts on moving parts are corre ctly tightened.

Tightening parts prevents moving parts from jarring.

Parts which are not correctly tightened can work themselves loose

95-018

and damage the machine.

Maintain the rotational speed on the tractor's P.T.O. outlet

It is dangerous to connect a tractor with a P.T.O. of 1000 RPM to a

machine intended for a P.T.O. of 540 RPM.

The machine is not designed for this speed.

It can result in damage to the machine and be dangerous to any

persons in the vicinity.

Check the transmission oil level regularly

Check that the transmission is filled with oil and that the oil level is

correct.

A correct oil level ensures the transmission a long and trouble free

95-017

service life.

An incorrect oil level will damage the transmission.

Stop the machine immediately in case of malfunction

In case of malfunction, the machine should be stopped immediately.

A mechanical malfunction can endanger persons and animals in the

vicinity.

Malfunctioning machines can give rise to dangerous situations.

17

Safety

95-031 fr

Disconnection

Increased risk of injury when disconnecting

There is an increased risk of injury when disconnecting the machine

from the tractor.

Paying full attention to the aforementioned point ensures your safety

and that of others.

Failure to pay attention to the aforementioned point may result in

serious injuries.

Therefore, when disconnecting:

• Make sure that the tractor can not roll.

• Never stand between the tractor and the machine during

disconnection.

• Use the hydraulic three/point suspension slowly and carefully.

• Make sure that the machine is standing on a safe, level surface.

• When depressurizing the hydraulic system for both tractor and

machine, first disconnect the hydraulic hoses.

18

Safety

95-007 fr

fr

Maintenance

Comply with the service and maintenance intervals given in the

instructions

Comply with the intervals for service and maintenance as given in the

instructions.

By complying with the maintenance intervals, you ensure that the

machine will operate without malfunctions and provide maximum

protection for the environment.

An incorrectly maintained machine is a danger to the environment.

Always use original spare parts on the machine

Always use original spare parts.

Original spare parts should be used for safety reasons

The manufacturer assumes no warranty responsibili ty in cases where

non-original spare parts are used.

High risk when performing service and maintenance work

When performing service or maintenance work, there is a higher risk

of injury.

Paying full attention to the aforementioned point ensures your safety

and that of others.

Failure to pay attention to the aforementioned point may result in

serious injuries.

Therefore, when you perform maintenance work:

• Disconnect the P.T.O. shaft.

• Depressurize the hydraulic system.

• Stop or disconnect the tractor.

• Check that the machine is parked safely; support it if necessary.

• Do not use parts of the machine to climb onto it; the correct

climbing devices must be used.

• Make sure that the machine can not start rolling.

Disconnect the power source when working on the electrical

systems

Always disconnect the power source before you start working on the

electrical system.

This will prevent short circuits and damage to the electric circuit.

There is a risk of burns and other serious injuries if the electrical

systems short circuit.

Replacing the hydraulic hoses

Replace the hydraulic hoses at least once every 6 years.

Hydraulic hoses also wear without any visible damage.

Defective hydraulic hoses may cause serious injury.

95-009

19

Safety

fr

95-014 fr

Be careful when cleaning with high pressure cleaning equipment

Only use low-pressure cleaning equipment to clean bearings,

hydraulic hoses, plastic components, electrical control boxes and

electrical equipment.

Using low water pressure to clean will protect the sensitive equipment

on the machine.

Using high water pressure to clean could damage vital parts of the

machine.

Disconnect the battery, the motor control unit and the generator

before doing any welding

The tractor battery and alternator should be disconnected before

performing welding work on the machine.

This will protect the tractor alternator during welding work.

The tractor alternator could be d amaged or destroyed if the electric

connections are not disconnected before welding.

Tighten all fittings on moving parts

Check that bolts on moving parts are tightened after performing

maintenance work.

Tightening parts prevents moving parts from jarring.

95-018

Parts which are not correctly tightened can work loose and damage

the machine.

Do not alter the machine construction

The technical construction of the machine should not be altered and

machine maintenance should be performed.

A well maintained machine will offer maximum protection.

A poorly maintained machine will not offer proper protection and could

be dangerous.

20

Safety

fr

95-013 fr

Further safety instructions

Follow the instructions when working on the machine

The machine safety instructions should always be followed.

This will protect you and others from injury.

Failure to follow the safety instructions may result in serious injuries.

In addition to the safety instructions, the following should be followed:

• Environmental legislation.

95-005

• The general technical, medical and road act regulations.

• Instructions in this instruction manual.

• Instructions for use, maintenance and service.

21

Blank page

Blank page

22

About the machine

About the machine

The machine's field of application

Correct usage of the

machine

This chapter includes general information about your machine. In

addition, the following information is included:

• The machine's field of application.

• The machine characteristics.

• View of the machine.

• Technical data.

8028R - 8032R - 8036R - 8536R is a trailed mower conditioner

intended for the harvesting of commonly occurring grass and grain

crops. The instructions for use are given in the following chapters.

The machine can be used in fields for mowing the following crops:

• All types of grass

• All types of clover

• Whole crop

• Alfalfa

• Sorghum

Incorrect use of the

machine

The machine must not, under any circumstances, be used for the

following:

• Cutting grass in park facilities and lawns

• Cutting grass on the boulevard strips of public roads

• Harvesting corn

• Clearing forest floors or other densely wooded areas

Similar use is outside the intended applications of the machine.

The manufacturer is not liable for any damages caused by incorrect

usage of the machine. The user is wholly liable for the machine.

23

About the machine

Machine characteristics

Description of the machine

8028R - 8032R - 8036R - 8536R is a trailed mower conditioner,

whereas:

• the 80xx model only operates o n th e right- hand side of the tractor .

• the 85xx model operates on both sides of the tractor.

The machine is towed behind the tractor via a drawbar which is

coupled to the tractor's lift arms or the drawbar tongue of the tractor.

The drawbar is connected to the main frame of the machine which

carries the whole machine on two (2) powerful wheels. The machine

can be set in either the transport mode or the working position using

the drawbar which is operated using the tractor's hydraulic system.

The machine's cutting unit is hydraulically connected to the main

frame of the machine and can be lowered using the tractor's hydraulic

system. The cutting unit is balanced using strong springs which

secure the machine's cutterbar, following the ground precisely and

cutting the crop uniformly.

The machine's cutting discs are equipped with durable, reversible

blades, which have a high capacity when used at a high speed of

rotation, even for difficult crops.

Even at high mowing speeds, the machine is able to mow the crop

cleanly and uniformly. For safety reasons, it is recommended that the

speed not exceed 9 mph (15 km/h).

The cutting unit is fitted with a powerful roller that provides effective

conditioning of the crop.

The cutting unit is fitted with a guard, which protects it against moving

objects. The guard, or parts o f the guard, must never be removed from

the machine and must always be kept in good condition.

Solid construction

Thanks to its solid construction and flexibility, the machine is both

strong and reliable.

Quick and easy lifting of the cutterbar when turning on the

headland

The machine's cutterbar is raised hydraulically without the use of tools

on the headland.

Your safety when using the machine

To make working with the machine as safe as possible, the machine

complies with EU regulations. The machine is CE labeled.

24

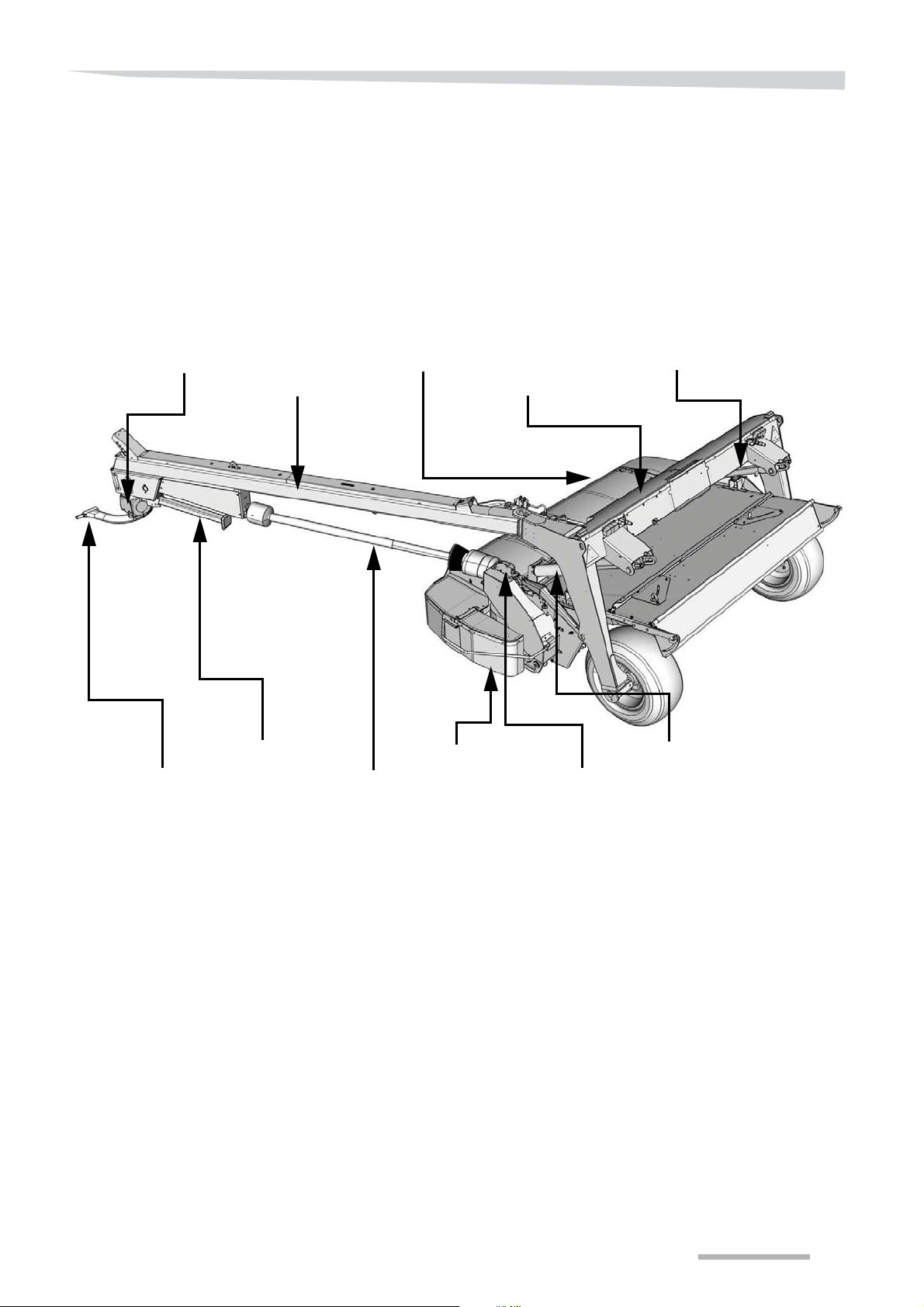

Synopsis

Spring

Main frame

Main gear

Cutting unit

Guard

Drawbar

Support leg

P.T.O. shaft

Swivel hitch

Swivel gear

Hydraulic cylinder

80xx model

About the machine

25

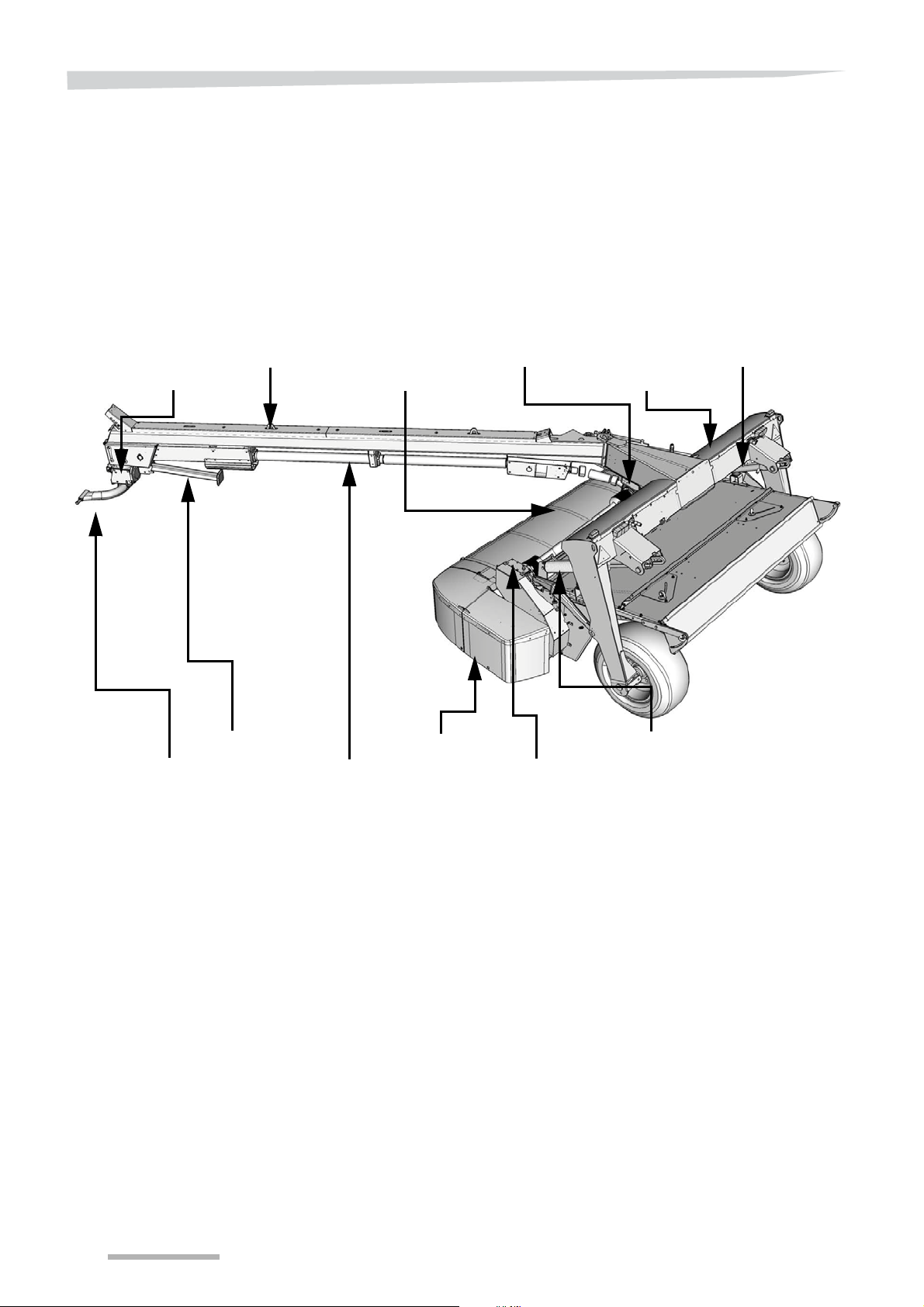

About the machine

Hydraulic cylinder

Main gear

Center gear

Guard

Drawbar

Main frame

Support leg

P.T.O. shaft

Swivel hitch

Swivel gear

Cutting unit

Spring

85xx model

26

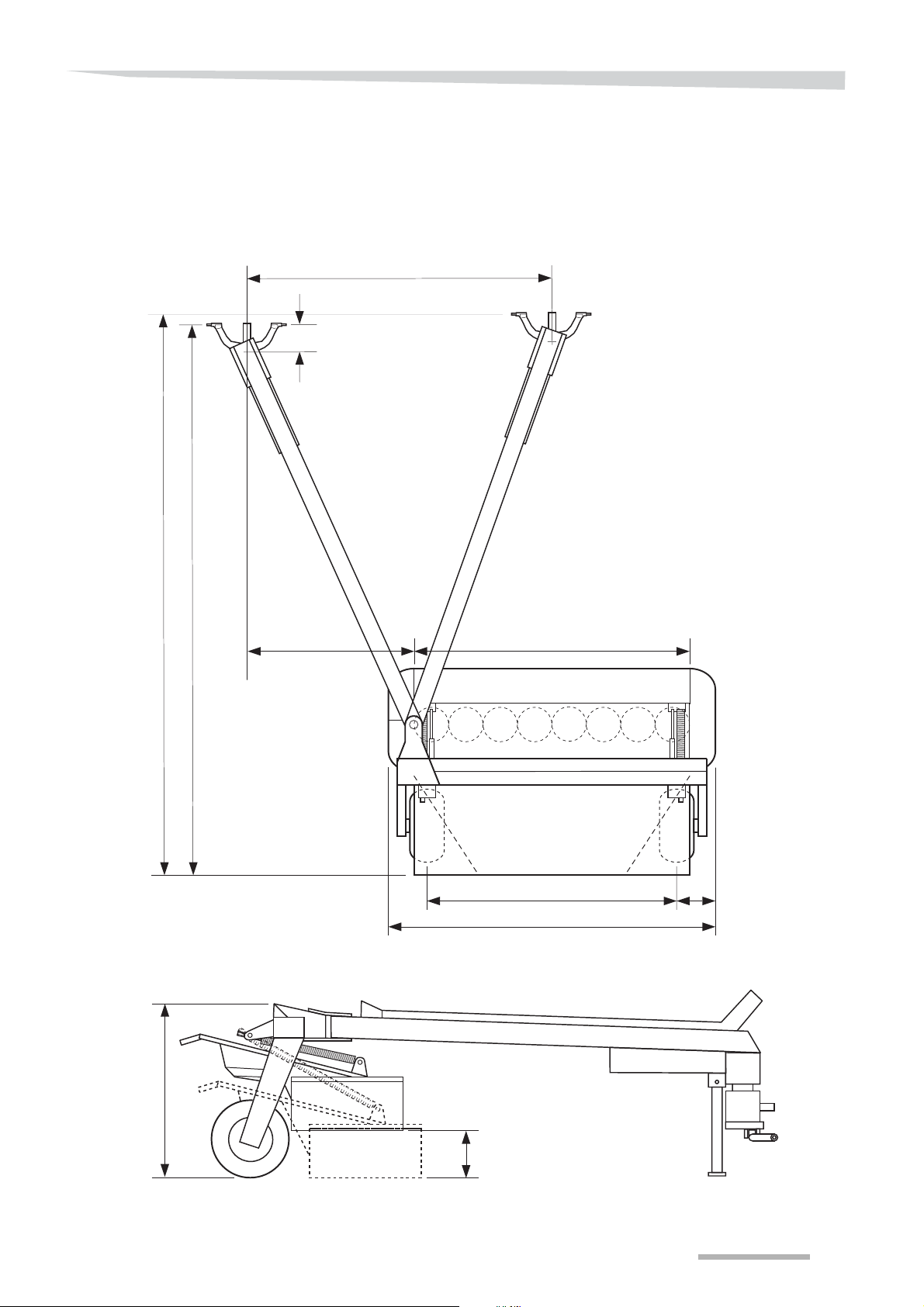

Technical data

D

GH

F

I

J

K

B

E

C

A

Machine dimensions

80xx model

About the machine

27

About the machine

Dim. Unit 8028R 8032R 8036R

A mm (’-’’) 5200 (17’ 1’’) 5650 (18’ 6’’) 5650 (18’ 6’’)

B mm (’-’’) 5125 (16’ 10’’) 5600 (18’ 4’’) 5600 (18’ 4’’)

C mm (’-’’) 350 (1’ 2’’) 350 (1’ 2’’) 350 (1’ 2’’)

D mm (’-’’) 2700 (8’ 10’’) 3050 (10’) 3050 (10’)

E mm (’-’’) 1200 (3’ 11’’) 1400 (4’ 7’’) 1400 (4’ 7’’)

F mm (’-’’) 2800 (9’ 2’’) 3200 (10’ 6’’) 3600 (11’ 10’’)

G mm (’-’’) 2100 (6’ 10’’) 2400 (7’ 10’’) 2800 (9’ 2’’)

H mm (’-’’) 675 (2’ 2’’) 675 (2’ 2’’) 675 (2’ 2’’)

I mm (’-’’) 3450 (11’ 4’’) 3750 (12’ 4’’) 4150 (13’ 7’’)

J mm (’-’’) 1700 (5’ 7’’) 1700 (5’ 7’’) 1700 (5’ 7’’)

K mm (’-’’) 425 (1’ 5’’) 425 (1’ 5’’) 425 (1’ 5’’)

28

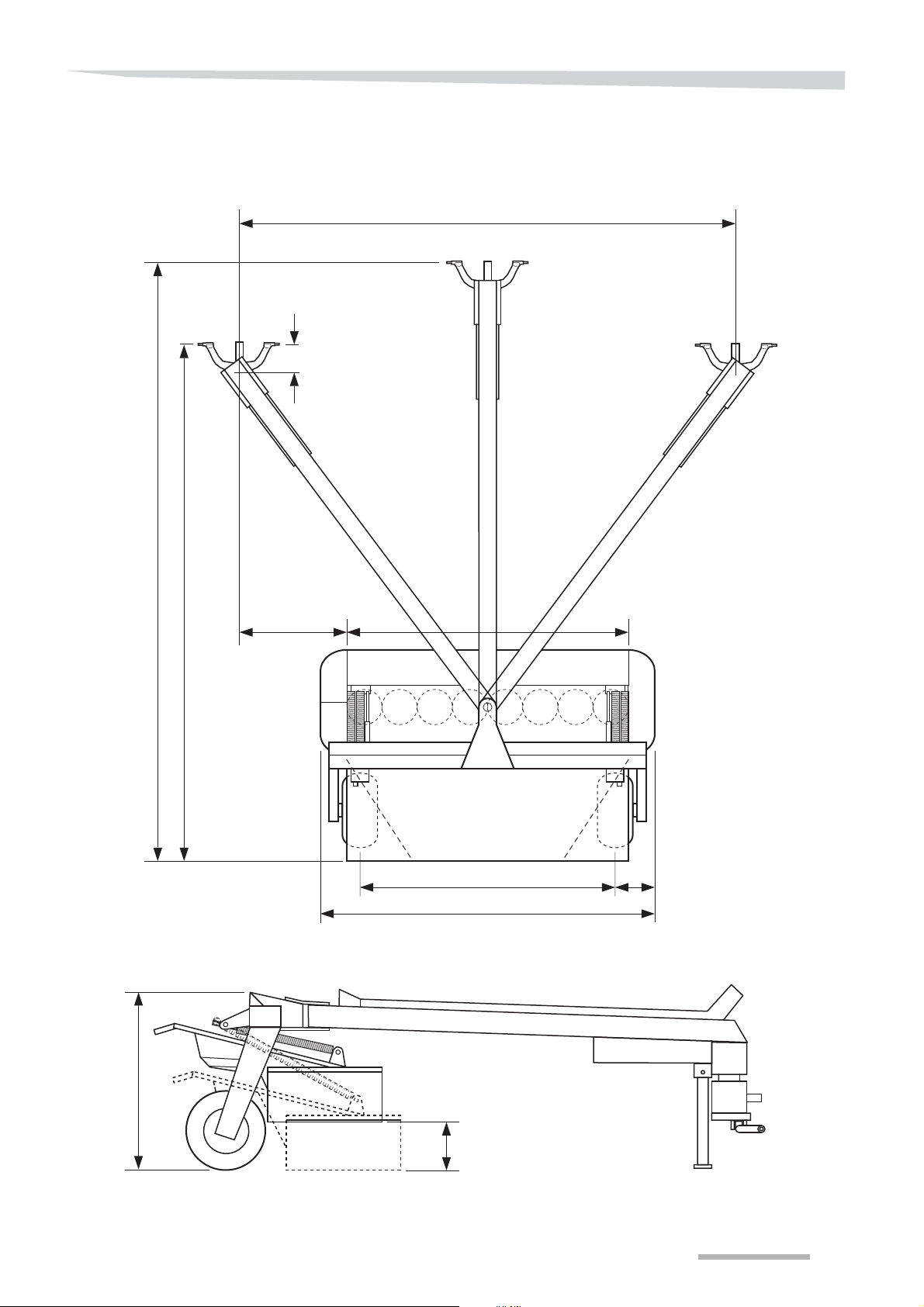

85xx model

About the machine

D

C

A

B

E

F

GH

I

J

K

29

About the machine

Dim. Unit 8536R

A mm (’-’’) 722 5 (2 3’ 8’’)

B mm (’-’’) 5900 ( 19’ 4’’)

C mm (’-’’) 350 (1’ 2’’)

D mm (’-’’) 6875 (22’ 7’’)

E mm (’-’’) 1650 (5’ 5’’)

F mm (’-’’) 3600 (11’ 10’’)

G mm (’-’’) 2800 (9’ 2’’)

H mm (’-’’) 675 (2’ 2’’)

I mm (’-’’) 4150 (13’ 7’’)

J mm (’-’’) 1700 (5’ 7’’)

K mm (’-’’) 425 (1’ 5’’)

30

Loading...

Loading...