Kubota D1503-M-DI, D1503-M-DI-T, V2203-M-DI, V2403-M-DI, D1703-M-DI Workshop Manual

...

WORKSHOP MANUAL

KiSC issued 10, 2009 A

DIESEL ENGINES

03-M-DI SERIES

TO THE READER

KiSC issued 10, 2009 A

This Workshop Manual has been prepared to provide servicing personnel with

information on the mechanism, service and maintenance of KUBOTA Diesel Engine 03M-DI Series. It is divided into two parts, “Mechanism” and “Servicing” for each section.

Q Mechanism

Information on the Features and New Mechanisms are described. This information

should be understood before proceeding with troubleshooting, disassembling and

servicing.

Q Servicing

The heading “General” includes general precautions, check and maintenance and

special tools. There are troubleshooting, checking and adjusting, disassembling and

assembling, and servicing which cover procedures, precautions, factory specifications

and allowable limits.

All information illustrations and specifications contained in this manual are based on

the latest product information available at the time of publication. The right is reserved

to make changes in all information at any time without notice.

Due to covering many models of this manual, illustration being used, have not been

specified as one model.

March 2002

© KUBOTA Corporation 2002

03-M-DI Series, WSM

KiSC issued 10, 2009 A

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

SAFETY FIRST

This symbol, the industry’s “Safety Alert Symbol”, is used throughout this manual and on labels on

the machine itself to warn of the possibility of personal injury. Read these instructions carefully.

It is essential that you read the instructions and safety regulations before you attempt to repair or use

this unit.

DANGER : Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING : Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION : Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Q IMPORTANT : Indicates that equipment or property damage could result if instructions are not

followed.

Q NOTE : Gives helpful information.

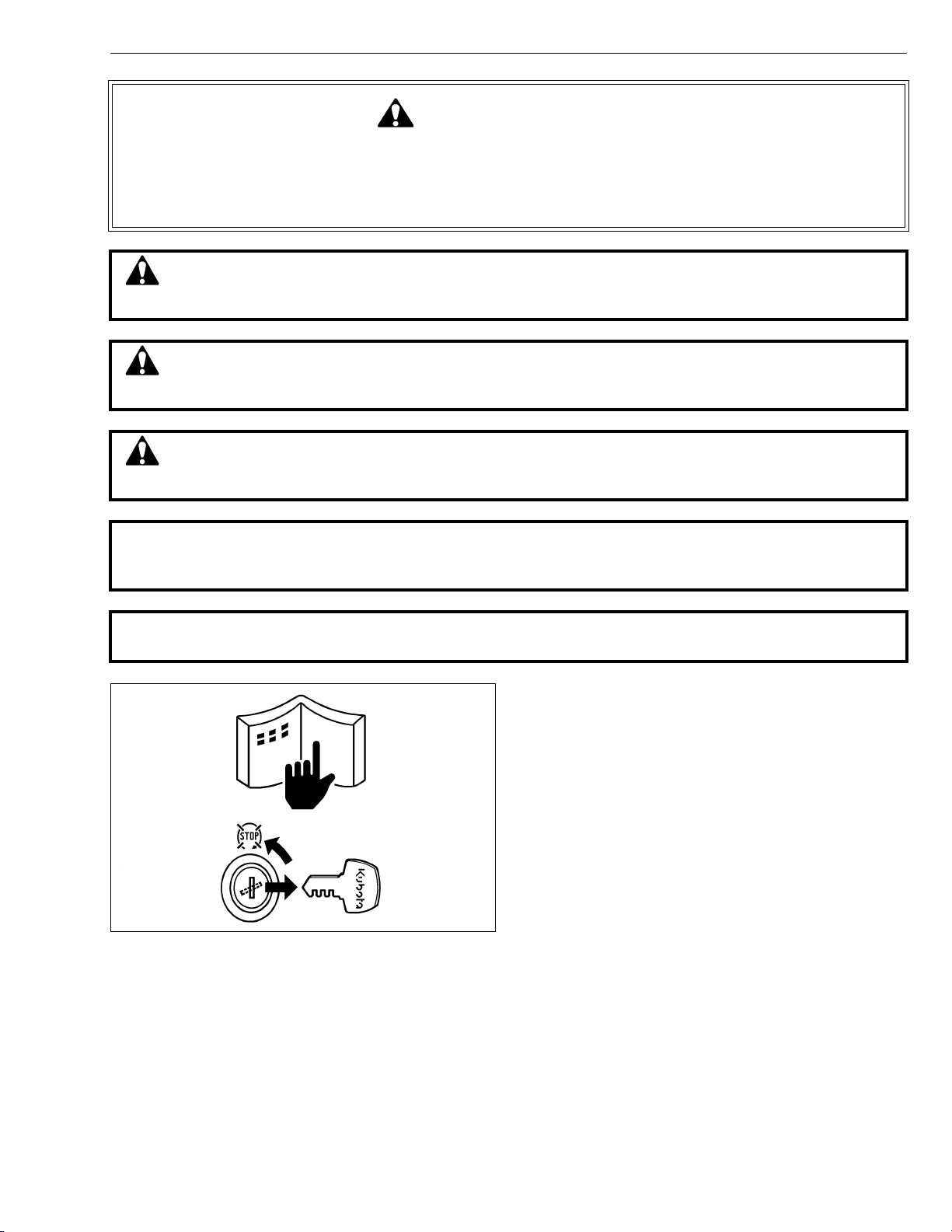

BEFORE SERVICING AND REPAIRING

• Read all instructions and safety instructions in this

manual and on your engine safety decals.

• Clean the work area and engine.

• Park the machine on a firm and level ground.

• Allow the engine to cool before proceeding.

• Stop the engine, and remove the key.

• Disconnect the battery negative cable.

• Hang a “DO NOT OPERATE” tag in operator

station.

1

03-M-DI Series, WSM

KiSC issued 10, 2009 A

SAFETY INSTRUCTIONS

SAFETY STARTING

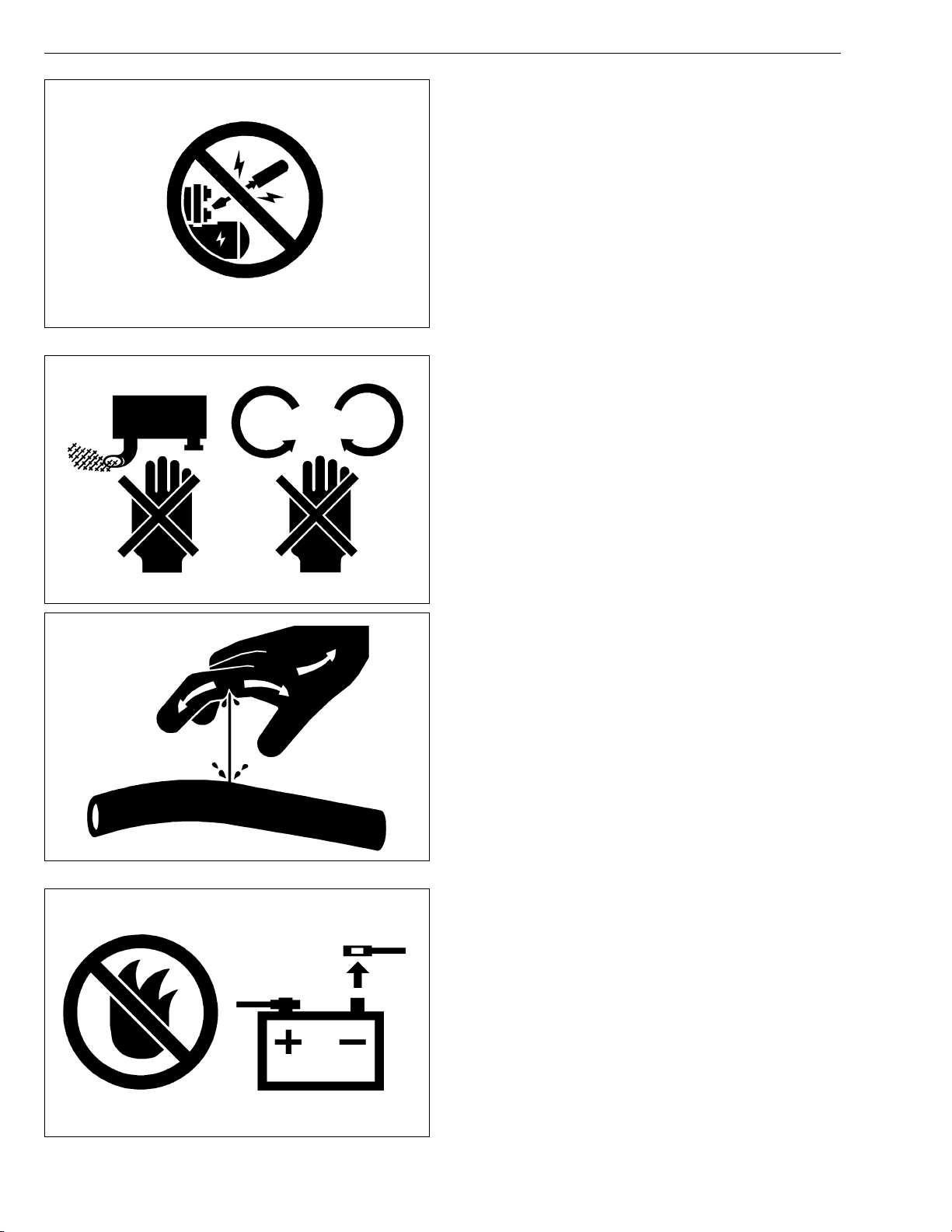

• Do not start the engine by shorting across starter

terminals or bypassing the safety start switch.

• Unauthorized modifications to the engine may impair

the function and / or safety and affect engine life.

SAFETY WORKING

• Do not work on the machine while under the influence

of alcohol, medication, or other substances or while

fatigued.

• Wear close fitting clothing and safety equipment

appropriate to the job.

• Use tools appropriate to the work. Makeshift tools,

parts, and procedures are not recommended.

• When servicing is performed together by two or more

persons, take care to perform all work safely.

• Do not touch the rotating or hot parts while the engine

is running.

• Never remove the radiator cap while the engine is

running, or immediately after stopping. Otherwise, hot

water will spout out from radiator. Only remove

radiator cap when cool enough to touch with bare

hands. Slowly loosen the cap to first stop to relieve

pressure before removing completely.

• Escaping fluid (fuel or hydraulic oil) under pressure

can penetrate the skin causing serious injury. Relieve

pressure before disconnecting hydraulic or fuel lines.

Tighten all connections before applying pressure.

• Wear a suitable hearing protective device such as

earmuffs or earplugs to protect against objectionable

or uncomfortable loud noises.

AVOID FIRES

• Fuel is extremely flammable and explosive under

certain conditions. Do not smoke or allow flames or

sparks in your working area.

• To avoid sparks from an accidental short circuit,

always disconnect the battery negative cable first and

connect it last.

• Battery gas can explode. Keep sparks and open

flame away from the top of battery, especially when

charging the battery.

• Make sure that no fuel has been spilled on the engine.

2

03-M-DI Series, WSM

KiSC issued 10, 2009 A

SAFETY INSTRUCTIONS

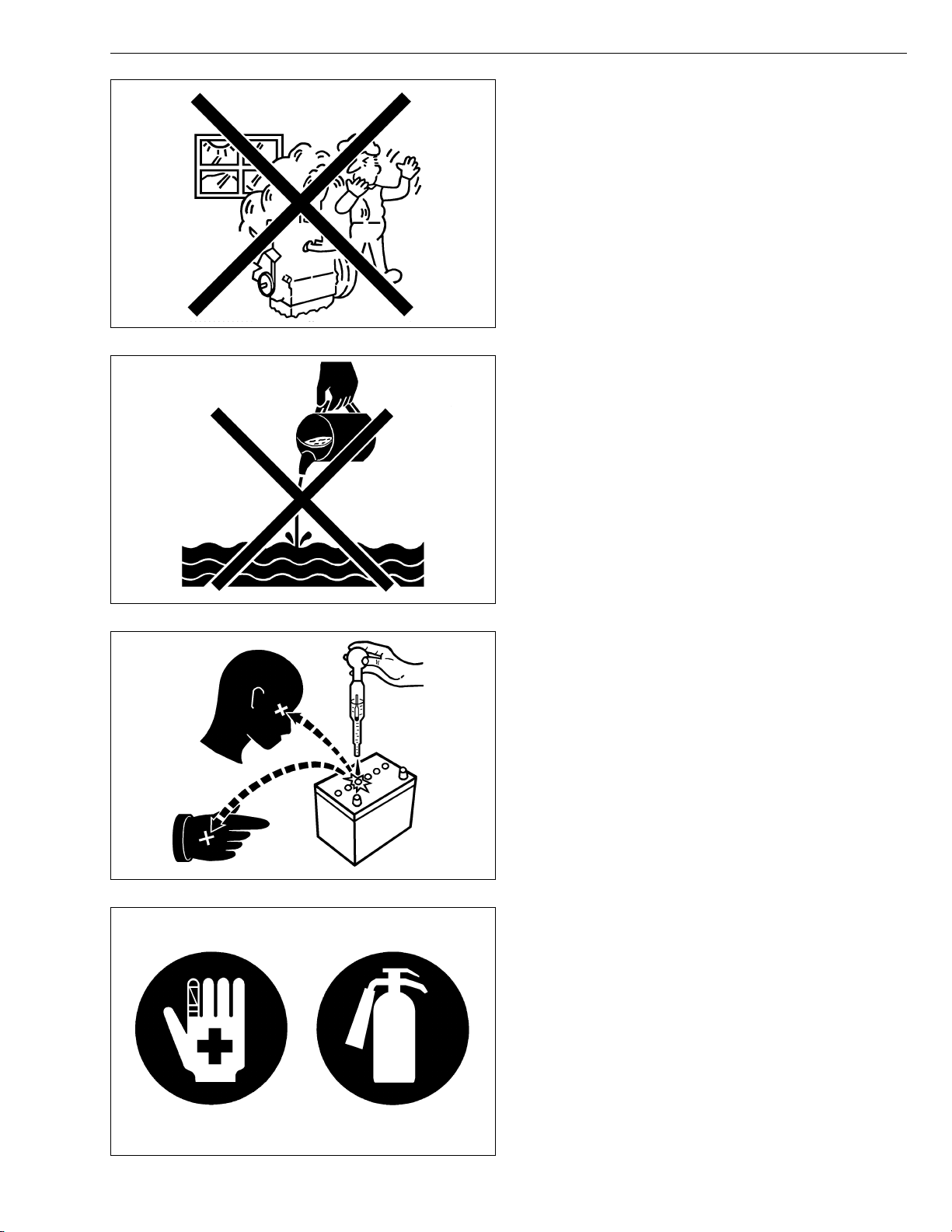

VENTILATE WORK AREA

• If the engine must be running to do some work, make

sure the area is well ventilated. Never run the engine

in a closed area. The exhaust gas contains poisonous

carbon monoxide.

DISPOSE OF FLUIDS PROPERLY

• Do not pour fluids into the ground, down a drain, or

into a stream, pond, or lake. Observe relevant

environmental protection regulations when disposing

of oil, fuel, coolant, electrolyte and other harmful

waste.

PREVENT ACID BURNS

• Sulfuric acid in battery electrolyte is poisonous. It is

strong enough to burn skin, clothing and cause

blindness if splashed into eyes. Keep electrolyte

away from eyes, hands and clothing. If you spill

electrolyte on yourself, flush with water, and get

medical attention immediately.

PREPARE FOR EMERGENCIES

• Keep a first aid kit and fire extinguisher handy at all

times.

• Keep emergency numbers for doctors, ambulance

service, hospital and fire department near your

telephone.

3

03-M-DI Series, WSM

KiSC issued 10, 2009 A

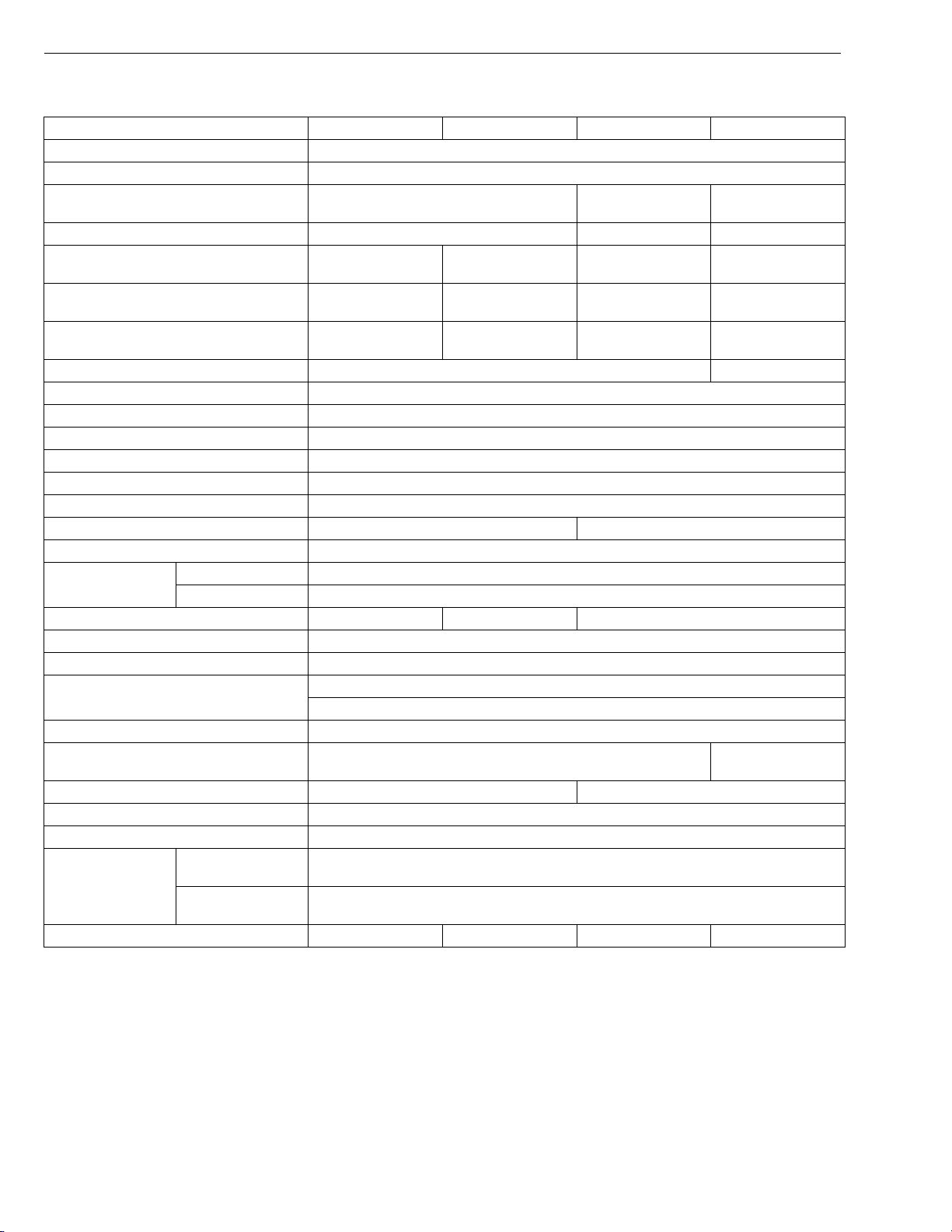

SPECIFICATIONS

SPECIFICATIONS

Model D1503-M-DI D1503-M-DI-T D1703-M-DI D1803-M-DI

Number of Cylinders 3

Type Vertical, Water-cooled, 4 cycle DI diesel engine

Bore × Stroke mm × mm

(in. × in.)

(HP/min

(HP/min

(HP/min

3

(cu.in.) 1499 (91.47) 1647 (100.51) 1826 (111.43)

-1

(rpm)

-1

(rpm))

-1

(rpm)

-1

(rpm))

-1

(rpm)

-1

(rpm))

-1

(rpm) 3000 2800

-1

(rpm) 750 to 850

20.1 / 2800

(27.0 / 2800)

23.5 / 2800

(31.5 / 2800)

24.8 / 2800

(33.2 / 2800)

Total Displacement cm

SAE Net Cont. kW/min

SAE Net Intermittent kW/min

SAE Gross Intermittent kW/min

Maximum Bare Speed min

Maximum Idling Speed min

Combustion Chamber Troiddal Type (Direct Injection)

Fuel Injection Pump Bosch “K” Type Mini Pump

Governor Centrifugal Ball Type, All Speed Mechanical Governor

Direction of Rotation Counter-Clockwise (viewed from flywheel side)

Injection Nozzle Bosch “P” Type Hole Nozzle

Injection Timing 0.201 rad (11.5 °) Before T.D.C. 0.175 rad (10 °) Before T.D.C.

Firing Order 1-2-3

Injection Pressure 1st. Stage 18.6 MPa (190 kgf/cm

2nd. Stage 22.6 MPa (230 kgf/cm

Compression Ratio 20 19 20

Lubricating System Forced Lubrication by Trochoid Pump

Cooling System Pressurized radiation, forced circulation with water pump

Starting System Electric Starting with Starter

Starting Support Device Pre-heating by Glow Plug in Combustion Chamber

Battery

12 V, 60 A (75D31R)

Charging Alternator 12 V, 360 W 12 V, 480 W

Fuel Diesel Fuel No.2-D or No.2-DLS

Lubricating Oil Better than CD class (API)

Lubricating Oil

Capacity

Oil Pan Depth

90 mm (3.54 in.)

Oil Pan Depth

124 mm (4.88 in.)

Weight (Dry) BB spec. kg (lbs) 148 (326) 152 (335) 148 (326) 151 (333)

* The specification described above is of the standard engine of each model.

* Conversion Formula : HP = 0.746 kW, PS = 0.7355 kW

83 × 92.4

(3.26 × 3.64)

27.2 / 2800

(36.5 / 2800)

31.3 / 2800

(42.0 / 2800)

32.7 / 2800

(43.8 / 2800)

5.6 L (1.48 U.S.gals)

7.0 L (1.85 U.S.gals)

12 V, 1.4 kW

87 × 92.4

(3.43 × 3.64)

22.7 / 2800

(30.4 / 2800)

26.1 / 2800

(35.0 / 2800)

27.4 / 2800

(36.7 / 2800)

2

, 2702 psi)

2

, 3271 psi)

87 × 102.4

(3.43 × 4.04)

23.9 / 2600

(32.1 / 2600)

27.2 / 2600

(36.5 / 2600)

28.4 / 2600

(38.1 / 2600)

12 V, 88 A

(115E41R)

W10275180

4

03-M-DI Series, WSM

KiSC issued 10, 2009 A

SPECIFICATIONS

Model V2203-M-DI V2403-M-DI

Number of Cylinders 4

Type Vertical, Water-cooled, 4 cycle DI diesel engine

Bore × Stroke mm × mm

(in. × in.)

3

Total Displacement cm

SAE Net Cont. kW/min

(HP/min

SAE Net Intermittent kW/min

(HP/min

SAE Gross Intermittent kW/min

(HP/min

Maximum Bare Speed min

Maximum Idling Speed min

(cu.in.) 2197 (134.07) 2434 (148.53)

-1

(rpm)

-1

(rpm))

-1

(rpm)

-1

(rpm))

-1

(rpm)

-1

(rpm))

-1

(rpm) 3000 3000

-1

(rpm) 750 to 850

87 × 92.4

(3.43 × 3.64)

30.2 / 2800

(40.5 / 2800)

34.8 / 2800

(46.7 / 2800)

36.4 / 2800

(48.8 / 2800)

87 × 102.4

(3.43 × 4.04)

31.8 / 2600

(42.6 / 2600)

36.6 / 2600

(34.8 / 2800)

38.0 / 2600

(51.0 / 2600)

Combustion Chamber Troiddal Type (Direct Injection)

Fuel Injection Pump Bosch “K” Type Mini Pump

Governor Centrifugal Ball Type, All Speed Mechanical Governor

Direction of Rotation Counter-Clockwise (viewed from flywheel side)

Injection Nozzle Bosch “P” Type Hole Nozzle

Injection Timing 0.192 rad (11 °) Before T.D.C.

Firing Order 1-3-4-2

2

Injection Pressure 1st. Stage 18.6 MPa (190 kgf/cm

2nd. Stage 22.6 MPa (230 kgf/cm

, 2702 psi)

2

, 3271 psi)

Compression Ratio 20

Lubricating System Forced Lubrication by Trochoid Pump

Cooling System Pressurized radiation, forced circulation with water pump

Starting System Electric Starting with Starter

12 V, 1.4 kW 12 V, 2.0 kW

Starting Suport Device Pre-heating by Glow Plug in Combustion Chamber

Battery 12 V, 88 A (115E41R) 12 V, 92 A (130E41R)

Charging Alternator 12 V, 480 W

Fuel Diesel Fuel No.2-D or No.2-DLS

Lubricating Oil Better than CD class (API)

Lubricating Oil

Capacity

Oil Pan Depth

90 mm (3.54 in.)

Oil Pan Depth

124 mm (4.88 in.)

7.6 L (2.01 U.S.gals)

9.5 L (2.51 U.S.gals)

Weight (Dry) BB spec. kg (lbs) 180 (397) 184 (406)

* The specification described above is of the standard engine of each model.

* Conversion Formula : HP = 0.746 kW, PS = 0.7355 kW

W10299960

5

03-M-DI Series, WSM

KiSC issued 10, 2009 A

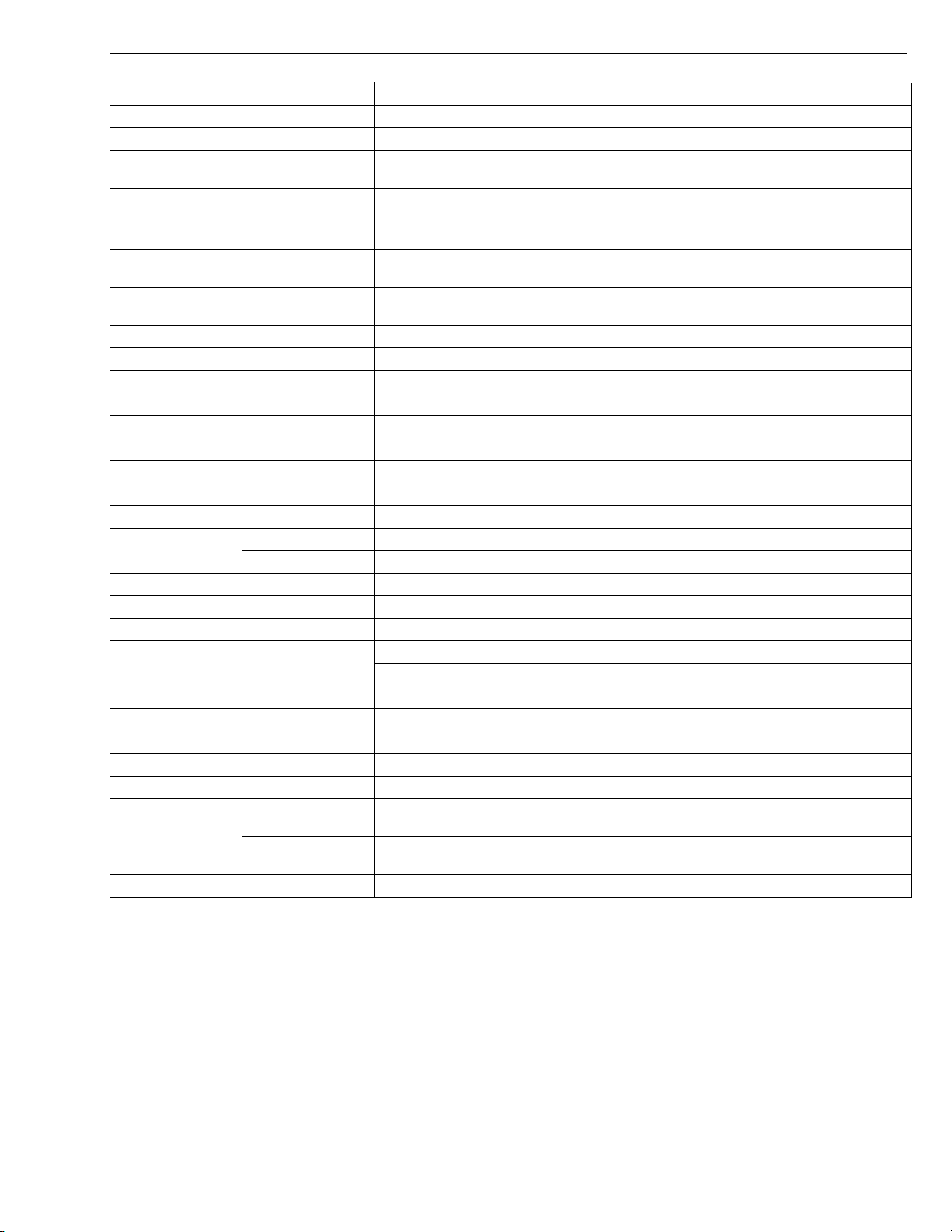

DIMENSIONS

DIMENSIONS

D1503-M-DI D1503-M-DI-T D1703-M-DI D1803-M-DI

A 599.2 mm

(23.59 in.)

B 643.5 mm

(25.33 in.)

C 414.2 mm

(16.31 in.)

D 229.3 mm

(9.03 in.)

E 514.4 mm

(20.25 in.)

599.2 mm

(23.59 in.)

644.0 mm

(25.35 in.)

414.2 mm

(16.31 in.)

229.8 mm

(9.05 in.)

514.4 mm

(20.25 in.)

572.1 mm

(22.52 in.)

643.3 mm

(25.33 in.)

414.0 mm

(16.30 in.)

229.3 mm

(9.03 in.)

507.1 mm

(19.96 in.)

575.9 mm

(22.67 in.)

685.0 mm

(26.97 in.)

419.0 mm

(16.50 in.)

266.0 mm

(10.47 in.)

499.0 mm

(19.65 in.)

W1031045

6

03-M-DI Series, WSM

KiSC issued 10, 2009 A

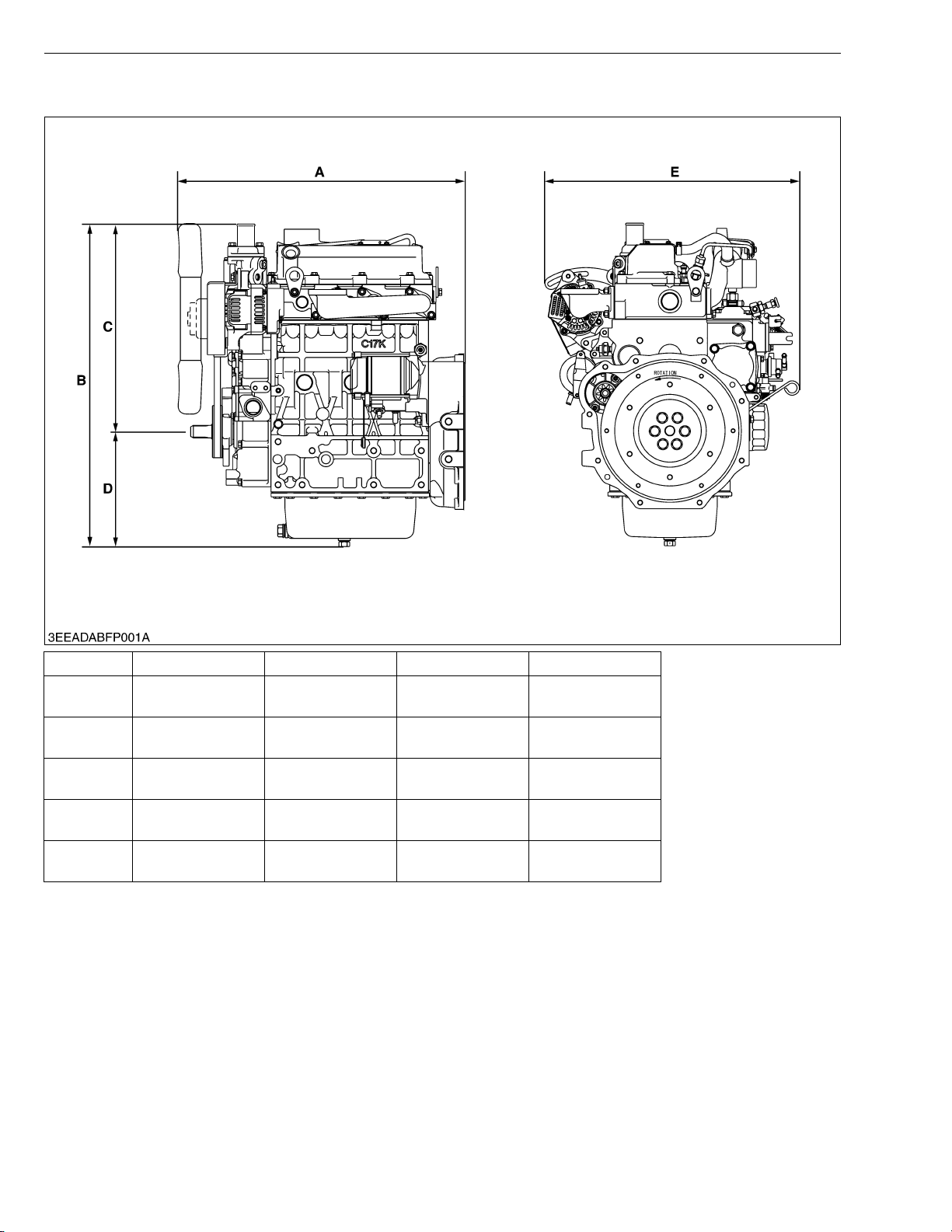

DIMENSIONS

V2203-M-DI V2403-M-DI

A 667.1 mm

(26.26 in.)

B 635.0 mm

(25.00 in.)

C 414.0 mm

(16.30 in.)

D 221.0 mm

(8.70 in.)

E 507.1 mm

(19.96 in.)

670.9 mm

(26.41 in.)

684.5 mm

(26.95 in.)

419.0 mm

(16.50 in.)

265.5 mm

(10.45 in.)

499.0 mm

(19.65 in.)

W1031355

7

MECHANISM

KiSC issued 10, 2009 A

CONTENTS

1. ENGINE BODY ............................................................................................... M-1

[1] HOLLOW CORE ....................................................................................... M-1

[2] PISTON...................................................................................................... M-1

[3] BUILT-IN DYNAMIC BALANCER (BALANCER MODEL ONLY) ......... M-2

[4] HALF-FLOATING HEAD COVER ............................................................ M-2

2. COOLING SYSTEM........................................................................................ M-3

[1] BOTTOM BYPASS SYSTEM................................................................... M-3

3. FUEL SYSTEM ............................................................................................... M-4

[1] GOVERNOR .............................................................................................. M-4

4. ELECTRICAL SYSTEM .................................................................................. M-6

[1] STARTER AUTO REDUCTION UNIT..................................................... M-6

(1) General ................................................................................................ M-6

(2) Basic Circuit ......................................................................................... M-6

(3) Component .......................................................................................... M-7

(4) Function ............................................................................................... M-7

03-M-DI Series, WSM

KiSC issued 10, 2009 A

1. ENGINE BODY

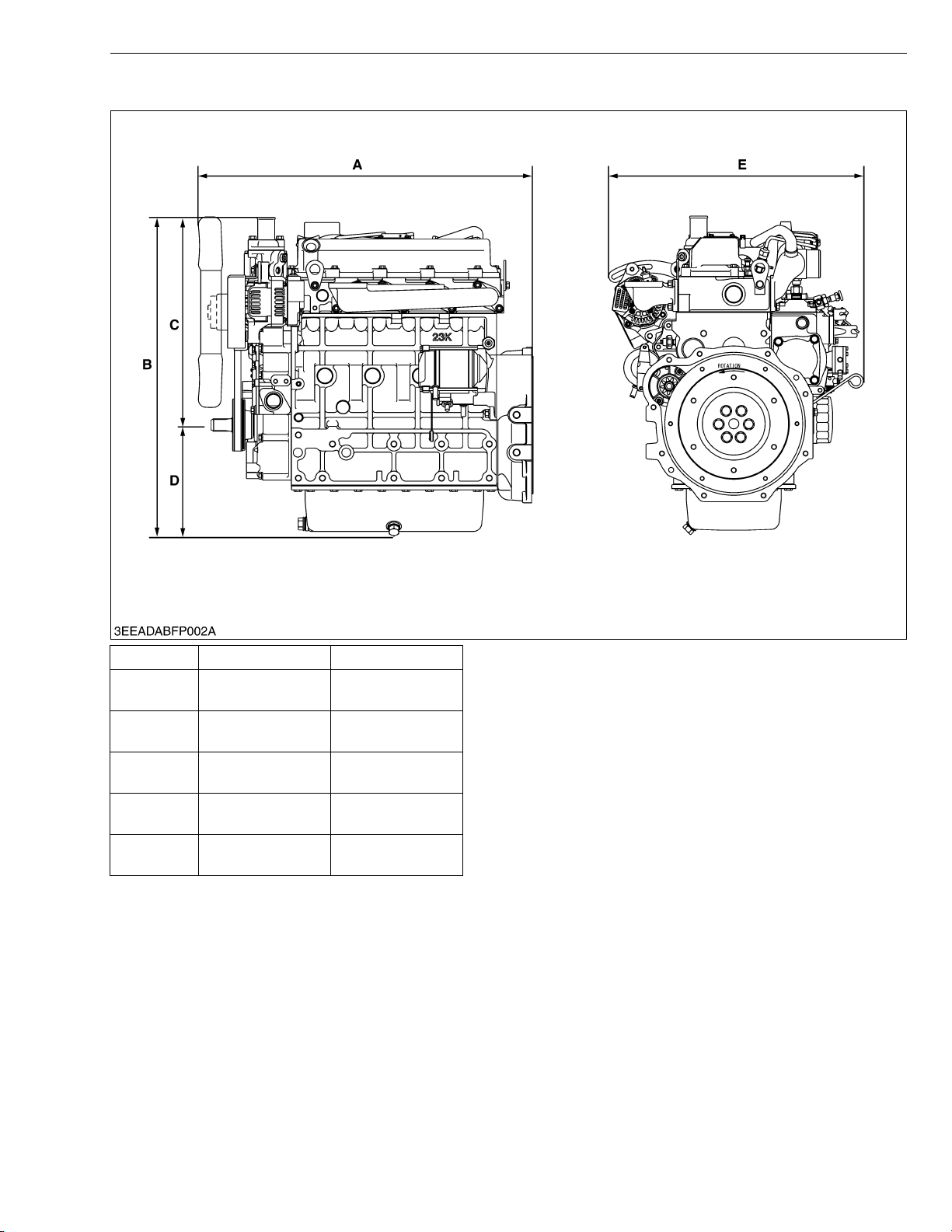

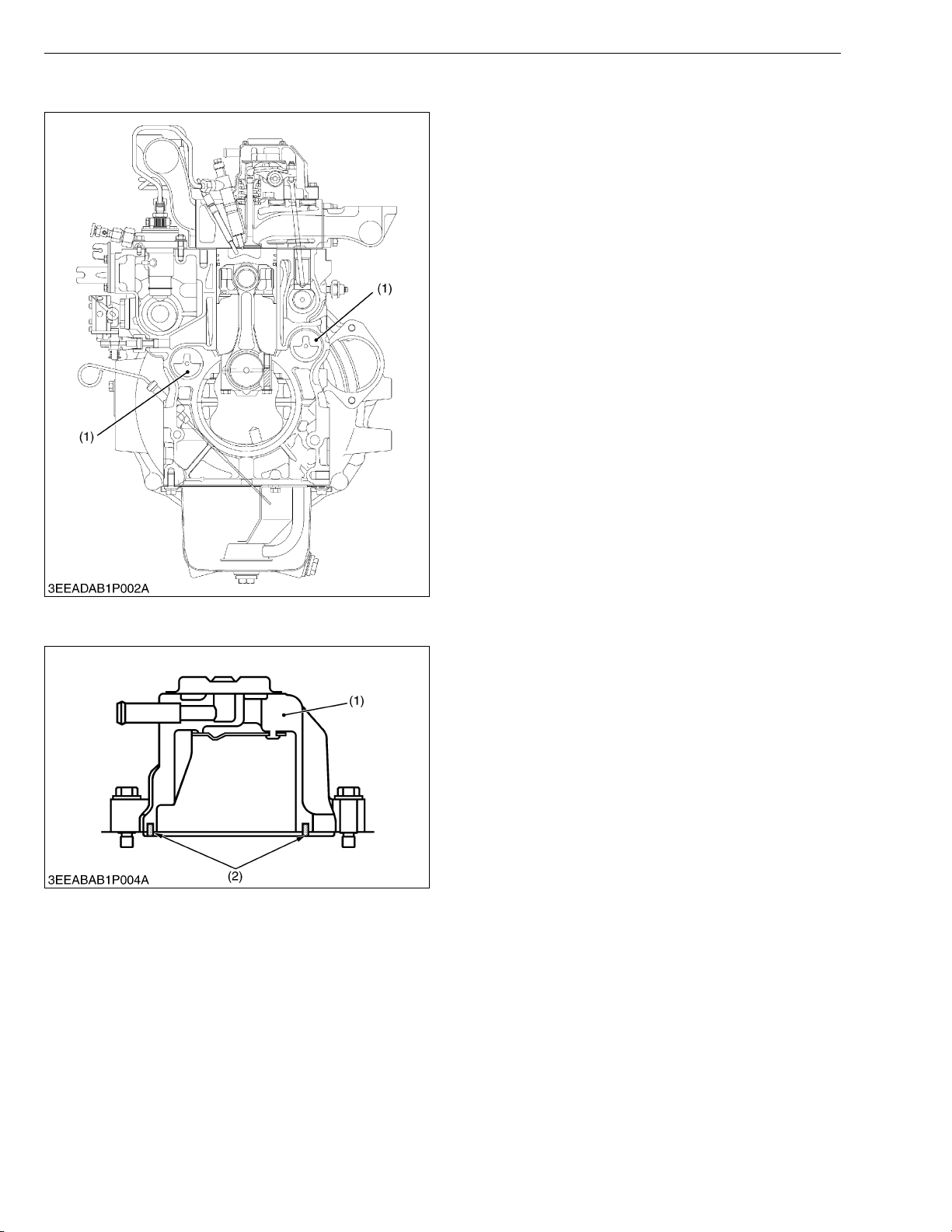

[1] HOLLOW CORE

[2] PISTON

DIESEL ENGINE

The cylinder block has a hollow core (1) already cast

inside the cylinder-to-cylinder water jacket.

In this core, there is a pair of vertical cooling

passages (right and left) as well as multiple horizontal

cooling channels that interconnect these cooling

passages. This design allows smoother cooling water

flow through the cylinder block, which cools down a wider

range between the cylinders more effectively.

(1) Hollow Core

W1013048

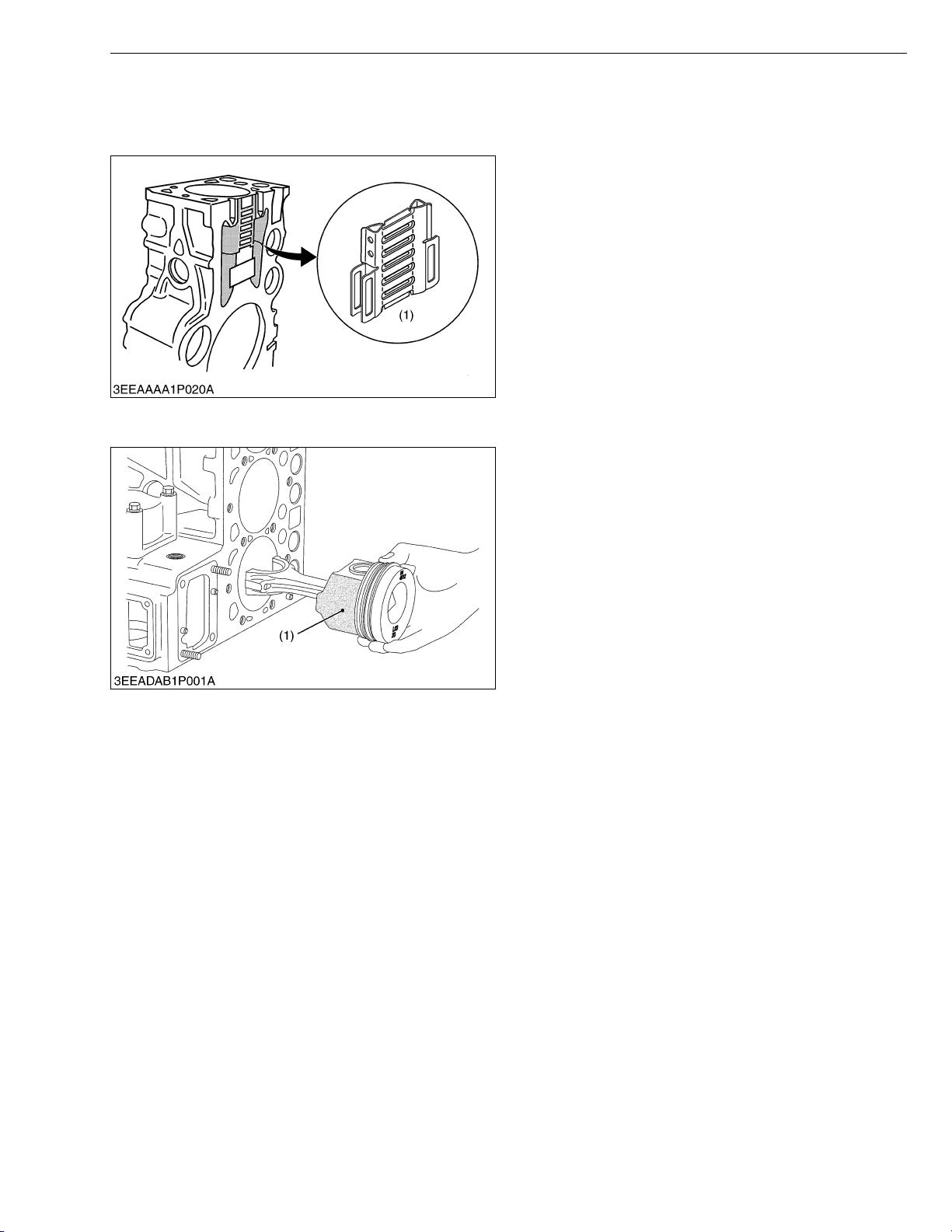

Piston’s skirt is coated with molybdenum

disulfide+, which reduces the piston slap noise and

thus the entire operating noise.

+Molybdenum disulfide (MoS

The molybdenum disulfide (1) serves as a solid

lubricant, like a Graphite or Teflon. This material helps

resist metal wears even with little lube oil.

(1) Molybdenum Disulfide

2)

W1013114

M-1

03-M-DI Series, WSM

KiSC issued 10, 2009 A

DIESEL ENGINE

[3] BUILT-IN DYNAMIC BALANCER (BALANCER MODEL ONLY)

Engine are sure to vibrate by piston’s reciprocation.

Theoretically, three-cylinder engines are much less

prone to cause vibration than four-cylinder ones (second

inertia, etc.). However, any engine has many moving

parts in addition to its pistons and cannot be completely

free from vibration.

The four cylinders engine V2203 and V2403 can be

fitted with balance weight on crankcase to absorb the

second inertia mentioned above and reduce vibration.

This engine is internally provide with two balancers

(1), one at the suction side and the other at the exhaust

side.

(1) Balancer

W1013221

[4] HALF-FLOATING HEAD COVER

The rubber packing (2) is fitted in to maintain the

cylinder head cover (1) 0.5 mm or so off the cylinder

head. This arrangement helps reduce noise coming from

the cylinder head.

(1) Cylinder Head Cover (2) Rubber Packing

W1013327

M-2

03-M-DI Series, WSM

KiSC issued 10, 2009 A

2. COOLING SYSTEM

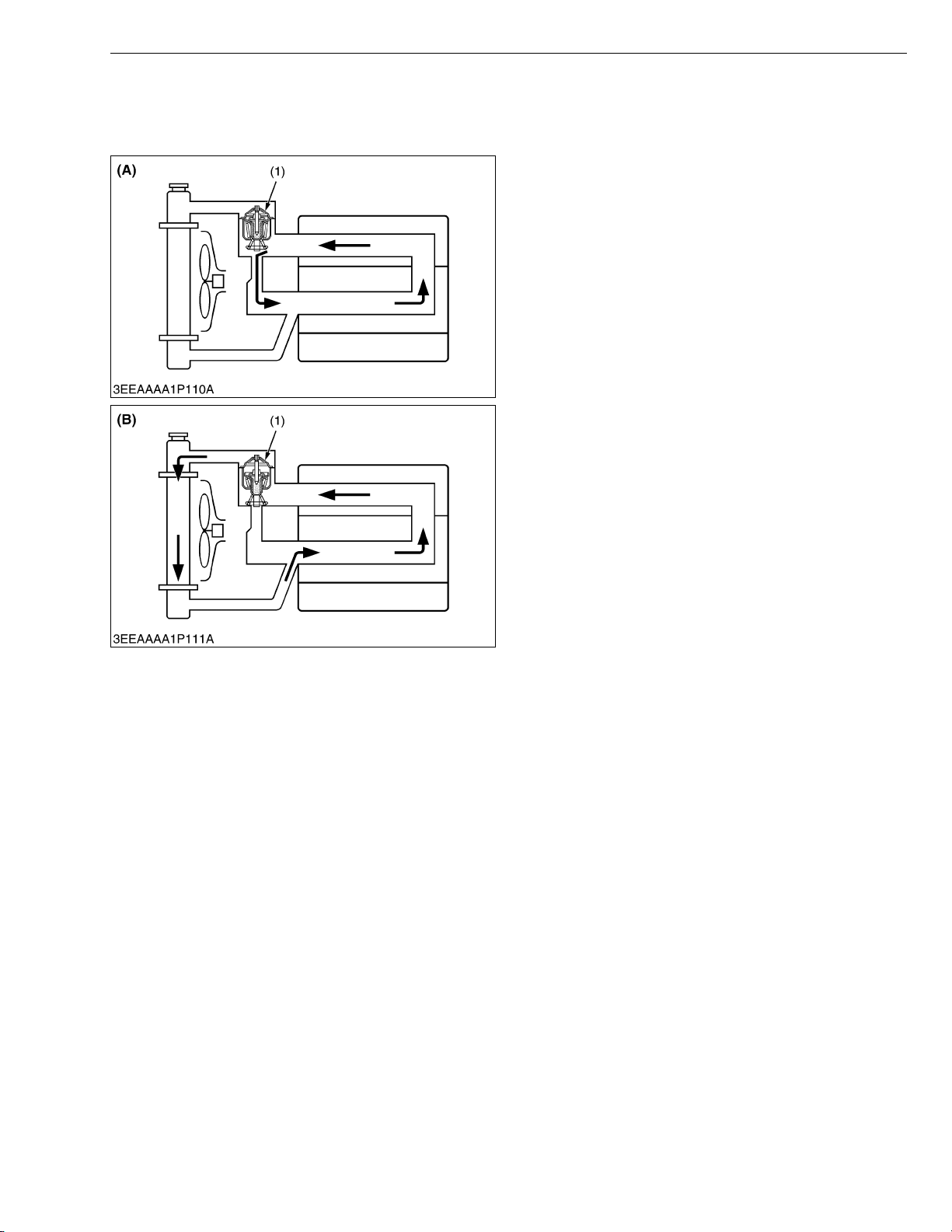

[1] BOTTOM BYPASS SYSTEM

DIESEL ENGINE

Bottom bypass system is introduced in 03-M-DI

Series for improving the cooling performance of the

radiator.

While the temperature of coolant in the engine is low,

the thermostat (1) is held closed and the coolant is

allowed to flow through the bypass pipe and to circulate

in the engine.

When the temperature exceeds the thermostat valve

opening level, the thermostat (1) fully opens itself to

prevent the hot coolant from flowing through the bypass

into the engine.

In this way, the radiator can increase its cooling

performance.

(1) Thermostat (A) Bypass Opened

(B) Bypass Closed

W1013406

M-3

03-M-DI Series, WSM

KiSC issued 10, 2009 A

3. FUEL SYSTEM

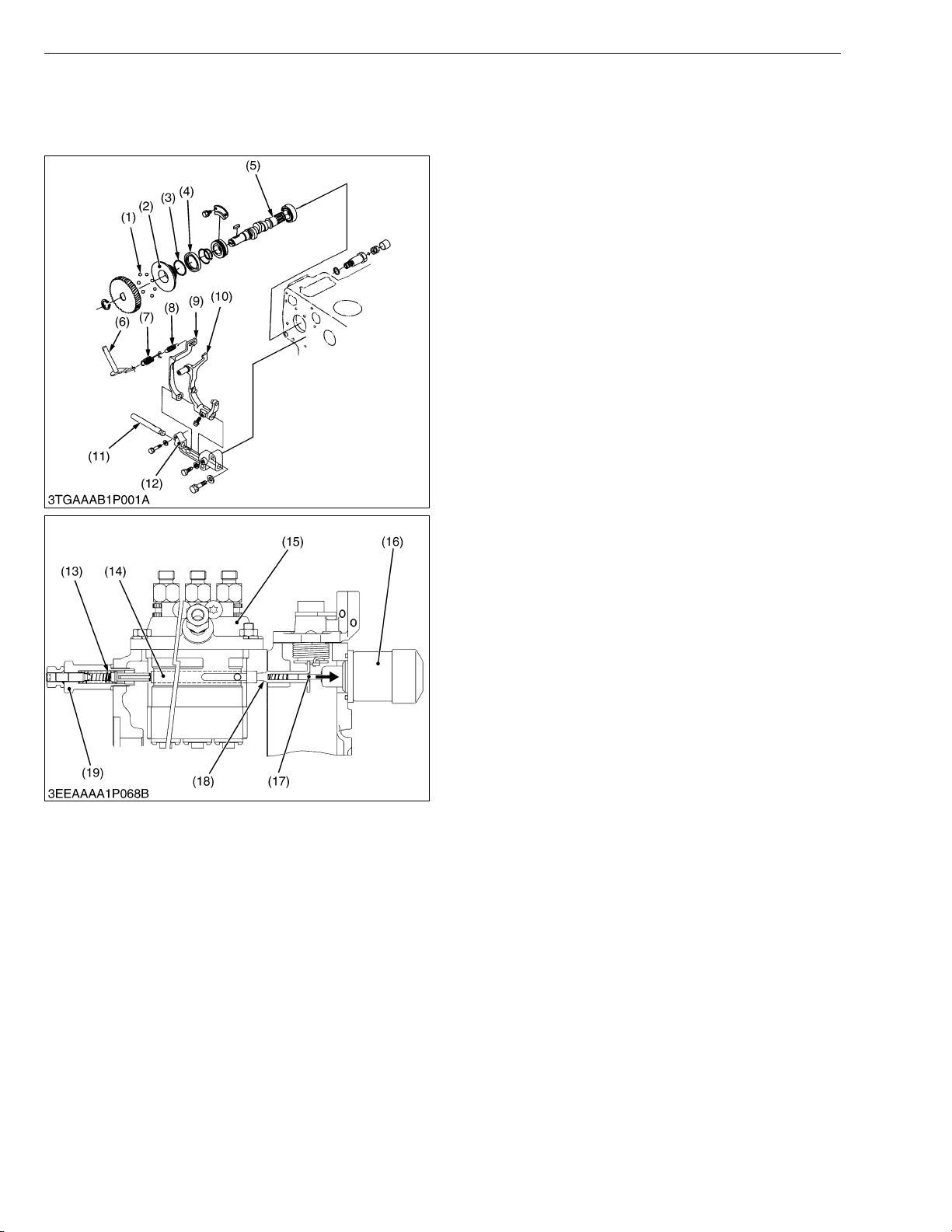

[1] GOVERNOR

DIESEL ENGINE

The governor serves to keep engine speed constant

by automatically adjusting the amount of fuel supplied to

the engine according to changes in the load. This engine

employs an all-speed governor which controls the

centrifugal force of the steel ball (1) weight, produced by

rotation of the fuel camshaft (5), and the tension of the

governor spring 1 (7) and 2 (8) are balanced.

(1) Steel Ball

(2) Governor Sleeve

(3) Steel Ball

(4) Governor Ball Case

(5) Fuel Camshaft

(6) Governor Lever

(7) Governor Spring 1

(8) Governor Spring 2

(9) Fork Lever 2

(10) Fork Lever 1

(11) Fork Lever Shaft

(12) Fork Lever Holder

W1017186

Q At Start

Flowing of the battery current into the engine stop

solenoid (16), the plunger (17) is actuated to arrow

direction.

Since the steel ball (1) have no centrifugal force, the

control rack (14) is pushed to the right by the start spring

(13). Accordingly, the control rack (14) moves to the

maximum injection position to assure easy starting.

(13) Start Spring

(14) Control Rack

(15) Injection Pump

(16) Engine Stop Solenoid

(17) Plunger

(18) Guide

(19) Idling Apparatus

W1017215

M-4

03-M-DI Series, WSM

KiSC issued 10, 2009 A

DIESEL ENGINE

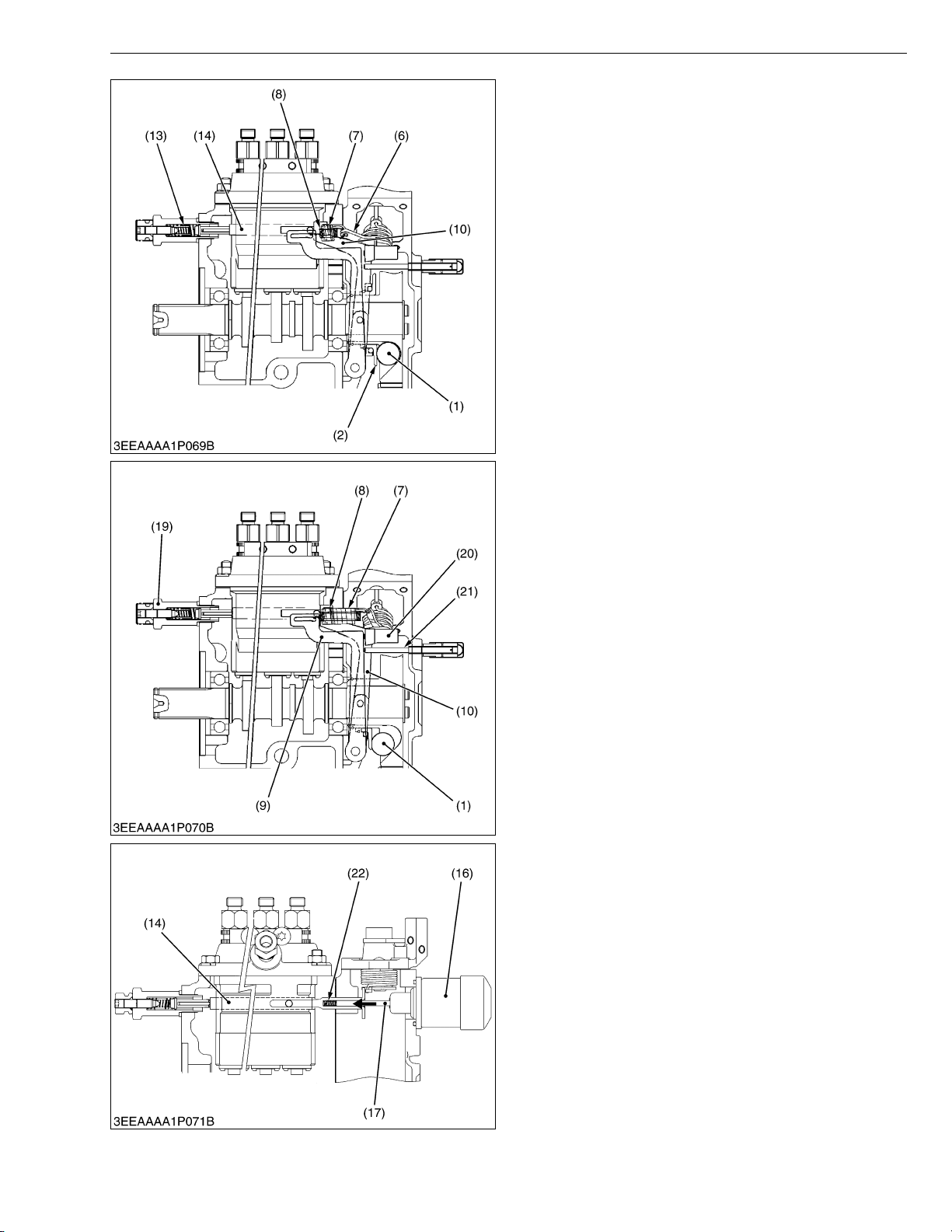

Q At Idling

When the speed control lever is set at the idling

position after the engine starts, the governor spring 1 (7)

does not work at all and the governor spring 2 (8) does

only act slightly. The governor sleeve (2) is pushed

leftward by a centrifugal force of steel ball (1).

Therefore, the fork lever 1 (10) and control rack (14)

are moved to the left by the governor sleeve (2) and then

the start spring (13) is compressed by the control rack

(14). As a result, the control rack (14) is kept at a position

where a centrifugal force of steel ball (1) and forces of

start spring (13), governor spring 2 (8) are balanced,

providing stable idling.

(1) Steel Ball

(2) Governor Sleeve

(6) Governor Lever

(7) Governor Spring 1

(8) Governor Spring 2

(10) Fork Lever 1

(13) Start Spring

(14) Control Rack

W1017317

Q At High Speed Running with Overload

When an overload is applied to the engine running at

a high speed, the centrifugal force of steel ball (1)

becomes small as the engine speed is dropped, and fork

lever 2 (9) is pulled to the right by the governor springs 1

(7) and 2 (8), increasing fuel injection. Though, fork lever

2 (9) becomes ineffective in increasing fuel injection

when it is stopped by the adjusting screw (21).

After that, when the force of torque spring (20)

becomes greater than the centrifugal force of the steel

ball (1), fork lever 1 (10) moves rightward to increase fuel

injection, causing the engine to run continuously at a high

torque.

(1) Steel Ball

(7) Governor Spring 1

(8) Governor Spring 2

(9) Fork Lever 2

(10)Fork Lever 1

(19) Idling Apparatus

(20) Torque Spring

(21) Adjusting Screw

W1017384

Q To Stop Engine

When the battery current stops, the plunger (17) of

engine stop solenoid (16) is returned to the original

position, the spring (22) to keep the control rack (14) in

“No fuel injection” position.

(14) Control Rack

(16) Engine Stop Solenoid

(17) Plunger

(22) Spring

M-5

W1018007

03-M-DI Series, WSM

KiSC issued 10, 2009 A

DIESEL ENGINE

4. ELECTRICAL SYSTEM

[1] STARTER AUTO REDUCTION UNIT

(1) General

The starter auto reduction unit (7) is designed to start the machine equipped with engine more reliably. This unit

has the following function by integrating an alternator (1) that puts out rpm-proportional pulses.

1. Fail-Safe Functions

a) Preventing the starter pinion from getting in mesh while the engine is runnning.

With the engine running, pulses from the alternator terminal P are constantly detected. Even if key switch (2) is

wrongly operated or the wiring gets short-circuited, the starter (5) can stay off, the starter (5) and flywheel ring gear

are effectively protected.

b) Starter auto reduction at a start of the engine.

When the engine has got started and the alternator (1) has reached the specified rpm, the electical current to the

starter (5) is automatically cut off, even if the key switch (2) is at the START position.

c) Safety mechanism in case of engine stall.

If the engine stalls with the key switch (2) at AC or START position, the key must be set once to OFF position for added

safety. The starter (5) is thus kept from turning on unexpectedly.

2. Other Features and Functions

a) Simplified wiring with built-in power relay.

The unit is internally provided with a power relay to get simpler wiring than ever before. If the key switch terminal AC,

ground cable or any other parts is wrongly connected, the starter (5) stays off. This helps identify wrong wiring more

easily.

b) With the output terminal for confirming engine start (Relay drive possible).

The unit has an external output terminal in order to confirm an engine start. An external relay (6) may also be

connected to this terminal. (Output current : below 200 mA)

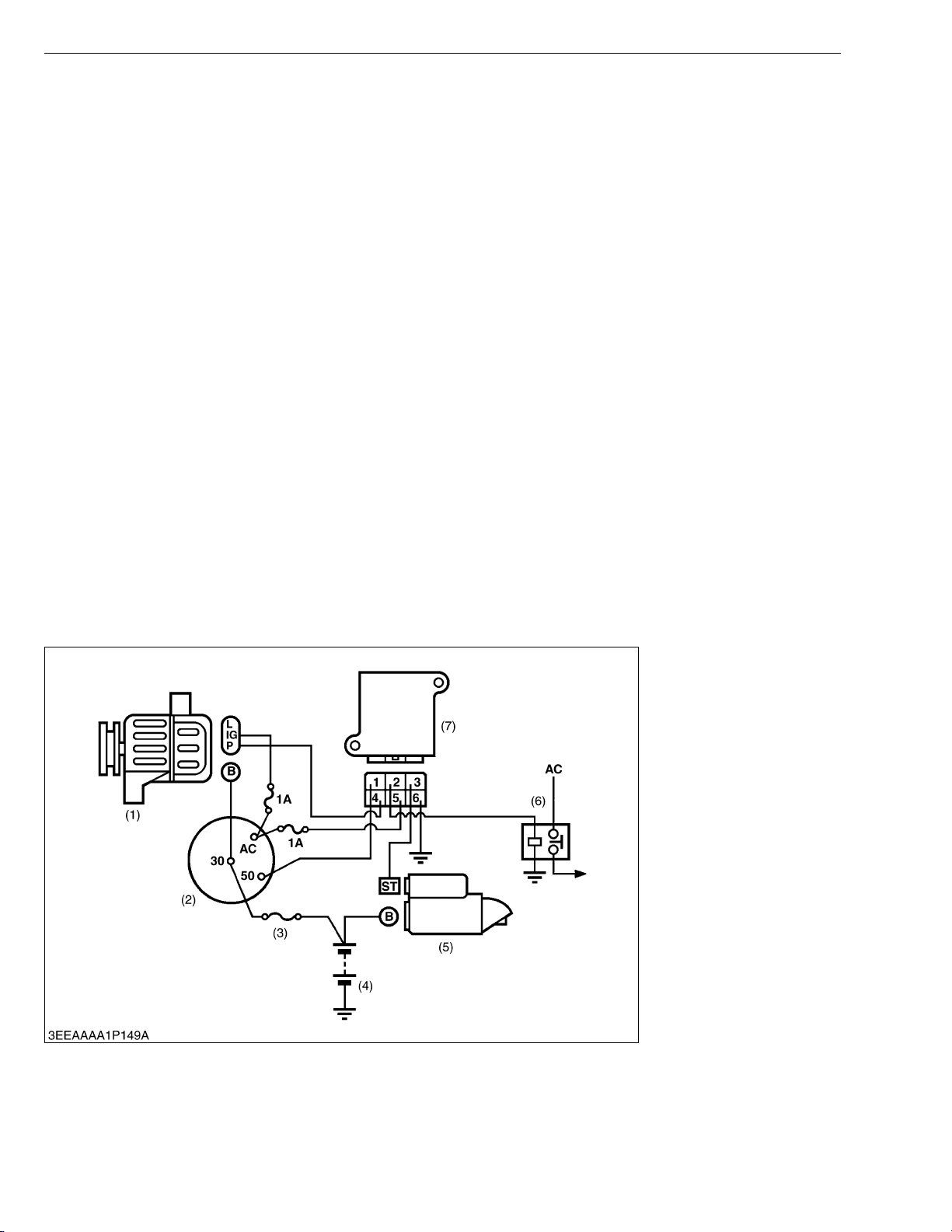

(2) Basic Circuit

(1) Alternator

(2) Key Switch

(3) Slow Blow Fuse

(4) Battery

(5) Starter

(6) External Relay

(7) Starter Auto Reduction Unit

W1014160

M-6

03-M-DI Series, WSM

KiSC issued 10, 2009 A

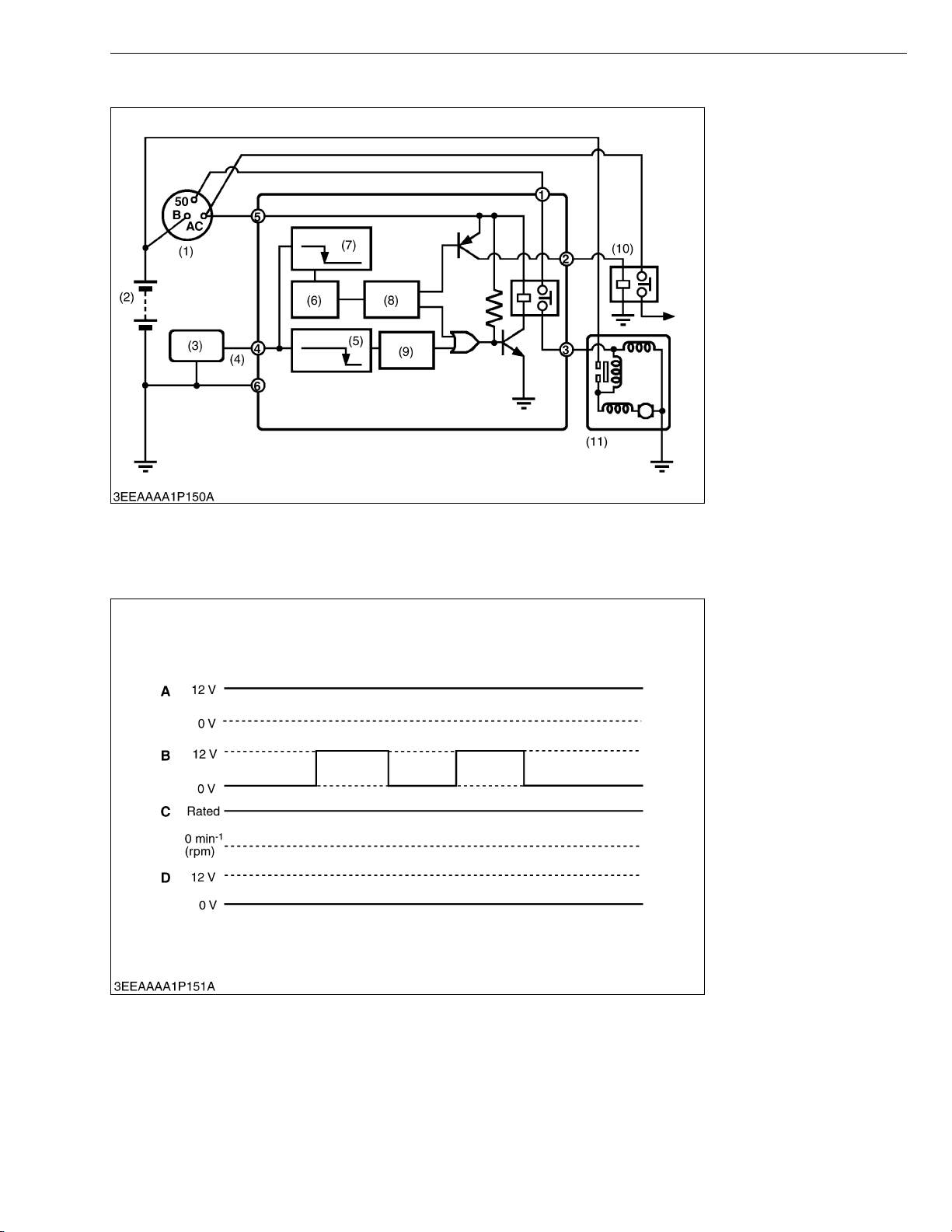

(3) Component

DIESEL ENGINE

(1) Key Switch

(2) Battery

(3) Alternator

(4) P terminal

(5) Detection High rpm (N2)

(6) Delay Curcuit

(7) Detection Low rpm (N1)

(8) Self Holding Circuit

(9) Self Holding Circuit

(10) External Relay

(11) Starter

W1014290

(4) Function

(A) Starter Auto Reduction

a) While Engine is Running

A : Key Switch AC Terminal

(Voltage)

B : Key Switch 50 Terminal

(Voltage)

C : Alternator Revolution

D : Starter ST Terminal

-1

(rpm))

(min

(Voltage)

W1014807

M-7

03-M-DI Series, WSM

KiSC issued 10, 2009 A

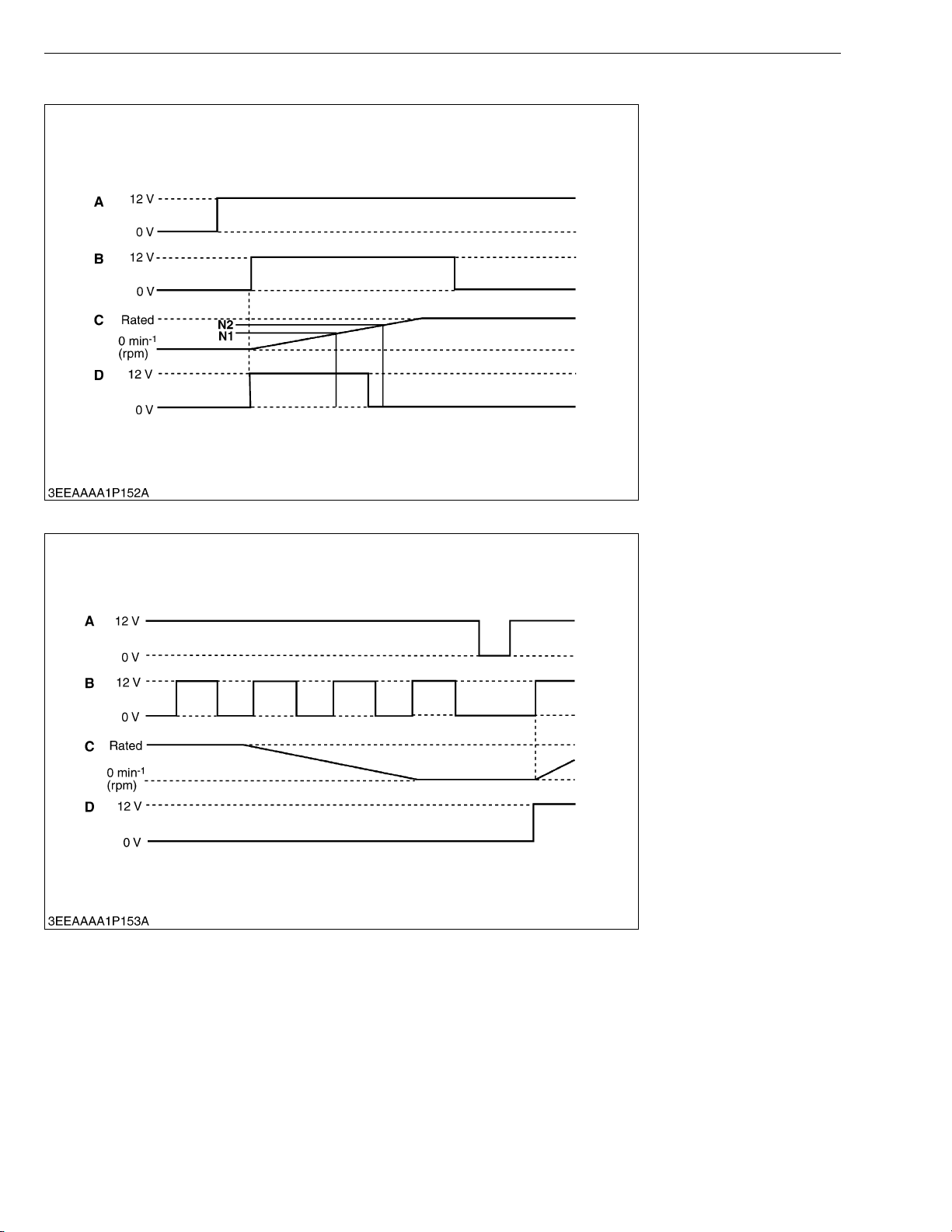

b) When Engine Starts Normally

DIESEL ENGINE

A : Key Switch AC Terminal

(Voltage)

B : Key Switch 50 Terminal

(Voltage)

C : Alternator Revolution

D : Starter ST Terminal

N1 :Detection Low rpm

N2 :Detection High rpm

-1

(rpm))

(min

(Voltage)

W1014965

c) When Engine Stalls

A : Key Switch AC Terminal

(Voltage)

B : Key Switch 50 Terminal

(Voltage)

C : Alternator Revolution

D : Starter ST Terminal

-1

(rpm))

(min

(Voltage)

W1015076

M-8

03-M-DI Series, WSM

KiSC issued 10, 2009 A

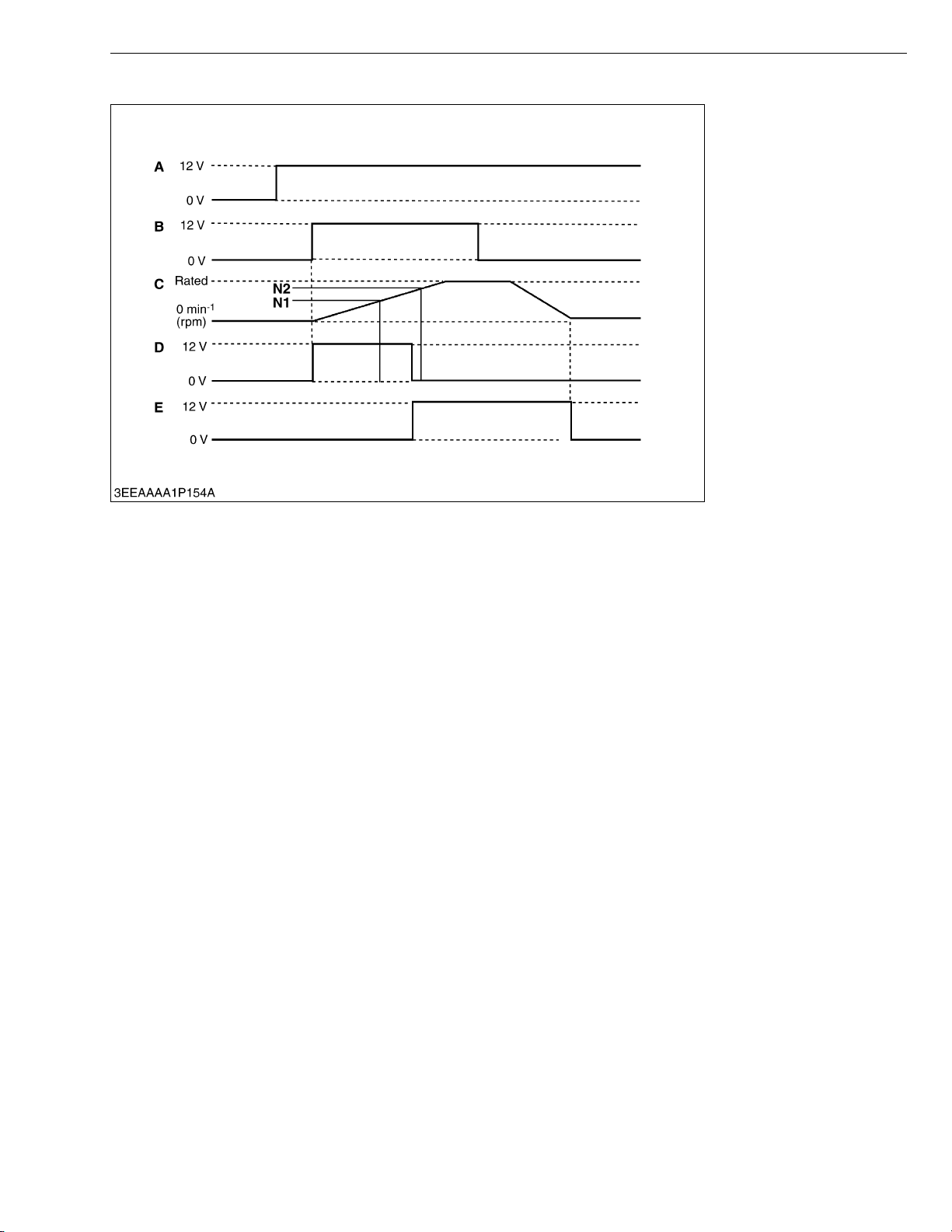

d) Output Terminal for Confirming Engine Start

DIESEL ENGINE

A : Key Switch AC Terminal

(Voltage)

B : Key Switch 50 Terminal

(Voltage)

C : Alternator Revolution

D : Starter ST Terminal

E : Output for Confirming

N1 :Detection Low rpm

N2 :Detection High rpm

-1

(rpm))

(min

(Voltage)

Engine Start (Voltage)

W1015212

M-9

SERVICING

KiSC issued 10, 2009 A

CONTENTS

1. GENERAL .........................................................................................................S-1

[1] ENGINE IDENTIFICATION ........................................................................S-1

(1) Model Name and Engine Serial Number ..............................................S-1

(2) Cylinder Number ...................................................................................S-2

[2] GENERAL PRECAUTION .........................................................................S-3

[3] TIGHTENING TORQUES ..........................................................................S-4

(1) Tightening Torques for Special Use Screws, Bolts and Nuts ...............S-4

(2) Tightening Torques for General Use Screws, Bolts and Nuts ..............S-4

[4] TROUBLESHOOTING ................................................................................S-5

[5] SERVICING SPECIFICATIONS ................................................................ S-8

[6] MAINTENANCE CHECK LIST ................................................................S-17

[7] CHECK AND MAINTENANCE ................................................................S-19

(1) Daily Check Points..............................................................................S-19

(2) Check Points of Every 50 Hours .........................................................S-20

(3) Check Points of Every 100 Hours .......................................................S-21

(4) Check Point of Every 200 Hours .........................................................S-23

(5) Check Points of Every 400 Hours .......................................................S-24

(6) Check Points of 500 Hours .................................................................S-26

(7) Check Points of Every 1 or 2 Months..................................................S-29

(8) Check Point of Every Year ..................................................................S-31

(9) Check Point of Every 800 Hours .........................................................S-31

(10)Check Points of Every 1500 Hours.....................................................S-32

(11)Check Point of Every 3000 Hours.......................................................S-33

(12)Check Points of Every 2 Years ...........................................................S-33

[8] SPECIAL TOOLS.....................................................................................S-34

2. ENGINE BODY ..............................................................................................S-42

[1] CHECKING AND ADJUSTING ...............................................................S-42

[2] DISASSEMBLING AND ASSEMBLING..................................................S-43

(1) Draining Coolant and Oil.....................................................................S-43

(2) External Components .........................................................................S-43

(3) Cylinder Head and Valves ..................................................................S-44

(4) Timing Gears, Camshaft and Fuel Camshaft......................................S-49

(5) Piston and Connecting Rod ................................................................S-55

(6) Crankshaft...........................................................................................S-58

[3] SERVICING ..............................................................................................S-61

(1) Cylinder Head and Valves ..................................................................S-61

(2) Timing Gears, Camshaft and Fuel Camshaft......................................S-66

(3) Piston and Connecting Rod ................................................................S-70

(4) Crankshaft...........................................................................................S-73

(5) Cylinder...............................................................................................S-79

3. LUBRICATING SYSTEM ...............................................................................S-81

[1] Checking ...................................................................................................S-81

[2] Servicing ...................................................................................................S-82

4. COOLING SYSTEM.......................................................................................S-83

[1] CHECKING AND ADJUSTING ...............................................................S-83

[2] DISASSEMBLING AND ASSEMBLING...................................................S-85

5. FUEL SYSTEM ..............................................................................................S-86

[1] CHECKING AND ADJUSTING ...............................................................S-86

(1) Injection Pump.................................................................................... S-86

KiSC issued 10, 2009 A

(2) Injection Nozzle .................................................................................. S-88

6. ELECTRICAL SYSTEM................................................................................. S-89

[1] CHECKING .............................................................................................. S-89

(1) Starter................................................................................................. S-89

(2) Alternator............................................................................................ S-90

(3) Glow Plug ........................................................................................... S-91

(4) Engine Stop Solenoid......................................................................... S-91

(5) Glow Lamp Relay ............................................................................... S-92

(6) Starter Auto Reduction Unit................................................................ S-92

[2] DISASSEMBLING AND ASSEMBLING ................................................. S-93

(1) Starter................................................................................................. S-93

(2) Alternator............................................................................................ S-93

[3] SERVICING.............................................................................................. S-96

(1) Starter................................................................................................. S-96

(2) Alternator............................................................................................ S-98

(3) Wiring Diagram................................................................................. S-100

7. TURBO CHARGER SYSTEM .................................................................... S-101

[1] CHECKING ............................................................................................ S-101

[2] DISASSEMBLING AND ASSEMBLING ............................................... S-102

03-M-DI Series, WSM

KiSC issued 10, 2009 A

1. GENERAL

[1] ENGINE IDENTIFICATION

(1) Model Name and Engine Serial Number

When contacting the manufacture, always specify your engine

model name and serial number.

The engine model and its serial number need to be identified

before the engine can be serviced or parts replaced.

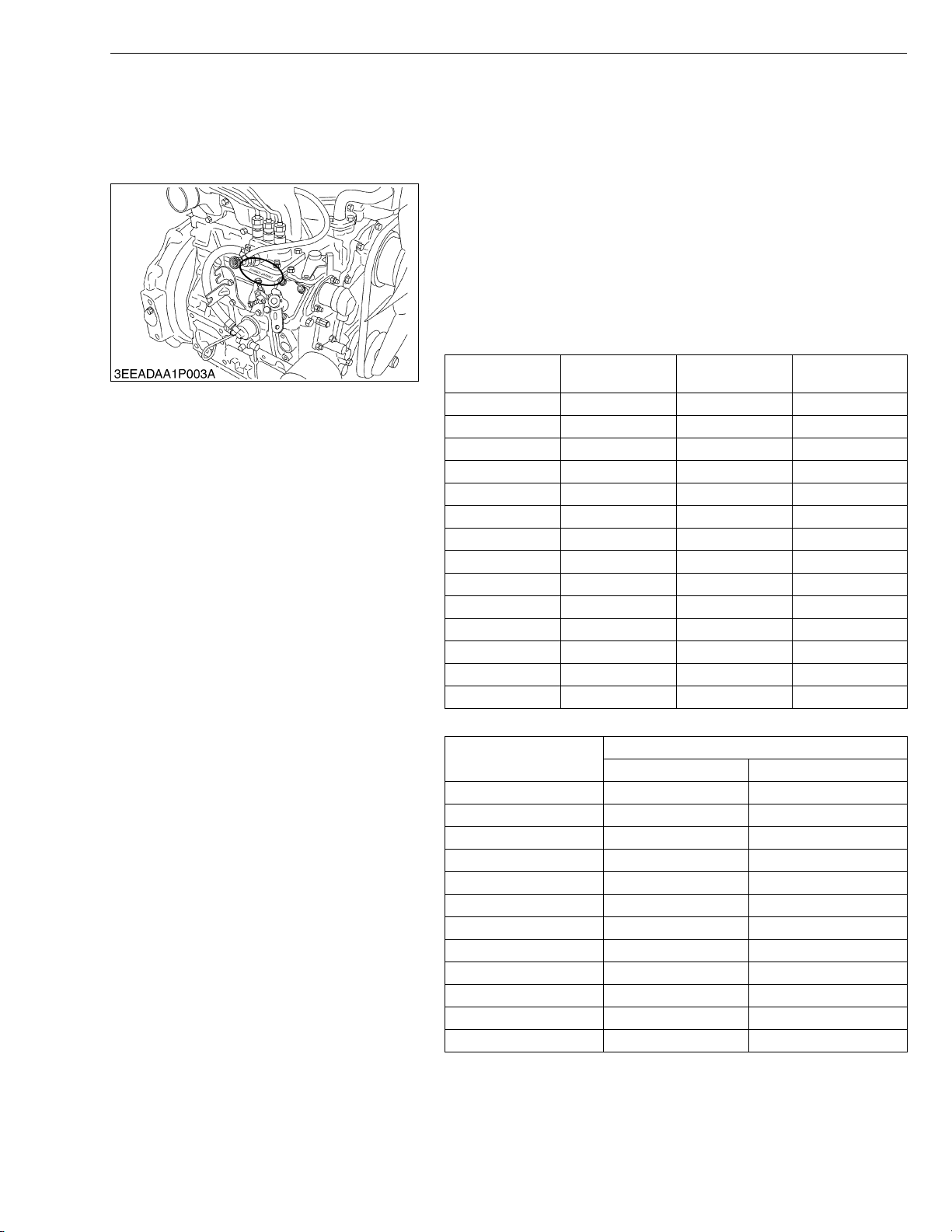

Q Engine Serial Number

The engine serial number is an identified number for the engine.

It is marked after the engine model number.

It indicates month and year of manufacture as follows.

• Year of manufacture

Alphabet or

Number

• Month of manufacture

January A0001 ~ A9999 B0001 ~

February C0001 ~ C9999 D0001 ~

March E0001 ~ E9999 F0001 ~

April G0001 ~ G9999 H0001 ~

May J0001 ~ J9999 K0001 ~

June L0001 ~ L9999 M0001 ~

July N0001 ~ N9999 P0001 ~

August Q0001 ~ Q9999 R0001 ~

September S0001 ~ S9999 T0001 ~

October U0001 ~ U9999 V0001 ~

November W0001 ~ W9999 X0001 ~

December Y0001 ~ Y9999 Z0001 ~

e.g. D1803-1A0001

“1” indicates 2001 and “A” indicates January.

So, 1A indicates that the engine was manufactured on January,

2001.

DIESEL ENGINE

Year

1 2001 F 2015

2 2002 G 2016

3 2003 H 2017

4 2004 J 2018

5 2005 K 2019

6 2006 L 2020

7 2007 M 2021

8 2008 N 2022

9 2009 P 2023

A 2010 R 2024

B 2011 S 2025

C 2012 T 2026

D 2013 V 2027

E 2014

Month

0001 ~ 9999 10000 ~

Alphabet or

Number

Engine Serial Number

Yea r

W1010477

S-1

03-M-DI Series, WSM

KiSC issued 10, 2009 A

(2) Cylinder Number

DIESEL ENGINE

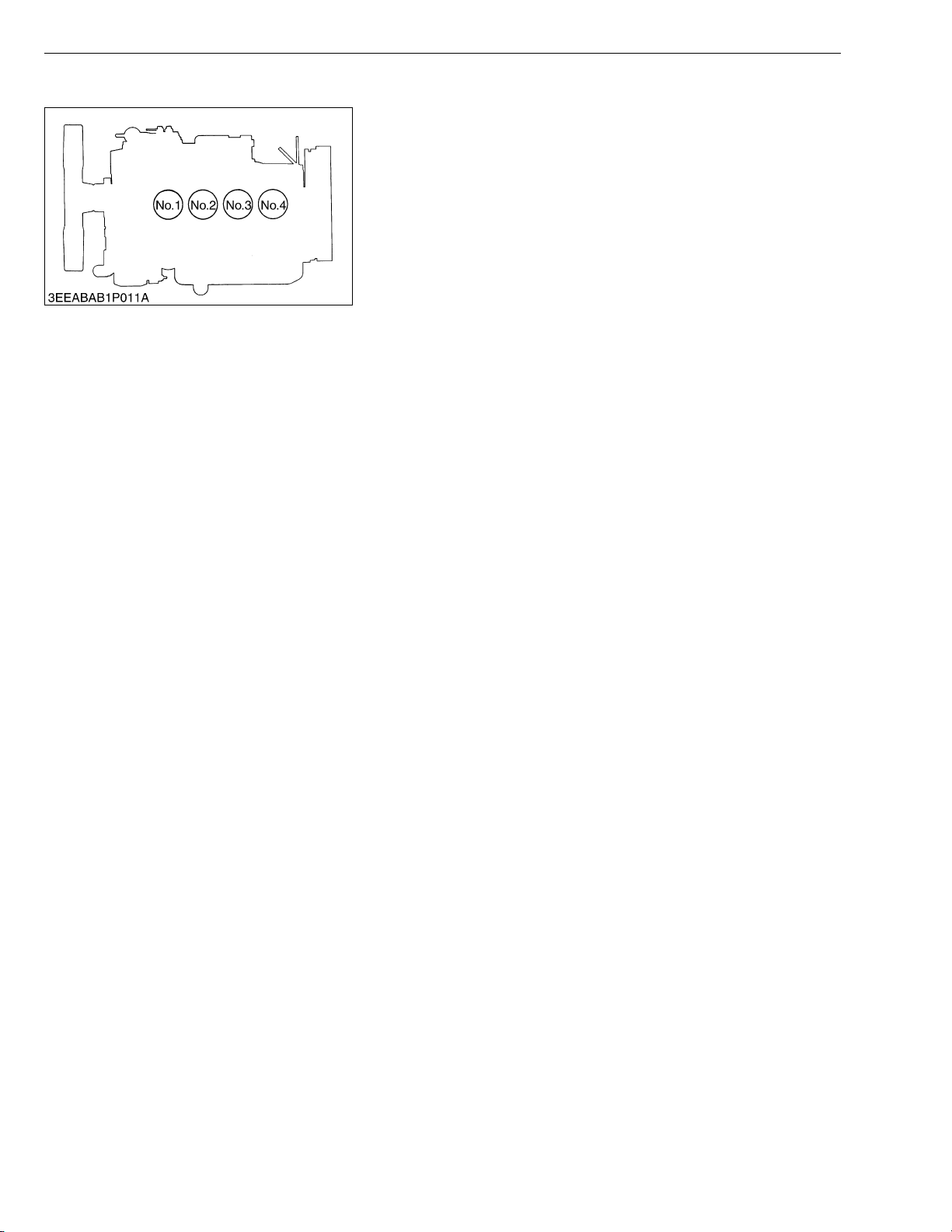

The cylinder numbers of 03-M-DI Series diesel engine are

designated as shown in the figure.

The sequence of cylinder numbers is given as No.1, No.2, No.3

and No.4 starting from the gear case side.

W1011077

S-2

03-M-DI Series, WSM

KiSC issued 10, 2009 A

[2] GENERAL PRECAUTION

DIESEL ENGINE

• During disassembly, carefully arrange removed parts in a clean

area to prevent confusion later. Screws, bolts and nuts should be

replaced in their original position to prevent reassembly errors.

• When special tools are required, use KUBOTA genuine special

tools. Special tools which are not frequently used should be

made according to the drawings provided.

• Before disassembling or servicing live wires, make sure to

always disconnect the grounding cable from the battery first.

• Remove oil and dirt from parts before measuring.

• Use only KUBOTA genuine parts for parts replacement to

maintain engine performance and to ensure safety.

• Gaskets and O-rings must be replaced during reassembly.

Apply grease to new O-rings or oil seals before assembling.

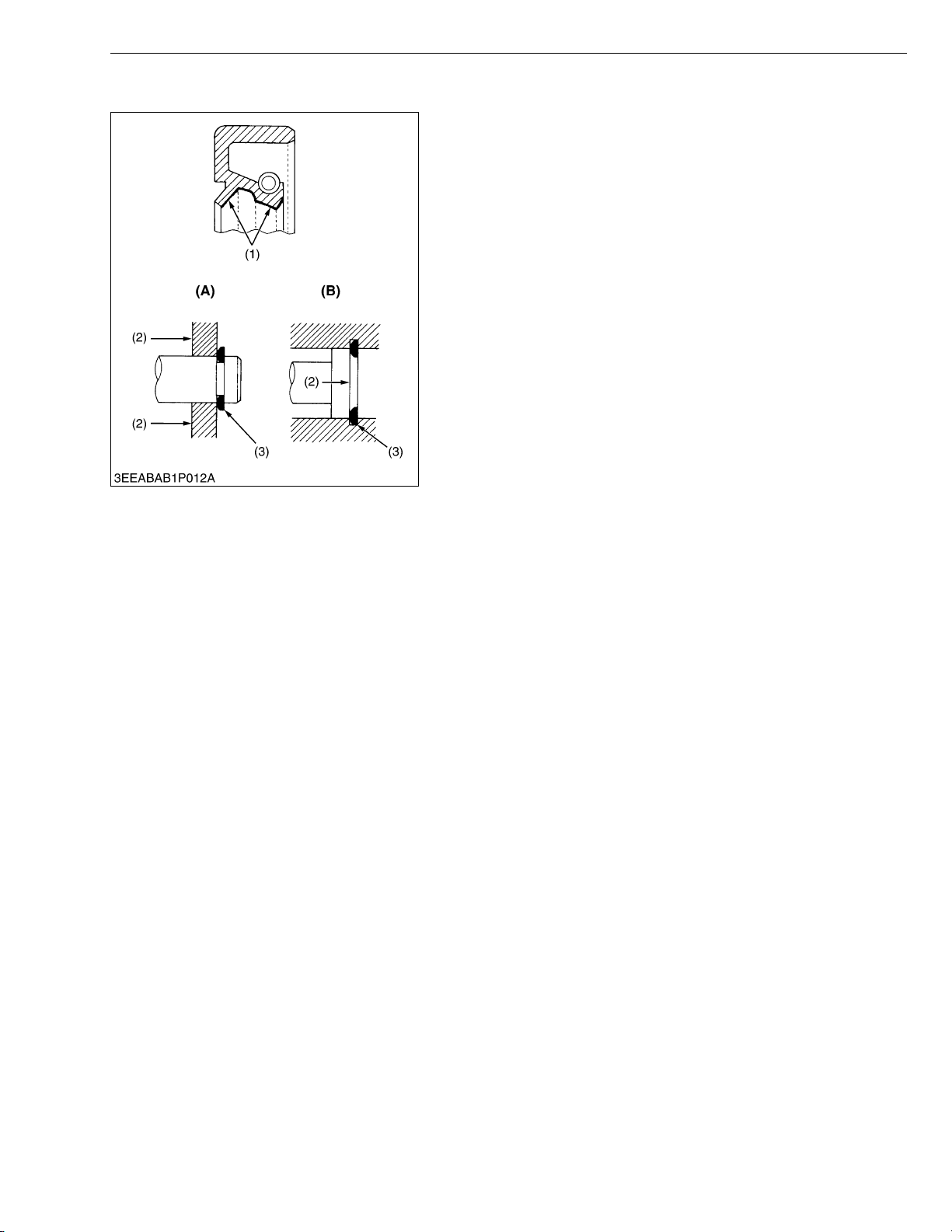

• When reassembling external or internal snap rings, position them

so that the sharp edge faces against the direction from which

force is applied.

• Be sure to perform run-in the serviced or reassembled engine.

Do not attempt to give heavy load at once, or serious damage

may result to the engine.

(1) Grease

(2) Force

(3) Place the Sharp Edge against the

Direction of Force

(A) External Snap Ring

(B) Internal Snap Ring

W1011734

S-3

03-M-DI Series, WSM

KiSC issued 10, 2009 A

DIESEL ENGINE

[3] TIGHTENING TORQUES

Screws, bolts and nuts must be tightened to the specified torque using a torque wrench, several screws, bolts and

nuts such as those used on the cylinder head must be tightened in proper sequence and the proper torque.

(1) Tightening Torques for Special Use Screws, Bolts and Nuts

NOTEQ

• In removing and applying the screws, bolts and nuts marked with “*”, a pneumatic wrench or similar

pneumatic tool, if employed, must be used with enough care not to get them seized.

• For “*” marked screws, bolts and nuts on the table, apply engine oil to their threads and seats before

tightening.

• The letter “M” in Size x Pitch means that the screw, bolt or nut dimension stands for metric. The size is

the nominal outside diameter in mm of the threads. The pitch is the nominal distance in mm between two

threads.

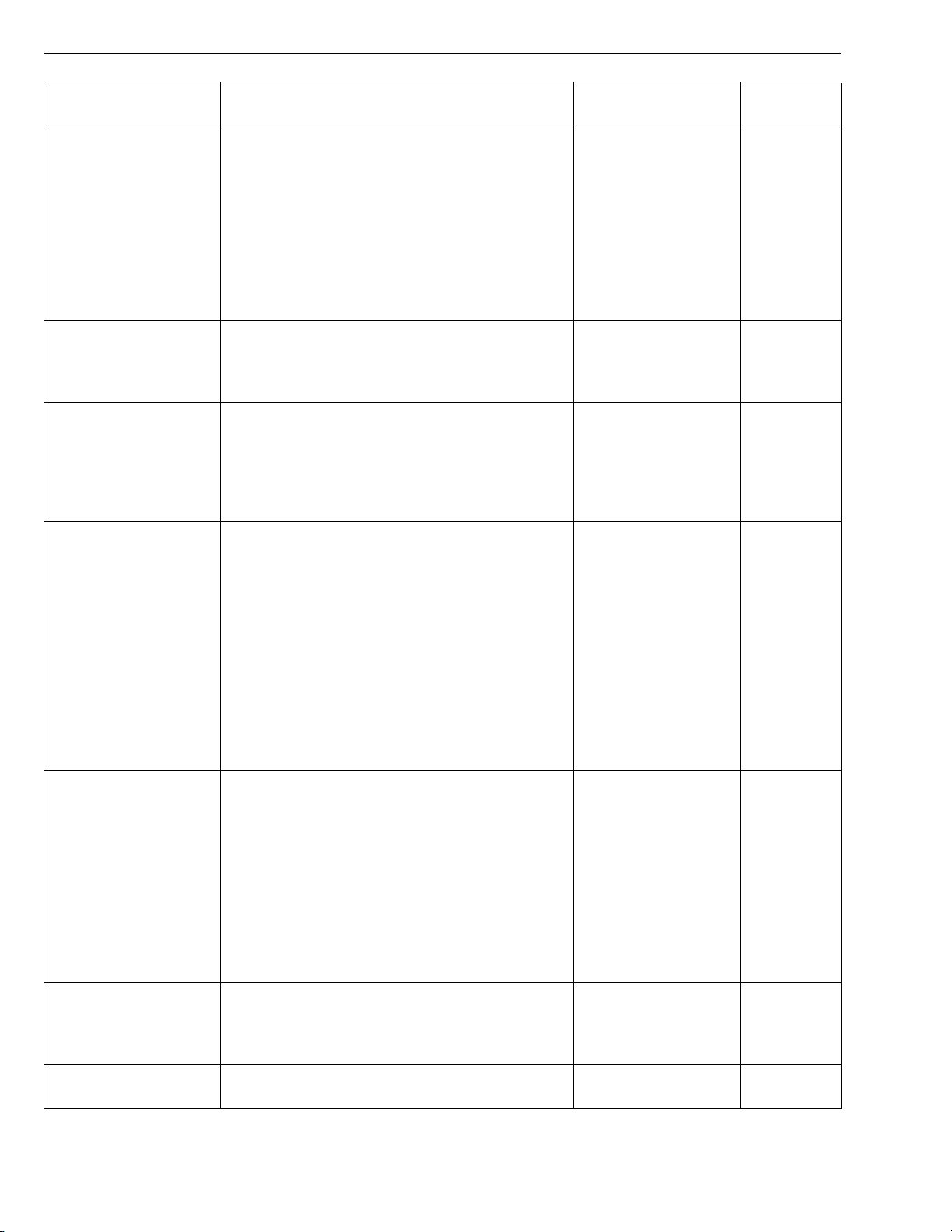

Item Size x Pitch N·m kgf·m ft-lbs

Cylinder head cover screw

* Cylinder head screw

* Main bearing case screw 1

* Main bearing case screw 2

* Flywheel screw

* Connecting rod screw

* Rocker arm bracket screw

* Idle gear shaft screw

Fan drive pulley mounting nut

* Bearing case cover screw

Glow plug

Nozzle holder clamp screw

Oil Switch taper screw

Injection pipe retaining nut

Overflow pipe assembly retaining screw

Camshaft set screw

Hi-idling body

M6 × 1.0

M11 × 1.25

M9 × 1.25

M10 × 1.25

M12 × 1.25

M8 × 1.0

M8 × 1.25

M8 × 1.25

–

M8 × 1.25

M10 × 1.25

–

PT 1/8

M12 × 1.5

–

M8 × 1.25

–

6.9 to 11.3

93.1 to 98.0

46.1 to 50.9

68.6 to 73.5

98.0 to 107.8

44.1 to 49.0

23.5 to 27.5

23.5 to 27.5

137.3 to 156.9

23.5 to 27.5

19.6 to 24.5

25.5 to 29.4

14.7 to 19.6

14.7 to 24.5

9.8 to 11.3

23.5 to 27.5

44.1 to 49.0

0.7 to 1.15

9.5 to 10.0

4.7 to 5.2

7.0 to 7.5

10.0 to 11.0

4.5 to 5.0

2.4 to 2.8

2.4 to 2.8

14.0 to 16.0

2.4 to 2.8

2.0 to 2.5

2.6 to 3.0

1.5 to 2.0

1.5 to 2.5

1.0 to 1.15

2.4 to 2.8

4.5 to 5.0

5.1 to 8.32

68.7 to 72.3

34.0 to 37.6

50.6 to 54.2

72.3 to 79.5

32.5 to 36.2

17.4 to 20.3

17.4 to 20.3

101.3 to 115.7

17.4 to 20.3

14.5 to 18.1

18.8 to 21.7

10.8 to 14.5

10.8 to 18.1

7.2 to 8.3

17.4 to 20.3

32.6 to 36.3

W1013236

(2) Tightening Torques for General Use Screws, Bolts and Nuts

Grade

Nominal Unit

Diameter

M6 7.9 to 9.3 0.80 to 0.95 5.8 to 6.9 9.8 to 11.3 1.00 to 1.15 7.23 to 8.32

M8 17.7 to 20.6 1.8 to 2.1 13.0 to 15.2 23.5 to 27.5 2.4 to 2.8 17.4 to 20.3

M10 39.2 to 45.1 4.0 to 4.6 28.9 to 33.3 48.1 to 55.9 4.9 to 5.7 35.4 to 41.2

M12 62.8 to 72.6 6.4 to 7.4 46.3 to 53.5 77.5 to 90.2 7.9 to 9.2 57.1 to 66.5

Screw and bolt material grades are shown by numbers punched on the screw and bolt heads. Prior to

tightening, be sure to check out the numbers as shown below.

Punched number Screw and bolt material grade

None or 4 Standard screw and bolt SS400, S20C

7 Special screw and bolt S43C, S48C (Refined)

Standard Screw and Bolt

Special Screw and Bolt

N·m kgf·m ft-lbs N·m kgf·m ft-lbs

W10371750

W1012705

S-4

03-M-DI Series, WSM

KiSC issued 10, 2009 A

[4] TROUBLESHOOTING

DIESEL ENGINE

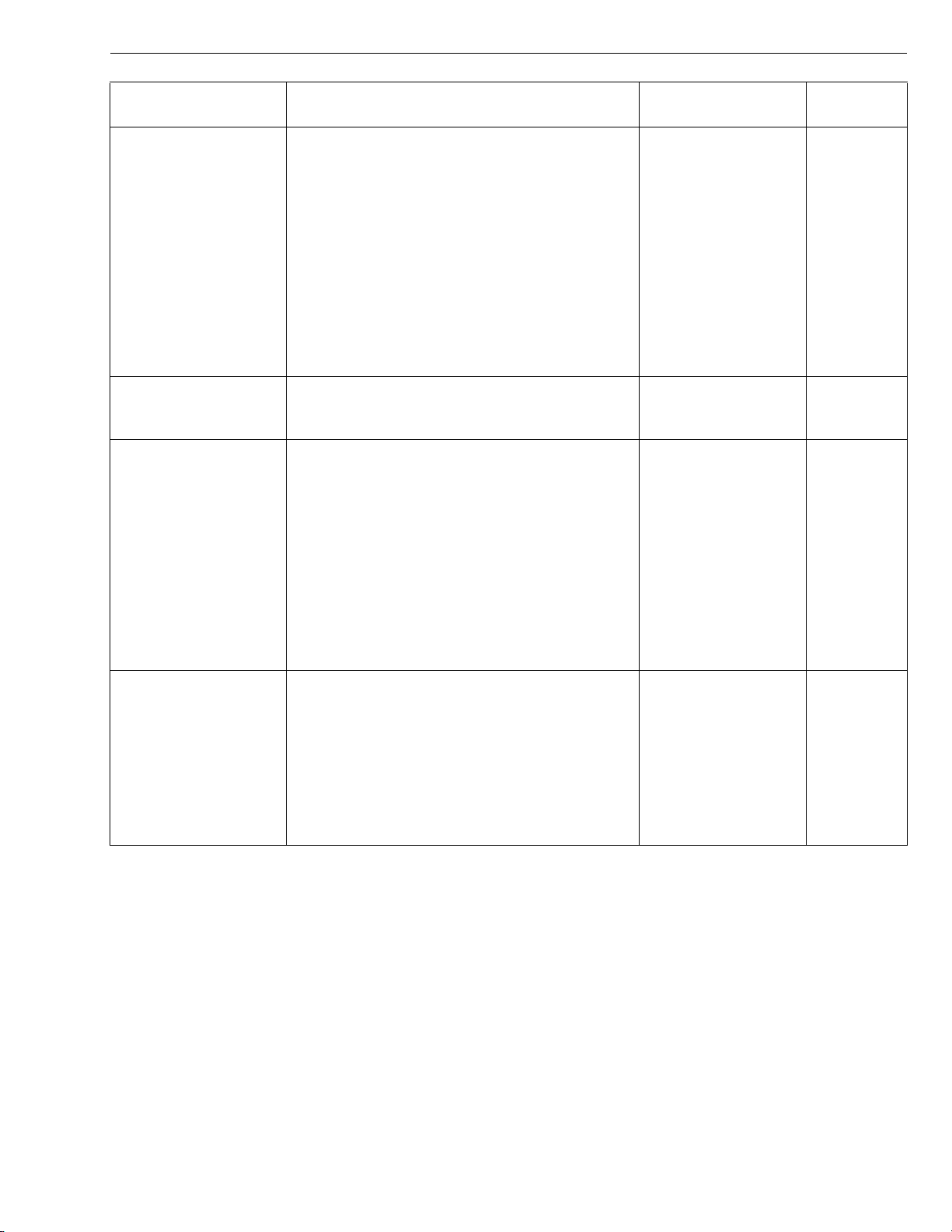

Symptom Probable Cause Solution

Engine Does Not

Start

• No fuel

• Air in the fuel system

• Water in the fuel system

Replenish fuel

Vent air

Change fuel and

repair or replace fuel

system

• Fuel pipe clogged

• Fuel filter clogged

• Excessively high viscosity of fuel or engine oil

at low temperature

• Fuel with low cetane number

• Fuel leak due to loose injection pipe retaining

Clean

Clean or change

Use specified fuel or

engine oil

Use specified fuel

Tighten retaining nut

nut

• Incorrect injection timing

• Fuel camshaft worn

• Injection nozzle clogged

• Injection pump malfunctioning

• Seizure of crankshaft, camshaft, piston,

Adjust

Replace

Replace

Replace

Repair or replace

cylinder or bearing

• Compression leak from cylinder

Replace head

gasket, tighten

cylinder head screw,

glow plug and nozzle

holder

• Improper valve timing

Correct or replace

timing gear

• Piston ring and cylinder worn

• Excessive valve clearance

Replace

Adjust

Reference

Page

–

S-20

S-20, 21,

25

S-20

S-21, 25

–

–

S-44

S-86

S-54

S-88

S-49

–

–

S-53

S-42, 56,

57, 71, 72,

79

S-31

(Starter Does Not

Run)

Engine Revolution Is

Not Smooth

• Battery discharged

• Starter malfunctioning

• Key switch malfunctioning

• Starter auto reduction unit defective

• Wiring disconnected

• Fuel filter clogged or dirty

• Air cleaner clogged

• Fuel leak due to loose injection pipe retaining

nut

• Injection pump malfunctioning

• Incorrect nozzle injection pressure

• Injection nozzle stuck or clogged

• Governor malfunctioning

• Bearing worn out

• Shaft bent

• Fin or other part damaged due to foreign

matters

Charge

Repair or replace

Repair or replace

Replace

Connect

Clean or change

Clean or change

Tighten retaining nut

Replace

Replace

Replace

Repair

Replace the

turbocharger

assembly

Replace the

turbocharger

assembly

Replace the

turbocharger

assembly

S-29

S-89, 93,

96

–

S-92, 100

S-100

S-21, 25

S-21

S-44

S-49

S-88

S-88

S-50, 54

S-101

S-101

S-101

W1014322

S-5

03-M-DI Series, WSM

KiSC issued 10, 2009 A

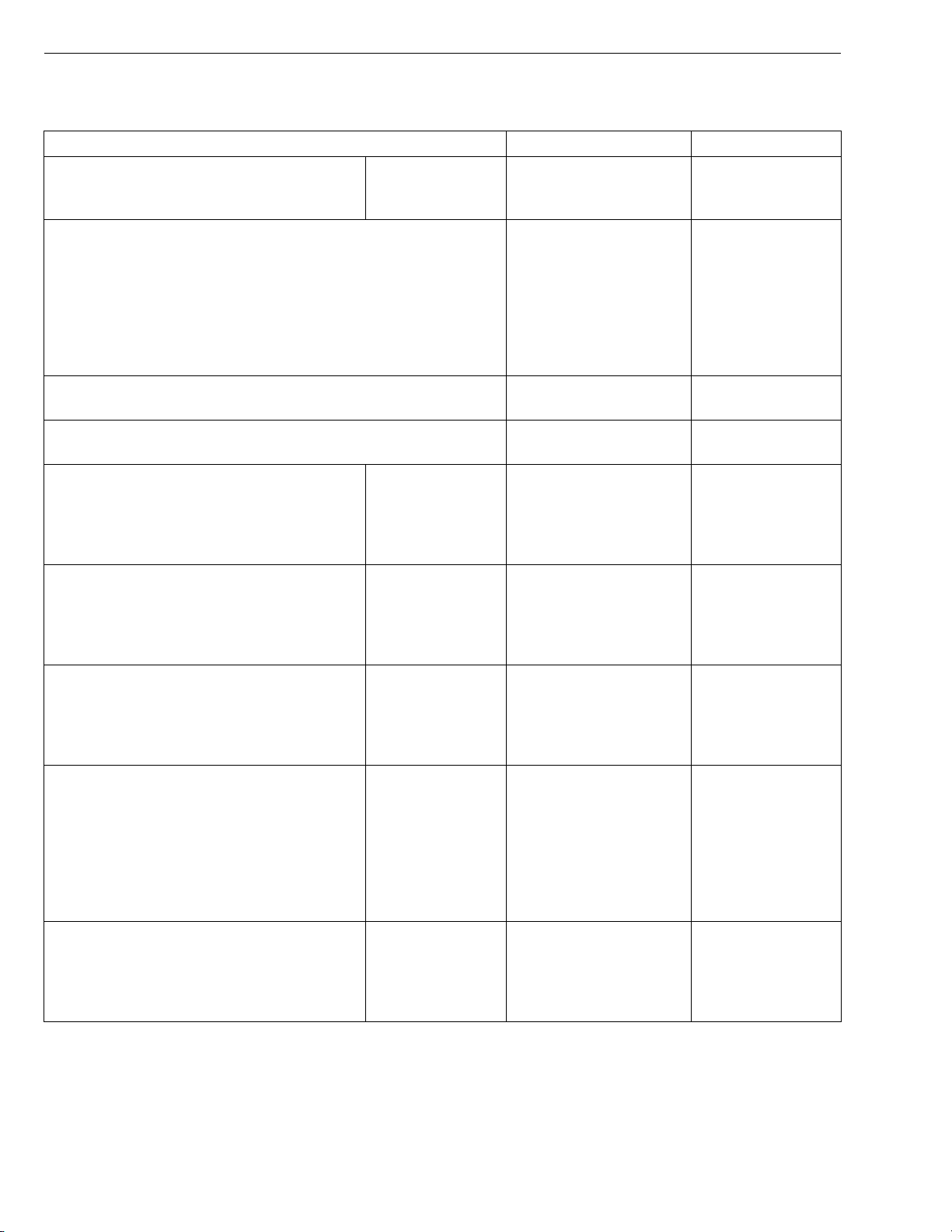

DIESEL ENGINE

Symptom Probable Cause Solution

Either White or Blue

Exhaust Gas Is

Observed

• Excessive engine oil

• Piston ring and liner worn or stuck

• Incorrect injection timing

• Deficient compression

Reduce to specified

level

Repair or replace

Adjust

Check the cylinder

compression

pressure and top

clearance

Oil Leak into Exhaust

Pipe or Suction Pipe

• Waste oil pipe clogged or deformed

• Piston ring seal faulty

Repair or replace

Replace the

turbocharger

assembly

Either Black or Dark

Gray Exhaust Gas Is

Observed

Deficient Output • Incorrect injection timing

• Overload

• Low grade fuel used

• Fuel filter clogged

• Air cleaner clogged

• Deficient nozzle injection

• Engine’s moving parts seem to be seizing

• Injection pump malfunctioning

• Deficient nozzle injection

• Compression leak

Lessen load

Use specified fuel

Clean or change

Clean or change

Replace nozzle

Adjust

Repair or replace

Replace

Replace nozzle

Check the

compression

pressure and repair

• Gas leak from exhaust system

• Air leak from compressor discharge side

• Air cleaner dirty or clogged

• Compressor wheel turning heavily

Repair or replace

Repair or replace

Clean or replace

Replace the

turbocharger

assembly

Excessive Lubricant

Oil Consumption

• Piston ring’s gap facing the same direction

• Oil ring worn or stuck

• Piston ring groove worn

• Valve stem and valve guide worn

• Crankshaft bearing, and crank pin bearing

Shift ring gap

direction

Replace

Replace piston

Replace

Replace

worn

Fuel Mixed into

Lubricant Oil

Water Mixed into

Lubricant Oil

• Oil leaking due to defective seals or packing

• Injection pump’s plunger worn

• Deficient nozzle injection

• Injection pump broken

• Head gasket defective

• Cylinder block or cylinder head flawed

Replace

Replace injection

pump

Replace nozzle

Replace

Replace

Replace

Reference

Page

S-19

S-42, 56,

57, 71, 72,

79

S-86

S-42

–

S-101

–

–

S-21, 25

S-21

S-88

S-86

–

S-49

S-88

S-42

S-101

S-101

S-24

S-101

S-56

S-56, 71,

72

S-56, 71,

72

S-48, 62,

63

–

–

S-49

S-88

S-49

S-46, 47

S-46, 61

W1014322

S-6

03-M-DI Series, WSM

KiSC issued 10, 2009 A

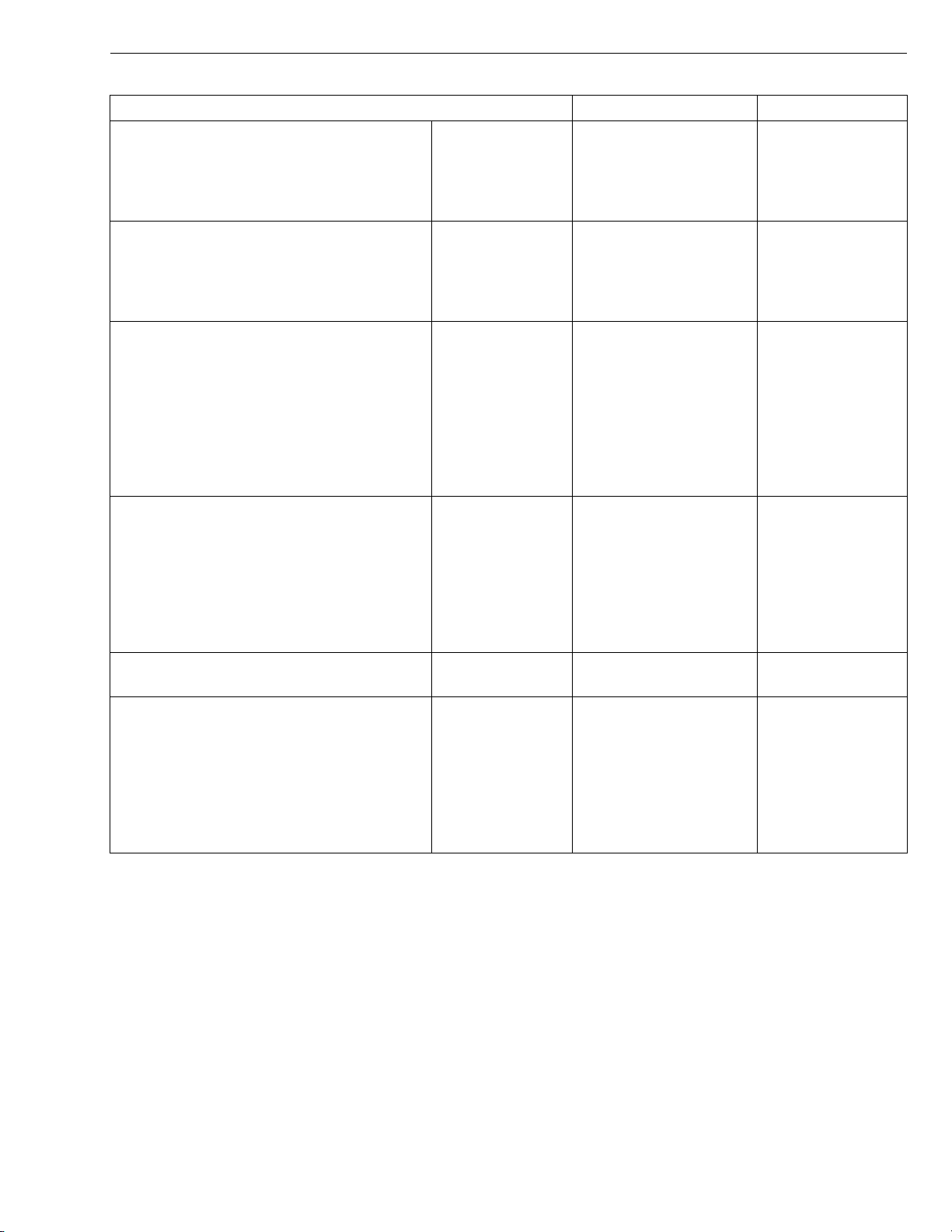

DIESEL ENGINE

Symptom Probable Cause Solution

Low Oil Pressure • Engine oil insufficient

• Oil strainer clogged

• Relief valve stuck with dirt

• Relief valve spring weaken or broken

• Excessive oil clearance of crankshaft bearing

• Excessive oil clearance of crankpin bearing

• Excessive oil clearance of rocker arm

• Oil passage clogged

• Different type of oil

Replenish

Clean

Clean

Replace

Replace

Replace

Replace

Clean

Use specified type of

oil

• Oil pump defective

High Oil Pressure • Different type of oil

Repair or replace

Use specified type of

oil

• Relief valve defective

Engine Overheated • Engine oil insufficient

• Fan belt broken or elongated

• Coolant insufficient

• Radiator net and radiator fin clogged with

Replace

Replenish

Replace or adjust

Replenish

Clean

dust

Battery Quickly

Discharge

• Inside of radiator corroded

• Coolant flow route corroded

• Radiator cap defective

• Overload running

• Head gasket defective

• Incorrect injection timing

• Unsuitable fuel used

• Battery electrolyte insufficient

• Fan belt slips

Clean or replace

Clean or replace

Replace

Loosen load

Replace

Adjust

Use specified fuel

Replenish distilled

water and charge

Adjust belt tension or

change

• Wiring disconnected

• Rectifier defective

• Alternator defective

Connect

Replace

Replace

Reference

Page

S-19

S-55

–

–

S-60, 75,

76, 77, 78

S-56, 74

S-45, 65

–

S-23

S-54, 81,

82

S-23

–

S-19

S-22, 28

S-19

–

S-26

–

S-84

–

S-46, 47

S-86

–

S-21, 29

S-22, 28

S-100

S-93, 99

S-93

• Battery defective

S-7

Change

–

W1014322

03-M-DI Series, WSM

KiSC issued 10, 2009 A

DIESEL ENGINE

[5] SERVICING SPECIFICATIONS

ENGINE BODY

Item Factory Specification Allowable Limit

Cylinder Head Surface Flatness – 0.05 mm / 500 mm

0.0020 in. /

19.69 in.

Compression Pressure

(When Cranking with Starting Motor)

2.94 to 3.24 MPa /

290 min

30 to 33 kgf/cm

290 min

427 to 469 psi /

290 min

-1

(rpm)

-1

(rpm)

-1

(rpm)

2

/

2.35 MPa /

290 min

24 kgf/cm

290 min

341 psi /

290 min

-1

(rpm)

-1

(rpm)

-1

(rpm)

2

/

Difference among Cylinders

–

Top Clearance 0.60 to 0.70 mm

0.0236 to 0.0276 in.

Valve Clearance (When Cold) 0.18 to 0.22 mm

0.0071 to 0.0087 in.

Valve Seat Width (Intake)

2.12 mm

0.0835 in.

Width (Exhaust)

2.12 mm

0.0835 in.

Valve Seat Angle (Intake)

1.047 rad

60 °

Angle (Exhaust)

0.785 rad

45 °

Valve Face Angle (Intake)

1.047 rad

60 °

Angle (Exhaust)

0.785 rad

45 °

Valve Stem to Valve Guide

Clearance

0.040 to 0.070 mm

0.0016 to 0.0028 in.

10 % or less

–

–

–

–

–

–

–

–

0.1 mm

0.0039 in.

Valve Stem

Valve Guide

Valve Recessing Protrusion

O.D.

I.D.

Recessing

S-8

7.960 to 7.975 mm

0.31339 to 0.31398 in.

8.015 to 8.030 mm

0.31555 to 0.31614 in.

0.65 mm

0.026 in.

to

0.85 mm

0.033 in.

–

–

–

1.20 mm

0.0472 in.

W1013874

03-M-DI Series, WSM

KiSC issued 10, 2009 A

ENGINE BODY (Continued)

Item Factory Specification Allowable Limit

Valve Timing (Intake Valve) Open

0.16 rad (9 °)

before T.D.C.

DIESEL ENGINE

–

Close

0.79 rad (45 °)

–

after B.D.C.

Valve Timing (Exhaust Valve) Open

0.87 rad (50 °)

–

before B.D.C.

Close

0.21 rad (12 °)

–

after T.D.C.

Valve Spring Free Length

Setting Load /

Setting Length

Tilt

41.7 to 42.2 mm

1.6417 to 1.6614 in.

117.6 N / 35.0 mm

12.0 kgf / 35.0 mm

26.4 lbs / 1.3780 in.

–

41.2 mm

1.6220 in.

100.0 N / 35.0 mm

10.2 kgf / 35.0 mm

22.5 lbs /1.3780 in.

1.0 mm

0.039 in.

Rocker Arm Shaft to Rocker Arm

Rocker Arm Shaft

Clearance

O.D.

0.016 to 0.045 mm

0.00063 to 0.00177 in.

13.973 to 13.984 mm

0.1 mm

0.0039 in.

–

0.55012 to 0.55055 in.

Rocker Arm

I.D.

14.000 to 14.018 mm

–

0.55118 to 0.55189 in.

Push Rod Alignment – 0.25 mm

0.0098 in.

Tappet to Tappet Guide

Clearance

0.020 to 0.062 mm

0.00079 to 0.00244 in.

0.07 mm

0.0028 in.

Tappet

Tappet Guide

O.D.

I.D.

S-9

23.959 to 23.980 mm

0.94327 to 0.94410 in.

24.000 to 24.021 mm

0.94488 to 0.94571 in.

–

–

W1013874

Loading...

Loading...