Kubota WG752 E3, WG972 E3, DG972 E2 Applications Manual

KUBOTA ENGINES

APPLICATION MANUAL

(WG752, WG972 E3 MODEL)

(DG972 E2 MODEL)

First Edition

January, 2011

KUBOTA

CONTENTS

1. PREFACE

2. GENERAL INFORMATION

0. GENERAL

1. EMISSION REGULATION

2. FUEL SYSTEM

3. EXHAUST SYSTEM

4. ELECTRICAL SYSTEM

3. TECHNICAL INFORMATION

4. APPLICATION CHECK SHEET

5. EXHAUST EMISSION CHECK SHEET

6. EMISSIONS-RELATED INSTALLATION

INSTRUCTION

1. PREFACE

1. This has been prepared so as to enable users to properly and efficiently utilize KUBOTA small SI

engines.

2. This manual describes the features of the engines, the cautions and the check items for mounting

the engines on various machines.

3. The contents of this manual are roughly divided into the following two items.

a) General information

b) Technical information

4. This manual describes only the content that should be mentioned specially for small SI engines.

Please also refer to the diesel engine application manual.

5. Phase3 emissions regulations require confirmation of “Emissions-Related Installation Instructions”,

“Contractual agreement” etc. between engine and equipment manufactures under 40CFR1068.

6. The specifications and features described in this manual are subject to change without advance

notice for technical improvement.

7. If you have any question about this manual, please contact with nearest KUBOTA sales

representatives or send e-mail to “k-iss@kubota.co.jp”

.

2 GENERAL INFORMATION

0. GENERAL

CONTENTS

1. SPECIFICATIONS......................................................................................................................... 0-1

2. PERFORMANCE CURVES........................................................................................................... 0-4

3. DIMENSIONS ................................................................................................................................ 0-6

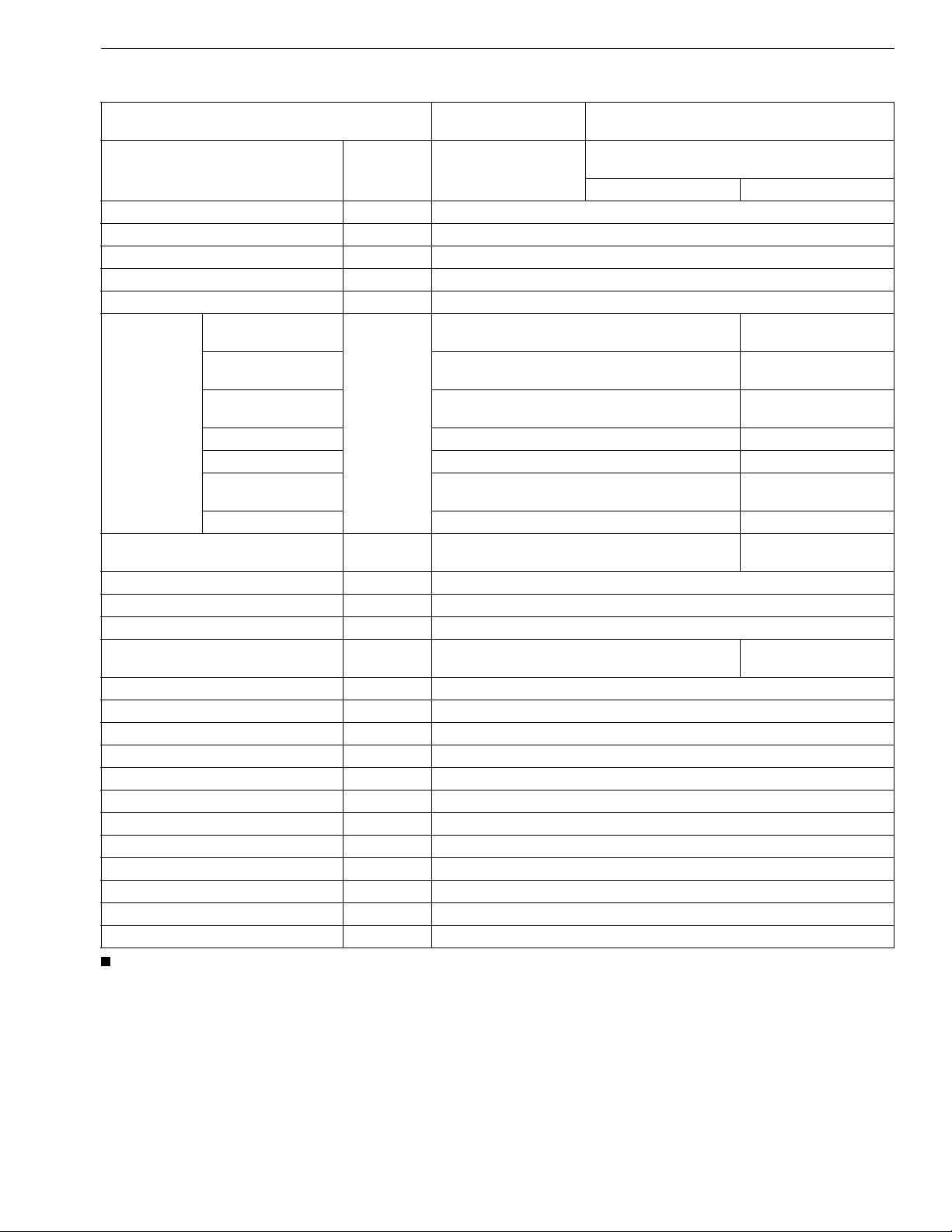

1. SPECIFICATIONS

NOTE

Model

Item

Type

Number of cylinders 3

Cylinder bore x Stroke mm (in) 68.0 (2.68) x 68.0 (2.68)

Total displacement L (cu. in) 0.740 (45.2)

High idle min

Low idle min

SAE J1995 Gross

intermittent

SAE J1349 Net

intermittent

Brake horse

power

Max. torque (SAE J1349)

Compression ratio 9.2

Firing order 1−2−3

Ignition timing B.T.D.C.18 °

Fuel

Direction of rotation Counter-clockwise from flywheel side

Starting system Electric starting with cell starter

Starter output V-kW 12−0.7

Alternator output V-W 12−150 (Standard)

Lubricating system Forced lubricating by trochoid pump

Lubricating oil Quality better than SH class

Lubricating oil capacity L (U.S. gal) 3.25 (0.86)

Catalytic Muffler / Converter Three Way Catalyst

Coolant capacity (with radiator) L (U.S. gal) 2.8 (0.74)

Governor type Centrifugal ball mechanical type governor

Dimensions (L x B x H) mm (in) 428.5 x 396.9 x 539.8 (16.87 x 15.63 x 21.25)

Dry weight kg (lb) Approx. 61.7 (136.0)

SAE J1349 Net

continuous

ISO Gross 18.5 (24.8) / 3600 17.7 (23.8) / 3600

ISO Continuous 13.4 (18.0) / 3600 12.7 (17.0) / 3600

JIS B8002 Net

Intermittent

JIS B8002 Continuous 13.4 (18.0) / 3600 12.7 (17.0) / 3600

-1

(rpm) 3850

-1

(rpm) 1500

kW (HP) /

-1

min

(rpm)

N·m (ft-lb)

-1

min

(rpm)

WG752-G-E3 WG752-GL-E3

Vertical, water cooled

4-cycle Gasoline engine

18.5 (24.8) / 3600 17.7 (23.8) / 3600

17.1 (23.0) / 3600 16.4 (22.0) / 3600

13.4 (18.0) / 3600 12.7 (17.0) / 3600

17.1 (23.0) / 3600 16.4 (22.0) / 3600

54.9 (40.5) / 2400 52.0 (38.3) / 2400

Unleaded

gasoline

Vertical, water cooled 4-cycle Dual Fuel

(Gasoline/LPG)

Gasoline fuel LPG fuel

Commercial

LPG *

• * LPG regulator with vaporizer operates on a liquid withdrawal type system.

0-1

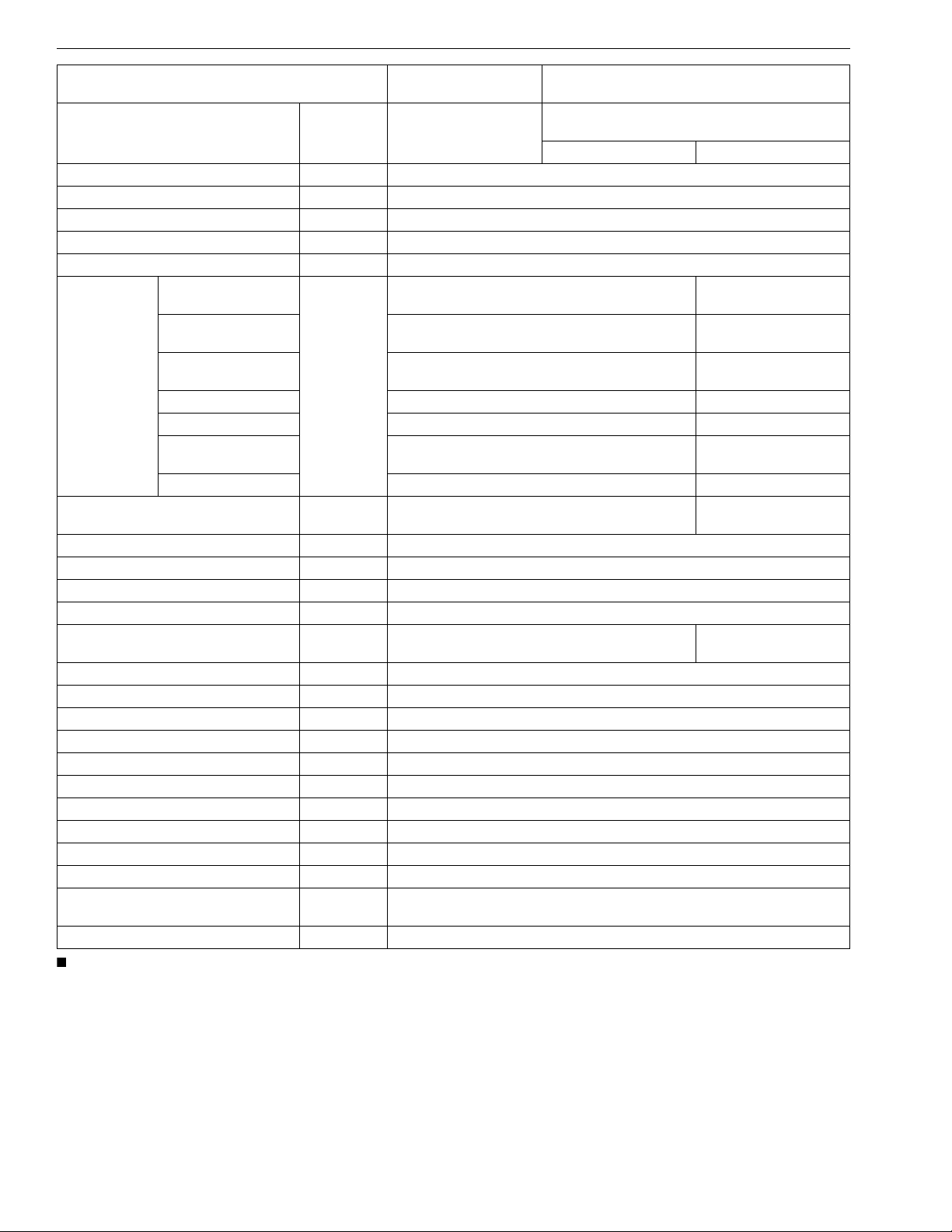

NOTE

Model

Item

Type

WG972-G-E3 WG972-GL-E3

Vertical, water cooled

4-cycle Gasoline engine

Vertical, water cooled 4-cycle Dual Fuel

(Gasoline/LPG)

Gasoline fuel LPG fuel

Number of cylinders 3

Cylinder bore x Stroke mm (in) 74.5 (2.93) x 73.6 (2.90)

Total displacement L (cu. in) 0.962 (58.7)

High idle min

Low idle min

SAE J1995 Gross

intermittent

SAE J1349 Net

intermittent

SAE J1349 Net

Brake horse

power

continuous

ISO Gross 24.2 (32.5) / 3600 23.1 (31.0) / 3600

-1

(rpm) 3850

-1

(rpm) 1500

24.2 (32.5) / 3600 23.1 (31.0) / 3600

23.1 (31.0) / 3600 22.0 (29.5) / 3600

kW (HP) /

-1

min

(rpm)

18.7 (25.0) / 3600 17.5 (23.5) / 3600

ISO Continuous 18.7 (25.0) / 3600 17.5 (23.5) / 3600

JIS B8002 Net

Intermittent

23.1 (31.0) / 3600 22.0 (29.5) / 3600

JIS B8002 Continuous 18.7 (25.0) / 3600 17.5 (23.5) / 3600

Max. torque (SAE J1349)

N·m (ft-lb)

-1

min

(rpm)

68.6 (50.6) / 2400 64.6 (47.6) / 2400

Compression ratio 9.2

Firing order 1−2−3

Ignition timing B.T.D.C. 8 ° / 1000 min

-1

(rpm) B.T.D.C. 21 ° / 3600 min-1 (rpm) *1

Ignition system Distributor-less Solid State type

Fuel

Unleaded

gasoline

Direction of rotation Counter-clockwise from flywheel side

Starting system Electric starting with cell starter

Starter output V-kW 12−1.0

Alternator output V-W 12-480 (Standard)

Lubricating system Forced lubricating by trochoid pump

Lubricating oil Quality better than SH class

Lubricating oil capacity L (U.S. gal) 3.4 (0.90)

Catalytic Muffler / Converter Three Way Catalyst

Coolant capacity (with radiator) L (U.S. gal) 3.5 (0.92)

Governor type Centrifugal ball mechanical type governor

Dimensions (L x B x H) mm (in)

BBH : 452.6 x 416.4 x 502.5 (17.82 x 16.39 x 19.78)

SAEH : 525.5 x 416.4 x 502.5 (20.69 x 16.39 x 19.78)

Dry weight kg (lb) Approx. 72.0 (159)

Commercial

LPG *2

• *1 Consult Kubota for further information.

• *2 LPG regulator with vaporizer operates on a liquid withdrawal type system.

0-2

NOTE

CAUTION

Model

Item

DG972

Type Vertical, water cooled 4-cycle Natural Gas engine

Number of cylinders 3

Cylinder bore x Stroke mm (in) 74.5 (2.93) x 73.6 (2.90)

Total displacement L (cu. in) 0.962 (58.7)

High idle min

Low idle min

SAE J1995 Gross

intermittent

SAE J1349 Net

intermittent

SAE J1349 Net

Brake horse

power

continuous

ISO Gross 18.7 (25.1) / 3600 *2

-1

(rpm) 3850

-1

(rpm) 1500

18.7 (25.1) / 3600 *2

17.6 (23.6) / 3600 *2

kW (HP) /

-1

min

(rpm)

14.5 (19.4) / 3600 *2

ISO Continuous 14.5 (19.4) / 3600 *2

JIS B8002 Net

Intermittent

17.6 (23.6) / 3600 *2

JIS B8002 Continuous 14.5 (19.4) / 3600 *2

Max. torque (SAE J1349)

N·m (ft-lb)

-1

min

(rpm)

55.0 (40.5) / 2400 *2

Compression ratio 9.2

Firing order 1−2−3

Ignition timing B.T.D.C. 15 ° / 1000 min

-1

(rpm) B.T.D.C. 28 ° / 3600 min-1 (rpm) *1

Ignition system Distributor-less Solid State type

Fuel Natural Gas only *2

Direction of rotation Counter-clockwise from flywheel side

Starting system Electric starting with cell starter

Starter output V-kW 12−1.0

Alternator output V-W 12-480 (Standard)

Lubricating system Forced lubricating by trochoid pump

Lubricating oil Quality better than SH class

Lubricating oil capacity L (U.S. gal) 3.4 (0.90)

Coolant capacity (with radiator) L (U.S. gal) 3.5 (0.92)

Governor type Centrifugal ball mechanical type governor

Dimensions (L x B x H) mm (in)

Dry weight kg (lb)

BBH : 452.5 x 415.4 x 502.53 (17.81 x 16.35 x 19.78)

SAEH : 525.5 x 415.4 x 502.53 (20.69 x 16.35 x 19.78)

BBH : Approx. 72.0 (159)

SAEH : Approx. 95.4 (210)

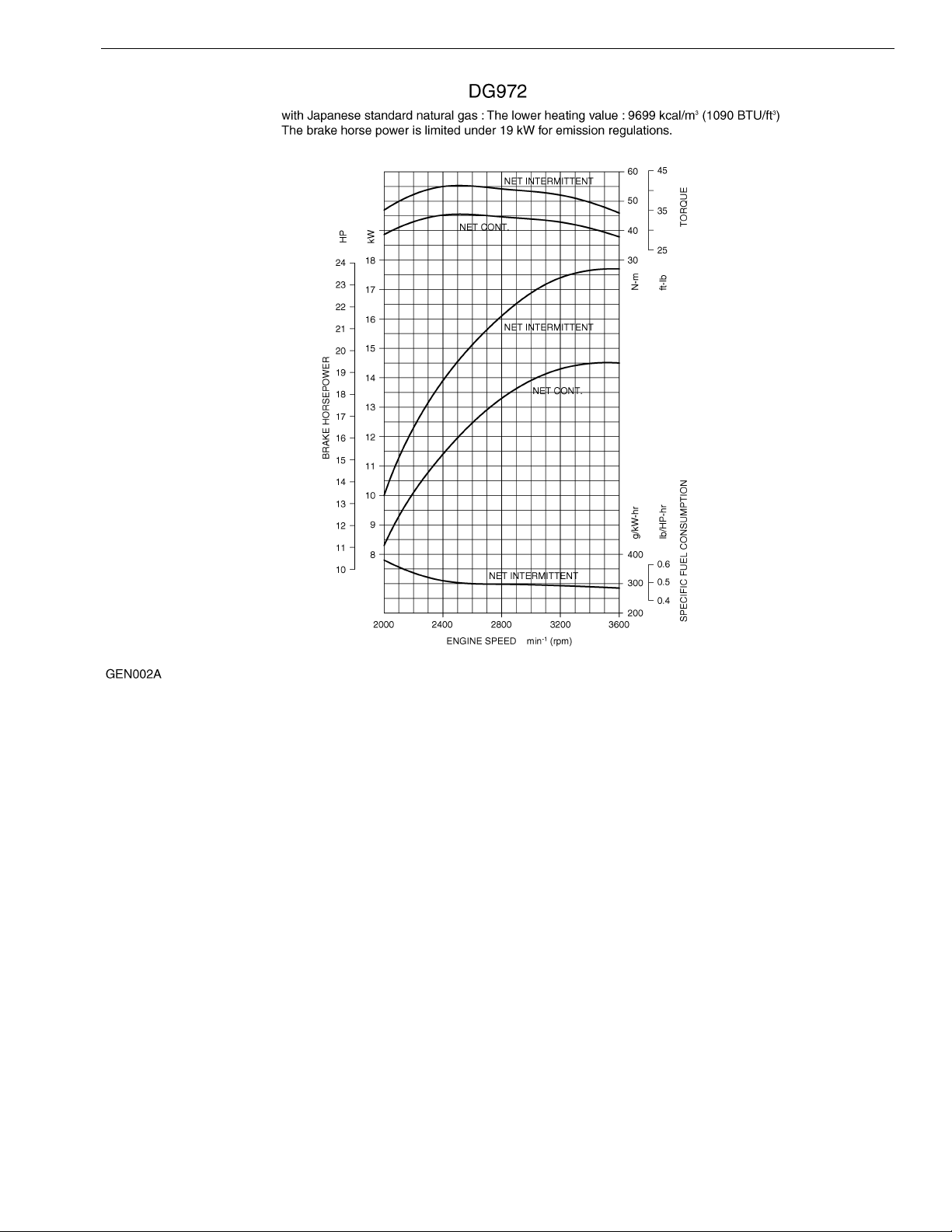

• *1 Consult Kubota for further information.

• *2 With Japanese standard natural gas.

The lower heating value : 9699kcal/m3 (1090BTU/ft3).

• This engine is only for stationary use. e.g. oil field and emergency generator.

• The brake horse power is limited under 19kW for emission regulations.

0-3

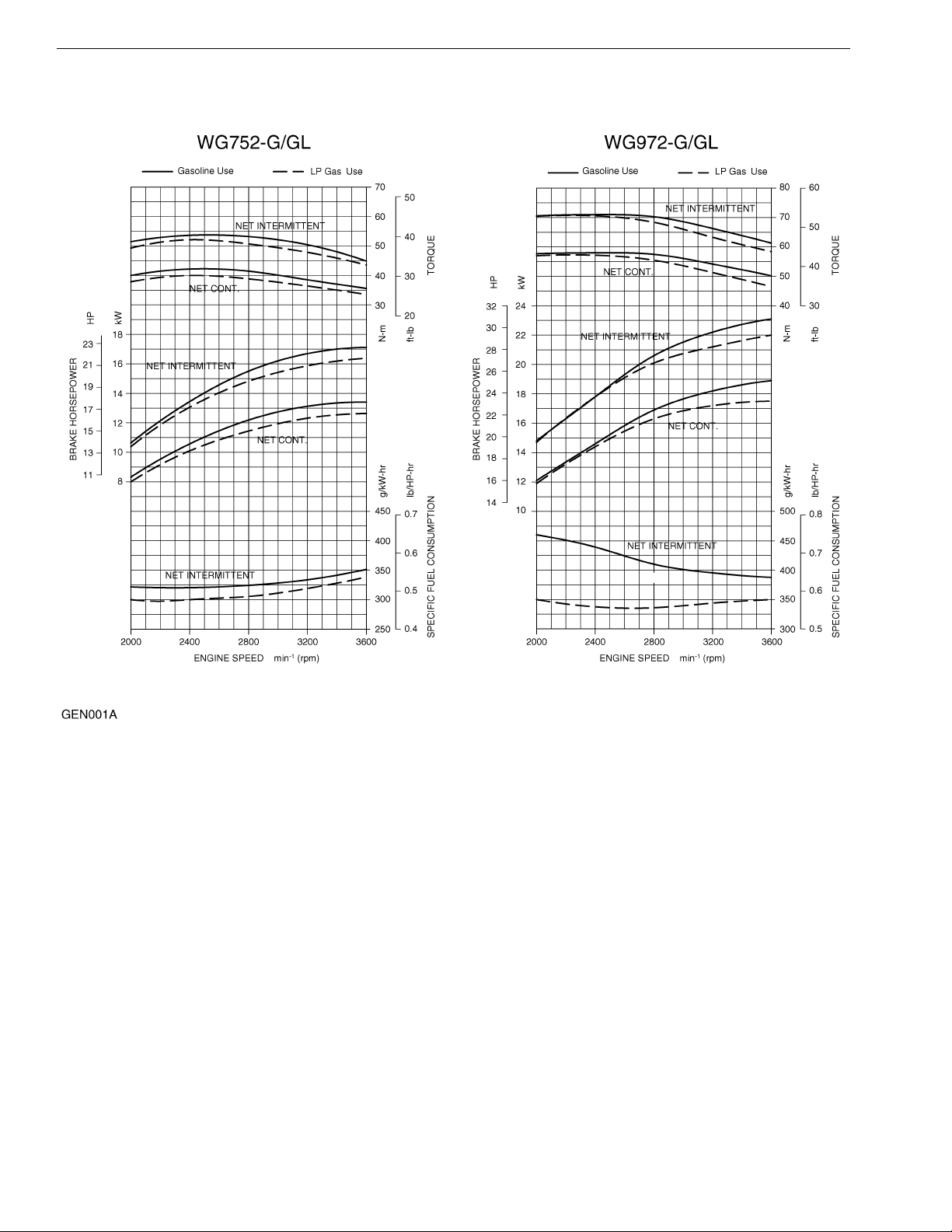

2. PERFORMANCE CURVES

0-4

0-5

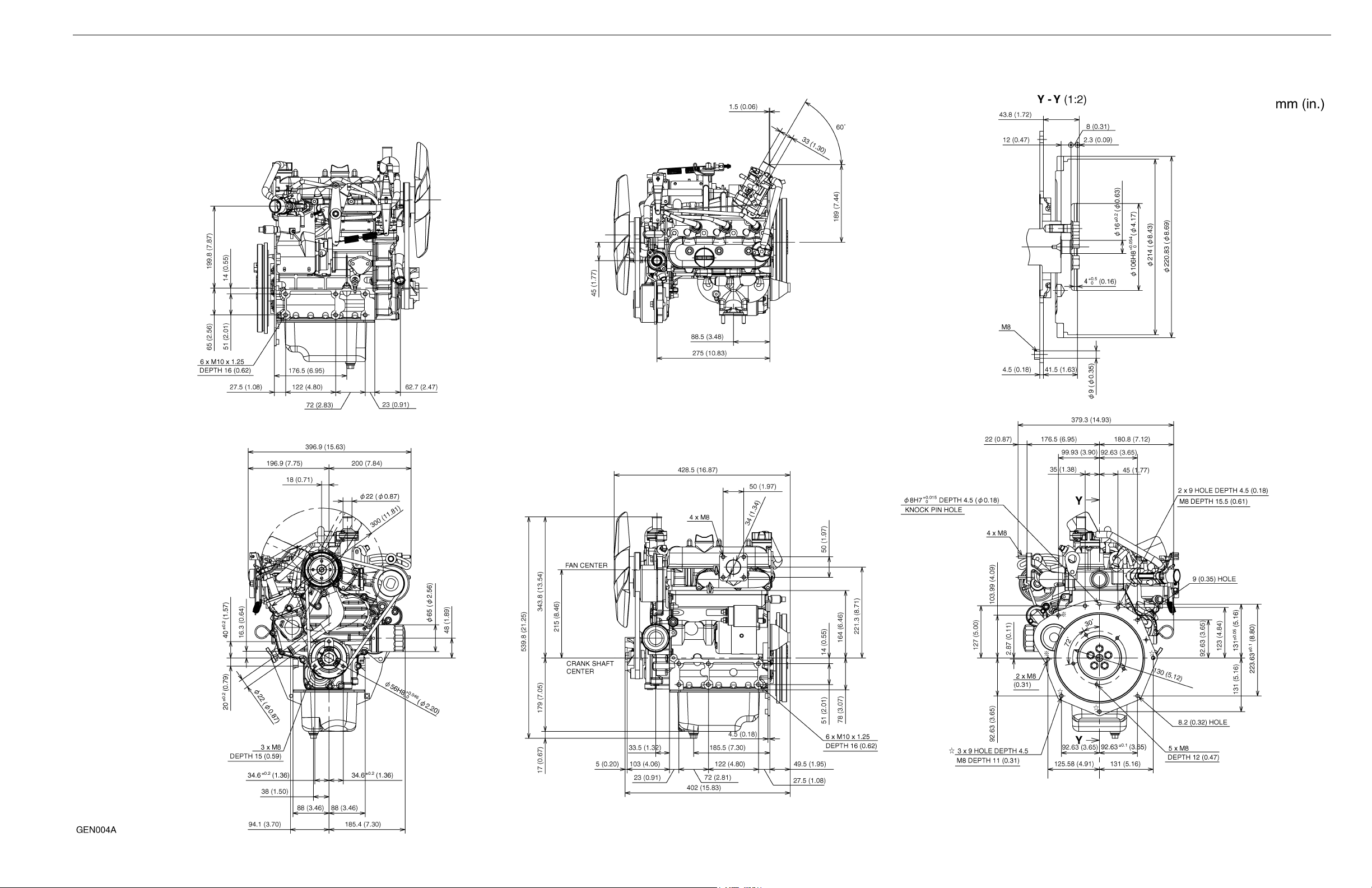

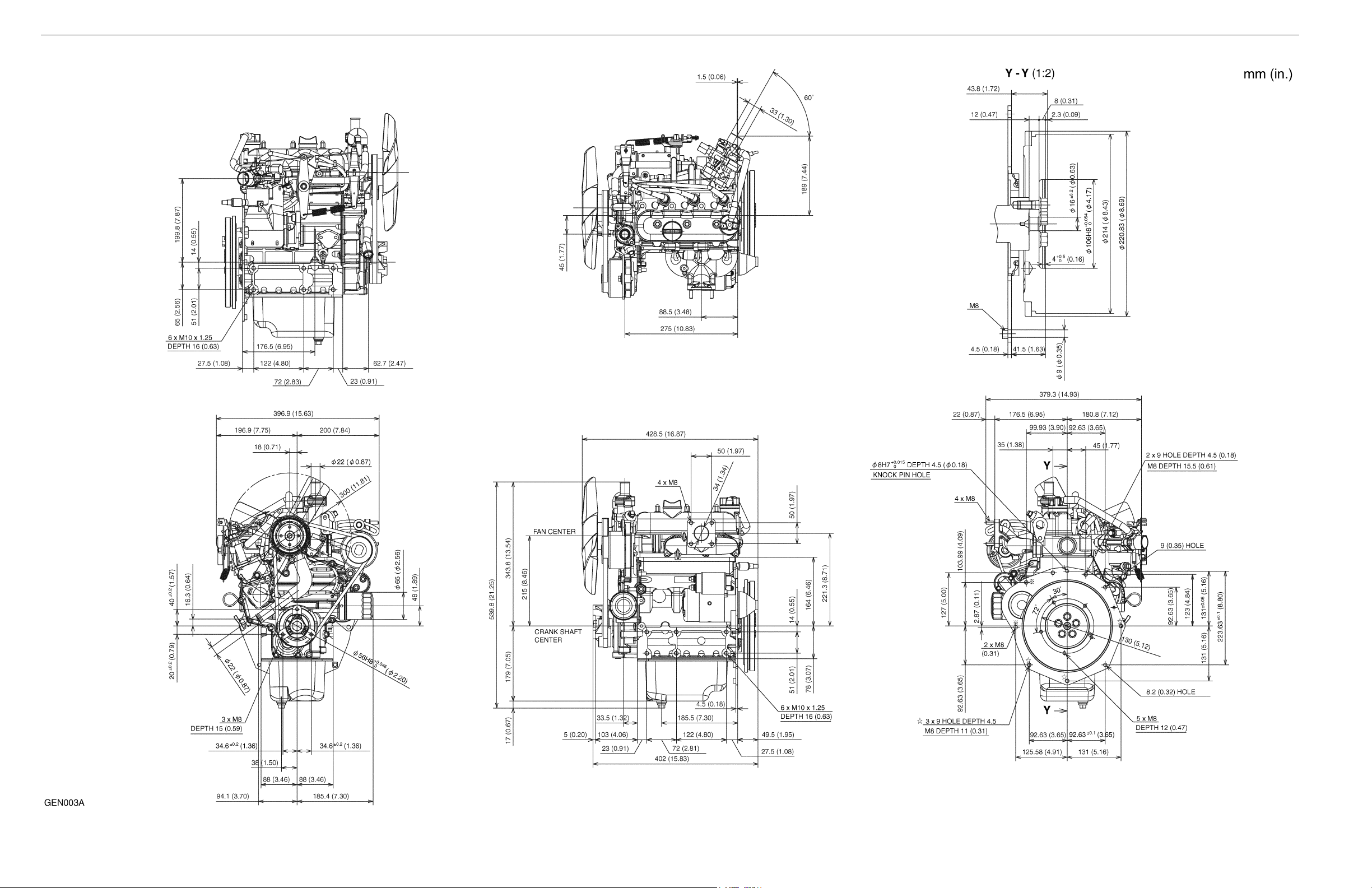

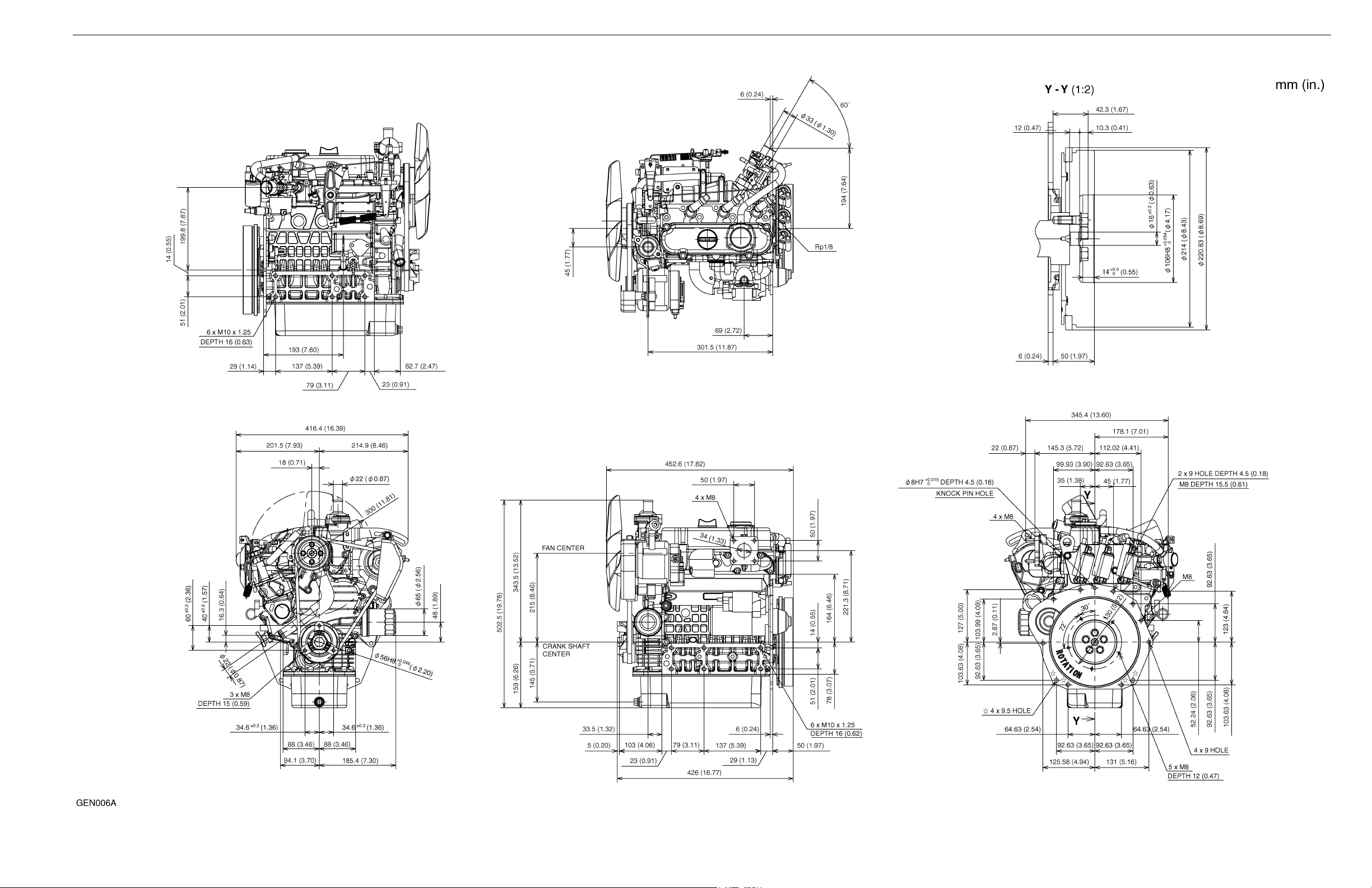

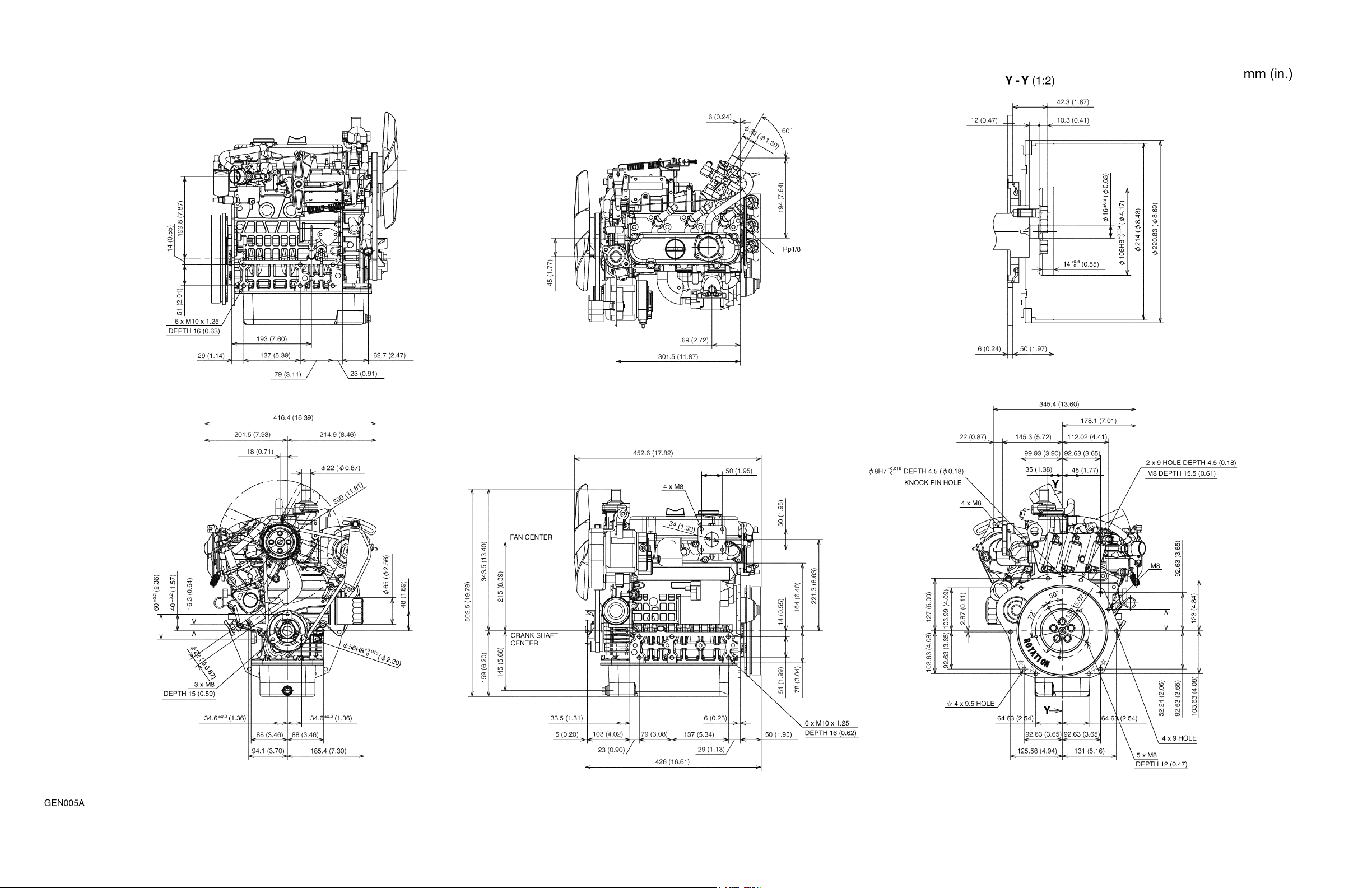

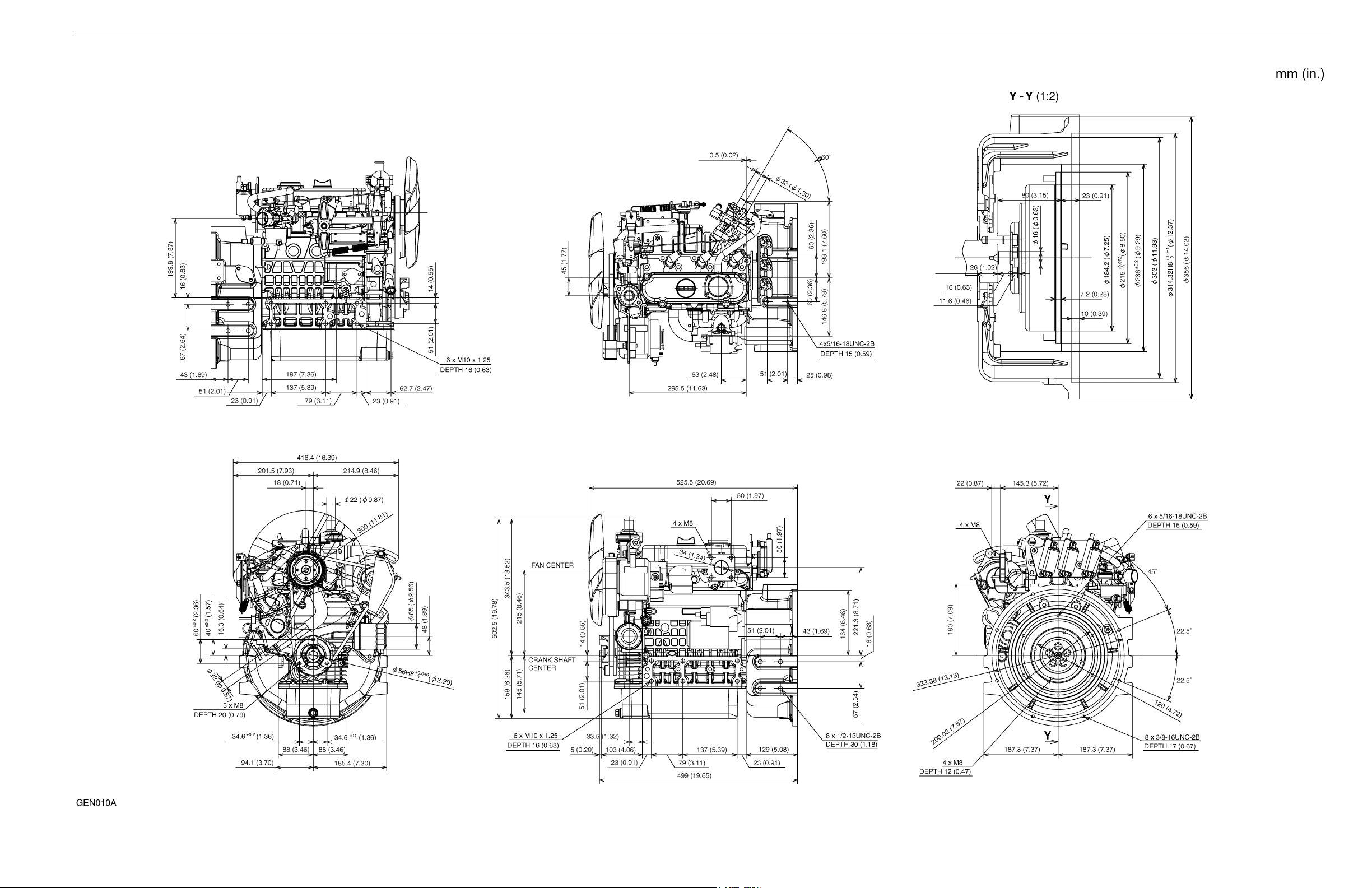

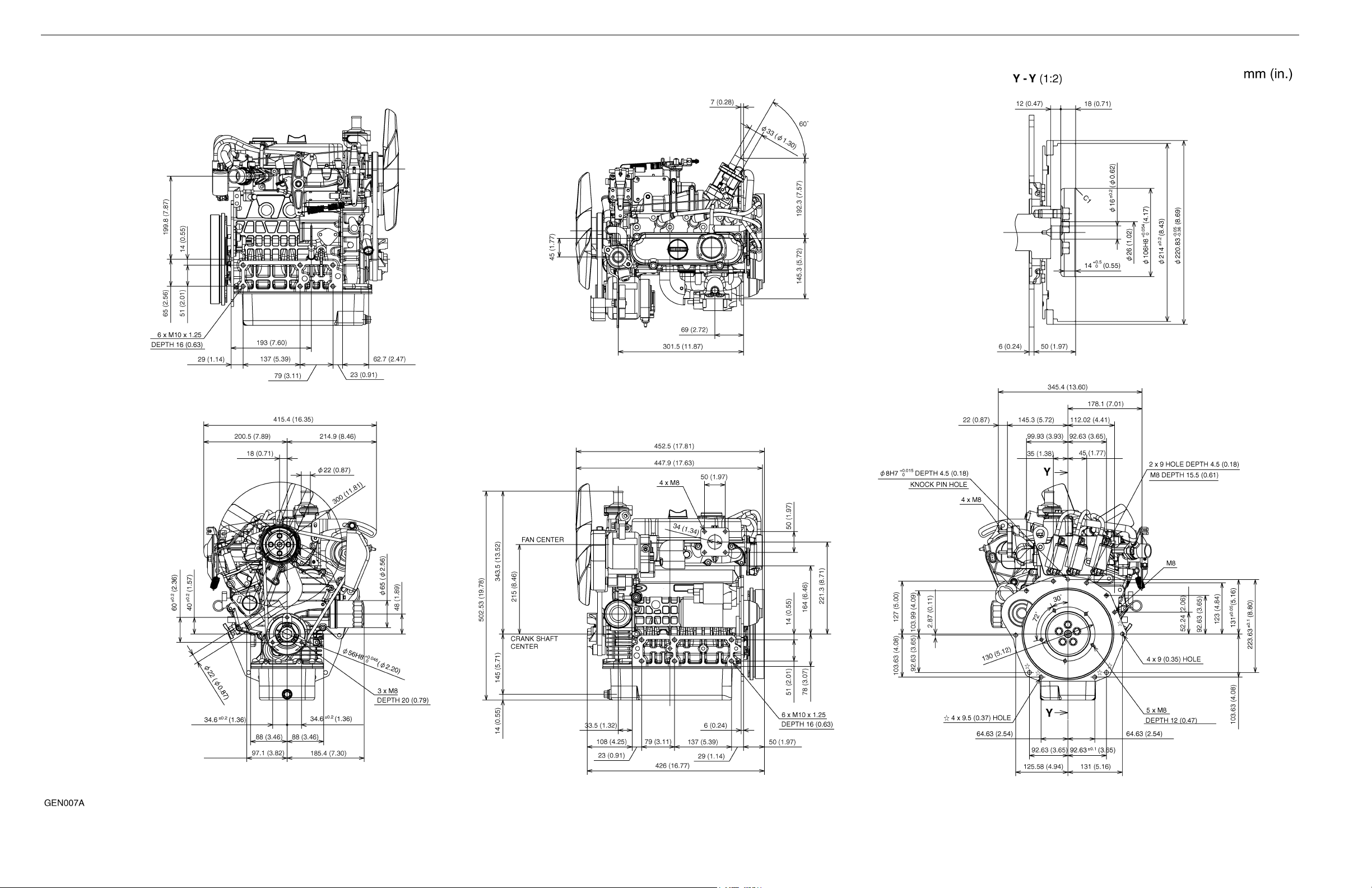

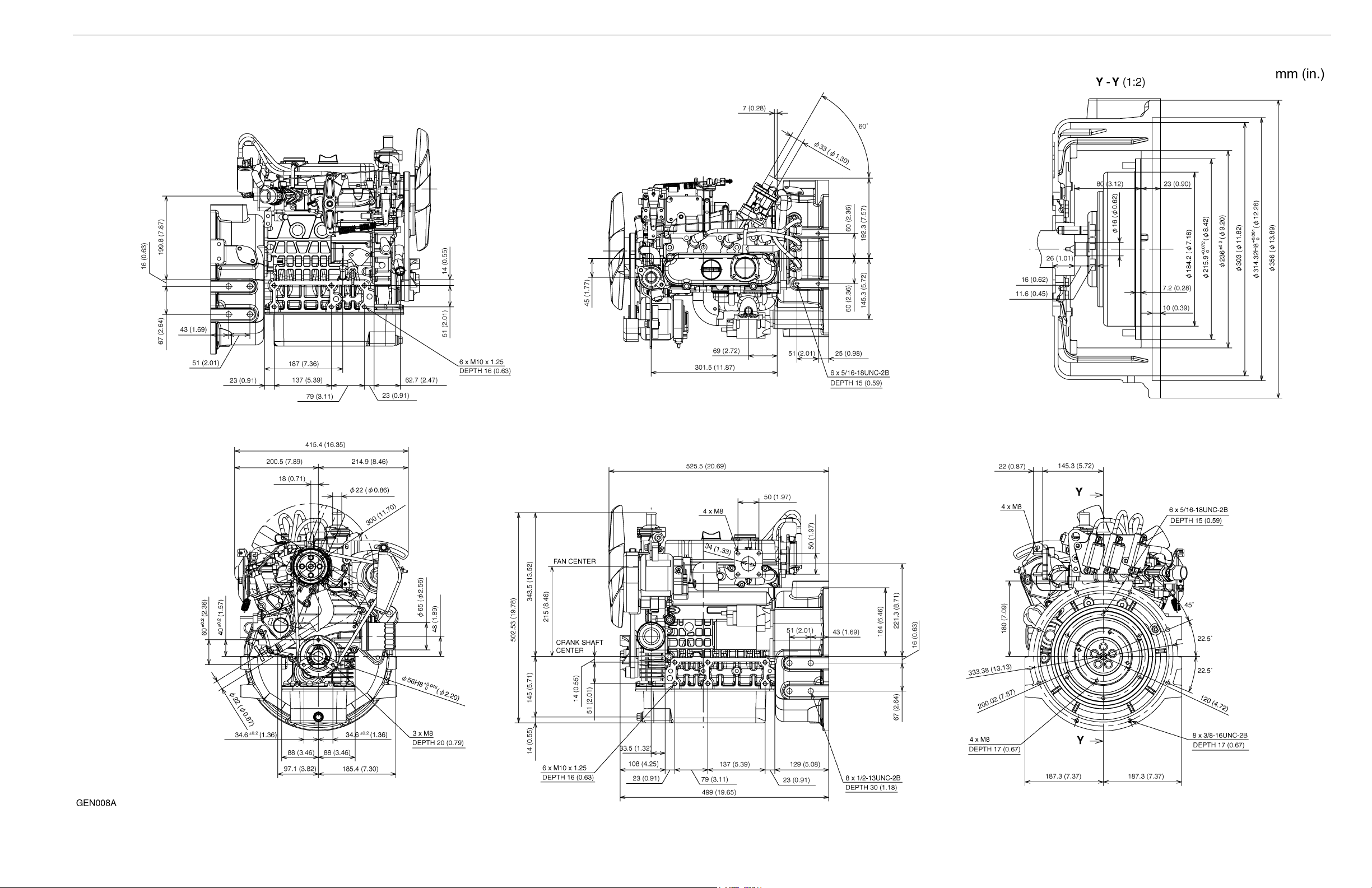

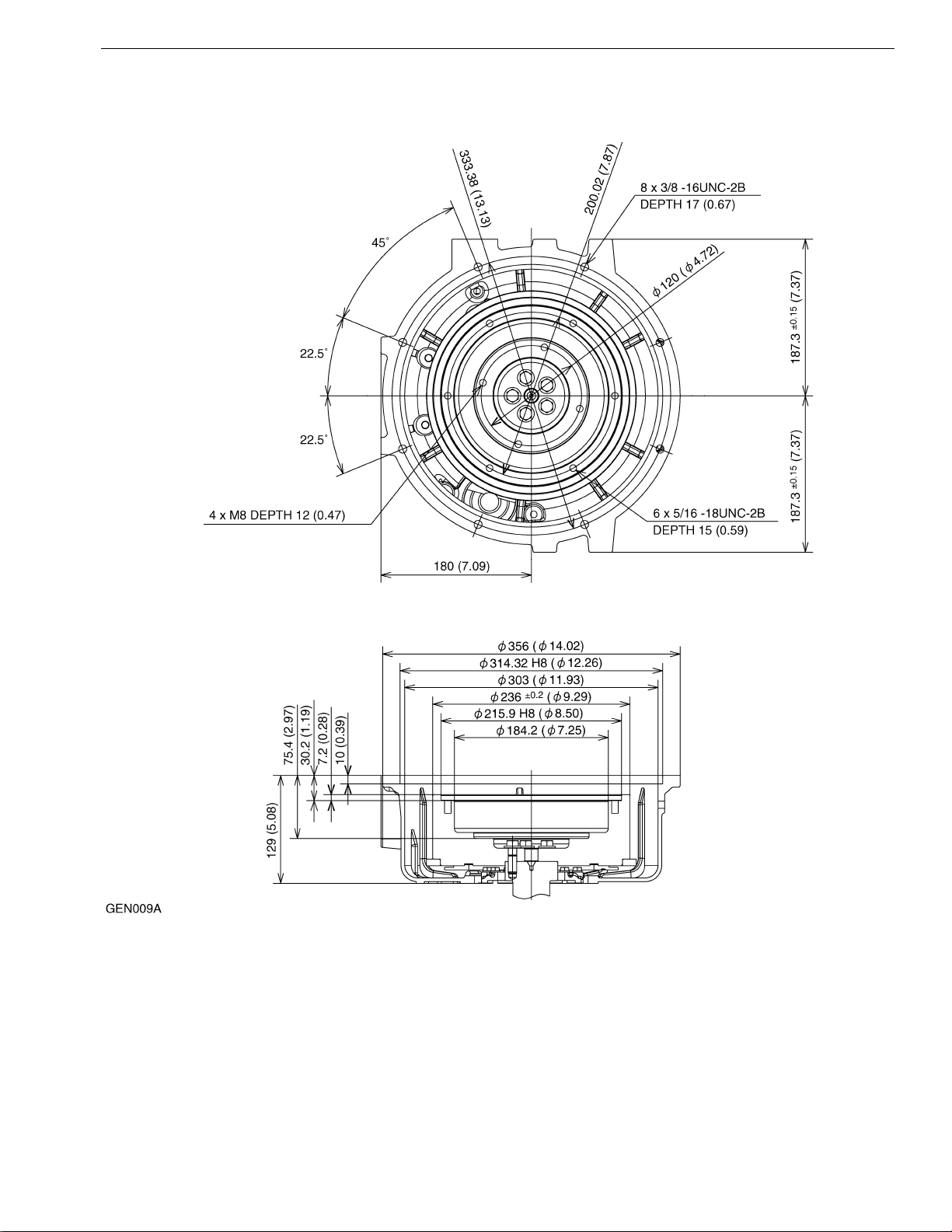

3. DIMENSIONS

WG752-G-E3BBH-1 (EG641-00000)

0-6

WG752-GL-E3BBH-1 (EG645-00000)

0-7

WG972-G-E3BBH-1 (EG801-00000)

0-8

WG972-GL-E3BBH-1(EG805-00000)

0-9

WG972-GL-E3SAEH-1 (EG802-00000)

0-10

DG972-E2-BBH-1 (EG581-00000)

0-11

DG972-E2-SAEH-1 (EG582-00000)

0-12

WG752, WG972, DG972

Flywheel : Normal SAE for Clutch No.6-1/2

Flywheel Housing : Normal SAE No.5

0-13

1. EMISSION REGULATION

CONTENTS

1. GENERAL...................................................................................................................................... 1-1

2. IMPORTANT ITEMS...................................................................................................................... 1-2

[1] Important Notice ...................................................................................................................... 1-2

[2] Emission-Related Installation Instructions ............................................................................... 1-3

(1) Air Intake System .............................................................................................................. 1-3

(2) Exhaust System (See EXHAUST SYSTEM section) : (WG752, WG972)......................... 1-5

(3) High Altitude Operation (See FUEL SYSTEM section) : (WG752, WG972) ..................... 1-5

(4) Evaporative Emission Controls.......................................................................................... 1-5

(5) Engine Set Speed.............................................................................................................. 1-5

(6) Engine Labels.................................................................................................................... 1-6

(7) Vaporizer (WG752−GL, WG972−GL), Gas Regulator (DG972) Connections................... 1-6

(8) Tamper Resistance ........................................................................................................... 1-6

1. GENERAL

NOTE

NOTE

Along with E3 models, E2 models are yet available to be used in the following countries per output category.

kW, disp. Model Type North America Europe Japan

P ≤ 19

0.225 ≤ L

19 < P ≤ 30

0.825 < L ≤ 1.0

• * DG972 is only for stationary use.

e.g.oil field and emergency generator.

Current and future emission regulations.

Countries kW, disp. 2009 2010 2011 2012 2013 2014 2015 2016

CARB

USA

EPA

Canada

Japan

EU

WG752-G/GL-E3 E3 Available Non-available Available

WG/DF752-E2 E2 Non-available Available Available

DG972 * E2 Available Available Available

WG972-G/GL-E3 E3 Available Available Non-available

WG/DF972-E2 E2 Non-available Available Non-available

HC+NO

P ≤ 19

0.225 ≤ L

19 < P

L ≤ 0.825

19 < P

0.825 < L ≤ 1.0

P ≤ 19

0.225 ≤ L

19 < P ≤ 30

L ≤ 1.0

P ≤ 19

0.225 ≤ L

P < 19

0.225 ≤ L

19 ≤ P < 560 HC/0.6 g/kWh, NO

P ≤ 19

0.225 ≤ L

19 < P None

12.0/549 8.0/549 *

12.0/549 6.5/375 * 0.8/20.6 *

12.1/610 8.0/610 *

12.1/610 8.0/610 *

12.1/610 8.0/610

8.0/549 *

12.1/610

/0.6 g/kWh, CO/20 g/kWh

X

12.1/610

/CO (g/kWh)

X

• * with evaporative emission regulation

1-1

2. IMPORTANT ITEMS

[1] Important Notice

There are necessary emission-related items for compliance with emission regulations.

Please confirm whether emission-related items are certain on application review

(Exhaust Emission Check Sheet).

For mass-production Kubota prepares the installation instructions.

These instructions are provided for the final engine assemblers who must ensure the engine, exhaust system

(catalyst), intake system, gasoline fuel system and etc, are Installed correctly in the engine’s certified configuration.

(for EPA only)

Failing to follow these instructions when installing a certified engine in a piece of non-road equipment violates

federal law (40CFR 1068. 105(b)),subject to fines or other penalties as described in the Clean Air Act.

The contractual agreement contract is necessary before mass-production.

1-2

[2] Emission-Related Installation Instructions

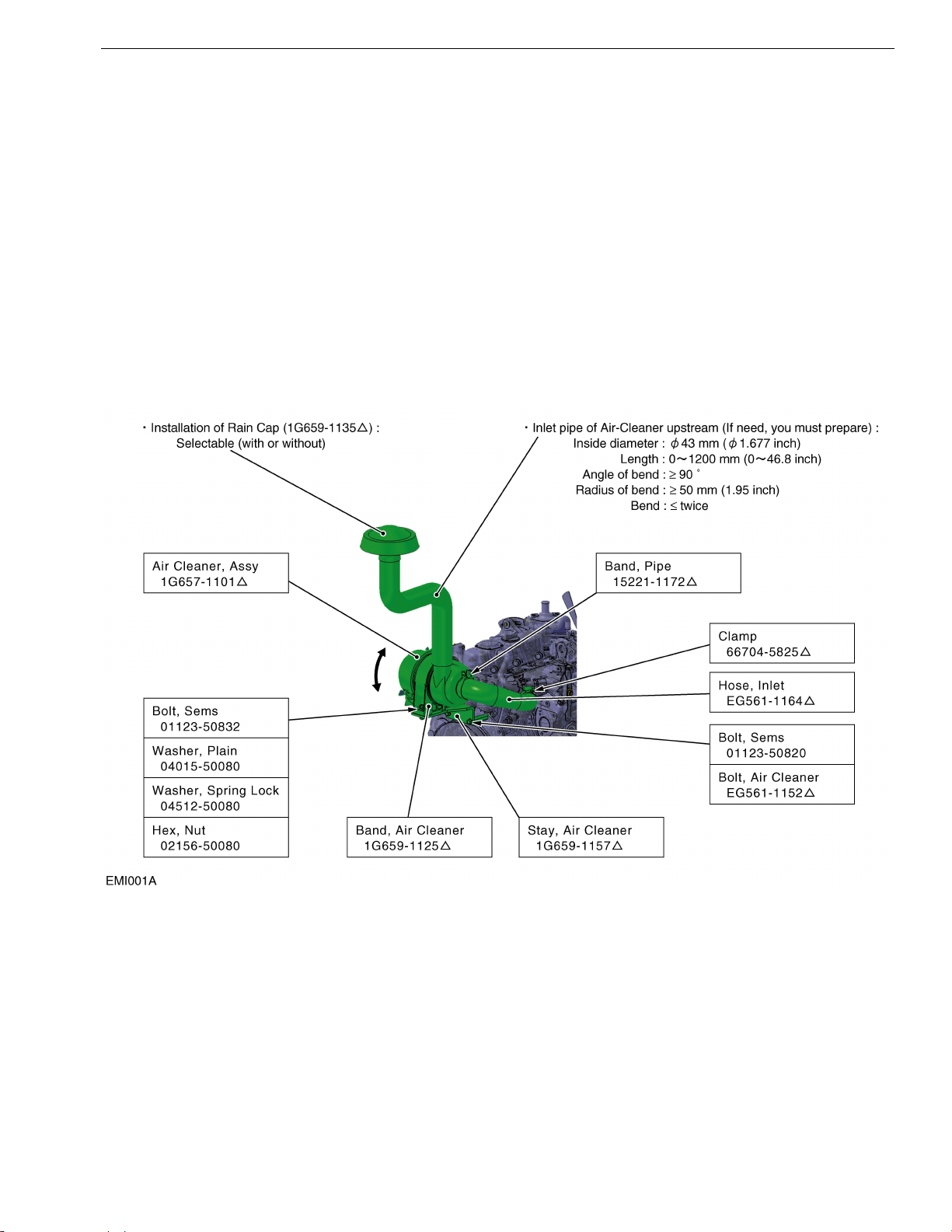

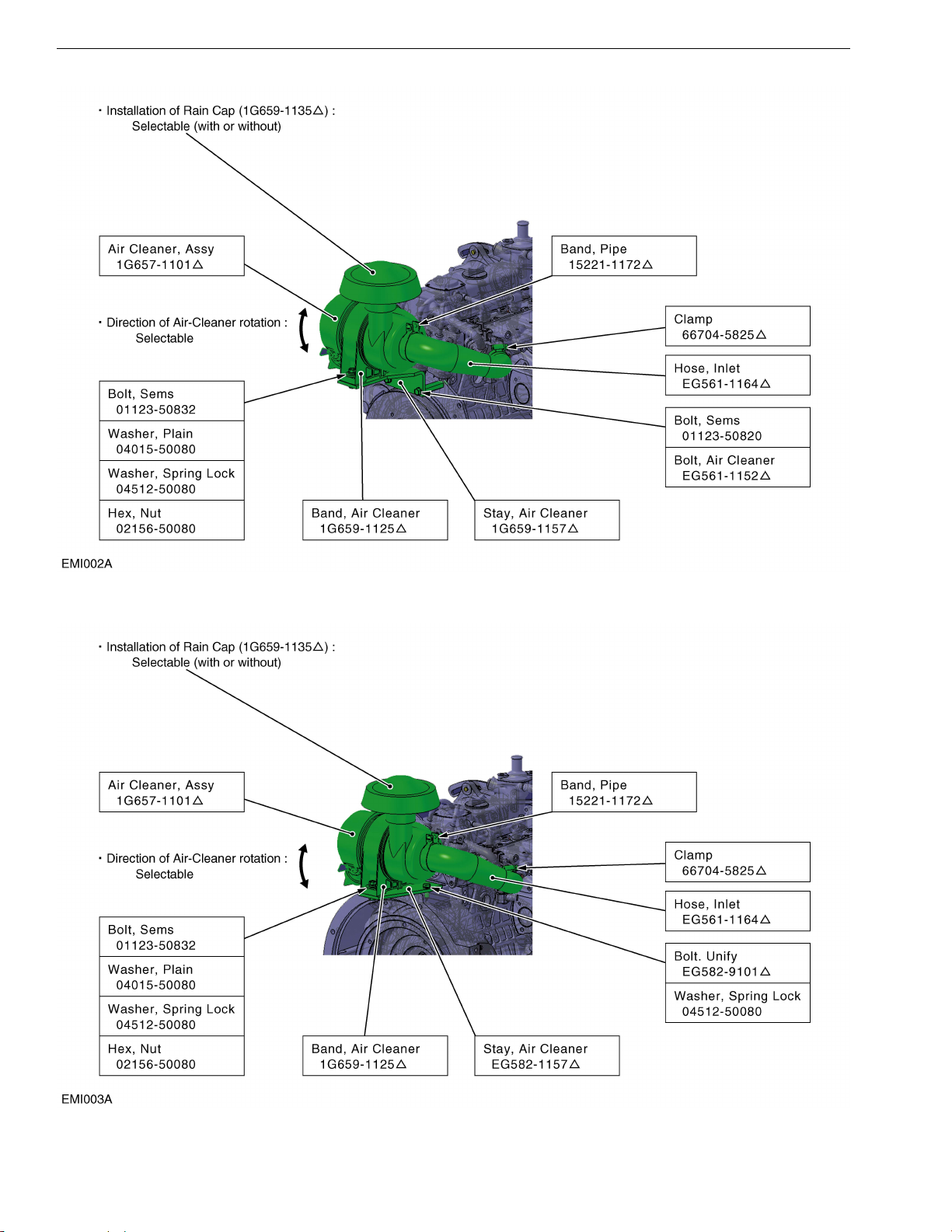

(1) Air Intake System

• Intake system means that layout of all parts from entrance of suction to air-cleaner flange.

• Kubota offers standard Air-cleaner kit. The intake parts should be installed as shown in figure below.

• If you use an OEM intake system for a spec engine, consult Kubota based on the Exhaust Emission Check Sheet

before the application review.

• When the same specification engine is installed on multiple applications, you will have to inform to Kubota prior

to the application review.

Also, the final intake system of each application must be confirmed at the application review and/or the Exhaust

Emission Check Sheet.

• You must install the intake system confirmed at the application review and/or the Exhaust Emission Check Sheet

for mass-production. (Important)

• You should consult Kubota based on the Exhaust Emission Check Sheet whenever you change the intake

system.

Do not change without consultation with Kubota.

WG752, WG972

1-3

DG972-E2-BBH

DG972-E2-SAEH, WG-972-GL-E3SAEH

1-4

(2) Exhaust System (See EXHAUST SYSTEM section) : (WG752, WG972)

• Exhaust system means the layout of all parts from exhaust manifold to exhaust exit to atmosphere.

• Kubota offers certified catalytic mufflers and catalytic converters.

You must only use Kubota certified catalyst parts (Important) and assemble the exhaust parts according to

instructions as specified in the EXHAUST SYSTEM section of this manual.

Catalyst parts other than Kubota must not be used because other catalyst is not certified our engine.

You must install the exhaust system confirmed at application review and/or the Exhaust Emission Check Sheet

for mass-production. (Important)

• You must consult Kubota based on the Exhaust Emission Check Sheet when you change the exhaust parts after

application review. Do not change without the consultation with Kubota.

(3) High Altitude Operation (See FUEL SYSTEM section) : (WG752, WG972)

• Kubota prepared genuine altitude compensation kit.

The ultimate users must comply with the regulations through the installation of the appropriate altitude

compensation kit.

(4) Evaporative Emission Controls

(See EVAPORATIVE EMISSION CONTROL section) : gasoline fuel

• If your equipments use a volatile liquid fuel (such as gasoline), they must meet the evaporative emission

standards of 40 CFR part 1060,as described in §1054.112.

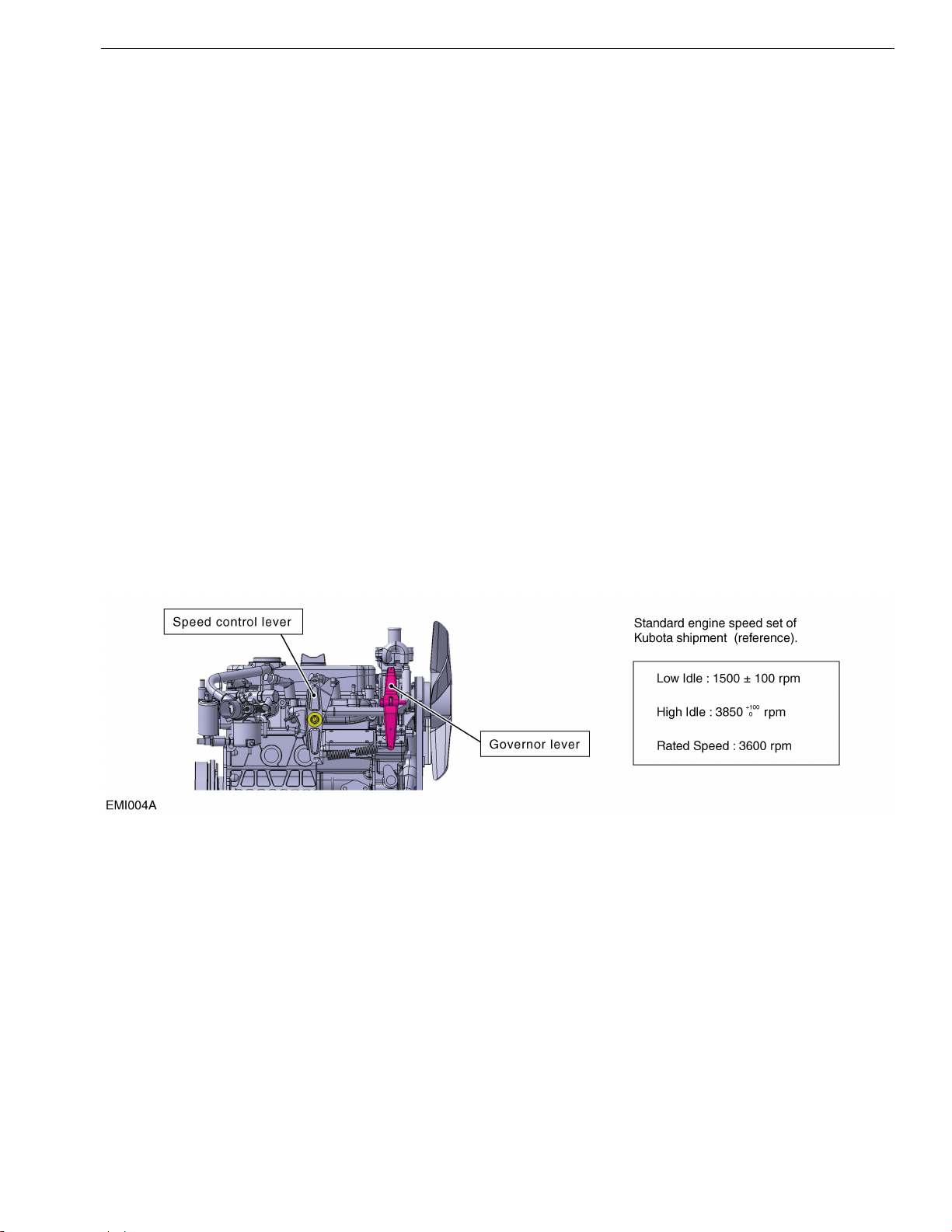

(5) Engine Set Speed

(Mechanical Governor specification)

• You should operate the engine within the range of engine speed set at the time of Kubota shipment

(without parasitic load).

• You should use the speed control lever and/or the governor lever when the speed change.

(Electronic Governor specification)

• If you use the electronic governor, consult Kubota before the application review.

1-5

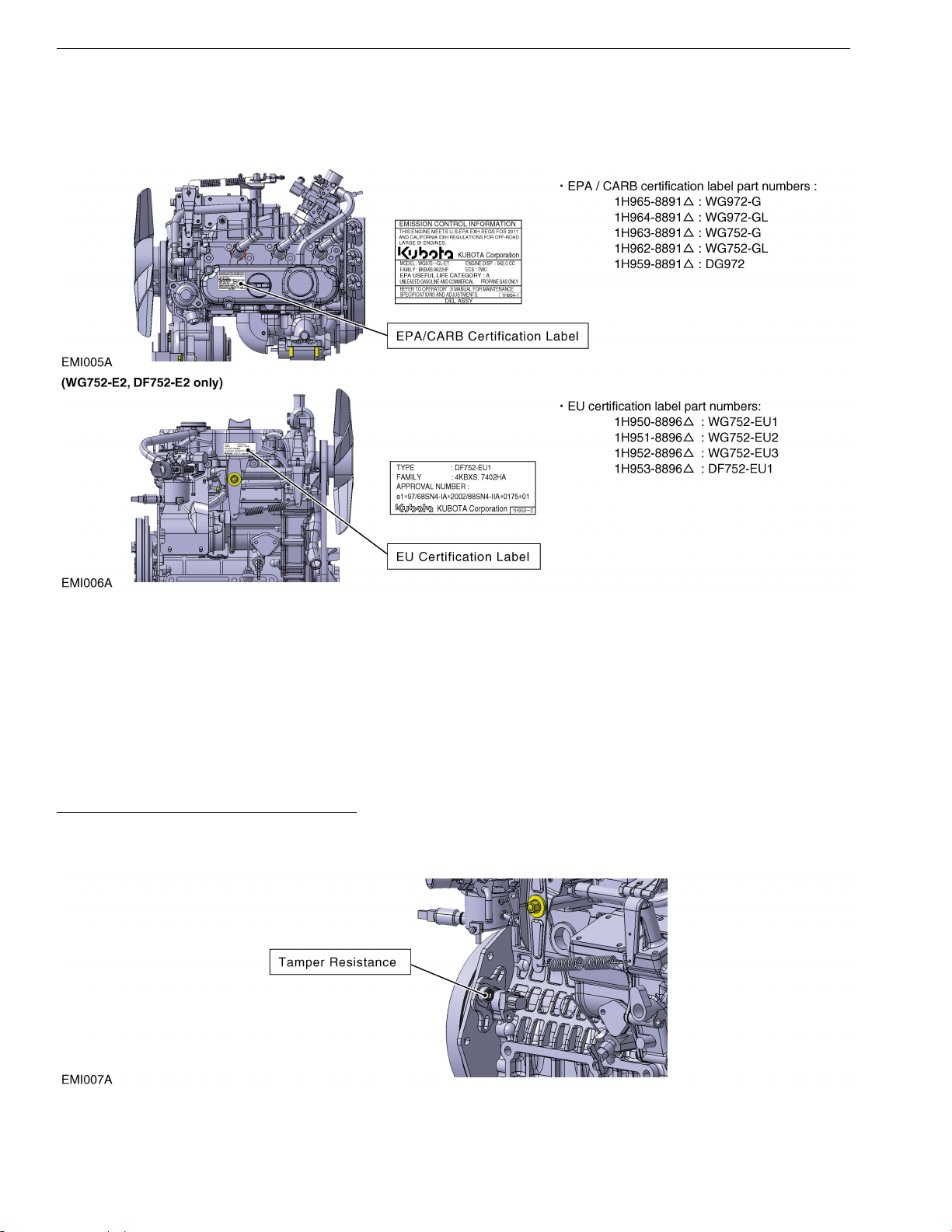

(6) Engine Labels

• The following labels must be visible. If you install the engine in a way that makes the engine’s emission control

information label hard to read during normal engine maintenance, you must place a duplicate label on the

equipment, as described in 40 CFR 1068.105.

(7) Vaporizer (WG752−GL, WG972−GL), Gas Regulator (DG972) Connections

(See FUEL SYSTEM section)

• The hose length between the vaporizer (gas regulator) and carburetor (gas mixer) must be within 300 ± 20 mm

(11.8 ± 0.78 inch). Only use hose appropriate for LPG.

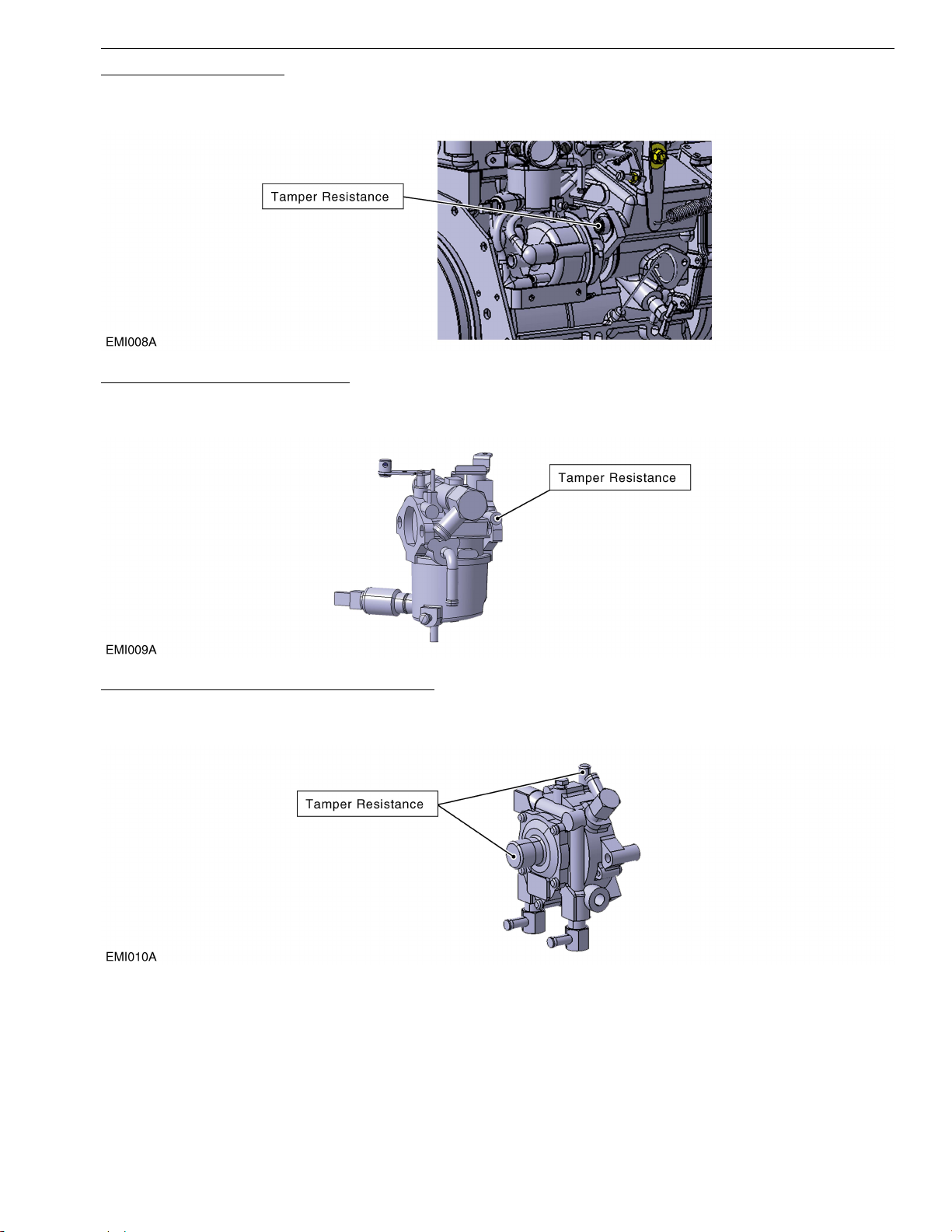

(8) Tamper Resistance

• Any modifications to the tamper resistance parts on this engine will cause this engine to be in noncompliance with

emission regulations.

SENSOR (CRANK ANGLE) : (WG/DG972)

The ignition timing sensor also has a function of tamper resistant and the adjustment screw has been covered

after adjustment at the factory. You CAN NOT adjust the ignition timing.

1-6

DISTRIBUTOR : (WG752)

The distributor is tamper resistant ; the ignition timing adjustment screw has been covered after adjustment at the

factory. You CAN NOT adjust the ignition timing.

CARBURETOR : (WG752, WG972)

The carburetor is tamper resistant ; the idle mixture screw has been covered by tamper plug after adjustment at

the factory. You CAN NOT adjust this screw.

LPG REGULATOR : (WG752

LPG regulator is tamper resistant ; the main and idle pressure adjustment screw have been covered by tamper

caps after adjustment at the factory. You CAN NOT adjust the screws.

−GL, WG972−GL)

1-7

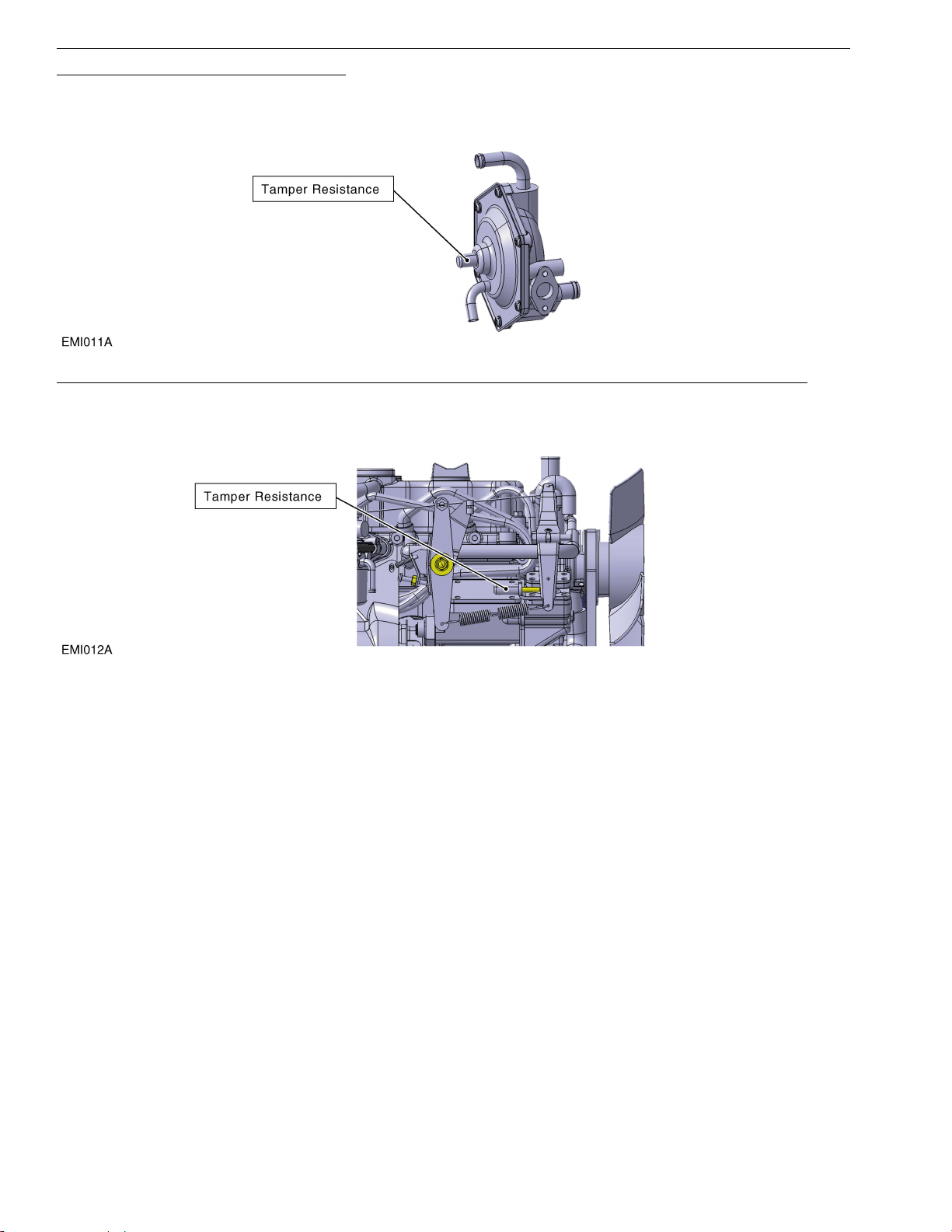

NATURAL GAS REGULATOR : (DG972)

Natural gas regulator is tamper resistant; idle pressure adjustment screws have been covered by tamper caps

after adjustment at the factory. You CANNOT adjust the screw.

GOVERNOR LEVER (THROTTLE ANGLE) : (Only spec model of specification that limits throttle angle)

The governor lever is tamper resistant; the governor lever adjustment screw has been covered after adjustment

at the factory. You CANNOT adjust the governor lever.

1-8

2. FUEL SYSTEM

CONTENTS

1. GENERAL...................................................................................................................................... 2-1

[1] Gasoline .................................................................................................................................. 2-1

[2] LPG ......................................................................................................................................... 2-1

[3] Natural gas .............................................................................................................................. 2-1

2. FUEL DIAGRAM............................................................................................................................ 2-2

3. CAUTIONS .................................................................................................................................... 2-4

[1] For safety (WG752−GL, WG972−GL, DG972)........................................................................ 2-4

(1) Tightening torque and leak check for vaporizer and gas regulator.................................... 2-4

(2) Change the angle of LPG fitting of dual fuel carburetor and Gas fitting of gas mixer........ 2-4

(3) Setting and vibration limits.................................................................................................2-4

(4) Starting the engine (WG752−GL, WG972−GL)................................................................. 2-4

[2] For emission regulations (WG752−GL, WG972−GL, DG972) ................................................ 2-5

(1) Vaporizer and Gas regulator ............................................................................................. 2-5

(2) Length of the gas hose ...................................................................................................... 2-5

4. HIGH ALTITUDE OPERATION (WG752, WG972) ....................................................................... 2-6

5. EVAPORATIVE EMISSION CONTROL (gasoline fuel)................................................................. 2-7

[1] Regulations.............................................................................................................................. 2-7

[2] Related Check Items ............................................................................................................... 2-7

Loading...

Loading...